Effect of steam curing conditions on mechanical properties and microstructure of electrolytic manganese residue cement mortar

-

摘要:

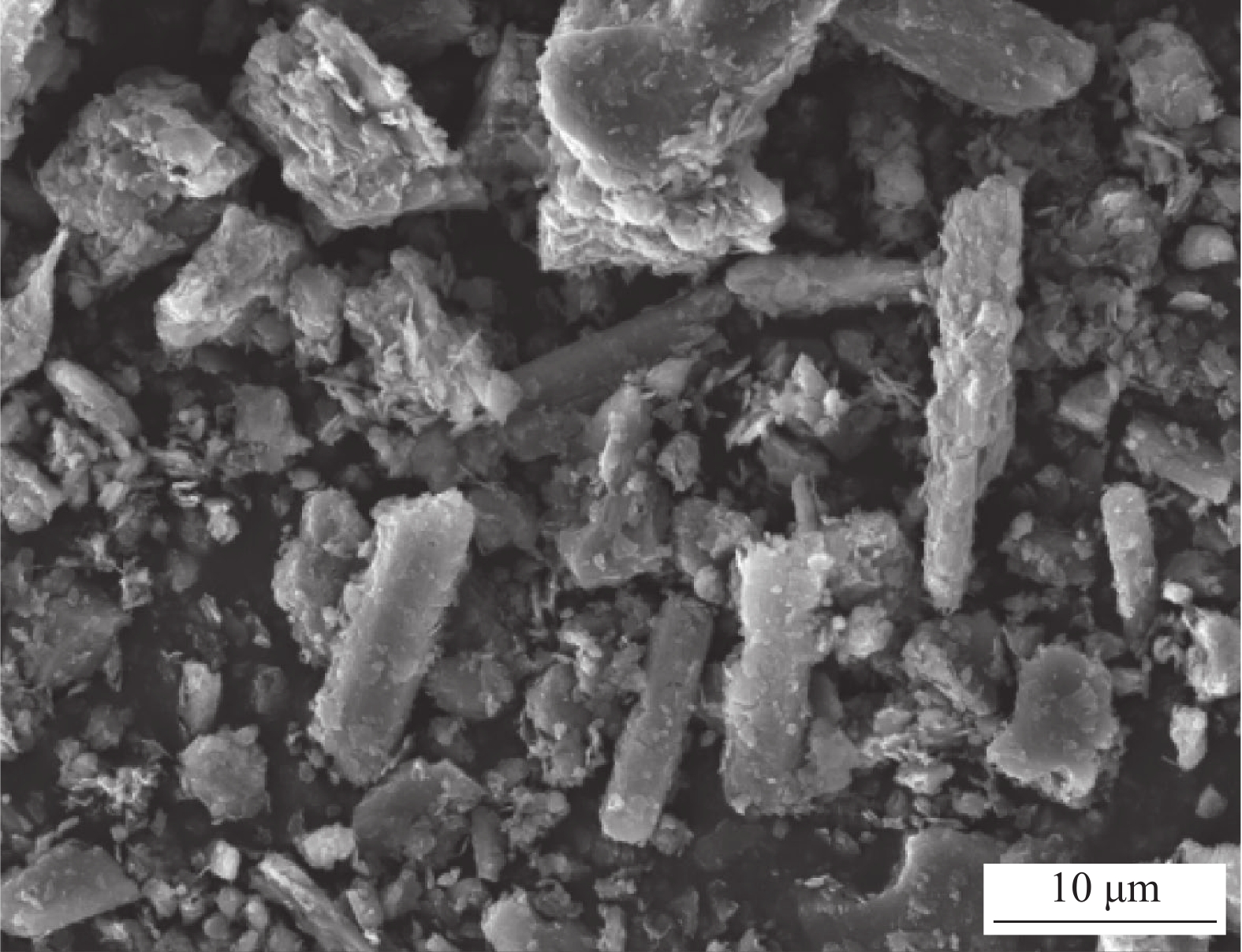

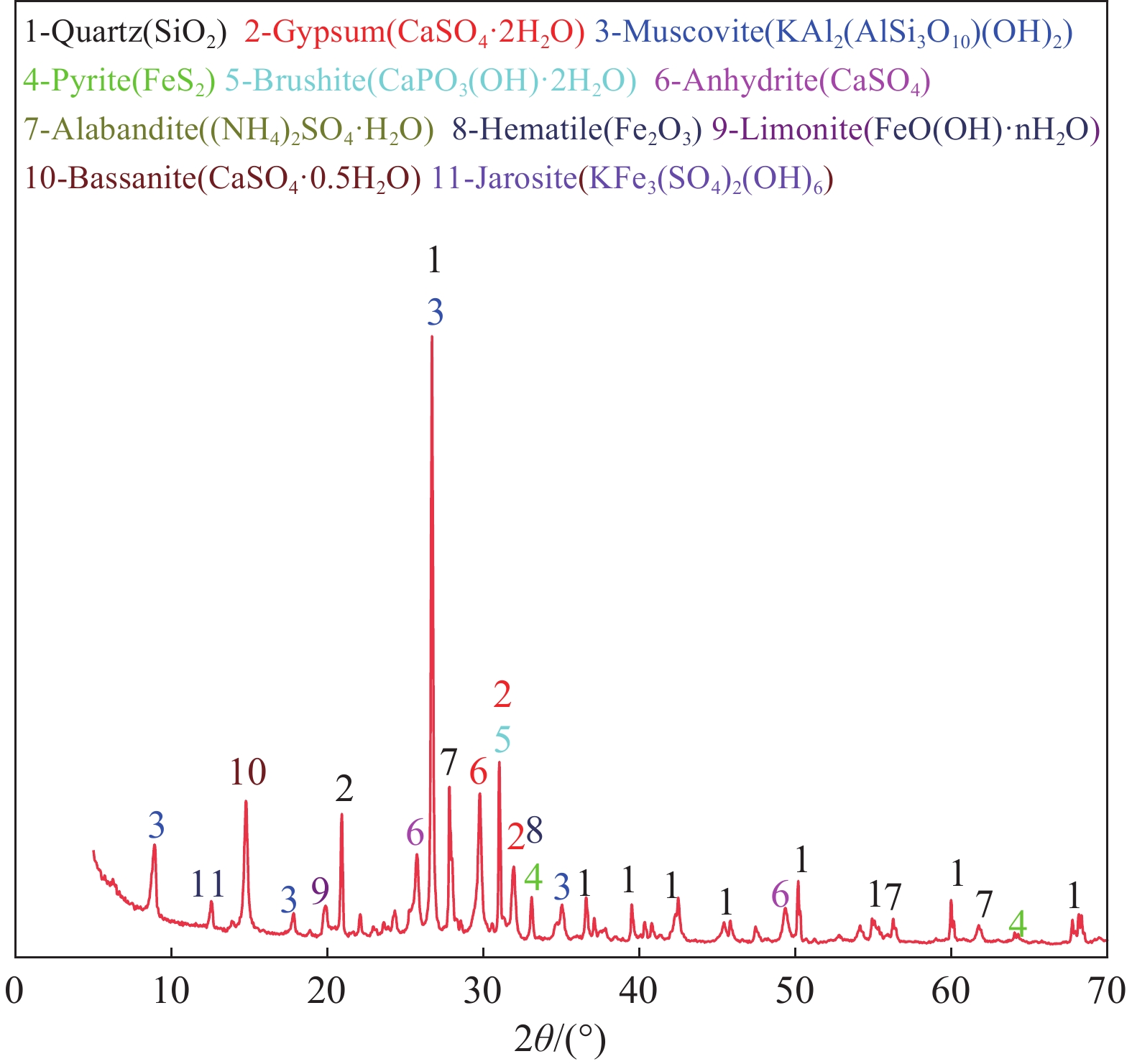

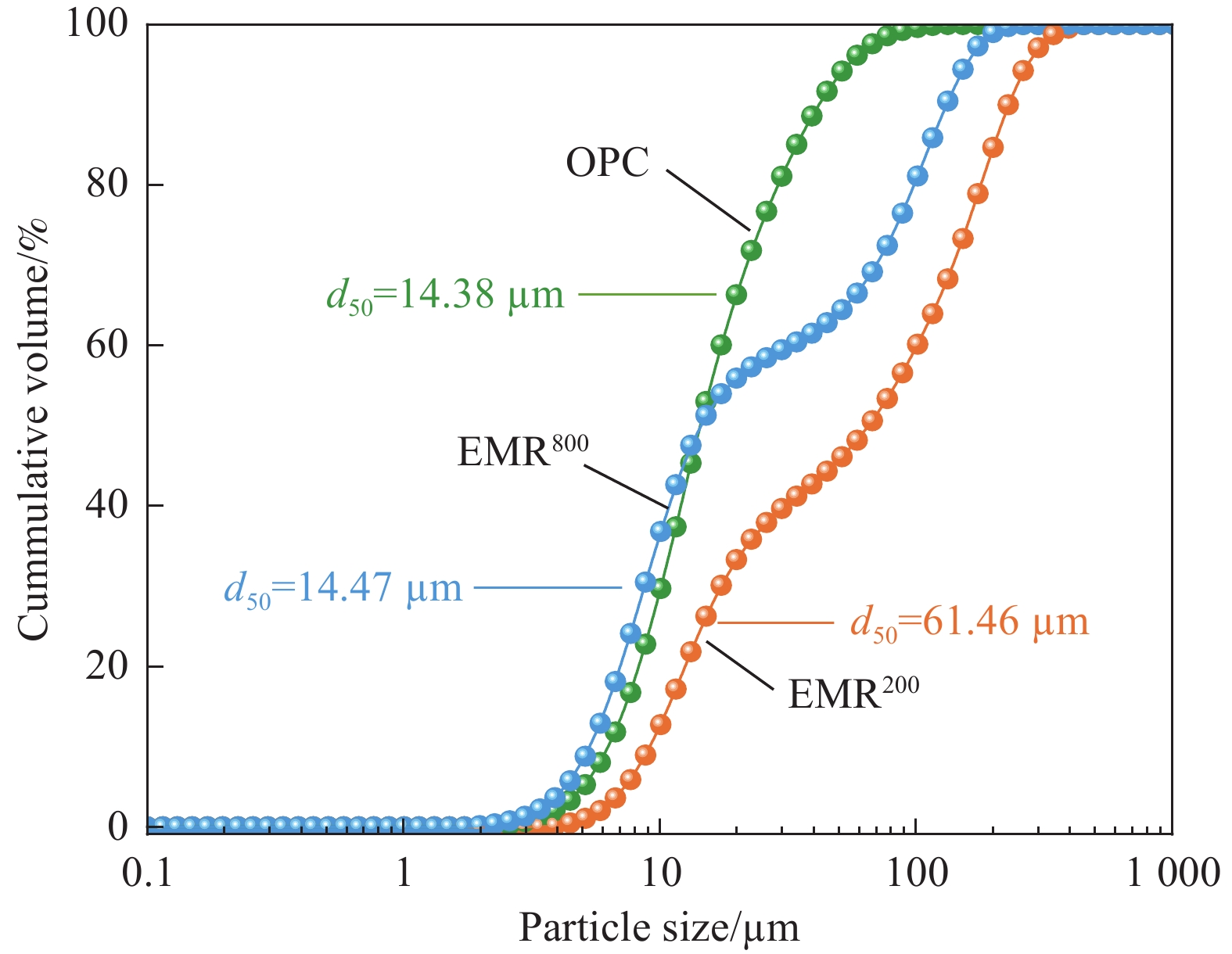

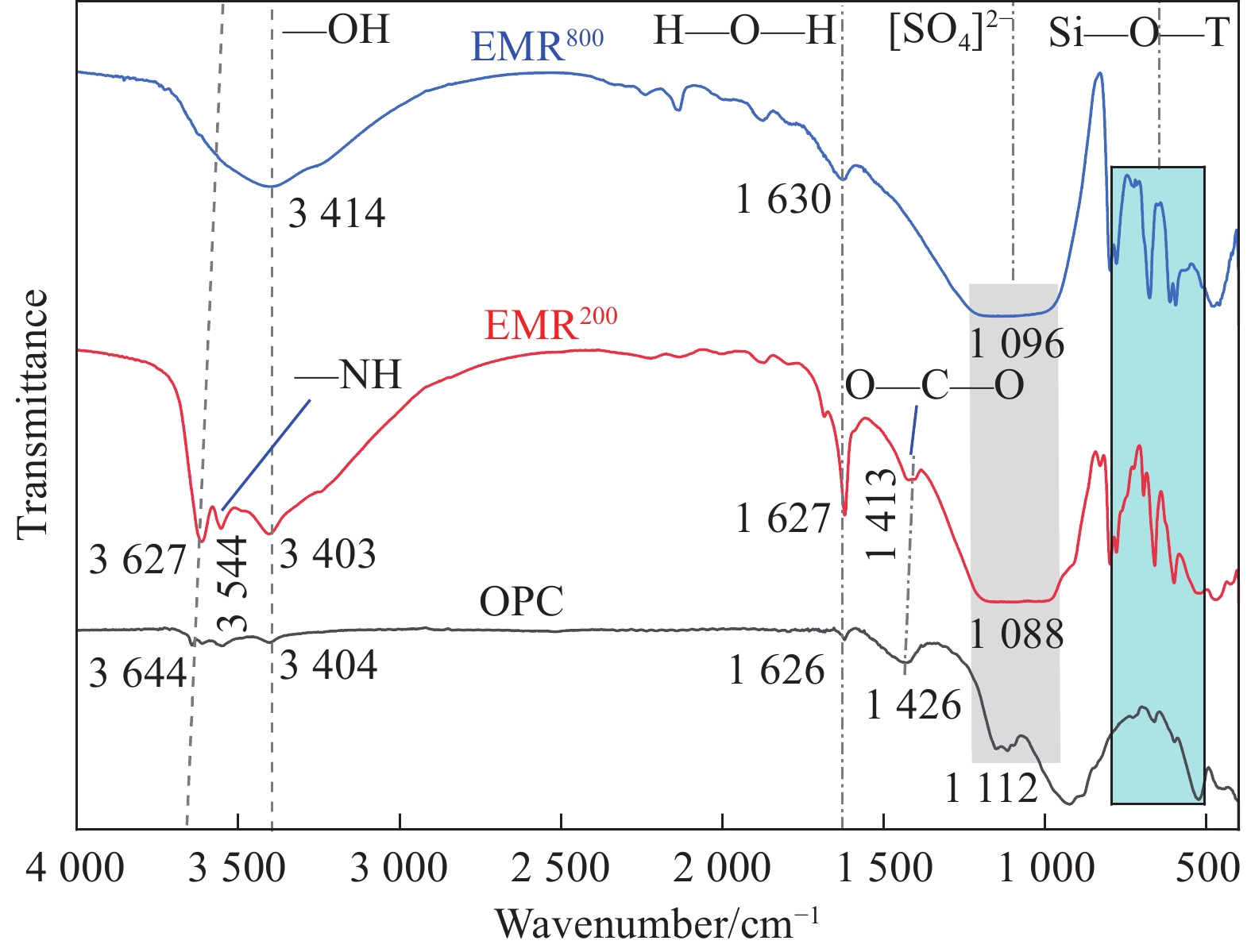

本文研究了不同煅烧温度(200℃和800℃)电解锰渣(EMR)火山灰活性及掺入0wt%、10wt%、20wt% EMR水泥胶砂在80℃蒸汽养护7 h、7 d和标准养护3 d、28 d条件下力学性能、水化产物与孔隙特征分布。采用低场核磁共振技术、XRD定量表征及SEM微观形貌共同揭示了EMR对水泥胶砂的水化产物、孔径分布及孔隙率等影响规律,并探究了不同养护条件对EMR水泥胶砂水化进程的影响。结果表明:800℃煅烧EMR火山灰活性明显高于200℃煅烧火山灰活性,当800℃煅烧EMR替代量为10wt%时,初凝、终凝时间和标准稠度用水量分别为对照组的1.52、1.06和1.05倍,而蒸养7 h、7 d抗压强度分别高于标准养护3 d和28 d抗压强度,而抗折强度仅仅在蒸养7 d时高于对照组17.3%;纯水泥胶砂的水化产物主要为纤维状水化硅酸钙(C-S-H)凝胶和片状氢氧化钙(CH),而EMR水泥胶砂中由于硫酸盐含量较高,除了上述水化产物之外,在蒸养或标准养护条件下均可观察到石膏相与针棒状钙矾石(AFt)的存在,标准养护28 d时,CH、AFt和无定性含量分别为14.50%、11.75%和46.25%,与蒸养7 d衍射峰基本相似。另外,蒸汽养护7 h与标准养护3 d对比孔隙率减少1.44%,蒸养7 d与标准养护28 d对比孔隙率减少0.06%。综上,蒸汽养护可以提高800℃煅烧EMR火山灰活性,同时还可以加速EMR水泥胶砂的水化进程和细化其内部孔结构,进而提高胶砂的力学性能。

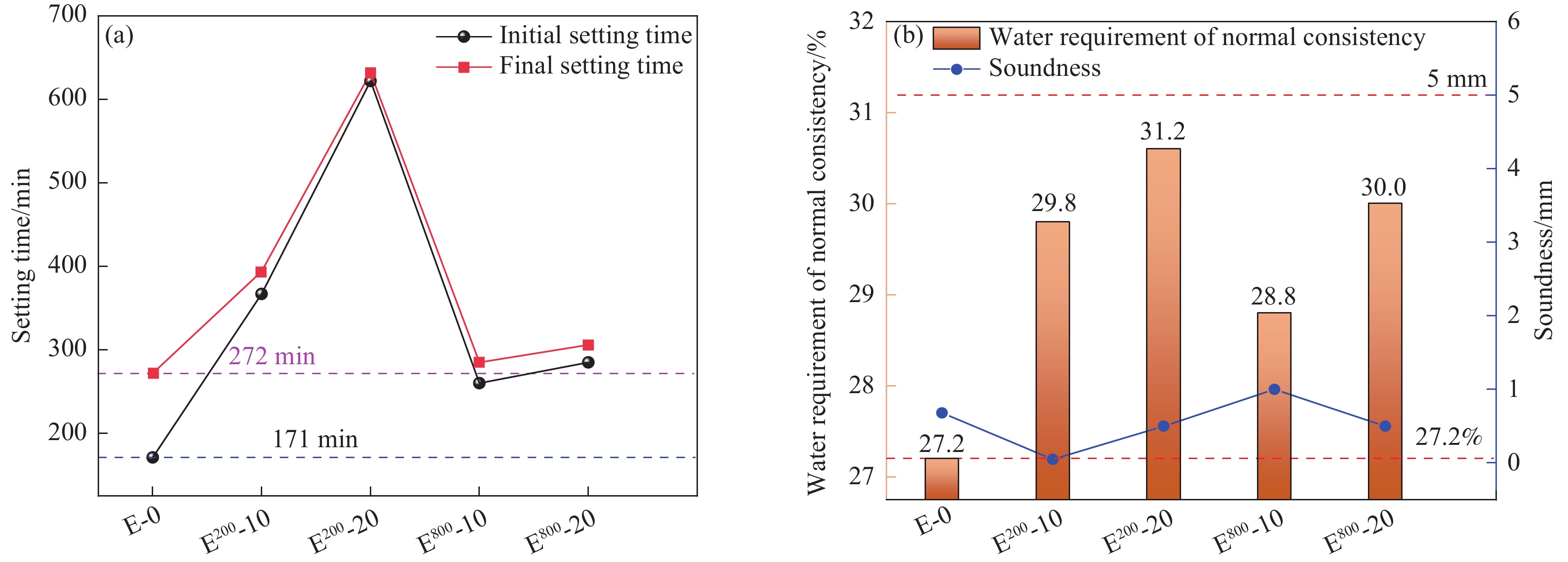

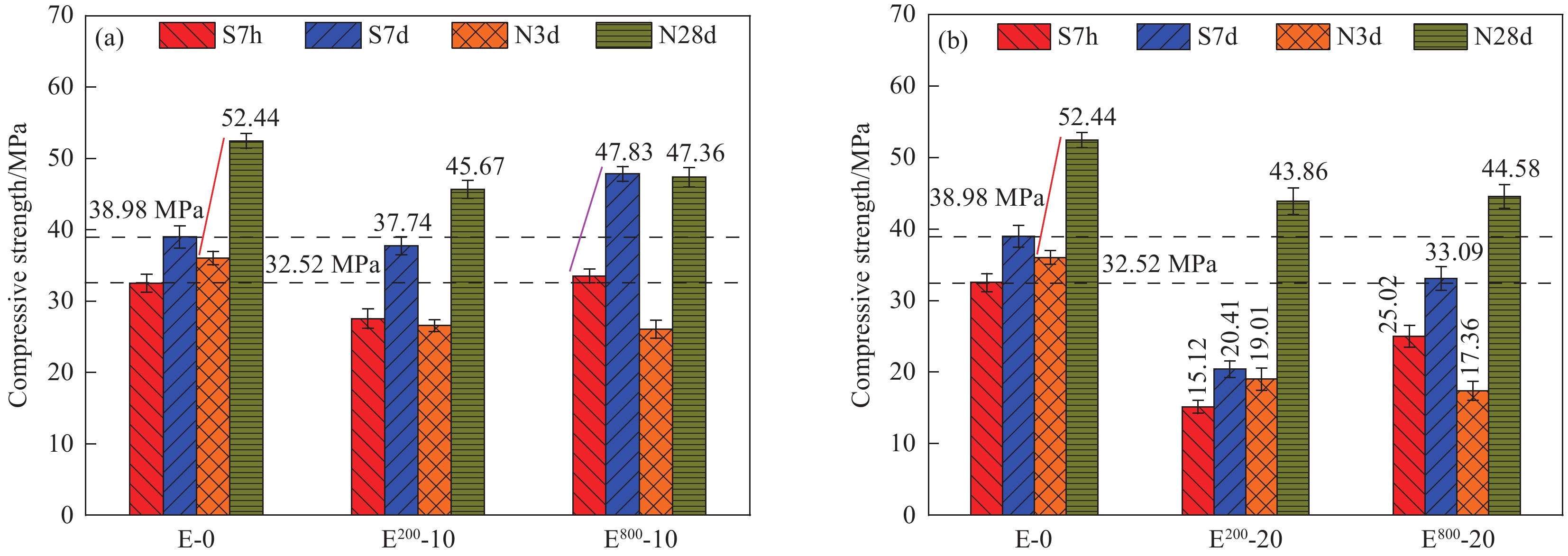

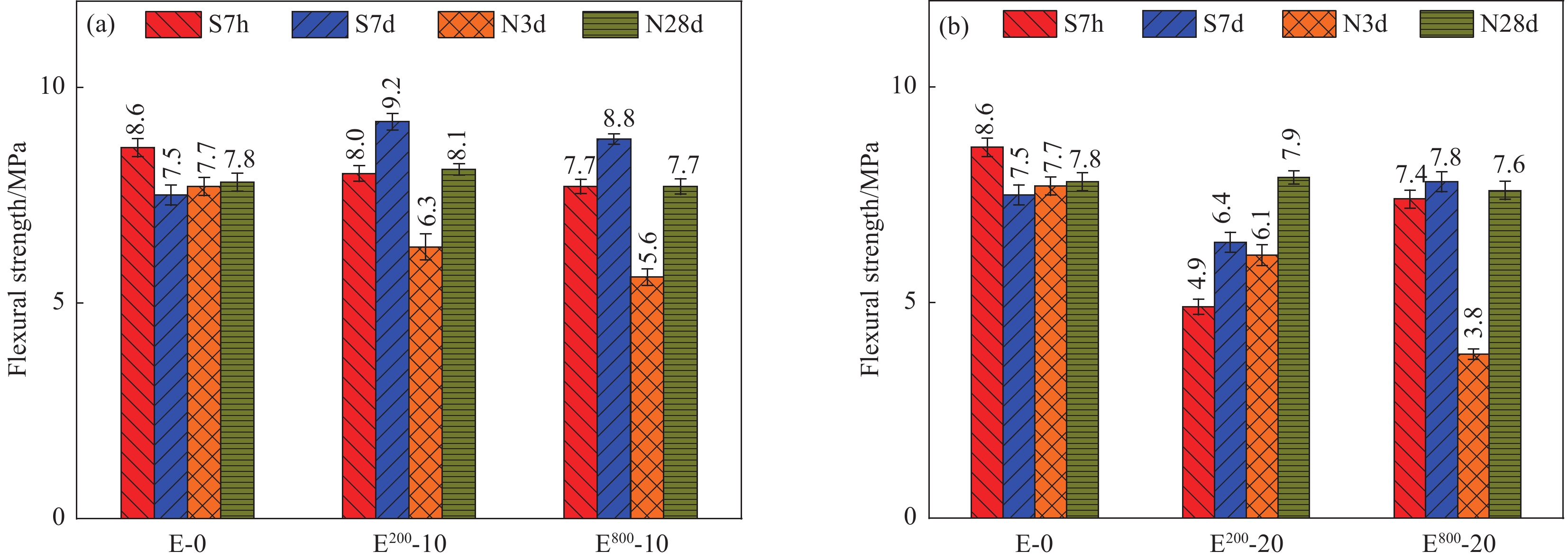

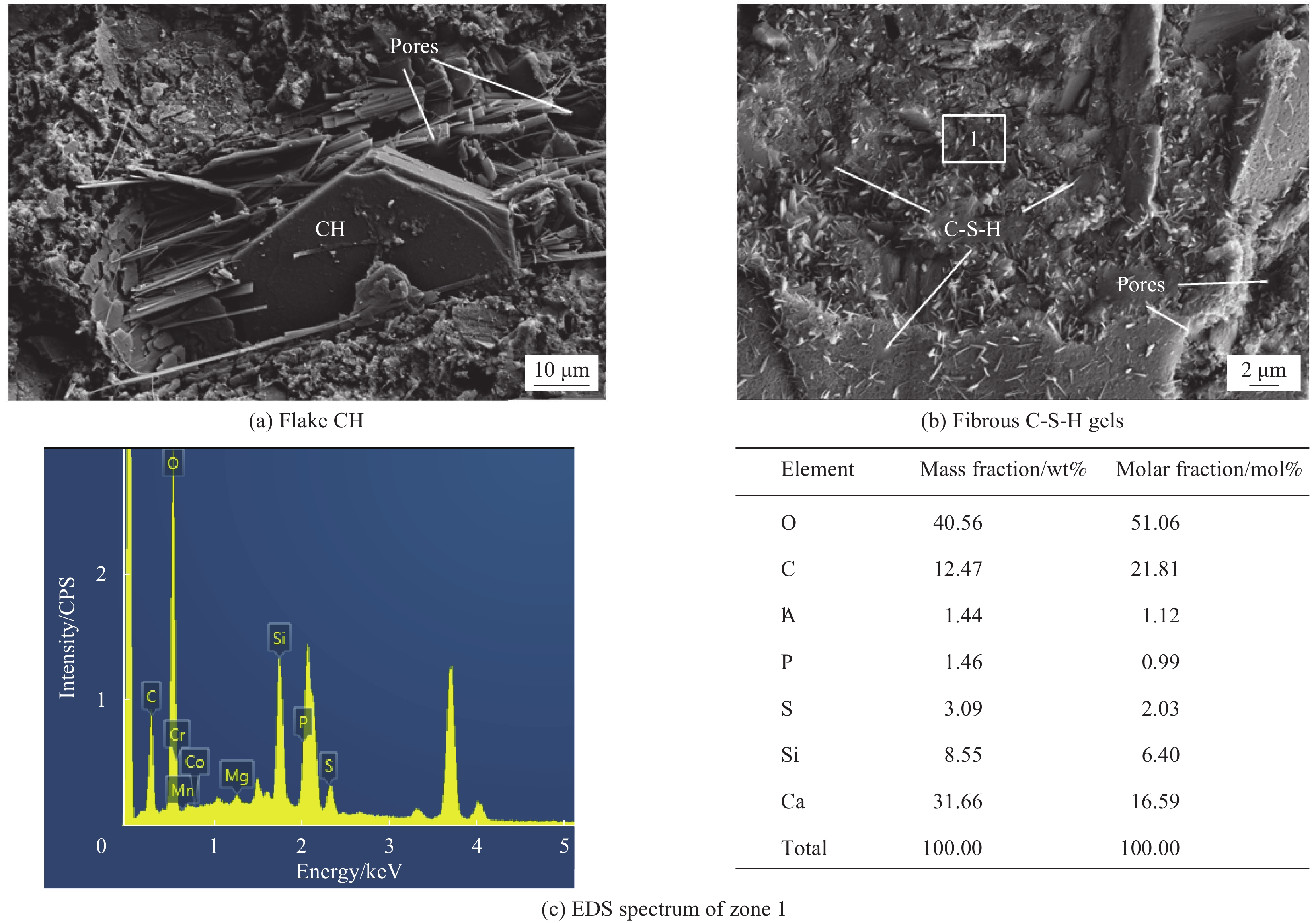

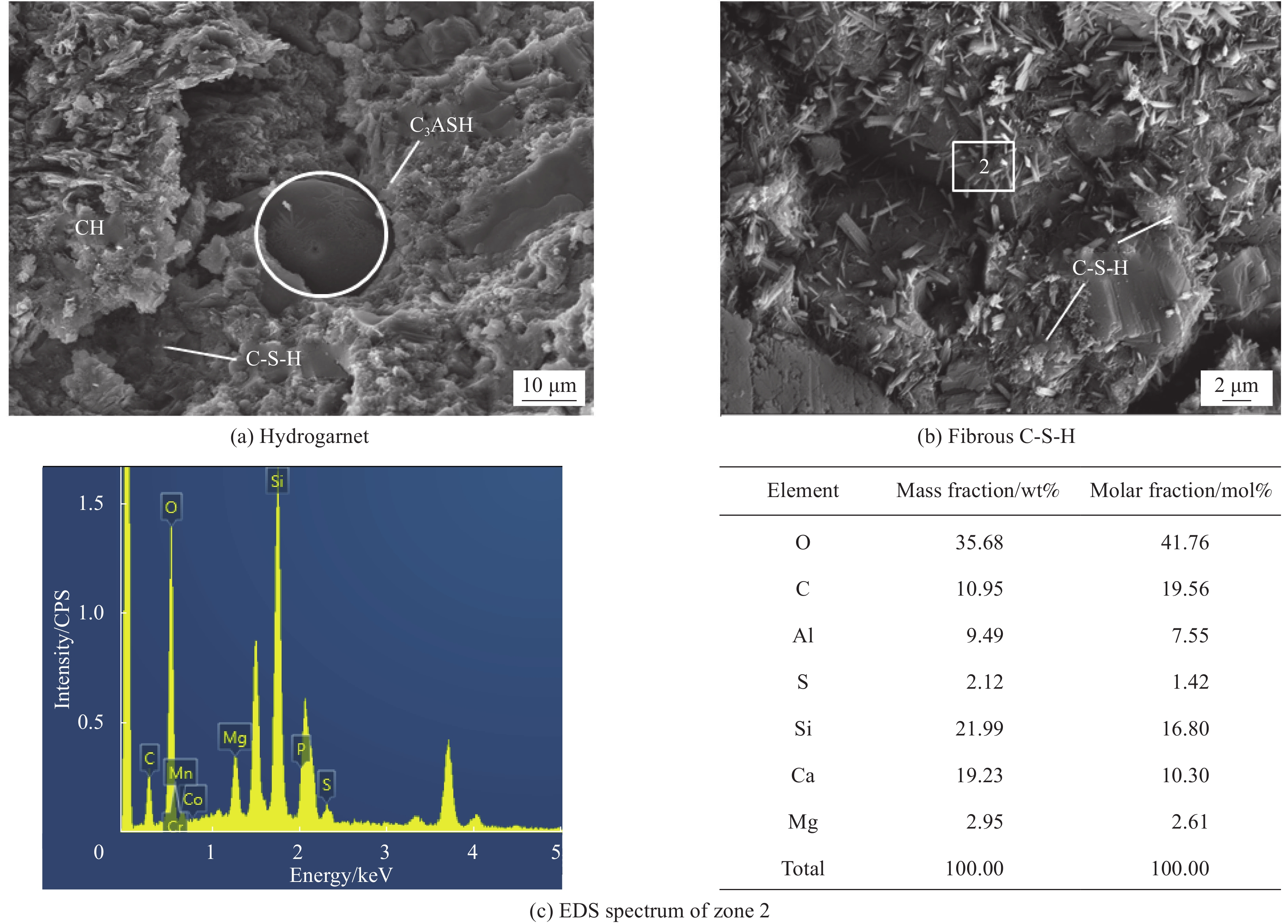

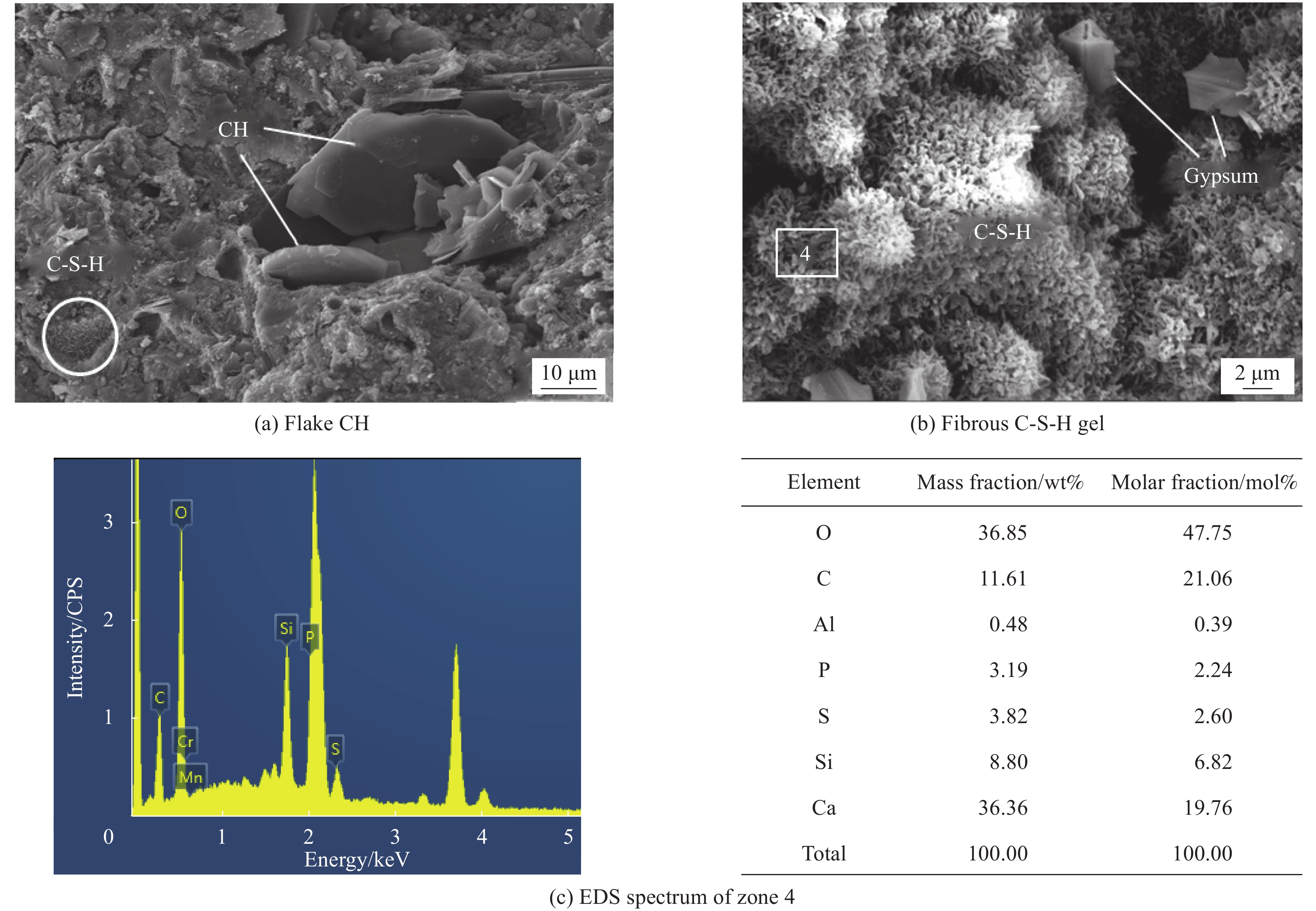

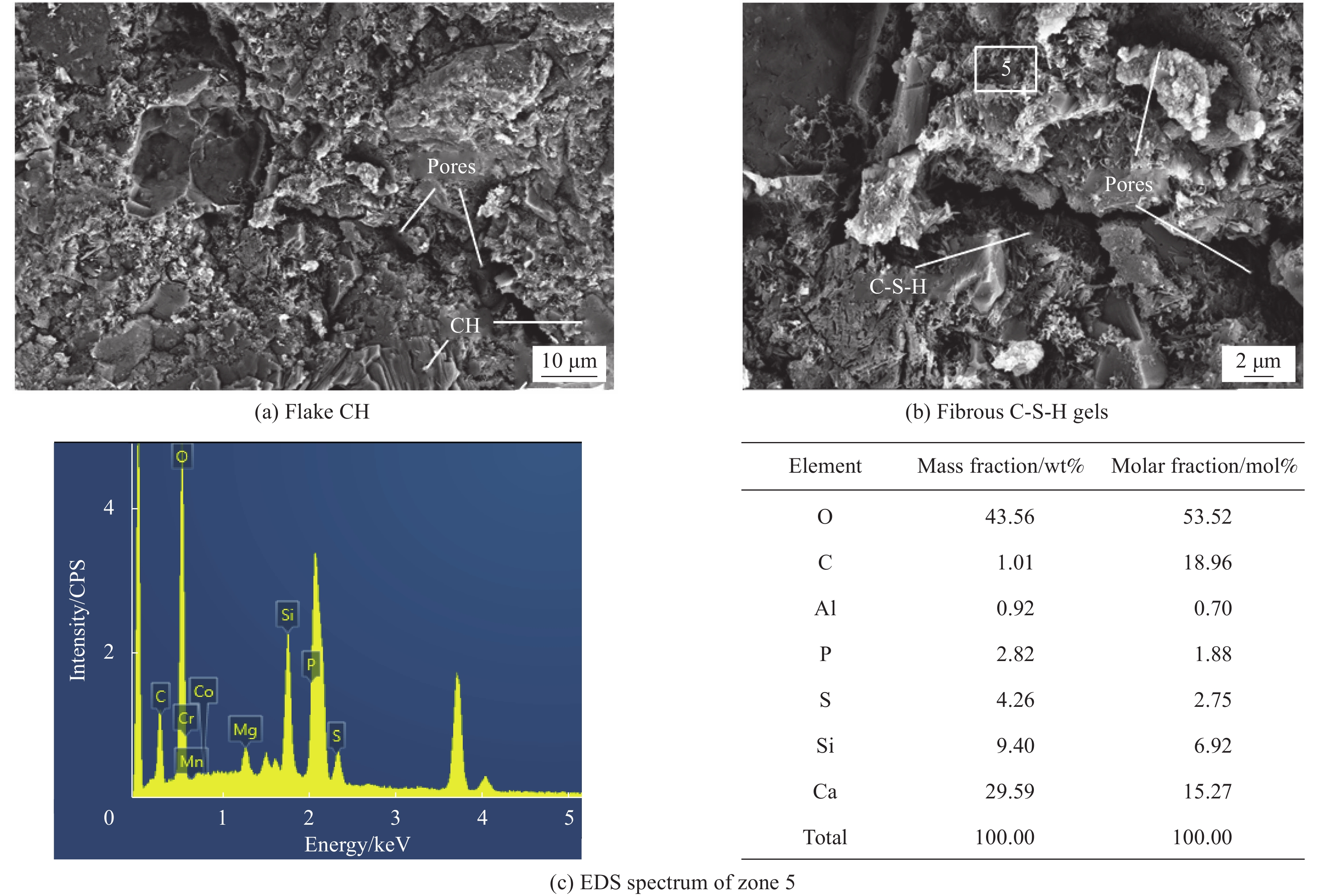

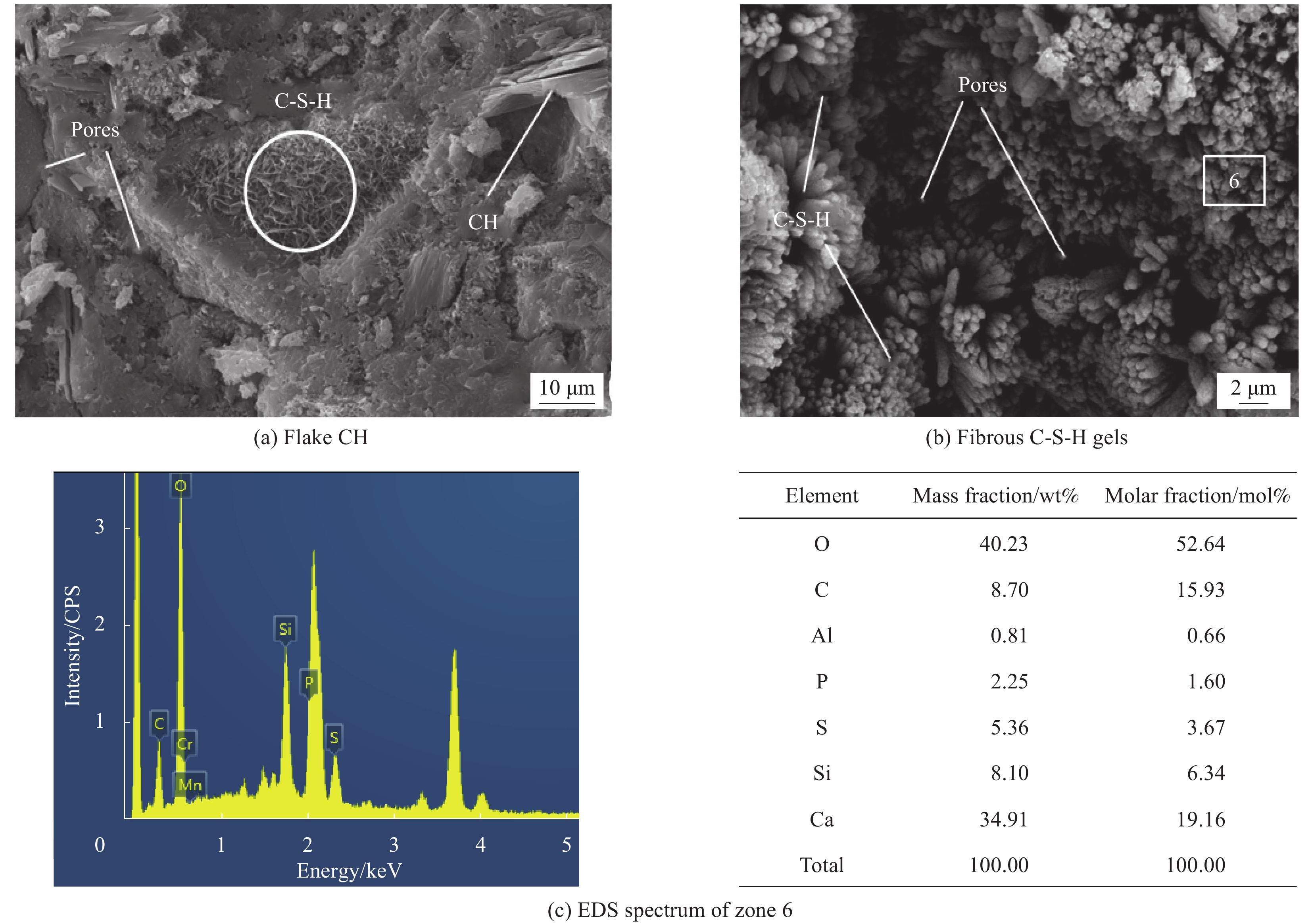

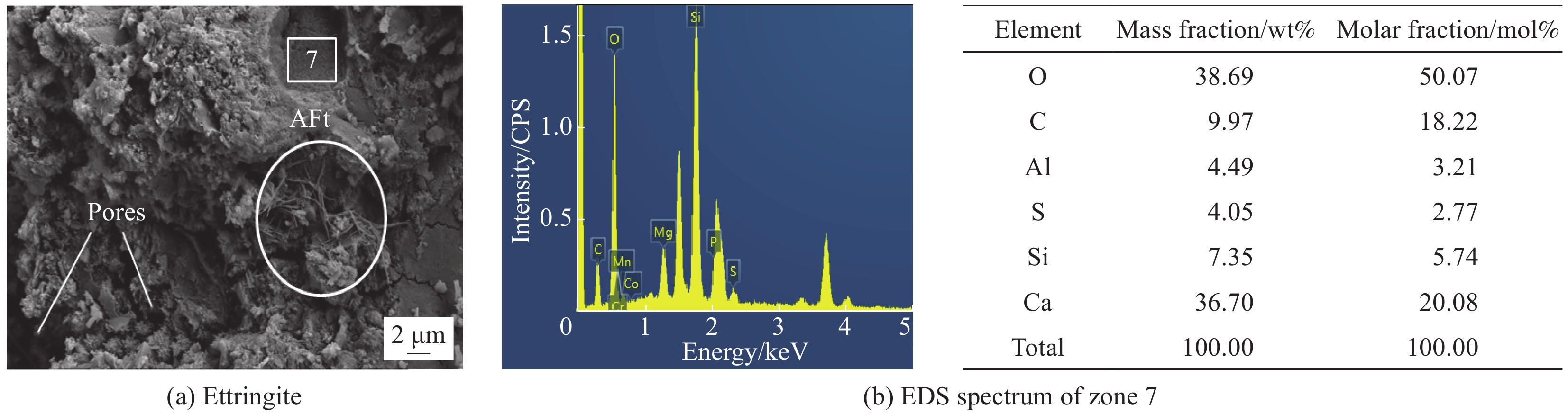

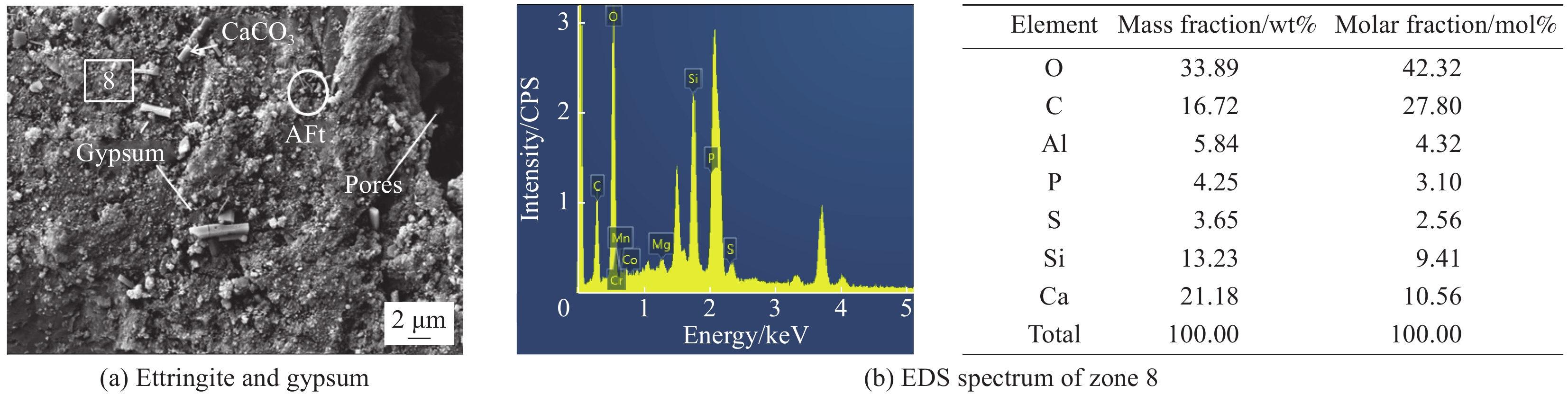

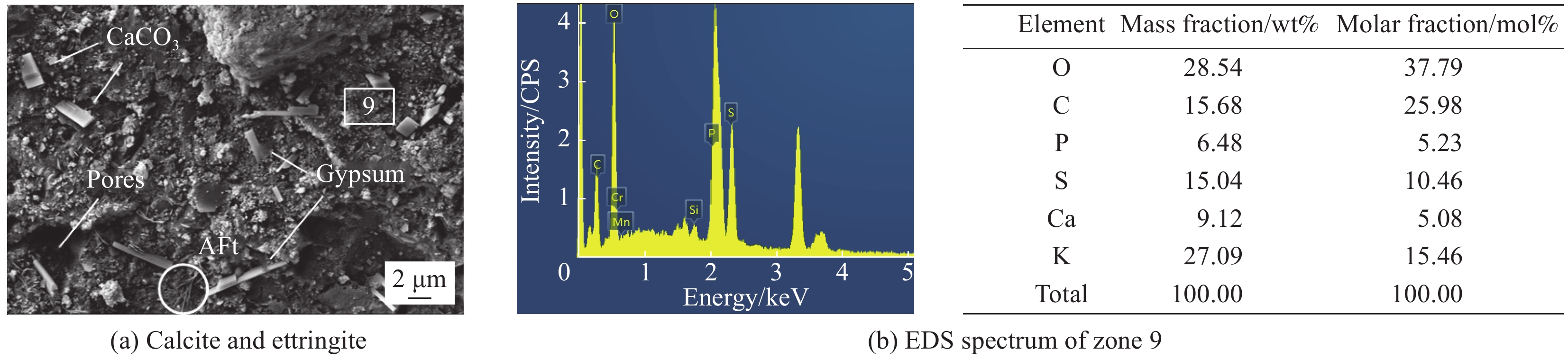

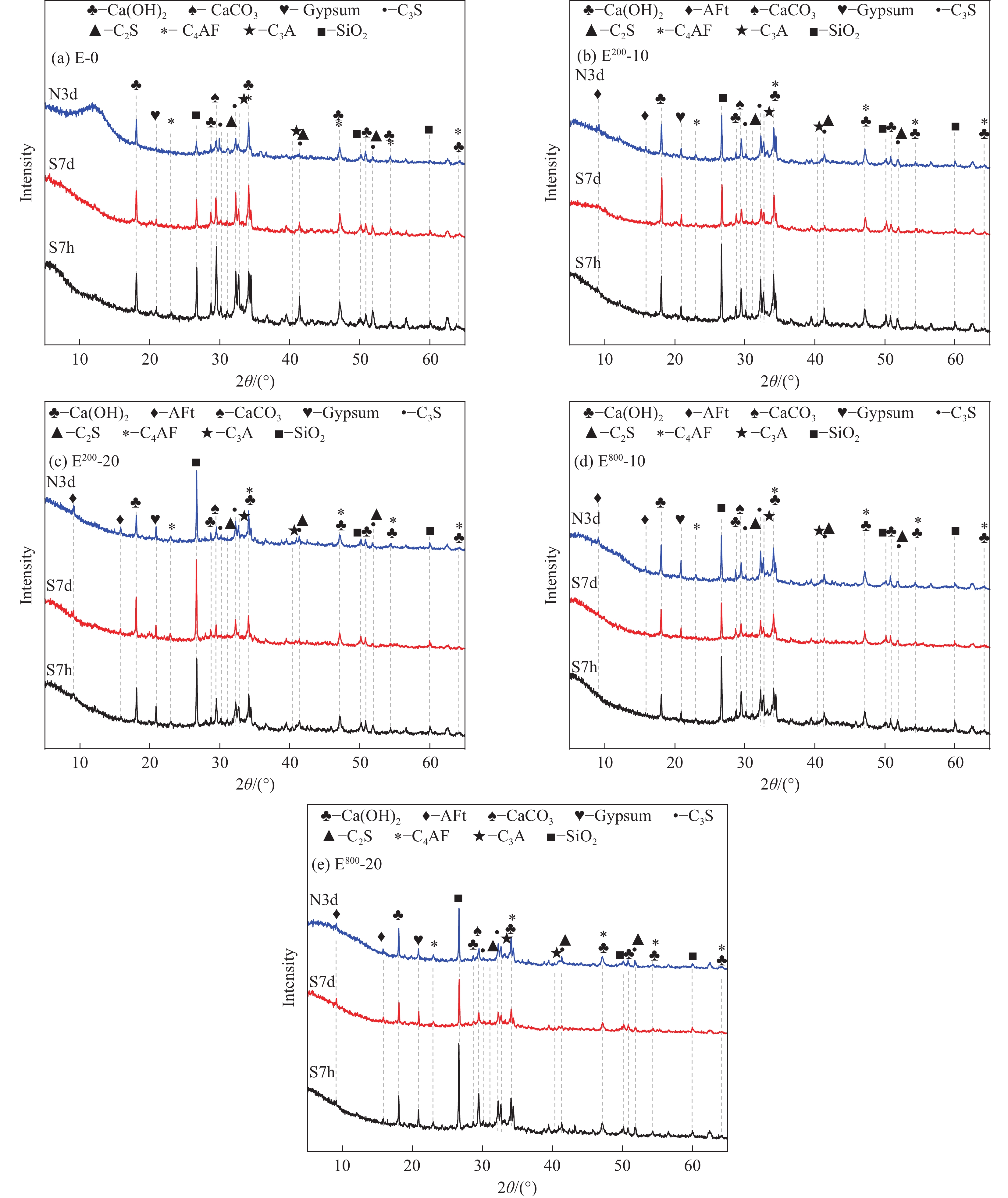

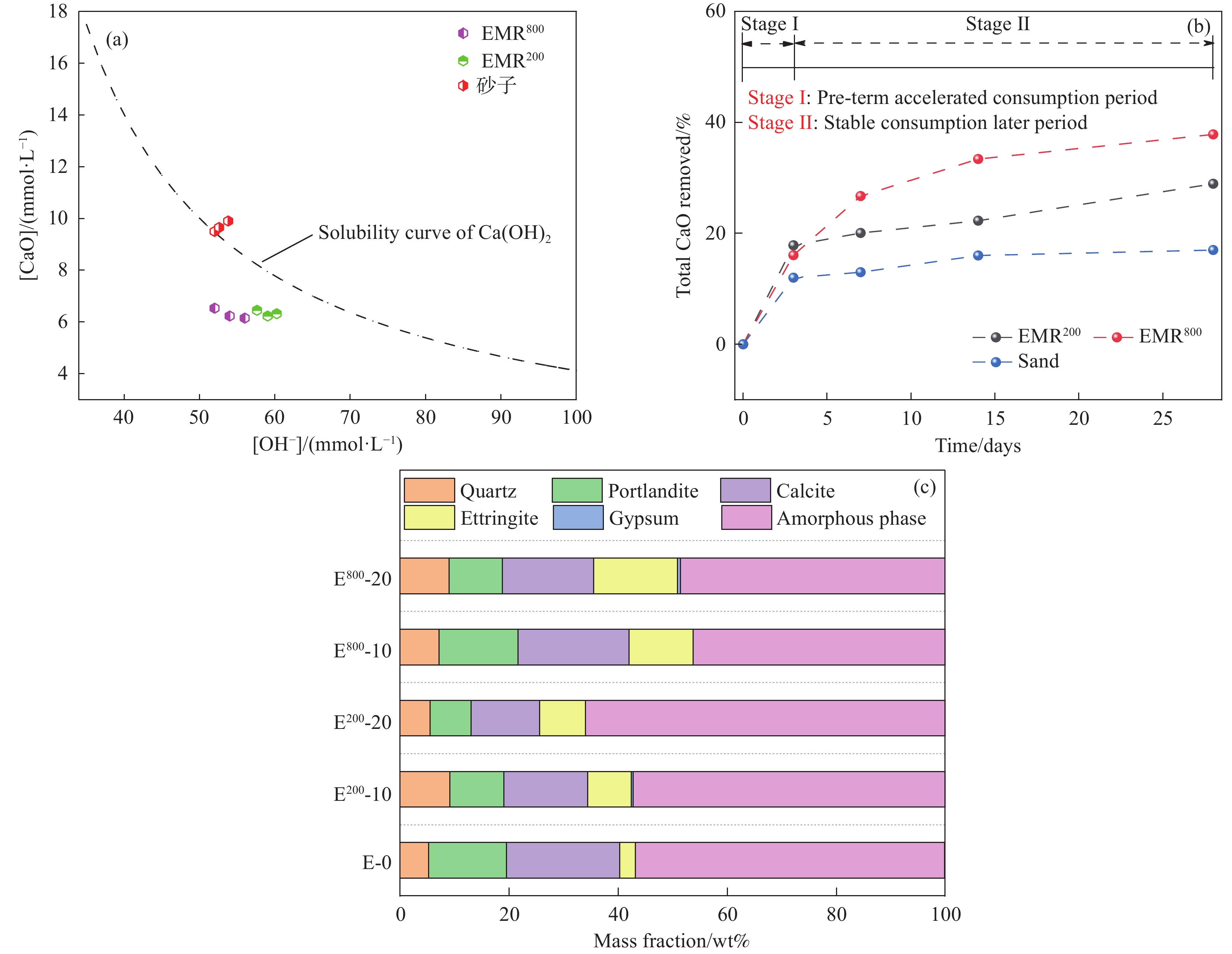

Abstract:The pozzolanic activity of electrolytic manganese residue (EMR) at different calcination temperatures (200℃ and 800℃), and the distribution of mechanical properties, hydration products, and pore characteristics of cement mortar with 0wt%, 10wt% and 20wt% EMR, subjected to 80℃ steam curing for 7 h and 7 d, as well as standard curing for 3 d and 28 d, were studied. The effects of EMR on the hydration products, pore size distribution and porosity of cement mortar were revealed by low field nuclear magnetic resonance technology, XRD quantitative characterization and SEM microstructure. The effects of different curing conditions on the hydration process of EMR cement mortar were also investigated. The results show that the pozzolanic activity of EMR calcined at 800℃ is significantly higher than that of EMR calcined at 200℃. When the substitution amount of EMR calcined at 800℃ is 10%, the initial setting time, final setting time and water requirement of normal consistency are 1.52, 1.06 and 1.05 times than that of the control group, respectively. The compressive strength of steam-cured 7 h and 7 d is higher than that of standard-cured 3 d and 28 d, respectively, while the flexural strength is only 17.3% higher than that of the control group at 7 d. The hydration products of pure cement mortar are mainly fibrous hydrate calcium silicate (C-S-H) and sheet-like calcium hydroxide (CH), while in EMR cement mortar, due to the high sulfate content, in addition to the above hydration products, the presence of gypsum phase and needle shaped ettringite (AFt) can be observed under steam curing or standard curing conditions. The CH, AFt and amorphous contents are 14.50%, 11.75% and 46.25% after 28 d of standard curing. These values are similar to the diffraction peaks after 7 d of steam curing. In addition, the porosity of steam-cured 7 h is 1.44% lower than that of standard curing 3 d, and the porosity of steam-cured 7 d is 0.06% lower than that of standard curing 28 d. In summary, steam curing can improve the pozzolanic activity of EMR calcined at 800℃, accelerate the hydration process, and refine the internal pore structure, thereby improving the mechanical properties of the mortar.

-

碳纤维增强聚合物复合材料(CFRP)具有高强、质轻、抗疲劳性能好和施工方便等优点,目前不仅被广泛应用于钢筋混凝土结构的加固中,同时也用在砌体结构的加固中[1-6]。CFRP加固砌体结构是通过CFRP与砌体材料界面间的粘结力,使两种材料组合在一起协同工作并传递荷载。因此,CFRP与砌体材料之间良好的粘结性能是保证CFRP与砌体结构共同受力变形的基础[7-8]。关于CFRP加固砌体结构,国内外学者做了大量研究,而关于CFRP-砌体界面性能只有少部分学者进行了研究并提出不同的界面粘结-滑移模型,这些模型基本上能准确模拟粘结界面的受力情况[9],但对于冻融环境下界面粘结-滑移模型未见公开报道。在冻融环境中,粘土砖的性能会随着时间的推移有所退化,在一定程度上会影响界面粘结性能,最终引起不可避免的耐久性问题[10-12]。因此,对冻融循环作用下CFRP与粘土砖之间粘结性能进行相应研究具有十分重要的意义。

通过简单可靠的单剪试验探究了冻融循环作用下CFRP-粘土砖界面在外力作用的破坏过程及破坏形态,得到了界面剥离承载力在循环作用下的变化规律,通过试验测得的应变得到了冻融循环过程中剪应力的发展及分布规律,并给出了考虑冻融循环影响的界面粘结-滑移关系。

1. 实验材料及方法

1.1 试件设计及制作

试验所使用碳纤维增强聚合物复合材料(CFRP)和树脂均为上海滠口实业有限公司生产,其主要性能如表1所示。试验所使用粘土砖的抗压强度平均值为9.28 MPa,吸水率约为17.58%,平均密度约为1 700 kg/m3。试验所用胶粘剂为SKO-碳纤维浸渍胶,其主要性能如表2所示。

表 1 碳纤维增强聚合物复合材料(CFRP)的性能Table 1. Properties of carbon fiber reinforced polymer(CFRP)Sample Tensile

strength/MPaModulus/

GPaElongation/

%Thickness/

mmCFRP ≥3 500 220 1.458 0.111 表 2 粘结树脂的性能Table 2. Properties of impregnation resinTensile shear strength/MPa Tensile strength/GPa Compressive strength/MPa Bending strength/MPa Positive tensile bond strength/MPa Modulus/MPa Elongation/% 24.29 40.12 73.62 72.95 4.44 2 605.7 2.45 本试验选用的粘土砖尺寸为235 mm×115 mm×55 mm,CFRP片材粘贴在粘土砖的一个表面(如图1所示),CFRP粘贴尺寸设计为6种规格,试件的具体参数如表3所示。

表 3 CFRP-粘土砖单剪试验试件参数Table 3. Specimen parameters of CFRP-clay brick specimens for single shear testCFRP size(Length×width)/mm Number of CFRP-clay brick specimen 0 cycle 20 cycles 40 cycles 60 cycles 80 cycles 80×50 5 5 5 5 5 100×80 5 5 5 5 5 80×80 5 5 5 5 5 100×80 5 5 5 5 5 80×100 5 5 5 5 5 100×100 5 5 5 5 5 参照CECS 146—2003[13]中相关要求将CFRP粘贴在粘土砖表面。为防止粘土砖出现局部拉剪破坏,粘结CFRP时在加载端留出30 mm非粘结区,制作完成的试件如图1所示,标准试件示意图如图2所示。

1.2 实验装置及加载程序

冻融循环试验参照GB/T 2542—2012[14]进行。将试件清理干净,在鼓风干燥箱内烘干达到质量要求后,将其在20℃的水中浸泡24 h后取出拭干水分,在冷冻箱内温度降至−15℃时开始计时。每次冷冻时间为3 h,融化2 h,控制冷冻温度为(−17±2)℃,融化水的温度控制在(15±2)℃。冻融循环次数分别取0次、20次、40次、60次和80次。

所有试件的单剪试验均在济南恒思盛大仪器有限公司生产的WDW-50微机控制电子万能试验机上通过自制单剪试验盒进行(如图3(a)所示),通过电脑控制加载速度,由荷载传感器输出CFRP与粘土砖的粘结荷载,CFRP的应变值通过江苏东华DH3816静态应变测试系统采集(如图3(b)所示)。为了使CFRP片材在加载过程中受力均匀,在试件加载端片材上下各粘贴一层30 mm长的CFRP加强片,加强片与试件同宽。加载过程采用位移控制,加载速率为0.5 mm/min。在CFRP试件拉伸前,先施加约为破坏荷载5%的预拉荷载(约为0.4 kN),检查夹具、拉力机和应变采集系统运行是否正常。

2. 试验现象

2.1 冻融循环对CFRP-烧结粘土砖界面的作用效果

试验发现,在经过若干次冻融循环后,CFRP-烧结粘土试件界面发生了较为明显的变化,以粘贴长度×宽度为80 mm×50 mm的单剪试件为例,图4为不同冻融循环作用下CFRP-烧结粘土砖界面破坏情况。可知,室温下试件破坏发生后,CFRP片材上粘有大颗粒粘土砖碎屑(如图4(a)所示);冻融20次和40次的试件破坏后,CFRP片材上粘有的粘土砖颗粒较小(如图4(b)所示);冻融60次后,其中2个试件破坏面较40次严重,界面上粘有大量粘土砖颗粒(如图4(c)所示),另1个试件与冻融40次的形态基本相同;冻融80次后,试件破坏发生在粘土砖,界面发生剪切破坏(如图4(d)所示),说明冻融循环作用对界面粘结性能有不利影响。

表4为粘贴长度×宽度为80 mm×50 mm的CFRP-粘土砖单剪试件试验结果。可以看出,随着冻融次数的增加,界面承载力逐渐降低,60次冻融后减小了约12%,表明冻融循环作用对CFRP-粘土砖的界面承载力有着不利影响。因此,当使用CFRP对粘土砖结构进行加固时,如果是在北方寒冷地区应适当考虑界面粘结折减系数。

表 4 CFRP-粘土砖界面承载力平均值和降低幅度Table 4. Average interfacial bearing capacity and reduction of CFRP-brick specimensCFRP size(Length×width)/mm Interfacial baring capacity/kN Decrease of bearing capacity/% 0 cycle 20 cycles 40 cycles 60 cycles 80 cycles 0 cycle 20 cycles 40 cycles 60 cycles 80 cycles 80×50 7.63 7.52 6.85 5.93 5.34 — 1.44 10.22 22.28 30.01 100×50 7.95 7.88 7.07 6.95 6.43 — 0.88 11.07 12.58 19.12 120×50 8.12 8.15 7.26 7.06 6.65 — –0.37 10.59 13.05 18.10 80×80 12.40 12.00 11.40 11.00 10.30 — 3.23 8.06 11.29 16.94 100×80 13.00 12.80 12.30 11.60 10.50 — 1.54 5.38 10.77 19.23 120×80 13.50 13.20 12.50 11.70 11.00 — 2.22 7.41 13.33 18.52 从试验及文献分析可知,造成界面承载力降低的原因主要有两点:(1)冻融作用导致粘土砖自身材料强度降低而引起CFRP-粘土砖试件粘结强度降低;(2) CFRP-粘土砖之间的胶体面层的粘结性能退化。由于CFRP的特殊构造,其聚合物基体的孔径较小,冻融循环作用下,其孔隙中的水不会冻结[15]。因此,可能是胶体吸水后,在冻融作用下,当溶胀和温度应力共同作用时,界面产生微裂纹,从而导致介质水在界面上冻结产生应力。

2.2 CFRP-粘土砖单剪试验破坏形态

由于本次试验在CFRP-粘土砖试件加载端预留了30 mm非粘结区,所有CFRP-粘土砖试件均是CFRP与粘土砖之间发生界面剥离而破坏的,没有发生CFRP布的撕裂破坏,也没有发生粘土砖的拉剪破坏。

所有CFRP-粘土砖试件剥离破坏是由纤维布传递荷载到粘土砖,从而使粘土砖内部产生的微小裂缝逐渐发展导致的。对于没有经过冻融循环的CFRP-粘土砖试件,其破坏过程是初始加载时除了碳纤维布开始绷紧外,试件并无明显变化,加载端的应变基本呈线性增加;当荷载增加至剥离荷载的40%左右时,可以听到“噼啪声”,加载端附近的应变迅速增加,粘土砖内部微裂缝逐渐开展,试件开始发生局部粘结破坏,总的粘结面积开始减少;随着荷载的进一步增大,应变急速增加,剥离深度也在加大,距离加载端较远处应变片的应变也逐渐增大,说明剥离逐渐向自由端发展。当剩余的粘结面积不足以抵抗荷载时,破坏瞬间发生。而在冻融循环作用下,破坏具有相似性,只是由于粘土砖与胶层之间的界面被削弱、粘土砖材料本身强度降低,开裂速度较未经循环试件更迅速,破坏更突然。

3. 结果与分析

3.1 冻融循环作用下粘土砖孔隙结构损伤

粘土砖为多孔材料,在水冻作用下,粘土砖内部孔隙中的水分子会出现冻结现象,造成孔隙体积膨胀,从而使粘土砖内部出现较大的微孔隙损伤和拉应力,使砖体的缝隙和节理出现加深和扩大;当粘土砖处于融化状态时,粘土砖内部微孔隙会出现迁移现象。当粘土砖在不同温度下进行反复冻结和溶解时,张力使孔隙壁的损伤不断加剧,最终造成砖体损伤。这种损伤反映到CFRP-粘土砖的粘结上,便会出现粘结退化现象。

图5为不同冻融循环作用下粘土砖孔隙度变化。图6为不同冻融循环作用下粘土砖弛豫时间T2谱分布。从图5可以看出,随着冻融循环次数的增加,粘土砖的孔隙度逐渐增大。由图6可知,随着冻融循环次数的增加,T2谱的峰值向右移动,说明大孔径比例增加,冻融使冻胀力逐渐大于颗粒间的粘聚力,造成砖样的孔隙发育和扩展程度加剧。

由CFRP-粘土砖单剪试验结果分析可知,冻融作用下,粘结界面破坏模式的变化与粘土砖微观变化是相统一的(如图4所示)。从单剪试件的破坏过程可以看出,不同冻融次数下,CFRP-粘土砖试件破坏后,粘土砖的表层破坏模式不尽相同。未经冻融的CFRP-粘土砖试件以CFRP粘结区域内靠近加载端部位的粘土砖剪切破坏为主。剪切破坏面被拉出的近似三角形粘土砖块与CFRP粘结较好,其余部位CFRP粘有大量被拉下的粘土砖碎屑与颗粒,破坏面一般在粘土砖基层一侧,深度约为2~5 mm。经过冻融循环的CFRP-粘土砖试件在冻融次数较低时,破坏模式与未受冻融的CFRP-粘土砖试件基本一致,冻融达到40次后,在加载端出现三角破坏区的概率随之减小,破坏以界面剥离破坏为主;当冻融时间达到60次时,所有试件均为剥离破坏,加载端不再出现三角破坏区,在CFRP上粘下的粘土砖层越来越均匀;当冻融时间达到80次时,在加载端出现类似三角区域的破坏情况,说明粘土砖的强度减弱。

3.2 CFRP-粘土砖界面承载力及平均粘结强度

图7为CFRP-粘土砖界面承载力随冻融循环次数的变化曲线。由表4和图7可知,随着冻融循环次数的增加,CFRP-粘土砖界面承载力总体呈下降趋势,而后期的下降速度要快于前期。同时,还可以看到,在CFRP的粘结宽度及冻融循环次数相同的情况下,当粘结长度从80 mm增加至120 mm时,CFRP-粘土砖界面承载力增加的幅度并不大,但当粘结宽度从50 mm增加到80 mm时,CFRP-粘土砖界面承载力却提高了60%~70%,说明CFRP的粘结宽度是影响界面承载力的主要因素之一,与以混凝土为基材的复合材料结果相似[16-18]。

在不考虑相关几何参数因素对试件界面粘结性能的影响下,通过界面粘结强度平均值来考察界面在冻融循环作用下的劣化情况,界面粘结强度平均值计算如下:

τf=PuA (1) 式中:

τf 为试件平均粘结强度(MPa);Pu为CFRP-粘土砖界面承载力(kN);A为粘结面积(mm2)。图8为CFRP-粘土砖界面平均粘结强度曲线。可知,平均粘结强度曲线根据长度和宽度组合分为三组,同一长度不同宽度的图形在位置上比较接近,再次证明粘结宽度对承载力的贡献较大,即只要保证粘结长度足够,CFRP-粘土砖试件的平均粘结强度基本和粘结宽度呈正相关关系。

3.3 CFRP-粘土砖界面剪应力的分布规律

由于试验无法得到粘结界面上任意点的应变值,因此在计算中以两个相邻应变片之间的平均剪应力作为界面剪应力。由于CFRP非常薄,可以假定CFRP在轴向力方向上的应力

σf 在横截面内是均匀分布的,并假定相邻两应变片间的应变线性分布,现取长度为微元长度dx的CFRP单元作为对象进行研究,CFRP-烧结粘土砖界面单元体剪应力分布如图9所示。由力的平衡条件可以得到粘结剪应力的计算公式为

τ(x)=dFbfdx=dσfdxtf=Eftfdεxdx=Eftfεi+1−εiΔxi (2) 式中:F为界面承载力;

bf 、tf 、Ef 和εi 分别为CFRP片材的宽度、厚度、弹性模量和应变。由于各个试件剪应力的分布具有一定相似性,因此以粘贴长度×宽度为80 mm×50 mm的单剪试件为例,其不同冻融循环作用下的剪应力分布如图10所示。可知,当荷载较小时,剪应力的峰值出现在加载端,而粘结剪应力只分布在距加载端20 mm左右的范围内;当荷载逐渐增加时,加载端附近的剪应力也随之逐渐增加,增加到峰值后剪应力开始向远端传递,此时的剪应力集中分布在一定区域内,区域外剪应力几乎为零,这一区域即为有效粘结区域,该区域的长度称为“有效粘结长度”,本试验中有效粘结长度基本保持不变,大约为60~80 mm,且其不随CFRP粘结尺寸及冻融循环次数而变化,说明随着荷载的增加,有效粘结区域在破坏过程中会以近似不变的长度由加载端向自由端平行移动,从而使剥离区域逐渐增加,直至试件破坏,与CFRP-混凝土试件的研究结果一致[19-20]。

3.4 CFRP-粘土砖界面粘结-滑移本构关系

为建立准确可靠的粘结-滑移曲线,需要进一步了解界面剥离机制及破坏过程中粘结剪应力与滑移值的变化情况,即

ττmax−ss0 曲线。其中,滑移值为CFRP与粘土砖的位移差,计算如下:s(x)=s(0)+∫x0ε(u)du (3) 式中:

s(0) 为最大剪应力对应的滑移值;s(x) 为CFRP上任一点滑移值;ε 为应变值。关于粘结-滑移关系,目前国内外学者对纤维增强聚合物复合材料(FRP)-混凝土界面深入研究较多,而对于FRP-粘土砖的研究鲜见报道。粘结-滑移模型的提出有试验方法、有限元模拟方法、理论推导方法等,图11为几种典型粘结-滑移关系模型曲线。由图11(a)可以看到,直角三角形模型属于早期模型,把界面近似看做弹性体,缺点是忽略了界面在加载后期的软化行为;由图11(b)~11(d)可知,粘结-滑移关系模型均为两阶段曲线模型,曲线由上升段和下降段组成,目前对CFRP-混凝土界面的研究大多采用该类型曲线模型。通过对比发现,图11(d)的Popovics模型比较适合本试验数据,如下式:

ττmax (4) 通过式(4)拟合效果较好(拟合系数n=3.032),可以较准确地表示CFRP-粘土砖面粘结-滑移的有关特征,如图12所示。可以看出,CFRP-粘土砖界面粘结-滑移曲线分为上升段和下降段,上升段为强化阶段,下降段为软化阶段。开始加载时,界面粘结剪应力和滑移均不大,粘结-滑移曲线近似呈线性关系,试件处于弹性状态;随着粘结剪应力逐步增大,粘结-滑移曲线表现出非线性,此时滑移量增加速度较剪应力增加速度要快,当界面逐渐达到最大剪应力,界面的粘结不足以抵抗剪应力时,试件开始出现滑移;当粘结剪应力增大至最大后,曲线进入下降段,此时剪应力下降速度和滑移量增加的速度均较快,且滑移量增加的速度越来越大,当粘结应力几乎为零时,滑移量达到最大值,此时CFRP和粘土砖在界面处完全剥离。对比Popovics曲线和实验数据可以发现,Popovics模型可以较好地描述CFRP-粘土砖界面粘结-滑移关系,上升段试验数据点几乎与Popovics模型曲线重合,下降段的试验数据分布于Popovics模型曲线两侧,但偏差较小,表明采用Popovics模型来描述CFRP-粘土砖界面的粘结-滑移本构关系是较准确的。

4. 结 论

分析了冻融循环作用和粘结尺寸对CFRP-粘土砖界面承载力及粘结强度的影响,通过试验数据和理论比较,建立了考虑冻融循环影响下的CFRP-粘土砖界面粘结-滑移模型。

(1)在冻融循环作用下,CFRP-粘土砖界面的破坏模式是由剪切破坏转变为粘结剥离破坏,剥离是从CFRP加载端开始逐渐向自由端发展。相对于长度,CFRP的宽度对试件界面承载力影响更为显著。

(2)随着冻融循环次数的增加,CFRP-粘土砖界面承载力总体呈下降趋势,而后期的下降速度要快于前期。

(3) CFRP-粘土砖界面粘结剪应力分布曲线具有相似性,当荷载水平逐渐增加,剪应力也随之逐渐增大,并从加载端向自由端传递,且所有剪应力集中分布在一定的“有效粘结区域”内,而区域外的剪应力几乎为零,有效粘结区域的长度约为60~80 mm,且与冻融循环次数无关。

(4) CFRP-粘土砖界面粘结-滑移关系有明显的上升段和下降段,上升段为强化阶段,下降段为软化阶段,Popovics模型可以很好地描述CFRP-粘土砖的界面粘结-滑移关系。

-

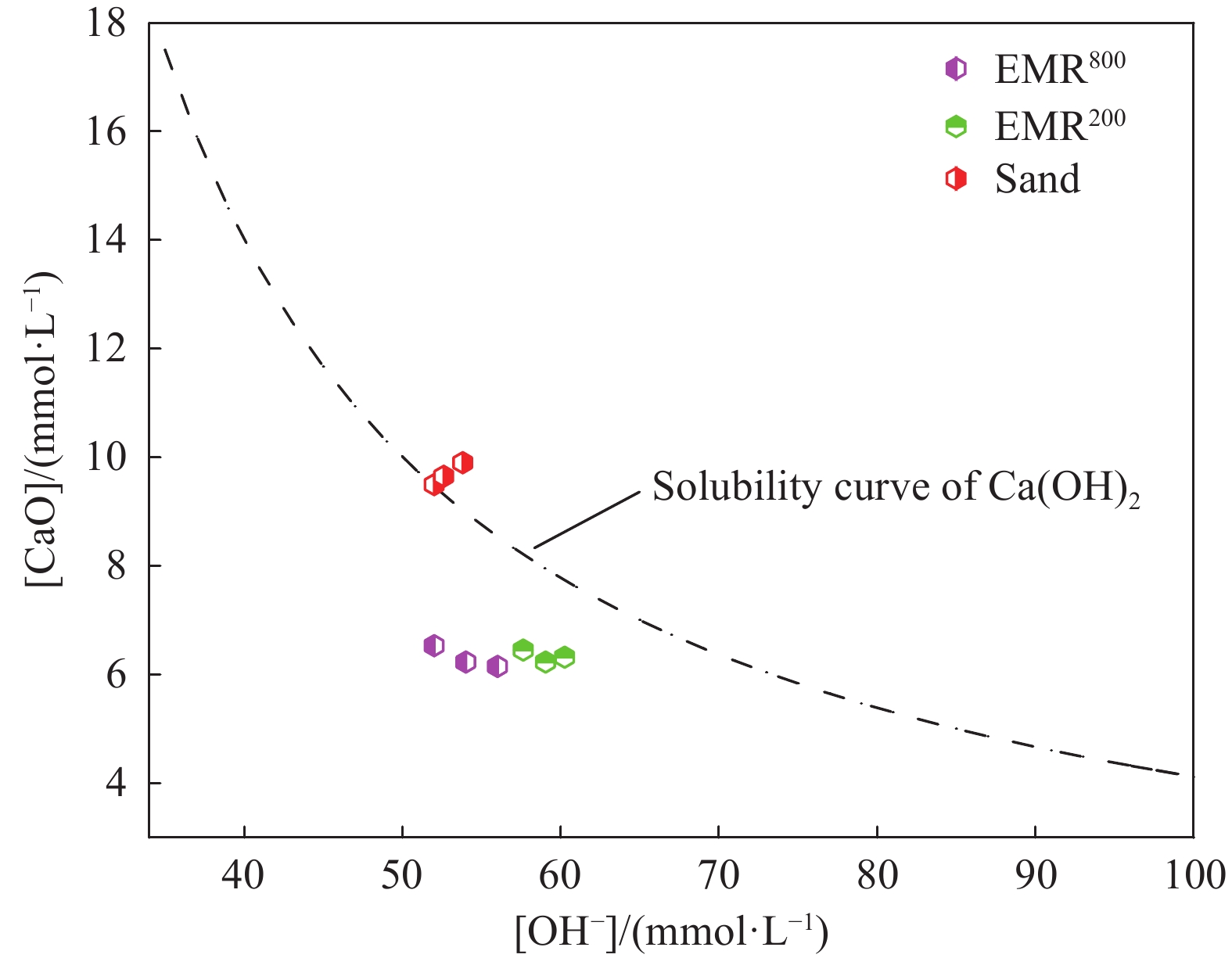

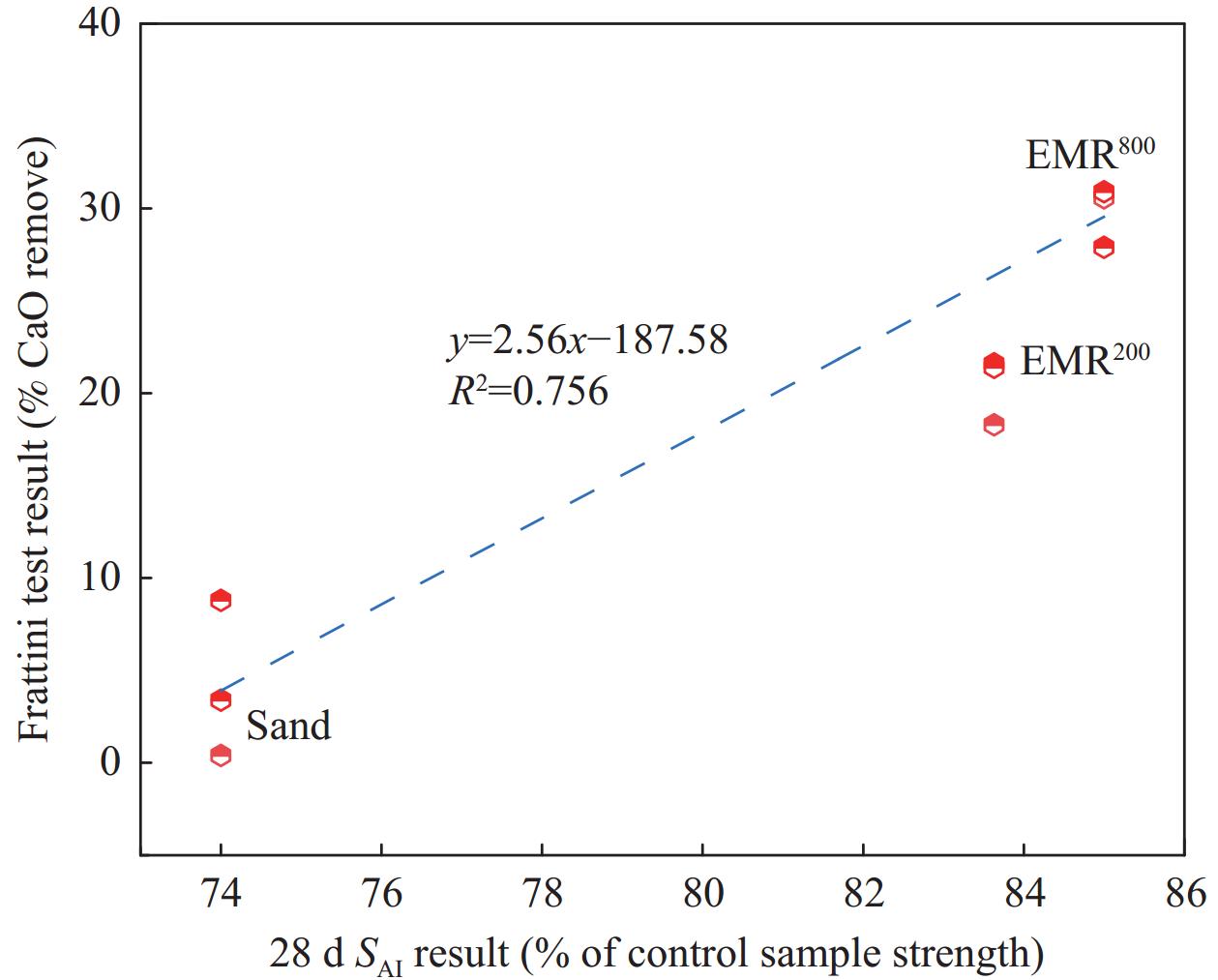

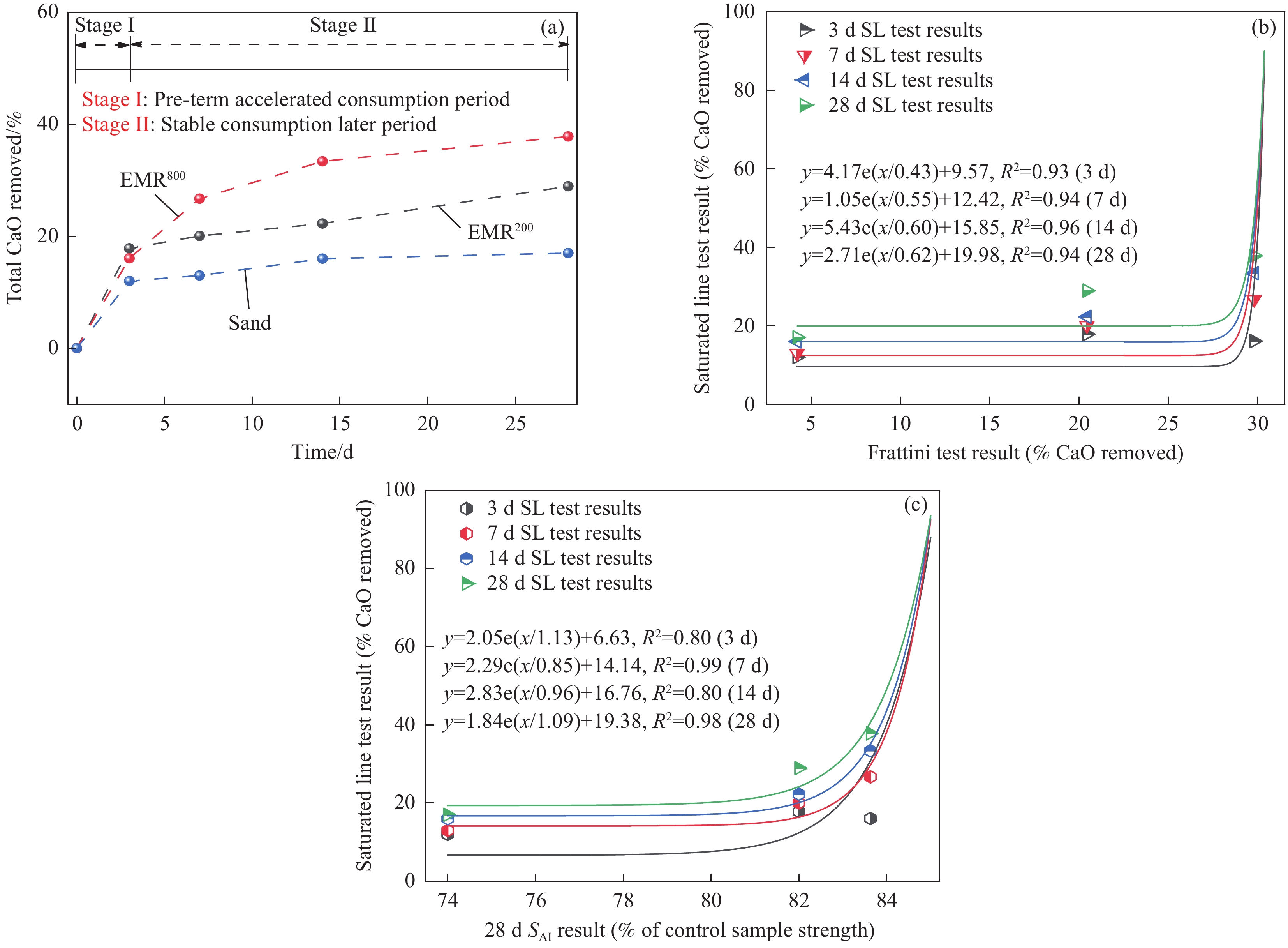

图 10 EMR200和EMR800在40℃的密封塑料瓶中养护1、3、7和28 d:(a)饱和石灰(SL)消耗试验;(b) SL消耗试验与Frattini试验相关性;(c) SL消耗试验与28 d活性指数(SAI)之间的相关性

Figure 10. EMR200 and EMR800 cured in sealed plastic bottles at 40℃ for 1, 3, 7 and 28 d: (a) Saturated lime (SL) consumption test; (b) Correlation between SL consumption test and Frattini test; (c) Correlation between SL consumption test and 28 d SAI

图 22 不同养护条件下纯水泥胶砂与EMR水泥胶砂横向弛豫时间T2图谱:(a) E-0;(b) E200-10;(c) E200-20;(d) E800-10;(e) E800-20;(f)孔隙率

Figure 22. The transverse relaxation time T2 spectra of pure cement mortar and EMR cement mortar under different curing conditions: (a) E-0; (b) E200-10; (c) E200-20; (d) E800-10; (e) E800-20; (f) Porosity

d—Diameter size

表 1 普通硅酸盐水泥(OPC)和电解锰渣(EMR)的化学组成

Table 1 Chemical composition of ordinary portland cement (OPC) and electrolytic manganese residue (EMR)

wt% Material Al2O3 SiO2 Fe2O3 CaO SO3 MgO Other OPC 6.57 19.34 3.22 47.95 1.23 1.58 4.06 EMR200 11.85 39.72 5.92 10.07 24.47 1.22 6.75 EMR800 10.79 37.03 6.66 12.29 24.60 1.24 7.21 Notes: "EMR200" represents EMR calcined at 200℃; "EMR400" represents EMR calcined at 400℃. 表 2 EMR水泥胶砂的配比与养护条件

Table 2 Proportioning and curing conditions of EMR cement mortar

Sample OPC/g EMR/g Sand/g Water/g Curing condition E-0 450 0 1350 225 80℃ steam curing for 7 h (S7h);

80℃ steam curing for 7 d (S7d);

Standard curing 3 d (N3d);

Standard curing 28 d (N28d)E200-10 405 45 1350 225 E200-20 360 90 1350 225 E800-10 405 45 1350 225 E800-20 360 90 1350 225 Notes: "E-0" indicates control specimen; E200-10, where "E200" indicates an EMR calcination temperature of 200℃, "10" indicates an EMR substitution rate of 10wt%, and other similar specimens. 表 3 EMR200和EMR800在8 d时Frattini测试结果

Table 3 Frattini test results of EMR200 and EMR800 at 8 d

Material [OH]/

(mmol·L−1)[CaO]/ (mmol·L−1) Theoretical

Max[CaO]/

(mmol·L−1)[CaO] reduction/% Sand 52.8 9.68 9.25 −4.4 EMR200 58.9 6.34 7.97 20.45 EMR800 54.0 6.30 8.79 28.3 -

[1] WANG Y, GAO S, LIU X, et al. Preparation of non-sintered permeable bricks using electrolytic manganese residue: Environmental and NH3-N recovery benefits[J]. Journal of Hazardous Materials, 2019, 378: 120768. DOI: 10.1016/j.jhazmat.2019.120768

[2] WANG D, WANG Q, XUE J. Reuse of hazardous electrolytic manganese residue: Detailed leaching characterization and novel application as a cementitious material[J]. Resources, Conservation & Recycling, 2020, 154: 104645.

[3] SHU J, CHEN M, WU H, et al. An innovative method for synergistic stabilization/solidification of Mn2+, NH4+-N, PO43− and F− in electrolytic manganese residue and phosphogypsum[J]. Journal of Hazardous Materials, 2019, 376: 212-222.

[4] SHU J, LIU R, LIU Z, et al. Simultaneous removal of ammonia and manganese from electrolytic metal manganese residue leachate using phosphate salt[J]. Journal of Cleaner Production, 2019, 135: 468-475.

[5] 聂霄悍, 雷学文, 刘磊, 等. 堆存陈化对电解锰渣重金属赋存形态及环境风险演化的影响[J]. 中国环境科学, 2024, 44(1): 242-250. NIE Xiaohan, LEI Xuewen, LIU Lei, et al. Effect of storage-aging on occurrence morphology of heavy metals and associated environmental risk evolution in electrolytic manganese residue[J]. China Environmental Science, 2024, 44(1): 242-250(in Chinese).

[6] FU Y, QIAO H, FENG Q, et al. Self-stabilisation of high-temperature calcined electrolytic manganese residue in mortar[J]. Construction and Building Materials, 2023, 386: 131460. DOI: 10.1016/j.conbuildmat.2023.131460

[7] FU Y, QIAO H, FENG Q, et al. Review of new methods for resource utilisation of electrolytic manganese residue and its application in building materials[J]. Construction and Building Materials, 2023, 401: 132901. DOI: 10.1016/j.conbuildmat.2023.132901

[8] YANG C, LYU X, TIAN X, et al. An investigation on the use of electrolytic manganese residue as filler in sulfur concrete[J]. Construction and Building Materials, 2014, 73: 305-310. DOI: 10.1016/j.conbuildmat.2014.09.046

[9] HE D, SHU J, WANG R, et al. A critical review on approaches for electrolytic manganese residue treatment and disposal technology: Reduction, pretreatment, and reuse[J]. Journal of Hazardous Materials, 2021, 418: 126235. DOI: 10.1016/j.jhazmat.2021.126235

[10] DUAN N, DAN Z, WANG F, et al. Electrolytic manganese metal industry experience based China's new model for cleaner production promotion[J]. Journal of Cleaner Production, 2011, 19: 2082-2087. DOI: 10.1016/j.jclepro.2011.06.024

[11] 王继林, 龙广成, 董荣珍, 等. 掺电解锰渣砂浆的强度与微结构及碳排放分析[J]. 铁道科学与工程学报, 2023, 20(4): 1382-1391. WANG Jilin, LONG Guangcheng, DONG Rongzhen, et al. Strength and microstructure of electrolytic manganese slag doped mortar and carbon emission analysis[J]. Journal of Railway Science and Engineering, 2023, 20(4): 1382-1391(in Chinese).

[12] LAN J, DONG Y, SUN Y, et al. A novel method for solidification/stabilization of Cd(II), Hg(II), Cu(II), and Zn(II) by activated electrolytic manganese slag[J]. Journal of Hazardous Materials, 2021, 409: 124933. DOI: 10.1016/j.jhazmat.2020.124933

[13] ZHANG Y, LIU X, XU Y. Preparation and characterization of cement treated road base material utilizing electrolytic manganese residue[J]. Journal of Cleaner Production, 2019, 232: 980-992. DOI: 10.1016/j.jclepro.2019.05.352

[14] QIAO D, QIAN J, WANG Q, et al. Utilization of sulfate-rich solid wastes in rural road construction in the Three Gorges Reservoir[J]. Resources, Conservation & Recycling, 2010, 54: 1368-1376.

[15] ZHANG Y, LIU X, XU Y. Preparation of road base material by utilizing electrolytic manganese residue based on Si-Al structure: Mechanical properties and Mn2+ stabilization/solidification characterization[J]. Journal of Hazardous Materials, 2020, 390: 122188. DOI: 10.1016/j.jhazmat.2020.122188

[16] ZHENG F, XIE W, ZHU H, et al. Water column leaching recovery manganese and ammonium sulfate from electrolytic manganese residue: Extremely low water consumption toward practical applications[J]. Environmental Science and Pollution Research, 2022, 29(53): 80323-80335. DOI: 10.1007/s11356-022-21463-9

[17] MARYAM S, SADEGHI CARLOS M H, FERREIRAHELENA M V M. Evaluation of two-step processes for the selective recovery of Mn from a rich Mn residue[J]. Minerals Engineering, 2019, 130: 148-155.

[18] WANG D, WANG Q, XUE J, et al. Reuse of hazardous electrolytic manganese residue: Detailed leaching characterization and novel application as a cementitious material[J]. Resources, Conservation & Recycling, 2020, 154: 104645.

[19] LI J, LIU Y, KE X, et al. Geopolymer synthesized from electrolytic manganese residue and lead-zinc smelting slag: Compressive strength and heavy metal immobilization[J]. Cement and Concrete Composites, 2022, 134: 104806. DOI: 10.1016/j.cemconcomp.2022.104806

[20] ZHAN X, WANG L, HU C, et al. Co-disposal of MSWI fly ash and electrolytic manganese residue based on geopolymeric system[J]. Waste Management, 2018, 82: 62-70. DOI: 10.1016/j.wasman.2018.10.014

[21] ZHOU C, DU B, WANG N, et al. Preparation and strength property of autoclaved bricks from electrolytic manganese residue[J]. Journal of Cleaner Production, 2014, 84: 707-714. DOI: 10.1016/j.jclepro.2014.01.052

[22] LAN J, ZHANG S, MEI T. Mechanochemical modification of electrolytic manganese residue: Ammonium nitrogen recycling, heavy metal solidification, and baking-free brick preparation[J]. Journal of Cleaner Production, 2021, 329: 129727. DOI: 10.1016/j.jclepro.2021.129727

[23] ZHAN X, WANG L, WANG L, et al. Co-sintering MSWI fly ash with electrolytic manganese residue and coal fly ash for light-weight ceramisite[J]. Chemosphere, 2021, 263: 127914. DOI: 10.1016/j.chemosphere.2020.127914

[24] 叶东东, 徐子芳, 赵怡梵, 等. 电解锰渣陶粒共烧结温度影响机理研究[J]. 材料导报, 2022, 36(11): 89-94. DOI: 10.11896/cldb.21120242 YE Dongdong, XU Zifang, ZHAO Yifan, et al. Study on the mechanism of temperature influence on the co-sintering of electrolytic manganese slag ceramics[J]. Materials Reports, 2022, 36(11): 89-94(in Chinese). DOI: 10.11896/cldb.21120242

[25] WANG D, FANG J, WANG Q. Utilizing desulphurized electrolytic-manganese residue as a mineral admixture: A feasibility study[J]. Cement and Concrete Composites, 2022, 134: 104822. DOI: 10.1016/j.cemconcomp.2022.104822

[26] WANG F, LONG G, BAI M, et al. Application of electrolytic manganese residues in cement products through pozzolanic activity motivation and calcination[J]. Journal of Cleaner Production, 2022, 338: 130629. DOI: 10.1016/j.jclepro.2022.130629

[27] HE W, LI R, NIE D, et al. Belite-calcium sulphoaluminate cement prepared by EMR and BS: Hydration characteristics and microstructure evolution behavior[J]. Construction and Building Materials, 2022, 333: 127415. DOI: 10.1016/j.conbuildmat.2022.127415

[28] 何德军, 舒建成, 陈梦君, 等. 电解锰渣建材资源化研究现状与展望[J]. 化工进展, 2020, 39(10): 4227-4237. HE Dejun, SHU Jiancheng, CHEN Mengjun, et al. Current status and prospect of the research on the resourcefulness of electrolytic manganese slag building materials[J]. Chemical Industry and Engineering Progress, 2020, 39(10): 4227-4237(in Chinese).

[29] SCRIVENER K L, NONAT A. Hydration of cementitious materials, present and future[J]. Cement and Concrete Research, 2011, 41: 651-665. DOI: 10.1016/j.cemconres.2011.03.026

[30] QUENNOZ A, SCRIVENER K L. Hydration of C3A-gypsum systems[J]. Cement and Concrete Research, 2012, 42: 1032-1041. DOI: 10.1016/j.cemconres.2012.04.005

[31] 刘博, 何莉莉, 岳波, 等. 基于地聚物体系的电解锰渣污染物的溶出风险及固化机理[J]. 中国环境科学, 2023, 43(12): 6465-6473. LIU Bo, HE Lili, YUE Bo, et al. Dissolution risk and solidification mechanism of pollutants in electrolytic manganese slag based on geopolymer system[J]. China Environmental Science, 2023, 43(12): 6465-6473(in Chinese).

[32] XIAO Q, CAI Y, XIANG Y. Regulating the early age hydration of cement-solidified electrolytic manganese residues paste by alternating current[J]. Construction and Building Materials, 2023, 404: 133336.

[33] 黄时玉, 霍彬彬, 陈春, 等. 蒸养条件下偏高岭土对钢渣水泥基复合体系水化的影响[J]. 材料导报, 2022, 36(5): 73-78. DOI: 10.11896/cldb.21010187 HUANG Shiyu, HUO Binbin, CHEN Chun, et al. The influence of Metakaolin on the hydration of steam-cured steel slag blended cement[J]. Materials Reports, 2022, 36(5): 73-78(in Chinese). DOI: 10.11896/cldb.21010187

[34] 李保亮, 尤南乔, 朱国瑞, 等. 蒸养条件下锂渣复合水泥的水化产物与力学性能[J]. 材料导报, 2019, 33(24): 4072-4077. DOI: 10.11896/cldb.18120096 LI Baoliang, YOU Nanqiao, ZHU Guorui, et al. Hydration products and mechanical properties of steam cured lithium slag blended cement[J]. Materials Reports, 2019, 33(24): 4072-4077(in Chinese). DOI: 10.11896/cldb.18120096

[35] 中华人民共和国环境保护部. 固体废物浸出毒性浸出方法 水平振荡法: HJ 557—2010[S]. 北京: 中国环境科学出版社, 2010. Ministry of Environmental Protection of the People's Republic of China. Solid waste—Extraction procedure for leaching toxicity—Horizontal vibration method: HJ 557—2010[S]. Beijing: China Environmental Press, 2010(in Chinese).

[36] 中华人民共和国环境保护部. 水质氨氮的测定 纳氏试剂分光光度法: HJ 535—2009[S]. 北京: 中国环境科学出版社, 2010. Ministry of Environmental Protection of the People's Republic of China. Water quality―Determination of ammonia nitrogen―Nessler’s reagent spectrophotometry: HJ 535—2009[S]. Beijing: China Environmental Press, 2010(in Chinese).

[37] 国家环境保护局, 国家技术监督局. 污水综合排放标准: GB 8978—1996[S]. 北京: 中国标准出版社, 1998. State Environmental Protection Administration, The State Bureau of Quality and Technical Supervision. Integrated wastewater discharge standard: GB 8978—1996[S]. Beijing: Standards Press of China, 1998(in Chinese).

[38] 国家市场监督管理总局, 国家标准化管理委员会. 水泥胶砂强度检验方法(ISO法): GB/T 17671—2021[S]. 北京: 中国标准出版社, 2022. State Administration for Market Regulation, National Standardization Administration. Test method of cement mortar strength (ISO method): GB/T 17671—2021[S]. Beijing: Standards Press of China, 2022(in Chinese).

[39] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 水泥标准稠度用水量、凝结时间、安定性检验方法: GB/T 1346—2011[S]. 北京: 中国标准出版社, 2012. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Test methods for water requirement of normal consistency, setting time and soundness of the portland cement: GB/T 1346—2011[S]. Beijing: Standards Press of China, 2012(in Chinese).

[40] TIRONI A, TREZZA M A, SCIAN A N, et al. Assessment of pozzolanic activity of different calcined clays[J]. Cement and Concrete Composites, 2013, 37: 319-327.

[41] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 用于水泥、砂浆和混凝土中的粒化高炉矿渣粉: GB/T 18046—2017[S]. 北京: 中国标准出版社, 2018. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Ground granulated blast furnace slag used for cement, mortar and concrete: GB/T 18046—2017[S]. Beijing: Standards Press of China, 2018(in Chinese).

[42] Technical Committee (CEN/TC). Methods of testing cement—Part 5: Pozzolanicity test for pozzolanic cement: EN 196-5: 2011[S]. Brussels: European Committee for Standardization, 2012.

[43] DONATELLO S, TYRER M, CHEESEMAN C R. Comparison of test methods to assess pozzolanic activity[J]. Cement and Concrete Composites, 2010, 32(2): 121-127.

[44] HARDJITO D, ANTONI WIBOWO G M, CHRISTIANTO D. Pozzolanic activity assessment of LUSI (LUmpur SIdoarjo) mud in semi high volume pozzolanic mortar[J]. Materials, 2012, 5: 1654-1660.

[45] 段喜平, 陈杰, 闫长旺, 等. 钢渣对固废基贝利特硫铝酸盐水泥水化的影响[J]. 内蒙古工业大学学报(自然科学版), 2023, 42(06): 549-554. DUAN Xiping, CHEN Jie, YAN Changwang, et al. The effect of steel slag on the hydration of solid waste-based belite sulphoaluminate cement[J]. Journal of Inner Mongolia University of Technology (Natural Science Edition), 2023, 42(06): 549-554(in Chinese).

[46] 朱翔琛, 张云升, 刘志勇, 等. 基于核磁共振技术的硫酸盐冻融下机制骨料混凝土孔结构演变规律研究[J]. 复合材料学报, 2024, 41(10): 5478-5491. ZHU Xiangchen, ZHANG Yunsheng, LIU Zhiyong, et al. Study on the pore structure evolution law of mechanism aggregate concrete under sulphate freezing and thawing based on nuclear magnetic resonance technique[J]. Acta Materiae Compositae Sinica, 2024, 41(10): 5478-5491(in Chinese).

[47] 曹锋, 乔宏霞, 李双营, 等. 生物质硅改性氯氧镁水泥复合材料的力学性能与作用机制[J]. 复合材料学报, 2023, 40(10): 5859-5870. CAO Feng, QIAO Hongxia, LI Shuangying, et al. Mechanical properties and mechanism of action of biomass silica-modified magnesium chloride-oxygen cement composites[J]. Acta Materiae Compositae Sinica, 2023, 40(10): 5859-5870(in Chinese).

-

其他相关附件

-

目的

研究了不同煅烧温度(200℃和800℃)电解锰渣(EMR)火山灰活性及掺入0wt%、10wt%、20wt% EMR水泥胶砂在80℃蒸养7 h、7 d和标准养护3 d、28 d条件下力学性能、水化产物与孔隙特征分布。

方法采用低场核磁共振技术、XRD定量表征及SEM微观形貌共同揭示了EMR对水泥胶砂的水化产物、孔径分布及孔隙率等影响规律,并探究了不同养护条件对EMR水泥胶砂水化进程的影响。结果表明:800℃煅烧EMR火山灰活性明显高于200℃煅烧火山灰活性,当800℃煅烧EMR替代量为10wt%时,初凝、终凝时间和标准稠度用水量分别为对照组的1.52、1.06和1.05倍,而蒸养7 h、7 d抗压强度分别高于标养3 d和28 d抗压强度,而抗折强度仅仅在蒸养7 d时高于对照组17.3%;纯水泥胶砂的水化产物主要为纤维状C-S-H和片状CH,而EMR水泥胶砂中由于硫酸盐含量较高,除了上述水化产物之外,在蒸养或标养条件下均可观察到石膏相与针棒状AFt的存在,标准养护28d时,CH、AFt和无定性含量分别为14.50%、11.75%和46.25%,与蒸养7 d衍射峰基本相似。另外,蒸养7 h与标准养护3 d对比孔隙率减少1.44%,蒸养7 d与标准养护28 d对比孔隙率减少0.06%。

结论综上,蒸养可以提高800℃煅烧EMR火山灰活性,同时还可以加速EMR水泥胶砂的水化进程和细化其内部孔结构,进而提高了胶砂的力学性能。

-

电解锰渣(EMR)是电解金属锰生产时压滤和提纯过程中产生危险固体废弃物,其中含有Mn和NH3-N危险物质。目前还没有有效的方式处理大量堆存的EMR,只能通过填埋或指定区域堆存,这种处理方式不仅会污染周围土壤和水体,同时也会对人类健康造成严重威胁。因此,为了减少巨大的环境风险并为电解金属锰行业的可持续发展做出贡献,迫切的需要资源化利用EMR。

本文通过煅烧方式来提高EMR火山灰活性和降低危险物质含量。将EMR作为矿物掺合料时,Mn和NH3-N的浸出在水泥体系提供的碱性环境和凝胶体系中可以完全封装和固定,使得浸出浓度远低于标准限值。另外重要的一点是EMR中石膏相含量较高,不仅严重影响了水泥体系的凝结时间、体积安定性及早期强度,且后期会导致耐久性较差。因此,本工作采用4种养护制度,分别为标养3 d、28 d和80 ℃蒸养7 h、7 d,旨在探明不同养护条件下石膏对水泥基材料水化反应及水化产物组成的影响。通过煅烧发现EMR在800 ℃煅烧时具有较好的火山灰活性,可以作为矿物掺合料使用,同时蒸养可以促进EMR水泥胶砂中C-S-H和CH的形成,另外还会形成石膏和AFt,有利于填充结构内部孔隙和缺陷,宏观表现为EMR水泥胶砂蒸养7 h、7 d的抗压强度分别高于标养3 d和28 d。因此,蒸养可以促使EMR水泥胶砂强度快速形成。

火山灰活性评价与XRD的Rietveld定量分析(a) Frattini结果(b) SL消耗试验(c)水化产物定量分析对比

下载:

下载: