Interlaminar shear behavior of glass-fibre reinforced polypropylene rod under seawater and sea sand concrete simulation environment

-

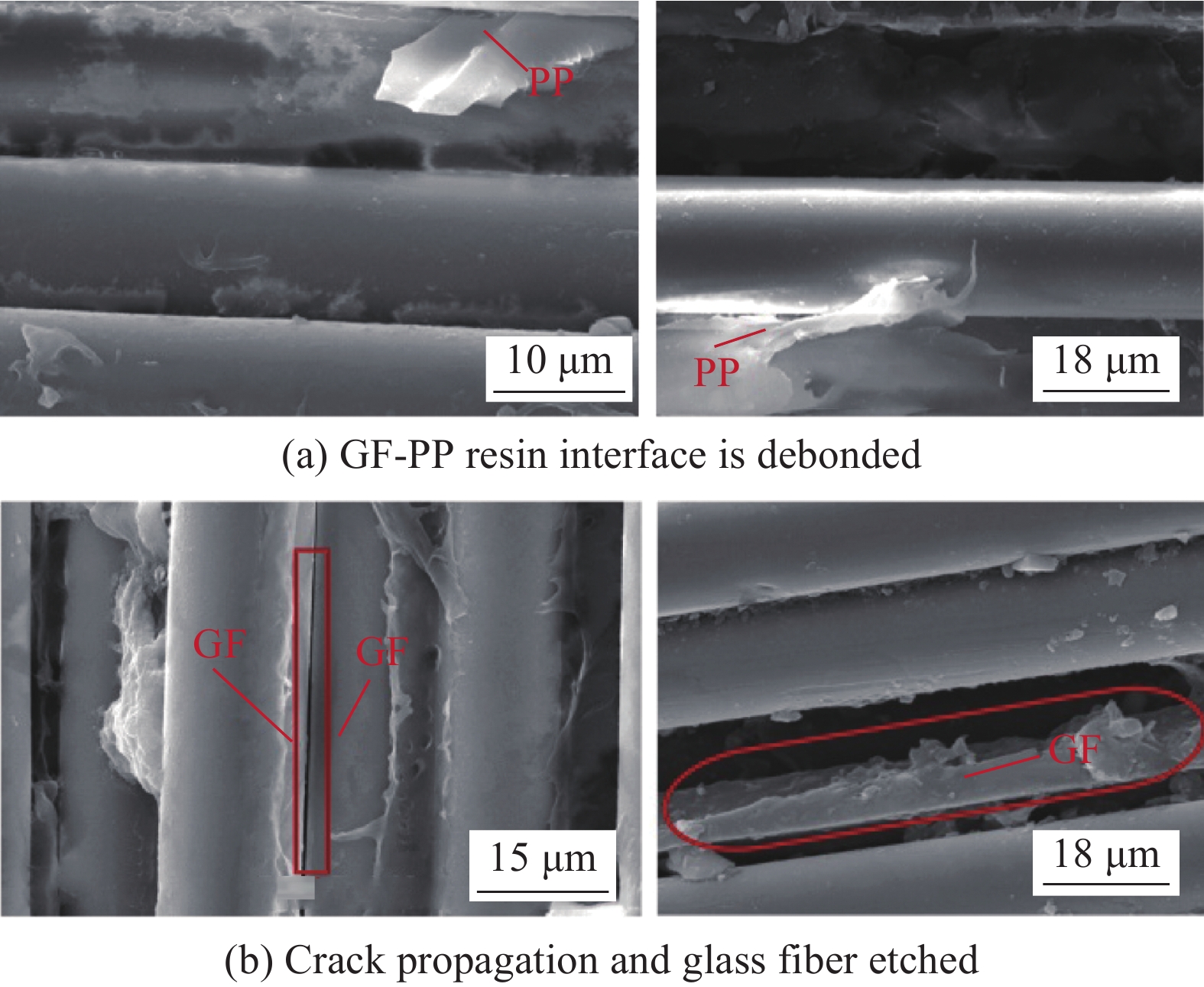

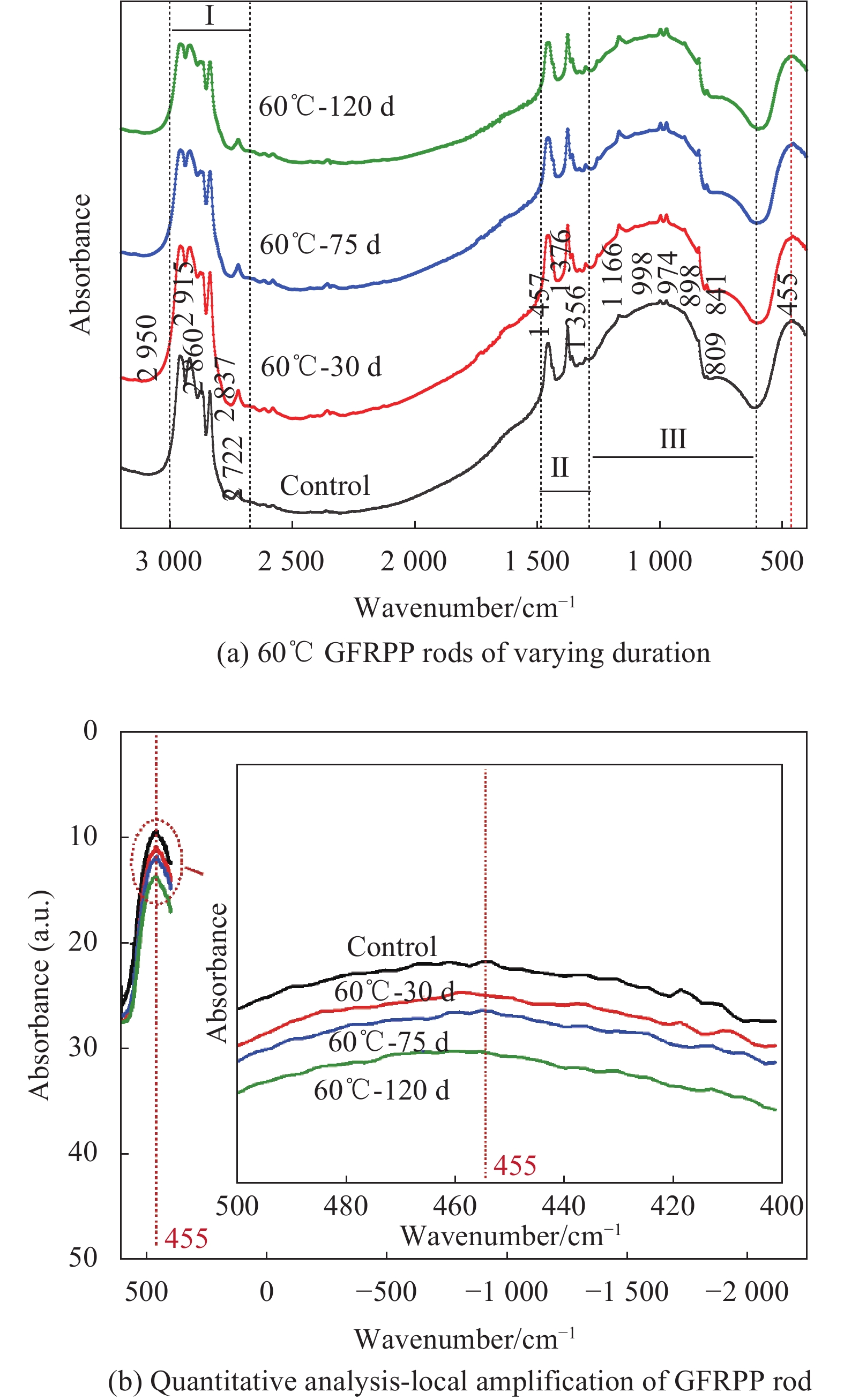

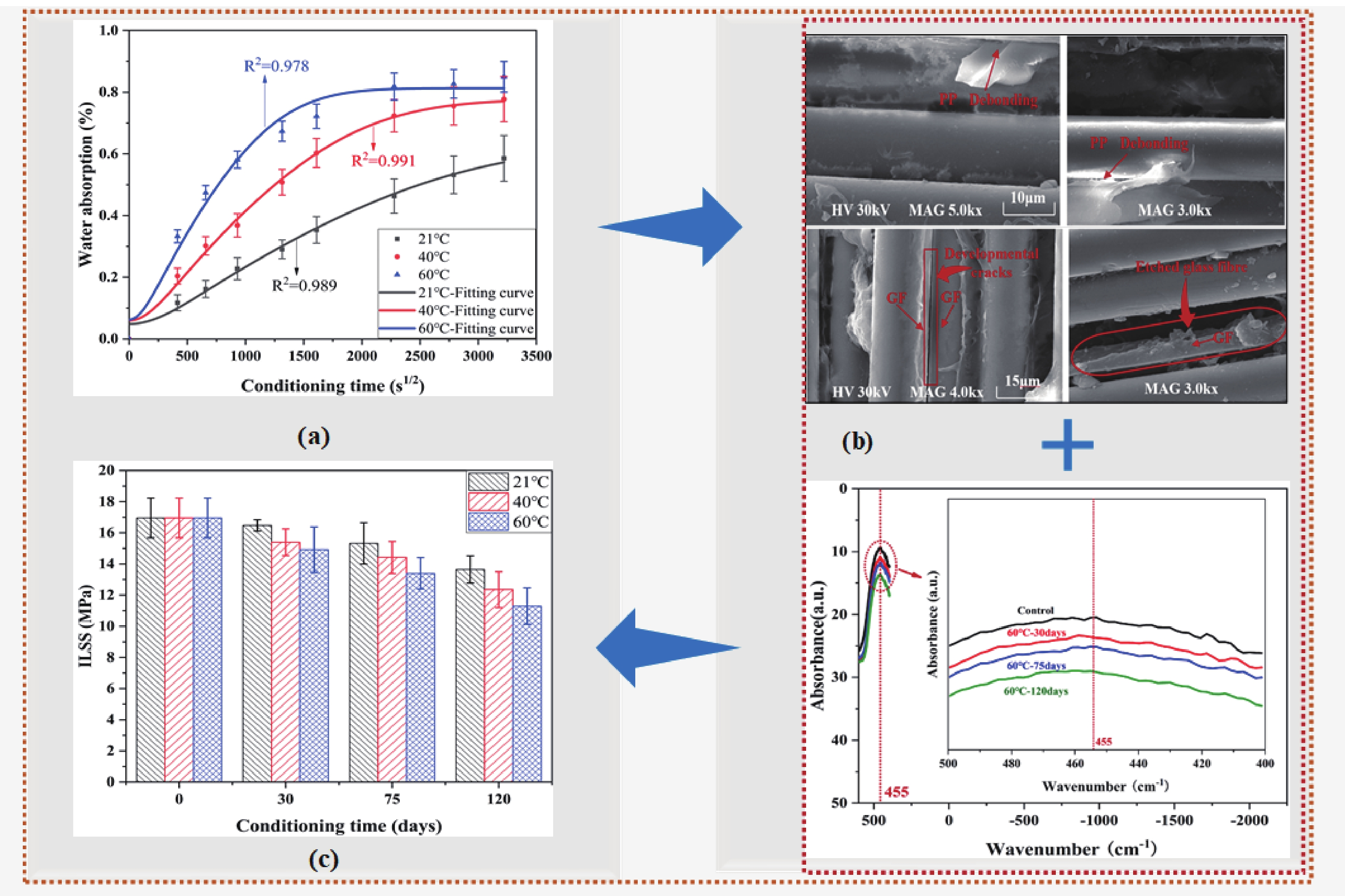

摘要: 连续玻璃纤维增强聚丙烯(GFRPP)复合材料杆集成了热塑性树脂可多次成型、环境友好、可回收利用和玻璃纤维高应变、低成本等优点,在混凝土结构领域,GFRPP复合材料有望替代钢筋和热固性纤维增强聚合物(FRP)筋成为新型热塑性复合材料。本文采用加速实验研究了模拟海水-海砂混凝土环境下GFRPP杆的水吸收及层间剪切性能长期演化规律与退化机制。研究结果表明:GFRPP杆吸水行为符合Fick定律,21℃、40℃和60℃浸泡温度下GFRPP杆的饱和吸水率分别为0.63%、0.78%和0.81%;经120天21℃、40℃和60℃模拟海水-海砂混凝土孔溶液浸泡后,GFRPP杆层间剪切强度保留率分别为80.5%、72.8%和66.5%。最后,结合SEM和FTIR表征技术,揭示模拟海水-海砂混凝土孔溶液浸泡下GFRPP杆性能退化机制。Abstract: Glass-fibre reinforced polypropylene (GFRPP) composite rod integrate the advantages of thermoplastic resin multi-molding, environmental friendliness, recyclability, and high strain and low cost of glass fiber. In the field of concrete structures, GFRPP rods are expected to replace steel bars and thermoset fibre reinforced polyer (FRP) bars as a new composite material. In this paper, accelerated experiments were used to study the long-term evolution of water absorption, interlaminar shear properties and degenerative mechanism of GFRPP rod under simulated seawater and sea sand concrete environment. The results show that the water absorption behavior of GFRPP rod conforms to Fick's law, and the saturation water absorption rates of GFRPP rods at immersion temperatures of 21°C, 40°C and 60°C are 0.63%, 0.78% and 0.81%, respectively. After 120 days of immersion in 21°C, 40°C and 60°C simulated seawater sea sand concrete pore solutions, the shear strength retention rates between GFRPP rods are 80.5%, 72.8% and 66.5%. Finally, the performance degradation mechanism of GFRPP rods under simulated seawater-sea sand concrete pore solution immersion was revealed by combining SEM and FTIR characterization techniques.

-

随着经济和生活水平的提高,能源的消耗问题日益严重,尤其是建筑能耗。而在建筑能耗中,由于围护结构隔热性能的不足带来的能量消耗所占比例最大。因此,欧美国家提出了采用夹芯(Sandwich)结构墙体作为外围护结构来改善其隔热性能。该结构是将保温材料置于难燃材料中间,并使用连接件连接内外叶面层,从而形成一个集保温、装饰、隔声于一体的复合墙体结构[1-2]。

传统的夹芯结构多采用普通混凝土材料作为面层,在实际使用中易出现面层较厚、整体质量较大、开裂、脱落等现象[3]。同时,在建筑外墙保温所采用的做法中,外墙外保温是目前国内外应用最广泛、最成熟的保温形式[4]。在使用这种做法时,外面层的开裂和脱落往往会加剧保温层与建筑主体结构或饰面层之间因光照、内外温差等原因产生的不同的收缩变形,从而降低了保温材料的保温效果。然而,作为一种有着显著的多缝开裂和应变硬化特征的材料,工程水泥基复合材料(Engineered cementitious composites,ECC)不仅具有卓越的抗拉性能,其裂缝宽度还可以控制在100 以下[5-6],同时还具有良好的韧性和耐久性[7]。因此,将ECC作为夹芯结构的面层不仅可以解决传统夹芯结构面层厚度较厚、易开裂等问题,还可以解决因普通混凝土脆性带来的一系列问题。

夹芯结构的面层与保温层之间的粘结性能是决定二者能否协同工作,并充分发挥各自优势的重要因素。对此,学者们主要从保温材料种类、保温层厚度、表面处理形式及连接件的采用等方面对夹芯结构面层间的粘结性能进行了研究。Choi等[8]、Tae等[9]、Sopal[10]通过试验研究发现保温材料为挤塑式聚苯乙烯(XPS)板试件的承载力比发泡式聚苯乙烯保温(EPS)板试件高,但EPS保温板与面层粘结性能和延性更好。宋小软等[11]对由玻璃纤维增强水泥板和不同保温材料组成的试件进行了抗剪试验研究,结果表明,聚氨酯(PUR)材料与水泥板间的界面粘结性能较好,能够满足使用要求,而XPS与水泥板间的界面粘结性能相对较差,并且不建议在试件中只将XPS与混凝土表面进行单纯的自然粘结。Hodicky等[12]通过试验研究发现,保温层厚度对界面粘结性能有很大影响,降低保温层厚度可以提高试件的界面粘结性能。高睿[13]、Kazem等[14]、Naito等[15]通过试验研究发现,在界面处设置锚钉、在保温板表面预留沟槽及提高混凝土强度都能提高试件界面间的粘结强度,其中对保温板进行表面处理的效果最佳。Jang等[16]和尹红宇等[17]对混凝土与保温层之间的界面粘结性能进行了研究发现,在混凝土表面预留沟槽可以有效提高界面间的粘结性能。Teixeira等[18]通过双面剪切试验研究了玄武岩纤维增强树脂复合材料(BFRP)筋直径和嵌入角度对试件的极限承载力和剪切刚度的影响,结果表明,增大连接件的嵌入角度和直径都能提高试件的极限荷载和刚度。

综上所述,EPS保温板与面层的粘结性能更好,因此本文仅对EPS保温板进行了研究。此外,由于BFRP筋具有耐腐蚀性、轻质高强、导热性低且低碳环保等特点[19],可用于替代普通钢筋作为夹芯结构墙板的连接件。但是,国内外只有少部分学者对采用BFRP筋作为连接件的夹芯结构的粘结性能进行了研究。同时,关于ECC作为面层、EPS作为保温层、BFRP筋作为连接件的夹芯结构的界面粘结性能研究较少,数据信息不够丰富。

因此,本文在前人研究的基础上,提出了将ECC与EPS相结合,并以BFRP筋作为夹芯墙板连接件,形成轻质、导热系数小、表层不易开裂的新型薄壁夹芯结构。同时,对夹芯结构进行了双面剪切试验,研究了制作方式、保温材料的厚度、有无连接件及其角度对ECC面层与保温材料间的界面粘结性能的影响,并推导了试件的抗剪承载力计算公式。

1. 试件设计与制备

1.1 原材料

试验采用EPS保温板的参数如表1所示。ECC的配合比如表2所示,该配合比下ECC材料在养护28天后的力学性能如表3所示,其中抗压试验采用70.7 mm×70.7 mm×70.7 mm的立方体试块,拉伸试验试件的总尺寸为32 mm×6 mm×13 mm、中间段长为8 mm、宽为30 mm,四点弯曲试验试件的尺寸为400 mm×100 mm×15 mm。聚乙烯醇(PVA)短切纤维的性能参数如表4所示。BFRP筋的直径及其力学性能如表5所示。

表 1 发泡式聚苯乙烯(EPS)性能参数Table 1. Performance parameters of the expanded polystyrene (EPS)Heat insulator Thermal conductivity/(W·(m·K)−1) Density/(kg·m−3) Tensile strength/MPa Compressive strength/MPa EPS 0.039 20 0.13 0.12 表 2 工程水泥基复合材料(ECC)配合比Table 2. Mix proportion of engineered cementitious composites (ECC)(kg/m3) Material Cement Fly ash Quartz sand Water Water reducing agent PVA fiber Mix proportion 379 885 455 379 17.4 26 Note: PVA—Polyvinyl alcohol. 表 3 ECC力学性能Table 3. Mechanical properties of ECCSpecimen

numberCompressive

strength/MPaUltimate tensile

strength/MPaUltimate tensile

strain/%Ultimate bending

load/kNUltimate mid-span

deflection/mmECC-1 57.5 8.76 3.47 0.81 21.90 ECC-2 52.2 7.12 2.63 0.83 24.62 ECC-3 49.3 6.34 3.25 0.79 21.83 Average value 53.0 7.41 3.12 0.81 22.78 Standard deviation 3.40 1.01 0.36 0.02 1.30 Coefficient of variation 0.06 0.14 0.12 0.02 0.06 表 4 聚乙烯醇(PVA)纤维性能参数Table 4. Performance parameters of polyvinyl alcohol (PVA) fiberType Length/mm Diameter/mm Tensile strength/MPa Elastic modulus/GPa Density/(g·cm−3) PVA fiber 12 0.04 1600 42 1.3 表 5 玄武岩纤维增强树脂复合材料(BFRP)筋的力学性能Table 5. Mechanical properties of basalt fiber reinforced polymer (BFRP) barsBFRP diameter/mm Ultimate tensile strength/MPa Elastic modulus/GPa Percentage elongation/% 6 1279 60.12 2.13 8 1194 60.75 1.97 10 1066 55.84 1.91 12 1350 59.40 2.27 1.2 试件设计

研究了不同制作方式、不同连接件角度及不同保温材料厚度对ECC面层与EPS保温层之间界面粘结性能的影响。试验共设置7组,每组试件各3个,共21个试件,试件的具体尺寸、配筋情况及制作方法如图1和表6所示。

表 6 ECC-EPS保温板试验分组Table 6. Test group of ECC-EPS insulation boardSpecimen number Type of insulation

materialProduction

methodInsulating layer

thickness/mmBFRP connector

or notConnector

insertion angle/(°)ECC(X)-EPS(70) EPS Cast-in-site 70 Without – ECC(Y)-EPS(70) EPS Prefabrication 70 Without – ECC(X)-EPS(50) EPS Cast-in-site 50 Without – ECC(X)-EPS(100) EPS Cast-in-site 100 Without – ECC(X)-EPS(70)-BFRP(90) EPS Cast-in-site 70 Having 90 ECC(X)-EPS(70)-BFRP(60) EPS Cast-in-site 70 Having 60 ECC(X)-EPS(70)-BFRP(45) EPS Cast-in-site 70 Having 45 Notes: In specimen number, X—Cast-in-site; Y—Prefabrication; BFRP bar insertion angle refers to the angle between the bar and the specimen in the vertical direction; Insertion depth is 20 mm[18]. 试件由三层ECC面板和两层EPS保温板交错分布而成,分布的顺序从左往右依次为ECC面层(厚度为25 mm)、EPS保温层(厚度分别为50 mm、70 mm、100 mm)、ECC面层(厚度为50 mm)、EPS保温层(厚度与前者保温层相同)、ECC面层(厚度为25 mm)。在本次试验中,由于保温层厚度的不同,试件的总体尺寸有三种,分别为400 mm×200 mm×150 mm(保温层厚度为50 mm)、400 mm×240 mm×150 mm(保温层厚度为70 mm)、400 mm×300 mm×150 mm(保温层厚度为100 mm)。同时,试件中共设置有两排连接件,其相对位置如图1的A-A剖面图所示,每一排连接件的布置情况如图1的B-B剖面图所示。最后,本试验中的连接件采用BFRP筋,其插入ECC面层中的深度为20 mm,插入角度分别45°、60°、90°。

试件按照ECC面层及制作方式、保温材料种类及厚度、连接件类型及角度的顺序进行命名。其中,第一项中的ECC(X)表示采用现浇ECC作为面层、ECC(Y)表示采用预制ECC作为面层,第二项中的EPS(50)、EPS(70)、EPS(100)分别表示采用50 mm、70 mm、100 mm厚的EPS保温层,第三项中的BFRP(45)、BFRP(60)、BFRP(90)分别表示插入BFRP连接件的角度为45°、60°、90°。对于无连接件的试件,不再写出第三项的组分信息。例如,表6中的ECC(X)-EPS(70)-BFRP(45)表示该试件的保温材料为EPS,制作方式为现浇,保温层厚度为70 mm,含有BFRP连接件并且连接件角度为45°。

1.3 试件制备

现浇试件的具体制作过程如下:首先,按照试件设计的尺寸制作木模板,同时用切割机将EPS保温板切割成指定尺寸;其次,在保温板表面标出连接件插入点的位置,然后根据定位点和指定的角度将BFRP筋插入保温板中(无连接件的试件省去此步骤);在连接件插入后,将EPS保温板上不与ECC材料粘结的四个表面用透明胶带裹住;处理完EPS保温板后,在木模板内部涂抹脱模剂,并将EPS保温板放入木模板中,用小木块将EPS保温板按试件设计时的位置进行固定,如图2(a)所示;最后,按照表2所示的配合比制备ECC材料,并将其浇筑到木模板内剩余的空隙中,浇筑完成后振捣并抹平形成完整的试件。此外,在试件制作完成7天后拆除木模板,并持续养护28天以保证试件达到设计强度。最终的试件成型图如图2(b)所示。

预制试件的具体制作过程如下:首先,按照ECC面层的设计尺寸制作木模板;其次,在木模板内部涂抹脱模剂,同时按照表2所示的配合比制备ECC材料;制备好ECC后将其浇筑到木模板中,振捣并抹平;待ECC面层浇筑成型7天后拆除模板,并用粘结砂浆将脱模的ECC面层与保温材料粘结成整体,形成预制试件;最后需将试件养护28天以确保其达到设计强度。此外,需要注意的是,EPS保温板与ECC面板是直接粘结,未使用界面粘结剂。

1.4 试件加载设计

本试验采用双面剪切试验方法,试验中的试件均为对称试件。这种设计与传统的剪切试验相结合,试件推出量近似等于界面滑移量。

在试验过程中,为使试件所受荷载为均布荷载,在中间层ECC的正上方放置一个尺寸为150 mm×50 mm×20 mm的钢垫块。通过DDL-300电子万能试验机和钢垫块将垂直荷载施加到中间层ECC的顶面,以产生穿过界面的直接剪切力。同时,在试验机底座上面和试件底部外侧的两个ECC板下方分别放置钢板和高度为8 mm的钢垫块,以便双面剪切试验的正常进行,如图3(a)所示。

此外,双面剪切试验所用仪器为中国矿业大学力学教学实验室30 吨压力机,位移速率为0.2 mm/min。试件中间ECC层前后中点及试件两侧分别放置两个量程为100 mm和两个量程为30 mm的位移计,分别测量滑移量及偏移量。双面剪切试验示意图,如图3(b)所示。

2. ECC-EPS保温板试验结果与分析

2.1 ECC-EPS保温板双面剪切试验结果

试件的界面粘结性能可通过试件的破坏模式和抗剪强度进行评价。当界面结合面积相同时,抗剪强度由试件在加载过程中所受的荷载决定。由于界面剪切应力的分布是不均匀的,并且距离加载端较近的界面的剪切应力往往会大于距离加载端较远的界面,因此在加载过程中距离加载端较近的两个界面会率先达到极限强度。于是,本试验选用中间两个界面的抗剪强度作为本次双面剪切试验的抗剪强度,其计算公式如下:

τmax = Pm/2A (1) 式中:τmax为试件抗剪强度(MPa);Pm为抗剪极限荷载值(N);A为EPS保温板与ECC面层单个结合面的面积(mm2)。

图4为ECC-EPS 保温板破坏形态。可以看出,出现界面破坏的试件都是中间两个界面脱粘引起的,因此根据中间层ECC面板与保温材料粘结的两个界面会率先达到极限强度并发生破坏这一特征提出的抗剪强度计算公式,能够准确地得到试件的抗剪强度。

双面剪切试验试件的极限荷载、抗剪强度、界面滑移量及破坏模式如表7所示。试件的破坏模式主要分为三种:ECC面层与EPS保温层界面脱粘,发生界面破坏;EPS保温层发生剪切破坏;两侧ECC面层发生受弯破坏。

表 7 ECC-EPS保温板双面剪切试验结果Table 7. Results of double-sided shear test of ECC-EPS insulation boardSpecimen number Order number Limit load/kN Absolute deviation Displacement/mm Shear

strength/

MPaMode of failure Front displacement Rear displacement Average value Absolute deviation ECC(X)-EPS(70) 1 7.25 0.08 15.90 15.68 15.79 0.49 0.060 2 7.43 0.10 17.60 17.86 17.73 1.45 0.062 Interfacial failure 3 7.30 0.03 15.40 15.23 15.32 0.96 0.060 Average value 7.33 – – – 16.28 – 0.060 ECC(Y)-EPS(70) 1 1.92 0.40 3.73 3.87 3.80 0.51 0.016 2 2.87 0.55 5.73 4.20 4.97 0.66 0.024 Interfacial failure 3 2.18 0.14 4.35 3.95 4.15 0.16 0.018 Average value 2.32 – – – 4.31 – 0.020 ECC(X)-EPS(50) 1 8.50 0.16 16.41 16.55 16.48 1.49 0.070 2 8.46 0.20 18.23 18.56 18.40 0.43 0.070 Shear failure of EPS and interfacial failure 3 9.02 0.36 18.93 19.15 19.04 1.07 0.076 Average value 8.66 – – – 17.97 – 0.072 ECC(X)-EPS(100) 1 6.07 0.00 13.12 15.27 14.20 1.36 0.050 2 5.74 0.33 11.00 12.31 11.66 1.18 0.048 Interfacial failure 3 6.39 0.32 11.24 14.10 12.67 0.17 0.054 Average value 6.07 – – – 12.84 – 0.050 ECC(X)-EPS(70)-BFRP(90) 1 11.13 0.45 27.75 29.33 28.54 4.52 0.092 2 11.89 0.31 19.49 20.38 19.94 4.08 0.100 Shear failure of EPS and BFRP bars splitting 3 11.72 0.14 23.22 23.95 23.59 0.43 0.098 Average value 11.58 – – – 24.02 – 0.096 ECC(X)-EPS(70)-BFRP(60) 1 20.53 1.07 12.81 13.64 13.23 0.01 0.172 2 20.60 1.00 11.16 10.40 10.78 2.46 0.172 Bending failure of two ECC boards on the outside 3 23.67 2.07 15.73 15.69 15.71 2.47 0.198 Average value 21.60 – – – 13.24 – 0.181 ECC(X)-EPS(70)-BFRP(45) 1 47.74 5.33 18.90 20.80 19.85 2.35 0.398 2 40.60 1.81 19.26 21.30 20.28 2.78 0.338 Interfacial failure 3 38.90 3.51 12.67 12.05 12.36 5.14 0.324 Average value 42.41 – – – 17.50 – 0.354 由表7可知,大部分试件的破坏模式均为界面破坏,如图4(a)所示,并且即使试件未发生界面破坏,其界面处仍出现部分脱粘现象。这是由于在加载过程中,外荷载最先由ECC面层与EPS保温层之间的界面粘结作用来承担。随着荷载的增大,试件底部的中间ECC面层与两侧EPS保温层界面处开始出现裂缝,并向上延伸。对于无连接件的试件,荷载完全由界面粘结作用承担,随着荷载继续增大,裂缝迅速开展直至贯穿整个试件并发生破坏。对于采用BFRP筋作为连接件的试件,试件在出现裂缝后会进行内力重分布,从主要由界面粘结作用来承担外荷载转变为由连接件与界面粘结作用共同承担。因此破坏模式为界面破坏的情况主要发生在无连接件的试件中。

EPS保温层剪切破坏如图4(b)、图4(c)所示。这种破坏模式主要发生在无连接件且保温层厚度为50 mm的试件和有90°连接件的试件中,但是这两种试件发生破坏的原因和形态各不相同。对于无连接件且保温层厚度为50 mm的试件,由于保温层厚度和刚度较小,使EPS保温层随着荷载的增大产生较大的压缩变形。当试件的界面粘结作用和荷载大于EPS的剪切强度时,EPS保温层便会发生剪切破坏,如图4(b)所示。而有90°连接件的试件发生破坏的主要原因是剪切过程中中间层ECC面板中的BFRP连接件会受拉变形,使连接件位置处的保温层出现剪切裂缝,并且裂缝宽度随着变形的增大而增大,直至保温层发生剪切破坏,如图4(c)所示。同时,有90°连接件的试件在加载过程中还伴有BFRP连接件被拔出、拉断和劈裂现象,这是由于连接件在承担荷载时主要依靠其自身的拉拔强度及与ECC之间的的粘结力,当两者不能抵抗所承受的荷载时,便会出现连接件破坏的现象,如图4(e)所示。

ECC面层受弯破坏如图4(d)所示。这种破坏模式主要发生在保温层厚度为70 mm且连接角度为60°的试件中。这是由于ECC中60°的连接件不仅能够承担竖向剪力,还能加强中间层ECC与两侧ECC面层的连接。在加载过程中,BFRP连接件的角度会随着中间层ECC位移的增大而增大。由于嵌入角度为60°的连接件与ECC面层的粘结性能较好,不会发生BFRP连接件拔出现象,因此随着连接件角度的增大,BFRP筋在水平方向的长度也增大。由于连接件与ECC面层的粘结强度大于ECC面层与EPS保温板的粘结强度,因此连接件附近的外侧ECC面层与EPS保温板会首先发生脱粘,进而该处ECC面板会随着BFRP筋水平距离的增大而向外偏移,当ECC面板的横向位移达到其极限弯曲应变时,ECC面板发生破坏。此外,由于外侧ECC面层与EPS保温层的粘结界面仍有部分未发生脱粘,因此这一部分的粘结力会约束ECC面板的弯曲变形,从而导致外侧ECC面板直接断裂。

2.2 ECC-EPS保温板双面剪切试验结果与分析

2.2.1 制作方式的影响

比较图5(a)中的荷载-滑移曲线和表7可知,制作方式的不同不仅会严重影响界面粘结强度,还会改变其破坏模式。如表7所示,现浇试件的极限承载力和抗剪强度是预制试件的2.5倍,这表明采用预制ECC面层制作夹芯结构墙体会严重降低材料的界面粘结性能。由现浇试件和预制试件的荷载-滑移曲线可以看出,二者的荷载-滑移曲线均可大致分为两部分,即上升段和下降段。在上升段,两种试件在加载初期所承受的荷载与界面滑移均呈线性关系,而后随着界面粘结作用的损失,滑移量的增量增大。在下降段,现浇试件在达到峰值荷载后荷载缓慢下降,滑移量显著增大,并且出现多条剪切裂缝,最终发生界面剪切破坏并呈现出延性破坏特征。而预制试件在达到峰值荷载后迅速发生破坏,破坏时中间层ECC面板与EPS保温板完全剥离,呈脆性破坏特征。

2.2.2 保温层厚度的影响

由图5(b)可以看出,EPS保温层厚度为50 mm、70 mm、100 mm试件的荷载-滑移曲线均呈现两个阶段,即线性上升阶段和缓慢下降阶段。在线性上升阶段,保温层厚度为50 mm和70 mm试件的荷载-滑移曲线基本重合,但保温层厚度为70 mm的试件的承载能力要低于50 mm的试件,而保温层厚度为100 mm的试件的承载力更低,曲线斜率也更大。这是由于当ECC面层厚度一定时,减小保温层厚度有助于提高试件的界面剪切刚度(如表7所示,保温层厚度为50 mm的试件相较于厚度为70 mm和100 mm的试件,平均抗剪强度分别提高了20%和44%,并且厚度为70 mm的试件平均抗剪强度比厚度为100 mm的试件提高了20%),同时较大的保温层厚度还会导致试件的变形能力变差。

2.2.3 有无连接件的影响

由图5(c)可以看出,在荷载-滑移曲线的上升阶段,无连接件试件与连接件角度为90°的试件的斜率相近,但二者的极限承载力和抗剪强度相差很大。这是由于在加载初期,两种试件受到的荷载主要由ECC面层与EPS保温层之间的界面粘结作用承担。随着荷载的增加,无连接件试件承担荷载的方式不变,而嵌入连接件的试件承担荷载的方式从主要由界面粘结作用承担转变为由连接件和界面粘结作用共同承担。因此嵌入连接件的试件具有更高的极限承载力和抗剪强度,如表7所示,ECC(X)-EPS(70)-BFRP(90)试件的平均极限荷载值是ECC(X)-EPS(70)试件的1.6倍,平均抗剪强度提高了60.0%。在荷载滑移曲线的下降段,两种试件的承载力均逐渐降低,但是有连接件的试件承载力的下降较缓慢,并且在较长一段时间内仍保持有一定的承载力。而无连接件的试件在相对较短的时间内承载力会降至最小值。因此,连接件对与夹芯结构墙体的受力、变形等方面有着极其重要作用。

2.2.4 连接件角度的影响

由图5(d)可以看出,对于连接件角度为90°和60°的试件,荷载-滑移曲线可大致分为上升阶段和缓慢下降阶段,而对于连接件角度为45°的试件,荷载-滑移曲线较前者多了增强阶段。对于连接件角度为45°的试件,荷载在达到峰值后承载力仅有少量降低,并且后续还会出现承载力增强的现象。这是由于试件在承受荷载时,界面粘结作用对承载力的贡献逐渐降低,在加载后期主要由连接件来承担,因此45°的连接件在提高试件承载力方面发挥了重大作用。而由于连接件角度为60°的试件提前发生了ECC受弯破坏,其荷载-滑移曲线只有上升阶段和缓慢下降阶段两部分。对于连接件角度为90°的试件,由于连接件与ECC面层的粘结性能相对较弱,在发生破坏时,界面未出现较大的剥离,粘结力仍在发挥作用,并且出现BFRP筋被拔出等现象,这也导致了这种类型的试件未出现增强阶段。此外,连接件角度为45°的试件的承载能力和抗剪强度都要远高于连接件角度为60°和90°的试件,其试件的平均抗剪强度是60°和90°试件的2倍和3.7倍,极限承载力也分别提高了96.3%、266.2%。

2.3 ECC-EPS保温板韧性

为了进一步评价试件的界面粘结性能,采用Kim等[20]提出的耗能理论,并引入韧性指数(Toughness index,αS)来评价试件达到峰值后的耗能能力。韧性指数反映了试件加载后期界面粘结性能与试件破坏所需能量之间的转换关系,其数值越大,则试件在承载后期的抗剪性能越好:

αS=Epost(Ppeakδpeak)/2 (2) 式中:αS为韧性指数;Epost为峰值荷载后的能量值(kN·mm);Ppeak为极限荷载值(kN);δpeak为极限荷载值时的界面滑移量(mm)。具有如下关系:

Epost=∫δpeakδpost-peakPdδ (3) 式中:Epost取峰值荷载处到滑移量为20 mm时的荷载-滑移曲线下的面积。对于滑移量不够20 mm的试件曲线,终点为曲线终止处,峰值荷载后的能量值对应的界面滑移量δpost-peak为20 mm。本文利用图6中网格分割法来估算Epost值。试件的Epost、Ppeak、δpeak及韧性指数值如表8所示。

由表8可知,有连接件的试件的韧性指数普遍较高,其中连接件角度为45°的试件的韧性指数最高,这表明了连接件的存在有助于提高试件的延性,避免发生脆性破坏。在无连接件试件中保温层厚度为50 mm的韧性指数最大,说明此类试件在加载后期界面间的粘结性能仍较好,延性较高,这与试验现象相吻合。

3. 夹芯结构墙体抗剪承载力计算

为了能够更加深入地了解夹芯结构墙体的破坏机制,基于Tomlinson等[18]的分析理论提出了双面剪切试验抗剪承载力公式,预测了有连接件试件的抗剪承载力和结构中各因素对荷载值的贡献比例,并采用试验结果对计算公式进行了验证。

表 8 ECC-EPS保温板韧性指数Table 8. Toughness index of ECC-EPS insulation boardSpecimen number Epost/(kN·mm) Ppeak/kN δpeak/mm αS ECC(X)-EPS(70) 36.7 7.25 3.49 2.90 ECC(Y)-EPS(70) 2.4 2.87 1.51 1.09 ECC(X)-EPS(50) 78.8 9.02 4.46 3.92 ECC(X)-EPS(100) 25.8 6.07 6.68 1.27 ECC(X)-EPS(70)-BFRP(90) 124.2 11.89 5.90 3.54 ECC(X)-EPS(70)-BFRP(60) 142.0 23.67 1.88 6.38 ECC(X)-EPS(70)-BFRP(45) 425.0 47.74 2.55 6.98 Notes: Epost—Energy value after the peak load (kN·mm); αS—Toughness index. 由图4(d)可以看出,嵌入角度为60°BFRP连接件的试件均发生ECC面板受弯破坏,因此试件的抗剪强度应为ECC面板的弯曲破坏强度。然而,在加载过程中,ECC面板的受力较复杂,其不仅受到BFRP筋的横向推力,还受到界面粘结力的作用,这便导致了试验中ECC面板的弯曲破坏,但这种破坏与四点弯曲破坏并不完全相同。因此,在计算此类型试件的承载力时不能直接采用ECC材料的弯曲破坏强度作为试件的抗剪强度。于是,ECC面板对于抗剪承载力的贡献近似采用连接件和界面粘结作用对抗剪承载力的贡献之和来表示。因此在计算试件的抗剪承载力时,嵌入角度为45°和60°BFRP连接件的试件的抗剪承载力计算公式相同。

抗剪承载力主要有两个方面组成,分别为绝缘保温层与ECC面层间的界面粘结力Fin(N)和连接件的抗剪作用。其中,90°连接件的抗剪作用采用Fdw(N)来表示;45°、60°连接件的抗剪作用采用Ftr(N)来表示。因此,试件的抗剪承载力F值可用下式来表示,并作出四个假设,即梁理论适用于试件中连内外叶ECC面层的连接件;BFRP连接件为线弹性;保温板的破坏是由于对角拉伸分裂而失效的;在双面剪切试验过程中ECC面层不会发生挤压破碎:

F=Fin+Fdw或Ftr (4) 3.1 夹芯结构中各因素对承载力的贡献

3.1.1 绝缘保温层对抗剪承载力的贡献

假设剪切变形很小,则剪切应变可用δ1/L来表示。进而可得到绝缘保温层对抗剪承载力的贡献,其计算公式如下:

Fin=GinAinδ1L (5) 其中,Fin的最大值Fin,max为

Fin,max=fu,inAin (6) 式中:Gin为保温材料的剪切模量(EPS材料为2.27 MPa);Ain为保温受剪切面面积(等于bh,b为剪切面宽度,h为剪切面高度)(mm2);

L 为保温层厚度(mm);δ1为相对滑移量(mm),选荷载-滑移曲线中荷载首次突降时的滑移值;fu,in为保温材料的抗拉强度(MPa)。根据双面剪切试验结果,对保温层厚度为50 mm、70 mm、100 mm的试件的极限抗剪承载力进行拟合,将λ作为保温层厚度影响系数,则式(5)可调整为

Fin=λGinAinδL (7) 其中,

λ=−5.411×10−4L2+0.080L−1.922 。3.1.2 嵌入90°的连接件对抗剪的贡献

由于嵌入90°连接件的销钉作用相当于结构中的固定梁,因此其对抗剪承载力的贡献可用下式表示:

Fdw=12EscIscδ2L3 (8) 其中,Fdw的最大值Fdw, max为

Fdw,max=4fu,scIscLϕ (9) 式中:Esc为连接件的弹性模量(MPa);Isc为连接件的转动惯量(mm4);δ2为相对滑移量(mm),选取荷载-滑移曲线中荷载第二次突降时的滑移值;fu,sc为连接件的抗压强度(MPa),取其抗拉强度的30%[21];

ϕ 为连接件直径(mm)。3.1.3 嵌入角度为45°、60°的连接件对抗剪承载力的贡献

由于连接件的轴向分量决定了连接系统的性能,于是采用连接件的轴向应变εsc,a进行计算,其计算公式如下:

εsc,a=Δdacdac=√(Ltanθ+δ2)2+L2−dacdac (10) 则连接件对抗剪性能的贡献Ftr可用下式表示:

Ftr=Facsinθ′=Escεsc,aAsctan−1(Ltanθ+δ2L) (11) 式中:dac为连接件原始长度;Fac为轴向力;Asc为连接件的横截面面积(mm2);

θ′ 为连接件在受力变形后与试件水平方向夹角(°);θ为连接件与试件水平方向夹角(°);Esc为连接件弹性模量(MPa)。当45°、60°连接件受到拉力而处于拉伸状态,并且杆所受的应力ftr,strength超过BFRP的抗拉强度fu,b时,连接件会发生断裂。此时,连接件发生拉伸破坏时的荷载值Ftr,strength应采用下式进行计算:

Ftr,strength=ftr,strengthAscsinθ′ (12) 其中:

ftr,strength=√(Ltanθ+δ)2+L2−dacdacEsc+3EscϕL2δ2 (13) 当45°、60°连接件与ECC发生脱粘被拔出时,Ftr,strength应采用下式进行计算:

Ftr,bond=ftr,bondAscsinθ (14) 其中:

ftr,bond=0.083√fu,eα(13.6deϕ+Cϕdeϕ+340) (15) 式中:fu,e为ECC抗压强度(MPa);de为连接件的嵌入长度(mm);C 为BFRP筋中心位置到ECC面层边缘的最小保护层厚度(mm);

α 为连接件位置系数(当C/ϕ 超过3.5时,取3.5,当嵌入深度小于20ϕ 时,α 取值为de/(20ϕ) );Ftr, bond为连接件发生脱粘破坏时的荷载值(N)。最后,嵌入角度为45°和60°BFRP连接件的承受能力取式(12)和式(14)中的最小值。

3.2 理论值验证

对带有连接件且已画出荷载-滑移曲线图的EPS试件的极限承载力理论值和试验值进行对比分析,结果如表9所示。可以看出,采用上述计算公式计算得到的理论值与试验值的吻合度较高,因此采用上述公式来预测试件的抗剪承载力具有一定的可靠性。同时由计算结果还可以看出,对于连接件角度为90°的试件,保温材料对抗剪承载力的理论贡献值要大于连接件的理论贡献值。而对于连接件角度为45°和60°的试件,连接件对抗剪承载力的理论贡献值更大,并且对于发生ECC面板弯曲破坏的试件采用连接件与界面粘结作用对抗剪承载力的贡献来计算抗剪承载力能够满足实际需要。

表 9 ECC-EPS保温板计算荷载与实际荷载值对比Table 9. Comparison of calculated load and actual load of ECC-EPS insulation boardSpecimen number Failure load/kN Theoretical contribution value/% Experimental

valueTheoretical

valueExperimental value/

Theoretical valueThermal insulating

materialConnectors ECC(X)-EPS(70)-BFRP(90) 11.89 11.11 1.07 70.21 29.79 ECC(X)-EPS(70)-BFRP(60) 23.67 22.77 1.04 16.51 83.49 ECC(X)-EPS(70)-BFRP(45) 47.74 32.56 1.47 15.66 84.34 4. 结 论

(1) 由于预制夹芯结构墙板的粘结性能比现浇墙板差很多,因此在制备夹芯结构墙体时应尽可能采用现浇方式。

(2) 由于保温层厚度过小会导致保温层发生剪切破坏,而厚度过大会导致界面剪切刚度下降,因此在设计夹芯墙体时应合理选择保温层厚度。

(3) 为了提高试件的韧性和降低脆性破坏的可能性,夹芯结构墙体应该设置有连接件,同时为了保证连接件能够有效发挥作用,连接件应尽可能选择自身抗拉性能好、抗剪强度高且与工程水泥基复合材料(ECC)面层有良好粘结的材料。

(4) 不同处理方式下的夹芯墙体结构粘结性能优劣顺序为:嵌入连接件角度45°>嵌入连接件角度60°>嵌入连接件角度90°>保温层厚50 mm>保温层厚70 mm>保温层厚100 mm>预制。

(5) 综合比较各处理方式对夹芯结构粘结性能的影响,在设计夹芯墙体时应优先选用现浇方式,连接件的嵌入角度选为45°,保温层厚度选为70 mm。

(6) 基于Teixeira的分析理论推导的夹芯结构抗剪承载力与试验结果的吻合度较高,可以用于预测试件的抗剪承载力。

-

Mechanical

propertyTensile

strength/

MPaTensile

modulus/

GPaFlexural

strength/

MPaFlexural

modulus/

GPaMean 632.0 26.2 750.0 20.0 Standard

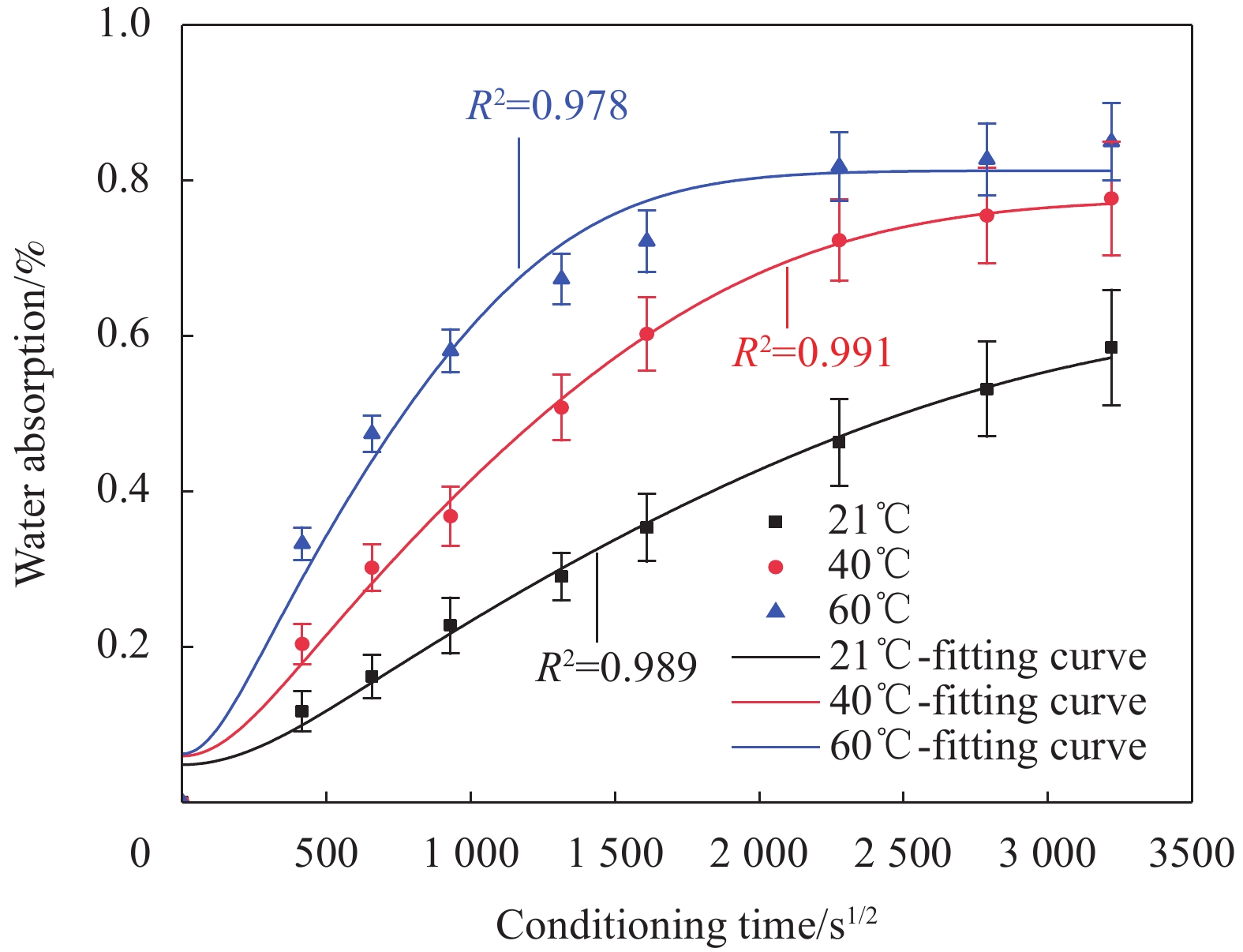

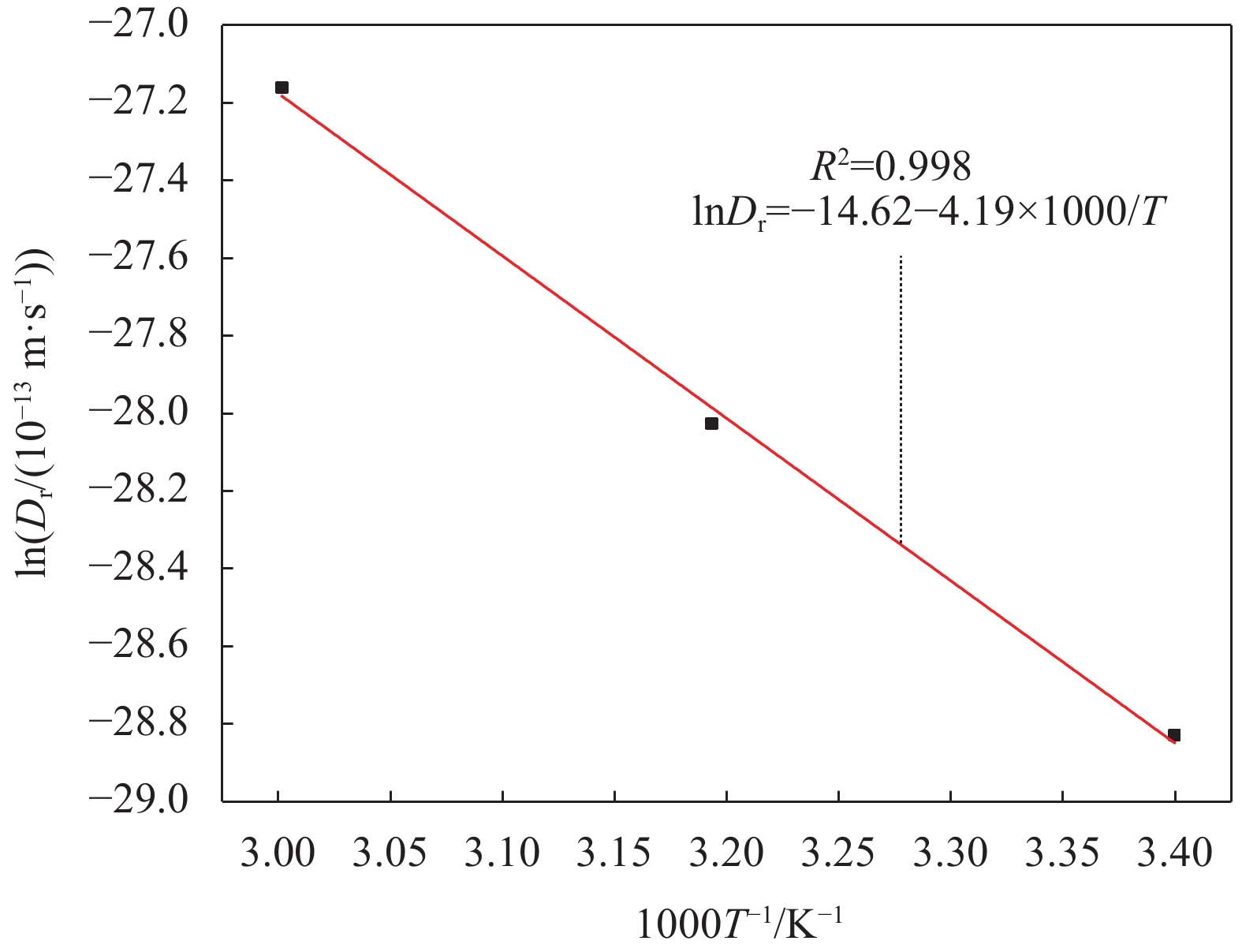

deviation31.4 2.2 118.0 2.7 表 2 GFRPP杆的水吸收拟合参数

Table 2 Water absorption fitting parameters of GFRPP rods

Temperature/℃ Dr/(10−13 m·s-1) M∞/% R2 21 3.02 0.63 0.989 40 6.73 0.78 0.991 60 16.03 0.81 0.978 Notes: Dr—Water absorption diffusion coefficient; M∞—Saturation water absorption rate. -

[1] 王自柯. FRP筋在模拟海水-海砂混凝土孔溶液浸泡下的耐久性研究[D]. 哈尔滨: 哈尔滨工业大学, 2018. WANG Zike. Study on the durability performances of fiber reinforced polymer (FRP) bars exposed to simulated seawater and sea sand concrete pore solution[D]. Harbin: Harbin Institute of Technology, 2018(in Chinese).

[2] KATANO K, TAKEDA N, ISHIZEKI Y, et al. Properties and application of concrete made with sea water and un-washed sea sand[C]. Proceedings of 3rd International Conference on Sustainable Construction Material and Technologies (SCMT3). Kyoto: Claisse, 2013: 10.

[3] TAREK U M, HIDENORI H, TORU Y. Performance of seawater-mixed concrete in the tidal environment[J]. Cement and Concrete Research,2004,34:593-601. DOI: 10.1016/j.cemconres.2003.09.020

[4] LI C G, YIN X L, LIU Y C, et al. Long-term service evaluation of a pultruded carbon/glass hybrid rod exposed to elevated temperature, hydraulic pressure and fatigue load coupling[J]. International Journal of Fatigue,2020,134:105480. DOI: 10.1016/j.ijfatigue.2020.105480

[5] ZHOU P, LI C G, BAI Y B, et al. Durability study on the interlaminar shear behavior of glass-fibre reinforced polypropylene (GFRPP) bars for marine applications[J]. Construction and Building Materials,2022,349:128694. DOI: 10.1016/j.conbuildmat.2022.128694

[6] WASIM M, TUAN D N, ABID M. Investigation of long-term corrosion resistance of reinforced concrete structures constructed with various types of concretes in marine and various climate environments[J]. Construction and Building Materials,2020,237:117701. DOI: 10.1016/j.conbuildmat.2019.117701

[7] 霍瑞丽, 陈登场, 方海, 等. 不同温度环境下轻木夹芯复合材料板弯曲疲劳性能试验[J]. 南京工业大学学报(自然科学版), 2021, 43(3): 344-350. HUO Ruili, CHEN Dengchang, FANG Hai, et al. Flexural fatigue test of composite sandwich plate with light wood core in different temperatures[J]. Journal of Nanjing Tech University (Natural Science Edition), 2021, 43(3): 344-350(in Chinese).

[8] CHANG Y F, WANG Y L, WANG M F, et al. Bond durability and degradation mechanism of GFRP bars in seawater sea-sand concrete under the coupling effect of seawater immersion and sustained load[J]. Construction and Building Materials,2021,307:124878. DOI: 10.1016/j.conbuildmat.2021.124878

[9] 常鑫泉, 汪昕, 刘长源, 等. 预应力FRP板加固RC梁抗弯性能有限元模型可靠性评价[J]. 南京工业大学学报(自然科学版), 2021, 43(3): 318-328. CHANG Xinquan, WANG Xin, LIU Changyuan, et al. Reliability evaluation of finite element model for flexural behavior of RC beams reinforced with prestressed FRP laminates[J]. Journal of Nanjing Tech University (Natural Science Edition), 2021, 43(3): 318-328(in Chinese).

[10] BENMOKRANE B, MOUSA S, MOHAMED K, et al. Physical, mechanical, and durability characteristics of newly developed thermoplastic GFRP bars for reinforcing concrete structures[J]. Construction and Building Materials,2021,276:122200. DOI: 10.1016/j.conbuildmat.2020.122200

[11] 吴超强, 王俊, 李帅, 等. 玻璃纤维增强复合材料 钢复合筋混凝土夹芯墙板抗弯性能[J]. 南京工业大学学报(自然科学版), 2021, 43(6): 782-786. WU Chaoqiang, WANG Jun, LI Shuai, et al. Bending behavior of concrete sandwich wall panels with GFRP-steel bar connectors[J]. Journal of Nanjing Tech University (Natural Science Edition), 2021, 43(6): 782-786(in Chinese).

[12] GAMBLE W L. Flexural strength and design analysis of circular reinforced concrete members with glass fiber-reinforced polymer bars and spirals[J]. ACI Structural Journal, 2019, 116(4): 301-302.

[13] KAMAL A S M, BOULFIZA M. Durability of GFRP rebars in simulated concrete solutions under accelerated aging conditions[J]. Journal of Composites for Construction,2011,15(4):473-481.

[14] WANG Z K, ZHAO X L, XIAN G J, et al. Effect of sustained load and seawater and sea sand concrete environment on durability of basalt- and glass-fibre reinforced polymer (B/GFRP) bars[J]. Corrosion Science,2018,138:200-218. DOI: 10.1016/j.corsci.2018.04.002

[15] MOSSAB E, KHALED G, VAN S H. New thermoplastic CFRP bendable rebars for reinforcing structural concrete elements[J]. Composites Part B: Engineering,2013,45(1):1207-1215. DOI: 10.1016/j.compositesb.2012.09.025

[16] SOUTIS C. Fibre reinforced composites in aircraft construction[J]. Progress in Aerospace Sciences,2005,41(2):143-151. DOI: 10.1016/j.paerosci.2005.02.004

[17] ASENSIO M, ESFANDIARI P, MARQUES A, et al. Processing of pre-impregnated thermoplastic towpreg reinforced by continuous glass fibre and recycled PET by pultrusion[J]. Composites Part B: Engineering,2020,200:108365. DOI: 10.1016/j.compositesb.2020.108365

[18] CHEN K, JIA M Y, SUN H, et al. Thermoplastic reaction injection pultrusion for continuous glass fiber-reinforced polyamide-6 composites[J]. Materials,2019,12(3):463. DOI: 10.3390/ma12030463

[19] ALEXANDER V, KIRILL M, SERGEY G, et al. Effects of the pre-consolidated materials manufacturing method on the mechanical properties of pultruded thermoplastic composites[J]. Polymers,2022,14(11):2246. DOI: 10.3390/polym14112246

[20] MAXIMILIAN V, JOANNA W, SHELLY A, et al. Pultrusion of large thermoplastic composite profiles up to Ø40 mm from glass-fibre/PET commingled yarns[J]. Composites Part B: Engineering,2021,227:109339. DOI: 10.1016/j.compositesb.2021.109339

[21] CURRIER J, FOGSTAD C, WALRATH D, et al. Bond development of thermoplastic FRP shear reinforcement stirrups[C]. The 3rd Materials Engineering Conference. San Diego: ASCE, 1994: 6.

[22] MEHRABI A E, VANDERPOOL D. Mechanical performance of thermoplastic fiber reinforced polymer rebars[Z]. Proceedings of the 6th International Symposium on FRP Reinforcement for Concrete Structures (FRPRCS-6). Singapore: World Scientific, 2003: 79-88.

[23] MICELLI F, NANNI A. Durability of FRP rods for concrete structures[J]. Construction and Building Materials,2004,18(7):491-503. DOI: 10.1016/j.conbuildmat.2004.04.012

[24] WANG X, PENG Z Q, DING L N, et al. Mechanical and bonding behavior of a bendable fiber-reinforced thermoplastic rebar[J]. Construction and Building Materials,2021,302:124222. DOI: 10.1016/j.conbuildmat.2021.124222

[25] FERRIER E, RABINOVITCH O, MICHEL L. Mechanical behavior of concrete-resin/adhesive-FRP structural assemblies under low and high temperatures[J]. Construction and Building Materials,2016,127:1017-1028. DOI: 10.1016/j.conbuildmat.2015.12.127

[26] American Society for Testing and Materials Committee. Standard test method for moisture absorption properties and equilibrium conditioning of polymer matrix composite materials: ASTM-D5229/D5229 M—14[S]. West Conshohocken: American Society for Testing and Materials Committee, 2014.

[27] CHEN Y, JULIO F D, INDRAJIT R, et al. Accelerated aging tests for evaluations of durability performance of FRP reinforcing bars for concrete structures[J]. Composite Structures,2007,78(1):101-111. DOI: 10.1016/j.compstruct.2005.08.015

[28] YU Y X, LIU S, PAN Y F, et al. Durability of glass fiber-reinforced polymer bars in water and simulated concrete pore solution[J]. Construction and Building Materials,2021,299:123995. DOI: 10.1016/j.conbuildmat.2021.123995

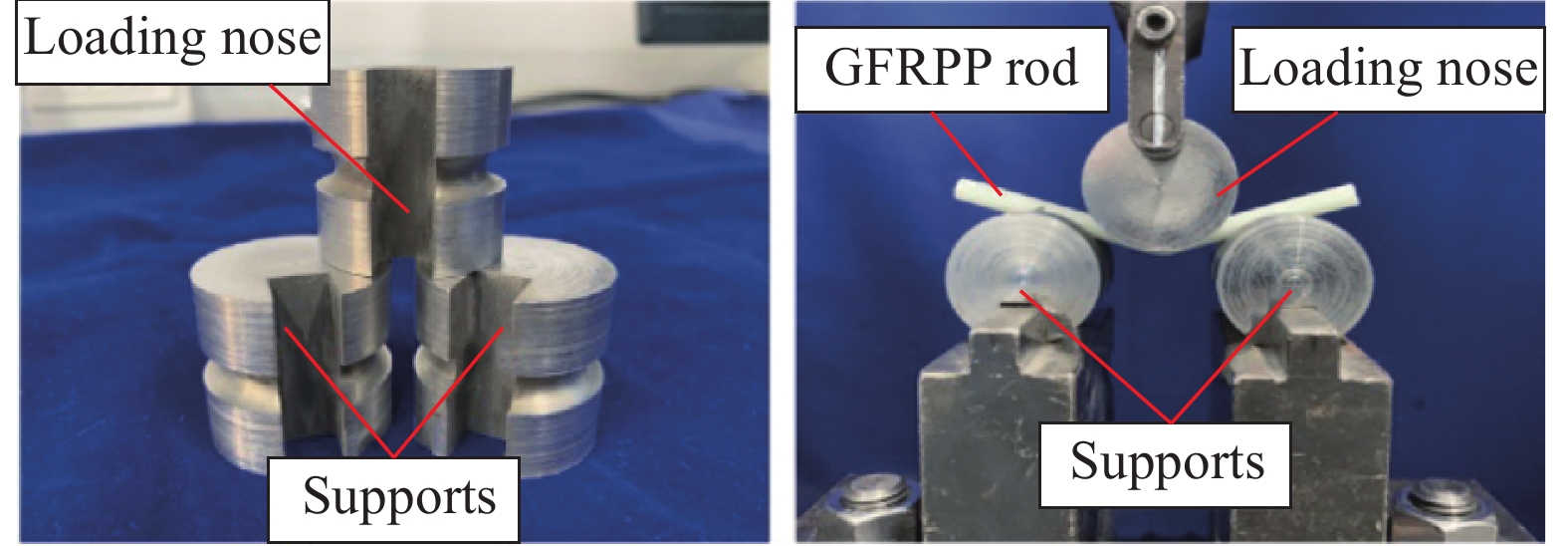

[29] American Society for Testing and Materials Committee. Standard test method for apparent horizontal shear strength of pultruded reinforced plastic rods by the short-beam method: ASTM D4475—02[S]. West Conshohocken: American Society for Testing and Materials Committee, 2002.

[30] GERARD J, PERRET P, CHABERT B. Study of carbon/epoxy interface (or interphase): Effect of surface treatment of carbon fibers on the dynamic mechanical behavior of carbon/epoxy unidirectional composites[M]. Controlled Interphases in Composite Materials. Cleveland: Springer, 1990: 449-456.

[31] 杨国威, 梅志远, 李华东, 等. 典型舰用复合材料DMA动态力学性能试验研究[J]. 玻璃钢/复合材料, 2018(6):66-72. YANG Guowei, MEI Zhiyuan, LI Huadong, et al. Experimental study on dynamic mechanical properties of typical naval ship composite materials[J]. Fiber Reinforced Plastics/Composites,2018(6):66-72(in Chinese).

[32] 李承高, 郭瑞, 王俊琦, 等. CFRP@GFRP 混杂复合材料杆体在水浸泡环境下的性能演化[J]. 复合材料学报, 2021, 38(10):3290-3301. LI Chenggao, GUO Rui, WANG Junqi, et al. Property evolution of CFRP@GFRP hybrid composite rod exposed in the distilled water[J]. Acta Materiae Compositae Sinica,2021,38(10):3290-3301(in Chinese).

[33] DENG H, REYNOLDS C T, CABRERA N O, et al. The water absorption behaviour of all-polypropylene composites and its effect on mechanical properties[J]. Composites Part B: Engineering,2010,41(4):268-275. DOI: 10.1016/j.compositesb.2010.02.007

[34] 王传伟, 肖玮佳, 刘晨光. 傅里叶变换红外光谱法快速测定聚丙烯/聚丁烯釜内合金的组分含量[J]. 青岛科技大学学报(自然科学版), 2022, 43(1):64-70. DOI: 10.16351/j.1672-6987.2022.01.009 WANG Chuanwei, XIAO Weijia, LIU Chenguang. Rapid determination of polypropylene/polybutene alloy composition by fourier transform infrared spectroscopy[J]. Journal of Qingdao University of Science and Technology (Natural Science Edition),2022,43(1):64-70(in Chinese). DOI: 10.16351/j.1672-6987.2022.01.009

[35] AZZURRI F, FLORES A, ALFONSE G C, et al. Polymorphism of isotactic polybutene-1 as revealed by microindentation hardness. Part II: Correlations to microstructure[J]. Polymer,2003,44(5):1641-1645. DOI: 10.1016/S0032-3861(02)00864-9

-

期刊类型引用(8)

1. 刘伟,杨继,袁春辉,夏旭,张锦光. 不同温度下碳纤维复合材料-钢胶接界面黏结性能研究. 复合材料科学与工程. 2025(03): 39-45+70 .  百度学术

百度学术

2. 邵家儒,刘牛,杨瑜,郑子君. CFRP复合材料构件胶接特性及失效规律研究. 应用力学学报. 2023(05): 1058-1067 .  百度学术

百度学术

3. 陈旭,曹亚周,崔健,葛继文. 碳纤维复合材料车体地板长大型材粘接工艺研究及装备设计. 机械. 2022(11): 63-69 .  百度学术

百度学术

4. 陈卓异,彭彦泽,李传习,郭靖. 高温下双搭接钢-CFRP板胶粘界面力学性能试验. 复合材料学报. 2021(02): 449-460 .  本站查看

本站查看

5. 李传习,李游,贺君,刘一鸣,彭彦泽. 固化剂对室温胶黏CFRP板/钢板界面性能的影响. 建筑材料学报. 2021(02): 339-347 .  百度学术

百度学术

6. 杨峰,陈玉龙,罗旺,史剑,贾林江,陈子光. TG800碳纤维/聚酰亚胺树脂复合材料带翻边开口圆柱壳机匣件高温气动载荷下的承载性能. 复合材料学报. 2021(07): 2184-2195 .  本站查看

本站查看

7. 桑海涛,周昕. 暖通空调胶接结构搭接接头承载力优化研究. 中国胶粘剂. 2021(11): 51-54+72 .  百度学术

百度学术

8. 李传习,李游,高有为,胡正,刘一鸣. 纳米SiO_2质量分数对胶粘碳纤维增强树脂复合材料板-钢搭接界面黏结性能的影响. 复合材料学报. 2020(10): 2619-2635 .  本站查看

本站查看

其他类型引用(7)

-

目的

连续玻璃纤维增强聚丙烯(Glass Fibre Reinforced Polypropylene,GFRPP)复合材料杆集成了热塑性树脂可多次成型、环境友好、可回收利用和玻璃纤维高应变、低成本等优点,在混凝土结构领域,GFRPP复合材料有望替代钢筋和热固性FRP筋成为新型热塑性复合材料。本文采用加速实验研究了模拟海水-海砂混凝土环境下GFRPP杆的水吸收及层间剪切性能长期演化规律与退化机理。

方法加速实验研究了模拟海水-海砂混凝土环境下GFRPP杆的水吸收及层间剪切性能长期演化规律与退化机理。首先,加速实验通过恒温21、40和60℃模拟海水-海砂混凝土孔溶液测定GFRPP杆的吸水性能,采用Fick定律获得GFRPP杆在模拟海水-海砂混凝土孔溶液在上述温度下的水吸收扩散系数与饱和吸水率。测试各工况下GFRPP杆层间剪切强度及热力学性能,并采用SEM和FTIR微观表征技术揭示模拟海水-海砂混凝土孔溶液环境下GFRPP杆长期剪切性能的退化机理。

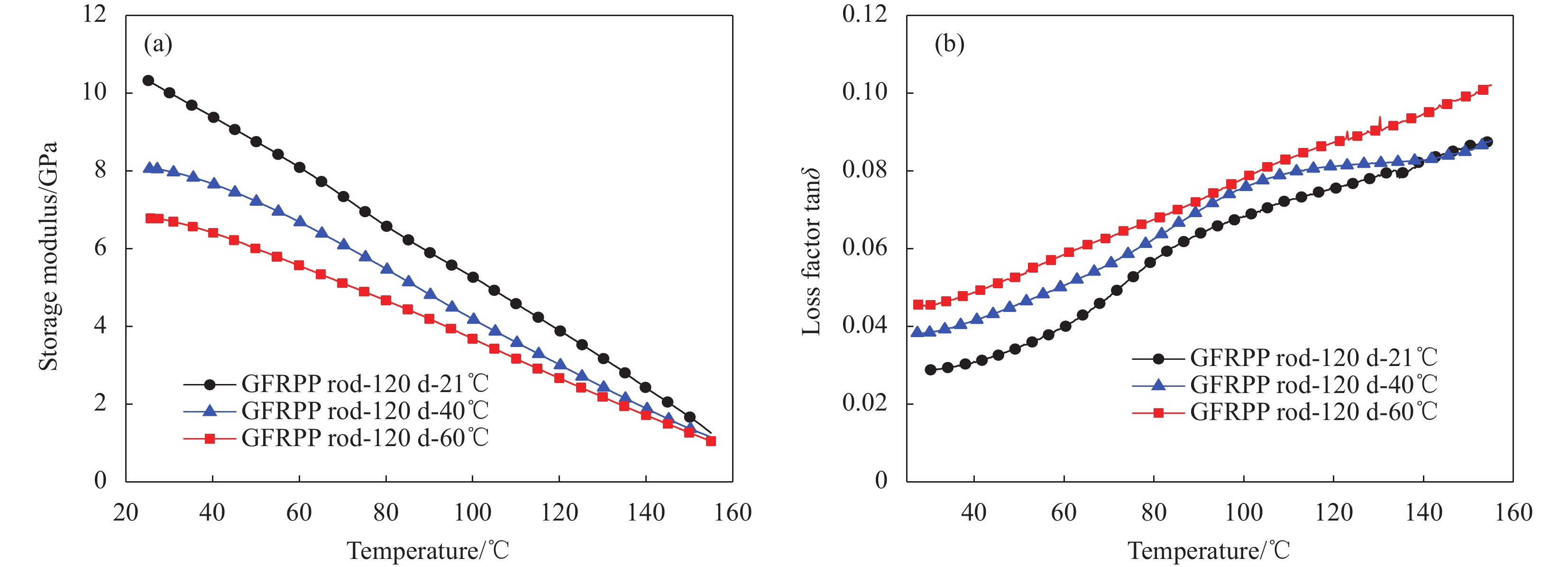

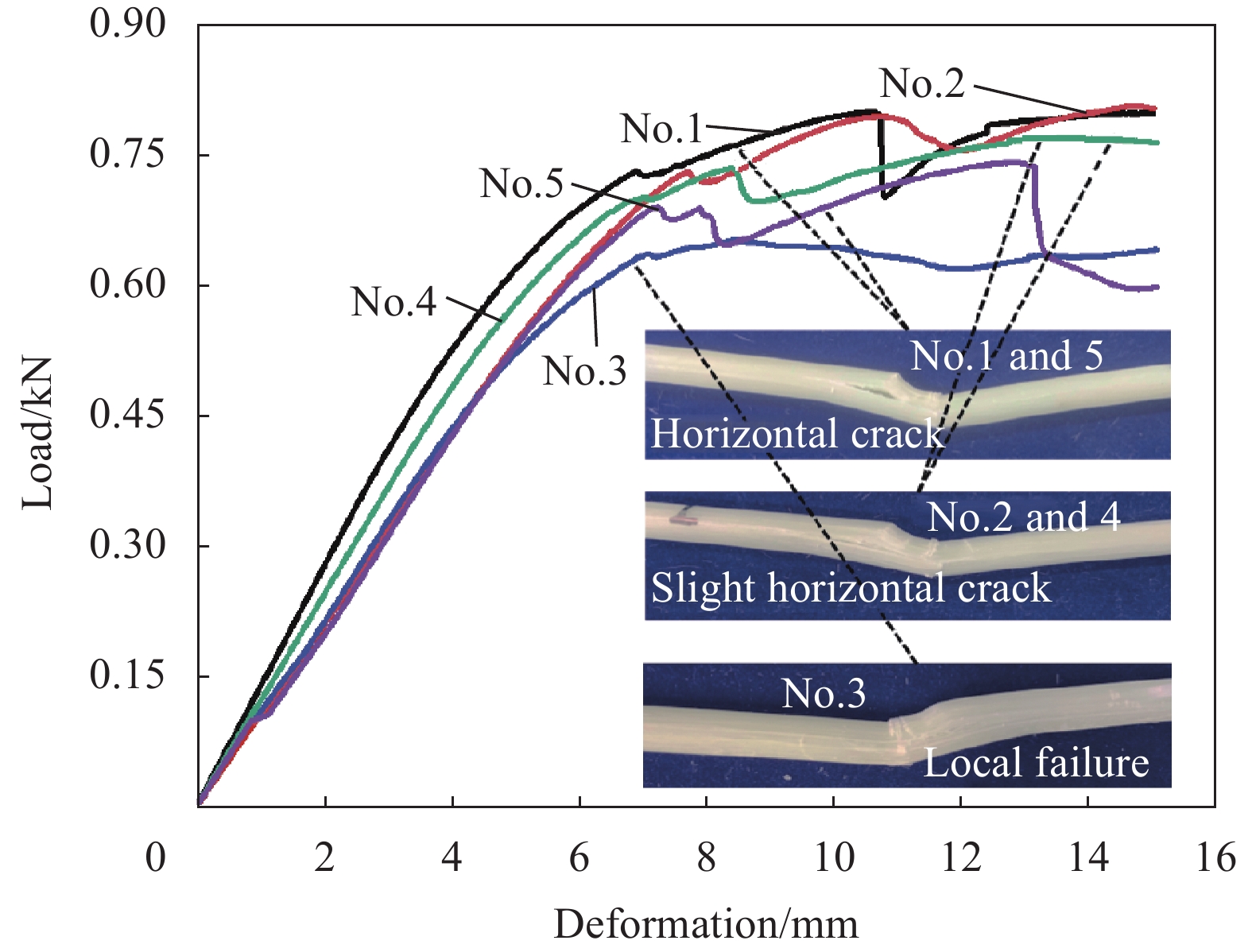

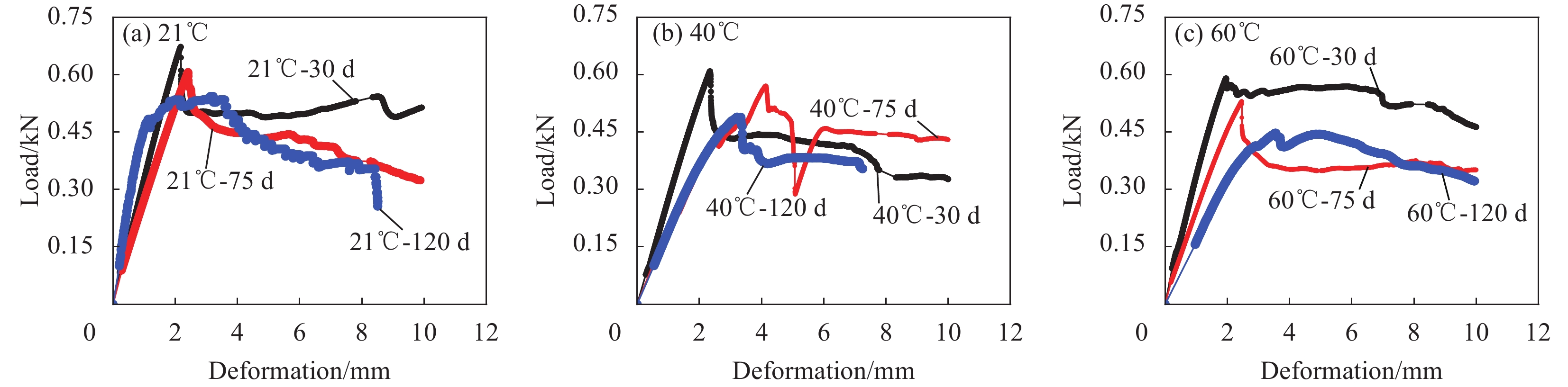

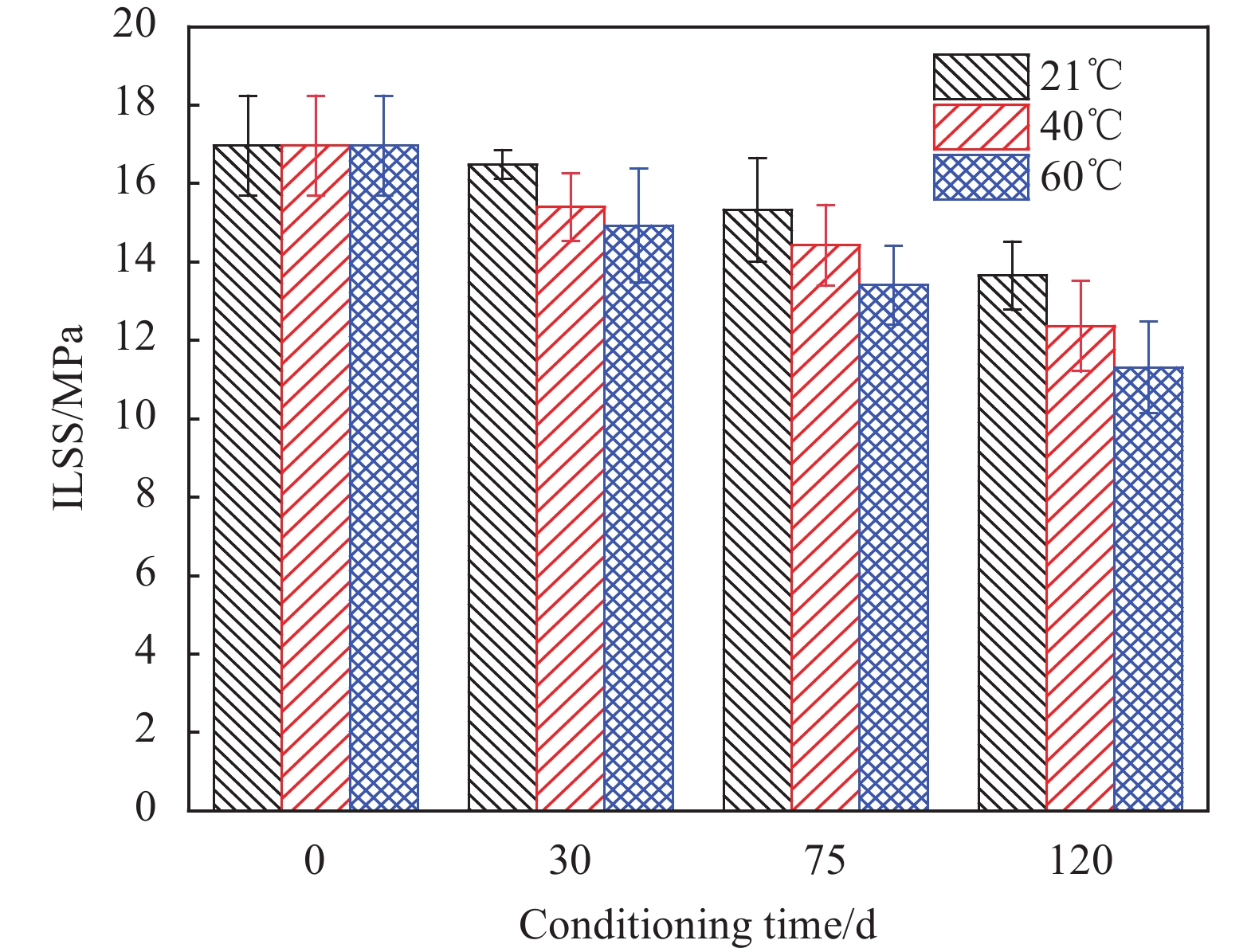

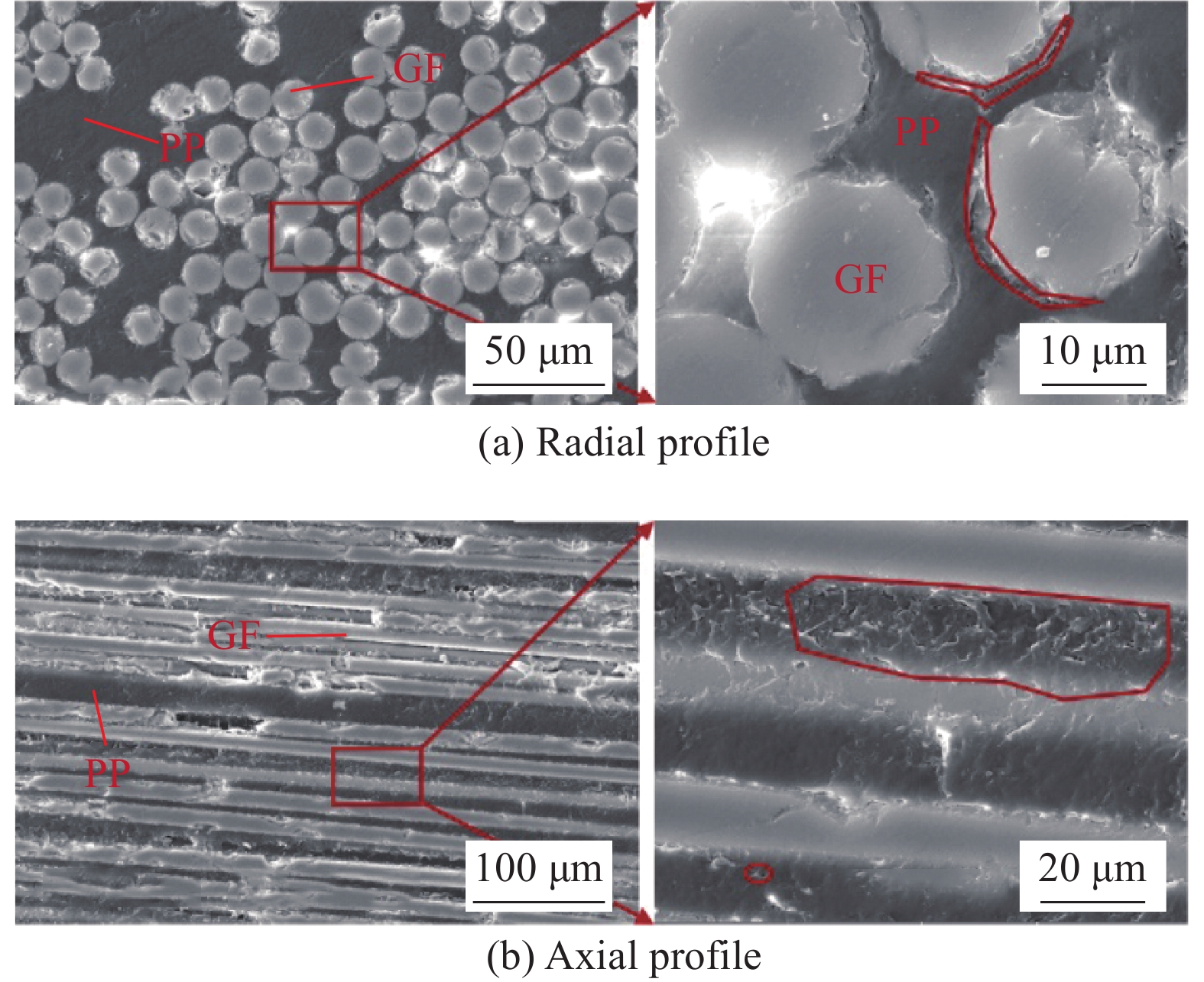

结果(1)水吸收测试结果表明,不同温度下的水吸收曲线均随着老化时间的增加,GFRPP杆的吸水率先线性增加,达到饱和状态后基本保持平衡,此规律复合典型的Fick吸水模型。GFRPP杆在60℃下的水吸收扩散速率和饱和吸水率明显高于40℃和21℃,其水吸收扩散速率为40℃和21℃的2.4和5.3倍。(2)GFRPP杆的剪切性能及热力学性能测试表明,GFRPP杆原始(未浸泡)试样层间剪切荷载-变形曲线起始阶段呈线性,且在水平剪切破坏前存在由拉力机压头引起的屈服段。模拟海水-海砂环境下GFRPP杆的层间剪切强度随温度升高和浸泡时间增大而降低。与未浸泡试样相比,经21℃、40℃和60℃模拟海水-海砂浸泡120天后其层间剪切强度保留率分别为80.5%、72.8%和66.5%。(3)热力学测试结果显示GFRPP杆在21℃和60℃浸泡温度下损耗因子分别增加0.053和0.058,增幅分别为1.23、1.83倍。40℃浸泡温度损耗因子增幅呈先增后减趋势,当测试温度高于140℃,40℃与21℃下材料损耗因子几乎相等。(4)微观表征表明,GFRPP杆中存在的微细观孔隙和裂缝是纤维-树脂界面脱粘的根本原因,孔隙、裂缝的发展进一步为环境中氢氧根等离子刻蚀提供了“通道”。

结论(1)连续玻璃纤维增强聚丙烯复合材料(GFRPP)杆的水吸收行为符合Fick定律,21℃的水吸收扩散速率为3.02(10m/s)、饱和吸水率0.63%,40和60℃水吸收扩散速率、饱和吸水率分别为21℃的2.23、1.24倍和5.31、1.29倍;高温明显加速模拟溶液沿杆体径向的扩散,但对吸水性能影响不显著。(2)21、40和60℃模拟海水-海砂混凝土孔溶液浸泡120天后GFRPP杆层间剪切强度保留率分别为80.5%、72.8%和66.5%,其60℃层间剪切强度保留率比浸泡84天热固性GFRP强度保留率高24%左右,且该优势在40、60℃尤为显著。(3)GFRPP杆体内部微细观孔隙和裂缝在模拟海水-海砂混凝土孔溶液中持续发育、扩展致使玻璃纤维暴露于浸泡溶液并使其发生不同程度的刻蚀是GFRPP杆剪切性能退化的主要原因;纤维-树脂界面脱粘也是层间剪切性能降低的另一重要原因,该结论通过SEM图片和FTIR能谱得以证实。

-

连续玻璃纤维增强聚丙烯(Glass Fibre Reinforced Polypropylene,GFRPP)复合材料杆集成了热塑性树脂可多次成型、环境友好、可回收利用和玻璃纤维高应变、低成本等优点,在混凝土结构领域,GFRPP复合材料有望替代钢筋和热固性FRP筋成为新型热塑性复合材料。

本文采用加速试验研究了模拟海水-海砂混凝土环境下GFRPP杆的水吸收及层间剪切性能长期演化规律与退化机理。研究结果表明:GFRPP杆吸水行为符合Fick定律,21、40和60℃浸泡温度下GFRPP杆的饱和吸水率分别为0.63、0.78和0.81%;经120天21、40和60℃模拟海水海砂混凝土孔溶液浸泡后,GFRPP杆层间剪切强度保留率分别为80.5、72.8和66.5%。最后,结合SEM和FTIR表征技术,揭示模拟海水-海砂混凝土孔溶液浸泡下GFRPP杆性能退化机理。

模拟海水-海砂混凝土孔环境GFRPP杆的层间剪切性能演化:(a)长期吸水性能;(b) SEM表征及FTIR能谱分析;(c)层间剪切强度退化

下载:

下载: