Fabrication and properties of multifunctional CeO2/cellulose nanofibers composite superhydrophobic coating

-

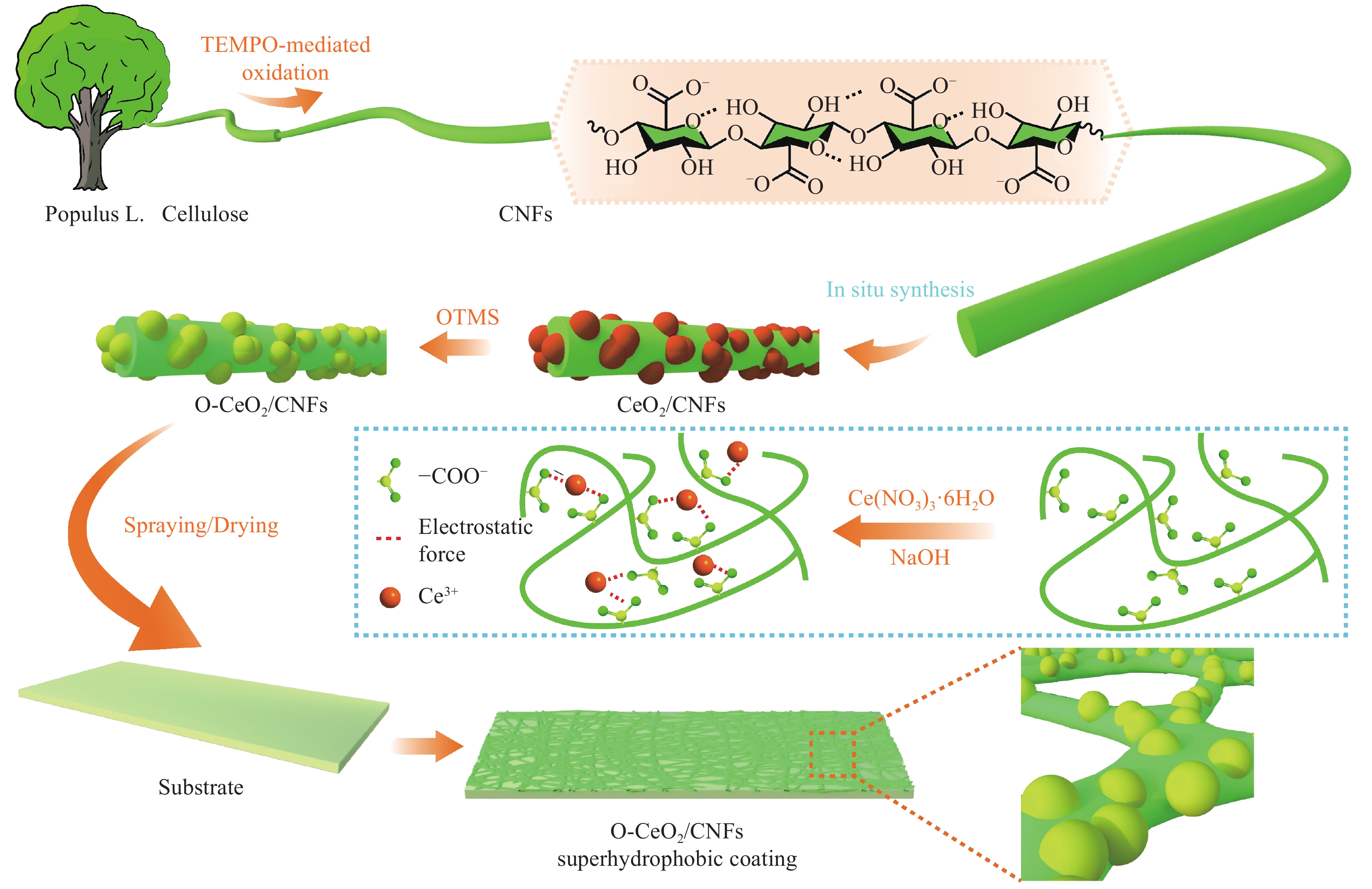

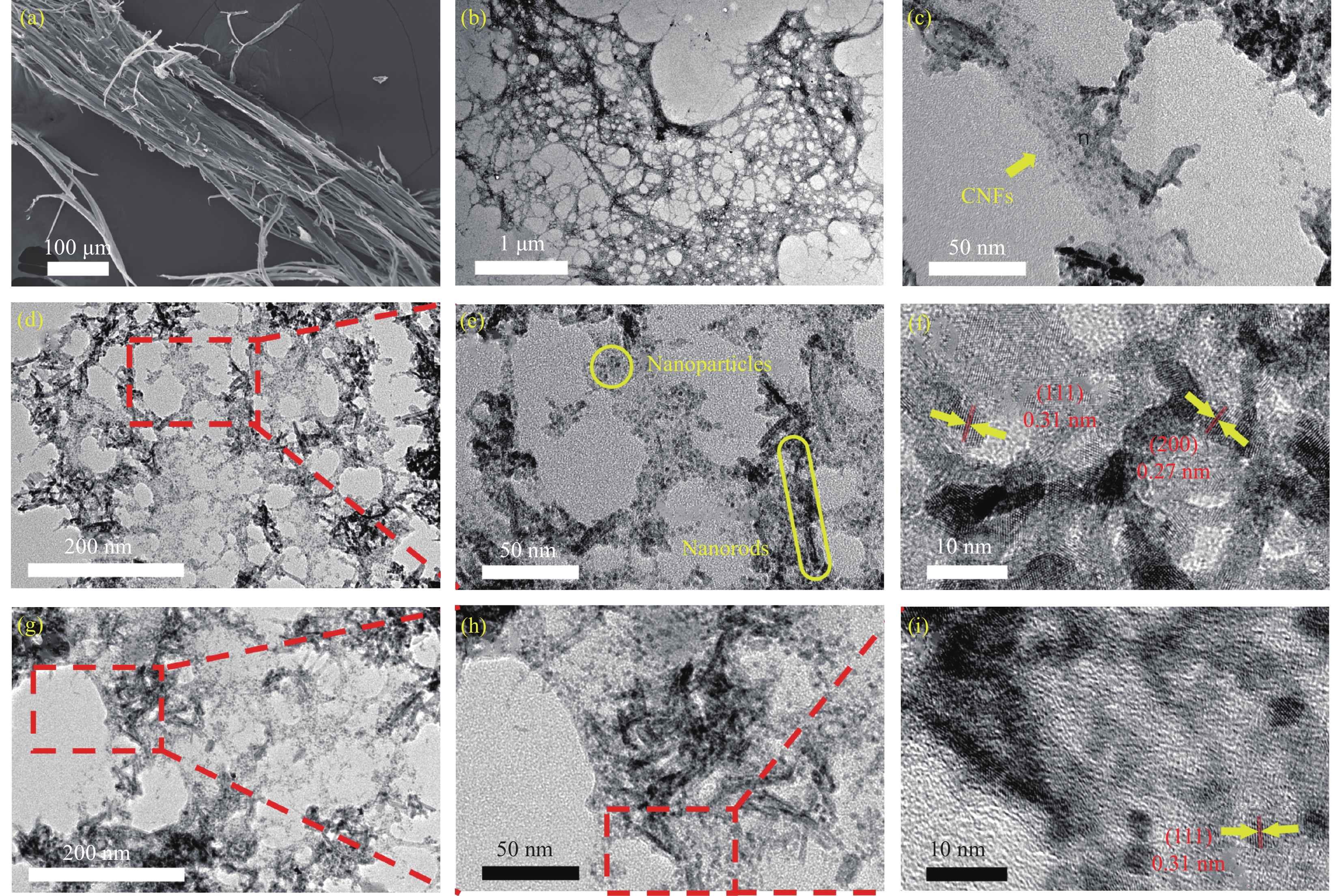

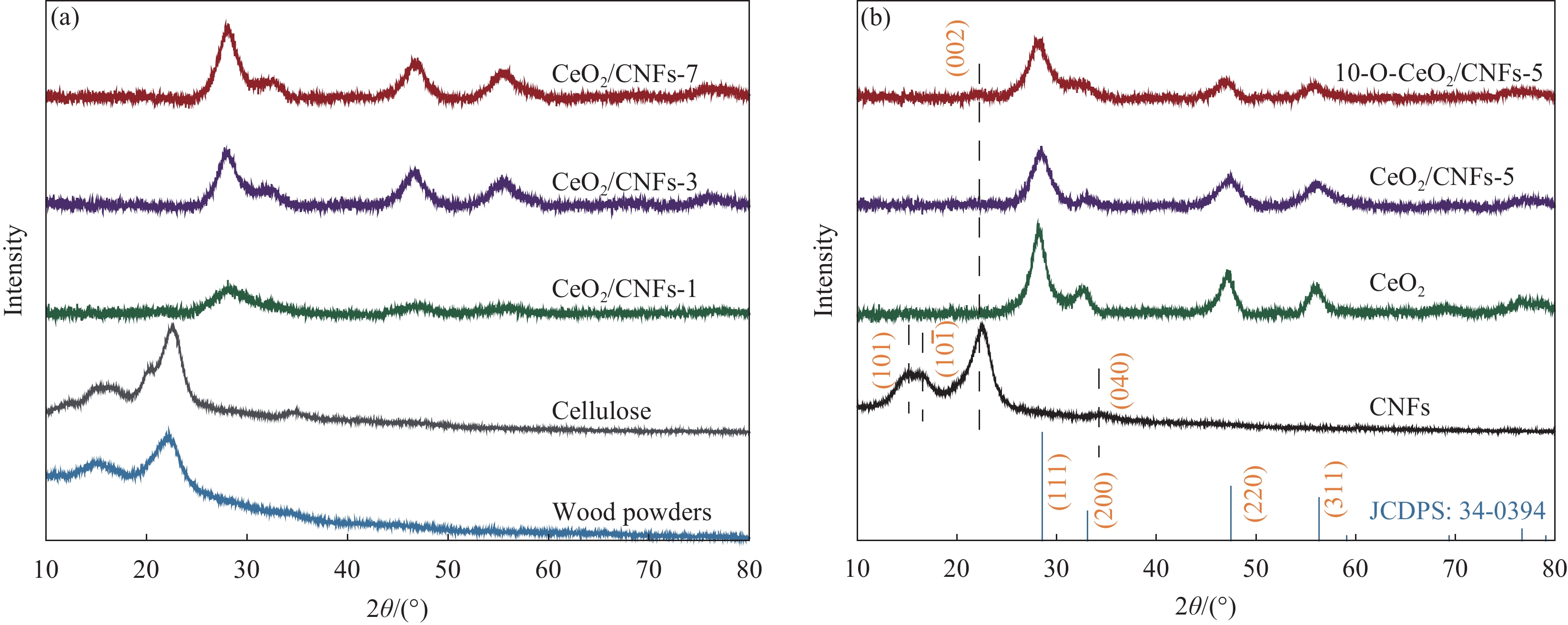

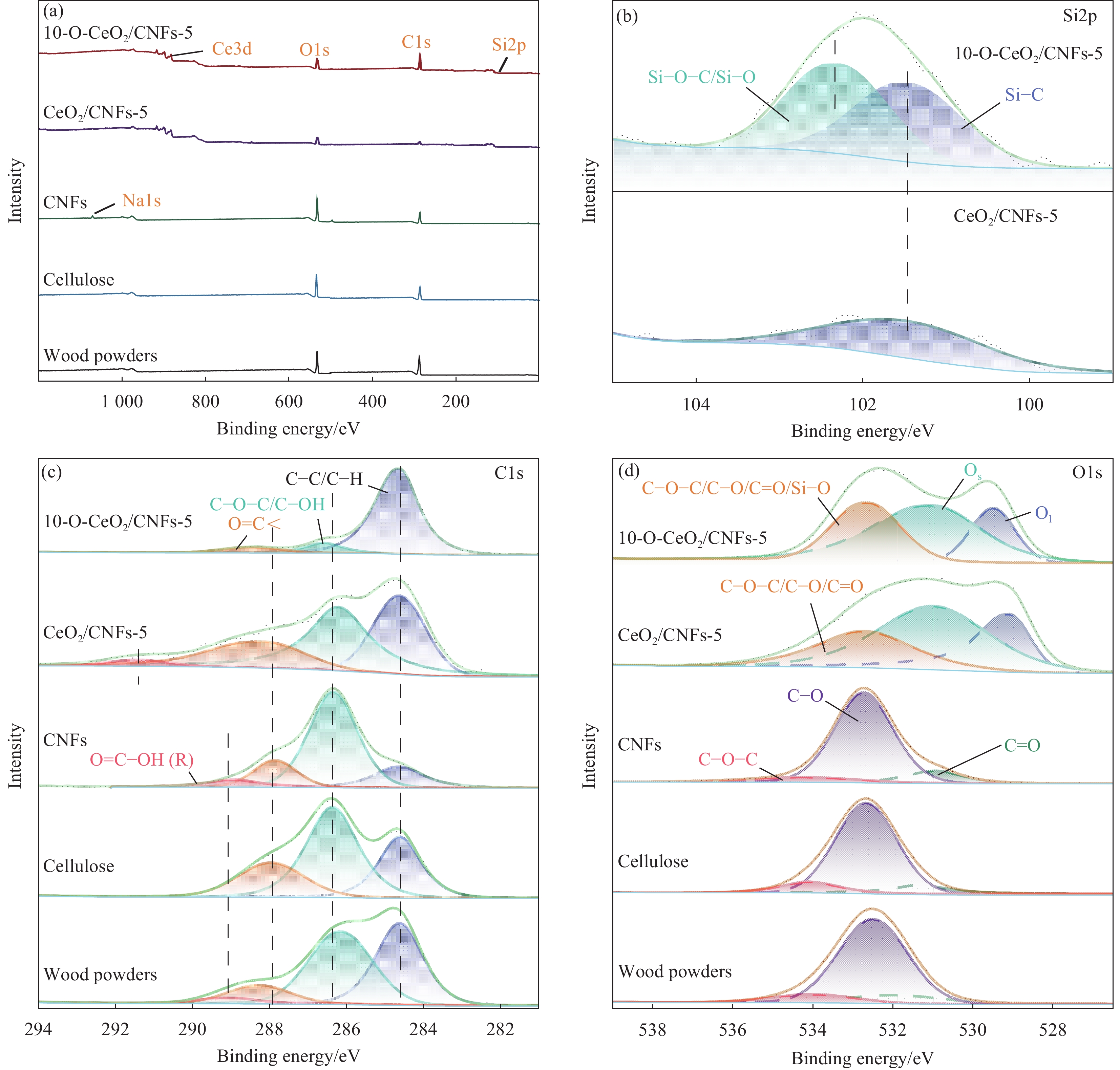

摘要: 自然界超疏水现象因独特的润湿性能被广泛关注,超疏水涂层的制备与应用尤为迫切。采用硝酸铈六水合物(Ce(NO3)3·6H2O)共沉淀法于纤维素纳米纤维(CNFs)表面合成二氧化铈(CeO2),通过十八烷基三甲基硅氧烷(OTMS)对其进行疏水改性,喷涂构筑得到超疏水涂层。探讨了CNFs、Ce(NO3)3·6H2O和OTMS不同质量比对超疏水涂层形貌和疏水性能的影响。结果表明:CNFs和Ce(NO3)3·6H2O质量比为1∶5和1∶7涂层具有实现超疏水特性的微/纳结构,其中CNFs、Ce(NO3)3·6H2O和OTMS质量比为1∶5∶10涂层接触角为(159.7±1.1)°,滚动角为(5.7±1.8)°,经过150°C高温处理3 h和UV照射36 h后接触角仍大于150°,同时具有良好的pH稳定性和一定的力学强度。涂层应用于玻璃、纸、木材和海绵等基体均可构筑超疏水表面并赋予其优异的自清洁性能,其中超疏水玻璃涂层对UV-A和UV-B紫外透过率分别为12.6%和0.1%,超疏水海绵吸油效率达94%左右。该超疏水涂层有望被用作保护材料并且拓展了稀土金属氧化物在纤维素基超疏水涂层领域的应用。Abstract: The superhydrophobic phenomenon in nature has attracted more attention due to its unique wettability. It is urgent that the preparation and application of superhydrophobic coating. Cerium dioxide (CeO2) was in situ synthesized on the surface of cellulose nanofibers (CNFs) by co-precipitation method using cerium nitrate hexahydrate (Ce(NO3)3·6H2O), following modified by octadecyltrimethoxysilane (OTMS) and the coating was constructed by spraying method. It investigated the effects of different mass ratios of CNFs, Ce(NO3)3·6H2O, and OTMS on coating morphology and hydrophobicity. The results show that the coatings consisting of CNFs, and Ce(NO3)3·6H2O with the mass ratios of 1∶5 and 1∶7 can construct the micro/nanostructure contributing to achieving superhydrophobic properties. When the mass ratios of CNFs, Ce(NO3)3·6H2O, and OTMS is 1∶5∶10, the coating static contact angle is (159.7±1.1)° and the sliding angle is (5.7±1.8)°. Its static contact angle can remain greater than 150° after the 150°C heating for 3 h and UV illumination for 36 h, meanwhile, possesses excellent pH stability and certain mecha-nical durability. When applied to glass, paper, wood, sponge, and other substrates, superhydrophobic surfaces can be constructed with excellent self-cleaning performance. The UV transmittance of superhydrophobic glass coating to UV-A and UV-B is 12.6% and 0.1%, respectively. The oil absorption efficiency of the superhydrophobic sponge is about 94%. This superhydrophobic coating is expected to use as a protective material and extends the application of rare earth metal oxidate in the cellulose-based superhydrophobic coating field.

-

Keywords:

- superhydrophobic /

- cellulose nanofibers /

- cerium dioxide /

- coating /

- in-situ synthesis /

- UV-shielding

-

近年来,碳化硅纤维(SiCf)由于电性能可调范围广、耐高温(≥1600℃)、高强高模等优点,由其增强的SiCf/SiC复合材料已成为新型空天高温隐身部件的理想候选材料[1-4]。目前,用于SiCf/SiC吸波复合材料的细观特征主要为二维层合结构。然而,该结构不仅吸波频带窄且可设计性差,还存在易分层和面外承载性能低问题,难以满足新型装备的结构-功能一体化苛刻服役要求[5-7]。相比之下,2.5D机织结构通过面内和面外不同电磁参数纤维同时排布,可实现高承载和优异吸波设计,为高可靠、多功能、高承载高温隐身结构部件提供了有效途径[8-10]。

近年来,学者们将吸波特性与三维纺织结构相结合,开展了诸多实验工作。Mu等[11]首先对SiCf进行脱碳处理,然后采用先驱体浸渍裂解(PIP)工艺制备了2.5D SiCf/SiC复合材料,测得其最大反射损耗可达−23.5 dB,有效吸波带宽可扩展至5.9 GHz。Han等[12]采用PIP工艺制备了三维四向和三维五向编织SiCf/SiC复合材料,并比较了两种结构在X波段的吸波性能。结果表明,由于三维五向结构中轴向纱的存在,致使三维五向编织 SiCf/SiC 复合材料呈现出更优异的微波吸收性能。吕丽华等[13]和Zhang等[14]以羰基铁粉 (CIP) 和炭黑 (CB) 为吸波剂,制备了蜂窝状三维机织结构型吸波复合材料。结果显示,该材料在高频 15.48 GHz 下的吸波损耗为−15.06 dB,且有效吸收带宽大于 3 GHz。Chen等[15]采用纬编工艺制备了菱形针织柔性吸波复合材料,测得其有效吸波带宽可达13 GHz。李丹丹[16]研究了三向正交、经向增强角联锁和层层角联锁结构碳纤维复合材料的吸波性能。结果表明,三向正交结构的吸波性能最好,层层角联锁结构的吸波性能相对最差,但3种结构吸波性能差异不明显。综上,目前所选用的三维纺织结构仍局限于传统的几种类型,导致吸波性能调节幅度有限。同时,受限于昂贵成本,有关2.5D 机织SiCf /SiC 复合材料的吸波性能研究尚处于探索阶段。

除此之外,电磁数值仿真也是研究三维纺织结构材料吸波性能的重要手段[17-19]。苏钦城等[20]和杨飙[21]利用基于有限积分法的CST软件,对二维平纹织物吸波性能进行了数值分析。孙娜等[22]将二维机织结构织物简化为网格模型,利用CST仿真分析了30~1500 MHz 频段内织物的屏蔽效能,并通过实验验证了仿真的准确性。Yin等[23]设计制备了一种具有双向角联锁结构的3D电磁吸波机织织物,并采用实验与仿真相结合的方法研究了吸波性能。结果表明,仿真与实验结果基本一致,该3D织物具有吸波频率宽、吸波性能好(−20 dB)的优点。Wang等[24]设计制备了双层蜂窝状三维编织吸波复合材料,将CST电磁模拟与实验分析相结合揭示了其电磁波吸收性能。结果表明,仿真和实验得到的反射峰位置分别为10.78 GHz和9.28 GHz,最大反射损耗分别为−24.35 dB和−23.5 dB,二者吻合良好。然而,围绕纺织复合材料的电磁仿真,学者们将细观结构模型进行了大幅简化,未准确体现纱线的交织特性,这也导致其预测数据的准确性和可靠性不足。

本文选用国产SiC纤维,采用PIP工艺制备了2.5D机织SiCf/SiC复合材料,利用弓形法开展反射损耗测试,获取了其吸收峰位置和有效吸波带宽。在此基础上,建立了基于X射线计算机断层扫描(Micro-CT)图像的全厚度细观模型,利用CST电磁仿真软件开展了数值分析,并与上述实验结果进行了对比验证。之后,进一步揭示了2.5D机织SiCf/SiC复合材料的吸波机制,分析了几何特性、电磁参数、电磁波电场极化方向和入射角度对材料吸波性能的影响规律,为具有优异吸波特性的三维纺织超材料结构设计和制备提供了方法和数据支撑。

1. 实验与仿真

1.1 2.5D机织SiCf/SiC复合材料的制备

图1给出了2.5D机织SiCf/SiC复合材料的制备工艺流程。首先,选用规格为0.5 K的国产SiC纤维(福建立亚新材有限公司商用的cansas3301 SiC纤维),并利用多综眼织机,织造了2.5D机织预制体;其次,以BCl3和NH3作为原料气(山东德芯特种气体有限责任公司),以Ar (北京普莱克斯实用气体有限公司)作为保护气,H2 (北京普莱克斯实用气体有限公司)作为催化气,通过物理气相沉积法制备了BN界面层[25];然后,以聚碳硅烷(PCS,中国科学院化学研究所)浆料为先驱体,采用PIP法制备了2.5D机织SiCf/SiC复合材料粗坯,浸渍-裂解循环为8~10次,直至质量增加<1.5wt%。最后,经过近净尺寸加工和再致密化等后处理得到2.5D机织SiCf/SiC复合材料样件。制备各阶段实物如图2所示,材料样件规格参数如表1所示。

1.2 2.5D机织SiCf/SiC复合材料的吸波性能测试

参照标准《雷达吸波材料反射率测试方法》(GJB 2038—94)[26],利用弓形法对2.5D机织SiCf/SiC复合材料的反射损耗进行测试。测试系统如图3所示:(1) 测试之前,需在弓形架上方安装好对称的发射天线和接收天线,并将2.5D机织SiCf/SiC复合材料测试试样放置在样品台上;(2) 开始测试后,电磁波由发射天线发射,经样品台反射到接收天线并传输到矢量网络分析仪上,建立起相应特性频率的参考功率电平,测出接收到的反射电磁波功率;(3) 用金属板取代测试试样,获取其反射电磁波的功率。上述金属板与测试试样接收的功率电平之差,即为反射率。本实验在中国航空技术研究院复合材料中心完成,测试试样尺寸为40 mm×40 mm×3 mm,测试频率范围为8~18 GHz。

表 1 2.5D机织SiCf/SiC复合材料规格参数Table 1. Specification parameters of 2.5D woven SiCf/SiC compositesPrefabricated structure Dimension/

mm3Warp density/

(yarn·cm−1)Weft density/

(yarn·cm−1)Yarn fineness/tex Number of

layerVolume

fraction/vol%2.5D woven angle interlock 40×40×3 9 3.5 185 8 45 1.3 基于Micro-CT图像的全厚度细观模型重构

使用德国Diondo-d2微焦点CT扫描系统扫描2.5D机织SiCf/SiC复合材料,扫描规格为20 mm×20 mm×3 mm。所得复合材料经向截面扫描形态和纬向截面扫描形态,分别如图4(a)和图4(b)所示。可知,其纱线截面可近似看作椭圆形或扁六边形。统计分析扫描结果,得到纱线截面几何参数如图4(c)和图4(d)所示。

基于图4所示纱线截面几何参数和表1所示复合材料规格参数,在SOLIDWORKS 2018对2.5D机织结构预制体进行全厚度细观模型重构。如图5所示,分别建立了以椭圆为纱线截面和以扁六边形为纱线截面的2.5D机织 SiCf/SiC 复合材料模型。仿真发现,两种不同截面的模型对仿真结果几乎没有影响。但从仿真速度来看,以扁六边形为截面所建模型远快于以椭圆为截面所建模型。这是由于在CST电磁仿真软件中,当网格无法分辨较精细曲面结构时,就会出现CST网格划分短路现象,称为CC短路现象(Critical cell),需要进行全局网格优化或者局部加密网格来解决问题。这导致以椭圆为截面所建模型划分网格数量要高于以六边形为截面所建模型划分网格数量。因此,后续研究以扁六边形为纱线截面所建模型为准。

![]() 图 4 2.5D机织SiCf/SiC复合材料的X射线计算机断层扫描(Micro-CT)扫描结果:(a) 经向截面扫描形态;(b) 纬向截面扫描形态;(c) 椭圆截面几何参数;(d) 扁六边形截面几何参数Figure 4. X-ray computed tomography (Micro-CT) scanning results of 2.5D woven SiCf/SiC composites: (a) Scanning morphology of warp cross-section; (b) Scanning morphology of weft cross-section; (c) Geometric parameters of ellipse cross-section; (d) Geometric parameters of flat hexagonal cross-section

图 4 2.5D机织SiCf/SiC复合材料的X射线计算机断层扫描(Micro-CT)扫描结果:(a) 经向截面扫描形态;(b) 纬向截面扫描形态;(c) 椭圆截面几何参数;(d) 扁六边形截面几何参数Figure 4. X-ray computed tomography (Micro-CT) scanning results of 2.5D woven SiCf/SiC composites: (a) Scanning morphology of warp cross-section; (b) Scanning morphology of weft cross-section; (c) Geometric parameters of ellipse cross-section; (d) Geometric parameters of flat hexagonal cross-section1.4 CST 电磁仿真计算

对于吸波材料,一般将A(ω)、R(ω)和T(ω)分别定义为吸收率、反射率和透射率。在CST Studio Suite 2020中,反射率R(ω)=|S11|2,透射率T(ω)=|S21|2,此时吸收率A(ω)如下式所示[27]:

A(ω)=1−R(ω)−T(ω)=1−|S11|2−|S21|2 (1) 其中:S11为反射系数;S21为透射系数。在仿真过程中,将边界条件中的Z轴负方向的Zmin设置为电边界,这可以防止入射电磁波传输透过底板,因此透射率为0,此时吸收率A(ω)如下式所示:

A(ω)=1−R(ω)=1−|S11|2 (2) 合格的吸波材料要求吸收率尽可能高,反射率尽可能低,而反射率由等效相对阻抗决定,如下式所示:

R(ω)=Zeff−η0Zeff+η0 (3) 将式(3)代入式(2),此时吸收率A(ω)如下式所示:

A(ω)=2η0Re(Zeff)+Im(Zeff)+η0 (4) 由式(4)可知,若要吸收率A(ω)接近1,则吸波材料的等效阻抗实部Re(Zeff)应接近空气阻抗η0,而虚部Im(Zeff)应接近0。由S参数反演法[28-29]计算等效相对阻抗如下式所示:

Zeff=√(1+S11)2−S212(1−S11)2−S212 (5) 图6示出了利用 CST 微波工作室分析2.5D 机织SiCf/SiC复合材料吸波性能的仿真流程。在CST Studio Suite 2020中,仿真频率设置为1~18 GHz、边界条件Zmin设置为电边界(无透射)、网格划分为四面体自适应性网格划分、求解器设置为频域求解器、材料参数为介电常数和损耗角正切(波导法测得,由中国航空技术研究院复合材料中心测试提供)。运行仿真后在1D Results中查看反射损耗曲线,在2D/3D Results中查看场分布图。仿真得到反射损耗曲线S11和S21后,在Post-processing模块的Result Templates Tools中键入式(5),重新运行仿真,在tables中查看等效电磁参数曲线。

2. 结果与讨论

2.1 2.5D 机织SiCf/SiC复合材料的吸波性能

图7对比分析了实验测试与仿真计算所得的反射损耗曲线。从图中可以看出,室温下实验测得的吸收峰出现在9.3 GHz处,吸收峰处反射损耗为−17 dB,反射损耗小于−10 dB的有效吸波带宽为3 GHz。而对应的仿真结果显示吸收峰出现在10.1 GHz处,吸收峰处反射损耗为−16 dB,有效吸波带宽也为3 GHz。且在高温800℃下,2.5D 机织SiCf/SiC复合材料仍然具有一定的吸波性能。显然,在8~18 GHz频率范围内,实验与仿真结果吻合良好,证明了所建模型的合理性和仿真结果的准确性,这为后续利用仿真模拟进行吸波机制分析的可靠性提供了有力支撑。但也不可否认的是,二者在吸收峰处略有差异,其中主要原因包括:(1) 仿真发生在理想条件下,而实验会受到材料性能差异、测量误差和环境等条件的真实影响;(2) 所建模型没有充分考虑材料内部孔隙和纱线挤压问题,这些因素会在后续研究中展开分析。

2.2 2.5D 机织SiCf/SiC复合材料的吸波机制分析

2.2.1 等效电磁参数分析

图8给出了2.5D 机织SiCf/SiC复合材料的等效电磁参数曲线。由图可知,在10.1 GHz处,Re(Zeff)和Im(Zeff)分别为1和0。此时,复合材料表面阻抗与空气阻抗近似相等,这能保证电磁波尽可能多的进入材料内部被吸收。而在10.1 GHz两侧,Re(Zeff)和Im(Zeff)分别越来越远离1和0,这导致材料表面阻抗与空气阻抗失配,复合材料产生了对电磁波的强反射作用。这也验证了图7所示反射损耗曲线中,吸收峰出现在10.1 GHz附近,吸收峰向两边的反射损耗越来越小,复合材料吸波性能越来越差。

2.2.2 基于场图的吸波机制分析

为了进一步研究2.5D机织SiCf/SiC复合材料与电磁波之间的相互作用,揭示其吸波机制, 开展了基于CST电磁仿真的场分布图研究。在频率1~18 GHz之间,分别仿真了频率两端1 GHz、18 GHz、中间点的频率9.5 GHz以及谐振点频率10.1 GHz共4个频点的电磁场分布。

图9(a)给出了电磁波在2.5D机织SiCf/SiC复合材料和空气中传输的电场分布图。从图中可以看出,当电磁波频率为1 GHz时,电场强度沿Y轴负方向分布,且在整个仿真空间内电场强度方向无变化;当电磁波频率升高至9.5 GHz时,吸波材料上方空气中场强沿Y轴负方向分布,而吸波材料内部场强转为沿Y轴正方向分布;当电磁波频率继续上升至18 GHz时,电场强度的方向发生了多次转变。这与苏钦城[30]的研究结果一致,即不同频率下的电场方向随着电磁波频率的变化而变化,且电磁波频率越高,电场方向改变越快。除此之外,电磁波频率为1 GHz时的最大电场强度为2938 V/m,随着电磁波频率升高至9.5 GHz,最大电场强度迅速升高至29523 V/m,谐振频率点10.1 GHz处的最大电磁强度为29361 V/m。而随着电磁波频率继续升高,最大电场强度开始逐渐下降,当电磁波频率为18 GHz时,最大电场强度下降至16669 V/m。可以看出,本文所制备的2.5D机织SiCf/SiC复合材料主要通过电损耗的方式吸收电磁波,且电场强度越大,损耗能力越强。又由于最大电场强度发生在9.5 GHz,而不是谐振频率10.1 GHz处,可以判断该复合材料对电磁波的损耗作用除了电损耗之外,还存在其他的损耗类型。

![]() 图 9 2.5D机织SiCf/SiC复合材料的场分布图:(a) 电场(E-Field)分布图;(b) 磁场(H-Field)分布图;(c) 表面电流密度分布图;(d) 能量损耗密度分布图Figure 9. Field distribution map of 2.5D woven SiCf/SiC composites: (a) Electric field (E-Field) distribution map; (b) Magnetic field (H-Field) distribution map; (c) Current density distribution map; (d) Power loss density distribution map

图 9 2.5D机织SiCf/SiC复合材料的场分布图:(a) 电场(E-Field)分布图;(b) 磁场(H-Field)分布图;(c) 表面电流密度分布图;(d) 能量损耗密度分布图Figure 9. Field distribution map of 2.5D woven SiCf/SiC composites: (a) Electric field (E-Field) distribution map; (b) Magnetic field (H-Field) distribution map; (c) Current density distribution map; (d) Power loss density distribution map图9(b)给出了电磁波在2.5D机织SiCf/SiC复合材料和空气中传输的磁场分布图。由图可知,当电磁波频率为1 GHz时,整个仿真空间内磁场强度沿X轴负方向分布。而随着电磁波频率的升高,磁场方向逐渐发生变化,且频率越高变化越快。频率为1 GHz时的最大磁场强度为34.9 A/m,随着电磁波频率升高至9.5 GHz时,最大磁场强度升高至55.7 A/m,谐振频率点10.1 GHz处的最大磁场强度为53.6 A/m。而随着电磁波频率继续升高,最大磁场强度开始逐渐下降,当电磁波频率为18 GHz时,最大磁场强度下降至31 A/m。可以看出,在1~18 GHz整个频段内,电磁波形成的磁场强度较弱,2.5D机织SiCf/SiC复合材料由磁损耗贡献的吸波效果较小。这是由于SiC纤维本身磁性较弱,难以在复合材料中形成强磁场。

图9(c)给出了2.5D机织SiCf/SiC复合材料内部的电流密度分布图。可以看出,电磁波频率为1 GHz时,材料内部电流均沿Y轴负方向分布,这与1 GHz处的电场方向一致。同样的,当电磁波频率为9.5 GHz、10.1 GHz和 18 GHz时,吸波材料内部电流方向均与对应频点处的电场方向一致,沿Y轴正方向分布。这是由于在电场的作用下,大量自由电子沿电场方向发生定向移动产生了电流。当电磁波频率为1 GHz时,材料内部电流密度仅为393 A/m2。随着电磁波频率升高至9.5 GHz时,电流密度迅速升高至31909 A/m2,谐振频率点10.1 GHz处的电流密度为32690 A/m2,此时2.5D机织SiCf/SiC复合材料吸波性能达到最佳。

图9(d)给出了1~18 GHz间的能量损耗密度分布图。由图可知,当电磁波频率为1 GHz时,能量损耗密度为3.03×105 W/m3,此时复合材料反射损耗绝对值为全频段最小的0.004 dB;随着电磁波频率的上升,能量损耗密度逐渐增大,在谐振点频率10.1 GHz处达到最大值2.66×108 W/m3,此时对应的反射损耗绝对值为全频段最大的16.2 GHz;随着电磁波频率继续升高,能量损耗密度逐渐减小,在18 GHz时能量损耗密度减小为1.44×108 W/m3,此时对应的反射损耗绝对值也减小至3.5 dB。因此,电磁波在2.5D机织SiCf/SiC复合材料内部以能量的形式进行传播,在传播过程中,复合材料将利用各种损耗机制将其转化为热量耗散掉。

为了更完整地表达2.5D机织SiCf/SiC复合材料的吸波机制,图10给出了电磁波在材料内部的传输路径。由图可知,入射电磁波在接触到复合材料表面时,一部分直接从表面反射回去,一部分穿过表面透波层进入复合材料内部的损耗层。在损耗层中,一方面,由于SiC纤维固有的材料属性,入射波在材料内部会发生电损耗而被吸收;另一方面,采用PIP法制备的2.5D机织SiCf/SiC复合材料内部存在较多随机分布的孔隙(Micro-CT扫描测得该2.5D机织SiCf/SiC复合材料样件内部孔隙率为10.7%),这些孔隙大大延长了电磁波在材料内部的传播路径,并使电磁波在材料内部发生多次散射,这进一步提高了其损耗能力。

2.3 2.5D 机织SiCf/SiC复合材料吸波性能的影响因素

在上述数值模型与实验结果对比分析基础上,本部分利用有限积分法和CST Studio Suite 2020仿真软件,着重分析几何特性、纤维电磁参数、电磁波电场极化方向和入射角度等对2.5D 机织SiCf/SiC复合材料吸波性能的影响规律,以期为耐高温结构吸波复合材料的选材与结构拓展提供设计依据。

2.3.1 几何特性对吸波性能的影响规律

图11(a)给出了厚度d为1.5 mm、3 mm和6 mm时2.5D机织SiCf/SiC复合材料的反射损耗曲线。可以看出,随着厚度的增加,有效吸波带宽无变化,但材料吸收峰明显向低频移动。同时,最大反射损耗随着厚度增加逐渐增大。且当厚度为6 mm时,在低频和高频处都出现了一个明显的吸收峰。这可以用1/4波长理论[31]来解释,厚度的增加延长了电磁波在材料内部的传播路径,使电磁波尽多被吸收。因此,材料厚度主要影响吸收峰的位置和个数,且在允许的范围内,厚度越大对吸波效能越有利。

图11(b)给出了纬密为2束/cm、3.5束/cm和5束/cm时2.5D机织SiCf/SiC复合材料的反射损耗曲线。由图可知,随着纬密的增大,材料吸收峰逐渐向低频移动,材料对电磁波的损耗能力逐渐增强,但有效吸收带宽无明显改善。这是由于纬密越大,高介电的SiC纤维所占体积分数越大,复合材料对电磁波的损耗能力越强。同样的,仿真分析经密对材料吸波性能的影响,结果同纬密,这与苏钦城等[20]的研究结论一致。

图11(c)给出了当厚度为3 mm,纤维层数为6层、8层和10层时2.5D机织SiCf/SiC复合材料的反射损耗曲线。可以看出,在一定厚度下,纤维层数越多,材料对电磁波的损耗能力越强,且吸收峰逐渐向低频移动,这与莫红松等[32]的研究结果一致。这是由于纤维层数越多,电磁波进入材料内部后在各层之间的散射次数越多,电磁波能发生多次损耗。

2.3.2 纤维电磁特性对吸波性能的影响规律

图12(a)给出了介电常数实部(ε')变化对2.5D机织SiCf/SiC复合材料反射损耗的影响规律。从图中可以看出,随着纤维ε'的增大,材料吸收峰明显向低频移动,最大反射损耗逐渐增大,但有效吸波带宽无明显变化。因此,纤维ε'主要影响2.5D机织SiCf/SiC复合材料的吸收峰位置和最大反射损耗值,而对有效吸波带宽影响较小。兰州大学应用磁学研究所研究表明[33],吸收峰的出现需要两种机制共同作用,一是材料具有较强的电磁损耗能力;二是吸波材料表面与电磁波产生相位相消作用。随着ε'的增大,材料特征阻抗与空气阻抗之间具有良好匹配特性的频点向低频移动,因此吸收峰逐渐向低频移动。

![]() 图 12 (a) 纤维介电常数实部ε'对吸波性能的影响;(b) 纤维介电损耗角正切tanδ对吸波性能的影响;(c) 材料厚度为3 mm时纤维混杂层数对吸波性能的影响;(d) 材料厚度为6 mm时纤维混杂层数对吸波性能的影响Figure 12. (a) Influence of the fiber real part of permittivity ε' on the absorption performance; (b) Influence of fiber dielectric loss angle tangent tanδ on the absorption performance; (c) Influence of fiber hybrid layers on the absorption properties when the material thickness is 3 mm; (d) Influence of fiber hybrid layers on the absorption properties when the material thickness is 6 mm

图 12 (a) 纤维介电常数实部ε'对吸波性能的影响;(b) 纤维介电损耗角正切tanδ对吸波性能的影响;(c) 材料厚度为3 mm时纤维混杂层数对吸波性能的影响;(d) 材料厚度为6 mm时纤维混杂层数对吸波性能的影响Figure 12. (a) Influence of the fiber real part of permittivity ε' on the absorption performance; (b) Influence of fiber dielectric loss angle tangent tanδ on the absorption performance; (c) Influence of fiber hybrid layers on the absorption properties when the material thickness is 3 mm; (d) Influence of fiber hybrid layers on the absorption properties when the material thickness is 6 mm图12(b)给出了介电损耗角正切(tanδ)变化对2.5D机织SiCf/SiC复合材料反射损耗的影响。可以看出,随着纤维tanδ的增大,材料有效吸波带宽和最大反射损耗都逐渐增大,但吸收峰位置无明显变化。不难得知,纤维tanδ主要影响2.5D机织SiCf/SiC复合材料的有效吸波带宽和最大反射损耗,而对吸收峰位置几乎没有影响。

为了进一步研究纤维电磁参数对2.5D机织SiCf/SiC复合材料吸波性能的影响,开展了不同电磁参数纤维的层间混杂分析。根据阻抗渐变原则,预制体上层应使用低介电常数纤维来提高材料和空气间的阻抗匹配,而在下层应使用高介电常数纤维提高电磁波损耗能力。按照上述混编思路,图12(c)给出了材料厚度为3 mm时,混杂不同层低介电常数SiC纤维对2.5D机织SiCf/SiC复合材料吸波性能的影响(左下角小图为混编思路示意图,黄色(上)为低介电匹配层,绿色(下)为高介电损耗层)。由图可知,随着混杂层数的增多,有效吸波带宽略有拓宽,但吸收峰逐渐向高频移动,且最大反射损耗逐渐减少。因此,当材料整体厚度较小时,不一定都是低介电常数纤维在上层作匹配层,高介电常数纤维在下层作损耗层。这与刘海韬等[34]的研究一致:阻抗渐变原则中的阻抗是指各层材料的输入阻抗,而输入阻抗不仅和材料电磁参数有关,还与材料厚度有关。为了进一步分析材料厚度对不同电磁参数纤维混杂效果的影响,图12(d)给出了材料厚度为6 mm时,混杂不同层低介电常数SiC纤维对2.5D机织SiCf/SiC复合材料吸波性能的影响。可以看出,3条反射损耗曲线都有两个明显的吸收峰。随着混杂层数的增多,两个吸收峰都略向高频移动,第一个峰对应的反射损耗逐渐减小,而第二个峰对应的反射损耗逐渐增大。整体而言,复合材料有效吸波带宽随着混杂层数的增多而逐渐增大。这说明只有当材料厚度较大时,不同电磁参数纤维混杂的方式才满足特征阻抗渐变原则,材料整体厚度越大,越有将低介电常数纤维放在上层的趋势。

2.3.3 电磁波电场极化方向和入射角度对吸波性能的影响

考虑到实际应用中,入射电磁波的电场极化方向是未知的,因此吸波材料的极化稳定性研究具有重要意义。图13(a)给出了不同极化角度下2.5D机织SiCf/SiC复合材料的反射损耗曲线。可以看出,当电磁波垂直入射到材料表面时,随着极化角度的增大,最大反射损耗逐渐减小,且吸收峰略向高频移动,不利于低频的高效吸收。因此本文所述的2.5D机织SiCf/SiC复合材料不具备很好的极化稳定性,这与材料的结构对称性有关。

图13(b)给出了不同电磁波入射角度下复合材料的反射损耗曲线。由图可知,在0°~60°之间,最大反射损耗随着入射角度的增大而增大,这是由于材料的感应电流密度在此范围内随入射角的变大而增加,且电流密度分布不均匀,产生了极化效应[30]。而当入射角度>60°时,无有效吸波带宽,这说明本文所研究的2.5D机织SiCf/SiC复合材料具有良好的宽角度入射特性。

3. 结 论

(1) 实验结果显示,2.5D机织SiCf/SiC复合材料吸收峰出现在9.3 GHz处,吸收峰处的反射损耗为−17 dB,反射损耗小于−10 dB的有效吸波带宽为3 GHz。对应的仿真结果显示,吸收峰出现在10.1 GHz处,吸收峰处的反射损耗为−16 dB,有效吸波带宽也为3 GHz。整体来看,实验与仿真结果吻合良好,证明了所建模型的合理性和仿真结果的准确性。二者在吸收峰处的差异一方面是由于实验环境和理想化仿真环境不同导致的,另一方面是由于所建模型没有充分考虑材料内部孔隙和纱线挤压问题。后续研究将进一步精细化仿真模型。

(2) 2.5D机织SiCf/SiC复合材料优异的吸波性能是材料特性和结构设计协同作用的结果。一方面,SiC纤维固有的材料属性使电磁波在材料内部以电损耗的形式被吸收;另一方面,2.5D机织SiCf/SiC复合材料内部随机分布的孔隙引起的多次反射和多次散射行为也是一个重要的吸波机制。关于材料内部孔隙分布和孔隙率对吸波性能的影响将在下一步研究中展开。

(3) 相比经纬密和纤维层数,厚度对2.5D机织SiCf/SiC复合材料吸波性能的影响更加显著。且当厚度较大时,通过不同介电常数纤维混杂来提升材料吸波性能的效果更好。除此之外,纤维介电常数实部对材料吸收峰的位置和有效吸波带宽都有明显影响,而纤维介电损耗角正切只对吸收峰深度有影响。由于该复合材料内部结构没有明显的对称性,因此不具备良好的极化特性。电磁波入射角度的变化会引起表面电流密度极化效应,该复合材料具有良好的宽角度入射特性。这些规律为吸波复合材料的选材和结构设计提供了可靠支撑。

-

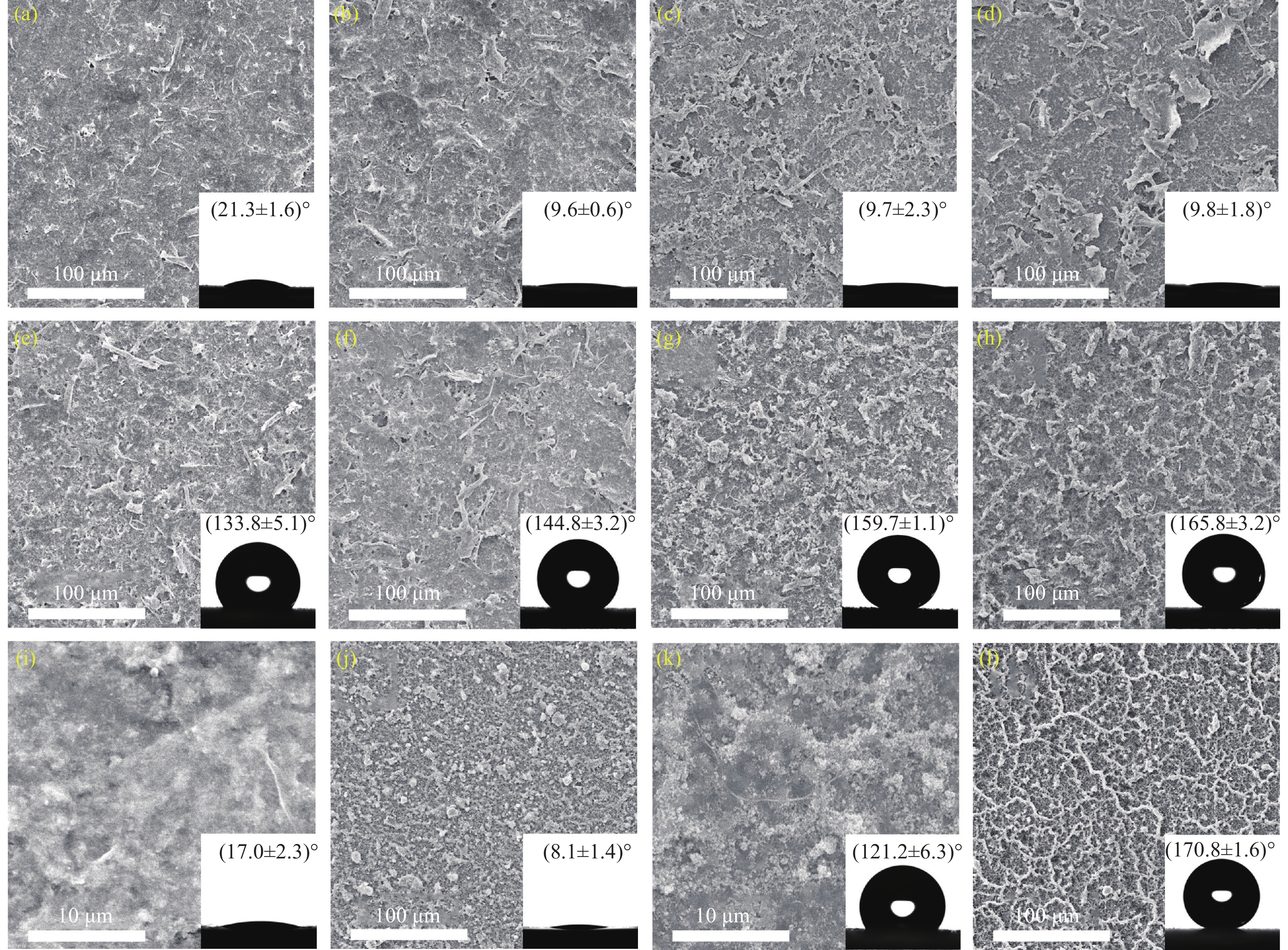

图 6 ((a)~(d)) CeO2/CNFs-X-Glass (X=1、3、5和7)的SEM图像;((e)~(h)) 10-O-CeO2/CNFs-X-Glass (X=1、3、5和7)的SEM图像;((i)~(l)) CNFs-Glass、CeO2-Glass、O-B-CeO2/CNFs-Glass和O-CeO2-Glass的SEM图像

Figure 6. ((a)-(d)) SEM images of O-CeO2/CNFs-X-Glass (X=1, 3, 5 and 7); ((e)-(h)) SEM images of 10-O-CeO2/CNFs-X-Glass (X=1, 3, 5 and 7); ((i)-(l)) SEM images of CNFs-Glass, CeO2-Glass, O-B-CeO2/CNFs-Glass and O-CeO2-Glass

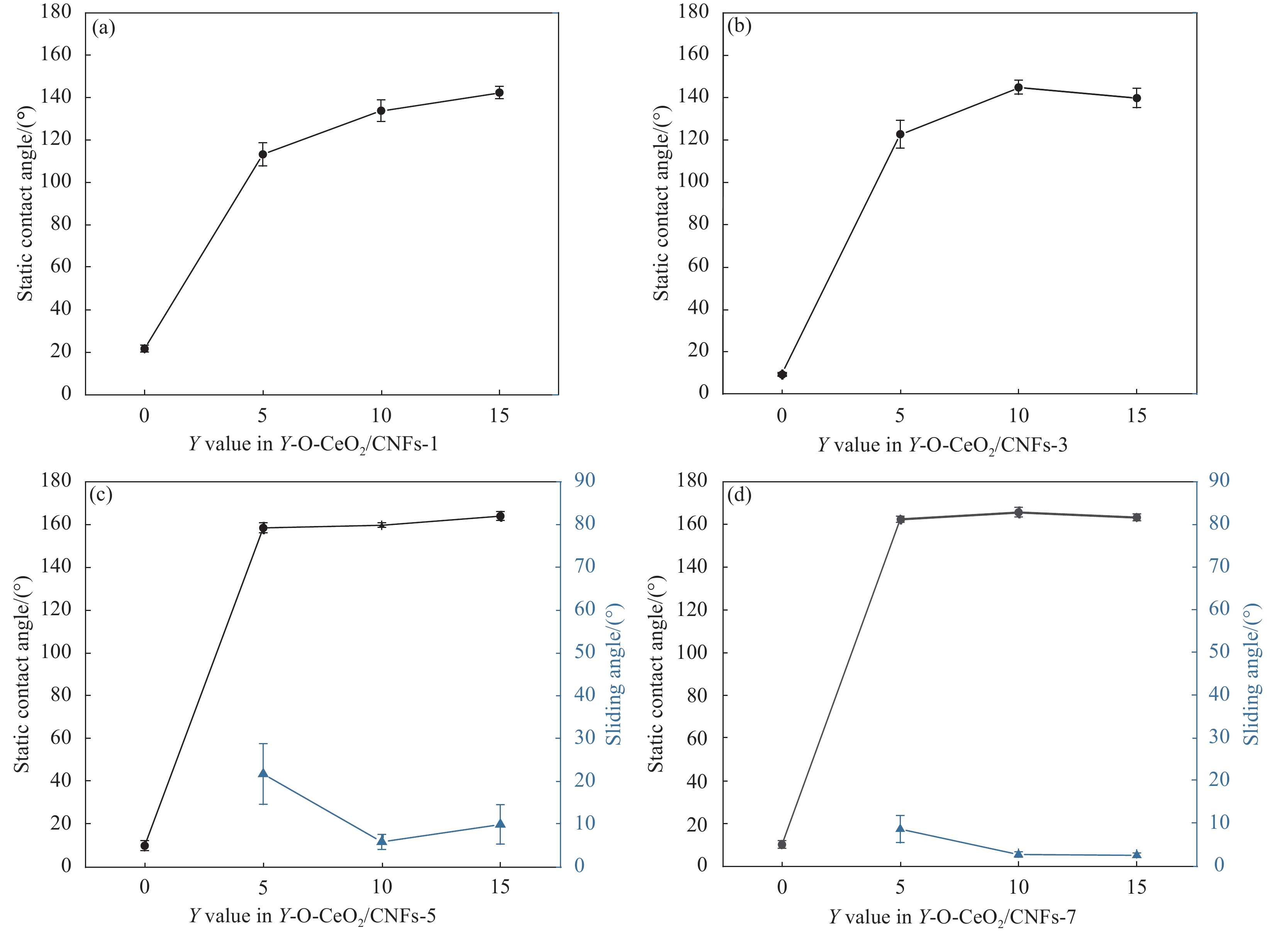

图 7 Y-O-CeO2/CNFs-1-Glass (a)、Y-O-CeO2/CNFs-3-Glass (b)、 Y-O-CeO2/CNFs-5-Glass (c)和 Y-O-CeO2/CNFs-7-Glass (d) (Y=0、5、10和15)的接触角和滚动角

Figure 7. Static contact angle and sliding angle of Y-O-CeO2/CNFs-1-Glass (a), Y-O-CeO2/CNFs-3-Glass (b), Y-O-CeO2/CNFs-5-Glass (c), andY-O-CeO2/CNFs-7-Glass (d) (Y=0, 5, 10, and 15)

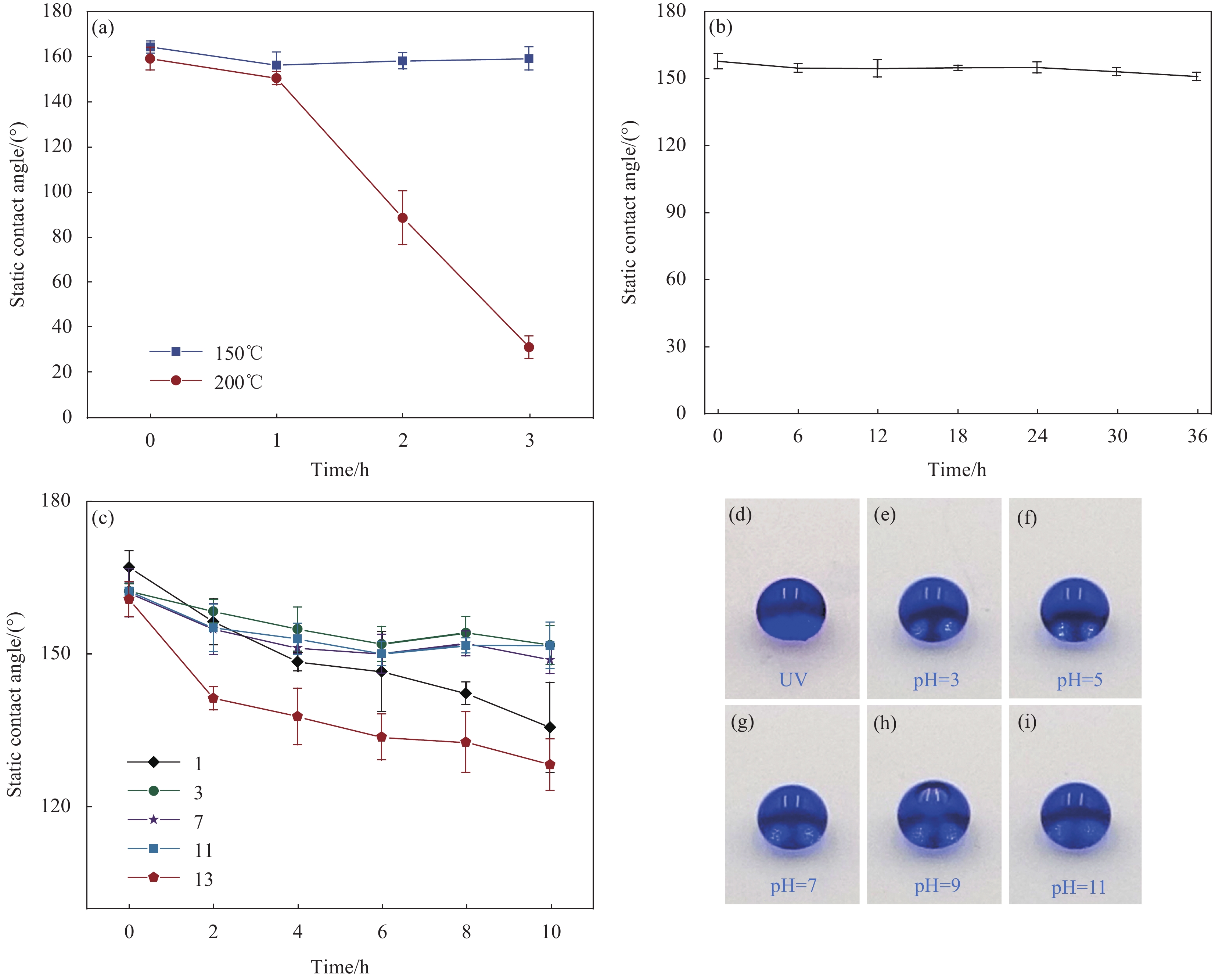

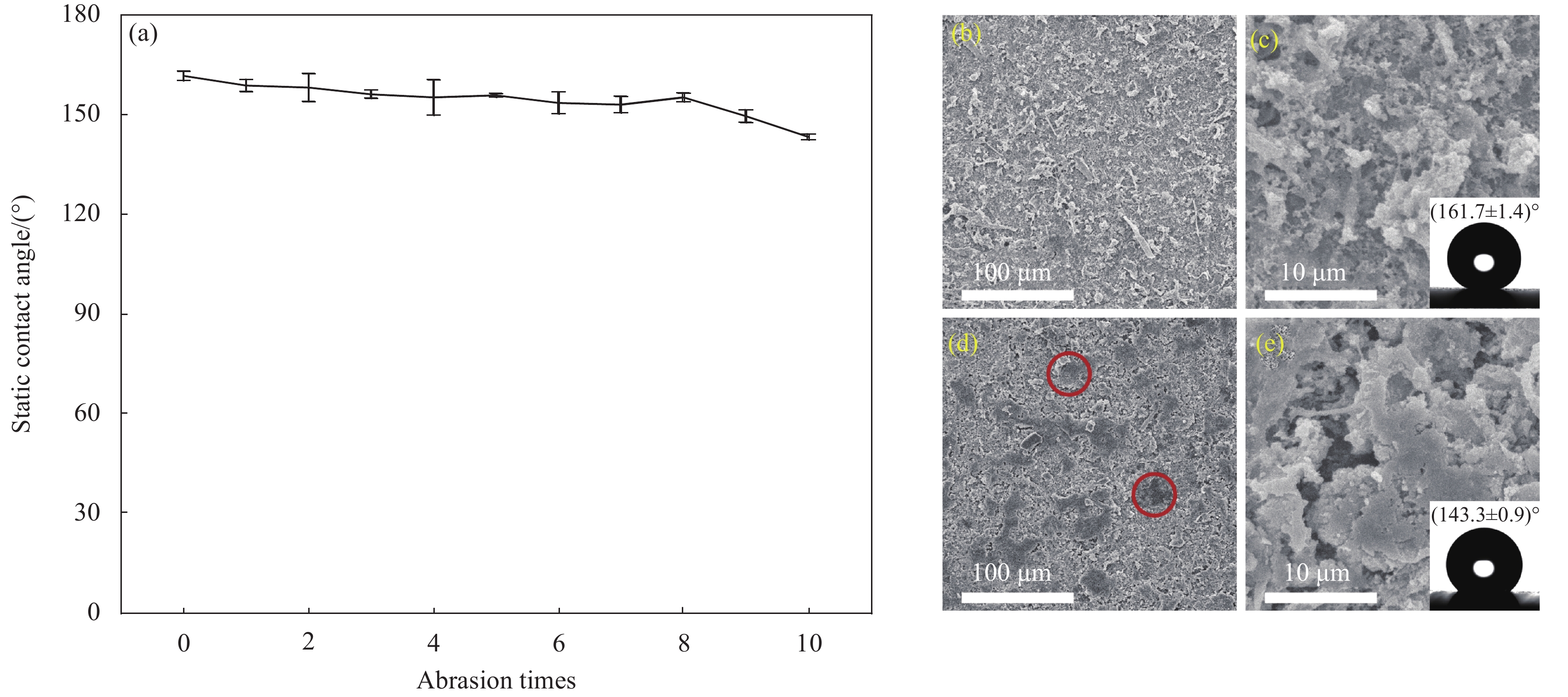

图 8 10-O-CeO2/CNFs-5-Glass在不同温度(a)、UV辐照(b)和不同pH值(c)处理一定时间后接触角变化;((d)~(i)) 在UV处理36 h和不同pH下处理10 h滴有亚甲基蓝的涂层照片

Figure 8. Change of static contact angle under different temperatures (a), UV illumination (b) and different pH treatment (c) of 10-O-CeO2/CNFs-5-Glass for a certain time; ((d)-(i)) Photographs of the coating with methylene blue droplets after treated with UV for 36 h and different pH for 10 h

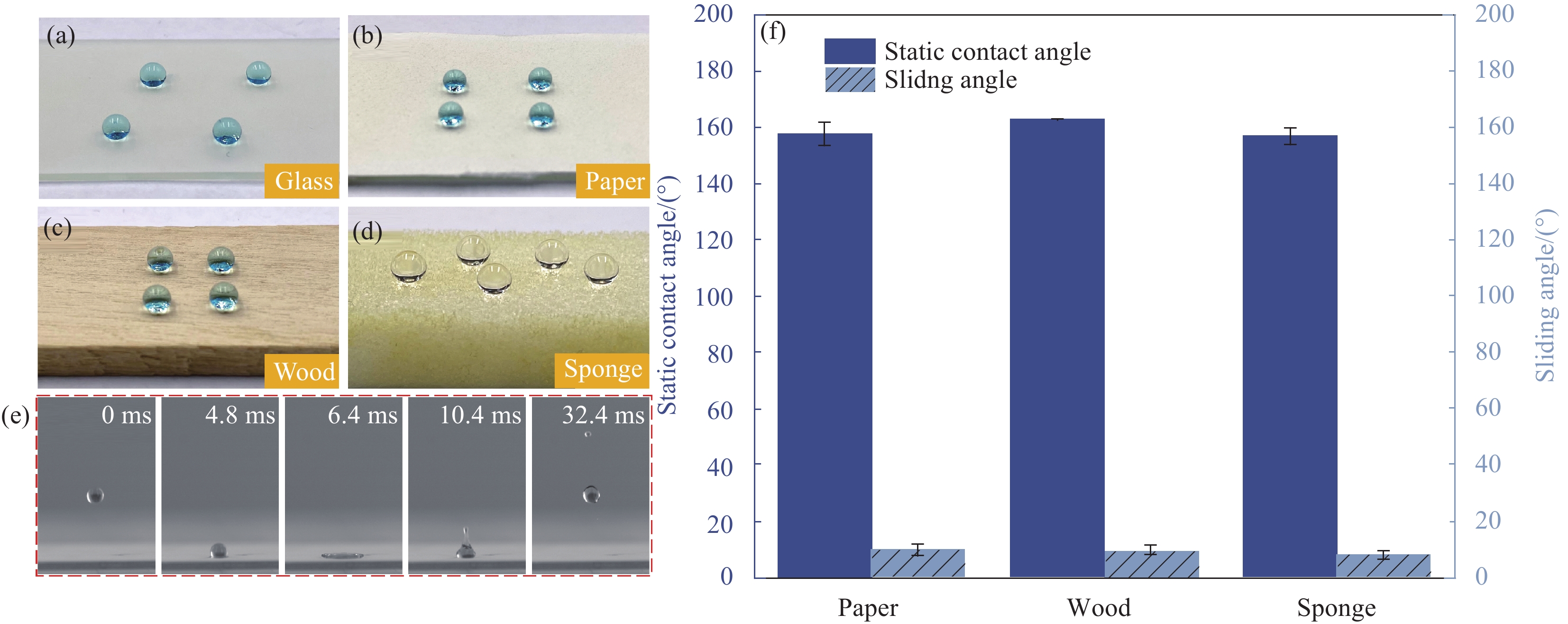

图 10 球形亚甲基蓝液滴在10-O-CeO2/CNFs-5-Glass (a)、10-O-CeO2/CNFs-5-Paper (b)、10-O-CeO2/CNFs-5-Wood (c) 和水滴在10-O-CeO2/CNFs-5-Sponge (d) 表面照片及其接触角和滚动角 (f);(e) 10-O-CeO2/CNFs-5-Glass表面液滴撞击照片

Figure 10. Photographs of spherical methylene blue aqueous dye on the surface of 10-O-CeO2/CNFs-5-Glass (a), 10-O-CeO2/CNFs-5-Paper (b), 10-O-CeO2/CNFs-5-Wood (c), and water droplets on the surface of 10-O-CeO2/CNFs-5-Sponge (d) as well as static contact angle and sliding angle (f); (e) Photographs of water droplet impact on the 10-O-CeO2/CNFs-5-Glass surface

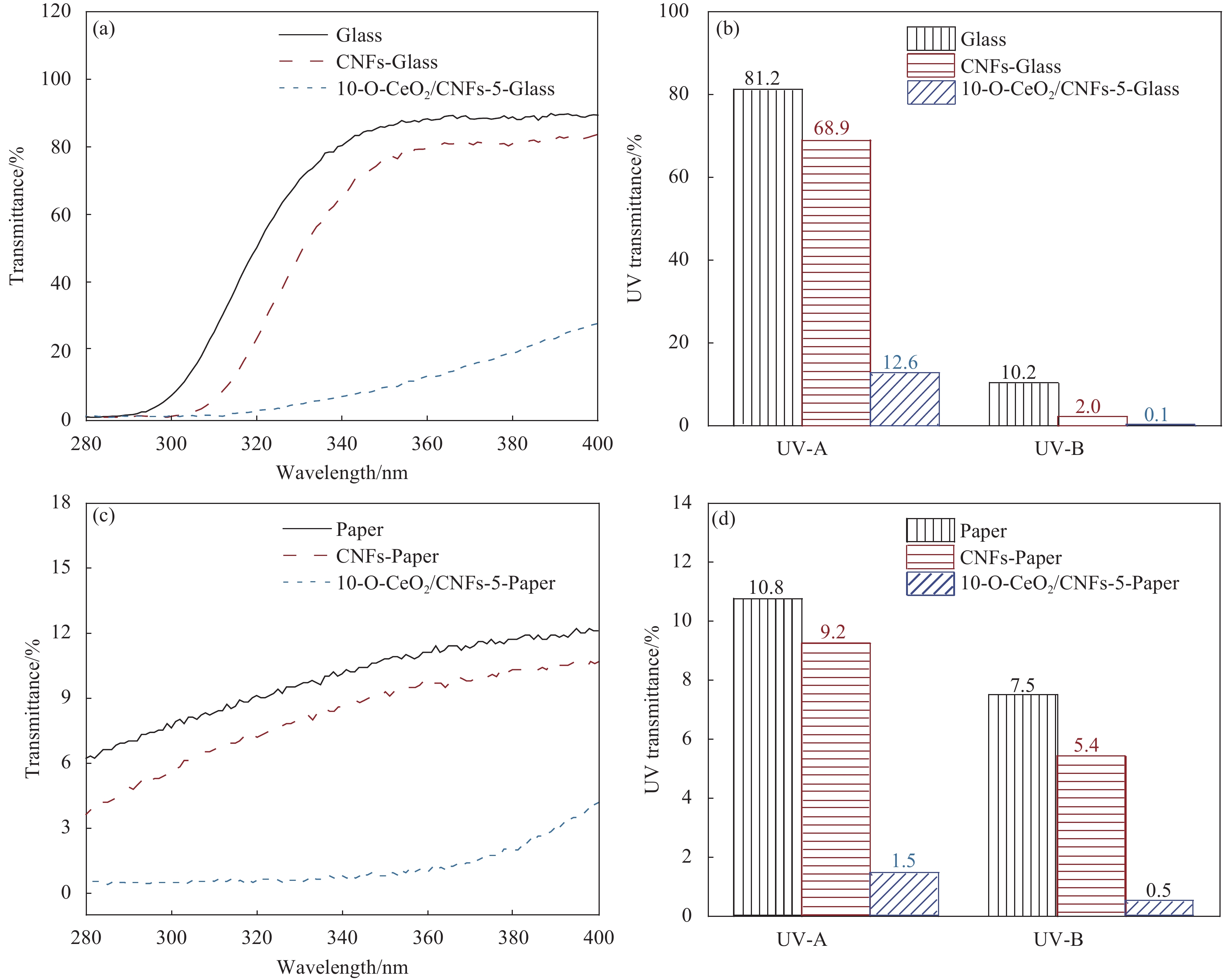

图 12 Glass、CNFs-Glass和10-O-CeO2/CNFs-5-Glass的 (a) 紫外线透过率曲线和 (b) 紫外线透过率;Paper、CNFs-Paper和10-O-CeO2/CNFs-5-Paper的 (c) 紫外线透过率曲线和 (d) 紫外线透过率

Figure 12. UV transmittance curves (a) and UV transmittance (b) of Glass, CNFs-Glass, and 10-O-CeO2/CNFs-5-Glass; UV transmittance curves (c) and UV transmittance (d) of Paper, CNFs-Paper, and 10-O-CeO2/CNFs-5-Paper

表 1 Y-O-CeO2/纤维素纳米纤维(CNFs)-X复合材料配方

Table 1 Y-O-CeO2/cellulose nanofibers (CNFs)-X composite formulations

Mass ratio Sample Ce(NO3)3·6H2O∶CNFs 1∶1 CeO2/CNFs-1 3∶1 CeO2/CNFs-3 5∶1 CeO2/CNFs-5 7∶1 CeO2/CNFs-7 X∶1 CeO2/CNFs-X OTMS:CeO2/CNFs-X 5∶1 5-O-CeO2/CNFs-X 10∶1 10-O-CeO2/CNFs-X 15∶1 15-O-CeO2/CNFs-X Y∶1 Y-O-CeO2/CNFs-X Notes: Y—Mass ratio of OTMS to CeO2/CNFs-X; X—Mass ratio of Ce(NO3)3·6H2O to CNFs. -

[1] YAN Y Y, GAO N, BARTHLOTT W. Mimicking natural superhydrophobic surfaces and grasping the wetting process: A review on recent progress in preparing superhydrophobic surfaces[J]. Advances in Colloid and Interface Science,2011,169(2):80-105. DOI: 10.1016/j.cis.2011.08.005

[2] HU C, XIE X, REN K. A facile method to prepare stearic acid-TiO2/zinc composite coating with multipronged robustness, self-cleaning property, and corrosion resistance[J]. Journal of Alloys and Compounds,2021,882:160636. DOI: 10.1016/j.jallcom.2021.160636

[3] LONG Y, YIN X, MU P, et al. Slippery liquid-infused porous surface (SLIPS) with superior liquid repellency, anti-corrosion, anti-icing and intensified durability for protecting substrates[J]. Chemical Engineering Journal,2020,401:126137. DOI: 10.1016/j.cej.2020.126137

[4] MA W, LI Y, ZHANG M, et al. Biomimetic durable multifunctional self-cleaning nanofibrous membrane with outstanding oil/water separation, photodegradation of orga-nic contaminants, and antibacterial performances[J]. ACS Applied Materials & Interfaces,2020,12(31):34999-35010.

[5] REN J, TAO F, LIU L, et al. A novel TiO2@stearic acid/chitosan coating with reversible wettability for controllable oil/water and emulsions separation[J]. Carbohydrate Polymers,2020,232:115807. DOI: 10.1016/j.carbpol.2019.115807

[6] ZHAO S, YANG X, XU Y, et al. A sprayable superhydrophobic dental protectant with photo-responsive anti-bacterial, acid-resistant, and anti-fouling functions[J]. Nano Research, 2022, 15: 5245-5255.

[7] GUI L, LIN J, LIU J, et al. Difference and association of antibacterial and bacterial anti-adhesive performances between smart Ag/AgCl/TiO2 composite surfaces with switchable wettability[J]. Chemical Engineering Journal,2022,431:134103. DOI: 10.1016/j.cej.2021.134103

[8] ZHANG X, LIU S, SALIM A, et al. Hierarchical structured multifunctional self-cleaning material with durable superhydrophobicity and photocatalytic functionalities[J]. Small,2019,15(34):1901822. DOI: 10.1002/smll.201901822

[9] SINHA R S, DANGAYACH R, KWON Y N. Surface engineering for anti-wetting and antibacterial membrane for enhanced and fouling resistant membrane distillation performance[J]. Chemical Engineering Journal,2021,405:126702. DOI: 10.1016/j.cej.2020.126702

[10] YOON J, RYU M, KIM H, et al. Wet-style superhydrophobic antifogging coatings for optical sensors[J]. Advanced Materials, 2020, 32(34): 2002710.

[11] GUO Z, LIU W, SU B L. Superhydrophobic surfaces: From natural to biomimetic to functional[J]. Journal of Colloid and Interface Science,2011,353(2):335-355. DOI: 10.1016/j.jcis.2010.08.047

[12] WANG T, ZHAO Y. Fabrication of thermally and mechani-cally stable superhydrophobic coatings for cellulose-based substrates with natural and edible ingredients for food applications[J]. Food Hydrocolloids,2021,120:106877. DOI: 10.1016/j.foodhyd.2021.106877

[13] BAI Z G, BAI Y Y, ZHANG G P, et al. A hydrogen bond based self-healing superhydrophobic octadecyltriethoxy silan-ligno cellulose/silica coating[J]. Progress in Organic Coatings,2021,151:106104. DOI: 10.1016/j.porgcoat.2020.106104

[14] ZHU Z, FU S, BASTA A H. A cellulose nanoarchitectonic: Multifunctional and robust superhydrophobic coating toward rapid and intelligent water-removing purpose[J]. Carbohydrate Polymers,2020,243:116444. DOI: 10.1016/j.carbpol.2020.116444

[15] 何江, 王大威. 纤维素材料的改性与研究进展[J]. 复合材料学报, 2022, 39(7):3121-3130. HE Jiang, WANG Dawei. Modification and research progress of cellulose materials[J]. Acta Materiae Compositae Sinica,2022,39(7):3121-3130(in Chinese).

[16] WANG X, GOU X, GUO Z. Robust superhydrophobic polyurea@cellulose nanocrystal coating[J]. New Journal of Chemistry,2020,44(27):11739-11745. DOI: 10.1039/D0NJ02261F

[17] KE W T, CHIU H L, LIAO Y C. Multifunctionalized cellulose nanofiber for water-repellent and wash-sustainable coatings on fabrics[J]. Langmuir,2020,36(28):8144-8151. DOI: 10.1021/acs.langmuir.0c01145

[18] 陈黄敬一, 俞娟, 蒋杰, 等. TEMPO氧化修饰的天然多糖纳米纤维增强复合材料及其功能化研究进展[J]. 复合材料学报, 2022, 39(4):1425-1445. CHEN HUANG Jingyi, YU Juan, JIANG Jie, et al. Research progress of TEMPO oxidation modified natural polysaccharide nanofiber reinforced composites and their functionality[J]. Acta Materiae Compositae Sinica,2022,39(4):1425-1445(in Chinese).

[19] PEGAH K, KING A W T, PARTL G J, et al. Superhydrophobic paper from nanostructured fluorinated cellulose esters[J]. ACS Applied Materials & Interfaces,2018,10(13):11280-11288.

[20] 周静, 沈葵忠, 房桂干, 等. 漂白竹浆疏水改性纳米纤丝化纤维素的制备和表征[J]. 林业工程学报, 2017, 2(2):101-106. ZHOU Jing, SHEN Kuizhong, FANG Guigan, et al. Preparation and characterization of hydrophobic nanofibrillated cellulose fiber from bleached bamboo pulp[J]. Journal of Forestry Engineering,2017,2(2):101-106(in Chinese).

[21] ZHAO X, PARK D S, CHOI J, et al. Robust, transparent, superhydrophobic coatings using novel hydrophobic/hydrophilic dual-sized silica particles[J]. Journal of Colloid and Interface Science,2020,574:347-354. DOI: 10.1016/j.jcis.2020.04.065

[22] XU P, LI X. Fabrication of TiO2/SiO2 superhydrophobic coating for efficient oil/water separation[J]. Journal of Environmental Chemical Engineering,2021,9(4):105538. DOI: 10.1016/j.jece.2021.105538

[23] 李洪峰, 林祥文, 王宏光, 等. 纳米TiO2超疏水涂层的制备与性能[J]. 森林工程, 2021, 37(5):111-117. DOI: 10.3969/j.issn.1006-8023.2021.05.015 LI Hongfeng, LIN Xiangwen, WANG Hongguang, et al. Fabrication and properties of nano-TiO2 superhydrophobic coating[J]. Forest Engineering,2021,37(5):111-117(in Chinese). DOI: 10.3969/j.issn.1006-8023.2021.05.015

[24] CHEN Q, XIONG J, CHEN G, et al. Preparation and characterization of highly transparent hydrophobic nanocellulose film using corn husks as main material[J]. International Journal of Biological Macromolecules,2020,158:781-789. DOI: 10.1016/j.ijbiomac.2020.04.250

[25] 孙晓晗, 郭于田, 龙瑞, 等. 磁性超疏水棉布的制备及应用[J]. 森林工程, 2019, 35(3): 54-62. SUN Xiaohan, GUO Yutian, LONG Rui, et al. Preparation and application of magnetic superhydrophobic cotton cloth[J]. Forest Engineering, 2019, 35(3): 54-62(in Chinese).

[26] XIE S, WANG Z, CHENG F, et al. Ceria and ceria-based nanostructured materials for photoenergy applications[J]. Nano Energy,2017,34:313-337. DOI: 10.1016/j.nanoen.2017.02.029

[27] WU Y, LIN X, CHEN L, et al. Preparation a skin disease UV protection polylactic acid film and crystallinity, mechani-cal properties characterization[J]. Materials Today Communications,2022,30:103085.

[28] ZHANG B, HUYAN Y, WANG J, et al. Synthesis of CeO2 nanoparticles with different morphologies and their pro-perties as peroxidase mimic[J]. Journal of the American Ceramic Society, 2018, 102: 2218-2227.

[29] LI X P, SUN Y L, XU Y Y, et al. UV-resistant and thermally stable superhydrophobic CeO2 nanotubes with high water adhesion[J]. Small,2018,14(27):1801040. DOI: 10.1002/smll.201801040

[30] WEI X L, LI N, YI W J, et al. High performance super-hydrophobic ZrO2-SiO2 porous ceramics coating with flower-like CeO2 micro/nano-structure[J]. Surface and Coatings Technology,2017,325:565-571. DOI: 10.1016/j.surfcoat.2017.06.004

[31] ZHANG C, LI C, SI X, et al. Mechanical durable ceria superhydrophobic coating fabricated by simple hot-press sintering[J]. Applied Surface Science,2020,529:147113. DOI: 10.1016/j.apsusc.2020.147113

[32] 何辉, 张忠明, 姜勇刚, 等. 稀土氧化物疏水涂层制备方法的研究进展[J]. 材料导报, 2021, 35(S2):50-55. HE Hui, ZHANG Zhongming, JIANG Yonggang, et al. Research progress on preparation methods of rare earth oxide hydrophobic coatings[J]. Materials Reports,2021,35(S2):50-55(in Chinese).

[33] ABE K, YANO H. Comparison of the characteristics of cellulose microfibril aggregates of wood, rice straw and potato tuber[J]. Cellulose,2009,16(6):1017-1023. DOI: 10.1007/s10570-009-9334-9

[34] ZHOU P, LV J, XU H, et al. Functionalization of cotton fabric with bismuth oxyiodide nanosheets: Applications for photodegrading organic pollutants, UV shielding and self-cleaning[J]. Cellulose,2019,26(4):2873-2884. DOI: 10.1007/s10570-019-02281-8

[35] MOHAMMAD A, KHAN M E, CHO M H, et al. Adsorption promoted visible-light-induced photocatalytic degradation of antibiotic tetracycline by tin oxide/cerium oxide nanocomposite[J]. Applied Surface Science,2021,565:150337. DOI: 10.1016/j.apsusc.2021.150337

[36] JIA S, LU Y, LUO S, et al. Thermally-induced all-damage-healable superhydrophobic surface with photocatalytic performance from hierarchical BiOCl[J]. Chemical Engi-neering Journal,2019,366:439-448. DOI: 10.1016/j.cej.2019.02.104

[37] CHEN F F, DAI Z H, FENG Y N, et al. Customized cellulose fiber paper enabled by an in situ growth of ultralong hydroxyapatite nanowires[J]. ACS Nano,2021,15(3):5355-5365. DOI: 10.1021/acsnano.0c10903

[38] CHEN S, SONG Y, XU F. Highly transparent and hazy cellulose nanopaper simultaneously with a self-cleaning superhydrophobic surface[J]. ACS Sustainable Chemistry & Engineering,2018,6(4):5173-5181.

[39] LIU Z, ZHENG J, DUAN L, et al. Biomass-assisted synthesis of CeO2 nanorods for CO2 photoreduction under visible light[J]. ACS Applied Nano Materials,2021,4(4):4226-4237. DOI: 10.1021/acsanm.1c00720

[40] CHEN W, YU H, LIU Y, et al. Isolation and characterization of cellulose nanofibers from four plant cellulose fibers using a chemical-ultrasonic process[J]. Cellulose,2011,18(2):433-442. DOI: 10.1007/s10570-011-9497-z

[41] WANG Q, XIE D, CHEN J, et al. Facile fabrication of superhydrophobic and photoluminescent TEMPO-oxidized cellulose-based paper for anticounterfeiting application[J]. ACS Sustainable Chemistry & Engineering,2020,8(35):13176-13184.

[42] WANG J, WANG H, WANG Y, et al. Rapid fabrication of a transparent superhydrophobic coating: Potential application with pollution-free under construction[J]. Applied Physics A, 2020, 126(7): 508.

[43] ZHU Q, CHU Y, WANG Z, et al. Robust superhydrophobic polyurethane sponge as a highly reusable oil-absorption material[J]. Journal of Materials Chemistry A, 2013, 1(17): 5386.

[44] MATIN A, BAIG U, GONDAL M A, et al. Superhydrophobic and superoleophilic surfaces prepared by spray-coating of facile synthesized cerium(IV) oxide nanoparticles for efficient oil/water separation[J]. Applied Surface Science,2018,462:95-104. DOI: 10.1016/j.apsusc.2018.08.104

[45] ZHANG Z, ZHANG X, NIU D, et al. Large-pore, silica particles with antibody-like, biorecognition sites for efficient protein separation[J]. Journal of Materials Chemistry B, 2017, 5(22): 4214-4220.

[46] LICHTENSTEIN K, LAVOINE N. Toward a deeper understanding of the thermal degradation mechanism of nanocellulose[J]. Polymer Degradation and Stability,2017,146:53-60. DOI: 10.1016/j.polymdegradstab.2017.09.018

-

期刊类型引用(1)

1. 邱海鹏,王晓猛,陈明伟,王岭,徐俊杰,赵马娟,张典堂,宋雨晴. 层合结构吸波陶瓷基复合材料设计及性能研究. 航空制造技术. 2024(Z2): 34-42 .  百度学术

百度学术

其他类型引用(0)

-

下载:

下载: