Design and performance validation of a zero-stiffness vibroisolating metamaterialbased on machine learning

-

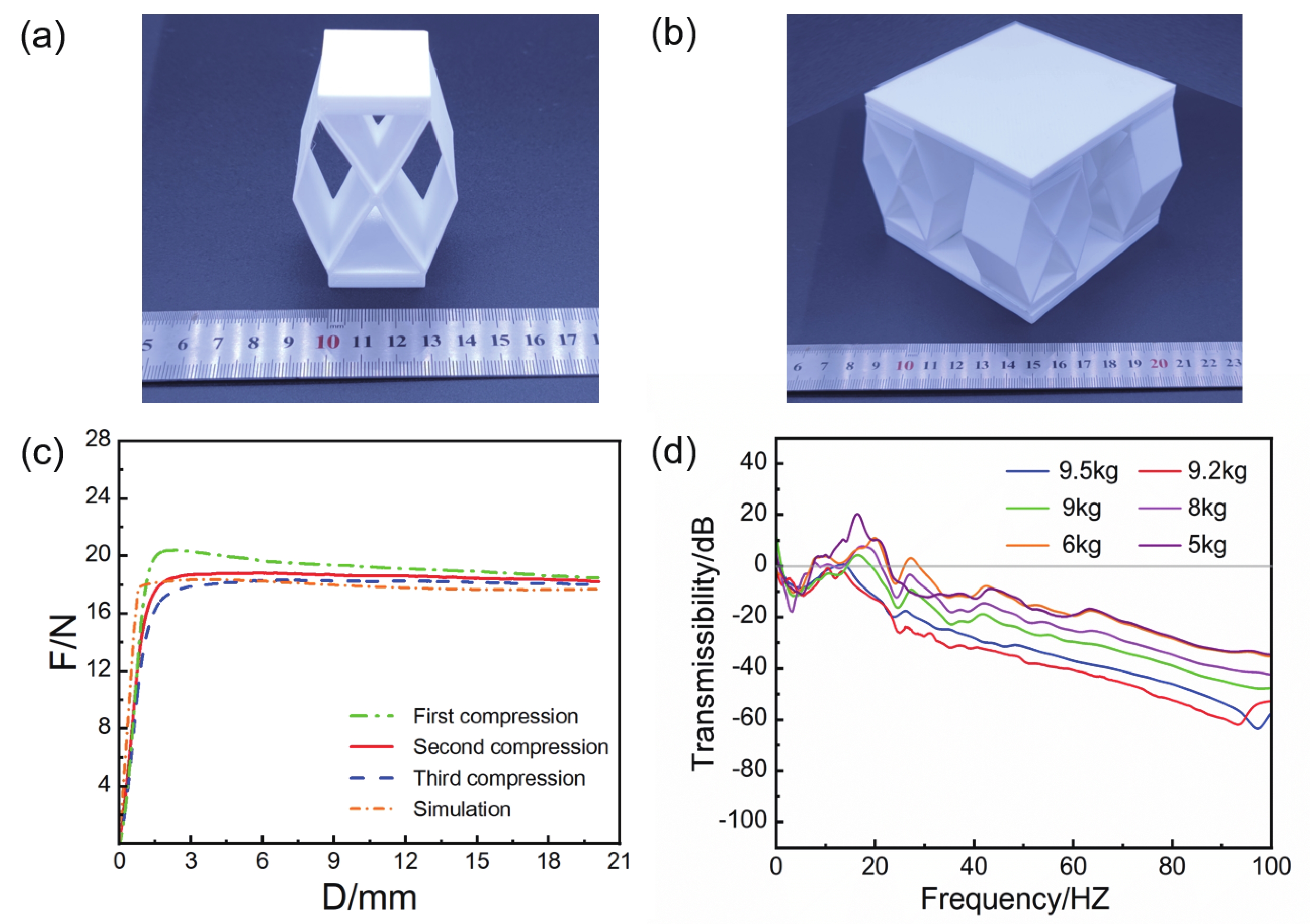

摘要: 准零刚度隔振器作为国内外主流的非线性隔振器,凭借其高静态刚度和低动态刚度力学特性,在机械工程领域应用较多,但近零刚度范围窄、后期组装繁琐等问题限制了其隔振的应用范围,通过结构设计使近零刚度范围增大,且能通过一体化成型技术快速制备方面的研究仍较稀缺。本文基于能量屏蔽理论设计了一种新型零刚度单元结构,通过将外界输入能量循环于超材料内部,从而屏蔽外界对隔振对象的能量输入,达到隔振效果。该研究首先设计出具有优化潜力的初始结构,然后使用机器学习与有限元分析结合的方法对初始结构进行优化,自动搜索出最优的超材料结构参数,且最优结构满足零刚度性能设计要求,之后使用3D打印对最优结构单元及2×2阵列结构进行一体化制造。并对样件进行静态实验验证,实验结果表明:在静态压缩过程中,该结构的等效刚度在大范围内近似于0。又对阵列结构进行动态振动实验,结果得出,阵列结构在23 mm振幅下0.1~100 Hz范围内,9.2 kg载荷隔振性能最优,最小传递率可达−61 dB,载荷越接近9.2 kg隔振性能越好。该结构具有结构简单、一体化成型等优势,可应用于列车座椅、康复医疗设备、精密仪器保护及微重力环境等领域下的隔振。Abstract: The quasi-zero stiffness isolator, as a mainstream nonlinear isolator both domestically and internationally, was widely applied in the field of mechanical engineering due to its high static stiffness and low dynamic stiffness mechanical characteristics. However, limitations such as a narrow range of quasi-zero stiffness, complicated post-assembly procedures, etc., had restricted its application scope in vibration isolation. Through structural design, the range of quasi-zero stiffness could be expanded, and research on rapid preparation through integrated molding technology was still relatively scarce. In that study, a novel zero stiffness unit structure was designed based on the theory of energy shielding. By circulating external input energy within the metamaterial, the energy input from the external environment to the isolated object was shielded, thus achieving the isolation effect. The research first designed an initial structure with optimization potential, then used a combination of machine learning and finite element analysis to optimize the initial structure, automatically searching for the optimal parameters of the metamaterial structure. The optimal structure met the requirements of zero stiffness performance design. Subsequently, 3D printing was employed to manufacture the optimal structural unit and a 2×2 array structure in an integrated manner. Static experiments were conducted on the samples for validation. The experimental results show that the equivalent stiffness of this structure approximates zero over a wide range during static compression. Dynamic vibration experiments were also conducted on the array structure. The results reveal that within the range of 0.1 Hz to 100 Hz and under a 23 mm amplitude, the array structure exhibites its best isolation performance with a 9.2 kg load, achieving a minimum transmissibility of up to −61 dB. The closer the load is to 9.2 kg, the better the isolation performance. This structure offers advantages such as simplicity in design, integrated molding, etc., and can be applied in vibration isolation for fields such as train seats, rehabilitation medical equipment, protection of precision instruments, and microgravity environments.

-

Keywords:

- metamaterial /

- machine learning /

- zero-stiffness /

- vibration isolation /

- 3D printing

-

-

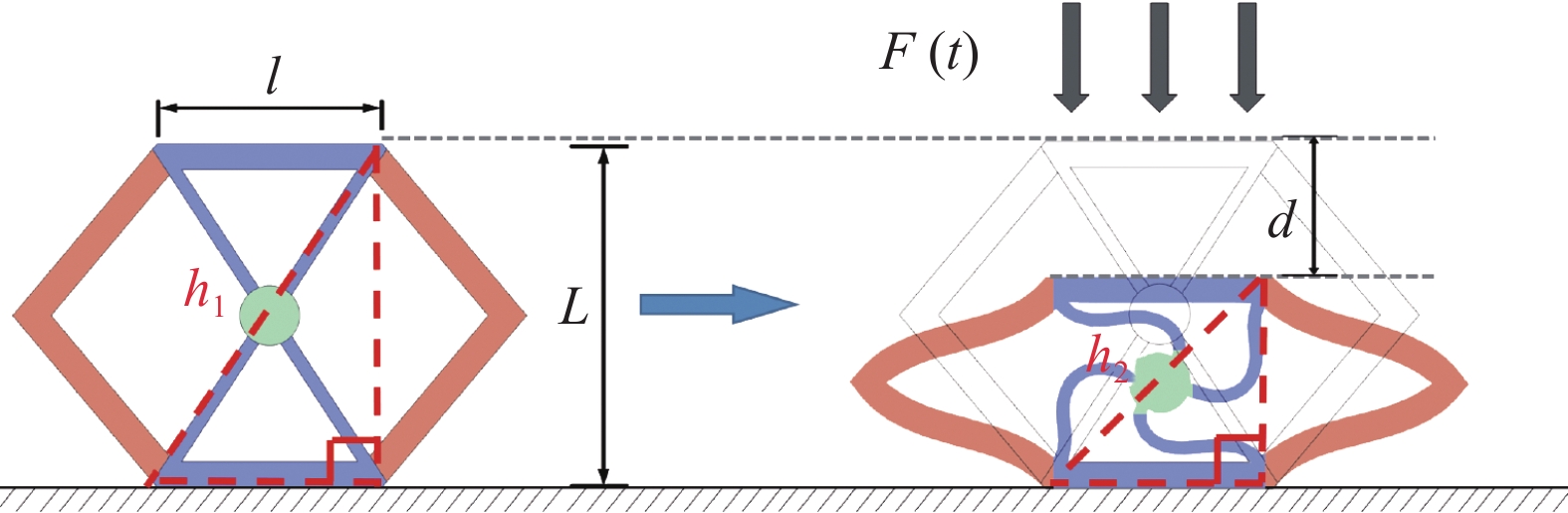

图 4 初始结构压缩位移示意图

h1—Length of the thin plate before buckling; h2—Length of the plate after buckling; L—Height of the vibration isolation unit structure before compression; t—Compression displacement; F(t)—The force applied to the upper surface

Figure 4. Schematic diagram of the initial structure's compression displacement

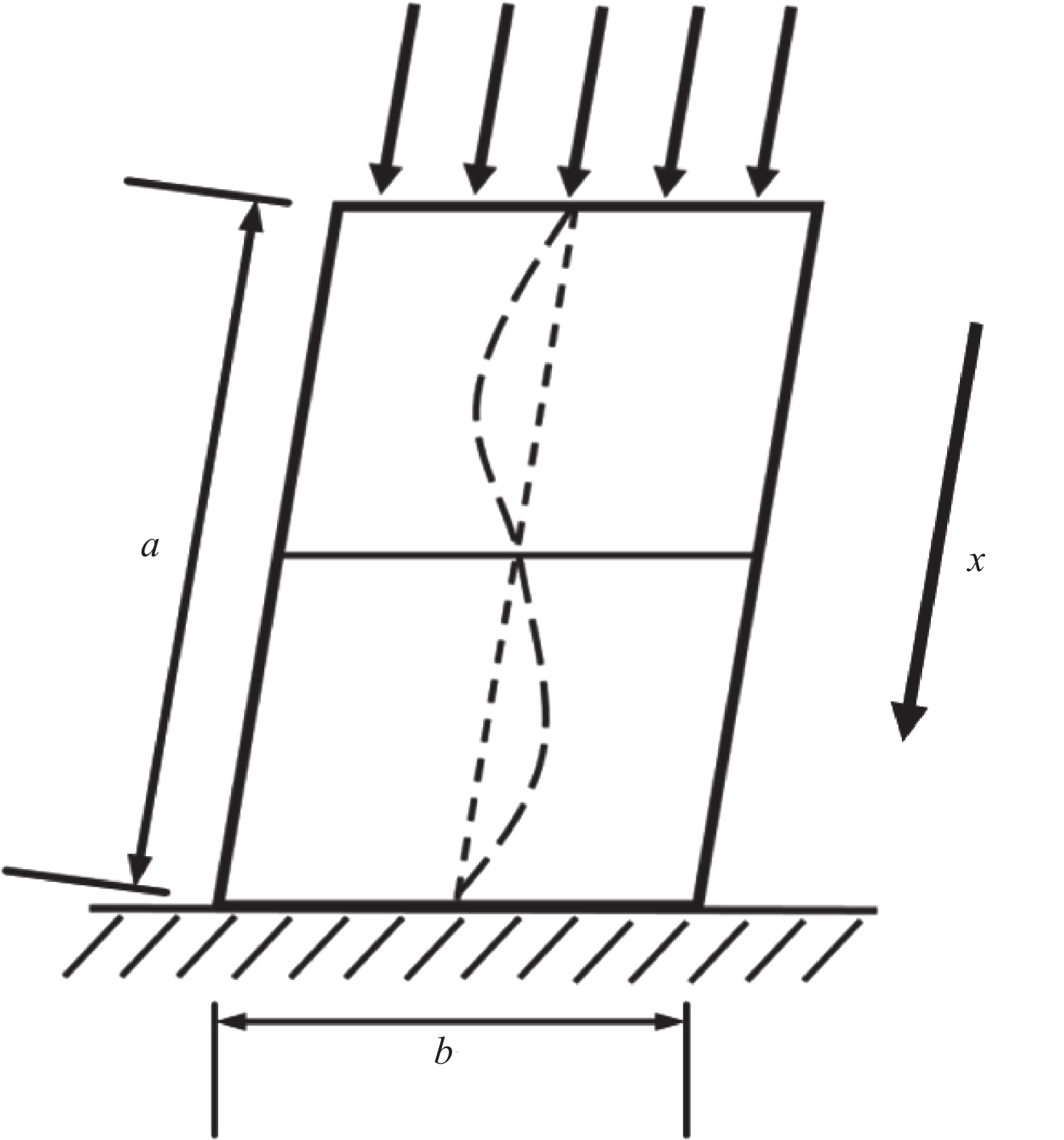

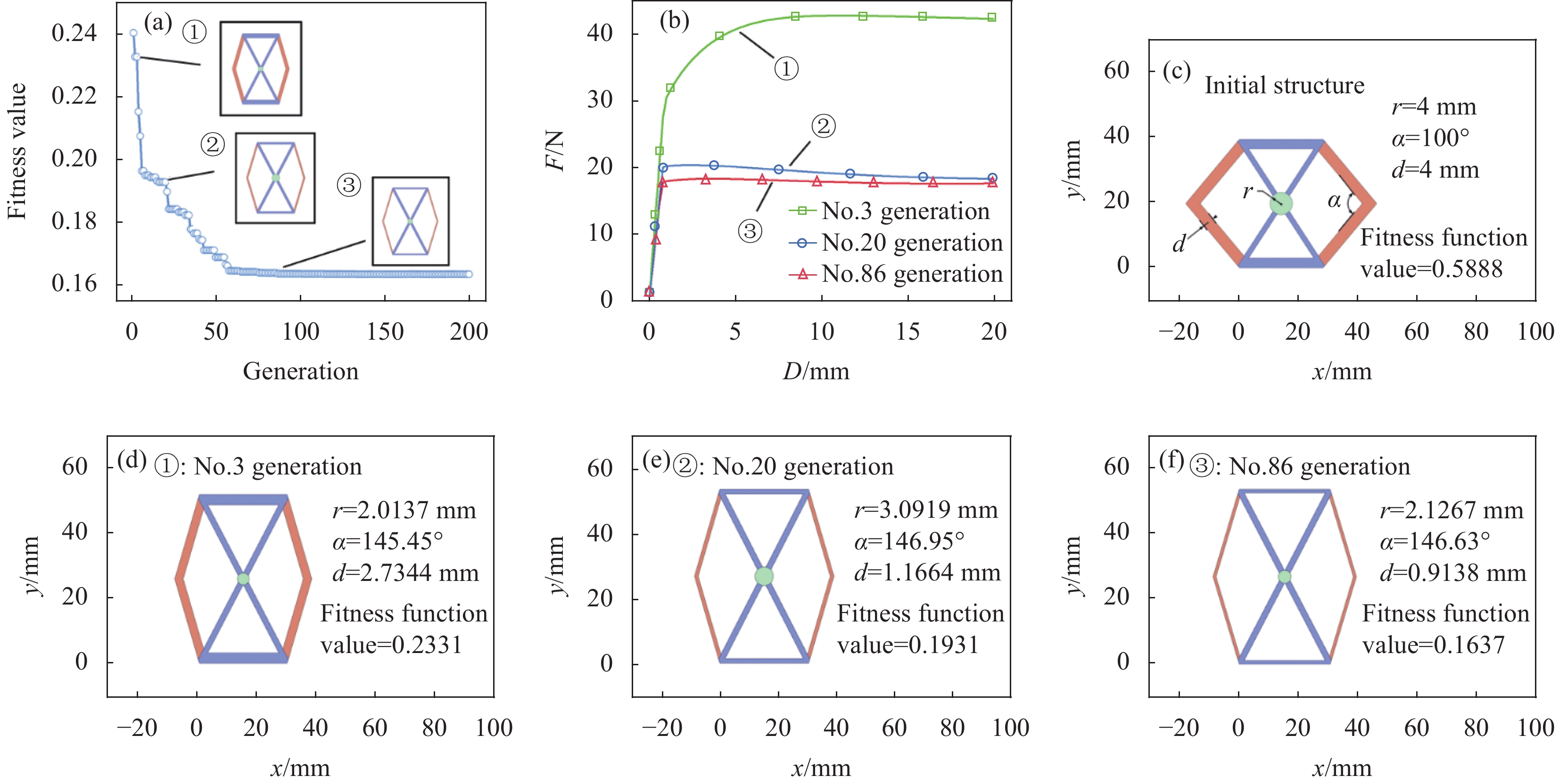

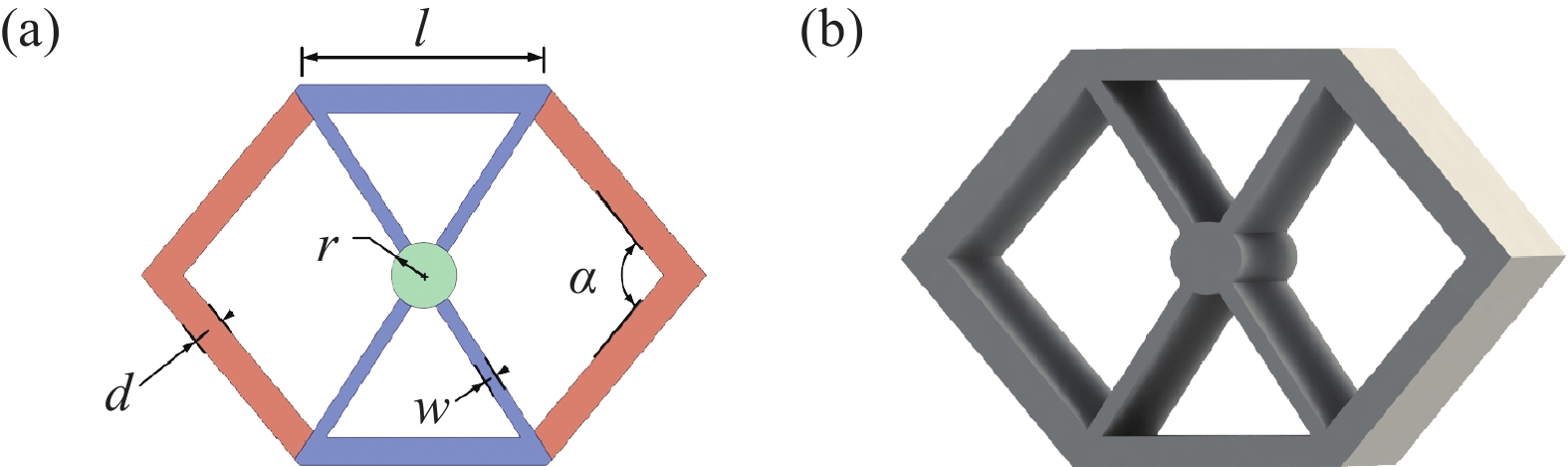

图 9 (a)基于遗传算法(GA)的优化迭代曲线;(b)优化过程中不同代数最优结构的力-位移曲线;((c)~(f))优化过程中不同代数最优结构的形状、参数和适应度值

r—Radius of the center circle; α—Inner angle of the hexagon side; d—Side width; ①, ② and ③ show the best configuration of the 3rd, 20th, and 86th generation, respectively; x, y—Different coordinate directions

Figure 9. (a) Optimization iteration history by applying genetic algorithm (GA); (b) Force-displacement curves of optimization process; ((c)-(f)) Structure shape, parameters and fitness value of different algebraic optimal structures in the optimization process

-

[1] 李婷. 工业生产振动的危害及其控防对策研究[J]. 中国个体防护装备, 2017(2): 48-52. DOI: 10.16102/j.cnki.cppe.2017.02.011 LI Ting. Explore the syrian industrial production vibration harm and control countermeasures[J]. China Personal Protective Equipment, 2017(2): 48-52(in Chinese). DOI: 10.16102/j.cnki.cppe.2017.02.011

[2] 黄自武, 何卫. 地铁列车对数据中心精密设备的振动影响评价[J]. 噪声与振动控制, 2023, 43(3): 167-174. DOI: 10.3969/j.issn.1006-1355.2023.03.026 HUANG Ziwu, HE Wei. Influence of subway trains on precision equipment vibration in a data center[J]. Noise and Vibration Control, 2023, 43(3): 167-174(in Chinese). DOI: 10.3969/j.issn.1006-1355.2023.03.026

[3] SOUKOULIS C, KAFESAKI M, ECONOMOU E. Negative-index materials: New frontiers in optics[J]. Advanced Materials, 2006, 18(15): 1941-1952. DOI: 10.1002/adma.200600106

[4] BALAJI P S, KARTHIK SELVAKUMAR K. Applications of nonlinearity in passive vibration control: A review[J]. Journal of Vibration Engineering & Technologies, 2021, 9(2): 183-213.

[5] MA Z Z, ZHOU R P, YANG Q C. Recent advances in quasi-zero stiffness vibration isolation systems: An overview and future possibilities[J]. Machines, 2022, 10(9): 813. DOI: 10.3390/machines10090813

[6] CARRELLA A, BRENNAN M J, WATERS T P. Static analysis of a passive vibration isolator with quasi-zero-stiffness characteristic[J]. Journal of Sound and Vibration, 2007, 301(3-5): 678-689. DOI: 10.1016/j.jsv.2006.10.011

[7] XU D L, YU Q P, ZHOU J X, et al. Theoretical and experimental analyses of a nonlinear magnetic vibration isolator with quasi-zero-stiffness characteristic[J]. Journal of Sound and Vibration, 2013, 332(14): 3377-3389. DOI: 10.1016/j.jsv.2013.01.034

[8] 陈文华, 黄伟稀, 郝夏影, 等. 面向大振幅低频振动的重力倒摆式准零刚度隔振器研究[J]. 振动与冲击, 2022, 41(18): 205-209, 227. DOI: 10.13465/j.cnki.jvs.2022.18.026 CHEN Wenhua, HUANG Weixi, HAO Xiaying, et al. On the quasi-zero-stiffness isolator with a gravity inverted pendulum applied in large amplitude low frequency vibration isolation[J]. Journal of Vibration and Shock, 2022, 41(18): 205-209, 227(in Chinese). DOI: 10.13465/j.cnki.jvs.2022.18.026

[9] JI J C, LUO Q T, YE K. Vibration control based metamaterials and origami structures: A state-of-the-art review[J]. Mechanical Systems and Signal Processing, 2021, 161: 107945. DOI: 10.1016/j.ymssp.2021.107945

[10] ZHANG Q, GUO D K, HU G K. Tailored mechanical metamaterials with programmable quasi-zero-stiffness features for full-band vibration isolation[J]. Advanced Functional Materials, 2021, 31(33): 2101428. DOI: 10.1002/adfm.202101428

[11] LU Z Q, ZHAO L, DING H, et al. A dual-functional metamaterial for integrated vibration isolation and energy harvesting[J]. Journal of Sound and Vibration, 2021, 509: 116251. DOI: 10.1016/j.jsv.2021.116251

[12] TAN X J, CHEN S, WANG B, et al. Real-time tunable negative stiffness mechanical metamaterial[J]. Extreme Mechanics Letters, 2020, 41: 100990. DOI: 10.1016/j.eml.2020.100990

[13] FAN H G, YANG L J, TIAN Y C, et al. Design of metastructures with quasi-zero dynamic stiffness for vibration isolation[J]. Composite Structures, 2020, 243: 112244. DOI: 10.1016/j.compstruct.2020.112244

[14] WU L L, WANG Y, ZHAI Z R, et al. Mechanical metamaterials for full-band mechanical wave shielding[J]. Applied Materials Today, 2020, 20: 100671. DOI: 10.1016/j.apmt.2020.100671

[15] KADIC M, MILTON G W, VAN HECKE M, et al. 3D metamaterials[J]. Nature Reviews Physics, 2019, 1(3): 198-210. DOI: 10.1038/s42254-018-0018-y

[16] YU X L, ZHOU J, LIANG H Y, et al. Mechanical metamaterials associated with stiffness, rigidity and compressibility: A brief review[J]. Progress in Materials Science, 2018, 94: 114-173. DOI: 10.1016/j.pmatsci.2017.12.003

[17] KATOCH S, CHAUHAN S S, KUMAR V. A review on genetic algorithm: Past, present, and future[J]. Multimedia Tools and Applications, 2021, 80(5): 8091-8126. DOI: 10.1007/s11042-020-10139-6

[18] CHIN C K, AL-BERMANI F G, KITIPORNCHAI S. Finite element method for buckling analysis of plate structures[J]. Journal of Structural Engineering, 1993, 119(4): 1048-1068.

[19] LOU J J, ZHU S J, HE L, et al. Experimental chaos in nonlinear vibration isolation system[J]. Chaos, Solitons & Fractals, 2009, 40(3): 1367-1375.

[20] WANG X, JIANG M, ZHOU Z W, et al. 3D printing of polymer matrix composites: A review and prospective[J]. Composites Part B: Engineering, 2017, 110: 442-458. DOI: 10.1016/j.compositesb.2016.11.034

[21] CANO-VICENT A, TAMBUWALA M M, HASSAN S S, et al. Fused deposition modelling: Current status, methodology, applications and future prospects[J]. Additive Manufacturing, 2021, 47: 102378. DOI: 10.1016/j.addma.2021.102378

-

期刊类型引用(2)

1. 李滋阳,王思佳,邓文举. 陶瓷颗粒增强金属基复合材料研究进展. 轻工科技. 2021(04): 41-44 .  百度学术

百度学术

2. 陈亚楠,金云学,牛牧野,陈洪美,杜文栋. Ni_3Al(Cr)合金室温干滑动摩擦磨损性能研究. 江苏科技大学学报(自然科学版). 2019(05): 18-26 .  百度学术

百度学术

其他类型引用(4)

-

目的

准零刚度隔振器作为国内外主流的非线性隔振器,凭借其高静态刚度和低动态刚度力学特性,在机械工程领域应用较多,但近零刚度范围窄、后期组装繁琐等问题限制了其隔振的应用范围,通过结构设计使近零刚度范围增大,且能通过一体化成型技术快速制备方面的研究仍较为稀缺。本文旨在利用机器学习方法设计一种新型零刚度超材料,使其具备大范围的零刚度工作区间,又可以通过一体化增材制造方式制备。

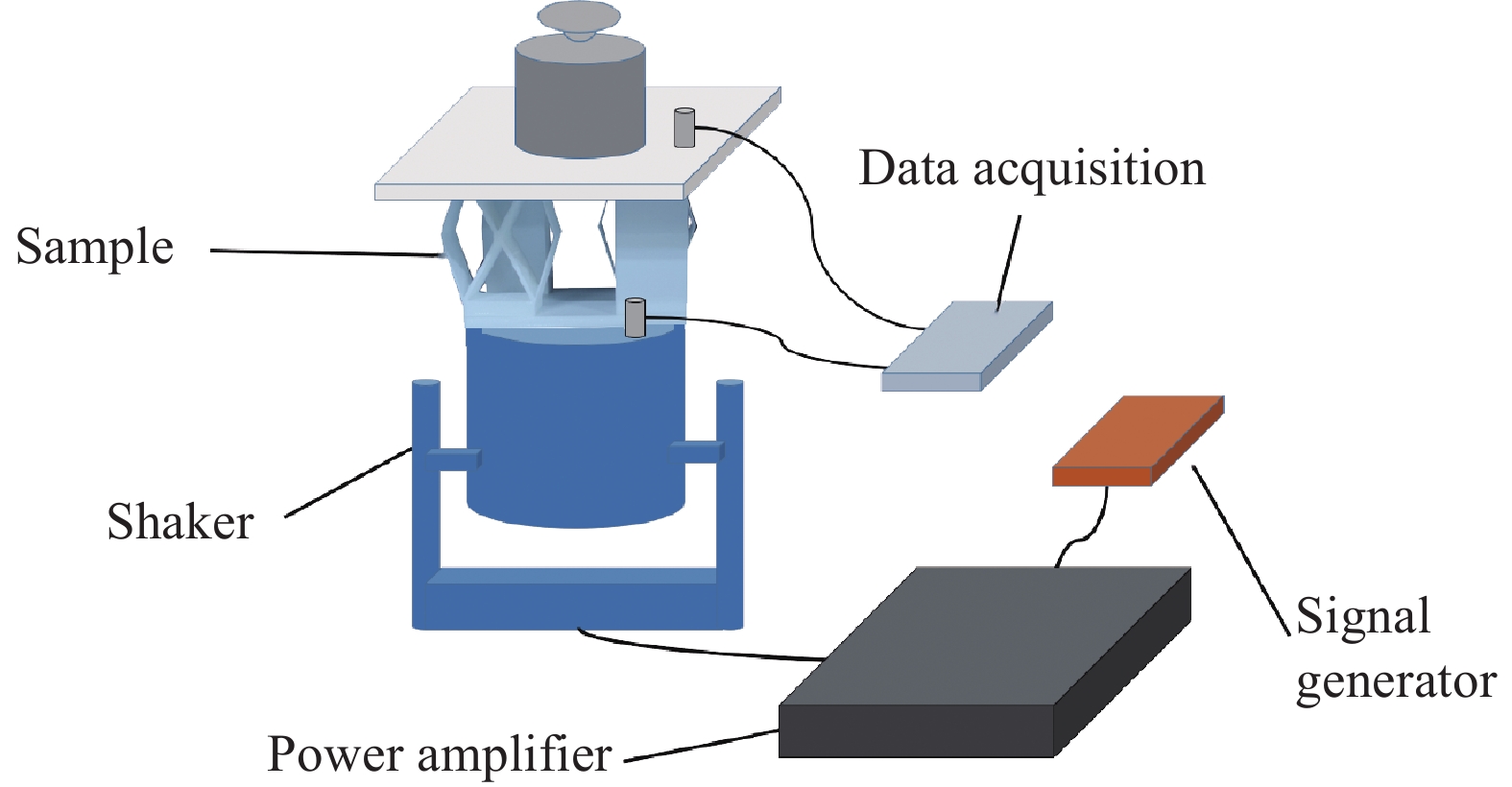

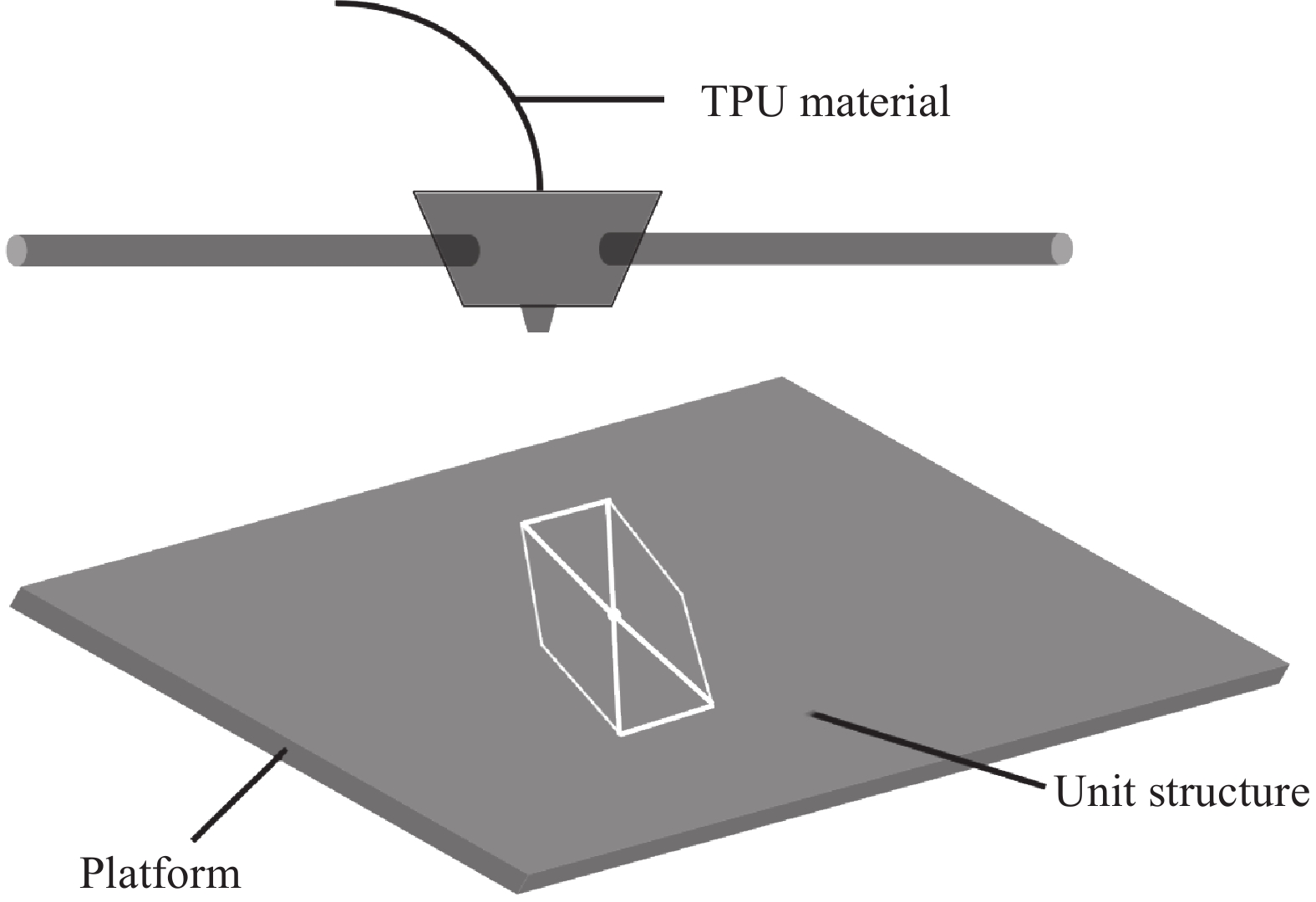

方法本文所用设计方法基于能量屏蔽理论,其原理是通过将外部机械能转化为结构内部势能,从而在动态振动期间屏蔽外界对隔振对象的能量输入,以达到良好的隔振效果。首先设计出具有优化潜力的初始结构,之后利用机器学习遗传算法对结构进行优化,将初始结构需要优化的参数作为“设计参数”,参数取值范围作为“设计空间”,不同优化参数间自由组合形成第一代参数组合群。之后,对参数组合群构成的不同结构进行有限元计算,以结构静态压缩过程中的刚度值为适应度函数,通过比较适应度函数值,以这一代中适应度值最小的个体为最优个体。之后利用遗传算法的交叉、选择和变异等优化算子参数进行迭代优化,得到第二代参数组合群,重复上述操作,直至搜索出最佳参数组合。之后,利用3D打印FDM工艺对最优结构样件进行制备,并进行静态压缩实验及动态振动实验检测。

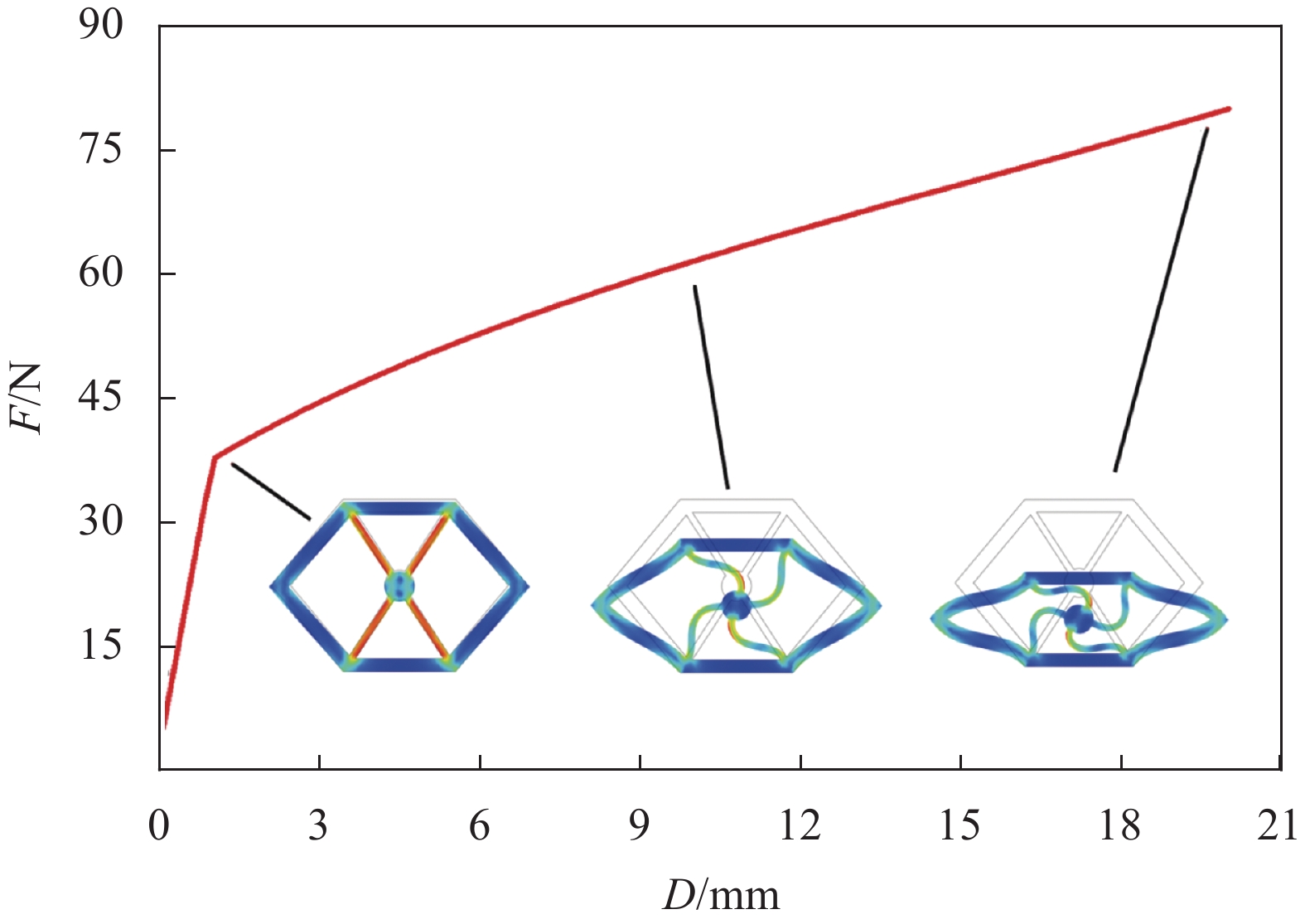

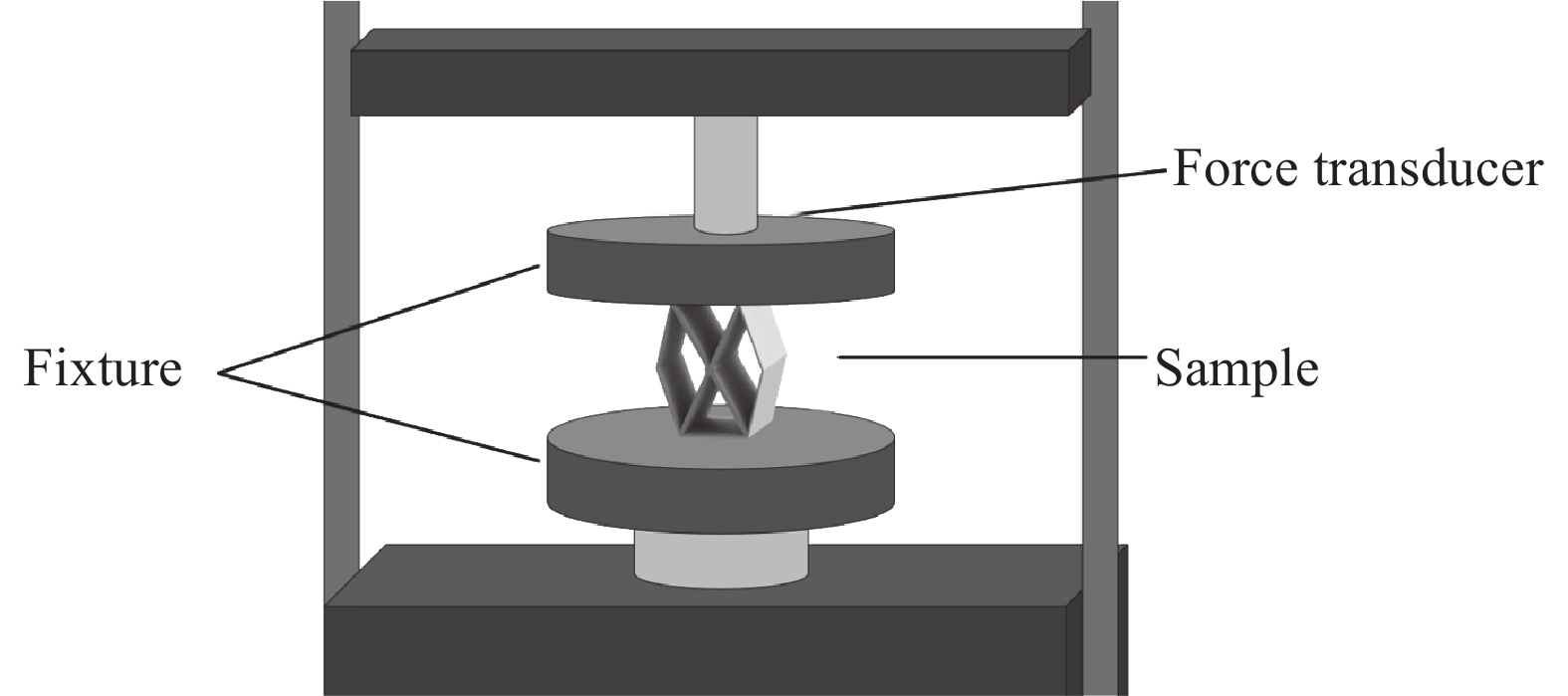

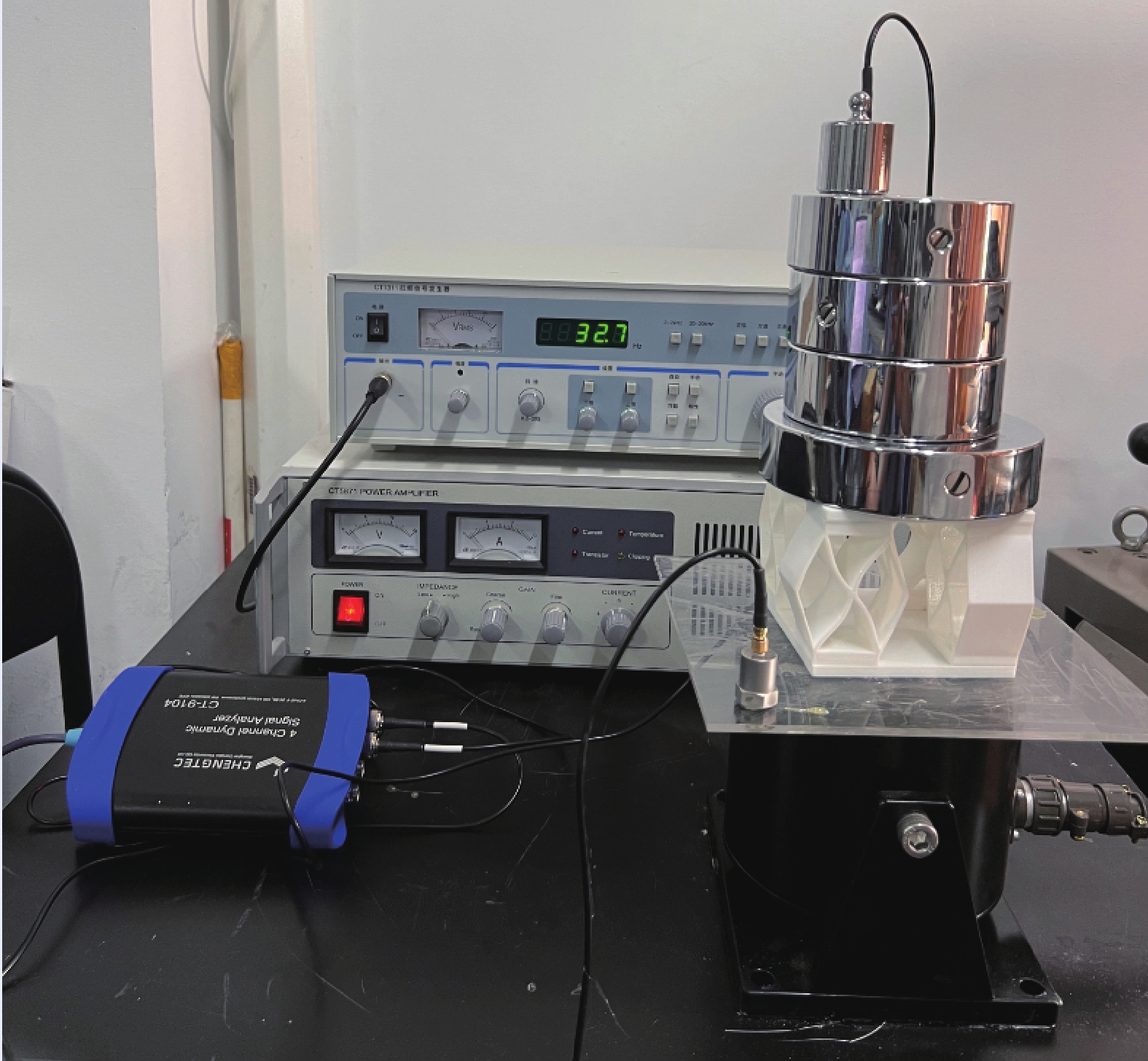

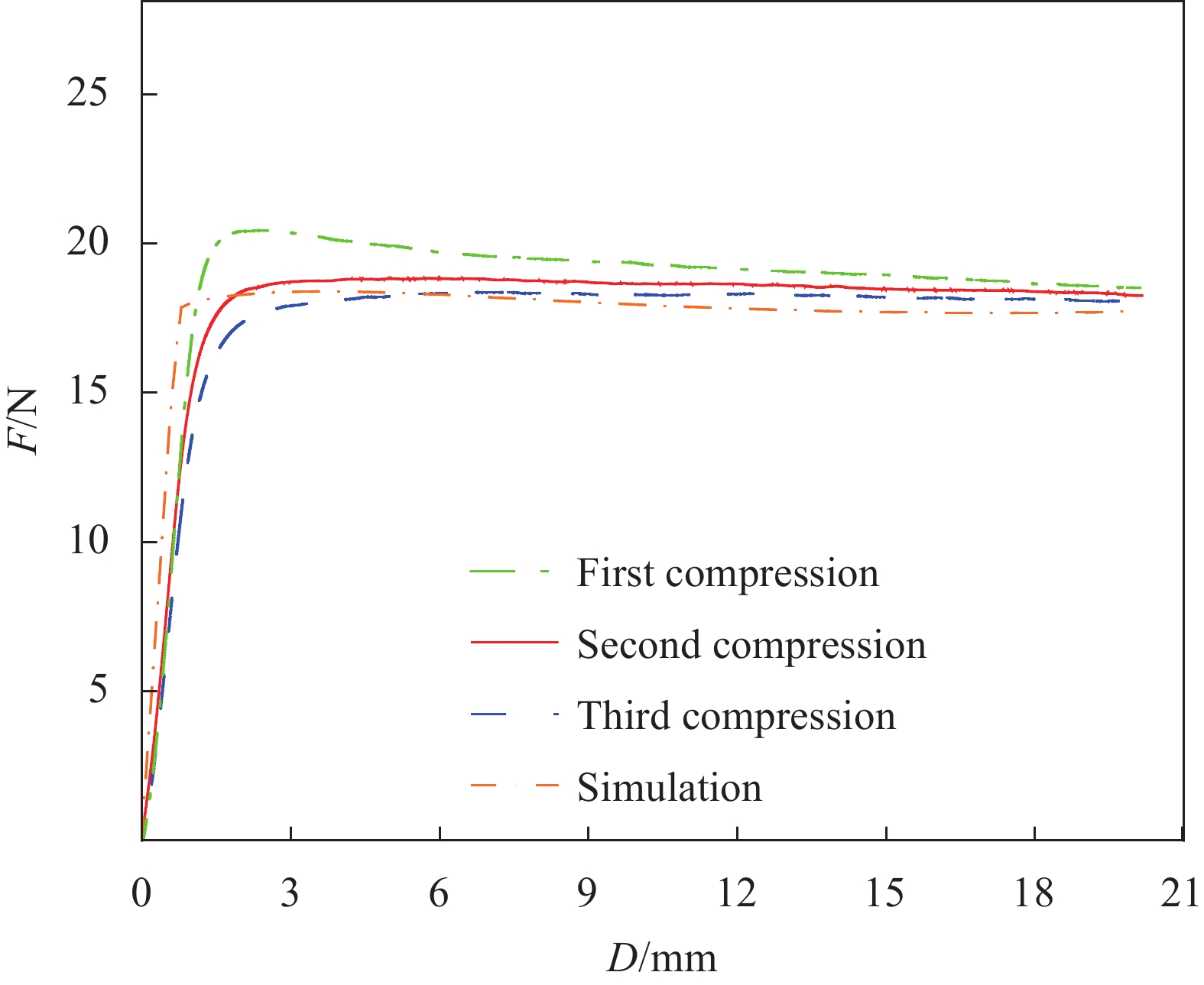

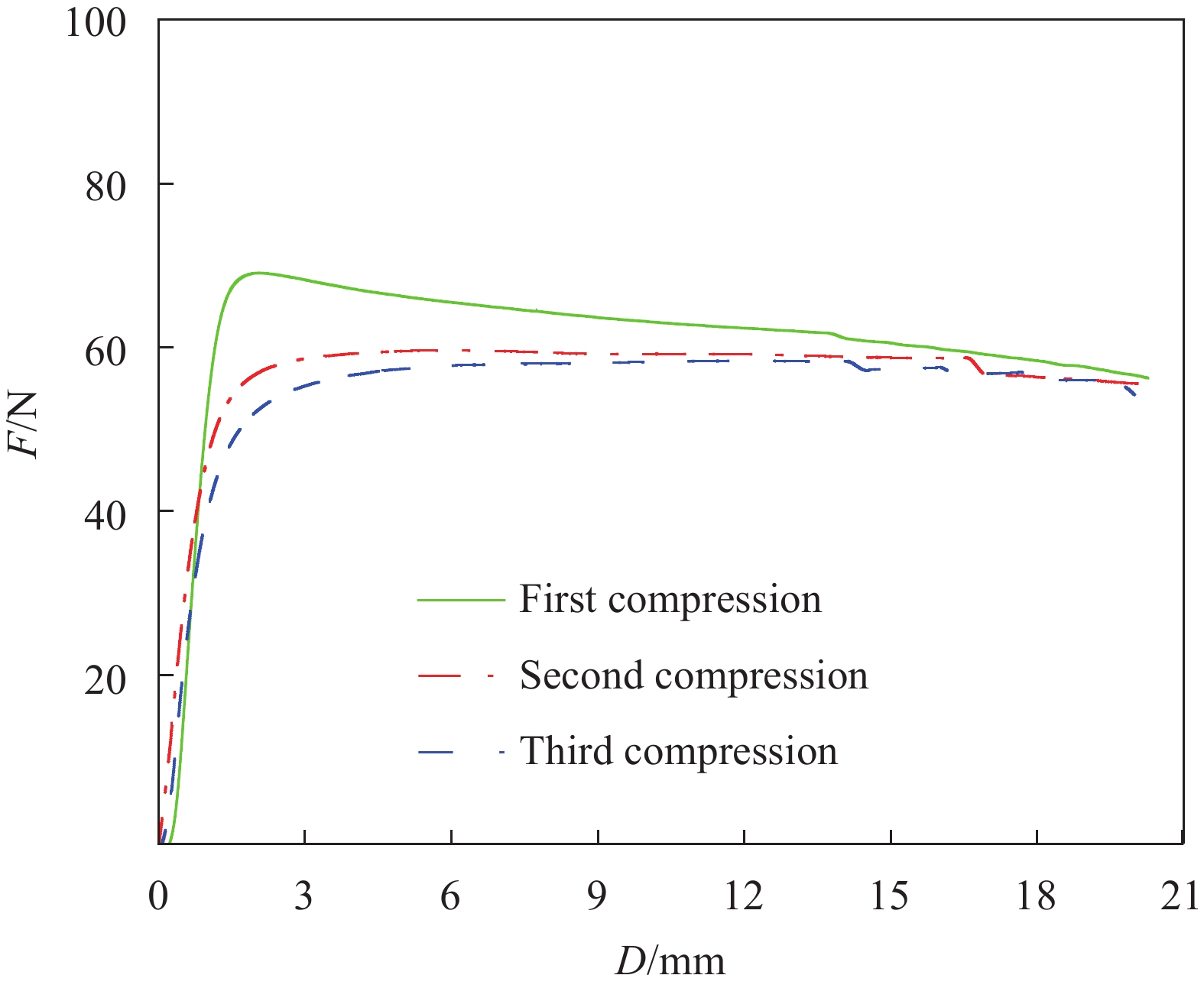

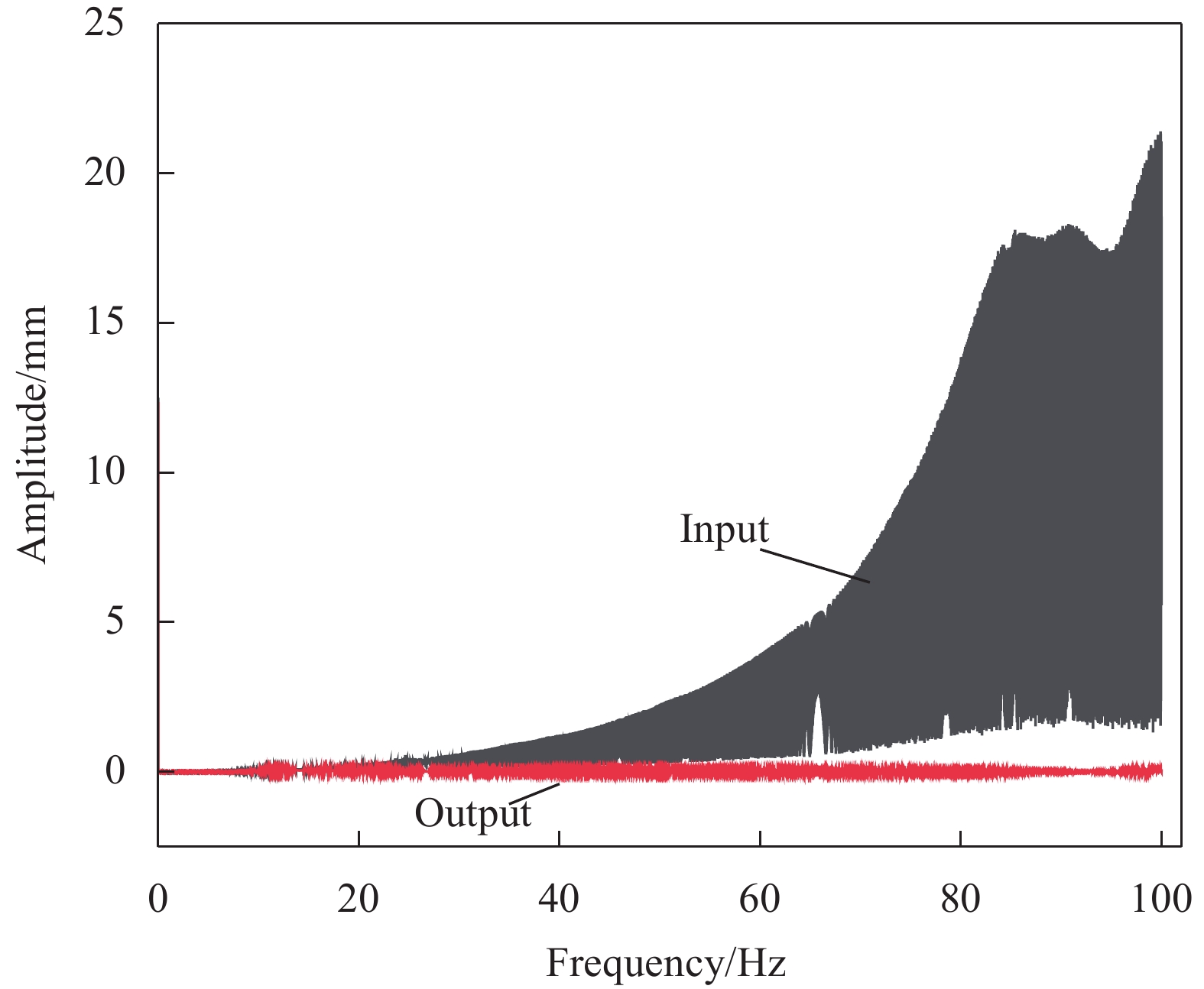

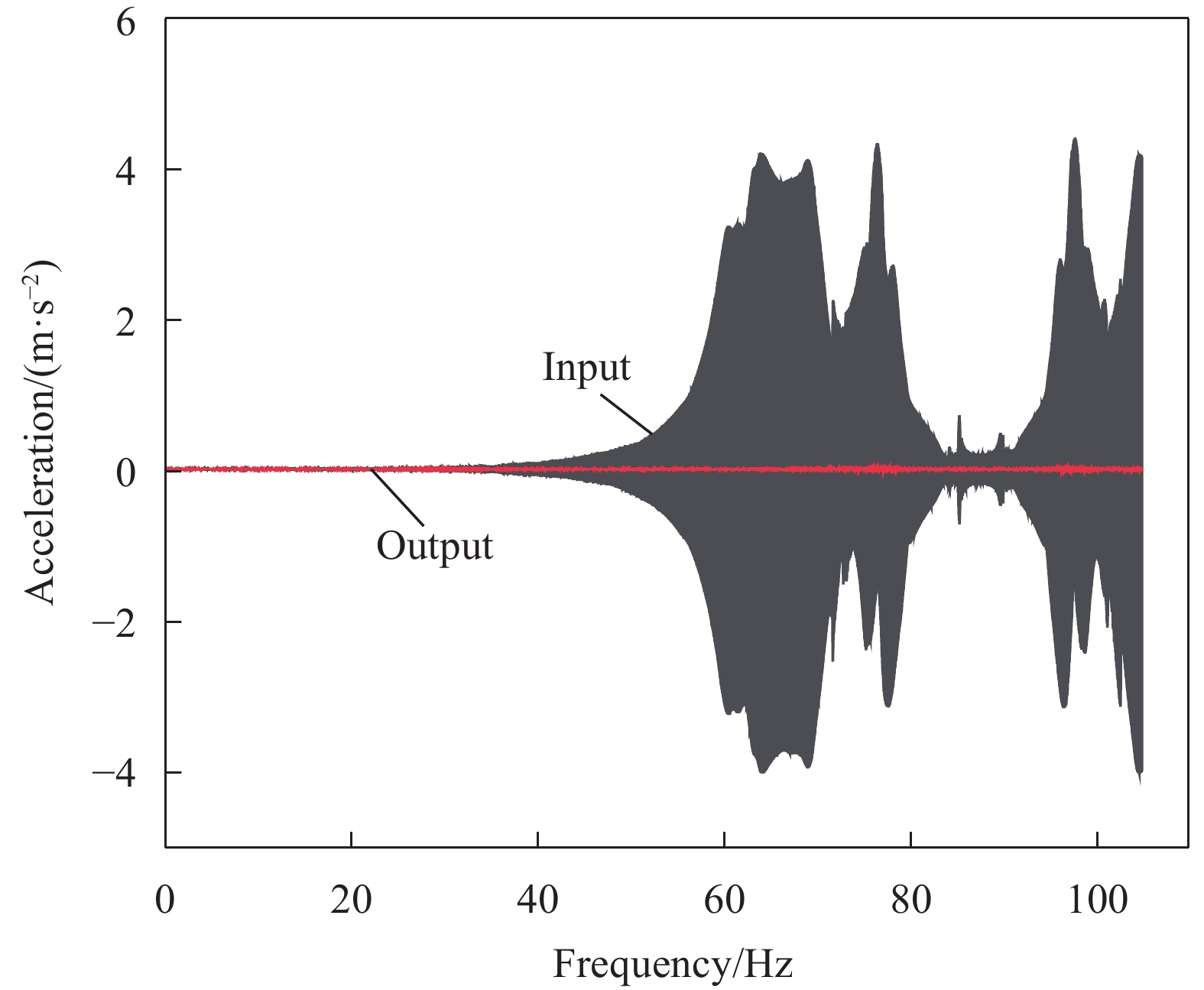

结果选定六边形边框、圆和矩形组合结构作为初始结构,矩形支柱屈曲变形作为主要储能部件。经过优化后,初始结构压缩过程仿真中具有大范围零刚度区间。隔振单元及阵列结构压缩实验过程中,发生了与有限元分析一致的屈曲变形。随着压缩位移的增大,屈曲变形程度也随之增大。压缩过程中,隔振单元结构各部分之间无干涉,压缩过程与仿真压缩过程一致。通过振动实验台系统对隔振阵列结构进行23mm振幅下的振动实验,分别有6种不同的承载载荷。通过分析23mm振幅下阵列结构的传递率可以得出,载荷越靠近9.2kg隔振性能越好,9.2kg载荷下最小传递率可达- 61dB。其原因为准零刚度区间要在指定的载荷下才可以得到,当载荷偏离指定大小后,结构的隔振性能减弱,因此相比其他载荷,9.2kg载荷下的阵列结构具有最优的隔振性能。阵列结构在23mm振幅下9.2 Kg负载的输入与输出振幅-频率曲线对比,可以得出输出振幅基本不受输入振幅影响。阵列结构在23mm振幅下9.2 Kg负载的输入和输出加速度对比,得出输入加速度在变化较大的情况下,输出加速度在整个时域内始终是一条波动较小的细直线,直观证实了阵列结构在23mm振幅下具有良好的隔振性能。振动实验结果符合载荷越接近准零刚度载荷隔振性能越好的结论,与设计预期一致。

结论基于能量屏蔽理论,合理设计出以屈曲变形为主要储能方式,且具有一定优化空间的初始隔振单元结构。将机器学习遗传算法与初始结构模型相结合,推导出以零刚度特性为目标的适应度函数,之后自动搜索出最佳的隔振结构参数组合。通过能量法从理论角度证实结构隔振的可行性,选用FDM3D打印工艺制备隔振单元结构和隔振阵列结构。对隔振单元及阵列结构进行静态压缩试验,从实验角度验证了结构近零刚度特性;又对阵列结构进行了动态振动实验,分析计算了阵列结构的传递率和扫频激励时的加速度输入与输出比,实验表明,阵列结构具有良好的隔振性能且9.2Kg载荷下隔振阵列结构的隔振性能最优。

-

传统准零刚度隔振器设计方法,其零刚度特性往往只存在很窄的范围内,当振动的幅度偏离这一范围时,隔振效果大打折扣。有学者研究发现,系统势能之和不恒定是准零刚度隔振系统无法实现完美隔振的重要原因,并基于能量屏蔽理论设计出性能优异的隔振系统,但因其结构复杂无法一体制造,导致在工业中难以广泛应用。

本文基于能量屏蔽的设计思路,通过将机器学习与超材料结构设计相结合的方法,设计出一种新型零刚度超材料,使其具备大范围的零刚度工作区间,又可以通过一体化增材制造方式制备。之后利用熔融沉积成型(FDM)3D打印工艺对超材料单元及阵列结构样件进行制备。同时,本研究也在实验上进行了验证,证实其制造的可行性和隔振性能。通过对超材料单元及阵列结构进行静态压缩试验,验证了结构近零刚度特性;又对阵列结构进行了动态振动实验,分析计算了阵列结构的传递率、输入与输出振幅—频率曲线对比和扫频激励时的加速度输入与输出比,实验表明,阵列结构在9.2Kg载荷下隔振阵列结构的隔振性能最优。

(a) Metamaterial unit structure, (b) Metamaterial 2 × 2 array structure, (c) Force-displacement curve of compression test and simulation of metamaterial unit structure, (d) Experimental transmissibility-frequency curve of metamaterial 2 × 2 array structure

下载:

下载: