Preparation and low-temperature electrochemical performance of Zn-ion battery based on a robust adhesion hydrogel electrolyte

-

摘要:

凝胶基固态锌离子电池作为柔性储能器件具有良好的机械稳定性、环境友好性和高安全性,在可穿戴设备领域日益受到关注,但存在因界面接触差和易冻结限制了凝胶基固态电池在低温环境中的使用性能。因此,如何设计和开发具有良好界面稳定性和低温适应性的凝胶基固态锌离子电池是亟待解决的问题。本文以丙烯酰胺(AAm)、银/木质素纳米粒子(Ag@Lignin NPs)、纳米羟基磷灰石(HAp)和氯化锌(ZnCl2)为原料制备具有强自粘性的抗冻凝胶电解质,将其与金属Zn电极、聚苯胺(PANI)层层组装制备成具有强界面作用的Zn|凝胶电解质|PANI锌离子电池,研究了界面粘接强度的影响规律及其低温电化学性能。研究结果表明:电解质中Ag@Lignin NPs丰富的邻苯二酚官能团赋予凝胶强粘接性能,使其与Zn电极的界面韧性和剪切强度在–60℃时分别达467.4 J·m−2和95.7 kPa。随后,对凝胶电解质与Zn电极的界面相容性进行研究,Ag@Lignin NPs的引入降低了Zn||Zn对称电池的过电位,且在–60℃的环境温度下仍保持稳定的沉积/剥离行为。制备的Zn||PANI固态电池表现出优异的耐低温性能,在–60℃下电容量最高可达22.1 mA·h·g−1。与此同时,Zn||PANI固态电池具有优异的循环稳定性,在–40℃下循环充/放电300次,平均库仑效率为95.83%,电容量保持率为65.20%。更重要的是,制备的锌离子电池具有良好的变形稳定性,在经历20%应变40次拉伸循环后其电容量保持率达88.3%,展示出优异的柔性性能。

Abstract:The hydrogel-based solid-state Zn-ion batteries have attracted increasing attention in the wearable electronics as flexible energy storage due to their good mechanical stability, eco-friendliness and safety. However, their performance is limited in low temperature owing to weak interfacial adhesion and easily freezing. Therefore, how to design and develop hydrogel-based solid Zn-ion batteries with excellent interface stability and low temperature adaptability is an urgent problem to be solved. In this paper, an anti-freezing hydrogel electrolyte with high self-adhesion was prepared by introducing nanohydroxyapatite (HAp), Ag@Lignin nanoparticles (Ag@Lignin NPs), and zinc chloride (ZnCl2) into the polyacrylamide (PAAm) network. Zn|hydrogel electrolyte|PANI Zn-ion battery with robust interfacial toughness was prepared in a layer-by-layer assembly with Zn metal electrode, hydrogel electrolyte and polyaniline (PANI). This work has investigated the effect of interfacial adhesion and low-temperature electrochemical performance. The results show that the abundant catechol groups of Ag@Lignin NPs in the hydrogel electrolyte endow the hydrogel with robust adhesion, reaching a high interfacial toughness of 467.4 J·m−2 and shear strength of 95.7 kPa at –60℃ for the hydrogel electrolyte/Zn. Then, the interfacial compatibility between the hydrogel electrolyte and Zn electrode was studied, which indicates that the introduction of Ag@Lignin NPs reduces the overpotential of the Zn|hydrogel electrolyte|Zn symmetric cell, thus enabling stable Zn plating/stripping cycles even at –60℃. The assembled Zn||PANI solid-state battery exhibits excellent low-temperature performance, delivering high capacity of 22.1 mA·h·g−1 at –60℃. Meanwhile, the Zn||PANI solid-state battery demonstrates satisfactory cycling stability, with an average coulombic efficiency of 95.83% and a capacity retention of 65.20% after 300 charging/discharging cycles at –40℃. More encouragingly, the assembled Zn-ion battery presents impressive deformation stability, which is able to tolerate dynamic tension deformations and sustain high capacity retention of 88.3% after 40 tension cycles at 20% strain, showing excellent flexible performance.

-

混凝土作为一种非均质、多相、多层次复合体系,具有极其复杂的微观孔隙结构[1],其孔形各异、孔径分布范围显著广于其他多孔材料。目前,纤维增强作为混凝土改性研究的一个重要手段,取得了良好的实质性效果,因此,纤维增强混凝土成为了一种新型的复合材料[2-3]。纤维增强混凝土一方面可以凭借纤维的性质,在混凝土中发挥纤维的性能优势,有利于减少混凝土的固有缺陷,优化孔隙结构,提高相应的力学强度[4],另一方面,也会增加混凝土的内部界面,而且混凝土需要更多时间进行搅拌,可能会引入更多的气泡并对孔隙结构产生不利影响[5-6]。

随着纤维增强混凝土的发展,人们发现采用单一纤维对混凝土的提升效果非常有限,而通过向混凝土中掺入混杂纤维发现混杂纤维可以在混凝土中发挥各自纤维的优势,使其在混凝土的不同结构和不同性能层次上逐级阻裂和强化,并且相互激发、相互补充,达到取长补短的效果[7]。但是也可能带来不利影响,如纤维结团、分布不均和引气等问题,过量的纤维还可使混凝土的内部结构发生改变,增大孔隙的出现机率[8]。因此混杂纤维混凝土的性能成为当前的研究热点。玄武岩纤维(BF)是一种高弹性模量的绿色环保纤维,可以提升混凝土的力学性能,降低混凝土的脆性[9];聚丙烯纤维(PF)弹性模量低,可以抑制混凝土早期塑性收缩微裂缝的形成和发展[10]。两种纤维混杂掺入混凝土中可以形成优势互补,提升混凝土的性能。但玄武岩-聚丙烯混杂纤维混凝土(HBPRC)作为一种新型的建筑材料尚处于一个初期的探索阶段,目前主要研究其力学性能和耐久性能[11-12],对其微观孔隙特征的报道较少,得到的结论也不一致。刘大昌[13]研究表明0.2%BF-PF混杂掺入混凝土时,HBPRC中的有害孔(100~200 nm)和多害孔(>200 nm)的数量增多,对HBPRC的孔隙结构产生不利影响,而骆冰冰等[14]研究了不同纤维体积掺量对混凝土的微观孔隙的影响,发现0.2%BF-PF混杂不仅可以降低混凝土的孔隙率,而且混凝土中的有害孔和多害孔数量明显降低,孔径分布得到改善,因此有必要对HBPRC的孔隙特征进行深入分析研究,并探讨其孔隙特征与力学性能的关系。

水泥基材料已经使用各种技术来研究其孔隙特征,例如压汞法[15]、扫描电子显微镜(SEM)[16]、气体吸附法[17]、核磁共振技术(NMR)和小角度X射线散射法[18]等,不同测试方法对应的孔径测试范围不同,准确性也有区别。核磁共振技术可以通过测量多孔材料内部氢原子的横向弛豫时间来准确获得孔隙特征,从而对多孔材料内部的微观结构进行直观的定量和定性分析[19],而且具有无损检测、连续监测等优点。相比于核磁共振技术,其他测试方法存在只能定性的分析孔隙的几何形状和分布[20]、孔径测试范围有限和破坏原有孔隙结构等局限[21],影响对多孔材料孔隙结构特征的表征。核磁共振技术作为一种对孔隙结构无损定量分析的有效方法,已经广泛应用于岩石和混凝土微观孔隙结构的表征[22-24]。

混凝土作为一种典型的分形介质,其内部孔隙极不规则,是一个高度混沌的系统,孔隙率、孔体积和孔径分布等传统参数难以充分表征其孔隙结构特征[25],且内部孔隙的曲折度和连通性非常复杂[26],测定难度较高。因此目前很多学者采用Mandelbrot提出的分形理论来表征混凝土的孔隙结构特征[27-28]。通过分形分析,可以有效地量化和比较混凝土孔隙结构的复杂性[29-30]。因此,可以利用核磁共振技术无损地获得HBPRC的孔隙参数信息,同时借助核磁共振参数和分形理论可以建立孔隙分形特征与物理参数之间的关系。

本文利用核磁共振技术得到了HBPRC的孔隙率和孔径分布,基于核磁共振T2谱和孔隙结构分形理论计算了不同孔隙范围的分形维数,对比分析了BF和PF及二者混杂对HBPRC的抗压强度、孔隙率、孔径分布、曲折度和孔隙结构分形维数的影响,并且进一步探讨了HBPRC孔隙结构分形特征的微观机制。

1. 实验材料及方法

1.1 原材料

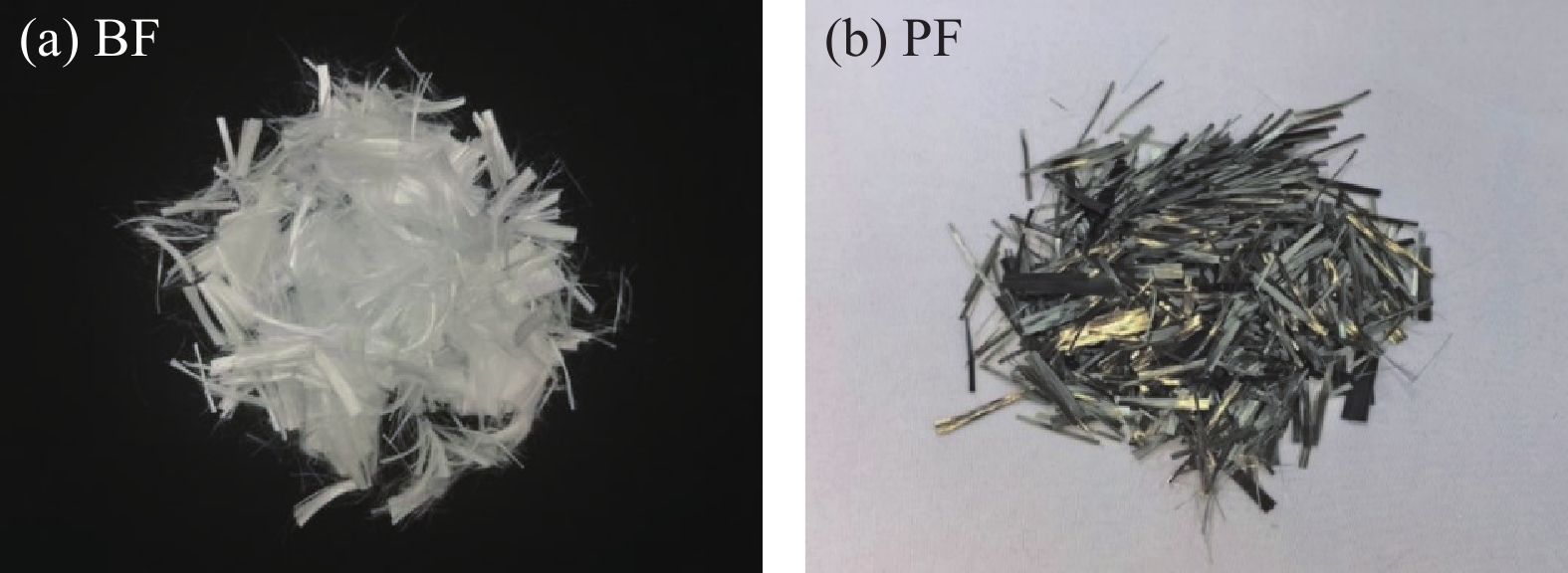

水泥选用祁连山牌P·O 42.5普通硅酸盐水泥(C),粉煤灰为甘肃靖远产的II级粉煤灰(FA)。粗骨料(CA)为花岗岩砾石,粒径为5~20 mm,表观密度为2.66 g/cm3;细骨料(S)为细度模数2.68、表观密度2.65 g/cm3的河砂。BF和PF分别产自中国四川航天拓鑫玄武岩工业有限公司和江苏苏博特新材料有限公司。胶凝材料和BF的化学组分如表1所示。BF和PF的物理性能指标和外观形貌分别见表2和图1,减水剂采用的是江苏苏博特新材料有限公司生产的聚羧酸高性能减水剂(PBS),减水率为30%。拌合水(W)采用的是兰州本地自来水。

表 1 胶凝材料和玄武岩纤维(BF)的化学组成(wt%)Table 1. Chemical composition of cementitious materials and basalt fiber (BF) (wt%)Composition SiO2 Al2O3 Fe2O3 CaO MgO Cement 34.67 7.90 2.93 35.50 1.77 Fly ash 50.77 22.68 5.64 5.98 1.74 BF 51.40 15.40 9.80 9.00 5.70 表 2 BF和聚丙烯纤维(PF)的物理力学性能Table 2. Physical and mechanical of BF and polypropylene fiber (PF)Type Density/(kg·m−3) Tensile strength/MPa Elastic modulus/GPa Diameter/μm Length/mm BF 2.65 ≥ 2400 ≥40 15 18 PF 0.91 270 0.3 30 19 1.2 配合比及试件制备

为了研究BF、PF及二者混杂对混凝土抗压强度和孔隙特征的影响,在保持混凝土配合比不变的情况下,通过变换BF和PF体积掺量(0vol%、0.05vol%、0.1vol%)和掺入形式(单掺、混杂)设计了9组配合比,HBPRC的配合比如表3所示。各组配合比的水灰比均为0.38,强度等级为C40。通常,添加纤维需要更多的减水剂来保持混凝土的和易性,但为了避免对其孔结构造成影响,将减水剂保持为恒定量。

表 3 玄武岩-聚丙烯混杂纤维混凝土(HBPRC)配合比Table 3. Mix proportions of hybrid basalt-polypropylene fiber-reinforced concrete (HBPRC)Mixture Mixture composition/(kg·m−3) C W CA S FA PBS BF PF BF0PF0 320 160 1068 712 100 6.3 0 0 BF0.05PF0 320 160 1068 712 100 6.3 1.3 0 BF0.1PF0 320 160 1068 712 100 6.3 2.6 0 BF0PF0.05 320 160 1068 712 100 6.3 0 0.5 BF0PF0.1 320 160 1068 712 100 6.3 0 0.9 BF0.05PF0.05 320 160 1068 712 100 6.3 1.3 0.5 BF0.1PF0.05 320 160 1068 712 100 6.3 2.6 0.5 BF0.05PF0.1 320 160 1068 712 100 6.3 1.3 0.9 BF0.1PF0.1 320 160 1068 712 100 6.3 2.6 0.9 Notes: "C" refers to cement; "W" refers to water; "CA" refers to coarse aggregate; "S" refers to river sand; "FA" refers to fly ash; "PBS" refers to performance water reducer; "0", "0.05", "0.1" represent the fiber volume content of 0vol%, 0.05vol%, 0.1vol%, respectively. 在制备混凝土试件时,首先将花岗岩砾石和河砂混合在一起搅拌30 s,然后加入水泥、粉煤灰混合在一起搅拌90 s,再加入BF和PF分别搅拌180 s和120 s,接着加入水和减水剂搅拌90 s,最后用100 mm×100 mm×100 mm的模具成型。值得注意的是,BF和PF是手工分散在拌合物中,尽可能实现纤维在拌合物中的均匀分布。浇筑完成后所有试件均在室内保温24 h后脱模,然后在温度为(20±2)℃,相对湿度为90%标准条件下养护28 d。

1.3 测试方法

1.3.1 抗压强度测试

依据GB/T 50081—2019《普通混凝土力学性能试验方法标准》[31],采用武汉格莱莫公司生产的WDW-100C型微机液压万能试验机对养护28 d的HBPRC试件进行抗压强度试验,加载速度为0.8 MPa/s。进行每组混凝土抗压强度测试时均有3个平行试样,并将它们的平均值作为抗压强度的最终值。

1.3.2 孔结构测试

核磁共振(NMR)用于测量样品中氢质子的信号,未受到干扰的氢质子长期处于自旋状态,在核磁共振实验中需使用射频脉冲,使自旋体系偏离稳态,当外部射频脉冲取消后,氢质子将回到原始状态,这个过程称为弛豫,完成横向弛豫过程所需要的时间称为横向弛豫时间(T2)。通过测量样品中孔隙水的氢质子信号的强弱,并利用数学反演可以获得T2谱,T2谱反映了孔径大小和孔隙体积等信息。横向弛豫时间T2如下式所示[32]:

1T2=1T2B+1T2D+1T2S (1) 式中:T2B为自由弛豫时间;T2D为扩散弛豫时间;T2S为表面弛豫时间。

由于本实验采用的是均匀磁场和短回调间隔,则T2B与T2D不予考虑,因此表面弛豫时间是影响T2的主要因素,则可以将式(1)简化为

1T2≈1T2S=ρ2SV (2) 式中:ρ2为弛豫速率(μm/s),根据经验取值为5 μm/s[33];S和V分别是孔的比表面积和体积。

为了将核磁共振横向弛豫T2谱转换为孔径分布,需要对孔隙形状进行假设。假设孔隙为理想球体,则可以得到S和V与孔隙半径r的关系如下式所示:

SV=3r (3) 将式(3)代入式(2),可以得到T2 与孔隙半径r的关系[34]如下式所示:

1T2≈1T2S=ρ2SV = ρ23r (4) 采用由苏州市纽迈分析仪器股份有限公司研发的MesoMR12-060H-I岩石微观孔隙结构分析与成像系统测试HBPRC的孔结构参数,设备如图2所示。磁体单元的温度设置为(32±0.05)℃,磁场设置为0.3 T,射频线圈直径为60 mm,采用CPMG序列。试件养护28 d后从养护室取出,接着通过钻心取样得到直径为50 mm、高度为50 mm的圆柱体样品,NMR测试取样流程如图3所示。为提高试验精度,将样品真空饱水24 h后进行NMR测试。

1.3.3 微观形貌测试

对养护28 d的HBPRC试件进行破碎,从混凝土试件断面的核心位置选取尺寸为3~5 mm的砂浆薄片用无水乙醇浸泡48 h,终止其水化反应后放入上海仪昕科学仪器产生产的DZF-6050Z型真空干燥箱烘至恒重,温度设置为50℃。烘干后使用胶带将样品固定于样品盘上,保持样品平整自然面朝上,测试时为了增加样品导电性在样品表面进行喷金处理,然后采用国仪量子技术股份有限公司生产的JSM-5600LV型低真空扫描电子显微镜对样品进行扫描,观察纤维与混凝土基体的粘结状态及纤维与水化产物的空间分布关系。

2. 结果与讨论

2.1 HBPRC的抗压强度

图4为普通混凝土和HBPRC抗压试件破坏形态,从试验现象可以看出,普通混凝土和HBPRC试件在加载过程中出现的破坏现象明显不同,普通混凝土在加荷过程中先出现小的剥落碎块,达到混凝土承受极限时,普通混凝土突然向四周崩裂,剥落现象严重。而HBPRC达到抗压极限时形态依然完好,很少出现大块的碎片剥落。

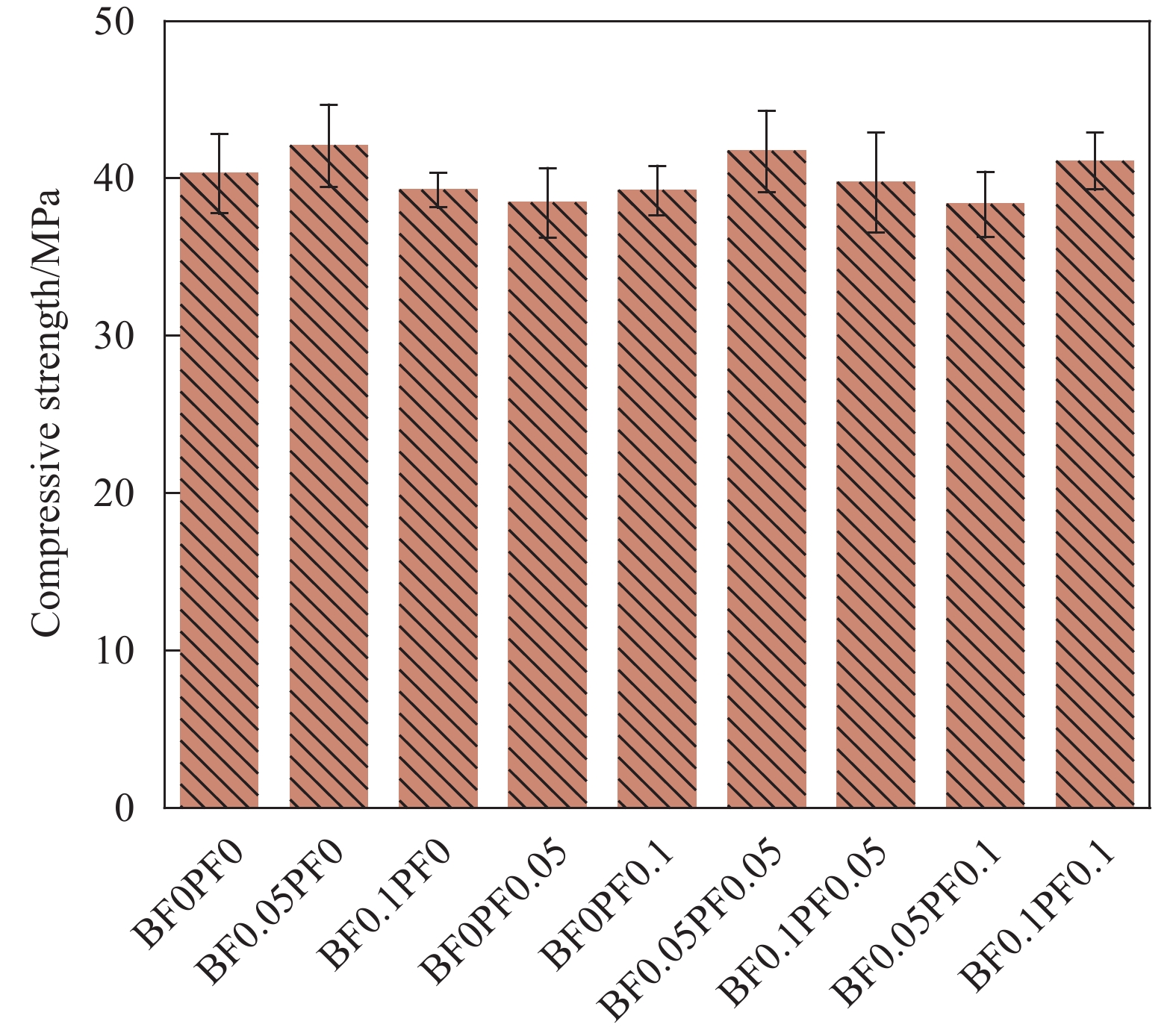

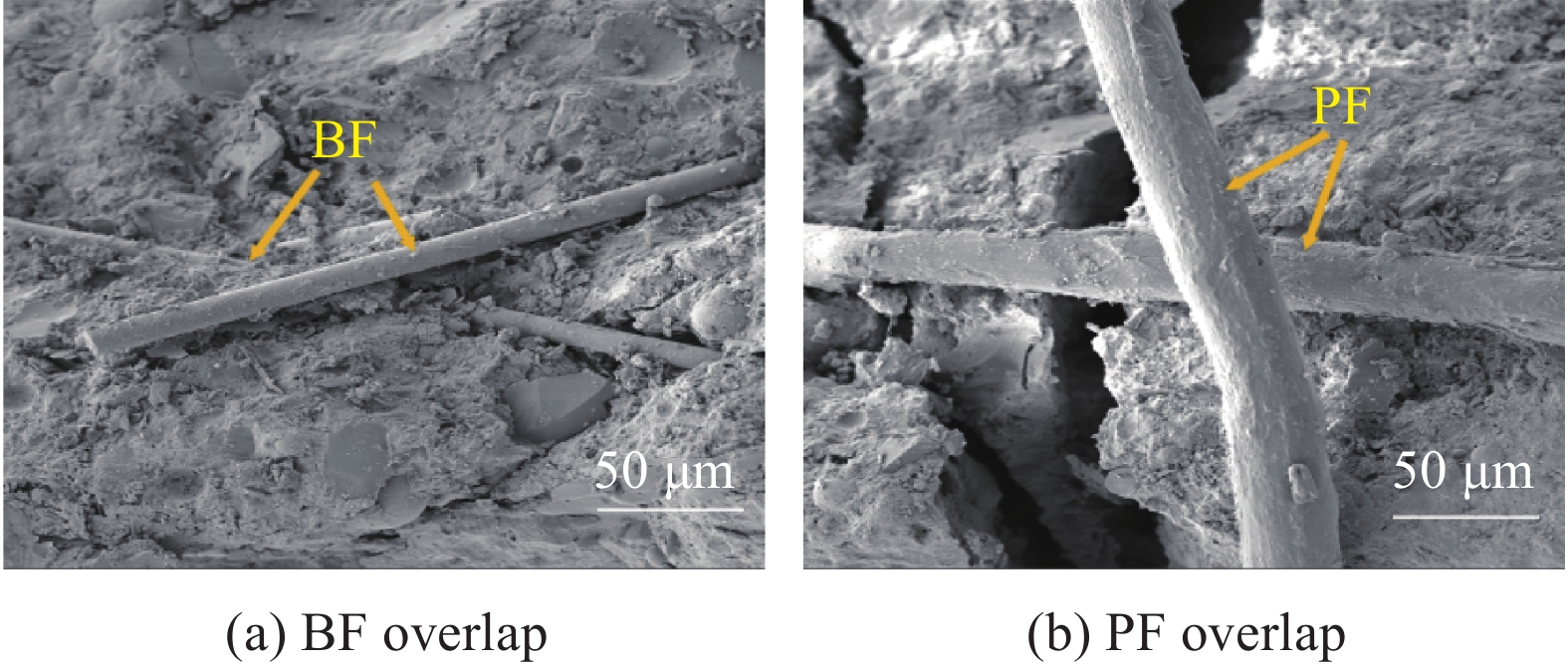

HBPRC的28 d抗压强度结果如图5所示。可知,不同的纤维掺量和掺入方式对混凝土抗压强度有不同程度的影响。BF和PF单掺时,与BF0PF0相比,BF0.05PF0和BF0PF0.05的抗压强度分别提高了4.42%和降低了4.59%,这主要是由于BF属于高弹性模量纤维,添加适量的BF可以提高混凝土的强度和韧性[35]。而PF是低弹性模量纤维,对混凝土的抗压强度提高不大,并且PF的直径比较大,且为柱状空心薄壁结构,PF断裂微观形貌如图6(a)所示,在混凝土中会产生引气作用[36],因此混凝土搅拌时会产生更多的气泡,混凝土内部孔隙增多,造成抗压强度下降。当BF和PF掺量为0.1vol%时,BF0.1PF0和BF0PF0.1的抗压强度均有所下降,分别降低了2.61%和5.11%。这是由于纤维掺量超过一定范围时,纤维会在混凝土基体中出现重叠、搭接现象,BF和PF搭接现象如图6(b)所示,此时纤维引起的负面影响大于纤维对混凝土的增强作用。

BF-PF混杂纤维掺入混凝土时,BF0.05PF0.05和BF0.1PF0.1的抗压强度分别达到41.71 MPa和41.14 MPa,与BF0.05PF0抗压强度接近,相比普通混凝土分别提高了3.52%和2.11%,较其他单掺纤维试件均有所提升,说明BF-PF混杂纤维在混凝土中起到了正协同作用。这是由于均匀分布在混凝土内部的BF和PF形成了稳定的三维空间承力结构,纤维间距理论认为纤维的间距会影响混凝土的增强效果[37]。BF密度大于PF,当BF含量较大时,BF在自重作用下发生沉降,导致纤维分布不均,造成在受力传递时发生局部应力集中现象,影响混凝土强度。当加入PF后,纤维与基体间的有效粘结面积增大,同时PF的存在抑制了BF的沉降,纤维分布较均匀,形成了三维纤维网。在BF0.05PF0.05观察到均匀分布的纤维网络结构如图6(c)所示,这种良好的网络结构使混凝土具有更好的抗压能力。当混凝土受压时,一旦裂缝延伸时,横跨裂缝的纤维马上通过纤维的脱粘滑移做功消耗能量抑制裂缝发展[38],降低了裂缝扩展的驱动力,从而提高了混凝土的抗压强度。当BF-PF混杂纤维掺量为0.15vol%时,在BF0.1PF0.5和BF0.05PF0.1未能形成均匀的纤维网络结构,与BF0PF0相比,BF0.1PF0.05和BF0.05PF0.1的抗压强度均有不同程度损失,分别降低了1.39%和4.86%,BF-PF混杂表现出负协同作用。

以上分析说明BF-PF混杂掺入混凝土中对抗压强度的影响既存在正协同作用,也存在负协同作用,与Wang等[39]研究结论一致,但由于纤维长度和直径的区别,得到的最佳混杂比例也存在区别。本试验结果得出当BF和PF体积掺量均为0.05vol%和0.1vol%混杂时,均对抗压强度产生正协同作用,其中BF和PF体积掺量均为0.05vol%混杂时,正协同作用最佳。其余混杂纤维体积掺量出现一定程度的负协同效应。

2.2 HBPRC的孔结构测试结果

2.2.1 BF对T2谱的影响

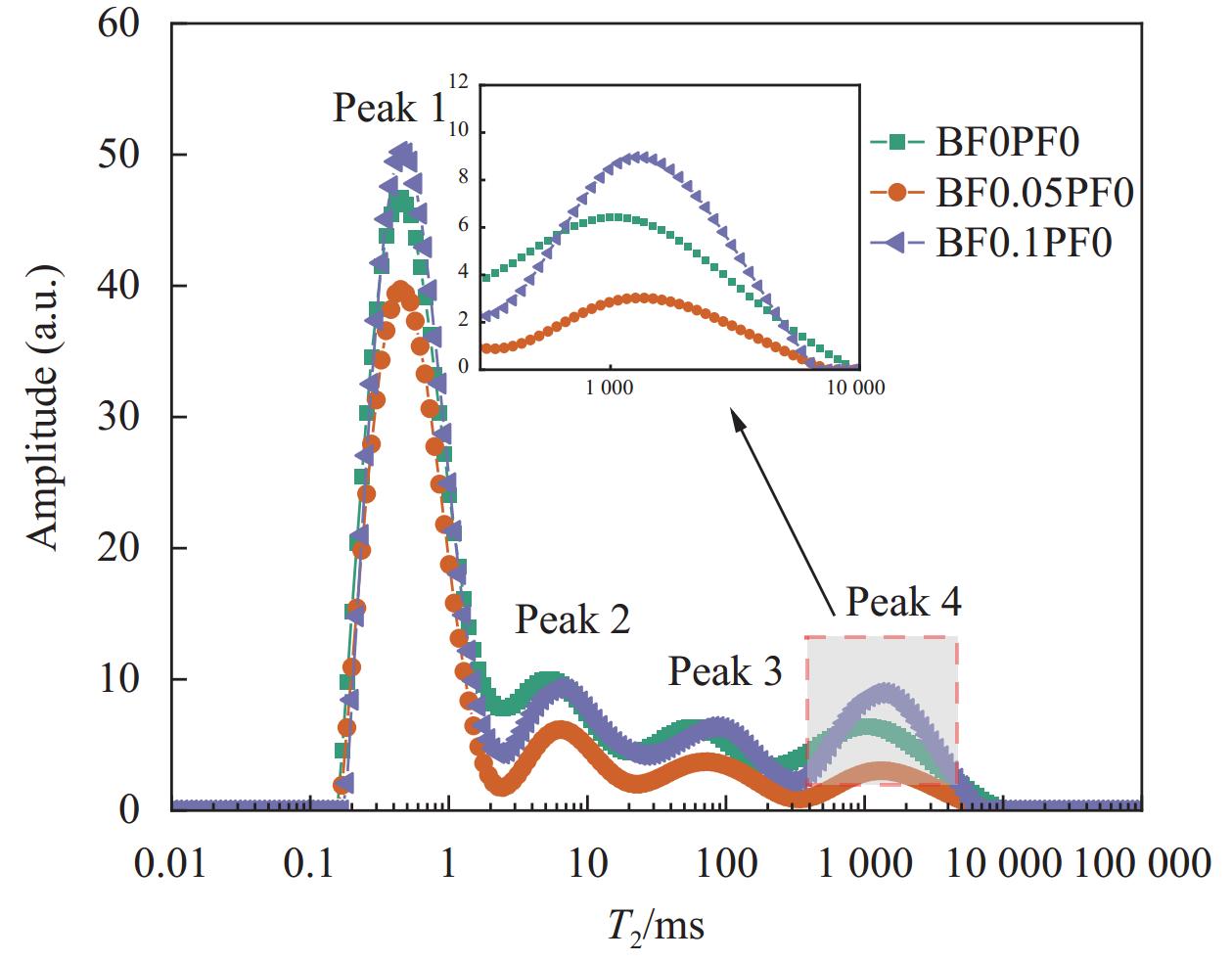

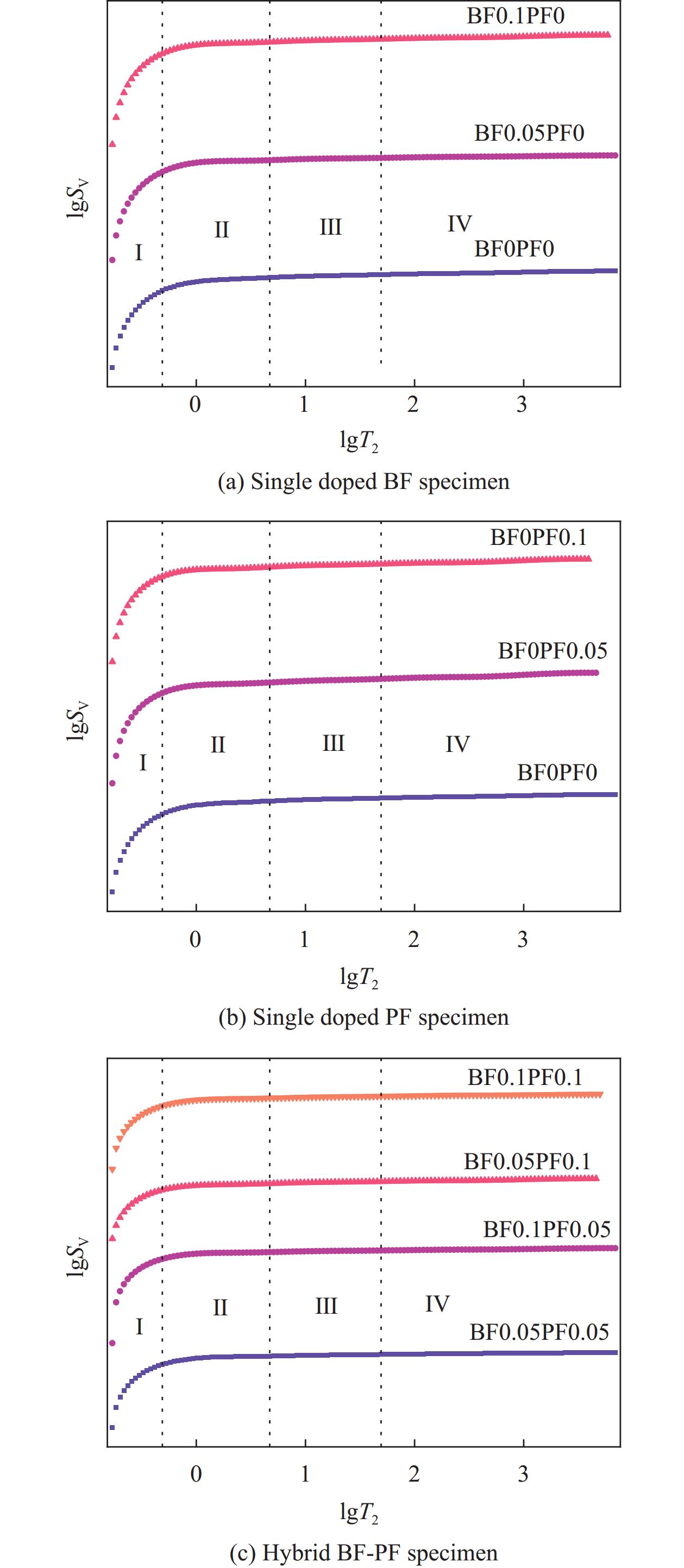

采用NMR对HBPRC的孔结构测试得到的T2谱主要存在4个信号峰,分别代表了HBPRC不同孔隙中孔隙水的弛豫情况。孔隙水的弛豫时间可以反映混凝土内部孔隙尺寸的分布情况,其中孔隙尺寸越小,孔隙水的弛豫时间越短,即T2谱峰越靠近左侧。T2谱曲线的面积则可以反映出HBPRC的孔隙率的大小,面积越大,说明含有的孔隙数量越多,孔隙率越大。

单掺BF试件的T2谱如图7所示。可以看出,随着BF掺量的增加,混凝土的T2谱面积先减少后增加,表明BF会对混凝土的孔隙特征造成影响。BF对T2谱的影响主要体现在第一峰和第四峰面积占比上,HBPRC的T2谱中各信号峰面积占比如表4所示。可以看出,与BF0PF0相比,BF0.05PF0和BF0.1PF0的第一峰面积占比分别提高了15.88%和降低了1.29%,第四峰面积占比分别降低了45.84%和提高了8.92%,即BF0.05PF0中产生了较多数量的小孔隙和较少数量的大孔隙,BF0.1PF0中则明显产生了更多数量的大孔隙。上述结果表明掺入0.05vol%的BF抑制了混凝土中大孔隙的生成,混凝土的孔径分布得到了优化。这与Chen等[40]的研究结果是一致的,BF的添加不仅可以减小混凝土的孔隙率,而且能够优化混凝土的孔径分布,对于混凝土的耐久性能和力学性能有重要作用。当BF掺量为0.1vol%时,BF对孔结构的优化作用会逐渐减弱,造成这一现象的原因可能是过量的BF相互重叠、搭接等,在内部分散不均容易结团,增加了混凝土中的粘结界面,同时也增加了纤维与水泥基体之间的孔隙数量,这些孔隙与现有的一些孔隙相互连接后变得更大,从而导致孔隙连通性增加[41-42]。

表 4 HBPRC的横向弛豫T2谱峰面积比例Table 4. Transverse relaxation-time T2 spectral peak area percentage of HBPRCMixture Peak 1/% Peak 2/% Peak 3/% Peak 4/% BF0PF0 62.60 13.91 10.18 13.28 BF0.05PF0 72.54 11.55 8.70 7.19 BF0.1PF0 61.79 13.66 10.07 14.46 BF0PF0.05 51.43 13.69 12.42 22.44 BF0PF0.1 56.05 13.77 10.25 19.92 BF0.05PF0.05 69.48 12.72 10.97 6.81 BF0.1PF0.05 64.08 13.52 9.44 12.94 BF0.05PF0.1 55.91 15.72 10.96 17.39 BF0.1PF0.1 65.80 14.44 12.14 7.60 2.2.2 PF对T2谱的影响

单掺PF试件的T2谱如图8所示。可以看出,随着PF含量增加,T2谱面积增加,T2谱最小弛豫时间明显向右发生了移动,说明混凝土内部孔隙有变大的趋势。与单掺BF混凝土试件相同,表4表明PF对混凝土孔隙特征的影响在T2谱中也主要体现为第一峰和第四峰面积的变化。与BF0PF0相比,随着PF含量的增加,单掺PF试件的T2谱第一峰面积占比下降,第四峰面积占比上升,表明随着PF的添加,小孔隙比例在减少,大孔隙比例在增加。这是由于PF与混凝土基体粘结性能较差,PF-基体界面过渡区较宽且含有更大的孔隙[43],而且PF含量过大时,纤维间也会产生搭接重叠现象,使混凝土内部缺陷增加,造成混凝土孔隙连通,对孔隙结构产生不利影响。

2.2.3 BF-PF混杂对T2谱的影响

混掺BF-PF试件的T2谱如图9所示,对每组试件的曲线进行面积计算,得出各组试件曲线面积大小排序为BF0.05PF0.1>BF0.1PF0.05>BF0PF0>BF0.1PF0.1>BF0.05PF0.05,由此可见BF-PF混杂纤维的体积掺量不同,对混凝土孔结构的影响也不一样。从表4可以看出,混掺BF-PF同样对T2谱第一峰和第四峰面积占比影响较大。相比于BF0PF0,T2谱第一峰面积占比增大较明显的是BF0.05PF0.05和BF0.1PF0.1,分别增大10.99%和5.11%,第四峰面积占比分别降低48.72%和42.71%,表明BF-PF混杂纤维在混凝土中表现出正协同作用,有效改善了混凝土的孔结构,且BF和PF掺量分别为0.05vol%时正协同作用最佳。BF0.05PF0.1和PF0.1BF0.05试件则出现负协同效应,两组试件的T2谱第四峰面积占比均增大,且BF掺量固定时,PF掺量越大,T2谱第四峰面积占比越大,表明大孔隙数量增加,对混凝土孔结构的不利影响加剧。

2.2.4 HBPRC的孔隙率与孔径分布

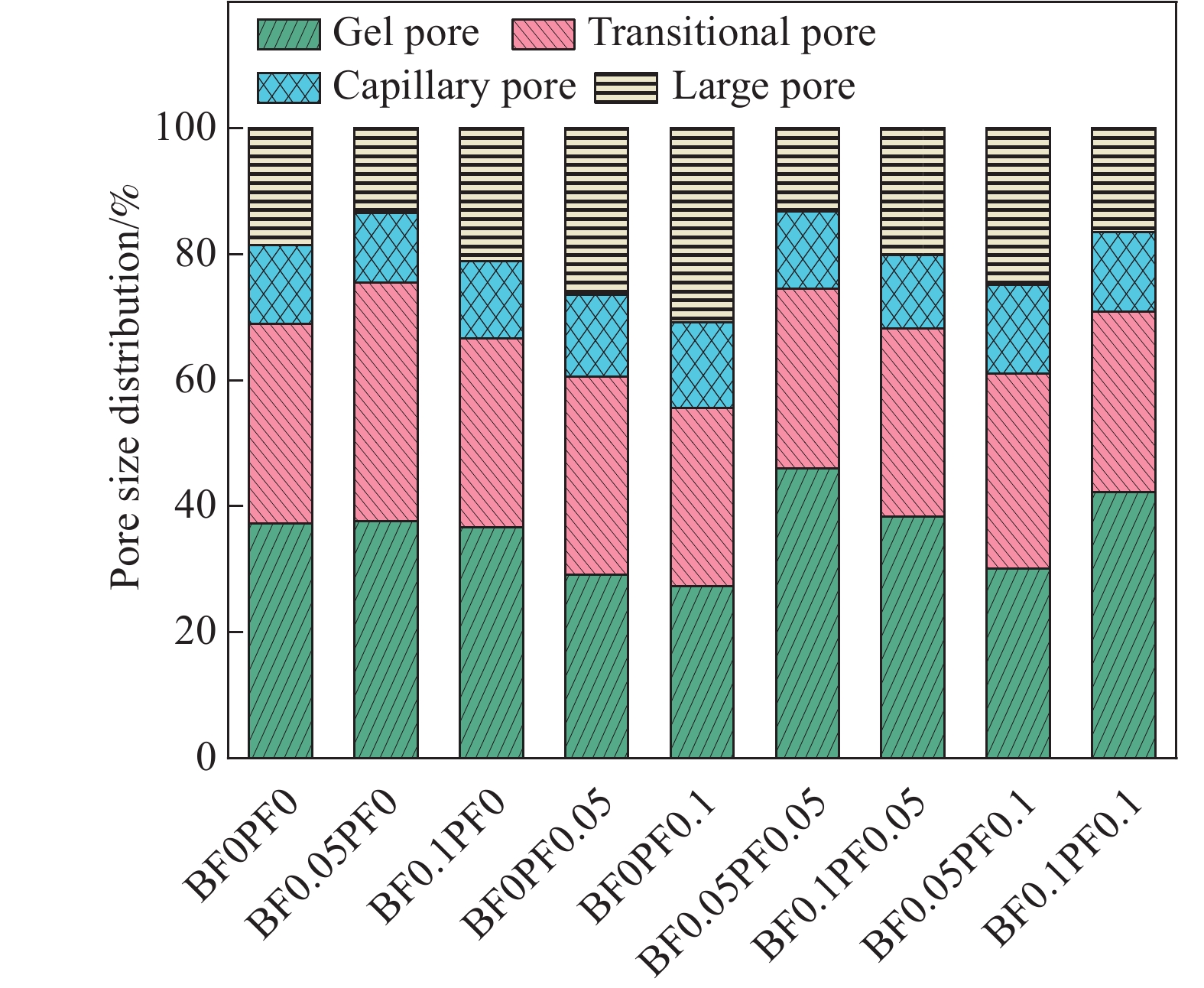

HBPRC的孔隙率如图10所示。可以看出BF和PF对混凝土的孔隙特征造成了明显影响。为了更直观地分析纤维对混凝土孔隙特征的影响,根据文献[44]中孔隙分类模型对HBPRC的孔隙进行分类,该模型将混凝土的孔隙分为凝胶孔(<10 nm)、过渡孔(10~100 nm)、毛细孔(100~

1000 nm)和大孔(>1000 nm)。HBPRC的孔径分类如图11所示。可知,HBPRC的孔隙主要为凝胶孔,占总孔隙体积的27%~46%,其次是过渡孔,占总孔隙体积的30%左右,大孔占总孔隙体积的13%~30%,体积占比最小的是毛细孔,所有试件区别不大,占比为12%~14%。从图10和图11中可以看出随着PF的添加,混凝土大孔隙占比明显增大,凝胶孔隙占比减小,孔隙率变大,与T2谱测试结果基本一致。掺入0.5vol%BF使混凝土的大孔占比减小,孔径分布得到优化。混掺BF-PF时,不同纤维混杂掺量对混凝土的孔隙率和孔径分布影响不同,BF0.05PF0.05和BF0.1PF0.1的孔隙率明显降低,与BF0PF0相比分别降低了1.47%和0.2%,孔隙率降低的同时,孔径分布也得到了优化,与BF0PF0相比,BF0.05PF0.05和BF0.1PF0.1的凝胶孔占比分别增大了8.76%和4.99%,大孔占比分别降低了5.30%和2.1%,表明BF和PF掺量均为0.05vol%和0.1vol%混杂时在混凝土中起到了正协同作用,降低了混凝土的孔隙率并且优化了混凝土的孔径分布,可以使混凝土表现出更好的宏观性能。而BF0.1PF0.05和BF0.05PF0.1孔隙率均有所提高,且大孔占比明显提高,对混凝土的孔隙率和孔径分布均造成了不利影响,产生负协同作用。2.2.5 HBPRC的曲折度

曲折度反映了孔隙的弯曲程度,曲折度越大,混凝土内部孔隙的弯曲程度越大,因此混凝土孔隙的曲折度是影响水和离子传输的重要因素[45-46],对混凝土的耐久性有重要影响。HBPRC的曲折度可以基于Yu和Li建立的多孔介质平均曲折度的几何模型计算[47]:

τ=12[1+12√1−φ+√1−φ√(1/√1−φ−1)2+1/41−√1−φ] (5) 式中:τ为平均曲折度;φ为基于NMR试验得到的HBPRC的孔隙率。

HBPRC的平均曲折度如图12所示。可以看出HBPRC的曲折度与孔隙率相反。单掺BF时,混凝土的曲折度随着BF含量先增大后减小。单掺PF时,PF含量越大,曲折度越小,表明PF的添加令混凝土的孔隙路线变得简单,弯曲程度变小。BF-PF混掺时,BF0.05PF0.05曲折度达到最大为4.25,相较于普通混凝土增加了8.20%,BF0.05PF0.1曲折度最小为3.62,下降了7.56%,表明BF-PF混杂纤维对HBPRC的曲折度的影响既存在正协同效应,也存在负协同效应,当BF和PF混杂掺量均为0.05vol%时可以令混凝土孔隙变得不规则,弯曲程度更大,令孔隙的延伸路线更复杂。

2.3 HBPRC孔隙结构分形维数

2.3.1 基于T2分布的HBPRC孔隙结构分形特征

孔隙结构分形模型的建立通常源于测定的孔隙结构。测定原理和技术不同,所建立的分形模型自然不同,一般常用于建立孔隙结构分形模型的测定孔隙的方法为光学法和压汞法[48]。但是前者的孔径测试范围有限,后者则会对孔隙结构造成破坏,影响混凝土孔结构分形特征的表征。而利用核磁共振技术,既可以测试连通孔隙,也可以测试非连通孔隙,且不会对材料结构造成破坏,这是其他测试方法所不具备的优点,因此利用核磁共振技术对HBPRC的孔隙结构分形特征进行分形表征准确度更高。

根据相关文献[49],基于核磁共振T2谱分布的分形维数计算如下:

lgSV=(3−D)lgT2+(D−3)lgT2,max (6) 式中:T2为横向弛豫时间;SV为低于相应T2的孔体积占总孔体积的比例;D为分形维数。

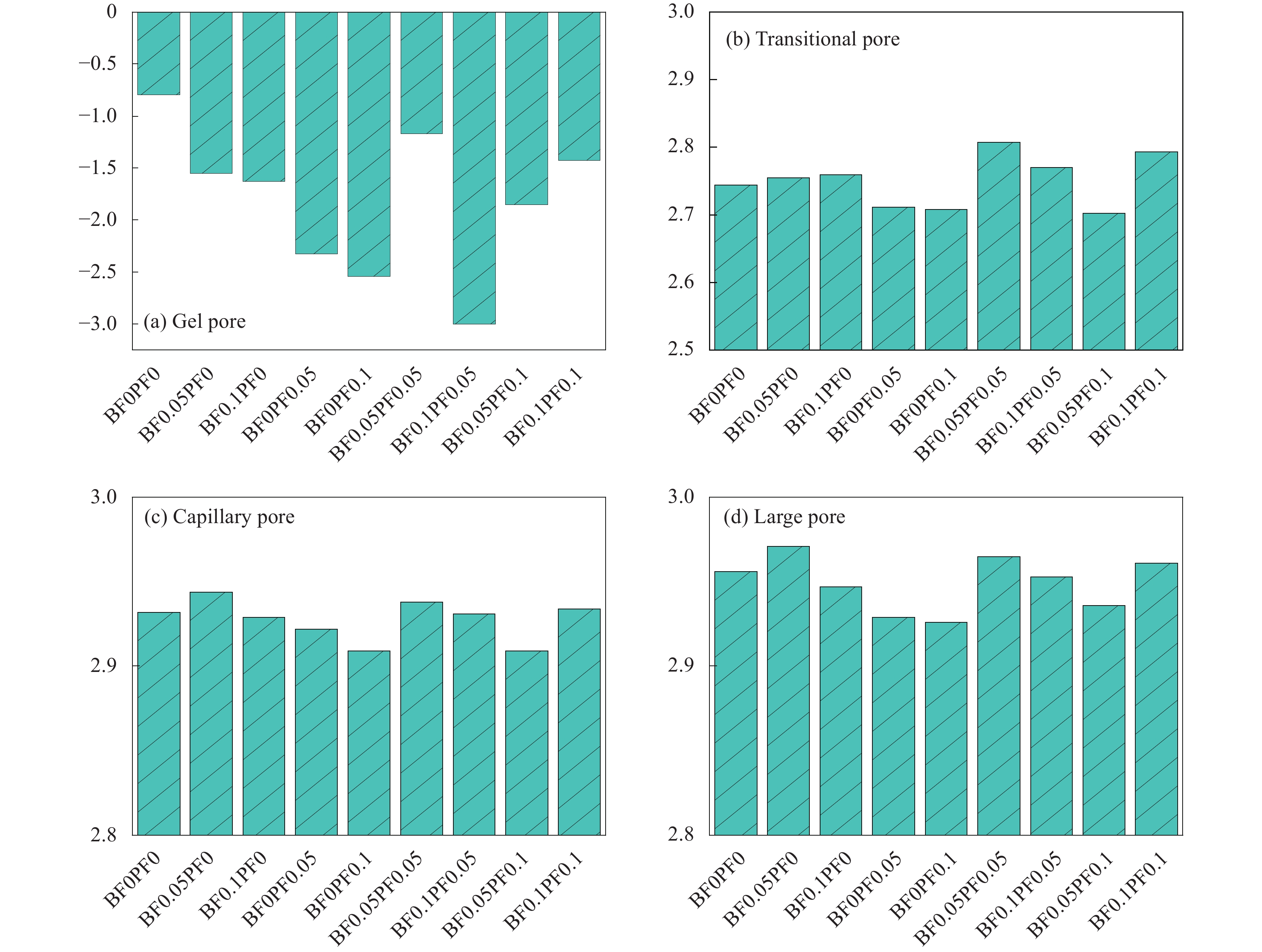

根据式(5)绘制出T2和SV的双对数曲线如图13所示,并对孔隙进行划分,将图13中每条曲线划分出4个区域,I~IV区分别对应于凝胶孔、过渡孔、毛细孔和大孔。通过对曲线拟合得到HBPRC的孔隙结构分形维数如图14所示。可以看出分形维数是连续的,这恰好符合张金喜等[50]的观点,即空间维数不是跃变的,而是可以连续变化的。

从图14(a)可以得知凝胶孔的分形维数不在2~3范围内,已经不能用欧式几何学去描述,失去了物理意义[51],因此在后续分析中排除此分形区域,以最大限度提高结果的准确性。同时由图14可以得知HBPRC的孔隙结构分形维数按大小排序均为大孔>毛细孔>过渡孔,这表明混凝土中的内部孔隙结构具有明显的分形特征,体现出混凝土作为分形介质所具备的自相似性和标度不变性,也是分形物体的基本性质,也反映出孔隙越大,结构越复杂,形状越不规则。

2.3.2 纤维对孔隙结构分形维数的影响

从图14(c)和图14(d)可以看出,单掺BF和PF主要对混凝土的毛细孔和大孔的分形维数产生影响,出现这种现象的原因是BF和PF的纤维-基体界面过渡区存在的孔隙一般为毛细孔和大孔。对单掺BF试件而言,掺入0.05vol%和0.1vol%BF时,毛细孔和大孔的分形维数先升高后降低。其中,毛细孔的分形维数分别增大了0.41%和下降了0.1%,大孔的分形维数分别增大了0.51%和下降了0.3%。对单掺PF试件而言,毛细孔和大孔的分形维数随着PF掺量的增大而降低,掺入0.05vol%和0.1vol%PF时,毛细孔的分形维数分别降低了0.34%和0.78%,大孔的分形维数分别降低了0.91%和1.01%。单掺BF和PF均对混凝土中大孔的分形维数影响幅度较大。

造成上述现象的原因主要是BF和PF与混凝土基体的粘结性存在差异。BF和PF与混凝土基体的界面过渡区的微观形貌如图15所示。可以看出,BF与混凝土基体的粘结性明显优于PF,这可能归结于BF和PF的化学性质。不同的湿润特性也会导致纤维-基体界面过渡区不同的粘结性能[43]。根据接触角是否小于或大于90°,BF属于亲水性材料。因此,BF表面能够吸收水分,促进表面胶凝材料的水化。从图15(a)可以看出,BF-基体界面过渡区较薄,孔隙也较少,同时BF表面覆盖有稠密的水泥水化基质,BF可以与周围的水泥基质形成较大的机械咬合力,因此BF与基体粘结性能好;同时,玄武岩是BF的原料,由表1可知,BF的化学成分接近于普通混凝土[52],可以和混凝土更好的包裹在一起。当适量的BF均匀分布于混凝土基体中,BF可与氢氧化钙(CH)发生二次水化反应,生成水化硅酸钙(C2S2H)凝胶[53],可以填充混凝土中的孔隙,进而有效细化混凝土的孔隙结构,增大相应区域分形维数;而PF属于疏水性纤维[54],且在水泥浆体的碱性环境中非常稳定,不会干扰水泥的水化反应[55]。如图15(b)所示,PF拔出后表面仅仅附着了少量的水泥浆体,而且PF-基体界面过渡区明显较厚且含有更多的孔隙,一般为大的毛细孔和大孔,表明PF与水泥基体的粘结性能较差,毛细孔和大孔的连通性增加,降低了毛细孔和大孔的复杂性,造成毛细孔和大孔的分形维数降低。

另一方面,混凝土在搅拌过程中会引入微气泡,BF搅拌后形成纤维网状结构,在抑制浆体离析过程也能限制气泡的移动,阻止气泡间的合并,使孔隙结构变得精细,部分大孔隙变成小孔隙或被破坏[40],孔隙连通性降低,因此BF0.05PF0的毛细孔和大孔的分形维数增大,但当BF含量过大时,BF相互团聚、搭接,如图16(a)所示,造成BF-基体界面过渡区数量增加并且相互重叠,毛细孔与其他孔隙连接[42],因此BF0.1PF0的毛细孔和大孔的分形维数降低。

由于PF不易分散,在搅拌时形成的网络结构效果远不及BF,无法有效阻止气泡间的合并,造成孔隙变大,孔隙连通性提高,大孔隙比例增加,因此PF的添加降低了毛细孔和大孔的分形维数。当PF掺量增大时,与BF相比,纤维间互相重叠、搭接(图16(b))和过渡区数量的增加对孔隙的劣化效果更明显,因此BF0PF0.1的大孔占比最大,达到30.87%。

掺入BF-PF混杂纤维同样对混凝土的毛细孔和大孔的分形维数产生了明显影响。当BF掺量固定时,随着PF的增加,毛细孔和大孔的分形维数减小;当BF-PF混杂纤维总体积掺量相同时,随着PF的增加,毛细孔和大孔的分形维数也在减小,说明PF是引起孔隙结构分形维数变小的主要因素。

当BF和PF混杂纤维体积掺量均为0.05vol%和0.1vol%时,与BF0PF0相比,BF0.05PF0.05和BF0.1PF0.1的毛细孔和大孔的分形维数均有所增加,其中BF0.05PF0.05的毛细孔和大孔的分形维数分别增加了0.2%和0.3%,BF0.1PF0.1分别相应增加0.07%和0.17%,表明BF-PF形成的均匀的三维纤维网(图14(c))也在孔结构的细化上起着积极作用,增大了其毛细孔和大孔的分形维数,进一步表明BF-PF混杂纤维在混凝土中存在正协同作用。当BF和PF体积掺量均为0.05vol%混杂时,大孔和毛细孔的分形维数增加幅度最大,同时由前文得到其抗压强度提升幅度最大、孔隙率最小、凝胶孔占比分别增大了8.76%,大孔占比分别降低了5.30%,孔径分布得到优化,因此其协同作用最佳。

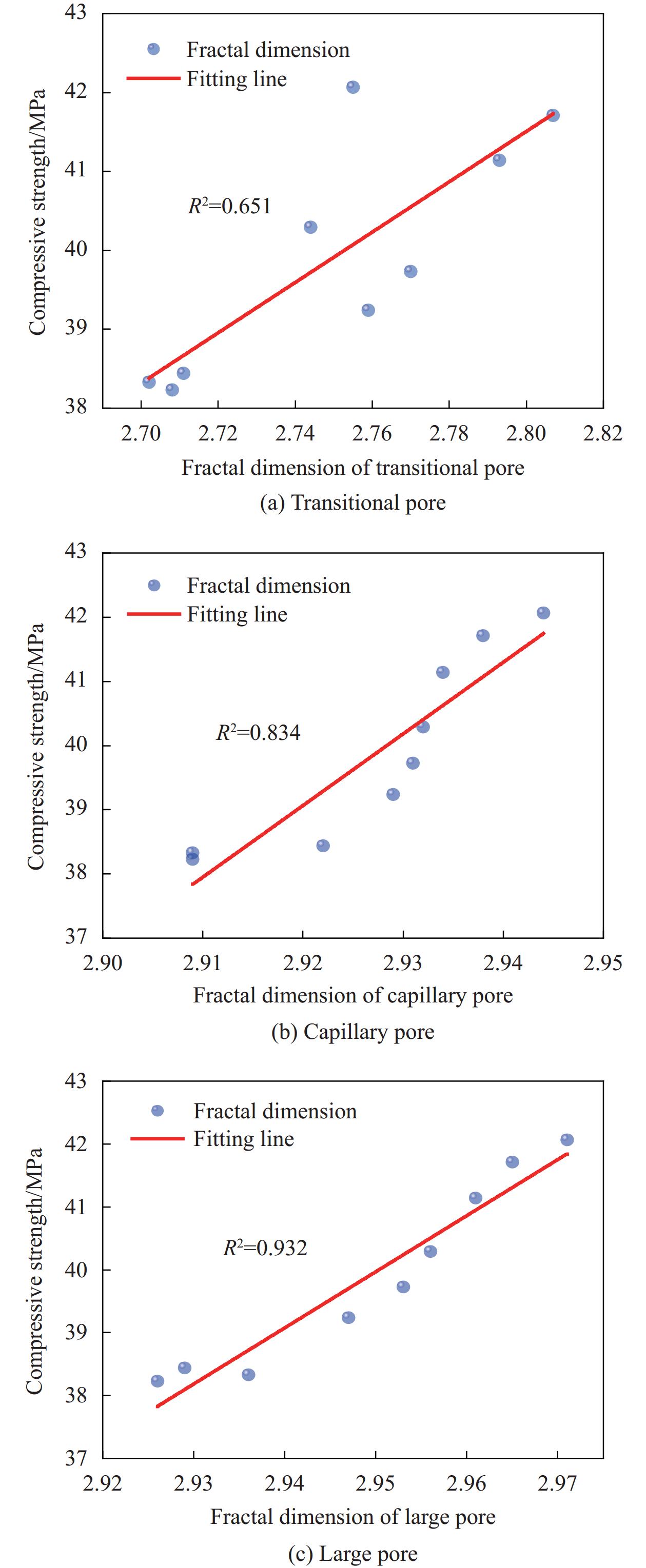

2.3.3 孔隙结构分形维数与抗压强度关系

Bensted[56]研究认为混凝土的抗压强度与毛细孔数量和大孔数量相关性较高,表明混凝土的抗压强度受孔隙结构的影响,因此可以用孔隙结构分形维数来表征混凝土的抗压强度。HBPRC的孔隙结构分形维数与强度关系如图17所示。可以看出,HBPRC的孔隙结构分形维数与抗压强度具有一定的相关性,HBPRC孔隙结构分形维数越大,抗压强度越大。拟合相关系数在过渡孔、毛细孔和大孔区域上分别为0.651、0.834和0.932,这是由于不同孔隙的形成方法不同,混凝土的多重分形特征与分形维数的相关系数也不同[57]。在本文中得出HBPRC的抗压强度与大孔的分形维数相关性最大,因此选择大孔的分形维数来表征HBPRC的抗压强度更准确。

HBPRC的孔隙结构普遍具有良好的分形特征,纤维类型、掺量和抗压强度与HBPRC的孔隙结构分形维数具有一定的相关性,尤其与毛细孔和大孔的分形维数关联性最高。因此,HBPRC的孔隙结构分形维数可以作为其孔隙分形特征的定量表达,也可以客观反映其抗压强度。

3. 结 论

采用NMR技术对玄武岩-聚丙烯混杂纤维混凝土(HBPRC)的孔隙特征进行试验研究,并进一步分析了玄武岩纤维(BF)和聚丙烯纤维(PF)对HBPRC孔隙特征的影响,得出结论如下:

(1) BF-PF混杂纤维可在混凝土内部形成均匀分布的三维纤维网,可以发挥出良好的承力效果,进一步提高混凝土的抗压强度;

(2)随着BF的添加,T2谱反映出适量的BF可以减小混凝土的孔隙率,而且有利于减小大孔体积占比;而随着PF含量增加,T2谱面积增加,混凝土内部孔隙有变大的趋势。BF和PF分别为0.05vol%混杂时在混凝土中发挥出正协同作用,T2谱面积最小,且较普通混凝土孔隙率降低了1.47%,凝胶孔占比增大了8.76%,大孔占比降低了5.30%,混凝土的孔径分布得到优化;

(3) HBPRC的孔隙结构具有明显的分形特征,孔隙结构分形维数随着孔径增大而减小。而BF和PF混杂在一定范围内可以在混凝土中发挥协同作用,弱化PF带来的不利影响,增大毛细孔和大孔的复杂程度,增大相应孔隙的分形维数;

(4) BF与PF与混凝土基体的粘结性能存在差异。BF-基体界面过渡区较薄,BF与混凝土基体粘结性能好,提升了混凝土的强度和增大了毛细孔和大孔的分形维数;PF-基体界面过渡区较厚,PF与混凝土基体的粘结性能较差,造成混凝土强度降低、毛细孔和大孔的分形维数降低;

(5) HBPRC的孔隙结构分形维数与抗压强度具有明显的相关关系,孔隙结构分形维数越大,抗压强度越大,其中选择大孔的分形维数来表征HBPRC的强度更准确;

(6) BF和PF混杂纤维体积掺量均为0.05vol%和0.1vol%时,均对混凝土抗压强度、孔隙率、孔径分布、曲折度和孔隙分形维数产生正协同作用,其中BF和PF体积掺量均为0.05vol%时,正协同作用最佳。在BF0.05PF0.1和BF0.1PF0.05中则出现一定程度的负协同效应。

-

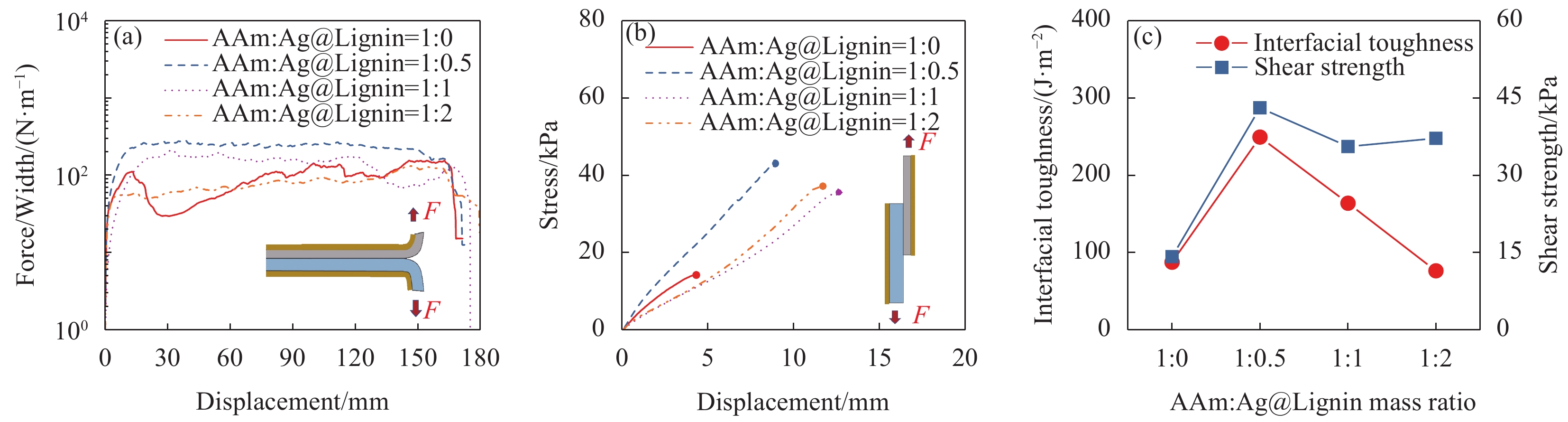

图 2 不同Ag@Lignin NPs用量对HAp-Ag@Lignin-ZnCl2/PAAm凝胶电解质的拉伸性能((a), (b))、循环拉伸性能及能量耗散率(c)、撕裂能(d)的影响

Figure 2. Effect of different Ag@Lignin NPs amount on tensile performance ((a), (b)), cycling tensile performance and dissipation ratio (c) and fracture energy (d) of HAp-Ag@Lignin-ZnCl2/PAAm hydrogel electrolytes

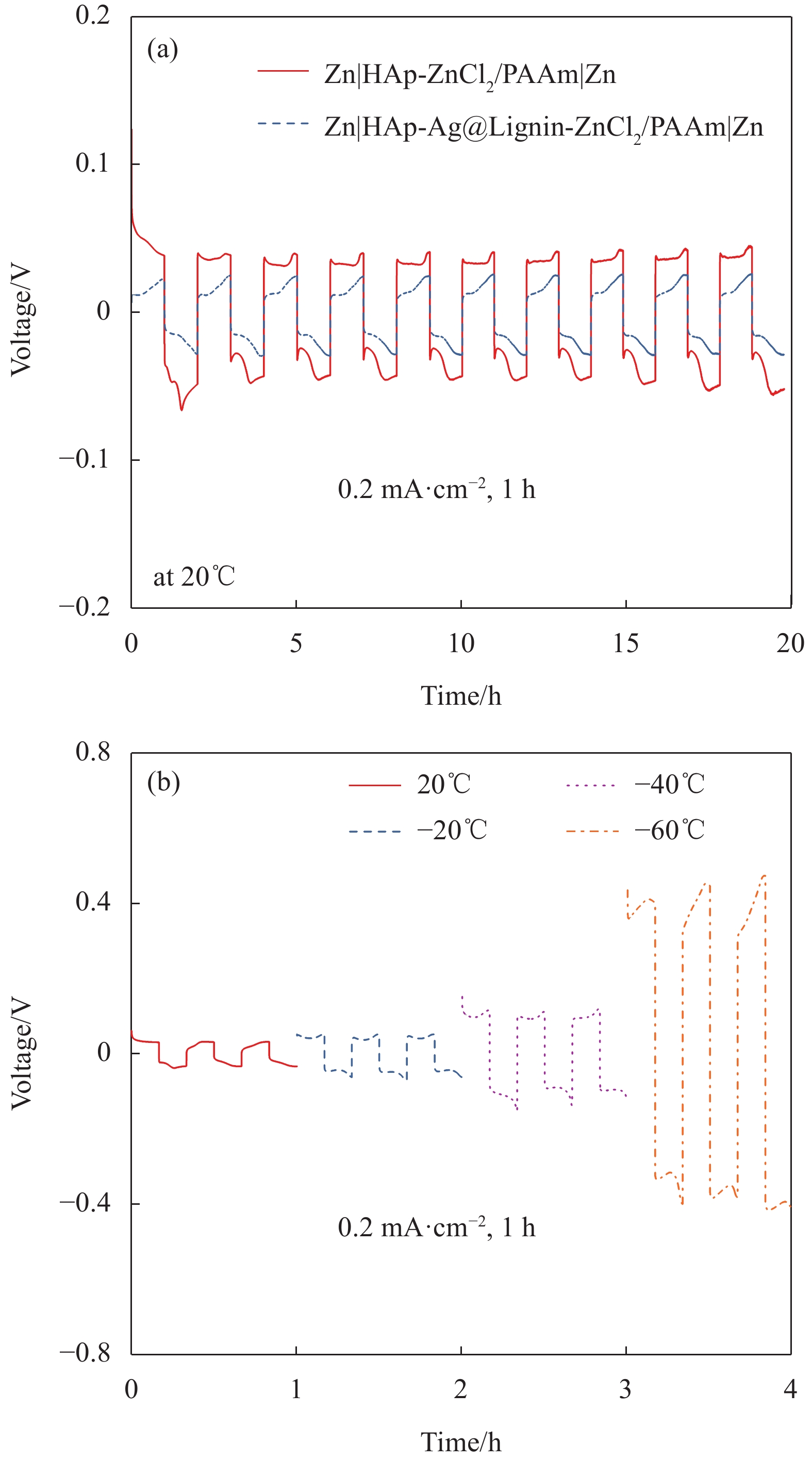

图 6 HAp-Ag@Lignin-ZnCl2/PAAm凝胶电解质和HAp-ZnCl2/PAAm凝胶电解质组装的Zn||Zn电池(a)及HAp-Ag@Lignin-ZnCl2/PAAm凝胶电解质组装的Zn||Zn电池在20~–60℃下(b)的电压分布

Figure 6. Voltage profiles of Zn||Zn cells assembled by HAp-Ag@Lignin-ZnCl2/PAAm hydrogel electrolyte, HAp-ZnCl2/PAAm hydrogel electrolyte (a) and HAp-Ag@Lignin-ZnCl2/PAAm hydrogel electrolyte-assembled Zn||Zn cells at 20-–60℃ (b)

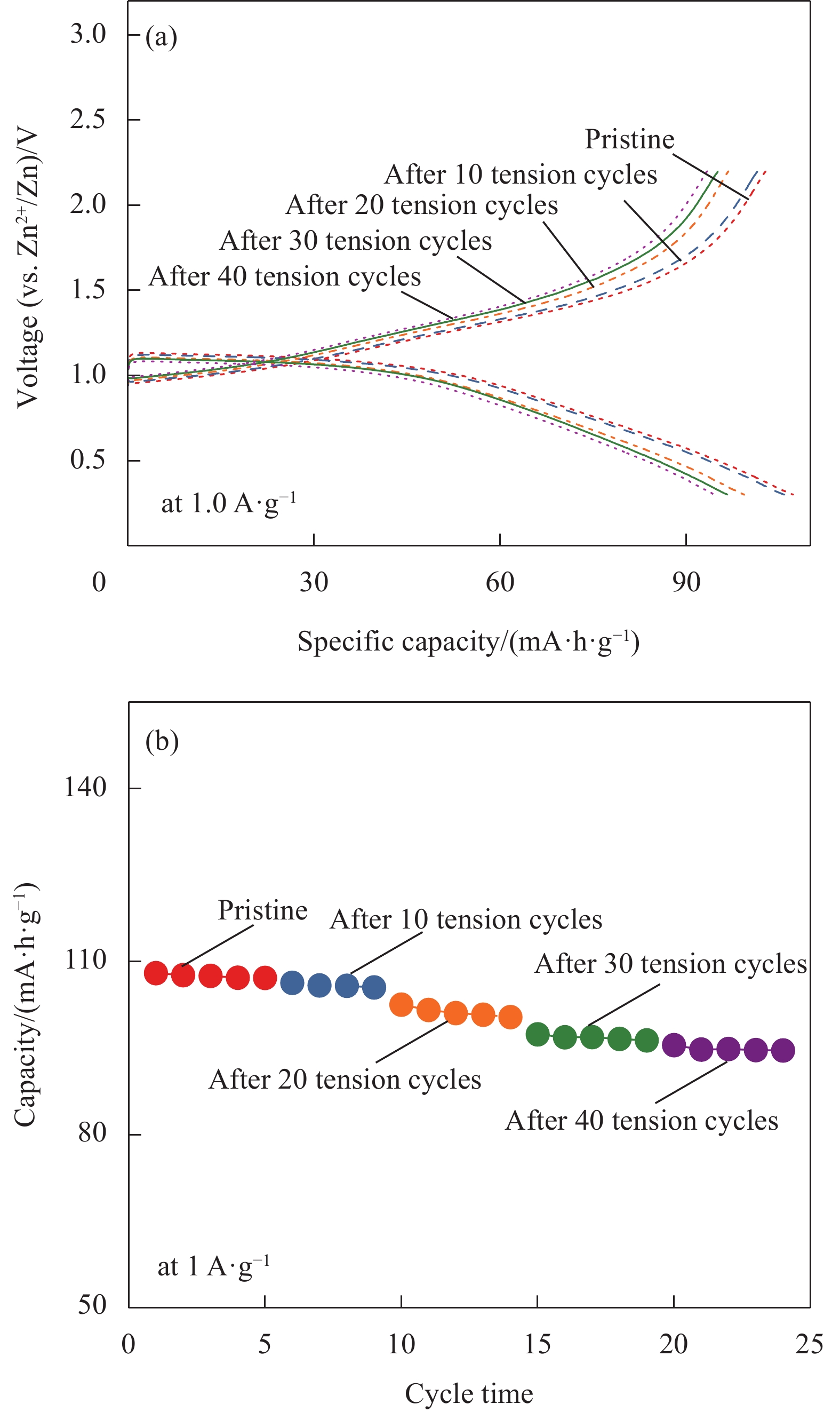

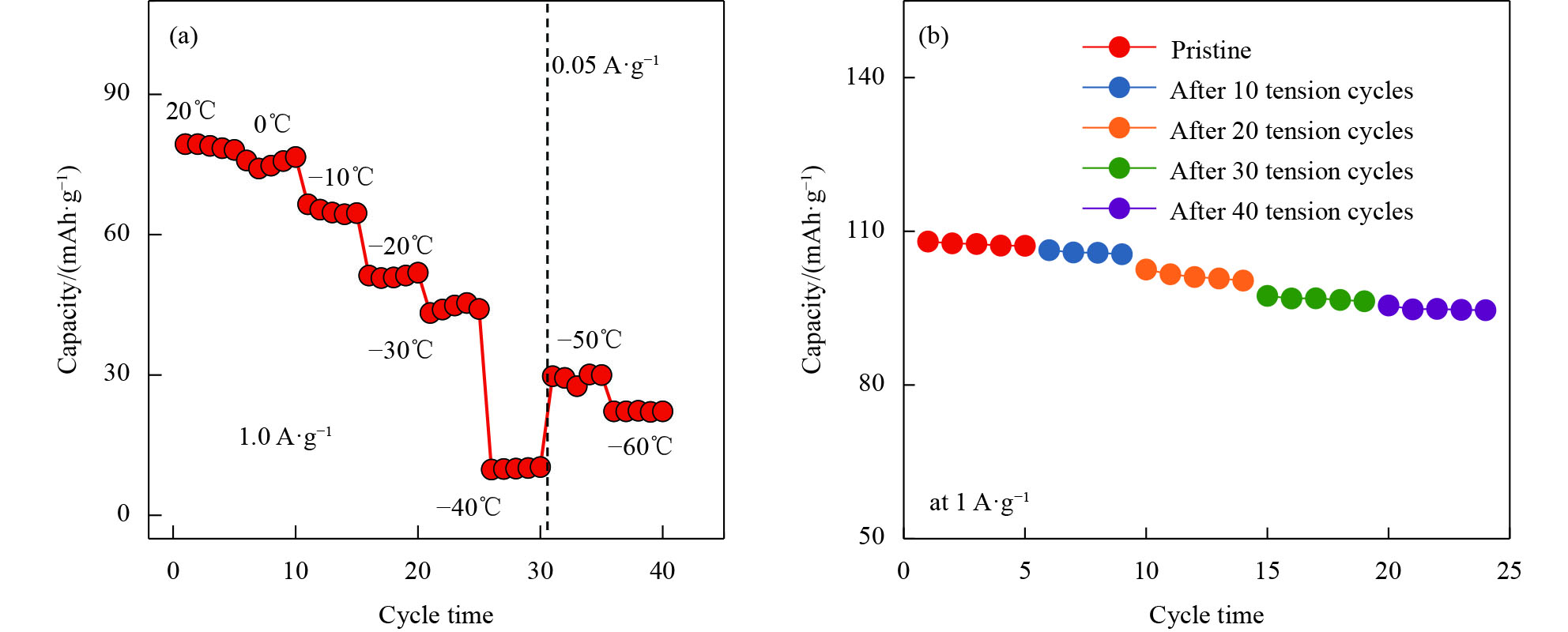

图 7 (a)层层组装的Zn||PANI锌离子电池随着温度的降低在循环伏安测试过程中氧化还原峰的变化趋势;氧化还原峰1 (b)和氧化还原峰2 (c)随着温度的变化;在20~–40℃ (d)和–50~–60℃ (e)下的充/放电的过程及电容量的变化(f);Zn||PANI锌离子电池在不同温度下的速率性能(g)和能量密度/功率密度变化(h);(i) Zn||PANI锌离子电池在20℃和–40℃温度下的循环性能

b—Peak curve slope; Avg CE—Average coulomb efficiency

Figure 7. (a) Trend of redox peaks during cyclic voltammetry test of layer-assembled Zn||PANI Zn-ion battery with decreasing temperature; Redox peaks 1 (b) and peaks 2 (c) with temperature; Charging and discharging process in the temperature range of 20-–40℃ (d) and –50-–60℃ (e) and capacity changes (f); Rate performance (g) and energy density/power density changes (h) of Zn||PANI Zn-ion battery at different temperatures; (i) Cycle performance of Zn||PANI Zn-ion battery at temperatures of 20℃ and –40℃

图 9 Zn||PANI固态锌离子电池与之前报道的固态锌离子电池和超级电容器在最低工作温度、电压窗口、沉积/剥离循环、能量密度、变形稳定性和安全性能方面的比较

Figure 9. Comparison of the Zn||PANI solid Zn-ion battery with previously reported solid Zn-ion battery and supercapacitor in the freezing tolerance, voltage window, plating/stripping cycles, energy density, deformation stability and safety property

表 1 不同水凝胶电解质的配比

Table 1 Contents of the different hydrogel electrolyte

Sample (AAm∶Ag@Lignin) AAm/g HAp/g MBAA/mg APS/mg Ag@Lignin NPs/mL Deionized water/mL ZnCl2/g 1∶0 3.15 0.63 9.45 37.8 0 15 15.34 1∶0.5 3.15 0.63 9.45 37.8 1.575 13.425 15.34 1∶1 3.15 0.63 9.45 37.8 3.15 11.85 15.34 1∶2 3.15 0.63 9.45 37.8 6.3 8.7 15.34 Notes: AAm—Acrylamide; HAp—Hydroxyapatite; MBAA—Methylene-bis-acrylamide; APS—Ammonium persulfate; Ag@Lignin NPs—Ag@Lignin nanoparticles. 表 2 Zn||PANI固态锌离子电池与之前报道的水系储能器件的比较

Table 2 Zn||PANI solid Zn-ion battery and compared with the previously reported aqueous-based energy storage devices

Device configuration Freezing tolerance/℃ Capacity retention

under deformation/%Energy density/

(W·h·kg−1)Voltage window/V Overpotential/V Zn||PANI battery –60 88.3 76.0 1.9 0.02 Zn||V2O5 battery[43] 20 86.0 − 1.3 0.10 PANI||PANI supercapacitor[17] –40 86.5 16.0 0.8 − Zn||LiFePO4 battery[34] –20 80.0 − 0.8 0.04 Zn||PANI-V2O5 battery[44] –40 − 75.0 1.4 0.05 -

[1] DUBAL D P, CHODANKAR N R, KIM D H, et al. Towards flexible solid-state supercapacitors for smart and wearable electronics[J]. Chemical Society Reviews, 2018, 47(6): 2065-2129. DOI: 10.1039/C7CS00505A

[2] LI X, YUAN L, LIU R, et al. Engineering textile electrode and bacterial cellulose nanofiber reinforced hydrogel electrolyte to enable high-performance flexible all-solid-state supercapacitors[J]. Advanced Energy Materials, 2021, 11(12): 2003010. DOI: 10.1002/aenm.202003010

[3] YU H, ROUELLE N, QIU A, et al. Hydrogen bonding-reinforced hydrogel electrolyte for flexible, robust, and all-in-one supercapacitor with excellent low-temperature tolerance[J]. ACS Applied Materials & Interfaces, 2020, 12(34): 37977-37985.

[4] LIU X, WU Z, JIANG D, et al. A highly stretchable, sensing durability, transparent, and environmentally stable ion conducting hydrogel strain sensor built by interpenetrating Ca2+-SA and glycerol-PVA double physically cross-linked networks[J]. Advanced Composites and Hybrid Materials, 2022, 5(3): 1712-1729. DOI: 10.1007/s42114-021-00396-w

[5] ZOU Y, CHEN C, SUN Y, et al. Flexible, all-hydrogel supercapacitor with self-healing ability[J]. Chemical Engineering Journal, 2021, 418: 128616. DOI: 10.1016/j.cej.2021.128616

[6] JIANG L, LI Y, ZOU F, et al. Highly self-adhesive, compressible, stretchable, all hydrogel-based supercapacitor for wearable/portable electronics[J]. Materials Today Physics, 2023, 33: e101046. DOI: 10.1016/j.mtphys.2023.101046

[7] LIU X, LIU J, LIN S, et al. Hydrogel machines[J]. Materials Today, 2020, 36: 102-124. DOI: 10.1016/j.mattod.2019.12.026

[8] MO F, LIANG G, MENG Q, et al. A flexible rechargeable aqueous zinc manganese-dioxide battery working at −20℃[J]. Energy & Environmental Science, 2019, 12(2): 706-715.

[9] YANG J, XU Z, WANG J, et al. Antifreezing zwitterionic hydrogel electrolyte with high conductivity of 12.6 mS·cm−1 at −40℃ through hydrated lithium ion hopping migration[J]. Advanced Functional Materials, 2021, 31(18): e2009438. DOI: 10.1002/adfm.202009438

[10] TAO F, QIN L, WANG Z, et al. Self-healable and cold-resistant supercapacitor based on a multifunctional hydrogel electrolyte[J]. ACS Applied Materials & Interfaces, 2017, 9(18): 15541-15548.

[11] MORELLE X P, ILLEPERUMA W R, TIAN K, et al. Highly stretchable and tough hydrogels below water freezing temperature[J]. Advanced Materials, 2018, 30(35): e1801541. DOI: 10.1002/adma.201801541

[12] ABBAS Q, BÉGUIN F. Sustainable carbon/carbon supercapacitors operating down to −40℃ in aqueous electrolyte made with cholinium salt[J]. ChemSusChem, 2018, 11 (5): 975-984.

[13] MO F, LI Q, LIANG G, et al. A self-healing crease-free supramolecular all-polymer supercapacitor[J]. Advanced Science, 2021, 8(12): 2100072. DOI: 10.1002/advs.202100072

[14] ZHANG Y, SUN Y, NAN J, et al. In situ polymerization of hydrogel electrolyte on electrodes enabling the flexible all-hydrogel supercapacitors with low-temperature adaptability[J]. Small, 2024, 20(22): 2309900.

[15] NIE C, WANG G, WANG D, et al. Recent progress on Zn anodes for advanced aqueous zinc-ion batteries[J]. Advanced Energy Materials, 2023, 13(28): 2300606. DOI: 10.1002/aenm.202300606

[16] LI G, ZHAO Z, ZHANG S, et al. A biocompatible electrolyte enables highly reversible Zn anode for zinc ion battery[J]. Nature Communications, 2023, 14(1): 6526. DOI: 10.1038/s41467-023-42333-z

[17] LIU Z, ZHANG J, LIU J, et al. Highly compressible and superior low temperature tolerant supercapacitors based on dual chemically crosslinked PVA hydrogel electrolytes[J]. Journal of Materials Chemistry A, 2020, 8(13): 6219-6228. DOI: 10.1039/C9TA12424A

[18] 卢小杰, 徐晶, 杨科, 等. 碳纳米纤维表面网络修饰及其锌离子电池应用[J]. 复合材料学报, 2023, 40(5): 2731-2740. LU Xiaojie, XU Jing, YANG Ke, et al. Surface network modification of carbon nanofibers and its application in zinc ion batteries[J]. Acta Materiae Compositae Sinica, 2023, 40(5): 2731-2740(in Chinese).

[19] LU J, JAUMAUX P, WANG T, et al. Recent progress in quasi-solid and solid polymer electrolytes for multivalent metal-ion batteries[J]. Journal of Materials Chemistry A, 2021, 9(43): 24175-24194. DOI: 10.1039/D1TA06606D

[20] WANG C, FU K, KAMMAMPATA S P, et al. Garnet-type solid-state electrolytes: Materials, interfaces, and batteries[J]. Chemical Reviews, 2020, 120(10): 4257-4300. DOI: 10.1021/acs.chemrev.9b00427

[21] WANG X, KERR R, CHEN F, et al. Toward high-energy-density lithium metal batteries: Opportunities and challenges for solid organic electrolytes[J]. Advanced Materials, 2020, 32(18): 1905219. DOI: 10.1002/adma.201905219

[22] ZHAO Q, STALIN S, ZHAO C Z, et al. Designing solid-state electrolytes for safe, energy-dense batteries[J]. Nature Reviews Materials, 2020, 5(3): 229-252. DOI: 10.1038/s41578-019-0165-5

[23] ZHOU J, ZHU Z, SHI W, et al. Design strategies and recent advancements of solid-state supercapacitor operating in wide temperature range[J]. Carbon Energy, 2024, 6(6): e504.

[24] ZHANG J, WAN L, GAO Y, et al. Highly stretchable and self-healable mxene/polyvinyl alcohol hydrogel electrode for wearable capacitive electronic skin[J]. Advanced Electronic Materials, 2019, 5(7): 1900285. DOI: 10.1002/aelm.201900285

[25] HAN L, HUANG H, FU X, et al. A flexible, high-voltage and safe zwitterionic natural polymer hydrogel electrolyte for high-energy-density zinc-ion hybrid supercapacitor[J]. Chemical Engineering Journal, 2020, 392: 123733. DOI: 10.1016/j.cej.2019.123733

[26] ZHAO Y, LU Y, LI H, et al. Few-layer bismuth selenide cathode for low-temperature quasi-solid-state aqueous zinc metal batteries[J]. Nature Communications, 2022, 13(1): 752. DOI: 10.1038/s41467-022-28380-y

[27] ZHANG Q, XIA K, MA Y, et al. Chaotropic anion and fast-kinetics cathode enabling low-temperature aqueous Zn batteries[J]. ACS Energy Letters, 2021, 6: 2704-2712. DOI: 10.1021/acsenergylett.1c01054

[28] NAN J, SUN Y, YANG F, et al. Coupling of adhesion and anti-freezing properties in hydrogel electrolytes for low-temperature aqueous-based hybrid capacitors[J]. Nano-Micro Letters, 2023, 16(1): 22.

[29] YUK H, ZHANG T, LIN S, et al. Tough bonding of hydrogels to diverse non-porous surfaces[J]. Nature Materials, 2016, 15(2): 190-196. DOI: 10.1038/nmat4463

[30] JIAN Y, HANDSCHUH-WANG S, ZHANG J, et al. Biomimetic anti-freezing polymeric hydrogels: Keeping soft-wet materials active in cold environments[J]. Materials Horizons, 2021, 8(2): 351-369. DOI: 10.1039/D0MH01029D

[31] GAN D, XING W, JIANG L, et al. Plant-inspired adhesive and tough hydrogel based on Ag-lignin nanoparticles-triggered dynamic redox catechol chemistry[J]. Nature Communications, 2019, 10(1): 1487. DOI: 10.1038/s41467-019-09351-2

[32] WANG D, YANG F, CONG L, et al. Lignin-containing hydrogel matrices with enhanced adhesion and toughness for all-hydrogel supercapacitors[J]. Chemical Engineering Journal, 2022, 450: 138025. DOI: 10.1016/j.cej.2022.138025

[33] WANG D, YANG F, WANG C, et al. In-situ polymerization of PANI on hydrogel electrolyte enabling all-in-one supercapacitors mechanically stable at low temperatures[J]. Chemical Engineering Journal, 2023, 455: 140949. DOI: 10.1016/j.cej.2022.140949

[34] ZHU M, WANG X, TANG H, et al. Antifreezing hydrogel with high zinc reversibility for flexible and durable aqueous batteries by cooperative hydrated cations[J]. Advanced Functional Materials, 2019, 30(6): 1907218.

[35] LU Y, LI L, ZHANG Q, et al. Electrolyte and interface engineering for solid-state sodium batteries[J]. Joule, 2018, 2(9): 1747-1770. DOI: 10.1016/j.joule.2018.07.028

[36] ZHANG Q, MA Y, LU Y, et al. Modulating electrolyte structure for ultralow temperature aqueous zinc batteries[J]. Nature Communications, 2020, 11(1): 4463. DOI: 10.1038/s41467-020-18284-0

[37] WANG F, BORODIN O, GAO T, et al. Highly reversible zinc metal anode for aqueous batteries[J]. Nature Materials, 2018, 17(6): 543-549. DOI: 10.1038/s41563-018-0063-z

[38] SHI Y, WANG R, BI S, et al. An anti-freezing hydrogel electrolyte for flexible zinc-ion batteries operating at −70℃[J]. Advanced Functional Materials, 2023, 33(24): 2214546. DOI: 10.1002/adfm.202214546

[39] WAN F, ZHANG L, WANG X, et al. An aqueous rechargeable zinc-organic battery with hybrid mechanism[J]. Advanced Functional Materials, 2018, 28(45): 1804975. DOI: 10.1002/adfm.201804975

[40] SINGH S B, TRAN D T, JEONG K U, et al. A flexible and transparent zinc-nanofiber network electrode for wearable electrochromic, rechargeable Zn-ion battery[J]. Small, 2021, 18(5): 2104462.

[41] YAN Y, DUAN S, LIU B, et al. Tough hydrogel electrolytes for anti-freezing zinc-ion batteries[J]. Advanced Materials, 2023, 35(18): 2211673. DOI: 10.1002/adma.202211673

[42] CHEN Z, LI X, WANG D, et al. Grafted MXene/polymer electrolyte for high performance solid zinc batteries with enhanced shelf life at low/high temperatures[J]. Energy & Environmental Science, 2021, 14(6): 3492-3501.

[43] LU Y, ZHU T, XU N, et al. A semisolid electrolyte for flexible Zn-ion batteries[J]. ACS Applied Energy Materials, 2019, 2(9): 6904-6910. DOI: 10.1021/acsaem.9b01415

[44] CHANG N, LI T, LI R, et al. An aqueous hybrid electrolyte for low-temperature zinc-based energy storage devices[J]. Energy & Environmental Science, 2020, 13(10): 3527-3535.

-

其他相关附件

-

目的

凝胶基固态锌离子电池作为柔性储能器件具有良好的机械稳定性、环境友好性和高安全性,在可穿戴设备领域日益受到关注,但存在因界面接触差和易冻结限制了凝胶基固态电池在低温环境中的使用性能。因此本文旨在开发一种新型凝胶基固态锌离子电池,具有强界面粘接、耐低温和抗形变特性,为低温柔性储能系统的稳定运行提供了一种可行的方法和技术支持。

方法本文采用银/木质素纳米颗粒诱导自由基聚合的方法制备了具有强自粘性的抗冻凝胶电解质;通过调整凝胶电解质中银/木质素纳米颗粒的含量,研究银/木质素纳米颗粒对凝胶电解质的韧性、凝胶电解质/锌电极之间界面粘接和界面相容性的影响;通过锌的沉积/剥离实验,测试凝胶电解质和锌电极之间的界面相容性;采用层层组装的方式将聚苯胺浆料、凝胶电解质和锌电极直接堆叠在一起,形成以锌金属为负极、聚苯胺为正极的锌|凝胶电解质|聚苯胺固态锌离子电池,对其进行不同温度下和循环拉伸下的充/放电实验,测试电池的低温电化学性能和变形稳定性。

结果实验结果表明:①银/木质素纳米颗粒(Ag@Lignin NPs)的引入增强了水凝胶的粘接性能,当丙烯酰胺(AAm)和Ag@Lignin NPs的用量比值为1:0.5时,凝胶电解质与锌(Zn)之间的粘接能和剪切强度在–60℃时达到467 J·m和96 kPa。②凝胶电解质与Zn之间的强界面粘接和耐低温性能提高了Zn的可逆和相容性能,实现了Zn||Zn对称电池在20~–60℃温度区间内稳定的Zn沉积/剥离循环。③Zn||PANI电池具有良好的低温电化学性能,最低工作温度可达–60℃,在–40℃下进行300次充/放电循环后,平均库伦效率为95.83%,电容量保持率为65.20%。④Zn||PANI电池具有良好的变形稳定性,经历40次的20%应变的拉伸循环后,电容量保持率维持在88.3%。

结论本文采用银/木质素纳米粒子诱导自由基聚合的方法制备了具有强自粘性的抗冻凝胶电解质,利用凝胶电解质中银/木质素邻苯二酚基团的金属配位作用实现了其对无孔Zn电极和多孔PANI电极的强界面粘接,从而提高了Zn的可逆和相容性能,实现了Zn金属电极在20~–60℃温度区间内稳定的沉积/剥离循环。基于凝胶电解质优异的粘接性能和抗冻性能,制备的Zn||PANI固态锌离子电池表现出良好的低温电化学性能和变形稳定性,为低温柔性储能系统的稳定运行提供了一种可行的方法和技术支持。

-

由于凝胶具有本征机械柔韧性、高离子电导率和阻燃特性等优势,使其作为固态电解质应用于柔性储能器件,具有广阔的应用前景。但存在因凝胶电解质与电极之间的界面接触差导致器件的界面阻抗大、机械稳定性弱等缺陷,从而限制了其在柔性储能技术的大规模投入应用。因此,设计和开发高性能凝胶基固态电池是解决柔性储能应用问题的关键挑战。

本文采用层层组装的方法,将Zn金属电极、强自粘性抗冻凝胶电解质和聚苯胺(PANI)电极组装成Zn||PANI锌离子电池。Ag@Lignin NPs和Zn电极之间产生配位键和共价键赋予凝胶电解质和Zn电极之间强的界面粘接。凝胶电解质与Zn之间界面粘接力的提升减少了界面阻抗,实现了Zn|凝胶电解质|Zn在20~–60℃温度区间内稳定的界面相容性能。与此同时,Zn||PANI锌离子电池具有良好的低温电化学性能和变形稳定性,在20~–60℃下具有稳定的电容量输出,在经过40次拉伸循环后具有88.3%的电容量保持率。

Zn||PANI锌离子电池在低温下的电化学性能(a)和变形后的电化学性能(b)

下载:

下载: