Adsorption of heavy metals by agricultural solid waste based hydrogel: A review

-

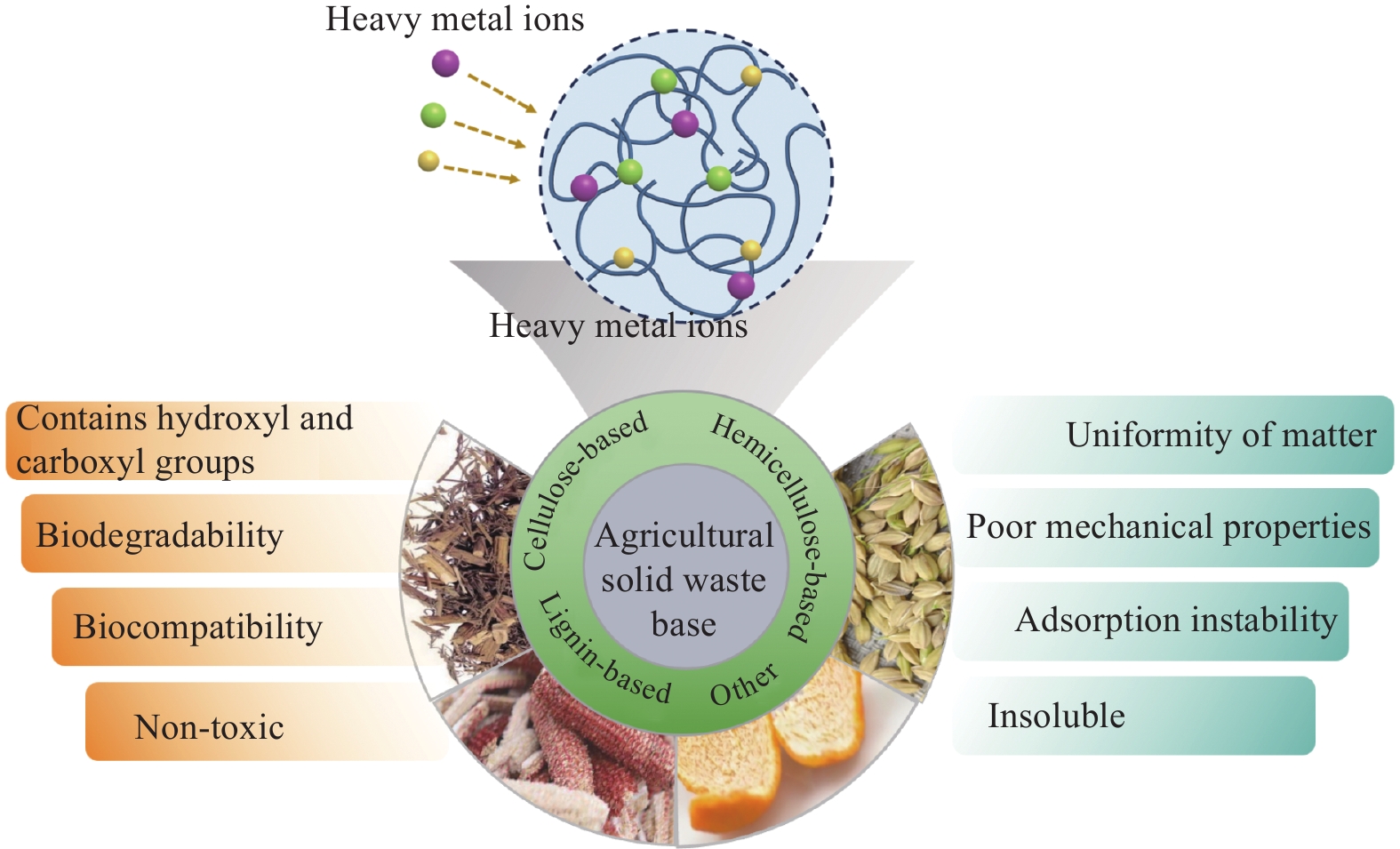

摘要: 随着经济的快速发展,水中重金属离子污染对人类健康以及生态系统造成威胁。水凝胶以其良好的吸附性能、可再生性和低毒性在处理重金属离子方面具有很大的潜力。本文论述了近年来国内外以农业固体废弃物为原料制备水凝胶(纤维素基水凝胶、半纤维素基水凝胶、木质素基水凝胶等)吸附重金属的研究进展。同时,讨论了农业固废基水凝胶的合成,对重金属的吸附效果、吸附机制及分析方法,并列举了工业固废基和其他固废基水凝胶吸附重金属的效果,以期帮助研究者对农业固废基水凝胶吸附重金属的探究有更深刻的理解。Abstract: With the rapid development of economy, the pollution of heavy metal ions in water poses a threat to human health and ecosystem. Hydrogels have great potential in the treatment of heavy metal ions because of their good adsorption properties, renewability and low toxicity. This paper discusses the research progress in recent years on the preparation of hydrogels (cellulose-based hydrogels, hemicellulose-based hydrogels, lignin-based hydrogels, etc.) for the adsorption of heavy metals from agricultural solid wastes at home and abroad. The synthesis of agricultural solid waste based hydrogels, the adsorption effect, adsorption mechanism, and analytical methods for the removal of heavy metals are also discussed, and the effects of heavy metal adsorption by industrial solid waste based and other solid waste based hydrogels are enumerated. In order to help the researchers to have a deeper understanding of the investigation of heavy metal adsorption by agricultural solid waste based hydrogels.

-

自动铺丝技术是先进的复合材料零件预制体的制造技术,综合了自动纤维缠绕和自动纤维带铺放的特点,具有铺放精度高、可重复性好的优点,可实现复杂曲面型复合材料构件的铺层制造[1-4]。与液体成型技术进行结合,能够实现复杂曲面型复合材料构件的高性能、低成本、高精度的制造[5]。目前,自动铺丝技术与液体成型技术相结合,已成功应用在俄罗斯M21单通道客机机翼的制造,使得机翼生产周期降低至30 h,飞机总减重45%,制造成本大大降低[6-7]。而国内,由于自动铺丝技术和液体成型技术的前期研究基础薄弱,使得材料的工艺适应性研究严重缺乏,研究进展相对缓慢[3-4]。综合以上,本文对一种成熟应用于航空级主承力构件的干纤维自动铺丝材料和一种研发级自动铺丝材料的层间粘结性能进行研究,采用不同热压参数模拟铺丝过程,用T型剥离的方法对干纤维层间剥离力进行测试,用于表征干纤维层间粘结性,研究热压参数对干纤维层间粘结性的影响;并结合多种材料性能表征手段,通过对干纤维表面性能、定型剂热力学性能的分析,研究两种干纤维的层间粘结机制;最后,为了证明热压工艺模拟自动铺丝工艺的可靠性,对比了分别用这两种工艺制备的层压样条的层间粘结性,并探究了喷涂热塑性树脂后干纤维的层间粘结性变化。通过本文的研究,验证了一种简便的评价干纤维层间粘结性能测试方法的可靠性,通过层间粘结机制的研究,为干纤维材料的自动铺丝工艺优化提供了数据和理论支持,促进了干纤维自动铺放技术的发展。

因此,对纤维自动铺放技术和液体成型技术的材料工艺适应性的研究具有重要的意义。采用自动铺丝技术制备预成型体过程中,需要制备出结构紧实、型面准确、保型性好的干纤维预成型体用于液体成型制备复合材料零件[1-4]。干纤维自动铺丝材料,与预浸丝束不同,表面分布少量呈点阵分布定型剂以实现干纤维丝束的良好粘结和贴覆[8-9]。为了避免纤维束自身发生错动,影响预成型体精度,在铺丝过程中需要精确控制铺丝温度、铺丝压力等关键参数[10-12]。尽管了解到自动铺丝过程中干纤维的铺放与温度、压力[13-14]、定型剂的状态变化有关[15-16],然而对于干铺放过程中的层间粘结力的形成机制,尚未进行充分研究[17]。另外,干纤维的自动铺丝过程消耗功率大、对材料和自动铺丝设备的要求高,若能提出一种可替代自动铺丝工艺的测试方法对材料粘结性进行评估,可大大简化工艺研究过程,促进相关技术的发展。实际应用中,为了提高复合材料的冲击阻抗和损伤容限,往往需要对复合材料进行层间增韧[18-21],而在增强干纤维表面涂覆高性能热塑性树脂增韧剂是层间增韧的常用方法[22-24],目前增韧剂的施加,对干纤维层间粘结性能的影响尚不明确,需要进一步探究。

1. 实验材料及方法

1.1 原材料

原材料为成熟应用于航空级主承力构件的干纤维自动铺丝材料(以下简称成熟干纤维)和一种研发级自动铺丝材料(以下简称研发干纤维)。两种材料均为碳纤维单向带,宽度6.35 mm,克重均为200 g/m2,两种单向带的一侧表面均覆盖着无规排列的短切纤维毡。两侧表面均有定型剂分布(图1)。在自动铺丝过程中,两层干纤维叠合在一起,下层干纤维的网纱与上层干丝的定型剂面贴合,在激光和压辊的作用下形成层间粘结力,制造出结构稳定性的预成型体。

1.2 干纤维层合样条的制备及测试方法

采用平板硫化机(XLB-D/S 0.5 MN热压机,上海德弘橡塑机械公司)将两根干纤维带重叠在一起后进行热压制备干纤维层合样条,并采用T型剥离的方法对干纤维层合样条的剥离力进行测试,用于表征干纤维的层间粘结性。平板硫化机的层压过程如图2所示,层压时上层干纤维带的定型剂面与下层干纤维的网纱面叠合,受压前模具在压机内加热30 min至受热均匀后开始压制,到达特定的压制时间后停止,工装冷却至室温后脱模,得到多个干纤维样条。

干纤维样条被压制好后进行T型剥离,此时干纤维样条长度20 cm,粘结部分长度15 cm,样条前段5 cm衬有隔离膜,作为T型剥离实验的夹持端(图3),宽度6.35 mm。T型剥离的测试方法参考国标GB/T 2791—1995[25],T型剥离试样长度为20 cm,宽度为2.5 cm,胶粘剂粘结部分长度15 cm,试样未胶接端分开并对称的夹在上下夹头中,上下夹头以(100±10) mm/min的速率分离。由于干纤维带实际形状较窄,在实际标准上进行了改进,样条宽度改为单根干纤维带的宽度,而样条长度、粘结长度保持不变。将样条置于E42.503万能试验机(美国MTS公司)进行拉伸(图4),上下夹头隔距6 cm,夹头的分离速度为100 mm/min,记录样条的拉伸-位移曲线。

采用差示扫描量热仪(DSC)取未热压的成熟干纤维进行测试,测试气氛为N2, 温度为40~240℃,上升速率为10℃/min。

采用GE Nanotom180显微断层扫描仪(Micro CT,Gerneral Electric)分别对未热压和经过170℃热压的研发干纤维进行扫描[26],观察干纤维内部的纤维排列状态。

1.3 实验设计(DOE)

本实验旨在研究干纤维在自动铺丝过程中,成熟干纤维和研发干纤维的层间粘结性能受铺放温度和铺放速度的影响,假设热压工艺可模拟自动铺丝工艺,本实验中假定压机压力不变,样条单位面积所受压强1.1~1.4 MPa,与自动铺丝过程中压辊压强基本一致。实验选取热压温度和压力作用时间这两个因子为变量,每个变量设置三水平,实验因子及水平设置见表1。由于因子个数不多,并且需要考察因子间的相互作用,选用全因子设计方法,包含测试名称、材料和压制参数的实验计划见表2,每组处理包括4~5次重复实验。

表 1 实验设计因子及水平信息Table 1. Experiment design factor and levels informationFactor Level Value Compression temperature/oC 3 110, 140, 170 Compression time/s 3 10, 30, 60 表 2 层合样条名称、材料和制备参数Table 2. Name, materials and experiments parameters of test samplesSample

lablesCompression temperature/℃ Compression time/s Sample

materialMA11010 110 10 Mature MA14010 140 10 Mature MA17010 170 10 Mature MA11030 110 30 Mature MA14030 140 30 Mature MA17030 170 30 Mature MA11060 110 60 Mature MA14060 140 60 Mature MA17060 170 60 Mature DE11010 110 10 Developing DE14010 140 10 Developing DE17010 170 10 Developing DE11030 110 30 Developing DE14030 140 30 Developing DE17030 170 30 Developing DE11060 110 60 Developing DE14060 140 60 Developing DE17060 170 60 Developing 1.4 热压工艺与自动铺丝工艺的对比

为了检验热压工艺代替自动铺丝进行干纤维层间粘结性测试的可靠性,采用自动铺丝设备在相同温度、压力等参数下铺放成熟干纤维预成型体(图5)。比较自动铺丝层合样条的平均剥离力和标准偏差与热压工艺制备层合样条的区别。

1.5 涂覆热塑性材料后的干纤维层间粘结性变化

为了提高复合材料的层间韧性,在研发干纤维表面涂覆定型剂后,将热塑性增韧乳剂以雾状形态均匀喷淋在研发干纤维的定型剂面,之后迅速经过200℃的热风进行固化。取增韧后的研发干纤维进行热压样条制备,测试喷淋乳剂后对层间粘结性的影响并与未喷淋乳剂的干纤维层间粘结性进行对比。

1.6 平均剥离力测试方法

采用平板硫化机制备干纤维层合样条后进行T型剥离,根据剥离力和夹具竖直位移的关系计算干纤维的平均剥离力及其波动。为了保证剥离力的稳定,避开试样前段的剥离,截取夹具竖直位移50 mm处作为起点,夹具竖直位移250 mm处作为终点(若试样在夹具竖直位移250 mm内某位置处完全剥离,则已完全剥离时的夹具位移为终点),提取起点与终点间的剥离力-位移曲线,对每条曲线的剥离力求积分后除以位移,计算样条的平均剥离力,并统计同一处理内样条平均剥离力的标准偏差。比较不同压制参数不同材料样条的平均剥离力大小和波动程度。

2. 结果与讨论

2.1 平均剥离力的大小与波动

2.1.1 成熟干纤维

成熟干纤维的样条分别在110℃、140℃及170℃的温度下压制,压力作用时间分别为10 s、30 s和60 s。当压力作用时间为10 s时,成熟干纤维样条的T型剥离力-位移曲线如图6所示。可知,当层压温度为110℃时和170℃时,样条在夹头位移小于250 mm处就产生了完全分离;而在层压温度140℃时,样条在夹头位移到达250 mm后才开始分离。样条剥离过程中,干纤维剥离力的最大值可达0.4 N左右,压制温度170℃的样条具有最多的剥离力峰值,其次是140℃压制的样条。样条的平均剥离力和波动程度如图6(d)所示,压力作用时间10 s时,从110℃至170℃,样条平均剥离力逐渐增大,而140℃热压样条的平均剥离力的波动程度最小。

![]() 图 6 压力作用时间10 s时成熟干纤维层合样条的T型剥离力-位移曲线:(a) 层压温度110℃;(b) 层压温度140℃;(c) 层压温度170℃;(d) 层间粘结力与标准偏差Figure 6. Relationship curves between T-peel force and displacement for mature dry fiber tow samples with compression time of 10 s: (a) Compression temperature 110℃; (b) Compression temperature 140℃; (c) Compression temperature 170℃; (d) Average T-peel force and standard deviation

图 6 压力作用时间10 s时成熟干纤维层合样条的T型剥离力-位移曲线:(a) 层压温度110℃;(b) 层压温度140℃;(c) 层压温度170℃;(d) 层间粘结力与标准偏差Figure 6. Relationship curves between T-peel force and displacement for mature dry fiber tow samples with compression time of 10 s: (a) Compression temperature 110℃; (b) Compression temperature 140℃; (c) Compression temperature 170℃; (d) Average T-peel force and standard deviation当压力作用时间为30 s时,成熟干纤维样条的T型剥离力-位移曲线如图7所示。此时,压制温度在110~170℃范围内,所有样条均在夹头位移到达250 mm后才开始分离。样条剥离过程中,压制温度170℃的样条的剥离力最大可达0.5 N左右,且出现的频率较多,分布均匀;其次是压制温度140℃的样条;最后,110℃压制的样条,最大剥离力较小,且出现的频率最低。样条的平均剥离力和波动程度如图7(d)所示,从110℃至170℃,样条平均剥离力逐渐增大,压制温度170℃的干纤维样条平均剥离力甚至可达110℃、140℃热压样条平均剥离力的2倍,且平均剥离力的波动程度也随之变大。

![]() 图 7 压力作用时间30 s时成熟干纤维层合样条的T型剥离力-位移曲线:(a) 层压温度110℃;(b) 层压温度140℃;(c) 层压温度170℃;(d) 本测试中平均T型剥离力与标准偏差Figure 7. Relationship curves between T-peel force and displacement for mature dry fiber tow samples wtth compression time of 30 s: (a) Compression temperature 110℃; (b) Compression temperature 140℃; (c) Compression temperature 170℃; (d) Average T-peel force and standard deviation

图 7 压力作用时间30 s时成熟干纤维层合样条的T型剥离力-位移曲线:(a) 层压温度110℃;(b) 层压温度140℃;(c) 层压温度170℃;(d) 本测试中平均T型剥离力与标准偏差Figure 7. Relationship curves between T-peel force and displacement for mature dry fiber tow samples wtth compression time of 30 s: (a) Compression temperature 110℃; (b) Compression temperature 140℃; (c) Compression temperature 170℃; (d) Average T-peel force and standard deviation当压力作用时间为60 s时,成熟干纤维样条的T型剥离力-位移曲线见图8。层压温度为110℃和170℃时,样条在夹头位移接近200 mm处即产生了完全分离;而在层压温度140℃时,样条在夹头位移到达250 mm后才开始分离。样条剥离过程中,压制温度140℃的样条的出现了最大剥离力,可达0.5 N左右,且出现的频率较高;而压制温度110℃和170℃的样条的最大剥离力较小。样条的平均剥离力和波动程度如图8(d)所示,从110℃至170℃,样条平均剥离力先增大后减小,最大剥离力在140℃热压样条处获得,平均剥离力波动程度的趋势相同。

![]() 图 8 压力作用时间60 s时成熟干纤维层合样条的T型剥离力-位移曲线:(a) 层压温度110℃;(b) 层压温度140℃;(c) 层压温度170℃;(d) 本测试中平均T型剥离力与标准偏差Figure 8. Relationship curves between T-peel force and displacement for mature dry fiber tow samples with compression time of 60 s: (a) Compression temperature 110℃; (b) Compression temperature 140℃; (c) Compression temperature 170℃; (d) Average T-peel force and standard deviation

图 8 压力作用时间60 s时成熟干纤维层合样条的T型剥离力-位移曲线:(a) 层压温度110℃;(b) 层压温度140℃;(c) 层压温度170℃;(d) 本测试中平均T型剥离力与标准偏差Figure 8. Relationship curves between T-peel force and displacement for mature dry fiber tow samples with compression time of 60 s: (a) Compression temperature 110℃; (b) Compression temperature 140℃; (c) Compression temperature 170℃; (d) Average T-peel force and standard deviation2.1.2 研发干纤维

同样,研发干纤维的样条分别在110℃、140℃及170℃的温度下压制,压力作用时间分别为10 s、30 s和60 s。当压力作用时间为10 s时,研发干纤维样条的T型剥离力-位移曲线如图9所示。可知,所有样条均在夹头位移到达250 mm后才开始分离。样条剥离过程中,压制温度110℃的样条的剥离力峰较陡峭,最大剥离力较高约为0.35 N;而热制温度为140℃和170℃的样条的剥离力峰较平缓,最大剥离力也更低。样条的平均剥离力和波动程度如图9(d)所示,压力作用时间10 s时,从110℃至170℃,样条平均剥离力呈现先下降然后略回升的趋势,在110℃时样条平均剥离力最大,平均剥离力波动程度也呈相同趋势。

![]() 图 9 压力作用时间10 s时研发干纤维层合样条的T型剥离力-位移曲线:(a) 层压温度110℃;(b) 层压温度140℃;(c) 层压温度170℃;(d) 本测试中平均T型剥离力与标准偏差Figure 9. Relationship curves between T-peel force and displacement for developing dry fiber tow samples with compression time of 10 s: (a) Compression temperature 110℃; (b) Compression temperature 140℃; (c) Compression temperature 170℃; (d) Average T-peel force and standard deviation

图 9 压力作用时间10 s时研发干纤维层合样条的T型剥离力-位移曲线:(a) 层压温度110℃;(b) 层压温度140℃;(c) 层压温度170℃;(d) 本测试中平均T型剥离力与标准偏差Figure 9. Relationship curves between T-peel force and displacement for developing dry fiber tow samples with compression time of 10 s: (a) Compression temperature 110℃; (b) Compression temperature 140℃; (c) Compression temperature 170℃; (d) Average T-peel force and standard deviation当压力作用时间为30 s时,研发干纤维样条的T型剥离力-位移曲线如图10所示。所有样条均在夹头位移到达250 mm后才开始分离。从110℃至170℃,样条的剥离力峰逐渐变得更加平缓,但最大剥离力一直维持在0.2 N左右。样条的平均剥离力和波动程度如图10(d)所示,从110℃至170℃,样条平均剥离力保持不变,平均剥离力的波动程度在热压140℃时具有最小值。

![]() 图 10 压力作用时间30 s时研发干纤维层合样条的T型剥离力-位移曲线:(a) 层压温度110℃;(b) 层压温度140℃;(c) 层压温度170℃;(d) 本测试中平均T型剥离力与标准偏差Figure 10. Relationship curves between T-peel force and displacement for developing dry fiber tow samples with compression time of 30 s: (a) Compression temperature 110℃; (b) Compression temperature 140℃; (c) Compression temperature 170℃; (d) Average T-peel force and standard deviation

图 10 压力作用时间30 s时研发干纤维层合样条的T型剥离力-位移曲线:(a) 层压温度110℃;(b) 层压温度140℃;(c) 层压温度170℃;(d) 本测试中平均T型剥离力与标准偏差Figure 10. Relationship curves between T-peel force and displacement for developing dry fiber tow samples with compression time of 30 s: (a) Compression temperature 110℃; (b) Compression temperature 140℃; (c) Compression temperature 170℃; (d) Average T-peel force and standard deviation当压力作用时间为60 s时,研发干纤维样条的T型剥离力-位移曲线如图11所示。所有样条均在夹头位移到达250 mm后才开始分离。从110℃至170℃,样条的剥离力峰逐渐变得更加平缓,但最大剥离力在压制温度为170℃的样条处急剧下降。样条的平均剥离力和波动程度如图11(d)所示,压力作用时间为60 s时,从110℃至170℃,样条平均剥离力逐渐下降,压制温度170℃的样条平均剥离力仅为压制温度110℃样条平均剥离力的一半,然而平均剥离力的波动程度却随温度增大有所上升。

![]() 图 11 压力作用时间60 s时研发干纤维层合样条的T型剥离力-位移曲线:(a) 层压温度110℃;(b) 层压温度140℃;(c) 层压温度170℃;(d) 本测试中平均T型剥离力与标准偏差Figure 11. Relationship curves between T-peel force and displacement for developing dry fiber tow samples with compression time of 60 s: (a) Compression temperature 110℃; (b) Compression temperature 140℃; (c) Compression temperature 170℃; (d) Average T-peel force and standard deviation

图 11 压力作用时间60 s时研发干纤维层合样条的T型剥离力-位移曲线:(a) 层压温度110℃;(b) 层压温度140℃;(c) 层压温度170℃;(d) 本测试中平均T型剥离力与标准偏差Figure 11. Relationship curves between T-peel force and displacement for developing dry fiber tow samples with compression time of 60 s: (a) Compression temperature 110℃; (b) Compression temperature 140℃; (c) Compression temperature 170℃; (d) Average T-peel force and standard deviation总的来说,成熟干纤维样条的平均层间剥离力大于研发干纤维样条。但是两种材料的平均剥离力随层压温度和层压时间的变化却不同。因此下面对两种材料进行主效应及交互效应等影响参数的显著性分析,对研究两种材料的层间粘结机制具有重要意义。

2.1.3 实验结果分析

采用统计学方法对以上实验结果进行方差分析,设定显著性水平为0.05,判断热压温度、压力作用时间及二者的协同因素对两种干纤维的层间粘结性是否有显著性影响。

成熟干纤维平均剥离力的方差分析如表3所示。可知,热压温度、压力作用时间及二者的协同因素的P值均小于0.05,表示以上三项均对成熟干纤维的层间粘结性有显著影响。而根据以上三项对应F值的大小,说明最显著影响成熟干纤维层间粘结性能的因子为压力作用时间,其次是热压温度,最后为二者的协同作用。成熟干纤维平均剥离力的主效应图见图12,发现因子热压温度、压力作用时间的回归线较陡,甚至出现弯折,说明对平均剥离力的主效应影响确实显著。成熟干纤维平均剥离力的交互作用见图13,结果显示,压力作用时间在10~30 s区间,热压温度在110~140℃区间时,两条效应线平行,说明此时压力作用时间和热压温度之间的交互作用不显著。其他效应线皆不平行,证明其他阶段内压力作用时间和热压温度之间具有显著的交互作用。

表 3 成熟干纤维测试结果方差分析Table 3. Analysis of variance of test results of developing dry fiberSources Degree of freedom Adjusted sum of squares of deviation from mean Adjusted mean value F-value of

hypothesis-testingP-value of

hypothesis-testingTemperature 2 0.022 0.011 40.78 0.000 Time 2 0.030 0.015 56.32 0.000 Temperature×time 4 0.018 0.004 16.33 0.000 研发干纤维平均剥离力的方差分析如表4所示。可知热压温度、压力作用时间及二者的协同因素的P值均小于0.05,同样表示以上三项均对研发干纤维的层间粘结性有显著影响。通过比较对应F值的大小,发现与成熟干纤维不同,最显著影响研发干纤维层间粘结性能的因子为热压温度,其次是压力作用时间,最后为二者的协同作用。研发干纤维平均剥离力的主效应如图14所示,发现在压力作用时间为10~30 s时,回归线较平,此时主效应影响不显著。而热压温度在140~170℃时,对主效应影响也相对不显著。研发干纤维平均剥离力的交互作用如图15所示,结果显示尽管压力作用时间和热压温度之间具有显著的交互作用,但研发干纤维各因子效应线的走势与成熟干纤维几乎完全不同。

表 4 国产干纤维测试结果方差分析Table 4. Analysis of variance of test results of developing dry fiberSources Degree of freedom Adj SS Adj MS F-value P-value Temperature 2 0.0107 0.005 43.55 0.000 Time 2 0.010 0.005 38.73 0.000 Temperature×time 4 0.006 0.001 12.16 0.000 2.2 层间粘结机制的分析

通过以上对热压参数及协同效应对干纤维层间粘结性能的影响分析,发现成熟干纤维和研发干纤维具有较大区别,因此对两种材料层间结合机制进行分析非常必要。根据材料的产品说明,研发干纤维材料的定型剂主要成分为线性环氧聚合物,而成熟干纤维材料的定型剂为含有环氧基团的多成分混合物。根据两种干纤维所用碳纤维的产品说明,对应的上浆剂也含有环氧基团。上浆剂和定型剂均含有极性集团,因此碳纤维和定型剂之间存在相互作用。

2.2.1 成熟干纤维

对成熟干纤维以不同温度热压后剥离的表面进行金相观测,分析不同温度下成熟干纤维层间的定型剂分布(见图16)。当热压温度≥110℃时,第一层定型剂面上的定型剂部分附着在第二层的网纱面上,说明定型剂开始发生了软化。热压温度≥140℃时,定型剂边缘存在明显收缩,且网纱纤维在剥离后留下抽拔痕迹,证明网纱纤维和定型剂具有很好的界面性能。热压温度到达170℃时,经剥离后第一层定型剂面上残存的定型剂明显变少,说明在140~170℃之间,定型剂受压后进行扩展,且扩展程度较其他温度区间都高,推断此时定型剂经历了一个黏度迅速下降的阶段。

取未热压的成熟干纤维,用热台显微镜观察干纤维两个表面上定型剂随温度的变化。温度上升速率10℃/min,到达指定温度后停留5 min(图17)。发现从80℃至170℃,网纱面上的定型剂随温度升高未发生明显变化,而定型剂面上的定型剂仅在边缘处略微变得平滑,无明显的扩展或收缩。说明尽管定型剂黏度随温度升高有所下降,但若不经过外界压力,定型剂仍然维持原有形状,并不向周边扩展。

由于成熟干纤维具体的定型剂成分无法获得,也难以分离出来,因此采用一种常用的环氧基树脂代替原成熟干纤维上的定型剂进行网纱面和定型剂面接触角的测试。实验在80℃和110℃两种温度下进行(140℃和170℃时环氧树脂黏度过小导致渗入干纤维内部不能进行接触角测试),实验结果如图18所示,两个表面与环氧树脂的接触角均小于90°,证明干纤维带表面具有亲环氧树脂的特性;随着温度增大,干纤维带两个表面与树脂的接触角均逐渐减小,且网纱面接触角小于定型剂面接触角,证明随着温度增大,干纤维表面上的环氧基定型剂在此阶段产生扩展,且在网纱面上扩展更加容易。

![]() 图 18 环氧树脂与成熟干纤维带在不同温度下的接触角:(a) 成熟干纤维定型剂面在80℃时与环氧树脂的接触角;(b) 成熟干纤维网纱面在80℃时与环氧树脂的接触角;(c) 成熟干纤维定型剂在110℃时与环氧树脂的接触角;(d) 成熟干纤维网纱面在110℃时与环氧树脂的接触角Figure 18. Contact angle between epoxy resin and mature dry fiber tow at varied temperature: (a) Contact angle between epoxy resin and binder surface of mature dry fiber tow at 80℃; (b) Contact angle between epoxy resin and fiber veil surface of mature dry fiber tow at 80℃; (c) Contact angle between epoxy resin and binder surface of mature dry fiber tow at 110℃; (d) Contact angle between epoxy resin and fiber veil surface of mature dry fiber tow at 110℃

图 18 环氧树脂与成熟干纤维带在不同温度下的接触角:(a) 成熟干纤维定型剂面在80℃时与环氧树脂的接触角;(b) 成熟干纤维网纱面在80℃时与环氧树脂的接触角;(c) 成熟干纤维定型剂在110℃时与环氧树脂的接触角;(d) 成熟干纤维网纱面在110℃时与环氧树脂的接触角Figure 18. Contact angle between epoxy resin and mature dry fiber tow at varied temperature: (a) Contact angle between epoxy resin and binder surface of mature dry fiber tow at 80℃; (b) Contact angle between epoxy resin and fiber veil surface of mature dry fiber tow at 80℃; (c) Contact angle between epoxy resin and binder surface of mature dry fiber tow at 110℃; (d) Contact angle between epoxy resin and fiber veil surface of mature dry fiber tow at 110℃取未热压的成熟干纤维连续测试两次,其热流与温度曲线分别如图19所示。在第一次的热流曲线中,发现存在一个明显的放热峰,放热开始温度为73℃,放热结束温度不明显。而第二次热流曲线中没有放热峰出现。对比两次测试结果,推断成熟干纤维上的定型剂可能存在活化基团,加热后发生不可逆转的固化交联反应。

根据以上测试结果,总结成熟干纤维带中层间粘结的形成因素。首先,成熟干纤维的定型剂在110~170℃的温度区间内保有一定黏度,几乎不渗入增强纤维内部,保证定型剂存在于层间。其次,温度上升后,定型剂发生了软化,与网纱面接触的部分会产生更大程度的扩展,提高了层间粘结面积。最后,推测定型剂具有活化基团,成熟干纤维在温度≥110℃经过热压时,定型剂在层间发生固化交联反应,使层间粘结力进一步提升,这也解释了2.1.1节中的测试结果,成为干纤维层间剥离力随着温度的升高大幅度增长的原因。2.1.3节中显著性分析表明,压力作用时间在10~30 s内、热压温度在110~140℃内,压力作用时间和热压温度之间的交互作用不显著,这可能由于温度在110~140℃之间时,定型剂黏度变化较小,因此压力作用时间的提升对剥离力的提升影响更大。

2.2.2 研发干纤维

对研发干纤维的剥离表面进行金相观测,分析不同热压温度下干纤维剥离后的定型剂分布(图20)。可以看到,当热压温度为110℃时,定型剂受压后出现明显的扩展,但是随着温度的升高,定型剂边缘逐渐收缩,分布密度也逐渐变小,直至170℃,第一层定型剂面和第二层网纱面上的定型剂几乎消失。

取未热压的研发干纤维,置于热台加热,用显微镜观察干纤维两个表面上定型剂随温度的变化(图21),热台加热速率10℃/min, 每个温度区间停留5 min。从80℃至170℃,网纱面上的定型剂随温度升高逐渐消失,定型剂面上的定型剂面积也随温度升高逐渐缩小。

观察干纤维内部的纤维排列状态(图22)。对于未层压的研发干纤维,探测到其内部结构松散、层间孔隙较多,甚至贯穿整个长度方向,单向带形态弯曲。而经过170℃热压后,干纤维内部结构变得紧密,内部孔隙裂缝变小,形态更加平直。这种现象证明定型剂熔融后逐渐渗入增强纤维内部,减少了内部空隙,提高了干纤维的整体性。

采用接触角测试的方法对研发干纤维的界面性能进行表征。测试方法与参数和成熟干纤维的接触角测试相同,实验结果如图23所示,研发干纤维两个表面与环氧树脂的接触角均小于90°,证明干纤维带表面具有亲环氧树脂的特性;随着温度增大,干纤维带两个表面与树脂的接触角均逐渐减小,证明随着温度增大,干纤维表面上的环氧基定型剂在此阶段扩展;然而,与成熟干纤维不同,研发干纤维定型剂面的接触角仅略大于网纱面的接触角,证明研发干纤维的网纱起的导流作用较小,所以相对于在表面扩展,研发干纤维的定型剂更容易渗入纤维内部。此外,在两种温度下,研发干纤维表面的接触角小于成熟干纤维的接触角,说明研发干纤维表面上的网纱和助剂较成熟干纤维具有更强的亲环氧树脂特性,这一特性使研发干纤维的环氧基定型剂更容易渗入干纤维内部。

![]() 图 23 环氧树脂与研发干纤维带在不同温度下的接触角:(a)定型剂面在80℃时与环氧树脂的接触角;(b)网纱面在80℃时与环氧树脂的接触角;(c)定型剂在110℃时与环氧树脂的接触角;(d)网纱面在110℃时与环氧树脂的接触角Figure 23. Contact angle between epoxy resin and developing dry fiber tow at varied temperature: (a) Contact angle between epoxy resin and binder surface at 80℃; (b) Contact angle between epoxy resin and veil surface at 80℃; (c) Contact angle between epoxy resin and binder surface at 110℃; (d) Contact angle between epoxy resin and veil surface at 110℃

图 23 环氧树脂与研发干纤维带在不同温度下的接触角:(a)定型剂面在80℃时与环氧树脂的接触角;(b)网纱面在80℃时与环氧树脂的接触角;(c)定型剂在110℃时与环氧树脂的接触角;(d)网纱面在110℃时与环氧树脂的接触角Figure 23. Contact angle between epoxy resin and developing dry fiber tow at varied temperature: (a) Contact angle between epoxy resin and binder surface at 80℃; (b) Contact angle between epoxy resin and veil surface at 80℃; (c) Contact angle between epoxy resin and binder surface at 110℃; (d) Contact angle between epoxy resin and veil surface at 110℃干纤维进热流-温度曲线如图24所示。发现热流曲线中没有放热峰出现,推断研发干纤维上的定型剂不存在任何活化基团,无化学反应发生。

根据以上测试结果,总结研发干纤维带中层间粘结的形成因素,由于研发干纤维的定型剂不含活性反应基团,因此其层间粘结只能通过表面定型剂的熔融冷却而形成的内聚力获得,定型剂软化到某种黏度后,热压后可停留在纤维表面且具有良好扩展性,此时层间粘结力达到最大值。之后,温度升高后定型剂黏度大幅度减小浸润到干纤维内部,干纤维表面上的定型剂几乎消失,导致了层间粘结力的下降。这也验证了2.1.2节中研发干纤维最大平均剥离力在110℃,压力作用时间10 s时获得,而温度的升高及压力作用时间的增大,都会导致平均剥离力的降低这一现象。根据2.1.3节中的显著性分析,压力作用时间为10~30 s时,对主效应影响不显著,这说明此时定型剂依然大部分停留在干纤维表面形成层间粘结,随着压力作用时间的增长,定型剂逐渐进入了干纤维内部,层间粘结迅速减小。热压温度在140~170℃时,对主效应影响也相对不显著,说明此时定型剂黏度已经很小且进入了干纤维内部,因此温度改变对剥离力的影响较小。

2.3 与自动铺丝工艺的对比

自动铺丝机(M.Torres公司)的铺丝头按照设定轨迹运动,使干纤维经铺丝头经过传送切割等操作,并在柔性压辊的作用下堆叠模具表面。铺丝过程中采用激光加热,并有红外温度显示仪实(M.Torres公司)时显示压辊与干纤维接触位置的温度。实际上,由于自动铺放过程无法准确设定温度,仅能设定激光功率,而激光所达到的温度取决于所需的铺贴速度、所用材料、加热面积等。本实验中设定铺丝头铺放速度为0.06 m/s,通过调试激光功率,使铺放时红外温度显示仪达到目标温度。自动铺丝实验的各项参数见表5。

表 5 自动铺丝(AFP)实验制备的层合样条名称及制备参数Table 5. Name and experiments parameters of test samples made by automated fiber placement (AFP)Sample lables Target temperature/℃ Setting power/W Actual temperature/℃ AFP110 110 260 107±15 AFP140 140 340 143±15 AFP170 170 420 176±15 铺放过程中,设定干纤维层与层间的错层距离为0,并在前段位置处放置隔离膜,避免形成层间粘结(图25)。铺放完毕后,预成型体与工装接触的首层弃之不用,将剩下两层干纤维叠合的预成型体沿长度方向裁开,制备T型剥离样条,并测试层间平均剥离力和波动程度。

由于研发干纤维尚未达铺丝水平,采用成熟干纤维进行铺丝实验。成熟干纤维样条的T型剥离力-位移曲线如图26所示。可知,铺丝温度为110℃左右时,部分样条一直维持着超低剥离力,且大部分样条在夹头未到达250 mm处即产生分离;当铺丝温度到达140℃左右后,样条在夹头位移到达250 mm后才开始分离,此时干纤维剥离力的最大值可达0.4 N左右;而铺丝温度为170℃时,样条具有最高的剥离力峰值,甚至超过了0.6 N,且剥离高峰分布的频率最高。样条的平均剥离力和波动程度如图26(d)所示,从110℃至170℃,样条平均剥离力逐渐增大,同时平均剥离力的波动程度也遵循这一趋势。

![]() 图 26 不同铺丝温度时,成熟干纤维层合样条的T型剥离力-位移曲线:(a) 铺丝温度110℃;(b) 铺丝温度140℃;(c) 铺丝温度170℃;(d) 本测试中平均T型剥离力与标准偏差Figure 26. Relationship curve between T-peel force and displacement for mature dry fiber tow samples when placed by automatic placement machine:(a) Placing temperature 110℃; (b) Placing temperature 140℃; (c) Placing temperature 170℃; (d) Average T-peel force and standard deviation

图 26 不同铺丝温度时,成熟干纤维层合样条的T型剥离力-位移曲线:(a) 铺丝温度110℃;(b) 铺丝温度140℃;(c) 铺丝温度170℃;(d) 本测试中平均T型剥离力与标准偏差Figure 26. Relationship curve between T-peel force and displacement for mature dry fiber tow samples when placed by automatic placement machine:(a) Placing temperature 110℃; (b) Placing temperature 140℃; (c) Placing temperature 170℃; (d) Average T-peel force and standard deviation将自动铺放干纤维样条的平均剥离力和热压干纤维样条的平均剥离力进行对比(图27)。发现当自动铺放干纤维样条铺放温度为110℃左右时,平均剥离力小于所有热压的干纤维样条平均剥离力,这是因为自动铺丝的温度由通过设定激光功率间接调试,偏差较大,而110℃时成熟干纤维的层间粘结性能较弱,介于有无之间,导致对比结果误差较大。事实上,当平均剥离力变大后,如温度介于140~170℃之间时,自动铺放干纤维样条的平均剥离力随温度变化的趋势与压力作用时间为30 s和10 s的热压干纤维样条的趋势类似。因此,可设定一个介于10~30 s的热压时间,能够较好地代替自动铺丝工艺制备层合样条用于评价干纤维层间粘结性。

2.4 涂覆热塑性材料后的研发干纤维层间粘结性

在研发级干纤维表面喷涂热塑性增韧乳剂后,对比其喷涂前和喷涂后的层间粘结性变化,计算涂覆乳剂的研发干纤维的平均层间粘结力,并与未涂覆乳剂的材料进行对比(图28)。其中,DE14030-1和DE17030-1分别为喷涂热塑乳剂后进行140℃和170℃热压并剥离的试验代号。发现涂覆乳剂的研发干纤维层间粘结力均有不同程度的下降。当热压温度140℃时,其平均剥离力下降18%。而热压温度为170℃时,喷涂乳剂的干纤维平均剥离力下降59%。因此在实际工艺中,为了保证增韧干纤维具有良好的层间粘结性能,需通过改性手段令增韧组分也具有良好的粘结性能。

3. 结 论

(1) 成熟干纤维的层间粘结力在一定范围内远大于研发干纤维,二者均显著受到层压温度、压力作用时间及协同作用的影响,但对成熟干纤维的最显著的影响为压力作用时间;而对研发干纤维的最显著的影响为温度。

(2) 成熟干纤维表面的定型剂保有一定黏度,在较大温度范围区间内几乎不渗入增强纤维内部,并且定型剂可能具有活化基团,定型时发生固化交联反应,进一步提高了层间粘结力,因此到达指定温度阶段后,为使交联反应充分发生,压力作用时间对成熟干纤维的层间粘结影响最显著。

(3) 而研发干纤维仅通过定型剂的熔融冷却后的内聚力形成层间粘结,其层间粘结力随着温度的增高而增大,达到最大后不再变化甚至略有下降,这与定型剂黏度降低后渗入纤维内部有关,由于温度与研发干纤维定型剂黏度直接相关,因此温度对研发干纤维的层间粘结影响最显著。

(4) 尽管自动铺丝工艺的温度离散型较大,若合理控制热压工艺的层压时间,热压可在一定程度上代替自动铺丝进行干纤维层间粘结性的评价。

(5) 研发级干纤维涂覆定型剂后继续在表面涂覆雾状热塑性增韧材料,层间粘结力进一步降低,下降范围可达18%~59%,为了保证增韧干纤维具有良好的层间粘结性能,增韧组分需进行改性使其具有足够的粘结性能。

致谢:感谢上海飞机制造有限公司复合材料中心同事孟嘉、章镇、陈晨对干纤维显微断层扫描测试和试样制造提供的帮助和给予的建议。

-

表 1 重金属对人类健康的危害

Table 1 Hazards of heavy metals to human health

Heavy metal Harm to mankind Pb Accumulates in the bones, brain, kidneys and muscles of the body, leading to brain damage, mental

retardation, anemia and cancer[21]Hg Lung, kidney and chest pain, dyspnea injury[22] Cd Cadmium ions pose a threat to many organs such as kidneys, lungs and liver[23] Cu Leading to liver damage, insomnia and Wilson disease[24] Zn Zinc not only irritates the skin, but also causes headache, dry cough, dizziness and other symptoms[25] Cr Destroy human metabolism, stimulate skin and lung cancer[26] As Skin damage and affect the nervous system of the human body[27] Ni Dermatitis, nausea, chronic asthma, cough[27] Mn Excessive manganese can cause dizziness and fatigue, mental retardation, and cause neurotransmitter disorders[28] 表 2 农业固废基水凝胶的制备及特点

Table 2 Synthesis and characterization of agricultural solid waste-based hydrogels

Solid waste-based raw materials and other reagents Method Characteristic Ref. Cellulose base Soybean residue cellulose,

chitosan, polyvinyl alcohol,

nano-Fe3O4Freeze-thaw method The increase of cellulose content is beneficial to improve the mechanical strength and swelling properties of the hydrogel. [44] Licorice residue cellulose,

crosslinker epichlorohydrinSolution polymerization The adsorption capacity, chemical stability, pore size distribution and mechanical properties of the hydrogel are improved by using epichlorohydrin as cross-linking agent. [45] Bagasse cellulose, polyvinyl alcohol, crosslinker glutaraldehyde Microwave assisted irradiation Microwave assisted irradiation technology can save time and energy. [46] Wheat straw cellulose, monomer acrylic acid and acrylamide, crosslinker N, N'-methylene-bis-acrylamide, initiator ammonium persulfate Free radical graft copolymerization Hydrogel has good thermal stability at temperature below 392℃. [47] Poplar wood flour cellulose, 3-mercaptopropionic acid, L-cysteamine hydrochloride, initiator ammonium persulfate Ultraviolet photoinitiation The cellulose ester synthesized by esterification of anhydride with cellulose under homogeneous condition has higher reaction activity. [48] Banana cellulose, chitosan, crosslinker epichlorohydrin Solution polymerization There are a large number of hydrophilic groups of hydroxyl and amino groups in the synthesized hydrogel, and the surface distributes irregular pore structure. [49] Lignin based Wheat straw lignin, montmorillonite, monomer acrylic acid, crosslinker N, N'-methylene-bis-acrylamide, initiator

K2S2O8-Na2SO3Solution polymerization Montmorillonite is introduced into lignin nanocomposites to improve the adsorption and mechanical properties of lignin nanocomposites. [50] Mulberry lignin, monomer acrylic acid, intercalation agent citric acid modified montmorillonite, crosslinker N, N'-methylene-bis-acrylamide, initiator (NH4)S2O8 Graft intercalation method When the amount of lignin is too high, the excess lignin produces too many cross-linking points, which affects the gel strength and hinders the cross-linking reaction. [51] Rice husk lignin, chitosan, polyacrylamide Free radical polymerization Lignin and chitosan are mixed as the first network to provide active functional groups for the removal of heavy metals.

As a malleable second network, polyacrylamide forms a stable structural hydrogel adsorbent.[52] Hemicellulose group Corn kernel hemicellulose, monomers acrylic acid and N-isopropyl acrylamide, crosslinker N, N'-methylene-bis-acrylamide, photoinitiator benzoin dimethyl ether Ultraviolet photoinitiation Pb2+ solution pH in the range of 3.5-4.5 and elevated temperature favored the adsorption of hydrogels. [53] Reed hemicellulose, monomer acrylic acid, crosslinker N, N, N', N'-tetramethylethylenediamine Free radical polymerization After 8 cycles of adsorption-desorption, the hydrogel still has high adsorption efficiency for metal ions. [39] Xylan hemicellulose, carrageenan, initiator ammonium persulfate, polyvinylpyrrolidone Microwave assisted irradiation Compared with cellulose, xylan hemicellulose is amorphous and consists of branched chains of various sugars, which is easier to dissolve in common solvents. [54] Other types of agriculture Citrus peel pectin, crosslinker calcium chloride, metal organic frame (MOF) In-situ method MOFs can interact with other components or adjust the properties of hydrogel matrix. [55] Pomelo peel pectin, monomers acrylic acid and acrylamide, initiator ammonium persulfate, crosslinker N, N'-methylene-bis-acrylamide Graft copolymerization Microwave extraction-alcohol precipitation method for pectin extraction has the advantages of strong selectivity, short operation time, low solvent consumption and excellent quality of extracted pectin. [56] Livestock bone powder, sodium alginate Solution polymerization Adsorption kinetics and adsorption isotherms indicate that adsorption is chemically and physically interactive. [57] 表 3 农业固废基水凝胶吸附重金属的优缺点

Table 3 Advantages and disadvantages of heavy metal adsorption on agricultural solid waste-based hydrogels

Common type Common ground Advantage Disadvantage Cellulose based hydrogel

Advantages: The raw materials are non-toxic, biodegradable and low cost; Make the hydrogel biocompatible, biodegradable and improve its adsorption performance.

Disadvantages: Unhomogeneity of raw materials, structural complexity, and difficulty in obtaining pure substances, and poor mechanical strength of prepared hydrogels.Contains hydroxyl, carboxyl and hydrogen bonding to improve the adsorption and mechanical properties

of hydrogels.Refractory; After several cycles of use, the morphology and mechanical properties of the hydrogel will change considerably, resulting in an unstable adsorption capacity. Hemicellulose based hydrogel Contains functional groups such as hydroxyl, acetyl and carboxyl groups; Good water solubility. The mechanical strength of the prepared hemicellulose-based hydrogels is poor due to the small molecular weight of hemicellulose and low degree of polymerization. Lignin based hydrogel Hydroxyl and carbonyl groups can chelate with metal ions; Active site for chemical reactions. The inhomogeneity and structural complexity of lignin and the difficulty of obtaining pure lignin;And when the amount of lignin is too high, excess lignin produces too many cross-linking points, which affects the gel strength and hinders the cross-linking reaction. Other agricultural solid waste-based hydrogels Pectin contains reactive groups such as carboxyl and hydroxyl groups. Insoluble; Pectins from different sources have different gelling and adsorption capacities due to different sizes and chemical structures, and are less stable. 表 4 农业固废基水凝胶对重金属的吸附性能总结

Table 4 Summary of adsorption properties of agricultural solid waste-based hydrogels for heavy metals

Hydrogel Target

pollutantAdsorption

conditionMaximum adsorption capacity/(mg·g−1) Adsorption kinetic/

adsorption isothermRecycling rate Ref. Cellulose base Soybean residue cellulose magnetic hydrogel Cu(II) pH=5.0 15.94 Pseudo-second-order/

Freundlich4 times

>80%[44] Licorice residue cellulose hydrogel Pb(II)

Cr(III)

Cu(II)pH=5.0(Pb)

t=120 min,

pH=4.0(Cr)(Cu)

t=60 min591.8

458.3

121.4Pseudo-second-order/

Langmuir5 times

>75%[45] Bagasse carboxymethyl cellulose hydrogel Cu(II) pH=5.0 2.3 — — [46] Wheat straw cellulose hydrogel Cu(II)

Mn(II)500 mg/L Co (Cu)

400 mg/L Co (Mn)238.1

176.9Pseudo-second-order — [47] Aspen cellulose methacrylate hydrogel Pb(II)

Hg(II)Hydrogel

dosage 0.2 g148.44

112.55Pseudo-second-order/

Langmuir— [48] Grapefruit peel cellulose-based hydrogel Cu(II)

Cr(VI)

Cd(II)Hydrogel dosage 10 g/L, pH=7.0, T=33℃, t=60 min, 10 mg/L Co Removal rate 96.21%, 98.02%,

95.43%— — [59] Banana fiber-chitosan hydrogel Cu(II)

Cd(II)

Pb(II)Hydrogel dosage 5 g/L, t=40 min Removal rate 98.35%, 79.22%,

77.3%Pseudo-second-order — [49] Lignin base Wheat straw lignin-montmorillonite hydrogel Cu(II) pH=6.5 74.35 Pseudo-second-order/

Freundlich5 times

>80%[50] Mulberry lignin hydrogel Mn(II)

Zn(II)

Pb(II)320 mg/L Co (Mn),

160 mg/L Co (Zn),

1000 mg/L Co (Pb),

t =720 min77.09

73.95

383.90— — [51] Hemicellulose based Reed hemicellulose-based hydrogel Pb(II)

Cd(II)

Zn(II)200 mg/L Co,

pH=5.5(Pb),

pH=6.5(Cd)(Zn)699

521

265Pseudo-second-order/

Langmuir— [39] Yellow bamboo xylan hemicellulose-acrylic hydrogel Pb(II)

Cd(II)

Zn(II)t=60 min,

pH=5.5(Pb),

pH=6.5(Cd)(Zn)859

495

274Pseudo-second-order/

Langmuir5 times

>90%[60] Other

categoriesMetal-organic frame composite citrus peel gum hydrogel Cr(VI)

Pb(II)pH=1(Cr),

pH=5(Pb)825.97

913.88Pseudo-second-order/

Langmuir8 times

>85%[55] Grapefruit peel pectin-based composite hydrogel Cu(II) pH=6.0 80.6 Pseudo-second-order/

Freundlich4 times

>90%[61] Bone hydrogel of abandoned livestock and poultry in rural area Cd(II) pH=4.0, t=720 min 1010.19 Pseudo-second-order and intra-particle diffusion models/

Langmuir and Freundlich3 times

>90%[57] Notes: T—Temperature; t—Time. 表 5 工业固废基水凝胶对重金属的吸附性能总结

Table 5 Summary of adsorption properties of industrial solid waste-based hydrogels for heavy metals

Hydrogel adsorption

materialTarget pollutant Adsorption condition Maximum adsorption

capacity/(mg·g−1)Ref. Red mud-sodium alginate hydrogel Pb(II) pH=6.0, T=25℃, t=900 min, 900 mg/L Co 454.54 [80] Fly ash-hydroxyethyl cellulose-chitosan hydrogel Cu(II) 100 mg/L Co 130.7 [81] Modified fly ash-sodium alginate crosslinked

acrylic hydrogelCu(II) 300 mg/L Co 131.09 [82] Magnetic attapulgite/fly ash/polyacrylic

acid hydrogelPb(II) pH=5.0, 100 mg/L Co, t=24 h 38 [83] Tobe mullite-starch hydrogel Cd(II) t=12 h, pH=5.21, T=25℃, hydrogel

dosage 0.05 g591.36 [84] -

[1] BHATNAGAR A, SILLANPÄÄ M, WITEK-KROWIAK A. Agricultural waste peels as versatile biomass for water purification—A review[J]. Chemical Engineering Journal, 2015, 270: 244-271. DOI: 10.1016/j.cej.2015.01.135

[2] ZAMORA-LEDEZMA C, NEGRETE-BOLAGAY D, FIGUEROA F, et al. Heavy metal water pollution: A fresh look about hazards, novel and conventional remediation methods[J]. Environmental Technology & Innovation, 2021, 22: 101504.

[3] ADEWUNMI A A, ISMAIL S, SULTAN A S. Laboratory scale study on rheological behavior, morphological and structural properties of crosslinked polyacrylamide composite hydrogels embedded with date seed powder[J]. Journal of Applied Polymer Science, 2015, 132(28): 42110. DOI: 10.1002/app.42110

[4] XU R, ZHOU G, TANG Y, et al. New double network hydrogel adsorbent: Highly efficient removal of Cd(II) and Mn(II) ions in aqueous solution[J]. Chemical Engineering Journal, 2015, 275: 179-188. DOI: 10.1016/j.cej.2015.04.040

[5] GOGOI N, BAROOAH M, MAJUMDAR G, et al. Carbon dots rooted agarose hydrogel hybrid platform for optical detection and separation of heavy metal ions[J]. ACS Applied Materials & Interfaces, 2015, 7(5): 3058-3067.

[6] ANITHA K, NAMSANI S, SINGH J K. Removal of heavy metal ions using a functionalized single-walled carbon nanotube: A molecular dynamics study[J]. The Journal of Physical Chemistry A, 2015, 119(30): 8349-8358. DOI: 10.1021/acs.jpca.5b03352

[7] ABDULLAH N, YUSOF N, LAU W J, et al. Recent trends of heavy metal removal from water/wastewater by membrane technologies[J]. Journal of Industrial and Engineering Chemistry, 2019, 76: 17-38. DOI: 10.1016/j.jiec.2019.03.029

[8] FU F, WANG Q. Removal of heavy metal ions from wastewaters: A review[J]. Journal of Environmental Management, 2011, 92(3): 407-418. DOI: 10.1016/j.jenvman.2010.11.011

[9] LIU X, MA R, WANG X, et al. Graphene oxide-based materials for efficient removal of heavy metal ions from aqueous solution: A review[J]. Environmental Pollution, 2019, 252: 62-73. DOI: 10.1016/j.envpol.2019.05.050

[10] SUN H, ZHAN J, CHEN L, et al. Preparation of CTS/PAMAM/SA/Ca2+ hydrogel and its adsorption performance for heavy metal ions[J]. Applied Surface Science, 2023, 607: 155135. DOI: 10.1016/j.apsusc.2022.155135

[11] CHEN X, ZHOU S, ZHANG L, et al. Adsorption of heavy metals by graphene oxide/cellulose hydrogel prepared from NaOH/urea aqueous solution[J]. Materials, 2016, 9(7): 582. DOI: 10.3390/ma9070582

[12] KHOZEMY E E, NASEF S M, MOHAMED T M. Radiation synthesis of superabsorbent hydrogel (wheat flour/acrylamide) for removal of mercury and lead ions from waste solutions[J]. Journal of Inorganic and Organometallic Polymers and Materials, 2020, 30(5): 1669-1685. DOI: 10.1007/s10904-019-01350-6

[13] WANG Z, LI T T, PENG H K, et al. Low-cost hydrogel adsorbent enhanced by trihydroxy melamine and β-cyclodextrin for the removal of Pb(II) and Ni(II) in water[J]. Journal of Hazardous Materials, 2021, 411: 125029. DOI: 10.1016/j.jhazmat.2020.125029

[14] 赵璐婷, 张健, 李娜, 等. 半纤维素基磁性水凝胶的制备及其对染料吸附性能的研究[J]. 材料工程, 2020, 48(11): 85-91. DOI: 10.11868/j.issn.1001-4381.2019.000076 ZHAO Luting, ZHANG Jian, LI Na, et al. Preparation of hemicellulose-based magnetic hydrogel and its adsorption properties for dye[J]. Journal of Materials Engineering, 2020, 48(11): 85-91(in Chinese). DOI: 10.11868/j.issn.1001-4381.2019.000076

[15] JAFARIGOL E, AFSHAR GHOTLI R, HAJIPOUR A, et al. Tough dual-network GAMAAX hydrogel for the efficient removal of cadmium and nickle ions in wastewater treatment applications[J]. Journal of Industrial and Engineering Chemistry, 2021, 94: 352-360. DOI: 10.1016/j.jiec.2020.11.006

[16] GIWA A, HASAN S W. Nucleophilic-functionalized β-cyclodextrin-polyethersulfone structures from facile lamination process as nanoporous membrane active layers for wastewater post-treatment: Molecular implications[J]. Journal of Membrane Science, 2018, 563: 914-925. DOI: 10.1016/j.memsci.2018.06.056

[17] PERUMAL S, ATCHUDAN R, EDISON T N J I, et al. A short review on recent advances of hydrogel-based adsorbents for heavy metal ions[J]. Metals, 2021, 11(6): 864. DOI: 10.3390/met11060864

[18] 张玮玮, 柳荫, 常璐璐. 砷哭了, 不是重金属的“重金属”[J]. 金属世界, 2023(4): 18-21. ZHANG Weiwei, LIU Yin, CHANG Lulu. Arsenic cried, which is not heavy metal, but was mistaken for[J]. Metal World, 2023(4): 18-21(in Chinese).

[19] 朱建龙, 徐伟杰, 郭硕铖, 等. 水体重金属污染危害及治理技术[J]. 现代农业科技, 2022(6): 129-132. ZHU Jianlong , XU Weijie, GUO Shuocheng, et al. Hazard of heavy metal pollution in water and its treatment technology[J]. Modern Agricultural Science and Technology, 2022(6): 129-132(in Chinese).

[20] PENG W, LI H, LIU Y, et al. Comparison of Pb(II) adsorption onto graphene oxide prepared from natural graphites: Diagramming the Pb(II) adsorption sites[J]. Applied Surface Science, 2016, 364: 620-627. DOI: 10.1016/j.apsusc.2015.12.208

[21] MA S C, ZHANG J L, SUN D H, et al. Surface complexation modeling calculation of Pb(II) adsorption onto the calcined diatomite[J]. Applied Surface Science, 2015, 359: 48-54. DOI: 10.1016/j.apsusc.2015.09.133

[22] ZHOU Y, HU X, ZHANG M, et al. Preparation and characterization of modified cellulose for adsorption of Cd(II), Hg(II), and acid fuchsin from aqueous solutions[J]. Industrial & Engineering Chemistry Research, 2013, 52(2): 876-884.

[23] NAWROT T S, STAESSEN J A, ROELS H A, et al. Cadmium exposure in the population: From health risks to strategies of prevention[J]. BioMetals, 2010, 23(5): 769-782. DOI: 10.1007/s10534-010-9343-z

[24] BEKIARI V, LIANOS P. Poly(sodium acrylate) hydrogels as potential pH-sensitive sorbents for the removal of model organic and inorganic pollutants from water[J]. Global NEST Journal, 2013, 12(3): 262-269. DOI: 10.30955/gnj.000720

[25] 杨瑶, 赵莹. 多微孔苄基化改性木粉的制备及其对废水中Cu2+、Pb2+和Zn2+的吸附性能研究[D]. 长沙: 中南林业科技大学, 2016. YANG Yao, ZHAO Ying. Preparation of microporous benzylated wood powder and study on adsorption ability of microporous benzylated wood powder to copper ions(II), lead ions(II) and zinc ions(II)[D]. Changsha: Central South Forestry University, 2016(in Chinese).

[26] BALLAV N, MAITY A, MISHRA S B. High efficient removal of chromium(VI) using glycine doped polypyrrole adsorbent from aqueous solution[J]. Chemical Engineering Journal, 2012, 198-199: 536-546. DOI: 10.1016/j.cej.2012.05.110

[27] CHEN B, CHEN Y, XU L, et al. Research and development on industrial heavy metal wastewater treatment technology[J]. IOP Conference Series: Earth and Environmental Science, 2020, 585(1): 012051. DOI: 10.1088/1755-1315/585/1/012051

[28] 叶操. 水库重金属锰污染特征及原因分析[J]. 陕西水利, 2023(9): 92-93. YE Cao. Characterization of heavy metal manganese pollution in reservoirs and analysis of its causes[J]. Shaanxi Water Resources, 2023(9): 92-93(in Chinese).

[29] 田长顺, 石亮. 农业废弃物吸附稀土离子的研究进展[J]. 有色金属科学与工程, 2019, 10(4): 113-122. TIAN Changshun, SHI Liang. Advances in adsorption of rare earth ions by agricultural wastes[J]. Nonferrous Metals Science and Engineering, 2019, 10(4): 113-122(in Chinese).

[30] LIU Z, ZHOU X, CHEN X, et al. Biosorption of clofibric acid and carbamazepine in aqueous solution by agricultural waste rice straw[J]. Journal of Environmental Sciences, 2013, 25(12): 2384-2395. DOI: 10.1016/S1001-0742(12)60324-6

[31] SYAFTIKA N, MATSUMURA Y. Comparative study of hydrothermal pretreatment for rice straw and its corresponding mixture of cellulose, xylan, and lignin[J]. Bioresource Technology, 2018, 255: 1-6. DOI: 10.1016/j.biortech.2018.01.085

[32] PENARANDA A J E, SABINO M A. Effect of the presence of lignin or peat in IPN hydrogels on the sorption of heavy metals[J]. Polymer Bulletin, 2010, 65(5): 495-508.

[33] SUN X F, ZENG Q, WANG H, et al. Preparation and swelling behavior of pH/temperature responsive semi-IPN hydrogel based on carboxymethyl xylan and poly(N-isopropyl acrylamide)[J]. Cellulose, 2019, 26(3): 1909-1922. DOI: 10.1007/s10570-018-2180-x

[34] LIANG S, WU J, TIAN H, et al. High-strength cellulose/poly(ethylene glycol) gels[J]. ChemSusChem, 2008, 1(6): 558-563. DOI: 10.1002/cssc.200800003

[35] FENG L, CHEN Z L. Research progress on dissolution and functional modification of cellulose in ionic liquids[J]. Journal of Molecular Liquids, 2008, 142(1-3): 1-5. DOI: 10.1016/j.molliq.2008.06.007

[36] 景占鑫, 孙晓锋, 王海洪, 等. 环境敏感型纤维素水凝胶及其在药物控释方面的应用[J]. 材料导报, 2012, 26(7): 83-88. DOI: 10.3969/j.issn.1005-023X.2012.07.019 JING Zhanxin, SUN Xiaofeng, WANG Haihong, et al. Environment-sensitive cellulose hydrogels and its application in drug delivery aspects[J]. Materials Reports, 2012, 26(7): 83-88(in Chinese). DOI: 10.3969/j.issn.1005-023X.2012.07.019

[37] ZERPA A, PAKZAD L, FATEHI P. Hardwood kraft lignin-based hydrogels: Production and performance[J]. ACS Omega, 2018, 3(7): 8233-8242. DOI: 10.1021/acsomega.8b01176

[38] 冯清华, 谌凡更. 含木质素水凝胶的研究进展[J]. 纤维素科学与技术, 2011, 19(4): 67-73. DOI: 10.3969/j.issn.1004-8405.2011.04.012 FENG Qinghua, CHEN Fangeng. Advances in lignin-containing hydrogels[J]. Journal of Cellulose Science and Technology, 2011, 19(4): 67-73(in Chinese). DOI: 10.3969/j.issn.1004-8405.2011.04.012

[39] 张文明, 黄莹, 朱厦, 等. 芦苇半纤维素基水凝胶的制备及对重金属离子的高效吸附[J]. 林产化学与工业, 2015, 35(4): 28-34. ZHANG Wenming, HUANG Ying, ZHU Sha, et al. Preparation of reed hemicelluloses-based hydrogels and its highly effective adsorption of heavy metal ions[J]. Chemistry and Industry of Forest Products, 2015, 35(4): 28-34(in Chinese).

[40] XU Y, LIU K, YANG Y, et al. Hemicellulose-based hydrogels for advanced applications[J]. Frontiers in Bioengineering and Biotechnology, 2023, 10: 1110004. DOI: 10.3389/fbioe.2022.1110004

[41] FARHAT W, VENDITTI R, AYOUB A, et al. Towards thermoplastic hemicellulose: Chemistry and characteristics of poly-(ε-caprolactone) grafting onto hemicellulose backbones[J]. Materials & Design, 2018, 153: 298-307.

[42] GERSCHENSON L N, FISSORE E N, ROJAS A M, et al. Pectins obtained by ultrasound from agroindustrial by-products[J]. Food Hydrocolloids, 2021, 118: 106799. DOI: 10.1016/j.foodhyd.2021.106799

[43] 林彦萍, 任源, 王晓娥, 等. 农业生物质废弃物转化功能材料的研究进展[J/OL]. 环境科学, 2023: 1-29[2024-05-21]. 网址: doi.org/10.13227/j.hjkx.202307264. LIN Yanping, REN Yuan, WANG Xiao'e, et al. Research progress of functional materials for conversion of agricultural biomass wastes[J/OL]. Environmental Science, 2023: 1-29[2024-05-21](in Chinese).

[44] LI P, ZHOU M, LIU H, et al. Preparation of green magnetic hydrogel from soybean residue cellulose for effective and rapid removal of copper ions from wastewater[J]. Journal of Environmental Chemical Engineering, 2022, 10(5): 108213. DOI: 10.1016/j.jece.2022.108213

[45] YIN X, KE T, ZHU H, et al. Efficient removal of heavy metals from aqueous solution using licorice residue-based hydrogel adsorbent[J]. Gels, 2023, 9(7): 559. DOI: 10.3390/gels9070559

[46] BAIYA C, NANNUAN L, TASSANAPUKDEE Y, et al. The synthesis of carboxymethyl cellulose-based hydrogel from sugarcane bagasse using microwave-assisted irradiation for selective adsorption of copper(II) ions[J]. Environmental Progress & Sustainable Energy, 2019, 38(s1): S157-S165.

[47] 吕晓萍, 王阳, 孙倩玉, 等. 麦秆水凝胶的制备及其对Cu(II)、Mn(II)的吸附[J]. 中国造纸, 2019, 38(11): 37-41. DOI: 10.11980/j.issn.0254-508X.2019.11.006 LYU Xiaoping, WANG Yang, SUN Qianyu, et al. Preparation of wheat straw hydrogel and its adsorption performance for Cu(II) and Mn(II)[J]. China Pulp & Paper, 2019, 38(11): 37-41(in Chinese). DOI: 10.11980/j.issn.0254-508X.2019.11.006

[48] 陈旭, 王硕, 汤相宇, 等. 纤维素甲基丙烯酸酯水凝胶的制备及重金属离子吸附性能研究[J]. 森林工程, 2023, 39(1): 82-91. DOI: 10.3969/j.issn.1006-8023.2023.01.010 CHEN Xu, WANG Shuo, TANG Xiangyu, et al. Study on preparation of cellulose methacrylate hydrogels and their adsorption performance of heavy metal ions[J]. Forest Engineering, 2023, 39(1): 82-91(in Chinese). DOI: 10.3969/j.issn.1006-8023.2023.01.010

[49] 郑丽丽, 艾斌凌, 郑晓燕, 等. 香蕉纤维-壳聚糖水凝胶的制备及其吸附重金属离子性能研究[J]. 中国麻业科学, 2019, 41(3): 136-144. ZHENG Lili, AI Binling, ZHENG Xiaoyan, et al. Study on the preparation and heavy metal adsorption of banana fiber-chitosan hydrogels[J]. Plant Fiber Sciences in China, 2019, 41(3): 136-144(in Chinese).

[50] SUN X F, HAO Y, CAO Y, et al. Superadsorbent hydrogel based on lignin and montmorillonite for Cu(II) ions removal from aqueous solution[J]. International Journal of Biological Macromolecules, 2019, 127: 511-519. DOI: 10.1016/j.ijbiomac.2019.01.058

[51] 王莹, 王星敏, 熊杰, 等. 接枝插层合成木质素基水凝胶的制备因素解析[J]. 环境化学, 2020, 39(8): 2217-2226. WANG Ying, WANG Xingmin, XIONG Jie, et al. Analysis of preparation factors of lignin-based hydrogels synthesized by graft-intercalation[J]. Environmental Chemistry, 2020, 39(8): 2217-2226(in Chinese).

[52] MA J, LI T, LIU Y, et al. Rice husk derived double network hydrogel as efficient adsorbent for Pb(II), Cu(II) and Cd(II) removal in individual and multicomponent systems[J]. Bioresource Technology, 2019, 290: 121793. DOI: 10.1016/j.biortech.2019.121793

[53] 梁志. 玉米芯半纤维素基水凝胶对Pb2+吸附性能和机制[J]. 化工新型材料, 2023, 51(2): 202-206. LIANG Zhi. Adsorption properties and mechanisms of corn cobs hemicelluloses-based hydrogels for Pb2+[J]. New Chemical Materials, 2023, 51(2): 202-206(in Chinese).

[54] MEENA R, LEHNEN R, SAAKE B. Microwave-assisted synthesis of kC/Xylan/PVP-based blend hydrogel materials: Physicochemical and rheological studies[J]. Cellulose, 2014, 21(1): 553-568. DOI: 10.1007/s10570-013-0155-5

[55] MAHMOUD M E, MOHAMED A K. Novel derived pectin hydrogel from mandarin peel based metal-organic frameworks composite for enhanced Cr(VI) and Pb(II) ions removal[J]. International Journal of Biological Macromolecules, 2020, 164: 920-931. DOI: 10.1016/j.ijbiomac.2020.07.090

[56] 张璇, 宋燕西. 柚子皮果胶的提取及其复合材料的制备及性能研究[D]. 上海: 东华大学, 2019. ZHANG Xuan, SONG Yanxi. Extraction of pectin from grapefruit peel and preparation and properties of its composites[D]. Shanghai: Donghua University, 2019(in Chinese).

[57] LI J, CHEN M, YANG X, et al. Preparation of a novel hydrogel of sodium alginate using rural waste bone meal for efficient adsorption of heavy metals cadmium ion[J]. Science of the Total Environment, 2023, 863: 160969. DOI: 10.1016/j.scitotenv.2022.160969

[58] ZHENG X, ZOU M, ZHANG B, et al. Remediation of Cd-, Pb-, Cu-, and Zn-contaminated soil using cow bone meal and oyster shell meal[J]. Ecotoxicology and Environmental Safety, 2022, 229: 113073. DOI: 10.1016/j.ecoenv.2021.113073

[59] 黄铂扬. 柚子皮纤维素基水凝胶对重金属离子吸附效果的研究[J]. 菏泽学院学报, 2018, 40(2): 62-65. DOI: 10.3969/j.issn.1673-2103.2018.02.012 HUANG Boyang. Adsorption effect of pomelo peel cellulose-based hydrogel on heavy metal ions[J]. Journal of Heze University, 2018, 40(2): 62-65(in Chinese). DOI: 10.3969/j.issn.1673-2103.2018.02.012

[60] PENG X W, ZHONG L X, REN J L, et al. Highly effective adsorption of heavy metal ions from aqueous solutions by macroporous xylan-rich hemicelluloses-based hydrogel[J]. Journal of Agricultural and Food Chemistry, 2012, 60(15): 3909-3916. DOI: 10.1021/jf300387q

[61] ZHANG W, SONG J, HE Q, et al. Novel pectin based composite hydrogel derived from grapefruit peel for enhanced Cu(II) removal[J]. Journal of Hazardous Materials, 2020, 384: 121445. DOI: 10.1016/j.jhazmat.2019.121445

[62] KUSHWAHA J, SINGH R. Cellulose hydrogel and its derivatives: A review of application in heavy metal adsorption[J]. Inorganic Chemistry Communications, 2023, 152: 110721. DOI: 10.1016/j.inoche.2023.110721

[63] 李佶衡, 彭良琼, 郭丽君, 等. 固液吸附等温线模型与热力学参数计算[J]. 皮革科学与工程, 2023, 33(6): 36-43. LI Jiheng, PENG Liangqiong, GUO Lijun, et al. Solid-liquid adsorption isotherm model and thermodynamic parameter calculation[J]. Leather Science and Engineering, 2023, 33(6): 36-43(in Chinese).

[64] MOHAMED W R, METWALLY S S, IBRAHIM H A, et al. Impregnation of task-specific ionic liquid into a solid support for removal of neodymium and gadolinium ions from aqueous solution[J]. Journal of Molecular Liquids, 2017, 236: 9-17. DOI: 10.1016/j.molliq.2017.04.013

[65] JIAO C, XIONG J, TAO J, et al. Sodium alginate/graphene oxide aerogel with enhanced strength-toughness and its heavy metal adsorption study[J]. International Journal of Biological Macromolecules, 2016, 83: 133-141. DOI: 10.1016/j.ijbiomac.2015.11.061

[66] ZHOU D, ZHANG L, ZHOU J, et al. Cellulose/chitin beads for adsorption of heavy metals in aqueous solution[J]. Water Research, 2004, 38(11): 2643-2650. DOI: 10.1016/j.watres.2004.03.026

[67] YETIMOĞLU E K, KAHRAMAN M V, BAYRAMOĞLU G, et al. Sulfathiazole-based novel UV-cured hydrogel sorbents for mercury removal from aqueous solutions[J]. Radiation Physics and Chemistry, 2009, 78(2): 92-97. DOI: 10.1016/j.radphyschem.2008.08.011

[68] ZHANG W, XU Y, MU X, et al. Research progress of polysaccharide-based natural polymer hydrogels in water purification[J]. Gels, 2023, 9(3): 249. DOI: 10.3390/gels9030249

[69] DENG S, BAI, CHEN J P. Aminated polyacrylonitrile fibers for lead and copper removal[J]. Langmuir, 2003, 19(12): 5058-5064. DOI: 10.1021/la034061x

[70] 杨志林, 周勤. 花生壳木质纤维素基水凝胶对水体镉、铅的吸附性能与机制研究[D]. 广州: 华南理工大学, 2023. YANG Zhilin, ZHOU Qin. Study on adsorption performance and mechanism of peanut husk lignocellulose-based hydrogel for cadmiumand lead in Water[D]. Guangzhou: South China University of Technology, 2023(in Chinese).

[71] PEREIRA R C, ANIZELLI P R, DI MAURO E, et al. The effect of pH and ionic strength on the adsorption of glyphosate onto ferrihydrite[J]. Geochemical Transactions, 2019, 20(1): 3. DOI: 10.1186/s12932-019-0063-1

[72] WEN Y, XUE C, JI D, et al. Eco-friendly enteromorpha polysaccharides-based hydrogels for heavy metal adsorption: From waste to efficient materials[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2023, 656: 130531. DOI: 10.1016/j.colsurfa.2022.130531

[73] BADSHA M A H, KHAN M, WU B, et al. Role of surface functional groups of hydrogels in metal adsorption: From performance to mechanism[J]. Journal of Hazardous Materials, 2021, 408: 124463. DOI: 10.1016/j.jhazmat.2020.124463

[74] SHAN S, SUN X F, XIE Y, et al. High-performance hydrogel adsorbent based on cellulose, hemicellulose, and lignin for copper(II) ion removal[J]. Polymers, 2021, 13(18): 3063. DOI: 10.3390/polym13183063

[75] 骆欣, 杨怡心, 徐东耀. 热改性粉煤灰对水中Cu(II)的吸附研究[J]. 应用化工, 2020, 49(9): 2242-2245, 2251. DOI: 10.3969/j.issn.1671-3206.2020.09.023 LUO Xin, YANG Yixin, XU Dongyao. Study on adsorption of Cu(II) by thermal modified fly ash[J]. Applied Chemical Industry, 2020, 49(9): 2242-2245, 2251(in Chinese). DOI: 10.3969/j.issn.1671-3206.2020.09.023

[76] 刘畅, 张建斌. 电石渣基纳米碳酸钙的制备及吸附重金属的研究[D]. 呼和浩特: 内蒙古工业大学, 2019. LIU Chang, ZHANG Jianbin. Studies on preparation of nano-CaCO3 from carbide slag and the adsorption of heavy metals[D]. Hohhot: Inner Mongolia University of Technology, 2019(in Chinese).

[77] 孙道兴, 王馥琴. 赤泥脱除废水中重金属离子的研究[J]. 无机盐工业, 2008(8): 47-49. DOI: 10.3969/j.issn.1006-4990.2008.08.016 SUN Daoxing, WANG Fuqin. Study on removal of heavy metal ions in wastewater by red mud[J]. Inorganic Chemicals Industry, 2008(8): 47-49(in Chinese). DOI: 10.3969/j.issn.1006-4990.2008.08.016

[78] 谢静怡, 赵晟锌, 陈忠林, 等. 粉煤灰基吸附剂去除水中重金属的研究进展[J]. 环境科学与技术, 2023, 46(S1): 116-124. XIE Jingyi, ZHAO Shengxin, CHEN Zhonglin, et al. Research progress on preparation of adsorbent based on fly ash and its application in the removal of heavy metals in water[J]. Environmental Science & Technology, 2023, 46(S1): 116-124(in Chinese).

[79] 雷小丽, 吴幼娥, 曾伟, 等. 改性赤泥吸附废水中典型重金属研究进展[J]. 环境科学导刊, 2021, 40(4): 1-8. LEI Xiaoli, WU You'e, ZENG Wei, et al. Research progress on adsorption of typical heavy metals in waste water by modified red mud[J]. Environmental Science Survey, 2021, 40(4): 1-8(in Chinese).

[80] 王威, 邓华, 胡乐宁, 等. 赤泥-海藻酸钠水凝胶对水中Pb(II)的吸附性能[J]. 广西师范大学学报(自然科学版), 2023, 41(5): 105-115. WANG Wei, DENG Hua, HU Lening, et al. Adsorption performance of red mud-sodium alginate hydrogel on Pb(II) in water[J]. Journal of Guangxi Normal University (Natural Science Edition), 2023, 41(5): 105-115(in Chinese).

[81] 王昆. 羟乙基纤维素复合水凝胶的制备及性能研究[D]. 天津: 天津科技大学, 2023. WANG Kun. Study on the preparation and properties of hydroxyethyl cellulose composite hydrogel[D]. Tianjin: Tianjin University of Science and Technology, 2023(in Chinese).

[82] 李露思, 赵梓年, 刘均科. 海藻酸钠交联丙烯酸基多元水凝胶的制备及性能研究[D]. 天津: 天津科技大学, 2021. LI Lusi, ZHAO Zinian, LIU Junke. Preparation and properties of sodium alginaite cross-linked acrylate based multicomponent hydrogel[D]. Tianjin: Tianjin University of Science and Technology, 2021(in Chinese).

[83] JIANG L, LIU P. Design of magnetic attapulgite/fly ash/poly(acrylic acid) ternary nanocomposite hydrogels and performance evaluation as selective adsorbent for Pb2+ ion[J]. ACS Sustainable Chemistry & Engineering, 2014, 2(7): 1785-1794.

[84] HE C, MOU H, HOU W, et al. Drought-resistant and water-retaining tobermorite/starch composite hydrogel for the remediation of cadmium-contaminated soil[J]. International Journal of Biological Macromolecules, 2024, 255: 127534.

[85] YUE X H, ZHANG F S, ZHANG C C, et al. Upcycling of blending waste plastics as zwitterionic hydrogel for simultaneous removal of cationic and anionic heavy metals from aqueous system[J]. Journal of Hazardous Materials, 2022, 432: 128746. DOI: 10.1016/j.jhazmat.2022.128746

[86] CHEN Y, LI L, LI Y, et al. Preparation of a double-network hydrogel based on wastepaper and its application in the treatment of wastewater containing copper(ii) and methylene blue[J]. RSC Advances, 2021, 11(29): 18131-18143.

[87] MAHMOUD M E, MOHAMED A K, SALAM M A. Self-decoration of N-doped graphene oxide 3-D hydrogel onto magnetic shrimp shell biochar for enhanced removal of hexavalent chromium[J]. Journal of Hazardous Materials, 2021, 408: 124951. DOI: 10.1016/j.jhazmat.2020.124951

[88] MA J, LIU Y, ALI O, et al. Fast adsorption of heavy metal ions by waste cotton fabrics based double network hydrogel and influencing factors insight[J]. Journal of Hazardous Materials, 2018, 344: 1034-1042. DOI: 10.1016/j.jhazmat.2017.11.041

[89] BI H, HUANG X, WU X, et al. Carbon microbelt aerogel prepared by waste paper: An efficient and recyclable sorbent for oils and organic solvents[J]. Small, 2014, 10(17): 3544-3550. DOI: 10.1002/smll.201303413

[90] CHEN Y, LIU Y, LI Y, et al. Functional wastepaper-montmorillonite composite aerogel for Cd2+ adsorption[J]. Environmental Science and Pollution Research, 2020, 27(31): 38644-38653. DOI: 10.1007/s11356-020-09907-6

-

目的

水凝胶是一种具有三维立体网状结构的多孔亲水聚合物,在处理重金属离子方面具有很大的潜力。随着经济化的发展,我国固体废弃物的产生量急剧增加。利用固废制备水凝胶作为一种新型绿色材料,在去除环境中的重金属方面具有广阔的应用前景。本文主要论述了农业固废基(纤维素、半纤维素、木质素、果胶等)用于水凝胶的制备,以及对重金属离子的吸附情况,以期为更深入地了解水凝胶在处理重金属的应用提供参考。

方法查阅国内外文献,论述了现阶段利用农业固废材料制备水凝胶的情况,主要包括农业固废基水凝胶的合成,吸附重金属的效果、分析方法以及吸附机理。

结果秸秆、甘蔗渣、稻壳等农业废弃生物质,含有大量的纤维素、半纤维素和木质素。木质素、半纤维素、纤维素分子含有羟基和羧基,具有螯合能力,可以与重金属离子发生静电相互作用。将其加入到水凝胶的制备当中,可以提高水凝胶的生物可降解性以及对重金属的吸附能力。农业固废基水凝胶对重金属离子的吸附机理主要通过络合作用、静电相互作用和离子交换作用。吸附等温线与Langmuir和Freundlich模型较为复合,表明吸附是通过重金属与水凝胶发生化学和物理作用进行的。吸附动力学模型与准二级动更为拟合。

结论(1)农业废弃生物质中含有丰富的纤维素、半纤维素、木质素,这些物质不仅具有无毒性、可生物降解等特点,还含有大量的羟基、羧基和氢键等官能团,能与重金属发生螯合作用。将其加入到水凝胶的制备中,可以使水凝胶具有生物相容性、生物可降解性,并增强对重金属的吸附效果。(2)但是这些物质的不均一性、结构复杂性、纯品物质难以获得,以及分子量较小,聚合度较低,制备的水凝胶的力学强度较差等问题还需要进一步探索。(3)目前大多的研究还停留在实验室阶段,未应用到实际工程中。除了以上的不足,还需考虑以下问题。首先,多数实验所用的重金属离子溶液为实验室模拟配置的废水,为了以后更好的实际工程应用,应选用实际废水进行研究。其次,关于将农业固废经过改性或许与其他物质复合形成水凝胶等手段,以及水凝胶的制备过程都涉及较多的化学试剂,并且工艺流程复杂性、成本问题都制约其发展。

下载:

下载: