Interface regulation and properties of boron nitride nanosheets reinforced copper matrix composites

-

摘要: 铜因其高导电和高延性的优点在电刷及电触头材料有着广泛的应用前景。随着电力输送行业的快速发展,铜本身低强度的劣势已无法满足需求,亟需开发一种高强高韧的铜基复合材料(CMCs)来弥补铜材料的缺陷。氮化硼纳米片(BNNSs)因其优异的力学及高温结构稳定性能,有望作为铜基复合材料良好增强体,为我国航空航天及交通运输等产业开发出极具战略意义的复合材料。本文采用粉末冶金工艺制备了具有高综合性能的BNNSs增强铜基复合材料(BNNSs/Cu)。研究了不同热处理条件下复合材料微观组织及界面演变特征,测试复合材料力学性能、电导率及摩擦磨损性能的变化规律。结果表明:通过铜基体微合金化处理(添加1wt%Ti),在BNNSs界面处生成了致密且均匀的TiN过渡层和TiB晶须,改善了BNNSs与铜基体的界面结合。BNNSs/Cu-(Ti)-900℃复合材料的抗拉强度为408 MPa,延伸率为15.5%,且电导率仍保持91%国际退火铜标准(IACS)的高水平,摩擦系数降低至0.58 (纯铜基体:0.80)。本文所得的铜基复合材料在获得优异力学性能和耐磨性能同时,仍保持良好的导电性,为开发高性能电接触材料及摩擦材料提供了技术指导。Abstract: Copper has a wide application prospect in brush and contact materials because of its high conductivity and high ductility. With the rapid development of power transmission industry, the disadvantage of low strength of copper itself cannot meet the demand, and it is urgent to develop a high-strength and high-toughness copper matrix composite material (CMCs) to make up for the defects of copper materials. Boron nitride nanosheets (BNNSs) is expected to be used as good reinforcements for copper matrix composites due to its excellent mechanical properties and high temperature structural stability. In this study, BNNSs reinforced copper matrix composites (BNNSs/Cu) with high comprehensive properties were prepared by powder metallurgy. Microstructure and interface evolution characteristics of composites at different heat treatment temperatures, as well as the changes of mechanical, electrical and tribological properties were studied. The results show that by matrix microalloying (adding 1wt%Ti) and heat treatment, the dense and uniform TiN interfacial transition layer and nano-TiB whisker are formed at the interface of BNNSs, which improve the interfacial bonding between BNNSs and matrix. Ultimate tensile strength (UTS) of BNNSs/Cu-(Ti)-900℃ is 408 MPa, the elongation (EL) is 15.5% and the conductivity remains high level of 91% International Annealed Copper Standard (IACS) and the friction coefficient is 0.58 (pure Cu is 0.8). BNNSs/Cu-(Ti) prepared in this study display excellent mechanical properties and wear resistance while maintaining good conductivity, which provide the technical guidance for high performance electrical materials.

-

-

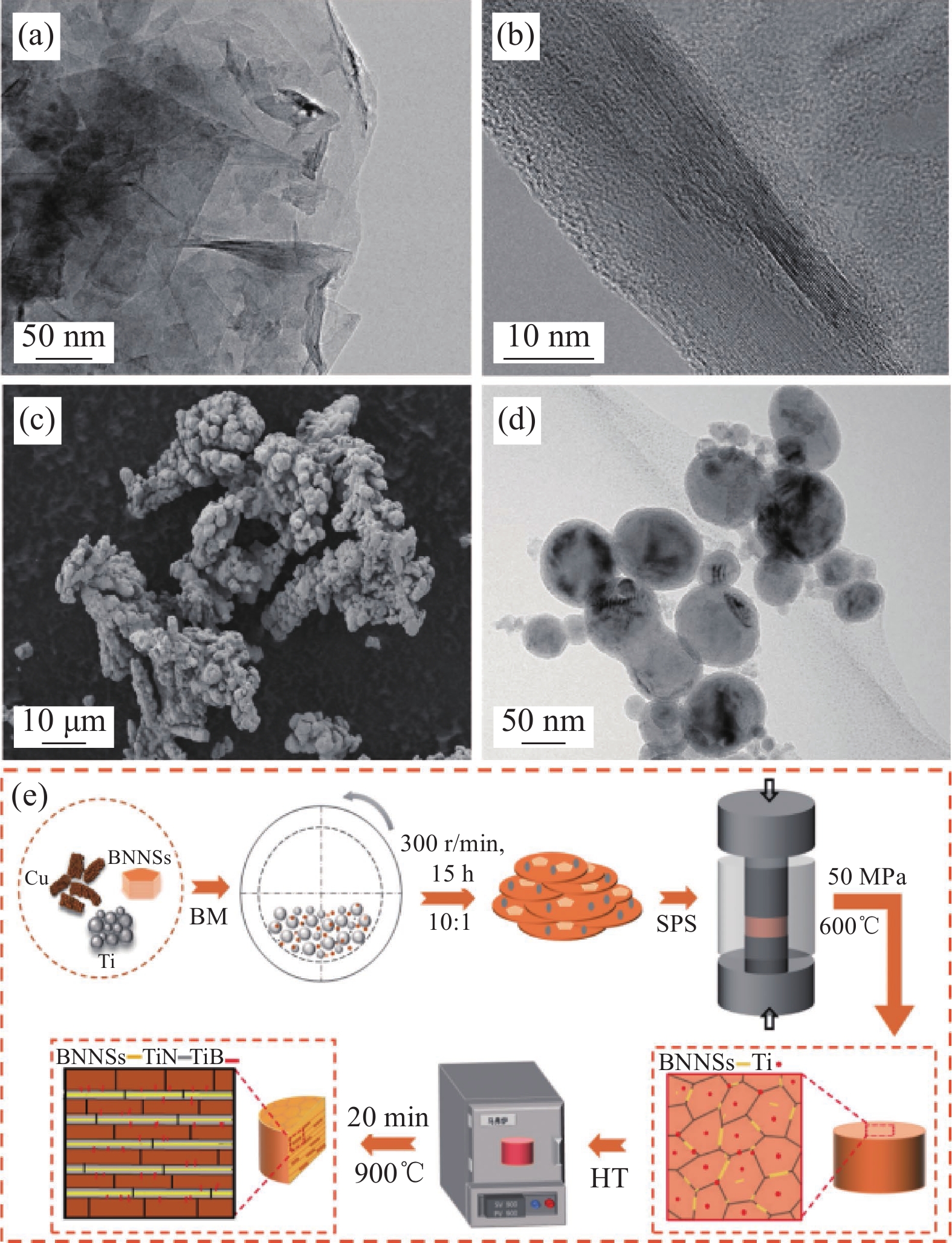

图 1 ((a), (b))原料氮化硼纳米片(BNNSs)的TEM图像;(c)电解铜粉SEM图像;(d)纳米钛粉TEM图像;(e) BNNSs/Cu-(Ti)复合材料的制备流程

BM—Ball milling; SPS—Spark plasma sintering; HT—Heat treatment

Figure 1. ((a), (b)) TEM images of boron nitride nanosheets (BNNSs); (c) SEM image of electrolytic copper powder; (d) TEM image of nano-titanium powder; (e) Flow chart of preparation of BNNSs/Cu-(Ti) composites

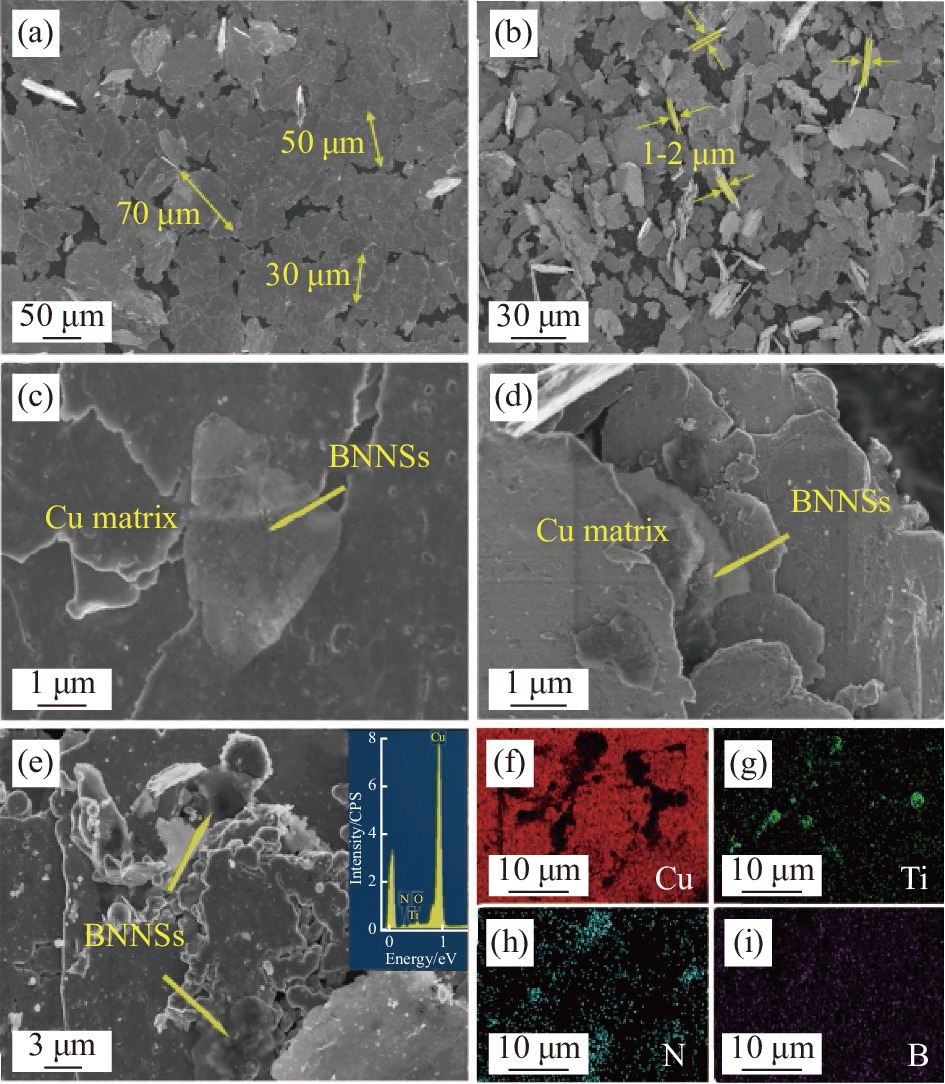

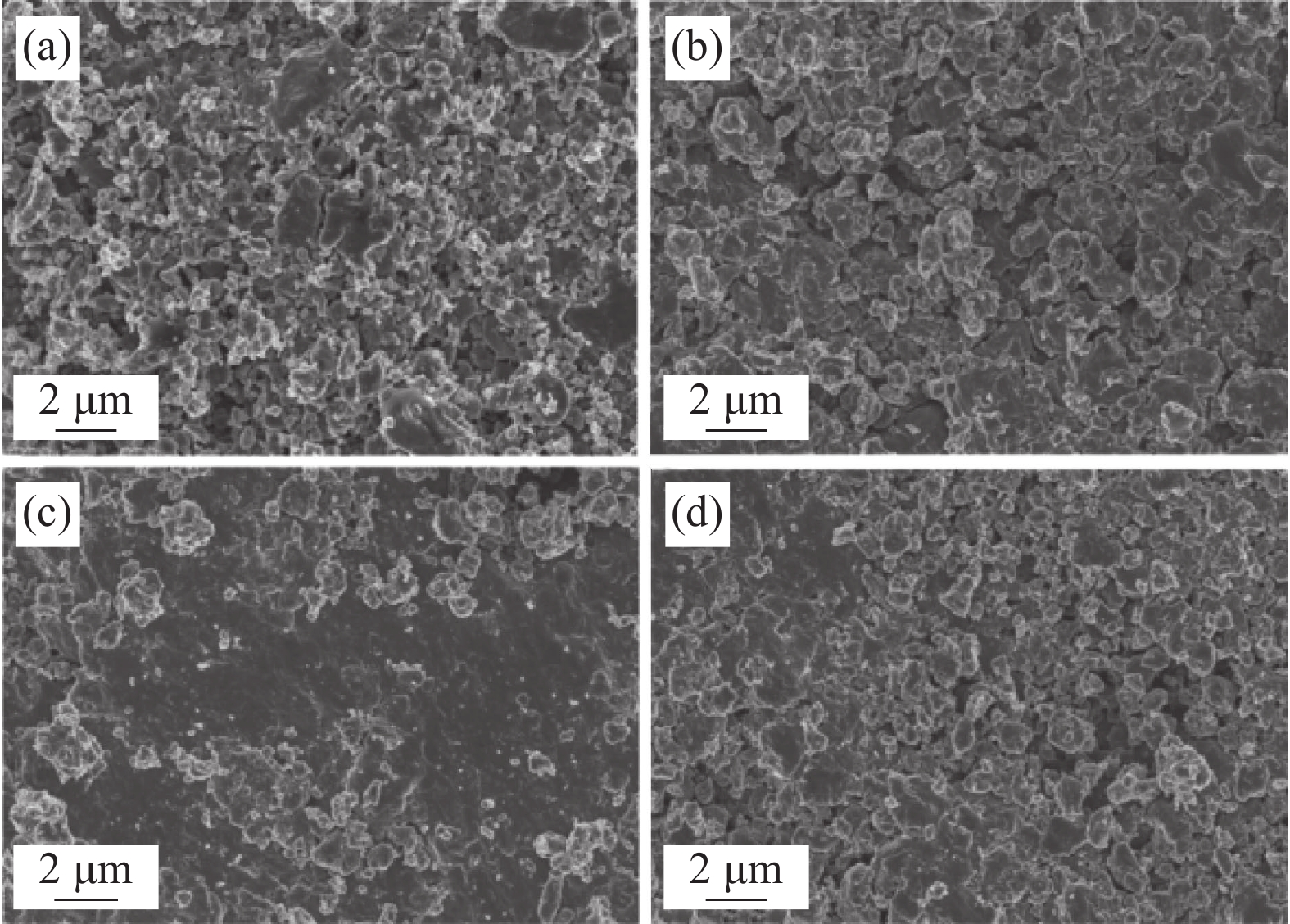

图 2 ((a), (b))球磨后BNNSs/Cu-(Ti)复合粉体的微观形貌;((c), (d)) BNNSs分布SEM图像;(e) BNNSs区域EDS面扫描结果:(f) Cu;(g) Ti;(h) N;(i) B

Figure 2. ((a), (b)) Microstructure of BNNSs/Cu-(Ti) composite powder after milled; ((c), (d)) SEM images of distribution of BNNSs; (e) Scan results of the area of BNNSs: (f) Cu; (g) Ti; (h) N; (i) B

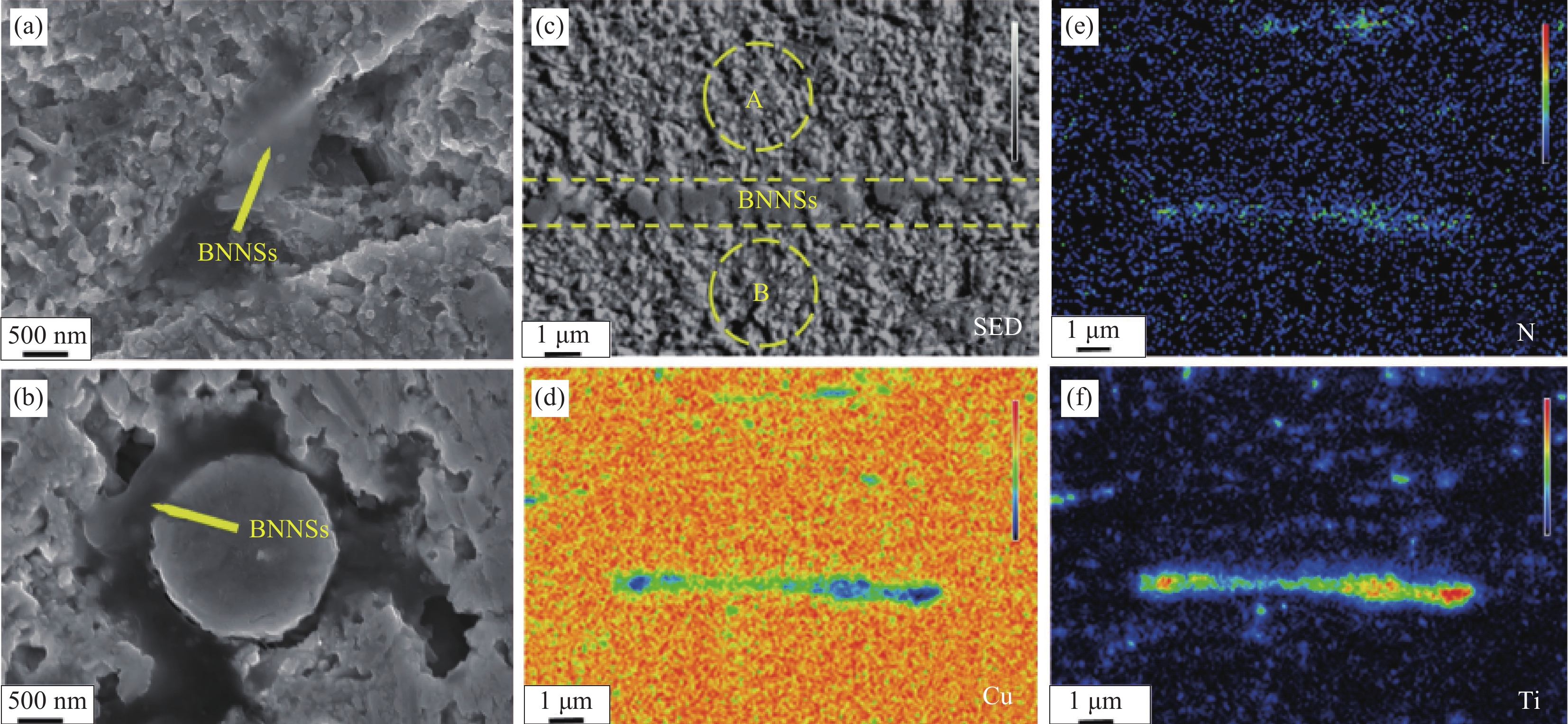

图 3 ((a), (b)) 600℃烧结坯体腐蚀后SEM图像;(c) BNNSs/Cu-(Ti)-900℃复合材料的电子探针的二次电子图像(SED)及元素面扫描结果:(d) Cu;(e) N;(f) Ti

Figure 3. ((a), (b)) SEM images of billet after corrosion and sintered at 600℃; (c) Secondary electron images of electron probes (SED) of BNNSs/Cu-(Ti)-900℃ composite and results of elemental mapping of EDS: (d) Cu; (e) N; (f) Ti

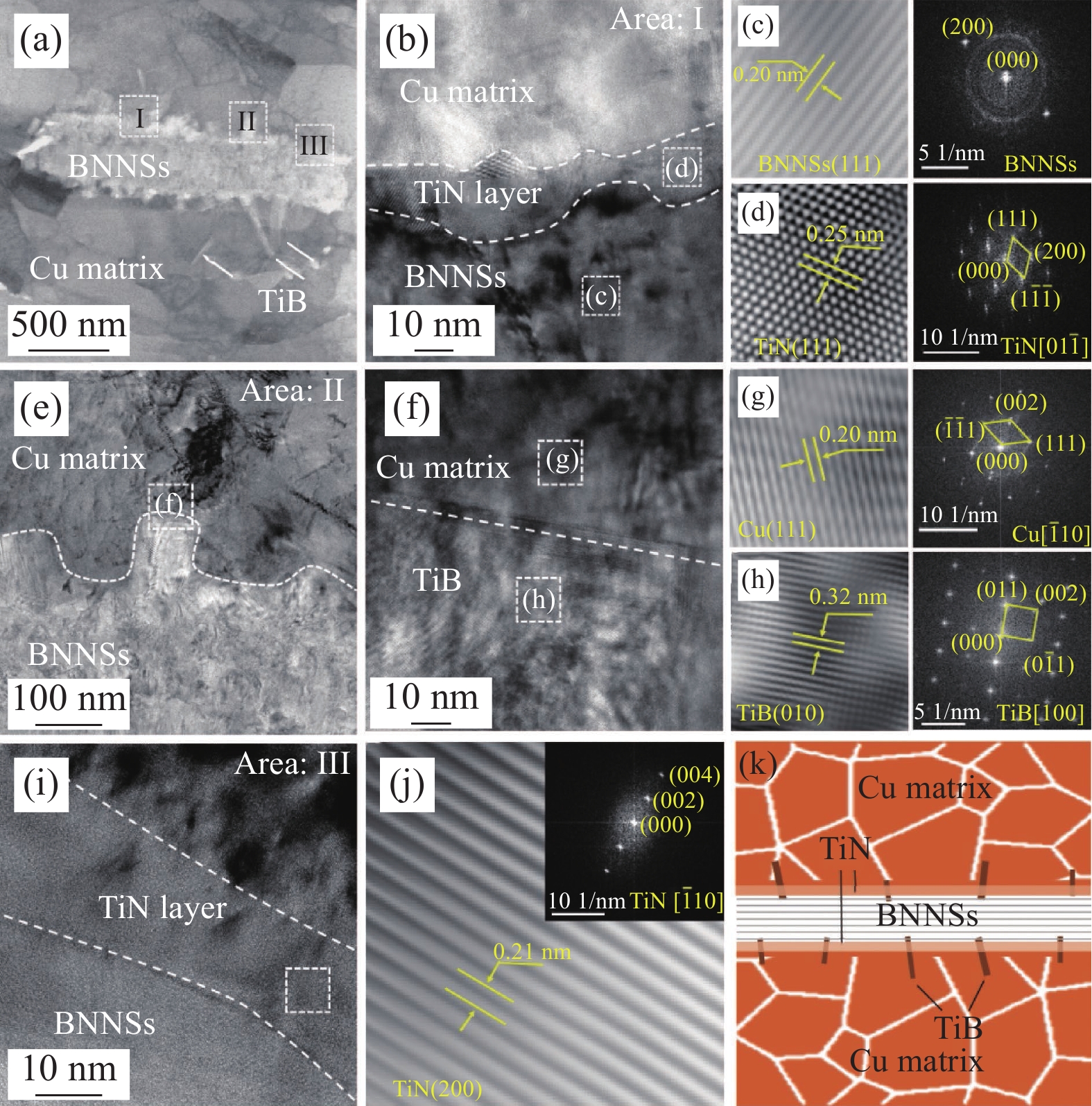

图 4 (a) BNNSs/Cu-(Ti)-900℃复合材料BNNSs区域的TEM图像:对应图4(a)区域I的TEM图像(b)及反傅里叶变换图((c), (d));对应图4(a)区域II的TEM图像((e), (f))及反傅里叶变换图((g), (h));对应图4(a)区域III的TEM图像(i)及反傅里叶变换图(j);(k)复合材料界面结构示意图

Figure 4. (a) TEM images of BNNSs region of BNNSs/Cu-(Ti)-900℃ composite: TEM diagram corresponding to area I (b) in Fig. 4(a) and inverse fourier transform (IFFT) diagram ((c), (d)); TEM diagram corresponding to area II ((e), (f)) in Fig. 4(a) and IFFT diagram ((g), (h)); TEM diagram corresponding to area III (i) in Fig. 4(a) and IFFT diagram (j); (k) Interface structure diagram of composites

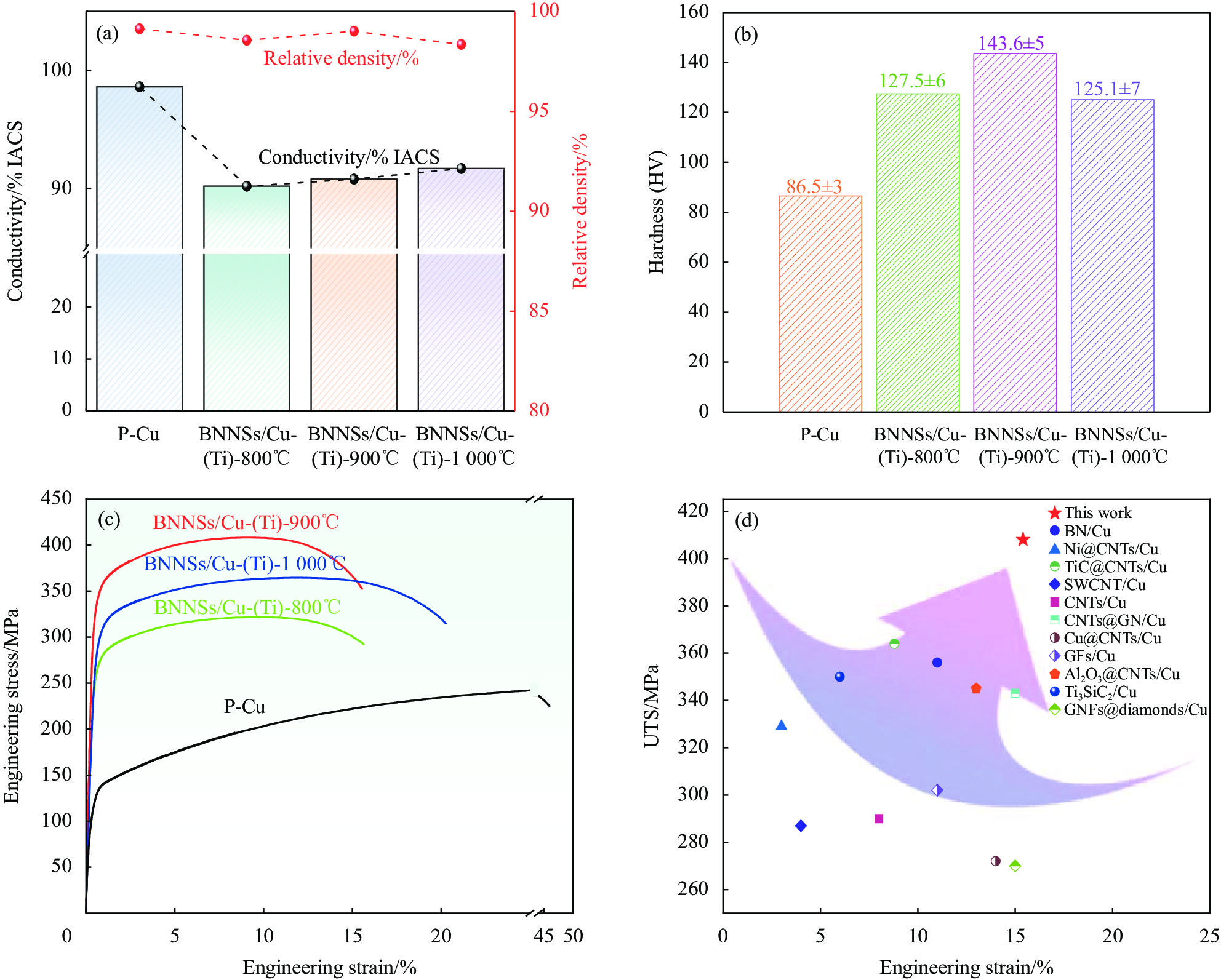

图 5 P-Cu和BNNSs/Cu-(Ti)-800℃、BNNSs/Cu-(Ti)-900℃和BNNSs/Cu-(Ti)-1000℃复合材料的电导率和相对密度(a)及维氏硬度的变化(b);(c)工程应力-应变曲线;(d)目前工作中复合材料的抗拉强度和延展性与其他铜基复合材料(CMCs)的比较

UTS—Ultimate tensile strength; IACS—International Annealed Copper Standard; CNTs—Carbon nanotubes; SWCNT—Single-walled carbon nanotubes; GN—Graphene nanosheets; GFs—Graphene flakes; GNFs—Graphene nanoflakes

Figure 5. Conductivity and relative density (a) and Vickers hardness (b) of P-Cu and BNNSs/Cu-(Ti)-800℃, BNNSs/Cu-(Ti)-900℃ and BNNSs/Cu-(Ti)-1000℃ composites; (c) Engineering stress-strain curves; (d) Comparison of the tensile strength and ductility of the composites in the present work with other copper matrix composite material (CMCs)

图 6 复合材料断口SEM形貌:(a) BNNSs/Cu-(Ti)-800℃;(b) BNNSs/Cu-(Ti)-900℃;(c) BNNSs/Cu-(Ti)-1000℃;((d)~(f)) BNNSs/Cu-(Ti)-900℃复合材料裂纹处BNNSs的形貌

Figure 6. SEM images of the fracture of composites: (a) BNNSs/Cu-(Ti)-800℃; (b) BNNSs/Cu-(Ti)-900℃; (c) BNNSs/Cu-(Ti)-1000℃; ((d)-(f)) Morphology of BNNSs at cracks of BNNSs/Cu-(Ti)-900℃ composite

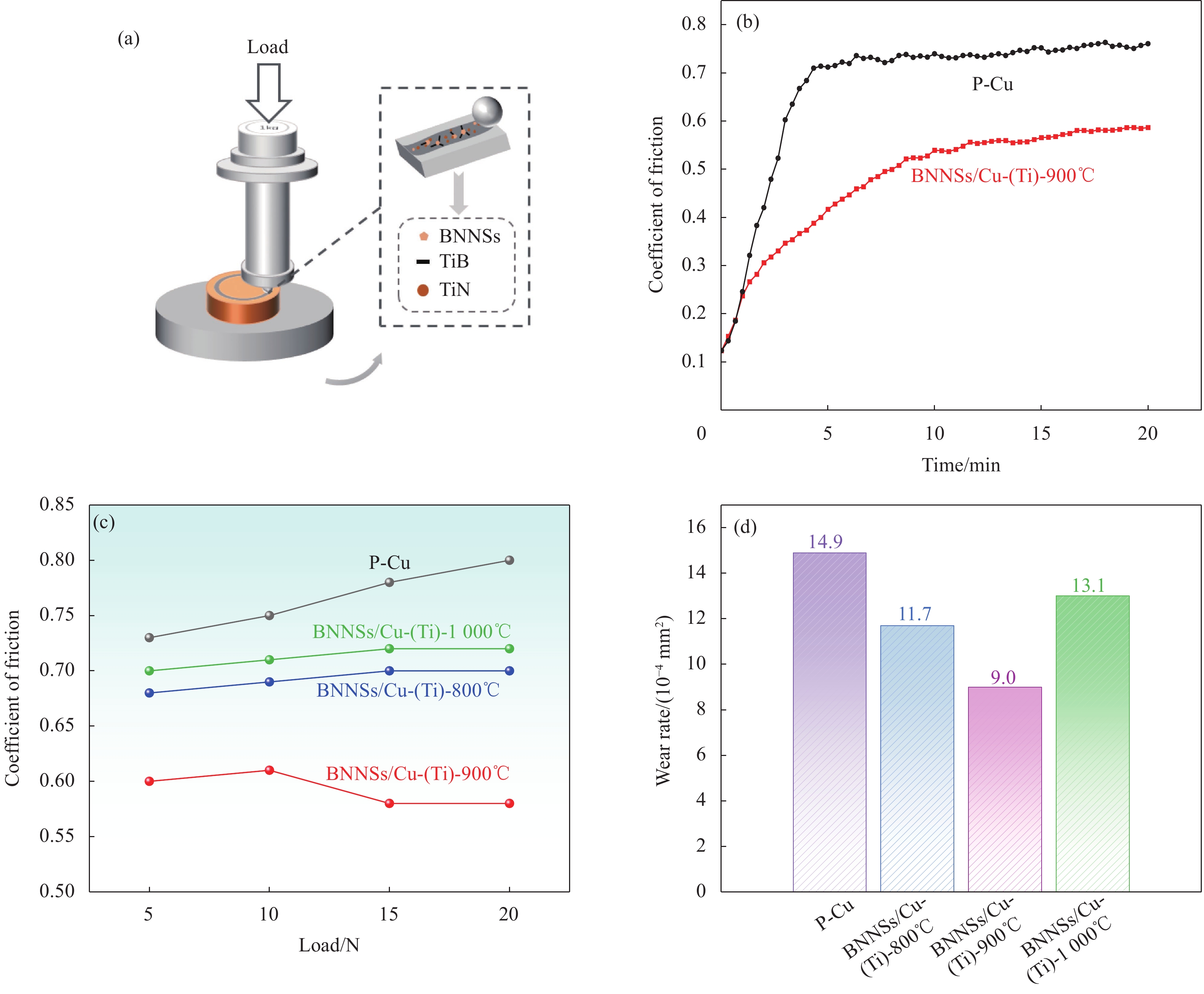

图 7 (a)摩擦行为机制图;(b) P-Cu和BNNSs/Cu-(Ti)-900℃复合材料的摩擦系数曲线;纯铜和复合材料的平均摩擦系数变化曲线(c)及磨损率结果(d)

Figure 7. (a) Mechanism diagram of frictional behavior; (b) Friction coefficient curves of P-Cu and BNNSs/Cu-(Ti)-900℃ composite; Average friction coefficient curves (c) and wear rate results (d) of pure copper and composites

表 1 烧结块体在不同热处理温度后命名

Table 1 Nomenclature of sintered bulks after different heat treatment temperatures

Sample Heat treatment temperature/℃ Pure Cu (P-Cu) — BNNSs/Cu-(Ti)-800℃ 800 BNNSs/Cu-(Ti)-900℃ 900 BNNSs/Cu-(Ti)-1000℃ 1000 表 2 P-Cu和BNNSs/Cu-(Ti)复合材料的力学性能

Table 2 Mechanical properties of P-Cu and BNNSs/Cu-(Ti) composites

Sample Relative

density/%Conductivity/% IACS Hardness (HV) Yield

strength/MPaUltimate tensile

strength/MPaElongation/% P-Cu 99.1 98.6 86.5±3 138.5±12 247.5±15 45.95±3.2 BNNSs/Cu-(Ti)-800℃ 98.5 90.2 127.5±6 273.6±16 321.6±11 15.60±3.5 BNNSs/Cu-(Ti)-900℃ 99.0 90.8 143.6±5 355.5±10 408.2±10 15.50±2.8 BNNSs/Cu-(Ti)-1000℃ 98.3 91.7 125.1±7 315.8±13 364.5±11 20.60±3.3 -

[1] 苏华光. 导体铜及铜合金的应用和加工工艺综述[J]. 电线电缆, 2022(5):22-29, 33. SU Huaguang. Overview of application and processing technology of conductor copper and copper alloy[J]. Wire and Cable,2022(5):22-29, 33(in Chinese).

[2] 潘信诚, 林政淇, 杨柳, 等. 石墨烯增强铜基复合材料制备工艺及性能的研究进展[J]. 机械工程材料, 2023, 47(1): 1-10. PAN Xincheng, LIN Zhengqi, YANG Liu, et al. Research progress on preparation technology and properties of graphene reinforced copper matrix composites[J]. Materials for Mechanical Engineering, 2023, 47(1): 1-10(in Chinese).

[3] 王媛文, 肖文清, 周红军, 等. 六方氮化硼的制备、改性及应用[J]. 化工新型材料, 2022, 50(12): 32-37. WANG Yuanwen, XIAO Wenqing, ZHOU Hongjun, et al. Preparation, modification and application of hexagonal boron nitride[J]. New Chemical Materials, 2022, 50(12): 32-37(in Chinese).

[4] HAGHSHENAS M, ISLAM R, WANG Y, et al. Depth sensing indentation of magnesium/boron nitride nanocomposites[J]. Journal of Composite Materials,2019,53(13):1751-1763.

[5] YOO S C, KIM J, LEE W, et al. Enhanced mechanical properties of boron nitride nanosheet/copper nanocomposites via a molecular-level mixing process[J]. Composites Part B: Engineering,2020,195:108088. DOI: 10.1016/j.compositesb.2020.108088

[6] ZANG C, YANG M, LIU E B, et al. Synthesis, characterization and tribological behaviors of hexagonal boron nitride/copper nanocomposites as lubricant additives[J]. Tribology International,2022,165:107312. DOI: 10.1016/j.triboint.2021.107312

[7] MA L S, ZHANG X, DUAN Y H, et al. Constructing the coherent transition interface structure for enhancing strength and ductility of hexagonal boron nitride nanosheets/Al composites[J]. Journal of Materials Science & Technology,2023,145:235-248.

[8] BHUIYAN M M H, LI L H, WANG J T, et al. Interfacial reactions between titanium and boron nitride nanotubes[J]. Scripta Materialia,2017,127:108-112.

[9] MEREIB D, SEU U C C, ZAKHOUR M, et al. Fabrication of biomimetic titanium laminated material using flakes powder metallurgy[J]. Journal of Materials Science,2018,53(10):7857-7868. DOI: 10.1007/s10853-018-2086-x

[10] CORTHAY S, KUTZHANOV M K, MATVEEV A T, et al. Nanopowder derived Al/h-BN composites with high strength and ductility[J]. Journal of Alloys and Compounds,2022,912:165199. DOI: 10.1016/j.jallcom.2022.165199

[11] FAN Y G, WANG C. Growth kinetics of interfacial reaction layer products between cubic boron nitride and Cu-Sn-Ti active filler metal[J]. Journal of Materials Science & Technology,2021,92:69-74.

[12] WEI C L, YE N, XIA W Y, et al. An electroless deposition strategy for preparing ultrathin CNTs/Cu composite foils with excellent mechanical properties[J]. Diamond & Related Materials,2022,121:108785.

[13] FENG J Q, TAO J M, LIU Y C, et al. Optimization of the mechanical properties of CNTs/Cu composite by regulating the size of interfacial TiC[J]. Ceramics International,2022,48(18):26716-26724.

[14] SHUAI J, XIONG L Q, ZHU L, et al. Enhanced strength and excellent transport properties of a super aligned carbon nanotubes reinforced copper matrix laminar composite[J]. Composites Part A: Applied Science and Manufacturing,2016,88:148-155. DOI: 10.1016/j.compositesa.2016.05.027

[15] JIN Y, ZHU L, XUE W D, et al. Fabrication of superaligned carbon nanotubes reinforced copper matrix laminar composite by electrodeposition[J]. Transactions of Nonferrous Metals Society of China,2015,25(9):2994-3001. DOI: 10.1016/S1003-6326(15)63926-7

[16] ZHANG X, SHI C S, LIU E Z, et al. In situ space-confined synthesis of well-dispersed three-dimensional graphene/carbon nanotube hybrid reinforced copper nanocomposites with balanced strength and ductility[J]. Composites Part A: Applied Science and Manufacturing,2017,103:178-187. DOI: 10.1016/j.compositesa.2017.09.010

[17] WEI X, TAO J M, HU Y, et al. Enhancement of mechanical properties and conductivity in carbon nanotubes (CNTs)/Cu matrix composite by surface and intratube decoration of CNTs[J]. Materials Science & Engineering: A,2021,816:141248.

[18] CHEN L, HOU Z C, LIU Y F, et al. High strength and high ductility copper matrix composite reinforced by graded distributeon of carbon nanotubes[J]. Composites Part A: Applied Science and Manufacturing,2020,138:106063. DOI: 10.1016/j.compositesa.2020.106063

[19] PAN Y, XIAO S Q, LU X, et al. Fabrication, mechanical properties and electrical conductivity of Al2O3 reinforced Cu/CNTs composites[J]. Journal of Alloys and Compounds,2018,782:1015-1023.

[20] YANG Z B, XU J J, QIAN Y H, et al. Electrical conductivities and mechanical properties of Ti3SiC2 reinforced Cu-based composites prepared by cold spray[J]. Journal of Alloys and Compounds,2023,946:169473. DOI: 10.1016/j.jallcom.2023.169473

[21] LUO F, JIANG X S, SUN H L, et al. Microstructures, mechanical and thermal properties of diamonds and graphene hybrid reinforced laminated Cu matrix composites by vacuum hot pressing[J]. Vacuum,2023,207:111610. DOI: 10.1016/j.vacuum.2022.111610

[22] DONG B X, LI Q Y, SHU S L, et al. Investigation on the elevated-temperature tribological behaviors and mechanism of Al-Cu-Mg composites reinforced by in situ size-tunable TiB2-TiC particles[J]. Tribology International,2023,177:107943. DOI: 10.1016/j.triboint.2022.107943

[23] DING L, HU S S, QUAN X M, et al. Microstructure and high temperature tribological performance of Co-based laser cladded coatings reinforced with in situ TiN-VC[J]. Vacuum,2022,198:110894. DOI: 10.1016/j.vacuum.2022.110894

[24] DEORE H A, NICHUL U, RAO A G, et al. Influence of SiC particles and post-heat treatment on the properties of Ti-6Al-4V based surface nanocomposite fabricated by friction stir processing[J]. Surface & Coatings Technology,2022,449:128985.

[25] SHIN S E, CHOI H J, SHIN J H, et al. Strengthening behavior of few-layered graphene/aluminum composites[J]. Carbon, 2015, 82: 143-151.

[26] YANG M, WENG L, ZHU H X, et al. Simultaneously enhancing the strength, ductility and conductivity of copper matrix composites with graphene nanoribbons[J]. Carbon, 2017, 118: 250-260.

[27] NI Z L, MA J S, LIU Y, et al. Microstructure evolution and mechanical property strengthening mechanisms of Cu/Cu NPs/Cu joint fabricated by ultrasonic spot welding[J]. Materials Science & Engineering: A,2023,866:144656.

[28] CHEN B, GONG J W, HUANG W, et al. Constructing a parallel aligned shish kebab structure of HDPE/BN composites: Toward improved two-way thermal conductivity and tensile strength[J]. Composites Part B: Engineering,2023,259:110699. DOI: 10.1016/j.compositesb.2023.110699

-

期刊类型引用(5)

1. 张有茶,贾成厂,贾鹏. 中间相碳微球/氰酸酯树脂复合材料的导电导热性能. 复合材料学报. 2019(03): 602-610 .  本站查看

本站查看

2. 张新庄,张书勤,闫鹏,裴婷,窦倩,董昭,王姗姗. 聚丙烯基石墨烯改性复合材料的导电及热稳定性. 化学工业与工程. 2019(06): 60-64 .  百度学术

百度学术

3. 胡荣杰,甯尤军,肖藤,雷玲,阿拉木斯,胡宁. 石墨烯/环氧树脂纳米复合材料的制备与热膨胀特性分析. 重庆大学学报. 2018(06): 50-57 .  百度学术

百度学术

4. 洪新密,肖小亭,吴雅莎,杨洁,何穗华. 超声振动对闪光铝颜料填充HDPE复合材料流变行为和性能的影响. 高分子材料科学与工程. 2018(04): 82-88 .  百度学术

百度学术

5. 徐子威,张婧婧,何穗华,赖永健,杨涛,余浩斌. 螺杆剪切对聚丙烯/石墨烯微片纳米复合材料形态和性能的影响. 塑料科技. 2018(02): 56-63 .  百度学术

百度学术

其他类型引用(4)

-

目的

铜因其高导电和高延性的优点在电刷及电触头材料有着广泛的应用前景。近年来,随着电力输送行业的快速发展,对材料的强韧性提出更高要求,而铜本身低强度的劣势也越来越明显,无法满足各领域日益增长的需求。在铜中添加增强体制备的具有高强度的铜基复合材料广泛用于工程领域。目前,常用的增强体有以碳纳米管、石墨烯为主的碳纳米增强相,但是,在制备过程中这些碳纳米材料会发生团聚,而且与铜的弱界面结合使复合材料的性能往往达不到预期效果,并且还会削弱其电学、热学及力学性能。因此,亟需开发一种新型的具有更加优异综合性能的铜基复合材料(CMCs)来弥补铜材料的缺陷,以满足各领域快速发展的需求。

方法本研究采用机械球磨结合放电等离子烧结法制备了氮化硼增强铜基复合材料(BNNSs/Cu)。首先,以酒精为球磨介质(球料比10:1,转速300 r/min),在氩气保护气氛下高能球磨均匀混合BNNSs、Ti和Cu混合粉末。其中,BNNSs、Ti占比分别为0.1wt%和1wt%。将球磨后的复合粉末真空干燥后装入石墨模具中,使用放电等离子烧结(Lab-ox325, SINTER LAND INC)设备,在600℃、50 MPa条件下保温5 min(升温速率100℃/min)得到烧结坯体。最后,将烧结后坯体分别在800℃、900℃和1000℃下热处理20 min。在室温条件下,对得到的复合材料进行电导率、力学性能以及摩擦磨损性能的测试,并进行了相关的微观结构表征分析。

结果(1)从微观结构表征分析可知,烧结态复合材料BNNSs与铜基体间仍是一种简单的机械结合;热处理态的复合材料Ti元素发生明显扩散并在BNNSs界面处富集,经过高温处理,Ti与BNNSs发生界面反应,生成了TiN过渡层以及纳米TiB晶须(从文章中TEM可以看出),显著改善了BNNSs与铜基体的界面结合;(2)经过热处理后的复合材料性能显著提高,其中,900℃热处理后的复合材料(BNNSs/Cu-(Ti)-900℃)极限抗拉强度为408 MPa,延伸率为15.5%,且电导率仍保持较高水平(91%IACS),摩擦系数降低至0.58(纯铜基体为0.80);(3)对BNNSs/Cu-(Ti)-900℃复合材料的三个主要强化机制进行了计算,其中,位错强化、晶粒细化和荷载传递强化的强化贡献值分别为49.1 MPa,18.6 MPa和80.3 MPa。载荷传递强化的贡献最为突出,这得益于BNNSs以及过渡界面所共同承担的载荷传递效果。

结论本研究通过机械球磨结合放电等离子烧结法制备了高强高耐磨的BNNSs增强铜基复合材料。在0.1wt%BNNSs-Cu体系的基础上,通过对铜基体(添加1wt% Ti)进行微合金化处理,成功构建了TiN过渡界面和纳米TiB晶须,显著提高了BNNSs与铜基体间的界面结合强度。研究结果表明,选择合适的增强相结合合理的界面调控是实现微观组织结构稳定以及显著提高综合性能的有效途径。这项工作为相关二维增强相增强金属基复合材料合理的界面设计提供了参考,也为后续开发高性能CMCs提供了新的契机。

下载:

下载: