Synthesis of W-doped Cr2O3 thin films and their application in isobutylene sensing

-

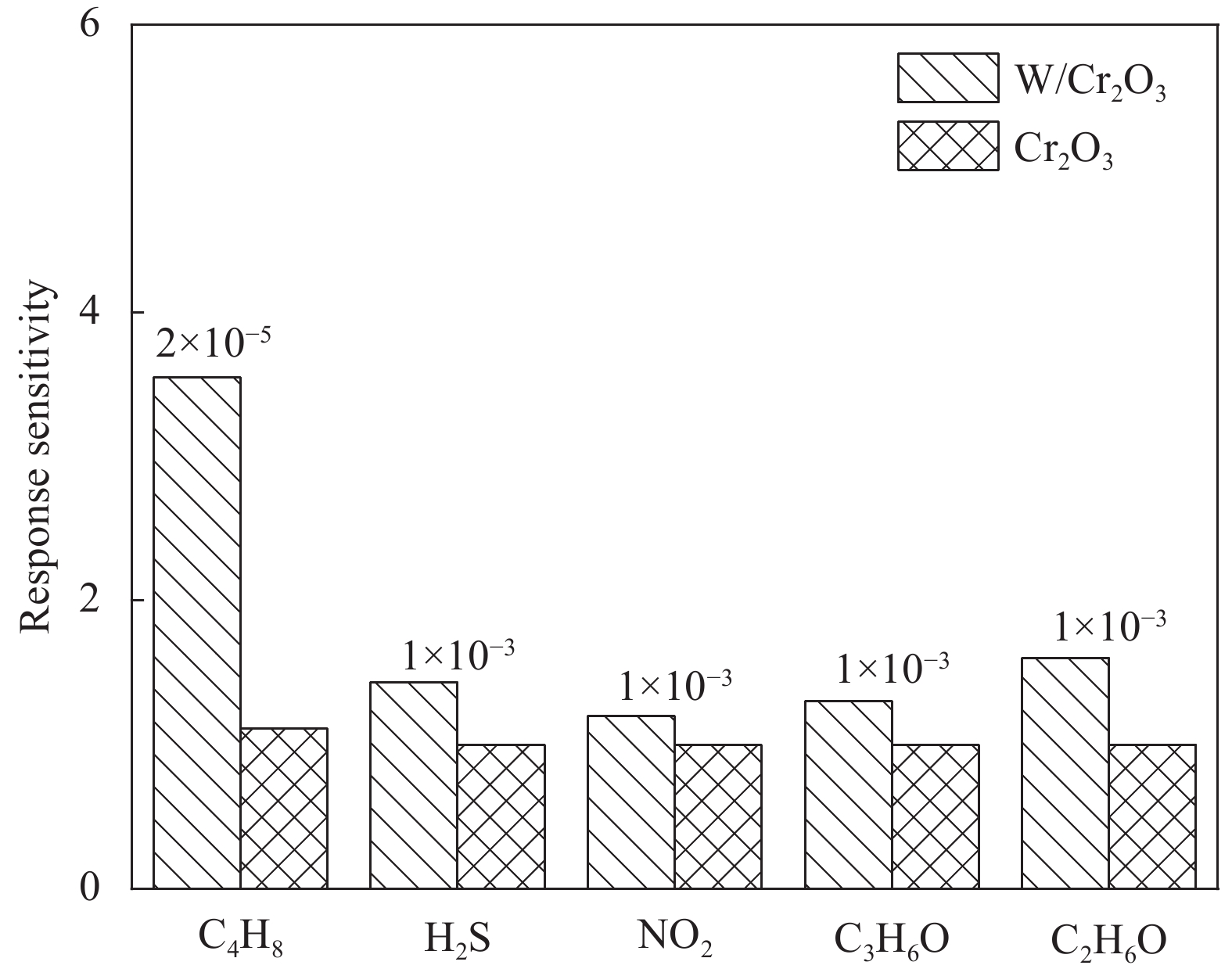

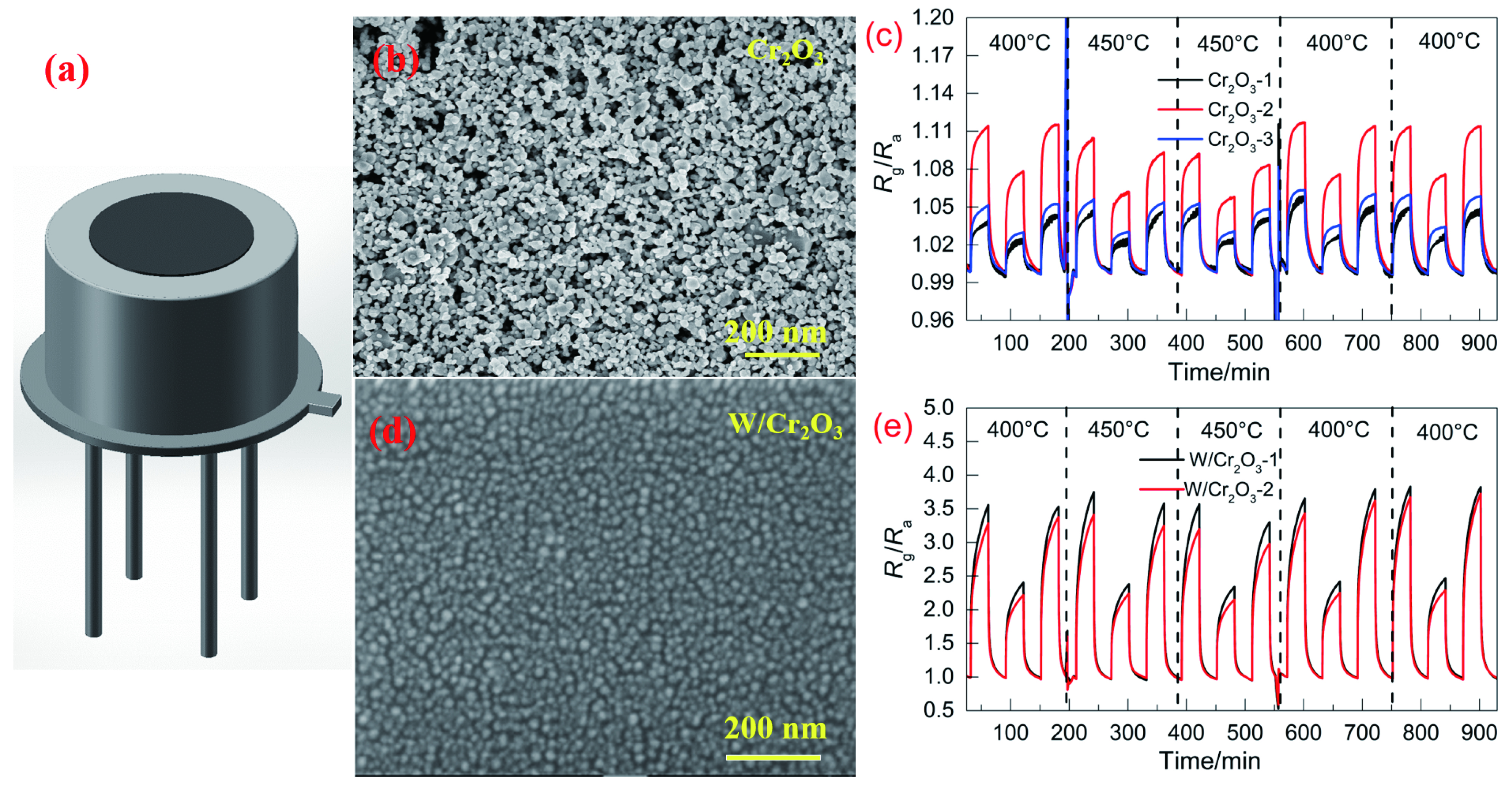

摘要: 为了实现对异丁烯气体的有效检测,采用气溶胶辅助化学气相沉积(AACVD)技术在氧化铝基底表面合成氧化铬(Cr2O3)及W掺杂Cr2O3(W/Cr2O3)薄膜。通过SEM、TEM、XRD及XPS等检测手段对Cr2O3及W/Cr2O3薄膜的微观形貌、晶体结构和元素结合价态进行分析。结果表明:Cr2O3薄膜厚度约为20 μm,由粒径为50 nm左右的纳米颗粒组成,其结构较松散,而W掺杂Cr2O3后所获薄膜结构致密,颗粒粒径约为15 nm,尺寸明显减小,Cr2O3及W/Cr2O3薄膜均具有单一的六方相晶体结构。气敏测试结果表明,在400℃工作温度条件下,基于W/Cr2O3薄膜所制备的气体传感器相较于Cr2O3气体传感器对2×10−5异丁烯的灵敏度由原来的1.11提升为3.55,并展现出良好的稳定性、抗湿性和气体选择性。Abstract: In order to effectively monitor isobutylene gas, Cr2O3 and W-doped Cr2O3 (W/Cr2O3) films were successfully synthesized via aerosol-assisted chemical vapor deposition (AACVD) technique on the surface of alumina substrate. The microstructure, crystal structure, and elemental binding valence of Cr2O3 and W/Cr2O3 films were analyzed by SEM, TEM, XRD and XPS. The results show that Cr2O3 film is composed of nanoparticles with the particle size of about 50 nm, a thickness of about 20 μm, and its structure is relatively loose. However, the thin film obtained by W doping Cr2O3 has a compact structure, and the size of nanoparticles is about 15 nm, which is remarkably reduced due to the introduction of W into the Cr2O3 crystal lattice. Both Cr2O3 and W/Cr2O3 films have a single hexagonal crystalline structure. The gas sensitivity test results show that the sensitivity of the gas sensor based on W/Cr2O3 film towards 2×10–5 isobutene increases from 1.11 to 3.55 compared with the Cr2O3 gas sensor at 400℃, and W/Cr2O3 gas sensor exhibits good stability, moisture resistance and gas selectivity.

-

Keywords:

- W doping /

- Cr2O3 thin films /

- gas sensor /

- isobutylene /

- gas sensing mechanism

-

-

表 1 传感器的重复性和一致性

Table 1 Repeatability and consistency of gas sensors

Sensor Repeatability RSD/% Average response Consistency RSD/% Cr2O3-1 0.72 1.04 3.42 Cr2O3-2 1.27 1.11 Cr2O3-3 0.49 1.05 W/Cr2O3-1 3.51 3.67 3.56 W/Cr2O3-2 4.94 3.49 Note: RSD—Relative standard deviation. -

[1] SEIYAMA T, KATO A, FUJIISHI K, et al. A new detector for gaseous components using semiconductive thin films[J]. Analytical Chemistry,1962,34(11):1502-1503. DOI: 10.1021/ac60191a001

[2] CHEN L, YU Q W, PAN C Y, et al. Chemiresistive gas sensors based on electrospun semiconductor metal oxides: A review[J]. Talanta,2022,246:123527. DOI: 10.1016/j.talanta.2022.123527

[3] LI Q T, ZENG W, LI Y Q. Metal oxide gas sensors for detecting NO2 in industrial exhaust gas: Recent developments[J]. Sensors and Actuators B: Chemical,2022,359:131579. DOI: 10.1016/j.snb.2022.131579

[4] GUTH U, VONAU W, ZOSEL J. Recent developments in electrochemical sensor application and technology—A review[J]. Measurement Science and Technology,2009,20(4):042002. DOI: 10.1088/0957-0233/20/4/042002

[5] 吴煜霞, 杜海英, 张钊睿, 等. 同轴异质In2O3/SnO2复合纤维的构筑及其甲醛敏感性能[J]. 复合材料学报, 2022, 39(5):2249-2257. WU Yuxia, DU Haiying, ZHANG Zhaorui, et al. Fabrication of In2O3/SnO2-coaxial-electrospinning fiber and investigation on its formaldehyde sensing properties[J]. Acta Materiae Compositae Sinica,2022,39(5):2249-2257(in Chinese).

[6] TANG H Y, SACCO L N, VOLLEBREGT S, et al. Recent advances in 2D/nanostructured metal sulfide-based gas sensors: Mechanisms, applications, and perspectives[J]. Journal of Materials Chemistry A,2020,8(47):24943-24976. DOI: 10.1039/D0TA08190F

[7] LEI W, SI W M, XU Y J, et al. Conducting polymer compo-sites with graphene for use in chemical sensors and biosensors[J]. Microchimica Acta,2014,181(7):707-722.

[8] KIM M, LEE Y. A comprehensive review of gas sensors using carbon materials[J]. Journal of Nanoscience & Nanotechnology,2016,16(5):4310.

[9] SUN Y H, WANG J, DU H Y, et al. Formaldehyde gas sensors based on SnO2/ZSM-5 zeolite composite nanofibers[J]. Journal of Alloys and Compounds,2021,868:159140. DOI: 10.1016/j.jallcom.2021.159140

[10] KIM J W, PORTE Y, KO K Y, et al. Micropatternable double-faced ZnO nanoflowers for flexible gas sensor[J]. ACS Applied Materials & Interfaces,2017,9(38):32876-32886.

[11] LU S H, ZHANG Y Z, LIU J Y, et al. Sensitive H2 gas sensors based on SnO2 nanowires[J]. Sensors and Actuators B: Chemical,2021,345:130334. DOI: 10.1016/j.snb.2021.130334

[12] WANG Q, CHENG X, WANG Y R, et al. Sea urchins-like WO3 as a material for resistive acetone gas sensors[J]. Sensors and Actuators B: Chemical,2022,355:131262. DOI: 10.1016/j.snb.2021.131262

[13] BAI J L, KONG Y, LIU Z L, et al. Ag modified Tb-doped double-phase In2O3 for ultrasensitive hydrogen gas sensor[J]. Applied Surface Science,2022,583:152521. DOI: 10.1016/j.apsusc.2022.152521

[14] SONG B Y, ZHANG X F, HUANG J, et al. Porous Cr2O3 architecture assembled by nano-sized cylinders/ellipsoids for enhanced sensing to trace H2S gas[J]. ACS Applied Materials & Interfaces,2022,14(19):22302-22312.

[15] NAKATE U T, LEE G H, AHMAD R, et al. Nano-bitter gourd like structured CuO for enhanced hydrogen gas sensor application[J]. International Journal of Hydrogen Energy,2018,43(50):22705-22714. DOI: 10.1016/j.ijhydene.2018.09.162

[16] LI C Y, CHOI P G, KIM K S, et al. High performance acetone gas sensor based on ultrathin porous NiO nanosheet[J]. Sensors and Actuators B: Chemical,2022,367:132143. DOI: 10.1016/j.snb.2022.132143

[17] DING C, MA Y L, LAI X Y, et al. Ordered large-pore mesoporous Cr2O3 with ultrathin framework for formaldehyde sensing[J]. ACS Applied Materials & Interfaces,2017,9(21):18170-18177.

[18] POKHREL S, NAGARAJA K S. Electrical and humidity sensing properties of chromium(III) oxide-tungsten(VI) oxide composites[J]. Sensors and Actuators B: Chemical,2003,92(1):144-150.

[19] 林秉群, 赵国敏, 潘明珠. 基于VOCs传感器敏感材料的研究进展[J]. 复合材料学报, 2022, 39(2):478-488. LIN Bingqun, ZHAO Guomin, PAN Mingzhu. Research progress of sensing materials for VOCs detection[J]. Acta Materiae Compositae Sinica,2022,39(2):478-488(in Chinese).

[20] GUSHCHIN P A, LUBIMENKO V A, PETROVA D A, et al. Catalytic oligomerization of isobutylene at the boiling point of liquid nitrogen[J]. Chemical Engineering Science,2020,227:115903. DOI: 10.1016/j.ces.2020.115903

[21] DUTTA S, PANDEY A, LEELADHA R, et al. Growth and characterization of ultrathin TiO2-Cr2O3 nanocomposite films[J]. Journal of Alloys and Compounds,2017,696:376-381. DOI: 10.1016/j.jallcom.2016.11.284

[22] CAREY J, LEGESSE M, NOLAN M. Low valence cation doping of bulk Cr2O3: Charge compensation and oxygen vacancy formation[J]. The Journal of Physical Chemistry C,2016,120(34):19160-19174. DOI: 10.1021/acs.jpcc.6b05575

[23] BARASKAR P, CHOUHAN R, AGRAWAL A, et al. Weak ferromagnetism at room temperature in Ti incorporated Cr2O3 thin film[J]. Physica B: Condensed Matter,2019,571:36-40. DOI: 10.1016/j.physb.2019.06.031

[24] SHEN Y B, LI T T, ZHONG X X, et al. ppb-level NO2 sensing properties of Au-doped WO3 nanosheets synthesized from a low-grade scheelite concentrate[J]. Vacuum,2020,172:109036. DOI: 10.1016/j.vacuum.2019.109036

[25] ZHANG W, SHEN Y B, ZHANG J, et al. Low-temperature H2S sensing performance of Cu-doped ZnFe2O4 nanoparticles with spinel structure[J]. Applied Surface Science,2019,470:581-590. DOI: 10.1016/j.apsusc.2018.11.164

-

期刊类型引用(5)

1. 张有茶,贾成厂,贾鹏. 中间相碳微球/氰酸酯树脂复合材料的导电导热性能. 复合材料学报. 2019(03): 602-610 .  本站查看

本站查看

2. 张新庄,张书勤,闫鹏,裴婷,窦倩,董昭,王姗姗. 聚丙烯基石墨烯改性复合材料的导电及热稳定性. 化学工业与工程. 2019(06): 60-64 .  百度学术

百度学术

3. 胡荣杰,甯尤军,肖藤,雷玲,阿拉木斯,胡宁. 石墨烯/环氧树脂纳米复合材料的制备与热膨胀特性分析. 重庆大学学报. 2018(06): 50-57 .  百度学术

百度学术

4. 洪新密,肖小亭,吴雅莎,杨洁,何穗华. 超声振动对闪光铝颜料填充HDPE复合材料流变行为和性能的影响. 高分子材料科学与工程. 2018(04): 82-88 .  百度学术

百度学术

5. 徐子威,张婧婧,何穗华,赖永健,杨涛,余浩斌. 螺杆剪切对聚丙烯/石墨烯微片纳米复合材料形态和性能的影响. 塑料科技. 2018(02): 56-63 .  百度学术

百度学术

其他类型引用(4)

-

目的

异丁烯是一种常见的挥发性有机污染物(VOCs)气体,其危害是容易让人窒息,且其与空气混合能形成爆炸性混合物,遇热源和明火有燃烧爆炸的危险,工业生产中亟需一种性能优良的气体传感器来对其进行快速检测,但市场上专门用于检测异丁烯的气体传感器还鲜有报道。本文采用气溶胶辅助化学气相沉积(AACVD)技术在氧化铝基底上分别沉积得到纯氧化铬(CrO)薄膜及W掺杂CrO(W/CrO)薄膜材料,并将其制备成气体传感器,对比研究两种气体传感器对异丁烯的气敏性能。

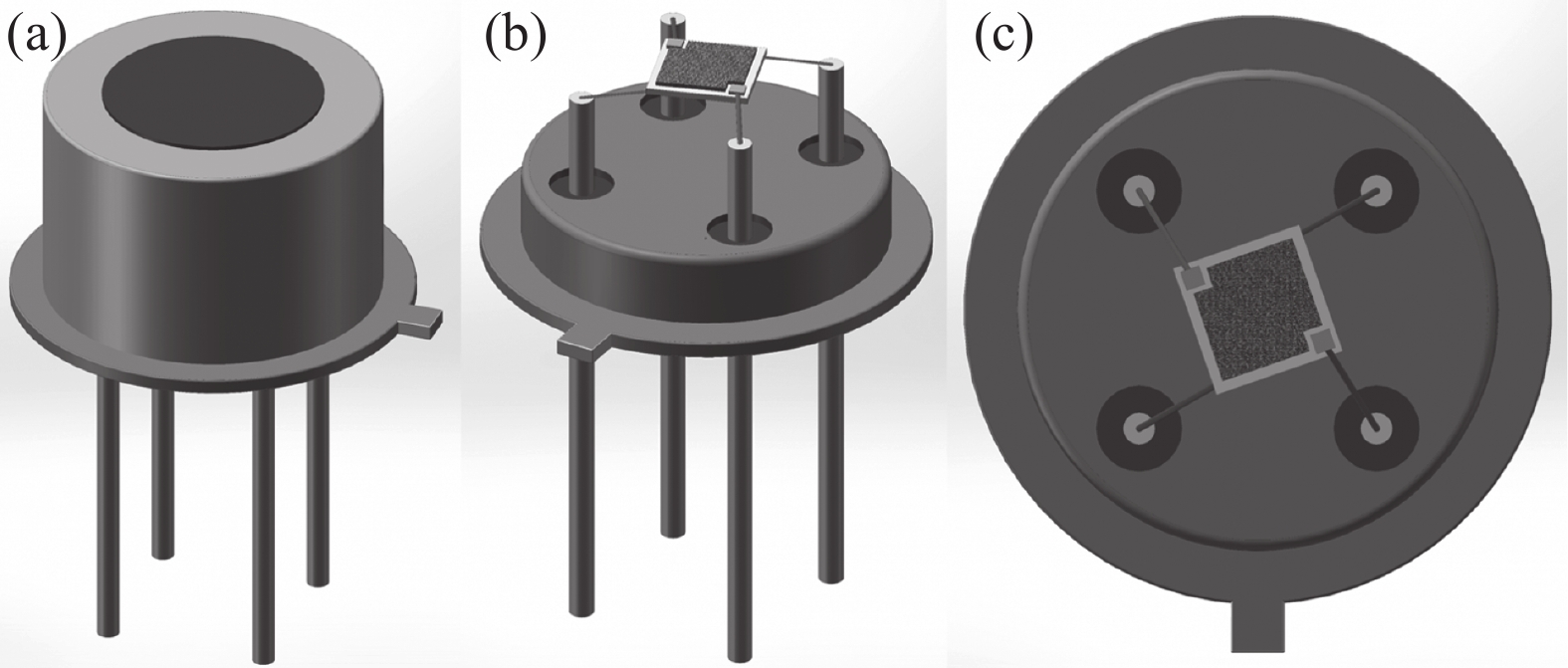

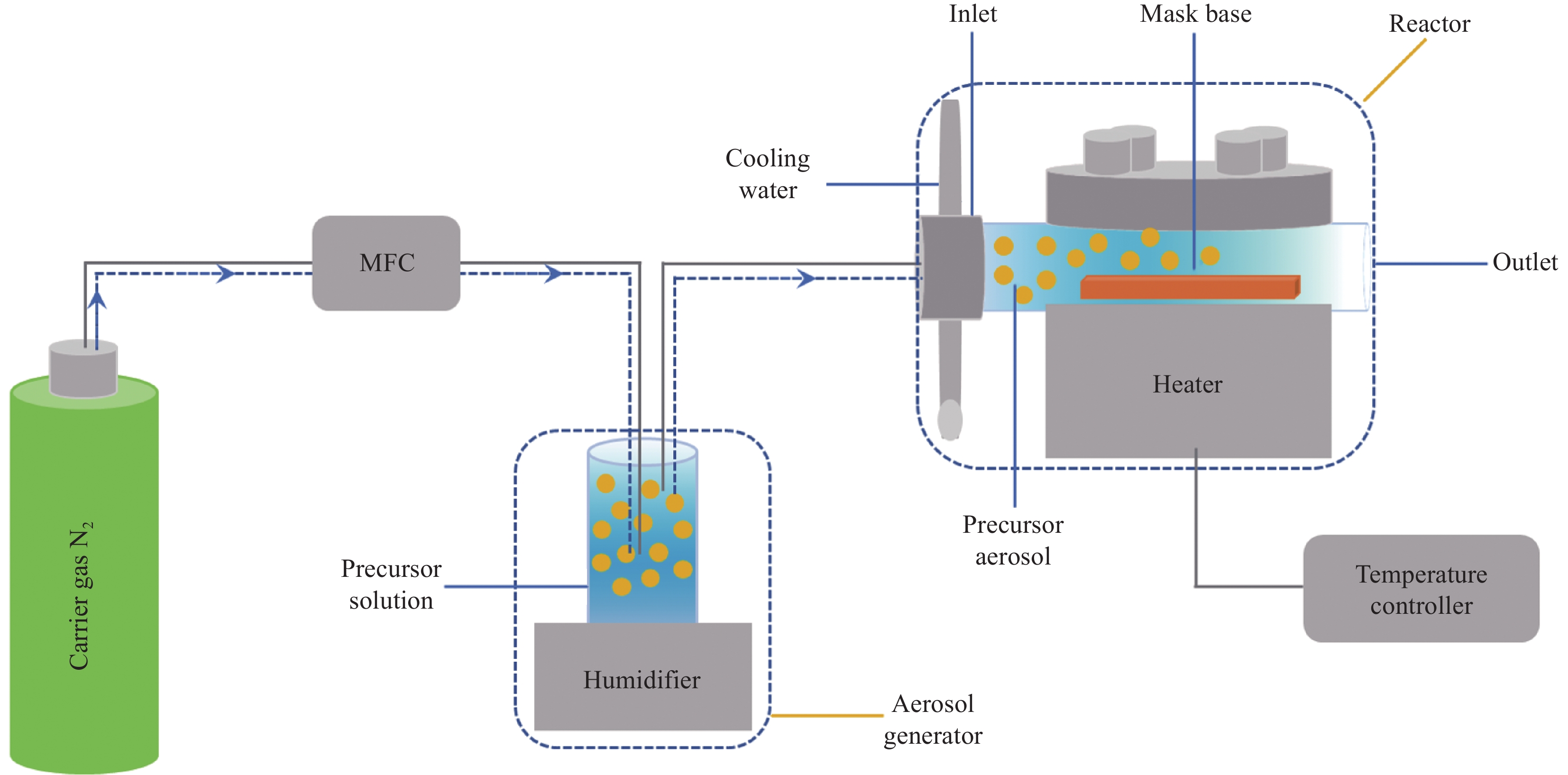

方法通过AACVD工艺将CrO和W/CrO薄膜气敏材料沉积在印刷有叉指金电极的氧化铝基底上,将元件进行封装后获得用于气敏性能测试的气体传感器。传感器的测试在英国ALPHASENSE公司的SMS-330电阻式气体传感器测试系统中进行,将气体传感器置入该系统的气敏测试腔中,测试腔的温度在室温至500°C之间可调,测试气体的浓度及测试时间通过LabVIEW软件控制流量控制器(MFC)来改变。当需要调节湿度时,采用鼓泡法将一路干燥空气通过一个密闭水瓶后再与其他路的气体混合而进行调制。在进行气敏测试前,需要将传感器置于测试腔体中,并通入1 h空气,以使传感器的电阻趋于稳定,随后通入30 min的异丁烯气体,再通入30 min空气使其电阻值完全恢复至起始值。灵敏度(S)定义为气体传感器在异丁烯气氛中的电阻值()与在空气氛围中的电阻值()的比值,即S=/。

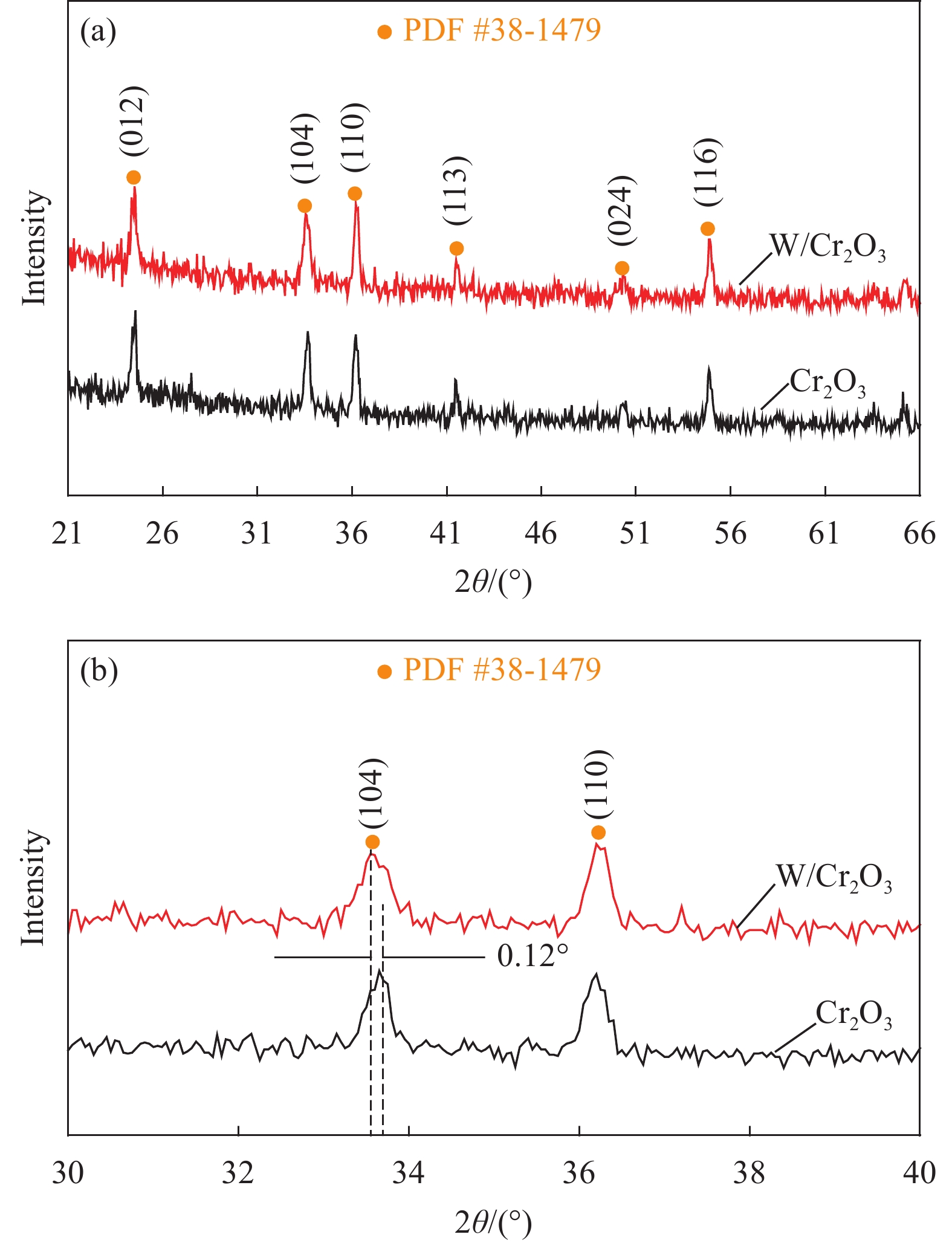

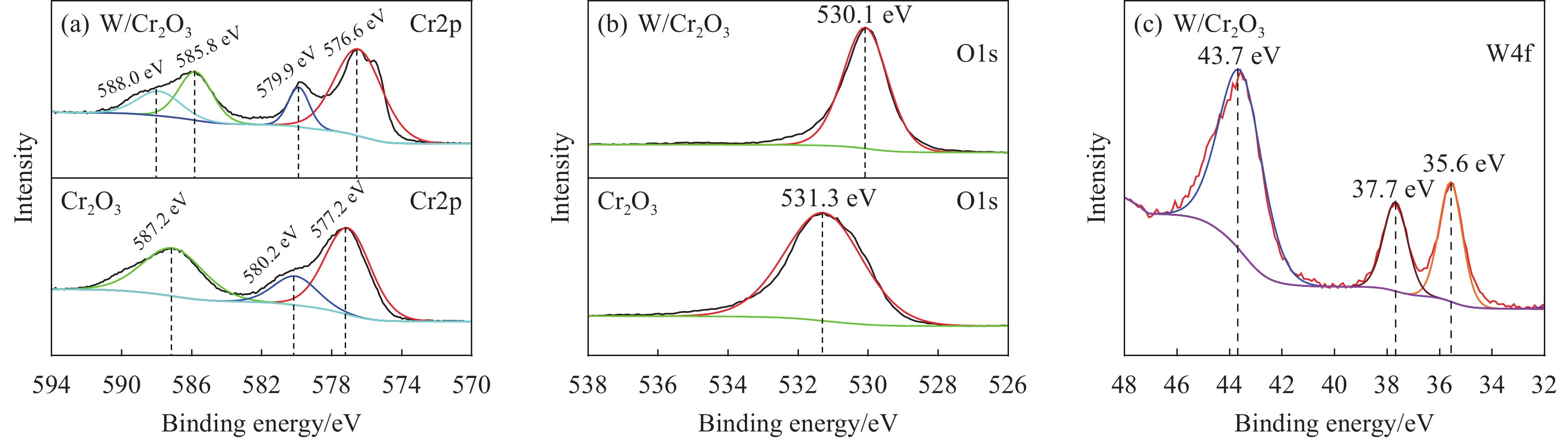

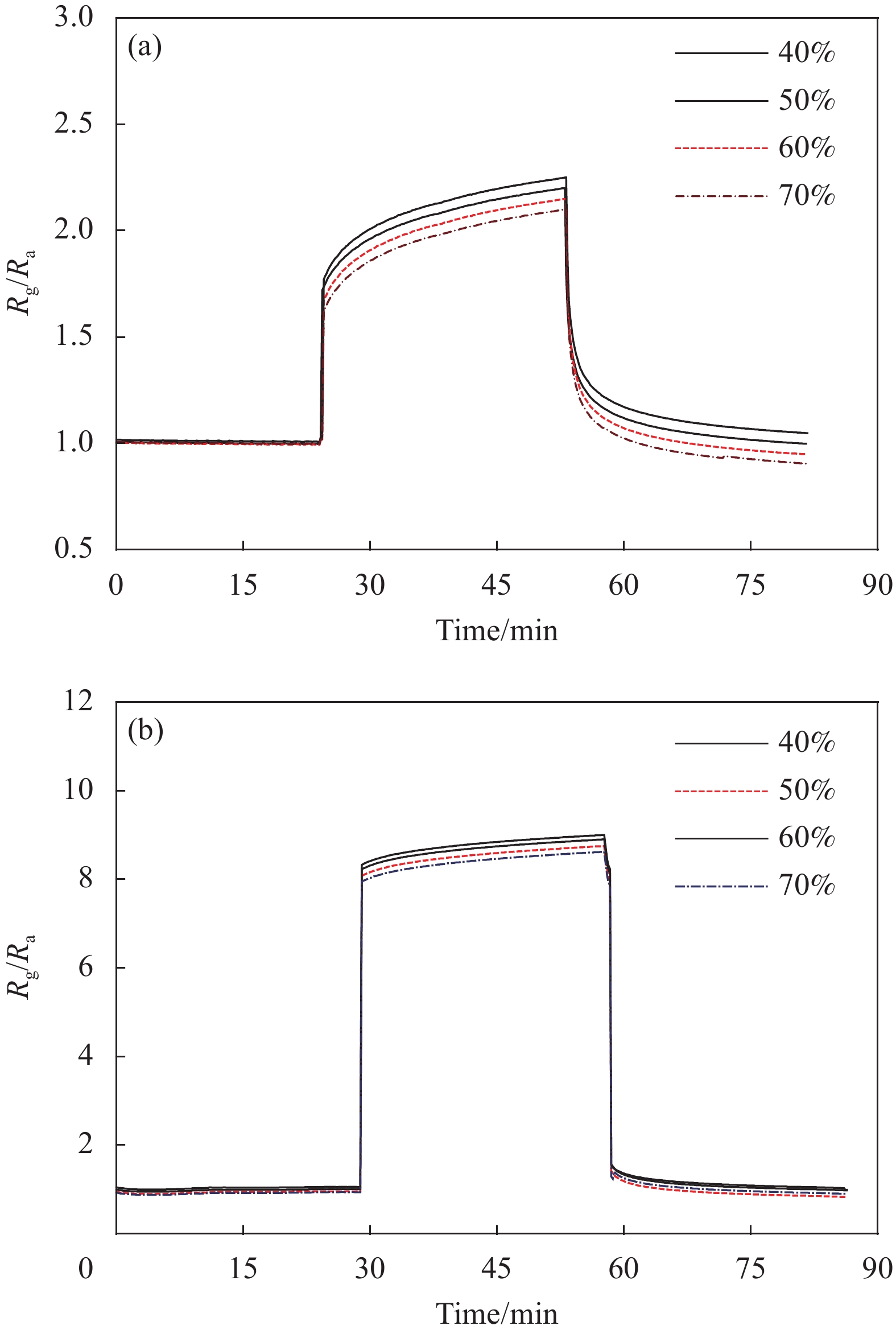

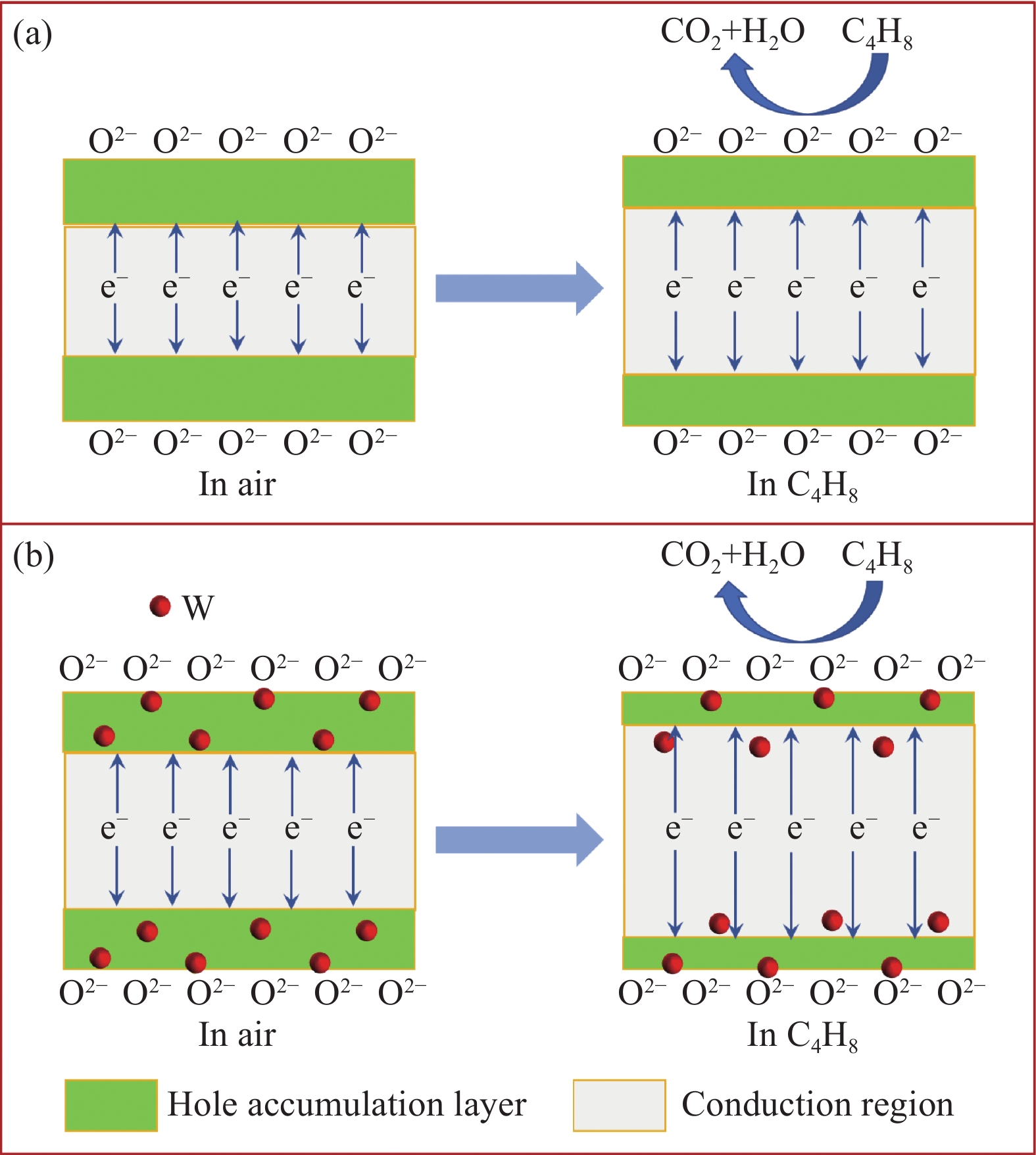

结果利用SEM、TEM、XRD及XPS等表征手段对CrO及W/CrO纳米薄膜的结构及价键进行分析可知:CrO薄膜是由很多不规则的椭球型颗粒组成,颗粒粒度在50 nm左右,而W/CrO纳米颗粒的粒径减小为15 nm左右;W/CrO在(104)晶面处的特征衍射峰相较于纯CrO向小角度发生了0.12°的偏移,这可能是由于W和Cr离子半径的差异使得W元素的掺入引起CrO晶格变形造成的,且XRD图谱中并未检测到其他杂质的衍射峰,表明制备得到的薄膜样品晶相单一且纯度较高;CrO及W/CrO纳米薄膜样品中的铬以Cr形式存在,氧以O形式存在,W元素是以W的氧化态形式存在于CrO晶体中。对CrO及W/CrO纳米薄膜的气敏性能测试表明:当工作温度在300-500°C范围内变化时,CrO气体传感器对2×10 CH气体的响应值变化不大,最大波动仅有0.8%,而W/CrO传感器的灵敏度随着工作温度的升高呈现出明显的先升高后降低的趋势,在400°C时获得最大灵敏度3.55,比300°C时的1.89提高了0.88倍;CrO和W/CrO气体传感器的灵敏度在最佳工作温度400°C时对5×10到8×10浓度范围内的CH气体表现出良好的线性拟合关系;CrO传感器的RSD误差在0.49-1.27%之间,而W/CrO传感器的RSD误差在3.51-4.94%之间,两者均小于5%,表明无论是CrO还是W/CrO传感器的气敏性能皆具有良好的稳定性和重复性;随着相对湿度的增大,CrO和W/CrO气体传感器对CH气体的灵敏度均呈现逐渐下降的趋势;纯CrO薄膜对异丁烯(CH)、硫化氢(HS),二氧化氮(NO),丙酮(CHO)和乙醇(CHO)五种气体的灵敏度相差不大,其在异丁烯和其他四种干扰气体之间具有约50倍的选择性,而W/CrO薄膜对较低浓度异丁烯气体的响应明显高于对其他四种高浓度干扰气体的响应,将气体的选择性进一步提高到100-150倍。

结论在氧化铝基底表面通过AACVD法制备得到纯度较高,结晶较好的CrO和W/CrO薄膜气敏材料,对异丁烯(CH)表现出良好的气敏特性;W/CrO薄膜相较于CrO表现出远远增强的温度依赖性,且W/CrO气体传感器的最佳灵敏度提高了3倍有余,抗湿性提高了1.5倍,对HS、NO、丙酮和乙醇四种干扰气体的选择性提高了2-3倍;两组传感器均具有良好的测试重复性和片间一致性。

-

挥发性有机污染物(VOCs)气体广泛存在于生产生活中,异丁烯是一种常见的VOCs气体,其危害是容易让人窒息,且其与空气混合能形成爆炸性混合物,遇热源和明火有燃烧爆炸的危险,工业生产中亟需一种性能优良的气体传感器来对其进行快速检测,但市场上专门用于检测异丁烯的气体传感器还鲜有报道。

本文采用气溶胶辅助化学气相沉积(AACVD)技术在氧化铝基底上分别沉积得到纯氧化铬(Cr2O3)薄膜及W掺杂Cr2O3(W/Cr2O3)的薄膜材料,并将其制备成气体传感器,对比研究了两种气体传感器对异丁烯的气敏性能,气敏测试结果表明,基于W/Cr2O3薄膜所制备的气体传感器相较于单一的Cr2O3气体传感器对异丁烯气体表现出较高的灵敏度,并展现出良好的稳定性、抗湿性和气体选择性,其性能优良,制备成本较低,有望实现商业化应用。

气体传感器示意图 (a), Cr2O3薄膜的SEM照片 (b), Cr2O3气体传感器对异丁烯气体的灵敏度变化曲线 (c), W/Cr2O3薄膜的SEM照片 (d), W/Cr2O3气体传感器对异丁烯气体的灵敏度变化曲线 (e).

下载:

下载: