Preparation and anti-corrosion properties of sulfuric acid secondary doped polyaniline/graphene/carbon nanotube composites

-

摘要:

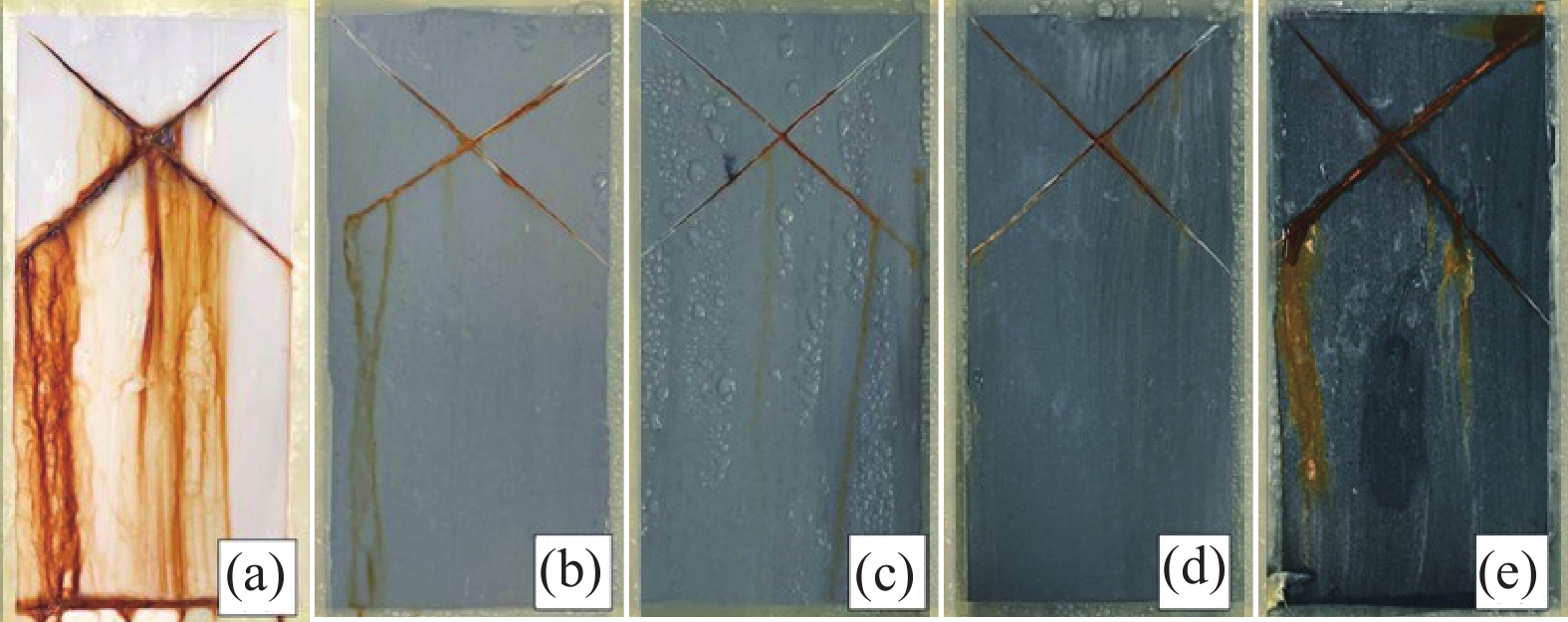

为改善纳米复合材料形貌结构和提高其防腐性能,减少材料腐蚀导致的经济损失和安全事故,本文在硫酸体系中通过原位聚合将苯胺(ANI)分别与不同配比的还原氧化石墨烯(RGO)和碳纳米管(CNTs)制备RGO/PANI和CNTs/PANI一次掺杂态产物,将一次掺杂态产物分别经氨水解掺杂后,在硫酸体系中对两种产物共同进行二次掺杂制备得到硫酸RGO CNTs/Redoped PANI复合材料。采用SEM、TEM、FTIR、UV-Vis对不同产物的形貌和结构进行表征,通过电化学测试研究了产物的防腐性能;并将二次掺杂制备的三元纳米复合材料与环氧树脂制备成涂层,对涂层进行交流阻抗测试和中性盐雾试验。结果表明:二次掺杂方法可有效提升原位聚合的产物性能;在RGO∶ANI为1∶10、CNTs∶ANI为1∶15时,产物形貌和防腐性能最优,缓蚀率可达81.18%;制备的复合涂层在3.5wt% NaCl溶液中浸泡

1440 h后,仍保持较高阻抗值,添加量为1wt%的涂层阻抗值达6.019×1010 Ω·cm2,且经1440 h中性盐雾试验后,涂层表面无鼓泡和其他劣化现象,仅在划痕处有少量锈蚀但未扩散蔓延,体现出优异的防腐性能。表明开发基于聚苯胺纳米复合材料重防腐涂料体系的可行性,可为金属材料提供长效防护。Abstract:In order to improve the morphology and structure of nanocomposites, improve their anti-corrosion properties, and reduce the economic losses and safety accidents caused by material corrosion, aniline (ANI) was combined with different ratios of graphene (RGO) and carbon nanotubes (CNTs) to synthesize RGO/polyaniline (PANI) primary doped products and CNTs/PANI primary doped products. After redoping with ammonia, the RGO CNTs/redoped PANI composite were prepared by secondary doping of the two products in the sulfuric acid system. The morphology and structure of different PANI products were characterized by means of scanning electron microscopy, transmission electron microscopy. The anti-corrosion properties of different products were tested by electrochemical workstation, the best performing PANI composite material was combined with resin to prepare PANI epoxy coating. Anticorrosive properties of the coatings soaked for a long time were studied by AC impedance test and verified by neutral salt spray test. The performances of the composite materials prepared by secondary doping alone are significantly improved compared to those prepared by direct blending, the product has the best morphology and anti-corrosion performance when RGO∶ANI is 1∶10 and CNTs∶ANI is 1∶15, with the corrosion inhibition rate of 81.18%, the PANI epoxy coatings still exhibit high impedance values after soaking in 3.5wt% NaCl solution for

1440 h, with the highest impedance value reaching 6.019×1010 Ω·cm2 when the PANI addition amount is 1wt%, and there is no obvious corrosion on the coating surface after1440 h neutral salt spray test, the coating surface has no bubbling and other deterioration phenomena, only a small amount of rust in the scratch but not spread, reflecting excellent anti-corrosion properties. It is feasible to develop a heavy anticorrosive coating system based on polyaniline nanocomposites, which can provide long-term protection for metal materials.-

Keywords:

- polyaniline /

- nanomaterials /

- doping /

- corrosion /

- epoxy coating

-

双稳态复合材料层板具有两种稳定状态,两种稳定状态之间的转换只需要一个较小激励便可获得较大变形,且无需持续的能量输入维持其稳定构型,在可变形结构和能量收集领域得到了高度关注。

Hyer[1]首次在实验中发现了非对称铺层的复合材料层板在固化后会呈现两个圆柱形稳定状态,与经典层板理论获得的马鞍形构型不同,随后建立了双稳态层板理论预报模型[2-3],开始了双稳态层板研究的先河。目前,国内外研究学者在双稳态层板的改进理论预报模型[4-6]、跳变过程分析[7-10]、驱动方法[11-14]与可变形结构应用[15-17]等方面展开了大量的研究。

在双稳态层板的基础上,发展复合材料层板的多稳态特性可以拓宽其在可变形结构中的应用范围。目前主要的实现途径分为两类,一类是分段铺层的变刚度设计,Mattioni等[18]提出了一种由对称与非对称两种不同铺层顺序组成的变刚度层板,并建立了层板的数值计算模型,验证了多稳态铺层设计。Sousa等[19]针对对称与非对称铺层区域相交处纤维不连续性所产生的应力集中问题,引入弯曲纤维来提高结构的稳定性。Arrieta等[20]提出了分段式铺层的多稳态结构,通过串联连续的复合铺层,在机翼结构中嵌入可变形单元来获得变刚度特性。Cui等[21]将多稳态层板的应用扩展至二维空间,设计了一种由9个双稳态方形单元组合而成的曲面层板,运用特定的铺层顺序减小变形单元连接处由于弯曲方向不一致而产生的几何不兼容现象。Wang等[22]引入了对称铺层的过渡单元设计来缓解各变形单元之间的几何兼容问题,提高了多稳态层板的可设计性与可变形性。Zhang等[23]受此启发,将不对称铺层层板应用于过渡单元,发现该方法不仅能减小过渡单元的面积,并且对各类变形单元都有较好的适应性。Annamalai[24]运用分布式铺层方法,对如十字形等各类不同几何外形的层板进行了多稳态结构的有限元设计,但该方法仍存在几何不兼容的问题。

第二类是使用组合叠加的方法,该方法能够优化分段铺层的几何兼容性问题,同时具有大变形与可设计性等优势。Dai等[25]采用螺栓固定的方法制备了一种多稳态晶格结构,利用刚性连接来获得相交处的几何兼容性,并且通过拼接可以使该结构具有各种变形形状。Zhang等[26]以机械连接形式将双稳态层板进行组合获得了具有多种稳态的捕蝇草结构系统。Panesar等[27]利用丝束转向技术制造了一种多稳态混合襟翼,确保了纤维在层板面内的连续性。Algmuni等[28]通过在变形单元之间连接柔性带,以提高周期性结构的稳定性。Risso等[29]提出了一种将预拉伸薄膜与条带状复合材料层板相结合的多稳态结构,通过条带状层板的调整,能够实现正多边形的多稳态结构设计。Phanendra等[30]从理论与仿真两方面对由多个矩形层板叠加铺层得到的星形多稳态层板进行了研究,但是没有考虑制备的可行性。组合叠加得到的层板,结构较复杂且需要额外的机械紧固件连接。

本文通过将两块矩形层板以交叉铺设的形式连接并采用热压罐共固化成型,期望获得多稳态层板。然而这种交叉连接的方式会引起中心胶接区域产生较大刚度,从而导致结构失去多稳态特性。因此,本文对十字形层板引入切口设计的方法削弱中心区域刚度,并获得层板的多稳态特性。通过有限元和试验手段研究了胶接面积、切口角度和层板纵横比等参数对新型十字形多稳态层板稳定构型的影响规律,并根据层板的跳变行为揭示其影响机制,为含切口十字形多稳态层板的构型调控奠定基础。

1. 含切口矩形非对称层板的双稳态特性

选用S4C9/SY-24型玻璃纤维增强环氧树脂复合材料(中航复合材料有限公司),材料属性如表1所示。对矩形层板进行切口设计,如图1所示,采用[902/02]非对称铺层,单层厚度为0.11 mm,固化温度135℃。令层板总长L=250 mm、宽度W=75 mm,中心区域边长a=25 mm、切口角度θ=45°,首先从仿真与实验两方面分析该切口设计对矩形层板稳定构型的影响情况。

表 1 S4C9/SY-24型玻璃纤维增强环氧树脂复合材料的材料属性Table 1. Material properties of S4C9/SY-24 glass fiber reinforced polymer compositeMaterial property E1/GPa E2/GPa ν12 G12/GPa G13/GPa G23/GPa α11/℃−1 α12/℃−1 α13/℃−1 Value 54.6 10.5 0.33 5.5 5.5 3.9 6.7×10−6 2.9×10−5 2.9×10−5 Notes: E1—Longitudinal modulus; E2—Transverse modulus; ν12—Poisson's ratio; G12—In-plane shear modulus; G13, G23—Inter-laminar shear modulus; α11—Longitudinal thermal expansion coefficient; α12, α13—Transverse thermal expansion coefficient. 在ABAQUS中采用隐式静态几何非线性分析方法,对矩形层板的几何中心点施加一个固定约束,并在设定的固化温度条件下获得层板的第一稳态,随后在矩形的四角点上添加方向与第一稳态弯曲方向相反的位移载荷,以获得其第二稳态。在网格划分中,主要选取SR4缩减积分壳单元,切口处填充S3单元,划分完成后得到

2673 个单元网格。仿真结果如图2(a)所示,矩形层板具有传统的双稳态变形特点,在第一稳态中,矩形层板首先沿长度方向发生变形,向90°铺层面进行弯曲(沿z轴正向),宽度方向上的纤维基本不发生改变,维持直线状态。在施加位移载荷后获得的第二稳态中,层板沿宽度方向发生反向弯曲(沿z轴反向),在长度方向上发生回弹。在图2(b)中,含切口层板的第一稳态与矩形层板具有几乎相同的弯曲变形,但是其第二稳态构型发生了不同的变形情况,层板发生了翘曲现象,最大翘曲位置出现在层板两端中点处,如图中红色标点所示。

采用热压罐成型工艺制备了普通及含切口的矩形非对称铺层层板,如图3所示。为获得层板的稳态构型及其面外最大位移值,使用示波器(美国Tektronix,MDO3024数字混合域示波器)、滑台、滑轨与激光测距仪(日本KEYENCE,IL-100)等搭建了双稳态试件稳定构型测量平台,如图4所示。将试件放置于平整表面,操纵滑台与滑轨以控制试件在水平面内的匀速平移,采用激光测距仪沿层板对称轴连续测量试件各点的面外相对位移,并通过示波器绘制构型曲线,曲线拐点所对应的值即面外最大位移。

为提高实验数据的准确性,对矩形及含切口矩形层板均制备了至少3个有效试件,实验结果通过计算均值与添加误差棒的形式表现。仿真与实验结果对比显示:矩形层板与含切口矩形层板的第一稳定构型几乎完全一致,如图5所示,切口设计对矩形层板的第一稳态影响甚微。第二稳态则出现了明显的差异,含切口矩形层板的两端出现了翘曲现象,通过对面外最大位移进行测量,得到矩形层板的面外最大位移均值仅为4.39 mm,含切口矩形层板的面外最大翘曲高度均值为11.96 mm,翘曲高度远大于纤维弯曲变形所产生的位移变化量,如图6所示。

2. 含切口十字形非对称层板的多稳态特性

2.1 十字形层板多稳态特性

将两块尺寸为250 mm×75 mm,铺层均为[902/02]的矩形层板在几何中心处交叉铺设,采用共固化成型工艺,预期获得的十字形层板具有多种稳态,且相较于传统的采用机械连接的双稳态层板组合叠加设计方案,简化了工艺步骤,降低了结构的复杂程度,拓展了多稳态层板在结构可重构领域内的实际应用价值。

然而通过实验发现,交叉铺设得到的十字形结构仅能获得第一稳态,层板跳变无法得到第二稳态。一是由于层板第二稳态以交叉形式连接时,上下胶接面的变形方向不同造成了几何不兼容问题,使共固化后胶接区域内会产生较大约束力;二是共固化引起胶接区域内的铺层厚度增大,并且铺层顺序改变为对称铺层[902/02]S,使中心区域刚度加强,二者阻碍了跳变发生,导致第二稳态失去稳定性。这一现象在仿真中表现为获得的第二稳态稳定性极差,施加的位移载荷发生微小改变就会大幅影响最终的计算结果。因此,对矩形层板进行切口设计,通过削弱中心区域的刚度减少胶接区域对第二稳态产生的影响,如图7所示。

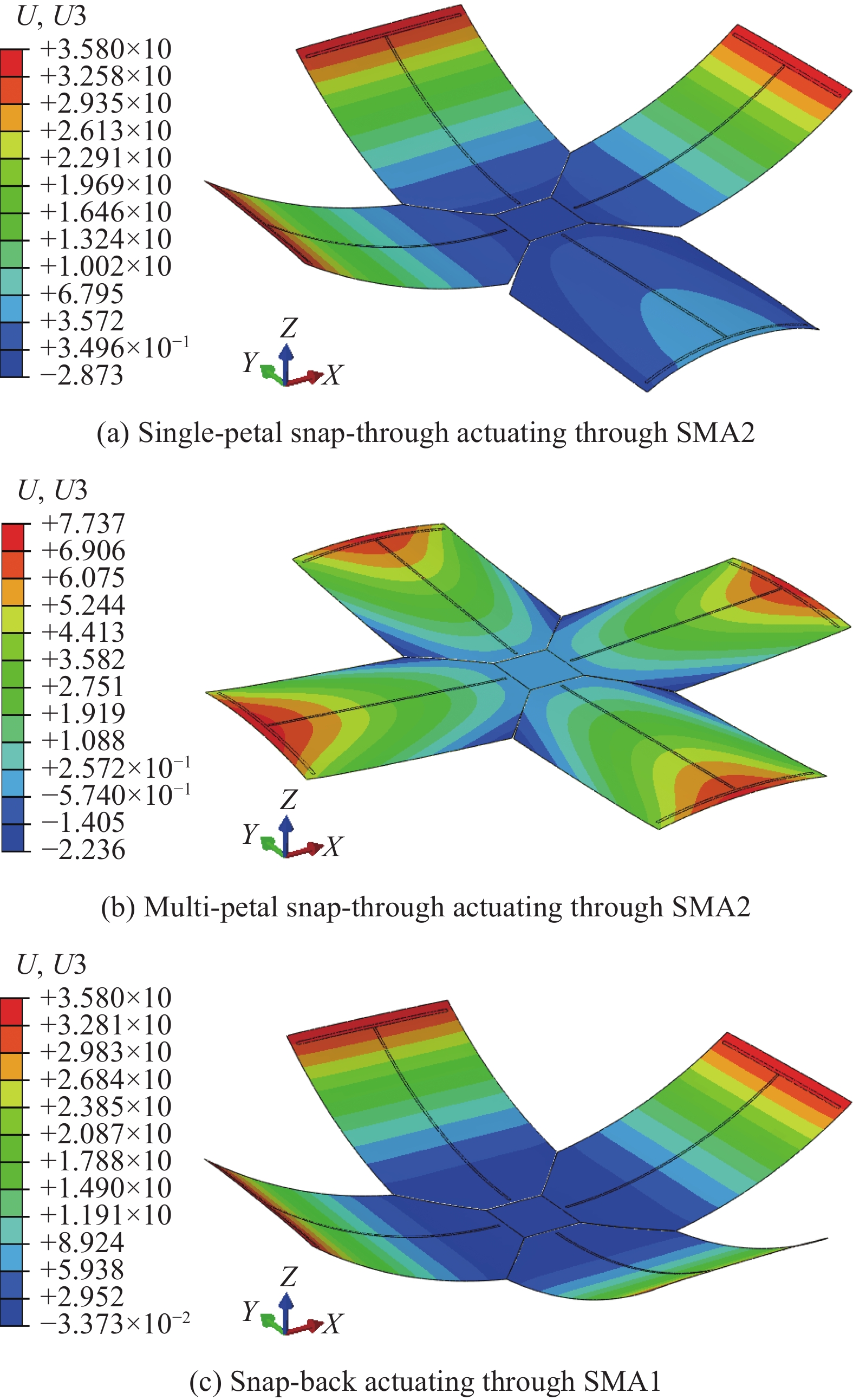

在ABAQUS中对两个非对称矩形层板进行单独建模,在胶接区域内施加TIE约束条件连接层板模拟共固化成型,获得含切口设计的十字形多稳态层板结构,如图8所示。在图8(a)中,第一稳态发生了较大变形,随后在十字形四边的8个角点上施加垂直向下的位移载荷,层板发生跳变并获得了如图8(b)中所示的第二稳态,十字形层板的四边都发生了一定程度的翘曲现象,且翘曲高度大于矩形层板自身第二稳态发生的弯曲变形,这与含切口矩形层板第二稳态的变化情况具有相似性。此时十字形层板第二稳态的面外最大位移不再取决于宽度方向上纤维产生的弯曲变形,而是由四边翘曲高度决定。此外,单独对十字形四瓣中的其中一瓣或多瓣施加位移载荷,能够使十字形层板出现多种不同的稳定状态,将双稳态特性进一步拓展至多稳态的特性研究,如图8(c)所示。同时对含切口设计的十字形层板进行实验制备,获得的试件具有与仿真结果相同的多稳态特性,证明了通过切口设计实现十字形多稳态复合材料层板的可行性。

在多稳态层板的有限元研究中,通常使用外力加载的方式实现层板构型变换的表征,但在实际应用中,则需要通过驱动方法来实现层板多稳态构型的转变。为此,本文设计了一种基于形状记忆合金(SMA)的多稳态驱动方案,利用形状记忆合金在温度作用下形状收缩的特点实现层板多稳态构型的转变。

在ABAQUS中,由于仅利用了形状记忆合金的形状收缩特性,因此可以对仿真模型进行简化,将形状记忆合金的形状收缩等效为热膨胀材料由于温度降低引起的形状收缩,赋予材料热膨胀系数α=

0.0008 ,其余材料属性取母相奥氏体,弹性模量E=81 GPa,泊松比ν=0.3。采用片状SMA驱动器,其厚度为0.05 mm,宽度为1 mm,加载方式如图9(a)所示,驱动元件与层板之间使用TIE刚性连接,驱动元件SMA1加载于90°铺层面上,控制层板由第二稳态向第一稳态发生转变,SMA2则加载于0°铺层面上,控制层板由第一稳态向第二稳态发生转变。在网格划分中,对驱动元件进行网格加密,最终得到9893 个单元网格,如图9(b)所示。仿真结果如图10所示,对于形状记忆合金驱动的十字形多稳态层板,通过控制SMA2的形状收缩,能够实现单瓣或多瓣的跳变驱动,使层板从第一稳态向第二稳态发生转变;同样,通过控制SMA1,也可以使层板由第二稳态向第一稳态发生单瓣或多瓣的跳回现象。通过对形状记忆合金的调控,实现了对十字形多稳态层板结构变形的主动控制。同时,对比形状记忆合金加载前后十字形层板多种稳态的稳定构型与面外位移,可以发现,由于采用的片状SMA驱动器尺寸很小,因此驱动元件的加载对十字形层板的构型影响甚微。

此外,研究发现,外力施加与形状记忆合金驱动下的十字形多稳态层板,单瓣片均具有独立变形能力,即对于未施加位移扰动的瓣片,其面外位移保持相对稳定,相较于第一稳态没有显著变化。而对于已经施加了位移扰动并完成了跳变的瓣片,其最大翘曲程度又与第二稳态具有的翘曲现象相当。

这一多稳态变形特点取决于胶接区域的大刚度特性。胶接区域的较大刚度导致了当一部分瓣片受到载荷作用时,其变形不会对其他未受载荷的瓣片产生显著影响,这种变形独立性体现了含切口十字形层板在设计上的优势,尤其是在需要精确控制局部变形的应用场景中。

2.2 胶接面积影响

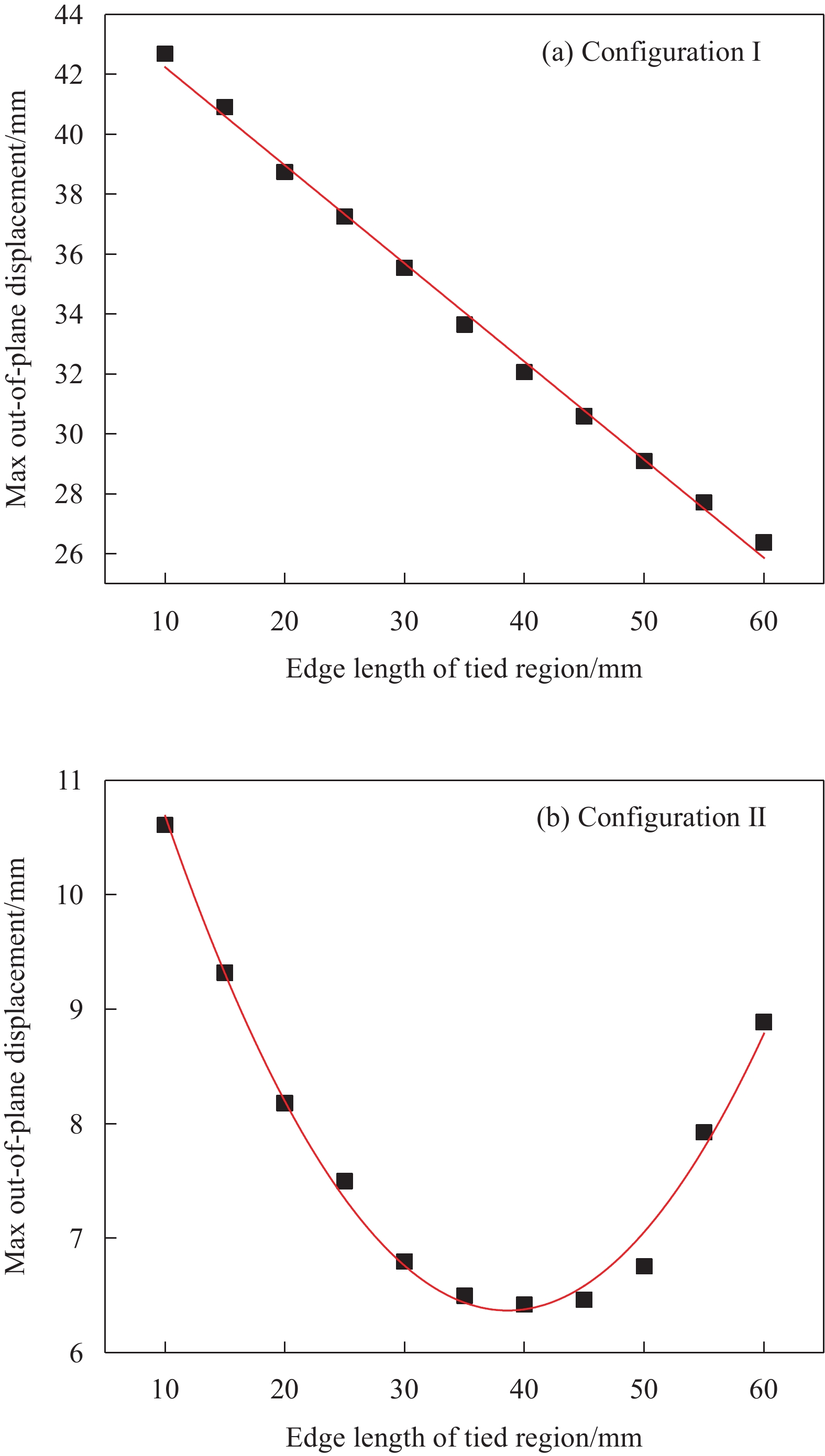

对含切口十字形多稳态层板进行参数影响研究。保持层板尺寸L=250 mm、W=75 mm不变,当中心胶接区域为正方形(θ=45°)时,就能够在不改变几何外形为十字形的前提下,通过改变胶接区域边长a,研究不同胶接面积对十字型多稳态层板稳定构型的影响规律。

令胶接区域边长a在10~60 mm范围内逐渐增大,单次增幅∆a为5 mm,不同胶接面积与层板面外最大位移之间的变化关系曲线,如图11所示。由图可知,第一稳态面外位移大小随胶接面积的增大而减小,且呈线性关系,这是由于胶接面积的增大使层板参与弯曲变形的长度缩小导致的。而第二稳态中面外最大位移的变化情况较复杂,如图11(b)所示,首先当a在10~40 mm的范围内增大时,面外最大位移减小,随后a继续在40~60 mm区间内增大时,面外最大位移则出现上升趋势。

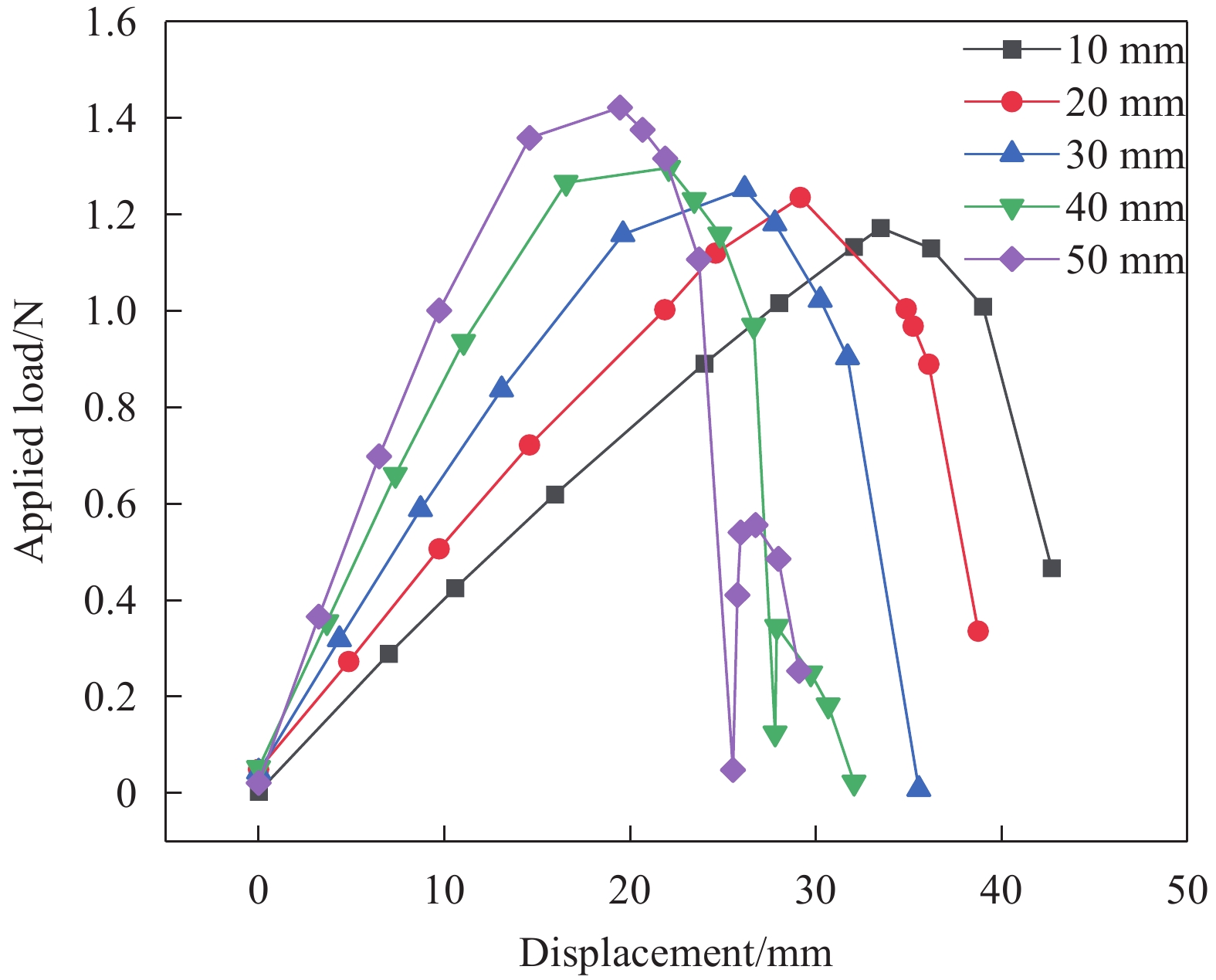

依次选择参数a=10、20、30、40、50 mm,研究不同胶接面积对层板跳变行为的影响情况,如图12所示。将仿真中层板固定端支反力,等效为十字形层板跳变所需的外部加载,获得了位移-载荷曲线图。从图中能够观察到层板的跳变行为:载荷首先随层板面外位移的增大线性增加,层板发生弹性形变;当载荷上升至峰值时,层板开始跳变,曲线的最大值即跳变载荷大小;随后载荷迅速降低,载荷的减小量随胶接面积的增大而增大。当a=30 mm时,维持层板变形所需的载荷大小降为0。这意味着对于a=30 mm的含切口十字形层板,当施加的外部载荷达到结构的跳变载荷后无需继续加载,即可使层板完成向第二稳态的转变。对于a=40 mm、50 mm的十字形层板,则表现出负刚度行为,载荷出现了回升,对应着图11(b)中a=40 mm处曲线出现拐点的现象,第二稳态的面外最大位移变化趋势发生改变。

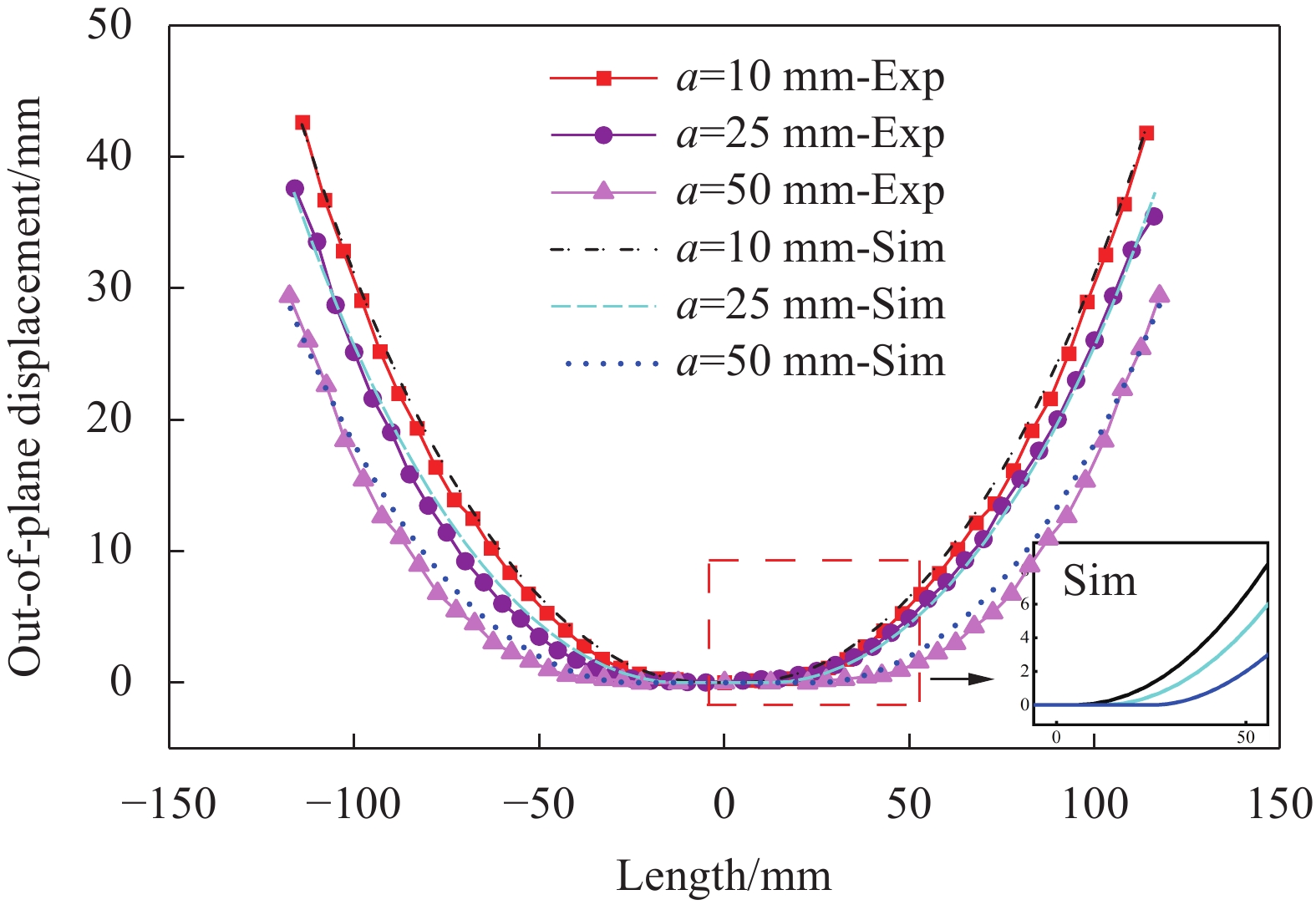

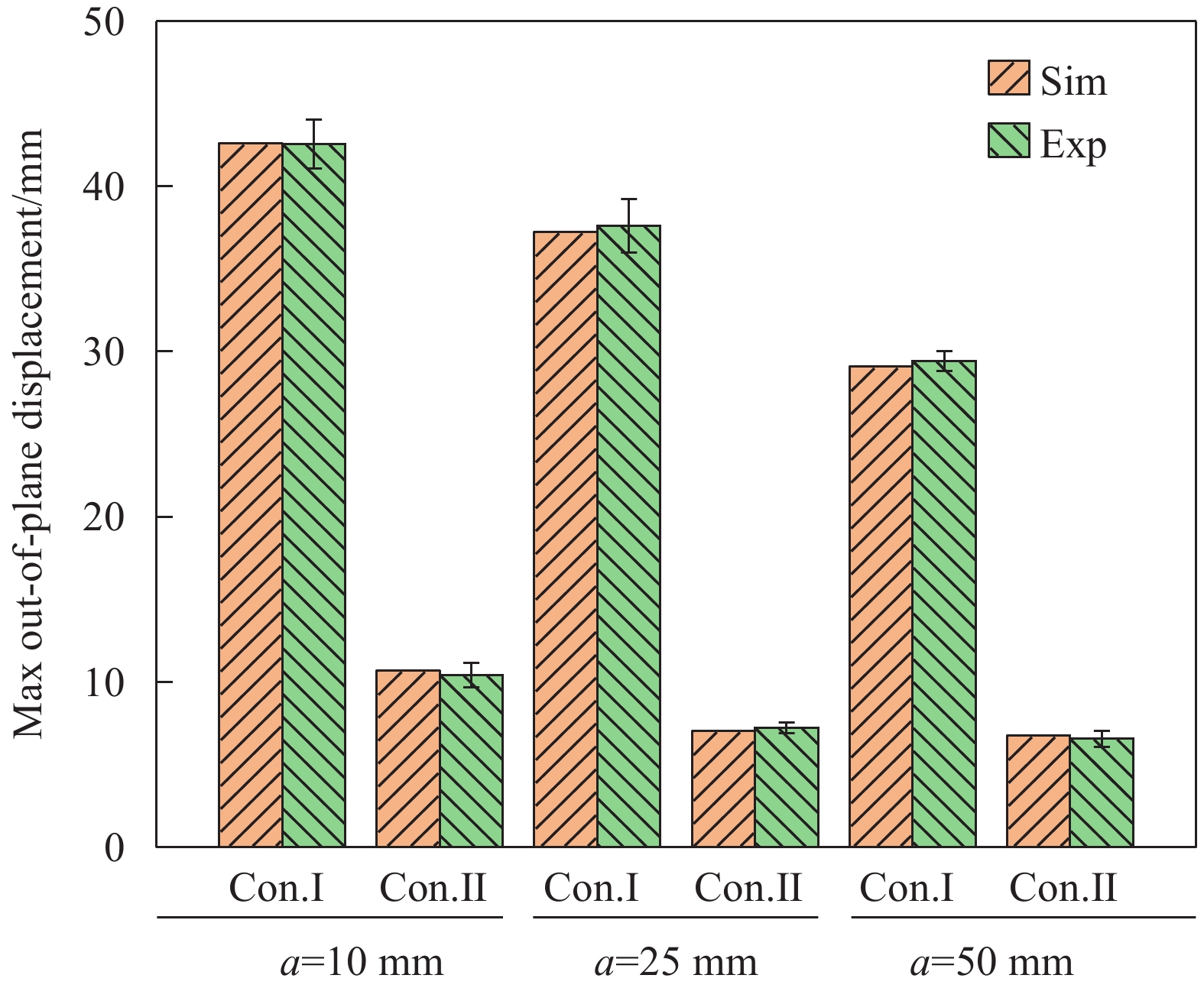

试验验证了不同胶接面积对十字形层板稳定构型的影响规律,如表2所示,分别制备了边长a=10、25、50 mm的3种十字形层板(红色框选表示实际的胶接区域),层板的两种稳态均具有良好的稳定性,且与仿真中两种稳定构型的变形情况吻合,第一稳态发生较大变形,第二稳态产生了四边翘曲现象,翘曲高度决定了层板的面外最大位移。同时,结构的稳定性还体现在,重复变换不同稳态多次后,结构仍然可以使用,层板的稳定构型与多稳态特性几乎不受到影响。

表 2 不同胶接面积下十字形多稳态层板的两种稳定构型Table 2. Two stable configurations of cruciform multistable laminates with different co-curing areaCo-curing area/(mm×mm) Configuration I Configuration II 10×10

25×25

50×50

采用激光测距仪对层板的稳定构型与面外最大位移进行测量,如图13、图14所示,实验结果与有限元结果之间吻合良好,最大误差不超过5%。对比图13中所示的层板第一稳态构型情况,可以发现:虽然层板第一稳态的面外最大位移会随着胶接面积的改变发生线性变化,但层板在胶接区域外发生的弯曲变形曲率基本一致,胶接面积的改变对构型曲率产生较小影响。

2.3 切口角度影响

为了获得在相同胶接面积下不同切口角度对十字形多稳态层板稳定构型的影响情况,保持胶接区域边长a=10 mm不变,改变切口角度θ。为了保证结构的稳定性,结构参数需要满足W≤L1及防止过度胶接切口角度需小于45°。

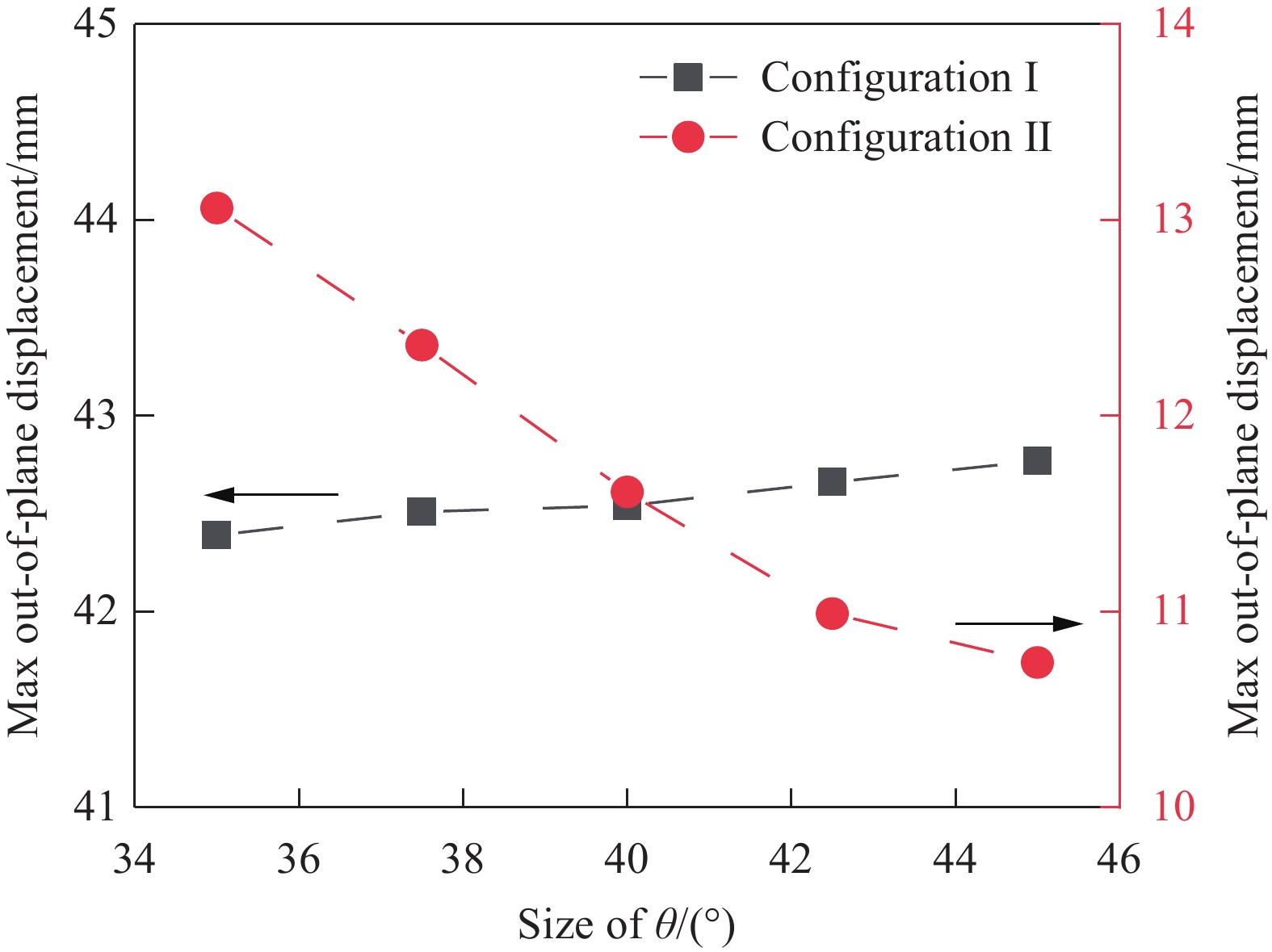

令切口角度分别为θ=35°、37.5°、40°、42.5°和45°,切口角度对面外最大位移的影响情况如图15所示。可知:随着切口角度θ的改变,第一稳态的面外最大位移基本不受影响,改变量仅为0.38 mm,百分比变化仅为0.8%;第二稳态的面外最大位移则随θ的减小而增大,总增量为2.32 mm,百分比变化为21.6%。

切口角度θ的减小,使胶接区域周边的纤维面积缩减。十字形层板第二稳态的面外最大位移受到中心区域内作用力影响,作用力主要取决于胶接区域内阻碍跳变发生的约束力及层板内部激发双稳态变形的热残余应力。在胶接面积不发生改变的条件下,引起层板四边翘曲的约束力大小保持不变,但切口角度与纤维面积的缩减减小了参与矩形层板第二稳态弯曲变形的热应力大小,在二者的相互作用下,导致翘曲现象更加明显,第二稳态面外最大位移增大。

2.4 纵横比影响

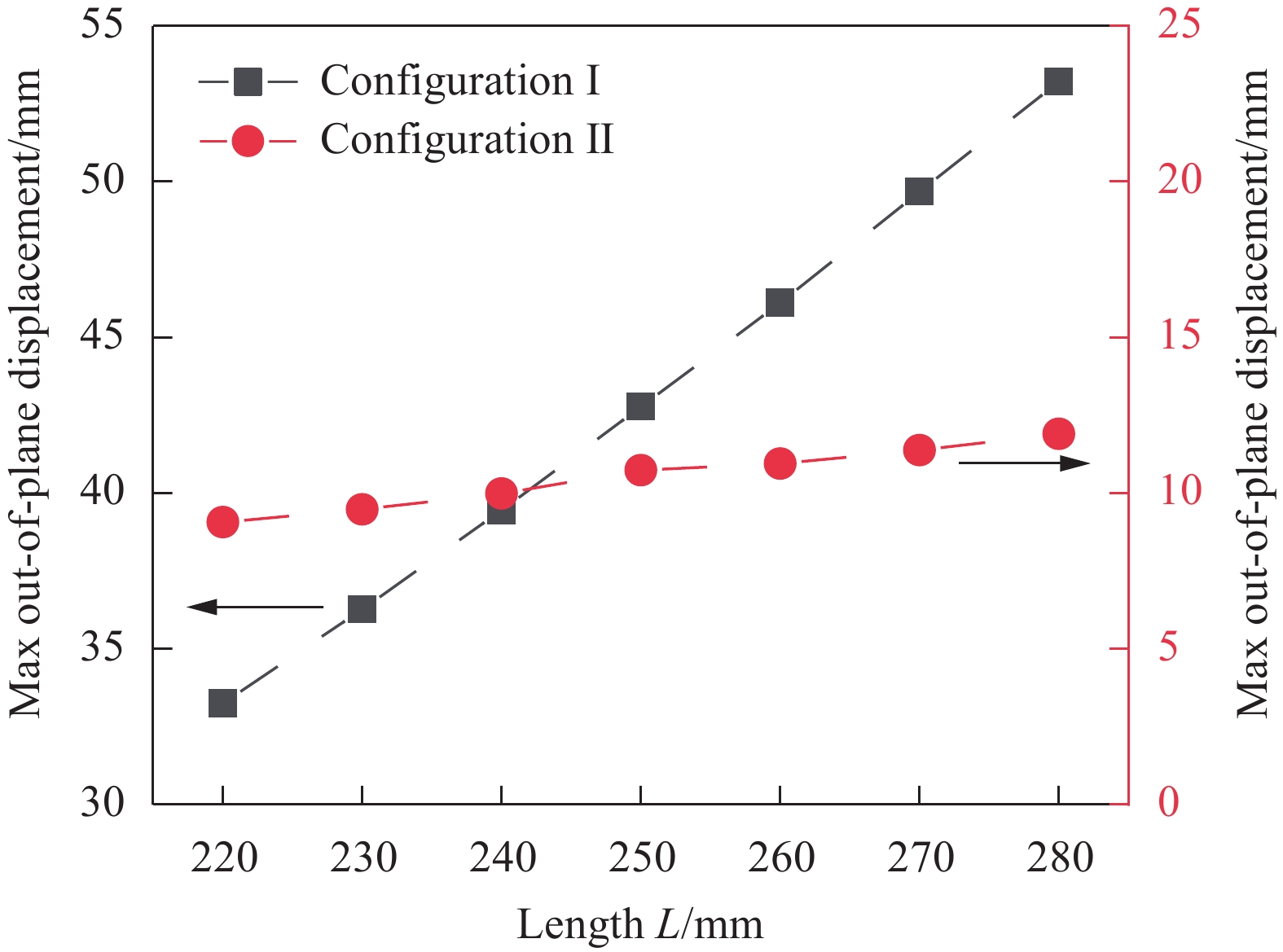

改变矩形层板纵横比,由于矩形宽度的改变会带动切口角度发生变化,因此保持宽度不变,令层板长度逐渐增大(L=220、230、240、250、260、270、280 mm),参数对面外最大位移的影响如图16所示。可知:随着长度L增大,第一稳态与第二稳态的面外最大位移均随之增大,并且L对第一稳态构型的影响远大于第二稳态,第一稳态的面外最大位移总增量为19.96 mm,百分比变化为46.7%;而第二稳态总增量仅为2.83 mm,百分比变化为26.4%。

十字形层板两种稳态的构型变化规律与矩形层板基本相同,长度L与面外最大位移呈线性关系,这是由于纵横比L/W的增大,使层板内部沿长度方向上的纤维长度增加,结构发生了更大的弯曲变形。

3. 结 论

(1)通过仿真与试验手段研究了普通及含切口矩形双稳态层板的稳定构型,获得了二者的稳定构型与变形规律。结果表明切口设计对层板第二稳定构型影响较大,含切口的矩形层板第二稳定状态两边产生了翘曲现象,且翘曲高度大于纤维自身所产生的弯曲变形量,面外最大位移变为由翘曲高度决定。

(2)通过将两块矩形双稳态层板交叉铺设共固化成型并引入切口设计,提出了一种新的十字形多稳态复合材料层板,通过有限元和试验验证了切口设计的可行性。

(3)胶接面积与十字形层板第一稳定构型面外最大位移呈线性减小关系;第二稳定构型面外最大位移随胶接面积的增加呈现出先减小后增大的趋势。

(4)研究了相同胶接面积下不同切口角度与纵横比对十字形层板稳定构型的影响规律,切口角度主要影响十字形层板的第二稳态,而纵横比则对第一稳态起重要作用。

-

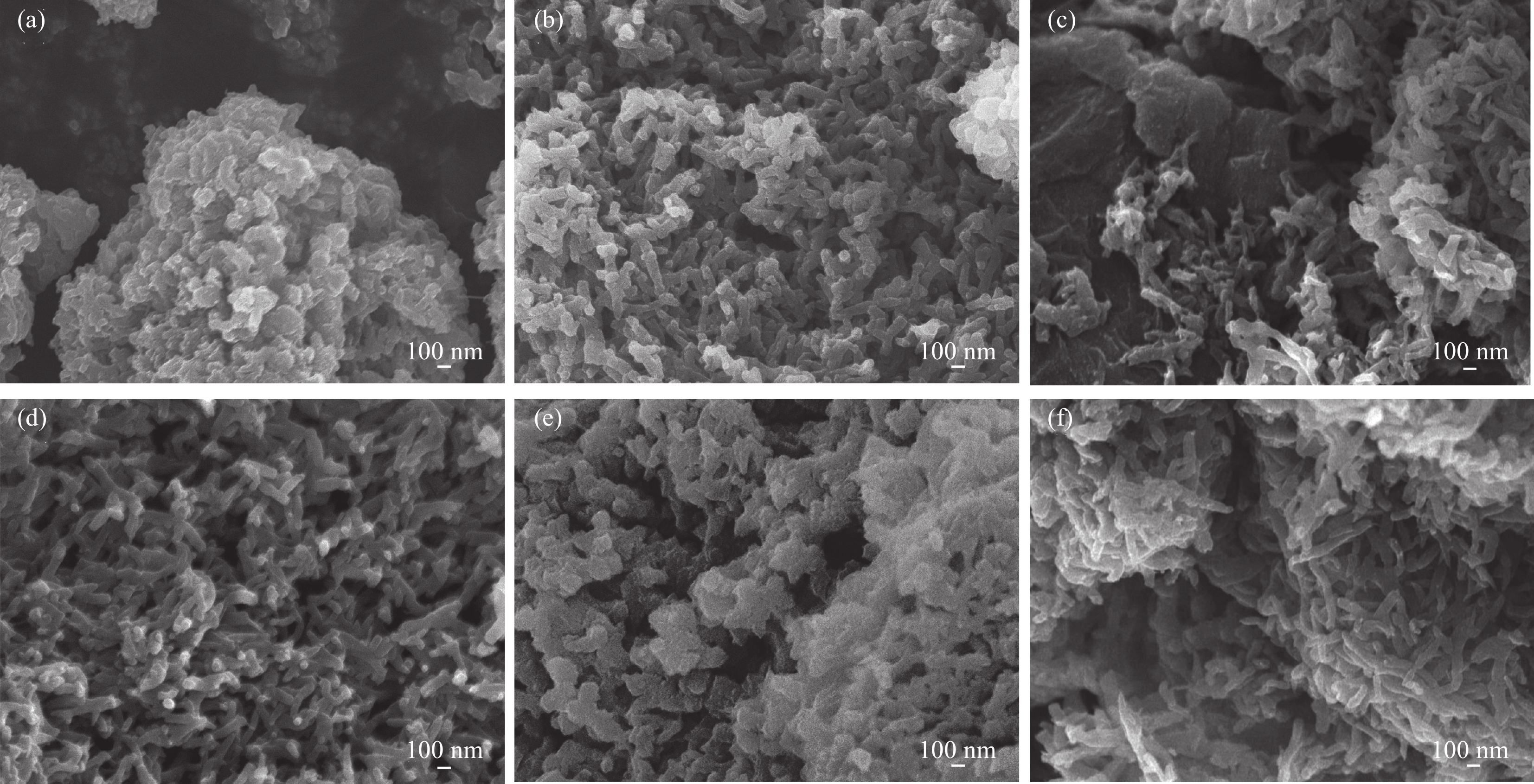

图 2 不同掺杂态PANI及复合材料的SEM图像:(a) Doped PANI;(b) Redoped PANI;(c) RGO/Redoped PANI;(d) CNTs/Redoped PANI;(e) RGO-CNTs/Redoped PANI;(f) RGO CNTs/Redoped PANI

Figure 2. SEM images of different doped polyaniline and its composites: (a) Doped PANI; (b) Redoped PANI; (c) RGO/Redoped PANI; (d) CNTs/Redoped PANI; (e) RGO-CNTs/Redoped PANI; (f) RGO CNTs/Redoped PANI

表 1 不同制备方法下的材料名称

Table 1 Names of materials under different preparation methods

Different preparation methods Abbreviation Doped polyaniline Doped PANI Carbon nanotubes/Doped polyaniline CNTs/Doped PANI Graphene/Doped polyaniline RGO/Doped PANI Redoped polyaniline Redoped PANI Carbon nanotubes/Redoped polyaniline CNTs/Redoped PANI Graphene/Redoped polyaniline RGO/Redoped PANI Graphene-carbon nanotubes/Redoped polyaniline prepared by in-situ polymerization RGO-CNTs/Redoped PANI Redoping of graphene carbon nanotubes/Secondary doping of polyaniline RGO CNTs/Redoped PANI 表 2 不同复合材料的配比

Table 2 Ratio of different composite materials

Abbreviation Mass of RGO∶

ANI/mgMass of CNTs∶

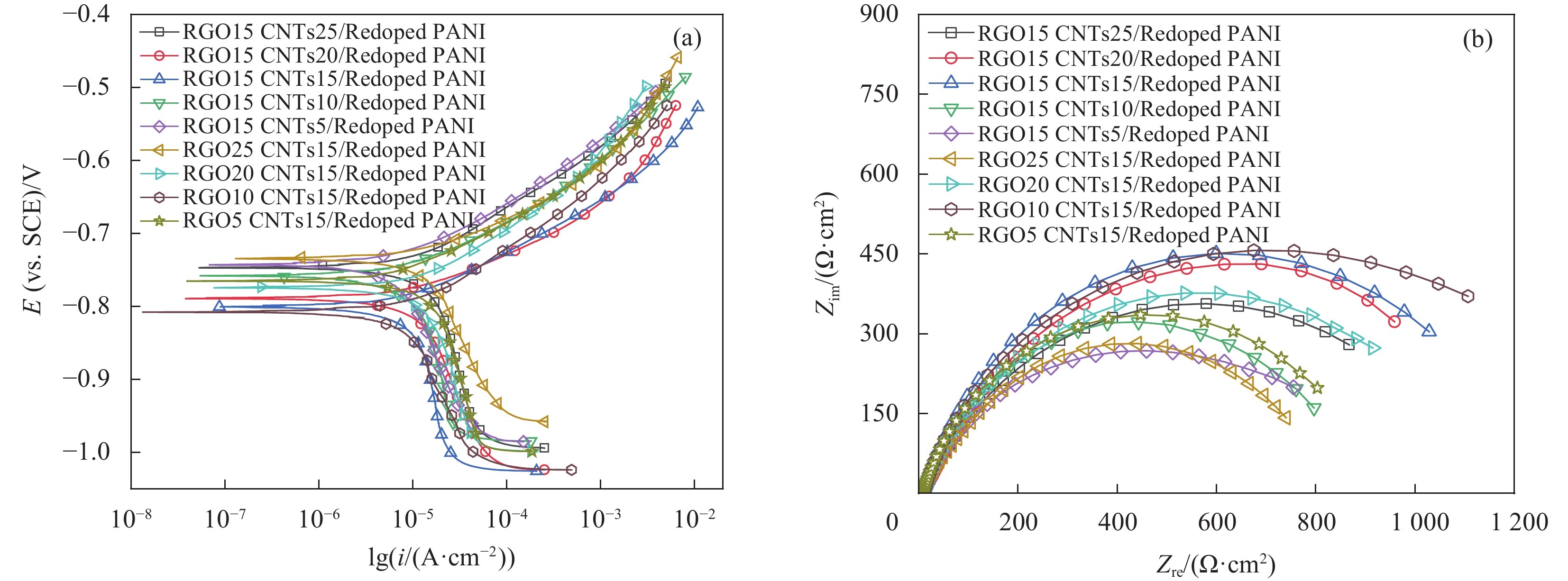

ANI/mgRGO15 CNTs25/Redoped PANI 1∶15 1∶25 RGO15 CNTs20/Redoped PANI 1∶15 1∶20 RGO15 CNTs15/Redoped PANI 1∶15 1∶15 RGO15 CNTs10/Redoped PANI 1∶15 1∶10 RGO15 CNTs5/Redoped PANI 1∶15 1∶5 RGO25 CNTs15/Redoped PANI 1∶25 1∶15 RGO20 CNTs15/Redoped PANI 1∶20 1∶15 RGO15 CNTs15/Redoped PANI 1∶15 1∶15 RGO10 CNTs15/Redoped PANI 1∶10 1∶15 RGO5 CNTs15/Redoped PANI 1∶5 1∶15 表 3 不同配比下PANI复合材料的极化曲线与交流阻抗的拟合结果

Table 3 Fitting results of polarization curves and AC impedance of PANI composites with different proportions

RGO∶ANI CNTs∶ANI Ecorr/mV Icorr/(µA·cm2) βc/(mV·dec−1) βa/(mV·dec−1) IE/% Rp/(Ω·cm2) 1∶15 1∶25 −759.844 7.124 196.402 67.641 77.49 916.924 1∶15 1∶20 −791.369 6.776 194.736 73.265 78.59 1010.890 1∶15 1∶15 −796.645 6.125 219.249 68.523 80.01 1072.340 1∶15 1∶10 −765.328 7.118 223.874 69.581 77.51 812.442 1∶15 1∶ 5 −745.703 7.225 203.387 68.524 76.72 780.932 1∶25 1∶15 −738.932 7.368 179.376 61.496 76.58 753.502 1∶20 1∶15 −783.295 6.328 195.984 75.415 76.72 954.743 1∶10 1∶15 −803.457 5.956 187.321 72.239 81.18 1167.152 1∶ 5 1∶15 −773.925 7.013 199.672 71.823 77.84 827.444 Notes:Ecorr—Corrosion potential; Icorr—Corrosion current density; βc—Cathode slope; βa—Anode slope; IE—Corrosion inhibition efficiency; Rp—Thin-film resistor. 表 4 不同制备方法下PANI及复合材料极化曲线与交流阻抗的拟合结果

Table 4 Fitting results of polarization curves and AC impedance of PANI and composite materials under different preparation methods

Different states Ecorr/mV Icorr/(µA·cm2) βc/(mV·dec−1) βa/(mV·dec−1) IE/% Rp/(Ω·cm2) Bare steel −600.614 31.653 162.540 63.456 – – Doped PANI −638.425 14.281 172.531 70.236 54.87 245.294 CNTs/Doped PANI −662.703 13.768 185.262 76.745 59.07 489.348 RGO/Doped PANI −709.654 12.956 178.710 79.263 66.67 560.501 Redoped PANI −667.257 10.553 179.482 60.879 56.50 373.387 CNTs/Redoped PANI −715.368 8.495 181.726 82.364 73.16 652.910 RGO/Redoped PANI −743.259 7.396 192.531 72.698 76.63 761.475 RGO-CNTs/Redoped PANI −673.970 13.954 185.398 88.631 55.92 440.883 RGO CNTs/Redoped PANI −803.457 5.956 187.321 72.239 81.18 1167.152 表 5 PANI复合材料不同添加量涂层的基本物理性能

Table 5 Basic physical properties of coatings with different additive amounts of polyaniline composites

Mass fraction of

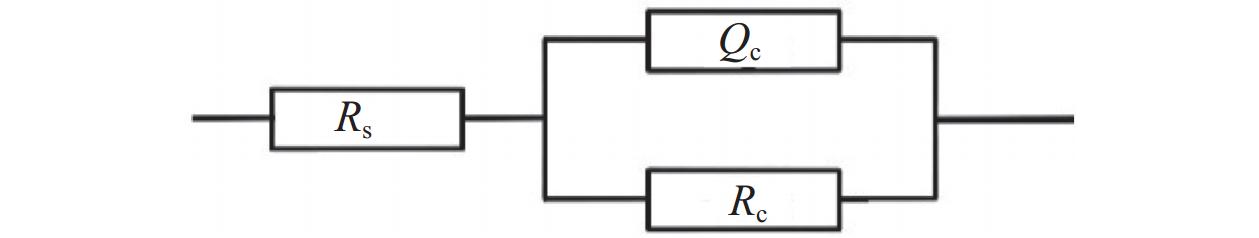

composite material/wt%Fineness/μm Viscosity/(mPa·s) Adhesive force/MPa Bacor hardness 0 17 5210 5.0 22 0.1 18 5302 5.5 23 0.5 18 5415 5.8 25 1 19 5529 6.7 26 2 22 5730 6.0 24 表 6 PANI复合材料不同添加量涂层不同浸泡时间下交流阻抗的拟合结果

Table 6 Fitting results of AC impedance of polyaniline composite coatings with different additive amounts under different soaking time

Mass fraction of composite material/wt% Rc/(1010 Ω·cm2) 24 h 360 h 720 h 1080 h1440 h0 14.216 6.290 3.169 1.238 0.394 0.1 17.423 11.169 5.989 3.147 2.491 0.5 19.505 14.066 7.226 5.101 4.259 1 19.946 15.690 9.320 6.726 6.019 2 16.276 9.334 5.433 2.374 1.058 -

[1] 黄惠, 郭忠诚. 导电聚苯胺的制备及应用[M]. 北京: 科学出版社, 2010, 9(3): 4-8. HUANG Hui, GUO Zhongcheng. Preparation and application of conductive polyaniline[M]. Beijing: Science Press, 2010, 9(3): 4-8(in Chinese).

[2] HEJJAJ C, AGHZZAF A, BOUALI I, et al. Layered aluminum tri-polyphosphate as intercalation host for 6-aminohexanoic acid-synthesis, characterization and application as corrosion protection inhibitor for low carbon steel[J]. Corrosion Science, 2021, 181: 109239. DOI: 10.1016/j.corsci.2021.109239

[3] ZHAO Y, MA J Q, CHEN K, et al. One-pot preparation of graphene-based polyaniline conductive nanocomposites for anticorrosion coatings[J]. Nano, 2017, 12(5): 1750056. DOI: 10.1142/S1793292017500564

[4] 杨小刚. 聚苯胺纳米结构的制备及其防腐性能的研究[D]. 青岛: 中国科学院研究生院(海洋研究所), 2008. YANG Xiaogang. Study on preparation of polyaniline nanostructures and its anticorrosive properties[D]. Qingdao: Graduate School of Oceanology, Chinese Academy of Sciences, 2008(in Chinese).

[5] GAO F J, MU Z X, BI Z X, et al. Recent advances of polyaniline composites in anticorrosive coatings: A review[J]. Progress in Organic Coatings, 2021, 151: 106071. DOI: 10.1016/j.porgcoat.2020.106071

[6] 杨小刚, 张国兵, 王志强, 等. 单宁酸二次掺杂聚苯胺纳米材料的制备及防腐性能[J]. 高分子材料科学与工程, 2017, 33(9): 120-125. YANG Xiaogang, ZHANG Guobing, WANG Zhiqiang, et al. Preparation and corrosion resistance of tannic acid secondary doped polyaniline nanomaterials[J]. Polymer Materials Science and Engineering, 2017, 33(9): 120-125(in Chinese).

[7] 王宝霞, 李大纲, 汪钟凯. 聚苯胺/(蒙脱土-纳米纤维素)三元复合电极材料的制备及电化学性能[J]. 复合材料学报, 2021, 38(4): 1242-1251. WANG Baoxia, LI Dagang, WANG Zhongkai. Preparation and electrochemical properties of polyaniline/(montmorillonite-nanocellulost) ternary composite electrode materials[J]. Acta Materiae Compositae Sinica, 2021, 38(4): 1242-1251(in Chinese).

[8] 姜旭东, 徐惠, 杨曙华, 等. 质子酸电化学掺杂本征态聚苯胺电化学性能的研究[J]. 化工新型材料, 2022, 50(12): 129-134. JIANG Xudong, XU Hui, YANG Shuhua, et al. Electrochemical properties of intrinsic polyaniline doped with proton acid[J]. New Chemical Materials, 2022, 50(12): 129-134(in Chinese).

[9] 马艾丽, 何晓红, 郭莹, 等. 碳纳米管改性涂层复合材料的制备设计及性能研究[J]. 中国胶粘剂, 2023, 32(9): 16-20, 26. MA Aili, HE Xiaohong, GUO Ying, et al. Preparation, design and properties of carbon nanotube modified coating composites[J]. China Adhesives, 2023, 32(9): 16-20, 26(in Chinese).

[10] 侯相弛, 周川, 周玉敬, 等. 还原氧化石墨烯改性碳纤维/聚苯硫醚复合材料层间性能及微观形貌[J]. 复合材料学报, 2022, 39(5): 2133-2140. HOU Xiangchi, ZHOU Chuan, ZHOU Yujing, et al. Interlayer properties and microstructure of carbon fiber/polyphenylene sulfide composites modified by reduced graphene oxide[J]. Acta Materiae Compositae Sinica, 2022, 39(5): 2133-2140(in Chinese).

[11] ZHANG M, WANG X L, YANG T, et al. Polyaniline/graphene hybrid fibers as electrodes for flexible supercapacitors[J]. Synthetic Metals, 2020, 268: 116484. DOI: 10.1016/j.synthmet.2020.116484

[12] 姜雄峰, 朱志平, 周艺, 等. 石墨烯/碳纳米管复合纳米材料改性导电涂料的性能[J]. 材料保护, 2019, 52(6): 20-26. JIANG Xiongfeng, ZHU Zhiping, ZHOU Yi, et al. Properties of conductive coatings modified by graphene/carbon nanotube composites[J]. Materials Protection, 2019, 52(6): 20-26(in Chinese).

[13] MOOSS A V, BHOPALE A A, DESHPANDE P P, et al. Graphene oxide-modified polyaniline pigment for epoxy based anti-corrosion coatings[J]. Chemical Papers, 2017, 71(8): 1515-1528. DOI: 10.1007/s11696-017-0146-3

[14] MADHAN K A, GASEM Z M. Effect of functionalization of carbon nanotubes on mechanical and electrochemical behavior of polyaniline nanocomposite coatings[J]. Surface and Coatings Technology, 2015, 276: 416-423. DOI: 10.1016/j.surfcoat.2015.06.036

[15] 崔世宏. 一维碳纳米材料/聚苯胺复合材料的制备与性能研究[D]. 青岛: 青岛科技大学, 2022. CUI Shihong. Preparation and properties of one-dmensional carbon nanomaterials/polyaniline composites [D]. Qingdao: Qingdao University of Science and Technology, 2022(in Chinese).

[16] 王传洁. 石墨烯/聚苯胺纳米复合材料的制备及防腐性能研究[D]. 青岛: 青岛科技大学, 2021. WANG Chuanjie. Preparation and anti-corrosion properties of graphene/polyaniline nanocomposites[D]. Qingdao: Qingdao University of Science and Technology, 2021(in Chinese).

[17] 中国国家标准化管理委员会. 色漆、清漆和印刷油墨研磨细度的测定: GB/T 1724—2019[S]. 北京: 中国标准出版社, 2019. Standardization Administration of the People's Republic of China. Determination of grinding fineness of paints, varnishes and printing inks: GB/T 1724—2019[S]. Beijing: Standards Press of China, 2019(in Chinese).

[18] 中国国家标准化管理委员会. 胶黏剂黏度的测定: GB/T 2794—2022 [S]. 北京: 中国标准出版社, 2022. Standardization Administration of the People's Republic of China. Determination of viscosity of adhesives: GB/T 2794—2022 [S]. Beijing: Standards Press of China, 2022(in Chinese).

[19] 中国国家标准化管理委员会. 色漆和清漆 拉开法附着力试验: GB/T 5210—2006[S]. 北京: 中国标准出版社, 2006. Standardization Administration of the People's Republic of China. Adhesion test of paint and varnish pulling method: GB/T 5210—2006[S]. Beijing: Standards Press of China, 2006(in Chinese).

[20] 中国国家标准化管理委员会. 增强塑料巴柯尔硬度试验方法: GB/T 3854—2017[S]. 北京: 中国标准出版社, 2017. Standardization Administration of the People's Republic of China. Reinforced plastic hardness test method: GB/T 3854—2017[S]. Beijing: Standards Press of China, 2017(in Chinese).

[21] CHANG C H, HUANG T C, PENG C W, et al. Novel anticorrosion coatings prepared from polyaniline/graphene composites[J]. Carbon, 2012, 50(14): 5044-5051. DOI: 10.1016/j.carbon.2012.06.043

[22] 郭洪飞, 赵增祺, 朝宝, 等. 2, 6-二氨基吡啶改性氧化石墨烯复合涂层的制备及防腐性能[J]. 中国表面工程, 2022, 35(2): 126-139. GUO Hongfei, ZHAO Zengqi, CHAO Bao, et al. Preparation and corrosion resistance of 2, 6-diaminopyridine modified graphene oxide composite coating[J]. China Surface Engineering, 2022, 35(2): 126-139(in Chinese).

[23] LÓPEZ-PALACIOS J, MUÑOZ E, HERAS M A, et al. Study of polyaniline films degradation by thin-layer bidimensional spectroelectrochemistry[J]. Electrochimica Acta, 2006, 52(1): 234-239. DOI: 10.1016/j.electacta.2006.04.061

[24] 蔡文曦. 石墨烯/聚苯胺纳米复合材料及其在防腐涂料中的应用[D]. 广州: 华南理工大学, 2016. CAI Wenxi. Graphene/polyaniline nanocomposites and their application in anti-corrosion coatings[D]. Guangzhou: South China University of Technology, 2016(in Chinese).

[25] KORENT A, SODERŽNIK Ž K, STURM S, et al. A correlative study of polyaniline electropolymerization and its electrochromic behavior[J]. Journal of the Electrochemical Society, 2020, 167(10): 106504. DOI: 10.1149/1945-7111/ab9929

[26] LI X, GAO Y, LIU F, et al. Synthesis of polyaniline/Ag composite nanospheres through UV rays irradiation method[J]. Materials Letters, 2008, 63(3-4): 467-469.

[27] PRASHANTH J, REDDY B V. Study on structure, vibrational analysis and molecular characteristics of some halogen substituted azido phenylethanones using FTIR spectra and DFT[J]. Journal of Molecular Structure, 2018, 1155: 582-597. DOI: 10.1016/j.molstruc.2017.11.049

[28] 颜海燕, 胡志毅, 寇开昌, 等. 功能磺酸掺杂聚苯胺的电导率及其光谱特征研究[J]. 材料工程, 2005(1): 50-52, 57. YAN Haiyan, HU Zhiyi, KOU Kaichang, et al. Study on electrical conductivity and spectral characteristics of polyaniline doped with functional sulfonic acid[J]. Journal of Materials Engineering, 2005(1): 50-52, 57(in Chinese).

[29] 于芳, 王翔, 张昭. 纳米填料在环氧防腐涂层中的应用研究进展[J]. 中国腐蚀与防护学报, 2023, 43(2): 220-230. YU Fang, WANG Xiang, ZHANG Zhao. Research progress on application of nano-fillers in epoxy anti-corrosion coatings[J]. Journal of Chinese Society for Corrosion and Protection, 2023, 43(2): 220-230(in Chinese).

[30] FAZLI-SHOKOUHI S, NASIRPOURI F, KHATAMIAN M. Polyaniline-modified graphene oxide nanocomposites in epoxy coatings for enhancing the anticorrosion and antifouling properties[J]. Journal of Coatings Technology and Research, 2019, 16(4): 983-997. DOI: 10.1007/s11998-018-00173-3

[31] 蔡雨晴, 章东雪, 周娇, 等. 己二酸/硫酸掺杂聚苯胺对Cr(Ⅵ)的吸附行为[J]. 化学试剂, 2023, 45(5): 148-154. CAI Yuqing, ZHANG Dongxue, ZHOU Jiao, et al. Adsorption behavior of polyaniline doped with adipic acid/sulfuric acid for Cr(Ⅵ)[J]. Chemical Reagents, 2023, 45(5): 148-154(in Chinese).

[32] 杨小刚, 崔世宏, 李斌, 等. 石墨烯/醋酸掺杂态聚苯胺的制备及其防腐性能[J]. 材料研究学报, 2021, 35(5): 357-363. YANG Xiaogang, CUI Shihong, LI Bin, et al. Preparation and corrosion resistance of polyaniline doped with graphene/acetic acid[J]. Chinese Journal of Materials Research, 2021, 35(5): 357-363(in Chinese).

[33] 姜志刚, 刘立新. 表面处理剂对钛白粉在丙烯酸涂料中性能的影响[J]. 涂料工业, 2014, 44(5): 57-60. JIANG Zhigang, LIU Lixin. Effect of surface treatment agent on properties of titanium dioxide in acrylic coatings[J]. Paint and Coatings Industry, 2014, 44(5): 57-60(in Chinese).

[34] 邢正, 罗静, 刘仁. 光固化涂料体系云母分散性的表征及分散性能研究[J]. 涂料工业, 2023, 53(6): 1-8, 21. XING Zheng, LUO Jing, LIU Ren. Characterization and dispersibility of mica in photocurable coating system[J]. Paint and Coatings Industry, 2023, 53(6): 1-8, 21(in Chinese).

[35] REZENDE T, SILVESTRE J, MENDONCA P, et al. Efficient dispersion of TiO2, in water-based paint formulation using well-defined poly[oligo (ethylene oxide) methyl ether acrylate] synthesized by ICAR ATRP[J]. Progress in Organic Coatings, 2022, 165: 106734. DOI: 10.1016/j.porgcoat.2022.106734

[36] 闭锦叶. 负载苯并三氮唑的聚苯胺/环氧涂层的制备及防腐性能研究[D]. 广州: 华南理工大学, 2022. BI Jinye. Study on preparation and anti-corrosion properties of polyaniline/epoxy coating loaded with benzotriazole[D]. Guangzhou: South China University of Technology, 2022(in Chinese).

[37] SCHAUER T, JOOS A, DULOG L, et al. Protection of iron against corrosion with polyaniline primers[J]. Progress in Organic Coatings, 1998, 33(1): 20-27. DOI: 10.1016/S0300-9440(97)00123-9

[38] 赵明月, 裴晓园, 王维, 等. 二维纳米材料/环氧树脂复合涂层在腐蚀防护中的应用[J]. 复合材料学报, 2022, 39(5): 2049-2059. ZHAO Mingyue, PEI Xiaoyuan, WANG Wei, et al. Application of two-dimensional nanomaterial/epoxy resin composite coating in corrosion protection[J]. Acta Materiae Compositae Sinica, 2022, 39(5): 2049-2059(in Chinese).

[39] 王犇, 李程, 黄文君, 等. 聚苯胺/环氧复合涂层的制备及其耐蚀性能[J]. 腐蚀与防护, 2011, 32(8): 605-608, 641. WANG Ben, LI Cheng, HUANG Wenjun, et al. Preparation and corrosion resistance of polyaniline/epoxy composite coating[J]. Corrosion and Protection, 2011, 32(8): 605-608, 641(in Chinese).

[40] 中国国家标准化管理委员会. 色漆和清漆耐中性盐雾性能的测定: GB/T 1771—2007[S]. 常州: 中国化工建设总公司常州涂料化工研究院, 2007. Standardization Administration of the People's Republic of China. Color paints and varnishes-determination of resistance to neutral salt spray: GB/T 1771—2007[S]. Changzhou: China National Chemical Construction Corporation Changzhou Research Institute of Coatings and Chemicals, 2007(in Chinese).

-

期刊类型引用(2)

1. 郭小杰,杜丽勇. 尿素掺杂CH_3NH_3PbI_3薄膜及其钙钛矿太阳能电池性能研究. 功能材料. 2024(01): 1086-1091 .  百度学术

百度学术

2. 张晨亮. 溴化锂材料浓度对太阳能电池蓄能力影响的计算机动态分析. 信息记录材料. 2023(02): 158-160 .  百度学术

百度学术

其他类型引用(5)

-

目的

金属材料应用广泛,具有强度高、韧性好、建筑周期短、施工速度快等优点,但由于使用环境的影响,金属易与周围环境互相作用发生腐蚀,引发安全隐患,造成灾难性事故。为了延缓材料腐蚀速率,延长设备使用寿命,需对金属基材提供有效防护,本文利用二次掺杂的方法,制备防腐性能优异的三元纳米复合材料,并将其应用到重防腐涂料体系中,对制备的聚苯胺复合材料形貌和防腐性能进行表征和研究。

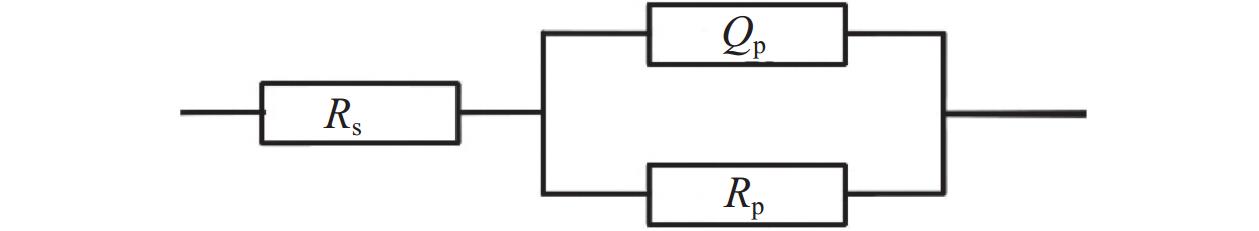

方法在硫酸体系中,通过原位聚合将苯胺分别与还原氧化石墨烯(RGO)和碳纳米管(CNTs)制备出石墨烯/一次掺杂态聚苯胺和碳纳米管/一次掺杂态聚苯胺,用氨水将两种一次掺杂态产物分别掺杂后,在同种酸体系中对两种产物共同进行二次掺杂,制备得到硫酸二次掺杂态石墨烯/碳纳米管/聚苯胺复合材料。利用SEM、TEM对不同产物的形貌进行表征,利用FTIR、UV-Vis不同产物的结构进行表征,通过电化学测试研究产物的防腐性能,并将制备的三元纳米复合材料按不同添加比例与环氧树脂制备成涂层,对其进行交流阻抗测试和中性盐雾试验,根据测试结果研究分析涂层的防腐性能。

结果通过对聚苯胺及其复合材料进行表征和防腐性能测试,得到以下研究

结果(1)在硫酸体系中,不同方法制备的PANI产物,还原氧化石墨烯/碳纳米管/二次掺杂态聚苯胺(RGO CNTs/Redoped PANI)的形貌最好,防腐性能最优,纤维长度达800 nm,阻抗值最高达1167.152 Ω·cm,明显优于RGO、CNTs和PANI直接原位聚合制备的复合材料。(2)当RGO与ANI的质量比为1:10、CNTs与ANI的质量比为1:15时,通过二次掺杂方法制备的RGO CNTs/Redoped PANI腐蚀电流最小,缓蚀率为81.18%,阻抗值为1167.152 Ω·cm,防腐性能均优于其他配比的产物。(3)交流阻抗测试和中性盐雾试验表明RGO CNTs/Redoped PANI复合材料的添加对涂料体系性能有明显的影响,在3.5 wt.%NaCl溶液中浸泡1440 h后,添加RGO CNTs/Redoped PANI涂层的阻抗值均高于10 Ω·cm,其中添加量为1 wt.%时防腐性能最优,阻抗值达6.019×10 Ω·cm,比无PANI复合材料添加的涂层高出一个数量级,且经过1440 h的中性盐雾试验,涂层仅在划痕区出现少量锈蚀,且锈蚀没有扩散蔓延,整个样板表面无鼓泡和其它劣化现象。

结论不同聚苯胺产物对金属均有较好的防腐作用,通过二次掺杂方法与RGO和CNTs复合,有效提升了聚苯胺复合材料的防腐性能,表明聚苯胺二次掺杂过程是一种制备三元甚至多元复合材料的有效途径,且通过此种途径制备的复合材料减少了石墨烯和碳纳米管的用量,降低了材料成本。将制备的聚苯胺复合材料按不同比例添加到环氧涂层中,有效提升了涂层的防腐性能,为金属材料提供长效防护。

下载:

下载: