Preparation of multi-walled carbon nanotubes@graphene/thermoplastic vulcanizate composites and study on its thermoelectric properties

-

摘要: 利用一维和二维两种填料(多壁碳纳米管(MWCNTs)@石墨烯(GE))的协同作用来改善热塑性动态硫化橡胶(TPV)的热电性能(导电和导热性能)和力学性能。本文通过熔融接枝共混法制备MWCNTs@GE/聚丙烯-马来酸酐(PP-MA)母粒,在表征MWCNTs@GE/PP-MA母粒的结构、结晶性和微观形貌的基础上,进一步采用动态硫化方法制备具有独特网络结构的MWCNTs@GE/TPV复合材料,研究了MWCNTs@GE用量对MWCNTs@GE/TPV复合材料的相态结构、导电性能、导热性能及力学性能的影响。研究结果表明:与单组分填料制备的复合母粒相比,MWCNTs@GE并用体系具有协同作用,在PP-MA中分散均匀,与基体结合力强,在结晶过程中作为成核剂能够促进基体结晶,提高基体的结晶峰温度(Tc)和结晶度(Xc),减小结晶尺寸(LCrystallite)。MWCNTs@GE/TPV复合材料呈现出明显的“海岛”相结构,交联的丁基橡胶 (IIR)相以微米级颗粒状分散在PP-MA相中。MWCNTs和GE均匀分散在连续相PP-MA中,MWCNTs和GE间距离小于1 µm,形成MWCNTs@GE网络结构。当MWCNTs@GE/TPV复合材料中MWCNTs@GE含量达到3wt%时,交流电导率、导热率、断裂伸长率和拉伸强度达到最佳值。

-

关键词:

- 多壁碳纳米管(MWCNTs) /

- 石墨烯(GE) /

- 热塑性动态硫化橡胶(TPV) /

- 复合材料 /

- 动态硫化

Abstract: This work mainly used the synergistic effect of one- and two-dimensional fillers (Multi-walled carbon nanotubes (MWCNTs)@graphene (GE)) to improve the thermoelectric and mechanical properties of thermoplastic vulcanizate (TPV). MWCNTs@GE/polypropylene-maleic anhydride (PP-MA) masterbatch were first prepared by melt-graft blending. The structure, crystallinity and microstructure of MWCNTs@GE/PP-MA masterbatch were characterized. Then MWCNTs@GE/TPV composites with unique network structure were prepared by dynamic vulcanization method. The effects of the amount of MWCNTs@GE on the phase structure, electrical conductivity, thermal conductivity and mechanical properties of MWCNTs@GE/TPV composites were studied. The results show that the combination of MWCNTs and GE has a synergistic effect and can be used as nucleating agent to improve crystallization peak temperature (Tc) and crystallinity of PP (Xc) and reduce crystal size of the PP crystal plane (LCrystallite) in the crystallization process, compared with the masterbatch prepared with single filler. In the MWCNTs@GE/PP-MA masterbatch, MWCNTs and GE are uniformly dispersed in PP-MA and have strong bonding force with the matrix. The MWCNTs@GE/TPV composites show an obvious "island" structure, and the cross-linked butyl rubber (IIR) rubber is dispersed in the PP-MA phase as micron size particles. MWCNTs and GE are uniformly dispersed in the continuous phase PP-MA, and the distance between MWCNTs and GE is less than 1 µm, forming the MWCNTs@GE network structure. When the content of MWCNTs@GE in MWCNTs@GE/TPV composites reaches 3wt%, the alternating current (AC) electrical conductivity, thermal conductivity, elongation at break and tensile strength reach the best value. -

热塑性动态硫化橡胶(TPV)是兼具热塑性塑料易加工特性、橡胶高弹性和可拉伸性相结合的一类弹性体[1]。TPV中加入填料不仅可以提高其力学性能,改善加工性能和降低成本,具有纳米级的填料还会赋予TPV特殊的功能性,如耐油、阻燃、导电和导热等特性[2-3]。由TPV掺杂导电填料制备的复合热塑性动态硫化橡胶材料在生物、化学传感器、抗静电涂料和电磁屏蔽等领域具有重要应用前景,是近年研究的热点问题[4-5]。

多壁碳纳米管(MWCNTs)和石墨烯(GE)因具有独特的sp2杂化碳原子结构和巨大的比表面积,赋予其优异的导电性、导热性、力学性能及较低的渗流阈值,在应变传感器、介电材料和形状记忆材料等领域具有潜在的应用价值[6-7]。目前,MWCNTs和GE在非极性聚合物中应用面临的主要挑战是如何减少填料的聚集和缠结程度,MWCNTs和GE的分散和形成的网络结构对聚合物性能有重要影响。虽然有不少报道将TPV分别与MWCNTs和GE结合在一起,但较少有研究将两种填料并用来提高TPV的性能。MWCNTs和GE在TPV基体中的分散性、分布和用量等问题对复合材料的力学性能和热电性能有重要影响[8-9]。此外,MWCNTs和GE与TPV基体之间的界面结合力是提高TPV复合材料性能的关键问题。

GE是一种二维层状碳纳米材料,MWCNTs是由多片石墨烯卷曲形成的一维管状碳纳米材料,如果将两者并用制备复合材料,可以发挥协同效应,在复合材料基体中形成独特的网络结构,赋予其导热、导电性能,提高力学性能。丁基橡胶(IIR)和聚丙烯(PP)制备的TPV具有气味低、阻尼、力学性能好,出色的耐热和耐潮湿性能,国内外针对MWCNTs和GE复合TPV制备复合材料鲜有报道。为了在非极性TPV中获得较高的热电性能和力学性能,本文采用马来酸酐(MAH)对PP进行熔融接枝(PP-MA),然后分别将MWCNTs、GE和MWCNTs@GE分散在PP-MA基体中制备成复合母粒,最后通过动态硫化方法将复合母粒与IIR进行动态硫化制备MWCNTs@GE复合热塑性硫化橡胶(MWCNTs@GE/TPV)。分析了复合母粒的结构、结晶性能和微观结构,研究了MWCNT@GE用量对MWCNTs@GE/TPV复合材料性能的影响。通过MWCNTs和GE的协同作用,在PP-MA基体中形成网络结构,提高MWCNTs@GE/TPV复合材料介电性能、导热性能和力学性能。旨在为高性能MWCNTs@GE/TPV复合材料提供数据基础。

1. 实验材料及方法

1.1 原材料

丁基橡胶,牌号IIR301,ML(1+8)125℃ 51,不饱和度1.85%,德国朗盛化工有限公司;聚丙烯,牌号PP4220,熔融指数MFI=0.36 g/10 min (210℃,2.16 kg),密度ρ=0.89 g/cm3,中国石化燕山石化公司;多壁碳纳米管,牌号TNIMC8,平均直径30 nm,平均长度300 nm,比表面积200 g/cm3,—COOH含量0.51wt%,中国科学院成都有机化学有限公司;羟基化石墨烯,比表面积为400~600 m2/g,羟基含量7.8%,山东圣泉新材料股份有限公司;对特辛基酚醛树脂,牌号RT4201,羟甲基含量9.51%,软化点95℃,山东圣泉新材料股份有限公司;SnCl2·2H2O,分析纯,天津市北联精细化学品开发有限公司;防老剂,牌号1010,上海山浦化工有限公司;增塑剂,牌号6030,克拉玛依石化公司。

1.2 MWCNTs@GE/TPV复合材料的制备

(1) MWCNTs@GE/TPV复合材料的基本配方为100 g IIR (质量,下同)、60 g MWCNTs@GE/PP-MA母粒、10 g RT4201、2 g SnCl2·2H2O,MWCNTs和GE为变量。

(2) MWCNTs@GE/PP-MA母粒制备:以过氧化二异丙苯(DCP)作为引发剂,采用熔融法对PP接枝,PP∶DCP∶MAH质量比为100∶1∶2,将DCP和MAH溶于丙酮中,将丙酮溶液、PP、MWCNTs和GE混合均匀,在南京杰恩特机电有限公司生产的SHJ-30型双螺杆挤出机上进行接枝挤出造粒,得到MWCNTs@GE/PP-MA母粒。为了研究MWCNTs和GE的协同效应,分别制备了MWCNTs/PP-MA母粒和GE/PP-MA母粒,并用体系质量百分数和单组分体系相同,均为PP质量百分数的3wt%,MWCNTs和GE质量比为1∶1,制备过程同上。双螺杆温度依次设置为180℃、185℃、185℃、185℃、170℃、140℃,螺杆转速为100 r/min。

(3) MWCNTs@GE/TPV复合材料制备:将上海科创橡塑机械设备有限公司生产的XSM1/10-120型橡塑试验密炼机升温至190℃,转速调整为60 r/min,加入MWCNTs@GE/PP-MA母粒熔融混合,加入IIR混合2 min;加入RT4201和SnCl2·2H2O进行动态硫化7 min,得到MWCNTs@GE/TPV复合材料。MWCNTs@GE/PP-MA母粒中MWCNTs@GE的质量百分数依次为1wt%、2wt%、3wt%、5wt%和7wt%。将样品在青岛环球机械股份有限公司生产的XLB-400×400×2E型平板硫化机上于10 MPa压力,180℃预热10 min,保压3 min,冷压5 min,制成标准样条用于分析与性能测试。

1.3 测试与表征

1.3.1 红外光谱

用德国BRUKER公司生产的VERTEX70型傅里叶变换红外光谱仪对样品进行红外结构分析。参数设置为光谱分辨率4 cm−1,采用衰减全反射(ATR)模式,光谱范围4000~600 cm−1。样品采用2 mm模压试片进行测试。

1.3.2 拉曼光谱

用英国雷尼绍公司生产的Renishaw 1000型激光共聚焦拉曼光谱仪对样品进行拉曼测试。激发光源为He-Ne激光,波长为532 nm,光谱范围为3200~700 cm−1。各个复合母粒样品采用2 mm模压试片放在载玻片上进行测试。MWCNTs和GE样品取少量粉末放在载玻片上进行测试。

1.3.3 导热性能

用美国TA公司生产的DTC-300型导热仪测试样品的导热率。将样品裁剪成直径50 mm,厚度为2 mm的圆片,测试温度30℃。

1.3.4 力学性能

用德国Zwick公司生产的Zwick Z005型拉力机对样品进行力学性能测试,参照国家标准GB/T 528—2009[10],试样形状为哑铃状,厚度为2 mm,拉伸速率500 mm·min−1。测得每个样品的拉伸性能至少为5个拉伸样条的平均值。

1.3.5 介电性能

用德国Novocontrol Gmbh公司生产的Concept 80型宽频介电阻抗谱仪测试样品的交流电导率和介电常数。样品直径20 mm,厚度2 mm,正反面喷金处理。测试条件,温度23℃,交流电压0.1 Vrms,频率100~106 Hz。

1.3.6 扫描电子显微镜

用日本电子株式会社生产的JSM-7500F型扫描电子显微镜对样品进行微观形貌观察,将样品在液氮下低温冷冻脆断,脆断面喷金处理,测试加速电压为20 kV。

1.3.7 透射电子显微镜

用日本电子株式会社生产的JEM-2100型透射电子显微镜对样品进行微观相态结构观察,将样品在Leica公司生产的EM-FC7型超薄切片机上用钻石刀切得100 nm的薄片,放在4.8×10−5 m的碳支持膜上,用四氧化锇对样品进行染色,测试加速电压为200 kV。

2. 结果与讨论

2.1 MWCNTs@GE/PP-MA母粒分析

2.1.1 MWCNTs@GE/PP-MA母粒的结构

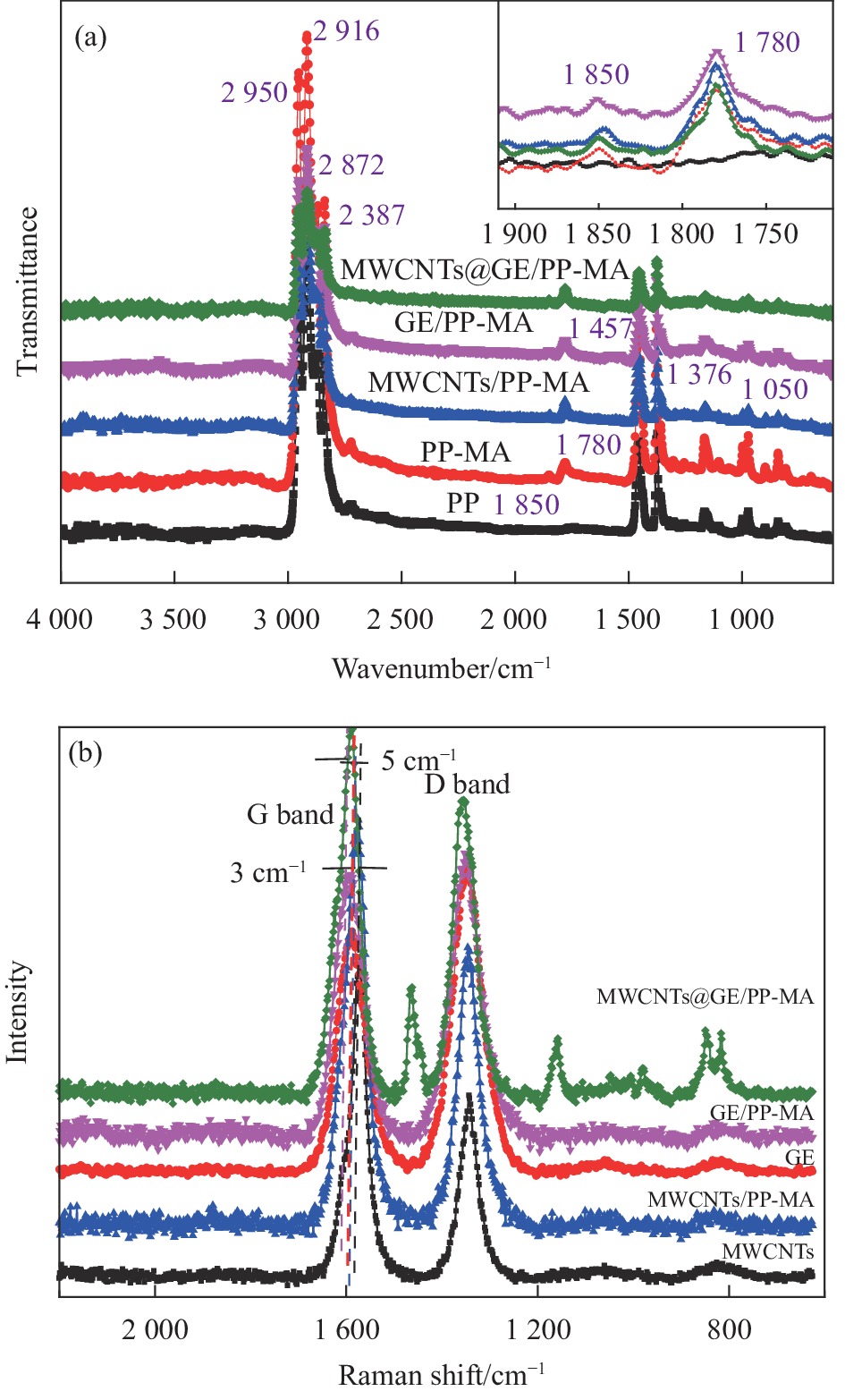

采用FTIR和Raman分析各个复合母粒的结构。PP、PP-MA、MWCNTs/PP-MA母粒、GE/PP-MA母粒、MWCNTs@GE/PP-MA母粒的FTIR如图1(a)所示,2950 cm−1、2916 cm−1和2872 cm−1处的特征峰依次对应PP中—CH3、—CH2—和—CH—的对称伸缩振动吸收峰,1457 cm−1处为PP中—CH2—的弯曲变形振动吸收峰。与纯PP相比,PP-MA的FTIR图谱上出现了新的特征峰(1850 cm−1和1780 cm−1),表明MAH接枝到PP上。与PP-MA相比,各个母粒的1850 cm−1处的特征峰减弱,这可能是由于接枝到PP上MAH中少量含氧基团与MWCNTs和GE表面的—COOH和—OH形成氢键所致,或者是少量MAH自聚合导致[11-12]。与MWCNTs/PP-MA母粒和GE/PP-MA母粒相比,MWCNTs@GE/PP-MA母粒的特征峰最弱,表明母粒中MWCNTs和GE与PP-MA相互作用力最强,分析原因可能为一维MWCNTs和二维GE填料起到协同作用,形成的氢键作用更强;通过PP接枝MAH,提高PP的极性,MWCNTs和GE并用与极性PP-MA相容性匹配更好[13]。

![]() 图 1 (a) 聚丙烯(PP)、PP熔融接枝马来酸酐(PP-MA)、多壁碳纳米管 (MWCNTs)/PP-MA母粒、石墨烯(GE)/PP-MA母粒和MWCNTs@GE/PP-MA母粒的FTIR图谱;(b) MWCNTs、GE、MWCNTs/PP-MA母粒、GE/PP-MA母粒和MWCNTs@GE/PP-MA母粒的Raman图谱Figure 1. (a) FTIR spectra of polypropylene (PP), PP fusion grafting maleic anhydride (PP-MA), multi-walled carbon nanotubes (MWCNTs)/PP-MA masterbatch, graphene (GE)/PP-MA masterbatch and MWCNTs@GE/PP-MA masterbatch; (b) Raman spectra of MWCNTs, GE, MWCNTs/PP-MA masterbatch, GE/PP-MA masterbatch and MWCNTs@GE/PP-MA masterbatch

图 1 (a) 聚丙烯(PP)、PP熔融接枝马来酸酐(PP-MA)、多壁碳纳米管 (MWCNTs)/PP-MA母粒、石墨烯(GE)/PP-MA母粒和MWCNTs@GE/PP-MA母粒的FTIR图谱;(b) MWCNTs、GE、MWCNTs/PP-MA母粒、GE/PP-MA母粒和MWCNTs@GE/PP-MA母粒的Raman图谱Figure 1. (a) FTIR spectra of polypropylene (PP), PP fusion grafting maleic anhydride (PP-MA), multi-walled carbon nanotubes (MWCNTs)/PP-MA masterbatch, graphene (GE)/PP-MA masterbatch and MWCNTs@GE/PP-MA masterbatch; (b) Raman spectra of MWCNTs, GE, MWCNTs/PP-MA masterbatch, GE/PP-MA masterbatch and MWCNTs@GE/PP-MA masterbatchMWCNTs、GE、MWCNTs/PP-MA母粒、GE/PP-MA母粒和MWCNTs@GE/PP-MA母粒的Raman图谱如图1(b)所示,MWCNTs和GE的特征峰出现在1586 cm−1(G带)和1348 cm−1(D带)[14]。G带代表多晶或非晶碳材料的特征峰,MWCNTs和GE熔融共混过程中借助强剪切力作用,使其表面—COOH和—OH与PP-MA形成更多结合点,提高与基体的相互作用。相比于GE,GE/PP-MA母粒的G带蓝移了5 cm−1;相比于MWCNTs,MWCNTs/PP-MA母粒G带蓝移了3 cm−1,MWCNTs@GE/PP-MA母粒蓝移最大。G带的蓝移表明MWCNTs和GE与PP-MA形成强的相互作用,进一步表明MWCNTs和GE起到协同增强作用[15]。强度比(ID/IG)表征GE纳米片原子结构的变化[16],GE的ID/IG为1.27,GE/PP-MA的ID/IG为1.08,MWCNTs@GE/PP-MA母粒的ID/IG最小为0.59,表明熔融过程中MWCNTs和GE上的官能团被还原,与PP-MA结合力较强,进一步证明通过PP接枝MAH共混MWCNTs和GE方法能够提高PP与MWCNTs和GE之间的结合力[17]。

2.1.2 MWCNTs@GE/PP-MA母粒的结晶性能

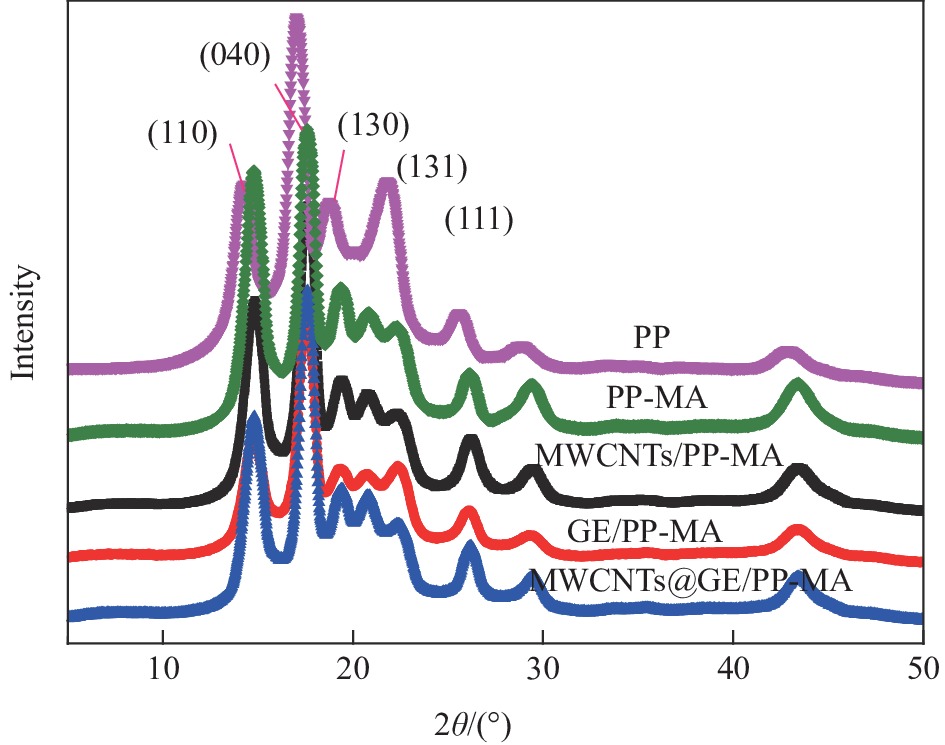

图2为PP、PP-MA、MWCNTs/PP-MA母粒、GE/PP-MA母粒和MWCNTs@GE/PP-MA母粒的XRD图谱。可以看出,PP的特征衍射峰2θ出现在13.8°、16.6°、18.4°、21.6°和25.4°处,依次对应聚丙烯α晶型(110)、(040)、(130)、(131)和(111)的晶面[18]。PP-MA衍射峰的位置与PP相同,表明PP改性接枝MAH没有改变PP晶型。MWCNTs/PP-MA母粒、GE/PP-MA母粒和MWCNTs@GE/PP-MA母粒没有出现新的衍射峰,表明在母粒的加工过程中,MWCNTs和GE之间互相堆积覆盖,填料间的距离大于10 nm,因此无法检测到较低角度的散射。进一步表明采用母粒制备方法能够使MWCNTs@GE分散均匀、团聚现象少[19]。

采用Scherrer公式计算样品的结晶尺寸LCrystallite,选取(040)晶面进行计算:

LCrystallite=KλBcosθ (1) 其中:λ为衍射波长;B为2θ峰宽的半值;θ为布拉格角;K为比例常数(立方对称球形晶体为0.94)。表1列出了PP、PP-MA、MWCNTs/PP-MA母粒、GE/PP-MA母粒和MWCNTs@GE/PP-MA母粒(040)晶面的LCrystallite和(110)与(040)晶面的衍射峰强度比值(I110/I040)。可以看出,与MWCNTs/PP-MA母粒和GE/PP-MA母粒相比,MWCNTs@GE/PP-MA母粒的LCrystallite最低,表明MWCNTs和GE起到协同作用,在结晶过程中作为成核剂促进PP结晶。MWCNTs@GE/PP-MA母粒的强度比(I110/I040)最小,说明MWCNTs和GE能够起到协同作用促进晶面的取向。

表 1 PP、PP-MA、MWCNTs/PP-MA母粒、GE/PP-MA母粒和MWCNTs@GE/PP-MA母粒的XRD数据Table 1. XRD data of PP, PP-MA, MWCNTs/PP-MA masterbatch, GE/PP-MA masterbatch and MWCNTs@GE/PP-MA masterbatchSample LCrystallite/nm I110/I040 PP 26.5 0.64 PP-MA 25.2 0.60 MWCNTs/PP-MA 24.3 0.52 GE/PP-MA 23.2 0.48 MWCNTs@GE/PP-MA 21.6 0.38 Notes: LCrystallite—Crystal size of the PP crystal plane (040); I110/I040—Ratio of diffraction peak intensity of PP crystal plane (110) and crystal plane (040). 图3为PP、PP-MA、MWCNTs/PP-MA母粒、GE/PP-MA母粒和MWCNTs@GE/PP-MA母粒的DSC曲线,利用DSC放热计算样品结晶度(Xc)的公式如下所示:

Xc(%)=ΔHm(1−ψ)ΔH0 (2) 其中:Ψ为PP的质量分数;ΔHm为样品的焓值;ΔH0为100%结晶PP的理论焓,取209 J/g[20]。从曲线计算各个样品的非等温结晶和熔融的数据如表2所示,Tc代表结晶峰温度、Tm代表熔融温度。从表中可以看出,与纯PP相比,PP-MA的Tc提高了2.6℃,这主要由于PP上适度接枝马来酸酐基团可以促进晶核形成,加快结晶速率[21]。与PP-MA相比,其他复合母粒的Tc向高温方向移动,这归因于碳纳米材料(MWCNTs和GE)起到成核剂作用,促进PP链冷却阶段的结晶。与PP-MA相比,加入3wt%的MWCNTs后,Tc升高了约4.8℃,表明MWCNTs能有效地促进PP的成核;与MWCNTs相比,GE对PP相Tc的影响较小,加入3wt%的GE,Tc升高了约3.4℃。可能由于二维高结构度的GE具有较大的比表面积,成核效率较差,大多数GE片层被包围,进入PP链晶体网络有阻滞作用。当MWCNTs和GE并用时,MWCNTs@GE/PP-MA母粒的Tc升高了6.5℃,表明MWCNTs和GE并用体系起到的协同作用明显高于单组分体系。MWCNTs和GE对MWCNTs@GE/PP-MA母粒的Tm的影响不如Tc明显,但PP接枝改性母粒的熔融和结晶峰之间的温度范围比纯PP的要窄。由XRD分析可知,通过PP接枝改性制备MWCNTs@GE/PP-MA母粒中PP结晶未发生变化,仍为α晶型,因此Tm不变;熔融和结晶峰之间的温度范围逐渐减小,主要由于MWCNTs@GE/PP-MA母粒的晶粒LCrystallite小(XRD分析已经证实),在冷却过程中促进了PP熔体分子链的重排。

表 2 PP、PP-MA、MWCNTs/PP-MA母粒、GE/PP-MA母粒和MWCNTs@GE/PP-MA母粒的结晶数据Table 2. Crystallization data of PP, PP-MA, MWCNTs/PP-MA masterbatch, GE/PP-MA masterbatch and MWCNTs@GE/PP-MA masterbatchSample Tc/℃ Tm/℃ △Hm/(J·g−1) Xc/% PP 100.2 142.7 93.6 44.8 PP-MA 102.8 141.2 99.5 48.3 MWCNTs/PP-MA 107.6 141.2 103.2 50.9 GE/PP-MA 106.2 141.1 107.6 53.1 MWCNTs@GE/PP-MA 109.3 140.8 115.3 56.9 Notes: Tc and Tm—Crystallization peak temperature and melting temperature; ΔHm—Enthalpy of PP; Xc—Crystallinity of PP. 2.1.3 MWCNTs@GE/PP-MA母粒的微观形貌

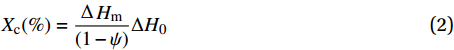

综上所述,FTIR和Raman分析结果表明MWCNTs@GE与PP-MA间形成了强烈的界面相互作用。MWCNTs@GE的引入可能对PP-MA基体有一定的影响,利用SEM观察了各个样品低温脆断面的形貌。

图4为MWCNTs、GE、PP-MA、MWCNTs/PP-MA母粒、GE/PP-MA母粒和MWCNTs@GE/PP-MA母粒样品的SEM图像。图4(a)是高度缠结的MWCNTs,由于MWCNTs间存在很强的范德华相互作用力,MWCNTs间堆积形态非常紧凑;图4(b)是二维片层的GE,GE表面褶皱状态明显,堆积紧密。从图4(c)中可以看出,PP-MA的脆断面有空洞出现,为明显的脆断面形貌,主要由于引入MAH与基体的相容性差。从图4(d)可以看出,MWCNTs均匀地分散在PP-MA中,断面有少许空洞,表明MWCNTs/PP-MA母粒中的MWCNTs与PP-MA大分子链之间存在相互作用力,相对松散地分散在基体中,但并不能提高基体的相容性。从图4(e)可以看出,GE/PP-MA母粒中具有褶皱和皱纹结构的GE均匀分散在基体中,并且空洞消失,表明GE在PP-MA基体中具有良好的润湿效果。从图4(f)可以看出,MWCNTs@GE/PP-MA母粒中GE和MWCNTs相互搭接、分散均匀,没有团聚现象,表面没有空洞,从放大图片可以看出,GE和MWCNTs的表面附有PP-MA基体,这可能是由接枝到PP上的MAH基团与GE和MWCNTs形成了许多相互连接的位点,这将有助于填料的润湿并均匀分散在PP-MA基体中。MWCNTs的一端搭接在GE附近,距离为1 µm左右,表明两者相容性较好,从前文分析可知,这种协同作用有助于提高基体的Tc和Xc,减小LCrystallite。

2.2 MWCNTs@GE/TPV复合材料性能

2.2.1 微观相态结构

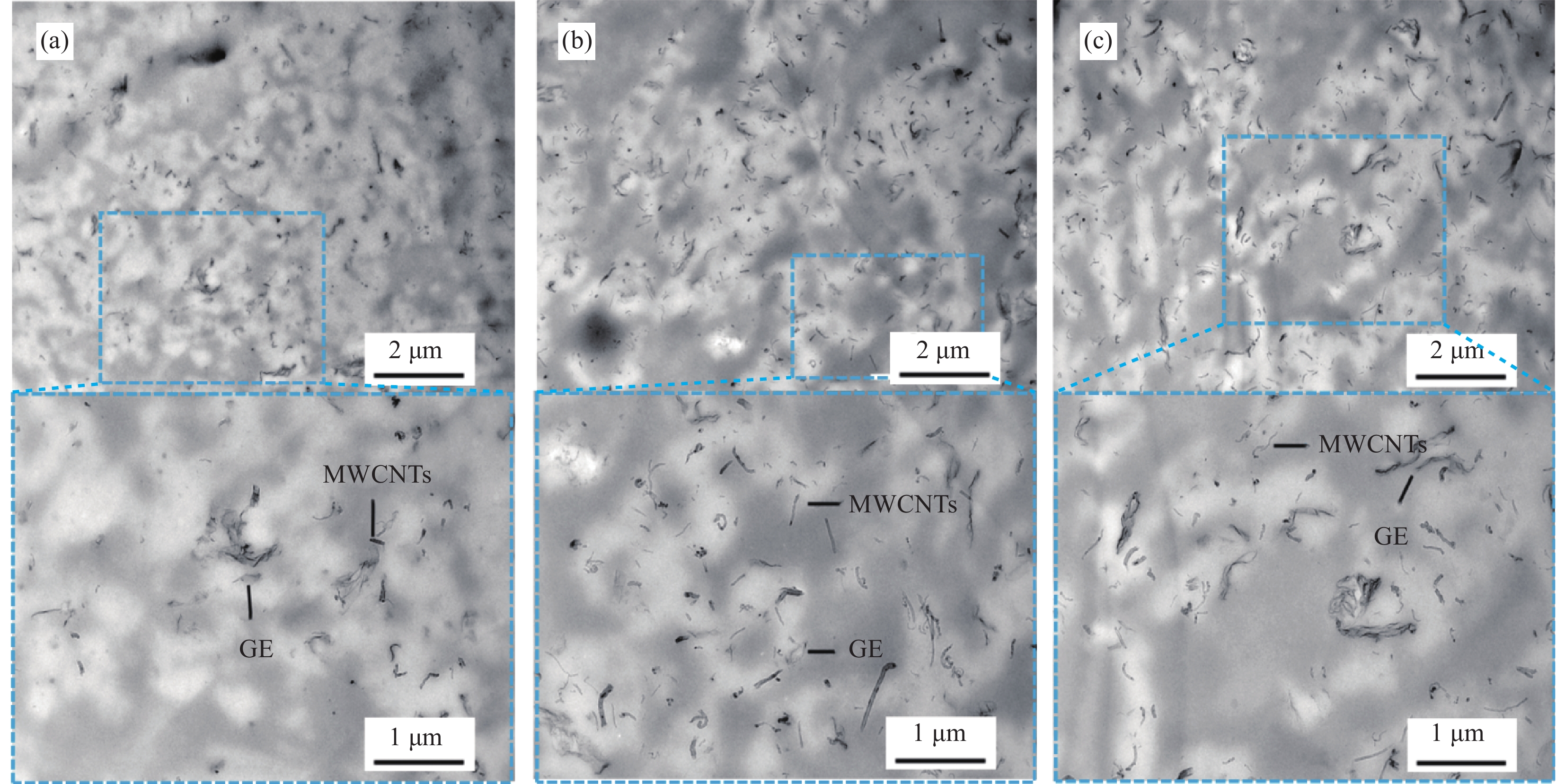

采用TEM表征MWCNTs@GE/TPV复合材料中一维MWCNTs和二维GE的分散状态及橡塑两相微观相态结构。图5为不同MWCNTs@GE含量的MWCNTs@GE/TPV复合材料的TEM图像,由于采用四氧化锇对样品进行染色,深色区域代表IIR橡胶相,白色区域代表PP相,空心管状的填料为MWCNTs,褶皱片状的填料为GE。MWCNTs@GE/TPV复合材料呈现出明显的“海岛”相结构,为典型的TPV特征。交联的IIR橡胶相以微米级颗粒状分散在PP-MA相中;MWCNTs呈现空心管状,整体分散均匀,大多数MWCNTs分散在PP-MA相;GE为褶皱的片层结构,由于GE之间存在较强的范德华相互作用力,很难发现单层的GE,GE主要分散在连续相PP-MA中。TPV的性能取决于填料在基体中独特的分布形态,填料的分布或迁移与TPV橡塑两相间界面相互作用力(润湿能力)和加工方法有关[22]。由于在PP上引入极性基团的同时与MWCNTs和GE混合,不仅增加了与MWCNTs和GE的亲合力,而且保证了填料在PP-MA中的分散,有利于MWCNTs@GE网络的形成。从图5(a)中可以看出,当复合材料中MWCNTs@GE的含量低于3wt%时,GE与MWCNTs间的距离较大,由于填料含量少导致的彼此间距离较大。当MWCNTs@GE/TPV复合材料中MWCNTs@GE的含量达到3wt%时(图5(b)),MWCNTs与GE间的距离降低(小于1 µm),每个大片层GE周围MWCNTs数量增加,分散在连续相PP-MA基体中的MWCNTs和GE能够形成MWCNTs@GE网络结构。当MWCNTs@GE的含量达到5wt%时(图5(c)),填料开始相互聚集。

2.2.2 热电性能

室温下MWCNTs@GE用量对MWCNTs@GE/TPV复合材料交流电导率的影响如图6(a)所示,图6(b)为频率102 Hz下MWCNTs@GE用量对MWCNTs@GE/TPV复合材料交流电导率的影响。可以看出,MWCNTs@GE/TPV复合材料的交流电导率随频率增加而增加。随着MWCNTs@GE含量的增加,MWCNTs@GE/TPV复合材料的交流电导率逐渐增加,当MWCNTs@GE总含量为3wt%时,MWCNTs@GE/TPV复合材料的交流电导率增加平缓,主要由于MWCNTs@GE在基体中形成了MWCNTs@GE网络结构。当MWCNTs@GE含量大于3wt%时,复合材料的交流电导率增加缓慢。这主要是由于当MWCNTs@GE含量大于3wt%时,MWCNTs@GE/TPV复合材料中导电网络结构已经完善,实验中橡塑比相同,分散在PP-MA基体中的橡胶颗粒阻碍了MWCNTs@GE的近距离搭接,影响导电通路的进一步形成。室温下不同MWCNTs@GE含量MWCNTs@GE/TPV复合材料的介电常数随频率变化的关系曲线如图6(c)所示,与交流电导率的分析相似,当MWCNTs@GE含量达到3wt%时,MWCNTs@GE/TPV复合材料的介电常数增加缓慢,表明此时MWCNTs@GE导电结构网络的形成较完善。MWCNTs@GE/TPV复合材料介电特性的原理主要是其独特的相态结构,通过MWCNTs@GE的网络增加介电常数,交联的橡胶颗粒能够阻碍MWCNTs@GE的导电网络通路形成而降低介电损耗[23]。MWCNTs@GE含量高的MWCNTs@GE/TPV复合材料的介电常数对频率更敏感,主要是由于MWCNTs@GE空间电荷极化导致的[24]。

![]() 图 6 不同MWCNTs@GE含量MWCNTs@GE/TPV复合材料的热电性能:(a) 交流电导率随频率的变化;(b) 不同MWCNTs@GE含量MWCNTs@GE/TPV复合材料在102 Hz下的交流电导率;(c) 介电常数随频率的变化;(d) 导热系数Figure 6. Thermoelectric properties of MWCNTs@GE/TPV composites with different MWCNTs@GE contents: (a) Alternating current (AC) conductivity vs frequency; (b) AC conductivity of MWCNTs@GE/TPV composites with different MWCNTs@GE contents at 102 Hz; (c) Dielectric permittivity vs frequency; (d) Thermal conductivity

图 6 不同MWCNTs@GE含量MWCNTs@GE/TPV复合材料的热电性能:(a) 交流电导率随频率的变化;(b) 不同MWCNTs@GE含量MWCNTs@GE/TPV复合材料在102 Hz下的交流电导率;(c) 介电常数随频率的变化;(d) 导热系数Figure 6. Thermoelectric properties of MWCNTs@GE/TPV composites with different MWCNTs@GE contents: (a) Alternating current (AC) conductivity vs frequency; (b) AC conductivity of MWCNTs@GE/TPV composites with different MWCNTs@GE contents at 102 Hz; (c) Dielectric permittivity vs frequency; (d) Thermal conductivityMWCNTs@GE含量对MWCNTs@GE/TPV复合材料导热性能的影响如图6(d)所示,可以看出,纯TPV(未加MWCNTs和GE)的导热系数为0.161 W/(m·K),当MWCNTs@GE含量为2wt%和3wt%时,MWCNTs@GE/TPV复合材料的导热系数分别为0.145 W/(m·K)和0.154 W/(m·K),相应提高了26%和34%。随着MWCNTs@GE含量的增加,MWCNTs@GE/TPV复合材料的热导率逐渐增加,当MWCNTs@GE的含量为3wt%时,MWCNTs@GE/TPV复合材料的热导率趋近平缓,表明完善的MWCNTs@GE网络结构能够显著增加MWCNTs@GE/TPV复合材料的导热性能。

2.2.3 力学性能

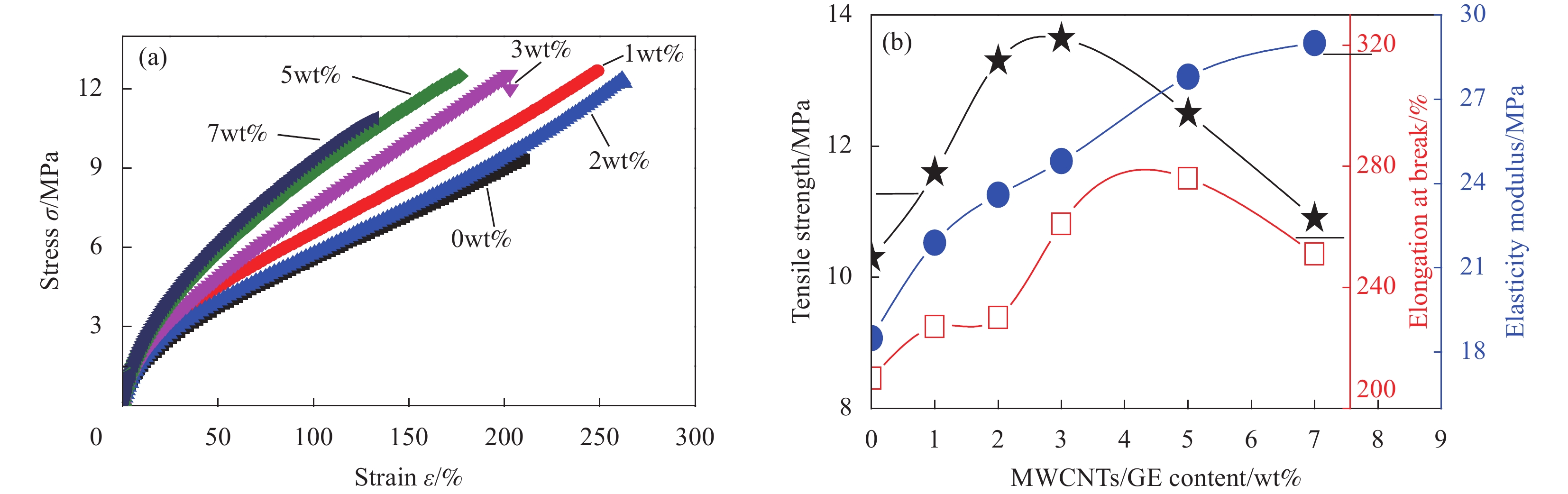

MWCNTs@GE用量对MWCNTs@GE/TPV复合材料的力学性能的影响如图7所示。图7(a)为应力-应变关系曲线,图7(b)为计算5%应力-应变曲线斜率得到的弹性模量,可以看出,MWCNTs@GE/TPV复合材料的弹性模量在低应变时急剧增加,主要由于连续相PP-MA韧带塑性变形导致的;当拉伸应变高于50%时,弹性模量增加缓慢,主要原因为MWCNTs@GE/TPV复合材料在高应变下以橡胶颗粒的滑移和取向变形为主[25]。随着MWCNTs@GE含量的增加,MWCNTs@GE/TPV复合材料的弹性模量逐渐增加,表明MWCNTs@GE形成的网络结构在基体中具有增强作用。从图7(b)可以看出,与纯TPV相比,MWCNTs@GE/TPV复合材料的拉伸强度和拉伸模量显著增加,主要由于MWCNTs@GE在TPV基体中的均匀分散起到了协同增强的作用。随着MWCNTs@GE含量的增加,MWCNTs@GE/TPV复合材料的拉伸强度先增大后减小,当MWCNTs@GE含量达到3wt%时,拉伸强度达到最大值13.64 MPa,断裂伸长率为261%。当MWCNTs@GE含量达到5wt%时,从TEM分析可知,由于MWCNTs和GE填料在基体出现团聚现象,拉伸时容易产生应力集中点,导致拉伸强度降低。

![]() 图 7 不同MWCNTs@GE含量MWCNTs@GE/TPV复合材料的力学性能:(a) 应力-应变曲线;(b) MWCNTs@GE含量对MWCNTs@GE/TPV复合材料拉伸强度、断裂伸长率和弹性模量的影响Figure 7. Mechanical properties of MWCNTs@GE/TPV composites with different MWCNTs@GE contents: (a) Stress-strain curves; (b) Effect of MWCNTs@GE content on tensile strength, elongation at break and elastic modulus of MWCNTs@GE/TPV composites

图 7 不同MWCNTs@GE含量MWCNTs@GE/TPV复合材料的力学性能:(a) 应力-应变曲线;(b) MWCNTs@GE含量对MWCNTs@GE/TPV复合材料拉伸强度、断裂伸长率和弹性模量的影响Figure 7. Mechanical properties of MWCNTs@GE/TPV composites with different MWCNTs@GE contents: (a) Stress-strain curves; (b) Effect of MWCNTs@GE content on tensile strength, elongation at break and elastic modulus of MWCNTs@GE/TPV composites2.2.4 拉伸断面形貌

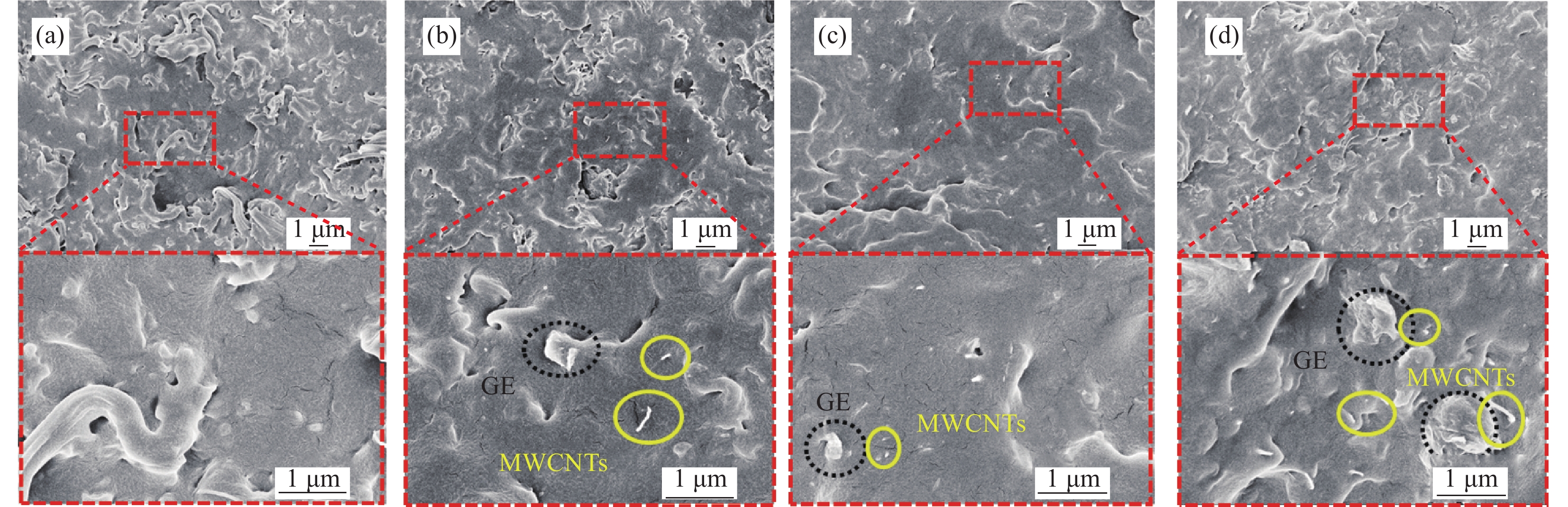

图8为不同MWCNTs@GE用量的MWCNTs@GE/TPV复合材料的拉伸断裂形貌。从图8(a)可以看出,未加MWCNTs和GE的TPV拉伸断面上有大量橡胶颗粒被拉出形成丝状,表明橡塑两相结合不牢固。MWCNTs@GE/TPV复合材料的拉伸断裂形貌整体较粗糙,拉伸断面可以观察到应力发白现象,说明韧性好。从高分辨率的SEM图像可以看出,GE与MWCNTs表面附有TPV基体,表明填料与基体之间结合界面牢固。主要是由于MWCNTs@GE/PP-MA母粒中接枝在PP上的MAH基团与MWCNTs和GE形成了许多活性位点,这将有助于填料的润湿,提高在TPV基体中的分散性。随着MWCNTs@GE含量的增加,过量的MWCNTs和GE不能结合到基体中,出现团聚现象,导致力学性能降低。当复合材料中MWCNTs@GE的含量低于3wt%时,GE与MWCNTs间距离大于1 µm;复合材料中MWCNTs/GE的含量达到3wt%时,GE与MWCNTs间距离小于1 µm,每个大片层GE周围MWCNTs数量增加,与低温脆断样品观察的现象相同,进一步证明了两种填料在拉伸过程中能够起到协同补强的作用,形成了独特的网络结构。

3. 结 论

为了在非极性热塑性动态硫化橡胶(TPV)中获得较高的热电性能和力学性能,利用多壁碳纳米管(MWCNTs)@石墨烯(GE)的协同增强效应制备功能性复合母粒,进一步采用动态硫化方法制备具有独特网络结构的MWCNTs@GE/TPV复合材料,主要得到以下结论:

(1) 与MWCNTs/聚丙烯-马来酸酐(PP-MA)母粒和GE/PP-MA/母粒相比,MWCNTs@GE并用具有协同作用,能够促进PP晶面的取向,在结晶过程中作为成核剂促进结晶提高结晶峰温度(Tc)和结晶度(Xc),减小结晶尺寸(LCrystallite);

(2) MWCNTs@GE/PP-MA母粒中MWCNTs和GE相互搭接、分散均匀,没有团聚现象;

(3) MWCNTs@GE/TPV复合材料呈现出明显的“海岛”相结构,交联的丁基橡胶(IIR)相以微米级颗粒状分散在PP-MA相中。MWCNTs和GE均匀分散在连续相PP-MA中,MWCNTs和GE间距离小于1 µm,形成MWCNTs@GE网络结构;

(4) 当MWCNTs@GE/TPV复合材料中MWCNTs@GE含量达到3wt%时, MWCNTs@GE/TPV复合材料的导电性能、导热性能和力学性能达到最佳值。

-

图 1 (a) 聚丙烯(PP)、PP熔融接枝马来酸酐(PP-MA)、多壁碳纳米管 (MWCNTs)/PP-MA母粒、石墨烯(GE)/PP-MA母粒和MWCNTs@GE/PP-MA母粒的FTIR图谱;(b) MWCNTs、GE、MWCNTs/PP-MA母粒、GE/PP-MA母粒和MWCNTs@GE/PP-MA母粒的Raman图谱

Figure 1. (a) FTIR spectra of polypropylene (PP), PP fusion grafting maleic anhydride (PP-MA), multi-walled carbon nanotubes (MWCNTs)/PP-MA masterbatch, graphene (GE)/PP-MA masterbatch and MWCNTs@GE/PP-MA masterbatch; (b) Raman spectra of MWCNTs, GE, MWCNTs/PP-MA masterbatch, GE/PP-MA masterbatch and MWCNTs@GE/PP-MA masterbatch

图 6 不同MWCNTs@GE含量MWCNTs@GE/TPV复合材料的热电性能:(a) 交流电导率随频率的变化;(b) 不同MWCNTs@GE含量MWCNTs@GE/TPV复合材料在102 Hz下的交流电导率;(c) 介电常数随频率的变化;(d) 导热系数

Figure 6. Thermoelectric properties of MWCNTs@GE/TPV composites with different MWCNTs@GE contents: (a) Alternating current (AC) conductivity vs frequency; (b) AC conductivity of MWCNTs@GE/TPV composites with different MWCNTs@GE contents at 102 Hz; (c) Dielectric permittivity vs frequency; (d) Thermal conductivity

图 7 不同MWCNTs@GE含量MWCNTs@GE/TPV复合材料的力学性能:(a) 应力-应变曲线;(b) MWCNTs@GE含量对MWCNTs@GE/TPV复合材料拉伸强度、断裂伸长率和弹性模量的影响

Figure 7. Mechanical properties of MWCNTs@GE/TPV composites with different MWCNTs@GE contents: (a) Stress-strain curves; (b) Effect of MWCNTs@GE content on tensile strength, elongation at break and elastic modulus of MWCNTs@GE/TPV composites

表 1 PP、PP-MA、MWCNTs/PP-MA母粒、GE/PP-MA母粒和MWCNTs@GE/PP-MA母粒的XRD数据

Table 1 XRD data of PP, PP-MA, MWCNTs/PP-MA masterbatch, GE/PP-MA masterbatch and MWCNTs@GE/PP-MA masterbatch

Sample LCrystallite/nm I110/I040 PP 26.5 0.64 PP-MA 25.2 0.60 MWCNTs/PP-MA 24.3 0.52 GE/PP-MA 23.2 0.48 MWCNTs@GE/PP-MA 21.6 0.38 Notes: LCrystallite—Crystal size of the PP crystal plane (040); I110/I040—Ratio of diffraction peak intensity of PP crystal plane (110) and crystal plane (040). 表 2 PP、PP-MA、MWCNTs/PP-MA母粒、GE/PP-MA母粒和MWCNTs@GE/PP-MA母粒的结晶数据

Table 2 Crystallization data of PP, PP-MA, MWCNTs/PP-MA masterbatch, GE/PP-MA masterbatch and MWCNTs@GE/PP-MA masterbatch

Sample Tc/℃ Tm/℃ △Hm/(J·g−1) Xc/% PP 100.2 142.7 93.6 44.8 PP-MA 102.8 141.2 99.5 48.3 MWCNTs/PP-MA 107.6 141.2 103.2 50.9 GE/PP-MA 106.2 141.1 107.6 53.1 MWCNTs@GE/PP-MA 109.3 140.8 115.3 56.9 Notes: Tc and Tm—Crystallization peak temperature and melting temperature; ΔHm—Enthalpy of PP; Xc—Crystallinity of PP. -

[1] LI X, KANG H L, LUO Q L, et al. Preparation and properties of a novel poly(lactic-acid)-based thermoplastic vulcanizate from both experiments and simulations[J]. RSC Advances,2022,12(16):9534-9542. DOI: 10.1039/D2RA00286H

[2] HUANG Y Y, LIU Z, XU H Y, et al. Conductive thermoplastic vulcanizates based on carbon black-filled bromo-isobutylene-isoprene rubber (BIIR)/polypropylene (PP)[J]. Reviews on Advanced Materials Science,2021,60(1):303-312. DOI: 10.1515/rams-2021-0013

[3] LI M C, WANG Y, SHEN C H, et al. PP/POE thermoplastic elastomer prepared by dynamic vulcanization and its flame retardant modification[J]. Journal of Elastomers & Plastics,2022,54(2):209-224.

[4] 汤琦, 颜桐桐, 孙豪, 等. 动态硫化制备多壁碳纳米管/热塑性硫化胶复合材料的相态结构及热电效应[J]. 材料导报, 2021, 35(6):6206-6211. DOI: 10.11896/cldb.19110144 TANG Qi, YAN Tongtong, SUN Hao, et al. Phase structure and thermo-electric effect of multi-walled carbon nanotubes/thermoplastic vulcanizate composites prepared by dynamic vulcanization[J]. Materials Reports,2021,35(6):6206-6211(in Chinese). DOI: 10.11896/cldb.19110144

[5] MA L F, BAO R Y, DOU R, et al. Conductive thermoplastic vulcanizates (TPVs) based on polypropylene (PP)/ethylene-propylene-diene rubber (EPDM) blend: From strain sensor to highly stretchable conductor[J]. Composites Science and Technology,2016,128:176-184. DOI: 10.1016/j.compscitech.2016.04.001

[6] YU J, CHOI H K, KIM H S, et al. Synergistic effect of hybrid graphene nanoplatelet and multi-walled carbon nanotube fillers on the thermal conductivity of polymer composites and theoretical modeling of the synergistic effect.[J]. Composites Part A: Applied Science and Manufacturing,2016,88:79-85. DOI: 10.1016/j.compositesa.2016.05.022

[7] 高浩, 时文欣, 宋维浩, 等. 氧化石墨烯/多壁碳纳米管影响天然橡胶性能的实验研究[J]. 复合材料学报, 2022, 39(5):2172-2182. DOI: 10.13801/j.cnki.fhclxb.20210615.001 GAO Hao, SHI Wenxin, SONG Weihao, et al. Effect of graphene oxide/multi-walled carbon nanotubes on the properties of natural rubber and experimental research[J]. Acta Materiae Compositae Sinica,2022,39(5):2172-2182(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20210615.001

[8] KHODABANDELOU M, AGHJEH M K. Impact behavior of CNT-filled PP/EPDM blends: Effect of dynamic vulcanization and PP-g-MA compatibilizer[J]. Polymer Bulletin,2016,73(6):1607-1626. DOI: 10.1007/s00289-015-1566-2

[9] YAN N, XIA H, WU J, et al. Compatibilization of natural rubber/high density polyethylene thermoplastic vulcanizate with graphene oxide through ultrasonically assisted latex mixing[J]. Journal of Applied Polymer Science,2012,15:933-941.

[10] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定: GB/T 528—2009[S]. 北京: 中国标准出版社, 2009. Standardization Administration of the People's Republic of China. Determination of tensile stress strain properties of vulcanized rubber or thermoplastic rubber: GB/T 528—2009[S]. Beijing: China Standards Press, 2009(in Chinese).

[11] MISHRA J K, RYOU J H, KIM G H, et al. Preparation and properties of a new thermoplastic vulcanizate (TPV)/organoclay nanocomposite using maleic anhydride functionalized polypropylene as a compatibilizer[J]. Materials Letters,2004,58(27):3481-3485.

[12] HSIAO M C, LIAO S H, LIN Y F, et al. Preparation and characterization of polypropylene-graft-thermally reduced graphite oxide with an improved compatibility with polypropylene-based nanocomposite[J]. Nanoscale,2011,3:1516-1522. DOI: 10.1039/c0nr00981d

[13] YUAN B, BAO C, SONG L, et al. Preparation of functionalized graphene oxide/polypropylene nanocomposite with significantly improved thermal stability and studies on the crystallization behavior and mechanical properties[J]. Chemical Engineering Journal,2014,237:411-420. DOI: 10.1016/j.cej.2013.10.030

[14] WANG D R, ZHANG X M, ZHA J W, et al. Dielectric properties of reduced graphene oxide/polypropylene composites with ultralow percolation threshold[J]. Polymer,2013,54(7):1916-1922. DOI: 10.1016/j.polymer.2013.02.012

[15] LI C Q, ZHA J W, LONG H Q, et al. Mechanical and dielectric properties of graphene incorporated polypropylene nanocomposites using polypropylene-graft-maleic anhydride as a compatibilizer[J]. Composites Science and Technology,2017,153:111-118. DOI: 10.1016/j.compscitech.2017.10.015

[16] SONG P G, CAO Z H, CAI Y Z, et al. Fabrication of exfoliated graphene-based polypropylene nanocomposites with enhanced mechanical and thermal properties[J]. Polymer,2011,52(18):4001-4010. DOI: 10.1016/j.polymer.2011.06.045

[17] MOHIUDDIN T M G, LOMBARDO A, NAIR R R, et al. Uniaxial strain in graphene by Raman spectroscopy: G peak splitting, Grueneisen parameters, and sample orientation[J]. Physical Review,2009,79(20):205433. DOI: 10.1103/PhysRevB.79.205433

[18] JONES A T, AIZLEWOOD J M, BECKETT D R. Crystalline forms of isotactic polypropylene[J]. Macromolecular Chemistry & Physics,1964,75(1):134-158.

[19] LIANG J J, HUANG Y, ZHANG L, et al. Molecular-level dispersion of graphene into poly(vinyl alcohol) and effective reinforcement of their nanocomposites[J]. Advanced Functional Materials,2009,19(14):2297-2302. DOI: 10.1002/adfm.200801776

[20] LEE G W, JAGANNATHAN S, CHAE H G, et al. Carbon nanotube dispersion and exfoliation in polypropylene and structure and properties of the resulting composites[J]. Polymer,2008,49(7):1831-1840. DOI: 10.1016/j.polymer.2008.02.029

[21] FRANTIŠEK K, JOSEF P, PETR P, et al. Controlled reactive modification of polypropylene with maleic anhydride via solvent-free technique[J]. Polymer Degradation & Stability,2019,168:1-8.

[22] SHI Y Y, YANG J H, HUANG T, et al. Selective localization of carbon nanotubes at the interface of poly(L-lactide)/ethylene-co-vinyl acetate resulting in lowered electrical resistivity[J]. Composites Part B: Engineering,2013,55:463-469. DOI: 10.1016/j.compositesb.2013.07.012

[23] LIU S T, TIAN M, ZHANG L Q, et al. Tailoring dielectric properties of polymer composites by controlling alignment of carbon nanotubes[J]. Journal of Materials Science,2016,51(5):2616-2626. DOI: 10.1007/s10853-015-9575-y

[24] TIAN M, YAN B Y, YAO Y, et al. Largely improved actuation strain at low electric field of dielectric elastomer by combining disrupting hydrogen bonds with ionic conductivity[J]. Journal of Materials Chemistry C,2014,2(39):8388-8397. DOI: 10.1039/C4TC01140F

[25] HUY T A, LUEPKE T, RADUSCH H J. Characterization of the deformation behavior of dynamic vulcanizates by FTIR spectroscopy[J]. Journal of Applied Polymer Science,2001,80(2):148-158. DOI: 10.1002/1097-4628(20010411)80:2<148::AID-APP1083>3.0.CO;2-W

-

下载:

下载: