Pull-out failure mechanism of C/SiC composite connection structure

-

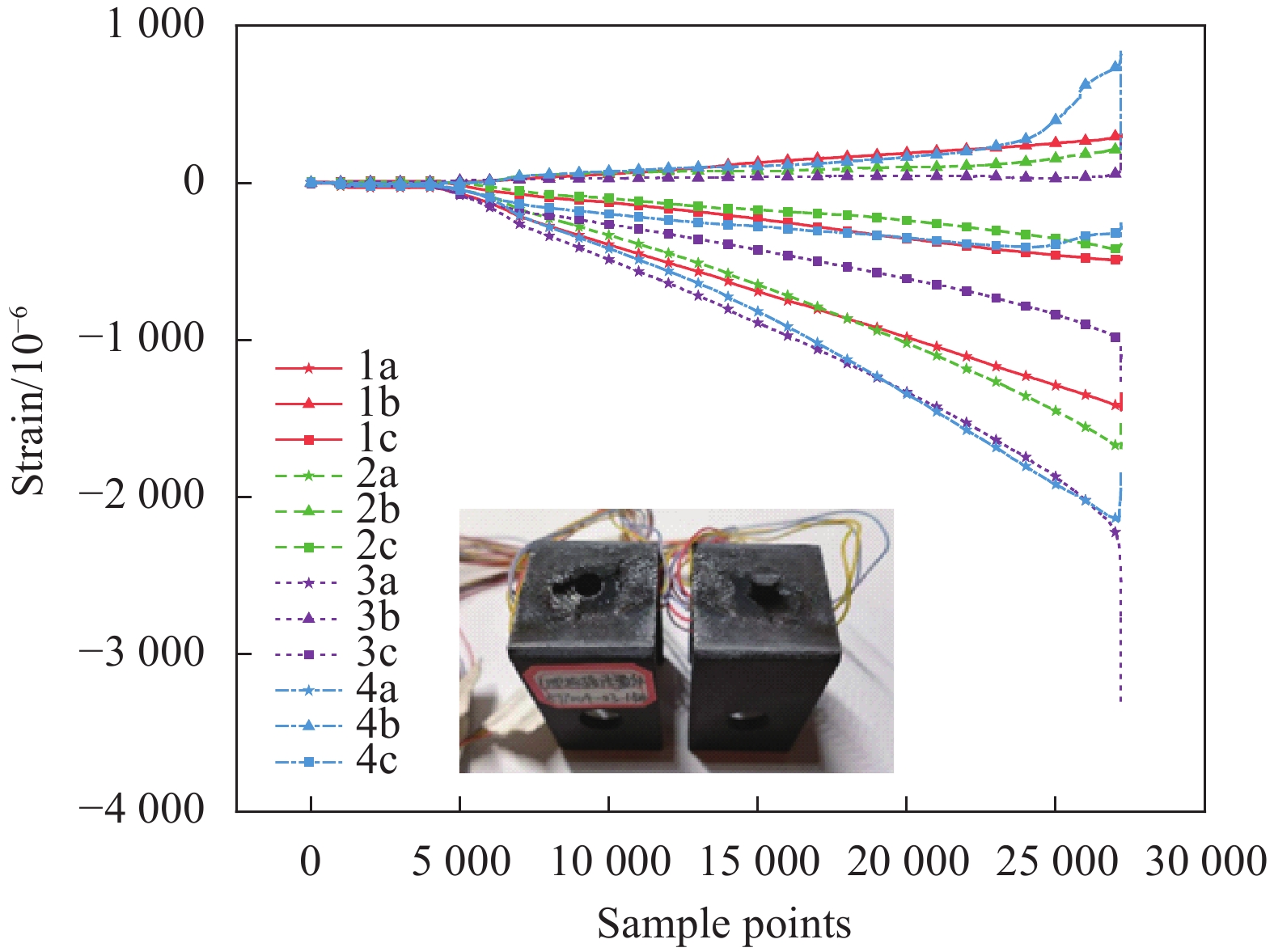

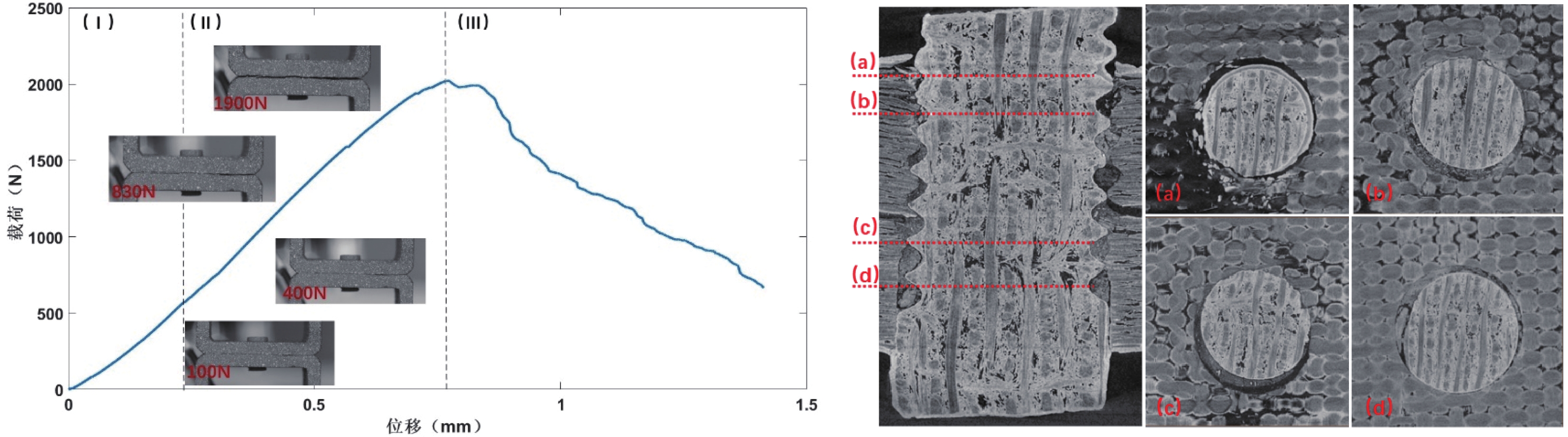

摘要: 通过C/SiC陶瓷基复合材料连接结构单轴拉伸试验,研究了连接结构拉脱失效过程的力学性能变化规律,结合应变测量、高速摄像、CT检测等测试手段从宏观角度和细观角度探究了连接结构拉脱失效过程中的损伤演化过程,确定了陶瓷基复合材料连接结构拉脱失效机制。结果表明:由于螺纹部位沉积及接触状态的差异,导致不同连接结构的初始刚度不一致;随着位移不断增加,连接部位的刚度趋于一致。加载过程中螺纹孔附近受到挤压产生损伤并发生分层现象;当螺纹孔局部的损伤达到一定程度时,连接结构达到最大承载能力,此时随着位移继续增加螺钉开始拉脱,承载能力开始下降,直至螺钉完全拉脱拔出。Abstract: Through uniaxial tensile test of C/SiC ceramic matrix composite connection structure, the change law of mechanical properties of connection structure during pull-off failure was studied. Combined with strain measurement, high-speed camera, CT detection and other test methods, the damage evolution process of the connection structure during the pull-off failure process was explored from the macro and micro perspectives, and the pull-out failure mechanism of the ceramic matrix composite connection structure was determined. The results show that the initial stiffness of different connection structures is inconsistent due to the difference of the deposition and contact state of the thread. As the displacement increasing, the stiffness of the connecting part tends to be consistent. Damage and delamination occur when the threaded hole is squeezed during loading. When the local damage of the threaded hole reaches a certain degree, the connecting structure reaches the maximum bearing capacity. At this time, as the displacement continues to increase, the screw begins to pull out, and the bearing capacity begins to decline until the screw is completely pulled out.

-

Keywords:

- C/SiC composites /

- connection structure /

- pull-out failure /

- damage evolution /

- CT detection

-

-

-

[1] 张立同. 纤维增韧碳化硅陶瓷复合材料—模拟、表征与设计[M]. 北京: 化学工业出版社, 2009. ZHANG Litong. Toughening silicon carbide ceramic fiber composite materials—Simulation, characterization and design[M]. Beijing: Chemical Industry Press, 2009(in Chinese).

[2] 张毅. CVI-2D C/SiC复合材料铆接单元的力学行为与失效机制[D]. 西安: 西北工业大学, 2017. ZHANG Yi. Numerical stimulation and experimental validation of stress in C/SiC riveted joints under shear load[D]. Xi'an: Northwestern Polytechnical University, 2017(in Chinese).

[3] LI G D, LI Y, YU G Q, et al. Effects of fiber preform structures on the mechanical properties of C/SiC nuts and bolts[J]. Ceramics International, 2016, 42(11): 12901-12906.

[4] LI X Q, TAN Z Y, ZHANG Y, et al. Shear behaviors and failure mechanisms of 2D C/SiC pins prepared by chemical vapor infiltration[J]. Ceramics International,2020,46(10):16693-16699. DOI: 10.1016/j.ceramint.2020.03.243

[5] FU M Q, FANG G D, LIU S, et al. Failure analysis of 2D C/SiC composite Z-pinned/bonded hybrid single-lap joints[J]. Ceramics International,2020,46(13):21216-21224. DOI: 10.1016/j.ceramint.2020.05.204

[6] 张青, 刘永胜, 门静, 等. 受剪载荷下C/SiC铆接接头应力数值模拟与实验验证[J]. 稀有金属材料与工程, 2014, 43(2):327-330. ZHANG Qing, LIU Yongsheng, MEN Jing, et al. Numerical stimulation and experimental validation of stress in C/SiC riveted joints under shear load[J]. Rare Metal Materials and Engineering,2014,43(2):327-330(in Chinese).

[7] 袁建宇, 逄锦程, 王影, 等. C/SiC复合材料紧固件拉-拉疲劳行为研究[J]. 宇航材料工艺, 2020, 50(3):81-86. DOI: 10.12044/j.issn.1007-2330.2020.03.014 YUAN Jianyu, PANG Jincheng, WANG Ying, et al. Tension-tension fatigue behavior of C/SiC composite fasteners[J]. Aerospace Materials & Technology,2020,50(3):81-86(in Chinese). DOI: 10.12044/j.issn.1007-2330.2020.03.014

[8] 袁建宇, 逄锦程, 王影, 等. C/SiC复合材料螺钉拉伸强度分布模型[J]. 宇航材料工艺, 2019, 49(5):74-78. DOI: 10.12044/j.issn.1007-2330.2019.05.015 YUAN Jianyu, PANG Jincheng, WANG Ying, et al. Tensile strength distribution model of C/SiC composite material bolts[J]. Aerospace Materials & Technology,2019,49(5):74-78(in Chinese). DOI: 10.12044/j.issn.1007-2330.2019.05.015

[9] 刘永胜, 胡成浩, 汪清, 等. 受拉载荷下C/SiC铆接接头应力的数值模拟与实验验证[J]. 复合材料学报, 2013, 30(3):205-210. LIU Yongsheng, HU Chenghao, WANG Qing, et al. Numerical stimulation and experimental validation of stress in C/SiC riveting joints under tensile load[J]. Acta Materiae Compositae Sinica,2013,30(3):205-210(in Chinese).

[10] 卢子兴, 廖强, 杨振宇, 等. C/SiC复合材料螺栓螺牙承载能力[J]. 复合材料学报, 2015, 32(1):182-187. LU Zixing, LIAO Qiang, YANG Zhenyu, et al. Load bearing capability of thread teeth of C/SiC composite bolts[J]. Acta Materiae Compositae Sinica,2015,32(1):182-187(in Chinese).

[11] LI G D, ZHANG C R, HU H F, et al. Preparation and mechanical properties of C/SiC nuts and bolts[J]. Materials Science and Engineering: A,2012,547:1-5.

[12] 朱宝城, 高希光, 宋迎东. 陶瓷基复合材料螺栓渐进损伤计算与强度预测[J]. 推进技术, 2020, 41(2):406-411. ZHU Baocheng, GAO Xiguang, SONG Yingdong. Progressive damage calculation and strength prediction of ceramic matrix composites bolt[J]. Journal of Propulsion Technology,2020,41(2):406-411(in Chinese).

[13] 李正禹. 螺钉参数对C/SiC复合材料连接结构高温拉伸性能的影响研究[D]. 哈尔滨: 哈尔滨工业大学, 2019. LI Zhengyu. Effects of fastener parameters on tensile properties of C/SiC composite joint structures at high temperatures[D]. Haerbin: Harbin Institute of Technology, 2019(in Chinese).

[14] 高魁垠, 李海波, 吴建国, 等. 2D-C/SiC复合材料螺栓连接结构可靠性分析[J]. 强度与环境, 2020, 47(1):33-40. GAO Kuiyin, LI Haibo, WU Jianguo, et al. Reliability analysis of 2D-C/SiC composite bolted joints[J]. Structure & Environment Engineering,2020,47(1):33-40(in Chinese).

[15] 刘宝瑞, 侯传涛, 赵丽滨, 等. 陶瓷基复合材料连接结构失效分析方法[J]. 装备环境工程, 2020, 17(1):63-70. LIU Baorui, HOU Chuantao, ZHAO Libin, et al. Failure analysis method of ceramic matrix composite joint structures[J]. Equipment Environmental Engineering,2020,17(1):63-70(in Chinese).

[16] ZHAO L B, YANG W, CAO T C, et al. A progressive failure analysis of all-C/SiC composite multi-bolt joints[J]. Composite Structures,2018,202:1059-1068. DOI: 10.1016/j.compstruct.2018.05.029

[17] HE Z B, ZHANG L T, ZHANG Y, et al. Microstructural characterization and failure analysis of 2D C/SiC two-layer beam with pin-bonded hybrid joints[J]. International Journal of Adhesion & Adhesives,2015,57:70-78.

[18] 李旭勤, 陈旭, 陈婧旖, 等. 平纹编织C/SiC单钉铆接单元的制备与拉伸行为[J]. 硅酸盐学报, 2021, 49(6):1206-1212. LI Xuqin, CHEN Xu, CHEN Jingyi, et al. Fabrication and tensile behaviors of plain woren C/SiC Z-pinned joint[J]. Journal of the Chinese Ceramic Society,2021,49(6):1206-1212(in Chinese).

[19] LI G D, ZHANG C R, HU H F, et al. Preparation and mechanical properties of C/SiC nuts and bolts[J]. Materials Science and Engineering: A, 2012, 547: 1-5.

[20] 刘杰, 李海滨, 刘小瀛. 3D针刺C/SiC复合材料螺栓的低成本制备及力学性能[J]. 航空学报, 2013, 34(7):1724-1730. LIU Jie, LI Haibin, LIU Xiaoying. Low cost preparation and mechanical property of three-dimensional needled C/SiC bolts[J]. Acta Aeronautica et Astronautica Sinica,2013,34(7):1724-1730(in Chinese).

[21] DELHAES P. Chemical vapor deposition and infiltration processes of carbon materials[J]. Carbon,2002,40(5):641-657. DOI: 10.1016/S0008-6223(01)00195-6

[22] ZHANG W G, HU Z J, HÜTTINGER K J. Chemical vapor infiltration of carbon fiber felt: Optimization of densification and carbon microstructure[J]. Carbon,2002,40(14):2529-2545. DOI: 10.1016/S0008-6223(02)00206-3

[23] 付茂青. C/SiC复合材料薄壁连接结构等效建模与强度分析[D]. 哈尔滨: 哈尔滨工业大学, 2020. FU Maoqing. Equivalent modeling and strength analysis of C/SiC composite thin-walled joint structrure[D]. Harbin: Harbin Institute of Technology, 2020(in Chinese).

[24] HE Z B, ZHANG L T, CHEN B, et al. Microstructure and mechanical properties of SiC bonded joints prepared by CVI[J]. International Journal of Adhesion and Adhesives,2016,64:15-22. DOI: 10.1016/j.ijadhadh.2015.09.009

[25] 马雪寒, 王守财, 陈旭, 等. 陶瓷基复合材料紧固件制造技术及其连接性能研究进展[J]. 复合材料学报, 2023, 40(6): 3075-3089. MA Xuehan, WANG Shoucai, CHEN Xu, et al. Review of preparation processes and joining performance of ceramic matrix composite fasteners[J]. Acta Materiae Compositae Sinica, 2023, 40(6): 3075-3089(in Chinese).

[26] 卢越, 张海鹏. 陶瓷基复合材料螺栓渐进损伤计算与强度预测[J]. 设备管理与维修, 2020(2):30-31. DOI: 10.16621/j.cnki.issn1001-0599.2020.01D.15 LU Yue, ZHANG Haipeng. Progressive damage calculation and strength prediction of ceramic matrix composite bolts[J]. Plant Maintenance Engineering,2020(2):30-31(in Chinese). DOI: 10.16621/j.cnki.issn1001-0599.2020.01D.15

[27] 谭志勇, 王捷冰, 孟繁夫, 等. 配合条件对C/SiC在线铆接单元的力学性能影响[J]. 复合材料学报, 2023, 40(7):4270-4281. DOI: 10.13801/j.cnki.fhclxb.20220930.004 TAN Zhiyong, WANG Jiebing, MENG Fanfu, et al. Effect of fit conditions on mechanical properties of C/SiC online riveting unit[J]. Acta Materiae Compositae Sinica,2023,40(7):4270-4281(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20220930.004

-

期刊类型引用(8)

1. 徐康康,程蹈,刘点,陈玉霞,涂道伍,郭勇,吴自成. 无损检测技术在纤维增强聚合物复合材料机械损伤监测中的应用进展. 塑料工业. 2024(02): 8-15 .  百度学术

百度学术

2. 孟凌霄,石文泽,卢超,黄良,凌建. 碳纤维增强树脂基复合材料气瓶电磁超声在线监测方法及失效机制. 复合材料学报. 2024(04): 1820-1829 .  本站查看

本站查看

3. 熊政辉,陈俊超,肖树坤,荆砚,何喜,陈尧. 应用于斜楔块的子孔径虚拟源全聚焦成像. 应用声学. 2024(03): 625-634 .  百度学术

百度学术

4. 曹欢庆,朱启民,赵培含,何梓科,郭师峰. 复杂型面结构超声成像检测研究进展. 仪器仪表学报. 2024(06): 42-53 .  百度学术

百度学术

5. 李荣光,朱甜甜,孙伶,陈斯迅,周文彬,周正干. 管道碳纤维复合材料修复层阵列超声检测方法提高检测精度. 石油钻采工艺. 2024(06): 728-742 .  百度学术

百度学术

6. 夏玉秀,张义凤,薛峰. 相控阵超声检测技术在航空领域应用研究进展. 无损探伤. 2023(04): 6-10+38 .  百度学术

百度学术

7. 杨红娟,杨正岩,杨雷,单一男,林奎旭,武湛君. 碳纤维复合材料损伤的超声检测与成像方法研究进展. 复合材料学报. 2023(08): 4295-4317 .  本站查看

本站查看

8. 陈学宽,龙盛蓉,宋奕霖,邹越豪,李志农. 基于二维等效声速的频域全聚焦超声成像研究. 仪器仪表学报. 2023(08): 130-140 .  百度学术

百度学术

其他类型引用(5)

-

目的

热端部件经历严酷的高温环境,常规的金属紧固件无法使用,因此C/SiC复合材料连接结构大量的使用在飞行器热端部件中。本文对C/SiC复合材料连接结构试件进行单轴拉伸试验,获取了拉脱失效过程中载荷及连接状态的变化,分析了连接结构拉脱过程的损伤演化机制。

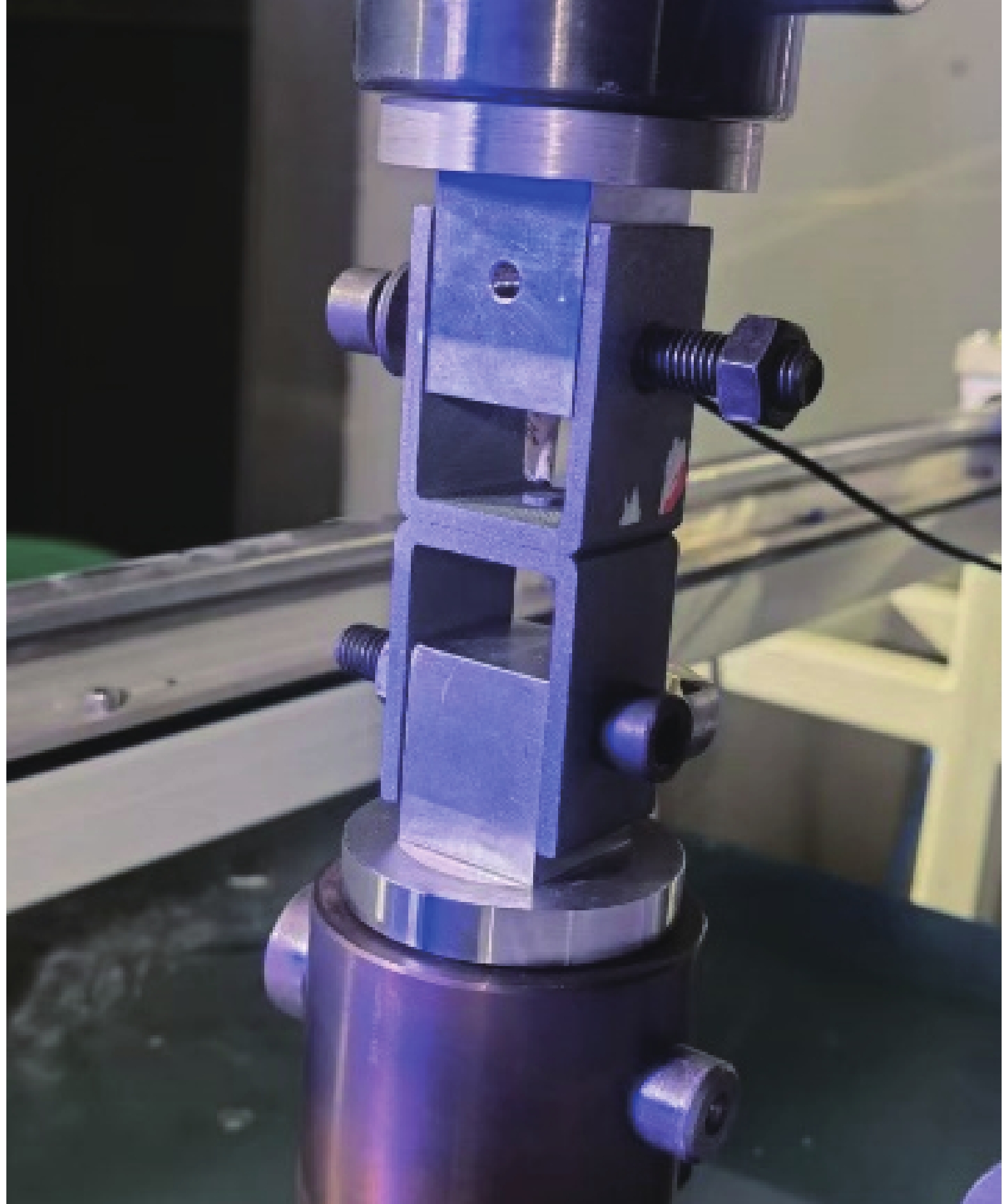

方法以H型C/SiC复合材料连接结构试件为对象,开展沿螺钉轴向的单轴拉伸试验。采用高速摄像、应变测试等方式监测连接部位的状态及力学特性的变化。采用CT测试的方式,扫描获取试件试验前后连接部位的特征。通过对比分析确定了C/SiC复合材料连接结构试件拉脱失效的机理。

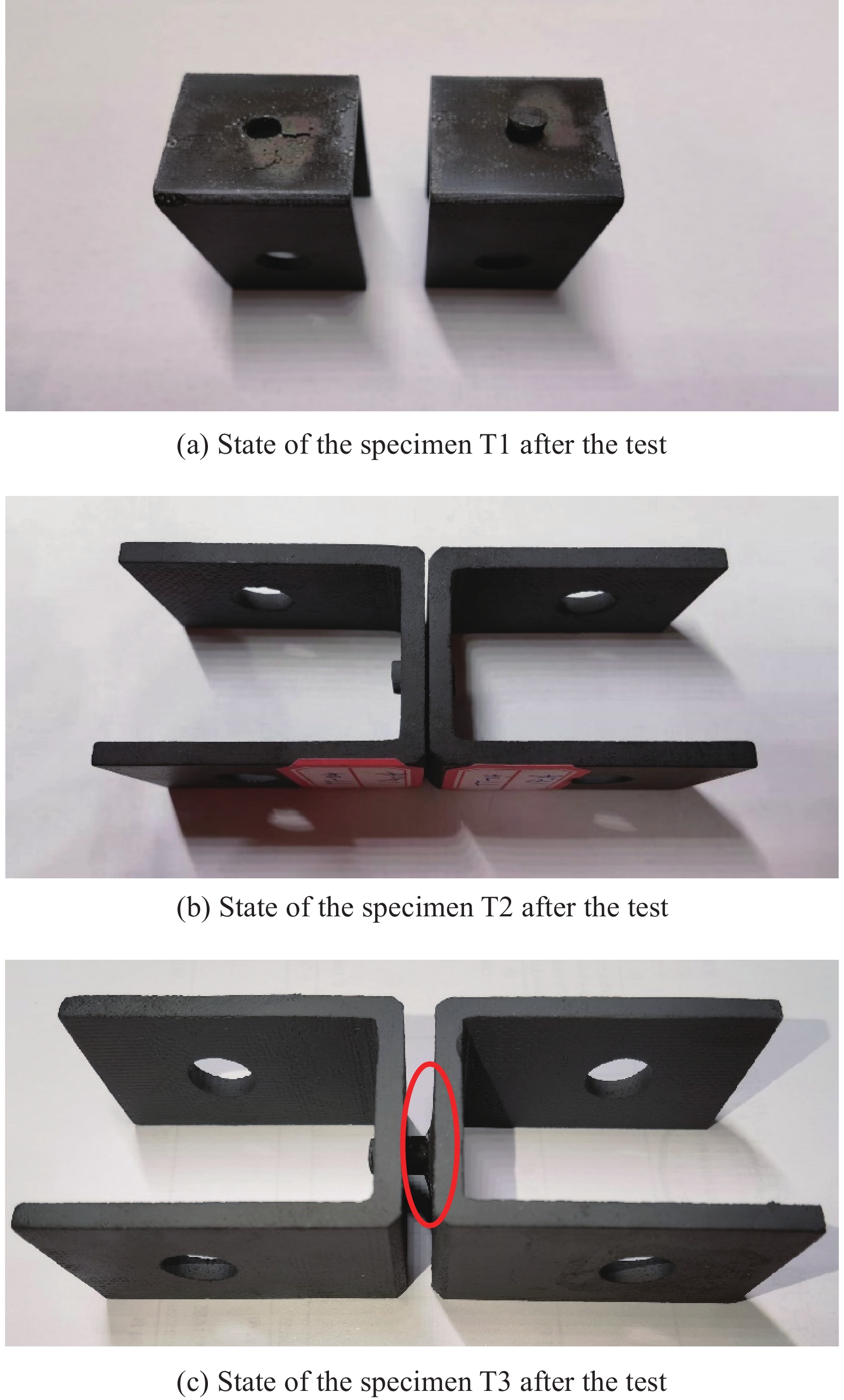

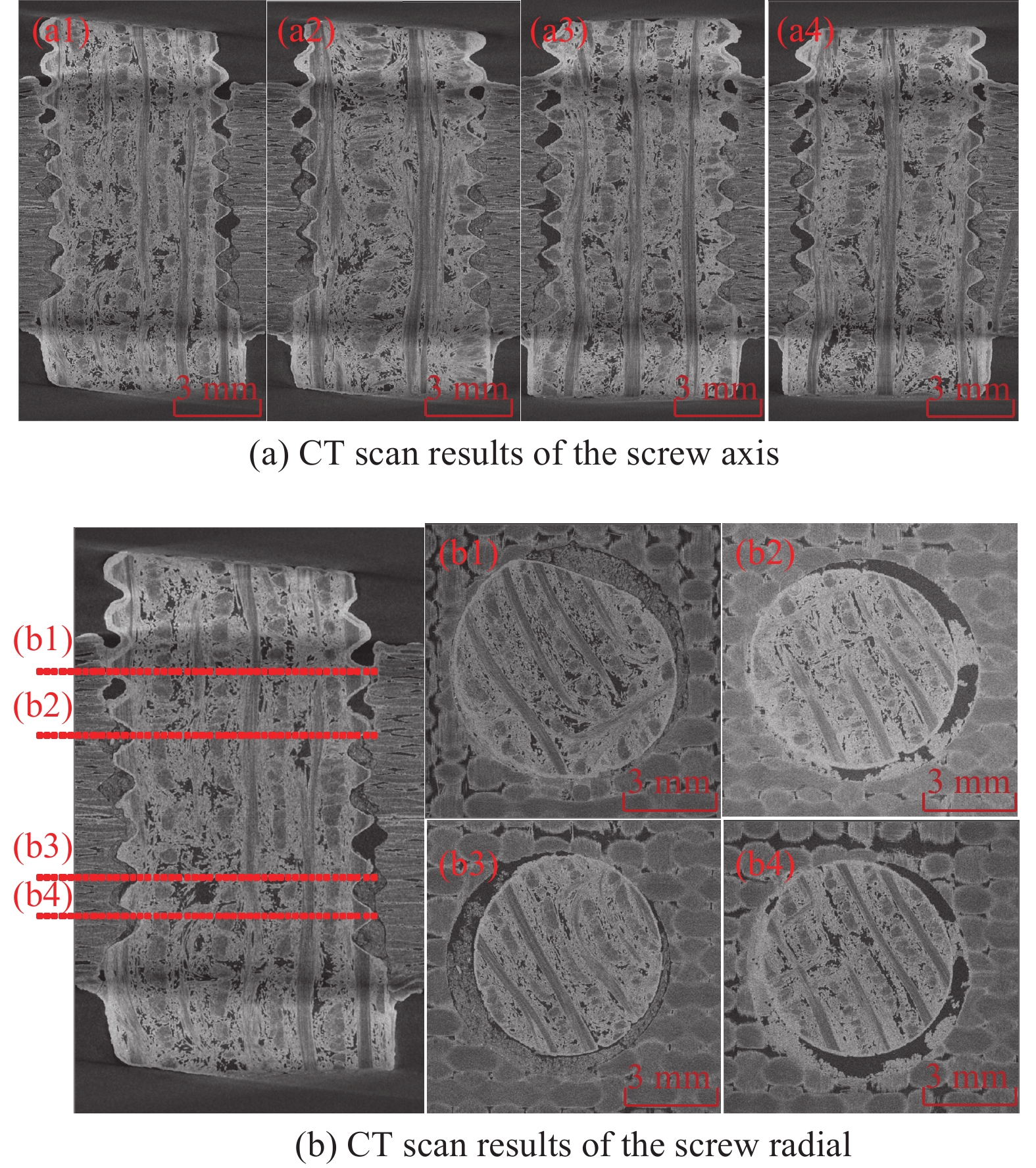

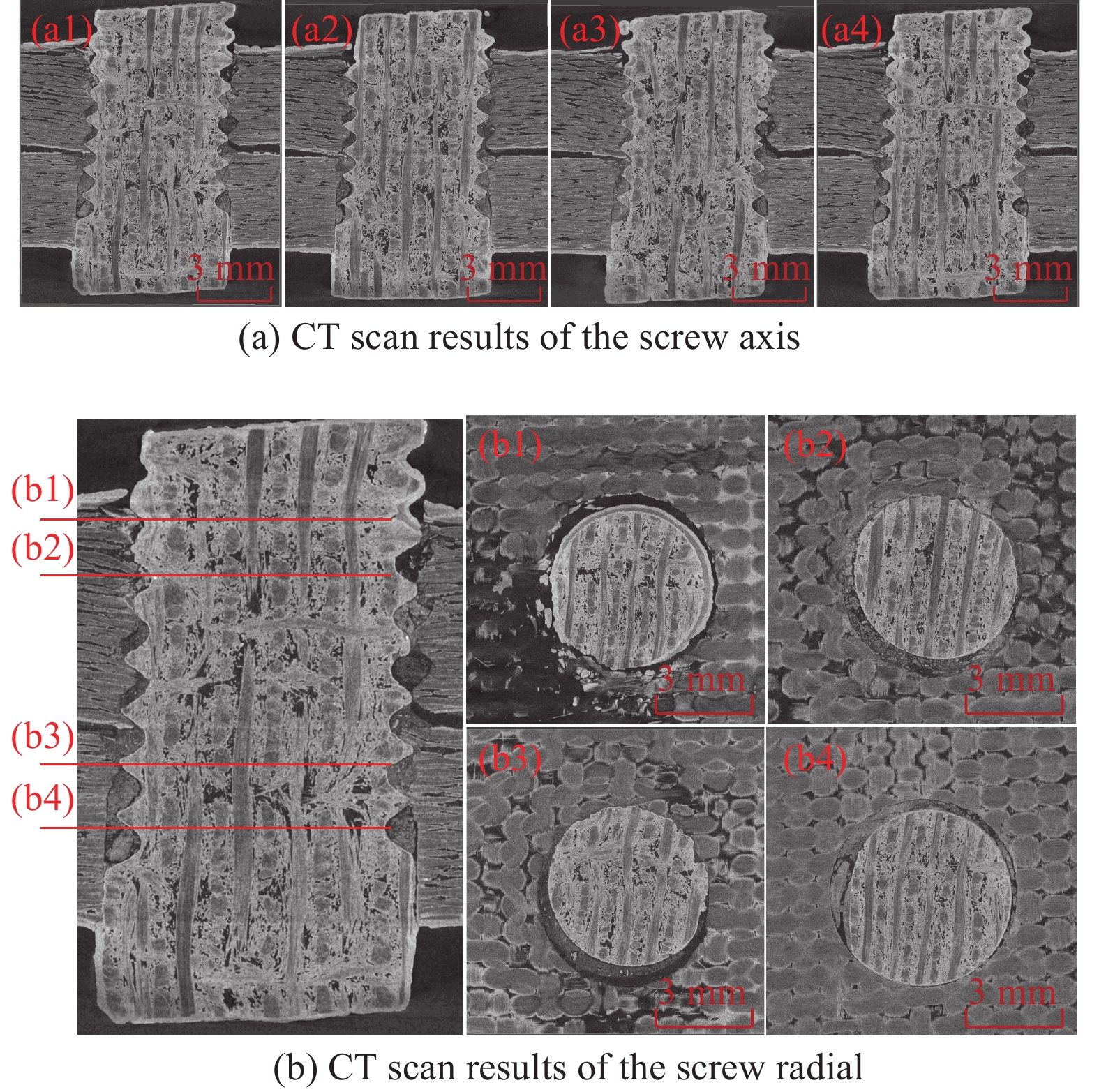

结果连接结构试件拉脱失效的载荷位移曲线分为三个阶段:初始加载阶段、稳定加载阶段、卸载阶段。C/SiC连接结构受到制备工艺、材料初始缺陷以及初始连接状态的影响导致初始加载阶段试件体现出的刚度有所差异;加载过程中伴随着结构的损伤演化会出现不同程度的局部卸载现象。最大拉伸载荷存在着一定的离散性,稳定加载阶段的刚度表明连接结构的拉伸行为规律整体上一致性较好。试件达到最大承载能力后,承载能力随着位移增加逐渐下降,直至螺钉拉脱拔出。CT测试结果表明制备过程中螺纹部位基体沉积不充分。试验后连接部位出现了“鼓起”,螺孔位置出现了分层和局部压溃的现象。螺钉未出现明显的压溃、螺纹破坏等失效现象

结论连接结构制备过程中,二次沉积工艺导致连接界面存在SiC基体,但试验中SiC基体的“粘接”效应并不显著。试件制备过程中螺钉安装、沉积效果差异等原因导致试件初始加载阶段存在刚度不一致及非线性特征,当螺钉完全承载后,连接结构得到刚度趋于一致。拉脱失效的主要原因是连接结构螺纹孔变形挤压导致材料分层,螺纹丧失承载能力。试件达到最大拉伸载荷后,螺钉开始拔出,承载能力逐渐下降,直至螺钉完全拉脱拔出。

-

C/SiC陶瓷基复合材料由于具备高强度、高模量、耐高温等特点,广泛应用于飞行器的热防护结构以及热端部件上。由于常规的金属紧固件无法承受热防护结构以及热端部件经历严酷的高温环境,因此C/SiC复合材料连接结构大量的使用在热端部件的紧固和连接中。

本文针对C/SiC复合材料连接结构设计了H型连接结构试件,开展沿螺钉轴向的单轴拉伸试验,采用宏观测试与细观测试相结合的方式研究了陶瓷基C/SiC连接结构的拉脱失效机制。研究结果表明C/SiC连接结构的受到制备工艺、材料初始缺陷以及初始连接状态的影响,导致连接结构初始加载阶段的刚度有所差异、最大拉伸载荷存在着离散性,并且加载过程中存在着非线性现象。CT测试结果表明连接结构螺纹孔变形挤压导致材料分层,螺纹丧失承载能力是引发结构拉脱失效的主要原因。

C/SiC连接结构力学行为规律(a)和细观损伤检测结果分析(b)

下载:

下载: