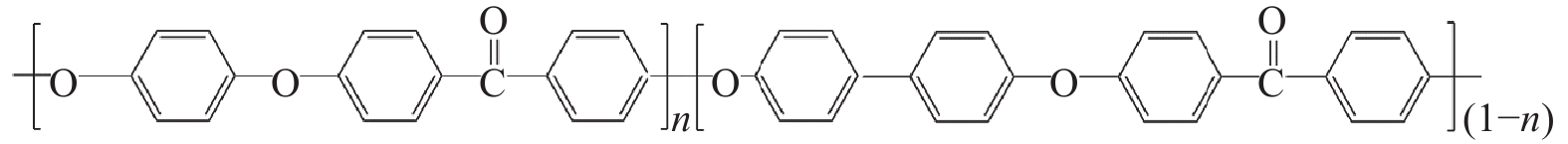

Effect of melt viscosity and impact energy of poly aryl ether ketone (PAEK) resins on the impact damage behavior of their composites

-

摘要: 采用两种不同熔体黏度的国产高性能聚芳醚酮树脂(PAEK-L、PAEK-H)及国产T300级碳纤维(SCF35),制备了碳纤维增强聚芳醚酮(SCF35/PAEK)热塑性复合材料,研究了树脂基体黏度及冲击能量对复合材料冲击性能的影响,采用Micro-CT表征了准静态压入试样的内部形貌,研究了复合材料的冲击损伤机制。结果显示流动性较低的PAEK-L树脂基复合材料比流动性较高的PAEK-H树脂基复合材料具有更高的抗冲击性能,SCF35/PAEK-L复合材料体系冲击能量的损耗比SCF35/PAEK-H复合材料体系低~7%,其损伤面积小~90%,在6.67 J/mm的冲击能量下,其冲击后压缩强度达到~307 MPa,比SCF35/PAEK-H复合材料体系冲击后压缩强度(205 MPa)高~50%;SCF35/PAEK-L复合材料中表面凹坑的深度随冲击能量的增加呈增加的趋势,冲击后压缩强度随冲击能量的增加呈降低的趋势,当复合材料的表面凹坑深度达到1.0 mm左右,即达到勉强目视可见冲击损伤(BVID)门槛值时,剩余压缩强度为~268 MPa。准静态压入实验结果显示,SCF35/PAEK-L复合材料受到冲击后表面凹坑主要由树脂基体的塑性变形及纤维屈曲造成,表面凹坑周围的裂纹由压缩应力造成,冲击过程中试样背面的纤维在拉伸应力的作用下发生断裂,试样底层的纤维在剪切力的作用下萌生层间裂纹,随着试样挠曲变形程度的增加,纤维的断裂程度增加且层间裂纹逐渐扩展。

-

关键词:

- 聚芳醚酮(PAEK) /

- 热塑性复合材料 /

- 低速冲击 /

- 勉强目视可见冲击损伤(BVID) /

- 冲击后压缩

Abstract: Carbon fiber reinforced poly aryl ether ketone (SCF35/PAEK) thermoplastic composites were prepared using two different melt viscosities of domestic high performance poly aryl ether ketone resins (PAEK-L and PAEK-H) and domestic T300 grade carbon fibers (SCF35), and the effects of resin matrix viscosity and impact energy and impact energy on the impact properties of the composites were investigated. In addition, the internal morphology of quasi-static indentation specimens was characterized by Micro-CT to study the impact damage mechanism of the composites. The results show that PAEK-L resin matrix composite with lower fluidity has higher impact resistance than PAEK-H resin matrix composite with higher fluidity. The impact energy loss of the SCF35/PAEK-L composite system is ~7% lower than that of the SCF35/PAEK-H composite system, its damage area is ~90% smaller, and its compression strength after impact reaches ~307 MPa at an impact energy of 6.67 J/mm, which is ~50% higher than that of SCF35/PAEK-H composite system (205 MPa). The depth of surface dent in SCF35/PAEK-L composites tends to increase with the increase of impact energy, and the compression strength after impact tends to decrease with the increase of impact energy, and the compression strength after impact is ~268 MPa when the depth of surface dent of the composites reaches about 1.0 mm, i.e., when the threshold value of barely visible impact damage (BVID) is reached. In addition, the results of quasi-static indentation tests show that the surface dent of SCF35/PAEK-L composite after impact is mainly caused by plastic deformation of the resin matrix and fiber flexure, the cracks around the surface dent are caused by compressive stress, the fiber on the back side of the specimen is fractured under the action of tensile stress during the impact process, the fiber on the bottom layer of the specimen sprouts interlayer cracks under the action of shear force, with the increase of flexural deformation of the specimen, the degree of fiber fracture increases and the interlayer cracks gradually expand. -

近年来,柔性压力传感器凭借其轻量、柔韧、生物相容等特点在生物医疗[1]、电子皮肤[2]、人机交互[3]、柔性机器人[4]等领域具有广泛的应用前景。根据传感原理,柔性压力传感器主要分为电阻式[5]、电容式[6]、压电式[7]、摩擦电式[8]4种。而柔性电容式压力传感器因其结构简单、信号稳定,且能与静态力测量兼容及低功耗优点,得到了研究人员的广泛关注[9]。但在电容式柔性压力传感器的性能优化研究中存在一个共性问题,即高灵敏度与宽检测范围之间的制约,如何解决两者之间的矛盾仍是亟需解决的瓶颈问题。

目前,研究人员在介电层结构方面主要通过设计介电层的表面微结构或介电层体相多孔结构,来提高柔性电容压力传感器的灵敏度和检测范围。一般,在介电层表面设计金字塔形[10]、半球形[11]、荷叶表面乳突[12]等微纳结构。但制作这些微纳结构一般需要光刻[13]、3D打印[14]和仿生模板复刻[15]等技术,存在工艺复杂、成本高、耗时长等缺陷。并且由于表面微纳结构在压力作用下的变形易快速达到饱和状态,只能提高一部分检测量程。而介电层的体相多孔结构,由于本身就存在孔隙,在压力作用下先后发生孔隙减小、孔壁接触和孔壁进一步挤压过程,延缓了形变达到饱和状态的过程,从而提高了检测量程。因此相较于表面微纳结构,多孔结构在传感器的设计中存在显著优势。而在介电层材料方面,研究人员主要提出在介电层中添加高介电常数、低介电损耗填料的方法,以形成复合介电层,提高介电层的有效介电常数,从而提高灵敏度和检测范围。通常,可以分为导电填料(炭黑(CB)[16]、碳纳米管(CNTs)[17]、石墨烯(GO)[18]等),压电填料(聚偏氟乙烯(PVDF)[19]、钛酸钡(BTO)[20]等)和磁性填料(金属镍(Ni)[21]等)。

本文针对高灵敏度、宽检测范围和制作成本不能兼顾的问题,利用模板组装法制备出了一种多孔结构的电容式柔性压力传感器。首先,在基底材料上选择了具有价格低廉、质量轻、弹性好、孔隙率高、比表面积大等特点的聚氨酯(PU)海绵。其次,在填料的选择上,分别选择了导电填料炭黑(Carbon black,CB)和压电填料钛酸钡(BaTiO3,BTO),由于CB不仅具有良好的附着能力,还可以改善压力下介电常数的变化,从而提高传感器的性能[22]。而选择BTO,则是因其具有高介电常数和低介电损耗特性。两者都可以利用范德华力和静电引力附着在PU骨架上。最后,利用PU海绵现有的多孔结构作为模板,采用超声浸渍涂覆的方法将CB和BTO附着在海绵骨架上,从而制备出高的有效介电常数及低介电损耗的CB-BTO/PU海绵体。并以此为介电层组装成电容式柔性压力传感器。同时,还对该压力传感器进行了性能测试和应用范围的研究,解决了在大量程范围压力信号检测中测量量程与灵敏度之间的矛盾。

1. 实验材料及方法

1.1 CB-BTO/PU海绵柔性电容式压力传感器的制备

前处理:将聚氨酯海绵(PU,大城好五金店,优质高密度)剪切成10 mm×10 mm×3 mm的立方体,用无水乙醇(Ethanol absolute,太仓新太酒精)与去离子水(浙江南岱实业)交替清洗2次,每次10 min,以除去PU海绵表面的杂质,并在恒温培养箱中干燥1 h,以待后用。

CB-BTO/PU海绵柔性电容式压力传感器的制备过程:将炭黑(CB,美国CABOT,粉末,~15 nm)与钛酸钡(BTO,麦克林,99.9%metals basis,粉末,~100 nm)按照质量比为2.5∶100、5∶100、7.5∶100、10∶100分别加入一定量无水乙醇中,用磁力搅拌器(ZNCL-BS,山东元创仪器)进行搅拌,30 min后搅拌停止,分别往各悬浮液中加入前处理后的PU海绵,随后在超声波细胞破碎仪(LC-JY98-IIIDN,上海力辰邦西仪器科技)中进行超声分散,超声过程中产生的局部高温和超声波,其一可大幅度地减弱CB和BTO纳米颗粒之间的作用力,防止纳米颗粒团聚;其二是让悬浮液中的纳米颗粒不断地无规则运动,均匀地分散在PU海绵内部。超声1 h后,将附着有CB与BTO的PU海绵放入80℃的恒温培养箱(XMTA-600,余姚市科洋仪表)中干燥1 h,随后将干燥完成的PU海绵进行机械压缩20 min,以达到海绵的老化处理和将附着不牢的纳米颗粒去除,当压缩过程中海绵不再脱落纳米颗粒和用纸擦拭海绵表面不再出现灰色污渍时,证明得到结构稳定的CB-BTO/PU海绵三维复合材料。最后在CB-BTO/PU海绵三维复合材料的两端贴附铜箔电极,并用聚对苯二甲酸乙二醇酯(Polyethlene terephthalate,PET)薄膜封装得到CB-BTO/PU海绵柔性电容式压力传感器。具体制备流程如图1所示。

1.2 表征方法

采用扫描电子显微镜(SEM,日立SU8020)对CB-BTO/PU复合材料的形貌进行表征。用能谱分析仪(EDS,美国edax)探究CB-BTO/PU复合材料中的碳(C)、钛(Ti)和钡(Ba)元素的分布。将CB-BTO/PU海绵固定在样品台上,然后放入真空镀膜仪内喷金,喷金结束后将样品置于SEM扫描电镜下,观察海绵断面形貌。电子加速电压为5.0 kV,工作距离为13.6 mm,上下探头同时成像;然后用扫描电镜上配置的EDS对海绵上的元素成分和含量进行观察分析。

压力传感器的传感性能测试主要通过万能试验机(ZQ-950B,东莞市智取精密仪器)、LCR测试仪(TH2830,上海双旭电子)等完成。将传感器放置到万能试验机的下端压头平台上,通过控制上端压头的位移,以10 mm/min的恒定速度将0~300 kPa压力施加于传感器表面上;将传感器电极板引出的导线连接LCR测试仪(工作电压1 V),使用远端接口模式连接到PC,实时测量传感器的电容信号。

2. 结果与讨论

2.1 CB-BTO/PU海绵传感器的表征与分析

图2(a)为PU海绵浸渍前后实物图,浸渍前PU海绵骨架清晰,孔隙分布均匀;浸渍后PU海绵由淡黄色转为黑灰色,这是CB与BTO有效沉积的结果。将制备的CB-BTO/PU海绵完全压缩,当撤去外力之后,仍能恢复到初始状态,展现了该材料具有很好的柔韧性和弹性,如图2(b)、图2(c)所示。图2(d)~图2(f)为CB-BTO/PU海绵骨架的断面SEM图像。可以看出,PU海绵骨架结构明显,孔隙清晰,且随着图像的放大,能看到CB与BTO(呈颗粒状,少量团聚)均匀地附着在PU海绵骨架上。从EDS能谱分析表明,Ba (图2(g))、Ti (图2(h))、C (图2(i))3种元素在PU海绵均匀分布,再一次验证了CB与BTO在PU海绵骨架上分布均匀。

![]() 图 2 CB-BTO/PU海绵的形貌与结构表征:(a)浸渍前后PU海绵实物图;((b), (c)) PU海绵压缩的初始状态和压缩状态图;((d)~(f)) PU海绵断面SEM图像;((g)~(i)) Ba元素、Ti元素、C元素的EDS分布图Figure 2. Morphology and structure characterization of CB-BTO/PU sponge: (a) Physical diagram of PU sponge before and after impregnation; ((b), (c)) Initial compression state and compression state diagrams of PU sponge respectively; ((d)-(f)) SEM images of PU sponge sections; ((g)-(i)) EDS distribution diagrams of Ba element, Ti element and C element respectively

图 2 CB-BTO/PU海绵的形貌与结构表征:(a)浸渍前后PU海绵实物图;((b), (c)) PU海绵压缩的初始状态和压缩状态图;((d)~(f)) PU海绵断面SEM图像;((g)~(i)) Ba元素、Ti元素、C元素的EDS分布图Figure 2. Morphology and structure characterization of CB-BTO/PU sponge: (a) Physical diagram of PU sponge before and after impregnation; ((b), (c)) Initial compression state and compression state diagrams of PU sponge respectively; ((d)-(f)) SEM images of PU sponge sections; ((g)-(i)) EDS distribution diagrams of Ba element, Ti element and C element respectively2.2 CB-BTO/PU海绵传感器的传感机制与性能分析

CB-BTO/PU 海绵压力传感器可视为平行板电容器[23],在外界压力作用下,平行板电容器的两极板之间的相对距离和介电层的相对介电常数都发生了改变,从而引起了电容的变化。传感器的电容的计算公式为

C=ε0εrAd (1) 其中:C是电容器的电容;ε0是真空介电常数;εr是介电层的相对介电常数;A是上下电极板的有效重叠表面积;d是上下两电极之间的距离。

CB-BTO/PU 海绵压力传感器的传感机制为:在没有外界压力作用的初始状态下,PU海绵骨架表面附着CB和BTO,空气充满了骨架空隙,介电层具有较低的相对介电常数εr。而当受到外界压力作用以后,介电层被压缩,上下两电极之间的距离d减小,并且PU海绵微孔开始闭合,介电层中的空气被排出,εr增加,导致电容C随着压力的增加而不断增大。

对于CB-BTO/PU 海绵介电层来说,可以根据一般的Lichtenecker 混合规则[24],求出有效的相对介电常数。有效相对介电常数的计算公式为

lnεr=Vairlnεair+VCBlnεCB+VBTOlnεBTO+VPUlnεPU (2) 其中:Vair、VCB、VBTO与VPU分别为复合材料中空气、炭黑、钛酸钡与聚氨酯海绵所占的体积比;εair、εCB、εBTO与εPU分别为空气、炭黑、钛酸钡与聚氨酯海绵的介电常数。

由上式可知,当介电层受力被压缩时,空气被逐渐排出,其他三相所占的体积比逐渐增大,介电层的相对介电常数也逐渐增大,因此电容传感器的电容才能逐渐增大。

通过制备CB与BTO不同质量比的CB-BTO/PU 海绵传感器,进行传感性能测试分析,从而对传感器进行工艺参数优化。

不同配比的传感器性能也不尽相同,而质量比为mCB:mBTO=5:100的CB-BTO/PU海绵传感性能是最好的,如图3所示。从图上可知,随着CB的含量增大,传感器的灵敏度逐渐增大然后逐渐减小并趋于一致。笔者认为,一方面,CB表面具有大量的羟基、羰基、酸基和吸附水分子等官能团[25],而PU海绵中除了氨基甲酸酯官能团外,还可含有醚、酯、脲、缩二脲、脲基甲酸酯等基团[26]。这些官能团可以使CB和BTO附着在PU海绵上,并且随着CB的含量增加,附着在PU海绵上的CB与BTO也越来越多,而CB作为导电填料既可以强化BTO在PU海绵上的附着能力,还能在PU海绵上形成零星微电容,提高复合材料的介电常数,进而提高器件性能。但当CB含量超过某阈值后,虽然能让更多的BTO附着在PU海绵上,但CB附着在PU海绵上的含量也会逐渐增大,随着外界压力的作用下,CB之间相互接近逐渐形成渗流和遂穿,从而形成部分导电通路降低电容,这与田玉玉等[22]分析的导电填料在介电层中的作用结果一致。另一方面,PU海绵的空隙是有限的,而随着填料的增加,附着在PU海绵上的填料逐渐变缓,并趋于一致。上述原因解释了为什么会出现随着CB含量的增加,传感器的灵敏度会先增加后减小并趋于一致的结果。

灵敏度是评价压力传感器对压力变化敏感程度的重要性能指标,电容式压力传感器的灵敏度公式为

S=(C−C0)/C0ΔP=ΔC/C0ΔP (3) 其中: ΔC是施加压力后的电容变化量;C0是不施加压力时的初始电容值;ΔP是压力变化量;ΔC/C0为电容信号的相对变化量;C是压缩过程中传感器的实时电容。

通过上述不同配比的介电层组装的传感器的压力-电容响应曲线,可以看出,CB与BTO质量比为5∶100的海绵介电层的传感器灵敏度是最高。从图4 可以看出,CB-BTO/PU 海绵压力传感器在较小的压力范围内(0~10 kPa)的灵敏度平均为

0.6311 kPa−1,而随着压力的不断增加,在10~140 kPa范围内传感器的平均灵敏度有所增加,达到了0.7911 kPa−1。在这两个压力范围内灵敏度快速增加的原因是,越来越大的压力,使介电层不断压缩,两电极板的相对距离逐渐变小,而海绵介电层中的空气也逐渐排出,使介电层的相对介电常数迅速变大,这两方面都能增大电容的变化量,因此灵敏度在这两个压力范围内快速提升。在较大的压力范围内(140~300 kPa)的平均灵敏度为0.1395 kPa−1,相较于前两个压力范围的灵敏度,较大的压力范围内(140~300 kPa)的灵敏度有所降低,但也达到了0.1395 kPa−1,这是由于随着压力的增大,介电层的变化趋于饱和,灵敏度也随之下降。线性度值越小,表明拟合的曲线与实测的曲线之间的偏差越小[27]。如图4所示,对压力传感器进行了线性度分析,结果表明,在0~10 kPa、10~140 kPa、140~300 kPa这3个压力范围内的线性度分别为5.3%、1.4%、0.8%。该结果也从侧面证明了传感器在3个压力范围的灵敏度拟合更加可靠和准确。

综上所述,从灵敏度与线性度可以得出,CB-BTO/PU 海绵压力传感器在宽的压力范围内能保持高的灵敏度,具备良好的传感性能。

此外,与近年来相关领域文献中报道的柔性电容式压力传感器性能比较如表1所示[26, 28-30]。

表 1 CB-BTO/PU传感器与文献报道性能比较Table 1. Performance comparison between CB-BTO/PU sensor and literature reportMaterials Sensitivity Detection range/kPa Ref. TiO2@PU 0.93 kPa−1 (0-0.37 kPa)

0.079 kPa−1 (0.37-2.83 kPa)

0.02 kPa−1 (2.83-10 kPa)0-10 [26] CCTO@PU 0.73 kPa−1 (0-1.6 kPa)

0.135 kPa−1 (1.6-22.8 kPa)

0.026 kPa−1 (22.8-100 kPa)0-100 [28]

GO/CNTs@TPU0.05777 kPa−1 (0-5 kPa)

0.33213 kPa−1 (5-60 kPa)0-60 [29]

GNPs/MWCNTs/SR/PS0.062 kPa−1 (0-0.3 kPa)

0.033 kPa−1 (0.3-4.5 kPa)0-4.5 [30] CB-BTO/PU 0.6311 kPa−1 (0-10 kPa)0.7911 kPa−1 (10-140 kPa)0.1395 kPa−1 (140-300 kPa)0-300 This work Notes: CCTO—Calcium copper titanate; GO—Graphene oxide; CNTs—Carbon nanotube; TPU—Thermoplastic polyurethane; GNPs—Graphene nanosheets; MWCNTs—Carboxyl-functionalized multiwalled carbon nanotubes; SR—Silicone rubber; PS—Commercial polyurethane sponge. 对于传感器性能而言,传感器的响应时间/恢复时间、最小压力检测极限、稳定性和耐久性等性能指标也是评估传感器的重要参数。如图5(a)所示,通过在传感器加/卸载100 g砝码测量传感器的响应与恢复时间。结果表明,响应时间与恢复时间分别为0.375 s、0.125 s,响应时间略长是由于PU海绵被快速压缩形变后在短时间内仍然会持续形变才能到达最终的稳定状态,而当卸载砝码时海绵却能快速恢复原状,因此恢复时间较短。但响应时间和恢复时间都接近于人体对压力的响应时间400 ms[31],因此该传感器在人体运动监测具备一定的可行性。如图5(b)所示,为了检测传感器的最小压力测量极限,将一颗质量为0.25 g (~24.5 Pa)的小磁子放置在传感器表面,通过观察加载和卸载前后的电容变化,检测出传感器的最低压力极限。根据Zang等[32]对压力范围的分类方法,该传感器的最低检测限处于微压范围内(1 Pa~1 kPa),表明了传感器在微小压力检测方面具有潜在的应用价值。稳定性是评估压力传感器维持稳定工作的重要参数。如图5(c)所示,为了评估该传感器的输出可靠性、稳定性和重复性,分别在不同的压力下对传感器进行了响应特性测试,电容变化随着压力的增加而增加,且能在压力撤销以后恢复到初始值,这说明了该传感器具有良好的分辨率及测压的应用潜力。此外,还对传感器进行了在200 kPa压力下的

2500 次循环响应恢复测试。如图5(d)所示,在上千次的测试中,传感器的电容变化率幅值无明显变化,电容变化率曲线波形保持了良好的一致,证明了该传感器具有良好的重复性和稳定性。还与近年来相关领域文献中报道的柔性传感器耐久性进行了比较,如表2所示[33-35]。2.3 CB-BTO/PU 海绵压力传感器的应用研究

通过上述对传感器的一系列力学传感性能检测,验证了基于CB-BTO/PU海绵柔性电容式传感器具有高灵敏度、宽检测范围等较优异的传感性能。在此基础上,对传感器的应用方面进行了拓展。首先,是对传感器在小压力范围内的应用,将传感器安装在鼠标上如图6(a)所示,通过对鼠标的单击快慢和双击时的力度变化,输出不同的电容信号。结果显示,对鼠标的单击力度的不相同,所输出的信号峰值也不相同,并且随着对鼠标的单击速度加快,所得到的电容信号也会越来越密集;而双击鼠标时,则会得到连续输出的信号。

![]() 图 6 CB-BTO/PU海绵压力传感器在各种变形信号监测中的应用:(a)手指点击鼠标上传感器的响应(0~5 kPa);(b)指关节弯曲的传感器响应(0~7 kPa);(c)抓取不同质量玻璃杯的传感器响应(0~40 kPa);(d)足底压力和步态监测的传感器响应(0~110 kPa)Figure 6. Application of CB-BTO/PU sponge pressure sensor in monitoring various deformation signals: (a) Response of sensor when finger clicks the mouse (0-5 kPa); (b) Sensor response of knuckle bending (0-7 kPa); (c) Sensor responses for grabbing glasses with different qualities (0-40 kPa); (d) Sensor response of plantar pressure and gait monitoring (0-110 kPa)

图 6 CB-BTO/PU海绵压力传感器在各种变形信号监测中的应用:(a)手指点击鼠标上传感器的响应(0~5 kPa);(b)指关节弯曲的传感器响应(0~7 kPa);(c)抓取不同质量玻璃杯的传感器响应(0~40 kPa);(d)足底压力和步态监测的传感器响应(0~110 kPa)Figure 6. Application of CB-BTO/PU sponge pressure sensor in monitoring various deformation signals: (a) Response of sensor when finger clicks the mouse (0-5 kPa); (b) Sensor response of knuckle bending (0-7 kPa); (c) Sensor responses for grabbing glasses with different qualities (0-40 kPa); (d) Sensor response of plantar pressure and gait monitoring (0-110 kPa)该传感器还可以监测人体的小规模活动,如图6(b)所示,将传感器安装在手指的关节处,监测手指关节在不同弯曲角度时的电容相对变化值。当手指关节的弯曲角度变大时,对传感器的压缩形变也越来越大,而传感器所输出的电容信号值也不断变大,因此通过传感器的电容相对变化,可以精确地区分手指的弯曲程度。

除了传感器在上述小压力范围内的应用以外,该传感器还能应用于较大的压力场景,如图6(c)所示,通过拿起和放下侧面安装有传感器的玻璃杯(重600 g),传感器的电容幅值也会产生相应的变化,而随着玻璃杯中水的质量不断增加(50 g、100 g、150 g、200 g、250 g、300 g),其电容的相对变化也不断变大,并且当玻璃杯被拿起和放下时,传感器都能产生稳定的信号。在图6(d)中,将传感器连接到鞋底,用于检测足底压力和步态监测。当落脚时,传感器被压缩,电容值立即增大;而当抬脚时,传感器被释放恢复原状,电容值立即恢复初始值,表明了该传感器具有良好的稳定性及快速响应的特性。

以上的4种不同压力范围的应用检测无不都验证了该传感器在人机交互、电子皮肤、运动监测等领域应用的巨大潜力。

3. 结 论

本工作利用模板组装的方法制备了炭黑(CB)-钛酸钡(BTO)/聚氨酯(PU)海绵型电容式柔性压力传感器。得出以下结论:

(1)通过对制备的CB-BTO/PU海绵骨架进行SEM、EDS表征,结果表明CB与BTO均匀地浸渍涂覆在PU海绵骨架上。从而使该传感器的介电层融合了PU海绵的低弹性模量和CB-BTO的高介电常数等特性,显著地增强了电容变化,使传感器拥有了良好的传感性能;

(2)通过控制CB和BTO的质量比可改善海绵介电层的传感性能,最佳的配比为mCB:mBTO=5:100。该配比所制备的电容传感器,兼具了高灵敏度与宽的检测范围,在0~10 kPa、10~140 kPa与140~300 kPa的灵敏度分别为

0.6311 kPa−1、0.7911 kPa−1与0.1395 kPa−1。同时,传感器还展示出较快的响应与恢复时间(<0.375 s)及低的检测限(~0.25 g),并且还具有良好的分辨率和长久的使用寿命(>2500 次);(3)本工作被成功地验证可用于在人机交互、电子皮肤、运动监测等领域的巨大潜力,并为低成本、大规模商业化制备柔性压力传感器提供了可能。

-

表 1 国产 T300 级碳纤维(SCF35)/PAEK预浸带参数及其复合材料基本性能

Table 1 Parameters of domestic T300 grade carbon fiber (SCF35)/PAEK prepreg and its basic composite properties

Prepregs FAW/

(g∙m−2)FC/% RC/% Tensile properties (0°) Compression properties (0°) Flexural properties (0°) Strength/

MPaModulus/

GPaStrength/

MPaModulus/

GPaStrength/

MPaModulus/

GPaSCF35/PAEK-L 145±5 52±3 40±2 1730 119 1140 116 1400 117 SCF35/PAEK-H 1720 125 1200 118 1560 118 Notes: FAW—Fiber areal weight of SCF35/PAEK prepreg; FC—Fiber content by volume of SCF35/PAEK prepreg; RC—Resin content by weight of SCF35/PAEK prepreg; SCF35/PAEK-L—Composites of SCF35 carbon fiber reinforced low flowability poly aryl ether ketone; SCF35/PAEK-H—Composites of SCF35 carbon fiber reinforced high flowability poly aryl ether ketone. 表 2 SCF35/PAEK复合材料的抗冲击损伤性能

Table 2 Impact damage resistance of SCF35/PAEK composites

System Impact energy/(J·mm−1) Dent depth/mm Damage area/cm2 CAI/MPa SCF35/PAEK-L 6.67 0.6 ± 0.04 5.3 ± 0.3 307 ± 16 SCF35/PAEK-H 1.0 ± 0.09 10.0 ± 0.9 205 ± 11 Domestic T300/EP 0.3 ± 0.03 11.0 ± 1.34 197 ± 15 TC1225[23] 30.5 J — — 310 ± 11 Notes: CAI—Compression after impact strength of SCF35/PAEK composites; TC1225—Standard modulus carbon fiber reinforced PAEK prepreg manufactured by Toray Corporation of Japan; EP—Epoxy resin. -

[1] LIU H B, LIU J, DING Y Z, et al. The behaviour of thermoplastic and thermoset carbon fiber composites subjected to low-velocity and high-velocity impact[J]. Journal of Materials Science,2020,55(33):15741-15768. DOI: 10.1007/s10853-020-05133-0

[2] JOGUR G, NAWAZ KHAN A, DAS A, et al. Impact properties of thermoplastic composites[J]. Textile Progress,2018,50(3):109-183. DOI: 10.1080/00405167.2018.1563369

[3] 谌广昌, 姚佳楠, 张金栋, 等. 高性能热塑性复合材料在直升机结构上的应用与展望[J]. 航空材料学报, 2019, 39(5):24-33. DOI: 10.11868/j.issn.1005-5053.2019.000035 CHEN Guangchang, YAO Jia'nan, ZHANG Jindong, et al. Application and prospect of high performance thermoplastic composites in helicopter structure[J]. Journal of Aeronautical Materials,2019,39(5):24-33(in Chinese). DOI: 10.11868/j.issn.1005-5053.2019.000035

[4] 杨洋, 见雪珍, 袁协尧, 等. 先进热塑性复合材料在大型客机结构零件领域的应用及其制造技术[J]. 玻璃钢, 2017, 4(194):3-17. YANG Yang, JIAN Xuezhen, YUAN Xieyao, et al. Application and manufacturing technology of advanced thermoplastic composites in structural parts of large passenge aircraft[J]. Fiber Reinforced Plastics,2017,4(194):3-17(in Chinese).

[5] 郭云竹. 热塑性复合材料研究及其在航空领域中的应用[J]. 纤维复合材料, 2016, 33(3):20-23. DOI: 10.3969/j.issn.1003-6423.2016.03.005 GUO Yunzhu. Research on thermoplastic composites and its application in the field of aviation[J]. Fiber Composites,2016,33(3):20-23(in Chinese). DOI: 10.3969/j.issn.1003-6423.2016.03.005

[6] 罗云烽, 姚佳楠. 高性能热塑性复合材料在民用航空领域中的应用[J]. 航空制造技术, 2021, 64(16):93-102. DOI: 10.16080/j.issn1671-833x.2021.16.093 LUO Yunfeng, YAO Jia'nan. Applications of high performance thermoplastic composites in civil aviation[J]. Aeronautical Manufacturing Technology,2021,64(16):93-102(in Chinese). DOI: 10.16080/j.issn1671-833x.2021.16.093

[7] 王兴刚, 于洋, 李树茂, 等. 先进热塑性树脂基复合材料在航天航空上的应用[J]. 纤维复合材料, 2011, 28(2):44-47. DOI: 10.3969/j.issn.1003-6423.2011.02.011 WANG Xinggang, YU Yang, LI Shumao, et al. The research on fiber reinforced thermoplastic composite[J]. Fiber Composites,2011,28(2):44-47(in Chinese). DOI: 10.3969/j.issn.1003-6423.2011.02.011

[8] 肇研, 刘寒松. 连续纤维增强高性能热塑性树脂基复合材料的制备与应用[J]. 材料工程, 2020, 48(8):49-61. DOI: 10.11868/j.issn.1001-4381.2019.000209 ZHAO Yan, LIU Hansong. Preparation and application of continuous fiber reinforced high performance thermoplastic resin matrix composites[J]. Materials Engineering,2020,48(8):49-61(in Chinese). DOI: 10.11868/j.issn.1001-4381.2019.000209

[9] LAGACE P A, WILLIAMSON J E, WILSON TSANG P H, et al. A preliminary proposition for a test method to measure (impact) damage resistance[J]. Journal of reinforced Plastics and Composites,1993,12(5):584-601. DOI: 10.1177/073168449301200508

[10] BYERS B A. Behavior of damaged graphite/epoxy laminates under compression loading[R]. Boeing Commercial Airplane Co. Seattle Wa, 1980.

[11] 王俭, 沈真. 复合材料冲击损伤阻抗性能的试验研究[J]. 航空制造技术, 2009(S1):161-164. DOI: 10.3969/j.issn.1671-833X.2009.z1.050 WANG Jian, SHEN Zhen. Experimental study on impact damage resistance property of composites[J]. Aeronautical Manufacturing Technology,2009(S1):161-164(in Chinese). DOI: 10.3969/j.issn.1671-833X.2009.z1.050

[12] 沈真, 杨胜春, 陈普会. 复合材料层压板抗冲击行为及表征方法的实验研究[J]. 复合材料学报, 2008, 25(5):125-133. DOI: 10.3321/j.issn:1000-3851.2008.05.021 SHEN Zhen, YANG Shengchun, CHEN Puhui. Experimental study on the behavior and characterization methods of composite laminates to withstand impact[J]. Acta Materiae Compositae Sinica,2008,25(5):125-133(in Chinese). DOI: 10.3321/j.issn:1000-3851.2008.05.021

[13] Department of Defense. Composite materials handbook: MIL-H DBK-17F[S]. Virginia: US Department of Defense, 2002.

[14] MORTEAU E, FUALDES C. Composites@airbus damage tolerance methodology[C]//Workshop for Composite Damage Tolerance and Maintenance. Chicago, IL: Federal Aeronautics Administration. 2006: 1.

[15] LIU H, LIU J, DING Y, et al. Investigations on the impact behaviour of fibre-reinforced composites: Effect of impact energy and impactor shape[J]. Procedia Structural Integrity,2020,28:106-115. DOI: 10.1016/j.prostr.2020.10.014

[16] GE X, ZHANG P, ZHAO F, et al. Experimental and numerical investigations on the dynamic response of woven carbon fiber reinforced thick composite laminates under low-velocity impact[J]. Composite Structures,2022,279:114792. DOI: 10.1016/j.compstruct.2021.114792

[17] BADER M G, BAILEY J E, BELL I. The effect of fibre-matrix interface strength on the impact and fracture properties of carbon-fibre-reinforced epoxy resin composites[J]. Journal of Physics D: Applied Physics,1973,6(5):572-586. DOI: 10.1088/0022-3727/6/5/314

[18] BULL D J, SPEARING S M, SINCLAIR I. Investigation of the response to low velocity impact and quasi-static indentation loading of particle-toughened carbon-fibre composite materials[J]. Composites Part A: Applied Science and Manufacturing,2015,74:38-46. DOI: 10.1016/j.compositesa.2015.03.016

[19] 顾洋洋, 姚佳楠, 王力风, 等. 聚芳醚酮树脂基体特性对复合材料界面性能和层间性能的影响[J]. 复合材料学报, 2023, 40(8): 4486-4495. GU Yangyang, YAO Jia'nan, WANG Lifeng, et al. Influence of poly aryl ether ketone resin matrix properties on interfacial properties and interlayer properties of composites[J]. Acta Materiae Compositae Sinica, 2023, 40(8): 4486-4495(in Chinese).

[20] ASTM. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event: ASTM D7136/D7136 M-20[S]. West Conshohocken: ASTM International, 2020.

[21] ASTM. Standard test method for measuring the damage resistance of a fiber-reinforced polymer-matrix composite to a concentrated quasi-static indentation force: ASTM D6264/D6264 M-17[S]. West Conshohocken: ASTM International, 2017.

[22] ASTM. Standard test method for compressive residual strength properties of damaged polymer matrix composite laminates: ASTM D7137/D7137 M-17[S]. West Conshohocken: ASTM International, 2017.

[23] CLARKSON E. Medium toughness PAEK thermoplastics toray (Formerly TenCate) Cetex® TC1225 (LM PAEK) T700 GC 12 K T1 E unidirectional tape 145 gsm 34% RC material allowables statistical analysis report[D]. Wichita: Wichita State University, 2020.

[24] LU T, CHEN X, WANG H, et al. Comparison of low-velocity impact damage in thermoplastic and thermoset composites by non-destructive three-dimensional X-ray microscope[J]. Polymer Testing,2020,91:106730. DOI: 10.1016/j.polymertesting.2020.106730

[25] YASAEE M, BOND I P, TRASK R S, et al. Damage control using discrete thermoplastic film inserts[J]. Composites Part A: Applied Science and Manufacturing,2012,43(6):978-989. DOI: 10.1016/j.compositesa.2012.01.011

[26] SHAH S Z H, KARUPPANAN S, MEGAT-YUSOFF P S M, et al. Impact resistance and damage tolerance of fiber reinforced composites: A review[J]. Composite Structures,2019,217:100-121. DOI: 10.1016/j.compstruct.2019.03.021

[27] ANDREW J J, SRINIVASAN S M, AROCKIARAJAN A, et al. Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: A critical review[J]. Composite Structures,2019,224:111007. DOI: 10.1016/j.compstruct.2019.111007

[28] TAN W, NAYA F, YANG L, et al. The role of interfacial properties on the intralaminar and interlaminar damage behaviour of unidirectional composite laminates: Experimental characterization and multiscale modelling[J]. Composites Part B: Engineering,2018,138:206-221. DOI: 10.1016/j.compositesb.2017.11.043

[29] LU C, WANG J, LU X, et al. Wettability and interfacial properties of carbon fiber and poly (ether ether ketone) fiber hybrid composite[J]. ACS Applied Materials & Interfaces,2019,11(34):31520-31531.

[30] YAVAS D, ZHANG Z, LIU Q, et al. Interlaminar shear behavior of continuous and short carbon fiber reinforced polymer composites fabricated by additive manufacturing[J]. Composites Part B: Engineering,2021,204:108460. DOI: 10.1016/j.compositesb.2020.108460

[31] XU W, DING J C. Correction of the large displacement effect on determination of mode I interlaminar fracture toughness of composite[J]. Engineering Fracture Mechanics,2020,238:107279. DOI: 10.1016/j.engfracmech.2020.107279

[32] WENZEL R N. Resistance of solid surfaces to wetting by water[J]. Industrial & Engineering Chemistry,1936,28(8):988-994.

[33] CASSIE A B D, BAXTER S. Wettability of porous surfaces[J]. Transactions of the Faraday Society,1944,40:546-551. DOI: 10.1039/tf9444000546

[34] DAVALLO M. Factors affecting fracture behaviour of composite materials[J]. International Journal of ChemTech Research,2010,2(4):2125-2130.

[35] 李东明. 塑料冲击试验方法的评价[J]. 塑料, 1989, 18(4):46-50. LI Dongming. Evaluation of plastics impact test method[J]. Plastics,1989,18(4):46-50(in Chinese).

[36] LOPRESTO V, CAPRINO G. Damage mechanisms and energy absorption in composite laminates under low velocity impact loads[M]//Dynamic Failure of Composite and Sandwich Structures. Dordrecht: Springer, 2013: 209-289.

[37] RICHARDSON M O W, WISHEART M J. Review of low-velocity impact properties of composite materials[J]. Composites Part A: Applied Science and Manufacturing,1996,27(12):1123-1131. DOI: 10.1016/1359-835X(96)00074-7

[38] SUN X C, HALLETT S R. Failure mechanisms and damage evolution of laminated composites under compression after impact (CAI): Experimental and numerical study[J]. Composites Part A: Applied Science and Manufacturing,2018,104:41-59. DOI: 10.1016/j.compositesa.2017.10.026

-

期刊类型引用(1)

1. 曾鹏程,肖书平,杨柳,谈灵操,徐百平. 较宽压强响应范围和较高灵敏度的聚丙烯基电容式压力传感器的研制. 机电工程技术. 2025(03): 58-63 .  百度学术

百度学术

其他类型引用(3)

-

目的

高性能热塑性复合材料被广泛的应用于航空、航天等领域,并且已经从非承力结构向主承力结构过渡。复杂的服役环境使得复合材料在使用过程中会遇到各种各样的冲击,复合材料受到冲击时易形成结构内部损伤,可能导致复合材料结构丧失其50 %的承载能力,因此,了解复合材料在不同冲击情况下的响应非常关键。本文采用了具有两种不同流动性的PAEK树脂基体(PAEK-L、PAEK-H)和国产T300级碳纤维(SCF35)制备了连续碳纤维增强聚芳醚酮(SCF35/PAEK)热塑性复合材料,研究了树脂熔体黏度及冲击能量对复合材料冲击性能的影响。

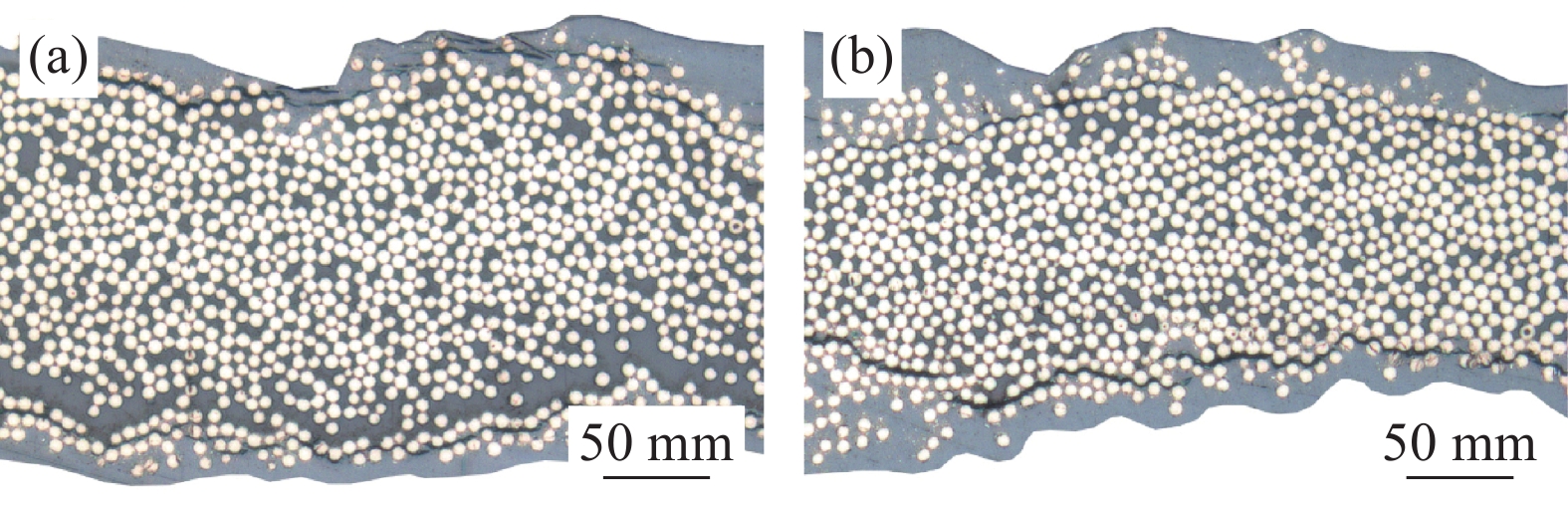

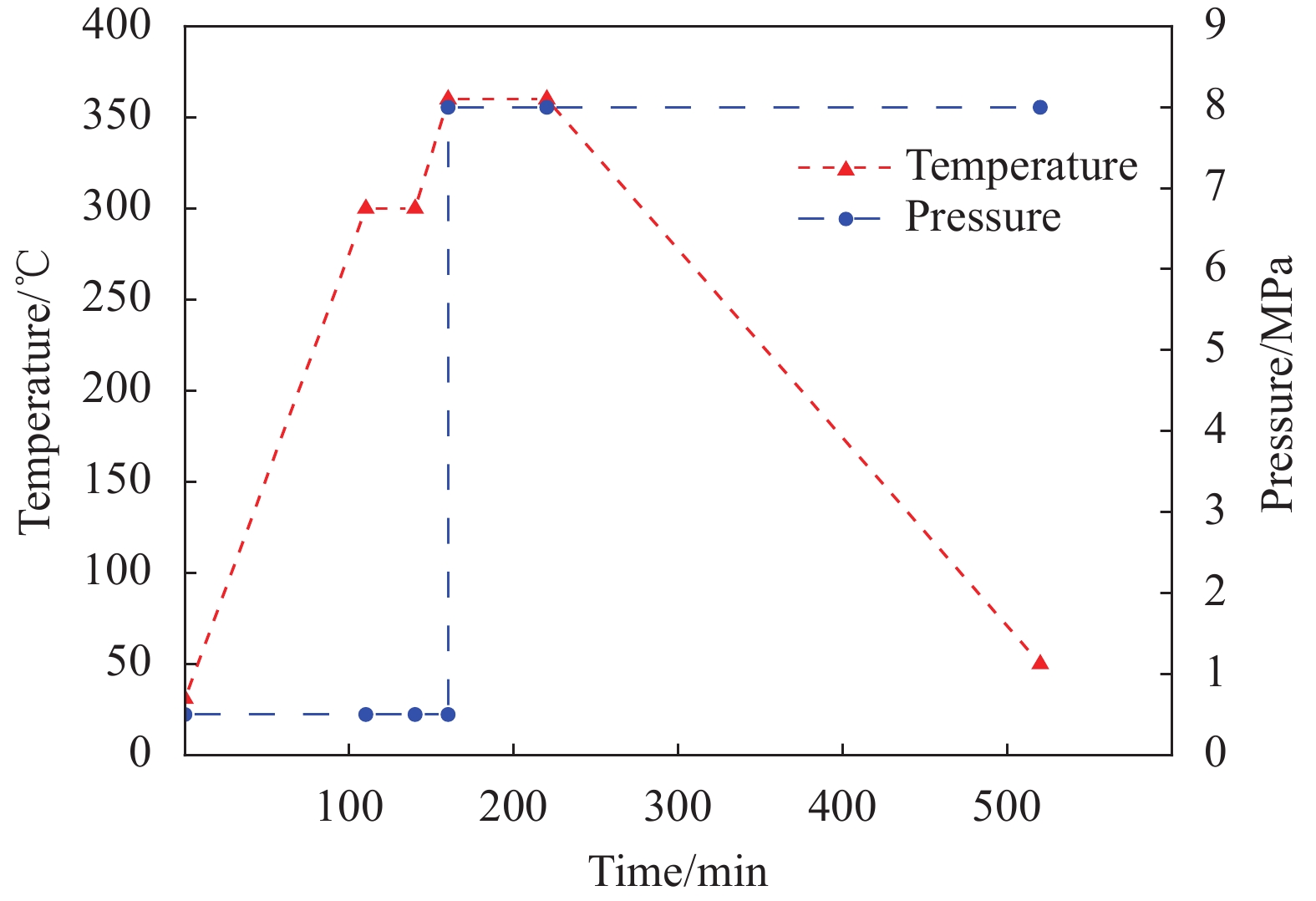

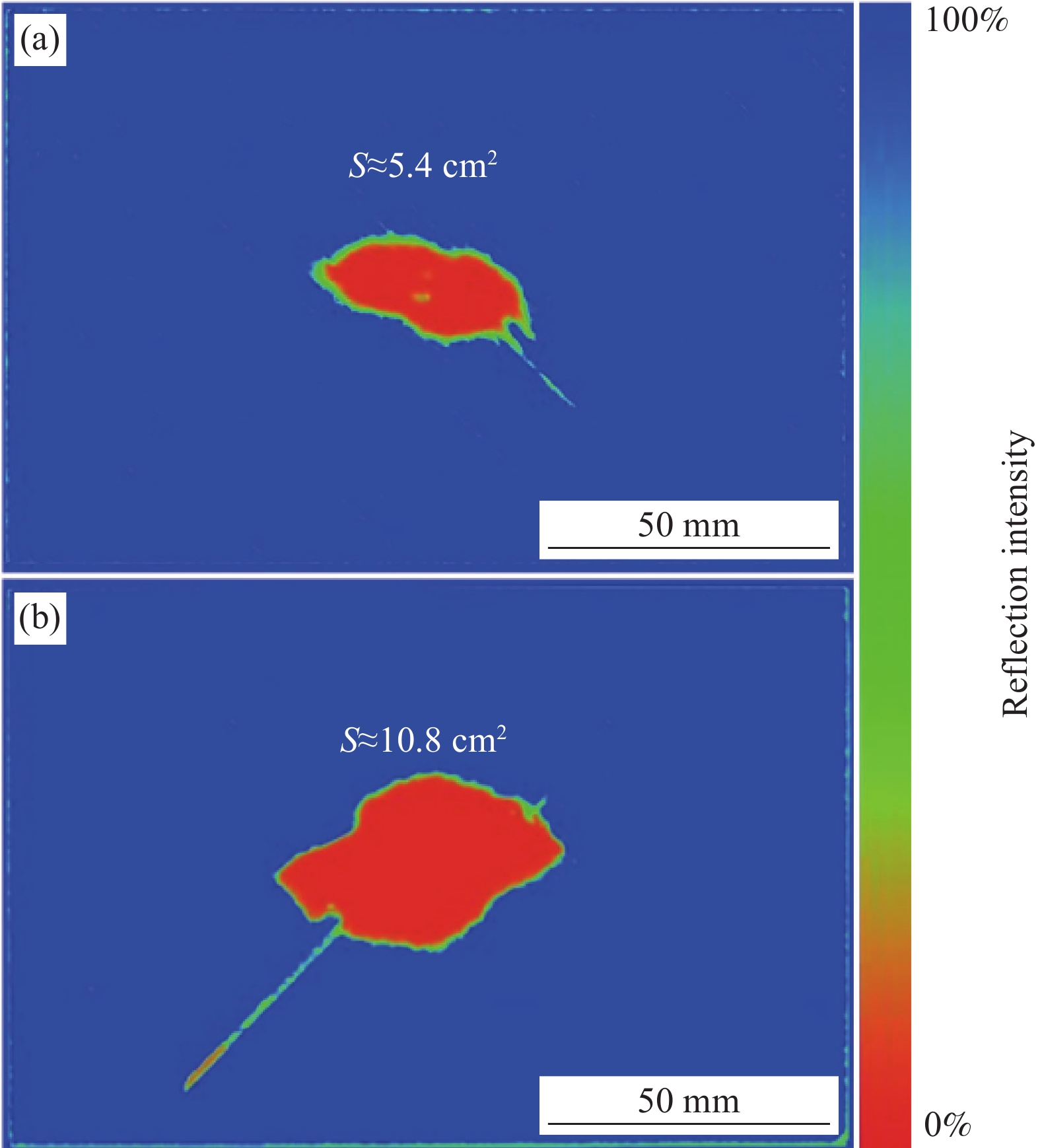

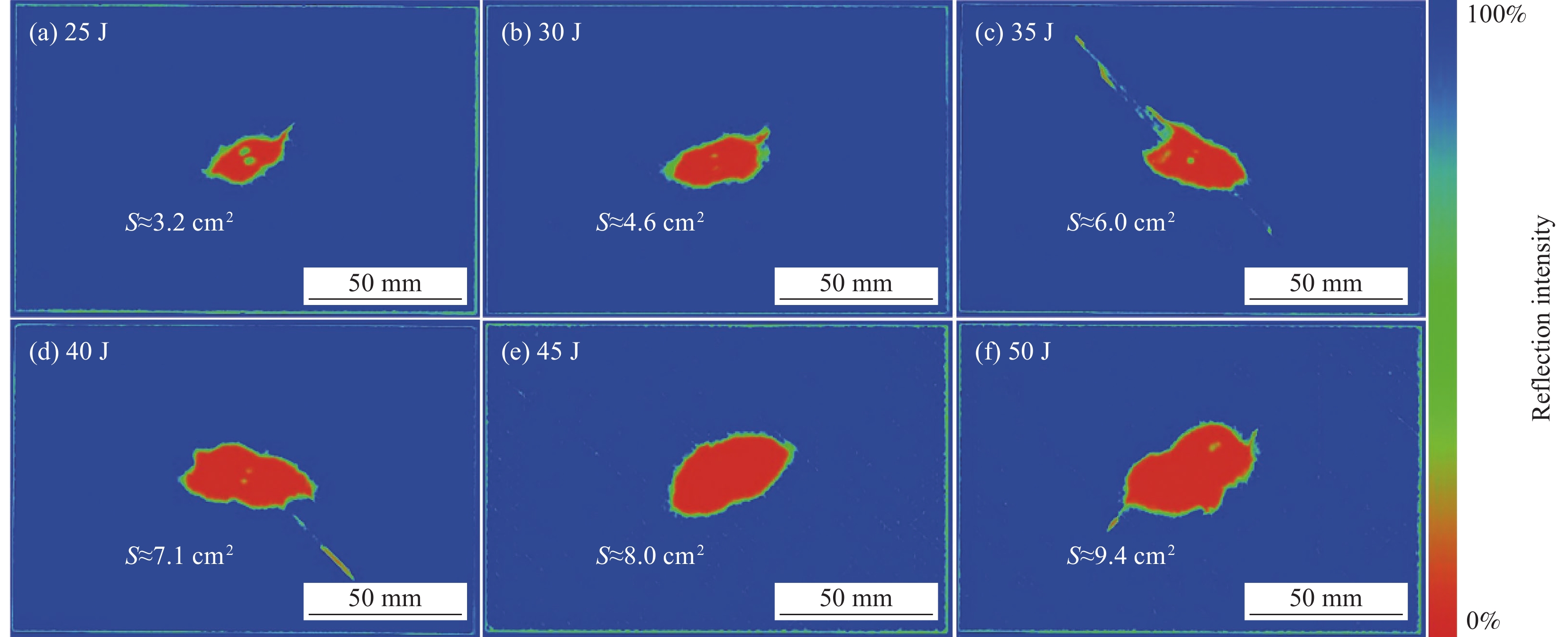

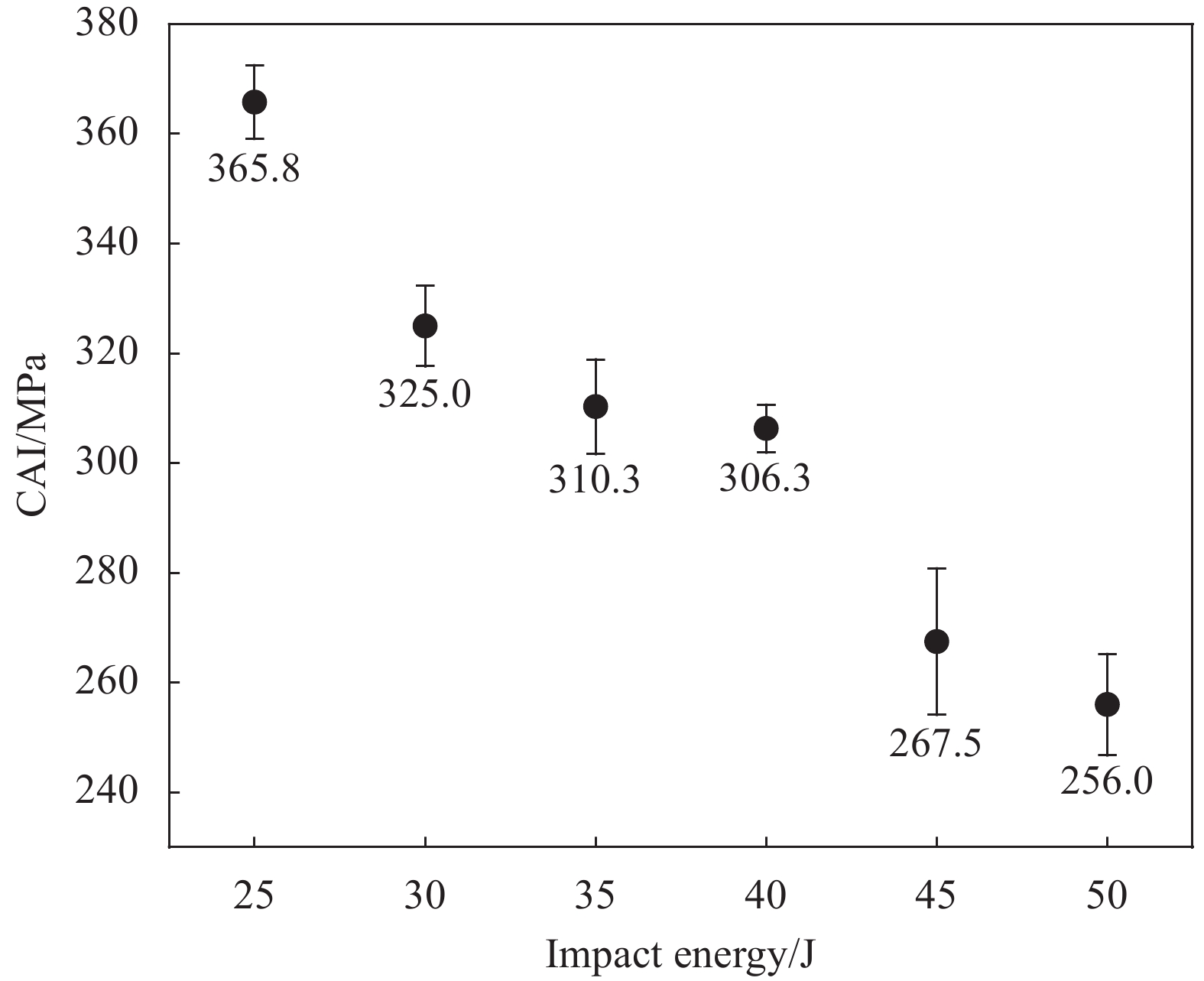

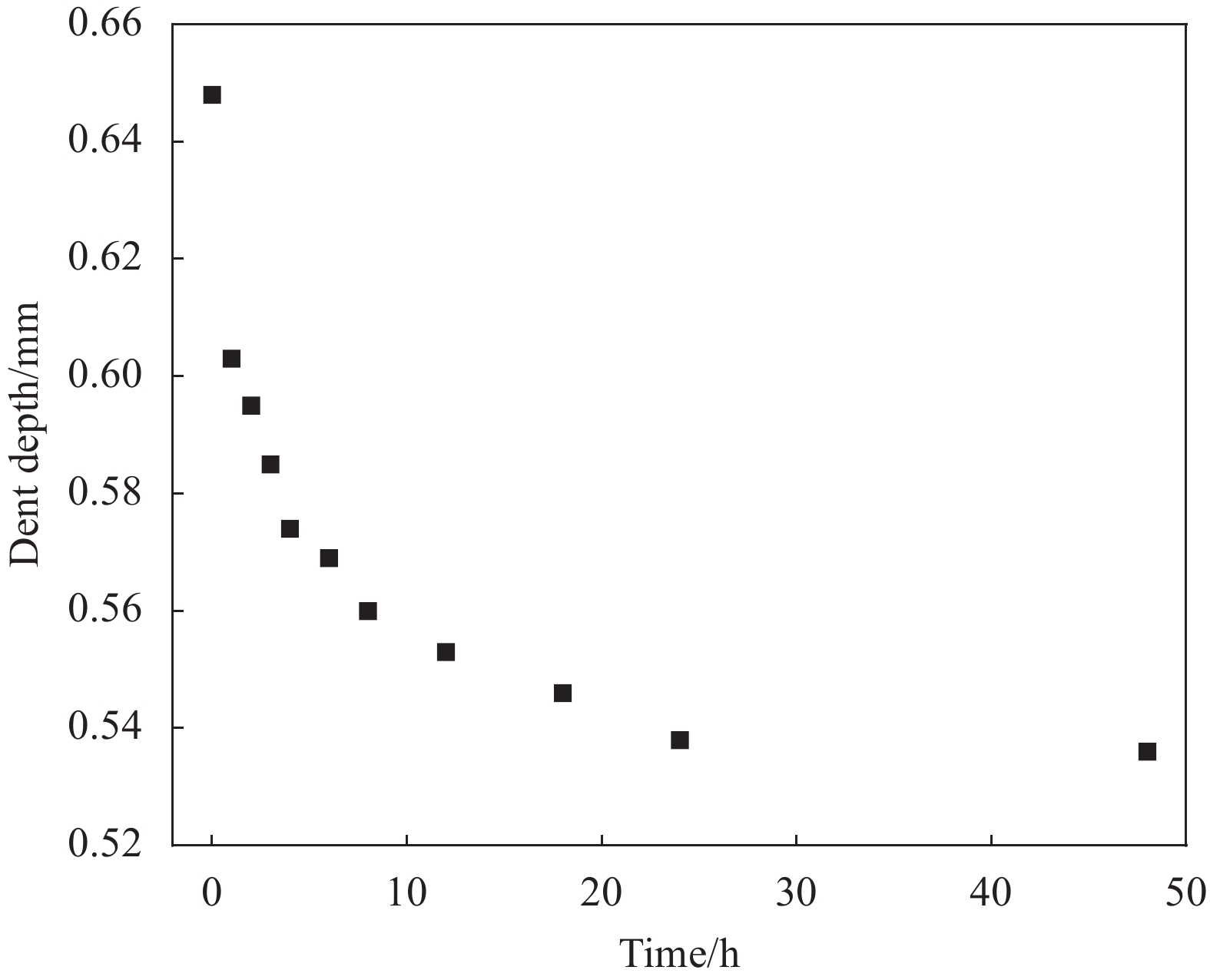

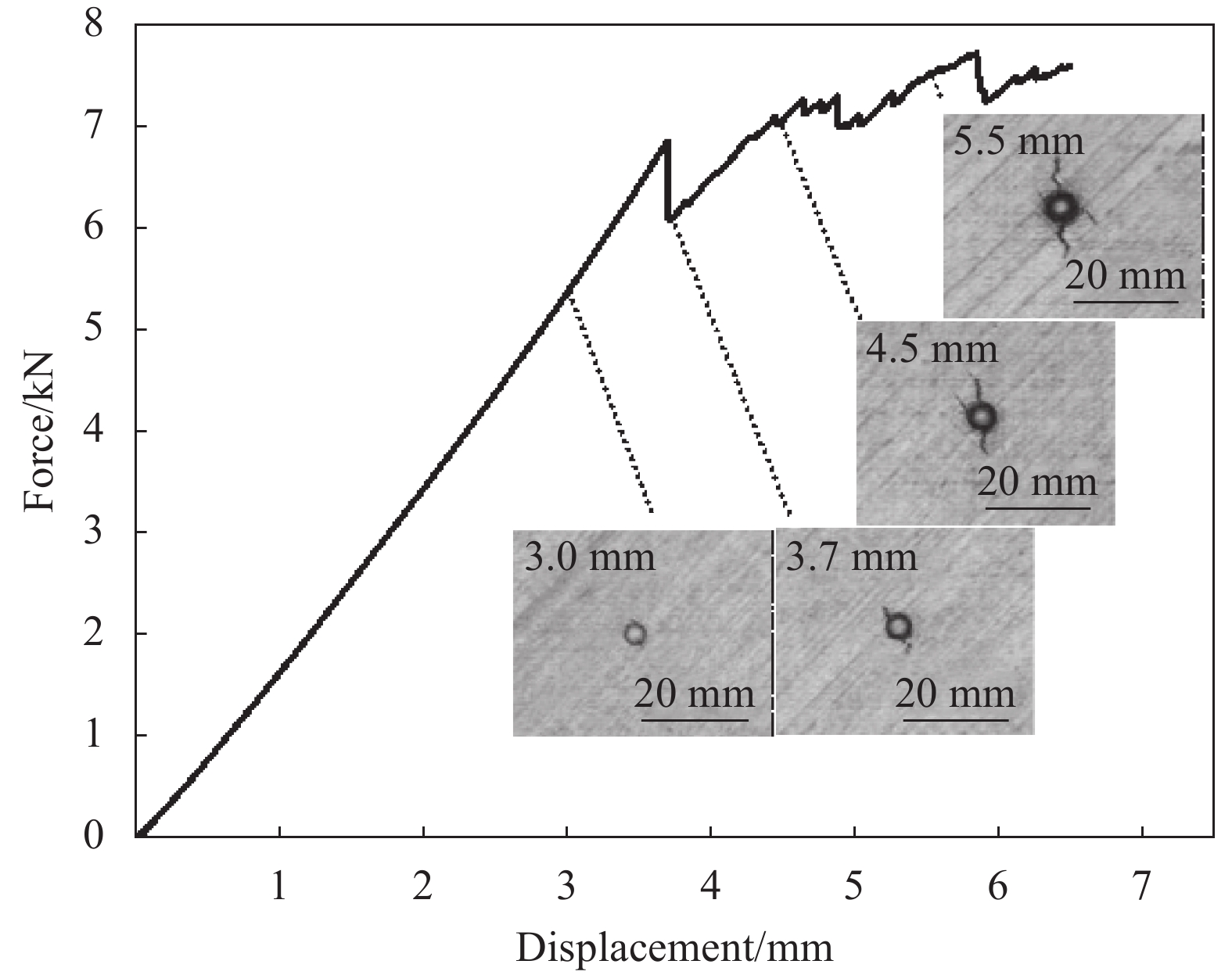

方法采用模压成型的方法制备国产T300级碳纤维(SCF35)增强聚芳醚酮(PAEK)热塑性复合材料(SCF35/PAEK),采用高压射流水切割机将复合材料裁成150 mm×100 mm的冲击试样,采用超声扫描显微镜检测复合材料的内部质量。采用落锤冲击的实验方法施加6.67 J/mm的冲击能量,研究树脂基体特性对复合材料抗冲击性能的影响;施加25 J、30 J、35 J、40 J、45 J、50 J的冲击能量,使复合材料试样从表面轻微损伤直至表面凹坑深度大于1.0 mm,研究冲击能量对复合材料抗冲击性能的影响,采用超声扫描显微镜检测冲击试样的内部分层尺寸,采用超景深3D显微镜表征复合材料的表面冲击损伤形貌,同时采集复合材料受到冲击损伤后的表面凹坑直径、凹坑深度、损伤面积等数据。采用准静态压入的实验方法研究复合材料不同阶段的损伤模式,配合Micro-CT无损检测表征复合材料不同阶段的内部损伤形貌。针对冲击后的复合材料试样,采用材料试验机配和相应的夹具按照美国材料与试验协会(ASTM)标准测试其冲击后压缩性能。

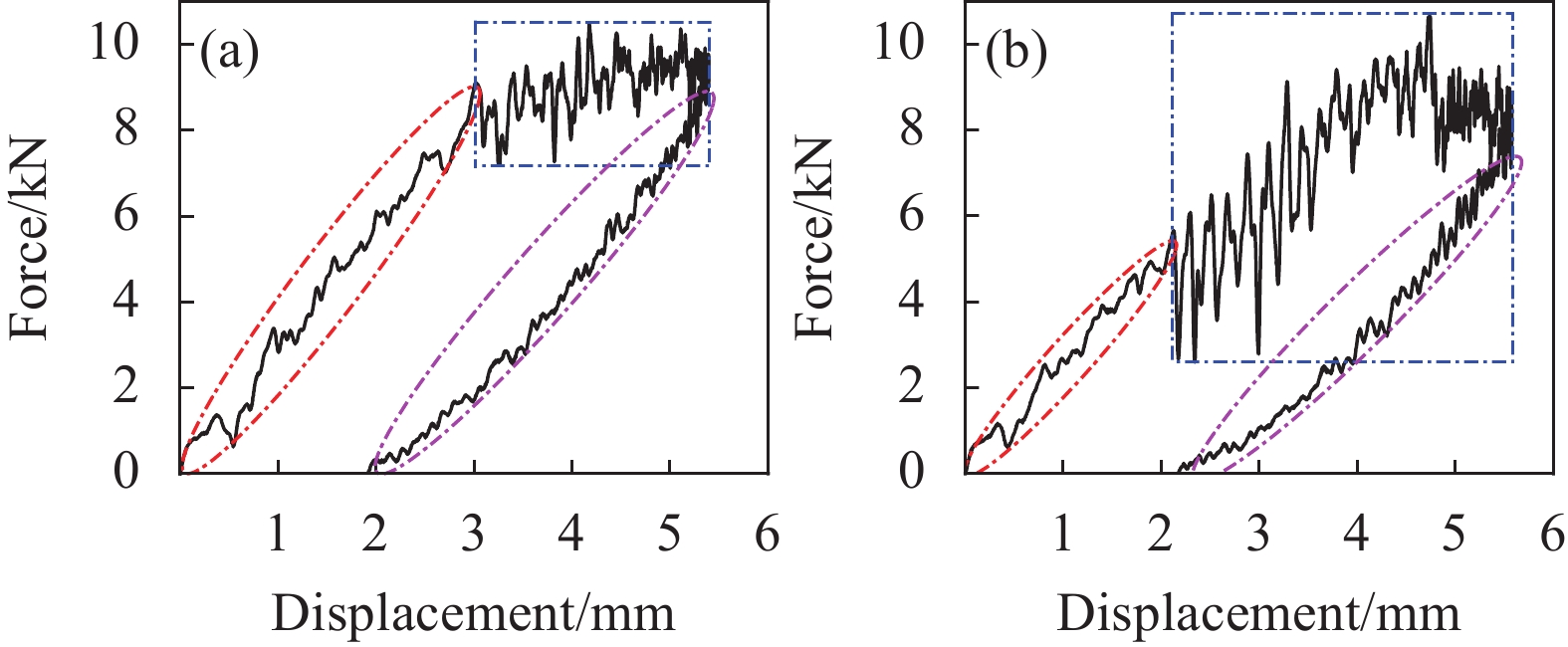

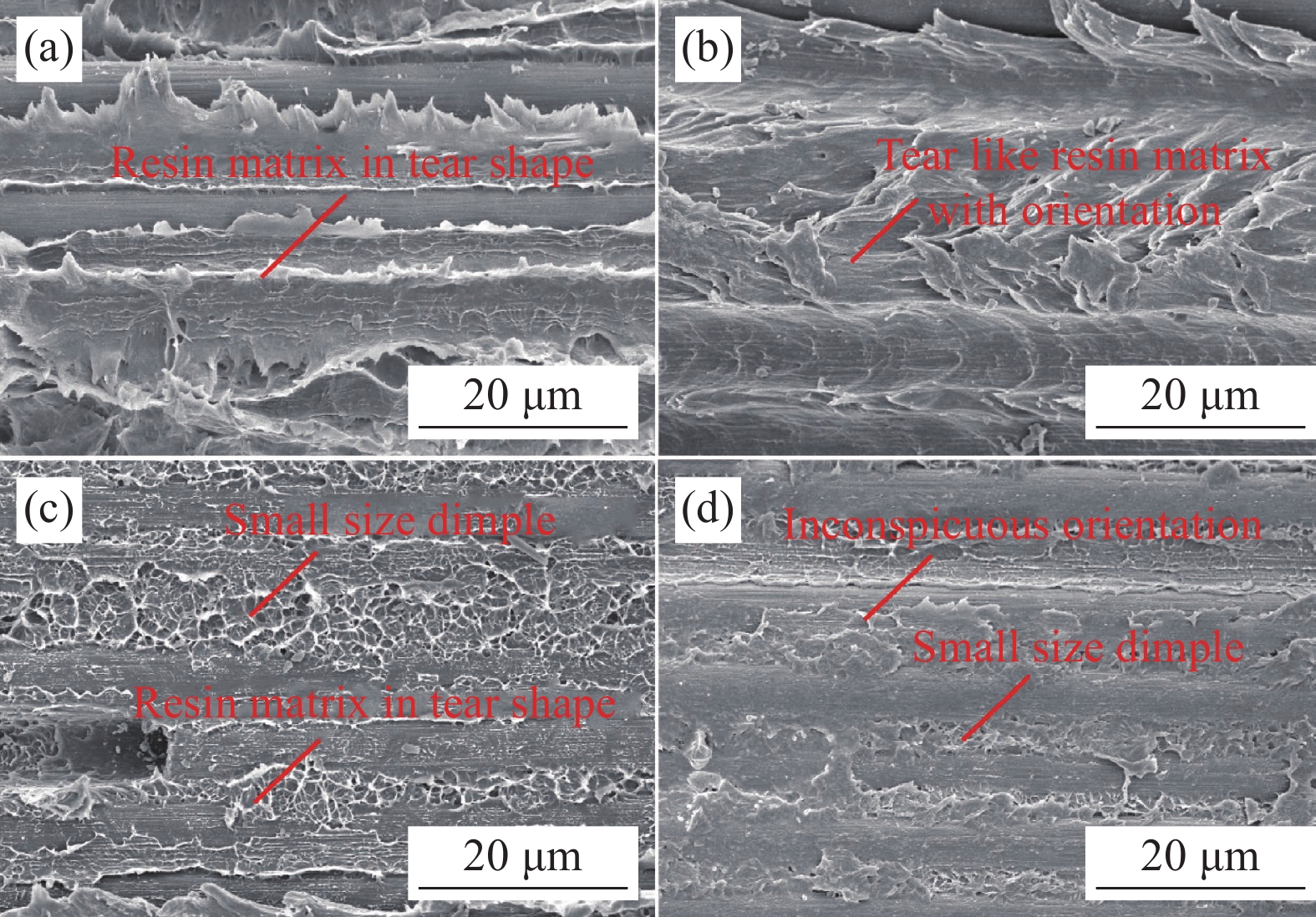

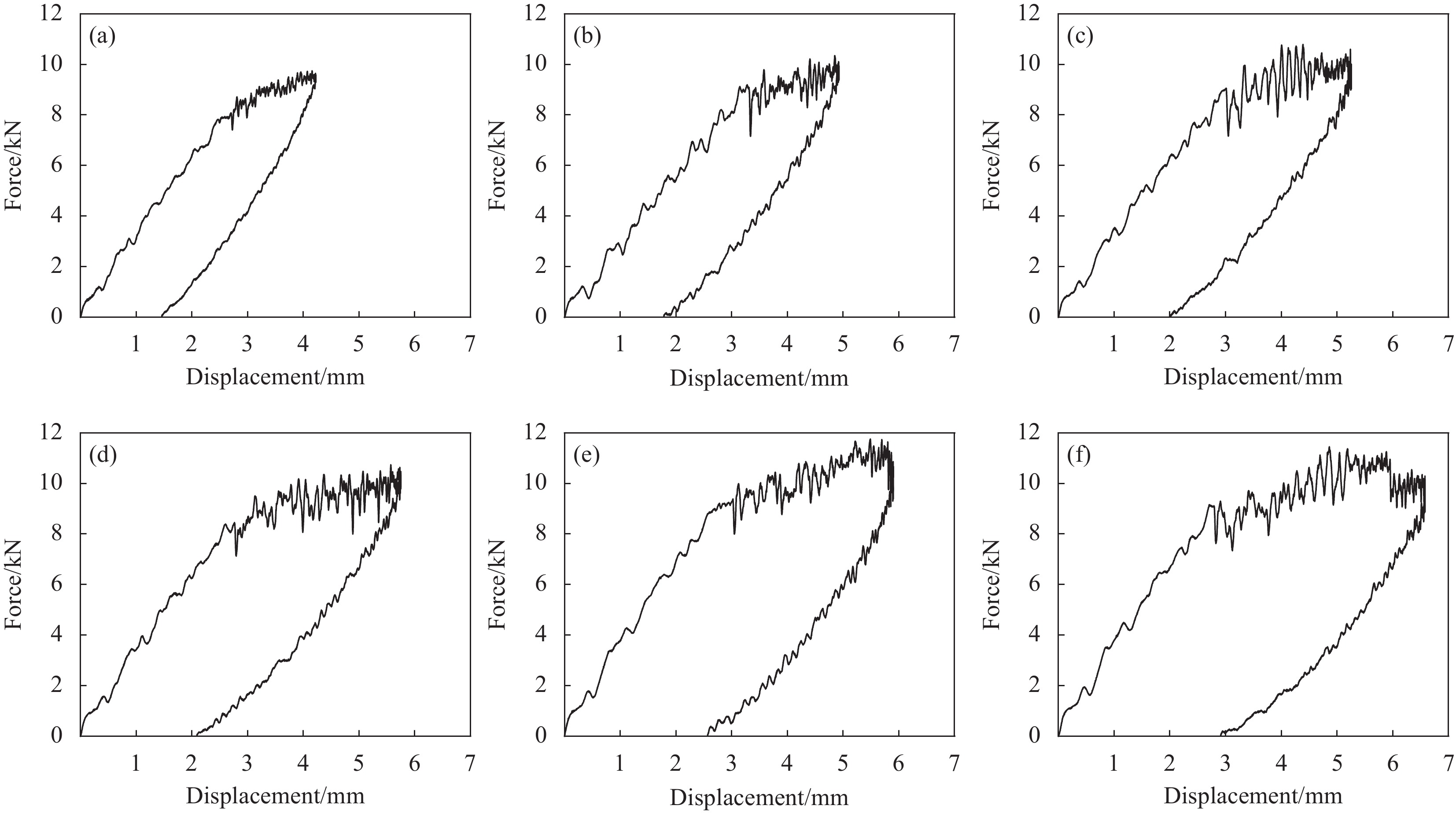

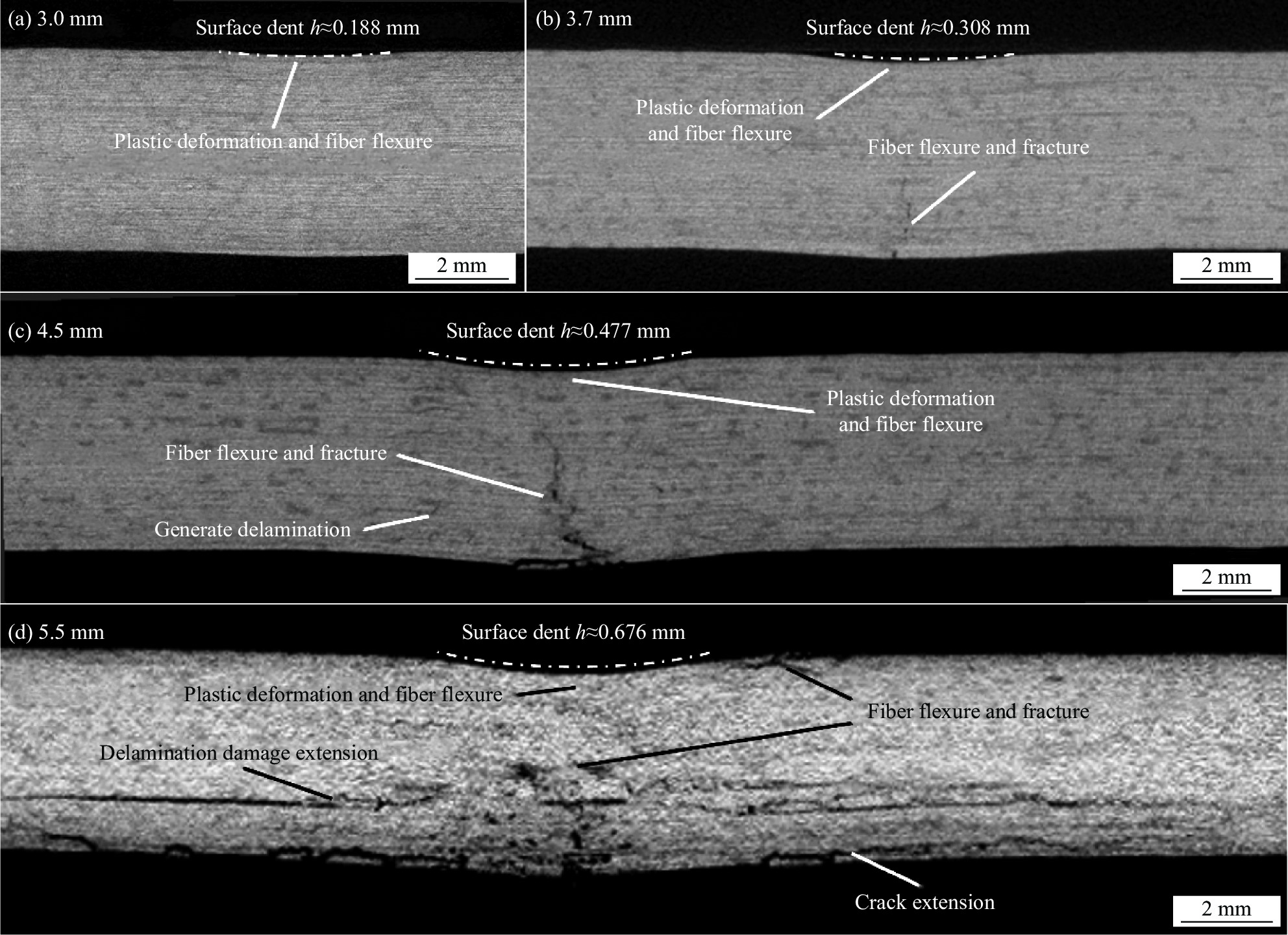

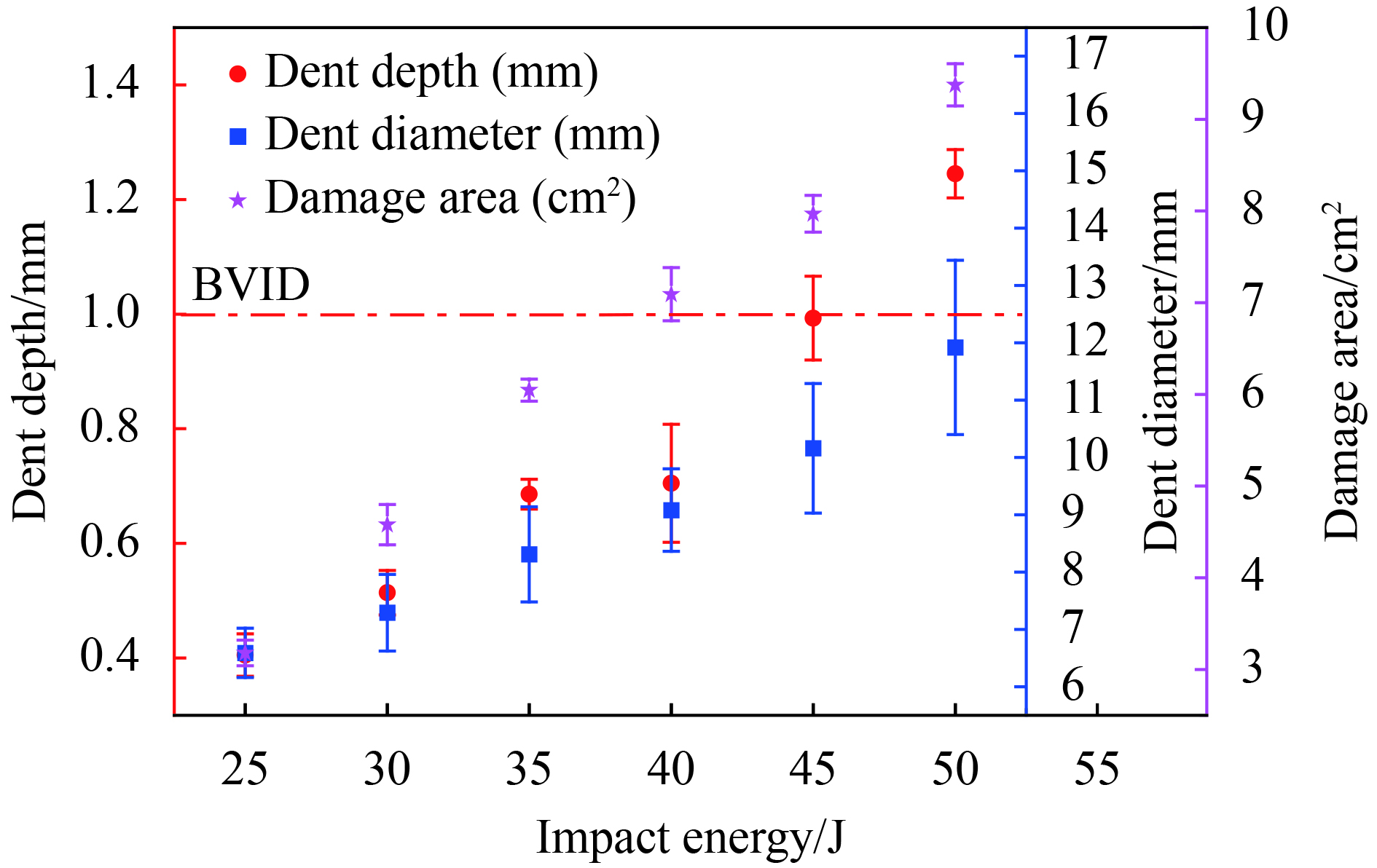

结果SCF35/PAEK-L复合材料的平均冲击凹坑深度为~0.6 mm,平均损伤面积为~5.3 cm,平均能量损耗为~61.7 %,冲击后压缩强度为~307 MPa;SCF35/PAEK-H复合材料的平均冲击凹坑深度为~1.0 mm,平均伤损面积为~10.0 cm,平均能量损耗为~68.4 %,冲击后压缩强度为~205 MPa,SCF35/PAEK-L复合材料体系冲击能量的损耗比SCF35/PAEK-H复合材料体系低~7%,其损伤面积小~90%,在6.67 J/mm的冲击能量下,其冲击后压缩强度比SCF35/PAEK-H复合材料体系冲击后压缩强度高~50%。不同能量对复合材料的冲击过程中,随着冲击能量从25 J逐渐增加至50 J,SCF35/PAEK-L复合材料的能量损耗也从56.1 %逐渐增加至73.8 %,复合材料内部的损伤面积与冲击面的凹坑深度及凹坑直径明显增加,与冲击能量呈现一定的正相关性,当冲击能量达到约45 J时,凹坑深度约为1.0 mm,复合材料的剩余压缩强度为~268 MPa。准静态压入过程中,复合材料经历弹性变形阶段、纤维断裂阶段、裂纹扩展阶段、损伤持续扩展阶段,锤头位移为3.0 mm时复合材料表面产生微小凹坑,复合材料的树脂基体在载荷作用下产生塑性变形,碳纤维则随着树脂基体的塑性变形产生弯曲,进而形成表面凹坑,锤头位移为3.7 mm时复合材料表面凹坑深度与凹坑直径进一步扩大,复合材料的背面产生裂纹,锤头位移为4.5 mm时复合材料背面产生的裂纹在拉伸应力的作用下逐渐向复合材料内部扩展,试样挠曲变形的过程中,复合材料中各层在剪切力的作用下产生分层,锤头位移为5.5 mm时,明显观察到复合材料表面凹坑周围的纤维在压缩应力的作用下发生断裂,复合材料中的分层损伤进一步扩展。

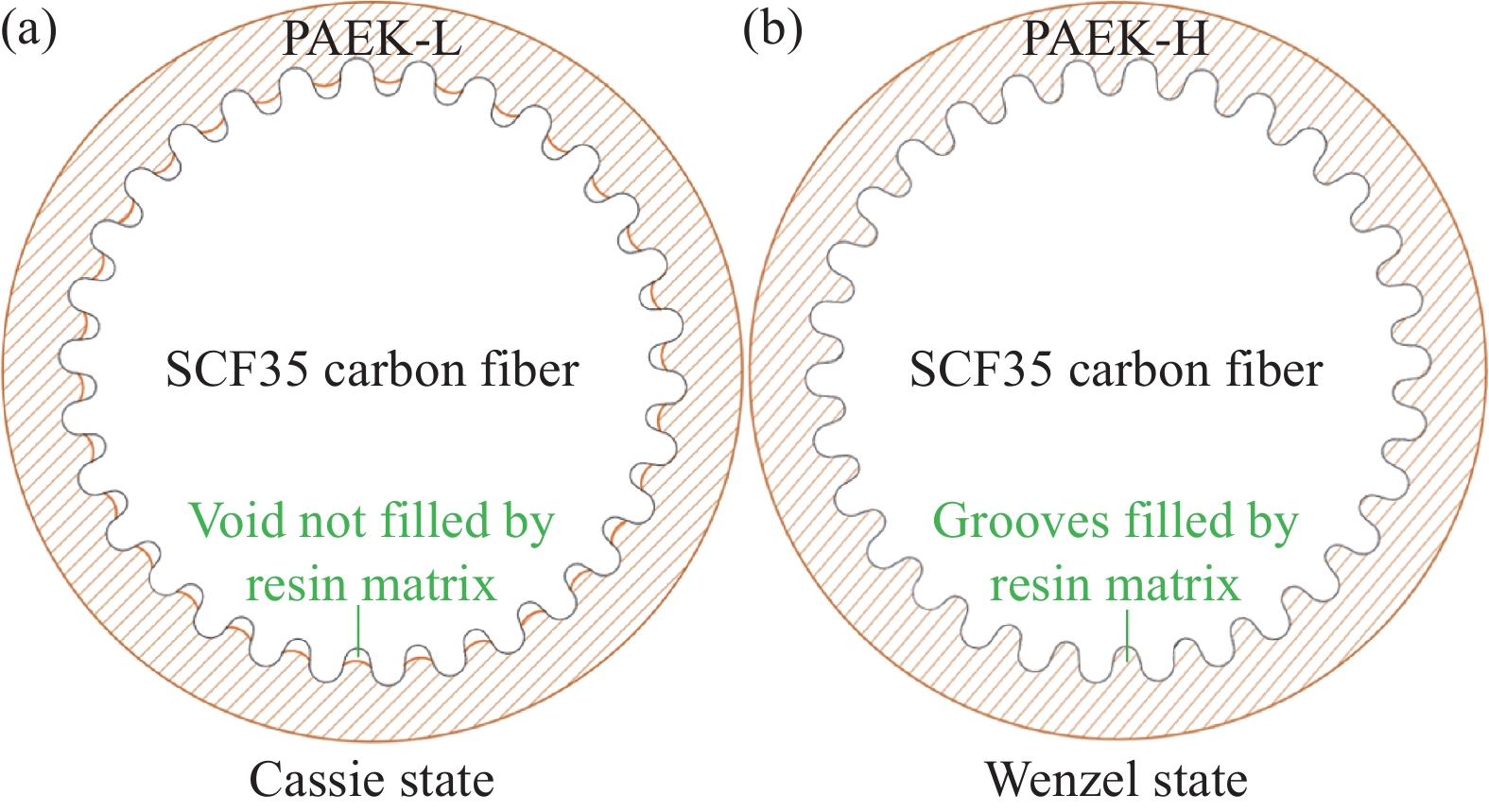

结论流动性低、黏度高的PAEK-L树脂相较于流动性高、黏度低的PAEK-H树脂,能够与SCF35碳纤维形成适中的界面强度,且具有较高的塑性变形能力,其复合材料具有更高的抗冲击性能。SCF35/PAEK-L复合材料中表面凹坑的深度随冲击能量的增加呈增加的趋势,冲击后压缩强度随冲击能量的增加呈降低的趋势。SCF35/PAEK-L复合材料冲击后表面凹坑主要由树脂基体的塑性变形及纤维屈曲造成,表面凹坑周围的裂纹由压缩应力造成,复合材料背面的裂纹由拉伸应力造成,复合材料的分层损伤由剪切力造成。

-

高性能热塑性复合材料具有高断裂韧性和抗冲击性、可修复性和耐疲劳等优点,国外已将其广泛应用于航空等高技术领域,并且已经从非承力结构向主承力结构过渡,面对复杂的服役环境,研究热塑性复合材料的冲击损伤特性尤为重要。研究者们对引入冲击损伤的外在实验条件,如冲头形状、入射角度、冲击能量等,以及受冲击材料的材料参数,如纤维性能、基体性能、铺层方式等,进行了大量的研究,旨在揭示复合材料的冲击损伤形式及冲击响应。针对树脂基体性能对复合材料冲击性能的影响的研究中,研究者们主要研究了不同树脂基体对复合材料冲击性能的影响,如环氧树脂和聚醚醚酮树脂对复合材料性能的影响,但是对具有不同特性的同一种热塑性树脂的冲击响应研究较少。

本文采用两种不同熔体黏度的国产高性能聚芳醚酮树脂(PAEK-L、PAEK-H)及国产T300级碳纤维(SCF35),制备了碳纤维增强聚芳醚酮(SCF35/PAEK)热塑性复合材料,研究了树脂基体黏度及冲击能量对复合材料冲击性能的影响,采用Micro-CT表征了准静态压入试样的内部形貌,研究了复合材料的冲击损伤机制。结果显示流动性较低的PAEK-L树脂基复合材料比流动性较高的PAEK-H树脂基复合材料具有更高的抗冲击性能,SCF35/PAEK-L复合材料体系冲击能量的损耗比SCF35/PAEK-H复合材料体系低~7 %,其损伤面积小~90 %,在6.67 J/mm的冲击能量下,其冲击后压缩强度达到~307 MPa,比SCF35/PAEK-H复合材料体系冲击后压缩强度(205 MPa)高~50 %;SCF35/PAEK-L复合材料中表面凹坑的深度随冲击能量的增加呈增加的趋势,冲击后压缩强度随冲击能量的增加呈降低的趋势,当复合材料的表面凹坑深度达到1.0 mm左右,即达到勉强目视可见冲击损伤(Barely Visible Impact Damage,BVID)门槛值时,剩余压缩强度为~268 MPa。准静态压入实验结果显示,SCF35/PAEK-L复合材料受到冲击后表面凹坑主要由树脂基体的塑性变形及纤维屈曲造成,表面凹坑周围的裂纹由压缩应力造成,冲击过程中试样背面的纤维在拉伸应力的作用下发生断裂,试样底层的纤维在剪切力的作用下萌生层间裂纹,随着试样挠曲变形程度的增加,纤维的断裂程度增加且层间裂纹逐渐扩展。

Relationship between dent depth, dent diameter, damage area and impact energy of SCF35/PAEK-L composite

下载:

下载: