Review and prospect of drilling heat for fiber reinforced composite

-

摘要: 纤维增强复合材料(Fiber reinforced composites,FRC)钻削过程中产生的切削热及冷却策略对其工艺参数的优化与加工表面质量的控制起着至关重要的作用。本文从钻削热理论研究、钻削热对加工质量的影响研究、钻削热的影响因素与控制策略3个方面对FRC钻削热进行系统性的分析与概述。首先,综述了FRC钻孔过程中的钻削热形成机制、热传导与热损伤预测、切削热的数值模拟等理论研究。然后,阐述了FRC钻削热的主要测量方法及切削热对孔加工质量的影响,并探讨了FRC制孔的切削热影响因素及其辅助加工控制钻削热方法。最后,总结了当前FRC钻削热研究存在的问题及今后研究的重点。Abstract: The research on the generated cutting heat and cooling strategies plays a crucial role in the optimization of process parameters and the control of hole's surface quality in drilling of fiber reinforced composite (FRC). In this paper, the review and prospect on the drilling heat during drilling FRC is systematically analyzed and summarized from three aspects: The theoretical research of drilling heat, research on the influence of drilling heat on machining quality, influencing factors and control strategies of drilling heat during drilling. Firstly, the theoretical research of drilling heat formation mechanism, heat conduction and heat damage prediction, and numerical simulation of cutting heat in FRC drilling process were summarized. Then, the main measurement methods of FRC drilling heat and the effect of cutting heat on the quality of hole machining were introduced. Meanwhile, the influencing factors of cutting heat and its auxiliary processing methods to control FRC drilling heat were discussed. Finally, the current existing problems and key points on the next study of FRC drilling heat were summarized.

-

纤维增强复合材料(Fiber reinforced composite,FRC)是由高比强度、比模量的纤维增强体(碳纤维、玻璃纤维、芳纶纤维和玄武岩纤维等[1])和质地软、韧性强的基体(聚合物、金属和无机非金属等[2-3])经过各种复合加工工艺制造而成的新型材料。强而脆的纤维提供高强度,主要起承受载荷的作用,基体主要起黏结增强体并提供支撑与保护作用,在承受载荷时使应力集中减弱,能够提供较强的断裂韧性[4]。

由FRC组成的零部件因其具有质量轻、刚性高、强度高、尺寸稳定、导热性好等诸多优点,在航空航天、武器装备、汽车领域得到了广泛的应用,其应用量占比已成为衡量新一代先进航空航天装备先进性的重要标志[5-6]。根据相关报告显示,空客公司的A380飞机构件大量采用了碳纤维增强复合材料,A380的外翼、发动机、平尾翼和垂直尾翼等部位都采用了FRC,FRC的质量占到整体结构质量的25%[7]。波音787主体结构的复合材料用量更是达到了50%,这极大地减轻了波音787的质量,使其能够在同航程下比同类型飞机减少15%~20%燃料使用量[8]。近年来国内外大型飞机的复合材料的用量呈现井喷式增长趋势,先进FRC在航空装备发展中具有举足轻重的地位与作用[9]。

FRC具有较多而复杂的成形工艺,主要包括预浸料、拉挤成型、增材制造等[10-11],但成形的FRC结构件通常需要进行以钻孔为主的二次加工以满足与其他航空结构件进行铆接、螺接等装配需求[12]。以飞机上的FRC零部件为例,制造一架波音747飞机需要加工300多万个连接孔,制孔工序占总加工量的80%以上。在实际加工与装配中,60%的FRC零件因钻孔质量差而报废,追其溯源是由于FRC具有各向异性、层间强度低、导热性差的特点。在钻削过程中由于钻头和工件的接触产生机械损伤和热损伤,钻削产生的钻屑仅能通过钻头的螺旋槽排出,钻屑、钻头与工件产生摩擦热主要是沿着纤维方向进行传导,垂直纤维方向上的热量则是通过树脂及树脂/纤维间的界面传导,又因FRC中树脂基体导热性差,且其玻璃转化温度不高,产生的热量促使基体性能下降,进而出现工件材料烧蚀、刀具热疲劳磨损等问题,最终影响工件的加工质量和刀具的使用寿命[13-15]。因此连接孔的加工质量直接影响构件的强度、刚度和可靠性,研究钻削热对FRC加工质量的影响具有重要意义[16]。

对不同工艺参数下FRC工件预制孔的钻削热对钻削质量影响的研究一直都是国内外学者的重要研究方向。Mu等[17]使用红外摄像机测量了对FRC的常规钻削工况下的工件温度,结果表明转速和进给速度增大都会使钻削温度升高。蔡建国等[18]进行了FRC的常规钻削测温实验,使用热电偶对钻削温度进行测量,建立了钻削温度与钻削参数的指数模型经验公式。陈文成等[19]进行了FRC钻削实验,并分别使用热电偶和红外热像仪测量了钻削温度,结果表明当钻削温度高于玻璃转化温度时,FRC性能下降,钻孔质量变差。Santiuste等[20]建立了FRC正交切削的有限元模型,预测结果表明FRC面内机械损伤和热损伤主要受纤维方向影响,而且热损伤影响区域比机械损伤影响区域大。王福吉等[21]研究了FRC钻削区域的热量分配问题,建立了FRC切削温度场模型,得出随纤维方向增大,FRC的热能分配比例表现为先增大后减小的结论。Geng等[22]对FRC开展了常规钻削和超声振动钻削对比实验,使用红外摄像机对钻削温度进行了测量,当进给速度等于75 mm/min和150 mm/min时,超声振动钻削能使最高温度降低约18.8%和13.1%。

根据上述描述,对FRC钻削热的形成机制,钻削热的数值模拟、工艺参数对热损伤的优化分析及钻削热控制方法等研究一直是国内外研究重点,FRC钻削加工中的许多经济和技术问题大都直接或间接地由钻削热所引起,它不仅影响刀具的磨损及耐用度,还影响工件的加工精度、已加工表面的质量和生产效率等。因此了解FRC切削热的形成机制、精确测量方法与降低钻削热并减少制孔损伤等研究,无论是对钻削机制的研究、刀具磨损机制的探讨,还是刀具的设计与制造、加工参数的选择及加工表面质量的控制等都是相当重要的。

故本文对国内外FRC钻削过程相关研究进行系统性的整理与分析,概述了近年来关于FRC钻削过程产生的切削热研究,主要包含钻削热理论研究、钻削热对加工质量的影响研究、温度的影响因素与辅助加工控制钻削热方法研究3个方面的分析与总结,最后探讨并总结了当前对FRC钻削热研究存在的问题及今后研究的发展趋势。

1. FRC钻削热理论研究

1.1 钻削热形成机制

FRC钻削热的形成过程,是纤维产生断裂,基体被破坏、发生老化、软化的复杂难分析过程。以碳纤维增强树脂基复合材料(Carbon fiber reinforced polymer,CFRP)为例,CFRP是典型的各向异性材料,具有非均质、层间强度低的特点。由于碳纤维增强相和基体的材料属性存在较大差异的原因,在钻削过程中两者的切屑断裂模式在细观尺度下表现不同,使在CFRP热力耦合作用下具有更复杂的钻削缺陷形成机制[23]。研究表明钻削力是影响CFRP制孔质量的重要因素,当主轴转速不变时,进给速度与轴向力呈现正比例关系,从而加剧撕裂和分层损伤[24]。如果为了降低轴向力,保持进给速度不变,增大主轴转速,则钻削温度会显著升高,从而导致加剧基体烧伤、孔径偏差增大、刀具磨损增大等问题[25],例如热塑性复合材料还容易出现热结晶问题[26]。若此时采用冷却辅助加工技术,虽然能有效降低钻削温度,改善毛刺和烧蚀现象,但又容易因温度过低导致CFRP材料力学性能增强,增大了轴向力[27]。因而研究钻削力对FRC制孔质量影响时需充分考虑钻削温度对各钻削缺陷的影响机制。

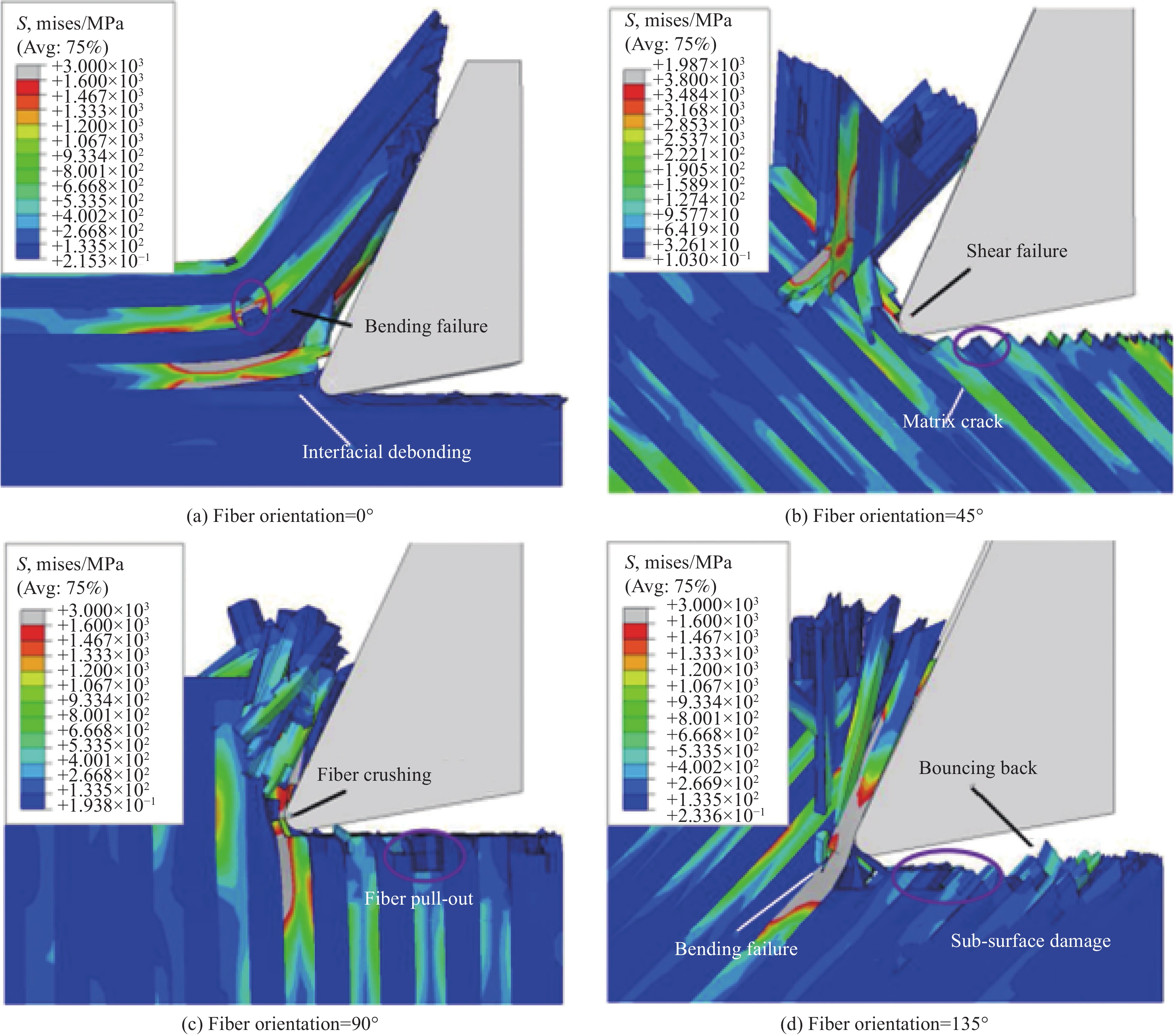

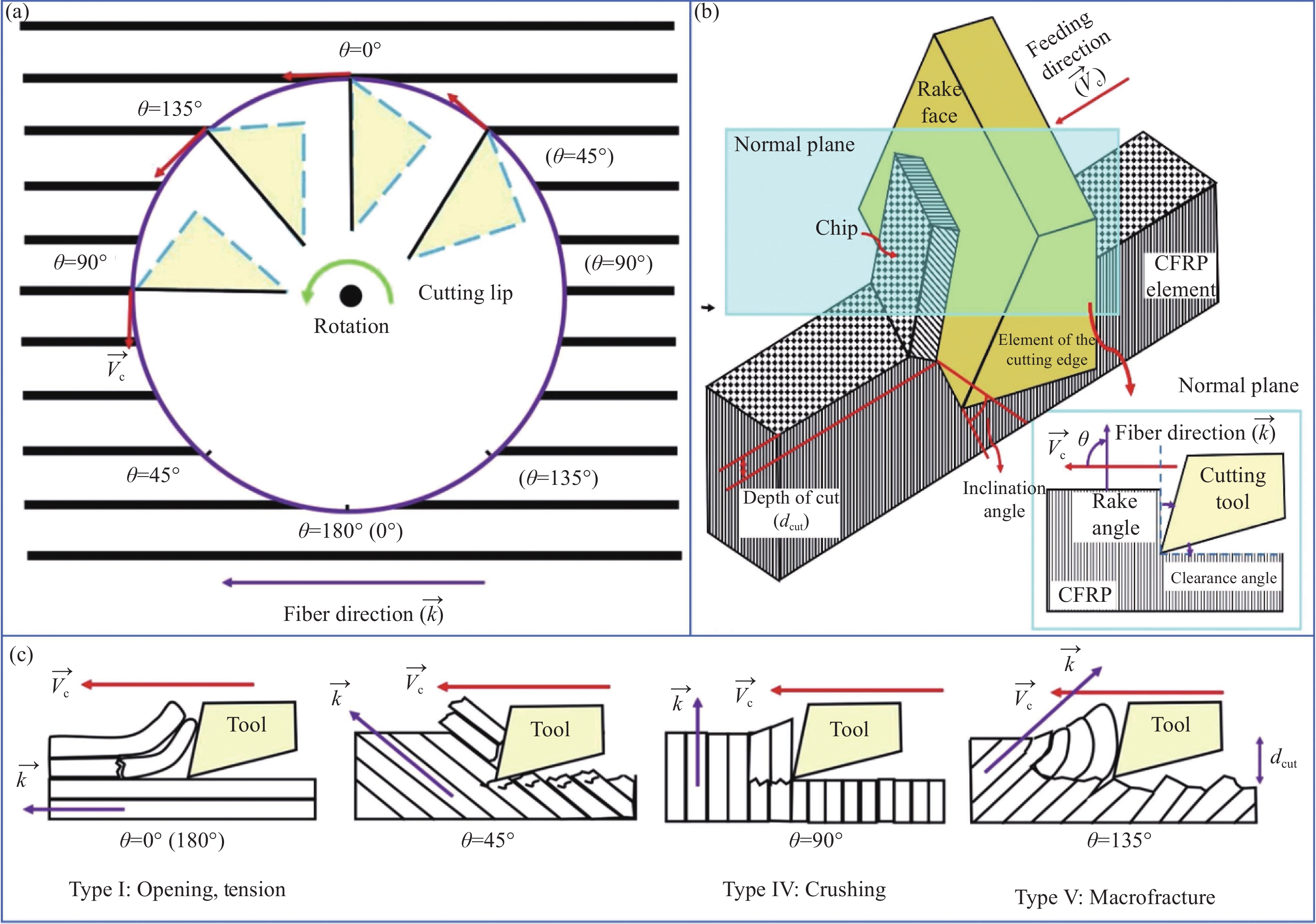

与此同时,学者研究发现FRC钻削热的形成与纤维排布方向有很大关联,为了简化FRC的钻削热形成过程,便于钻削热形成机制的研究,从微观层面更深层次地研究钻削过程中切削热、切削力的作用机制,学者们按照纤维分布方向与刀具运动方向的夹角将其分为3种切削模式:(1) 切削方向与纤维方向平行,材料发生层间分离而断裂产生切削热;(2) 切削方向与纤维方向形成锐角,纤维被切断而形成切屑而产生切削热;(3) 切削方向与纤维方向为钝角,纤维的弯曲作用和剪切作用交互作用,材料断裂而形成切削热[12]。如图1所示,可采用微元法将单向(Unidirectional,UD)层合板结构的CFRP按照刀具运动方向与纤维方向的夹角将微观切削加工机制分为0°、45°、90°和135°这4种模式[28]。在纤维方向角约为0°时,刀具尖端的纤维被压缩,而前刀面的纤维主要被挤压弯曲。这一过程中由于分层减少了刀具去除材料时的纤维断裂数量,刀具去除材料所需的力变小,且具有较好的表面粗糙度;在纤维方向角约为45°时,刀具尖端和前刀面的纤维受到挤压直至挤压剪切断裂,又由于塑性作用,加工后纤维会产生回弹,这使表面粗糙度增大;在纤维方向角约为90°时,刀具垂直于纤维进行切削,当一根纤维被切削时,其周围起支撑作用的纤维与基体也同时受到挤压弯曲变形,此时切削过程中塑性作用比45°时更明显,表面粗糙度进一步增大;在纤维方向角约为135°时,纤维主要受弯曲作用,纤维去除模式主要为弯曲断裂,此时表面粗糙度较差。

![]() 图 1 单向(UD)-碳纤维增强树脂基复合材料(CFRP)切削加工机制:(a) 刀具与纤维夹角;(b) 微观切削模型;(c) 四种切削模式[28]θ—Cutting direction; →Vc—Cutting speed; →k—Fiber directionFigure 1. Unidirectional (UD)-carbon fiber reinforced polymer (CFRP) cutting mechanism: (a) Angle between cutter and fiber; (b) Micro-cutting model; (c) Four cutting modes[28]

图 1 单向(UD)-碳纤维增强树脂基复合材料(CFRP)切削加工机制:(a) 刀具与纤维夹角;(b) 微观切削模型;(c) 四种切削模式[28]θ—Cutting direction; →Vc—Cutting speed; →k—Fiber directionFigure 1. Unidirectional (UD)-carbon fiber reinforced polymer (CFRP) cutting mechanism: (a) Angle between cutter and fiber; (b) Micro-cutting model; (c) Four cutting modes[28]以CFRP切削加工过程为例,如图2所示,切削热主要产生于以弹性变形和塑性变形消耗变形功生热为主的第一变形区、前刀面与切屑摩擦生热的第二变形区、后刀面与工件表面摩擦生热的第三变形区。其中,第三变形区由于刀具在切削CFRP时,已加工表面会产生回弹现象,产生较高的切深抗力,在切深抗力的作用下,刀具会与工件摩擦产生大量切削热,因而切削热主要来源于第三变形区[29]。因此在简化的微观切削过程中,纤维方向约为90°时纤维受刀具挤压断裂,纤维与刀具之间具有明显的摩擦,会产生大量切削热。而纤维方向约为0°时,纤维更容易被去除,摩擦较小,因此产生的切削热也较少[30]。

基于能量守恒定律,切削过程中摩擦产生的热量会传入工件、刀具和切屑。Wang等[32]根据傅里叶定律计算得到单位时间传入刀具的热量Qtool可表示为

Qtool=kΔTLA (1) 其中:k为刀具导热系数;∆T为刀具的温升;L为热电偶预埋孔中心到刀尖的距离;A为接触区域面积。进一步地,A可表示为

A=(90∘+α0+γ0180∘πRe+1sinα0(3Fy4E∗√Re)2/3)lt (2) 其中:α0为刀具后角;γ0为刀具前角;Re为刀具切削刃半径;Fy为法向切削力;E*为刀具和工件的等效弹性模量;lt为CFRP工件的厚度。

因此,最终传入刀具的热量λ1可由下式计算:

λ1=QtoolQtotal (3) {\lambda }_{1}=\frac{k{l}_{\mathrm{t}}}{{F}_{{x}}{V}_{{{\rm{c}}}}} \frac{\Delta T}{L}\left[\frac{90°+{\alpha }_{0}+{\gamma }_{0}}{180°}{\text{π}} {R}_{\mathrm{e}}+\frac{1}{{\sin}{\alpha }_{0}} {\left(\frac{3{F}_{y}}{4{E}^*\sqrt{{R}_{\mathrm{e}}}}\right)}^{2/3}\right] (4) 其中:Qtotal为摩擦产生的总热量;Fx为水平切削力;Vc为切削速度。

式(4)为研究切削区热量分配机制、适温切削散热量确定方法提供了重要依据。

通过上述对钻削热形成机制的分析可以看出:FRC钻孔过程中的材料去除机制可简化为刀具不断地切削不同纤维排布方向的UD-FRC。刀具在对UD-FRC进行切削进给时,由于纤维具有高强度、高硬度,刀具与工件摩擦产生大量的热,而这些热量主要来自于已加工表面的第三变形区。钻削过程产生的热量会传入刀具、工件和被切屑带走,其中切屑带走的热量可忽略不计。

1.2 热传导与损伤预测

目前关于FRC的钻孔工艺中涉及的切削热理论大多基于传热学的温度场模型分析。Bao等[33]建立了图3中的单向碳纤维增强树脂基复合材料(Unidirectional carbon fiber reinforced polymer,UD-CFRP)钻孔的热传导模型,并推导建立了其温度场模型用于预测钻削温度。杨帆等[34]基于传热学原理,建立了CFRP/Ti(钛合金,简称Ti)叠层的钻削温度场模型,并采用有限差分方法进行求解,最后通过实验测量叠层钻削中的界面温度验证了模型的正确性。Liu等[35]建立了CFRP轨道铣孔的热传导模型,指出铣孔过程中主要有两个热源,位于刀具边缘切削刃与工件接触区域和刀具底部切削刃与工件接触区域,其几何形状分别为半圆形和线形。在Liu等[35]学者的研究基础上,刘亚军等[15]使用有限差分法对CFRP/Ti轨道铣孔过程的温度场模型进行数值仿真求解,并最后通过实验测量确定了Ti与CFRP的界面温度传导率为6%。

![]() 图 3 UD-CFRP钻削热传导模型[33]ω—Angular velocity; νf—Feed velocity of the drill; q1—Heat flux load which comes from the major cutting edges and chisel edge; q2—Heat flux load generated from the side edges; lx—CFRP length; ly—CFRP width; lz—CFRP thickness; d—Tool diameterFigure 3. UD-CFRP drilling heat conduction model[33]

图 3 UD-CFRP钻削热传导模型[33]ω—Angular velocity; νf—Feed velocity of the drill; q1—Heat flux load which comes from the major cutting edges and chisel edge; q2—Heat flux load generated from the side edges; lx—CFRP length; ly—CFRP width; lz—CFRP thickness; d—Tool diameterFigure 3. UD-CFRP drilling heat conduction model[33]学者们不仅建立了用于温度预测的热传导理论模型,还建立了考虑了温度影响、可用于预测钻削损伤的损伤理论模型。Sikiru等[36]考虑了钻头几何形状(横刃和顶角)对推出分层的影响和温度对工件力学性能的影响,基于钻头切削刃上受力为均布载荷,横刃上受到一个集中力的假设,建立了CFRP层合板钻孔的分层损伤数值模型,有效预测了发生分层的临界轴向力。贾振元等[37]建立了考虑树脂及界面温变特性和被切纤维周围支撑材料对被切纤维约束作用的单纤维切削数值模型,揭示了CFRP的微观切削机制,但该模型基于双参数弹性地基梁理论,其预测宏观切削力的误差可达20%。Fattahi 等[38]建立了考虑热力耦合作用的分层损伤预测模型,解释了分层损伤如何从入口处的圆形截面演化成出口处的椭圆形截面。

从相关学者对热传导与损伤预测的研究可知,近年来关于钻削热模型的建立大多只考虑了宏观结构的热传导,且尚未充分考虑切削力对温度场的影响。而实际钻削加工过程中,FRC工件钻削预制孔形成的分层、撕裂、毛刺等损伤受温度影响显著,FRC的钻孔过程是复杂的热力耦合作用过程。目前FRC钻孔的微观尺度下的切削模型揭示了FRC的微观切削机制,但其对切削热、切削力的预测与实际结果相比有较大偏差。更深次的切削热理论模型来解释温度场分布及变化规律需进一步探讨,进而能够准确预测热力耦合作用下的不同损伤。

1.3 基于数值模拟分析的切削热分析

近年来,除了试验和解析法,基于数值模拟的有限元法(Finite element method,FEM)对FRC在钻削工况下的钻削热求解越来越受到复合材料领域的学者们重视。针对FRC全过程钻孔工艺的分析,FEM具有可以节省大量人力物力和时间,可实现钻削温度的数值可视化、预测材料加工中的表面缺陷、优化钻削加工工艺参数和指导钻削刀具的设计与刀具参数的优化等优点[39-40]。同时,FEM可以从微观尺度上模拟材料的去除,直接获取微观应力、应变、温度分布等云图[3,41],而这些都是在实验中难以实现的。因而,采用FEM使研究者们能够直接研究纤维和基体在刀具作用下的微观损伤过程,以便于更深入、准确地解释宏观切削去除机制[42]。

虽然近年来计算机计算能力有了很大的进步,对于FRC钻孔的模拟仍需耗费较长时间,其中的缘由是复杂结构的有限元模型必须要有足够多的精细网格来保证模型精度,而网格数量的增加将导致模拟时间呈指数性增长。为了确保有限元模型的可靠性,并尽可能提高模型计算效率与计算精度,学者们做出了大量的具有重要指导意义的研究[43-44]。

在微观层面,学者们直接对纤维进行建模,主要模拟了纤维单向分布的FRC微观切削过程。齐振超等[45]模拟了正交切削过程中不同纤维方向角下CFRP切削温度分布的差异,结果显示切削温度的峰值受纤维方向角影响,当方向角为90°时切削温度最高,并且其应力和温度的分布具有相似性。Gao等[46]研究了CFRP三维细观直角切削热力耦合模型,如图4所示,在不同切削参数下对比分析了4种典型纤维方向角下切屑形成机制、表面质量,并与实际加工表面轮廓进行了对比。Xu等[47]实现了超声振动辅助CFRP正交切削的热力耦合仿真,其建模方式如图5所示,结果表明相比无振动辅助加工,超声振动辅助加工条件下的切削温度始终更低,其模拟结果如图6所示,并指出切削力受温度影响不大,切削力数值的震荡是由于刀具间歇性地切割纤维,且只有当进给量小于进给方向上的最大振动速度,超声振动能够有效地减小切削力。Han等[31]模拟了不同预处理温度下UD-CFRP的正交切削过程,阐述了其微观变形机制、切削力演化与切削温度演化之间的关系,研究结果表明低温预处理会加剧纤维和基体以脆性断裂为主的面下损伤,加热预处理会导致基体软化,从而加剧以纤维断裂为主的面下损伤。

对微观结构更复杂的编织FRC,学者们主要模拟了其微观尺度下的热物理行为。Dong等[48]模拟了三维编织CFRP的多尺度热传导行为,结果表明,热导率随温度的增加而增大,并近似呈线性增长。Zhai等[49]模拟了编织角与温差对FRC热物理属性的影响,并提出了一种优化的多尺度渐近均质化方法来,有效减少了有限元建模工作量。He等[50]建立了三维编织复合材料的多尺度模型,揭示了其在高温下的失效机制,使用了弹塑性损伤本构定律来表征微观结构和细观结构的力学行为。Cheng等[51]模拟了UD-CFRP的热力耦合作用下的微观切削,模拟结果显示UD-CFRP切削过程中工件存在两个应力集中区,如图7(a)所示,区域(I)靠近刀具尖端,区域(II)处于加工表面下,是纤维之间相互作用力主要作用区域。

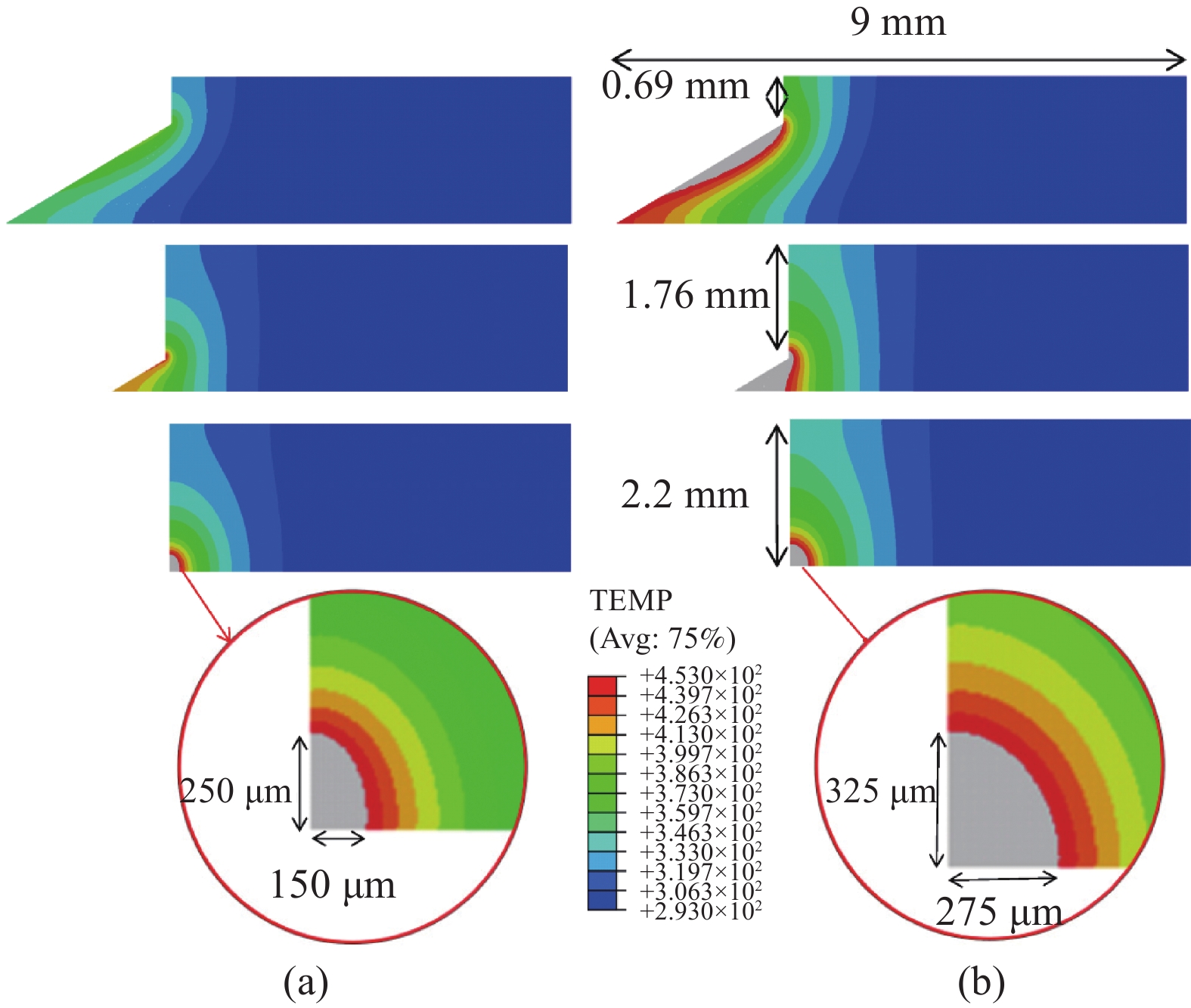

在宏观层面,学者们建立了FRC的均质化模型,主要模拟了FRC钻削温度场分布变化规律。Díaz-Álvarez等[52]建立了一种简单高效的二维CFRP钻孔热传导有限元模型,模拟结果如图8所示,相比新刀具,磨损后的刀具会引起更高的切削温度,具有更大范围的切削高温区。Sadek等[53]认为FRC的钻孔过程中,热传导受刀具的几何形状、刀具上力与力矩分布的影响,提出将刀具分成K个等厚层,刀具所受总的轴向力与力矩可由主切削刃和横刃上每层的力与力矩求和得到,该理论模型对刀具设计具有指导意义。Sorrentino等[54]建立了二维轴对称的钻削热热传导有限元模型,极大地减少了仿真所需计算时间,但模型只能预测温度,不能反应钻削过程中损伤、应力等其他状态。Bao等[55]将建立的预测钻削过程中温度分布的三维数值模型运用于芳纶纤维增强树脂基复合材料(Aramid fiber reinforced polymer composites,AFRP)的钻孔仿真,结果表明,编织结构的AFRP钻削热云图呈近圆形的菱形,仿真结果与实验结果有较好的一致性。Kubher等[56]的研究中指出多向(Multidirectional,MD)CFRP热力耦合钻削仿真模型中层内损伤应考虑正应力σ33和剪应力σ13、σ23,并认为附加层间损伤模式中,黏性单元的损伤起始基于二次强度准则,仿真结果更加符合实验所测得结果。

![]() 图 8 CFRP钻孔时的二维热传导有限元模拟结果(高温区由尺寸标注,温度高于180°C):(a) 新刀具;(b) 磨损刀具[52]Figure 8. Two-dimensional finite element simulation results of heat conduction during drilling with CFRP (The high temperature zone is marked by dimensions, the temperature is higher than 180 C): (a) New tool; (b) Wear the cutting tools[52]

图 8 CFRP钻孔时的二维热传导有限元模拟结果(高温区由尺寸标注,温度高于180°C):(a) 新刀具;(b) 磨损刀具[52]Figure 8. Two-dimensional finite element simulation results of heat conduction during drilling with CFRP (The high temperature zone is marked by dimensions, the temperature is higher than 180 C): (a) New tool; (b) Wear the cutting tools[52]基于上述分析,近年来有关于不同尺度下的切削热的数值模拟主要研究的统计如表1所示,其研究类型可按图7进行分类,学者们从微观尺度和宏观尺度对不同FRC模拟了其材料性能影响因素、加工质量影响因素、温度场分布变化规律和损伤本构优化。但由于计算机计算能力限制,目前对FRC的钻削热、传热机制的仿真模拟大多只模拟了机械损伤或热传导,而对钻孔缺陷或损伤进行热力耦合模拟的研究又较理想化,与实际结果存在一定偏差。关于FRC的有限元模型中使用的损伤判据与损伤演化与实际情况仍存在一定偏差,从更深层次建立热力耦合作用下的损伤模型预测FRC的钻孔缺陷与损伤是目前的难点。

表 1 切削热的数值模拟分析Table 1. Numerical simulation analysis of cutting heatSimulation scale Object Keyword Reference Micro-scale UD-CFRP Fiber orientation angle [41] UD-CFRP Ultrasonic vibration [43] UD-CFRP Temperature

pretreatment[26] 3D braided composites Thermal conductivity [44] 3D braided composites Braiding angle [45] 3D braided composites Elastic-plastic damage constitutive laws [46] UD-CFRP Stress concentration [47] Macro-scale CFRP Thermal damage area prediction [48] Tool Cutting tool structure

design[49] CFRP, GFRP Temperature prediction [50] AFRP Temperature prediction [51] CFRP Intralaminar damage [52] 2. FRC钻削热的影响及其控制策略分析

2.1 钻削热测量方法研究

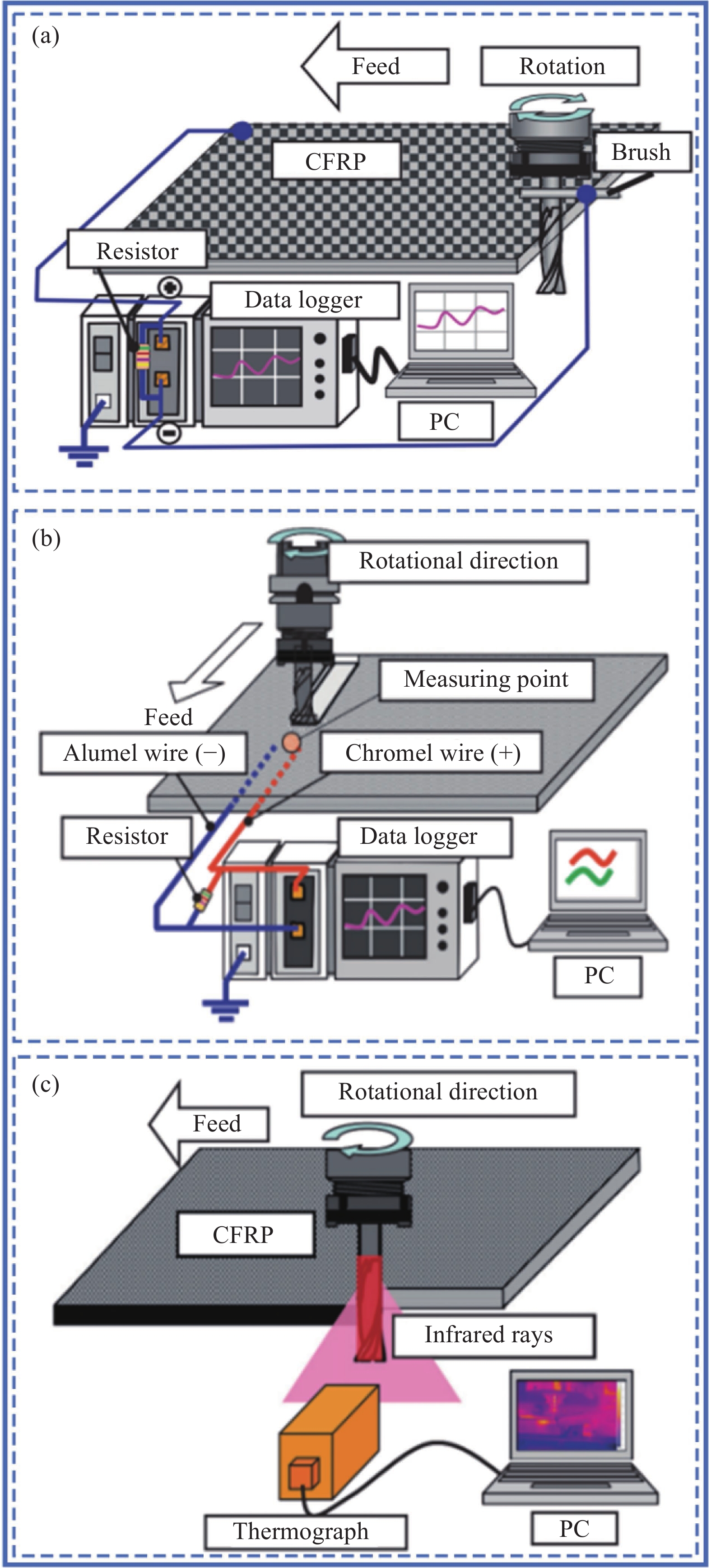

由于FRC特殊的材料性能(各向异性、不均质性、层间强度低)及半封闭式的钻削加工特点,一般的金属切削测温方法对FRC钻削温度测量是不适用的。Liu等[35]研究指出,钻削CFRP的过程中,K型热电偶的测温精确度与可靠性比高温计、红外测温仪高。Kerrigan等[57]在边缘切削实验中,通过在刀具中嵌入无线热电偶测量刀具温度,同时使用热成像测量工件温度的方法,研究了进给量、工件厚度和轴向切削深度对切削温度的影响。Sorrentino等[58]使用热电偶测温的方法,研究了CFRP和玻璃纤维增强树脂基复合材料(Glass fiber reinforced polymer,GFRP)钻削温度与进给速度的关系,指出进给速度与钻削温度呈现出正比关系。Merino-Pérez等[59]在研究钻削热过程中比较了利用热成像测量温度和动态热电偶测量温度两种测温方法,指出与热成像相测量温度相比,热电偶测量温度的方法由于其响应时间低和测温设备更复杂而存在一定的局限性。Loja等[60]使用热成像测温方法研究证明了分层损伤的形成是热力耦合作用的过程,研究结果发现温度升高,分层损伤具有加重的趋势。Takeshi等[61]结合使用多种温度测量方法:(1) 刀具-工件间热电偶直接测量切削点的温度;(2) 热成像仪测量全局温度;(3) 预埋K型热电偶测量层间温度,提高了温度测量的精确度。

根据上述研究可以看出:当前FRC钻削测温方法主要有刀具-工件热电偶法[62]、工件嵌入热电偶法[63-64]和热像仪测温法3种方法[61],其测量装置示意图分别如图9所示。实现钻削温度的精准测量是目前研究的难题,而直接测量钻头的温度,让工件旋转也仅能在低速钻削中实现,且与实际加工的工况存在一定的差别。因而采用更先进、更简便的方法实现钻削温度的精准测量是近10年的研究热点。例如,采用多种测温方法相结合、或采用多点、多角度测量方法测量同一加工工况下温度的办法,从而获取更可靠的数据,这将有助于分析各种影响钻削热因素的权重系数,进一步探究热损伤机制,从而建立更精准的传热数值模型、多尺度下的有限元损伤等其他预测模型,最终实现工艺的优化等目的。

![]() 图 9 三种不同测温方法的实验原理图:(a) 刀具-工件热电偶法;(b) 工件嵌入热电偶法;(c) 热像仪测量法[61]PC—Personal computerFigure 9. Experimental schematic diagram of three different temperature measurement methods: (a) Tool-workpiece thermocouple method; (b) Workpiece embedding thermocouple method; (c) Thermal imager measurement method[61]

图 9 三种不同测温方法的实验原理图:(a) 刀具-工件热电偶法;(b) 工件嵌入热电偶法;(c) 热像仪测量法[61]PC—Personal computerFigure 9. Experimental schematic diagram of three different temperature measurement methods: (a) Tool-workpiece thermocouple method; (b) Workpiece embedding thermocouple method; (c) Thermal imager measurement method[61]2.2 钻削热对制孔质量影响研究

制孔加工质量包括孔壁表面质量、制孔尺寸精度和分层、毛刺、撕裂等损伤缺陷程度,其主要损伤形式如图10所示。FRC具有温度敏感性,特别是环氧基体其力学性能和变形行为显著受温度影响,因此钻削热对制孔加工质量有重要影响。以分层损伤为例:一方面由于纤维增强体和基体的热导率、热膨胀系数都存在显著差异,在钻孔过程中,随着工件和刀具的温度升高,工件容易由于受热而发生应力集中,进而使工件内部产生局部应变导致分层缺陷。另一方面由于基体与纤维均为传热的不良导体,钻孔过程产生的热量难及时向外传导,因此易产生热量积聚,导致刀具因温度过高产生热疲劳磨损,而刀具磨损也会加重分层缺陷[65]。

为了探究温度对FRC加工质量的影响,许多学者研究了温度变化对FRC物理性能的影响。Luigi等[67]研究指出碳纤维增强聚苯二甲酸乙二醇酯复合材料的抗冲击性能随温度升高而增强,但弯曲强度随温度升高而下降。Xavier等[68]研究指出UD碳纤维/聚酰亚胶树脂复合材料在达到玻璃化转变温度之前具有高温稳定性,当温度达到玻璃化温度后,材料的储能模量、强度都显著下降。Um等[69]研究了碳纤维增强聚对苯二甲酸乙二酯复合材料在不同温度影响下结晶后的力学性能变化,结果表明温度升高纤维方向拉伸模量、拉伸强度、面内剪切模量、面内剪切强度都降低。

基于FRC温度变化与物理性能的研究基础,许多学者更进一步研究了切削热与加工质量之间的关联。Siddharth等[70]系统地研究了CFRP钻削分别在干钻和低温条件下的可加工性,并提出了一种引入最大轴向力与临界轴向力的比值的新分层损伤评价方法,结果表明分层因子和表面粗糙度随着温度的降低均呈减小趋势,而轴向力呈增大趋势。Fu等[71]使用热成像测温的方法,详细揭示了UD和MD-CFRP钻出口温度分布与变化机制,并指出UD和MD-CFRP钻出口的最高温度都在纤维方向角为–25°到25°,公称直径向内约0.5 mm处。Ge等[72]研究了热塑性碳纤维/聚醚醚酮(CF/PEEK)复合材料的制孔性能,首次系统地阐明了碳纤维增强热塑性塑料制孔过程中,热力耦合作用对钻孔损伤的影响机制,并指出CF/PEKK的分层损伤在低进给速率时温度对分层损伤的影响较大,在高进给速率时轴向力对分层损伤影响更大。

综上所述,由于FRC的基体有着传递热载荷与机械载荷的作用,而基体的力学性能和变形行为受温度影响显著,当温度升高,FRC的弯曲强度、刚度、储能模量和拉伸强度都会降低,导致分层损伤加重、孔壁表面粗糙度增大和纤维拔出增多等问题,并且温度升高会加剧刀具磨损,刀具磨损则又会影响孔壁形貌等加工质量,因此钻削温度与钻孔损伤存在着千丝万缕的联系,研究钻削热的影响因素及其冷却控制策略依旧是控制孔损伤的首要工作[73]。

2.3 钻削刀具对钻削热的影响

在FRC钻孔加工过程中,由于纤维具有很高的硬度和强度,钻头会受到强烈的摩擦磨损,又加之钻孔是半封闭加工过程,易造成热量聚集。在高温条件下钻孔不仅会增加热损伤和刀具磨损,还会造成黏刀等问题,严重影响制孔质量。因此FRC制孔加工对刀具材料的硬度、强度及耐磨性有很高要求[74]。通过改变刀具的几何尺寸与形貌或优化涂层的方法来降低温度对孔的加工质量的影响,大量研究人员对此方面研究做出了贡献,并取得了一些突破性的结果[75]。

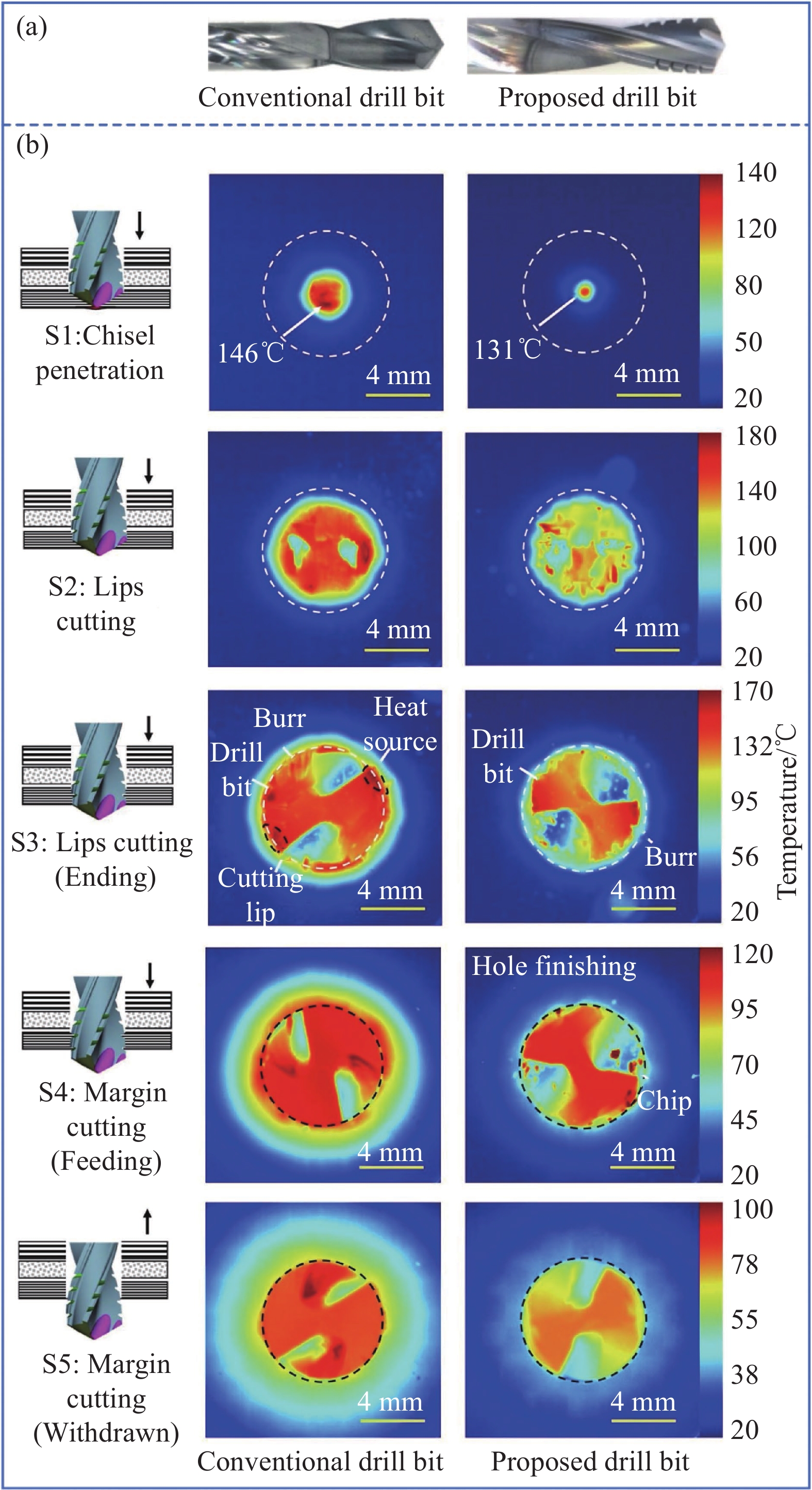

在刀具结构方面,以对现有刀具结构进行改型及其微结构修整为主的研究已成为现阶段的研究重点。例如,陈浩等[76]研究了麻花钻几何参数对钻削温度的影响,结果表明钻尖角和螺旋角对钻削温度无明显影响,钻削温度随横刃长度的减小有所降低。Shu等[28]基于减小前角从而改变切削机制的原理设计了一种新钻孔刀具,其刀具结构如图11(a)中右侧所示,相比传统麻花钻,该刀具横刃更薄,并具有锯齿结构,能够有效降低钻削温度,如图11(b)所示,使用新型刀具的CFRP钻出口处温度更低。同年,Kong等[77]更进一步设计了一种新的螺旋钻孔刀具,如图12所示,其设计的新型刀具特点在于使用轨道磨削制孔中刀具的运动轨迹并采用类似阶梯钻的结构。

![]() 图 11 CFRP钻出口热像图:(a) 实验所用刀具;(b) 钻出口处随钻孔深度变化的热像图(其中左侧使用常规刀具,右侧为新型刀具)[28]Figure 11. Thermal images of CFRP drill hole: (a) Tool used in the experiment; (b) Thermal image of the drilling outlet with the change of drilling depth (In which conventional tools are used on the left side and new tools are used on the right side)[28]

图 11 CFRP钻出口热像图:(a) 实验所用刀具;(b) 钻出口处随钻孔深度变化的热像图(其中左侧使用常规刀具,右侧为新型刀具)[28]Figure 11. Thermal images of CFRP drill hole: (a) Tool used in the experiment; (b) Thermal image of the drilling outlet with the change of drilling depth (In which conventional tools are used on the left side and new tools are used on the right side)[28]![]() 图 12 轨道钻孔及其刀具示意图[77]ap—Screw pitch of the helical path; D—Diameter of the peripheral cutting edges; e—Eccentricity of the helical path; d—Diameter of the milling part; R—Radius of the arc of the ODR tool; ODR—Orbital drilling and reamingFigure 12. Schematic diagram of track drilling and its tools[77]

图 12 轨道钻孔及其刀具示意图[77]ap—Screw pitch of the helical path; D—Diameter of the peripheral cutting edges; e—Eccentricity of the helical path; d—Diameter of the milling part; R—Radius of the arc of the ODR tool; ODR—Orbital drilling and reamingFigure 12. Schematic diagram of track drilling and its tools[77]除了以上研究,Xu等[78]设计了一种排屑槽平行于刀具轴线的新型聚晶金刚石(PCD)匕首钻,并研究指出该匕首钻有助于减少分层损伤、降低孔壁粗糙度和延长刀具寿命,但匕首钻排屑槽空间较小,易造成排屑不畅。Xu等[14]研究了使用具有金刚石涂层烛心钻和阶梯钻的CFRP钻孔可加工性,结果表明由于第二切削刃的扩孔效应,阶梯钻比烛心钻具有更好的孔壁形貌和较低的表面粗糙度值,并指出为了减小孔径偏差,烛心钻适合采用高转速和中速进给,而阶梯钻适合采用中转速和小进给。

在刀具材料与涂层方面,由于刀具磨损会导致热量积聚,钻削温度升高,降低制孔质量,因此控制刀具磨损是学者们的重点研究方向[74]。Xu等[78]研究指出,PCD刀具相对于高速钢和硬质合金刀具钻削CFRP时具有更高的加工质量和刀具寿命。伍俏平等[79]对比了超细晶硬质合金钻头与普通硬质合金钻头钻削AFRP的性能,结果表明超细晶硬质合金钻头相比普通硬质合金钻头具有更高耐磨性,钻削温度和钻削力都更低。Gaugel等[80]研究指出金刚石涂层刀具比无涂层具有更高的耐磨性,但只有在加工高质量复合材料时具有显著寿命优势。但有涂层刀具并不总是性能优于无涂层刀具,Xu等[81]的研究指出在钻削CFRP/Ti时,相同切削条件下,TiAIN涂层钻头并没有比无涂层钻头有明显优势,反而无涂层钻头具有更低的轴向力、更好的孔出口边缘处加工质量。Redouane等[82]研究了金刚石涂层与纳米复合多层涂层对加工温度和刀具磨损的影响,结果表明涂有金刚石层或纳米复合层的刀具具有良好的导热系数与更小的摩擦系数,可以降低加工温度,减少基体的热降解。

由于设计特殊钻头降低FRC钻削热的成本较高,仅有少数学者针对特殊结构刀具设计进行研究,关于优化刀具控制钻削热的相关研究类型如图13所示,学者主要从改变刀具结构、几何尺寸和涂层的角度研究了控制钻削热方法。钻孔过程中,钻削温度会随着刀具与工件接触面积增大而升高,这可以通过减小钻头直径来降低钻削热。刀具与工件间的后角大小也会影响钻削温度,当后角较小时,刀具与工件的接触面积会增大,导致摩擦力增大,产生更多的热量,这可以通过减小切削刃半径的方法来降低钻削温度。改变刀具几何尺寸控制钻削热的研究已经比较成熟,针对考虑钻孔过程中切削机制的刀具结构设计和刀具几何尺寸参数优化分析从而控制切削热是以后研究的重要方向。在刀具材料方面,目前刀具基体材料主要以硬质合金和PCD为主,刀具涂层材料则以金刚石涂层为主。虽然综合考虑金刚石涂层耐磨性最优,但单一涂层无法满足硬度、耐磨性和耐热性等综合性能,刀具的多层、复合涂层研究是目前的主要方向[83]。

2.4 工艺参数对钻削热的影响

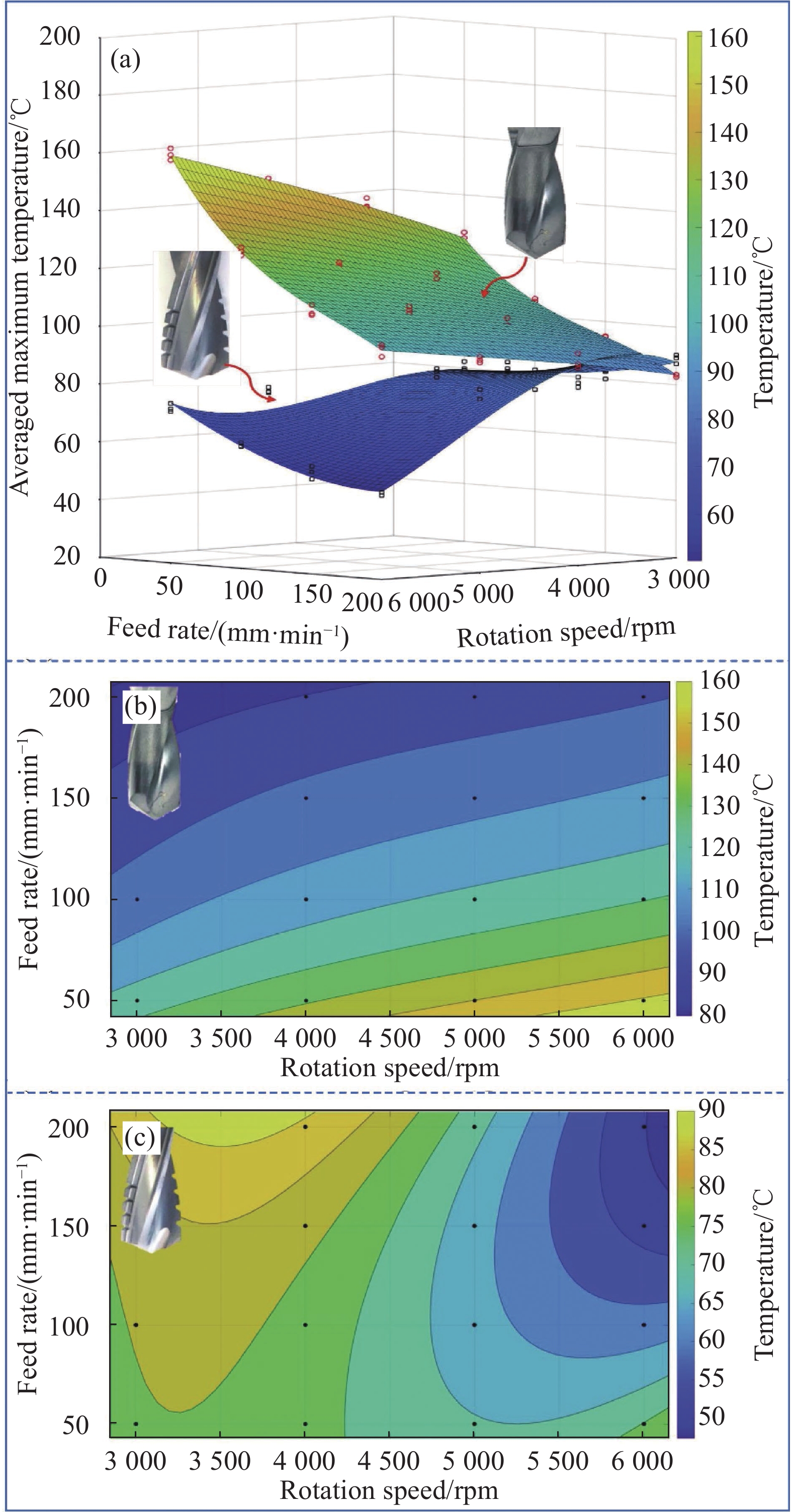

在常规的FRC钻削加工中,大量研究成果指出切削速度和进给量是影响切削热最显著的两个因素[85]。早在Chen等[86]研究中,结果表明钻削温度受切削速度和进给速度的影响,当切削速度过高或进给速度太低时,钻削温度均会升高,钻削温度与加工参数的关系可参考图14[28]。王福吉等[21]的研究结果显示当每齿进给的增大,最大切削力、温升速率都会随之会增加。除了以加工参数为变量,学者们还针对不同类型FRC,以其他工艺参数为变量做了进一步研究。

对于热固性复合材料,Merino-Pérez等[59]研究了交联密度和结晶度对CFRP钻孔过程中的最高温度的影响,结果表明具有更高交联密度和更紧密的分子网络的树脂表现出更强的散热性、更高的玻璃化转变温度和热稳定性。Wang等[87]建立了不同纤维方向角下UD-CFRP的热导率数值模型,并通过边缘铣削实验研究了热导率对CFRP切削温度的影响,结果表明当纤维方向角为45°时CFRP有最大的有效散热区,而135°时最小,因此在不同切削速度下45°角的切削温度始终为较低,135°角的切削温度始终较高。Hou等[88]使用陶瓷片加热待切削区域后,通过正交切削实验观测CFRP的切屑形成与面下损伤,结果表明纤维方向角在约150°时,孔出口处表面松弛、基体开裂和纤维拉出较明显。

对于热塑性复合材料,王福吉等[89]研究了进给速度对玻璃纤维增强聚丙烯复合材料的出口温度的影响,结果表明在低速进给时钻削出口温度随进给速度增加显著升高,在高速进给时钻出口温度受进给速度影响较小,并研究指出进给速度过高或过低都会加重钻出口处撕裂,而入口处撕裂损伤随进给速度增加基本呈单调递增趋势。Xu等[90]研究了碳纤维增强聚酰亚胺(CF/PI)和CF/PEEK钻削加工的可加工性,结果表明以CF/PI和CF/PEEK为代表的热塑性复合材料具有与热固性复合材料相似的切削热规律,钻削温度会随切削速度增加而增加,分层因子随进给量增大而增大,分层因子随切削速度增大而减小,并指出相比CF/PI,CF/PEEK具有更好的孔壁形貌和尺寸精度,但是刀具磨损更剧烈。

综上所述,传统钻削工艺下,钻削的主轴速度和进给量是影响钻削热的主要因素。由于基体有着传递热载荷与机械载荷的作用,FRC在进给方向上的热物理性能主要由基体决定,因此FRC工件的材料属性本身很大程度上影响钻削热,质地较硬、工艺较好的材料其产生的钻削热较多,FRC的结晶度、材料交联密度、基体热物理属性和纤维排布方式也会影响钻削热。相比于热固性树脂基复合材料,以基体使用PEEK、聚苯硫醚(PolyphenyleneSulfide,PPS)和聚醚酰亚胺(Polyetherimide,PEI)为代表的先进热塑性复合材料因其具有低吸湿、损伤容限高等独特优势,目前已成为FRC研究的主流[91-93]。

2.5 辅助加工控制钻削热方法

对于FRC的制孔方式有多种,例如水射流、高能粒子束、电火花制孔是常用的制孔方式,但综合考虑加工质量、加工效率和成本等因素,实际生产中FRC制孔仍以机械切削为代表的接触式加工为主[94]。由于FRC具有硬度高、强度大、导热性差、层间强度低等特点,在孔加工时易产生分层、毛刺、撕裂,刀具极易磨损,加工表面质量低。除了上述单一FRC制孔容易产生的问题外,叠层结构的复合材料有额外的制孔难题:(1) 铝/钛合金本身就是难加工材料,钻孔加工过程中会产生极高的热量,增加热损伤;(2) 叠层顺序会影响加工质量;(3) 金属和复合材料接合面处切削力、切削热呈现阶跃变化,刀具受力热冲击,易磨损崩刃。针对上述问题,国内外许多学者尝试优化加工方法减少切削热[90]。

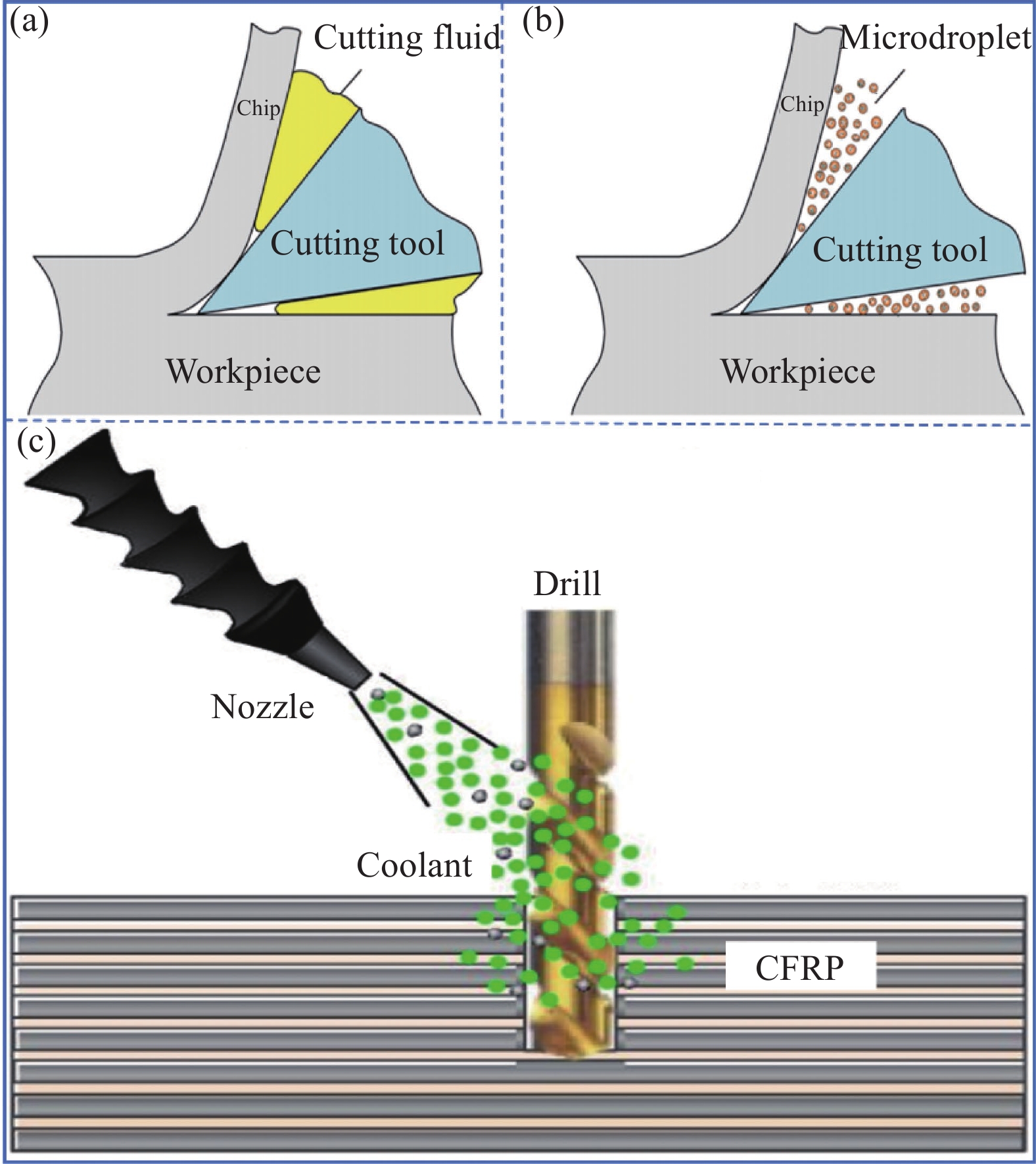

2.5.1 最小润滑辅助钻削加工

为了克服钻削加工中热交换困难、温升过快、保证零件加工精度等问题,采用最小润滑(Minimum quantity lubrication,MQL)辅助加工技术也在FRC加工中逐步采用。其原理是将压缩气体与少量润滑油(通常小于100 mL/h)混合,形成微米大小的液滴油雾,通过喷嘴高速喷射到切削区域从而实现充分润滑[95]。MQL辅助加工技术原理如图15所示,传统润滑液无法靠近刀具切削的尖端部分,而最小润滑技术能够使刀具切削区域得到充分润滑。

进一步地,MQL辅助加工技术可以通过添加纳米增强生物润滑剂改善刀具-工件界面的摩擦状态,减少刀具磨损,且切削区域与外界的传热效率会由于纳米增强剂的布朗运动的作用得到提高。此外MQL辅助加工技术可大大减少冷却介质的用量,极大地减少了加工成本。但是MQL辅助加工还存在一些问题,比如MQL辅助加工会增大加工表面粗糙度[96]。关于MQL辅助钻FRC,相关学者做了一些尝试性的探索研究。Gao等[66]研究结果表明MQL能显著防止毛刺缺陷和热损伤,但润滑剂会使粉末状CFRP切屑很容易黏附在刀具表面和孔壁上,并研究指出高空气流速和低油流速的结合更有助于液滴的细化和喷雾效果,从而提高加工精度与减少刀具磨损。Xu等[97]比较了不同加工方式与刀具涂层对CFRP/Ti6 Al4 V层叠结构复合材料钻孔加工质量的影响,结果表明MQL辅助加工相比干钻能够提高孔的表面质量并有利于抑制Ti毛刺的形成,同时指出虽然金刚石涂层刀具能够降低钻孔扭矩并具有较低的比切削能,然而在MQL加工条件下,金刚石涂层钻头相比TiALN涂层钻头更容易导致Ti屑的堵塞,TiALN涂层更有利于抑制Ti毛刺的形成。基于先前的研究,Xu等[98]又发现MQL加工比干钻有更高的轴向力,认为这是由于纤维的脆性断裂和基体的吸水性使FRC表面吸收了润滑剂,而没有在钻头-工件界面形成稳定润滑膜,并且MQL加工会导致CFRP切屑堵塞,使轴向力更大,因此MQL加工不能有效减少分层损伤。Arjun等[99]比较了CFRP在干钻、MQL加工和低温冷却条件下的钻孔性能,结果表明低温冷却钻孔的轴向力比干钻高36%,MQL加工比干钻高17.6%,低温冷却钻孔的扭矩比干钻高15%,MQL加工比干钻低17%,干钻分层最轻微,低温冷却钻孔最严重,低温冷却钻孔的圆度误差最小。

综上所述,MQL辅助加工技术能够有效减少FRC钻孔的毛刺、热损伤和刀具磨损,并且相比于低温冷却辅助钻削加工(如液氮、液氧、冷风等冷却方式)技术,MQL辅助钻削加工技术能够极大地减少冷却介质的用量,降低了加工成本。但由于其对润滑剂的种类、颗粒尺寸和流速有高技术要求、基体材料的吸水性使刀具-工件界面不能形成稳定的润滑膜、切屑易排出不畅导致加工质量不稳定,因此目前关于MQL辅助加工的应用和研究较少,也是有待进一步突破的难点。

2.5.2 低温冷却辅助钻削加工

FRC的低温冷却辅助钻孔加工通常使用液氮、二氧化碳或冷冻空气作为冷却介质来实现快速散热,从而降低切削温度。低温冷却辅助通过降低切削温度,增加了工件在钻削时的杨氏模量和抗拉强度,提高了抗断裂强度、刚度、层间的剪切强度和硬脆性,从而提高了分层临界轴向力,增强了抗分层失效的能力。此外,低温冷却辅助钻孔在抑制毛刺、裂纹、热损伤和减少刀具磨损方面也有明显优势[66],国内外学者对此也做了深入的研究分析。

关于液氮冷却辅助加工,Gültkein等[100]采用液氮低温冷却加工方法钻削CFRP,研究指出该方法降低了孔壁表面粗糙度和刀具磨损,但增加了轴向力和分层系数。Marcelo等[101]对热塑性和热固性CFRP分别进行干钻和液氮冷却辅助钻削,结果表明对于热塑性和热固性CFRP,低温冷却辅助加工都均能改善孔的表面质量、保证孔径尺寸,但热塑性CFRP在低温环境下具有更高的刚度,钻孔时的轴向力和扭矩更大,导致其分层因子受冷却条件影响更大。Navneet等[102]研究指出,与干钻相比液氮冷却钻孔的圆柱度和圆度偏差更大,但表面形貌更好,反分层因子数值更优。王晋宇等[103]研究了液氮作为冷却介质的AFRP复合材料钻孔试验,结果表明低温冷却辅助加工能有效减少毛刺面积,抑制烧蚀现象,改善AFRP的孔加工质量。

关于液化二氧化碳冷却辅助加工,Rodríguez等[104]学者的研究指出在对CFRP-Ti6 Al4 V钻削时使用液化二氧化碳作为低温冷却剂,可保证孔径偏差在0.5%以内、刀尖温度显著降低、CFRP相的表面完整性增加、刀刃磨损减少、刀具寿命延长,并研究指出相比干钻使用液化二氧化碳低温冷却会增加能耗,但随着钻孔数量增加,能耗逐渐降低。邹凡等[105]为了减少冷却介质用量,研究了超临界二氧化碳低温冷却方法应用于CFRP复合材料机械加工的可行性,结果表明相比干式切削超临界二氧化碳低温冷却辅助加工能明显提高表面质量。

关于冷风辅助加工,王福吉等[106]比较了干式切削、正向冷风冷却和逆向冷风冷却条件下钻削CFRP加工质量,结果表明相比干钻正逆向冷风冷却均能够有效抑制刀具磨损,并研究指出在使用逆向冷风冷却时,由于孔内气流运动情况更加稳定,切屑去除能力更强,换热效果更明显,因此逆向冷风冷却能够更好地抑制刀具磨损,延长刀具寿命。由于正向冷风冷却的气流对出口纤维有顶出作用,因此其引起的毛刺高度最大,干式切削的毛刺高度次之,由于逆向冷风的气流对纤维有拉回作用,因此逆向冷风冷却的毛刺高度最小。此外,采用冷风冷却不论气流流向如何,由于气流对纤维的牵扯作用,都会导致撕裂损伤的增加。

根据以上学者的研究,表2总结了近年来低温冷却辅助加工控制切削热的相关研究,以上学者的研究表明了通过低温冷却辅助加工方法控制切削热已经是一种成熟的加工技术。不同辅助加工方法的实验装置如图16所示[107],相比于常用的干式切削,液氮低温冷却剂更有助于降低刀具损伤,但会增大切削力和扭矩,二氧化碳为冷却剂的节流低温冷却钻孔更有助于提高孔的表面质量和尺寸精度(孔径尺寸和圆柱度等),而冷风辅助加工更有利于抑制毛刺损伤。

表 2 辅助加工控制温度研究Table 2. Study on control temperature of auxiliary machiningAuxiliary method Object Subject Reference MQL CFRP/Ti6Al4V Torque, specific cutting energy, hole wall morphologies, burr [89] CFRP/Ti6Al4V Thrust force, delamination damage, tool wear, [90] CFRP torque, thrust force, delamination damage, hole diameter, roundness [91] LN2 CFRP Hole wall morphologies, hole wall surface roughness, tool wear, thrust force [92] CFRP, CFRPs Torque, thrust force, delamination damage, hole diameter, roundness [93] CFRPs Hole wall surface roughness, roundness, cylindricity, delamination damage [94] AFRP Thrust force, delamination damage, burr, ablation [95] LCO2 CFRP/Ti6Al4V Hole diameter, power consumption [96] CFRP Hole wall morphologies, hole wall surface roughness, torque [97] Air CFRP Burr, tear, tool wear [98] Ultrasonic vibration CFRPs Hole wall surface roughness, thrust force, torque, delamination damage, burr, tear [108] CFRP Thrust force [43] CFRPs Hole wall morphologies [22] CFRP Hole wall surface roughness, thrust force, delamination damage, burr, tear [110] 2.5.3 振动辅助钻削加工

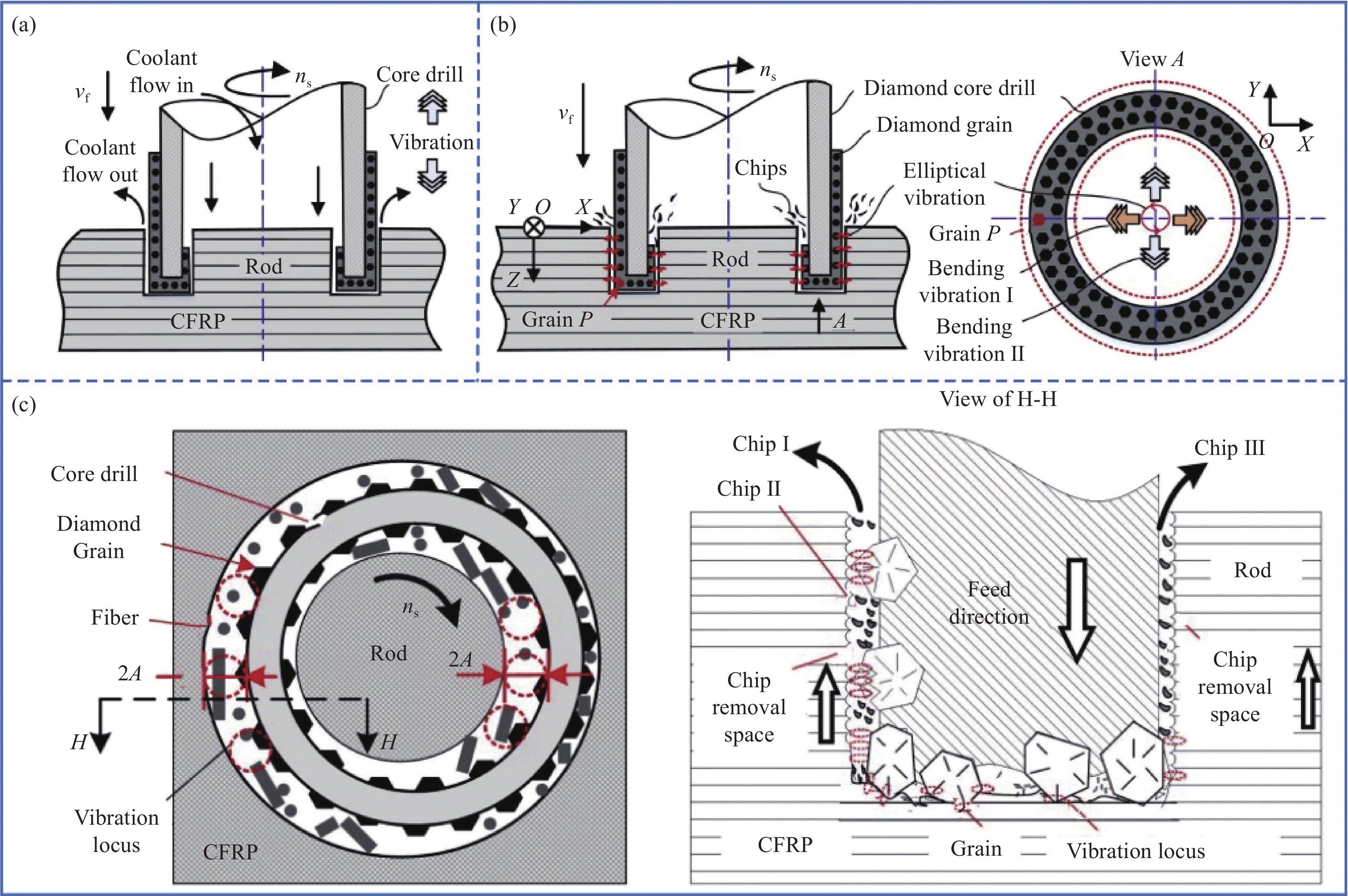

振动辅助钻削技术充分利用了超声/低频振动加工技术中的锤击、磨抛及划擦等机制,利用瞬间的振动切削快速切断纤维,实现在钻削过程中反复的切削。这种加工方式可有效降低钻削硬脆材料时的钻削力,降低了材料的加工难度,从而显著提升刀具使用寿命[108-110]。振动辅助加工技术可分为低频振动辅助和超声振动辅助,其中多维的旋转超声振动辅助钻削技术是一种新兴的复合加工技术,在FRC切削领域已有较多的应用,国内外学者尝试了采用两种振动技术降低切削热,并取得了一定得研究成果。

在低频振动辅助方面,Sadek等[111]研究指出采用低频振动辅助钻削CFRP可降低切削温度约50%,轴向力约40%,有效减少了撕裂和分层损伤。Oliver等[112]研究指出低频振动钻削工艺也适用于CFRP/Ti6 Al4 V叠层材料,可有效降低切削温度,从而减少刀具磨损。张世杰等[113]研究指出高低频复合振动钻削可有效抑制CFRP/Ti中CFRP入口处撕裂损伤,提高孔壁质量。但是陈冒风等[114]研究表明CFRP/Ti低频振动钻削会使Ti切屑在排出过程中对CFRP孔壁造成二次切削作用,扩大CFRP的孔径,而Ti层的孔径变化很小,导致孔径存在阶差。谢大叶等[115]分析了低频振动辅助钻削的运动学原理,总结了提高制孔质量及断屑的机制,指出低频振动装置的加工参数需满足使切削刃轨迹发生干涉的条件才能实现断屑,断屑有助于减少切屑对CFRP孔壁的划伤和切屑与孔壁的摩擦,从而降低切削热的产生。

在超声振动辅助方面,Liu等[116-117]研究指出纵向扭转耦合旋转超声辅助钻孔会随着振幅的增加,孔出口处的表面粗糙度和缺陷都具有先减小后增大的变化趋势,并且当振幅为7~9 μm时,毛刺因子、撕裂因子和分层因子最小,遗憾的是未对钻削热进行研究并控制。Xu等[47]研究指出,超声振动切削中,由于工件与刀具接触时间短和切屑被快速去除,温升速率被有效抑制,进而工件的温度可以始终保持在基体玻璃化转变温度以下。Geng等[22]测量了旋转超声椭圆振动加工(Rotary ultrasonic elliptical machining,RUEM)和磨削钻孔的切削温度,如图17所示,与磨削钻孔相比,RUEM有效地改善了切屑去除方式,切削区有更好的散热条件,并且RUEM中刀刃的间歇性切削减少了刀具与工件接触时间,使钻孔过程中产生的热量更少,降低了切削温度。为了进一步降低钻削热引起的损伤,李树健等[118]提出一种将超声振动、超低温液氮和超低温环境相结合的辅助加工方法,结果表明超声振动能够降低轴向钻削力,而超低温液氮及形成的冰冻支撑层能够为出口层提供支撑,并降低钻削温度。

综上所述,目前振动辅助加工技术已经被成熟地应用到FRC钻孔加工过程中以控制钻削热的产生。作为先进复合加工技术,旋转超声振动辅助钻削技术在常规纵向振动的基础上实现轴向的振动切削加工有助于大幅度减少切削热,纵扭耦合振动、旋转超声振动和旋转椭圆超声振动则在多维振动工况下进一步减少了切削热,提高了加工质量。学者们更多地研究了多维旋转超声振动辅助钻削,但主要内容是不同钻削方式下的对比实验研究,且部分学者的研究结果存在差异性,钻削参数与钻削温度的影响规律研究尚未深入研究,对于钻削参数与钻削温度之间的拟合模型也有待进一步的突破。

![]() 图 17 旋转超声椭圆振动加工原理:(a) 旋转超声振动加工;(b) 旋转超声椭圆振动加工;(c) 切屑排出示意图[22]vf—Feed speed; ns—Spindle speed; A—Vibration amplitude; H—Local section view H—HFigure 17. Principle of rotary ultrasonic elliptical vibration machining: (a) Rotary ultrasonic vibration machining; (b) Rotary ultrasonic elliptical vibration processing; (c) Schematic diagram of chip discharge[22]

图 17 旋转超声椭圆振动加工原理:(a) 旋转超声振动加工;(b) 旋转超声椭圆振动加工;(c) 切屑排出示意图[22]vf—Feed speed; ns—Spindle speed; A—Vibration amplitude; H—Local section view H—HFigure 17. Principle of rotary ultrasonic elliptical vibration machining: (a) Rotary ultrasonic vibration machining; (b) Rotary ultrasonic elliptical vibration processing; (c) Schematic diagram of chip discharge[22]3. 结 论

重点对纤维增强复合材料(Fiber reinforced composite,FRC)钻削加工中切削热理论研究、钻削热对加工质量影响研究、钻削热影响因素及控制策略等研究进行了综述。目前,虽然国内外学者在FRC钻孔加工过程中热量的产生及其控制策略方面开展了一定的研究,但着眼于有效提高加工质量和优化加工工艺方面仍存在一定的挑战,具体可描述为

(1) 需建立考虑热力耦合作用的FRC钻削损伤形成理论。目前FRC钻孔切削热理论的研究内容主要集中在通过仿真及实验相结合的方法探究单向(UD)-FRC的切削去除机制、切削力、切削温度及切屑的宏观形貌观察上。而关于FRC钻削的热传导理论模型大多基于均质化的理想假设,通过实验观测直接建立FRC钻削过程中的损伤形成理论模型较难实现,而基于有限元法的数值模拟则能有效帮助研究者们分析FRC微观切削过程,建立考虑热力耦合作用的FRC钻削损伤形成理论;

(2) 尚未形成完善的理论来指导多尺度的FRC热力耦合钻削模型的建立。受计算机能力限制,大多数模型只模拟了机械损伤或热传导,而对钻孔缺陷或损伤进行热力耦合模拟的研究大多将工件理想化为均质化模型,不能模拟出FRC钻孔过程中的毛刺、撕裂和分层等微观损伤。FRC的有限元模型中使用的损伤判据与损伤演化也存在一定局限性,一般只能有效预测单一损伤类型。建立更准确的热力耦合作用下的损伤模型从而更全面地预测FRC钻孔缺陷与损伤是目前的难点;

(3) 需要建立“刀具-工艺-控制策略-数据库”一体化研究方法。关于在钻削热对FRC钻孔加工质量影响方面的研究主要停留在表层直观的实验观测层面,已经有大量研究说明了加工参数、材料属性等变量对钻削温度和加工质量的影响。目前控制钻削热的策略主要从刀具、工艺参数和辅助加工技术3个角度考虑。由于FRC的钻削缺陷与损伤由复杂的热力耦合作用引起,单一的控制策略无法实现综合制孔质量的最优,需采用先进的刀型、刀具材料和涂层并配合先进钻削工艺来解决问题。因此需针对FRC从材料的切削机制和刀具疲劳磨损的角度建立系统的刀具设计理论、建立钻削数据库和专家系统、优化辅助加工控制钻削热方法,从而实现刀具、工艺参数和辅助控制方法的快速选择;

(4) 需要优化新型复合振动辅助加工策略与新工艺相互结合的钻削热控制方法。钻削热控制策略中采用有效辅助加工工艺控制FRC切削热已是当前研究的热点问题。其中低温冷却辅助加工和超声振动辅助加工技术被广泛采用来控制切削热。但单一的辅助加工技术存在一定局限性,低温冷却辅助加工会增加钻削轴向力,而超声振动辅助加工对叠层结构工件的制孔质量提升效果不显著,最小润滑(MQL)辅助加工则对设备的技术要求较高,加工系统复杂,且加工质量不稳定。因而学者们多尝试使用复合辅助加工技术控制钻削热,如低温冷却与超声振动相结合,但针对控制FRC钻削热的新型工艺的开发仍任重道远。

-

图 1 单向(UD)-碳纤维增强树脂基复合材料(CFRP)切削加工机制:(a) 刀具与纤维夹角;(b) 微观切削模型;(c) 四种切削模式[28]

θ—Cutting direction; \overrightarrow {V_{{\rm{c}}}} —Cutting speed; \overrightarrow k —Fiber direction

Figure 1. Unidirectional (UD)-carbon fiber reinforced polymer (CFRP) cutting mechanism: (a) Angle between cutter and fiber; (b) Micro-cutting model; (c) Four cutting modes[28]

图 3 UD-CFRP钻削热传导模型[33]

ω—Angular velocity; νf—Feed velocity of the drill; q1—Heat flux load which comes from the major cutting edges and chisel edge; q2—Heat flux load generated from the side edges; lx—CFRP length; ly—CFRP width; lz—CFRP thickness; d—Tool diameter

Figure 3. UD-CFRP drilling heat conduction model[33]

图 8 CFRP钻孔时的二维热传导有限元模拟结果(高温区由尺寸标注,温度高于180°C):(a) 新刀具;(b) 磨损刀具[52]

Figure 8. Two-dimensional finite element simulation results of heat conduction during drilling with CFRP (The high temperature zone is marked by dimensions, the temperature is higher than 180 C): (a) New tool; (b) Wear the cutting tools[52]

图 9 三种不同测温方法的实验原理图:(a) 刀具-工件热电偶法;(b) 工件嵌入热电偶法;(c) 热像仪测量法[61]

PC—Personal computer

Figure 9. Experimental schematic diagram of three different temperature measurement methods: (a) Tool-workpiece thermocouple method; (b) Workpiece embedding thermocouple method; (c) Thermal imager measurement method[61]

图 11 CFRP钻出口热像图:(a) 实验所用刀具;(b) 钻出口处随钻孔深度变化的热像图(其中左侧使用常规刀具,右侧为新型刀具)[28]

Figure 11. Thermal images of CFRP drill hole: (a) Tool used in the experiment; (b) Thermal image of the drilling outlet with the change of drilling depth (In which conventional tools are used on the left side and new tools are used on the right side)[28]

图 12 轨道钻孔及其刀具示意图[77]

ap—Screw pitch of the helical path; D—Diameter of the peripheral cutting edges; e—Eccentricity of the helical path; d—Diameter of the milling part; R—Radius of the arc of the ODR tool; ODR—Orbital drilling and reaming

Figure 12. Schematic diagram of track drilling and its tools[77]

图 17 旋转超声椭圆振动加工原理:(a) 旋转超声振动加工;(b) 旋转超声椭圆振动加工;(c) 切屑排出示意图[22]

vf—Feed speed; ns—Spindle speed; A—Vibration amplitude; H—Local section view H—H

Figure 17. Principle of rotary ultrasonic elliptical vibration machining: (a) Rotary ultrasonic vibration machining; (b) Rotary ultrasonic elliptical vibration processing; (c) Schematic diagram of chip discharge[22]

表 1 切削热的数值模拟分析

Table 1 Numerical simulation analysis of cutting heat

Simulation scale Object Keyword Reference Micro-scale UD-CFRP Fiber orientation angle [41] UD-CFRP Ultrasonic vibration [43] UD-CFRP Temperature

pretreatment[26] 3D braided composites Thermal conductivity [44] 3D braided composites Braiding angle [45] 3D braided composites Elastic-plastic damage constitutive laws [46] UD-CFRP Stress concentration [47] Macro-scale CFRP Thermal damage area prediction [48] Tool Cutting tool structure

design[49] CFRP, GFRP Temperature prediction [50] AFRP Temperature prediction [51] CFRP Intralaminar damage [52] 表 2 辅助加工控制温度研究

Table 2 Study on control temperature of auxiliary machining

Auxiliary method Object Subject Reference MQL CFRP/Ti6Al4V Torque, specific cutting energy, hole wall morphologies, burr [89] CFRP/Ti6Al4V Thrust force, delamination damage, tool wear, [90] CFRP torque, thrust force, delamination damage, hole diameter, roundness [91] LN2 CFRP Hole wall morphologies, hole wall surface roughness, tool wear, thrust force [92] CFRP, CFRPs Torque, thrust force, delamination damage, hole diameter, roundness [93] CFRPs Hole wall surface roughness, roundness, cylindricity, delamination damage [94] AFRP Thrust force, delamination damage, burr, ablation [95] LCO2 CFRP/Ti6Al4V Hole diameter, power consumption [96] CFRP Hole wall morphologies, hole wall surface roughness, torque [97] Air CFRP Burr, tear, tool wear [98] Ultrasonic vibration CFRPs Hole wall surface roughness, thrust force, torque, delamination damage, burr, tear [108] CFRP Thrust force [43] CFRPs Hole wall morphologies [22] CFRP Hole wall surface roughness, thrust force, delamination damage, burr, tear [110] -

[1] SHI Z Y, CUI P, LI X. A review on research progress of machining technologies of carbon fiber-reinforced polymer and aramid fiber-reinforced polymer[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science,2019,233(13):4508-4520. DOI: 10.1177/0954406219830732

[2] 陈春姣, 包宏伟, 李燕, 等. 石墨烯增强铜基复合材料研究进展[J]. 复合材料学报, 2023, 40(3):1248-1262. CHEN Chunjiao, BAO Hongwei, LI Yan, et al. Research progress of graphene reinforced copper matrix compo-sites[J]. Acta Materiae Compositae Sinica,2023,40(3):1248-1262(in Chinese).

[3] 冯志海, 李俊宁, 田跃龙, 等. 航天先进复合材料研究进展[J]. 复合材料学报, 2022, 39(9):4187-4195. FENG Zhihai, LI Junning, TIAN Yuelong, et al. Research progress of advanced composite materials for aerospace applications[J]. Acta Materiae Compositae Sinica,2022,39(9):4187-4195(in Chinese).

[4] QI Z C, LIU Y, CHEN W L. An approach to predict the mechanical properties of CFRP based on cross-scale simulation[J]. Composite Structures,2019,210:339-347. DOI: 10.1016/j.compstruct.2018.11.056

[5] 赵天, 李营, 张超, 等. 高性能航空复合材料结构的关键力学问题研究进展[J]. 航空学报, 2022, 43(6):526851. ZHAO Tian, LI Ying, ZHANG Chao, et al. Fundamental mechanical problems in high performance aerospace composite structures: State-of-art review[J]. Acta Aeronautica et Astronautica Sinica,2022,43(6):526851(in Chinese).

[6] 肖遥, 李东升, 吉康, 等. 大型复合材料航空件固化成型模具技术研究与应用进展[J]. 复合材料学报, 2022, 39(3):907-925. XIAO Yao, LI Dongsheng, JI Kang, et al. Research and application progress of curing tooling technology for large composite aeronautical components[J]. Acta Materiae Compositae Sinica,2022,39(3):907-925(in Chinese).

[7] 罗云烽, 姚佳楠. 高性能热塑性复合材料在民用航空领域中的应用[J]. 航空制造技术, 2021, 64(16):93-102. LUO Yunfeng, YAO Jianan. Application of high-performance thermoplastic composites in civil aviation[J]. Aviation Manufacturing Technology,2021,64(16):93-102(in Chinese).

[8] 陈冰, 徐虎, 王健, 等. 纤维增强复合材料磨削制孔加工技术研究进展[J]. 复合材料学报, 2023, 40(1): 13-37. CHEN Bing, XU Hu, WANG Jian, et al. Research progress of fiber reinforced composites by grinding technology for hole making[J]. Acta Materiae Compositae Sinica, 2023, 40(1): 13-37(in Chinese).

[9] 邢丽英, 李亚锋, 陈祥宝. 先进复合材料在航空装备发展中的地位与作用[J]. 复合材料学报, 2022, 39(9):4179-4186. XING Liying, LI Yafeng, CHEN Xiangbao. Status and role of the advanced composite materials in the development of aviation equipment[J]. Acta Materiae Compositae Sinica,2022,39(9):4179-4186(in Chinese).

[10] 王显峰, 段少华, 唐珊珊, 等. 复合材料自动铺放技术在航空航天领域的研究进展[J]. 航空制造技术, 2022, 65(16):64-77. WANG Xianfeng, DUAN Shaohua, TANG Shanshan, et al. Progress of composite automated placement technology in aviation field[J]. Aeronautical Manufacturing Technology,2022,65(16):64-77(in Chinese).

[11] 顾轶卓, 李敏, 李艳霞, 等. 飞行器结构用复合材料制造技术与工艺理论进展[J]. 航空学报, 2015, 36(8):27732797. GU Yizhuo, LI Min, LI Yanxia, et al. Progress on manufacturing technology and process theory of aircraft compo-site structure[J]. Acta Aeronautica et Astronautica Sinica,2015,36(8):27732797(in Chinese).

[12] 张月欣, 杨明君, 刘耿, 等. CFRP的钻削加工研究现状[J]. 复合材料科学与工程, 2021(12):120-128. ZHANG Yuexin, YANG Mingjun, LIU Geng, et al. A review about drilling of CFRP[J]. Composites Science and Engi-neering,2021(12):120-128(in Chinese).

[13] 鲍永杰, 高航, 梁延德, 等. 碳纤维/环氧树脂复合材料钻削温度场建模与试验[J]. 兵工学报, 2013, 34(7):846-852. BAO Yongjie, GAO Hang, LIANG Yande, et al. Modeling and experimental research on drilling temperature field of carbon fiber/epoxy reinforced composites[J]. Acta Armamentarii,2013,34(7):846-852(in Chinese).

[14] XU J Y, LIN T Y, DAVIM J P. On the machining tempera-ture and hole quality of CFRP laminates when using diamond-coated special drills[J]. Journal of Composites Science, 2022, 6(2): 45.

[15] 刘亚军, 李皓, 李士鹏, 等. 钛合金/CFRP叠层构件螺旋铣孔界面切削热研究[J]. 机械科学与技术, 2019, 38(9):1406-1413. LIU Yajun, LI Hao, LI Shipeng, et al. Investigation of cutting heat of interface in helical milling of titanium and carbon fiber reinforced plastic stack[J]. Mechanical Science and Technology for Aerospace Engineering,2019,38(9):1406-1413(in Chinese).

[16] 杨国林, 董志刚, 康仁科, 等. 螺旋铣孔技术研究进展[J]. 航空学报, 2020, 41(7):623311. YANG Guolin, DONG Zhigang, KANG Renke, et al. Research progress of helical milling technology[J]. Acta Aeronautica et Astronautica Sinica,2020,41(7):623311(in Chinese).

[17] MU J, XU J H, CHEN Y, et al. Experimental research on temperature of drilling CFRP with brazed diamond core drill[J]. Materials Science Forum, 2014, 3256(800-801): 776-781.

[18] 蔡建国, 林正英. C/E复合材料高速钻削温度测量研究[J]. 机械制造与自动化, 2015, 44(2):201-202, 214. CAI Jianguo, LIN Zhengying. Research on temperature measurement of high-speed drilling of C/E composites[J]. Machinery Manufacturing and Automation,2015,44(2):201-202, 214(in Chinese).

[19] 陈文成, 王宏晓, 段玉岗, 等. 温变特性对C/E复合材料制孔质量影响的试验研究[J]. 机械制造, 2019, 57(8):84-90. CHEN Wencheng, WANG Hongduan, DUAN Yugang, et al. Experimental study on the influence of temperature change characteristics on the hole quality of C/E compo-sites[J]. Machinery Manufacturing,2019,57(8):84-90(in Chinese).

[20] SANTIUSTE C, DIAZ-ALVAREZ J, SOLDANI X, et al. Modelling thermal effects in machining of carbon fiber reinforced polymer composites[J]. Journal of Reinforced Plastics & Composites,2011,33(8):758-766.

[21] 王福吉, 殷俊伟, 贾振元, 等. CFRP复合材料铣削力、温度及表层损伤分析[J]. 机械工程学报, 2018, 3(3):186-195. WANG Fuji, YIN Junwei, JIA Zhenyuan, et al. Measurement and analysis of cutting force, temperature and cutting-induced top-layer damage in edge trimming of CFRPs[J]. Journal of Mechanical Engineering,2018,3(3):186-195(in Chinese).

[22] GENG D X, LU Z H, YAO G, et al. Cutting temperature and resulting influence on machining performance in rotary ultrasonic elliptical machining of thick CFRP[J]. International Journal of Machine Tools and Manufacture,2017, 123:160-170.

[23] 徐锦泱. 碳纤维增强树脂基复合材料钻削缺陷研究进展[J]. 航空制造技术, 2022, 65(22):24-33. XU Jinyang. Research advances in drilling-induced defects of carbon fiber reinforced polymers[J]. Aeronautical Manufacturing Technology,2022,65(22):24-33(in Chinese).

[24] 吴小飞, 马保吉, 高红红, 等. 基于多目标优化的碳纤维复合材料钻削参数优化[J]. 工具技术, 2022, 56(9):43-47. WU Xiaofei, MA Baoji, GAO Honghong, et al. Optimization of drilling parameters for carbon fibre reinforced plastics based on multi-objective optimization[J]. Tool Technology,2022,56(9):43-47(in Chinese).

[25] HOU G Y, ZHANG K F, FAN X T, et al. Analysis of exit-ply temperature characteristics and their effects on occurrence of exit-ply damages during UD CFRP drilling[J]. Composite Structures,2020,231:111456. DOI: 10.1016/j.compstruct.2019.111456

[26] 李丰辰, 齐振超, 陈文亮, 等. CF/PEEK钻削热历史对孔承载能力的影响规律研究[J]. 工具技术, 2022, 56(12):56-63. [27] 刘书暖, 夏文强, 王宁, 等. CFRP/钛合金叠层构件低温钻削的轴向力与成孔质量研究[J]. 航空制造技术, 2019, 62(13):82-86. LIU Shunuan, XIA Wenqiang, WANG Ning, et al. Research on thrust force and hole 1uality of drilling CFRP/Ti stacks in low temperature[J]. Aeronautical Manufacturing Technology,2019,62(13):82-86(in Chinese).

[28] SHU L M, LI S H, FANG Z L, et al. Study on dedicated drill bit design for carbon fiber reinforced polymer drilling with improved cutting mechanism[J]. Composites Part A: Applied Science and Manufacturing,2020,142:106259.

[29] 邹适, 李树健, 李鹏南, 等. CFRP钻削过程的切削热研究进展[J]. 宇航材料工艺, 2020, 50(4):13-18. ZOU Shi, LI Shujian, LI Pengnan, et al. Research progress of cutting heat in drilling process of CFRP[J]. Aerospace Materials and Technology,2020,50(4):13-18(in Chinese).

[30] SEYEDBEHZAD G, GILBERT L, JEAN-FRANÇOIS C. Experimental investigation of the cutting temperature and surface quality during milling of unidirectional carbon fiber reinforced plastic[J]. Journal of Composite Materials,2016,50(8):1007-1142. DOI: 10.1177/0021998315586078

[31] HAN L, ZHANG J J, LIU Y, et al. Finite element investigation on pretreatment temperature-dependent orthogonal cutting of unidirectional CFRP[J]. Composite Structures,2021,278:114678. DOI: 10.1016/j.compstruct.2021.114678

[32] WANG F J, YIN J W, MA J W, et al. Heat partition in dry orthogonal cutting of unidirectional CFRP composite lami-nates[J]. Composite Structures,2018,197:28-38.

[33] BAO Y J, WANG Y Q, GAO H, et al. Investigation on temperature field of unidirectional carbon fiber/epoxy composites during the drilling process[J]. Journal of Central South University,2019,26(10):2717-2728. DOI: 10.1007/s11771-019-4208-2

[34] 杨帆, 王福吉, 贾振元. CFRP/钛合金叠层钻削中的温度场计算研究[J]. 机电工程, 2019, 36(12):1261-1265. YANG Fan, WANG Fuji, JIA Zhenyuan. Temperature field calculation of CFRP/Ti alloy laminated drilling[J]. Electromechanical Engineering,2019,36(12):1261-1265(in Chinese).

[35] LIU J, CHEN G, JI C H, et al. An investigation of workpiece temperature variation of helical milling for carbon fiber reinforced plastics (CFRP)[J]. International Journal of Machine Tools and Manufacture,2014,86:89-103. DOI: 10.1016/j.ijmachtools.2014.06.008

[36] SIKIRU O I, SAHEED O O, HOM N D. Thermo-mechani-cal modelling of FRP cross-ply composite laminates drilling: Delamination damage analysis[J]. Composites Part B: Engineering,2017,108:45-52. DOI: 10.1016/j.compositesb.2016.09.100

[37] 贾振元, 毕广健, 王福吉, 等. 碳纤维增强树脂基复合材料切削机理研究[J]. 机械工程学报, 2018, 54(23):199-208. DOI: 10.3901/JME.2018.23.199 JIA Zhenyuan, BI Guangjian, WANG Fuji, et al. The research of machining mechanism of carbon fiber reinforced plastic[J]. Journal of Mechanical Engineering,2018,54(23):199-208(in Chinese). DOI: 10.3901/JME.2018.23.199

[38] FATTAHI M Z, KISHAWY H A. Prediction of critical thrust force generated at the onset of delamination in machining carbon reinforced composites[J]. The International Journal of Advanced Manufacturing Technology,2019,103(5-8):2751-2759. DOI: 10.1007/s00170-019-03517-4

[39] LIU Y, LI Q N, QI Z C, et al. Rapid prediction of thrust force coupling scale-span model and revised ANN in drilling CFRPs[J]. The International Journal of Advanced Manufacturing Technology,2021,116:2255-2268. DOI: 10.1007/s00170-021-07491-8

[40] LIU Y, QI Z C, CHEN W L, et al. An approach to design high-performance unidirectional CFRPs based on a new sensitivity analysis model[J]. Composite Structures,2019,224:111078. DOI: 10.1016/j.compstruct.2019.111078

[41] LIU Y, LI Q N, QI Z C, et al. Scale-span modelling of dynamic progressive failure in drilling CFRPs using a tapered drill-reamer[J]. Composite Structures,2021,278:114710. DOI: 10.1016/j.compstruct.2021.114710

[42] DU J G, GENG M, MING W Y, et al. Simulation machining of fiber-reinforced composites: A review[J]. The International Journal of Advanced Manufacturing Technology, 2021, 117(1- 2): 1-15.

[43] LIU Y, QI Z C, CHEN W L, et al. Mesh size optimization of unidirectional fiber-reinforced composites model for precisely characterizing the effective elastic property[J]. Journal of Material Engineering and Performance,2020,29:2701-2719.

[44] LIU Y, PAN Z T, LI Q N, et al. Comparative analysis of dynamic progressive failure of CFRPs using the scale-span and macroscopic modeling method in drilling[J]. Engi-neering Fracture Mechanics,2022,268:108434. DOI: 10.1016/j.engfracmech.2022.108434

[45] 齐振超, 李丰辰, 王二化. 基于热力耦合仿真的CFRP直角切削机理研究[J]. 工具技术, 2019, 53(10):36-41. QI Zhenchao, LI Fengchen, WANG Erhua. Research on orthogonal cutting mechanism of CFRP based on thermo-mechanical couple simulation[J]. Tool Technology,2019,53(10):36-41(in Chinese).

[46] GAO C, XIAO J, XU J, et al. Factor analysis of machining parameters of fiber-reinforced polymer composites based on finite element simulation with experimental investigation[J]. The International Journal of Advanced Manufacturing Technology,2016,83(5-8):1113-1125. DOI: 10.1007/s00170-015-7592-2

[47] XU W X, ZHANG L C. Heat effect on the material removal in the machining of fibre-reinforced polymer compo-sites[J]. International Journal of Machine Tools and Manufacture,2019,140:1-11. DOI: 10.1016/j.ijmachtools.2019.01.005

[48] DONG K, ZHANG J J, JIN L M, et al. Multi-scale finite element analyses on the thermal conductive behaviors of 3D braided composites[J]. Composite Structures,2016,143:9-22. DOI: 10.1016/j.compstruct.2016.02.029

[49] ZHAI J J, CHENG S, ZENG T, et al. Thermo-mechanical behavior analysis of 3D braided composites by multiscale finite element method[J]. Composite Structures,2017,176:664-672. DOI: 10.1016/j.compstruct.2017.05.064

[50] HE C W, GE J R, ZHANG B B, et al. A hierarchical multiscale model for the elastic-plastic damage behavior of 3D braided composites at high temperature[J]. Composites Science and Technology,2020,196:108230. DOI: 10.1016/j.compscitech.2020.108230

[51] CHENG H, GAO J Y, KAFKA O L, et al. A micro-scale cutting model for UD CFRP composites with thermo-mechanical coupling[J]. Composites Science and Technology,2017,153:18-31. DOI: 10.1016/j.compscitech.2017.09.028

[52] DÍAZ-ÁLVAREZ J, OLMEDO A, SANTIUSTE C, et al. Theoretical estimation of thermal effects in drilling of woven carbon fiber composite[J]. Materials,2014,7(6):4442-4454. DOI: 10.3390/ma7064442

[53] SADEK A, SHI B, MESHREKI M, et al. Prediction and control of drilling-induced damage in fibre-reinforced polymers using a new hybrid force and temperature modelling approach[J]. CIRP Annals,2015,64(1):89-92. DOI: 10.1016/j.cirp.2015.04.074

[54] SORRENTINO L, TURCHETTA S, BELLINI C. In process monitoring of cutting temperature during the drilling of FRP laminate[J]. Composite Structures,2017,168:549-561. DOI: 10.1016/j.compstruct.2017.02.079

[55] BAO Y J, HAO W, GAO H, et al. Numerical and experimental investigations on temperature distribution of plain-woven aramid fiber-reinforced plastics composites with low-mild spindle velocities[J]. The International Journal of Advanced Manufacturing Technology, 2018, 99(1-4): 613-622.

[56] KUBHER S, GURURAJA S, ZITOUNE R. Coupled thermo-mechanical modeling of drilling of multi-directional polymer matrix composite laminates[J]. Composites Part A: Applied Science and Manufacturing,2022,156:106802. DOI: 10.1016/j.compositesa.2022.106802

[57] KEVIN K, GARRET E O. On the relationship between cutting temperature and workpiece polymer degradation during CFRP edge trimming[J]. Procedia CIRP,2016,55:170-175. DOI: 10.1016/j.procir.2016.08.041

[58] SORRENTINO L, TURCHETTA S, COLELLA L, et al. Analysis of thermal damage in FRP drilling[J]. Procedia Engineering,2016,167:206-215. DOI: 10.1016/j.proeng.2016.11.689

[59] MERINO-PÉREZ J L, ROYER R, AYVAR-SOBERANIS S, et al. On the temperatures developed in CFRP drilling using uncoated WC-Co tools Part I: Workpiece constituents, cutting speed and heat dissipation[J]. Composite Structures,2015,123:161-168. DOI: 10.1016/j.compstruct.2014.12.033

[60] LOJA M A R, ALVES M S F, BRAGANÇA I M F, et al. An assessment of thermally influenced and delamination-induced regions by composites drilling[J]. Composite Structures,2018,202:413-423. DOI: 10.1016/j.compstruct.2018.02.046

[61] TAKESHI Y, TAKAYUKI O, HIROYUKI S. Temperature measurement of cutting tool and machined surface layer in milling of CFRP[J]. International Journal of Machine Tools and Manufacture,2013,70:63-69. DOI: 10.1016/j.ijmachtools.2013.03.009

[62] 付鹏强, 蒋银红, 王义文, 等. CFRP制孔加工技术的研究进展与发展趋势[J]. 航空材料学报, 2019, 39(6):32-45. FU Pengqiang, JIANG Yinhong, WANG Yiwen, et al. Research progress and perspective trend of drilling technology for carbon fiber reinforced polymer[J]. Journal of Aeronautical Materials,2019,39(6):32-45(in Chinese).

[63] 蔡建国, 林正英. 碳纤维复合材料钻削温度对孔壁微观形貌的影响分析研究[J]. 机械设计与制造工程, 2017, 46(7):69-73. CAI Jianguo, LIN Zhengying. The influence analysis of carbon fiber reinforced composites drilling temperature on morphology of hole wall[J]. Machine Design and Manufacturing Engineering,2017,46(7):69-73(in Chinese).

[64] CHRISTOPHE R, GERARD P, FREDERIC R, et al. Tool wear monitoring and hole surface quality during CFRP drilling[J]. Procedia CIRP,2014,13:163-168. DOI: 10.1016/j.procir.2014.04.028

[65] 王春浩, 李鹏南, 李树健, 等. CFRP钻削加工过程的分层缺陷研究进展[J]. 兵器材料科学与工程, 2019, 42(6):109-115. WANG Chunhao, LI Pengnan, LI Shujian, et al. Research progress on delamination defect in CFRP cutting process[J]. Ordnance Material Science and Engineering,2019,42(6):109-115(in Chinese).

[66] GAO T, LI C H, WANG Y Q, et al. Carbon fiber reinforced polymer in drilling: From damage mechanisms to suppression[J]. Composite Structures,2022,286:115232. DOI: 10.1016/j.compstruct.2022.115232

[67] LUIGI S, DAVI S, MARCO D, et al. Effect of temperature on static and low velocity impact properties of thermoplastic composites[J]. Composites Part B: Engineering,2017,113:100-110. DOI: 10.1016/j.compositesb.2017.01.010

[68] XAVIER G, VINCENT P, FRÉDÉRIQUE T, et al. About the thermomechanical behaviour of a carbon fibre reinforced high-temperature thermoplastic composite[J]. Composites Part B: Engineering,2016,95:386-394. DOI: 10.1016/j.compositesb.2016.03.068

[69] UM H J, HWANG Y T, CHOI K H, et al. Effect of crystalli-nity on the mechanical behavior of carbon fiber reinforced polyethylene-terephthalate (CF/PET) composites considering temperature conditions[J]. Composites Science and Technology,2021,207:108745. DOI: 10.1016/j.compscitech.2021.108745

[70] SIDDHARTH J, KRISHNA R, BALAN A S S. A novel approach to predict the delamination factor for dry and cryogenic drilling of CFRP[J]. Journal of Materials Processing Tech,2018,262:521-531. DOI: 10.1016/j.jmatprotec.2018.07.026

[71] FU R, JIA Z Y, WANG F J, et al. Drill-exit temperature characteristics in drilling of UD and MD CFRP composites based on infrared thermography[J]. International Jour-nal of Machine Tools and Manufacture,2018,135:24-37. DOI: 10.1016/j.ijmachtools.2018.08.002

[72] GE J, CATALANOTTI G, FALZON B G, et al. Towards understanding the hole making performance and chip formation mechanism of thermoplastic carbon fibre/polyetherketoneketone (CF/PEKK) composite[J]. Composites Part B: Engineering, 2022, 234: 109752.

[73] MERINO-PÉREZ J L, ROYER R, MERSON E, et al. Influence of workpiece constituents and cutting speed on the cutting forces developed in the conventional drilling of CFRP composites[J]. Composite Structures,2016,140:621-629. DOI: 10.1016/j.compstruct.2016.01.008

[74] 伍俏平, 赵恒, 王煜, 等. 纤维增强复合材料制孔刀具研究现状与展望[J]. 兵器材料科学与工程, 2018, 41(6):113-118. WU Qiaoping, ZHAO Heng, WANG Yan, et al. Research status and perspectives of cutting tools for drilling fibre reinforced composites[J]. Weapon Materials Science and Engineering,2018,41(6):113-118(in Chinese).

[75] NORBERT G J, PAULO D, TIBOR S. Advanced cutting tools and technologies for drilling carbon fibre reinforced polymer (CFRP) composites: A review[J]. Composites Part A: Applied Science and Manufacturing,2019,125:105552. DOI: 10.1016/j.compositesa.2019.105552

[76] 陈浩, 李鹏南, 唐思文, 等. 麻花钻几何参数对碳纤维复合材料钻削性能的影响[J]. 宇航材料工艺, 2015, 45(3):63-67. CHEN Hao, LI Pengnan, TANG Siwen, et al. Effects of the geometrical parameter of twist drill on the drilling properties of carbon fiber reinforced plastics[J]. Aerospace Materials Technology,2015,45(3):63-67(in Chinese).

[77] KONG L H, GAO D, LU Y, et al. Novel orbital drilling and reaming tool for machining holes in carbon fiber-reinforced plastic (CFRP) composite laminates[J]. The International Journal of Advanced Manufacturing Technology,2020,110(3-4):977-988. DOI: 10.1007/s00170-020-05928-0

[78] XU J Y. A comparative evaluation of polycrystalline diamond drills in drilling high-strength T800 S/250 F CFRP[J]. Composite Structures,2014,117:71-82. DOI: 10.1016/j.compstruct.2014.06.034

[79] 伍俏平, 刘平, 邓朝晖, 等. 基于超细晶硬质合金钻头的AFRP钻削性能[J]. 复合材料学报, 2017, 34(10):2246-2253. WU Qiaoping, LIU Ping, DENG Zhaohui, et al. Drilling performance of ultrafine cemented carbide drill inmachining aramid fiber reinforce polymer composites[J]. Acta Materiae Compositae Sinica,2017,34(10):2246-2253(in Chinese).

[80] GAUGEL S, SRIPATHY P, HAEGER A, et al. A comparative study on tool wear and laminate damage in drilling of carbon-fiber reinforced polymers(CFRP)[J]. Composite Structures,2016,155:173-183. DOI: 10.1016/j.compstruct.2016.08.004

[81] XU J, EL MANSORI M. Experimental study on drilling mechanisms and strategies of hybrid CFRP/Ti stacks[J]. Composite Structures,2016,157:461-482. DOI: 10.1016/j.compstruct.2016.07.025

[82] REDOUANE Z, NICOLAS C, COLLOMBET F, et al. Temperature and wear analysis in function of the cutting tool coating when drilling of composite structure: In situ measurement by optical fiber[J]. Wear,2017, 376-377:1849-1858.

[83] 宿友亮, 孟志坚, 郜雪楠, 等. CFRP切削加工中刀具磨损研究进展[J/OL]. 表面技术: 1-20[2023-05-30]. . SU Youliang, MENG Zhijian, GAO Xuenan, et al. Research progress of tool wear in cutting of CFRP[J/OL]. Surface Technology: 1-20[2023-05-30]. (in Chinese).

[84] JIA Z Y, FU R, NIU B, et al. Novel drill structure for damage reduction in drilling CFRP composites[J]. International Journal of Machine Tools & Manufacture,2016,110:55-65.

[85] 陈燕, 葛恩德, 傅玉灿, 等. 碳纤维增强树脂基复合材料制孔技术研究现状与展望[J]. 复合材料学报, 2015, 32(2):3013-3016. CHEN Yan, GE Ende, FU Yucan, et al. Review and prospect of drilling technologies for carbon fiber reinforced polymer[J]. Acta Materiae Compositae Sinica,2015,32(2):3013-3016(in Chinese).

[86] CHEN W C. Some experimental investigations in the drilling of carbon fiber-reinforced plastic (CFRP) compo-site laminates[J]. International Journal of Machine Tools and Manufacture,1997,37(8):1097-1108. DOI: 10.1016/S0890-6955(96)00095-8

[87] WANG H J, SUN J, ZHANG D D, et al. The effect of cutting temperature in milling of carbon fiber reinforced polymer composites[J]. Composites Part A: Applied Science and Manufacturing,2016,91:380-387. DOI: 10.1016/j.compositesa.2016.10.025

[88] HOU G Y, LUO B, ZHANG K F, et al. Investigation of high temperature effect on CFRP cutting mechanism based on a temperature cont1 rolled orthogonal cutting experiment[J]. Composite Structures,2021,268:113967. DOI: 10.1016/j.compstruct.2021.113967

[89] 王福吉, 郭会彬, 贾振元, 等. 玻璃纤维增强聚丙烯复合材料制孔损伤[J]. 复合材料学报, 2018, 35(8):2023-2031. WANG Fuji, GUO Huibing, JIA Zhenyuan, et al. Drilling damage of glass fiber reinforced polypropylene compo-sites[J]. Acta Materiae Compositae Sinica,2018,35(8):2023-2031(in Chinese).

[90] XU J Y, HUANG X H, PAULO D J, et al. On the machining behavior of carbon fiber reinforced polyimide and PEEK thermoplastic composites[J]. Polymer Composites, 2020, 41(9): 3649-3663.

[91] 胡记强, 王兵, 张涵其, 等. 热塑性复合材料构件的制备及其在航空航天领域的应用[J]. 宇航总体技术, 2020, 4(4):61-70. HU Jiqiang, WANG Bing, ZHANG Hanqi, et al. Fabrication of thermoplastic composite components and their application in aerospace[J]. Astronautical Systems Engi-neering Technology,2020,4(4):61-70(in Chinese).

[92] 肇研, 孙铭辰, 张思益, 等. 连续碳纤维增强高性能热塑性复合材料的研究进展[J]. 复合材料学报, 2022, 39(9):4274-4285. DOI: 10.13801/j.cnki.fhclxb.20220809.008 ZHAO Yan, SUN Mingchen, ZHANG Siyi, et al. Advance in continuous carbon fiber reinforced high performance thermoplastic composites[J]. Acta Materiae Compositae Sinica,2022,39(9):4274-4285(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20220809.008

[93] 刘彬, 安卫龙, 倪楠楠. 国外热塑性复合材料工程应用现状[J]. 航空制造技术, 2021, 64(22):80-90. LIU Bing, AN Weilong, NI Nannan. Application status of thermoplastic composite materials in foreign engineering[J]. Aeronautical Manufacturing Technology,2021,64(22):80-90(in Chinese).

[94] 张加波, 张开虎, 范洪涛, 等. 纤维复合材料激光加工进展及航天应用展望[J]. 航空学报, 2022, 43(4):525735. DOI: 10.7527/j.issn.1000-6893.2022.4.hkxb202204010 ZHANG Jiabo, ZHANG Kaihu, FAN Hongtao, et al. Progress in laser processing of fiber composite materials and prospects of its applications in aerospace[J]. Acta Aeronautica et Astronautica Sinica,2022,43(4):525735(in Chinese). DOI: 10.7527/j.issn.1000-6893.2022.4.hkxb202204010

[95] WANG X M, LI C H, ZHANG Y B, et al. Vegetable oil-based nanofluid minimum quantity lubrication turning: Academic review and perspectives[J]. Journal of Manufacturing Processes,2020,59:76-97. DOI: 10.1016/j.jmapro.2020.09.044

[96] ZHANG Y B, LI H N, LI C H, et al. Nano-enhanced biolubricant in sustainable manufacturing: From processability to mechanisms[J]. Friction,2022,10(6):803-841. DOI: 10.1007/s40544-021-0536-y

[97] XU J Y, JI M, CHEN M, et al. Experimental investigation on drilling machinability and hole quality of CFRP/Ti6 Al4 V stacks under different cooling conditions[J]. The International Journal of Advanced Manufacturing Technology,2020,109(5-6):1527-1539. DOI: 10.1007/s00170-020-05742-8

[98] XU J Y, JI M, PAULO D J, et al. Comparative study of minimum quantity lubrication and dry drilling of CFRP/titanium stacks using TiAlN and diamond coated drills[J]. Composite Structures,2020,234(C):111727.

[99] ARJUN N, ALPER U, JAWAHIR I S. An investigation of process performance when drilling carbon fiber reinforced polymer (CFRP) composite under dry, cryogenic and MQL environments[J]. Procedia Manufacturing,2020,43(C):551-558.

[100] GÜLTEKIN B, YORUK A S, UGUR K, et al. Impact of cryogenic condition and drill diameter on drilling performance of CFRP[J]. Applied Sciences, 2017, 7(7): 667.

[101] MARCELO F B, IGOR B, FRANCISCO DE A T, et al. Cryogenic drilling of carbon fibre reinforced thermoplastic and thermoset polymers[J]. Composite Structures,2020,251:112625. DOI: 10.1016/j.compstruct.2020.112625

[102] NAVNEET K, FRANCI P, CHETAN A, et al. Measurement and evaluation of hole attributes for drilling CFRP composites using an indigenously developed cryogenic machining facility[J]. Measurement,2020,154(C):107504.

[103] 王晋宇, 刘海波, 刘阔, 等. 芳纶纤维增强树脂复合材料液氮冷却钻孔试验[J]. 复合材料学报, 2020, 37(1):89-95. WANG Jinyu, LIU Haibo, LIU Kuo, et al. Experiment of liquid nitrogen cooling drilling test of aramid fiber-reinforced polymer composites[J]. Acta Materiae Compositae Sinica,2020,37(1):89-95(in Chinese).

[104] RODRÍGUEZ A, CALLEJA A, DE LACALLE L N LÓPEZ, et al. Drilling of CFRP-Ti6 Al4 V stacks using CO2-cryogenic cooling[J]. Journal of Manufacturing Processes,2021,64:58-66. DOI: 10.1016/j.jmapro.2021.01.018

[105] 邹凡, 王贤锋, 张烘州, 等. 超临界二氧化碳低温铣削CFRP复合材料试验研究[J]. 航空制造技术, 2021, 64(19):14-19. ZOU Fan, WANG Xianfeng, ZHANG Hongzhou, et al. Experimental investigation on milling characteristic of CFRP composites under supercritical carbon dioxide based cryogenic environment[J]. Aeronautical Manufacturing Technology,2021,64(19):14-19(in Chinese).

[106] 王福吉, 成德, 赵猛, 等. 冷却空气流向对CFRP制孔刀具磨损及孔质量的影响[J]. 复合材料学报, 2019, 36(2):410-417. WANG Fuji, CHENG De, ZHAO Meng, et al. Influence of cooling air direction on tool wear and hole quality in CFRP drilling[J]. Acta Materiae Compositae Sinica,2019,36(2):410-417(in Chinese).

[107] IQBAL A, ZHAO G L, ZAINI J, et al. CFRP drilling under throttle and evaporative cryogenic cooling and micro-lubrication[J]. Composite Structures,2021,267:113916. DOI: 10.1016/j.compstruct.2021.113916

[108] 李远霄, 焦锋, 张世杰, 等. 高低频复合振动钻削CFRP/钛合金叠层结构试验[J]. 航空学报, 2021, 42(10):524802. LI Yuanxiao, JIAO Feng, ZHANG Shijie, et al. Experiment on high and low frequency compound vibration-assisted drilling of CFRP/titanium alloy laminated structure[J]. Acta Aeronautica et Astronautica Sinica,2021,42(10):524802(in Chinese).

[109] 彭振龙, 张翔宇, 张德远. 航空航天难加工材料高速超声波动式切削方法[J]. 航空学报, 2022, 43(4):52558. DOI: 10.7527/j.issn.1000-6893.2022.4.hkxb202204007 PENG Zhenlong, ZHANG Xiangyu, ZHANG Deyuan. High-speed ultrasonic vibration cutting for difficult-to-machine materials in aerospace field[J]. Acta Aeronautica et Astronautica Sinica,2022,43(4):52558(in Chinese). DOI: 10.7527/j.issn.1000-6893.2022.4.hkxb202204007

[110] 赵波, 李鹏涛, 张存鹰, 等. 超声振动方向对TC4钛合金铣削特性的影响[J]. 航空学报, 2020, 41(2):62330. ZHAO Bo, LI Pengtao, ZHANG Cunying, et al. Effect of ultrasonic vibration direction on milling characteristics of TC4 titanium alloy[J]. Acta Aeronautica et Astronautica Sinica,2020,41(2):62330(in Chinese).

[111] SADEK A, ATTIA M H, MESHREKI M, et al. Characterization and optimization of vibration-assisted drilling of fibre reinforced epoxy laminates[J]. CFRP Annals-Manufacturing Technology,2013,62(1):91-94. DOI: 10.1016/j.cirp.2013.03.097

[112] OLIVER P, EKKARD B. Tool wear analyses in low frequency vibration assisted drilling of CFRP/Ti6 Al4 V stack material[J]. Procedia CIRP,2014,14(14):142-147.

[113] 张世杰, 焦锋, 李远霄, 等. 碳纤维复合材料/钛合金叠层结构高低频复合振动钻削试验[J]. 机械设计与研究, 2020, 36(6):120-124, 129. ZHANG Shijie, JIAO Feng, LI Yuanxiao, et al. Experimental study on high and low frequency compound vibration drilling of carbon fiber reinforced plastic/titanium alloy laminated structure[J]. Machine Design and Research,2020,36(6):120-124, 129(in Chinese).

[114] 陈冒风, 张臣, 方军, 等. 振动辅助钻削对CFRP/钛合金叠层结构孔径阶差影响规律实验研究[J]. 宇航材料工艺, 2022, 52(3):88-93. CHEN Maofeng, ZHANG Cheng, FANG Jun, et al. Experimental study on the influence of vibration-assisted drilling on CFRP/titanium alloy laminated structures[J]. Aerospace Materials Technology,2022,52(3):88-93(in Chinese).

[115] 谢大叶, 孙忠海, 刘标. CFRP/Ti叠层材料低频振动辅助钻削时不同参数对刀具磨损的影响[J]. 工具技术, 2021, 55(9):88-91. XIE Daye, SUN Zhonghai, LIU Biao. Effects of different parameters on tool wear during low frequency vibration assisted drilling of CFRP/Ti laminates[J]. Tool Technology,2021,55(9):88-91(in Chinese).

[116] LIU Y, LI Q N, QI Z C, et al. Defect suppression mecha-nism and experimental study on longitudinal torsional coupled rotary ultrasonic assisted drilling of CFRPs[J]. Journal of Manufacturing Processes,2021,70:177-192. DOI: 10.1016/j.jmapro.2021.08.042

[117] LIU Y, PAN Z T, LI Q N, et al. Experimental and scale-span numerical investigations in conventional and longitudi-nal torsional coupled rotary ultrasonic assisted drilling of CFRPs[J]. The International Journal of Advanced Manufacturing Technology,2022,119:1707-1724. DOI: 10.1007/s00170-021-08286-7

[118] 李树健, 陈蓉, 李常平, 等. 一种超声超低温冰层支撑辅助CFRP钻削方法[J]. 复合材料学报, 2022, 39(3):1044-1054. LI Shujian, CHEN Rong, LI Changping, et al. A method of CFRP drilling assisted by ultrasonic, cryogenic tempera-ture and ice support[J]. Acta Materiae Compositae Sinica,2022,39(3):1044-1054(in Chinese).

-

期刊类型引用(4)

1. 陶能如,蔡颂,陈根余,肖铮铭,韦怡. 碳纤维复合材料皮秒激光旋切制备大孔工艺. 光学学报. 2024(14): 218-230 .  百度学术

百度学术

2. 束静,廖文和,郑侃,董松,孙连军. 旋转超声加工碳纤维复合材料研究现状与展望. 航空学报. 2024(13): 114-138 .  百度学术

百度学术

3. 李玉峰,赵积鹏,张海,于斌. 高低温对碳纤维/环氧树脂复合材料高压气瓶的性能影响. 工程塑料应用. 2024(09): 119-125 .  百度学术

百度学术

4. 邹喆. 镁合金层合板麻花钻削工艺对轴向力的影响. 山西冶金. 2024(10): 63-64+67 .  百度学术

百度学术

其他类型引用(2)

-

目的

明晰纤维增强复合材料(Fiber Reinforced Composites,简称FRC)切削热的形成机制、精确测量方法、降低钻削热和减少制孔损伤等研究,无论是对进行钻削机制的研究、刀具磨损机制的探讨,还是刀具的设计与制造、加工参数的选择及加工表面质量的控制等均起着至关重要的作用。本文对国内外FRC钻削过程相关研究进行系统性的整理与分析,概述了近年来关于FRC钻削过程产生的切削热的研究,主要包含钻削热理论研究、钻削热对加工质量的影响研究、温度的影响因素与辅助加工控制钻削热方法研究三个方面的分析与总结,最后探讨并总结了当前对FRC钻削热研究存在的问题及今后研究的发展趋势。

方法通过对近年来FRC钻削热相关研究文献的整理归纳,将全文的综述研究内容主要做如下分类处理:1)基于数学推导与有限元模拟的钻削热理论研究,其内容主要包含了钻削热形成机制、热传导与损伤预测和基于数值模拟分析的切削热分析;2)钻削热对加工质量的影响研究,其内容主要为钻削温度对毛刺、分层、表面粗糙度、撕裂等损伤的影响;3)钻削热的影响因素研究,其内容主要为刀具对钻削温度影响、加工参数对钻削温度影响、材料性能等其他因素对钻削温度影响;4)钻削温度的辅助控制方法研究,其内容主要为最小润滑辅助加工控制钻削温度、低温冷却辅助钻削加工控制钻削温度、振动辅助钻削加工控制钻削温度。

结果从近年来FRC钻削热相关研究文献可以看出,研究钻削热的方法主要有试验、解析法和基于数值模拟的有限元法(Finite Element Method,简称FEM)。1)关于FRC钻孔切削热理论的研究内容主要集中在通过仿真及实验相结合的方法探究UD-FRC的切削去除机制、切削力、切削温度以及切屑的宏观形貌观察上。其中,切削热形成机制、钻削热分配问题、温度场模型是主要研究内容;2)为了获取更准确的FRC钻削热数据,对FRC钻削测温方法主要有刀具-工件热电偶法、工件嵌入热电偶法和热像仪测温法三种方法;3)在钻削热对制孔质量影响研究方面,已经有大量研究说明了钻削温度对毛刺、分层、表面粗糙度、撕裂等损伤的影响;4)在钻削温度影响因素研究方面,进给量和转速是能够显著改变钻削温度、影响制孔质量的主要影响因素,而改变刀具结构、刀具材料、刀具涂层和辅助加工方法则是有效降低钻削温度的途径;5)能够降低钻削温度的辅助加工技术主要有最小润滑辅助钻削加工、低温冷却辅助钻削加工和振动辅助钻削加工。

结论虽然国内外学者在FRC钻孔加工过程中热量的产生及其控制策略方面开展了一定的研究,但着眼于有效提高加工质量和优化加工工艺方面仍存在一定的挑战,具体可描述为:1)FRC的钻削损伤形成过程是复杂的热力耦合作用形成的,需建立完善的考虑热力耦合作用的FRC钻削损伤形成理论;2)由于计算机的算力有限,对FRC钻削过程的能够较精准模拟机械损伤或热传导行为,需要完善的理论来指导多尺度的FRC热力耦合钻削模型的建立。3)FRC的钻削损伤形成受多个因素影响,需要建立“刀具-工艺-控制策略-数据库”一体化研究方法,实现刀具、工艺参数和辅助控制方法的快速选择。4)当前研究中采用单一的辅助FRC钻削的加工技术存在一定局限性,需要优化新型复合振动辅助加工策略与新工艺相互结合的钻削热控制方法。

下载:

下载: