Folding properties of carbon fiber triaxial woven fabric/epoxy resin composites

-

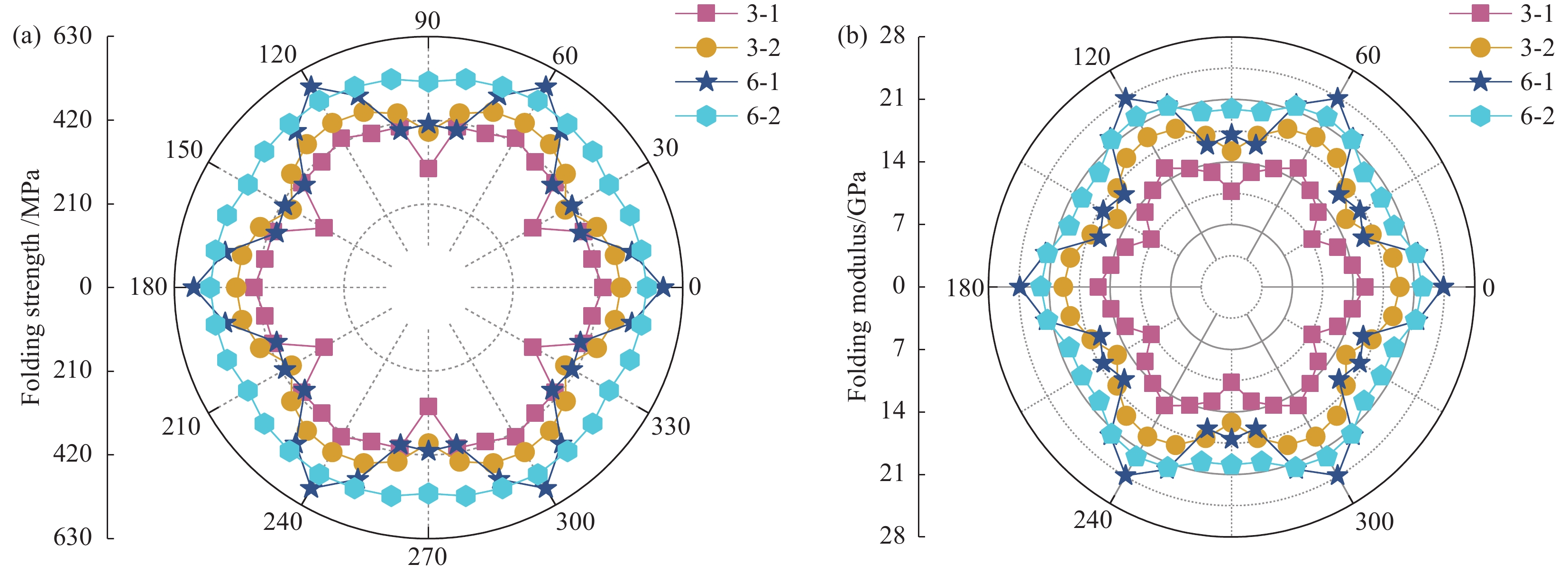

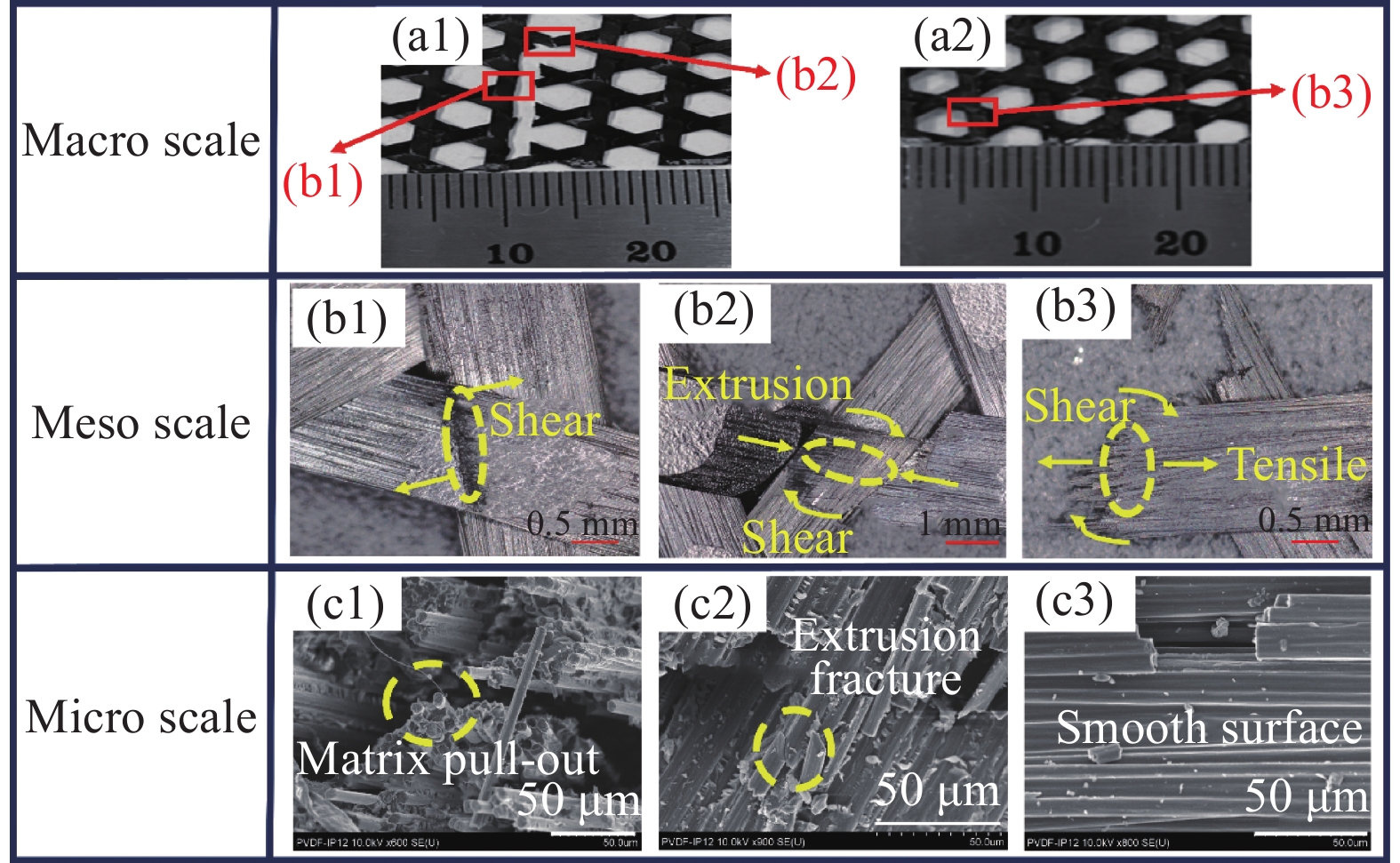

摘要: 以碳纤维为增强材料,平面三轴机织物为增强体结构,环氧树脂为基体,通过真空辅助树脂传递模塑技术(Vacuum assisted resin transfer molding ,VARTM)制备了碳纤维三轴机织物增强环氧树脂基(Triaxial woven fabric/epoxy resin,TWF/EP)复合材料。借鉴金属材料薄板弯折性能试验方法,采用万能试验机开展TWF/EP的弯折实验,探究其弯折性能和损伤机制。研究结果表明:TWF/EP复合材料的弯折强度和模量与纤维束规格呈显著正相关性,与角度呈负相关性。在0°~30°范围内,TWF/EP复合材料的弯折性能变化幅度较小,表现出准各向同性。TWF/EP复合材料的力学响应表现为脆断,破坏模式分完全折断和不完全折断,TWF/EP复合材料的弯折断裂机制主要为纯剪切破坏、压剪耦合破坏及拉剪耦合破坏。

-

关键词:

- 碳纤维三轴机织复合材料 /

- 弯折性能 /

- 损伤力学模式 /

- 各向同性 /

- 力学响应

Abstract: Carbon fiber triaxial woven fabric/epoxy resin (TWF/EP) composite was prepared by vacuum assisted resin transfer molding (VARTM) method, in which carbon fiber TWF was reinforced material, and epoxy resin was matrix. Referring to the metallic materials-sheet and strip-test method for bending and folding properties, the bending experiment of TWF/EP was carried out to explore its bending performance, and the damage morphology and damage mechanism were analyzed. The results show that the folding strength and modulus of TWF/EP composites have a significant positive correlation with the fiber bundle specification and a negative correlation with the angle. In the range of 0°-30°, the folding properties of TWF/EP composites change slightly and show quasi-isotropy. The mechanical response of TWF/EP composites is brittle fracture, and the failure mode can be divided into complete fracture and incomplete fracture. The folding fracture mechanisms are mainly pure shear failure, compression-shear coupling failure and tenso-shear coupling failure. -

挥发性有机物(VOCs)由于其种类多、挥发性强、毒性强、刺激性强等特点已日益成为室内污染的主要元凶。家具、板材、油漆、车内饰品等环境中多含有并释放甲醛[1-4],甲醛于2005年被国际癌症研究机构列为I类致癌物,人类吸入高浓度甲醛可导致支气管哮喘、肺炎等呼吸道疾病,若经口摄入10~20 mL的甲醛溶液会致死[5]。从某种意义上讲,甲醛的存在已与人们的生命安全息息相关[6]。

甲醛治理技术主要有吸附法[7]、低温等离子体技术[8]、微生物过滤法[9]、光催化技术,其中光催化技术由于其操作方便和成本低的优点逐渐被人们所关注。石墨相氮化碳(g-C3N4)作为光催化材料,化学合成方法简单,成本低廉,并且具有较窄的带隙(2.7 eV)、较高的可见光响应,但由于其比表面积较小且具有光生载流子的复合率较高的缺陷,导致其光催化活性偏低,因此g-C3N4材料难以单独作为光催化剂[10-11]。增强材料光催化活性的常见方法有形态结构调整、金属/非金属掺杂、异质结工程等方法[10]。较小尺寸的颗粒具有更高的光催化性能和活性,Wang等[12]成功制备了具有较大比表面积的g-C3N4材料,作为催化剂在可见光条件下的产氢速率比块状g-C3N4高出1个数量级。Ag的修饰可以提升光生电子和空穴分离,Zhou等[13]利用光还原沉积法将纳米Ag颗粒成功负载到g-C3N4的表面,并且该材料在可见光下降解罗丹明B的效率为单一g-C3N4的7倍。硅铝胶球的主要成分为SiO2和Al2O3,虽然硅铝胶球化学性质稳定,主要成分不参与光催化过程,但其中SiO2[14]以其优异的机械强度、高的内表面积和均匀的孔径,被广泛用作载体和稳定的介孔载体。对其扩孔可增加催化剂负载量,提供更多反应位点,是优秀的催化剂载体。

为此,本研究采用扩孔硅铝胶球作为光催化剂载体负载Ag掺杂的薄层g-C3N4光催化降解甲醛,探究了合成材料的最佳影响参数和提升光催化性能的机理,选取最佳光催化材料进行了循环稳定性实验和不同湿度梯度的降解实验,以期为光催化降解甲醛及其他有机污染物提供科学依据和技术支持。

1. 材料与方法

1.1 原材料

本实验采用的二氰二胺、乙二醇、乙醇、硝酸银、酚试剂指示剂、硫酸铁铵、硫代硫酸钠、甲醛标准溶液等化学试剂均为分析纯,购自上海阿拉丁生化科技股份有限公司。

1.2 材料制备

1.2.1 薄层g-C3N4的制备

块状g-C3N4制备:将10 g二氰二氨固体置于氧化铝坩埚中后放入马弗炉,在空气气氛下煅烧,540℃加热2 h(升温速率2℃/min),冷却至室温,得到淡黄色固体研磨成粉末,g-C3N4粉末标记为g-C3N4-B。

薄层g-C3N4制备:取150 mg g-C3N4粉末于玻璃瓶中,加入200 mL无水乙醇和水的混合液,超声处理一定时间使其分散均匀,离心分离固体,经洗涤、烘干和研磨得到薄层g-C3N4,标记为g-C3N4-F。

1.2.2 薄层g-C3N4掺杂Ag的制备

分别取500 mg g-C3N4-F粉末于6支100 mL玻璃管中,加入25 mL蒸馏水,磁力搅拌10 min,加入5 mL浓度分别为0、1 mg/mL、2 mg/mL、4 mg/mL、8 mg/mL、12 mg/mL、16 mg/mL的AgNO3溶液。再加入2 mL浓度为1 mg/mL硫化钠溶液作为空穴牺牲剂,然后通10 minN2。将玻璃管置于光反应器中,300 W氙灯照射2 h后,洗涤、烘干、研磨,获得g-C3N4掺杂不同质量比的Ag的粉末。分别记为0、1%Ag-g-C3N4-F、2%Ag-g-C3N4-F、4%Ag-g-C3N4-F、8%Ag-g-C3N4-F、12%Ag-g-C3N4-F、16%Ag-g-C3N4-F(见表1)。

1.2.3 g-C3N4-Ag/SiO2光催化材料的制备

扩孔硅铝胶球:将一定量的硅铝胶球(粒径8 mm,孔径范围为10~50 nm)置入40 mg/L碳酸钠溶液中,磁力搅拌30 min,80℃烘干,放入马弗炉中300℃煅烧2 h (1℃/min升温),冷却至室温,用乙醇和蒸馏水洗涤,80℃烘干后备用。

g-C3N4-Ag/SiO2:取2.2.1节中甲醛降解效率最高的Ag-g-C3N4-F样品10 mg、20 mg、30 mg、40 mg、50 mg加入100 mL无水乙醇,超声分散均匀,然后分别加入30 g经过扩孔处理的硅铝胶球,磁力搅拌30 min,80℃烘干,置于马弗炉中200℃煅烧2 h(升温速率1℃/min)。将样品分别标记为g-C3N4-Ag/SiO2-10、g-C3N4-Ag/SiO2-20、g-C3N4-Ag/SiO2-30、g-C3N4-Ag/SiO2-40、g-C3N4-Ag/SiO2-50(见表2)。

表 1 Ag-薄层石墨相氮化碳(g-C3N4-F)复合材料的命名Table 1. Naming of Ag-thin layer graphite phase carbon nitride (g-C3N4-F) compositesSample g-C3N4-F/mg Concentration of AgNO3/(mg·mL−1) AgNO3/mL Na2S/mL 0 500 0 5 2 1%Ag-g-C3N4-F 500 1 5 2 2%Ag-g-C3N4-F 500 2 5 2 4%Ag-g-C3N4-F 500 4 5 2 8%Ag-g-C3N4-F 500 8 5 2 12%Ag-g-C3N4-F 500 12 5 2 16%Ag-g-C3N4-F 500 16 5 2 表 2 石墨相氮化碳(g-C3N4)-Ag/SiO2复合材料的命名Table 2. Naming of graphite phase carbon nitride (g-C3N4)-Ag/SiO2 compositesSample Ag-g-C3N4-F/mg SiO2/g Ethyl alcohol/mL g-C3N4-Ag/SiO2-10 10 30 100 g-C3N4-Ag/SiO2-20 20 30 100 g-C3N4-Ag/SiO2-30 30 30 100 g-C3N4-Ag/SiO2-40 40 30 100 g-C3N4-Ag/SiO2-50 50 30 100 1.3 材料的表征

利用X射线衍射(X-Ray Diffraction,XRD,日本岛津公司,Empyrean型,测试条件:Cu Kα射线,加速电压40 kV,2θ范围20°~90°)对材料的晶体结构、晶格缺陷和组成成分表征。利用场发射扫描电子显微镜(JSM-7900F,日本电子株式会社(JEOL))和场发射透射电子显微镜(Tecnai G2 F20 S-TWIN,美国FEI公司)展示材料微观形态。采用X射线能谱仪(EDS,Escalab 250Xi型,美国费希尔公司)对材料进行元素分析。利用紫外-可见漫反射光谱(UV-vis DRS,Cary 5000,以BaSO4为标准白板,分辨率低于0.2 nm,平均停留时间为0.2 s,数据间隔1 nm)测试样品对光的吸收能力及分析能带结构。利用荧光光谱(PL,Cary 100,Xe灯为激发光源)分析半导体光生电子-空穴负荷率,探究其分离效率。采用电化学工作站(LK1100A,300 W Xe灯,波长范围420~780 nm)作为激发光源对样品的电化学特性进行表征,测试样品的光电流响应曲线和电化学阻抗。

1.4 光催化降解甲醛实验

图1为自制的甲醛降解实验舱,光催化降解甲醛实验在此中进行,测试时,将光催化剂放入支架,密封后注入甲醛,打开风扇和甲醛挥发装置,待甲醛完全挥发且混合均匀后,进行暗反应,然后打开灯照射光催化剂,进行光催化反应2 h,采用酚试剂分光光度法测量甲醛浓度,甲醛的初始浓度为0.5 mg/m3。光源为家庭常用8 W白光LED灯,波长范围为450~460 nm。

2. 结果与讨论

2.1 g-C3N4-Ag/SiO2材料的表征结果与分析

2.1.1 成分组成与分析

图2为g-C3N4-B、g-C3N4-F和4%Ag-g-C3N4-F材料的XRD图谱。可见,g-C3N4-B、g-C3N4-F和4%Ag-g-C3N4-F在2θ为13.6°和27.3°处存在g-C3N4的特征衍射峰,依次对应g-C3N4的碳氮杂环结构的(100)晶面和层间堆叠结构的(002)晶面[15-16],峰型尖锐且没有其他杂峰,说明g-C3N4结晶度较高,超声处理和光沉积没有改变g-C3N4的晶型,在2θ=13.6°的特征衍射峰位置上,g-C3N4-F明显低于g-C3N4-B,说明超声处理破坏了(002)晶面对应的层状堆叠结构,纵向尺寸减小[17],薄层g-C3N4制备成功;4%Ag-g-C3N4-F的XRD图谱在2θ为38.1°和44.2°的位置上出现Ag的特征衍射峰,依次对应Ag面心立方晶型的(111)和(200)晶面[18],另外与g-C3N4-B/g-C3N4-F对比看出,Ag掺杂后的4%Ag-g-C3N4-F材料,仍然存在明显且尖锐的g-C3N4特征衍射峰,没有其他杂峰,表明超声处理和光沉积没有改变4%Ag-g-C3N4-F中g-C3N4的晶型。

2.1.2 微观形貌与分析

图3为g-C3N4-B、g-C3N4-F和4%Ag-g-C3N4-F材料的SEM、TEM图像和EDS图谱。如图3(a)所示,g-C3N4-B表面呈现弯曲褶皱,横向尺寸达到微米级以上。图3(b)显示g-C3N4经过超声处理后,横向尺寸减小,并且材料表面均匀光滑,没有破碎和褶皱。如图3(d)所示,g-C3N4-F表面负载了椭球体和不规则片层状的颗粒,TEM图像表明该纳米级颗粒分散均匀,结合EDS结果说明成功将纳米级单质Ag负载到4%Ag-g-C3N4-F表面。

图4为SiO2和g-C3N4-Ag/SiO2-30的SEM图像。如图4(b)所示,经扩孔处理的硅铝胶球(g-C3N4-Ag/SiO2-30)的孔容积增大,孔径最大达到微米级,负载了Ag-g-C3N4的SiO2表面更粗糙,表明4%Ag-g-C3N4-F成功负载到扩孔硅铝胶球的表面和部分孔道结构中。但是可以看出部分孔道和表面没有Ag-g-C3N4的负载,负载的并不均匀。

2.1.3 紫外可见光吸光性与分析

图5为g-C3N4-B、g-C3N4-F和4%Ag-g-C3N4-F材料的紫外可见光吸收光谱图。如图5(a)所示,g-C3N4-B、g-C3N4-F和4%Ag-g-C3N4-F这3种材料都有吸收带边。g-C3N4-B吸收带边位于460 nm附近,能带间隙为2.69 eV,说明g-C3N4-B有可见光响应,与文献[19]报道一致。g-C3N4-F的吸收带边相对g-C3N4-B,发生蓝移在450 nm附近,带隙约为2.75 eV,这是由于超声处理后g-C3N4-F的量子尺寸效应导致能隙变大,使其吸收带边发生蓝移[15,20]。4%Ag-g-C3N4-F的吸收带边相对于g-C3N4-F,发生了明显的红移,在480 nm附近,带隙为2.58 eV,说明掺杂的纳米单质Ag,能显著地提升g-C3N4-F对可见光的吸收强度和吸收范围,出现这种情况的原因在于纳米单质Ag的等离子体产生了共振效应[18,21]。

2.1.4 荧光光谱结果与分析

图6为g-C3N4-B、g-C3N4-F和4%Ag-g-C3N4-F材料的荧光光谱图。可见,3种材料均在450 nm附近有明显的g-C3N4特征峰,与Zhou等[22]和Shi等[23]研究结果一致。g-C3N4-F的荧光强度明显低于g-C3N4-B,表明经超声处理后的g-C3N4-F比g-C3N4-B具有更低的光生载流子复合率,更高的分离率和迁移率,从而产生更多的光生电子和空穴参与光催化。g-C3N4主要依靠范德华力和氢键作用于材料的层状结构,因此具有较高的势垒,阻碍了光生电子与空穴的迁移,而超声剥离使g-C3N4纵向尺寸变小,降低了层与层之间的氢键和范德华力,减小了势垒[20],促进光生电子和空穴的分离和迁移,进而增强了光催化效率。4%Ag-g-C3N4-F的荧光强度明显低于g-C3N4-F,表明纳米单质Ag的掺杂,极大地提升了光生电子和空穴的分离率和迁移率,这是由于Ag具有较大的电负性,可在g-C3N4与Ag的交界处形成电子势阱,进而提升光生电子向交界处的迁移率。同时Ag具有优异的导电性,迁移到交界处的光生电子会迅速迁移到Ag表面并传递给受体,从而提升了光催化效率[21]。

2.1.5 电化学结果与分析

图7是g-C3N4-B、g-C3N4-F和4%Ag-g-C3N4-F材料的光电流响应曲线和电化学阻抗曲线。光电流响应曲线显示光催化材料在光照条件下产生光电流的强度,电化学阻抗显示光生载流子在材料内部转移的阻抗大小。如图7(a)所示,3种材料在光照条件下均产生了光电流,g-C3N4-F和4%Ag/g-C3N4-F的光电流密度分别达到了g-C3N4-B的1.7倍和4倍,这是由于调控g-C3N4的尺寸和掺杂纳米单质Ag可以有效提高其光生电子和空穴的分离效率,并且Ag的掺杂可以显著加快光生载流子的迁移效率。图7(b)所示,3种材料的化学阻抗曲线均为圆弧状曲线,圆弧半径越大电荷迁移阻抗就越大,圆弧半径的大小排列顺序为g-C3N4-B>g-C3N4-F>4%Ag-g-C3N4-F,说明尺寸调控和纳米单质Ag的掺杂能够降低阻抗,加快光生载流子的迁移效率,这与荧光光谱和光电流响应曲线的结果一致。

2.2 g-C3N4掺杂Ag、SiO2对光催化性能的影响

2.2.1 薄层g-C3N4掺杂不同质量比Ag对甲醛光催化降解效果的影响

图8是薄层g-C3N4掺杂不同质量比Ag对甲醛光催化降解效果图。可见,随着Ag质量比的增加,甲醛的降解率先上升后下降,在Ag质量比为4%时,为甲醛降解率的最大值52.82%。当Ag的质量比超过4%时,Ag较容易聚集成较大颗粒,使Ag与g-C3N4接触面积减少,进而减降低了Ag与g-C3N4交界面光电子的迁移效率[24],因此在Ag质量比超过4%时,光催化效率下降。可以得出适量掺杂Ag,能有效地提升量子产率,提升光催化降解效率。

2.2.2 g-C3N4-Ag/SiO2对甲醛光催化降解效果的影响

图9是g-C3N4-Ag/SiO2对甲醛光催化降解效果图。可见,降解甲醛的效率最好的是g-C3N4-Ag/SiO2-30,120 min后降解率达到65.6%。随着4%Ag-g-C3N4-F含量的增加,甲醛降解率先增加后降低。因为活性组分4%Ag-g-C3N4-F的增加,使降解甲醛的活性位点增多,所以甲醛降解率升高。而随着其负载量的继续增加,使硅铝胶球的部分孔道堵塞,从而抑制了甲醛的吸附和降解产物的脱附,进而导致甲醛降解率降低。

2.3 环境湿度对甲醛降解效果的影响

图10是相对湿度对甲醛降解效果的影响。因为空气中的水分子会一定程度地影响光催化反应,而不同地区的相对湿度不同,所以相对湿度作为环境因素有一定的代表性和重要性。选择g-C3N4-Ag/SiO2-30作为催化剂,探究相对湿度对甲醛光催化降解的影响。可见,随着相对湿度的增加,甲醛降解率呈显先上升后下降的趋势。这是由于在光催化反应中,水分子作为空穴的受体,与光生空穴反应会生成羟基自由基,随着水分子的增加,会产生更多的羟基自由基来氧化甲醛分子;随着相对湿度的继续增加,水分子和甲醛分子变成竞争关系,而SiO2表面的硅氧键更容易与水分子结合形成氢键,使水分子占据更多的吸附点位,从而削弱了对甲醛分子的吸附,同时由于水分子在较高的相对湿度下会液化,在硅铝胶球的表面形成液膜,使甲醛分子的传质阻力增大,阻碍了甲醛分子与催化剂的接触,导致甲醛的降解效率降低。

2.4 催化剂使用次数对甲醛降解效果的影响

图11是催化剂使用次数对甲醛降解效果的影响。催化剂的循环稳定性是评价其实际应用的重要指标。本试验使用g-C3N4-Ag/SiO2-30样品进行重复降解甲醛实验,每个周期降解时间为120 min,甲醛初始浓度均为0.5 mg/m3,催化剂每次循环前不作处理。可见,随着催化剂使用次数的增加,甲醛降解率呈缓慢下降趋势,16次使用过后,甲醛的降解率仅降低了9.71%,说明g-C3N4-Ag/SiO2-30的循环稳定性较好。使用多次催化效率下降的原因是由于SiO2 内部的孔道形状不平整,容易阻碍气体流动,不利于气体分子的脱附和扩散,进而导致降解产物逐渐在催化剂上积累,抑制了光催化活性[25]。

2.5 g-C3N4-Ag/SiO2光催化降解机制

图12是g-C3N4-Ag/SiO2材料光催化降解机制图。可见,经超声处理后的g-C3N4具有更低的光生载流子复合率,更高的分离率和迁移率,产生更多的光生电子流向g-C3N4表面,同时Ag具有优异的导电性,迁移到交界处的光生电子会迅速迁移到Ag表面并被空气中的氧气捕获,产生超氧自由基(·O2)[26],从而将甲醛氧化。超声处理降低了g-C3N4的势垒,促进了光生电子和空穴的分离,纳米单质Ag等离子体的共振效应增强了g-C3N4对可见光的吸收强度和吸收范围,并且Ag较大的电负性在g-C3N4与Ag的交界处形成电子势阱,提升光生电子向交界处的迁移率。因此g-C3N4-Ag/SiO2材料在LED白光光源下表现出良好的催化能力。

扩孔硅铝胶球可供降解产物吸附的位点较多,而水分子作为空穴的受体,与光生空穴反应会生成羟基自由基来氧化甲醛分子。

3. 结 论

(1) 成功制备薄层石墨相氮化碳(g-C3N4)-Ag/SiO2光催化复合材料,通过XRD、SEM、DES、TEM、紫外可见光吸收光谱、荧光光谱和电化学等表征显示材料光催化性能良好。

(2) g-C3N4-Ag/SiO2材料对甲醛具有良好的催化降解性能。超声处理使g-C3N4的势垒降低,促进了光生电子和空穴的分离,纳米单质Ag的掺杂通过等离子体的共振效应提升了光的吸收强度和吸收范围,依靠其较大的电负性加快光生电子的迁移速度,g-C3N4-Ag/SiO2-30催化降解率达到65.6%。

(3) g-C3N4-Ag/SiO2材料有良好的应用前景,g-C3N4-Ag/SiO2-30(Ag-薄层g-C3N4(g-C3N4-F)为30 mg)循环使用16次时,甲醛降解效率仅下降9.71%;g-C3N4-Ag/SiO2材料对环境因素具有一定的选择性,其中环境湿度对甲醛降解效果影响比较明显,相对湿度为40%时,甲醛降解效率达最大值64.56%。

-

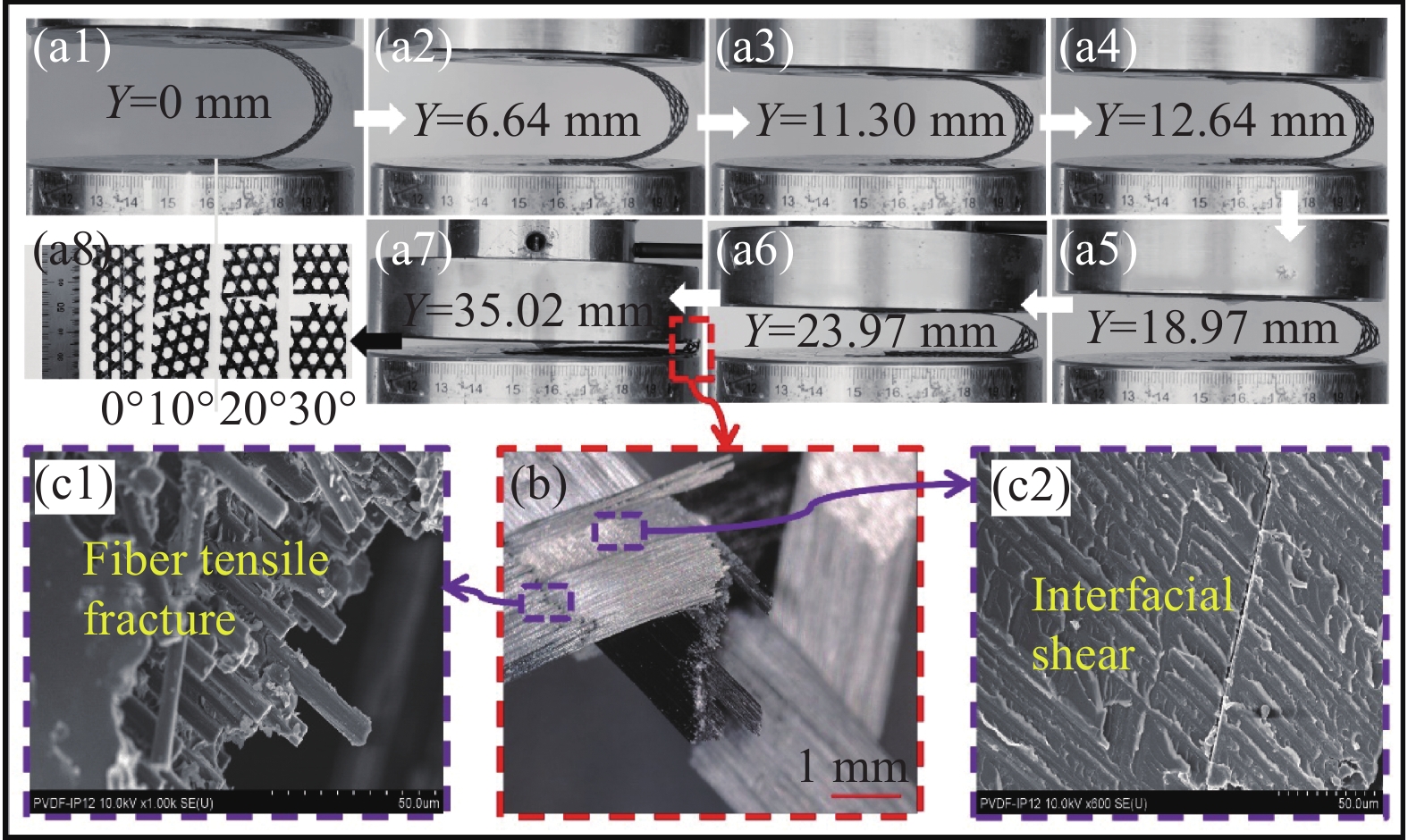

图 3 碳纤维TWF/EP复合材料在宏观尺度上的弯折过程及其损伤形貌:((a1)~(a7)) TWF/EP复合材料的弯折响应过程;(a8) 不同角度试样的弯折断口走向;(b) 断口的细观形貌;((c1)~(c2)) 断口的微观形貌

Figure 3. Folding process of carbon fiber TWF/EP composites on macro scale: ((a1)-(a7)) Folding response process TWF/EP composites; (a8) Trend of folding fracture of samples with different angles; (b) Micro morphology of fracture; ((c1)-(c2)) Micro morphologies of fracture

Y—Displacement

表 1 三轴机织复合材料结构参数

Table 1 Structural parameters of triaxial woven fabric composites

No. Carbon fiber Yarn width/mm Yarn center distance/mm Porosity/% Thickness/mm Area density/(g·m−2) Fiber volume/vol% 3-1 T300-3 k 1.4 4.5 34 0.389 250.0 33.3 3-2 5.5 41 0.345 212.2 27.9 6-1 T300-6 k 2.1 5.5 34 0.458 383.3 35.7 6-2 6 37 0.403 330.3 32.4 -

[1] 唐雅琼. 空间网状天线多源误差与形面稳定性研究[D]. 西安: 西安电子科技大学, 2017. TANG Yaqiong. Study on multi-source error and shape stability of spatial mesh antenna[D]. Xi'an: Xidian University, 2017(in Chinese).

[2] 李欣雪, 龙小丽, 訾梦超. 小型基站定向天线性能研究分析[J]. 现代工业经济和信息化, 2011, 11(4):25-27. LI Xinxue, LONG Xiaoli, ZI Mengchao. Performance research and analysis of directional antenna for small base station[J]. Modern Industrial Economy and Informatization,2011,11(4):25-27(in Chinese).

[3] 段宝岩. 大型空间可展开天线的研究现状与发展趋势[J]. 电子机械工程, 2017, 33(1):1-14. DOI: 10.3969/j.issn.1008-5300.2017.01.001 DUAN Baoyan. Research status and development trend of large space deployable antenna[J]. Electro-Mechanical Engineering,2017,33(1):1-14(in Chinese). DOI: 10.3969/j.issn.1008-5300.2017.01.001

[4] 孔令辉, 朱俊杰, 李泽健, 等. 国内外星载ADS-B应用现状及展望[J]. 科技风, 2021(13):20-22. KONG Linghui, ZHU Junjie, LI Zejian, et al. Current situation and prospect of spaceborne ADS-B application at home and abroad[J]. Technology Wind,2021(13):20-22(in Chinese).

[5] BOLLI P, ORFEI A, ZANICHELLI A, et al. An international survey of front-end receivers and observing performance of telescopes for radio astronomy[J]. Publications of the Astronomical Society of the Pacific,2019,131(1002):137-161.

[6] 魏善祥, 王启明, 孔德庆, 等. 大型双反射面天线指向误差评估算法[J]. 天文研究与技术, 2020, 17(4):513-521. WEI Shanxiang, WANG Qiming, KONG Deqing, et al. Evaluation algorithm for pointing error of large dual reflector antenna[J]. Astronomical Research and Technology,2020,17(4):513-521(in Chinese).

[7] 张华振, 马小飞, 宋燕平, 等. 星载高精度环形网状天线设计方法[J]. 中国空间科学技术, 2013, 33(5):1-6. DOI: 10.3780/j.issn.1000-758X.2013.05.001 ZHANG Huazhen, MA Xiaofei, SONG Yanping, et al. Design method of high precision ring mesh antenna on satellite[J]. Chinese Space Science and Technology,2013,33(5):1-6(in Chinese). DOI: 10.3780/j.issn.1000-758X.2013.05.001

[8] 万小平, 杨粉莉, 杨军刚. 空间大型可展开高精度天线的应用现状及发展趋势[J]. 空间电子技术, 2020, 17(6):1-7. DOI: 10.3969/j.issn.1674-7135.2020.06.001 WAN Xiaoping, YANG Fenli, YANG Jungang. Application status and development trend of large deployable high precision antenna in space[J]. Space Electronic Technology,2020,17(6):1-7(in Chinese). DOI: 10.3969/j.issn.1674-7135.2020.06.001

[9] 田大可, 范小东, 郑夕健, 等. 空间可展开天线微重力环境模拟研究现状与展望[J]. 机械工程学报, 2021, 57(3):11-25. DOI: 10.3901/JME.2021.03.011 TIAN Dake, FAN Xiaodong, ZHENG Xijian, et al. Research status and Prospect of microgravity environment simulation for space deployable antenna[J]. Journal of Mechanical Engineering,2021,57(3):11-25(in Chinese). DOI: 10.3901/JME.2021.03.011

[10] SOYKASAP O, KARAKAYA S. Analysis and testing of ultrathin shell 2 m diameter reflector demonstrator[J]. Journal of Reinforced Plastics and Composites,2013,32(7):450-462. DOI: 10.1177/0731684412465778

[11] DATASHVILI L. Multifunctional and dimensionally stable flexible fibre composites for space applications[J]. Acta Astronautica,2010,66(7):1081-1086.

[12] TYLER T. Developments in triaxial woven fabrics[M]. London: Woodhead Publishing, 2011: 141-163.

[13] RAO Y, ZHNAG C, LI W. Structural analysis for triaxial woven fabric composites of carbon fiber[J]. Composite Structures,2019,219:42-50. DOI: 10.1016/j.compstruct.2019.03.013

[14] DATASHVILI, LERI S. Multi-scale analysis of structures made of triaxially woven fabric composites with stiff and flexible matrix materials[C]//52nd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference. Colorado: AIAA, 2011.

[15] 易淼. 三向织物织造及其复合材料拉伸机理研究[D]. 上海: 东华大学, 2019. YI Miao. Study on the tensile mechanism of triaxial woven fabric weaving and its composites[D]. Shanghai: Donghua University, 2019(in Chinese).

[16] 沙迪, 禹旭敏, 赵将, 等. 碳纤维三向织物/环氧树脂复合材料的制备与力学性能[J]. 高等学校化学学报, 2020, 41(4):838-845. DOI: 10.7503/cjcu20190513 SHA Di, YU Xumin, ZHAO Jiang, et al. Preparation and mechanical properties of carbon fiber triaxial woven fabric/epoxy resin composites[J]. Chemical Journal of Chinese Universities,2020,41(4):838-845(in Chinese). DOI: 10.7503/cjcu20190513

[17] 毕华阳. 碳纤维三向织物复合材料拉伸性能及拉伸破坏模式研究[D]. 上海: 东华大学, 2018. BI Huayang. Study on tensile properties and tensile failure mode of carbon fiber triaxial woven fabric composites[D]. Shanghai: Donghua University, 2018(in Chinese).

[18] ZHOU X, MA X. Tensile and bending behavior of thin-walled triaxial weave fabric composites[J]. Journal of Engineered Fibers and Fabrics,2019,14:1-10.

[19] 张平, 桂良进, 范子杰. 三向编织复合材料弹性性能研究[J]. 工程力学, 2009, 26(1):31-36. ZHANG Ping, GUI Liangjin, FAN Zijie. Study on the elastic properties of trixially braided composites[J]. Engineering Mechanics,2009,26(1):31-36(in Chinese).

[20] KUEH A, PELLEGRINO S. Thermo-elastic behaviour of single ply triaxial woven fabric composites[C]//47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference. Rhode Island: AIAA, 2006.

[21] AOKI T, YOSHIDA K, WATANABE A. Feasibility study of triaxially-woven fabric composite for deployable structures[C]//48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Hawaii: AIAA, 2007.

[22] 贾明皓, 裴佳慧, 肖学良, 等. 基于三向交织结构玄武岩纤维增强水泥基复合材料力学性能研究[J]. 硅酸盐通报, 2019, 38(2):517-521. JIA Minghao, PEI Jiahui, XIAO Xueliang, et al. Study on mechanical properties of basalt fiber reinforced cement-based composites based on three-dimensional interlaced structure[J]. Bulletin of the Chinese Ceramic Society,2019,38(2):517-521(in Chinese).

[23] SOYKASAP O. Folding design of composite structures[J]. Composite Structures,2007,79(2):280-287. DOI: 10.1016/j.compstruct.2006.01.008

[24] ZHAO Q, HOA S V, OUELLETTE P. Progressive failure of triaxial woven fabric (TWF) composites with open holes[J]. Composite Structures,2004,65(3-4):419-431. DOI: 10.1016/j.compstruct.2003.12.004

[25] 中国钢铁工业协会. 金属材料—薄板和薄带—弯折性能试验方法: GB/T 38806—2020[S]. 北京: 中国标准出版社, 2020. China Iron Steel Association. Metallic materials—Sheet and strip—Test method for bending and folding properties: GB/T 38806—2020[S]. Beijing: Standards Press of China, 2020(in Chinese).

[26] FUKUDA H, WATANABE T, ITABASHI M, et al. Compression bending test for CFRP pipe[J]. Composites Science and Technology,2002,62(15):2075-2081. DOI: 10.1016/S0266-3538(02)00150-1

[27] 杨晓亚, 焦亚男, 何业茂, 等. 孔洞型碳纤维三轴机织物/环氧树脂复合材料的弯曲和拉伸性能[J]. 复合材料学报, 2022, 39(7):3191-3201. YANG Xiaoya, JIAO Ya'nan, HE Yemao, et al. Bending and tensile properties of carbon fiber triaxial woven fabric/epoxy resin composites with holey structure[J]. Acta Materiae Compositae Sinica,2022,39(7):3191-3201(in Chinese).

[28] 韩帅, 段跃新, 李超, 等. 不同针织结构经编碳纤维复合材料弯曲性能[J]. 复合材料学报, 2011, 28(5):52-57. HAN Shuai, DUAN Yuexin, LI Chao, et al. Flexural properties of warp knitted carbon fiber composites with different knitting structures[J]. Acta Materiae Compositae Sinica,2011,28(5):52-57(in Chinese).

-

期刊类型引用(7)

1. 陈楚晓,郝京华. AuPt/还原氧化石墨烯/氮化碳的制备及其在室内挥发性有机物处理中的应用. 环境工程学报. 2025(01): 178-187 .  百度学术

百度学术

2. 崔春丽,郝振华,舒永春,徐继香,王磊. MoO_3-Cu_2O/CN三相复合光催化剂的制备及其降解四环素性能. 复合材料学报. 2025(03): 1361-1374 .  本站查看

本站查看

3. 孙术博,于海瀚,李强,葛慎光,姜葱葱,王丹,张丽娜,程新,高超民. NaNbO_3@g-C_3N_4复合材料的可控构筑及其压电光催化性能. 复合材料学报. 2023(03): 1534-1540 .  本站查看

本站查看

4. 陈书航,郝亚超,赵阳灿,杨潘,王斯琰,徐宏妍. 硫酸改性g-C_3N_4的制备及其光催化产氢性能研究. 功能材料. 2023(07): 7126-7130 .  百度学术

百度学术

5. 徐凯旋,亢玉龙,高晓明,贺红斌,袁中强,胡亚楠. 内电场增强S型异质结N-C_3N_4/BiOCl_xI_(1-x)的制备及其光催化性能. 复合材料学报. 2023(09): 5134-5144 .  本站查看

本站查看

6. 肖力光,杨子力. Ag改性的g-C_3N_4基纳米复合光催化材料的研究进展. 现代化工. 2022(03): 37-40+45 .  百度学术

百度学术

7. 范新容,李成,许岩. 多酸基分子材料在图书馆清洁与用户环境保护中的应用研究. 化学研究与应用. 2022(07): 1674-1679 .  百度学术

百度学术

其他类型引用(6)

-

下载:

下载: