Axial compression behavior of novel concrete-filled circular CFRP-UHPC composite tubular columns

-

摘要: 为研究超高性能混凝土(UHPC)管替代碳纤维增强聚合物(CFRP)-钢管混凝土组合柱中钢管的可行性,提出一种外部缠绕CFRP的UHPC预制管、内部现浇填充普通混凝土的新型CFRP-UHPC组合管混凝土(Concrete-filled CFRP-UHPC tube,CFFUT)柱。对10个CFFUT圆柱(包含2个对比柱)进行了单调轴压试验,研究了UHPC管壁厚度、CFRP环向包裹层数和核心混凝土强度等的影响规律。结果表明:CFRP-UHPC管可以有效提高组合柱的承载力、变形能力和延性;CFFUT圆柱破坏形态为核心混凝土压溃、UHPC管开裂和CFRP拉断,破坏后整体性较好,属延性破坏模式;CFFUT圆柱的极限承载力与UHPC管壁厚度、CFRP层数和核心混凝土强度呈正相关;延性系数随UHPC管壁厚度、CFRP层数增加而提高,随核心混凝土强度增加先提高后降低。揭示了CFFUT柱的界面增强作用机制,CFFUT柱极限承载力与同等截面普通混凝土柱相比提高93.9%~203.5%,且CFFUT柱极限承载力一定程度上与CFRP-钢管混凝土柱相当。建立了CFFUT圆柱轴压极限承载力理论计算模型,并通过有限元模拟验证,理论值、模拟值和试验结果吻合较好。Abstract: In order to study the feasibility of replacing steel tubes of concrete filled carbon fiber-reinforced polymer (CFRP)-steel tube columns with ultra high performance concrete (UHPC) tubes, a novel concrete-filled CFRP-UHPC tube (CFFUT) column was proposed. The CFFUT column consists of a combination of UHPC precast tubes externally wrapped with CFRP and an internal cast-in-place filled normal concrete. Ten CFFUT columns, including two contrast columns, were tested under monotonic axial compression, and the influences of UHPC tube thickness, CFRP layer numbers and filled concrete strength were investigated. The results show that CFRP-UHPC tube can effectively improve the bearing capacity, deformation capacity and ductility of composite columns. The failure of CFFUT column is mainly manifested as the collapse of filled concrete, cracking of UHPC tube and rupture of CFRP. The integrity of CFFUT column is good after failure, and it belongs to ductility failure mode. The ultimate bearing capacity of CFFUT column is positively correlated with the thickness of UHPC tube, the number of CFRP layers and the strength of filled concrete. Ductility factor increases with the increase of UHPC tube thickness and CFRP layer number, and increases first and then decreases with the increase of filled concrete strength. The interface strengthening mechanism of CFFUT column is revealed. The ultimate bearing capacity of CFFUT columns is 93.9%-203.5% higher than that of normal concrete columns with the same section, and the ultimate bearing capacity of CFFUT columns is equivalent to that of concrete-filled CFRP- steel tube columns to a certain extent. The theoretical calculation model of ultimate bearing capacity is established and verified by finite element analysis. The calculated and simulated values are in good agreement with the test results.

-

碳纤维增强聚合物(Carbon fiber-reinforced polymer,CFRP)具高比强度、耐腐蚀和施工性能好等优点,是混凝土加固领域广泛使用的一种复合材料。为解决传统钢管混凝土局部屈曲问题,Xiao等[1]较早提出约束钢管混凝土柱概念;王庆利等[2]也提出CFRP-钢管混凝土组合结构,即在钢管混凝土柱外表面按照一定方式缠绕一层或多层CFRP实现全截面或局部约束。近20年来,众多学者[3-9]研究证实了CFRP-钢管混凝土柱的有效性,并极大地拓展了约束钢管混凝土柱研究范畴。采用聚氯乙烯(Polyvinyl chloride,PVC)管替代钢管后形成CFRP-PVC管混凝土柱,研究发现同样取得较好的组合效果[10-15]。然而,由于钢管、PVC管与混凝土为不同材料属性,界面可能存在脱空风险,如混凝土浇筑和凝结硬化阶段界面剥离,承载阶段钢管等与混凝土泊松比差异大,无法有效提供套箍约束甚至发生局部屈曲,从而导致组合柱承载力得不到充分发挥[16]。

超高性能混凝土(Ultra-high performance concrete,UHPC)是当今最先进一代水泥基材料,具有超高强度、高韧性和高耐久性的“三高”特点[17],成为当前研究和工程应用热点。目前UHPC组合结构主要包括UHPC薄层修复既有混凝土结构和UHPC预制模壳现浇混凝土组合结构,均取得较好组合性能和经济效益,如UHPC不显著增加截面和造价,但极大提升抗裂性和承载力;UHPC基体致密可有效阻止水分子和侵蚀介质,显著提高耐久性和使用寿命。基于海洋环境钢筋混凝土桥梁墩柱和桩的耐久性劣化问题,Sun等[18]提出了UHPC护套桩概念;Xie等[19]通过对UHPC护套(仅起约束作用)加固混凝土柱的研究,表明轴压承载力随UHPC厚度增加而提高;Hadi等[20]采用活性粉末混凝土(Reactive powder concrete,RPC)、CFRP和RPC+CFRP 3种方式加固混凝土圆柱,结果表明:仅RPC加固对承载力和耗能能力提高较大,仅CFRP加固对延性提高较大,而RPC+CFRP联合加固对极限承载力、延性和耗能能力提升均最大;吴香国[21]较早提出了基于结构耐久性的UHPC叠合墩柱设计概念;林上顺等[22]以平潭海峡大桥为工程背景,测算采用UHPC-钢筋混凝土组合桥墩替代原方案可节省造价约30%,研究还表明UHPC具有一定套箍作用。此外,有学者提出配筋或编织网UHPC预制模板,杨医博等[23]研究了配筋UHPC模板方柱、圆柱,开裂荷载分别提高38%、90%,极限荷载分别提高49%、85%,建议优选圆柱;单波等[24]研究了配螺旋箍筋RPC预制管柱,表明组合柱承载力具有超叠加效应,且RPC管配箍率越高抗压性能越好;Tian等[25]研究了配编织网UHPC预制模板柱,表明组合柱轴压承载力随UHPC厚度增加而增大,但编织网类型和层数的影响较小。

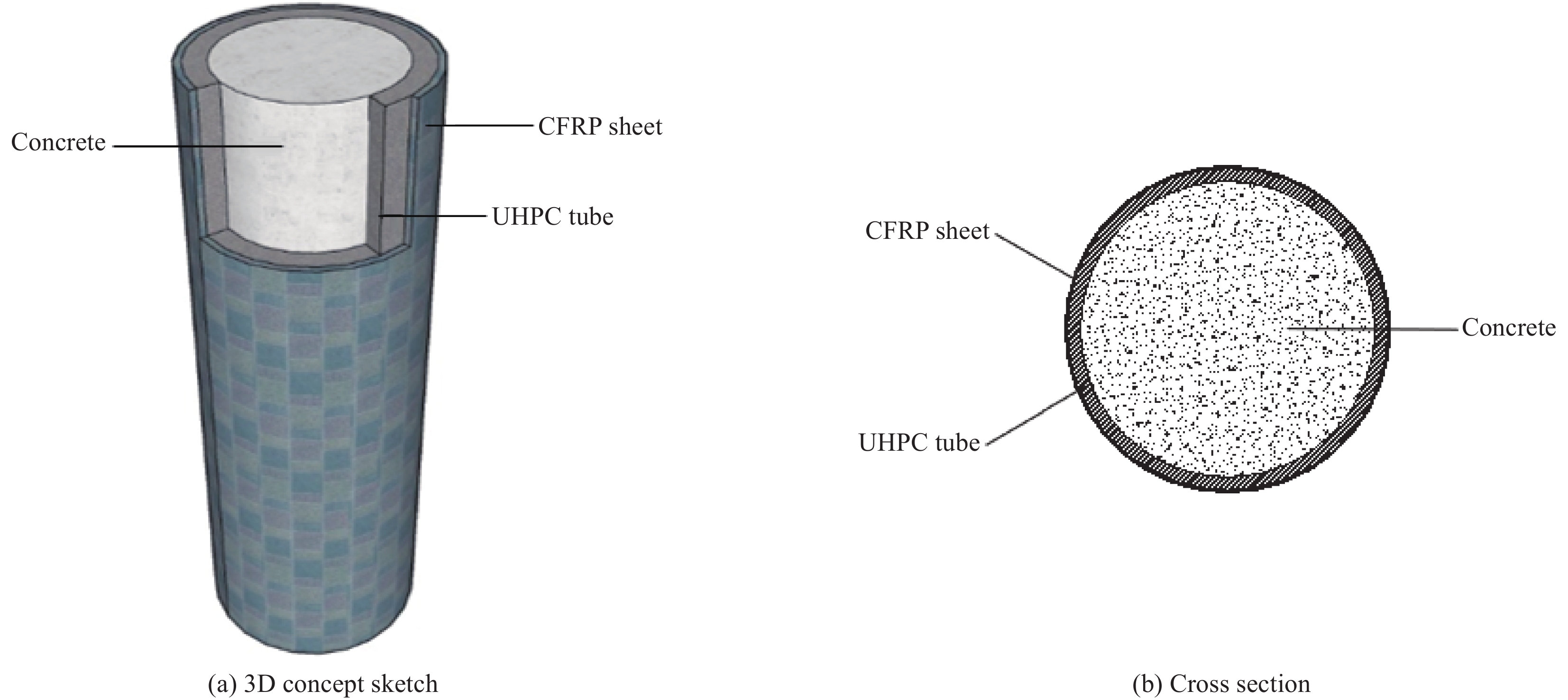

UHPC由于其拉伸应变硬化和高断裂韧性等典型特征,又被称作“类钢混凝土”[26-27],为研究UHPC管替代CFRP-钢管混凝土柱中钢管的可行性,本文提出一种外部缠绕CFRP的UHPC预制管、内部现浇填充普通混凝土的新型CFRP-UHPC组合管混凝土(Concrete-filled CFRP-UHPC tube,CFFUT)柱,CFFUT柱具高强、耐高温、施工方便、绿色环保、经济性和耐久性好等设计理念。作为CFFUT柱的初步探索研究,纤维增强聚合物 (Fiber-reinforced polymer,FRP)采用了目前研究和应用较广泛CFRP,并首先开展了CFFUT柱的轴压性能试验研究,建立了极限承载力计算模型,以期为该类组合柱的深入研究和工程推广应用提供一定参考。

1. 试验研究

1.1 试件设计

图1为CFFUT柱示意图,试验共设计了8根CFFUT柱和2根对比柱(普通混凝土、UHPC管混凝土柱各1根),CFRP-钢管混凝土(Concrete-filled CFRP-steel tube,CFFST)对比柱试验数据参考文献[28]。所有试验试件外径D为150 mm,高度H为450 mm,UHPC管壁厚度tu为12.5 mm、20 mm、30 mm,CFRP环向全包覆层数ncf为0、1、2层,核心混凝土强度等级为C30、C50、C80、C100,试件具体参数见表1。以试件编号MA-F0200-U12.5-C50为例,表示单调轴压短柱,CFRP层数为2,UHPC管壁厚度为12.5 mm,核心混凝土强度等级为C50(C30时省略)。

表 1 试件编号及参数Table 1. Number and parameters of specimensNo. tu/mm ncf fcu/MPa fc/MPa fts/MPa E/GPa Pu/kN α Δu/mm β μ MA-0-0 — — 32.8 28.9 2.62 26.5 724.0 1.000 2.429 1.000 1.14 MA-0-U12.5 12.5 0 32.8 28.9 2.62 26.5 977.0 1.349 4.213 1.734 1.31 MA-F0100-U12.5 12.5 1 32.8 28.9 2.62 26.5 1403.8 1.939 8.164 3.361 1.45 MA-F0100-U20 20.0 1 32.8 28.9 2.62 26.5 1476.0 2.039 7.577 3.119 1.52 MA-F0100-U30 30.0 1 32.8 28.9 2.62 26.5 1650.2 2.279 5.823 2.397 1.59 MA-F0200-U12.5 12.5 2 32.8 28.9 2.62 26.5 1811.8 2.502 11.295 4.650 1.55 MA-F0200-U30 30.0 2 32.8 28.9 2.62 26.5 2197.6 3.035 8.929 3.676 1.64 MA-F0200-U12.5-C50 12.5 2 53.5 47.3 3.69 32.0 2186.0 3.019 9.697 3.992 1.59 MA-F0200-U12.5-C80 12.5 2 90.4 69.6 4.13 36.8 2418.0 3.340 9.214 3.793 1.66 MA-F0200-U12.5-C100 12.5 2 118.0 105.7 6.65 44.1 2664.2 3.680 5.424 2.233 1.31 Notes: tu—Thickness of UHPC tube; ncf—Number of CFRP layers; fcu—Cubic compressive strength of filled concrete; fc—Axial compressive strength of filled concrete; fts—Splitting tensile strength of filled concrete; E—Elastic modulus of filled concrete; Pu—Ultimate load; α—Ratio of ultimate load between CFFUT column and contrast column (MA-0-0) ; Δu—Ultimate displacement; β—Ratio of ultimate displacement between CFFUT column and contrast column (MA-0-0); μ—Ductility factor. The letter MA denotes the monotonic axial load condition, the letter F denotes the number of CFRP layers, the letter U denotes the thickness of UHPC tube, the letter C denotes the nominal filled concrete strength, omitted when C30 filled concrete is used. For example, the MA-F0200-U12.5-C50 indicates that the load condition of specimen is monotonic axial compression, the number of CFRP layers is 2, the thickness of UHPC tube is 12.5 mm, and the nominal filled concrete strength is 50 MPa. 1.2 材料性能

表2为核心混凝土和UHPC的配合比,原材料主要包括陕西乾县海螺水泥厂P·O 42.5(C30、C50)、P·O 52.5(C80、C100、UHPC)普通硅酸盐水泥,挪威埃肯公司硅粉,陕西蒲城电力实业有限公司II级粉煤灰(C30、C50)、天津筑城新材料科技有限公司微珠(C100、UHPC),陕西当地碎石粗骨料(C30、C50、C80),陕西当地机制砂(C30、C50、C80)、陕西城固县永杰矿产品厂石英砂(C100、UHPC)细骨料,江苏苏博特新材料有限公司聚羧酸减水剂,上海真强纤维有限公司端钩形钢纤维(用于UHPC)。

表 2 混凝土和UHPC配合比Table 2. Mixture proportion of concrete and UHPCkg·m−3 Type Cement Silica fume Fly ash CAGG FAGG Water SP Steel fiber C30 280 — 70 1043 826 175 5.1 — C50 363 — 80 1055 738 155 9.0 — C80 455 40 — 1080 665 150 9.9 — C100 787 126 136 — 1050 189 26.0 — UHPC 787 126 136 — 1050 189 26.0 195 Notes: CAGG—Coarse aggregate; FAGG—Fine aggregate; SP—Superplasticizer. 按照《混凝土物理力学性能试验方法标准》(GB/T 50081—2019)[29]和《超高性能混凝土基本性能与试验方法》(T/CBMF 37—2018/T/CCPA 7—2018)[30],加载时实测混凝土的性能参数见表1,实测UHPC立方体抗压强度156.8 MPa、弹性模量46.5 GPa。

采用单向碳纤维布和配套环氧树脂粘合剂(质量比,主剂∶硬化剂 = 2∶1),碳纤维布单层名义厚度0.167 mm,抗拉强度3961 MPa,弹性模量240 GPa。

1.3 试验方案

1.3.1 CFFUT柱制备

图2为CFFUT柱具体制作流程:(1) 采用特制模具(包含外钢管、内PVC管、盖板)预制UHPC空心管,分层装料并用橡皮锤轻击外模保证UHPC浇筑密实,UHPC空心管拆模后立即蒸汽养护(80℃,48 h);(2) UHPC管兼做模板,分层浇筑核心混凝土并用振捣棒振捣密实;(3) 采用打磨和补浇高强石膏薄层找平上下端面,表面清污并粘贴混凝土应变片;(4) 参考《碳纤维片材加固混凝土结构技术规程》(CECS 146: 2003) [31] 湿粘包裹CFRP,沿纤维方向搭接130 mm以避免脱粘失效,且两端附加2层50 mm宽CFRP以防止端部受压提前破坏。试件制作完成于室内静置7天且待环氧树脂充分固化后再加载。

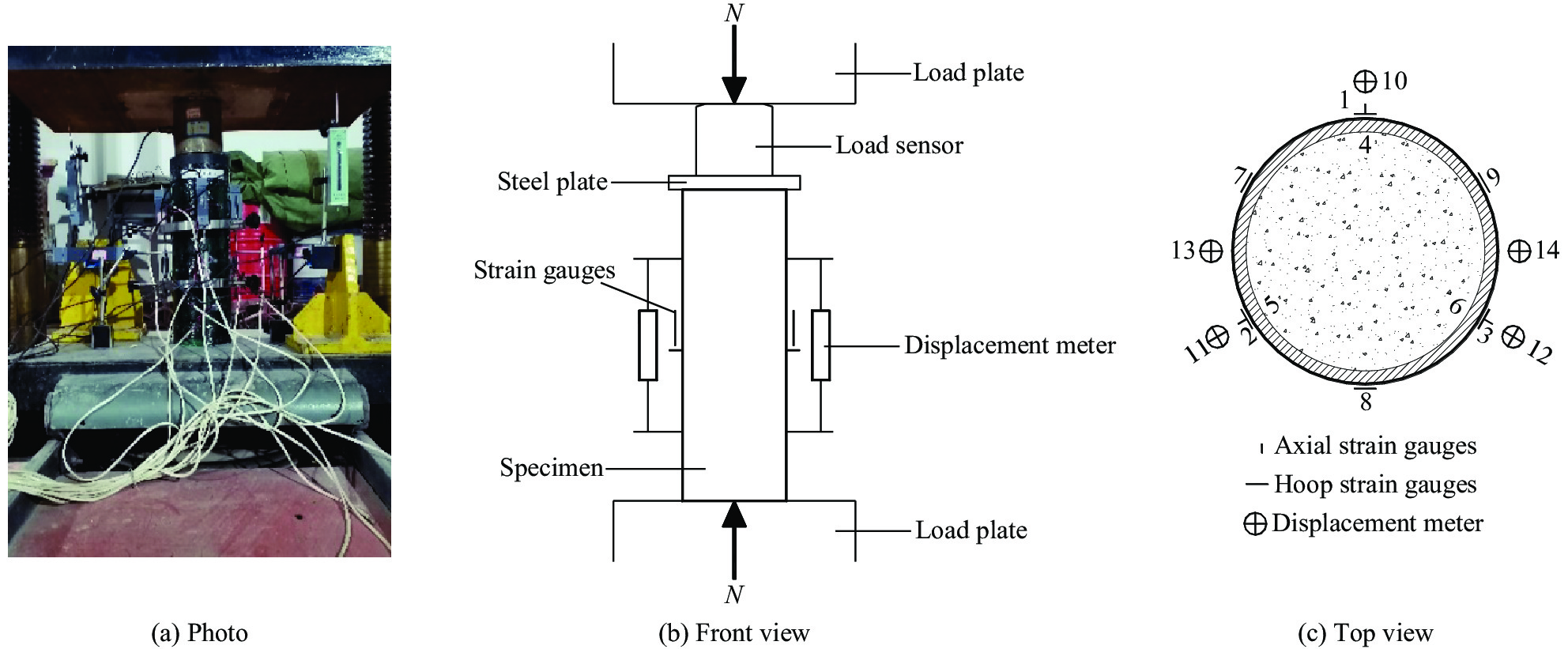

1.3.2 试验装置与加载制度

加载装置为长春新试验机有限公司的YAW-5000型(最大试验力5000 kN)电液伺服长柱压力机,同时采用江苏东华测试技术有限公司的DH3816 N测试系统采集试验力、位移和应变等数据,测试装置和加载现场见图3。试件顶部设置荷载传感器测量轴压力;UHPC外表面中部沿环向间隔120°粘贴3组1纵1横共6个应变片(1~6),以观察UHPC纵向、环向应变发展;试件高度四分点沿CFRP环向各粘贴1个应变片(7~9),以观察CFRP环向应变发展;试验柱共布置5个纵向位移计测量轴向变形,其中3个位移计(10~12)安装在固定支架上沿周边120°布置,测量柱中部250 mm范围竖向压缩变形,柱端对称设置2个位移计(13、14),测定试验柱纵向总变形;试验柱高度中部对称布置2个横向位移计,测量横向膨胀变形。采用等速位移加载,速率为0.18 mm/min,每加载0.5 mm持荷2 min,待每级荷载稳定后观察并详细记录试验现象。当下降至峰值荷载的70%以下,或试件破坏无法继续加载时停止试验。

2. 试验结果与分析

2.1 试验现象与CFFUT柱破坏模式

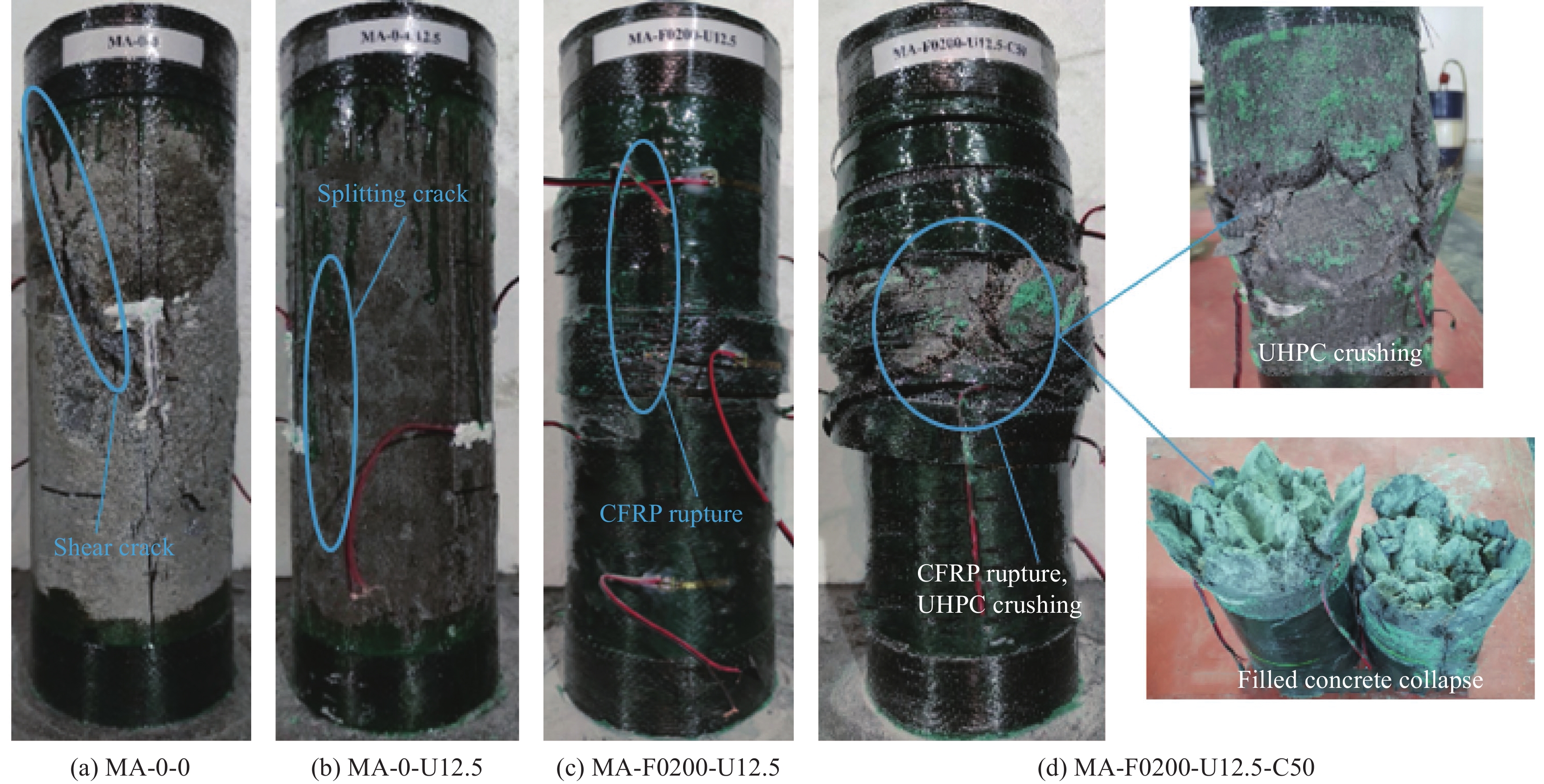

图4为对比柱、典型CFFUT柱的轴压破坏模式。普通混凝土柱(MA-0-0)加载前期外观没有明显变化,加载至混凝土抗压强度时试件瞬间被压坏,表现为明显的脆性破坏,主破裂面为剪切裂缝。UHPC管混凝土柱(MA-0-U12.5)加载至约峰值荷载的80%,UHPC管局部起皮,听到钢纤维“滋滋”拔出轻响,荷载继续加大,UHPC形成竖向裂缝且缓慢延伸,同时伴随新裂缝不断产生,随着较大声响试件达峰值荷载同时小幅陡降,但仍具有一定残余承载力和塑性变形能力,直至第二声巨响荷载急剧下降试件宣告破坏,主破裂面为劈裂裂缝。

CFFUT柱加载初期表面无明显变化,UHPC轴向应变随荷载的增加而线性增大,此时处于弹性阶段。加载至无约束混凝土抗压强度时核心混凝土开裂膨胀,UHPC管中部环向变形增大加快,CFRP开始发挥约束作用。荷载继续增大,UHPC管局部起皮听到钢纤维拔出的持续“滋滋”声。随着较大沉闷响声UHPC管形成宏观裂缝,同时荷载第一次小幅陡降,此时试件并未破坏,在CFRP约束作用下荷载和轴向压缩量持续增大,该阶段UHPC已有裂缝持续发展并伴随新裂缝不断产生。随着钢纤维拔出响声密集,CFRP陆续发出数声“啪啪”断裂清脆响声,核心混凝土被压碎,荷载持续下降,形成主破裂面试件宣告破坏。CFRP属于线弹性材料且断裂变形较小,因此CFFUT柱最终破坏瞬间表现较突然,但考虑CFFUT柱破坏失效前的两个典型标志——UHPC管开裂、CFRP断裂均发出较大声响,实现了“二道防线”破坏模式,破坏前具有一定的预兆,且混凝土压溃前经历了较长的塑性变形,属延性破坏。由于CFRP包裹约束和UHPC钢纤维“桥联”作用机制,CFFUT柱的裂缝发生与扩展得到有效抑制,破坏试件整体性较好表现为“裂而不碎”。加载试验结束后,将CFFUT柱的CFRP、UHPC管依次剖开,如图4(d)所示,观察发现CFRP断裂处UHPC管挤压开裂严重、核心混凝土压碎。随着CFRP层数、核心混凝土强度的增加,UHPC挤压开裂和核心混凝土压溃现象越严重。

2.2 CFFUT柱的力学性能

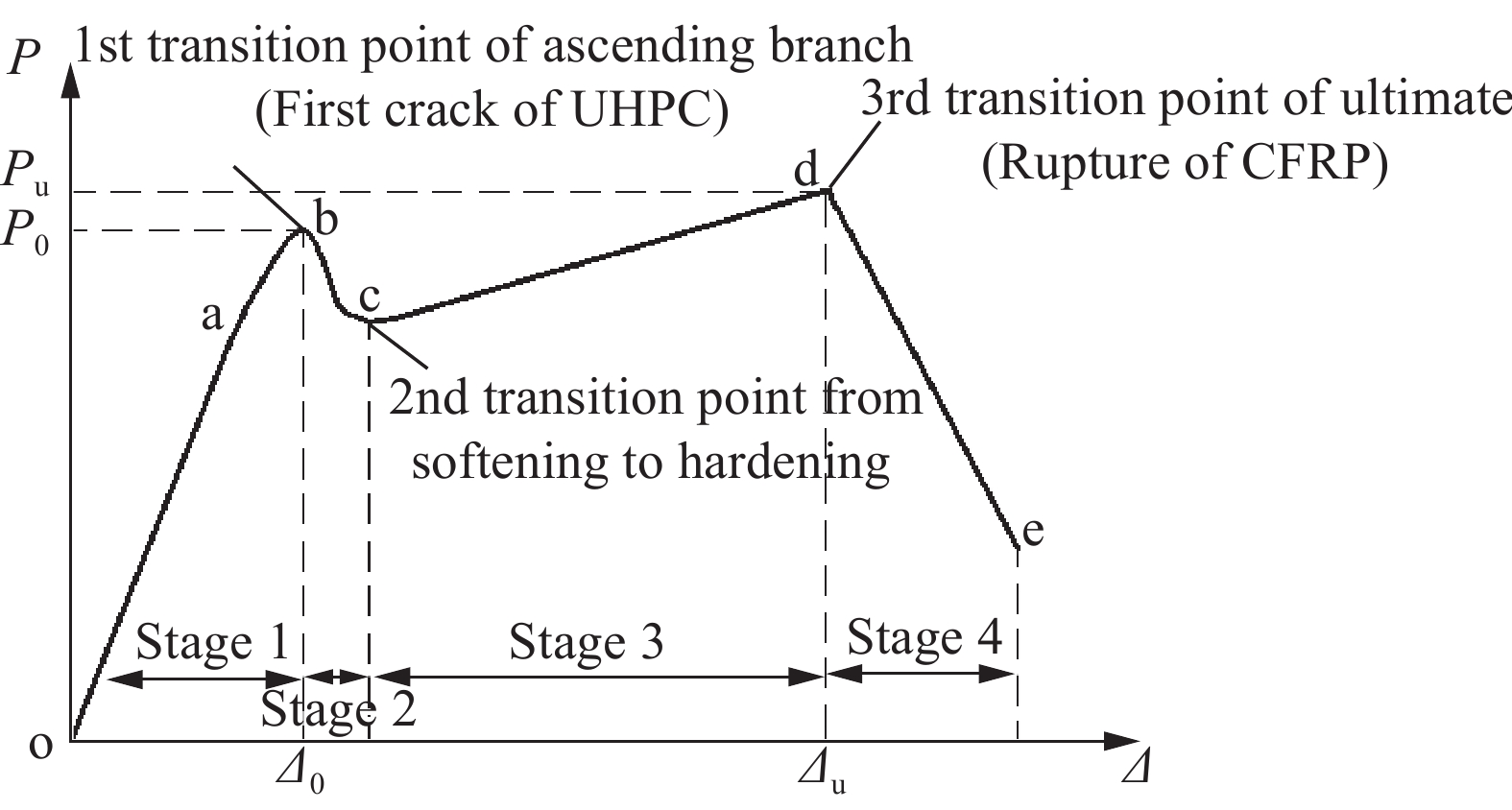

图5为CFFUT柱的典型荷载-位移(P-Δ)曲线,可划分为4个阶段:(1) 初始上升段(oab段),该阶段包括线弹性段(oa段)和弹塑性段(ab段),加载前期为线弹性阶段,UHPC和核心混凝土共同受力,二者之间不发生相互挤压,随着荷载增大进入弹塑性阶段,核心混凝土产生微裂纹,UHPC与核心混凝土之间产生径向压力,CFRP产生环向拉应力,试件纵向刚度逐渐降低,表现为曲线斜率减小;(2) UHPC开裂陡降段(bc段),该阶段的标志为UHPC出现宏观裂缝,包含第1峰值点b(对应开裂承载力)及荷载小幅(10%~20%)陡降造成的软化段;(3) CFRP约束强化段(cd段),在CFRP紧箍约束和UHPC钢纤维“桥联”作用下承载力和轴向变形进一步提高,该阶段核心混凝土处于三向受压应力状态,CFRP处于环向拉应力状态,UHPC处于轴向压应力、径向压应力和环向拉应力的三向应力状态;(4) CFRP断裂下降段(de段),该阶段的标志为CFRP陆续拉断,包含第2峰值点d(对应极限承载力)及稳定软化段。

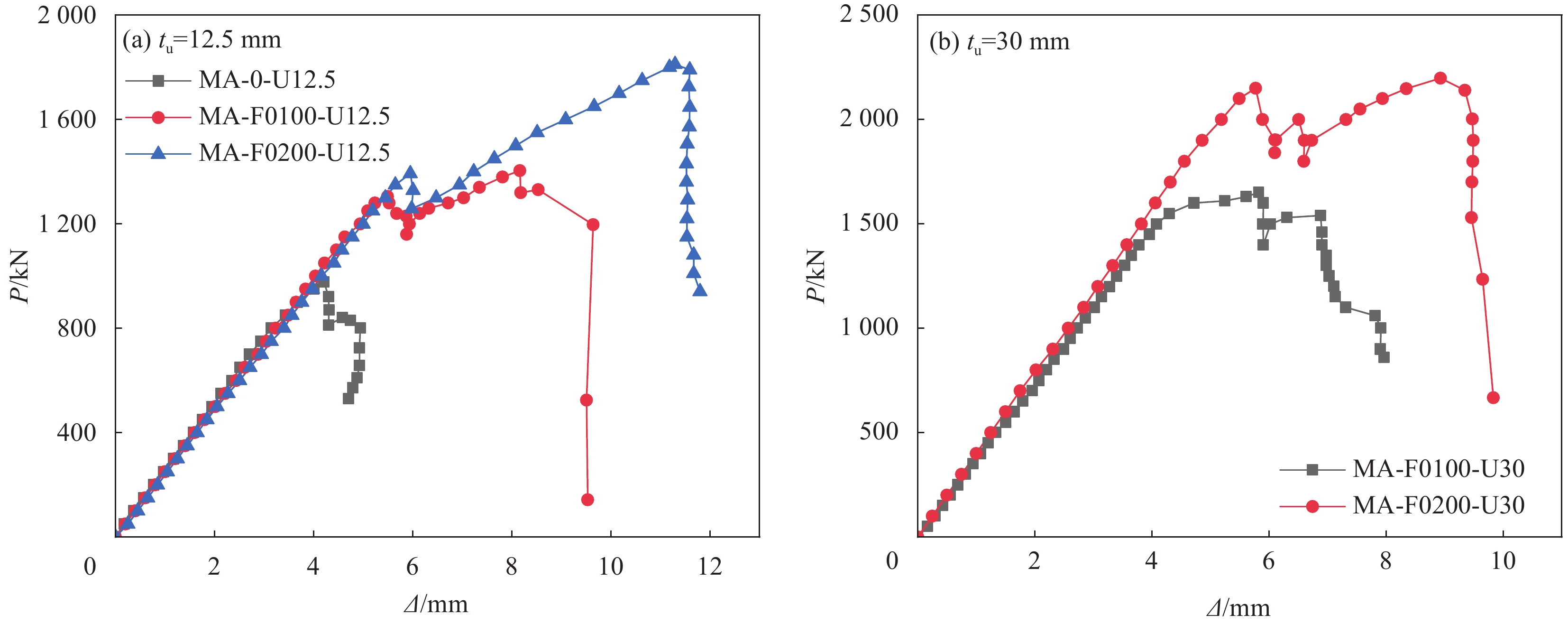

2.2.1 CFRP层数的影响

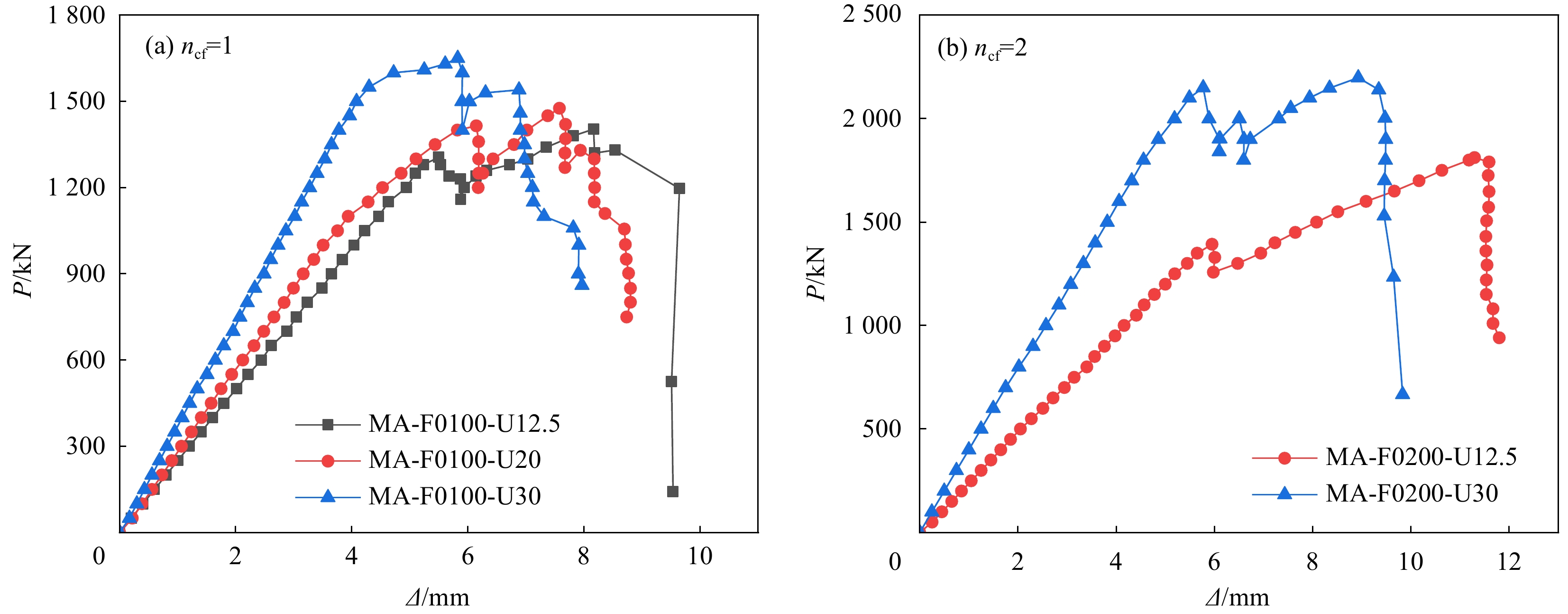

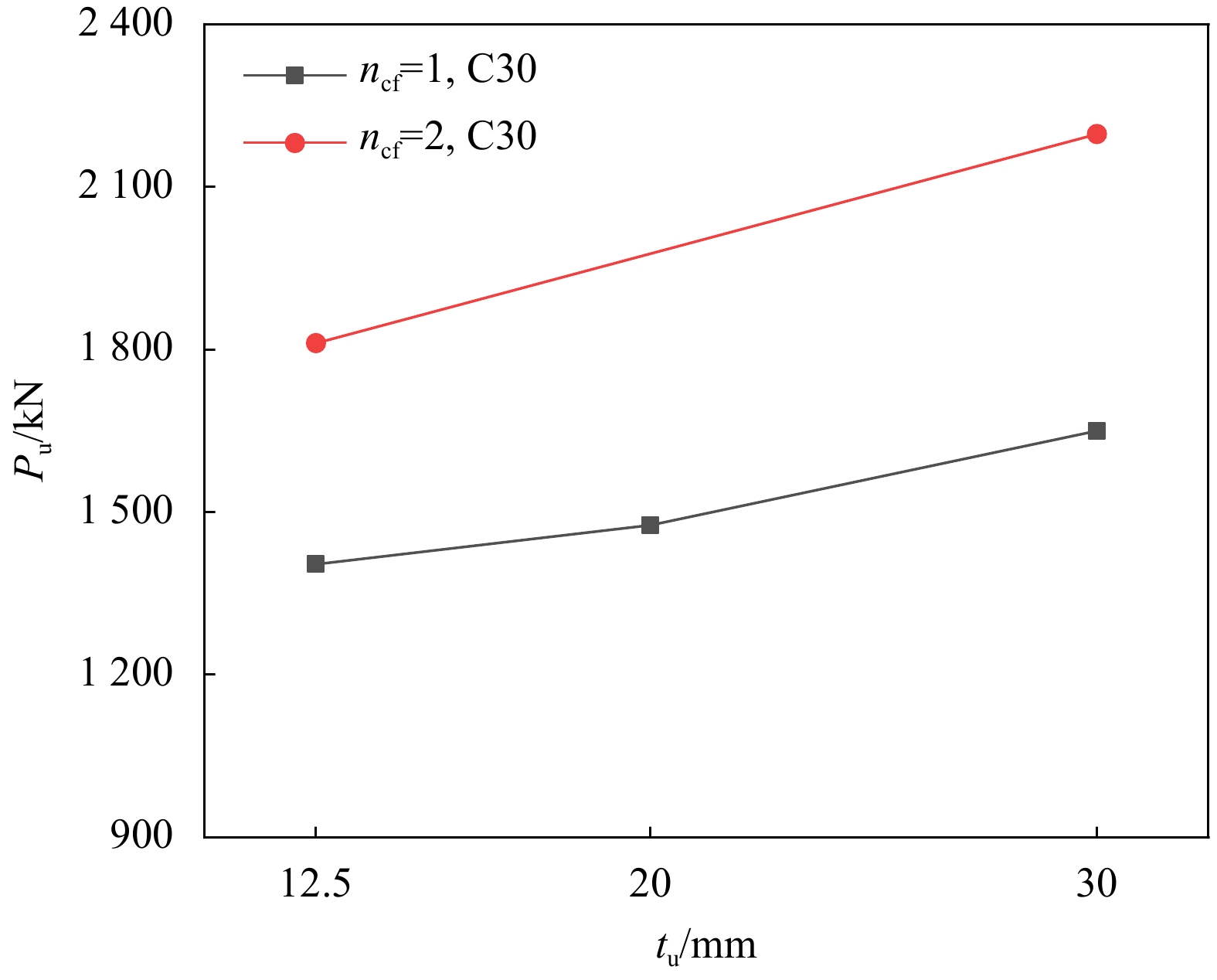

图6为不同CFRP层数ncf的CFFUT柱轴向荷载-位移曲线,图7为Pu随ncf的变化规律。可以看出,ncf对试件P-Δ曲线初始上升段斜率影响较小,说明CFRP对纵向刚度贡献较低;随着ncf增加,约束强化段斜率呈增大趋势且强化段更长,表明CFRP约束提高了轴压承载力和变形能力。当tu相同时,CFFUT柱承载力和轴向压缩量随ncf的增加而增大,与MA-0-U12.5相比,MA-F0100-U12.5的Pu、Δu分别提高43.7%、93.8%,MA-F0200-U12.5的Pu、Δu分别提高85.4%、168.1%。

2.2.2 UHPC管壁厚度的影响

图8为不同tu的CFFUT柱轴向荷载-位移曲线,图9为Pu随tu的变化规律。可以看出,当ncf相同时,试件Pu随着tu的增加而增大,这是由于组合柱的UHPC与核心混凝土共同承压,且UHPC抗压强度远大于核心普通混凝土;随tu的增加,P-Δ关系曲线向左上方移动,即曲线初始上升段斜率增大,表明UHPC管对组合柱刚度的增强作用,这与UHPC弹性模量大于核心普通混凝土有关。

2.2.3 核心混凝土强度的影响

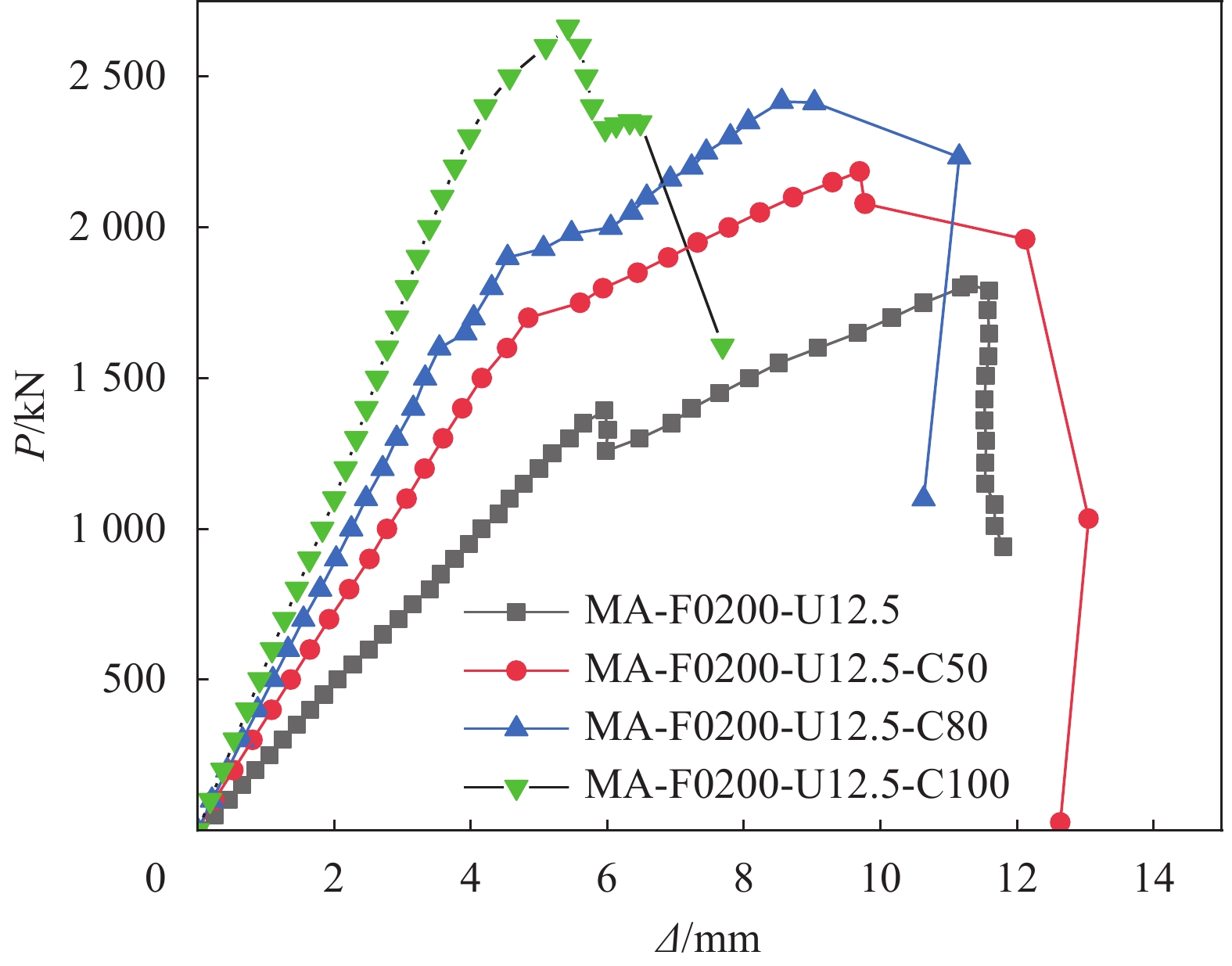

图10为不同核心混凝土强度的CFFUT柱轴向荷载-位移曲线,图11为Pu随核心混凝土强度的变化规律。可以看出,当ncf、tu相同时,随着核心混凝土强度的增加,CFFUT柱的P-Δ关系曲线呈左上方移动趋势,即Pu和刚度同时增大,CFRP强化段曲线斜率基本保持平行。与MA-F0200-U12.5试件(C30)相比,MA-F0200-U12.5-C50、MA-F0200-U12.5-C80、MA-F0200-U12.5-C100极限承载力分别提高20.7%、33.5%、47%。其中,MA-F0200-U12.5-C100试件核心混凝土强度较高,呈现出一定脆性破坏特征,CFFUT柱设计应特别注意CFRP、UHPC和核心混凝土的合理匹配。

2.3 CFFUT柱延性性能

为研究CFFUT柱的延性性能,根据不同的P-Δ曲线定义位移延性系数μ 指标[32],如图12所示,μ = Δcu/Δ1,其中,Δcu为极限位移,CFFUT柱取CFRP断裂失效时对应轴向位移,普通混凝土和UHPC管混凝土对比柱取荷载下降至峰值荷载85%时对应轴向位移;Δ1为峰值荷载水平线与初始切线模量(Et)斜线相交点对应的轴向位移。经计算得到的μ 值见表1,可以看出,与MA-0-0相比,CFFUT柱的μ呈增大趋势,位于1.31~1.66,说明CFFUT柱的变形能力得到不同程度提升。μ随ncf、tu的增加而增大,随核心混凝土强度的增大而先增大后减小,主要是由于核心混凝土强度较高(C100)时脆性破坏所致。

3. CFFUT柱增强机制及与CFRP-钢管混凝土柱对比

3.1 CFFUT柱增强作用机制

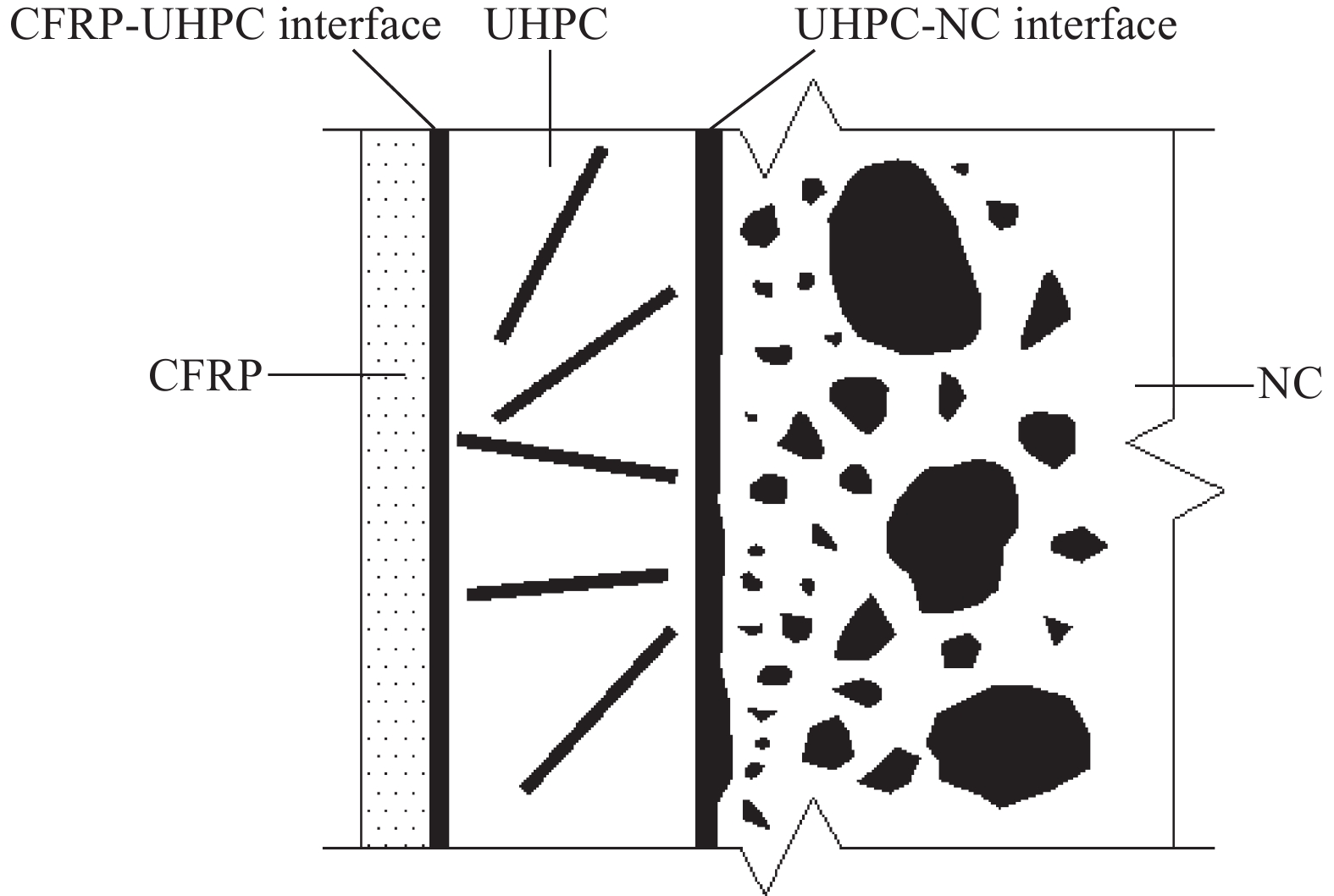

CFFUT柱充分发挥了CFRP、UHPC和混凝土3种材料的性能优势,UHPC与核心混凝土共同承压,且UHPC管一定程度限制和延缓核心混凝土膨胀变形和开裂,外部CFRP进一步环箍约束,使核心混凝土处于三向受压状态,从而大幅提升组合柱的力学性能。复合材料、水泥基材料之间的界面性能对组合柱宏观力学性能和破坏模式至关重要,图13为CFFUT柱的界面概念图。

目前已有大量研究[33-35]表明UHPC-普通混凝土(Normal concrete,NC)有良好的界面粘结效果,UHPC-NC界面粘结作用与新旧混凝土类似,主要包括化学胶结力、机械咬合力和摩擦力,其中化学胶结力与混凝土性质有关,机械咬合力取决于表面粗糙程度,摩擦力随受力阶段而变化。CFFUT柱的UHPC-NC界面粘结增强作用主要体现为:(1) UHPC和混凝土物理和化学相容性较好,UHPC存在大量未完全水化胶凝材料颗粒,二次浇筑NC时界面发生二次水化,水化产物交错生长形成致密界面过渡区;(2) UHPC与NC的收缩微差,可视为UHPC管对NC预先施加法向约束作用;(3) UHPC与NC泊松比接近,承载阶段不发生局部屈曲破坏。但逐层剥去CFFUT柱的CFRP、UHPC观察界面破坏模式,如图4(d)、图14所示,发现开裂和压溃位置仍难以避免的发生UHPC与NC界面局部剥离现象。

CFRP通过环氧树脂硬化后与UHPC管形成整体,并通过界面层传递应力。复合材料界面作用包括宏观和微观结合力,其中宏观结合力主要是表面粗糙度产生的机械咬合力,微观结合力包括化学键和次价键结合力,其中化学键结合力最强,对界面结合强度起主要作用[36]。试验观察CFFUT柱破坏时CFRP接头粘结完好未见滑移脱粘现象。

3.2 CFFUT柱与CFRP-钢管混凝土柱承载力比较

为进一步探究本文CFFUT柱的极限承载力水平,与文献[28]中CFRP-钢管混凝土(CFFST)柱试验数据进行比较研究(核心混凝土立方体抗压强度fcu = 54.0 MPa,CFRP弹性模量228 GPa,极限伸长率1.98%),如图15所示,fequ为组合柱等效抗压强度,fequ = Pu/A,A为全部横截面面积,ts为钢管厚度,tcf为CFRP厚度。可见同等CFRP配置情况下,本文CFFUT柱的力学性能一定程度上与CFFST柱相当。CFFUT柱力学性能具有一定的优势,但规模化推广应用仍需进一步克服UHPC材料成本高、UHPC预制管制作工艺和现场拼接安装等技术难题。

4. CFFUT柱极限承载力

4.1 CFFUT柱理论计算模型

图16为CFFUT轴压柱各组成部件的受力情况,σf为CFRP对核心混凝土提供的侧压力;σur为UHPC管对核心混凝土提供的侧压力;σuh为UHPC管的环向拉应力;σcf为CFRP的环向拉应力;σc为核心混凝土轴向压应力;σuc为UHPC管轴向压应力;N为CFFUT柱总的轴压力。

![]() 图 16 CFFUT柱轴心受力示意图Figure 16. Schematic diagram of CFFUT columns under uniaxial compressionσf—Radial compressive stress of CFRP; σur—Radial compressive stress of UHPC; σuh—Circumferential tensile stress of UHPC; σcf—Circumferential tensile stress of CFRP; σc—Axial compressive stress of concrete; σuc—Axial compressive stress of UHPC

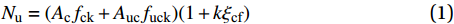

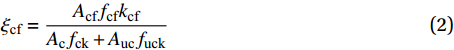

图 16 CFFUT柱轴心受力示意图Figure 16. Schematic diagram of CFFUT columns under uniaxial compressionσf—Radial compressive stress of CFRP; σur—Radial compressive stress of UHPC; σuh—Circumferential tensile stress of UHPC; σcf—Circumferential tensile stress of CFRP; σc—Axial compressive stress of concrete; σuc—Axial compressive stress of UHPC为简化计算做以下计算假定:(1) 仅考虑CFRP环向受拉,且满足虎克定律;(2) 不考虑CFRP、UHPC和核心混凝土之间粘结滑移,即满足变形协调;(3) 轴压承载极限状态时,忽略UHPC管的σur和σuh;(4) 约束混凝土、UHPC的轴向压应力与侧向压应力呈线性关系。根据极限平衡法原理,CFFUT短柱的轴压极限承载力计算式可表示为

Nu=(Acfck+Aucfuck)(1+kξcf) (1) ξcf=AcffcfkcfAcfck+Aucfuck (2) 式中:Nu为CFFUT短柱的轴压极限承载力;Ac、fck分别为核心混凝土截面面积和轴心抗压强度标准值;Auc、fuck分别为UHPC截面面积和轴心抗压强度标准值;Acf、fcf分别为CFRP的横截面积和极限抗拉强度;ξcf为约束效应系数;kcf为考虑CFRP包覆方式的约束折减系数,全包覆时取kcf=1.0;k为经验系数,本文CFFUT柱的平均值、标准差和变异系数分别为1.08、0.437和0.406,偏安全考虑建议取k=1.05。对于其他种类FRP、配筋CFFUT短柱及CFFUT中长柱等情况,k值的适用性需进一步研究验证。

4.2 CFFUT柱有限元模型

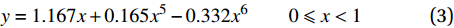

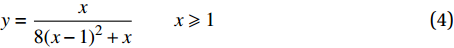

采用ABAQUS软件对CFFUT柱进行有限元分析,模型参数取ncf=1、2,tu=12.5 mm、20 mm、30 mm,C30核心混凝土。核心混凝土和UHPC采用C3D8R三维实体单元,网格单元尺寸一般为10 mm,UHPC沿管壁厚度适当加密。核心混凝土单轴应力-应变关系及参数采用《混凝土结构设计规范》(GB/T 50010—2010)[37]附录C;UHPC单轴本构关系通过实测拟合得到,受压应力-应变关系如下:

y=1.167x+0.165x5−0.332x60⩽ (3) y = \frac{x}{{8{{(x - 1)}^2} + x}} \qquad x \geqslant 1 (4) x = \frac{{{\varepsilon _{{\text{uc}}}}}}{{{\varepsilon _{{\text{uc,0}}}}}} (5) y = \frac{{{\sigma _{{\text{uc}}}}}}{{{\sigma _{{\text{uc,0}}}}}} (6) 受拉应力-应变关系如下:

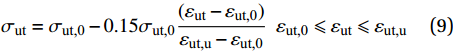

{\sigma _{{\text{ut}}}} = {E_{{\text{ut}}}}{\varepsilon _{{\text{ut}}}} \qquad 0 \leqslant {\varepsilon _{{\text{ut}}}} \leqslant {\varepsilon _{{\text{ut,e}}}} (7) {\sigma _{{\text{ut}}}} = {\sigma _{{\text{ut,e}}}} + ({\sigma _{{\text{ut,0}}}} - {\sigma _{{\text{ut,e}}}}) \frac{{({\varepsilon _{{\text{ut}}}} - {\varepsilon _{{\text{ut,e}}}})}}{{{\varepsilon _{{\text{ut,0}}}} - {\varepsilon _{{\text{ut,e}}}}}} \;\; {\varepsilon _{{\text{ut,e}}}} \leqslant {\varepsilon _{{\text{ut}}}} \leqslant {\varepsilon _{{\text{ut,0}}}} (8) {\sigma _{{\text{ut}}}} = {\sigma _{{\text{ut,0}}}} - 0.15{\sigma _{{\text{ut,0}}}} \frac{{({\varepsilon _{{\text{ut}}}} - {\varepsilon _{{\text{ut,0}}}})}}{{{\varepsilon _{{\text{ut,u}}}} - {\varepsilon _{{\text{ut,0}}}}}} \;\; {\varepsilon _{{\text{ut,0}}}} \leqslant {\varepsilon _{{\text{ut}}}} \leqslant {\varepsilon _{{\text{ut,u}}}} (9) CFRP采用S4R壳单元,网格单元尺寸为5 mm,CFRP的应力-应变关系采用理想线弹性模型,见下式:

{\sigma _{{\text{cf}}}} = {E_{{\text{cf}}}}{\varepsilon _{{\text{cf}}}} (10) 式中:σuc,0为UHPC峰值轴压应力,实测值为117.0 MPa;εuc为UHPC轴压应变;εuc,0为UHPC峰值轴压应变,实测值为0.1882%;σut为UHPC轴拉应力;σut,e为UHPC弹性极限抗拉强度,实测值为5.50 MPa;σut,0为UHPC峰值轴拉应力,实测值为7.77 MPa;σut,u为UHPC极限抗拉强度,取σut,u = 0.85σut,0;εut为UHPC轴拉应变;εut,e为UHPC弹性极限拉应变,实测值为0.014%;εut,0为UHPC峰值轴拉应变,实测值为0.1223%;εut,u为UHPC极限拉应变;Eut为抗拉弹性模量,Eut = σut,e/εut,e;σcf为CFRP环向拉应力;εcf为CFRP的环向应变;Ecf为CFRP沿纤维方向的弹性模量。

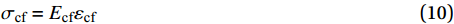

图17为各部件网格划分和CFFUT柱组装模型,混凝土、UHPC、CFRP间约束设置为绑定,采用位移加载模式。

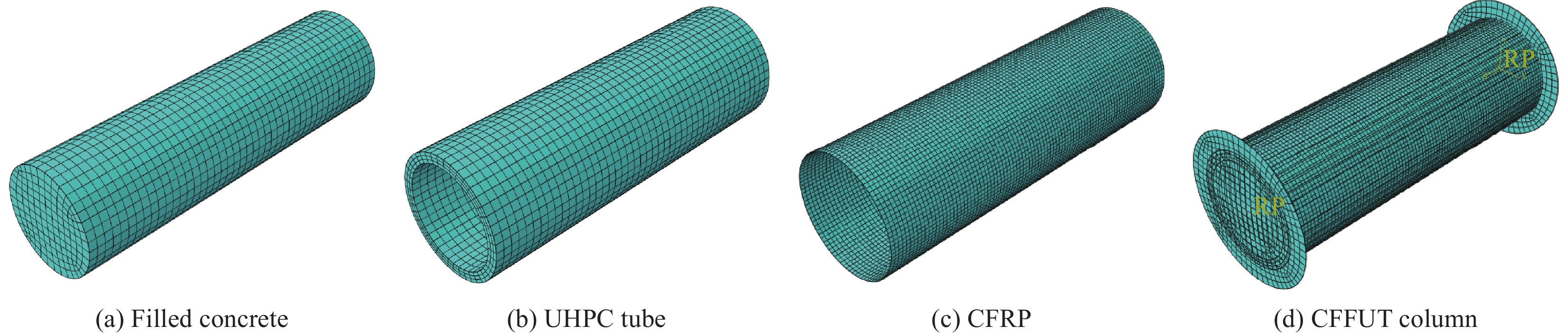

图18为典型CFFUT柱的试验和有限元破坏模式比较,图19、图20为CFRP、UHPC、混凝土的损伤和等效塑性应变云图。可以看出,有限元模型呈一定程度腰鼓变形,靠近中部位置CFRP局部断裂,且靠近中部高度应变和损伤因子较大,有限元模型破坏规律与试验现象吻合较好。

4.3 CFFUT柱极限承载力结果对比

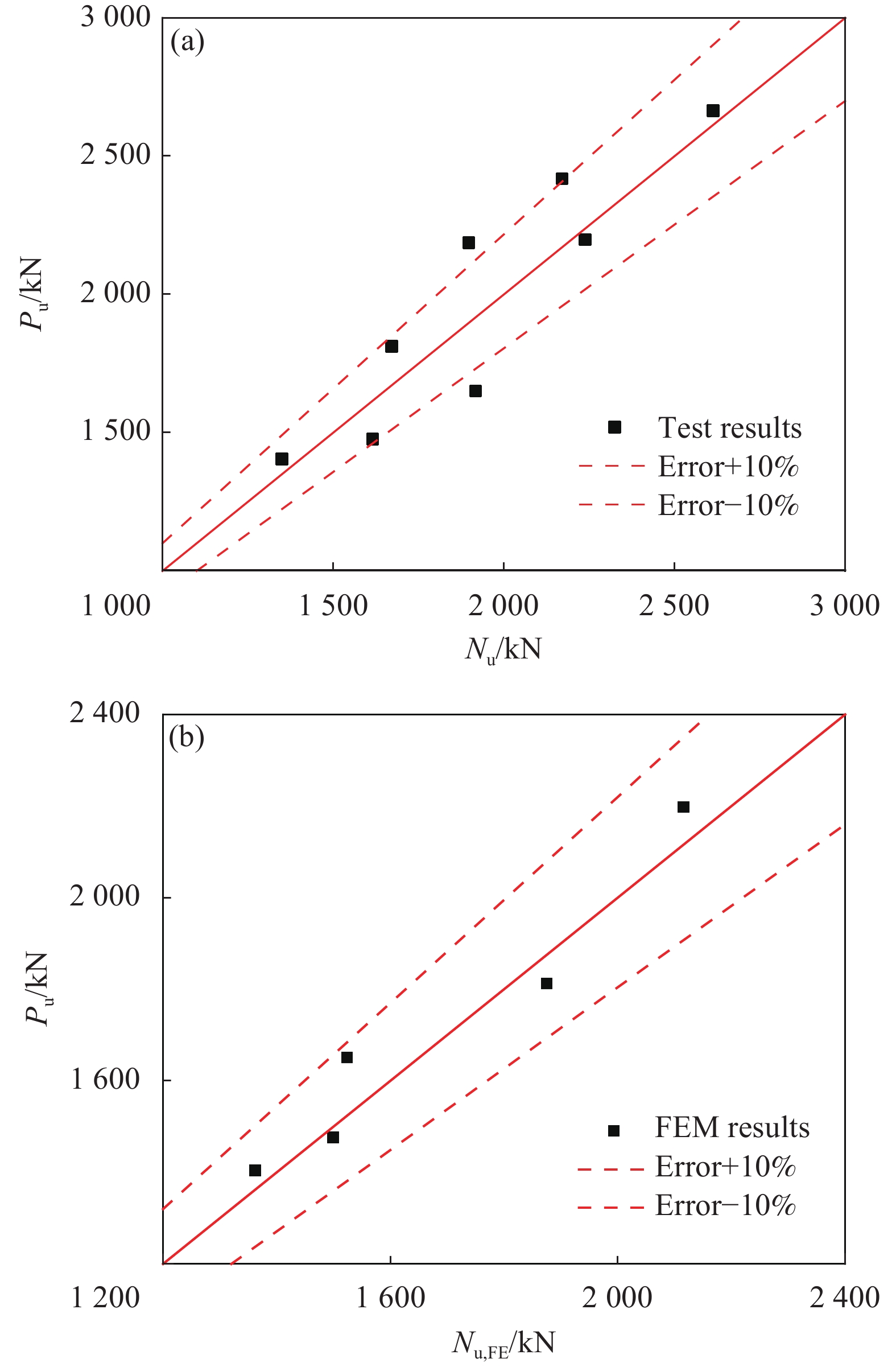

由式(1)计算的CFFUT柱极限承载力理论值Nu、模拟值Nu,FE与试验值Pu对比结果见表3。可以看出,计算值、模拟值均与试验值吻合较好,相对比值Nu/Pu、Nu,FE/Pu的平均值为0.988、0.980,标准差为0.0936、0.0444,变异系数为0.0947、0.0452,相对误差基本均在 ±10%以内,如图21所示。

表 3 CFFUT柱计算值Nu、模拟值 Nu,FE与试验值Pu的比较Table 3. Comparison of calculated values Nu, simulated values Nu,FE and test results Pu of CFFUT columnsNo. Nu/kN Nu,FE/kN Nu/Pu Nu,FE/Pu MA-F0100-U12.5 1350.0 1362.4 0.96 0.97 MA- F0100-U20 1615.7 1499.4 1.09 1.02 MA- F0100-U30 1917.1 1523.9 1.16 0.92 MA-F0200-U12.5 1671.5 1875.1 0.92 1.03 MA- F0200-U30 2238.6 2116.1 1.02 0.96 MA-F0200-U12.5-C50 1897.2 — 0.87 — MA-F0200-U12.5-C80 2170.7 — 0.90 — MA-F0200-U12.5-C100 2613.5 — 0.98 — 5. 结 论

通过8根新型碳纤维增强聚合物(CFRP)-超高性能混凝土(UHPC)组合管混凝土(Concrete-filled CFRP-UHPC tube,CFFUT)柱和2根对比柱(普通混凝土柱、UHPC管混凝土柱各1根)的轴压试验研究,得到以下主要结论:

(1) CFFUT短柱破坏具有两个典型标志—UHPC管开裂和CFRP拉断,实现了“二道防线”破坏模式,破坏失效前具有一定预兆,且混凝土压溃前经历了较长塑性变形阶段,破坏后整体性较好,属延性破坏模式;

(2) CFFUT柱的极限承载力随CFRP层数、UHPC管壁厚度和核心混凝土强度增加而增大,与同等截面普通混凝土柱相比,UHPC管混凝土柱极限承载力提高34.9%,CFFUT柱极限承载力提高93.9%~203.5%;延性系数随CFRP层数和UHPC管壁厚度的增加而提高,但随着核心混凝土强度增加呈先提高后降低;

(3) CFFUT柱的界面粘结和变形协调性能良好,CFFUT柱极限承载力一定程度上与CFRP-钢管混凝土柱相当;

(4) CFFUT柱的轴向荷载-位移曲线可划分为4个阶段:初始上升段、UHPC开裂陡降段、CFRP约束强化段和CFRP断裂下降段。CFRP层数、UHPC管壁厚度和核心混凝土强度对轴向荷载-位移曲线有一定的影响,CFRP和UHPC共同作用下,CFFUT柱的承载力、刚度和延性同时得到提高;

(5) 基于极限平衡理论建立了CFFUT短柱的轴压极限承载力计算模型,计算值与试验值基本吻合,两者相对误差基本在±10%以内;

(6) 采用ABAQUS软件对CFFUT短柱进行了非线性有限元计算分析,有限元模型和试件的破坏形态接近,极限承载力模拟值与试验值基本吻合,两者相对误差在±10%以内。

-

图 16 CFFUT柱轴心受力示意图

Figure 16. Schematic diagram of CFFUT columns under uniaxial compression

σf—Radial compressive stress of CFRP; σur—Radial compressive stress of UHPC; σuh—Circumferential tensile stress of UHPC; σcf—Circumferential tensile stress of CFRP; σc—Axial compressive stress of concrete; σuc—Axial compressive stress of UHPC

表 1 试件编号及参数

Table 1 Number and parameters of specimens

No. tu/mm ncf fcu/MPa fc/MPa fts/MPa E/GPa Pu/kN α Δu/mm β μ MA-0-0 — — 32.8 28.9 2.62 26.5 724.0 1.000 2.429 1.000 1.14 MA-0-U12.5 12.5 0 32.8 28.9 2.62 26.5 977.0 1.349 4.213 1.734 1.31 MA-F0100-U12.5 12.5 1 32.8 28.9 2.62 26.5 1403.8 1.939 8.164 3.361 1.45 MA-F0100-U20 20.0 1 32.8 28.9 2.62 26.5 1476.0 2.039 7.577 3.119 1.52 MA-F0100-U30 30.0 1 32.8 28.9 2.62 26.5 1650.2 2.279 5.823 2.397 1.59 MA-F0200-U12.5 12.5 2 32.8 28.9 2.62 26.5 1811.8 2.502 11.295 4.650 1.55 MA-F0200-U30 30.0 2 32.8 28.9 2.62 26.5 2197.6 3.035 8.929 3.676 1.64 MA-F0200-U12.5-C50 12.5 2 53.5 47.3 3.69 32.0 2186.0 3.019 9.697 3.992 1.59 MA-F0200-U12.5-C80 12.5 2 90.4 69.6 4.13 36.8 2418.0 3.340 9.214 3.793 1.66 MA-F0200-U12.5-C100 12.5 2 118.0 105.7 6.65 44.1 2664.2 3.680 5.424 2.233 1.31 Notes: tu—Thickness of UHPC tube; ncf—Number of CFRP layers; fcu—Cubic compressive strength of filled concrete; fc—Axial compressive strength of filled concrete; fts—Splitting tensile strength of filled concrete; E—Elastic modulus of filled concrete; Pu—Ultimate load; α—Ratio of ultimate load between CFFUT column and contrast column (MA-0-0) ; Δu—Ultimate displacement; β—Ratio of ultimate displacement between CFFUT column and contrast column (MA-0-0); μ—Ductility factor. The letter MA denotes the monotonic axial load condition, the letter F denotes the number of CFRP layers, the letter U denotes the thickness of UHPC tube, the letter C denotes the nominal filled concrete strength, omitted when C30 filled concrete is used. For example, the MA-F0200-U12.5-C50 indicates that the load condition of specimen is monotonic axial compression, the number of CFRP layers is 2, the thickness of UHPC tube is 12.5 mm, and the nominal filled concrete strength is 50 MPa. 表 2 混凝土和UHPC配合比

Table 2 Mixture proportion of concrete and UHPC

kg·m−3 Type Cement Silica fume Fly ash CAGG FAGG Water SP Steel fiber C30 280 — 70 1043 826 175 5.1 — C50 363 — 80 1055 738 155 9.0 — C80 455 40 — 1080 665 150 9.9 — C100 787 126 136 — 1050 189 26.0 — UHPC 787 126 136 — 1050 189 26.0 195 Notes: CAGG—Coarse aggregate; FAGG—Fine aggregate; SP—Superplasticizer. 表 3 CFFUT柱计算值Nu、模拟值 Nu,FE与试验值Pu的比较

Table 3 Comparison of calculated values Nu, simulated values Nu,FE and test results Pu of CFFUT columns

No. Nu/kN Nu,FE/kN Nu/Pu Nu,FE/Pu MA-F0100-U12.5 1350.0 1362.4 0.96 0.97 MA- F0100-U20 1615.7 1499.4 1.09 1.02 MA- F0100-U30 1917.1 1523.9 1.16 0.92 MA-F0200-U12.5 1671.5 1875.1 0.92 1.03 MA- F0200-U30 2238.6 2116.1 1.02 0.96 MA-F0200-U12.5-C50 1897.2 — 0.87 — MA-F0200-U12.5-C80 2170.7 — 0.90 — MA-F0200-U12.5-C100 2613.5 — 0.98 — -

[1] XIAO Y, HE W H, MAO X Y, et al. Confinement design of CFT columns for improved seismic performance[C]//Proceedings of the International Workshop on Steel and Concrete Composite Construction (IWSCCC-2003). Taipei, 2003: 217-226.

[2] 王庆利, 赵颖华, 顾威. 圆截面CFRP-钢复合管混凝土结构的研究[J]. 沈阳建筑工程学院学报(自然科学版), 2003, 19(4):272-274. WANG Qingli, ZHAO Yinghua, GU Wei. Presumption on the concrete filled circular CFRP-steel composite tube structures[J]. Journal of Shenyang Jianzhu University (Natural Science),2003,19(4):272-274(in Chinese).

[3] XIAO Y, HE W H, CHOI K K. Confined concrete-filled tubular columns[J]. Journal of Structural Engineering,2005,131(3):488-497. DOI: 10.1061/(ASCE)0733-9445(2005)131:3(488)

[4] PARK J W, HONG Y K, HONG G S, et al. Design formulas of concrete filled circular steel tubes reinforced by carbon fiber reinforced plastic sheets[J]. Procedia Engineering,2011,14(1):2916-2922.

[5] SUNDARRAJA M C, PRABHU G G. Experimental study on CFST members strengthened by CFRP composites under compression[J]. Journal of Constructional Steel Research,2012,72:75-83. DOI: 10.1016/j.jcsr.2011.10.014

[6] TAO Z, HAN L H, ZHUANG J P. Axial loading behavior of CFRP strengthened concrete-filled steel tubular stub columns[J]. Advances in Structural Engineering,2007,10(1):37-46. DOI: 10.1260/136943307780150814

[7] OSTROWSKI K, DUDEK M, SADOWSKI L. Compressive behaviour of concrete-filled carbon fiber-reinforced polymer steel composite tube columns made of high performance concrete[J]. Composite Structures,2020,234:111668. DOI: 10.1016/j.compstruct.2019.111668

[8] 郭莹, 许天祥, 刘界鹏. 圆CFRP-钢复合管约束高强混凝土短柱轴压试验研究[J]. 建筑结构学报, 2019, 40(5):124-131. DOI: 10.14006/j.jzjgxb.2019.05.012 GUO Ying, XU Tianxiang, LIU Jiepeng. Experimental study on axial behavior of circular CFRP-steel composite tubed high-strength concrete stub columns[J]. Journal of Building Structures,2019,40(5):124-131(in Chinese). DOI: 10.14006/j.jzjgxb.2019.05.012

[9] 焦楚杰, 李松, 崔力仕, 等. CFRP约束钢管-活性粉末混凝土短柱轴压性能[J]. 复合材料学报, 2021, 38(2):439-448. DOI: 10.13801/j.cnki.fhclxb.20200608.003 JIAO Chujie, LI Song, CUI Lishi, et al. Axial compression behaviour of CFRP confined reactive power concrete filled steel tube stub columns[J]. Acta Materiae Compositae Sinica,2021,38(2):439-448(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20200608.003

[10] TOUTANJI H. Design equations for concrete columns confined with hybrid composite materials[J]. Advanced Composite Materials,2001,10(2-3):127-138. DOI: 10.1163/156855101753396609

[11] 于峰. PVC-FRP管混凝土柱力学性能的试验研究与理论分析[D]. 西安: 西安建筑科技大学, 2007. YU Feng. Experimental study and theoretical analysis on mechanical behavior of PVC-FRP confined concrete column[D]. Xi'an: Xi'an University of Architecture and Technology, 2007(in Chinese).

[12] JIANG S F, MA S L, WU Z Q. Experimental study and theoretical analysis on slender concrete-filled CFRP-PVC tubular columns[J]. Construction and Building Materials,2014,53:475-487. DOI: 10.1016/j.conbuildmat.2013.11.089

[13] FAKHARIFAR M, CHEN G D. Compressive behavior of FRP-confined concrete-filled PVC tubular columns[J]. Composite Structures,2016,141:91-109. DOI: 10.1016/j.compstruct.2016.01.004

[14] GAO C, HUANG L, YAN L B, et al. Strength and ductility improvement of recycled aggregate concrete by polyester FRP-PVC tube confinement[J]. Composites Part B: Engineering,2019,162:178-197. DOI: 10.1016/j.compositesb.2018.10.102

[15] ZHANG H Q, HADI M N S. Geogrid-confined pervious geopolymer concrete piles with FRP-PVC confined concrete core: Concept and behaviour[J]. Construction and Building Materials,2019,211:12-25. DOI: 10.1016/j.conbuildmat.2019.03.231

[16] 李晓飞, 黄紫青, 蒋治鑫, 等. 轴压下CFRP-钢管约束混凝土柱试验研究[J]. 广西大学学报(自然科学版), 2019, 44(1):68-76. LI Xiaofei, HUANG Ziqing, JIANG Zhixin, et al. Experimental study on axial compression of CFRP-steel tube confined concrete short column[J]. Journal of Guangxi University (Natural Science Edition),2019,44(1):68-76(in Chinese).

[17] 赵筠, 师海霞, 路新瀛. 超高性能混凝土基本性能与试验方法[M]. 北京: 中国建材工业出版社, 2019. ZHAO Jun, SHI Haixia, LU Xinying. Fundamental characteristics and test methods of ultra-high performance concrete[M]. Beijing: China Building Materials Press, 2019(in Chinese).

[18] SUN C S, BABARINDE O, FARZANA N, et al. Use of UHPC jackets in coastal bridge piles[C]//The 2nd International Interactive Symposium on Ultra-high Performance Concrete. Albany, 2019.

[19] XIE J, FU Q, YAN J B. Compressive behaviour of stub concrete column strengthened with ultra-high performance concrete jacket[J]. Construction and Building Materials,2019,204:643-658. DOI: 10.1016/j.conbuildmat.2019.01.220

[20] HADI M N S, ALGBURI A H M, SHEIKH M N, et al. Axial and flexural behaviour of circular reinforced concrete columns strengthened with reactive powder concrete jacket and fibre reinforced polymer wrapping[J]. Construction and Building Materials,2018,172:717-727. DOI: 10.1016/j.conbuildmat.2018.03.196

[21] 吴香国. 基于耐久性的超高性能纤维改性混凝土叠合墩柱设计概念[J]. 华北水利水电学院学报, 2012, 33(6):73-77. WU Xiangguo. Design conception of ultra-high-performance fiber reinforced concrete hybrid pier with durability consideration[J]. Journal of North China Institute of Water Conservancy and Hydroelectric Power,2012,33(6):73-77(in Chinese).

[22] 林上顺, 黄卿维, 陈宝春, 等. 跨海大桥U-RC组合桥墩设计[J]. 交通运输工程学报, 2017, 17(4):55-65. DOI: 10.3969/j.issn.1671-1637.2017.04.006 LIN Shangshun, HUANG Qinwei, CHEN Baochun, et al. Design of U-RC composite pier of sea-crossing bridge[J]. Journal of Traffic and Transportation Engineering,2017,17(4):55-65(in Chinese). DOI: 10.3969/j.issn.1671-1637.2017.04.006

[23] 杨医博, 杨凯越, 吴志浩, 等. 配筋超高性能混凝土用作免拆模板对短柱力学性能影响的实验研究[J]. 材料导报, 2017, 31(12):120-124. DOI: 10.11896/j.issn.1005-023X.2017.023.017 YANG Yibo, YANG Kaiyue, WU Zhihao, et al. An experimental study on the influence of reinforced ultra-high performance concrete permanent template to short column's mechanical property[J]. Materials Reports,2017,31(12):120-124(in Chinese). DOI: 10.11896/j.issn.1005-023X.2017.023.017

[24] 单波, 刘志, 肖岩, 等. RPC预制管混凝土组合柱组合效应试验研究[J]. 湖南大学学报(自然科学版), 2017, 44(3):88-96. DOI: 10.16339/j.cnki.hdxbzkb.2017.03.011 SHAN Bo, LIU Zhi, XIAO Yan, et al. Experimental research on composite action of concrete-filled RPC tube under axial load[J]. Journal of Hunan University (Natural Sciences),2017,44(3):88-96(in Chinese). DOI: 10.16339/j.cnki.hdxbzkb.2017.03.011

[25] TIAN H W, ZHOU Z, ZHANG Y, et al. Axial behavior of reinforced concrete column with ultra-high performance concrete stay-in-place formwork[J]. Engineering Structures,2020,210:110403. DOI: 10.1016/j.engstruct.2020.110403

[26] WILLE K, EI-TAWIL S, NAAMAN A E. Properties of strain hardening ultra high performance fiber reinforced concrete (UHP-FRC) under direct tensile loading[J]. Cement and Concrete Composites,2014,48:53-66. DOI: 10.1016/j.cemconcomp.2013.12.015

[27] 王俊颜, 郭君渊, 肖汝诚, 等. 高应变强化超高性能混凝土的裂缝控制机理和研究[J]. 土木工程学报, 2017, 50(11):10-17. WANG Junyan, GUO Junyuan, XIAO Rucheng, et al. Study on crack control mechanism of strain-hardening ultra-high performance concrete[J]. China Civil Engineering Journal,2017,50(11):10-17(in Chinese).

[28] 王庆利. CFRP-钢管混凝土[M]. 北京: 科学出版社, 2017. WANG Qingli. Concrete filled CFRP-Steel tube[M]. Beijing: Science Press, 2017(in Chinese).

[29] 中华人民共和国住房和城乡建设部. 混凝土物理力学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国建筑工业出版社, 2019. Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test methods of concrete physical and mechanical properties: GB/T 50081—2019[S]. Beijing: China Architecture & Building Press, 2019(in Chinese).

[30] 中国建筑材料联合会. 超高性能混凝土基本性能与试验方法: T/CBMF 37—2018/T/CCPA 7—2018[S]. 北京: 中国建材工业出版社, 2018. China Building Materials Federation. Fundamental characteristics and test methods of ultra-high performance concrete: T/CBMF 37—2018/T/CCPA 7—2018[S]. Beijing: China Building Materials Press, 2018(in Chinese).

[31] 中国工程建设标准化协会. 碳纤维片材加固混凝土结构技术规程: CECS 146: 2003[S]. 北京: 中国计划出版社, 2003. China Engineering Construction Standardization Association. Technical specification for strengthening concrete structures with carbon fiber reinforced polymer laminate: CECS 146: 2003[S]. Beijing: China Planning Press, 2003(in Chinese).

[32] CUI C, SHEIKH S A. Experimental study of normal and high strength concrete confined with fiber reinforced polymers[J]. Journal of Composites for Construction,2010,14(5):553-561. DOI: 10.1061/(ASCE)CC.1943-5614.0000116

[33] AALETI S, SRITHARAN S. Quantifying bonding characteristics between UHPC and normal-strength concrete for bridge deck application[J]. Journal of Bridge Engineering,2019,24(6):04019041. DOI: 10.1061/(ASCE)BE.1943-5592.0001404

[34] ZHANG Y, ZHU P, LIAO Z Q, et al. Interfacial bond properties between normal strength concrete substrate and ultra-high performance concrete as a repair material[J]. Construction and Building Materials,2020,235:117431. DOI: 10.1016/j.conbuildmat.2019.117431

[35] FENG S, XIAO H G, LIU R, et al. The bond properties between ultra-high-performance concrete and normal strength concrete substrate: Bond macro-performance and overlay transition zone microstructure[J]. Cement and Concrete Composites,2022,128:104436. DOI: 10.1016/j.cemconcomp.2022.104436

[36] 朱和国, 张爱文. 复合材料原理[M]. 北京: 国防工业出版社, 2013. ZHU Heguo, ZHANG Aiwen. The fundamental principles of composites[M]. Beijing: National Defense Industry Press, 2013(in Chinese).

[37] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB/T 50010—2010[S]. 北京: 中国建筑工业出版社, 2010. Ministry of Housing and Urban-Rural Development of the People's Republic of China. Code for design of concrete structures: GB/T 50010—2010[S]. Beijing: China Architecture & Building Press, 2010(in Chinese).

-

期刊类型引用(0)

其他类型引用(4)

-

下载:

下载: