Effect of temperature on dynamic compression properties of PVA/ECC

-

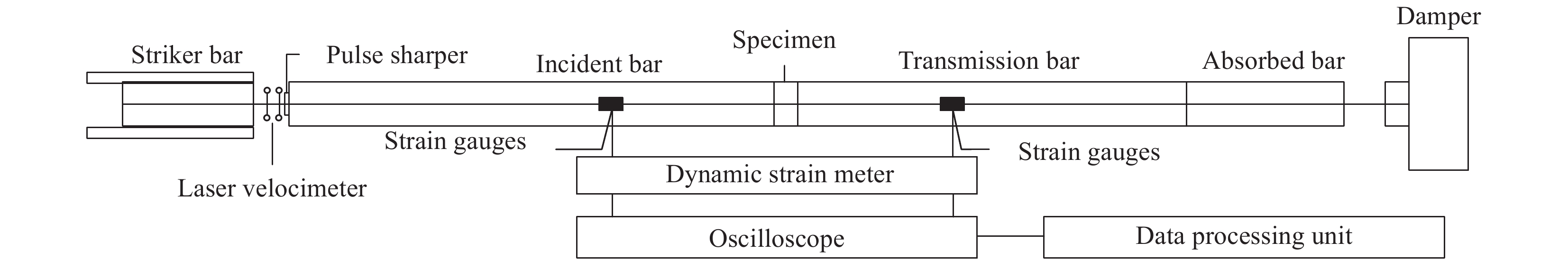

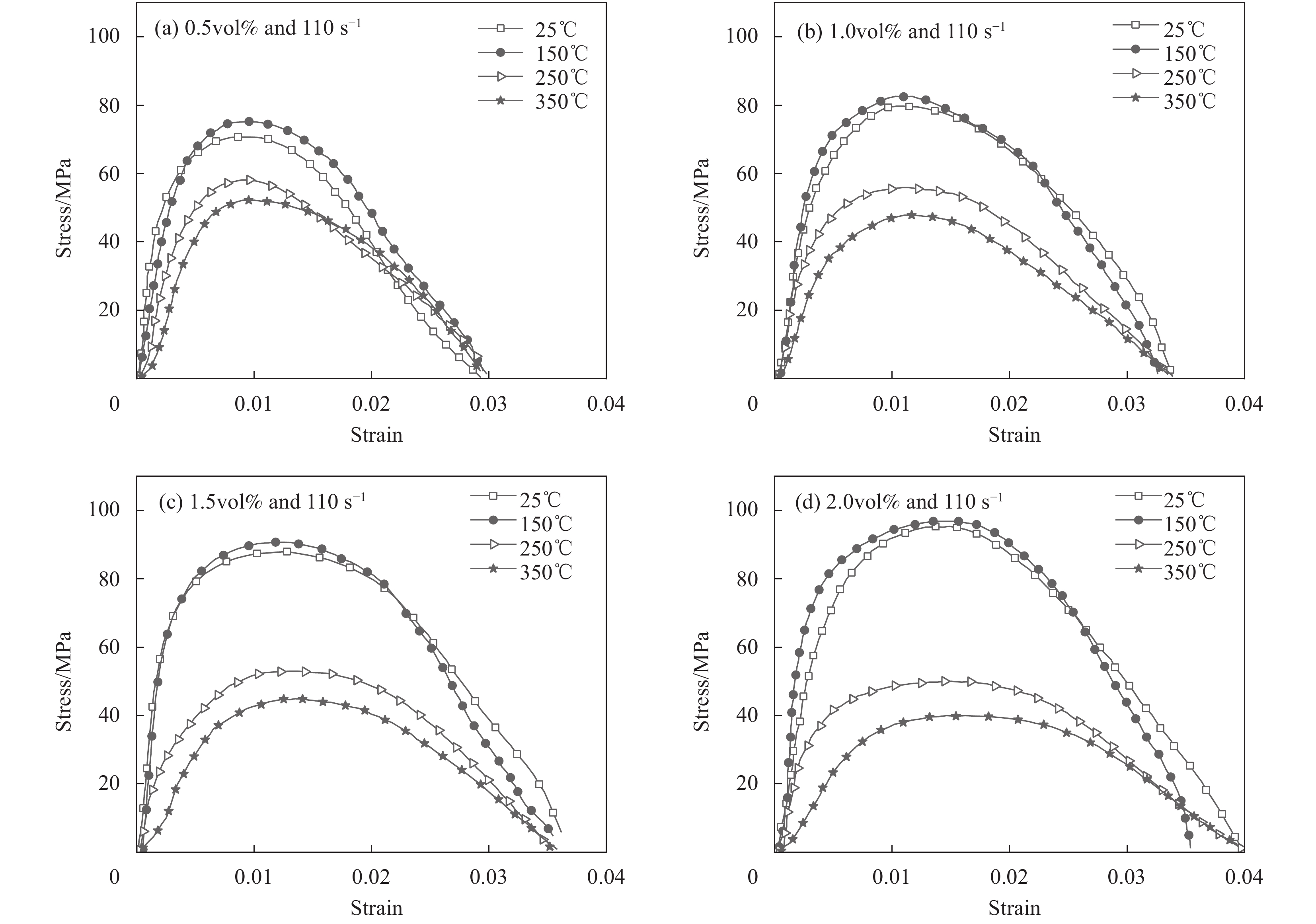

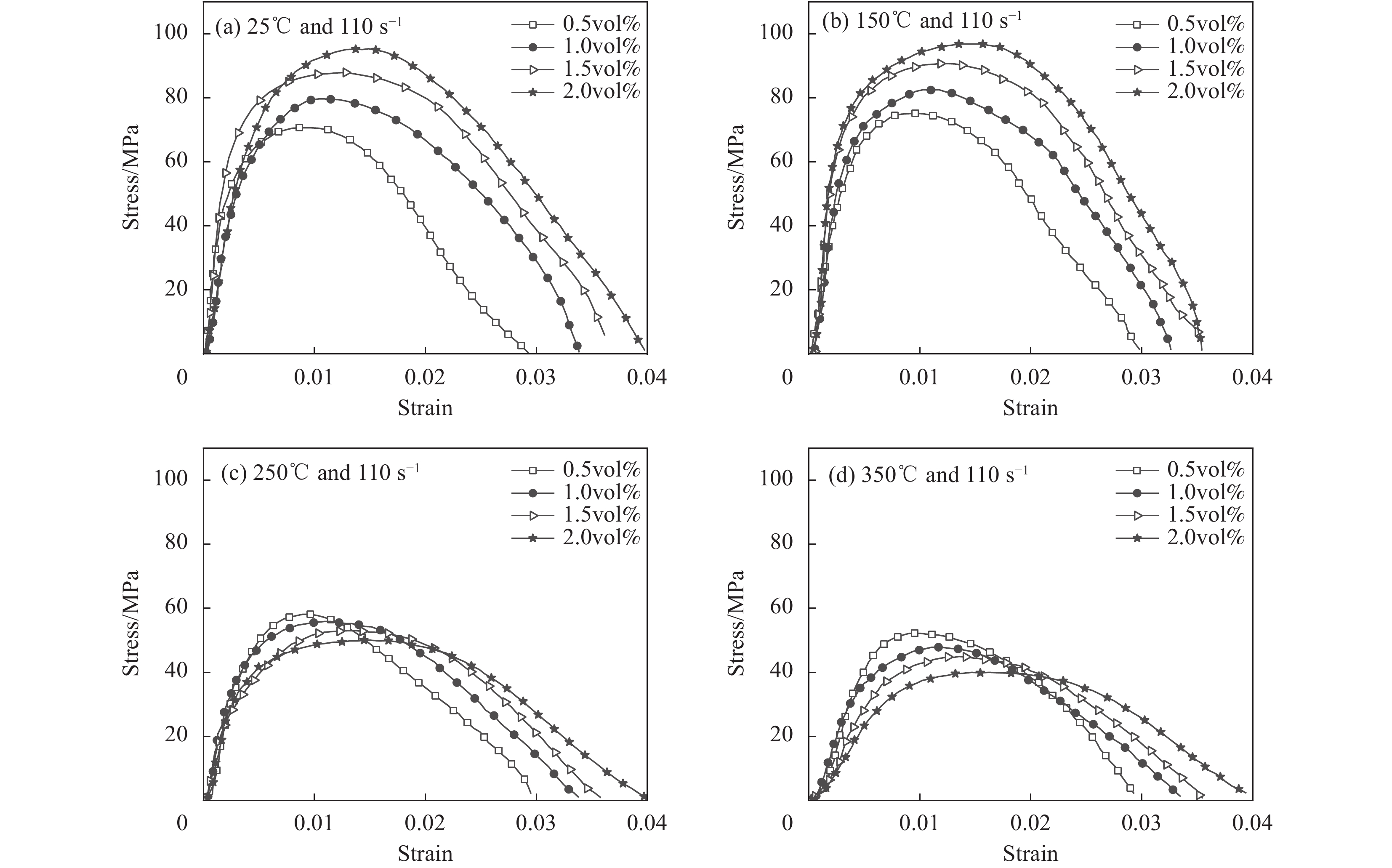

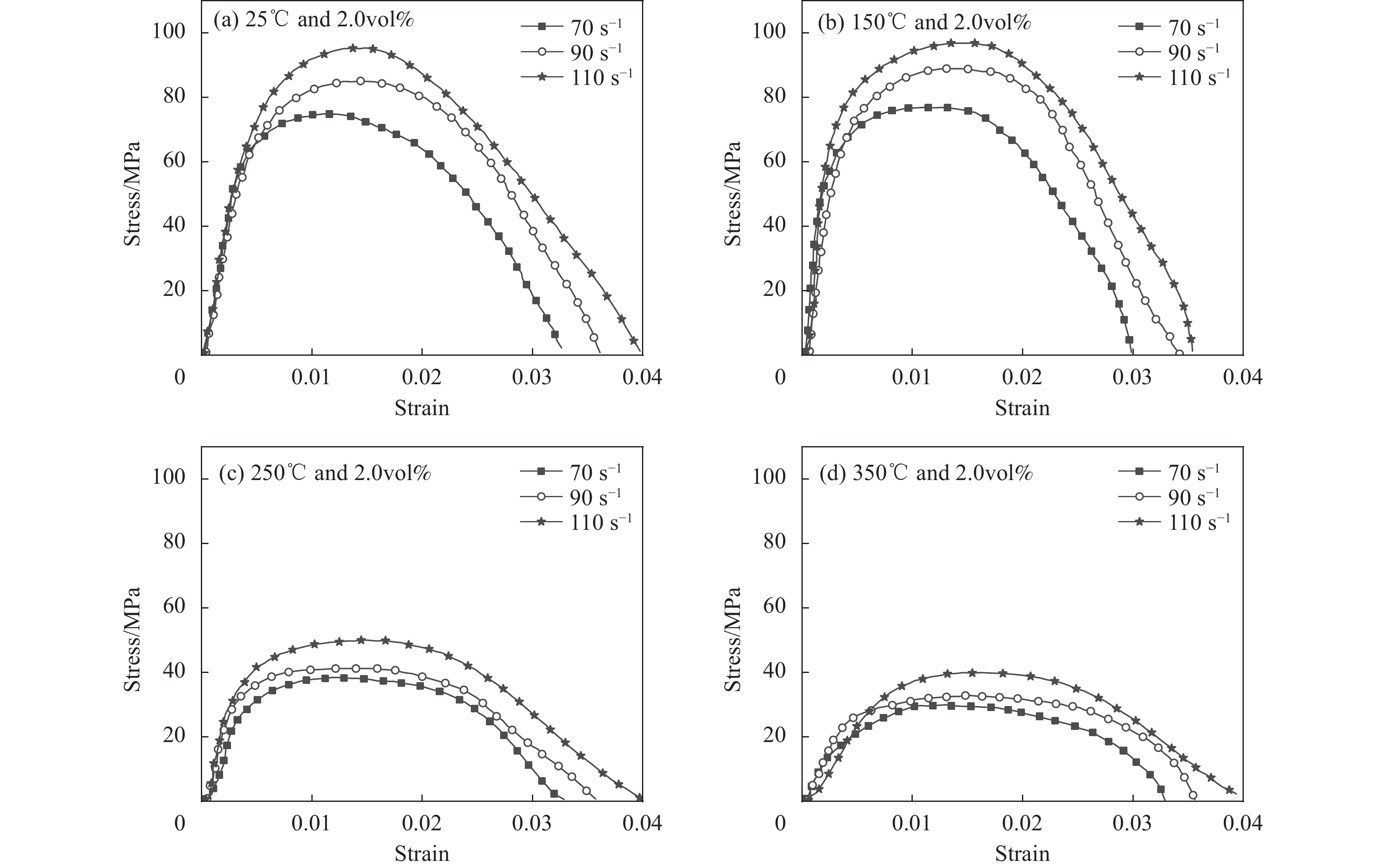

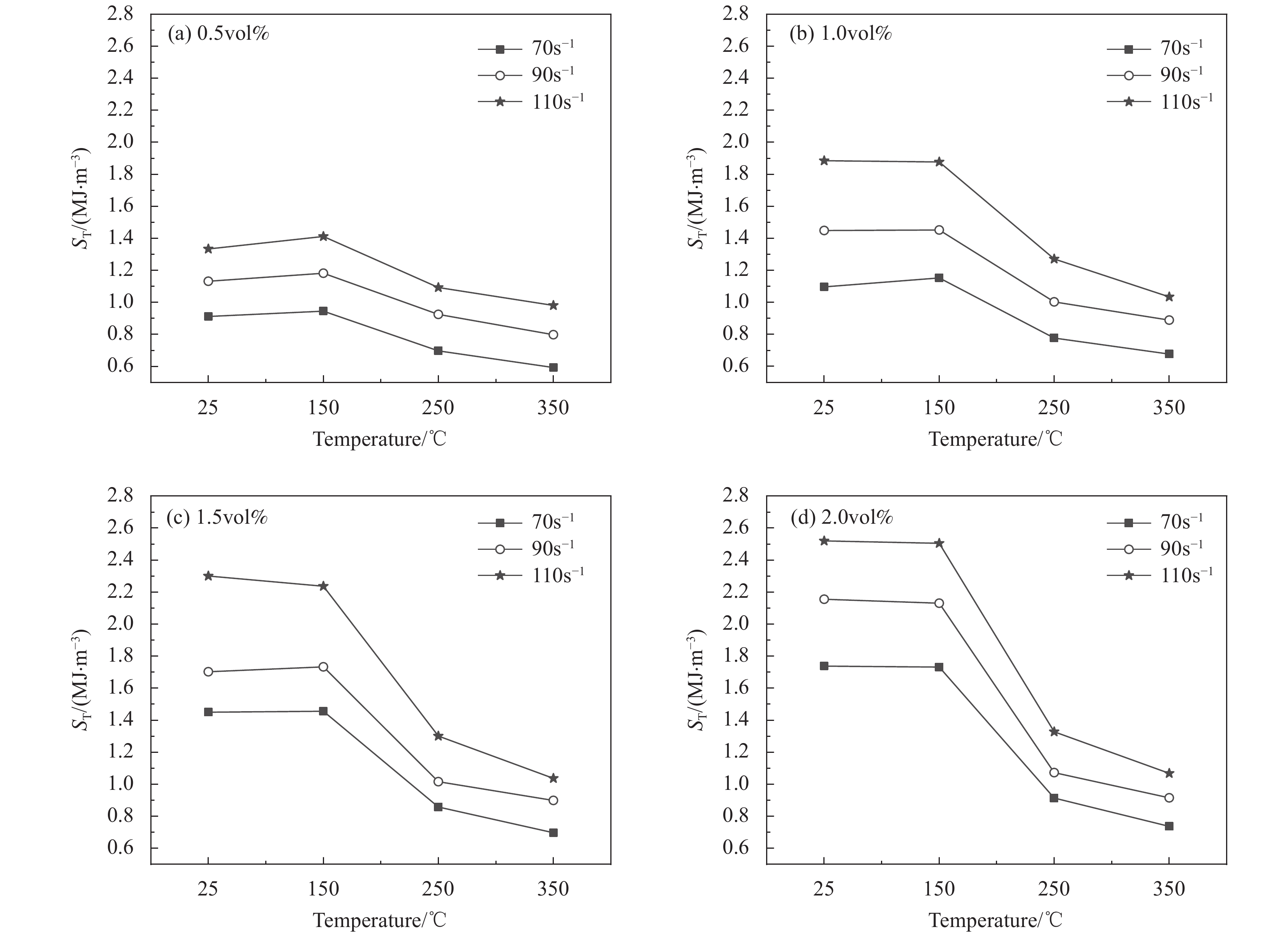

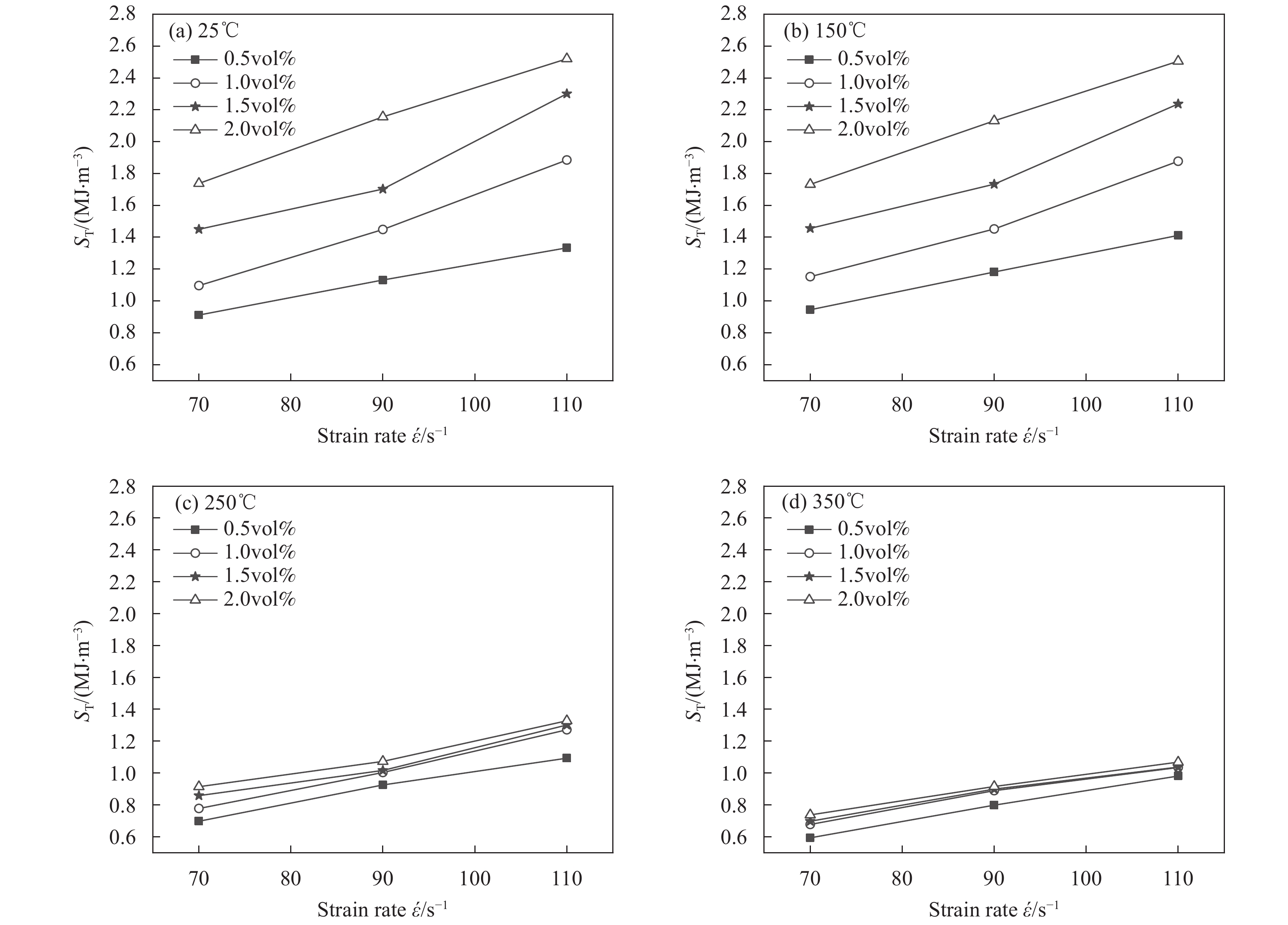

摘要: 为研究不同温度、不同聚乙烯醇(PVA)纤维体积掺量和不同应变率对高延性纤维增强水泥基复合材料(PVA/ECC)动态压缩性能的影响,采用直径50 mm分离式霍普金森压杆(SHPB),对高温浸水冷却后的PVA/ECC进行了冲击压缩试验,结果表明:当温度≥250℃,PVA/ECC试件冲击破坏后的整体性变差,应力-应变曲线更趋于扁平,其动态峰值应变提高不明显但动态峰值应力、冲击韧度显著降低,且高温对较大纤维体积掺量PVA/ECC动态峰值应力、冲击韧度的劣化效应更明显;温度≤150℃时,增大PVA纤维体积掺量,PVA/ECC动态峰值应力、峰值应变和冲击韧度均明显提高,但当温度≥250℃时,增大PVA纤维体积掺量,PVA/ECC动态峰值应变增大,而冲击韧度的提高幅度显著降低且动态峰值应力下降;高温水冷后的PVA/ECC仍具有明显的应变率效应,但温度≥150℃后,其抗压强度的应变率敏感性有所降低。

-

关键词:

- 高延性纤维增强水泥基复合材料 /

- 聚乙烯醇 /

- 分离式霍普金森压杆 (SHPB) /

- 温度 /

- 动态压缩性能

Abstract: In order to study the effects of different temperatures, different polyvinyl alcohol (PVA) fiber contents by volume and different strain rates on the dynamic compressive properties of engineered fiber reinforced cementitious composite (PVA/ECC), impact compression tests were conducted on PVA/ECC after the high-temperature and water-cooled by using a 50 mm diameter split Hopkinson compression bar (SHPB). The results show that when the temperature is greater than or equal to 250℃, the integrity of PVA/ECC specimens becomes worse after impact damage and the stress-strain curves tend to be flatter. The dynamic peak strain doesn’t increase obviously but the dynamic peak stress and impact toughness decrease remarkably. Furthermore, the deterioration effect of high temperature on the dynamic peak stress and impact toughness of PVA/ECC with larger fiber contents by volume is more obvious. When the temperature is less than or equal to 150℃, the dynamic peak stress, peak strain and impact toughness of PVA/ECC improve significantly with increasing the PVA fiber contents by volume. When the temperature is greater than or equal to 250 ℃, the dynamic peak strain increases with increasing the PVA fiber contents by volume, but the improvement extent of impact toughness reduces significantly and the dynamic peak stress decreases. PVA/ECC still has a significant strain rate effect after the high temperature and water-cooled. While when the temperature is greater than or equal to 150 ℃, the strain rate sensitivity of compressive strength reduces. -

-

表 1 聚乙烯醇(PVA)纤维性能

Table 1 Properties of polyvinyl alcohol (PVA) fiber

Diameter

/μmLength

/mmElasticity modulus

/GPaUltimate strain

/%Tensile strength

/MPaDensity

/(g·cm−3)39 12 42.8 7.0 1620 1.2 表 2 PVA/ECC试件拉伸试验结果

Table 2 PVA/ECC specimen tensile test results

Fiber volume fraction/vol% Ultimate tensile strain εtu/% Tensile strength ftu/MPa 0.5 0.42 3.01 1.0 1.64 3.64 1.5 2.81 4.16 2.0 3.21 4.44 表 3 PVA/ECC试件动态压缩试验结果

Table 3 Test results of PVA/ECC specimens under dynamic compression

Specimen Measured strain rate/s−1 fcu/MPa fc/MPa fcd/MPa εP/10−6 ST/(MJ·m−3) 0.5vol%PVA/ECC-25-70 74 43.47 35.30 52.9 6656 0.912 0.5vol%PVA/ECC -25-90 93 59.8 8200 1.132 0.5vol%PVA/ECC -25-110 110 70.9 8930 1.334 1.0vol%PVA/ECC -25-70 75 44.84 36.89 60.9 7420 1.097 1.0vol%PVA/ECC -25-90 96 69.1 8760 1.449 1.0vol%PVA/ECC -25-110 115 79.9 10630 1.885 1.5vol%PVA/ECC -25-70 71 45.80 37.56 68.0 10540 1.450 1.5vol%PVA/ECC -25-90 92 78.4 11020 1.703 1.5vol%PVA/ECC -25-110 111 87.8 12190 2.301 2.0vol%PVA/ECC -25-70 72 46.20 38.84 74.8 11240 1.738 2.0vol%PVA/ECC -25-90 93 85.1 13650 2.156 2.0vol%PVA/ECC -25-110 112 95.7 14760 2.520 0.5vol%PVA/ECC -150-70 72 45.40 37.20 55.9 6670 0.945 0.5vol%PVA/ECC -150-90 91 63.0 8360 1.182 0.5vol%PVA/ECC -150-110 112 74.9 9030 1.412 1.0vol%PVA/ECC -150-70 73 47.00 39.50 64.9 7550 1.153 1.0vol%PVA/ECC -150-90 89 74.0 8840 1.452 1.0vol%PVA/ECC -150-110 111 82.9 10750 1.877 1.5vol%PVA/ECC -150-70 72 50.10 40.60 71.8 10700 1.456 1.5vol%PVA/ECC -150-90 94 81.4 11160 1.733 1.5vol%PVA/ECC -150-110 113 90.9 12300 2.237 2.0vol%PVA/ECC -150-70 71 51.20 41.70 76.8 11450 1.732 2.0vol%PVA/ECC -150-90 91 89.1 13820 2.131 2.0vol%PVA/ECC -150-110 112 97.0 15100 2.505 0.5vol%PVA/ECC -250-70 73 38.20 31.50 44.8 6920 0.697 0.5vol%PVA/ECC -250-90 95 51.4 8430 0.925 0.5vol%PVA/ECC -250-110 112 58.0 9060 1.093 1.0vol%PVA/ECC -250-70 72 36.80 29.60 42.9 7540 0.777 1.0vol%PVA/ECC -250-90 95 47.1 8930 1.003 1.0vol%PVA/ECC -250-110 111 55.9 11240 1.271 1.5vol%PVA/ECC -250-70 72 35.70 28.50 40.9 10800 0.858 1.5vol%PVA/ECC -250-90 93 43.8 11250 1.016 1.5vol%PVA/ECC -250-110 115 53.1 12350 1.301 2.0vol%PVA/ECC -250-70 73 34.10 27.20 38.5 11460 0.914 2.0vol%PVA/ECC -250-90 91 41.4 14060 1.073 2.0vol%PVA/ECC -250-110 113 50.0 15160 1.328 0.5vol%PVA/ECC -350-70 74 34.60 28.30 38.1 7060 0.593 0.5vol%PVA/ECC -350-90 91 43.9 9140 0.798 0.5vol%PVA/ECC -350-110 112 52.1 9340 0.981 1.0vol%PVA/ECC -350-70 71 32.80 26.90 35.0 7900 0.677 1.0vol%PVA/ECC -350-90 92 39.9 9140 0.889 1.0vol%PVA/ECC -350-110 113 47.8 11260 1.034 1.5vol%PVA/ECC -350-70 72 31.20 25.20 33.3 11350 0.697 1.5vol%PVA/ECC -350-90 91 36.9 11560 0.899 1.5vol%PVA/ECC -350-110 115 44.8 12890 1.037 2.0vol%PVA/ECC -350-70 74 28.30 23.10 29.8 11950 0.737 2.0vol%PVA/ECC -350-90 95 33.1 14130 0.915 2.0vol%PVA/ECC -350-110 115 40.0 15480 1.068 Notes: 0.5vol%PVA/ECC-25-70 represents that the fiber content by volume of PVA/ECC specimen is 0.5vol%, the temperature is 25℃, and the design strain rate is 70 s−1; fcu—Cubic compressive strength of PVA/ECC; fc—Axial compressive strength of PVA/ECC; fcd—Dynamic peak stress of PVA/ECC; εP—Dynamic peak strain of PVA/ECC; ST— Impact toughness of PVA/ECC. -

[1] 赵昕, 徐世烺, 李庆华. 高温后超高韧性水泥基复合材料冲击破碎分形特征分析[J]. 土木工程学报, 2019, 52(2):44-55. ZHAO Xin, XU Shilang, LI Qinghua. Fractal characteristics of fire-damaged ultra high toughness cementitious composite after impact loading[J]. China Civil Engineering Journal,2019,52(2):44-55(in Chinese).

[2] 贾彬, 陶俊林, 李正良, 等. 高温混凝土动态力学性能的SHPB试验研究[J]. 兵工学报, 2009, 30(S2):208-212. JIA Bin, TAO Junlin, LI Zhengliang, et al. SHPB test for dynamic mechanical performances of concrete at high temperatures[J]. Acta Armamentarii,2009,30(S2):208-212(in Chinese).

[3] 任韦波, 许金余, 刘远飞, 等. 高温后玄武岩纤维混凝土冲击破碎分形特征[J]. 振动与冲击, 2014, 33(10):167-171, 188. REN Weibo, XU Jinyu, LIU Yuanfei, et al. Fractal characteristics of fragments of basalt fiber reinforced concrete after elevated temperatures under impact loading[J]. Journal of Vibration and Shock,2014,33(10):167-171, 188(in Chinese).

[4] GROTE D L, PARK S W, ZHOU M. Dynamic behavior of concrete at high strain rates and pressures: I. experimental characterization[J]. International Journal of Impact Engineering,2011,25(9):869-886. DOI: 10.1016/S0734-743X(01)00020-3

[5] THOMAS R J, SORENSEN A D. Review of strain rate effects for UHPC in tension[J]. Construction and Building Materials,2017,153:846-856. DOI: 10.1016/j.conbuildmat.2017.07.168

[6] ZHAI C, CHEN L, FANG Q, et al. Experimental study of strain rate effects on normal weight concrete after exposure to elevated temperature[J]. Materials and Structures,2017,50(1):40. DOI: 10.1617/s11527-016-0879-4

[7] 胡时胜, 王道荣, 刘剑飞. 混凝土材料动态力学性能的实验研究[J]. 工程力学, 2001, 18(5):115-118. DOI: 10.3969/j.issn.1000-4750.2001.05.015 HU Shisheng, WANG Daorong, LIU Jianfei. Experimental study of dynamic mechanical behavior of concrete[J]. Engineering Mechanics,2001,18(5):115-118(in Chinese). DOI: 10.3969/j.issn.1000-4750.2001.05.015

[8] 李志武, 许金余, 白二雷, 等. 高温后混凝土SHPB试验研究[J]. 振动与冲击, 2012, 31(8):143-147. DOI: 10.3969/j.issn.1000-3835.2012.08.028 LI Zhiwu, XU Jinyu, BAI Erlei, et al. SHPB test for post-high-temperature concrete[J]. Journal of Vibration and Shock,2012,31(8):143-147(in Chinese). DOI: 10.3969/j.issn.1000-3835.2012.08.028

[9] LI L, ZHANG R, JIN L, et al. Experimental study on dynamic compressive behavior of steel fiber reinforced concrete at elevated temperatures[J]. Construction and Building Materials,2019,210:673-684. DOI: 10.1016/j.conbuildmat.2019.03.138

[10] YANG Y K, WU C Q, LIU Z X, et al. Experimental investigation on the dynamic behaviors of UHPFRC after exposure to high temperature[J]. Construction and Building Materials,2019,227:116679. DOI: 10.1016/j.conbuildmat.2019.116679

[11] 杨少伟, 巴恒静. 钢纤维混凝土高温后SHPB试验研究[J]. 中国矿业大学学报, 2009, 38(4):562-565. DOI: 10.3321/j.issn:1000-1964.2009.04.020 YANG Shaowei, BA Hengjing. Split Hopkinson Bar measurements of steel fiber reinforced concrete exposed to high temperature[J]. Journal of China University of Mining & Technology,2009,38(4):562-565(in Chinese). DOI: 10.3321/j.issn:1000-1964.2009.04.020

[12] CHEN Z T, YANG Y Z, YAO Y. Impact properties of engineered cementitious composites with high volume fly ash using SHPB test[J]. Journal of Wuhan University of Technology-Materials Science Edition,2012,27(3):590-596. DOI: 10.1007/s11595-012-0511-6

[13] KAI M F, XIAO Y, SHUAI X L, et al. Compressive behavior of engineered cementitious composites under high strain-rate loading[J]. Journal of Materials in Civil Engineering,2017,29(4):541-548.

[14] 李艳, 张文彬, 刘泽军. PVA/ECC动态压缩性能研究[J]. 建筑材料学报, 2020, 23(3):513-520. LI Yan, ZHANG Wenbin, LIU Zejun. Study on dynamic compressive properties of PVA/ECC[J]. Journal of Building Materials,2020,23(3):513-520(in Chinese).

[15] 徐世烺, 陈超, 李庆华, 等. 超高韧性水泥基复合材料动态压缩力学性能的数值模拟研究[J]. 工程力学, 2019, 36(9):50-59. XU Shilang, CHEN Chao, LI Qinghua, et al. Numerical simulation on dynamic compressive behavior of ultra-high toughness cementitious-composites[J]. Engineering Mechanics,2019,36(9):50-59(in Chinese).

[16] 李庆华, 徐世烺. 超高韧性水泥基复合材料基本性能和结构应用研究进展[J]. 工程力学, 2009, 26(S2):23-67. LI Qinghua, XU Shilang. Performance and application of ultra-high toughness cementitious composite: A review[J]. Engineering Mechanics,2009,26(S2):23-67(in Chinese).

[17] 丁一, 陈小兵, 李荣. ECC材料的研究进展与应用[J]. 建筑结构, 2007, 37(S1):378-382. DING Yi, CHEN Xiaobing, LI Rong. The research and application of engineered cementitious composites[J]. Building Structure,2007,37(S1):378-382(in Chinese).

[18] 陈杨, 章红梅. 高延性纤维增强水泥基复合材料在建筑结构中的应用现状[J]. 结构工程师, 2017, 33(3):208-221. DOI: 10.3969/j.issn.1005-0159.2017.03.028 CHEN Yang, ZHANG Hongmei. State of the application of engineered cementitious composites in structure[J]. Structural Engineers,2017,33(3):208-221(in Chinese). DOI: 10.3969/j.issn.1005-0159.2017.03.028

[19] 王万鹏, 胡永乐, 林俊德, 等. 高应变率下混凝土准一维大变形压缩实验研究[J]. 兵工学报, 2010, 31(S1):246-250. WANG Wanpeng, HU Yongle, LIN Junde, et al. Experimental study on concrete under quasi-one-dimension large deformation compression in high strain rate[J]. Acta Armamentarii,2010,31(S1):246-250(in Chinese).

[20] 王礼立. 应力波基础[M]. 2版. 北京: 国防工业出版社, 2005: 8. WANG Lili. Foundation of stress waves [M]. 2nd edition. Beijing: National Defense Industry Press, 2005: 8(in Chinese).

[21] FREW D J, FORRESTAL M J, CHEN W. Pulse shaping techniques for testing brittle materials with a split Hopkinson pressure bar[J]. Experimental Mechanics,2002,42(1):93-106. DOI: 10.1007/BF02411056

[22] 商兴艳, 陆洲导. 冷却方式对高温后ECC力学性能的影响[J]. 湖南大学学报(自然科学版), 2015, 42(7):81-86. SHANG Xingyan, LU Zhoudao. Influence of cooling regimes on the mechanical properties of ECC after high temperatures[J]. Journal of Hunan University (Natural Sciences),2015,42(7):81-86(in Chinese).

[23] 田砾, 史建丽, 赵铁军, 等. 应变硬化水泥基复合材料高温后弯曲韧性研究[J]. 硅酸盐通报, 2015, 34(4):1011-1014. TIAN Li, SHI Jianli, ZHAO Tiejun, et al. Research on flexural toughness of strain hardening cementitious composites (SHCC) after high temperature[J]. Bulletin of the Chinese Ceramic Society,2015,34(4):1011-1014(in Chinese).

[24] 赖建中, 徐升, 杨春梅, 等. 聚乙烯醇纤维对超高性能混凝土高温性能的影响[J]. 南京理工大学学报, 2013, 37(4):633-639. LAI Jianzhong, XU Sheng, YANG Chunmei, et al. Influence of polyvinyl alcohol fibers on properties of ultra-high performance concrete at high temperature[J]. Journal of Nanjing University of Science and Technology,2013,37(4):633-639(in Chinese).

[25] 孙超杰. 极端温度下高韧性混凝土及其组合结构性能研究[D]. 杭州: 浙江大学, 2020. SUN Chaojie. Research on performance of ultra-high toughness cementitious composite and composite structures under extreme temperatures[D]. Hangzhou: Zhejiang University, 2020(in Chinese).

[26] 赵昕. 超高韧性水泥基复合材料动态力学性能试验与理论研究[D]. 杭州: 浙江大学, 2018. ZHAO Xin. Experimental and theoretical study on dynamic mechanical properties of ultra-high toughness cementitious composites[D]. Hangzhou: Zhejiang University, 2018(in Chinese).

[27] 彭宇, 赵昕, 徐世烺, 等. 高温后超高韧性水泥基复合材料的微观结构特征研究[J]. 电子显微学报, 2019, 38(3):236-244. DOI: 10.3969/j.issn.1000-6281.2019.03.005 PENG Yu, ZHAO Xin, XU Shilang, et al. Microstructure characteristics of ultra-high toughness cementitious composites after exposure to high temperature[J]. Journal of Chinese Electron Microscopy Society,2019,38(3):236-244(in Chinese). DOI: 10.3969/j.issn.1000-6281.2019.03.005

[28] 任韦波, 许金余, 白二雷, 等. 高温后玄武岩纤维增强混凝土的动态力学特性[J]. 爆炸与冲击, 2015, 35(1):36-42. DOI: 10.11883/1001-1455(2015)01-0036-07 REN Weibo, XU Jinyu, BAI Erlei, et al. Dynamic mechanical properties of basalt fiber reinforced concrete after elevated temperatures[J]. Explosion and Shock Waves,2015,35(1):36-42(in Chinese). DOI: 10.11883/1001-1455(2015)01-0036-07

[29] 杜曦, 陈有亮, 王苏然, 等. 喷水冷却对聚丙烯纤维混凝土高温后力学性能的影响[J]. 力学季刊, 2015, 36(1):148-155. DU Xi, CHEN Youliang, WANG Suran, et al. Effect of water spraying on post-high-temperature mechanical properties of polypropylene fiber concrete[J]. Chinese Quarterly of Mechanics,2015,36(1):148-155(in Chinese).

[30] LI Q M, MENG H. About the dynamic strength enhancement of concrete-like materials in a split Hopkinson pressure bar test[J]. International Journal of Solids and Structures,2003,40(2):343-360. DOI: 10.1016/S0020-7683(02)00526-7

[31] COTSOVOS D M, PAVLOVIĆ M N. Numerical investigation of concrete subjected to compressive impact loading. Part 1: A fundamental explanation for the apparent strength gain at high loading rates[J]. Computers and Structures,2008,86(1-2):145-163. DOI: 10.1016/j.compstruc.2007.05.014

-

期刊类型引用(2)

1. 李滋阳,王思佳,邓文举. 陶瓷颗粒增强金属基复合材料研究进展. 轻工科技. 2021(04): 41-44 .  百度学术

百度学术

2. 陈亚楠,金云学,牛牧野,陈洪美,杜文栋. Ni_3Al(Cr)合金室温干滑动摩擦磨损性能研究. 江苏科技大学学报(自然科学版). 2019(05): 18-26 .  百度学术

百度学术

其他类型引用(4)

-

下载:

下载: