Preparation and properties of corrosion inhibited poly(o-toluidine)-graphene oxide-based anticorrosive materials

-

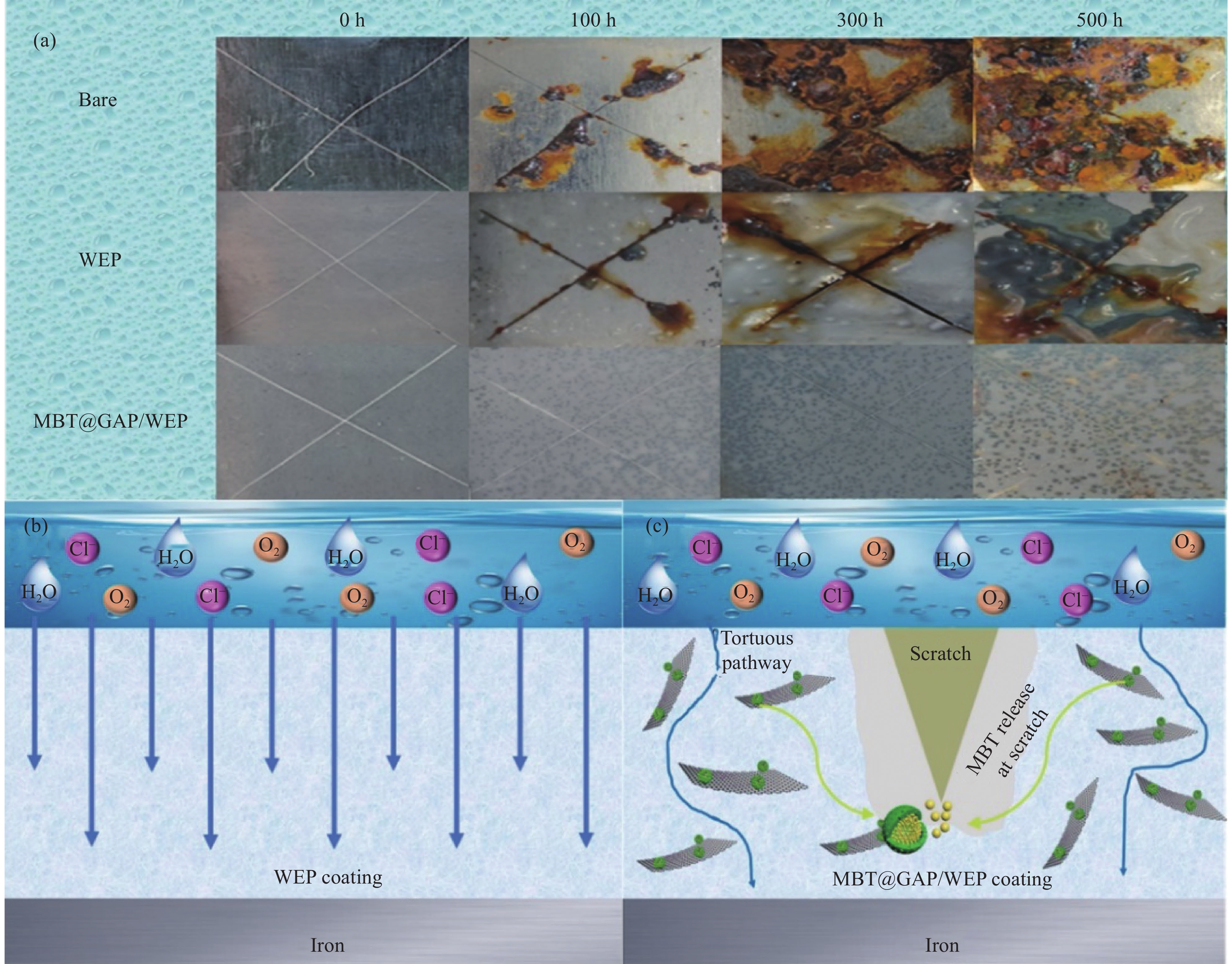

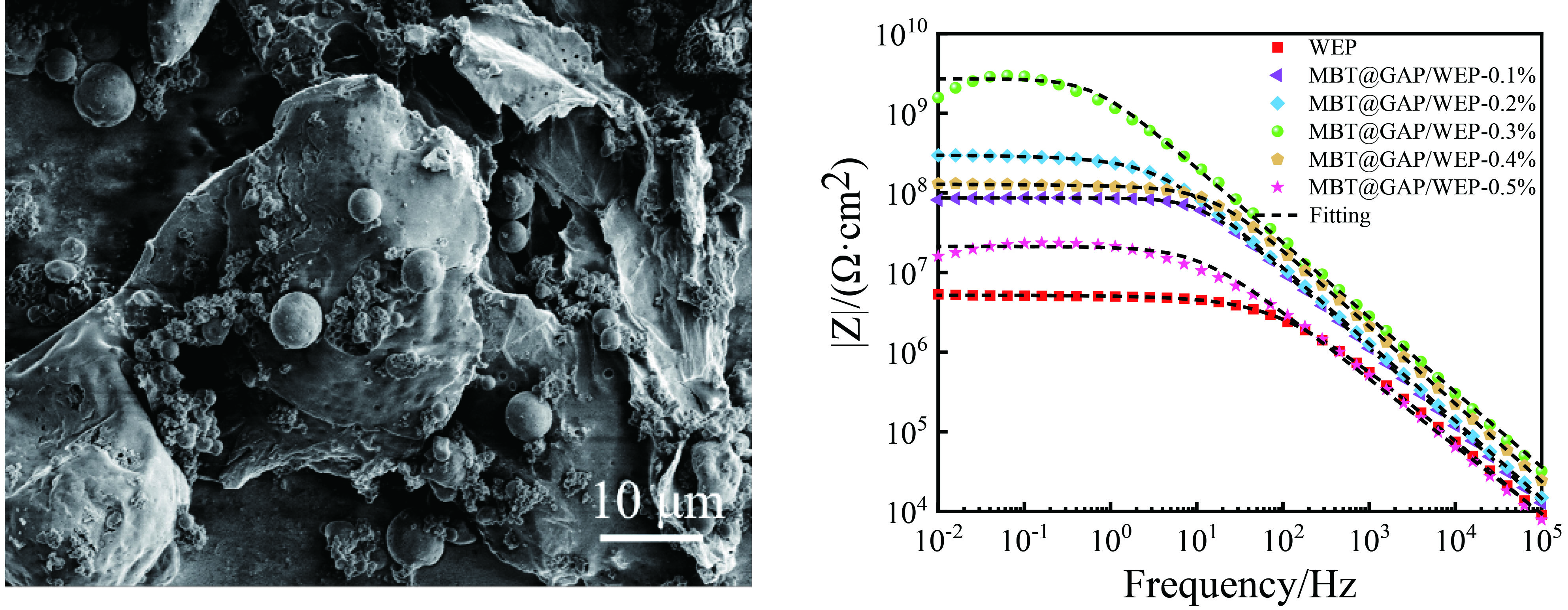

摘要: 为开发缓蚀剂高效利用的新途径,选取氧化石墨烯为基材、聚邻甲苯胺微胶囊为壁材、缓蚀剂2-巯基苯并噻唑为芯材,制备了缓蚀型聚邻甲苯胺-氧化石墨烯基防腐材料,并将其作为填料用于水性环氧树脂涂层(WEP)的改性。通过FTIR、XRD、XPS和SEM等对材料进行了结构和形貌的表征,采用紫外可见光谱对缓蚀剂的释放行为进行分析,采用万能试验机、电化学测试和盐雾实验对涂层的拉伸性能和防腐性能进行了评价。结果表明:缓蚀剂成功包覆于聚邻甲苯胺微胶囊内部,并通过共价键方式将微胶囊连接在改性氧化石墨烯表面,使缓蚀剂得到了充分利用,提高了涂层的拉伸性能、自修复性能及对腐蚀介质的屏蔽性能。紫外可见光谱测试结果表明,微胶囊在人工破损96 h后,内部缓蚀剂的释放量达78%;拉伸性能测试结果表明,与纯WEP相比,当填料加入量为0.3wt%时,涂层应力从14.281 MPa增加到24.25 MPa;SEM结果表明,被划伤的涂层在常温下放置10 h后自修复;电化学测试和盐雾实验结果表明,涂层腐蚀电位从−0.6216 V提高到−0.1554 V,腐蚀电流密度从4.271×10−7 A·cm−2减小到1.016×10−11 A·cm−2,阻抗模量可达到1.5757×109 Ω·cm2,在盐雾500 h后仍表现出较好的防腐性能。Abstract: In order to develop a new way of efficient utilization of corrosion inhibitors, a corrosion inhibited poly(o-toluidine)-graphene oxide-based anticorrosive materials was prepared by using graphene oxide as the substrate, poly(o-toluidine) microcapsules as the wall material and 2-mercaptobenzothiazole as the corrosion inhibitor as the core material, and it was used as the filler for the modification of waterborne epoxy resin coating (WEP). The structure and morphology of the coating were characterized by FTIR, XRD, XPS and SEM. The release behavior of the corrosion inhibitor was analyzed by UV-Vis spectroscopy. The tensile property and anti-corrosion properties of the coating were evaluated by universal testing machine, electrochemical test and salt spray test. The results show that the corrosion inhibitor is successfully coated inside poly(o-toluidine) microcapsules, and the microcapsules are connected to the surface of the modified graphene oxide by covalent bond, so that the corrosion inhibitor is fully utilized, and the tensile property, self-healing properties and shielding properties of the coating against corrosive media are improved. UV-vis spectrum test results show that the release of corrosion inhibitor in microcapsules reaches 78% after 96 h of artificial damage. The tensile property test results show that, compared with pure WEP, the coating stress increases from 14.281 MPa to 24.25 MPa when the filler content is 0.3wt%. SEM results show that the scratched coating self-healing after 10 h at room temperature. The electrochemical test and salt spray test results show that the corrosion potential of the coating increases from −0.6216 V to −0.1554 V, the corrosion current density decreases from 4.271×10−7 A·cm−2 to 1.016×10−11 A·cm−2, and the impedance modulus can reach 1.5757×109 Ω·cm2. After 500 h of salt spray, the corrosion resistance is still good.

-

Keywords:

- graphene oxide /

- poly(o-toluidine) /

- microcapsule /

- water-based epoxy resin /

- anticorrosive coating

-

聚(N-异丙基丙烯酰胺)(PNIPAM)是由单体N-异丙基丙烯酰胺(NIPAM)通过自由基溶液聚合法聚合出的一种具有温度敏感特性的聚合物。PNIPAM的分子链上同时含有疏水基团异丙基和亲水基团酰胺基,温度的变化会导致基团之间相互作用的改变,即在其低临界相变温度(Low critical solution temperature,LCST)前后会产生可逆的非连续体积相变,具体表现为线型PNIPAM在常温下溶于水中形成溶液,而升高温度后发生相变析出[1-4]。

目前得到普遍认可的温度响应机制是PNIPAM长链内的亲、疏水基团和水分子在分子内和分子间存在相互作用,并在氢键和疏水相互作用力的驱动下引起体积相变。当温度低于LCST时,分子链上酰胺基与水形成氢键,溶剂化作用增强,使聚合物的亲水性增强,表现为线型PNIPAM溶于水或吸水膨胀;当温度高于LCST时,酰胺基与水间氢键被破坏,异丙烯基间的相互作用增强,导致分子链附近的水分子减少,聚合物的疏水性增强,表现为相变析出或收缩 [5-8]。

目前PNIPAM主要被制备成温敏性水凝胶应用于生物医药材料和分离材料中。在生物医药材料领域,Chai等[9]将具有生物活性的肽链接枝到PNIPAM上制备出了一种温敏性水凝胶,这类肽接枝水凝胶具有促进血管生长因子表达、减少促炎症因子的分泌和抑制胶质瘢痕组织的形成等功能,为中枢神经系统组织工程材料的设计提供了新的方案。Zhu等[10]用两种PNIPAM的均聚物作为主客体进行正交自组装,结合了材料的温敏特性和自愈特性,且具有低细胞毒性和生物相容性,可用于大面积创口的敷料并在控制温度的情况下自行自修复,可以应用于伤口敷料、电子皮肤及穿戴生物传感器等领域。Wang等[11]制备了一种多功能复合纳米载体聚(N-异丙基丙烯酰胺)改性氧化石墨烯(PNIPAM-GO)的温度响应型农药制剂,通过温度控制纳米载体的变化从而控制农药的释放。农药在该制剂中显示出良好的水溶性和分散稳定性,且具有抗紫外线和无毒无害的优点。在分离材料领域,Xu等[12]将PNIPAM接枝到含溴聚酰胺层上,制造出一种高度抗污的纳米过滤膜,且渗透性较原始聚酰胺纳米膜增加一倍。当温度高于LCST时,PNIPAM发生链收缩,在膜与污染物间形成缓冲层,进一步加强污染物的分离。Zhao等[13]用原子转移自由基聚合合成PNIPAM接枝二氧化硅纳米颗粒,并将与聚偏二氟乙烯超滤膜进行共混,增强了滤膜的亲水性和水渗透性,且随着温度的降低,滤膜会产生自清洁特性,成功研发出一种热响应防污自清洁的过滤膜。

虽然具有的温度敏感特性的PNIPAM作为智能响应材料被广泛应用,但由纯PNIPAM制备得到的相关产品力学性能较差,温敏响应速率较慢且温度响应范围较小[14-18]。利用聚乙二醇甲醚(mPEG)与PNIPAM进行共聚处理是解决上述问题的一个有效的策略。聚乙二醇甲醚(mPEG)是一种在单端基上修饰了甲基的聚乙二醇衍生物,具有良好的韧性、水溶性、生物相容性及生物可降解性等优异性能,且mPEG仅有一端单官能团参与反应,因而具有极高的反应选择性[19-23]。

本文采用静电纺丝技术,将合成的PNIPAM电纺成为纳米纤维膜,将其独特的温敏特性与纳米材料质轻、比表面积大及孔隙率高等优点相结合,并尝试将mPEG与PNIPAM共聚,希望提升PNIPAM的力学性能、热稳定性、亲水性及扩大PNIPAM的温度响应范围,以期制备出一种综合性能优异的PNIPAM基纳米纤维膜。

1. 实验材料及方法

1.1 原材料

N-异丙基丙烯酰胺(NIPAM)、四甲基乙二胺(TEMED)、过二硫酸钾(KPS)、N', N'-二甲基甲酰胺(DMF)、聚乙二醇甲醚(mPEG)、偶氮二异丁腈(AIBN)和1, 4-二氧六环等均购自上海阿拉丁生化科技股份有限公司且均为分析纯,可直接使用无需进一步纯化。

1.2 实验过程

1.2.1 线型PNIPAM的制备

向50 mL锥形瓶中加入5 g单体N-异丙基丙烯酰胺(NIPAM)、0.1 g催化剂四甲基乙二胺(TEMED)和40 g去离子水后放入冰水浴中搅拌30 min至溶液澄清,再向溶液中加入引发剂过硫酸钾(KPS),通N2后密封锥形瓶,在低于25℃环境中反应24 h后生成黏稠胶状物质。反应后将锥形瓶中生成物转移到烧杯中,于70℃水浴中反应1 h,产生白色胶状聚合物。用50℃热水淋洗,抽滤聚合物,于70℃的烘箱中干燥,得到干燥的块状聚(N-异丙基丙烯酰胺)(PNIPAM)。

1.2.2 PNIPAM-co-mPEG的制备

在50 mL的烧杯加入聚乙二醇甲醚(mPEG)、NIPAM和AIBN,将上述三组份溶解在30 mL的1,4-二氧六环溶液中并通氮气脱气30 min。将烧杯密封并放置于恒温磁力搅拌器(70℃,90 rpm(每分钟转数))上搅拌24 h,待反应结束,装置冷却后,将烧杯中的溶液转移到旋转蒸发仪中进行提纯,待溶液黏稠度较大并略显黄色时,停止旋转蒸发。将旋蒸后的浓溶液转移至表面皿内蒸发、干燥后收集得到膜状PNIPAM-co-mPEG(表1)。

1.2.3 温敏纤维膜的制备

将PNIPAM溶于N', N'-二甲基甲酰胺(DMF)中,25℃下搅拌24 h制备出均一透明的聚合物电纺溶液;使用北京永康乐业生产的静电纺丝机(ET-1334 H,YKLY)在设定合适的电纺参数后制备得到PNIPAM基温敏纤维膜。具体电纺参数如表2所示。

表 1 制备聚(N-异丙基丙烯酰胺)(PNIPAM)-co-聚乙二醇甲醚(mPEG)的投料比例Table 1. Feeding ratio for preparation of poly(N-isopropylacrylamide) (PNIPAM)-co-polyethylene glycol methyl ether (mPEG)Sample NIPAM/g mPEG/g 1,4-dioxane/mL AIBN/g PNIPAM-

co-5mPEG5 1.22 30 0.15 PNIPAM-

co-10mPEG5 2.43 30 0.15 PNIPAM-

co-15mPEG5 3.65 30 0.15 Note: AIBN—Azodiisobutyronitrile. 表 2 制备PNIPAM基温敏纤维膜的电纺参数Table 2. Electrospinning parameters of PNIPAM based membranesSample Distance/

cmVoltage

(+/−)/kVVelocity/

(mm·min−1)PNIPAM

(11wt%)18.5 13.45/−2.5 0.15 PNIPAM

(13wt%)19.5 14.94/−2.5 0.20 PNIPAM

(15wt%)20.0 15.65/−2.5 0.20 PNIPAM-

co-mPEG17.0 13.45/−2.5 0.30 1.3 结构与性能表征

1.3.1 凝胶渗透色谱分析(GPC)

通过凝胶渗透色谱法(PL-GPC50,Agilent)测量共聚物的分子量及其分子量分布。测试使用DMF作为溶剂,测试温度稳定在25℃。

1.3.2 FTIR

通过傅里叶红外光谱仪(iS20,Nicolet)在室温下检测反应单体和聚合物的结构,扫描次数为32次,波长范围为4 000~400 cm−1,并根据特征官能团的吸收峰位置来判断反应的进行。

1.3.3 XPS

通过电子能谱仪(Thermo Scientific K-Alpha)对样品进行表征分析。设置电子能谱的范围为250~300 eV,测试聚合物中碳元素的化学环境来进一步确认聚合物的化学组成与结构。

1.3.4 SEM

通过场发射电子显微镜(SU8000,HITACHI) 镀金处理后在3000 kV的发射电压下观察温敏纤维膜的纤维直径及其分布形态。

1.3.5 DSC

通过差示扫描量热仪(DSC200,NETZSCH) 测量温敏纤维膜的低临界相变温度(LCST)。称取样品的质量为5~10 mg,测试过程在N2气氛下进行,测试温度为20~50℃,升温速率为5℃/min。

1.3.6 TGA

通过TGA2热分析仪(METTLER TOLEDO)获得温敏纤维膜的热失重曲线。称取样品的质量为5~10 mg,测试过程在N2气氛下进行,测试温度为0~700℃,升温速率为10℃/min,气体流量50 mL/min。

1.3.7 水接触角分析(WCA)

通过接触角分析仪(JC 2000 D,上海坤诚科学仪器有限公司)观察纤维膜的热响应行为,并使用加热平台控制温度。液滴图像采用高速相机连拍方式生成,每秒拍摄25张图像。水接触角数值采用五点法计算。

2. 结果与讨论

2.1 PNIPAM和PNIPAM-co-mPEG的分子量及化学结构

PNIPAM和PNIPAM-co-mPEG通过自由基共聚方法制备。通过凝胶渗透色谱法测量共聚物的分子量及其分子量分布,结果显示制备得到的共聚物具有相对较大的分子量(Mw>1000000,Mn>300000)和较宽的分子量分布(聚合物分散性指数PDI>2),这导致共聚物性质的不稳定,详细结果总结在表3中。

表 3 PNIPAM和PNIPAM-co-mPEG的分子量及其分布Table 3. Molecular weight and molecular weight distribution of PNIPAM and PNIPAM-co-mPEGSample Mn/(g·mol−1) Mw/(g·mol−1) PDI PNIPAM 595156 1250589 2.10 PNIPAM-co-5mPEG 434110 1079342 2.49 PNIPAM-co-10mPEG 520070 1784472 3.43 PNIPAM-co-15mPEG 348551 1534512 4.40 Notes: Mn—Number-average molecular weight; Mw—Mass-average molecular mass; PDI—Polydispersity index (Ratio of the mass average molecular mass to the number average molecular mass). 图1(a)是NIPAM和PNIPAM-co-mPEG的FTIR图谱。单体NIPAM的特征基团胺基(—NH)对应的特征峰为3280 cm−1,异丙基中—CH3对应的特征峰为2973 cm−1,碳碳双键(C=C)对应的特征峰为1643 cm−1。聚合物PNIPAM-co-mPEG由单体经自由基聚合而成,聚合过程中单体的双键打开,单体的碳链连接在一起实现链增长,故在PNIPAM-co-mPEG的FTIR图谱中未发现C=C双键的特征峰,只存在特征基团—C=O在1741 cm−1对应的特征峰,且在1300~1020 cm−1处出现了一处新的峰,即出现了新的C—O—C键,表明mPEG和PNIPAM共聚形成共聚物。

图1(b)是NIPAM和PNIPAM-co-mPEG的XPS能谱。通过测试碳元素的结合能,确定物质中化学键的种类,来分析其化学结构。从图1(c)中可以看出,单体NIPAM含有C=C特征官能团,C=C结合能为284.8 eV,C=O键结合能为288.7 eV,C—C键结合能为284.7 eV,C—H键结合能为285.5 eV,C—N键结合能为291.5 eV。而PNIPAM-co-mPEG分子中碳元素的光电子能谱图,其能谱图中只含有C=O、C—N等特征能谱,不含有C=C键的特征能谱,这说明单体NIPAM通过自由基聚合成功合成PNIPAM-co-mPEG。

2.2 PNIPAM和PNIPAM-co-mPEG纤维膜的表面形貌

通过SEM来观察PNIPAM和PNIPAM-co-mPEG纳米纤维膜的纤维直径及其分布情况。主要对不同质量分数电纺溶液制备得到的温敏纤维膜进行表征(图2)。

如图2(a)所示,当溶液浓度较低(<13wt%)时,液滴经高压静电力作用后分散成喷雾状,溶剂在纺丝过程中难以挥发完全,造成接收装置上残留较多溶剂,样品的成膜状态较差,只在接收装置两侧边缘沉积少量纳米纤维,得不到完整的纳米纤维膜。当溶液浓度过高时(>17wt%),电纺溶液存在较大的表面张力,即使增大电压也难以将液滴有效分裂,此时针头处的溶液分裂后的直径远超纳米尺度,接收装置上无法得到完整的纳米纤维膜。

![]() 图 2 (a) 不同浓度的电纺溶液在接收装置上的成膜状态;(b) 13wt%线型PNIPAM电纺纤维膜的SEM图像;(c) 15wt%线型PNIPAM电纺纤维膜的SEM图 像;(d) 17wt%线型PNIPAM电纺纤维膜的SEM图像;(e) PNIPAM-co-mPEG纳米纤维膜的SEM图像Figure 2. (a) Nano-membranes state on receiver device with different electrospinning solution concentrations; (b) SEM images of 11wt% PNIPAM nano-membranes; (c) SEM images of 13wt% PNIPAM nano-membranes; (d) SEM images of 15wt% PNIPAM nano-membranes; (e) SEM images of PNIPAM-co-mPEG nano-membranes

图 2 (a) 不同浓度的电纺溶液在接收装置上的成膜状态;(b) 13wt%线型PNIPAM电纺纤维膜的SEM图像;(c) 15wt%线型PNIPAM电纺纤维膜的SEM图 像;(d) 17wt%线型PNIPAM电纺纤维膜的SEM图像;(e) PNIPAM-co-mPEG纳米纤维膜的SEM图像Figure 2. (a) Nano-membranes state on receiver device with different electrospinning solution concentrations; (b) SEM images of 11wt% PNIPAM nano-membranes; (c) SEM images of 13wt% PNIPAM nano-membranes; (d) SEM images of 15wt% PNIPAM nano-membranes; (e) SEM images of PNIPAM-co-mPEG nano-membranes图2(b)是质量分数13wt%的PNIPAM电纺纤维的SEM图像。该浓度下纤维密集程度适中,纤维直径分布于350~400 nm之间。图2(c)是质量分数15wt%的电纺纤维的SEM图像。该浓度下纳米纤维直径集中在300~350 nm间,纤维密集程度更大,孔隙更小且成膜效果较好。图2(d)是质量分数为17wt%的电纺纳米纤维的SEM图像。该质量分数下的纳米纤维直径超过400 nm,纤维密集程度为3个浓度中最低,孔隙更大且成膜效果较差,出现大量空洞及电纺溶液过浓带有的丝状结构。图2(e)为PNIPAM-co-mPEG纳米纤维膜的SEM图像。纤维分散程度及空隙分布与线型PNIPAM相似,但纤维半径小于线型PNIPAM。

2.3 PNIPAM和PNIPAM-co-mPEG的热性能

2.3.1 低临界溶解温度(LCST)测试结果分析

由于温敏聚合物的相变,在升温过程中出现了一个显着的吸热峰,而DSC曲线吸热变化的起始点称为低临界溶解温度(LCST)。PNIPAM的 LCST可以通过调节聚合物亲水和疏水链段的比例来改变,而将温敏型高分子共聚其他单体是调节LCST的有效方法。图3(a)展示了PNIPAM、PNIPAM-co-5mPEG、PNIPAM-co-10mPEG和 PNIPAM-co-15mPEG随温度升高的DSC曲线。测试结果表明,PNIPAM聚合物的LCST为31.7°C,随着亲水性mPEG的加入,共聚物PNIPAM-co-mPEG的LCST显著增加,当mPEG的共聚比例为10wt%时,共聚物的LCST达到36.8℃,该温度与人体体温十分接近,有利于拓展该类材料在组织工程领域中的应用。

2.3.2 TGA结果分析

图3(b)、图3(c)和表4为线型PNIPAM和不同共聚比例的PNIPAM-co-mPEG热失重数据。可以看出,PNIPAM、PNIPAM-co-5mPEG、PNIPAM-co-10mPEG和 PNIPAM-co-15mPEG都有三段明显失重温度。初始升温阶段,低分子物质和溶剂的挥发导致质量的下降,4种纤维膜的初始分解温度(T10%)分别为112.12℃、250.50°C、269.29°C和290.46°C,随着共聚比例的增加,纤维膜的初始分解温度显著提升。随着温度的升高,大分子链开始断裂分解,相较于纯PNIPAM,共聚后样品的残重率最高提升321%,初始分解温度最高提升240%。

表 4 PNIPAM和不同比例共聚物热失重信息Table 4. TGA and DTG information of PNIPAM and PNIPAM-co-mPEGSample Residue/% T10%/℃ TMax/℃ PNIPAM 0.42 112.12 409.10 PNIPAM-co-5mPEG 1.67 250.50 394.30 PNIPAM-co-10mPEG 1.35 269.29 387.60 PNIPAM-co-15mPEG 1.27 290.46 352.40 Notes: T10%—Initial decomposition temperature; TMax—Maximum decomposition temperature. 2.4 PNIPAM和PNIPAM-co-mPEG纤维膜的温敏特性分析

图4(a)展示了纯 PNIPAM的电纺纤维膜在25°C(温度T<LCST)的水溶液中快速溶解的过程。这是由于其在水性介质中吸水膨胀到一定程度时,纤维膜中聚合物的密度急剧降低,使纤维膜无法保持其固有形态。相比之下,共聚后的温敏纤维膜在吸水溶胀后仍能够保持其纤维结构,这是由于在共聚过程中PNIPAM与mPEG 之间发生物理交联,不同的分子连接在一起使其整体力学性能得到显著提升,达到防止其溶解在水中的效果。图4(b)显示了PNIPAM和PNIPAM-co-mPEG电纺温敏纤维的拉伸强度,结果显示在共聚比例为100∶10的条件下,温敏纤维在25℃的水溶液中吸水膨胀后的拉伸强度达到1.75 MPa,展现出一定的力学性能。而纯PNIPAM温敏纤维在25℃的水溶液中大量吸水发生溶解,故无法测得该条件下的拉伸强度值。温敏纤维在45℃的水溶液中呈现出迅速收缩状态,展现出较强的韧性,拉伸强度大幅提升。在共聚比例为100∶5的条件下,纤维膜的拉伸强度达到7.45 MPa,与纯PNIPAM温敏纤维相比,拉伸强度提升30%。

![]() 图 4 (a) 将 PNIPAM-co-mPEG和纯PNIPAM纤维膜浸入25℃和45℃的水溶液中的状态;(b) PNIPAM和PNIPAM-co-mPEG纳米纤维膜的拉伸强度对比图;(c) PNIPAM和PNIPAM-co-mPEG纳米膜的水接触角图像Figure 4. (a) Nano-membranes obtained from PNIPAM-co-mPEG and pure PNIPAM were immersed in water at 25℃ and 45°C; (b) Tensile strength comparison of PNIPAM and PNIPAM-co-mPEG nano-membranes; (c) Water contact angle images of PNIPAM and PNIPAM-co-mPEG nano-membranesCA—Contact angle

图 4 (a) 将 PNIPAM-co-mPEG和纯PNIPAM纤维膜浸入25℃和45℃的水溶液中的状态;(b) PNIPAM和PNIPAM-co-mPEG纳米纤维膜的拉伸强度对比图;(c) PNIPAM和PNIPAM-co-mPEG纳米膜的水接触角图像Figure 4. (a) Nano-membranes obtained from PNIPAM-co-mPEG and pure PNIPAM were immersed in water at 25℃ and 45°C; (b) Tensile strength comparison of PNIPAM and PNIPAM-co-mPEG nano-membranes; (c) Water contact angle images of PNIPAM and PNIPAM-co-mPEG nano-membranesCA—Contact angle如图4(c)所示,在25°C(T<LCST)的环境温度下,温敏纤维膜的水接触角为51.71°,表现出亲水性。相反,在45°C(T>LCST)的环境温度下温敏纤维膜的水接触角为113.64°,表现出疏水性。值得注意的是,随着共聚比例的增加,温敏纤维膜的水接触角降低16°,亲水性有一定程度的提高。这是由于mPEG属于亲水性聚合物,聚合物链中含有大量亲水性的—OH,在与PNIPAM共聚过程中,这些亲水性的—OH接枝到PNIPAM聚合物链中,使共聚物的亲水性增强。上述现象均表明电纺温敏纤维膜具有优异的力学性能和显著的温度响应特性。

3. 结 论

采用自由基聚合的方法制备得到聚(N-异丙基丙烯酰胺)(PNIPAM)与PNIPAM-co-聚乙二醇甲醚(mPEG),并通过静电纺丝法将其制备成为具有温敏特性纳米纤维膜,得到以下主要结论:

(1) 温敏单体N-异丙基丙烯酰胺(NIPAM)在聚合过程中单体的碳碳双键打开,单体之间的碳链连接在一起实现链增长,通过GPC、FTIR和XPS等测试证明了聚合物的成功合成;

(2) 制备得到的温敏纤维膜能随着温度的变化呈现出显著的亲、疏水性转变,响应速率灵敏,具有独特的温度敏感特性;

(3) 共聚mPEG后,温敏纤维膜的力学性能得到显著提升,能在25℃大量吸水溶胀的状态下保持纤维固有形态,展现出一定的力学性能。与此同时,在45℃高温收缩状态下,温敏纤维展现出较强的韧性,在共聚比例为100∶5时,纤维膜的拉伸强度达到7.45 MPa;

(4) 共聚mPEG后,温敏纤维膜的残重率最高提升321%,初始分解温度最高提升240%,但最高分解温度有所下降;

(5) 共聚mPEG后,温敏纤维膜在室温下的接触角减小超过16°,亲水性得到一定程度提高;

(6) mPEG的共聚可以调节PNIPAM的低临界相变温度,随着共聚比例的增加,其低临界相变温度逐渐上升。

总之,由静电纺丝法制备得到的温敏纤维膜展现出显著的温度敏感特性,mPEG与PNIPAM的共聚显著改善了PNIPAM温敏纤维膜的各项性能,扩大了其应用范围,有利于该类材料朝着智能化、自适应化和多功能化的方向发展。

-

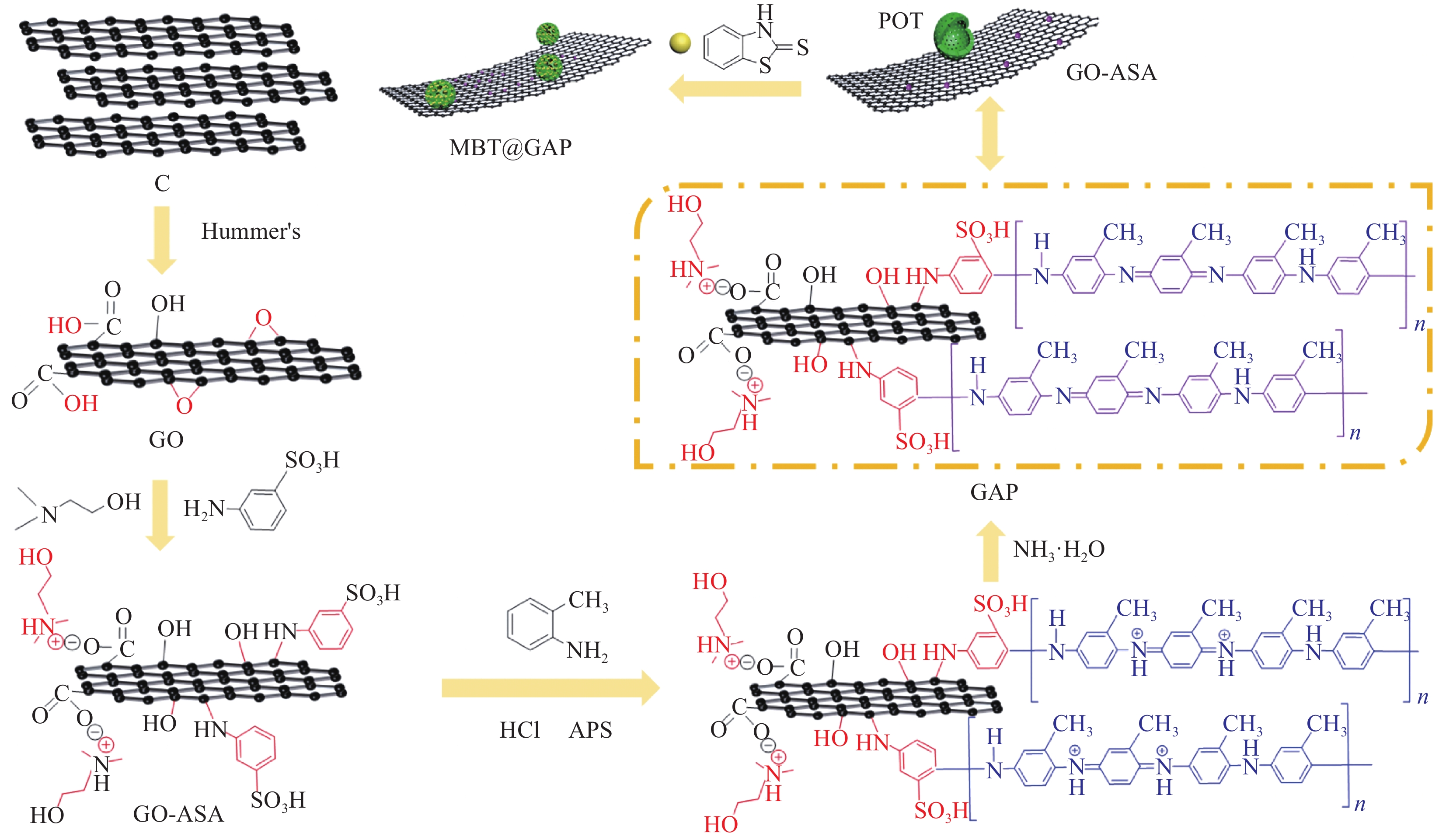

图 1 缓蚀型聚邻甲苯胺-氧化石墨烯基(MBT@GAP)复合材料的制备过程

Figure 1. Preparation process of corrosion inhibited poly(o-toluidine)-graphene oxide-based (MBT@GAP) composite materials

C—Graphite; GO—Graphene oxide; ASA—3-aminobenzenesulfonic acid; APS—Ammonium persulphate; POT—Poly(o-toluidine); MBT—2-mercaptobenzothiazole; GAP—POT-GO

图 11 MBT@GAP/WEP-0.3wt%涂层不同盐雾时间下的阻抗模量曲线(a)、相位角曲线(b)、Nyquist图(c)、等效电路模型(d)

Figure 11. Impedance modulus curves (a), phase angle curves (b), Nyquist diagram (c), electrical equivalent circuit models (d) of MBT@GAP/WEP-0.3wt% coating under different salt spray time

Rcoat—Coating resistance; CPEcoat—Coating non-ideal capacitance; CPEdl—Double layer non-ideal capacitor; RCT—Charge transfer resistance; Rs—Solution resistance

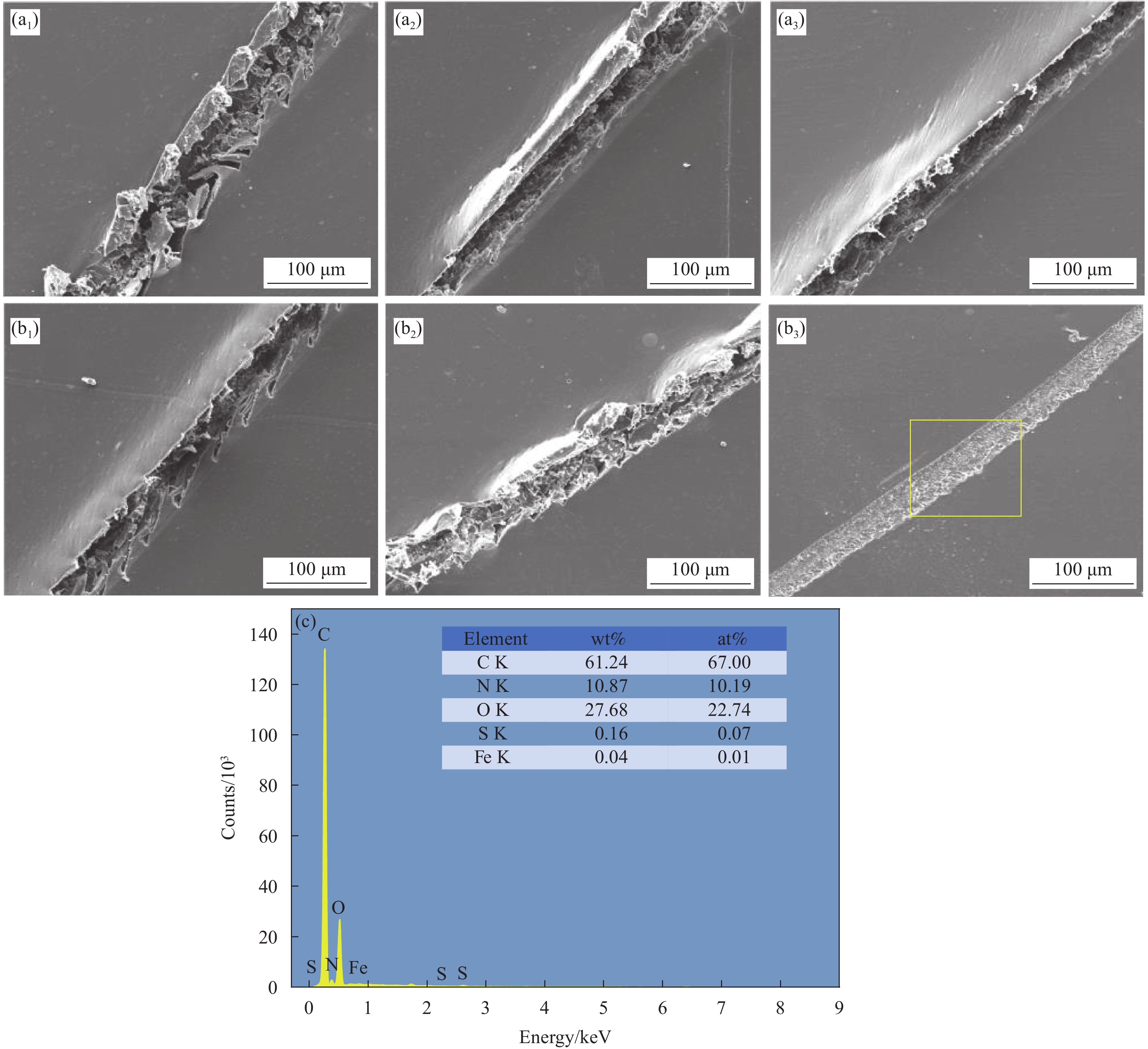

图 13 WEP涂层划伤后0 h (a1)、5 h (a2)、10 h (a3)和MBT@GAP/WEP-0.3wt%涂层划伤后0 h (b1)、5 h (b2)、10 h (b3)的SEM图像;(c) MBT@GAP/WEP-0.3wt%复合涂层划痕自修复后的EDS谱图

Figure 13. SEM images of 0 h (a1), 5 h (a2), 10 h (a3) after scratch of WEP coating and 0 h (b1), 5 h (b2), 10 h (b3) after scratch of MBT@GAP/WEP-0.3wt% coating; (c) EDS spectrum of MBT@GAP/WEP-0.3wt% composite coating scratches after self-healing

表 1 不同MBT@GAP添加量时复合涂层极化曲线参数

Table 1 Polarization curve parameters of composite coating with different contents of MBT@GAP

Ecorr/V Icorr/(A·cm−2) βa/(V·dec−1) βc/(V·dec−1) Rp/(Ω·cm2) WEP −0.6216 4.271×10−7 0.1781 0.2112 9.823×104 MBT@GAP/WEP-0.1wt% −0.4380 3.150×10−10 0.1962 0.1877 1.322×108 MBT@GAP/WEP-0.2wt% −0.2828 1.937×10−10 0.1397 0.2002 1.845×108 MBT@GAP/WEP-0.3wt% −0.1554 1.016×10−11 0.1212 0.0644 1.797×109 MBT@GAP/WEP-0.4wt% −0.3204 2.262×10−10 0.1453 0.2212 1.683×108 MBT@GAP/WEP-0.5wt% −0.5481 6.507×10−10 0.1957 0.1579 5.832×107 Notes: Ecorr—Corrosion potential; Icorr—Corrosion current density; βa—Anode slope; βc—Cathode slope; Rp—Polarization resistance. 表 2 不同MBT@GAP添加量时复合涂层交流阻抗谱图拟合参数

Table 2 Fitting parameters of alternating current impedance spectra of composite coating with different contents of MBT@GAP

Sample Rcoat/(Ω·cm2) CPEcoatγ/(Ω−1·cm−2·sn) n WEP 4.967×106 9.129×10−10 0.8288 MBT@GAP/WEP-0.1wt% 8.643×107 2.816×10−10 0.8915 MBT@GAP/WEP-0.2wt% 2.781×108 1.107×10−10 0.9185 MBT@GAP/WEP-0.3wt% 2.837×109 9.922×10−11 0.9388 MBT@GAP/WEP-0.4wt% 1.234×108 2.015×10−10 0.9101 MBT@GAP/WEP-0.5wt% 2.132×107 3.313×10−10 0.8667 Notes: n—Empirical index of CPEcoat; γ—Proportional factor. 表 3 MBT@GAP/WEP-0.3wt%复合涂层随盐雾时间变化的电化学阻抗拟合参数

Table 3 Electrochemical impedance fitting parameters for MBT@GAP/WEP-0.3wt% composite coatings with salt spray time

Salt spray time/h Rcoat/(Ω·cm2) CPEcoatγ/(Ω−1·cm−2·sn) n RCT/(Ω·cm2) CPEdlγ/(Ω−1·cm−2·sn') n' 0 2.837×109 9.922×10−11 0.9388 — — — 100 7.760×108 3.725×10−10 0.9225 — — — 200 2.454×108 4.339×10−10 0.9981 — — — 300 1.243×108 1.024×10−10 0.9662 — — — 400 4.885×107 5.424×10−10 0.8778 — — — 500 8.169×106 5.606×10−10 0.8401 3.111×106 8.138×10−8 0.4673 Note: n'—Empirical index of CPEdl. -

[1] WILDS N. Corrosion under insulation[M]//EL-SHERIK A M. Trends in Oil and Gas Corrosion Research and Technologies. Cambridge: Woodhead Publishing, 2017: 409-429.

[2] XAVIER J R. Effect of surface modified WO3 nanoparticle on the epoxy coatings for the adhesive and anticorrosion properties of mild steel[J]. Journal of Applied Polymer Science,2020,137(5):48323. DOI: 10.1002/app.48323

[3] SARI M G, RAMEZANZADEH B. Epoxy composite coating corrosion protection properties reinforcement through the addition of hydroxyl-terminated hyperbranched polyamide non-covalently assembled graphene oxide platforms[J]. Construction and Building Materials,2020,234:117421. DOI: 10.1016/j.conbuildmat.2019.117421

[4] OU B L, WANG Y W, LU Y. A review on fundamentals and strategy of epoxy-resin-based anticorrosive coating materials[J]. Polymer-Plastics Technology and Materials,2021,60(6):601-625. DOI: 10.1080/25740881.2020.1819317

[5] CAI G Y, XIAO S, DENG C M, et al. CeO2 grafted carbon nanotube via polydopamine wrapping to enhance corrosion barrier of polyurethane coating[J]. Corrosion Science,2021,178:109014. DOI: 10.1016/j.corsci.2020.109014

[6] DAGDAG O, HSISSOU R, BERISHA A, et al. Polymeric-based epoxy cured with a polyaminoamide as an anticorrosive coating for aluminum 2024-T3 surface: Experimental studies supported by computational modeling[J]. Journal of Bio- and Tribo-Corrosion,2019,5(3):58. DOI: 10.1007/s40735-019-0251-7

[7] ATTA A M, MOHAMED N H, ROSTOM M, et al. New hydrophobic silica nanoparticles capped with petroleum paraffin wax embedded in epoxy networks as multifunctional steel epoxy coatings[J]. Progress in Organic Coatings,2019,128:99-111. DOI: 10.1016/j.porgcoat.2018.12.018

[8] LU F S, LIU C Q, CHEN Z H, et al. Polypyrrole-functionalized boron nitride nanosheets for high-performance anti-corrosion composite coating[J]. Surface Coatings Technology,2021,420:127273. DOI: 10.1016/j.surfcoat.2021.127273

[9] YEGANEH M, ASADI N, OMIDI M, et al. An investigation on the corrosion behavior of the epoxy coating embedded with mesoporous silica nanocontainer loaded by sulfamethazine inhibitor[J]. Progress in Organic Coatings,2019,128:75-81. DOI: 10.1016/j.porgcoat.2018.12.022

[10] YAN H, LI W, LI H, et al. Ti3C2 MXene nanosheets toward high-performance corrosion inhibitor for epoxy coating[J]. Progress in Organic Coatings,2019,135:156-167. DOI: 10.1016/j.porgcoat.2019.06.013

[11] CAO X K, PAN J L, CAI G Y, et al. A chemically robust and self-healing superhydrophobic polybenzoxazine coating without fluorocarbon resin modification: Fabrication and failure mechanism[J]. Progress in Organic Coatings,2022,163:106630. DOI: 10.1016/j.porgcoat.2021.106630

[12] SAMIEE R, RAMEZANZADEH B, MAHDAVIAN M, et al. Designing a non-hazardous nano-carrier based on graphene oxide@polyaniline-praseodymium (III) for fabrication of the active/passive anti-corrosion coating[J]. Journal of Hazardous Materials,2020,398:123136. DOI: 10.1016/j.jhazmat.2020.123136

[13] KEYVANI A, YEGANEH M, REZAEYAN H. Application of mesoporous silica nanocontainers as an intelligent host of molybdate corrosion inhibitor embedded in the epoxy coated steel[J]. Progress in Natural Science: Materials International,2017,27(2):261-267. DOI: 10.1016/j.pnsc.2017.02.005

[14] KASAEIAN M, GHASEMI E, RAMEZANZADEH B, et al. Construction of a highly effective self-repair corrosion-resistant epoxy composite through impregnation of 1H-benzimidazole corrosion inhibitor modified graphene oxide nanosheets (GO-BIM)[J]. Corrosion Science,2018,145:119-134. DOI: 10.1016/j.corsci.2018.09.023

[15] JIANG D, XIA X C, HOU J, et al. A novel coating system with self-reparable slippery surface and active corrosion inhibition for reliable protection of Mg alloy[J]. Chemical Engineering Journal,2019,373:285-297. DOI: 10.1016/j.cej.2019.05.046

[16] LU H, ZHANG S T, LI W H, et al. Synthesis of graphene oxide-based sulfonated oligoanilines coatings for synergistically enhanced corrosion protection in 3.5% NaCl solution[J]. ACS Applied Materials & Interfaces,2017,9(4):4034-4043.

[17] HAO Y S, SUN W, JIANG L L, et al. Self-healing effect of epoxy coating containing mesoporous polyaniline hollow spheres loaded with benzotriazole[J]. Progress in Organic Coatings,2021,159:106445. DOI: 10.1016/j.porgcoat.2021.106445

[18] MOHAMMADZADEH A, GHAFOURI TALEGHANI H, LASHKENARI M S. Preparation and comparative study of anticorrosion nanocomposites of polyaniline/graphene oxide/clay coating[J]. Journal of Materials Research and Technology,2021,13:2325-2335. DOI: 10.1016/j.jmrt.2021.05.098

[19] 张青青, 陈亚鑫, 刘仁, 等. 基于聚苯胺微胶囊的双重自修复防腐涂层[J]. 高分子学报, 2023, 54(5):720-730. ZHANG Qingqing, CHEN Yaxin, LIU Ren, et al. Dual-action self-healing anticorrosive coating based on polyaniline microcapsules[J]. Acta Polymerica Sinica,2023,54(5):720-730(in Chinese).

[20] DONG J H, PAN W H, LUO J, et al. Synthesis of inhibitor-loaded polyaniline microcapsules with dual anti-corrosion functions for protection of carbon steel[J]. Electrochimica Acta, 2020, 364: 137299.

[21] ZHANG Y J, LI M Y, WEN J, et al. Preparation of polyaniline encapsulated acrylic resin microcapsules and its active corrosion protection of coating for magnesium alloy[J]. Arabian Journal of Chemistry,2023,16(10):105129. DOI: 10.1016/j.arabjc.2023.105129

[22] CAO Y, YUAN X W, WANG X, et al. Synthesis and controlled release kinetics of pH-sensitive hollow polyaniline microspheres encapsuled with the corrosion inhibitor[J]. Journal of Molecular Liquids, 2021, 342: 117497.

[23] LIANG X, LI X J, TANG Y, et al. Hyperbranched epoxy resin-grafted graphene oxide for efficient and all-purpose epoxy resin modification[J]. Journal of Colloid and Interface Science,2021,611:105-117.

[24] TAHERI N N, RAMEZANZADEH B, MAHDAVIAN M, et al. In-situ synthesis of Zn doped polyaniline on graphene oxide for anti-corrosive reinforcement of epoxy coating[J]. Journal of Industrial and Engineering Chemistry,2018,63:322-339. DOI: 10.1016/j.jiec.2018.02.033

[25] AN H R, LIU K B, WANG S Q, et al. Enhanced corrosion resistance of waterborne epoxy coatings by polyaniline nanorods and nitrogen and fluorine dual-doped graphene oxide composites[J]. ACS Applied Nano Materials,2023,6(14):13250-13259. DOI: 10.1021/acsanm.3c01964

[26] LIU S Y, LIU L, GUO H X, et al. Electrochemical polymerization of polyaniline-reduced graphene oxide composite coating on 5083Al alloy: Role of reduced graphene oxide[J]. Electrochemistry Communications,2019,98:110-114. DOI: 10.1016/j.elecom.2018.12.004

[27] ZHU K, LI X R, WANG H H, et al. Electrochemical and anti-corrosion behaviors of water dispersible graphene/acrylic modified alkyd resin latex composites coated carbon steel[J]. Journal of Applied Polymer Science,2017,134(11):44445.

[28] 中国国家标准化管理委员会. 漆膜一般制备法: GB/T 1727—2021[S]. 北京: 中国标准出版社, 2021. Standardization Administration of the People's Republic of China. General methods for preparation of coating films: GB/T 1727—2021[S]. Beijing: Standards Press of China, 2021(in Chinese).

[29] 邹明明, 李小瑞, 沈一丁, 等. 改性氧化石墨烯/聚苯胺防腐材料的制备及性能[J]. 精细化工, 2018, 35(5):891-900. DOI: 10.13550/j.jxhg.20170370 ZOU Mingming, LI Xiaorui, SHEN Yiding, et al. Preparation and properties of modified graphene oxide/polyaniline anticorrosive materials[J]. Fine Chemicals,2018,35(5):891-900(in Chinese). DOI: 10.13550/j.jxhg.20170370

[30] WANG J J, SU W H, ZHANG J M, et al. Improving the volumetric specific capacitance of flexible polyaniline electrode: Solution casting method and effect of reduced graphene oxide sheets[J]. Science China Materials,2021,64(3):571-580. DOI: 10.1007/s40843-020-1472-3

[31] ZHOU C, HONG M, YANG Y, et al. Engineering sulfonated polyaniline molecules on reduced graphene oxide nanosheets for high-performance corrosion protective coatings[J]. Applied Surface Science,2019,484(1):663-675.

[32] PARANGUSAN H, BHADRA J, AHMAD Z, et al. Investigation of the structural, optical and gas sensing properties of PANI coated Cu-ZnS microsphere composite[J]. RSC Advances,2020,10(45):26604-26612. DOI: 10.1039/D0RA04991C

[33] PIRHADY TAVANDASHTI N, GHORBANI M, SHOJAEI A, et al. Inhibitor-loaded conducting polymer capsules for active corrosion protection of coating defects[J]. Corrosion Science,2016,112:138-149. DOI: 10.1016/j.corsci.2016.07.003

[34] VETHANATHAN S J K, ABOORVAKANI R, MADHU K U. Yttrium doped ZnO nanofillers reinforced epoxy coating for anticorrosion application[J]. Inorganic Chemistry Communications,2022,144:109929. DOI: 10.1016/j.inoche.2022.109929

[35] MENG Y B, GAO Y F, LI J Y, et al. Preparation and characterization of cross-linked waterborne acrylic/PTFE composite coating with good hydrophobicity and anticorrosion properties[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2022,653:129872. DOI: 10.1016/j.colsurfa.2022.129872

[36] DUAN H L, JI J W, CAO C C, et al. Enhanced anti-corrosion performance of carbon steels via CeO2@BNNSs/epoxy resin composite coatings[J]. Macromolecular Chemistry and Physics, 2023, 224(11): 2300006.

[37] DONG H Y, ZHAN Y Q, CHEN Y W, et al. Fabrication of hydrophobic and enhanced anticorrosion performance of epoxy coating through the synergy of functionalized graphene oxide and nano-silica binary fillers[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2023,664:131086. DOI: 10.1016/j.colsurfa.2023.131086

[38] LI J Y, ZHU K, FU Z L. A waterborne uniform graphene oxide-epoxy complex with enhanced anticorrosive properties enabled by intercalation polymerization[J]. Journal of Polymer Engineering,2023,43(5):443-453. DOI: 10.1515/polyeng-2022-0295

-

期刊类型引用(25)

1. 董连成,金圣豪. 损伤水泥混凝土路面非线性湿度翘曲应力分析. 公路交通科技. 2025(03): 78-86 .  百度学术

百度学术

2. 陆春华,朱学武,平安,杨钰婷. 含引气剂海工混凝土的抗冻性能及其梁受弯承载力. 硅酸盐通报. 2024(02): 418-427 .  百度学术

百度学术

3. 董连成,金圣豪,王金玉. 盐冻作用下水泥路面毛细吸水系数演化及应力状态分析. 黑龙江科技大学学报. 2024(01): 77-84 .  百度学术

百度学术

4. 王晨霞,周阳升,王高峰,刘涛,王晓云,曹芙波. 冻融环境下钢渣细骨料混凝土微观结构及损伤演化模型. 应用力学学报. 2024(03): 585-593 .  百度学术

百度学术

5. 袁立月,陈克政,彭飞,付翼博,孙剑飞,丁琳. 冻融循环作用下陶粒混凝土抗压性能研究. 黑龙江大学工程学报(中英俄文). 2023(04): 81-87 .  百度学术

百度学术

6. 张晓锋,卢浩,高渊. 冻融循环下混凝土动态力学性能试验研究. 混凝土. 2023(11): 12-16+19 .  百度学术

百度学术

7. 孙杰,孙明星,冯川,吴爽,马稳. 碳-玻璃混杂纤维改性橡胶混凝土抗冻性研究. 水利与建筑工程学报. 2022(02): 101-107+117 .  百度学术

百度学术

8. 甘磊,冯先伟,沈振中. 盐冻作用下水工混凝土强度演化模型. 水利水运工程学报. 2022(04): 131-139 .  百度学术

百度学术

9. 童彧斐,严鹏飞,张虎彪,延常玉,李宏波. 水泥粉煤灰稳定炉渣煤矸石混合料抗冻试验. 中国科技论文. 2022(10): 1078-1083 .  百度学术

百度学术

10. 蔡荨,杨妙帆,周克发. 考虑冻融作用的混凝土拱坝结构可靠度分析. 水电能源科学. 2021(04): 76-79+189 .  百度学术

百度学术

11. 张婵韬,段政彬. 可分散性乳胶粉对玻化微珠保温砂浆干湿循环下损伤影响研究. 混凝土世界. 2020(02): 63-67 .  百度学术

百度学术

12. 薛翠真,申爱琴,乔宏霞. 掺CWCPM混凝土的冻融损伤机理及演化模型. 华南理工大学学报(自然科学版). 2020(03): 136-144 .  百度学术

百度学术

13. 张卫东,董云,彭宁波,高延安. 冻融循环下透水再生混凝土力学性能损伤分析. 建筑材料学报. 2020(02): 292-296 .  百度学术

百度学术

14. 张经双,段雪雷,马冬冬. 氯盐和冻融耦合下水泥土的强度和破坏特征. 冰川冻土. 2020(02): 515-522 .  百度学术

百度学术

15. 程猛,张经双,段雪雷,朱建华. 冻融循环作用下混杂纤维粉煤灰混凝土力学性能试验. 科学技术与工程. 2020(27): 11288-11294 .  百度学术

百度学术

16. 赵小明,李奥阳,乔宏霞,李江川,王新科. 纤维混凝土抗冻性能及损伤劣化模型研究. 硅酸盐通报. 2020(10): 3196-3202 .  百度学术

百度学术

17. 张广泰,刘诗拓,耿天娇,彭瑞,陈勇. 基于Weibull分布的冻融循环下纤维混凝土损伤模型. 科学技术与工程. 2020(29): 12078-12084 .  百度学术

百度学术

18. 张兆文,周茗如,魏琴玲,谢国鑫. 基于冻融损伤下的高性能混凝土力学性能衰减规律研究. 混凝土与水泥制品. 2019(04): 16-19 .  百度学术

百度学术

19. 龙广成,杨振雄,白朝能,马昆林,谢友均. 荷载-冻融耦合作用下充填层自密实混凝土的耐久性及损伤模型. 硅酸盐学报. 2019(07): 855-864 .  百度学术

百度学术

20. 张经双,段雪雷. 冻融循环下不同龄期水泥土损伤特性和能量耗散. 硅酸盐通报. 2019(07): 2144-2151 .  百度学术

百度学术

21. 徐存东,李振,朱兴林,姚志鹏,王铭岩,张鹏. 盐冻侵蚀作用下混凝土力学性能变化研究. 人民黄河. 2019(09): 132-136 .  百度学术

百度学术

22. 姚贤华,冯忠居,王富春,管俊峰. 复合盐浸下多元外掺剂-混凝土抗干湿-冻融循环性能. 复合材料学报. 2018(03): 690-698 .  本站查看

本站查看

23. 王磊,刘欢,张旭辉. 不同介质冻融对高强混凝土的损伤及抗氯盐侵蚀性的影响. 长沙理工大学学报(自然科学版). 2018(02): 43-50 .  百度学术

百度学术

24. 张祺,裴向军,张佳兴,冉耀. 黏度时变浆液结石体冻融条件下力学特性试验研究. 工程地质学报. 2018(06): 1508-1515 .  百度学术

百度学术

25. 李英娜,张井财. 季节性冻土CFG桩复合地基冻融循环后承载力数值模拟. 低温建筑技术. 2017(11): 125-128 .  百度学术

百度学术

其他类型引用(24)

-

目的

氧化石墨烯(GO)具有比表面积大的优势,但难以对破损涂层实现修复,限制了其在涂层防腐方面的应用。然而,聚邻甲苯胺(POT)在兼具防腐功能的同时,也可作为微胶囊负载缓蚀剂,但美中不足的是涂层的屏蔽性能有待提高。因此,开发一种屏蔽性强且具有缓蚀作用的涂层具有重要意义。

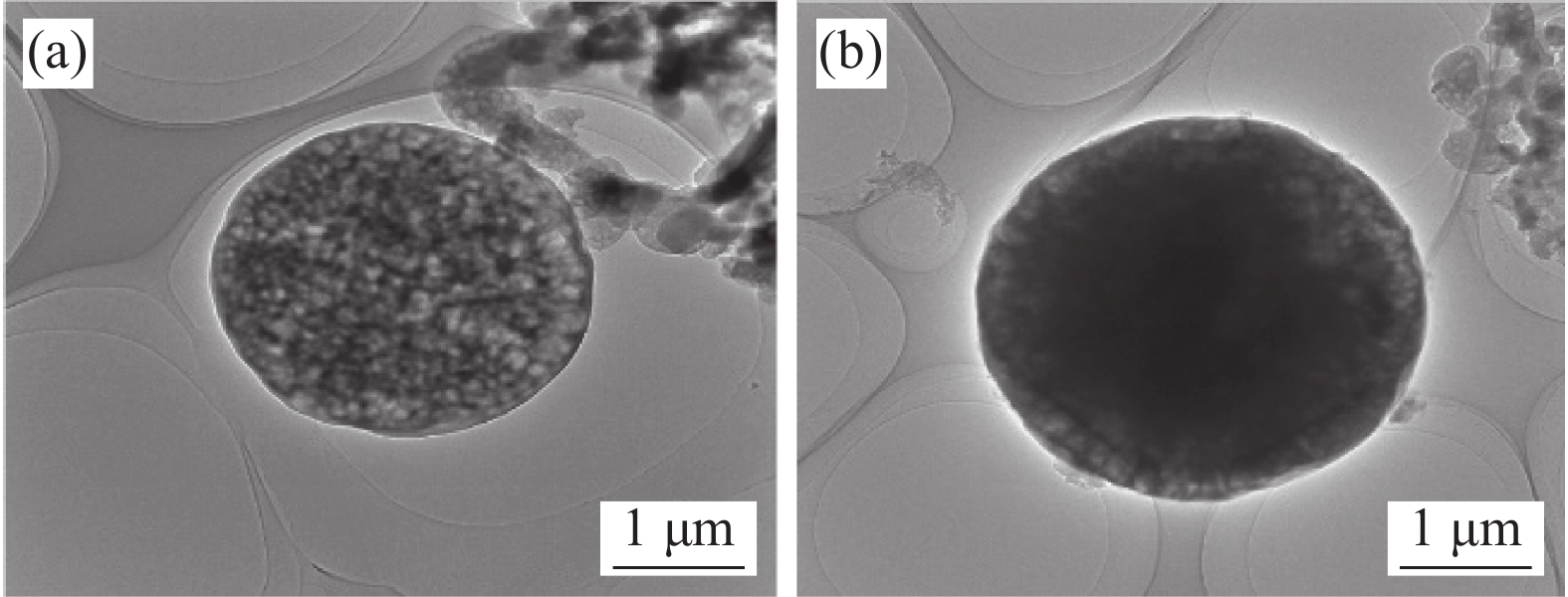

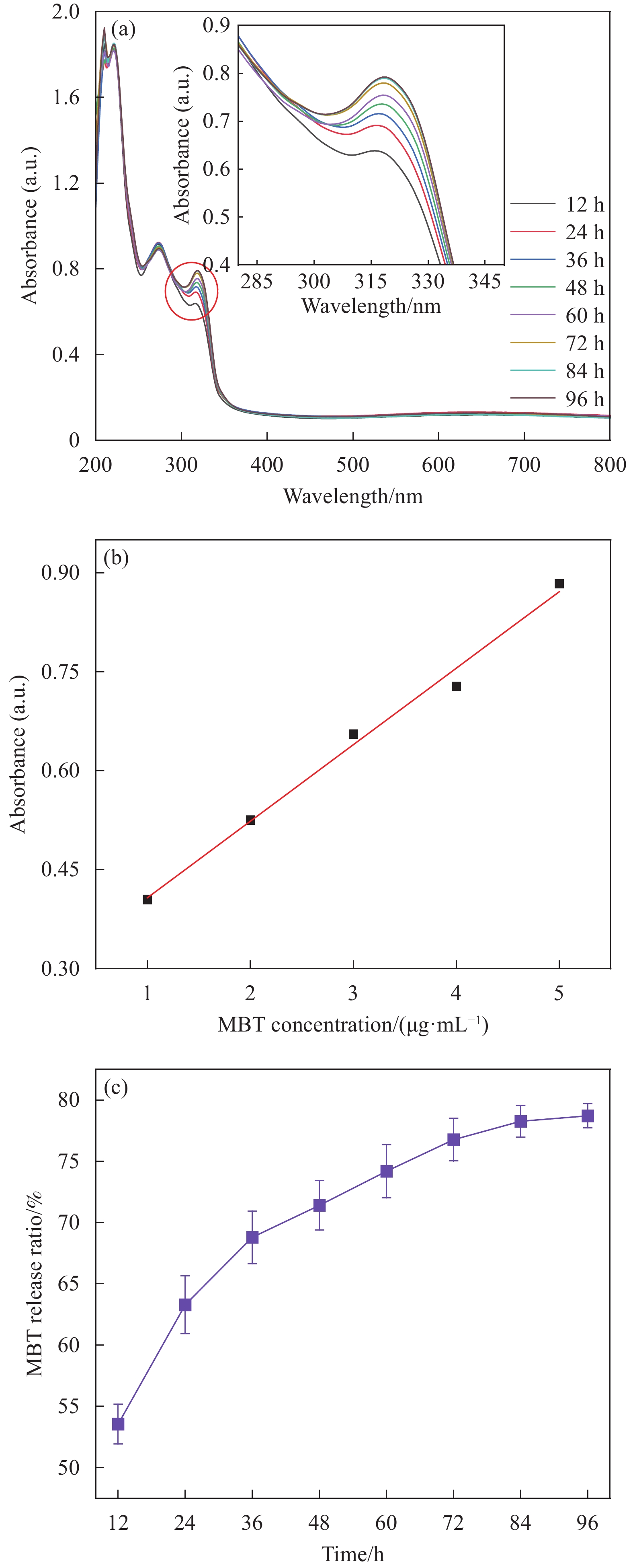

方法采用红外光谱对样品的官能团类型进行分析。采用XPS对样品的元素含量及其价态分布进行分析。采用SEM观察样品平面和液氮淬断后断面的形貌。采用TEM观察缓蚀剂封装前后微胶囊的形貌。为了测量微胶囊中缓蚀剂的负载率,采用索氏提取器对微胶囊内部的芯材进行提取,提取溶剂为丙酮。然后将产物进行干燥,记录微胶囊的质量。最后,对缓蚀剂的负载率进行计算。此外,采用紫外光谱仪对缓蚀剂的释放量进行分析。采用万能试验机对涂层的拉伸性能进行测试。采用百格板法对涂层的附着力进行测试。采用电化学工作站对涂层进行极化曲线和交流阻抗谱(EIS)测试,以1 cm的铂电极为对电极,饱和甘汞电极为参比电极,暴露表面积1 cm样品涂层为工作电极,3.5wt%的NaCl水溶液为电解液,在电磁屏蔽箱内构筑三电极体系。

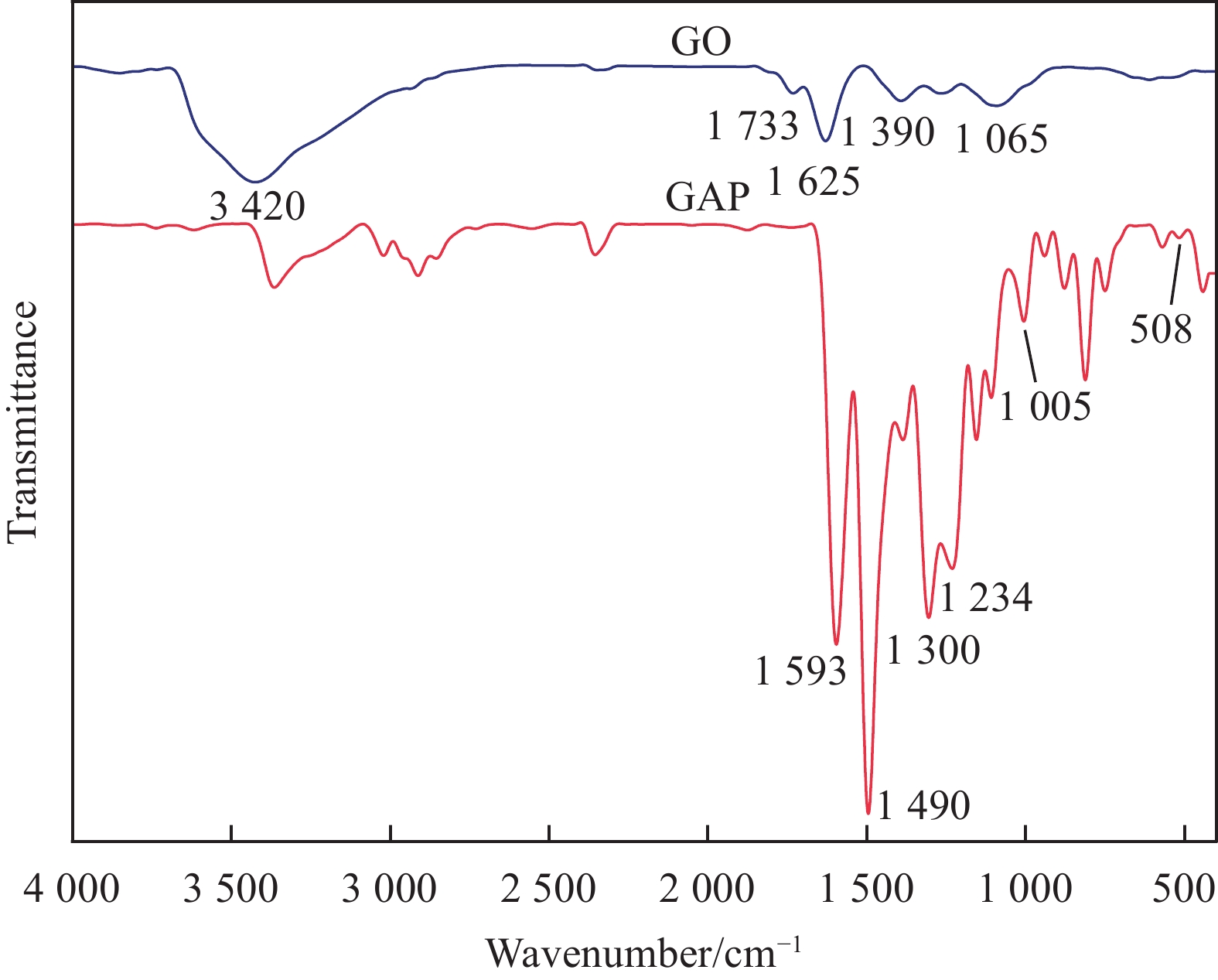

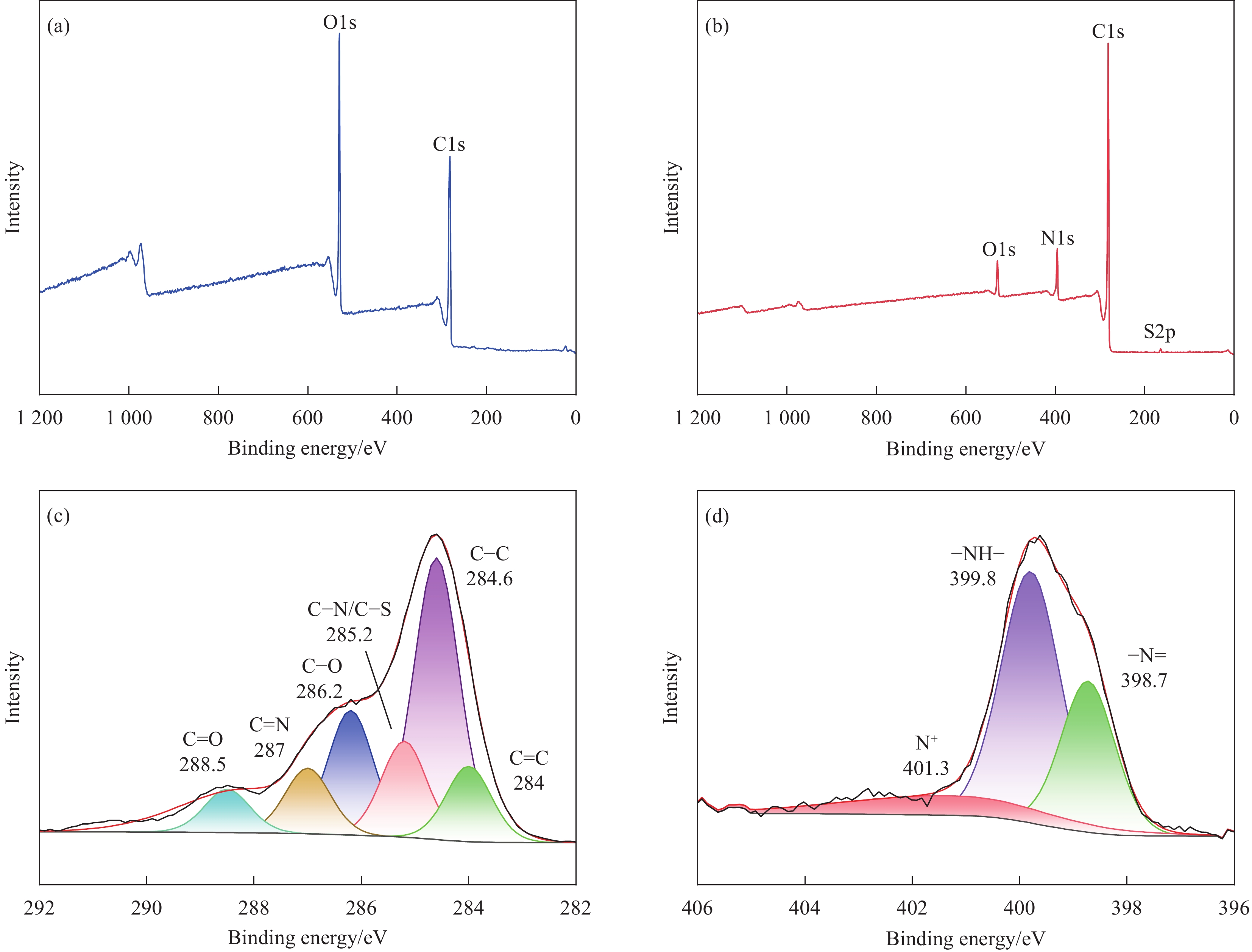

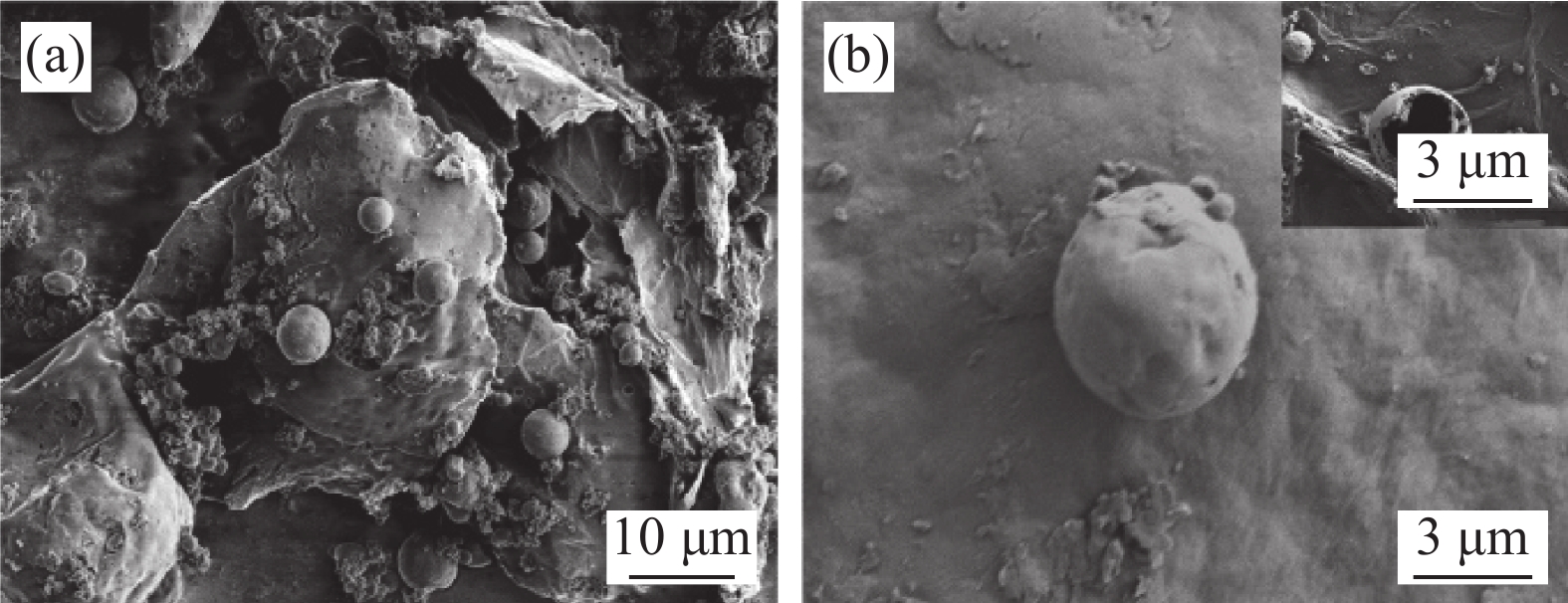

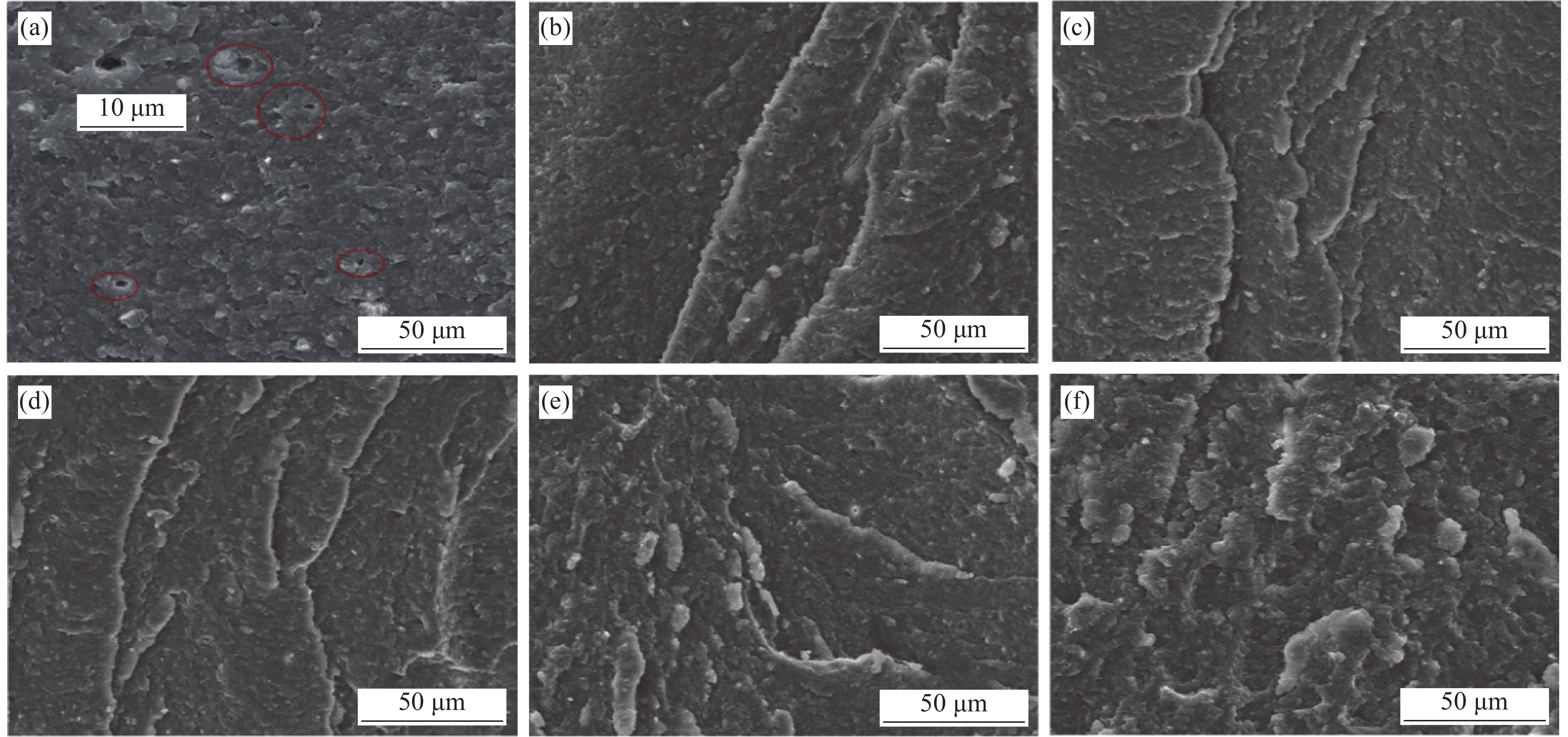

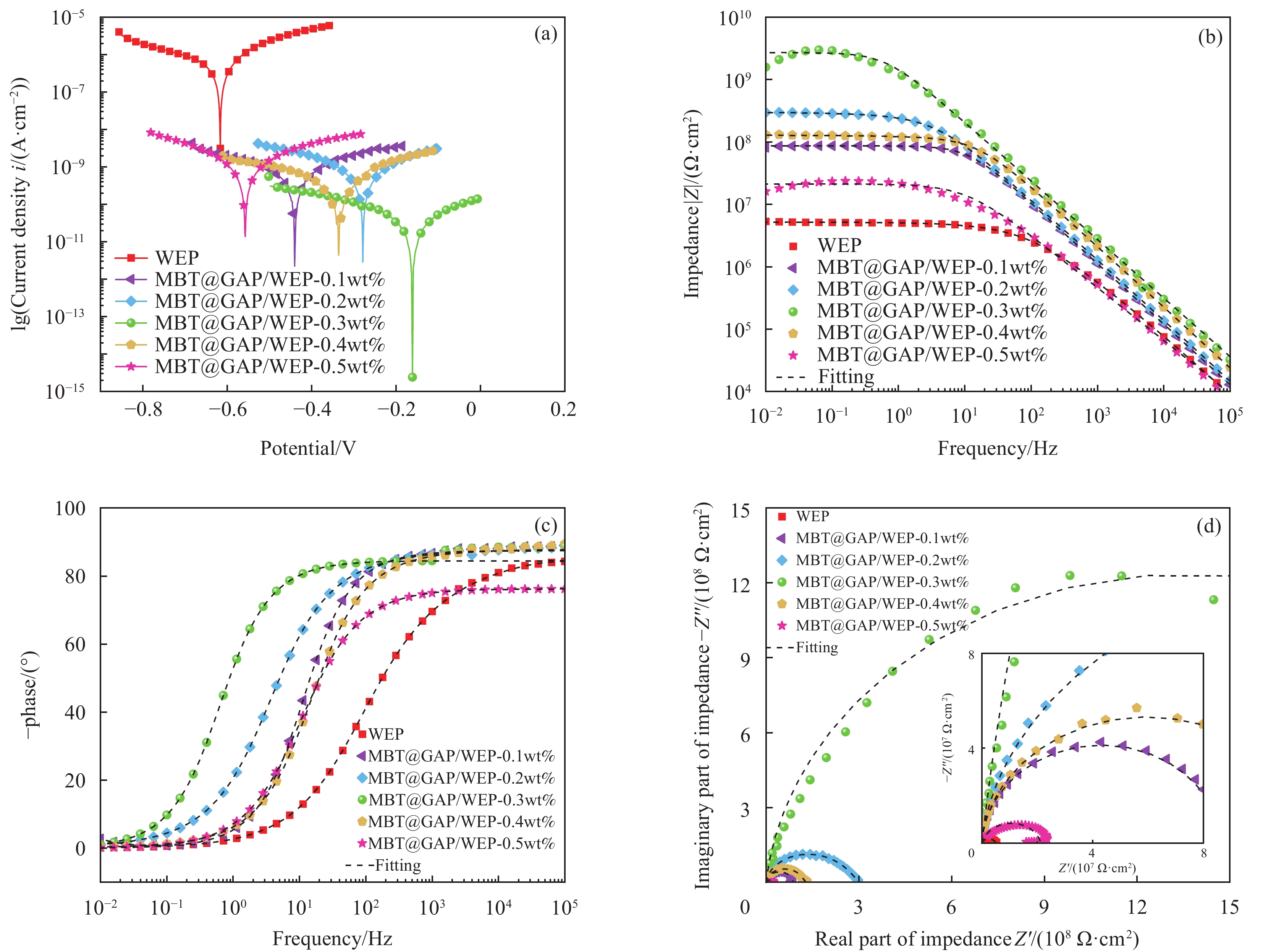

结果采用红外光谱和XPS对比研究了GO与聚邻甲苯胺-氧化石墨烯基复合材料(GAP)的差异。相比于GO,GAP中同时具有C=C醌类拉伸和C=C苯类拉伸振动,这证明氧化和还原形式的POT同时存在,同时也表明,POT在GO片层上的反应,成功合成了GAP复合材料。采用SEM表征了GAP的微观形貌,结果表明,所制得的微胶囊为均一的球形,均匀的反应至GO的片层之上。将微胶囊用研磨法粉碎,进一步观察发现其内部呈现中空结构,较大的空腔为缓蚀剂的负载提供了更多的可能。利用TEM进一步分析了缓蚀剂(MBT)封装前后POT的微观形貌。相比于未封装时,胶囊由原来的中空、透明变为现在的实心、均匀填充。这是由于MBT被包覆于微胶囊内部所造成的,增加了缓蚀型聚邻甲苯胺-氧化石墨烯基复合材料(MBT@GAP)核壳之间的对比。将微胶囊人工破损,每隔12 h进行紫外可见光谱测试,由结果可知,胶囊在破损的96 h后MBT释放百分比达到最大,为78%。对复合涂层进行拉伸性能、断面扫描、附着力和电化学测试发现,当填料添加量为0.3%时,胶膜的性能最佳。对填料添加量为0.3%的复合涂层进行盐雾试验,发现其在500 h的盐雾后相比于水性环氧树脂涂层(WEP)腐蚀程度较小,不仅切口处的锈痕没有向内扩散,而且没有小水泡出现。用刀片划伤涂层模拟其机械受损,用SEM观察涂层的愈合情况,相比于纯WEP涂层,改性后复合涂层的划痕在10 h后出现了明显的修复情况,伤口基本完全愈合。

结论通过FTIR、XPS和SEM测试证明,OT在改性GO表面的成功反应,进而增大了GO的层间距,改善了二维填料易团聚的现象。TEM和紫外可见光谱测试表明,缓蚀剂在微胶囊中的进一步封装,成功制备了MBT@GAP复合材料。应力应变曲线和涂层断面的SEM表明,相比于纯WEP涂层,改性后复合涂层的拉伸性能提高、涂层的屏蔽性能提高。采用极化曲线和交流阻抗谱测试拟合分析表明,当填料MBT@GAP添加量为0.3%时,极化曲线的腐蚀电位最大,为-0.1554 V,腐蚀电流密度最小,为1.016×10 A·cm;Bode图显示,|Z|值高达1.5757×10 Ω·cm,高出纯WEP涂层3个数量级且未出现二次时间常数;Nyquist图显示,该涂层具有最大的阻抗半径。改性后复合涂层盐雾500 h未发生腐蚀扩散和起泡现象,相比于纯WEP涂层有更好的防腐性能和附着强度。

-

氧化石墨烯具有比表面积大的优势,但难以对破损涂层实现修复,限制了其在涂层防腐方面的应用。然而,聚邻甲苯胺在兼具防腐功能的同时,也可作为微胶囊负载缓蚀剂,但美中不足的是涂层的屏蔽性能有待提高。因此,开发一种屏蔽性强且具有缓蚀作用的涂层具有重要意义。

本文选取氧化石墨烯为基材、聚邻甲苯胺微胶囊为壁材、缓蚀剂2-巯基苯并噻唑为芯材,制备了缓蚀型聚邻甲苯胺-氧化石墨烯基防腐材料,并将其作为填料用于水性环氧树脂涂层(WEP)的改性。通过FTIR、XRD、XPS和SEM等对该材料进行了结构和形貌的表征,采用紫外可见光谱对缓蚀剂的释放行为进行分析,采用万能试验机、电化学测试和盐雾实验对涂层的拉伸性能和防腐性能进行了评价。结果表明,缓蚀剂成功包覆于聚邻甲苯胺微胶囊内部,并通过共价键方式将微胶囊连接在改性氧化石墨烯表面,使缓蚀剂得到了充分利用,提高了涂层的拉伸性能、自修复性能、以及对腐蚀介质的屏蔽性能。紫外可见光谱测试结果表明,微胶囊在人工破损96 h后,内部缓蚀剂的释放量达78%;拉伸性能测试结果表明,与纯WEP相比,当填料加入量为0.3%时,涂层应力从14.281 MPa增加到24.25 MPa;SEM结果表明,被划伤的涂层常温下放置10 h后自修复;电化学测试和盐雾实验结果表明,涂层腐蚀电位从-0.6216 V提高到-0.1554 V,腐蚀电流密度从4.271×10-7 A·cm-2减小到1.016×10-11 A·cm-2,阻抗模量可达到1.5757×109 Ω·cm2,在盐雾500 h后仍表现出较好的防腐性能。

聚邻甲苯胺-氧化石墨烯基复合材料的微观形貌及缓蚀型聚邻甲苯胺-氧化石墨烯基/水性环氧树脂复合涂层的阻抗模量曲线

下载:

下载: