Effect of polysiloxane modified epoxy on high temperature residual strength of glass fiber/phenolic composites

-

摘要: ASTM 3059-18标准将高温残余力学性能纳入树脂基复合材料阻燃指标,突破了复合材料传统化学阻燃概念,标志着结构阻燃概念得到了设计方的重视。本文将自制的聚硅氧烷改性环氧树脂(EP-Si)与酚醛树脂(PF)共混,并辅以无机粉料和玻璃纤维增强体,通过力学性能、热失重(TGA)、锥形量热(CCT)和扫描电镜(SEM)等测试方法,研究了EP-Si和无机粉料对玻璃纤维/酚醛复合材料高温残余强度的影响。实验结果表明:当EP-Si用量为40wt%,复合材料的常温及高温残余弯曲强度分别为384.4 MPa、53.3 MPa,相比PF复合材料提高了78.7%、85.1%;辅以适当比例无机粉料,高温残余弯曲强度最高可达85.1 MPa,相比PF复合材料提升了195.5%。高温处理后含硅PF复合材料厚度膨胀而PF复合材料厚度收缩;含硅PF复合材料的热解残留率更高,表层氧化降解更快,但内层生成CO含量低于PF复合材料;含硅树脂基体的无机热解产物保护了内层树脂和纤维,原位热解无机产物分布更均匀、与无机粉料相容性好及可能存在的共烧结作用进一步隔离了氧气侵入,提高了结构完整性和高温残余强度。

-

关键词:

- 酚醛树脂 /

- 聚硅氧烷改性环氧树脂 /

- 高温残余强度 /

- 氧化降解 /

- 复合材料

Abstract: The ASTM 3059-18 standard incorporated high temperature residual mechanical properties into the flame retardant index of resin matrix composites, which broke through the traditional chemical flame retardant concept of composites, and marked that the concept of structural flame-retardant has been valued by the designer. In this work, the self-made polysiloxane modified epoxy resin (EP-Si) was blended with phenolic resin (PF), supplemented with inorganic powder and glass fiber reinforcement. The effects of polysiloxane modified epoxy resin and inorganic powder on the high temperature residual strength of glass fiber/phenolic composites were studied by means of mechanical properties, thermogravimetric analysis (TGA), cone calorimeter (CCT) and scanning electron microscope (SEM). The experimental results show that when the amount of EP-Si is 40wt%, the flexural strength and high temperature residual flexural strength of the composite is 384.4 MPa and 53.3 MPa, respectively, which is 78.7% and 85.1% higher than PF composite. With appropriate proportion of inorganic powder, the maximum residual flexural strength can reach 85.1 MPa, which is 195.5% higher than PF composite. After heat-treated, PF composite containing silicon expands along thickness, while PF composite shrinks along thickness. The pyrolysis residual rate of the PF composite containing silicon is higher and oxidative degradation of the surface layer is faster, but the content of CO generated in the inner layer is lower than that of PF composite. The inorganic pyrolysis product of resin matrix containing silicon protects inner layer resin and fibers. The distribution of the in-situ pyrolysis inorganic product is more uniform, the good compatibility with inorganic powder and possible co-sintering effect further isolates the oxygen intrusion, improves structural integrity and high temperature residual strength. -

世界环境污染问题日趋严重,其中有机废水污染对人类健康和环境构成了极大的威胁[1-2]。光催化技术作为一种高效、安全的环境友好型净化技术,被广泛应用于降解环境中的有机污染物,具有广阔的应用前景[3-6]。

TiO2是众多光催化材料中最具有潜力的,因其无毒、稳定、廉价、可循环利用等优点而得到广泛的研究和商业应用[7-9],但是TiO2存在低表面积、禁带宽、电子空穴对复合率高、光吸收能力低等问题限制了它的光催化性能[10-11]。为此,研究者们提出了多种方法来提高TiO2的光催化性能,如贵金属掺杂[12]、非金属元素掺杂[13-14]、稀土或过渡金属掺杂、构建异质结等[15-16]。结果表明,经复合改性后的TiO2催化效率均有不同程度的提高[17]。但是,制备一种禁带宽度小、光吸收范围大、光生电子还原能力强的基于TiO2的光催化复合材料仍然是一个关键挑战[18]。在众多改性方法中,构建异质结是较有效的方法[19]。相比于成本较高的贵金属等催化材料,碳材料具有特殊的结构和形态,而在不同结构的碳材料中,空心碳球(HCS)为独特的中空结构[20],具有比表面积大、亲水性好、化学稳定性高、热稳定性高、密度低等特点[21]。

本文基于HCS与TiO2两者之间可以通过氢键和范德华力,形成HCS@TiO2范德华异质结,HCS作为导电基板的引入,提高了光生电子对从TiO2中的分离效率[22],高比表面积和良好的亲水性增大了TiO2与染料的接触面积[23]及对染料颗粒的吸附性能,使染料被高效地光催化降解,同时具有优异的重复使用性和广谱性,为光催化降解有机染料的复合材料的设计和制备提供了一条新的途径。通过简单的湿化学法制备了HCS@TiO2光催化复合材料,探索了在模拟太阳光下光催化降解活性红195 (RR195)的光催化性能。通过SEM、TEM、XRD、XPS、TG、N2吸附-脱附曲线、接触角测试对其进行形貌与结构的表征;通过紫外-可见吸收光谱(UV-Vis DRS)、Mott-Schottky测试分析其光学特性;通过UV-Vis DRS、电化学阻抗谱(EIS)测试、瞬态光电流响应图和循环降解试验分析其光催化降解性能,同时对HCS@TiO2光催化复合材料的光催化机制进行了探究,结合自由基捕获实验、电子顺磁共振波谱(ESR)表征的方法提出了HCS@TiO2光催化复合材料的光催化降解机制。

1. 实验材料及方法

1.1 原材料

活性红195,工业级,浙江龙盛化工研究有限公司;乙酰丙酮钛、吡咯、过硫酸铵、硝酸、氢氧化钠、硫酸、无水乙醇,分析纯,均购自国药集团化学试剂有限公司。

1.2 HCS@TiO2复合材料的合成

HCS的制备:采用乳液聚合法[24]合成了聚苯乙烯(PS)纳米球。PS母液(1 mg·mL−1,2 mL)作为模板,分散在去离子水(100 mL)中,搅拌10 min,然后,向溶液中加入吡咯单体(0.2 mL)的同时逐滴添加过硫酸铵(0.13 g,30 mL),反应4 h,将沉淀物过滤并用水和乙醇洗涤数次,所得产物记为PS@聚吡咯(PPy)。最后,将PS@PPy在5℃·min−1的加热速率下从20℃碳化至850℃,并在氩气(Ar)流下保持2 h,得到HCS。

HCS的酸化处理:将制备的HCS加入体积比为1∶3的H2SO4/HNO3混合物中,在60℃下搅拌24 h。然后过滤沉淀用水和乙醇洗涤数次,直至pH值达到7.0。接着在70℃下真空干燥酸化的HCS。

HCS@TiO2复合材料的制备:将HCS (5 mg)加入到无水乙醇(4 mL)和去离子水(1 mL)的混合物中。在超声波作用下持续振荡0.5 h至形成黑色悬浮液。然后,在HCS悬浮液中加入乙酰丙酮钛(50 mg),搅拌24 h,去除残留溶剂;所得产物记为HCS@二氧化钛前驱体(TOAC)。然后,将一定数量的HCS@TOAC (质量比1∶10)在空气气流下以350℃碳化1 h,然后在Ar气流下以5℃·min−1的加热速率加热至650℃,保温2 h。冷却至室温后,经后处理得到HCS@TiO2。采用不同煅烧温度(250℃、300℃、350℃、550℃、650℃)可制备不同煅烧温度下的HCS@TiO2复合材料。图1为HCS@TiO2复合材料的合成示意图。

1.3 样品表征

采用Gemini 300扫描电镜(德国蔡司)、Tecnai G2F20 200 kV场发射透射电子显微镜(美国FEI公司)分析光催化复合材料的整体形貌和结构。利用Philips X'pert PRO X射线衍射仪(荷兰帕纳科公司)分析了煅烧温度和煅烧气流对TiO2结晶度的影响。以MgKα为X射线源在Shimadzu ESCA-3400型 X 射线光电子能谱仪(宁波欧普仪器有限公司)上对样品进行XPS测量。采用ASAP 2020 比表面与孔隙度分析仪(麦克仪器),在77 K下以N2为吸附剂测得样品的N2吸附-脱附等温线,并利用BET方程计算其表面积。采用TGA400型热重分析仪(珀金埃尔默),在空气下,温度范围为30~650℃,对样品进行热重(TG)分析,加热速率为10℃·min−1。通过接触角测试分析样品的亲疏水性能。采用TU-1901 UV-Vis 分光光度计(普析)测试样品的漫反射光谱,以BaSO4为参比,扫描范围为200~600 nm。在上海辰华CHI660 E 电化学工作站上测量制备的复合材料的电化学阻抗谱、瞬态光电流响应图和Mott-Schottky曲线,测试条件:三电极系统(对电极:铂电极;参比电极:银/氯化银电极;工作电极:氧化铟锡(Indium tin oxide,ITO);底液:0.1 mol/L硫酸钠溶液;偏压:0 V;光源:氙灯(> 420 nm),光电流测试光照时间间隔为5 s (开灯5 s,关灯5 s),进行14个循环,EIS测试频率范围为0.1 Hz~100 kHz,Mott-Schottky曲线测试范围为−0.4~0.8 V,频率为500、1000、1500 Hz。采用EMX-8 spectrometer电子顺磁共振波谱仪(德国布鲁克公司)测试反应体系中自由基和光生电子空穴。测试方法:取适量光催化剂分散到含有四甲基哌啶(TEMPO)的甲醇溶液中,超声3 min使其均匀分散,然后打开氙灯,光照2 min后,放入仪器中进行检测e−。

1.4 光催化性能测试

以RR195为实验对象,测试制备的HCS@TiO2复合材料的光催化性能,同时分析各种样品对浓度为20 mg/L (100 mL)的RR195溶液的降解率,验证HCS和TiO2之间是否存在协同效应。另外,利用HCS@TiO2复合材料分别对RR195、活性黑5 (RB5)和碱性蓝9 (MB)进行光催化降解,验证复合材料的广谱性。在进行光催化降解RR195的实验之前,使用H2SO4/NaOH ±(0.5 mol/L)将染料废水的pH调整到3~11 (±0.1)。然后,将复合材料(10 mg)加入到100 mL的RR195溶液中。超声分散后,在黑暗中搅拌30 min达到吸附平衡。然后打开氙气灯(250 W,输出波长290~800 nm),开始光催化反应。光反应开始后,以给定的时间间隔,取约4 mL的悬浮液,离心(4000 r/ min,3 min)去除光催化剂,然后使用UV-Vis分光光度计进行测试,在543 nm处分析残留染料浓度,计算其降解率,如下式所示:

D=C0−CtC0×100% (1) 其中:D为降解率;C0为染料初始浓度;Ct为时间t的染料浓度。

2. 结果与讨论

2.1 HCS@TiO2的形貌和结构分析

为了观察光催化复合材料的形貌,通过SEM、TEM对TiO2和HCS@TiO2进行表征,结果如图2所示。由图2(a)和图2(b)可以看出,HCS为规整光滑、尺寸均匀的中空球体,粒径约为200 nm。图2(c)可以看出TiO2 均匀地负载在HCS上,且HCS负载TiO2后仍保持球形结构,稳定性好。图2(d)可以看出该材料没有出现TiO2纳米颗粒聚集的现象。图2(e)的C、N (来自吡咯衍生物)、O、Ti元素的映射图说明TiO2纳米颗粒分布在HCS表面。图2(f)可以观察到无定形碳包围着TiO2晶格条纹,其晶格间距为0.352 nm,对应锐钛矿型TiO2的(101)晶面[25],图2(g)也证实了晶面间距为0.352 nm。

通过XRD分析煅烧温度和煅烧气流对TiO2结晶度的影响,结果如图3和图4所示。图3为Ar气流下650℃煅烧制备HCS@TiO2的XRD图谱,其中TiO2的衍射峰不尖锐,晶体结构不够规整。图4为不同煅烧温度下制备HCS@TiO2的XRD图谱,TiO2的衍射峰与锐钛矿型TiO2 (JCPDS No. 21-1272) 和金红石型TiO2 (JCPDS No. 21-1276)相匹配良好,表明在空气中650℃煅烧得到的TiO2是一种双晶结构[26-27]。HCS在空气气流下400℃左右碳化时,其骨架开始坍塌,HCS@TiO2需先在O2气流中煅烧,后在Ar气流下进行煅烧。将不同煅烧温度下的HCS@TiO2的XRD进行分析对比,可得HCS@TiO2 350℃(O2)-650℃(Ar)的锐钛矿型衍射峰最强,说明晶体结构最规整,在2θ=25.2°、37.8°、48.0°、53.8°、55.0°和62.6°处的特征衍射峰与锐钛矿相的(101)、(004)、(200)、(105)、(211)、(204)晶面对应,而锐钛矿型TiO2具有比金红石型TiO2更优异的光催化性能[28]。

此外,在不同热解温度(O2和Ar气流)下制备的HCS@TiO2在TiO2相同的2θ位置上出现衍射峰,表明HCS对TiO2晶体结构的影响可以忽略不计。

图5为TiO2、HCS及HCS@TiO2的XPS全谱图,可以看出HCS@TiO2在284.8 eV、459.4 eV和530.0 eV的位置存在C1s峰、Ti2p峰和O1s峰,表明HCS@TiO2中仅存在C、O和Ti元素,没有被污染。

图6为样品不同元素的高分辨XPS光谱。图6(a)和图6(b)分别为HCS和HCS@TiO2在C1s区域的高分辨XPS光谱,可以看出HCS的C1s XPS有3个特征峰,对应C=C、C—C和O—C=O键,分别位于284.4 eV、285.2 eV和288.3 eV处,而在HCS@TiO2中观察到两个处于283.3 eV(C—Ti)和286.1 eV(C=O)的新峰,说明HCS和TiO2之间有很强的相互作用,且前3个峰均呈轻微的负位移。由TiO2和HCS@TiO2的O1s高分辨XPS光谱(图6(c)、图6(d))可以看出,TiO2在529.5 eV和530.8 eV处显示的两个特征峰,属于Ti—O—Ti和Ti—OH键。与TiO2相比,HCS@TiO2的O1s XPS中的两个特征峰发生了负位移。在TiO2和HCS@TiO2的Ti2p高分辨XPS光谱(图6(e)、图6(f))中,TiO2的Ti2p3/2和Ti2p1/2[29]的结合能分别为458.2 eV和463.9 eV,而HCS@TiO2的Ti2p3/2和Ti2p1/2峰值信号与TiO2相比,向上移动了约0.5 eV,可能是TiO2和HCS之间形成C—Ti的原因。基于上述说明TiO2成功锚定在HCS上。

TiO2和HCS@TiO2的N2吸附-脱附等温线如图7所示,两种材料均为IV型等温线,表明两种材料中均存在大孔或介孔,TiO2等温线中存在H3型磁滞回环,而HCS@TiO2的滞回环类型变为H1型,这归功于HCS具有大量孔隙。根据BET方程计算得出,TiO2和HCS@TiO2的比表面积分别为19.6 m2/g和91.1 m2/g,表明HCS的加入,大大增加了HCS@TiO2的比表面积,减少了TiO2的团聚。

为了测试HCS@TiO2的定量组分和热稳定性,采用TGA对HCS@TiO2的热稳定性进行了研究,结果如图8所示。

可以看出,样品发生两次明显的质量损失。第一次质量损失是样品在100℃以下损失2.4wt%,主要归因于物理吸附和水的蒸发;第二次质量损失是样品在400℃以上损失17.2wt%,主要归因于燃烧HCS去除碳框架。最后,在600℃以上保持在80wt%不变。因此,确定HCS@TiO2中TiO2的质量分数为80wt%,具有优异的热稳定性。

通过接触角测试,分析HCS、酸化后的HCS、TiO2、HCS@TiO2的亲疏水性能,测试结果如图9所示,HCS、酸化后的HCS、TiO2、HCS@TiO2的接触角分别为135°、38°、85°和55°。HCS为疏水性材料,经过强酸酸化后,接触角明显减小了,说明酸化使HCS表面引入了大量极性基团,使其具有优异的亲水性和分散性。TiO2的接触角为85°,易发生团聚现象。与TiO2相比,HCS@TiO2的亲水性得到了明显提升,利于染料的吸附。

2.2 HCS@TiO2的光学特性

TiO2和HCS@TiO2的紫外-可见吸收光谱如图10(a)所示。可以看出,TiO2的吸收边带在390 nm左右,而HCS@TiO2的吸收边带发生了红移,在450 nm左右。

采用公式

(αhv)n=A(hv−Eg) (2) 其中:α为吸光度;h为普朗克常数;v为频率;指数n与半导体类型直接相关;A为比例常数;Eg为半导体的能隙,可以计算得到TiO2和HCS@TiO2的能量间隙图,利用切线法较精确地得到TiO2和HCS@TiO2复合材料的带隙能图,如图10(b)所示,TiO2的带隙能为3.13 eV,而HCS@TiO2的带隙能为2.83 eV,即HCS@TiO2的带隙能降低了,对光吸收范围更大了。

对TiO2和HCS@TiO2进行了Mott-Schottky测试,结果如图11所示。样品的曲线斜率均为正,这说明TiO2和HCS@TiO2均为n型半导体;且HCS@TiO2的斜率明显小于TiO2的斜率,表明HCS@TiO2的载流子浓度比TiO2的载流子浓度高。

2.3 HCS@TiO2复合材料的光催化降解染料性能

通过EIS研究TiO2和HCS@TiO2的电荷转移效率,结果如图12(a)所示。可以看出,HCS@TiO2的圆弧半径明显小于TiO2,说明其电荷转移电阻较低,促进电荷转移的同时抑制光生电子空穴对的复合,有利于光催化性能的提高[30]。图12(b)展示了HCS@TiO2和TiO2在可见光下反复开/关时的瞬态光电流,两种材料均展示出快速可逆的瞬态光电流响应,且随着光照时间的增强,光电流密度没有明显的衰减,同时,HCS@TiO2的光电流密度明显高于TiO2。表明HCS@TiO2的光生电子空穴对复合率更低,为光催化过程中提供稳定数量的光生电子[6]。

图13为HCS、TiO2 和HCS@TiO2这3种材料对RR195的降解曲线图,图14为HCS@TiO2光催化降解RR195、RB5和MB的曲线图。由图13可以看出,在暗箱吸附30 min 后,HCS的吸附达到平衡,之后一直保持不变;光照120 min后,TiO2降解率为62.93%,而HCS@TiO2降解率为95.36%,这是由于HCS和TiO2之间存在协同效应,提高了光生电子空穴对的分离效率,加速了污染物的降解。由图14可以看出,HCS@TiO2在光照120 min内对3种不同结构染料的降解率均高达95.00%,故HCS@TiO2具有广谱性。

图15为HCS@TiO2降解RR195的紫外-可见光吸收光谱图及降解过程中的染液颜色变化图。可以看出,反应初始,RR195在510 nm和543 nm处均出现了吸收峰,对应—N=N—。随着反应的进行,RR195的颜色由艳红逐渐变为无色,最大吸收峰逐渐降低,说明其发色基团被有效降解。另外,为了考察HCS@TiO2的可重复利用性,进行了5次降解RR195的循环实验,每个循环周期都要进行30 min的暗箱吸附和120 min的光降解,结果如图16所示。可以看出,该复合材料5次循环后,降解率为93.34%,依旧保持很高的光催化活性,这归因于其本身独特的3D球形结构,可以防止负载在HCS上的TiO2掉落。另外,降解后,HCS@TiO2的回收率可达91.30%。

2.4 HCS@TiO2的光催化降解机制

为了研究光催化降解中起主要作用的活性物质,采用苯醌(BQ)、乙二胺四乙酸钠(EDTA-2Na)和异丙醇(IPA)分别作为•O−2、h+和•OH的捕获试剂,结果如图17所示。

可以看出,在反应体系中加入捕获试剂后,光催化降解效率都会受到不同程度的抑制。其中加入BQ后,光催化效率下降最明显,降解率为49.83%,说明•O−2在光催化反应体系中起主要作用;而加入EDTA-2Na和IPA,降解率分别为83.50%和89.67%,说明h+和•OH在光催化反应体系中起次要作用,由此说明3种自由基的降解效率,•O−2最高,h+次之,•OH最低。可以推断,RR195可能在紫外照射下主要被•O2 −和h+分解。

为了进一步探究光催化机制,通过ESR研究了自由基产生和转移机制,结果如图18所示。由于四甲基哌啶(TEMPO)作为电子e−的自旋标记分子,能够被检测到信号强度为1∶1∶1的信号峰,信号峰越弱,表明该样品生成的光生电子越多。可以看出,0 min即不光照时,TiO2的信号强度低于HCS@TiO2的信号强度;辐照10 min后,TiO2和HCS@TiO2的信号强度均有所减弱,且HCS@TiO2信号强度明显低于TiO2的信号强度,这是由于HCS作为电子陷阱促进了电子的转移,提高了光生电子空穴对的分离效率,因而HCS@TiO2相比于TiO2可以生成更多的光生电子。

基于上述实验结果与分析,提出了HCS@TiO2复合材料光催化活性增强机制,如图19所示。由图可以看出:在光照下,e−从TiO2的价带(VB)跃迁到导带(CB)上,HCS功函高于TiO2,e−从TiO2的CB转移到HCS表面;TiO2上的h+会与H2O发生反应生成•OH;HCS表面的e−会与O2发生反应,使其生成•O−2,O−2还会与H+反应,生成过氧化氢自由基(H2O•),H2O•是H2O2的前躯体,后续反应生成H2O2,氧化反应和还原反应分别在TiO2和HCS上进行。此外,HCS的高比表面积可以使TiO2均匀负载,改善TiO2团聚现象,增加吸附点和活性位点,提高反应体系的降解速率。

3. 结 论

(1)利用简单的湿化学法可以制备空心碳球(HCS)@TiO2光催化复合材料,且TiO2均匀负载在HCS上,形成亲水性强、比表面积大、热稳定性优异的球形复合材料。

(2)光电化学性质分析表明,HCS@TiO2比TiO2禁带宽度更小,光响应范围更大,光生电子还原能力更强。

(3) HCS和TiO2之间的协同效应,提高了光生电子空穴对的分离效率,加速了污染物的降解。相同条件下,TiO2降解率仅为62.93%,而HCS@TiO2的降解率为95.36%,5次循环后降解率为93.34%,回收率为91.30%,且具有广谱性。

(4) 结合自由基捕获实验及电子顺磁共振光谱,提出了HCS@TiO2光催化复合材料的光催化降解机制,证实了•O−2在光催化反应体系中起主要作用。

-

表 1 EP(40)/PF和EP-Si(x)/PF的命名

Table 1 Naming of EP(40)/PF and EP-Si(x)/PF

Sample Mass ratio of EP

(Total mass of resin

matrix is 100)Mass ratio of EP-Si

(Total mass of resin

matrix is 100)EP(40)/PF 40 — EP-Si(10)/PF — 10 EP-Si(20)/PF — 20 EP-Si(30)/PF — 30 EP-Si(40)/PF — 40 EP-Si(50)/PF — 50 表 2 粉料成分及含量对复合材料弯曲强度的影响

Table 2 Effect of powder composition and content on flexural strength of composite

Kaolin/wt% Flyash

/wt%Silica

/wt%EP-Si

/wt%PF

/wt%Resin residual rate/% Residual flexural

strength/MPaFlexural

strength

/MPa0 0 0 0 100 21.8 28.8 215.1 10 20 0 0 100 30.8 34.4 177.3 10 20 1 0 100 31.5 37.1 150.0 10 20 5 0 100 29.7 36.3 120.8 0 0 0 40 60 23.6 53.3 384.4 10 20 0 40 60 33.0 74.7 340.3 10 20 1 40 60 37.0 85.1 330.8 10 20 5 40 60 36.6 80.6 310.3 表 3 PF、EP(40)/PF和EP-Si(40)/PF树脂热重分析数据

Table 3 Thermogravimetric analysis data of PF, EP(40)/PF and EP-Si(40)/PF resin

Atmosphere Sample T−5%/℃ Tmax1/℃ Tmax2/℃ R800/% Air PF 297.5 — 623.0 1.5 EP(40)/PF 244.8 410.7 591.0 1.4 EP-Si(40)/PF 277.5 412.5 633.5 8.2 Notes: T−5%—Thermal degradation temperature at 5wt% mass loss; Tmax1 and Tmax2—Maximum thermal degradation temperature in the first and second stage; R800—Pyrolysis residue rate at 800℃. 表 4 EP-Si(40)/PF试样断面热解残留物表面元素原子分数

Table 4 Surface element atomic percentages of pyrolysis residue of EP-Si(40)/PF sample cross section

Sample C/at% O/at% Si/at% 1 81.06 18.75 0.19 2 72.69 26.10 1.21 Notes: Sample 1—EP-Si(40)/PF composite at room temperature; Sample 2—EP-Si(40)/PF composite after heat treatment. -

[1] 杨晓光, 贾旭宏, 徐松涛, 等. 酚醛树脂/玻璃纤维型飞机货舱衬板复合材料火灾危险性评价[J]. 消防科学与技术, 2022, 41(3):367-370. DOI: 10.3969/j.issn.1009-0029.2022.03.018 YANG Xiaoguang, JIA Xuhong, XU Songtao, et al. Fire hazard evaluation of phenolic resin/glass fiber aircraft cargo lining composite material[J]. Fire Science and Technology,2022,41(3):367-370(in Chinese). DOI: 10.3969/j.issn.1009-0029.2022.03.018

[2] REN X W, ZHU Y P, WANG F, et al. Flame-retardant properties of polyester fabrics reinforced phenolic resin modified with silazanes composites[J]. Advanced Materials Research,2015,1120-1121(1):519-522.

[3] AVILA M B, DEMBSEY N A, DORE C. Effect of resin type and glass content on the reaction to fire characteristics of typical FRP composites[J]. Composites Part A: Applied Science and Manufacturing, 2008, 39(9): 1503-1511.

[4] ASTM Committee. Standard spec-ification for fiber-reinforced polymer (FRP) gratings used in marine construction and shipbuilding: ASTM F3059-18[S]. West Conshehoken: ASTM, 2018.

[5] 华幼卿, 金日光. 高分子物理[M]. 北京: 化学工业出版社, 2013. HUA Youqing, JIN Riguang. Polymer physics[M]. Beijing: Chemical Industry Press, 2013(in Chinese).

[6] ZHANG X P, ZHANG L X, ZHANG D X, et al. Mechanism of the temperature-responsive material regulating porous morphology on epoxy phenolic novolac resin microcapsule surface[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2020,593:124581.

[7] KNOP A, PILATO L A. Phenolic resins: Chemistry, applications and performance[M]. Berlin: Springer Science & Business Media, 2013: 139-147.

[8] 严侃, 黄朋. 复合材料在海洋工程中的应用[J]. 玻璃钢/复合材料, 2017(12):99-104. DOI: 10.3969/j.issn.1003-0999.2017.12.018 YAN Kan, HUANG Peng. Application of composite materials in marine engineering[J]. Fiber Reinforced Plastics/Composites,2017(12):99-104(in Chinese). DOI: 10.3969/j.issn.1003-0999.2017.12.018

[9] SUTHERLAND L S. A review of impact testing on marine composite materials: Part I-Marine impacts on marine composites[J]. Composite Structures,2018,188:197-208. DOI: 10.1016/j.compstruct.2017.12.073

[10] 石锦坤, 刘辉, 张西伟, 等. 复合材料水下防护结构在海洋油气开发的应用[J]. 复合材料科学与工程, 2021(12):78-81,128. DOI: 10.19936/j.cnki.2096-8000.20211228.012 SHI Jinkun, LIU Hui, ZHANG Xiwei, et al. Application of composite materials protector in the subsea of offshore oil[J]. Composites Science and Engineering,2021(12):78-81,128(in Chinese). DOI: 10.19936/j.cnki.2096-8000.20211228.012

[11] GU P, ASARO R J. Structural buckling of polymer matrix composites due to reduced stiffness from fire damage[J]. Composite Structures,2005,69(1):65-75.

[12] MOURITZ A P, MATHYS Z. Post-fire mechanical properties of marine polymer composites[J]. Composite Structures,1999,47(1):643-653.

[13] GARDINER C P, MATHYS Z, MOURITZ A P. Post-fire structural properties of burnt GRP plates[J]. Marine Structures,2004,17(1):53-73. DOI: 10.1016/j.marstruc.2004.03.003

[14] SHI S B, LIANG J, GU L X, et al. Degradation in compres-sive strength of silica/phenolic composites subjected to thermal and mechanical loading[J]. Journal of Reinforced Plastics and Composites,2016,35(7):579-588. DOI: 10.1177/0731684415624769

[15] GIBSON A G, HUMPHREY J K, DI-MODICA P, et al. Post-fire integrity of composite gratings for offshore platforms[J]. Journal of Reinforced Plastics and Compo-sites,2014,33(6):543-555. DOI: 10.1177/0731684413495933

[16] MOURITZ A P, MATHYS Z. Mechanical properties of fire-damaged glass-reinforced phenolic composites[J]. Fire and Materials,2000,24(2):67-75. DOI: 10.1002/1099-1018(200003/04)24:2<67::AID-FAM720>3.0.CO;2-0

[17] RALLINI M, TORRE L, KENNY J M, et al. Effect of boron carbide nanoparticles on the thermal stability of carbon/phenolic composites[J]. Polymer Composites,2017,38(9):1819-1827. DOI: 10.1002/pc.23752

[18] RALLINI M, WU H, NATALI M, et al. Nanostructured phenolic matrices: Effect of different nanofillers on the thermal degradation properties and reaction to fire of a resol[J]. Fire and Materials,2017,41(7):817-825. DOI: 10.1002/fam.2425

[19] NAJAFABADIE P, KHANEGHAHI M H, AMIRI H A, et al. Experimental investigation and probabilistic models for residual mechanical properties of GFRP pultruded profiles exposed to elevated temperatures[J]. Composite Structures,2019,211:610-629. DOI: 10.1016/j.compstruct.2018.12.032

[20] KATSOULIS C, KANDOLA B K, MYLER P, et al. Post-fire flexural performance of epoxy-nanocomposite matrix glass fibre composites containing conventional flame retardants[J]. Composites Part A: Applied Science and Manufacturing,2012,43(8):1389-1399.

[21] DING J, HUANG Z, LUO H, et al. Preparation and thermal stability of boron-containing phenolic resin/microcrystalline muscovite composites[J]. Materials Research Innovations,2015,19(S8):440-444.

[22] 刘强, 赵玉, 张兴刚, 等. 船舶与海洋工程用高耐火复合材料格栅研究[J]. 材料开发与应用, 2022, 37(3):45-51. LIU Qiang, ZHAO Yu, ZHANG Xinggang, et al. Development of high fire resistant composites grating for ship and ocean engineering[J]. Development and Application of Materials,2022,37(3):45-51(in Chinese).

[23] 徐博, 丁杰, 王兵, 等. AlB2对高硅氧纤维/可瓷化酚醛树脂复合材料及其裂解产物力学性能的影响[J]. 复合材料学报, 2021, 38(1):129-136. XU Bo, DING Jie, WANG Bing, et al. Effects of AlB2 on mechanical properties of high silica fiber/ceramicizable phenolic resin composites and their pyrolysis products[J]. Acta Materiae Compositae Sinica,2021,38(1):129-136(in Chinese).

[24] 李志强, 江艳艳, 冀运东, 等. 聚硅氧烷改性环氧树脂及其热解残留物研究[J]. 热固性树脂, 2022, 37(4):1-8. DOI: 10.13650/j.cnki.rgxsz.2022.04.006 LI Zhiqiang, JIANG Yanyan, JI Yundong, et al. Study on polysiloxane modified epoxy resin and its pyrolysis residue[J]. Thermosetting Resin,2022,37(4):1-8(in Chinese). DOI: 10.13650/j.cnki.rgxsz.2022.04.006

[25] 文钦, 刘博伟, 冀运东. 端羟基聚二甲基硅氧烷改性环氧树脂研究[J]. 热固性树脂, 2020, 35(1):25-28. DOI: 10.13650/j.cnki.rgxsz.2020.01.005 WEN Qin, LIU Bowei, JI Yundong. Study on the hydroxylterminated polydimethylsiloxane modified epoxy resins[J]. Thermosetting Resin,2020,35(1):25-28(in Chinese). DOI: 10.13650/j.cnki.rgxsz.2020.01.005

[26] 冀运东, 江艳艳, 曹东风, 等. 聚硅氧烷改性环氧/酚醛共混物热氧降解残留物的结构及组分演变[J]. 高分子材料科学与工程, 2022, 38(10):90-97. JI Yundong, JIANG Yanyan, CAO Dongfeng, et al. Structure and composition evolution of polysiloxane modified epoxy/phenolic blends under the condition of hot oxygen[J]. Polymer Materials Science and Engineering,2022,38(10):90-97(in Chinese).

[27] 中国国家标准化管理委员会. 玻璃纤维增强塑料树脂含量试验方法: GB/T 2577—2005[S]. 北京: 中国标准出版社, 2005. Standardization Administration of the People's Republic of China. Test method for resin content of glass fiber reinforced plastics: GB/T 2577—2005[S]. Beijing: China Standards Press, 2005(in Chinese).

[28] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005. Standardization Administration of the People's Republic of China. Fiber-reinforced plastic composites—Determination of flexural properties: GB/T 1449—2005[S]. Beijing: China Standards Press, 2005(in Chinese).

[29] International Organization for Standarization. Reaction-to-fire tests-Heat release, smoke production and mass loss rate-Part 1: Heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement) ISO 5660-1: 2015[S]. Geneva: International Organization for Standarization, 2015.

[30] PENG Y L, ZENG L. Study on the phenolic-epoxy resin system[J]. Advanced Materials Research,2015,1088:439-443. DOI: 10.4028/www.scientific.net/AMR.1088.439

[31] VORONKOV M G, YUZHELEVSKII Y A, MILESHKEVICH V P. The siloxane bond and its influence on the structure and physical properties of organosilicon compounds[J]. Russian Chemical Reviews,1975,44(4):355-372. DOI: 10.1070/RC1975v044n04ABEH002273

[32] NATALI M, KENNY J M, TORRE L. Science and technology of polymeric ablative materials for thermal protection systems and propulsion devices: A review[J]. Progress in Materials Science,2016,84:192-275. DOI: 10.1016/j.pmatsci.2016.08.003

[33] LI S, HAN Y, CHEN F H, et al. The effect of structure on thermal stability and anti-oxidation mechanism of silicone modified phenolic resin[J]. Polymer Degradation and Stability,2016,124:68-76. DOI: 10.1016/j.polymdegradstab.2015.12.010

[34] TRICK K A, SALIBA T E. Mechanisms of the pyrolysis of phenolic resin in a carbon/phenolic composite[J]. Carbon,1995,33(11):1509-1515. DOI: 10.1016/0008-6223(95)00092-R

[35] QIAN X D, SONG L, HU Y, et al. Thermal degradation and flammability of novel organic/inorganic epoxy hybrids containing organophosphorus-modified oligosiloxane[J]. Thermochimica Acta,2013,552:87-97. DOI: 10.1016/j.tca.2012.11.010

[36] JIA P, LIU H C, LIU Q, et al. Thermal degradation mechanism and flame retardancy of MQ silicone/epoxy resin composites[J]. Polymer Degradation and Stability,2016,134:144-150. DOI: 10.1016/j.polymdegradstab.2016.09.029

[37] MCKEON T. Ablative degradation of a silicone foam[J]. Journal of Macromolecular Science: Part A-Chemistry,1969,3(4):585-612. DOI: 10.1080/10601326908053831

[38] WU C S, LIU Y L, CHIU Y S. Epoxy resins possessing flame retardant elements from silicon incorporated epoxy compounds cured with phosphorus or nitrogen containing curing agents[J]. Polymer,2002,43(15):4277-4284. DOI: 10.1016/S0032-3861(02)00234-3

-

期刊类型引用(3)

1. 李梦涵,魏娜,徐瑞琪,杨泽钰,崔洪芝. 三维碳纳米管/硅藻土基多孔陶瓷复合材料的制备及其光热水蒸发性能. 复合材料学报. 2023(08): 4577-4586 .  本站查看

本站查看

2. 吴玉萍,王乾廷,孙炜,周忠华,谢宗丽,宋铭雨. 含椭圆叶片状SiO_2/聚乙烯醇渗透汽化复合膜的制备与性能. 复合材料学报. 2022(06): 2783-2791 .  本站查看

本站查看

3. 赵士雄. 反渗透复合膜制备及其改性方法研究进展. 云南化工. 2022(06): 20-21+38 .  百度学术

百度学术

其他类型引用(1)

-

目的

ASTM 3059-18标准将树脂基复合材料的高温残余力学强度纳入阻燃指标,是突破传统化学阻燃概念迈向结构阻燃的标志。高温环境树脂热降解迅速劣化复合材料宏观承载性能,限制树脂基复合材料在需考虑结构高温残余强度场景的应用。为提高树脂基复合材料高温后的残余性能,将聚硅氧烷改性环氧树脂(EP-Si)引入玻璃纤维/酚醛树脂(PF)复合材料的树脂基体中,旨在制备一种具有更高残余强度、同时保持优异常温力学强度的树脂基复合材料,提供一种提高残余强度的新思路。方法;高分子树脂材料元素化及掺杂无机粉料是提高树脂基体高温残余力学强度的重要技术方案。有机硅分子结构中Si—O键高键能、大键角的特性赋予其耐热性,将其引入酚醛树脂的交联网络中,可改善酚醛树脂的热稳定性。环氧树脂的活性基团可与酚醛树脂发生化学反应,可实现对酚醛树脂的常温增韧。有机硅在高温下热解产生的SiO等无机相结构可提升酚醛树脂的残碳率和耐烧蚀性,对材料高温后的性能保留有积极作用。无机粉料则通过高温烧结作用提高复合材料的致密度或形成可瓷化保护层,改善复合材料的结构完整性。将EP-Si作为一种硅元素的前驱体,与PF物理共混形成微观均相体系EP-Si/PF,辅以无机粉料,制得玻璃纤维增强EP-Si/PF基复合材料,测试及分析其力学强度、热性能、燃烧过程中的热解气体含量变化和微观结构,探究高温残余强度及作用机制。

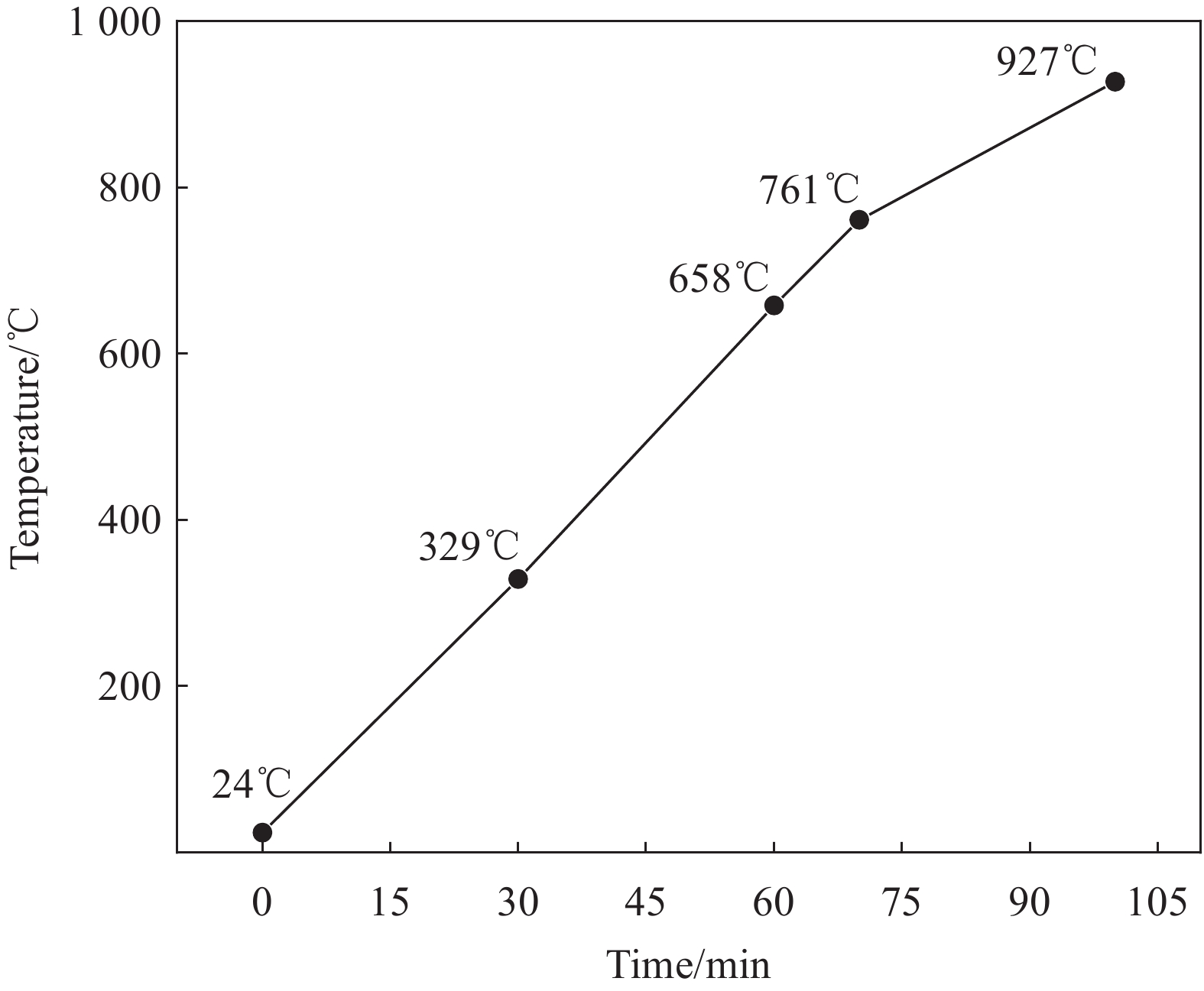

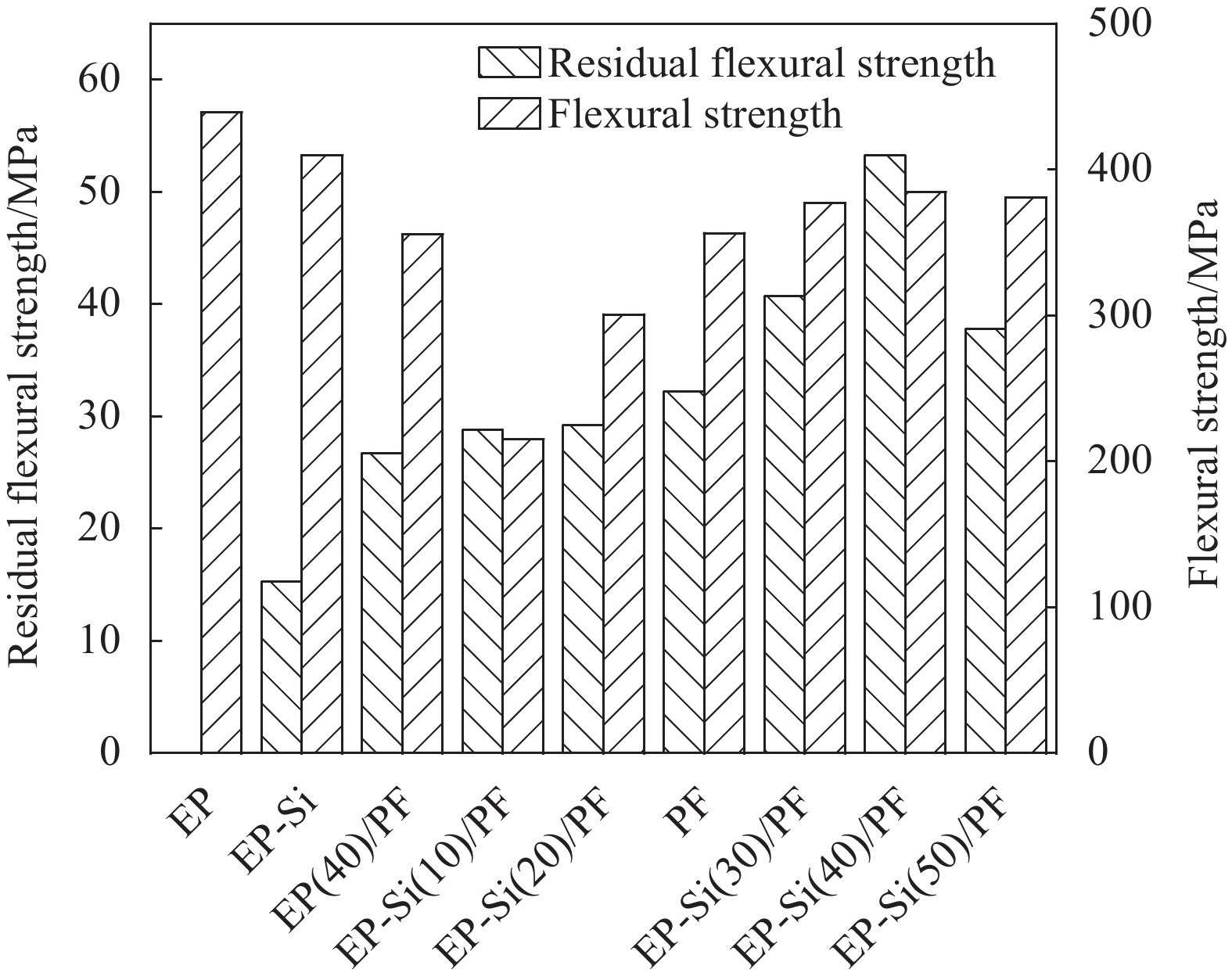

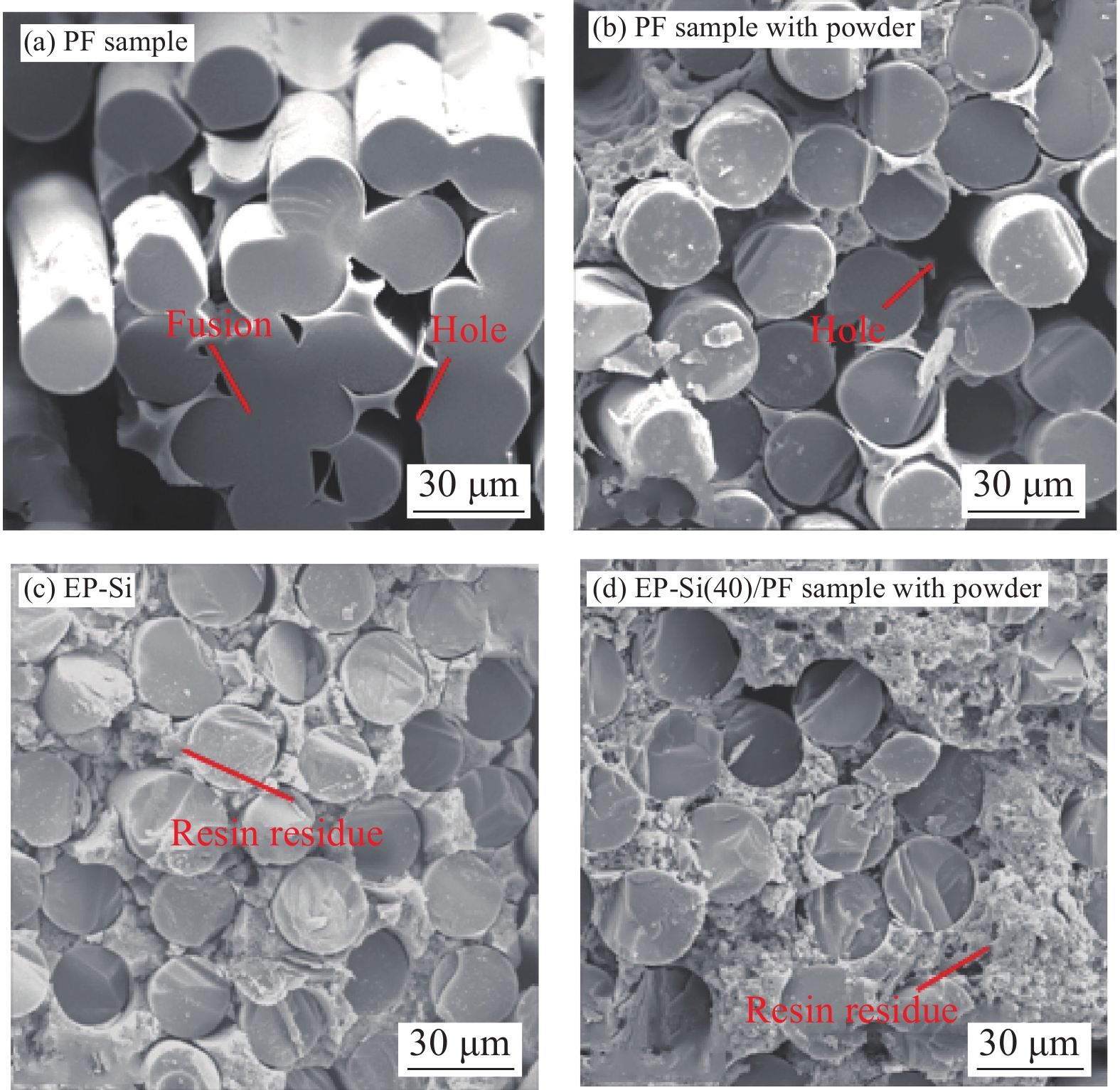

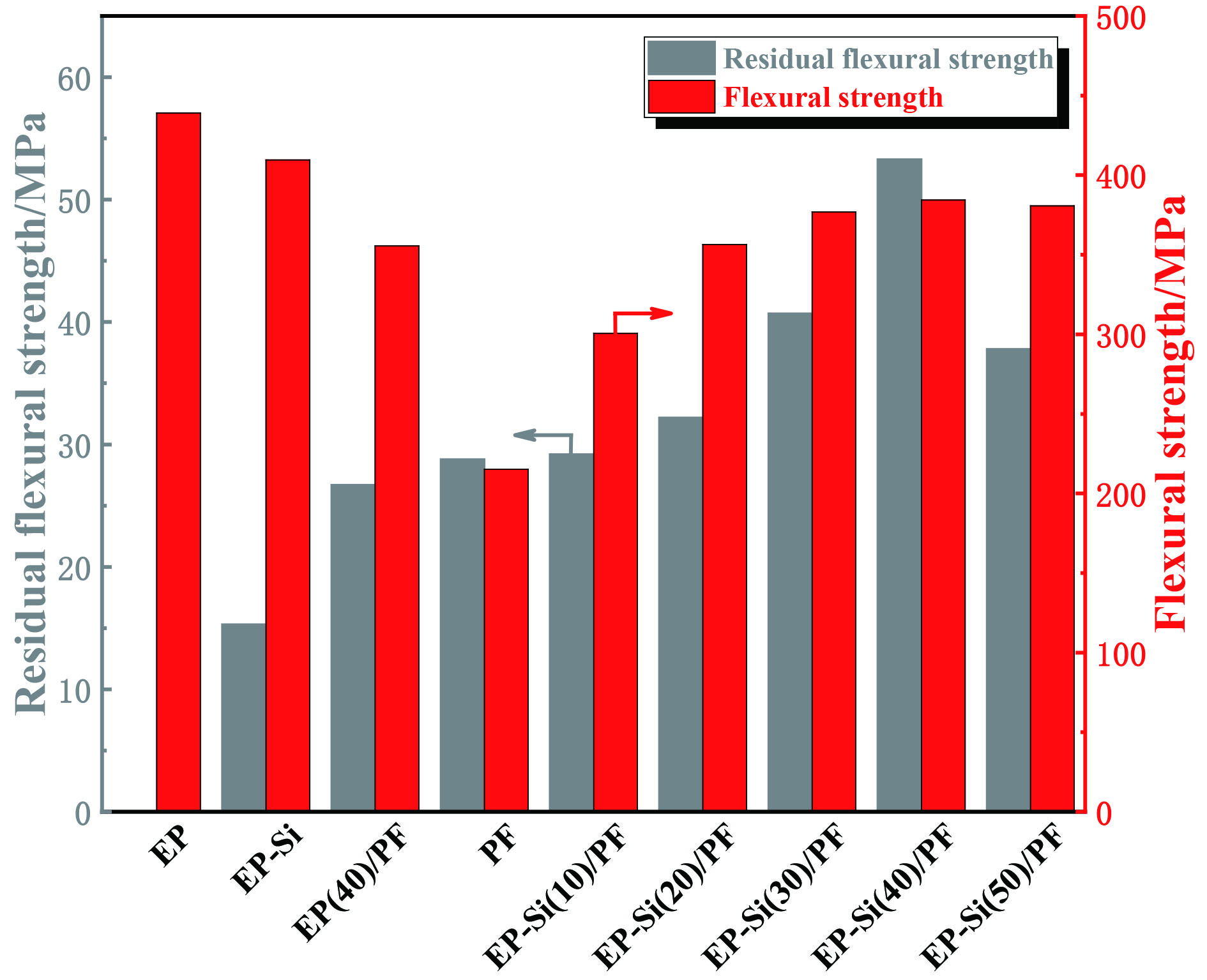

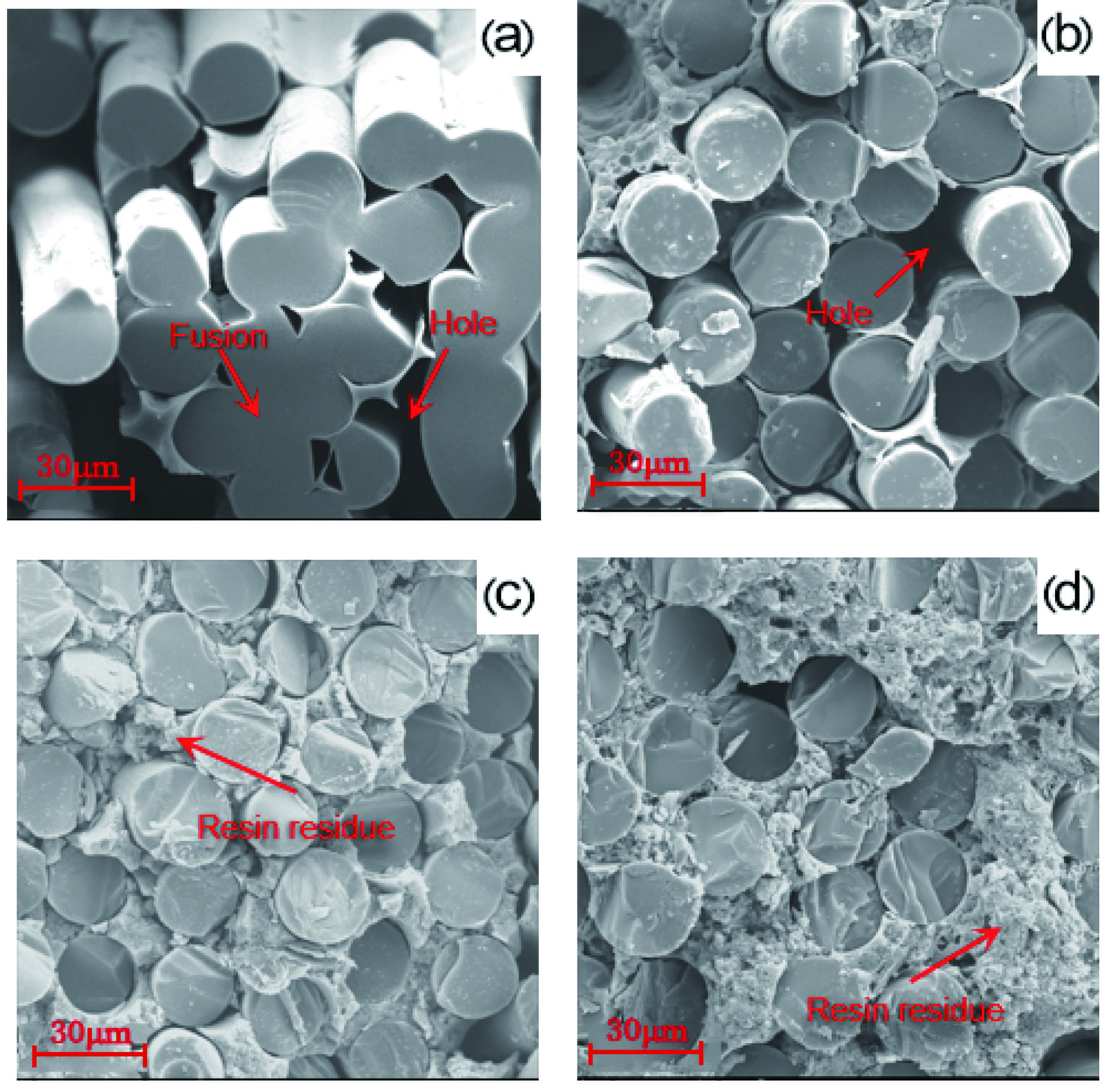

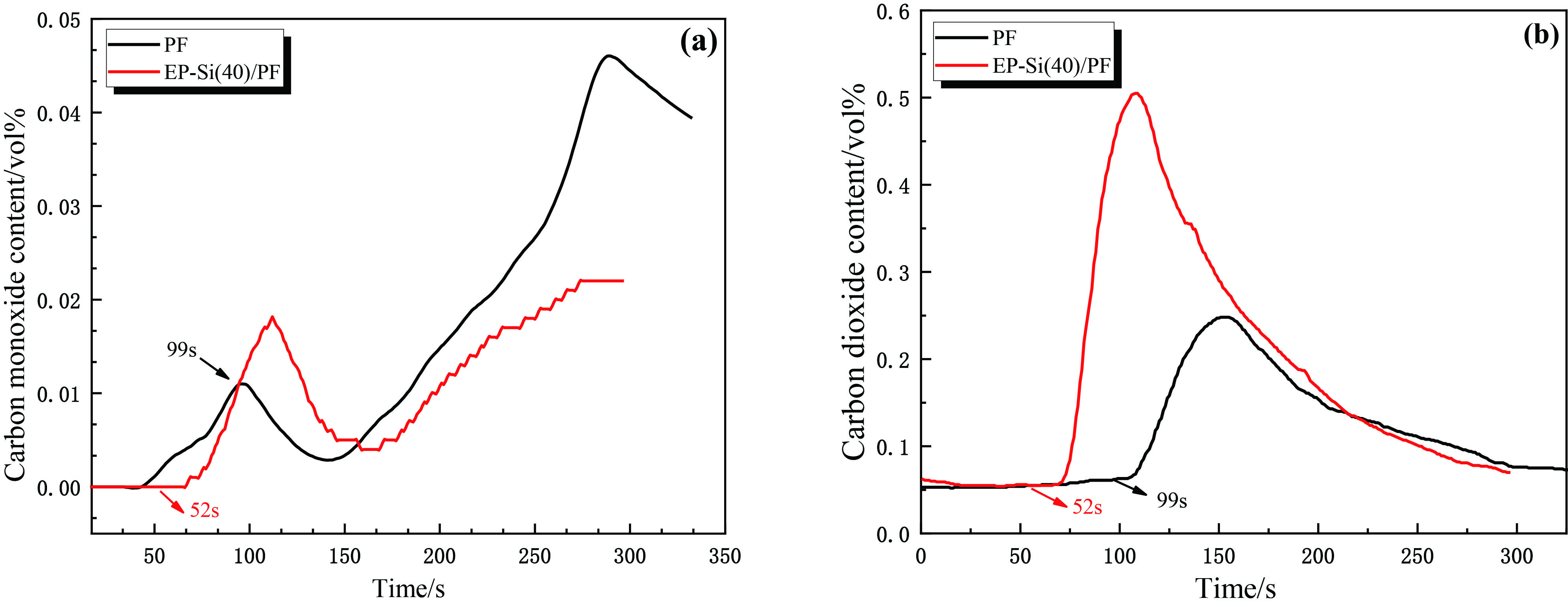

结果(1)环氧树脂(EP)使得PF复合材料的高温残余弯曲强度下降7.3%;EP-Si/PF试样高温残余弯曲强度最高达53.3 MPa,相比PF试样提高85.1%。添加EP-Si树脂40wt%时,EP-Si/PF复合材料试样的常温弯曲强度为384.4 MPa,与PF复合材料相比提高了78.7%。(2)高岭土、粉煤灰和白炭黑使得PF复合材料的高温残余弯曲强度最高提升28.8%,常温弯曲强度下降超过30%,同样粉料配方,EP-Si/PF复合材料高温残余弯曲强度最高达85.1 MPa,比PF提高195.5%。添加粉料的EP-Si/PF试样没有纤维熔接且空隙较少,结构完整性损伤较轻。(3)添加EP-Si使EP-Si/PF树脂前期(300-470 ℃)热降解速度加快,前期生成的热降解产物抑制了后期(470-650 ℃)快速热失重。(4)锥形量热仪测试EP-Si/PF试样比PF试样多消耗约一倍的氧气。CO含量变化曲线出现2个峰,CO含量变化曲线只有1个峰。EP-Si/PF试样的第1个CO峰值约为PF的两倍;第2个CO峰约为PF的40%,两种试样CO含量的峰值大小关系相反。

结论(1)EP-Si对PF树脂增韧作用提高了复合材料的常温弯曲强度,主要是Si—O—Si柔性的链段以及EP中的羟基和环氧基团参与到PF固化反应中。(2)EP-Si/PF复合材料高温残余弯曲强度提高,是由于硅氧烷在高温下生成白色黏稠、耐高温的SiO等无机物覆盖在表面,减弱了热流侵蚀作用,延缓了内层树脂的热氧化降解。添加无机粉料降低材料的膨胀、使材料结构更致密,进一步提高残余弯曲强度,这是由于EP-Si热解无机产物与粉料相容性好且可能产生了共烧结作用。(3)EP-Si产生了具有较高热稳定性富硅产物,且与PF热解炭具有较好的相容性和反应性,从而延缓了树脂基体的快速降解。(4)试样在氧化降解过程中形成热解层和热影响层的两相结构,O谷值和CO达峰时刻一致,标志着热解层的形成;CO含量从谷值开始上升至第二个峰值,标志着热影响层形成。EP-Si/PF复合材料表层氧化降解快,内层得到了含硅树脂热解产物的保护,从而提升了复合材料的高温残余强度。

-

高温环境树脂热降解劣化复合材料宏观承载性能,限制了树脂基复合材料在需考虑结构高温残余强度场景的应用。ASTM 3059标准将树脂基复合材料的高温残余力学性能纳入阻燃指标,是传统化学阻燃概念向结构阻燃的突破。目前添加无机粉料是提高玻璃纤维增强复合材料(GFRP)高温残余强度的主流技术,据报道添加粉料的玻纤酚醛基复合材料高温残余强度可以提升至30 MPa左右,这依然无法满足实际需求。

本文提供了一种提高GFRP高温残余强度的新思路,将自制聚硅氧烷改性环氧树脂(EP-Si)和酚醛树脂(PF)的共混物作为树脂基体,制备了一种常温及高温残余弯曲强度达384.4 MPa、53.3 MPa的GFRP,相比PF复合材料分别提升了78.7%、85.1%。辅以无机粉料的GFRP高温残余弯曲强度可达85.1 MPa,相比PF复合材料提升了195.5%。本文研究了EP-Si及无机粉料提高PF复合材料高温残余强度的机制,发现:高温处理后含硅PF复合材料厚度膨胀而PF复合材料厚度收缩;含硅PF复合材料的热解残留率更高,表层氧化降解更快,但内层生成CO含量低于PF复合材料;含硅树脂基体的无机热解产物保护了内层树脂和纤维,原位热解无机产物分布更均匀,与无机粉料相容性好及可能存在的共烧结作用进一步隔离了氧气侵入,提高了结构完整性,提高了高温残余强度。

EP、EP-Si、EP(40)/PF、PF和EP-Si(x)/PF复合材料试样常温及高温残余弯曲强度

热处理后复合材料试样断面SEM图((a)PF sample;(b)PF sample with powder;(c) EP-Si(40)/PF sample;(d) EP-Si(40)/PF sample with powder.)

PF和EP-Si(40)/PF复合材料试样锥形量热仪CO(a)和CO2(b)含量曲线

下载:

下载: