Ballistic performance of Kevlar fiber UD sheets composite materials

-

摘要:

为探究Kevlar纤维单向(UD)片材复合材料防弹性能,以水性丙烯酸树脂/水性聚氨酯为基体,采用湿法缠绕技术与热压工艺制备了Kevlar纤维UD片材复合材料。探究共混树脂配比、树脂含量、热压工艺等因素对Kevlar纤维UD片材复合材料防弹性能的影响规律,揭示材料的防弹机制,以及对靶板结构进行优化。结果表明:随着水性丙烯酸树脂在共混树脂中比重的增加,Kevlar纤维UD片材复合材料防弹性能呈先增大后减小的趋势,当水性聚氨酯与水性丙烯酸树脂质量比为1∶2时,防弹性能较好。随着树脂含量的增加,Kevlar纤维UD片材复合材料防弹性能呈先增大后减小的趋势,当树脂含量为19wt%时,防弹性能较好。Kevlar纤维UD片材复合材料防弹性能随着热压压力、热压温度、热压时间的增大呈先增大后减小的趋势。Kevlar纤维UD片材复合材料的防弹机制主要分成3个阶段:第一阶段主要以纤维剪切破坏的方式吸收能量;第二阶段主要以纤维拉伸断裂的方式吸收能量为主;第三阶段主要以纤维拉伸变形的方式吸收能量。8UD/4UD/8UD结构的Kevlar纤维UD片材复合材料防弹性能较好。

Abstract:In order to investigate the bulletproof property of Kevlar fiber unidirectional (UD) sheet composite, the Kevlar fiber UD sheet composite was prepared by wet winding technology and hot pressing process using water-based acrylic acid/water-based polyurethane as matrix. The effects of blending resin ratio, resin content, hot pressing process and other factors on the bulletproof performance of Kevlar fiber UD sheet composite were investigated, the bulletproof mechanism of the material was revealed, and the structure of the target plate was optimized. The results show that the bulletproof property of Kevlar fiber UD sheet composite increases first and then decreases with the increase of the specific gravity of water-based acrylic acid resin in the blend resin. When the mass ratio of water-based polyurethane to water-based acrylic acid is 1∶2, the bulletproof property is better. With the increase of resin content, the bulletproof property of Kevlar fiber UD sheet composite material increases first and then decreases. When the resin content is 19wt%, the bulletproof property is better. The bulletproof performance of Kevlar fiber UD sheet composite increases first and then decreases with the increase of hot pressing pressure, hot pressing temperature and hot pressing time. The bulletproof mechanism of Kevlar fiber UD sheet composite material is mainly divided into three stages, the first stage mainly absorbs energy in the way of fiber shear damage, the second stage mainly absorbs energy in the way of fiber tensile fracture, and the third stage mainly absorbs energy in the way of fiber tensile deformation. The Kevlar fiber UD sheet composite with 8UD/4UD/8UD structure has better bulletproof performance.

-

近年来,国际局势风云突变,地区冲突不断升级,各个国家对于防弹衣的需求量不断增加,要求也更加严苛,不仅要求其具有优异的防弹性能,还要兼具轻量化、服用性能好等特点[1-2]。防弹衣材料经历了从金属材料到陶瓷材料,再到高性能纤维增强树脂基复合材料的更新换代过程[3-4]。高性能纤维增强复合材料相比金属材料和陶瓷材料,前者具有密度低、比吸能高、比强度和比模量大等优点,已成为防弹领域的理想候选材料[5-6]。

Kevlar纤维和超高分子量聚乙烯(UHMWPE)纤维由于高强度、高模量、高韧性等特征,被广泛应用于防弹领域[7]。为了提高纤维复合材料防弹性能,通常选择单向(UD)结构,UD结构特点为纤维平行排列、无交织点、能够快速传递应力波、吸收和扩散冲击能量[8]。Karahan等[9]研究发现Kevlar纤维UD层合板比芳纶机织物层合板的创伤深度低,创伤直径较大,能够更好地传递弹道冲击能量。影响芳纶UD片材防弹性能因素很多。艾青松等[10]研究发现,将芳纶机织布放置在无纬布前,防弹性能优于将芳纶机织布放置在中间。吴中伟等[11]研究发现树脂固含量为18wt%~20wt%时,芳纶无纬布防弹与防刺性能最优;且当靶片层数为42层时,产品的性价比最高。

由于UHMWPE纤维密度小、强度大,且成本相对较小,UHMWPE纤维UD层压板复合材料得到了广泛关注。Yang等[12]、Cao等[13]、Lässig等[14]对UHMWPE纤维UD层合板的防弹机制、影响因素等展开了大量研究。但是,UHMWPE纤维抗蠕变性能差。研究发现,对位芳纶纤维制备的靶板抗凹陷性能优于UHMWPE纤维制备的靶板[15],且UHMWPE纤维的熔点较低,约140℃,限制了该纤维在防护领域的应用[16]。与树脂基体的界面结合性能是决定复合材料性能与应用的关键因素[17]。Kevlar纤维其分子链排列高度规整,易发生结晶取向,且纤维表面光滑,缺少化学活性基团,与大部分树脂基体结合时界面粘结性差,可选择热塑性树脂范围小,导致关于Kevlar纤维UD复合材料研究较少[18]。

研究发现通过将水性聚氨酯与丙烯酸树脂共混改性,可以结合两种树脂的优异性能,进而受到了广泛关注[19]。本研究选择Kevlar纤维作为增强纤维,水性聚氨酯/水性丙烯酸树脂共混树脂作为基体,UD结构作为织物增强结构,采用叠层的方式制备片材靶,相对于层压板更加柔软,服用性能好;探究共混树脂配比、树脂含量、热压工艺等影响因素对其防弹性能的影响规律,揭示其防弹机制,并对其结构优化,为进一步优化设计柔性防弹衣提供参考。

1. 实验部分

1.1 原材料

Kevlar纤维:线密度400 D,单丝强度18 cN/dtex,山东烟台泰和新材料科技股份有限公司。水性聚氨酯树脂:固含量30wt%,江苏东润安全科技有限公司。水性丙烯酸树脂:固含量30wt%,深圳吉田化工有限公司。

5969H 型 Instron万能材料试验机,美国INSRTON公司;S-3400NII扫描电镜,日本Hitachi公司。

1.2 样品制备

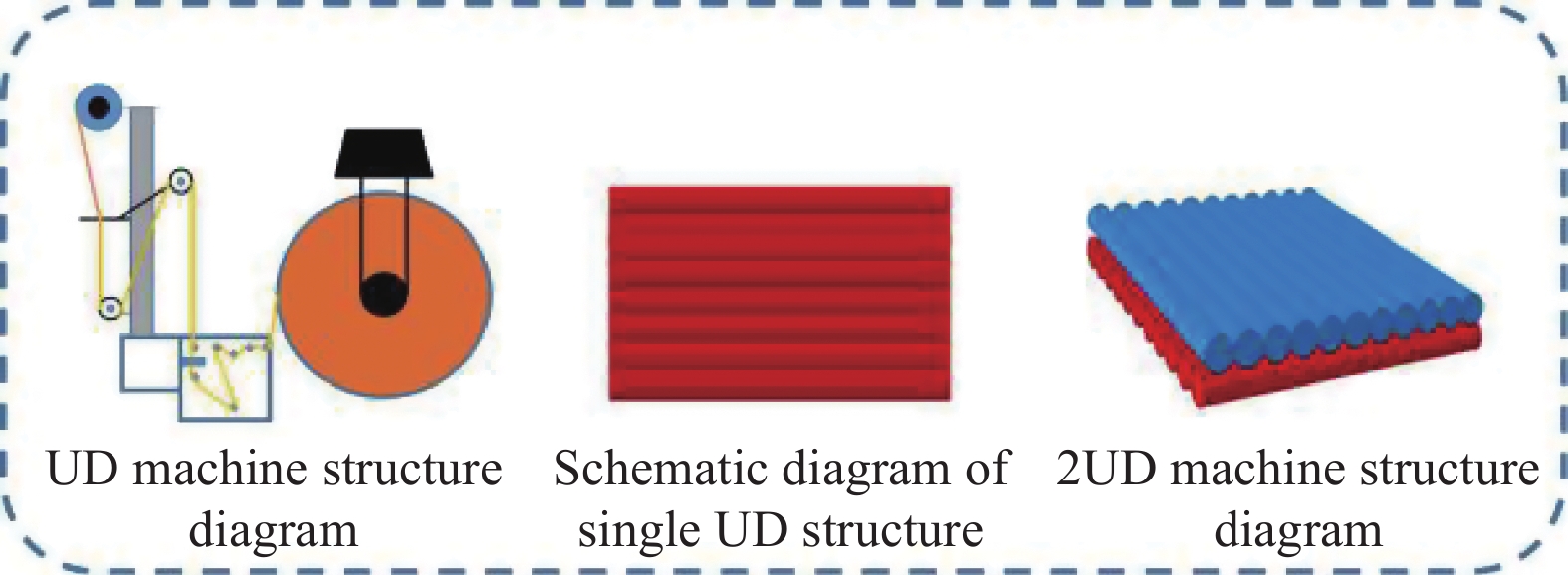

Kevlar纤维单向(UD)片材的制备过程如图1所示,首先通过滚筒式UD机(嘉兴谢尔德防护科技有限公司),将Kevlar纤维长丝均匀铺展得到单UD片材,将单UD片材旋转90°,在单UD片材基础上,再次通过UD机,得到2UD结构片材。

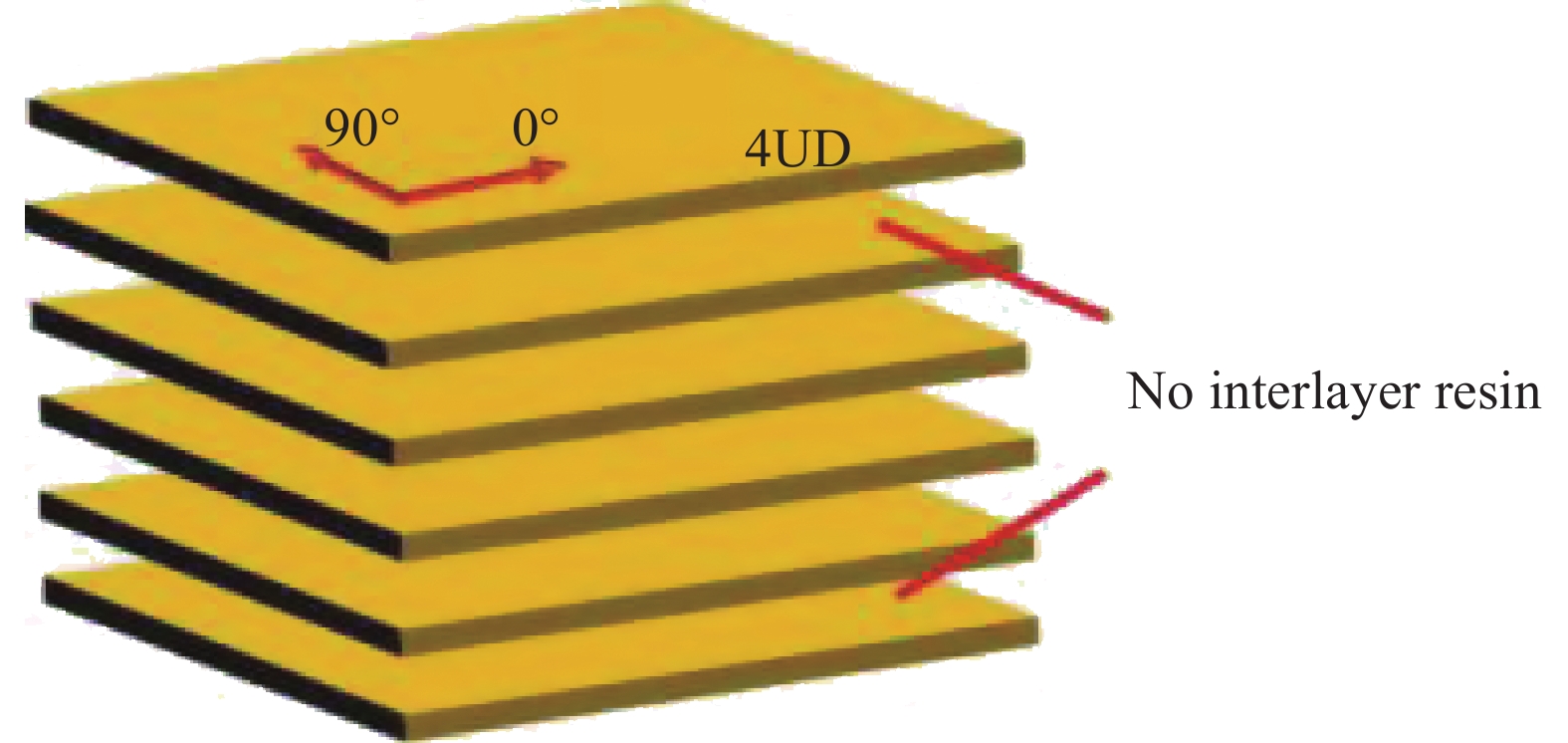

靶板的制备分为3个阶段:如图2所示,第一阶段,根据靶板面密度,裁剪所需的2UD单元结构片材(250 mm×250 mm),热压时需要用隔离膜将每层靶片隔离,避免粘黏。根据靶板对靶片单元结构和面密度的要求,将相应片数的2UD单元结构片材与隔离膜交叉铺层,保证靶片按照0°/90°/0°……的方式排列。

第二阶段,热压机(Carver 4386,迈可诺科有限公司)预热到设定温度,将上述铺设好的材料放入热压机,开始加压到预设值,然后保压、保温一定时间,当时间到达预设值后,进行卸压、降温。

第三阶段,当靶片温度降到室温后,将靶片按照0°/90°叠层放置,制备靶板,靶片之间无树脂粘结,如图3所示。再次称重,确认面密度、含胶量等是否达到预设值。

1.3 防弹性能测试

参照GA 141—2010《警用防弹衣》2级防弹标准[20],对尺寸为250 mm×250 mm的Kevlar纤维UD片材复合材料靶板进行3次射击,射击距离为5 m。弹道试验装置如图4所示,选择胶泥为衬底,以深度尺测量背凸深度(BFS)。弹道侵彻实验标准参数如表1所示。

表 1 弹道侵彻试验标准参数Table 1. Ballistic penetration test standard parametersBullet specification Impact velocity/(m·s−1) Back face deformation depth/mm Shooting distance/m Impact angle/(°) 7.62×17 445±10 <25 5 0 2. 结果与讨论

2.1 Kevlar纤维UD片材复合材料的防弹性能

2.1.1 共混树脂配比对Kevlar纤维UD片材复合材料防弹性能的影响

合适的树脂与纤维可以形成良好的界面,使增强纤维和树脂基体形成一个整体,可以更好传递应力,吸收和耗散能量[21-22]。

本研究采用物理共混的方法,探究两种树脂的共混比例对Kevlar纤维UD布防弹性能的影响,不同配比的共混树脂制备的Kevlar纤维UD片材靶板打靶结果如表2和图5所示。

表 2 不同树脂质量比靶板打靶结果Table 2. Shooting results of target plates with different resin mass ratiosSerial number Resin (Polyurethane∶

Acrylic acid)Number of layers Resin content/wt% Single-layer areal

density/(g·m−2)Target plate areal

density/(kg·m−2)Penetration 1 2∶1 45 17 187 8.40 No 2 1∶1 44 18 190 8.36 No 3 2∶3 45 17 188 8.46 No 4 1∶2 44 19 192 8.42 No 5 2∶5 44 17 189 8.30 No 6 Acrylic acid 44 18 190 8.36 Yes 结合表2和图5可知,(1)随着水性丙烯酸树脂所占比重的增加,靶板的背凸深度近似呈先减小后增大的趋势,当水性聚氨酯与水性丙烯酸树脂质量比为1∶2时,靶板的背凸深度平均值最小,背凸深度为14 mm,靶板具有良好的抗凹陷性能;(2)随着水性丙烯酸树脂所占比重增加,靶板贯穿层所占比例总体呈先减小后增大的趋势,水性聚氨酯与水性丙烯酸树脂质量比为1∶2时,靶板贯穿层所占比例平均值最小,贯穿层所占比例为36%,靶板损伤容限较好。

综上所述,随着水性丙烯酸树脂所占比重的增加,靶板防弹性能呈先增大后减小的趋势,当水性聚氨酯与水性丙烯酸树脂质量比为1∶2时,防弹性能较好。原因分析:实际制备中发现水性聚氨酯与Kevlar纤维界面性能差,UD布无法成型,水性丙烯酸树脂与Kevlar纤维界面性能优于水性聚氨酯树脂。(1)当水性丙烯酸树脂所占比重过低,纤维与树脂界面性能差,纤维容易脱粘,在遭到子弹冲击,易滑移,有效参与防弹的纤维减少,且无法有效发挥纤维拉伸性能;(2)丙烯酸树脂含量过大,丙烯酸树脂力学性能较差[23],靶板遭到子弹冲击时,树脂基体容易遭到破坏,应力波传递不均匀,树脂与Kevlar纤维无法协同发挥作用,造成Kevlar纤维UD片材靶板防弹性能降低。

选取冲击后的1#、3#、4#、5#靶板进行观察,破坏形貌如图6所示。

(1)靶板的迎弹面破坏形貌类似,迎弹面弹孔表面平整,无纤维炸出,弹孔内部出现黑色附着物,孔径基本在7 mm左右,且近似呈正方形,迎弹面弹孔处纤维呈现剪切冲塞现象。这是由于子弹初速度大,Kevlar纤维的横向剪切强度远远小于轴向拉伸强度,在高速冲击下,纤维未发挥拉伸性能,就遭到剪切破坏失效,靶板出现剪切冲塞现象。

(2)靶板背弹面靶片变形,在弹着点处出现鼓包,部分纤维出现脱粘。这是由于在子弹冲击过程中,应力波通过树脂与纤维界面传递与扩散,随着应力波不断地传播与叠加,靶片拉伸变形面积增大,在背弹面能量积累达到极限,形成鼓包,部分纤维达到拉伸应力极限,断裂脱粘。

(3)随着水性丙烯酸树脂所占比重的增大,靶板背弹面鼓包面积呈先减小后增大趋势,靶板4#的鼓包面积最小。这是由于随着水性丙烯酸树脂所占比例的增加,纤维与共混树脂的界面性能提高,在高速冲击下,纤维不易发生脱粘,避免纤维滑移,使更多的纤维有效吸收子弹能量,鼓包面积减小,但水性丙烯酸树脂所占比重过大,丙烯酸树脂力学性能较差,靶板遭到子弹冲击时,树脂基体在拉伸变形过程中容易被破坏,无法有效传递应力波,使得靶板背弹面破坏面积增大。

2.1.2 树脂含量对Kevlar纤维UD片材复合材料防弹性能影响

树脂含量是影响复合材料性能的重要影响因素之一,为探究树脂含量对其防弹性能的影响,不同树脂含量的Kevlar纤维UD片材靶板打靶结果如表3和图7所示。

表 3 不同树脂含量靶板打靶结果Table 3. Shooting results of target plates with different resin contentsSerial number Resin (Polyurethane∶

Acrylic acid)Number of layers Resin content/wt% Single-layer areal

density/(g·m−2)Target plate areal

density/(kg·m−2)Penetration 7 1∶2 50 10 168 8.32 No 4 1∶2 44 19 192 8.42 No 8 1∶2 40 26 208 8.30 No 9 1∶2 37 32 227 8.37 No 从表3和图7可知,(1)随着树脂含量的增加,靶板的背凸深度呈先减小后增大逐渐趋于平缓的趋势,当树脂含量为19wt%时,靶板的背凸深度平均值最小,靶板具有良好的抗凹陷性能;(2)随着树脂含量的增加,靶板贯穿层所占比例呈增大的趋势,且增幅不断提高,树脂含量为19wt%靶板贯穿层所占比例最小,与32wt%靶板的贯穿层所占比例相比下降40%,靶板损伤容限较好。

综上所述,随着树脂含量的增加,靶板的防弹性能呈先增大后减小的趋势,当树脂含量为19wt%时,防弹性能较好。原因分析:(1)当树脂含量过低,树脂不能完全均匀地包覆纤维,在遭到子弹冲击时,树脂不能有效传递应力,且纤维与纤维粘结强度低,易脱粘,纤维滑移,无法有效发挥纤维自身强力,导致防弹性能下降[24];(2)树脂含量较大,会导致纤维受到的粘结力过大,在遭到子弹冲击时,纤维受到树脂束缚过大,纤维塑化,易发生脆性断裂,无法有效拉伸断裂,吸收能量[25];纤维是吸收子弹能量的主体,相同面密度下,树脂增加,纤维含量减少,防弹性能下降[26]。含胶量过多,靶板变形能力受到限制,这导致靶板的背凸深度逐渐趋近于平缓;子弹需要穿透更多的层数耗散能量,导致贯穿层比例骤增现象出现。

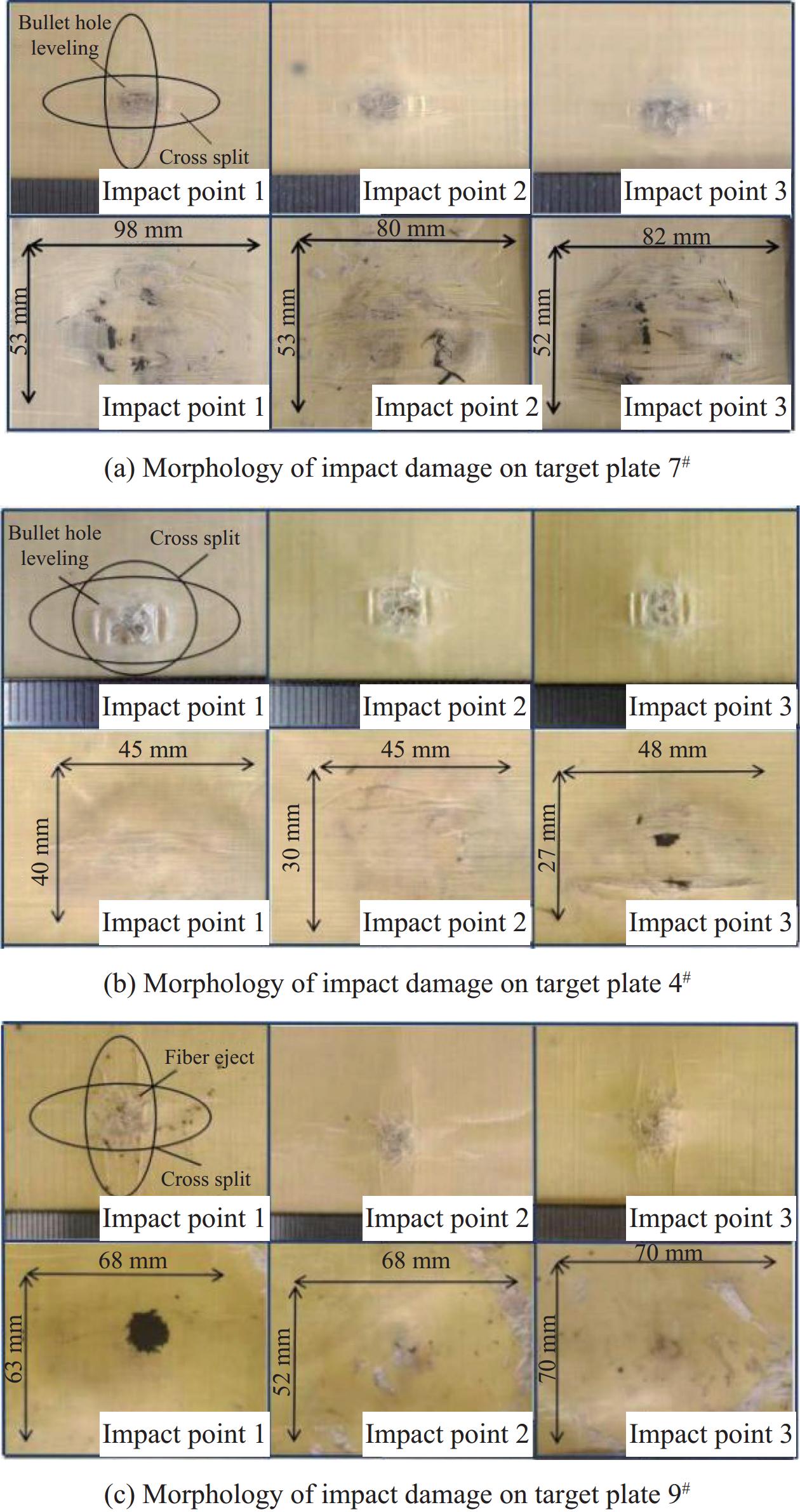

选取冲击后7#、4#、9#靶板进行观察,破坏形貌如图8所示。

(1)当树脂含量为10wt%时,迎弹面弹孔表面平整,无纤维炸出,且近似呈正方形,迎弹面弹孔出现剪切冲塞现象,纤维呈十字形劈裂;背弹面变形程度较大,且纤维与树脂脱粘严重;(2)当树脂含量为19wt%时,迎弹面弹孔表面平整,纤维呈十字形劈裂,背弹面鼓包面积减小,变形程度减弱,且纤维与树脂有脱粘现象;(3)树脂含量为32wt%时,迎弹面弹孔处纤维轻微炸出,纤维呈十字劈裂,背凸面积增大,背弹面光滑,纤维与树脂无明显脱粘现象。

原因分析:(1)树脂含量较小时,纤维与树脂覆盖不均匀,纤维与树脂粘结性差,无法形成有效整体,在子弹高速冲击时,靶板容易发生变形,在拉伸过程中,纤维易于树脂脱粘,造成背弹面大量纤维与树脂脱粘;(2)树脂含量过大时,靶片刚度大,靶板类似层合板,应力波被迅速反射,且能量较大,导致迎弹面纤维随着应力波反射轻微炸出;纤维与树脂粘结力过大,导致纤维不能有效拉伸,发挥自身强力,通过纤维断裂吸收能量较小,因此,需要背弹面更多的形变和纤维拉伸吸收能量,因此,背凸鼓包面积相对于19wt%含胶量靶板增大,但背弹面无明显纤维脱粘。

2.1.3 热压工艺对Kevlar纤维UD片材复合材料防弹性能影响

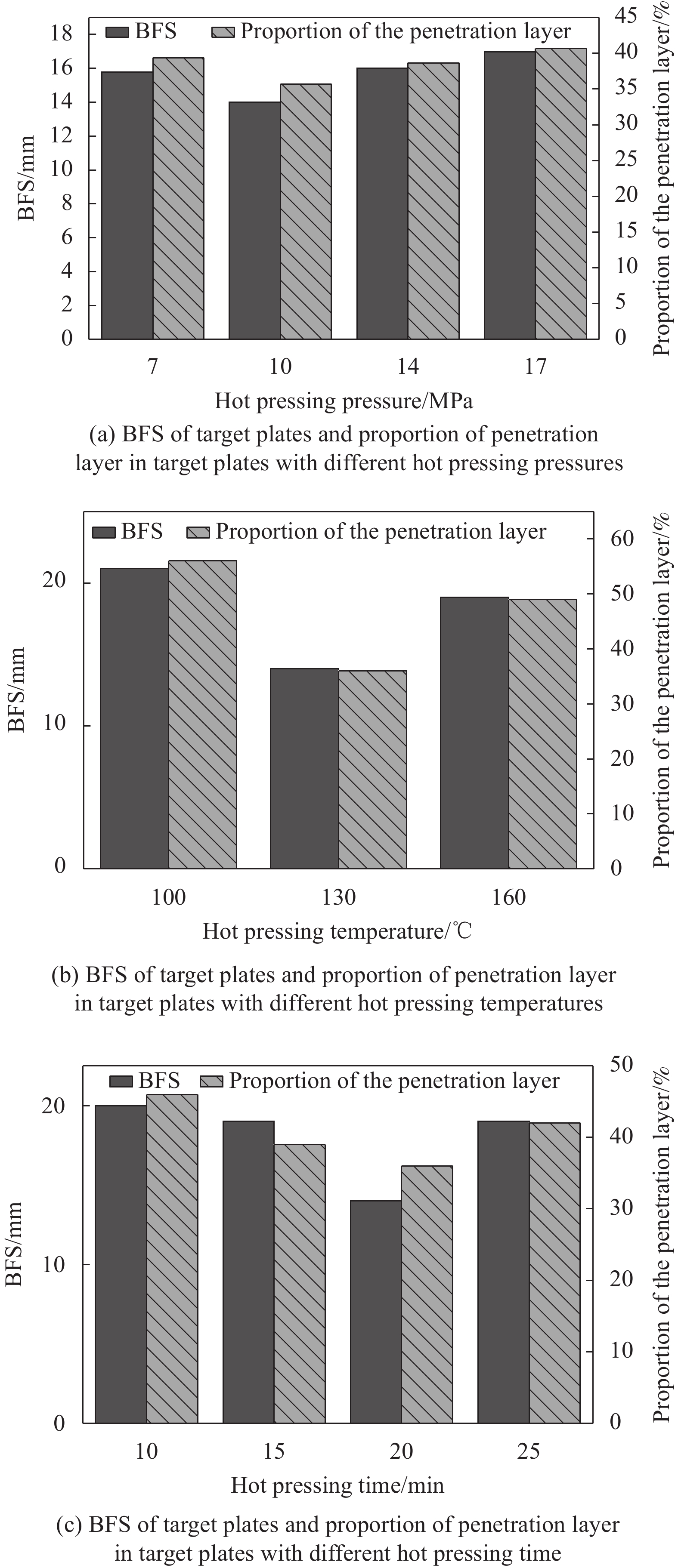

热压工艺包括热压压力、热压温度、热压时间,为探究热压工艺对Kevlar纤维UD布靶板防弹性能影响,进行单因素实验。不同热压工艺制备的靶板打靶测试结果如表4和图9所示。

表 4 不同热压工艺靶板打靶结果Table 4. Shooting results of target plates with different hot pressing processesSerial number Hot pressing process Number of layers Resin content/wt% Target plate areal density/(kg·m−2) Penetration 10 7 MPa, 130℃, 20 min 42 21 8.34 No 4 10 MPa, 130℃, 20 min 44 19 8.40 No 11 14 MPa, 130℃, 20 min 42 21 8.30 No 12 17 MPa, 130℃, 20 min 42 22 8.42 No 13 10 MPa, 100℃, 20 min 42 22 8.39 No 14 10 MPa, 160℃, 20 min 44 18 8.37 No 15 10 MPa, 190℃, 20 min 43 20 8.43 Yes 16 10 MPa, 130℃, 10 min 43 20 8.33 No 17 10 MPa, 130℃, 15 min 43 20 8.37 No 18 10 MPa, 130℃, 25 min 44 17 8.30 No 由表4和图9可知,(1)随着热压压力的增加,靶板的背凸深度和贯穿层所占比例呈先减小后增大的趋势。当热压压力为10 MPa时,防弹性能较好;(2)随着热压温度的增加,靶板的背凸深度和贯穿层所占比例呈先减小后增大的趋势,直至穿透。当热压温度为130℃时,防弹性能较好;(3)随着热压时间的增加,靶板BFS值和靶板贯穿层所占比例呈先减小后增大的趋势。当热压时间为20 min时,防弹性能较好。

综上所述,随着热压压力、热压温度、热压时间的增加,靶板的防弹性能呈先增大后减小的趋势。原因分析:(1)树脂受热熔融,当热压压力过小、温度过低、时间过短时,共混树脂黏度大,流动性差,不能均匀浸渍纤维,界面性能差,应力波不能有效快速传播,易在树脂不均匀处反射造成破坏,不能有效吸收能量;(2)合适的压力、温度和时间可以使共混树脂充分熔融,在压力和时间的作用下,树脂流动性好,靶片逐渐被压实,均匀填补纤维与纤维之间的空隙,界面性能提高,有利于应力波的快速传递,纤维与树脂可以协同发挥作用,充分吸收冲击能量[27];(3)当热压压力过大、热压温度过高、热压时间过长,容易造成靶片中的纤维与树脂过于紧密,填充于纤维间隙的树脂在压力作用下被挤出靶片,影响树脂与纤维的界面性能[28]。

2.2 Kevlar纤维UD片材复合材料防弹机制

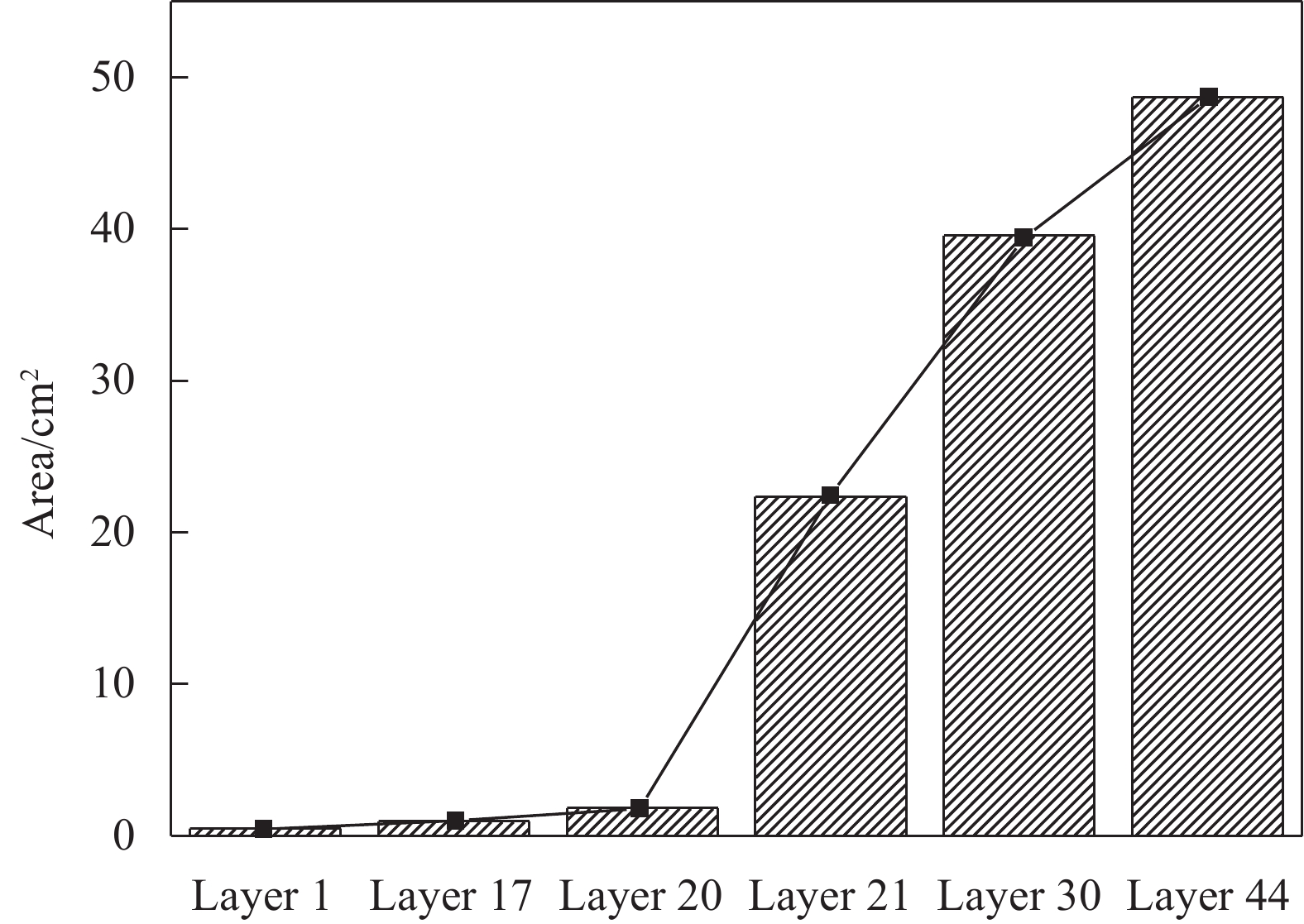

基于4#靶板的破坏形貌,结合应力波机制,分析铅芯弹侵彻Kevlar纤维UD片材靶板的过程,探究Kevlar纤维UD片材靶板的防弹机制,如图10~图12所示。

结合图10、图11和图12,第1层靶片弹孔孔径近7 mm与子弹直径相似,纤维断裂面平整,呈剪切破坏,靶片无明显变形。这是由于子弹接触靶板,迅速产生应力波,沿着纤维轴向与靶板厚度方向传播,在应力波的作用下,靶板被迅速挤压,弹着点处纤维与其他区域纤维存在速度差,产生剪切力,迎弹面纤维还未拉伸变形就被直接剪切破坏[24]。

第17层靶片弹孔孔径增大到11 mm,呈近似正方形,纤维炸出方向与子弹侵彻方向一致,靶片弹着点处呈撕裂冲剪破坏,无明显变形。这是由于子弹在侵彻过程中,不断受到各层靶片的阻力导致子弹产生形变,从而增大与靶板接触面积,造成弹孔孔径增大,由于子弹速度仍较大,纤维呈剪切破坏,少量纤维呈现原纤化,拉伸破坏。

第20层靶片弹孔孔径进一步增大到21 mm,纤维向背弹面方向炸出,纤维原纤化,呈拉伸破坏方式,弹孔周围靶片变形,向背弹面方向微凸,变形面积为14.71 cm2。这是由于随着子弹进一步变形,弹孔与靶板接触面积进一步增大,中后层靶片有足够的响应时间,应力波沿着轴向传播,产生拉应力,纤维充分拉伸,达到拉伸应力极限断裂,吸收子弹能量,应力波在纤维断裂之前传播扩散,造成靶片变形。

第21层靶片无孔洞,子弹被拦截,背弹面以弹着点为中心呈近似四角星背凸,变形面积为22.36 cm2,相比上一层面积增加34%。一方面由于随着横波沿着轴向传播,产生拉应力;另一方面由于靶板层间没有树脂,纵波在靶片自由面发生反射,沿着纤维轴向产生与压缩应力相反的拉应力作用在靶片上。在两种拉应力的共同作用下,纤维被拉伸变形,由于UD结构,纤维呈0°/90°排列,且应力波在纤维与树脂界面呈各向同性传递扩散,造成靶片出现近四角星背凸[29]。

第30层靶片背弹面出现以弹着点为中心近四角星背凸,与21层相似,变形面积进一步增大为40.98 cm2。第44层靶片迎弹面弹着点处出现泛白区域,背弹面呈近似四角星背凸,变形面积达到最大值48.70 cm2,且纤维部分脱粘。这是由于随着应力波的不断传递与叠加,随着层数的增加不断积累,靶片变形面积逐渐增大,在最后一层能量达到最大值。

综上所述,Kevlar纤维UD布防弹机制分成3个阶段:第一阶段主要以纤维剪切破坏吸收子弹能量;第二阶段主要以纤维拉伸破坏吸收能量;第三阶段主要以纤维拉伸变形吸收子弹能量。

2.3 Kevlar纤维UD片材复合材料结构优化

基于对Kevlar纤维UD片材复合材料防弹机制的研究,优化Kevlar纤维UD片材复合材料结构,设计4种结构如图13所示。打靶结果如表5和图14所示。

表 5 不同结构 Kevlar纤维UD片材复合材料打靶结果Table 5. Target shooting results of Kevlar fiber UD sheet composites with different structuresSerial number Structure Number of layers Mass ratio Resin content/wt% Target plate areal density/(kg·m−2) Penetration 20 4UD 44 — 18 8.37 No 21 8UD/4UD 34 1∶1.2 18 8.37 No 22 4UD/8UD 34 1.2∶1 18 8.38 No 23 8UD/4UD/8UD 29 1∶1.1∶1 19 8.43 No 由表5和图14可知,(1) 8UD/4UD结构靶板的背凸深度最大,4UD结构靶板和8UD/4UD/8UD结构靶板次之,4UD/8UD结构靶板的背凸深度最小,因此,4UD/8UD结构靶板的抗凹陷性能较好;(2) 4UD/8UD结构靶板的贯穿层比例最大,4UD结构靶板和8UD/4UD/8UD结构靶板的贯穿层所占比例次之,8UD/4UD结构靶板的贯穿所占比例最小,因此,8UD/4UD结构靶板的损伤容限较高。

综上所述,4UD/8UD结构的抗凹陷性能最好,但损伤容限较低,8UD/4UD结构的抗凹陷性能较差,但损伤容限较高;考虑两方面因素影响,8UD/4UD/8UD结构靶板的防弹性能最优,原因是8UD/4UD/8UD结构靶板的背凸深度仅比4UD/8UD结构靶板大1 mm,8UD/4UD/8UD结构靶板比8UD/4UD结构靶板的贯穿层所占比例仅大10%,其他两种结构靶板的贯穿层所占比例高出19%和29%。原因分析:(1) 8UD/4UD结构靶板的背凸深度最大,贯穿层所占比例最小,这是由于子弹侵彻过程中,子弹初速度平均达到450 m/s,8UD结构靶片在前,靶片厚度方向上的层间剪切强度大,使子弹变形程度更大,增大与靶片接触面积,增加4UD结构靶片的响应时间,4UD靶片塑性变形能力强,能够更大范围地通过纤维拉伸变形吸收能量,导致8UD/4UD结构靶板的背凸深度最大,贯穿层所占比例最小;(2) 4UD/8UD结构靶板的背凸深度最小,贯穿层所占比例最大,这是由于受到子弹侵彻时,迎弹面4UD结构靶片厚度方向上层间剪切强度小,容易被剪切破坏,背弹面8UD结构靶片刚度大,限制纤维变形,提供背衬硬度,导致4UD/8UD结构靶板的贯穿层数所占比例远远高于8UD/4UD结构靶板,但背凸深度小于8UD/4UD结构靶板;(3) 8UD/4UD/8UD结构靶板相较于其他3种结构靶板,靶板前面的8UD结构靶片增加了后面靶片的响应时间,使得后面纤维能够拉伸变形,靶板中间的4UD结构靶片纤维变性能力强,能够通过拉伸断裂等方式吸收能量,靶板后面的8UD结构靶片也能够拉伸变形吸收能量,且提供背衬硬度,限制纤维过度变形,避免背凸深度过大[28]。

3. 结 论

本文研究了共混树脂配比、树脂含量、热压成型工艺对Kevlar纤维单向(UD)片材复合材料防弹性能的影响,并探究其防弹机制,对靶板进行结构优化,得到如下结论:

(1) Kevlar纤维UD片材复合材料的防弹性能随着水性丙烯酸树脂比重的增加呈先增大后减小趋势。当水性聚氨酯与水性丙烯酸树脂质量比为1∶2时,防弹性能较好;

(2) Kevlar纤维UD片材复合材料防弹性能随着树脂含量的增加呈先增大后减小趋势。当树脂含量为19wt%时,防弹性能较好;

(3) Kevlar纤维UD片材复合材料的防弹性能随着热压压力、热压温度和热压时间的增加呈先增大后减小趋势;

(4) Kevlar纤维UD片材复合材料的防弹机制分成3个阶段:第一阶段主要以纤维剪切破坏为主;第二阶段主要以纤维拉伸断裂为主;第三阶段主要以纤维拉伸变形为主。

(5) 8UD/4UD/8UD混杂结构的Kevlar纤维UD片材复合材料防弹性能较好。

-

表 1 弹道侵彻试验标准参数

Table 1 Ballistic penetration test standard parameters

Bullet specification Impact velocity/(m·s−1) Back face deformation depth/mm Shooting distance/m Impact angle/(°) 7.62×17 445±10 <25 5 0 表 2 不同树脂质量比靶板打靶结果

Table 2 Shooting results of target plates with different resin mass ratios

Serial number Resin (Polyurethane∶

Acrylic acid)Number of layers Resin content/wt% Single-layer areal

density/(g·m−2)Target plate areal

density/(kg·m−2)Penetration 1 2∶1 45 17 187 8.40 No 2 1∶1 44 18 190 8.36 No 3 2∶3 45 17 188 8.46 No 4 1∶2 44 19 192 8.42 No 5 2∶5 44 17 189 8.30 No 6 Acrylic acid 44 18 190 8.36 Yes 表 3 不同树脂含量靶板打靶结果

Table 3 Shooting results of target plates with different resin contents

Serial number Resin (Polyurethane∶

Acrylic acid)Number of layers Resin content/wt% Single-layer areal

density/(g·m−2)Target plate areal

density/(kg·m−2)Penetration 7 1∶2 50 10 168 8.32 No 4 1∶2 44 19 192 8.42 No 8 1∶2 40 26 208 8.30 No 9 1∶2 37 32 227 8.37 No 表 4 不同热压工艺靶板打靶结果

Table 4 Shooting results of target plates with different hot pressing processes

Serial number Hot pressing process Number of layers Resin content/wt% Target plate areal density/(kg·m−2) Penetration 10 7 MPa, 130℃, 20 min 42 21 8.34 No 4 10 MPa, 130℃, 20 min 44 19 8.40 No 11 14 MPa, 130℃, 20 min 42 21 8.30 No 12 17 MPa, 130℃, 20 min 42 22 8.42 No 13 10 MPa, 100℃, 20 min 42 22 8.39 No 14 10 MPa, 160℃, 20 min 44 18 8.37 No 15 10 MPa, 190℃, 20 min 43 20 8.43 Yes 16 10 MPa, 130℃, 10 min 43 20 8.33 No 17 10 MPa, 130℃, 15 min 43 20 8.37 No 18 10 MPa, 130℃, 25 min 44 17 8.30 No 表 5 不同结构 Kevlar纤维UD片材复合材料打靶结果

Table 5 Target shooting results of Kevlar fiber UD sheet composites with different structures

Serial number Structure Number of layers Mass ratio Resin content/wt% Target plate areal density/(kg·m−2) Penetration 20 4UD 44 — 18 8.37 No 21 8UD/4UD 34 1∶1.2 18 8.37 No 22 4UD/8UD 34 1.2∶1 18 8.38 No 23 8UD/4UD/8UD 29 1∶1.1∶1 19 8.43 No -

[1] 袁子舜, 陆振乾, 许玥, 等. 超高分子量聚乙烯纤维平纹织物-单向布混合堆叠板的防弹机制[J]. 复合材料学报, 2022, 39(6): 2707-2715. YUAN Zishun, LU Zhenqian, XU Yue, et al. Ballistic mechanism of the hybrid panels with UHMWPE woven fabrics and UD laminates[J]. Acta Materiae Compositae Sinica, 2022, 39(6): 2707-2715(in Chinese).

[2] BHATNAGAR A. Lightweight fiber-reinforced composites for ballistic applications[M]//Comprehensive Composite Materials II. Amsterdam: Elsevier, 2017: 527-544.

[3] CHEESEMAN B A, BOGETTI T A. Ballistic impact into fabric and compliant composite laminates[J]. Composite Structures, 2003, 61(1-2): 161-173. DOI: 10.1016/S0263-8223(03)00029-1

[4] ABTEW M A, BOUSSU F, BRUNIAUX P, et al. Ballistic impact mechanisms—A review on textiles and fibre-reinforced composites impact responses[J]. Composite Structures, 2019, 223: 110966. DOI: 10.1016/j.compstruct.2019.110966

[5] WANG M, ZHONG L, CAO H, et al. Research on bending and ballistic performance of three-dimensional ply-to-ply angle interlock Kevlar/EP armor material[J]. Materials, 2022, 15(19): 6994. DOI: 10.3390/ma15196994

[6] CROUCH I G. Body armour—New materials, new systems[J]. Defence Technology, 2019, 15(3): 241-253. DOI: 10.1016/j.dt.2019.02.002

[7] 董彬, 魏汝斌, 王小伟, 等. 纤维增强树脂基复合材料防弹头盔研究进展[J]. 兵器材料科学与工程, 2022, 45(4): 125-132. DONG Bin, WEI Rubin, WANG Xiaowei, et al. Progress of bulletproof helmet made by fibre reinforced polymer composites[J]. Ordnance Material Science and Engineering, 2022, 45(4): 125-132(in Chinese).

[8] 艾青松, 潘智勇, 吴中伟, 等. 胶粘剂配方对芳纶防弹板性能的影响[J]. 高科技纤维与应用, 2019, 44(6): 33-37. AI Qingsong, PAN Zhiyong, WU Zhongwei, et al. The influence of adhesive formula on the performance of aramid bulletproof board[J]. Hi-Tech Fiber and Application, 2019, 44(6): 33-37(in Chinese).

[9] KARAHAN M. Comparison of ballistic performance and energy absorption capabilities of woven and unidirectional aramid fabrics[J]. Textile Research Journal, 2008, 78(8): 718-730. DOI: 10.1177/0040517508090487

[10] 艾青松, 李宗家, 吴中伟, 等. 芳纶机织布混杂芳纶无纬布的防弹性能研究[J]. 高科技纤维与应用, 2022, 47(1): 27-31. DOI: 10.3969/j.issn.1007-9815.2022.01.003 AI Qingsong, LI Zongjia, WU Zhongwei, et al. Study on bulletproof performance of aramid woven fabric mixed with aramid UD cloth[J]. Hi-Tech Fiber and Application, 2022, 47(1): 27-31(in Chinese). DOI: 10.3969/j.issn.1007-9815.2022.01.003

[11] 吴中伟, 张慧, 艾青松, 等. 芳纶防弹防刺材料研究[J]. 合成纤维, 2021, 50(6): 36-40. WU Zhongwei, ZHANG Hui, AI Qingsong, et al. Study on bullet-proof and stab-proof aramid materials[J]. Synthetic Fiber in China, 2021, 50(6): 36-40(in Chinese).

[12] YANG Y, CHEN X. Investigation of failure modes and influence on ballistic performance of ultra-high molecular weight polyethylene (UHMWPE) uni-directional laminate for hybrid design[J]. Composite Structures, 2017, 174: 233-243. DOI: 10.1016/j.compstruct.2017.04.033

[13] CAO M, ZHOU D, WANG Z, et al. An experimental study of the penetration resistance of UHMWPE laminates with limited thickness[J]. Thin-Walled Structures, 2024, 196: 111438.

[14] LÄSSIG T R, MAY M, HEISSERER U, et al. Effect of consolidation pressure on the impact behavior of UHMWPE composites[J]. Composites Part B: Engineering, 2018, 147: 47-55. DOI: 10.1016/j.compositesb.2018.04.030

[15] 贾文星, 贾子琪, 田国峰, 等. 聚酰亚胺/超高分子量聚乙烯纤维混杂增强复合材料防弹性能[J]. 复合材料学报, 2023, 40(7): 3921-3927. JIA Wenxing, JIA Ziqi, TIAN Guofeng, et al. Bulletproof performance of polyimide/UHMWPE fiber hybrid reinforced composites[J]. Acta Materiae Compositae Sinica, 2023, 40(7): 3921-3927(in Chinese).

[16] HAN F, ZHANG Y, WANG C, et al. Analysis of ballistic performance and penetration damage mechanisms of aramid woven fabric reinforced polycarbonate composites with different matrix content[J]. Chemical Engineering Journal, 2023, 453: 139470. DOI: 10.1016/j.cej.2022.139470

[17] 胡建海, 唐鋆磊, 李湉, 等. 碳纤维和芳纶纤维的蚀刻改性及其复合材料界面结合性能研究进展[J]. 表面技术, 2021, 50(10): 94-116. HU Jianhai, TANG Junlei, LI Tian, et al. Research progress on etching modification of carbon fiber and aramid fiber and the interface bonding performance of their composite materials[J]. Surface Technology, 2021, 50(10): 94-116(in Chinese).

[18] 李婷, 王增效, 胡祖明, 等. 对位芳纶表面改性的最新研究进展[J]. 合成纤维工业, 2018, 41(6): 42-47. DOI: 10.3969/j.issn.1001-0041.2018.06.016 LI Ting, WANG Zengxiao, HU Zuming, et al. Latest research progress in surface modification of p-aramid fiber[J]. China Synthetic Fiber Industry, 2018, 41(6): 42-47(in Chinese). DOI: 10.3969/j.issn.1001-0041.2018.06.016

[19] 曾国屏, 董清龙, 刘德旺, 等. 水性聚氨酯/丙烯酸树脂合成及改性技术的研究进展[J]. 化工新型材料, 2021, 49(12): 12-15, 26. ZENG Guoping, DONG Qinglong, LIU Dewang, et al. Research progress on synthesis and modification of waterborne polyurethane/acrylic resin[J]. New Chemical Materials, 2021, 49(12): 12-15, 26(in Chinese).

[20] 中华人民共和国公安部. 警用防弹衣: GA 141—2010[S]. 北京: 中国标准出版社, 2011. Ministry of Public Security of the People's Republic of China. Police bulletproof vest: GA 141—2010[S]. Beijing: Standards Press of China, 2011(in Chinese).

[21] FUNCHESS P N, KRAMER L D, BINETTI V R, et al. Ballistic material with enhanced polymer matrix and method for production thereof: US Patent, 2010047549A1[P]. 2010-02-25.

[22] ZHENG Z, HUANG X, LI Y, et al. Influence factors of internal structure and interfacial compatibility of UHMWPE fiber/SEBS resin composites: Processing parameters, structure of fiber and nature of resin[J]. Composites Part B: Engineering, 2012, 43(3): 1538-1544. DOI: 10.1016/j.compositesb.2011.11.011

[23] 成航航. 核壳型丙烯酸树脂乳液的制备及性能研究[D]. 西安: 陕西科技大学, 2021. CHENG Hanghang. Preparation and properties of core-shell acrylic resin emulsion[D]. Xi'an: Shaanxi University of Science & Technology, 2021(in Chinese).

[24] LANGSTON T. An analytical model for the ballistic performance of ultra-high molecular weight polyethylene composites[J]. Composite Structures, 2017, 179: 245-257. DOI: 10.1016/j.compstruct.2017.07.074

[25] 马华菁, 时娟娟, 沈文东, 等. 防弹无纬布的研究概况[J]. 棉纺织技术, 2021, 49(5): 14-18. DOI: 10.3969/j.issn.1001-7415.2021.05.005 MA Huajing, SHI Juanjuan, SHEN Wendong, et al. Research overview of bulletproof unidirectional cloth[J]. Cotton Textile Technology, 2021, 49(5): 14-18(in Chinese). DOI: 10.3969/j.issn.1001-7415.2021.05.005

[26] 闫卫星, 郭艳文, 陈红霞, 等. 防弹防刺面料研究概况[J]. 产业用纺织品, 2022, 40(7): 1-7, 32. DOI: 10.3969/j.issn.1004-7093.2022.07.001 YAN Weixing, GUO Yanwen, CHEN Hongxia, et al. Research overview of bulletproof and stab-resistant fabrics[J]. Technical Textiles, 2022, 40(7): 1-7, 32(in Chinese). DOI: 10.3969/j.issn.1004-7093.2022.07.001

[27] 王孟, 刘程, 张玉, 等. 成型温度对CF/PPEK复合材料的缺陷和力学性能影响[J]. 复合材料科学与工程, 2024(3): 5-12. WANG Meng, LIU Cheng, ZHANG Yu, et al. Effect of molding temperature on defects and mechanical properties of CF/PPEK composites[J]. Composites Science and Engineering, 2024(3): 5-12(in Chinese).

[28] 徐英凯, 朱姝, 袁象恺, 等. 纺织结构碳纤维增强尼龙6 (CFF/PA6)复合材料的模压成型工艺[J]. 塑料工业, 2015, 43(7): 48-51, 68. DOI: 10.3969/j.issn.1005-5770.2015.07.012 XU Yingkai, ZHU Shu, YUAN Xiangkai, et al. Compression molding processing of carbon fiber fabric reinforced nylon 6 (CFF/PA6) composites[J]. China Plastics Industry, 2015, 43(7): 48-51, 68(in Chinese). DOI: 10.3969/j.issn.1005-5770.2015.07.012

[29] 周庆, 何业茂, 刘婷. 层间混杂复合材料装甲板防弹性能及其防弹机制[J]. 复合材料学报, 2019, 36(4): 837-847. ZHOU Qing, HE Yemao, LIU Ting. Bulletproof performance and bulletproof mechanism of interlaminar hybrid composite armor plate[J]. Acta Materiae Compositae Sinica, 2019, 36(4): 837-847(in Chinese).

-

目的

Kevlar纤维与大部分树脂基体结合时界面性能差,导致关于Kevlar纤维UD复合材料防弹性能的研究较少,本文利用物理共混的方法,将水性聚氨酯和水性丙烯酸树脂混合,提高Kevlar纤维与树脂的界面性能,并制备Kevlar纤维UD片材复合材料,探究其防弹性能。

方法借弹道侵彻实验装置对不同比例共混树脂、树脂含量,热压工艺制备的Kevlar纤维UD片材复合材料进行防弹性能测试,使用Origin、扫描电镜对打靶数据和靶板破坏形貌进行分析。

结果①随着共混树脂中水性丙烯酸树脂比重的增加,Kevlar纤维UD片材复合材料防弹性能呈先增大后减小的趋势,当水性聚氨酯与水性丙烯酸树脂的比例为1∶2时,靶板背凸深度和靶板贯穿层所占均小于其他不同配比共混树脂的靶板。②随着树脂含量的增加,Kevlar纤维UD片材复合材料防弹性能呈先增大后减小的趋势,当树脂含量为19 wt%时,靶板背凸深度和靶板贯穿层所占比例均小于其他不同树脂含量的靶板。③Kevlar纤维UD片材复合材料防弹性能随着热压压力的增大呈先增大后减小的趋势,当热压压力为10 MPa时,靶板背凸深度和靶板贯穿层所占比例均小于其他不同热压压力的靶板。④Kevlar纤维UD片材复合材料防弹性能随着热压温度的增大呈先增大后减小的趋势,当热压温度为130 ℃时,靶板背凸深度和靶板贯穿层所占比例均小于其他不同热压温度的靶板。⑤Kevlar纤维UD片材复合材料防弹性能随着热压时间的增大呈先增大后减小的趋势,当热压时间为20 mina时,靶板背凸深度和靶板贯穿层所占比例均小于其他不同热压时间的靶板。⑥Kevlar纤维UD片材复合材料的防弹机制主要分成三个阶段,第一阶段主要以纤维剪切破坏的方式吸收能量,第二阶段主要以纤维拉伸断裂的方式吸收能量为主,第三阶段主要以纤维拉伸变形的方式吸收能量。⑦4UD/8UD结构靶板的背凸深度最小,靶板的抗凹陷性能较好;8UD/4UD结构靶板的贯穿所占比例最小,靶板的损伤容限较高;8UD/4UD/8UD结构靶板的背凸深度仅比4UD/8UD结构靶板大1 mm,8UD/4UD/8UD结构靶板比8UD/4UD结构靶板的贯穿层所占比例仅大10 %,综合考虑,8UD/4UD/8UD结构靶板的防弹性能最优。

结论①当混合树脂比例为2∶4时,共混树脂既能改善Kevlar纤维与水性聚氨酯界面性能差的缺点,又能解决水性丙烯酸树脂自身力学性能差的问题,使得Kevlar纤维UD片材复合材料的防弹性能较好。②当Kevlar纤维UD片材复合材料的树脂含量为19 wt%,树脂既可以均匀覆盖纤维,快速传递载荷,纤维与树脂协同发挥作用,也可以使纤维发挥自身力学性能。③合适的压力、温度和时间可以使共混树脂充分熔融,在压力和时间的作用下,树脂流动性好,靶片逐渐被压实,均匀填补纤维与纤维之间的空隙,界面性能提高,有利于应力波的快速传递,纤维与树脂可以协同发挥作用,充分吸收冲击能量。④8UD/4UD/8UD结构靶板前面的8UD结构靶片增加了后面靶片的响应时间,使得后面纤维能够拉伸变形,靶板中间的4UD结构靶片纤维变性能力强,能够通过拉伸断裂等方式吸收能量,靶板后面的8UD结构靶片也能够拉伸变形吸收能量,且提供背衬硬度,限制纤维过度变形,避免背凸深度过大。

下载:

下载: