Constitutive model of recycled brick aggregate geopolymer concrete under compression before and after elevated temperature

-

摘要: 再生砖骨料地聚物混凝土(RBGC)是一种极具潜力的可持续建筑材料,但高温前后RBGC性能的相关研究较少。本文首先探究了胶凝材料用量和粗骨料类型对地聚物混凝土轴压本构模型的影响,发现随着胶凝材料的增加,RBGC抗压强度、劈拉强度、弹性模量和峰值压应变的变化幅度均小于普通骨料地聚物混凝土(NAGC),RBGC的应力-应变曲线上升段线性段更长,下降段应力下降速度更快。其次研究了高温后RBGC和NAGC的力学性能,800℃时,RBGC强度和刚度损失分别比NAGC小22.1%和18.3%,发现RBGC表现出更好的耐高温性能,两种混凝土力学性能指标的计算应采用不同的模型。这是由于砖骨料温度膨胀系数接近地聚物砂浆,且高温下RBGC内部温度梯度小。最后,通过修正下降段形状参数,确定了高温前后RBGC和NAGC的应力-应变关系模型,模型与试验结果吻合较好。Abstract: Recycled brick aggregate geopolymer concrete (RBGC) is a sustainable building material with great potential, but there are few studies on the performance of RBGC before and after high temperatures. Firstly, the influence of the amount of cementitious material and the type of coarse aggregate on the axial compression constitutive model of geopolymer concrete was explored. It is found that with the increase of cementitious material, the compressive strength, split tensile strength, elastic modulus and peak compressive strength of RBGC decrease. The change amplitude of strain is smaller than that of ordinary aggregate geopolymer concrete (NAGC). The linear section of the rising section of the stress-strain curve of RBGC is longer, and the stress decreases faster in the falling section. Secondly, the mechanical properties of RBGC and NAGC after high temperature were studied. At 800℃, the strength and stiffness loss of RBGC are 22.1% and 18.3% smaller than that of NAGC respectively. And it is found that RBGC shows better high temperature resistance, and different models should be used to calculate the mechanical performance indicators of the two concretes. This is because the temperature expansion coefficient of brick aggregate is close to that of geopolymer mortar, and the internal temperature gradient of RBGC is small at high temperatures. Finally, by correcting the shape parameters of the descending section, the stress-strain relationship model of RBGC and NAGC before and after high temperature is determined, and the model is in good agreement with the test results.

-

碳纤维增强聚合物复合材料(CFRP)具有高强、质轻、抗疲劳性能好和施工方便等优点,目前不仅被广泛应用于钢筋混凝土结构的加固中,同时也用在砌体结构的加固中[1-6]。CFRP加固砌体结构是通过CFRP与砌体材料界面间的粘结力,使两种材料组合在一起协同工作并传递荷载。因此,CFRP与砌体材料之间良好的粘结性能是保证CFRP与砌体结构共同受力变形的基础[7-8]。关于CFRP加固砌体结构,国内外学者做了大量研究,而关于CFRP-砌体界面性能只有少部分学者进行了研究并提出不同的界面粘结-滑移模型,这些模型基本上能准确模拟粘结界面的受力情况[9],但对于冻融环境下界面粘结-滑移模型未见公开报道。在冻融环境中,粘土砖的性能会随着时间的推移有所退化,在一定程度上会影响界面粘结性能,最终引起不可避免的耐久性问题[10-12]。因此,对冻融循环作用下CFRP与粘土砖之间粘结性能进行相应研究具有十分重要的意义。

通过简单可靠的单剪试验探究了冻融循环作用下CFRP-粘土砖界面在外力作用的破坏过程及破坏形态,得到了界面剥离承载力在循环作用下的变化规律,通过试验测得的应变得到了冻融循环过程中剪应力的发展及分布规律,并给出了考虑冻融循环影响的界面粘结-滑移关系。

1. 实验材料及方法

1.1 试件设计及制作

试验所使用碳纤维增强聚合物复合材料(CFRP)和树脂均为上海滠口实业有限公司生产,其主要性能如表1所示。试验所使用粘土砖的抗压强度平均值为9.28 MPa,吸水率约为17.58%,平均密度约为1 700 kg/m3。试验所用胶粘剂为SKO-碳纤维浸渍胶,其主要性能如表2所示。

表 1 碳纤维增强聚合物复合材料(CFRP)的性能Table 1. Properties of carbon fiber reinforced polymer(CFRP)Sample Tensile

strength/MPaModulus/

GPaElongation/

%Thickness/

mmCFRP ≥3 500 220 1.458 0.111 表 2 粘结树脂的性能Table 2. Properties of impregnation resinTensile shear strength/MPa Tensile strength/GPa Compressive strength/MPa Bending strength/MPa Positive tensile bond strength/MPa Modulus/MPa Elongation/% 24.29 40.12 73.62 72.95 4.44 2 605.7 2.45 本试验选用的粘土砖尺寸为235 mm×115 mm×55 mm,CFRP片材粘贴在粘土砖的一个表面(如图1所示),CFRP粘贴尺寸设计为6种规格,试件的具体参数如表3所示。

表 3 CFRP-粘土砖单剪试验试件参数Table 3. Specimen parameters of CFRP-clay brick specimens for single shear testCFRP size(Length×width)/mm Number of CFRP-clay brick specimen 0 cycle 20 cycles 40 cycles 60 cycles 80 cycles 80×50 5 5 5 5 5 100×80 5 5 5 5 5 80×80 5 5 5 5 5 100×80 5 5 5 5 5 80×100 5 5 5 5 5 100×100 5 5 5 5 5 参照CECS 146—2003[13]中相关要求将CFRP粘贴在粘土砖表面。为防止粘土砖出现局部拉剪破坏,粘结CFRP时在加载端留出30 mm非粘结区,制作完成的试件如图1所示,标准试件示意图如图2所示。

1.2 实验装置及加载程序

冻融循环试验参照GB/T 2542—2012[14]进行。将试件清理干净,在鼓风干燥箱内烘干达到质量要求后,将其在20℃的水中浸泡24 h后取出拭干水分,在冷冻箱内温度降至−15℃时开始计时。每次冷冻时间为3 h,融化2 h,控制冷冻温度为(−17±2)℃,融化水的温度控制在(15±2)℃。冻融循环次数分别取0次、20次、40次、60次和80次。

所有试件的单剪试验均在济南恒思盛大仪器有限公司生产的WDW-50微机控制电子万能试验机上通过自制单剪试验盒进行(如图3(a)所示),通过电脑控制加载速度,由荷载传感器输出CFRP与粘土砖的粘结荷载,CFRP的应变值通过江苏东华DH3816静态应变测试系统采集(如图3(b)所示)。为了使CFRP片材在加载过程中受力均匀,在试件加载端片材上下各粘贴一层30 mm长的CFRP加强片,加强片与试件同宽。加载过程采用位移控制,加载速率为0.5 mm/min。在CFRP试件拉伸前,先施加约为破坏荷载5%的预拉荷载(约为0.4 kN),检查夹具、拉力机和应变采集系统运行是否正常。

2. 试验现象

2.1 冻融循环对CFRP-烧结粘土砖界面的作用效果

试验发现,在经过若干次冻融循环后,CFRP-烧结粘土试件界面发生了较为明显的变化,以粘贴长度×宽度为80 mm×50 mm的单剪试件为例,图4为不同冻融循环作用下CFRP-烧结粘土砖界面破坏情况。可知,室温下试件破坏发生后,CFRP片材上粘有大颗粒粘土砖碎屑(如图4(a)所示);冻融20次和40次的试件破坏后,CFRP片材上粘有的粘土砖颗粒较小(如图4(b)所示);冻融60次后,其中2个试件破坏面较40次严重,界面上粘有大量粘土砖颗粒(如图4(c)所示),另1个试件与冻融40次的形态基本相同;冻融80次后,试件破坏发生在粘土砖,界面发生剪切破坏(如图4(d)所示),说明冻融循环作用对界面粘结性能有不利影响。

表4为粘贴长度×宽度为80 mm×50 mm的CFRP-粘土砖单剪试件试验结果。可以看出,随着冻融次数的增加,界面承载力逐渐降低,60次冻融后减小了约12%,表明冻融循环作用对CFRP-粘土砖的界面承载力有着不利影响。因此,当使用CFRP对粘土砖结构进行加固时,如果是在北方寒冷地区应适当考虑界面粘结折减系数。

表 4 CFRP-粘土砖界面承载力平均值和降低幅度Table 4. Average interfacial bearing capacity and reduction of CFRP-brick specimensCFRP size(Length×width)/mm Interfacial baring capacity/kN Decrease of bearing capacity/% 0 cycle 20 cycles 40 cycles 60 cycles 80 cycles 0 cycle 20 cycles 40 cycles 60 cycles 80 cycles 80×50 7.63 7.52 6.85 5.93 5.34 — 1.44 10.22 22.28 30.01 100×50 7.95 7.88 7.07 6.95 6.43 — 0.88 11.07 12.58 19.12 120×50 8.12 8.15 7.26 7.06 6.65 — –0.37 10.59 13.05 18.10 80×80 12.40 12.00 11.40 11.00 10.30 — 3.23 8.06 11.29 16.94 100×80 13.00 12.80 12.30 11.60 10.50 — 1.54 5.38 10.77 19.23 120×80 13.50 13.20 12.50 11.70 11.00 — 2.22 7.41 13.33 18.52 从试验及文献分析可知,造成界面承载力降低的原因主要有两点:(1)冻融作用导致粘土砖自身材料强度降低而引起CFRP-粘土砖试件粘结强度降低;(2) CFRP-粘土砖之间的胶体面层的粘结性能退化。由于CFRP的特殊构造,其聚合物基体的孔径较小,冻融循环作用下,其孔隙中的水不会冻结[15]。因此,可能是胶体吸水后,在冻融作用下,当溶胀和温度应力共同作用时,界面产生微裂纹,从而导致介质水在界面上冻结产生应力。

2.2 CFRP-粘土砖单剪试验破坏形态

由于本次试验在CFRP-粘土砖试件加载端预留了30 mm非粘结区,所有CFRP-粘土砖试件均是CFRP与粘土砖之间发生界面剥离而破坏的,没有发生CFRP布的撕裂破坏,也没有发生粘土砖的拉剪破坏。

所有CFRP-粘土砖试件剥离破坏是由纤维布传递荷载到粘土砖,从而使粘土砖内部产生的微小裂缝逐渐发展导致的。对于没有经过冻融循环的CFRP-粘土砖试件,其破坏过程是初始加载时除了碳纤维布开始绷紧外,试件并无明显变化,加载端的应变基本呈线性增加;当荷载增加至剥离荷载的40%左右时,可以听到“噼啪声”,加载端附近的应变迅速增加,粘土砖内部微裂缝逐渐开展,试件开始发生局部粘结破坏,总的粘结面积开始减少;随着荷载的进一步增大,应变急速增加,剥离深度也在加大,距离加载端较远处应变片的应变也逐渐增大,说明剥离逐渐向自由端发展。当剩余的粘结面积不足以抵抗荷载时,破坏瞬间发生。而在冻融循环作用下,破坏具有相似性,只是由于粘土砖与胶层之间的界面被削弱、粘土砖材料本身强度降低,开裂速度较未经循环试件更迅速,破坏更突然。

3. 结果与分析

3.1 冻融循环作用下粘土砖孔隙结构损伤

粘土砖为多孔材料,在水冻作用下,粘土砖内部孔隙中的水分子会出现冻结现象,造成孔隙体积膨胀,从而使粘土砖内部出现较大的微孔隙损伤和拉应力,使砖体的缝隙和节理出现加深和扩大;当粘土砖处于融化状态时,粘土砖内部微孔隙会出现迁移现象。当粘土砖在不同温度下进行反复冻结和溶解时,张力使孔隙壁的损伤不断加剧,最终造成砖体损伤。这种损伤反映到CFRP-粘土砖的粘结上,便会出现粘结退化现象。

图5为不同冻融循环作用下粘土砖孔隙度变化。图6为不同冻融循环作用下粘土砖弛豫时间T2谱分布。从图5可以看出,随着冻融循环次数的增加,粘土砖的孔隙度逐渐增大。由图6可知,随着冻融循环次数的增加,T2谱的峰值向右移动,说明大孔径比例增加,冻融使冻胀力逐渐大于颗粒间的粘聚力,造成砖样的孔隙发育和扩展程度加剧。

由CFRP-粘土砖单剪试验结果分析可知,冻融作用下,粘结界面破坏模式的变化与粘土砖微观变化是相统一的(如图4所示)。从单剪试件的破坏过程可以看出,不同冻融次数下,CFRP-粘土砖试件破坏后,粘土砖的表层破坏模式不尽相同。未经冻融的CFRP-粘土砖试件以CFRP粘结区域内靠近加载端部位的粘土砖剪切破坏为主。剪切破坏面被拉出的近似三角形粘土砖块与CFRP粘结较好,其余部位CFRP粘有大量被拉下的粘土砖碎屑与颗粒,破坏面一般在粘土砖基层一侧,深度约为2~5 mm。经过冻融循环的CFRP-粘土砖试件在冻融次数较低时,破坏模式与未受冻融的CFRP-粘土砖试件基本一致,冻融达到40次后,在加载端出现三角破坏区的概率随之减小,破坏以界面剥离破坏为主;当冻融时间达到60次时,所有试件均为剥离破坏,加载端不再出现三角破坏区,在CFRP上粘下的粘土砖层越来越均匀;当冻融时间达到80次时,在加载端出现类似三角区域的破坏情况,说明粘土砖的强度减弱。

3.2 CFRP-粘土砖界面承载力及平均粘结强度

图7为CFRP-粘土砖界面承载力随冻融循环次数的变化曲线。由表4和图7可知,随着冻融循环次数的增加,CFRP-粘土砖界面承载力总体呈下降趋势,而后期的下降速度要快于前期。同时,还可以看到,在CFRP的粘结宽度及冻融循环次数相同的情况下,当粘结长度从80 mm增加至120 mm时,CFRP-粘土砖界面承载力增加的幅度并不大,但当粘结宽度从50 mm增加到80 mm时,CFRP-粘土砖界面承载力却提高了60%~70%,说明CFRP的粘结宽度是影响界面承载力的主要因素之一,与以混凝土为基材的复合材料结果相似[16-18]。

在不考虑相关几何参数因素对试件界面粘结性能的影响下,通过界面粘结强度平均值来考察界面在冻融循环作用下的劣化情况,界面粘结强度平均值计算如下:

τf=PuA (1) 式中:

τf 为试件平均粘结强度(MPa);Pu为CFRP-粘土砖界面承载力(kN);A为粘结面积(mm2)。图8为CFRP-粘土砖界面平均粘结强度曲线。可知,平均粘结强度曲线根据长度和宽度组合分为三组,同一长度不同宽度的图形在位置上比较接近,再次证明粘结宽度对承载力的贡献较大,即只要保证粘结长度足够,CFRP-粘土砖试件的平均粘结强度基本和粘结宽度呈正相关关系。

3.3 CFRP-粘土砖界面剪应力的分布规律

由于试验无法得到粘结界面上任意点的应变值,因此在计算中以两个相邻应变片之间的平均剪应力作为界面剪应力。由于CFRP非常薄,可以假定CFRP在轴向力方向上的应力

σf 在横截面内是均匀分布的,并假定相邻两应变片间的应变线性分布,现取长度为微元长度dx的CFRP单元作为对象进行研究,CFRP-烧结粘土砖界面单元体剪应力分布如图9所示。由力的平衡条件可以得到粘结剪应力的计算公式为

τ(x)=dFbfdx=dσfdxtf=Eftfdεxdx=Eftfεi+1−εiΔxi (2) 式中:F为界面承载力;

bf 、tf 、Ef 和εi 分别为CFRP片材的宽度、厚度、弹性模量和应变。由于各个试件剪应力的分布具有一定相似性,因此以粘贴长度×宽度为80 mm×50 mm的单剪试件为例,其不同冻融循环作用下的剪应力分布如图10所示。可知,当荷载较小时,剪应力的峰值出现在加载端,而粘结剪应力只分布在距加载端20 mm左右的范围内;当荷载逐渐增加时,加载端附近的剪应力也随之逐渐增加,增加到峰值后剪应力开始向远端传递,此时的剪应力集中分布在一定区域内,区域外剪应力几乎为零,这一区域即为有效粘结区域,该区域的长度称为“有效粘结长度”,本试验中有效粘结长度基本保持不变,大约为60~80 mm,且其不随CFRP粘结尺寸及冻融循环次数而变化,说明随着荷载的增加,有效粘结区域在破坏过程中会以近似不变的长度由加载端向自由端平行移动,从而使剥离区域逐渐增加,直至试件破坏,与CFRP-混凝土试件的研究结果一致[19-20]。

3.4 CFRP-粘土砖界面粘结-滑移本构关系

为建立准确可靠的粘结-滑移曲线,需要进一步了解界面剥离机制及破坏过程中粘结剪应力与滑移值的变化情况,即

ττmax−ss0 曲线。其中,滑移值为CFRP与粘土砖的位移差,计算如下:s(x)=s(0)+∫x0ε(u)du (3) 式中:

s(0) 为最大剪应力对应的滑移值;s(x) 为CFRP上任一点滑移值;ε 为应变值。关于粘结-滑移关系,目前国内外学者对纤维增强聚合物复合材料(FRP)-混凝土界面深入研究较多,而对于FRP-粘土砖的研究鲜见报道。粘结-滑移模型的提出有试验方法、有限元模拟方法、理论推导方法等,图11为几种典型粘结-滑移关系模型曲线。由图11(a)可以看到,直角三角形模型属于早期模型,把界面近似看做弹性体,缺点是忽略了界面在加载后期的软化行为;由图11(b)~11(d)可知,粘结-滑移关系模型均为两阶段曲线模型,曲线由上升段和下降段组成,目前对CFRP-混凝土界面的研究大多采用该类型曲线模型。通过对比发现,图11(d)的Popovics模型比较适合本试验数据,如下式:

ττmax (4) 通过式(4)拟合效果较好(拟合系数n=3.032),可以较准确地表示CFRP-粘土砖面粘结-滑移的有关特征,如图12所示。可以看出,CFRP-粘土砖界面粘结-滑移曲线分为上升段和下降段,上升段为强化阶段,下降段为软化阶段。开始加载时,界面粘结剪应力和滑移均不大,粘结-滑移曲线近似呈线性关系,试件处于弹性状态;随着粘结剪应力逐步增大,粘结-滑移曲线表现出非线性,此时滑移量增加速度较剪应力增加速度要快,当界面逐渐达到最大剪应力,界面的粘结不足以抵抗剪应力时,试件开始出现滑移;当粘结剪应力增大至最大后,曲线进入下降段,此时剪应力下降速度和滑移量增加的速度均较快,且滑移量增加的速度越来越大,当粘结应力几乎为零时,滑移量达到最大值,此时CFRP和粘土砖在界面处完全剥离。对比Popovics曲线和实验数据可以发现,Popovics模型可以较好地描述CFRP-粘土砖界面粘结-滑移关系,上升段试验数据点几乎与Popovics模型曲线重合,下降段的试验数据分布于Popovics模型曲线两侧,但偏差较小,表明采用Popovics模型来描述CFRP-粘土砖界面的粘结-滑移本构关系是较准确的。

4. 结 论

分析了冻融循环作用和粘结尺寸对CFRP-粘土砖界面承载力及粘结强度的影响,通过试验数据和理论比较,建立了考虑冻融循环影响下的CFRP-粘土砖界面粘结-滑移模型。

(1)在冻融循环作用下,CFRP-粘土砖界面的破坏模式是由剪切破坏转变为粘结剥离破坏,剥离是从CFRP加载端开始逐渐向自由端发展。相对于长度,CFRP的宽度对试件界面承载力影响更为显著。

(2)随着冻融循环次数的增加,CFRP-粘土砖界面承载力总体呈下降趋势,而后期的下降速度要快于前期。

(3) CFRP-粘土砖界面粘结剪应力分布曲线具有相似性,当荷载水平逐渐增加,剪应力也随之逐渐增大,并从加载端向自由端传递,且所有剪应力集中分布在一定的“有效粘结区域”内,而区域外的剪应力几乎为零,有效粘结区域的长度约为60~80 mm,且与冻融循环次数无关。

(4) CFRP-粘土砖界面粘结-滑移关系有明显的上升段和下降段,上升段为强化阶段,下降段为软化阶段,Popovics模型可以很好地描述CFRP-粘土砖的界面粘结-滑移关系。

-

图 5 NAGC和RBGC弹性模量和抗压强度的关系

Figure 5. Relationship between elastic modulus and compressive strength of NAGC and RBGC

RBPC—Recycled brick aggregate ordinary portland cement concrete; LAGC—Lightweight aggregate geopolymer concrete; E—Elastic modulus; fc—Axial compressive strength; R2—Coefficient of determination

图 9 NAGC和RBGC温度对相对抗压强度、弹性模量、峰值应变和劈拉强度的影响

Figure 9. Effect of temperature on the relative compressive strength, elastic modulus, peak strain and splitting strength of NAGC and RBGC

EcT , εpT, fstT—Elastic modulus, peak strain and splitting tensile strength of the concrete after high temperature; Ec , εp, fst—Elastic modulus, peak strain and splitting tensile strength of the concrete at room temperature; NOPC—Normal ordinary portland cement concrete

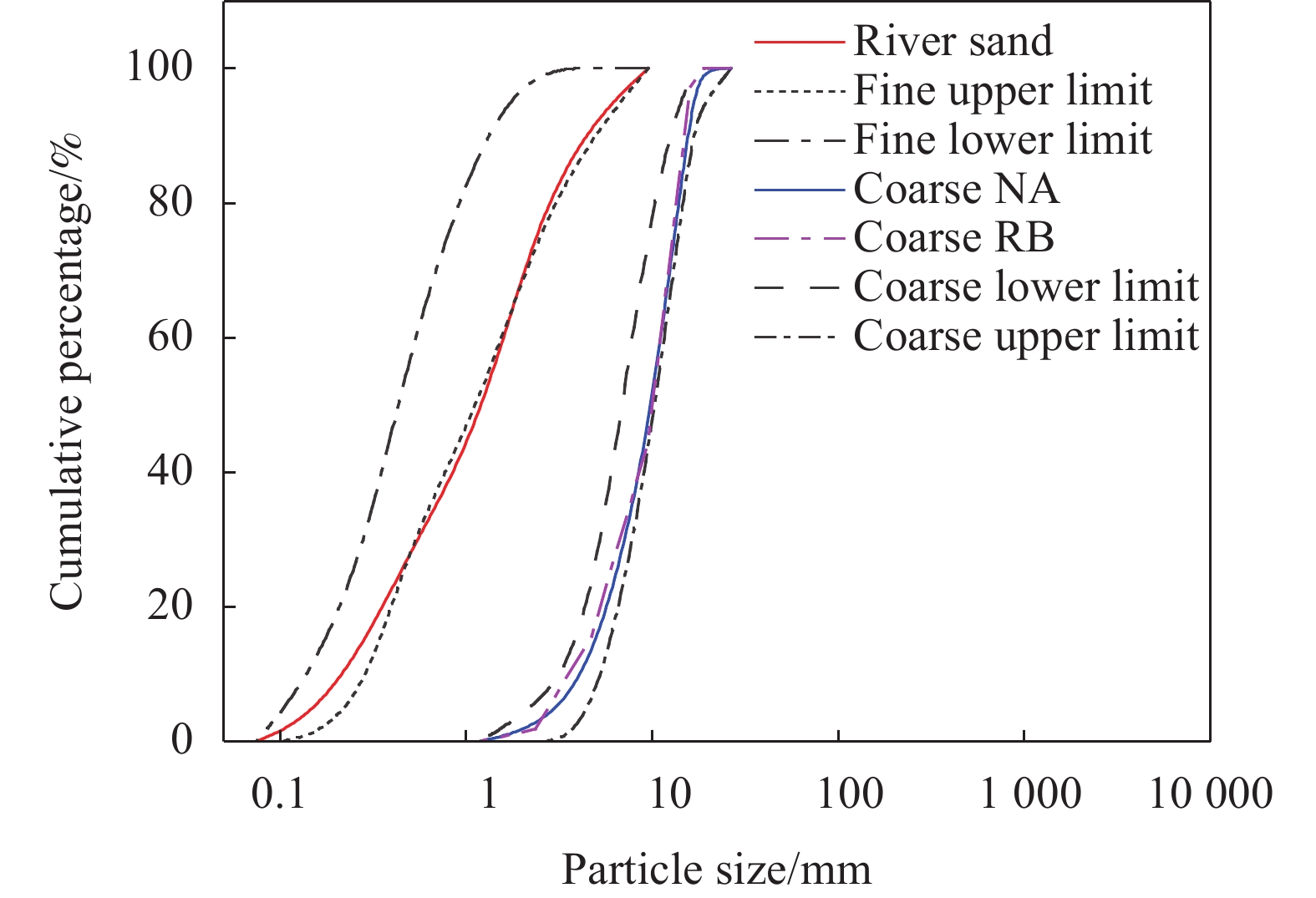

表 1 粗骨料和细骨料的物理性能

Table 1 Physical properties of coarse and fine aggregates

Type Particle

size/mmSpecific

gravity24 h water

absorption/%Fineness

modulusCrush

index/%Cylinder compressive

strength/MPaNatural river sand ≤5 2.67 1.2 2.6 — — Limestone 5-20 2.64 0.83 — 7.9 — Recycled brick aggregate 5-20 1.74 10.92 — 21.3 4.7 表 2 配合比设计和力学性能

Table 2 Mix proportion design and mechanical properties

No. Mix proportion/(kg·m−3) Dry density/

(kg·m−3)Elastic

modulus/GPafc/

MPaBinder SS SH Sand Coarse

aggregateAdded

waterSP NAGC-1 300 188 75 568 1224 35.5 2.5 2231 21.58 26.10 NAGC-2 400 188 75 504 1224 35.5 4.5 2244 25.17 39.13 NAGC-3 500 188 75 450 1224 35.5 5.5 2287 27.60 50.29 RBGC-1 300 188 75 568 1105 73.5 3.5 1893 11.03 21.23 RBGC-2 400 188 75 504 1105 73.5 4.5 1915 13.38 29.97 RBGC-3 500 188 75 450 1105 73.5 5.5 1931 15.39 34.50 Notes:GC—Geopolymer concrete; Numbers 1 to 3 represent the target strength from lowest to highest; fc—Compressive strength of NAGC and RBGC; SS—Sodium silicate; SH—Sodium hydroxide; SP—Superplasticizer. 表 3 NAGC和RBGC抗压强度、弹性模量、峰值应变和劈拉强度拟合公式

Table 3 Fitting formulas of compressive strength, elastic modulus, peak strain and splitting tensile strength of NAGC and RBGC

Properties NAGC RBGC Compressive strength \dfrac{{{f_{{\text{cT}}}}}}{{{f_{\text{c}}}}} = \dfrac{1}{{1 + 13.75{{(T/1000)}^{3.70}}}} \dfrac{{{f_{{\text{cT}}}}}}{{{f_{\text{c}}}}} = - 0.84(T/1000) + 1.02 Elastic modulus \dfrac{{{E_{{\text{cT}}}}}}{{{E_{\text{c}}}}} = \dfrac{1}{{1 + 50.40{{(T/1000)}^{4.03}}}} \dfrac{{{E_{{\text{cT}}}}}}{{{E_{\text{c}}}}} = - 1.03(T/1000) + 1.02 Peak strain \dfrac{\varepsilon_{\text{pT}}}{\varepsilon_{\text{p}}}=1+4.20(T/1000)^{2.78} \dfrac{\varepsilon_{\text{pT}}}{\varepsilon_{\text{p}}}=1+1.16(T/1000)^{1.76} Splitting tensile strength \dfrac{{{f_{{\text{stT}}}}}}{{{f_{{\text{st}}}}}} = - 1.13(T/1000) + 1.00 \dfrac{f_{\text{stT}}}{f_{\text{st}}}=\left\{\begin{gathered}-0.69(T/1000)+1.02\text{, 25}\mathrm{^{\circ}C\leqslant\mathit{{T}}\leqslant400^{\circ}C} \\ -1.52(T/1000)+1.36\text{, 400}\mathrm{^{\circ}C < \mathit{{T}}\leqslant800^{\circ}C} \\ \end{gathered}\right. 表 4 NAGC和RBGC回归参数α、β和n

Table 4 Regression parameters α, β and n of NAGC and RBGC

Type Parameter Temperature/℃ 25 200 400 600 800 NAGC n 1.50 1.48 0.99 0.95 1.06 α 2.24 2.09 2.33 3.24 2.94 RBGC n 5.47 4.47 3.33 6.39 5.14 β 44.09 9.27 — — — α — — 7.54 5.73 4.62 -

[1] 孙杰, 陈国珍, 吕康琪, 等. 橡胶地聚物混凝土力学性能及阻尼特性试验研究[J]. 复合材料学报, 2022, 39(11): 5321-5332. DOI: 10.13801/j.cnki.fhclxb.20211201.002 SUN Jie, CHEN Guozhen, LYU Kangqi, et al. Experimental study on mechanical properties and damping characteristics of rubber geopolymer concrete[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5321-5332(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20211201.002

[2] 丁兆洋, 苏群, 李明泽, 等. 水玻璃模数对地聚物再生混凝土力学性能的影响[J]. 建筑材料学报, 2023, 26(1): 61-70. DOI: 10.3969/j.issn.1007-9629.2023.01.009 DING Zhaoyang, SU Qun, LI Mingze, et al. Effect of modulus of water glass on mechanical properties of geopolymer recycled aggregate concrete[J]. Journal of Building Materials, 2023, 26(1): 61-70(in Chinese). DOI: 10.3969/j.issn.1007-9629.2023.01.009

[3] 万聪聪, 姜天华. 高性能地聚物混凝土早期收缩特性[J]. 复合材料学报, 2024, 41(2): 952-964. WAN Congcong, JIANG Tianhua. Early shrinkage characteristics of high performance geopolymer concrete[J]. Acta Materiae Compositae Sinica, 2024, 41(2): 952-964(in Chinese).

[4] MAHMOOD A H, FOSTER S J, CASTEL A. Effects of mixing duration on engineering properties of geopolymer concrete[J]. Construction and Building Materials, 2021, 303: 124449.

[5] YANG Y M, FANG S, FENG W H, et al. Flexural and compressive performance of BFRP-reinforced geopolymer sea-sand concrete beams and columns: Experimental and analytical investigation[J]. Composite Structures, 2023, 318: 117089. DOI: 10.1016/j.compstruct.2023.117089

[6] CHEN Z, YU J M, NONG Y M, et al. Beyond time: Enhancing corrosion resistance of geopolymer concrete and BFRP bars in seawater[J]. Composite Structures, 2023, 322: 117439. DOI: 10.1016/j.compstruct.2023.117439

[7] 高丹盈, 景嘉骅, 周潇. 混杂纤维增强再生砖骨料混凝土增强机制与抗压性能计算方法[J]. 复合材料学报, 2018, 35(12): 3441-3449. DOI: 10.13801/j.cnki.fhclxb.20180516.003 GAO Danying, JING Jiahua, ZHOU Xiao. Reinforcing mechanism and calculation method of compressive behavior of hybrid fiber reinforced recycled brick aggregates concrete[J]. Acta Materiae Compositae Sinica, 2018, 35(12): 3441-3449(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20180516.003

[8] 朱超, 赵文韬, 余伟航, 等. 再生砖混骨料混凝土基本力学性能与本构模型[J]. 复合材料学报, 2024, 41(2): 898-910. ZHU Chao, ZHAO Wentao, YU Weihang, et al. Basic mechanical properties and constitutive model of recycled brick-concrete aggregate[J]. Acta Materiae Compositae Sinica, 2024, 41(2): 898-910(in Chinese).

[9] ZHENG Y Q, DU J T, ZHENG L Y, et al. Compressive behavior of geopolymer recycled brick aggregate concrete confined by steel tubes[J]. Journal of Building Engineering, 2023, 70: 106350. DOI: 10.1016/j.jobe.2023.106350

[10] 李升涛, 陈徐东, 张伟, 等. 基于长江下游超细疏浚砂的碱激发矿渣混凝土力学性能[J]. 复合材料学报, 2022, 39(1): 335-343. DOI: 10.13801/j.cnki.fhclxb.20210419.003 LI Shengtao, CHEN Xudong, ZHANG Wei, et al. Mechanical properties of alkali activated slag concrete with ultra fine dredged sand from Yangtze River[J]. Acta Materiae Compositae Sinica, 2022, 39(1): 335-343(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20210419.003

[11] REN W B, XU J Y, BAI E L. Strength and ultrasonic characteristics of alkali-activated fly ash-slag geopolymer concrete after exposure to elevated temperatures[J]. Journal of Materials in Civil Engineering, 2016, 28(2): 4015124. DOI: 10.1061/(ASCE)MT.1943-5533.0001406

[12] KHATTAB M, HACHEMI S, AL AJLOUNI M F. Evaluating the physical and mechanical properties of concrete prepared with recycled refractory brick aggregates after elevated temperatures' exposure[J]. Construction and Building Materials, 2021, 311: 125351. DOI: 10.1016/j.conbuildmat.2021.125351

[13] 中华人民共和国住房和城乡建设部. 混凝土物理力学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国建筑工业出版社, 2019. Ministry of Housing and Urban-Rural Development of the People's Republia of China. Standard for test methods of concrete physical and mechanical properties: GB/T 50081—2019[S]. Beijing: China Architecture & Building Press, 2019(in Chinese).

[14] Comite Euro-Inernational Du Beton. CEB-FIP model code 1990: CEB-FIP MC90[S]. Lausanne: Thomas Telford Ltd., 1993.

[15] DABBAGHI F, DEHESTANI M, YOUSEFPOUR H, et al. Residual compressive stress-strain relationship of lightweight aggregate concrete after exposure to elevated temperatures[J]. Construction and Building Materials, 2021, 298: 123890.

[16] SOFI M, VAN DEVENTER J S J, MENDIS P A, et al. Engineering properties of inorganic polymer concretes (IPCs)[J]. Cement and Concrete Research, 2007, 37(2): 251-257. DOI: 10.1016/j.cemconres.2006.10.008

[17] LEE N K, LEE H K. Setting and mechanical properties of alkali-activated fly ash/slag concrete manufactured at room temperature[J]. Construction and Building Materials, 2013, 47: 1201-1209. DOI: 10.1016/j.conbuildmat.2013.05.107

[18] UDDIN M T, MAHMOOD A H, KAMAL M R I, et al. Effects of maximum size of brick aggregate on properties of concrete[J]. Construction and Building Materials, 2017, 134: 713-726. DOI: 10.1016/j.conbuildmat.2016.12.164

[19] ISLAM A, ALENGARAM U J, JUMAAT M Z, et al. Engineering properties and carbon footprint of ground granulated blast-furnace slag-palm oil fuel ash-based structural geopolymer concrete[J]. Construction and Building Materials, 2015, 101: 503-521. DOI: 10.1016/j.conbuildmat.2015.10.026

[20] American Concrete Institute Committee. Building code requirements for structural concrete and commentary: ACI 318[S]. Michigan: American Concrete Institute, 2014.

[21] KONG D L Y, SANJAYAN J G. Effect of elevated temperatures on geopolymer paste, mortar and concrete[J]. Cement and Concrete Research, 2010, 40(2): 334-339. DOI: 10.1016/j.cemconres.2009.10.017

[22] ANDIÇ-ÇAKıR Ö, HıZAL S. Influence of elevated temperatures on the mechanical properties and microstructure of self consolidating lightweight aggregate concrete[J]. Construction and Building Materials, 2012, 34: 575-583. DOI: 10.1016/j.conbuildmat.2012.02.088

[23] ABDULKAREEM O A, BAKRI A M A, KAMARUDIN H, et al. Effects of elevated temperatures on the thermal behavior and mechanical performance of fly ash geopolymer paste, mortar and lightweight concrete[J]. Construction and Building Materials, 2014, 50: 377-387. DOI: 10.1016/j.conbuildmat.2013.09.047

[24] European Committee for Standardization. Eurocode 4: Design of composite steel and concrete structures, part 1-2: Genal rules-structural fire design: EN 1994-1-2[S]. London: Thomas Telford Ltd., 2005.

[25] American Concrete Institute Committee. Code requirements for determining fire resistance of concrete and masonry construction assemblies: ACI/TMS 216.1M-14[S]. Michigan: American Concrete Institute, 2014.

[26] CHANG Y F, CHEN Y H, SHEU M S, et al. Residual stress-strain relationship for concrete after exposure to high temperatures[J]. Cement and Concrete Research, 2006, 36(10): 1999-2005. DOI: 10.1016/j.cemconres.2006.05.029

[27] LIU H B, LI Q Y, WANG P H. Assessment of the engineering properties and economic advantage of recycled aggregate concrete developed from waste clay bricks and coconut shells[J]. Journal of Building Engineering, 2023, 68: 106071. DOI: 10.1016/j.jobe.2023.106071

[28] SHAIKH F U A, HOSAN A. Mechanical properties of steel fibre reinforced geopolymer concretes at elevated temperatures[J]. Construction and Building Materials, 2016, 114: 15-28. DOI: 10.1016/j.conbuildmat.2016.03.158

[29] ALBIDAH A, ALQARNI A S, ABBAS H, et al. Behavior of Metakaolin-based geopolymer concrete at ambient and elevated temperatures[J]. Construction and Building Materials, 2022, 317: 125910. DOI: 10.1016/j.conbuildmat.2021.125910

[30] JUNAID M T, KHENNANE A, KAYALI O. Stress-strain behaviour of alkali activated fly ash concrete at elevated temperatures[C]//2nd International Conference on Advances in Cement and Concrete Technology in Africa. Tanzania: BAM Federal Institute for Materials Research, 2016.

[31] ZHANG H Y, KODUR V, WU B, et al. Effect of temperature on bond characteristics of geopolymer concrete[J]. Construction and Building Materials, 2018, 163: 277-285. DOI: 10.1016/j.conbuildmat.2017.12.043

[32] TURKEY F A, BEDDU S B, AHMED A N, et al. Effect of high temperatures on the properties of lightweight geopolymer concrete based fly ash and glass powder mixtures[J]. Case Studies in Construction Materials, 2022, 17: e01489.

-

目的

随着可持续发展的需求,开发新型绿色建材迫在眉睫。再生砖骨料地聚物混凝土(RBGC)是一种极具潜力的可持续建筑材料,但高温前后RBGC性能的相关研究较少。本文针对再生砖骨料混凝土(RBGC)和普通骨料地聚物混凝土(NAGC)的高温前后力学性能进行系统研究,为RBGC的工程应用探索理论基础。

方法对常温条件下的RBGC和NAGC试块进行强度测试,分别测出RBGC和NAGC的轴压应力-应变关系曲线、弹性模量和劈拉强度。高温试验采用工业电热炉进行,高温试验温度分别为200℃、400℃、600℃和800℃。冷却后,立即测试试块的残余性能。使用热膨胀仪在20至800℃的温度范围内,测量地聚物浆体、石灰石骨料和再生砖骨料的热膨胀应变。

结果常温下,NAGC和RBGC单轴压缩的破坏特征相似,即试块均为对角剪切破坏。而劈拉试验结果表明,对NAGC,劈裂面多穿过粗骨料和砂浆体之间的界面区域,粗骨料无断裂现象;对RBGC,劈裂面直接穿过粗骨料,再生砖骨料多发生断裂,劈裂面平整。从不同胶凝材料用量NAGC和RBGC的受压应力-应变曲线,可以发现,NAGC和RBGC整体应力-应变行为与水泥混凝土没有太大区别。NAGC强度等级随着胶凝材料用量的提高而增加,破坏时变形相对较小,刚度大,脆性随着强度的增加而变大。对于RBGC,其强度随着胶凝材料用量的增加变化不大,与具有同样胶凝材料用量的NAGC相比,RBGC的应力-应变曲线上升段线性段更长,峰后软化段应力下降速度更快。高温后,NAGC和RBGC试块单轴压缩均表现出脆性破坏,以对角剪切破坏的形式发生。随着温度升高,NAGC和RBGC试块表面裂纹逐渐增多,试块逐渐变得酥软。与NAGC相比,RBGC加热时温度梯度低,剥落少,破坏时试块完整性较好。而对于劈拉试验,低于400°C时,NAGC和RBGC试块的破坏形态与常温时无明显区别。在高于600°C时,NAGC和RBGC试块均变得酥软。随着温度升高,NAGC试块劈拉面更加平整,而RBGC试块在所有温度等级下劈拉面均平整。热膨胀系数实验结果得出,地聚物砂浆与烧结页岩陶粒、再生砖骨料等轻骨料的温度膨胀系数接近。而与普通骨料地聚物混凝土相比,高温下砖骨料地聚物混凝土内部温差梯度较低。对于高温后力学性能试验结果得出随着经历温度的升高,两种地聚物混凝土劈拉强度、抗压强度与弹性模量减小,峰值压应变增大,其刚度下降趋势高于强度的下降趋势。升温至800℃时,RBGC强度和刚度损失分别比NAGC小22.1%和18.3%。最后建立了的NAGC和RBGC应力-应变全曲线的数学表达式,通过计算可得出,NAGC和RBGC的R均值分别为0.9774和0.9631,MSE均值分别为0.0175和0.0283,MAE均值分别0.1337和0.1642,说明本文所提出的本构模型能够较好地预测高温后两种地聚物混凝土的单轴压缩应力应变响应。

结论常温下随着胶凝材料的增加,再生砖骨料地聚物混凝土(RBGC)抗压强度和弹性模量分别增加,其变化幅度均小于普通骨料地聚物混凝土(NAGC),应力-应变曲线上升段线性段更长,峰后软化段应力下降速度更快。随着经历温度的升高,两种地聚物混凝土劈拉强度、抗压强度与弹性模量减小,峰值压应变增大,其刚度下降趋势高于强度的下降趋势。由于砖骨料温度膨胀系数接近地聚物砂浆,且高温下RBGC内部温度梯度小,RBGC表现出更好的耐高温能力。本文建立的NAGC和RBGC应力-应变全曲线的数学表达式,适用于天然石灰石骨料和再生砖骨料制作的NAGC和RBGC高温前后本构关系的数值模拟。

-

地聚物混凝土是用具有火山灰活性的硅铝酸盐类矿物与碱性激发剂反应而形成的一种无水泥建筑材料,其原料主要为工业废料,具有环保、力学性能好、黏结性能强及早强快硬等优势。而再生砖骨料往往呈现表观密度低、吸水率大、压碎指标高等特性,制约了废弃黏土砖在再生混凝土构件中的应用。粉煤灰-高炉矿渣复合基地聚物胶凝材料内部结构致密,可以起到更好强化再生砖骨料的效果,所以预计再生砖骨料地聚物混凝土有着更广阔的应用前景。

高温可以使地聚物其进一步发生地质聚合反应,地聚物胶凝材料相较于水泥胶凝材料耐高温能力更强。再生砖骨料的导热系数和热膨胀系数较低,孔隙率大,具有更好的耐火性能。然而尚未见到高温作用后再生砖骨料地聚物混凝土受压性能的相关研究。

本文首先比较了常温下不同胶凝材料用量下砖骨料地聚物混凝土(RBGC)和普通骨料地聚物混凝土(NAGC)的力学性能指标,探究了胶凝材料用量和粗骨料类型对地聚物混凝土轴压应力-应变全曲线的影响;其次提出了历经不同温度等级(25、200、400、600、800°C)后RBGC和NAGC的力学性能指标计算模型。发现与普通骨料地聚物混凝土(NAGC)相比,砖骨料地聚物混凝土(RBGC)具有更好的耐高温能力。最后,通过修正下降段形状参数,提出了高温前后RBGC和NAGC的应力-应变关系模型,模型与试验结果吻合较好。

Comparison of proposed stress-strain relationships with experimental results

下载:

下载: