Experiment on RC beams strengthened with high-strength steel strand meshes and ECC under secondary load

-

摘要: 高强钢绞线网/工程水泥基复合材料(Engineered cementitious composites,ECC)作为新型高性能复合材料,充分利用了高强钢绞线网及ECC优良的力学性能,具有超高延性、韧性、优异的裂缝控制能力及强度高等优点。为探究二次受力对该新型复合材料加固钢筋混凝土(Reinforced concrete,RC)梁受弯性能的影响,本文考虑是否持载加固、原梁损伤程度、纵向高强钢绞线配筋率的影响,进行了高强钢绞线网/ECC加固RC梁受弯试验,分析了二次受力对加固梁受弯性能的影响机制,探明了各影响因素对持载加固RC梁受弯性能的影响规律。结果表明:采用高强钢绞线网/ECC持载加固RC梁,使原梁承载力、刚度、延性、韧性分别提升了38%~65%、20%~81%、0%~18%、33%~116%,且能很好约束RC梁裂缝而减小裂缝宽度;相比于卸载加固梁,持载加固梁的加固层由于存在明显应变滞后,对原梁混凝土裂缝约束效果变差,其受弯承载力、刚度、韧性有所降低,但其延性有所提高;持载加固梁的受弯承载力、刚度、延性、韧性随原梁损伤程度增加而降低,而随钢绞线配筋率的适当提高而增大。

-

关键词:

- 高强钢绞线网/ECC /

- 二次受力 /

- 持载加固 /

- 损伤程度 /

- 钢筋混凝土梁

Abstract: As a new type of high performance composite material, high-strength steel wire strand (HSWS) meshes reinforced engineered cementitious composites (ECC), which makes full use of the excellent mechanical properties of HSWS meshes and ECC, has the advantages of ultra-high ductility and toughness, excellent crack-control ability and high strength. In order to explore the effect of secondary load on the flexural behavior of reinforced concrete (RC) beam strengthened with this new composite material, the bending test of RC beams strengthened with HSWS meshes reinforced ECC was conducted, considering the effects of strengthening in load-carrying state, damage degree of the original beam, and reinforcement ratio of longitudinal HSWS. The influence mechanism of secondary load on the flexural performance of strengthened RC beams was analyzed, and the influence laws of these factors on the flexural behavior of RC beams strengthened with HSWS meshes reinforced ECC in load-carrying state were explored. The results show that the flexural capacity, stiffness, ductility and toughness of RC beams strengthened with high-strength steel wire meshes reinforced ECC in load-carrying state are increased by 38%-65%, 20%-81%, 0%-18% and 33%-116%, respectively, and the crack development of RC beam can be well restrained, and the crack width can be reduced. Compared with the RC beams strengthened in unloading state, the beams strengthened in load-carrying state exhibit obvious strain hysteresis in the reinforcement layer, resulting in the worse constraint effect on the crack of the original beam, and its flexural capacity, stiffness and toughness decrease, but its ductility is improved. The flexural capacity, stiffness, ductility and toughness of the beams strengthened in load-carrying state decrease as the original beam damage degree increases, but grow as the reinforcement ratio of HSWS increases properly. -

-

表 1 试件设计参数

Table 1 Specimen design parameters

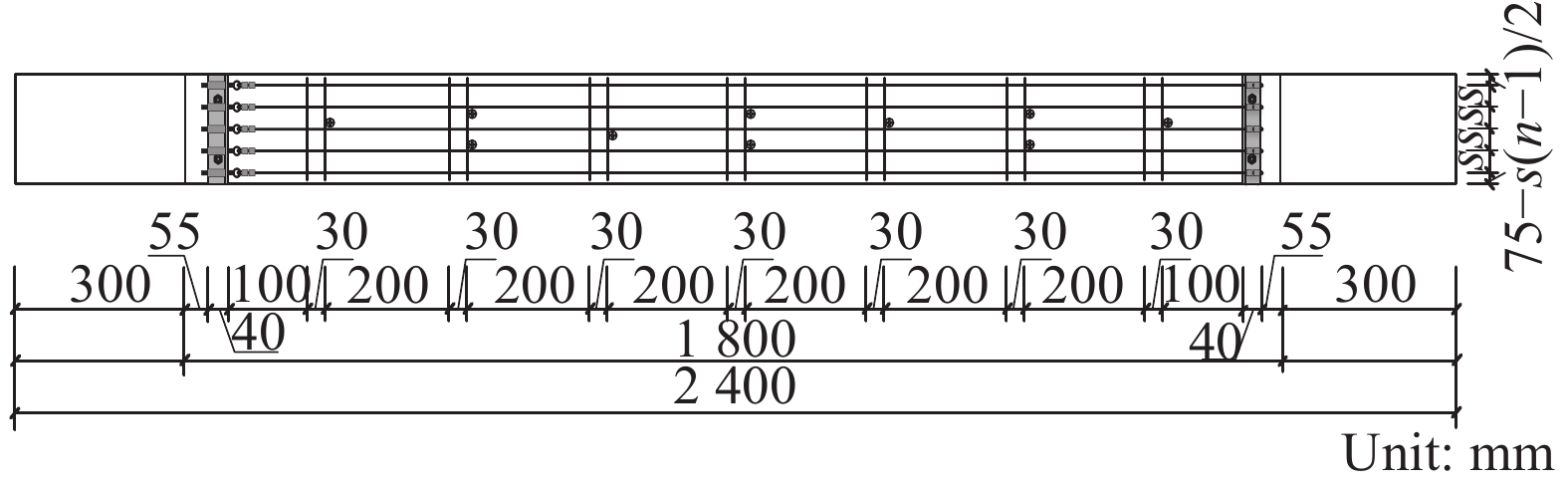

Group Specimen number d

/mmPreload level/% ρ

/%s/mm

(n)Load reinforcement A CSLA0 2.4 0 0.413 30(5) Y CSLA1 2.4 50 0.413 30(5) Y CSLA2 2.4 65 0.413 30(5) Y CSLA3 2.4 80 0.413 30(5) Y B CSLB1 2.4 65 0.248 50(5) Y CSLB3 2.4 65 0.579 21(5) Y C USLC1 2.4 65 0.413 30(5) N Notes: Specimen number (C—Loading status; U—Unloading Status; S—Strengthening; L—RC beam); d—Diameter of steel strand; ρ—Reinforcement ratio of longitudinal high-strength steel wire strand (HSWS); s—Spacing of longitudinal steel strands; n—Number of longitudinal steel strands; N—Not load reinforcement; Y—Load reinforcement. 表 2 工程水泥基复合材料(ECC)配合比

Table 2 Mix proportions of engineered cementitious composites (ECC)

Cement Sand Fly ash Silica powder Water PVA

fiberWater reducer Thickening agent 1 0.4 2.5 0.073 0.893 0.072 0.0407 0.00182 Note: PVA—Polyvinyl alcohol. 表 3 ECC材料性能

Table 3 Material properties of ECC

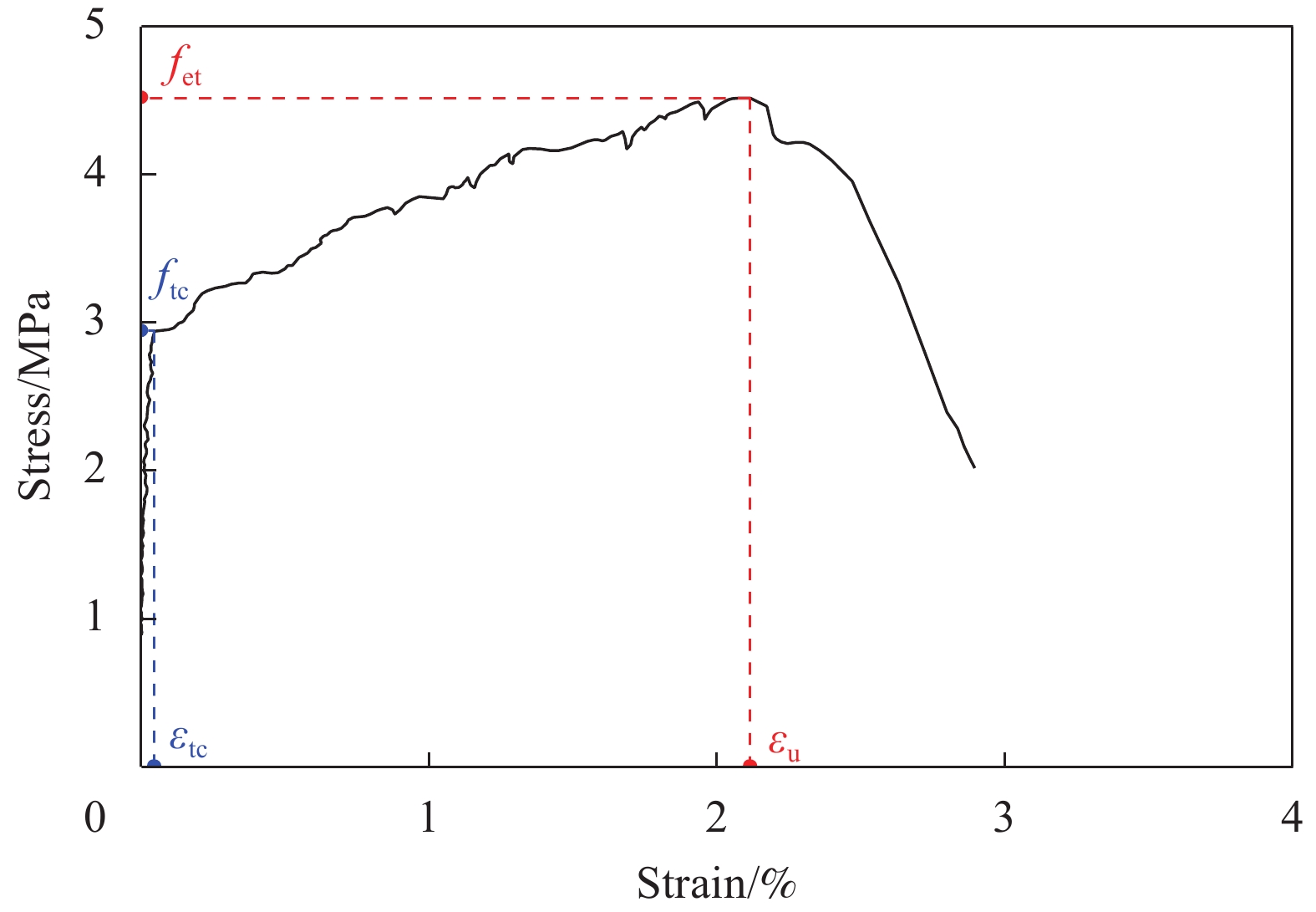

fcu/

MPaftc/

MPaεtc/% Es/

GPafet/

MPaεu

/%45.8 2.97 0.046 18.1 4.55 2.13 Notes: fcu—ECC compressive strength; ftc—ECC cracking strength; εtc—ECC cracking strain; Es—ECC elastic modulus; fet—ECC tensile strength; εu—ECC ultimate tensile strain. 表 4 高强钢绞线网/ECC加固RC梁受弯试验结果

Table 4 Bending test results of RC beams strengthened with HSWS meshes reinforced ECC

Specimen number Mc/

(kN·m)Mec-d/

(kN·m)My/

(kN·m)Mswy/

(kN·m)Mu/

(kN·m)Δy/

mmΔu/

mmμΔ Dmax ωc,0.8 y/

mmωc,0.9 y/

mmωc,y/

mmL0 2.86 — 12.78 — 14.98 7.46 23.30 3.12 876.03 0.20 0.27 0.36 CSLA0 6.60 2.62 19.97 22.06 24.30 9.04 30.29 3.35 1894.15 0.14 0.19 0.29 CSLA1 3.72 0.98 18.91 21.79 23.50 9.02 29.92 3.32 1744.05 0.18 0.21 0.29 CSLA2 3.39 0.93 17.08 21.12 22.77 8.82 28.50 3.23 1509.68 0.21 0.23 0.30 CSLA3 3.43 0.66 16.19 20.25 21.85 8.85 27.67 3.13 1384.42 0.30 0.31 0.34 CSLB1 3.31 0.68 15.17 19.56 20.70 7.74 24.53 3.17 1169.79 0.21 0.23 0.32 CSLB3 3.35 1.06 17.70 22.31 24.66 8.08 29.71 3.68 1710.61 0.21 0.22 0.29 USLC1 — 2.47 19.20 19.96 23.30 8.80 27.50 3.13 1519.75 0.21 0.22 0.29 Notes: Mc—Cracking moment of concrete; Mec-d—Absolute value of ECC cracking moment minus pre-damage moment; My—Yielding moment of the specimen; Mswy—Nominal yield moment of steel strand; Mu—Ultimate bending moment of the specimen; Δy—Deflection of the specimen at My; Δu—Deflection of the specimen at Mu; μΔ—Ductility coefficient of the specimen; Dmax—Flexural toughness coefficient of the specimen; ωc,0.8 y—Concrete crack width at 80%My; ωc,0.9 y—Concrete crack width at 90%My; ωc,y—Concrete crack width at My. -

[1] LI V C. On engineered cementitious composites (ECC)[J]. Journal of Advanced Concrete Technology,2003,1(3):215-230. DOI: 10.3151/jact.1.215

[2] LEE B Y, CHO C G, LIM H J, et al. Strain hardening fiber reinforced alkali-activated mortar-A feasibility study[J]. Construction and Building Materials,2012,37:15-20. DOI: 10.1016/j.conbuildmat.2012.06.007

[3] KAN L L, SHI H S, SAKULICH A R, et al. Self-healing characterization of engineered cementitious composite materials[J]. ACI Materials Journal,2010,107(6):617-624.

[4] 余江滔, 许万里, 张远淼. ECC-混凝土黏结界面断裂试验研究[J]. 建筑材料学报, 2015, 18(6):958-963, 970. DOI: 10.3969/j.issn.1007-9629.2015.06.008 YU Jiangtao, XU Wanli, ZHANG Yuanmiao. Experiment study on fracture property of ECC-concrete interface[J]. Journal of Building Materials,2015,18(6):958-963, 970(in Chinese). DOI: 10.3969/j.issn.1007-9629.2015.06.008

[5] 朱方之, 王鹏刚, 赵铁军, 等. SHCC修复试件黏结滑移性能研究[J]. 建筑材料学报, 2016, 19(1):72-77. DOI: 10.3969/j.issn.1007-9629.2016.01.012 ZHU Fangzhi, WANG Penggang, ZHAO Tiejun, et al. Studies on bond slippage properties of concrete specimen repaired with strain hardening cementitious composites (SHCC)[J]. Journal of Building Materials,2016,19(1):72-77(in Chinese). DOI: 10.3969/j.issn.1007-9629.2016.01.012

[6] ZHENG A H, LIU Z Z, LI F P, et al. Experimental investigation of corrosion-damaged RC beams strengthened in flexure with FRP grid-reinforced ECC matrix composites[J]. Engineering Structures,2021,244:112779. DOI: 10.1016/j.engstruct.2021.112779

[7] 乔治, 潘钻峰, 梁坚凝, 等. ECC/RC组合梁受弯性能试验研究与分析[J]. 东南大学学报(自然科学版), 2017, 47(4):724-731. QIAO Zhi, PAN Zuanfeng, LIANG Jianning, et al. Experimental study and analysis of flexural behavior of ECC/RC composite beams[J]. Journal of Southeast University (Natural Science Edition),2017,47(4):724-731(in Chinese).

[8] 袁微微, 杜文平, 杨才千, 等. 二次受力下PVA-RFCC加固RC梁抗弯性能试验研究[J]. 建筑结构, 2020, 50(15):15-19, 41. YUAN Weiwei, DU Wenping, YANG Caiqian, et al. Experimental study on flexural behavior of RC beams strengthened with PVA-RFCC under secondary load[J]. Building Structure,2020,50(15):15-19, 41(in Chinese).

[9] 卜良桃, 陈军, 鲁晨. PVA-ECC加固RC足尺梁二次受力试验研究[J]. 湖南大学学报(自然科学版), 2011, 38(1):1-7. BU Liangtao, CHEN Jun, LU Chen. Experiment on full-scale RC beam reinforced by polyvinyl alcohol-engineered cementitious composite mortar in flexure subjected to secondary load[J]. Journal of Hunan University (Natural Science Edition),2011,38(1):1-7(in Chinese).

[10] 林于东, 宗周红, 林秋峰. 高强钢绞线网-聚合物砂浆加固混凝土及预应力混凝土梁的抗弯性能试验研究[J]. 工程力学, 2012, 29(9):141-149. DOI: 10.6052/j.issn.1000-4750.2011.04.0193 LIN Yudong, ZONG Zhouhong, LIN Qiufeng. Experiment study on flexural behavior of RC/PRC beams strengthened with high strength steel wire mesh and permeable polymer mortar[J]. Engineering Mechanics,2012,29(9):141-149(in Chinese). DOI: 10.6052/j.issn.1000-4750.2011.04.0193

[11] LI K, LIU W K, ZHANG K, et al. Bond behavior of stainless steel wire ropes embedded in engineered cementitious composites[J]. Construction and Building Materials,2021,281:122622. DOI: 10.1016/j.conbuildmat.2021.122622

[12] 李可, 赵佳丽, 李志强, 等. 高强钢绞线网增强ECC抗弯加固无损RC梁试验[J]. 复合材料学报, 2022, 39(7):3428-3440. LI Ke, ZHAO Jiali, LI Zhiqiang, et al. Experiment on non-damaged RC beams strengthened by high-strength steel wire strand meshes reinforced ECC in bending[J]. Acta Materiae Compositae Sinica,2022,39(7):3428-3440(in Chinese).

[13] WANG X L, YANG G H, QIAN W W, et al. Tensile behavior of high-strength stainless steel wire rope (HSSSWR)-reinforced ECC[J]. International Journal of Concrete Structures and Materials,2021,15(1):1-15. DOI: 10.1186/s40069-021-00480-x

[14] 李可, 卫垚鑫, 金蕾蕾, 等. 高强不锈钢绞线网/ECC约束混凝土抗压强度[J]. 华中科技大学学报(自然科学版), 2021, 49(12):126-132. LI Ke, WEI Yaoxing, JIN Leilei, et al. Compressive strength of concrete confined by high-strength stainless steel stranded wire meshes and engineered cementitious composites[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition),2021,49(12):126-132(in Chinese).

[15] 李苗浩夫. 高强不锈钢绞线网/ECC加固钢筋混凝土柱受压性能研究[D]. 郑州: 郑州大学, 2019. LIMIAO Haofu. Research on compressive performance of reinforced concrete columns strengthened by high-strength stainless steel wire mesh/ECC[D]. Zhengzhou: Zhengzhou University, 2019(in Chinese).

[16] 周擎威. 高强不锈钢绞线与ECC黏结性能试验研究[D]. 郑州: 郑州大学, 2018. ZHOU Qingwei. Experimental study on the bonding performance between high-strength stainless steel strand and EEC[D]. Zhengzhou: Zhengzhou University, 2018(in Chinese).

[17] NAPOLI A, REALFONZO R. Reinforced concrete beams strengthened with SRP/SRG systems: Experimental investigation[J]. Construction and Building Materials,2015,93(2):654-677.

[18] 中华人民共和国住房和城乡建设部. 混凝土结构试验方法标准: GB/T 50152—2012[S]. 北京: 中国建筑工业出版社, 2012. Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test method of concrete structures: GB/T 50152—2012[S]. Beijing: China Architecture & Building Press, 2012(in Chinese).

[19] DONG S F, ZHOU D C, ASHRAF A, et al. Flexural toughness and calculation model of super-fine stainless wire reinforced reactive powder concrete[J]. Cement and Concrete Composites,2019,104:103367. DOI: 10.1016/j.cemconcomp.2019.103367

[20] 黄华. 高强钢绞线网—聚合物砂浆加固钢筋混凝土梁式桥试验研究与机理分析[D]. 西安: 长安大学, 2008. HUANG Hua. Experimental study and theoretical analysis on strengthening RC girder bridge with steel wire mesh and polymer mortar[D]. Xi'an: Chang'an University, 2008(in Chinese).

-

期刊类型引用(2)

1. 柯俊,李志虎,秦玉林. 金属主簧-复合材料副簧复合刚度计算模型. 汽车实用技术. 2021(05): 39-43 .  百度学术

百度学术

2. 曾婷,王咏莉,尹忠旺,苏婷慧,师志峰,饶猛. 端面凸轮下压机构支承轴承冲击失效分析及优化(英文). 机床与液压. 2017(24): 37-42 .  百度学术

百度学术

其他类型引用(5)

-

目的

高强钢绞线网/ECC(Engineered Cementitious Composites)作为新型高性能复合材料,充分利用高强钢绞线网及ECC优良的物理力学性能,具有超高延性、高韧性、优异的裂缝控制能力及强度高等优点。而现阶段采用该新型复合材料加固RC梁的研究未考虑二次受力对加固梁受弯性能的影响。为完善现有研究成果,进一步将该新型复合材料应用于实际工程加固中,本文进行高强钢绞线网/ECC持载加固RC梁受弯性能的试验研究。

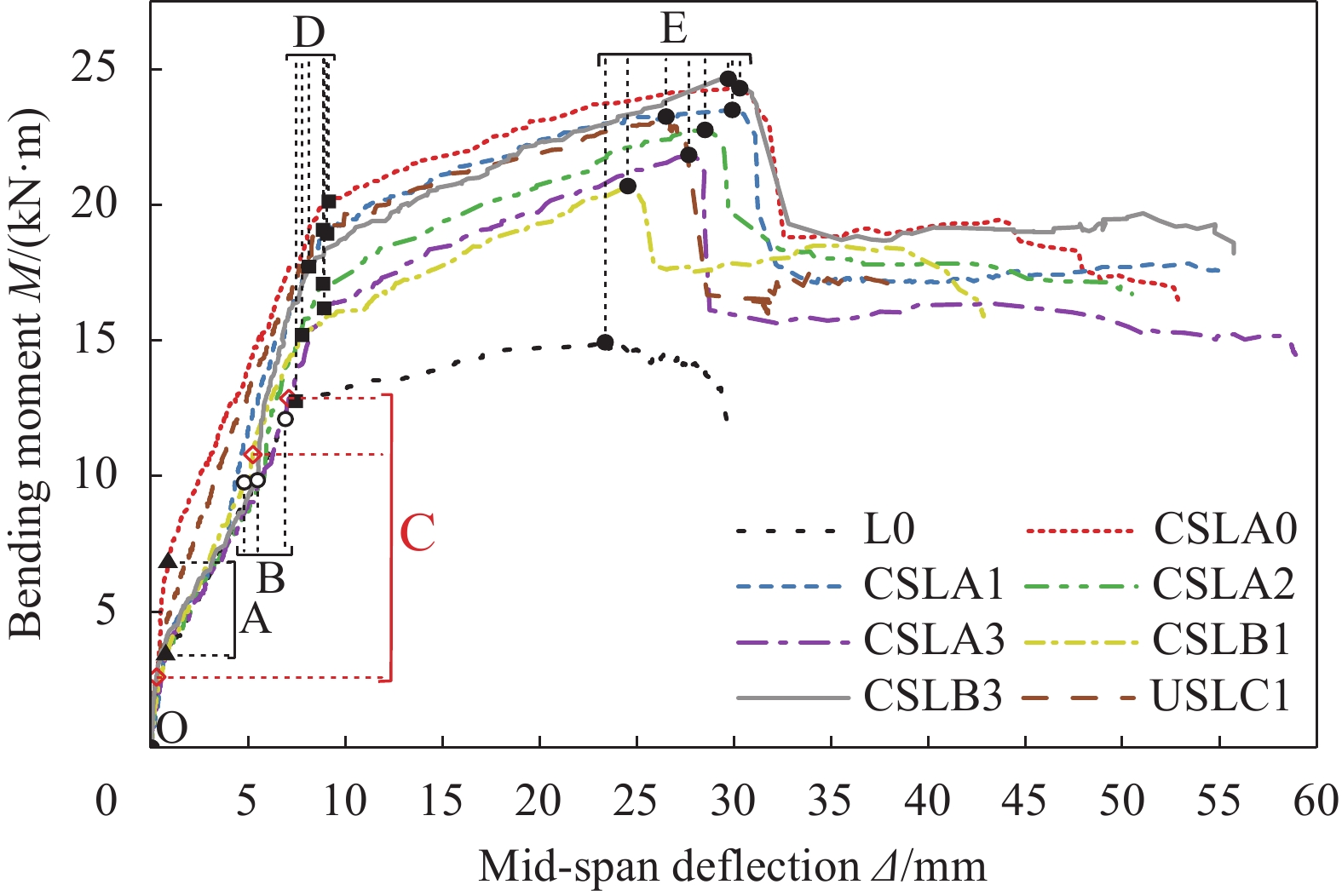

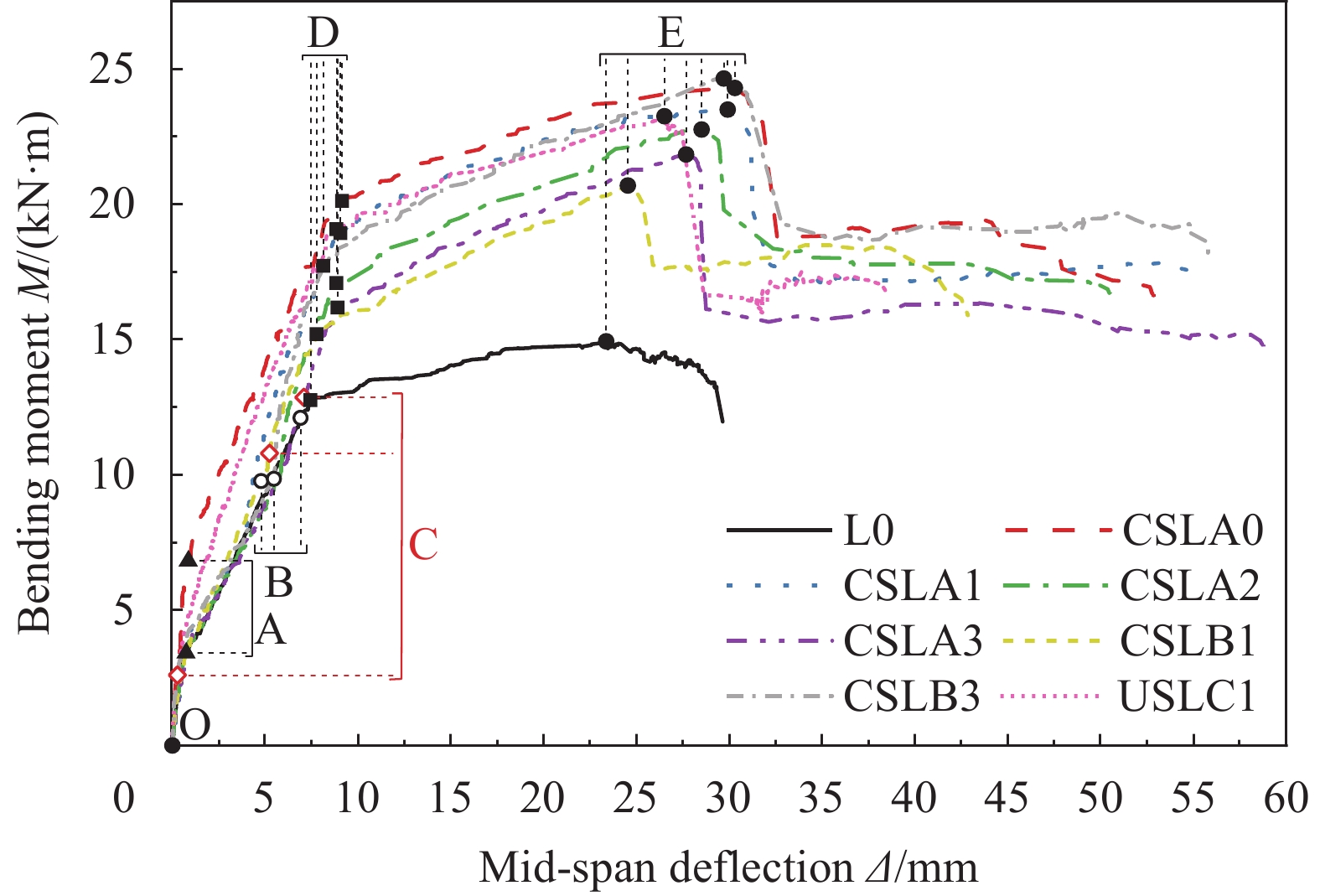

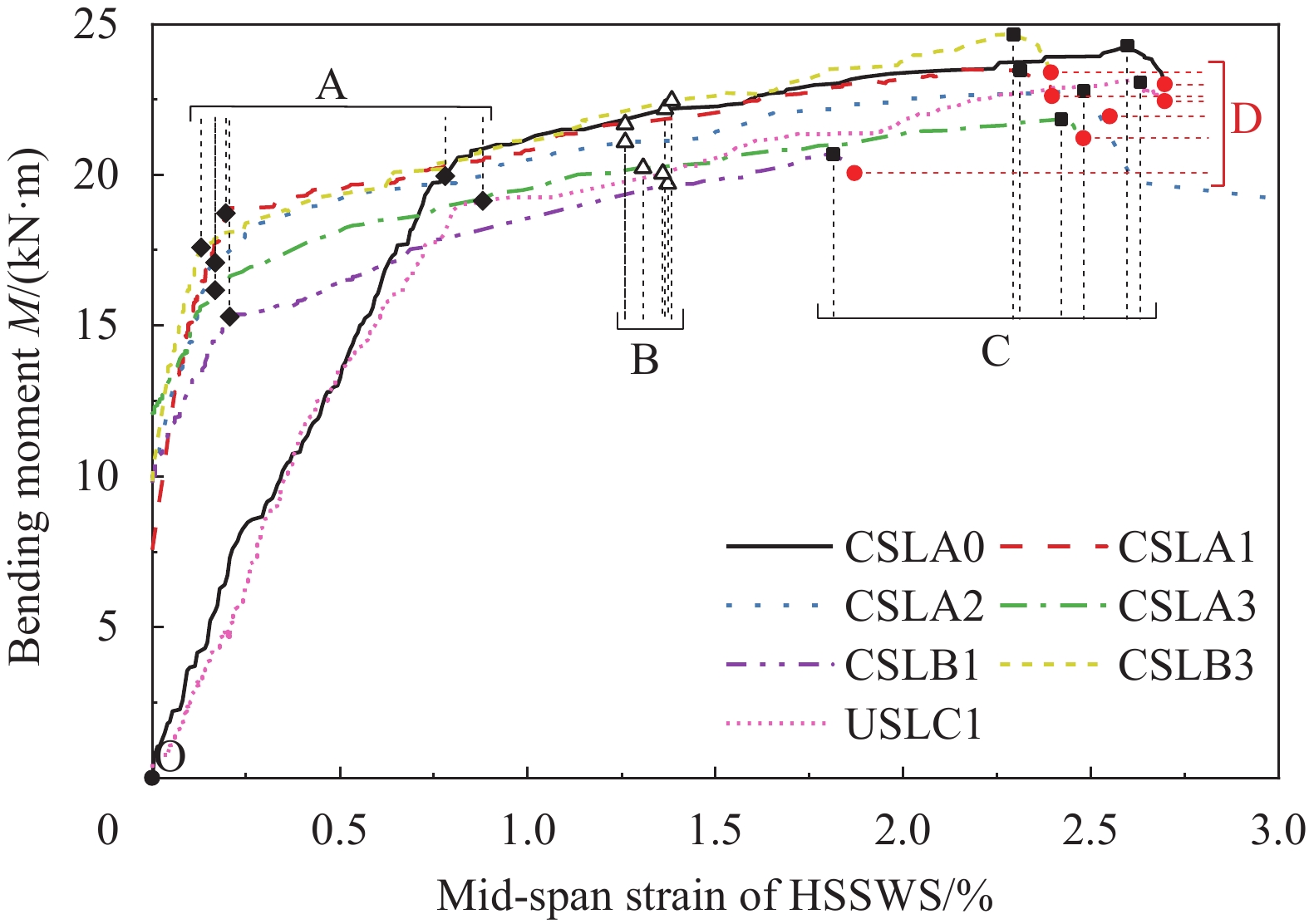

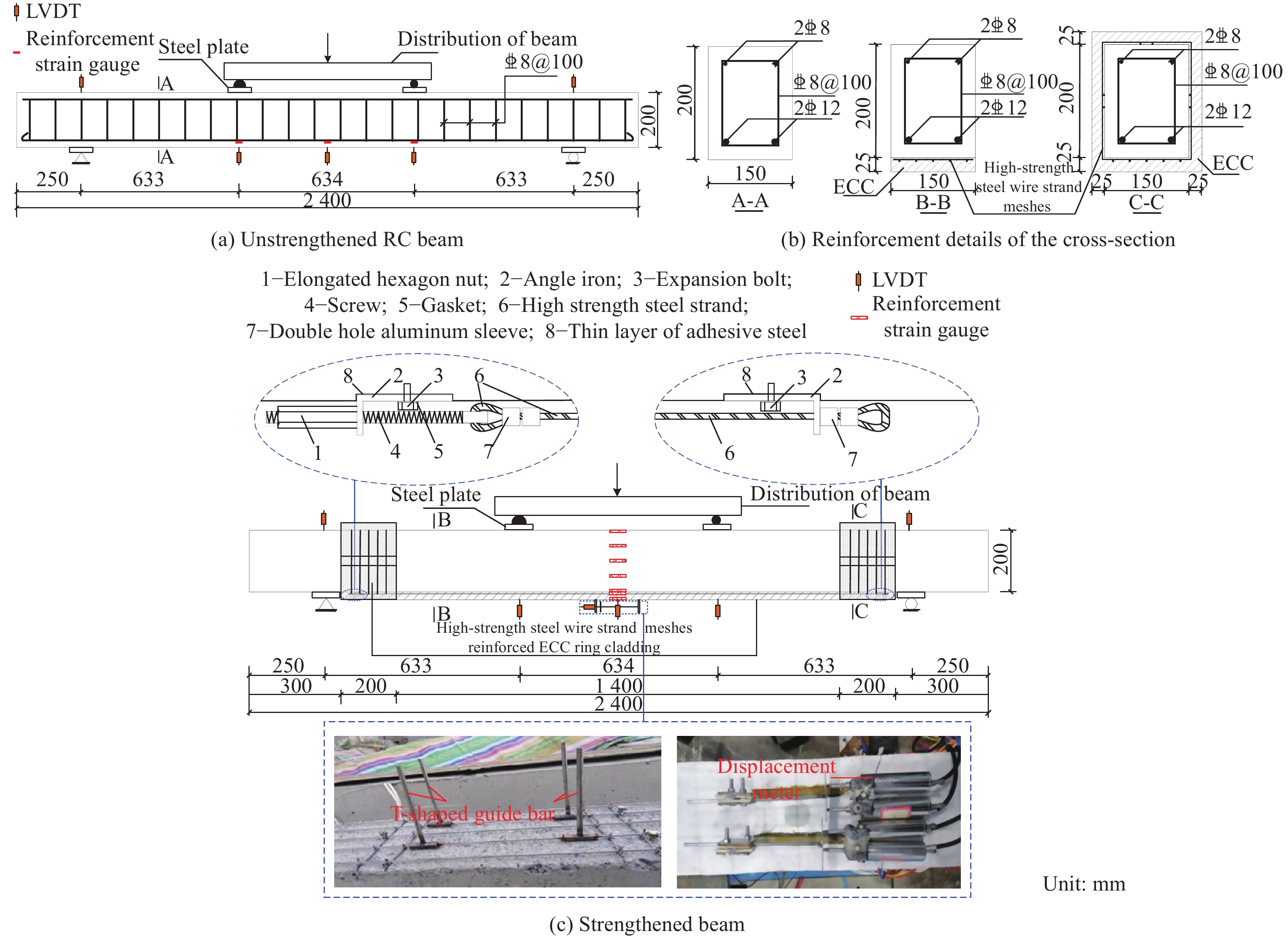

方法本文考虑是否持载加固、原梁损伤程度、纵向高强钢绞线配筋率的影响,进行了高强钢绞线网/ECC加固RC梁受弯试验,分析了二次受力对加固梁受弯性能的影响机理,探明了各影响因素对持载加固RC梁受弯性能的影响规律。首先对试验现象分析得到不同类型梁的破环特征,然后基于试验绘制各试件曲线进行曲线分析,同时对试件的承载力、裂缝、刚度、延性和韧性进行影响因素分析。试验采用三分点加载方法、液压千斤顶反向加载的加载方式,即受拉区在上,受压区在下,高强钢绞线网/ECC加固层位于RC梁上表面,千斤顶位于RC梁下表面,试验采用力控制加载,加载速率为0.1kN/s,加载过程主要分为预损伤加载阶段、持载加固阶段和加固后加载阶段。

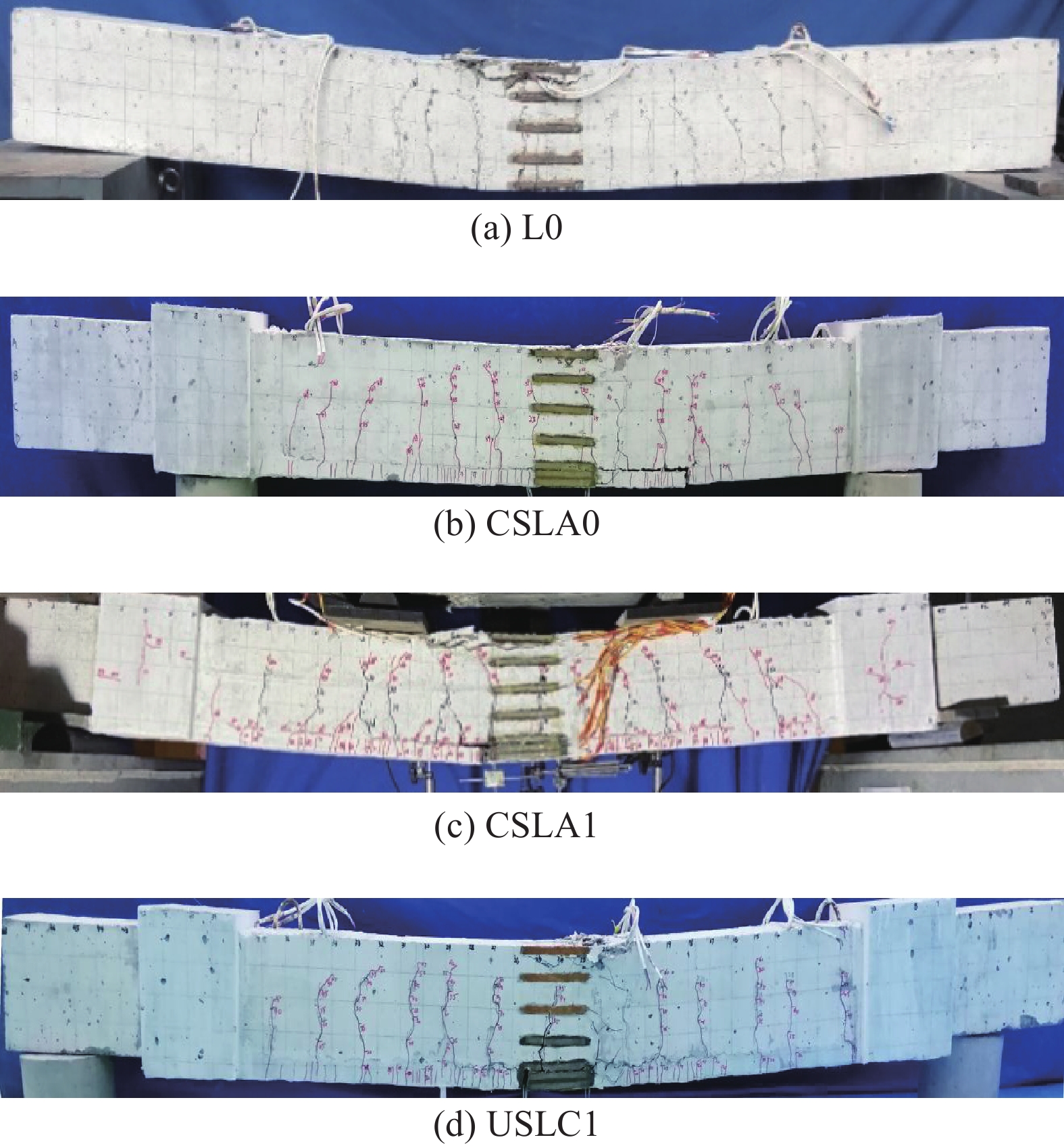

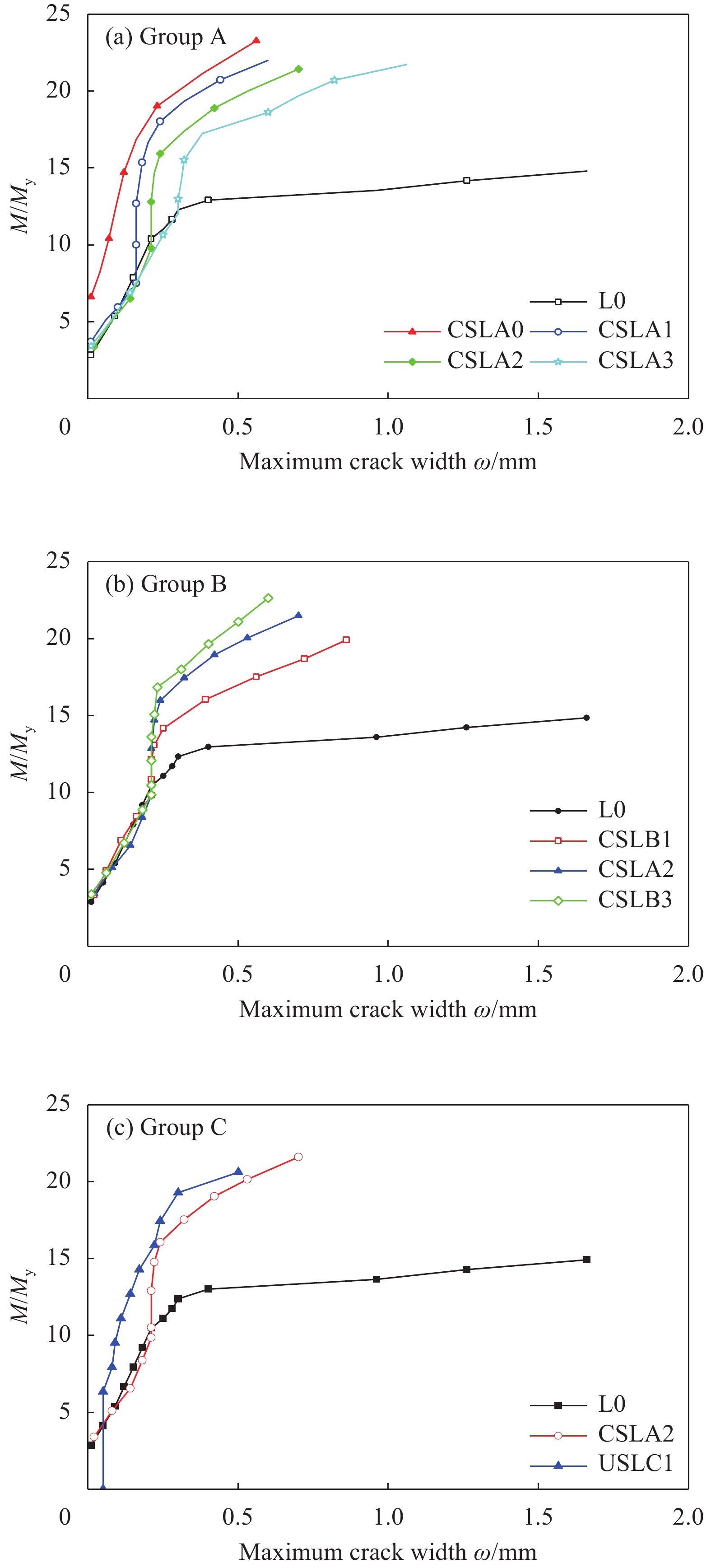

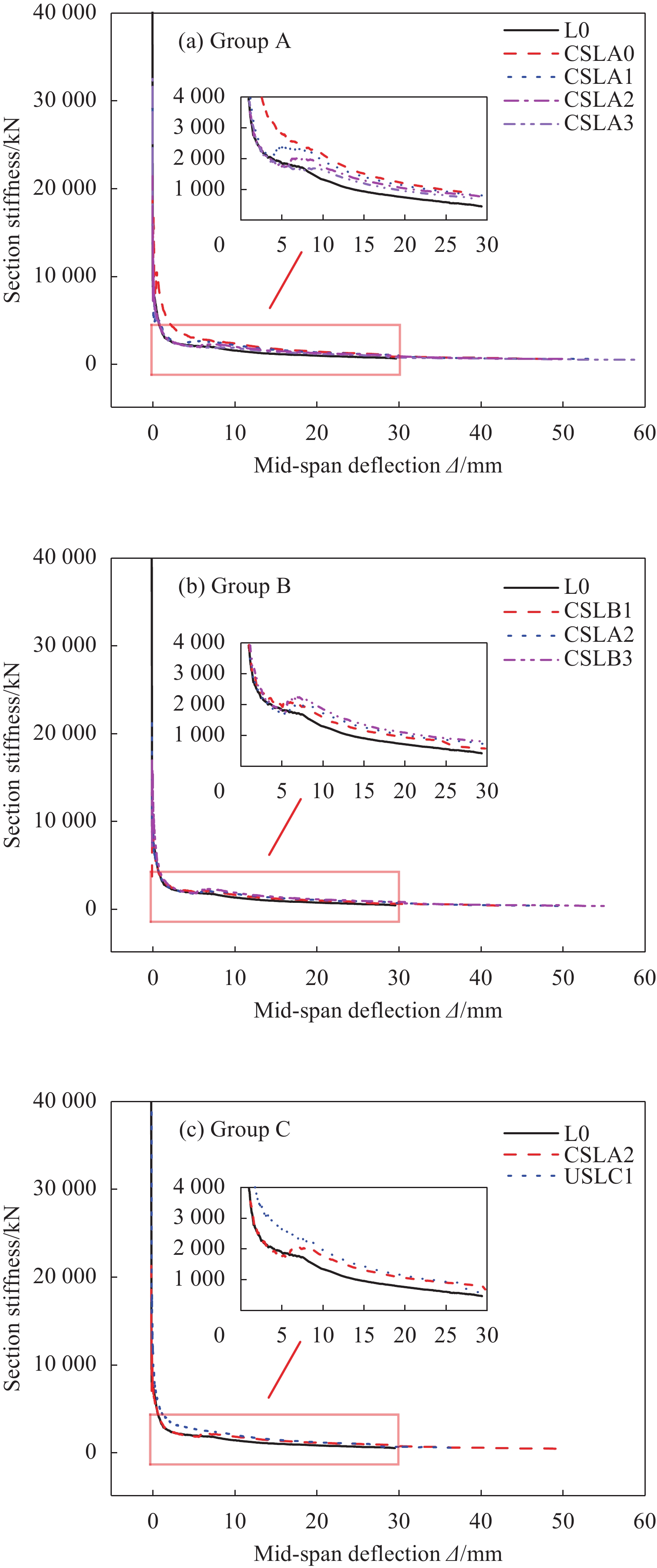

结果(1)高强钢绞线网/ECC持载加固梁破坏模式均为:原梁钢筋首先屈服,之后受压区混凝土被压碎而达到极限承载力,紧接着加固层被拉断而破坏。(2)采用高强钢绞线网/ECC持载加固RC梁,能够较好约束RC梁裂缝的发展,减小裂缝宽度。相比原梁,加固梁的承载力、刚度、延性、韧性分别提升了38%~65%、20%~81%、0%~18%、33%~116%;

结论(1)采用高强钢绞线网/ECC持载加固RC梁,可以使其正截面受弯承载力、刚度、延性、弯曲韧性等整体受弯性能得到显著的提升,能很好约束RC梁裂缝而减小裂缝宽度。(2)其他工况相同时,原梁损伤程度越高,加固层相对于原梁的应力滞后越明显,对混凝土裂缝发展的约束效果越差,使得钢筋和钢绞线的应力不均匀系数增大,钢绞线更容易因应力集中而断裂,导致梁的变形能力变差,所以损伤程度的增加对持载加固RC梁的受弯承载力、截面刚度、延性、韧性、控裂能力均有不同程度的削弱;(3)其他工况相同时,在合理范围内提高高强钢绞线配筋率,会使加固层裂缝控制能力增强,钢绞线应力分布更均匀,应力集中更小,增加梁的变形能力,而且在相同荷载下截面曲率变小,从而大幅提高持载加固RC梁的受弯承载力、刚度、延性、韧性,减小裂缝宽度;(4)其他工况相同时,与卸载加固RC梁相比,持载加固RC梁加固层应变滞后更明显,对裂缝发展的约束效果更差,挠度增长较快,故其正截面承载力、刚度、韧性及加固层对混凝土裂缝约束效果不如卸载加固梁,但延性因应变滞后钢绞线断裂推迟而提高。

-

高强钢绞线网/ECC(Engineered Cementitious Composites)作为新型高性能复合材料,充分利用高强钢绞线网及ECC优良的物理力学性能,具有超高延性、高韧性、优异的裂缝控制能力及强度高等优点。而现阶段采用该新型复合材料加固RC梁的研究未考虑二次受力对加固梁受弯性能的影响。为完善现有研究成果,进一步将该新型复合材料应用于实际工程加固中,本文进行高强钢绞线网/ECC持载加固RC梁受弯性能的试验研究。

试验结果表明:整个加载阶段并未发生剥离现象,说明加固层与原RC梁能较好的协同工作,充分发挥加固材料性能;持载加固梁破坏模式均为原梁钢筋首先屈服,之后受压区混凝土被压碎而达到极限承载力,紧接着加固层被拉断而破坏。采用高强钢绞线网/ECC持载加固RC梁后,其承载力、刚度、延性、韧性分别提升了38%-65%、20%-81%、0%-18%、33%-116%,且能很好约束RC梁裂缝而减小裂缝宽度;相比于卸载加固梁,持载加固梁的加固层由于存在明显应变滞后,对原梁混凝土裂缝约束效果变差,其受弯承载力、刚度、韧性有所降低,但其延性有所提高;持载加固梁的受弯承载力、刚度、延性、韧性随原梁损伤程度增加而降低,而随钢绞线配筋率的适当提高而增大。

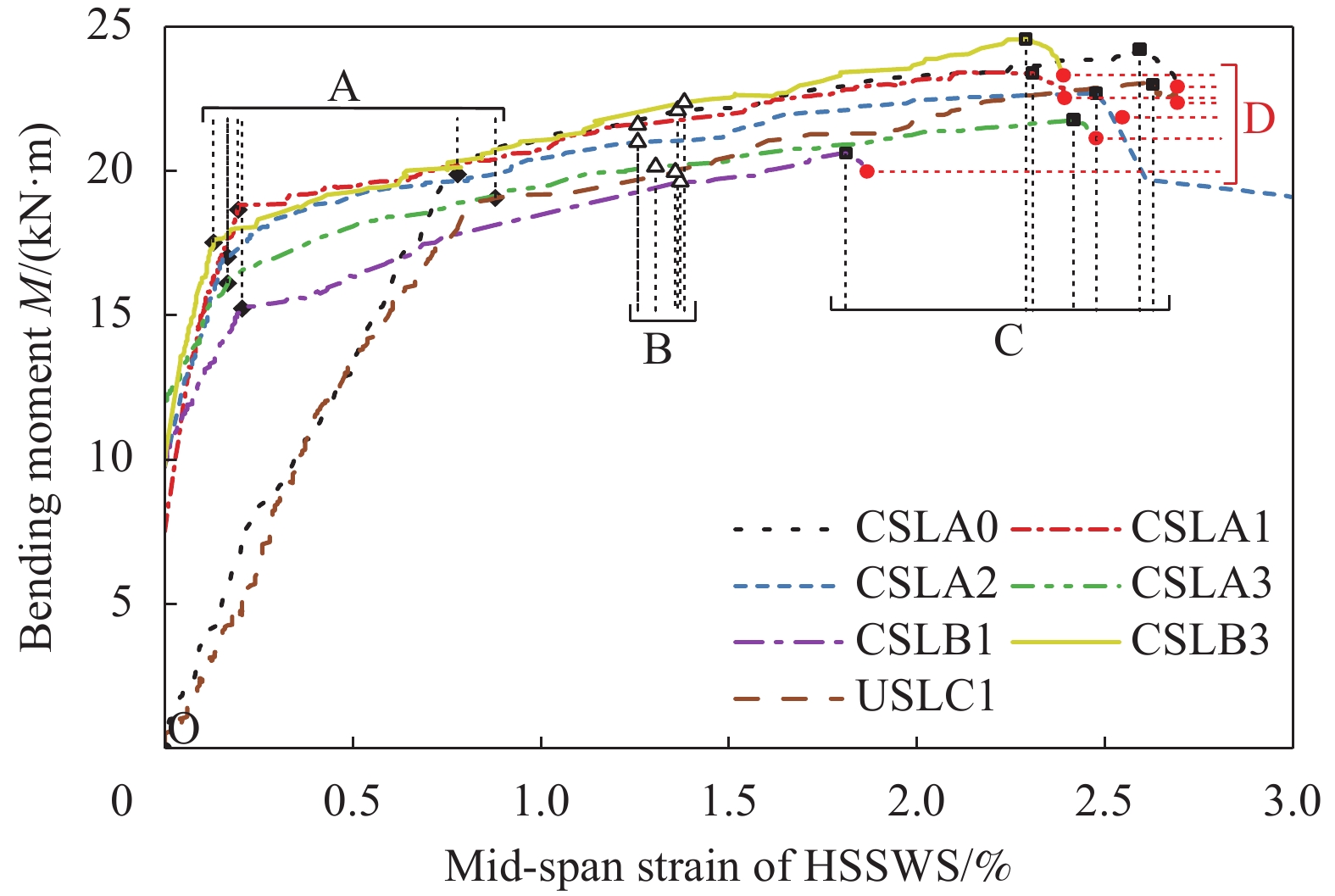

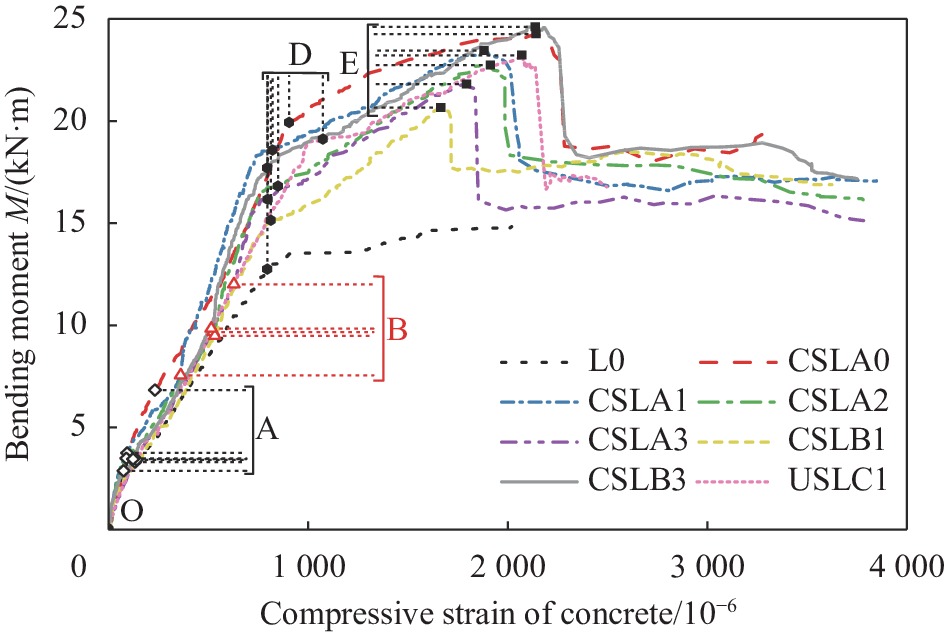

弯矩-跨中挠度曲线

跨中弯矩-高强钢绞线应变曲线

下载:

下载: