Sandwich flexible strain sensor based on silver nanoparticles-polydopamine-carbon nanotube conductive material

-

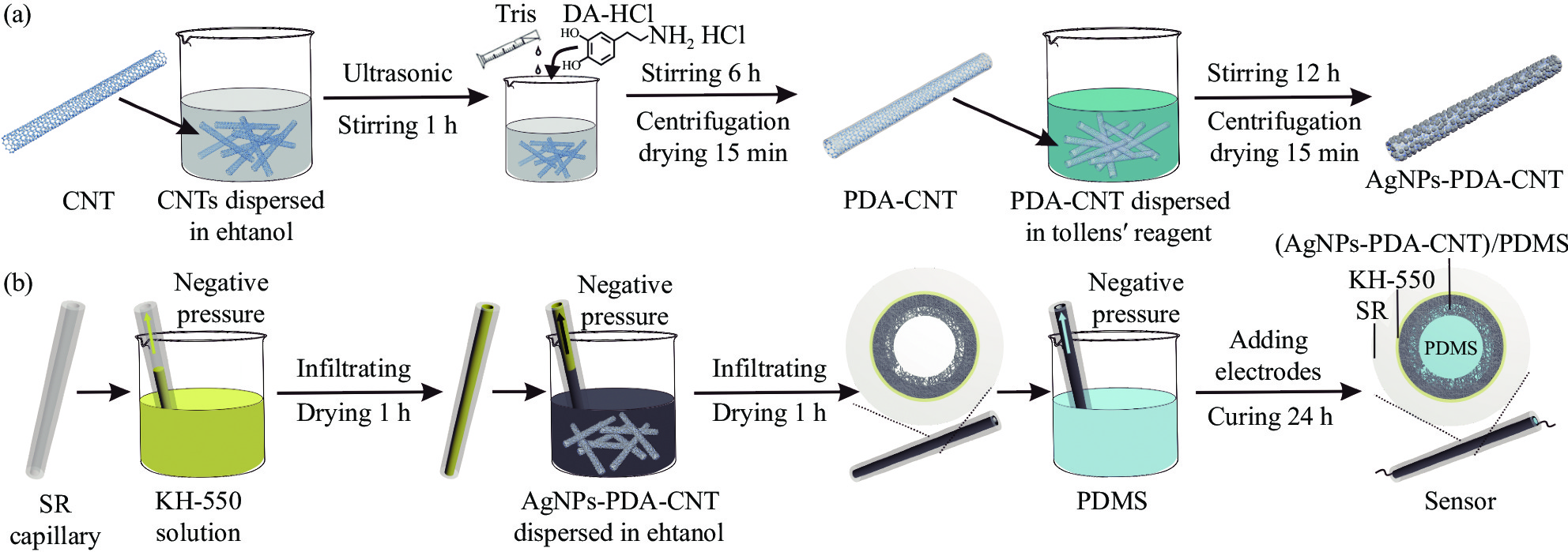

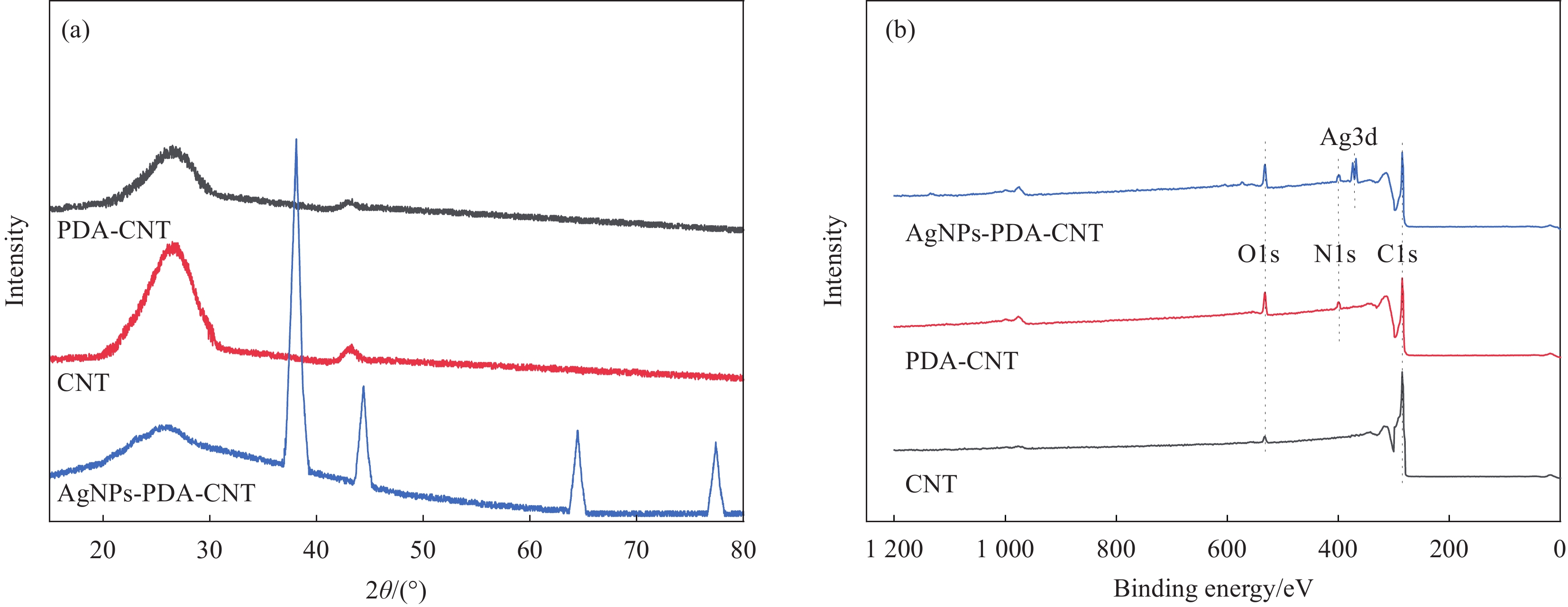

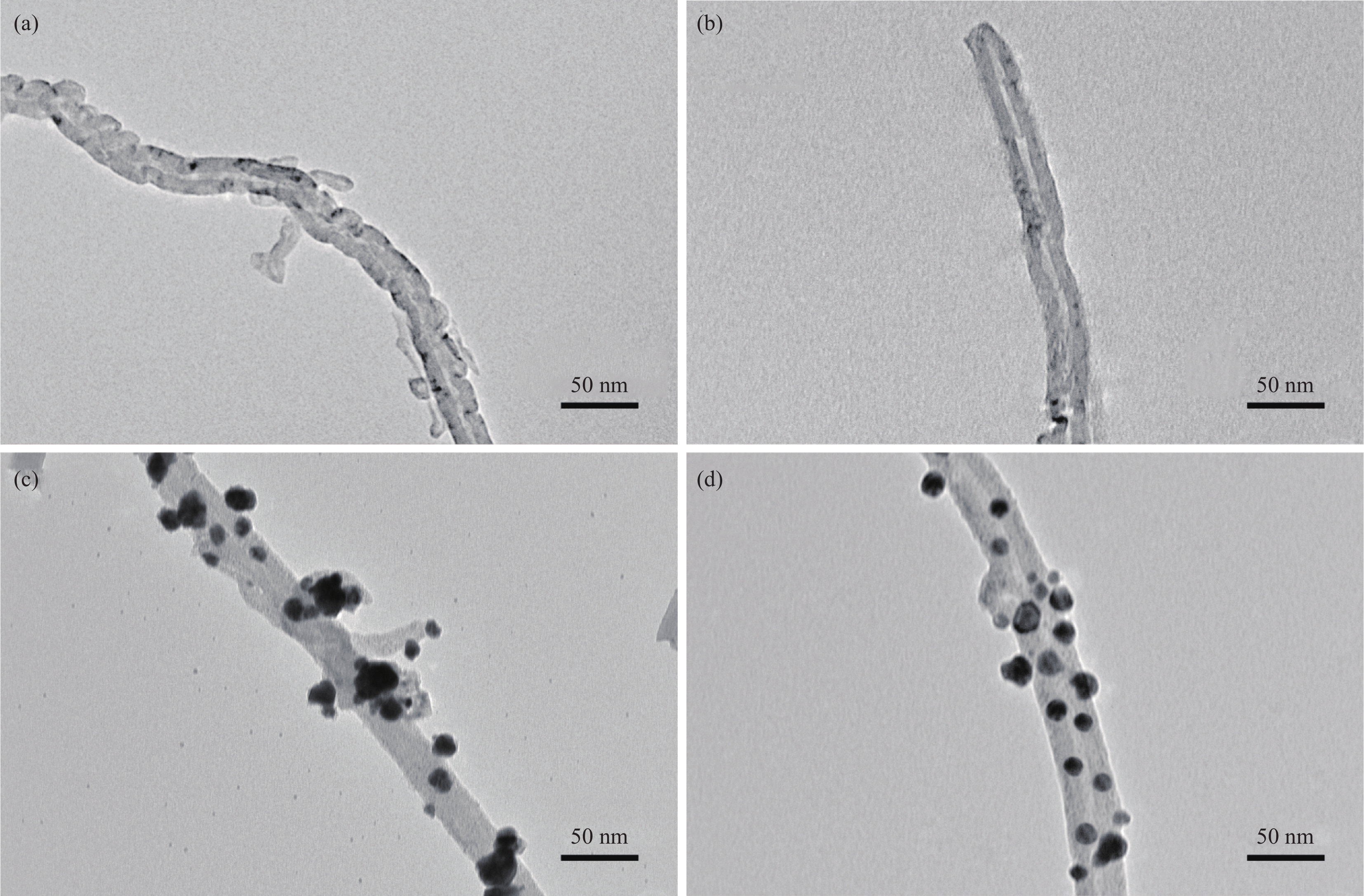

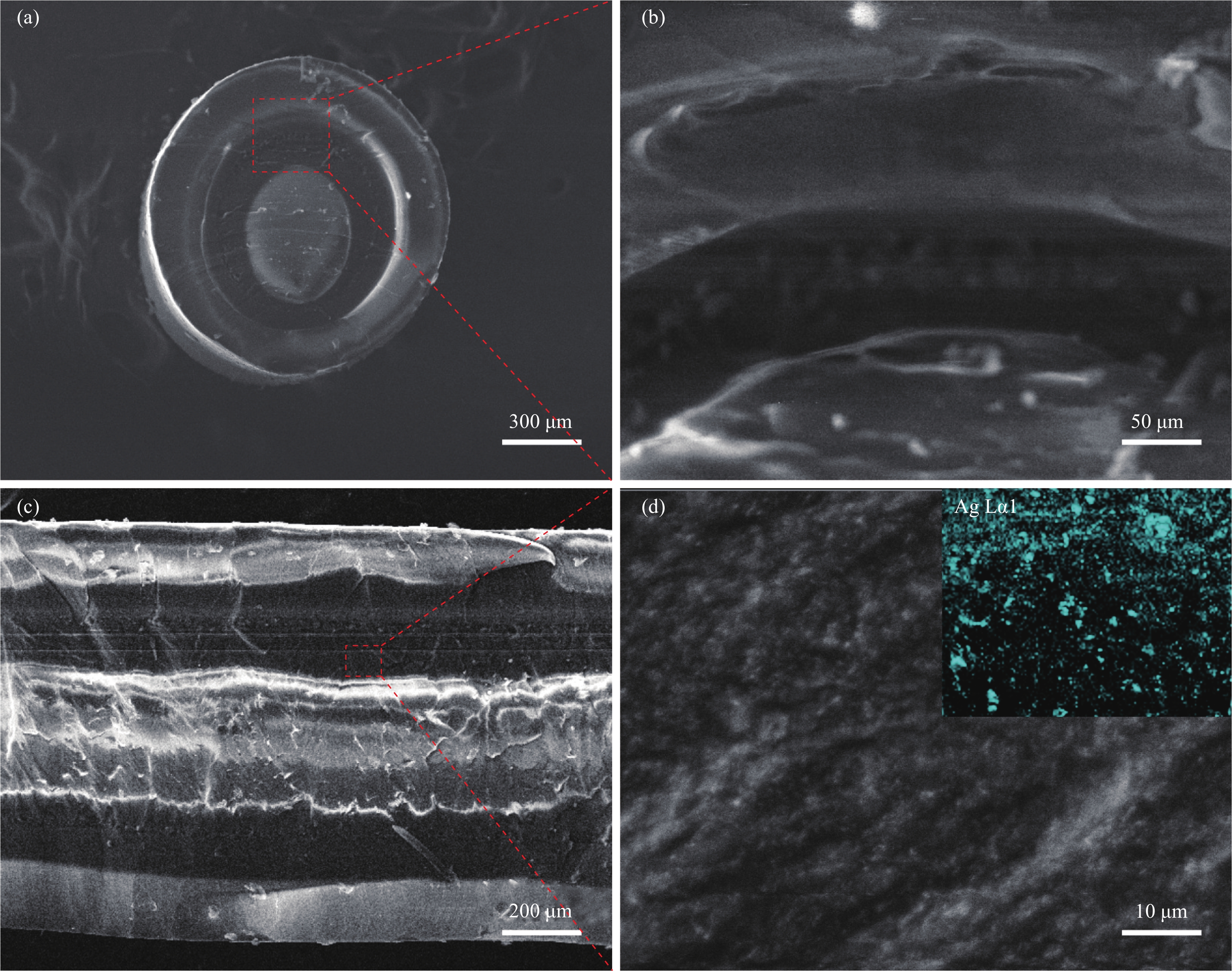

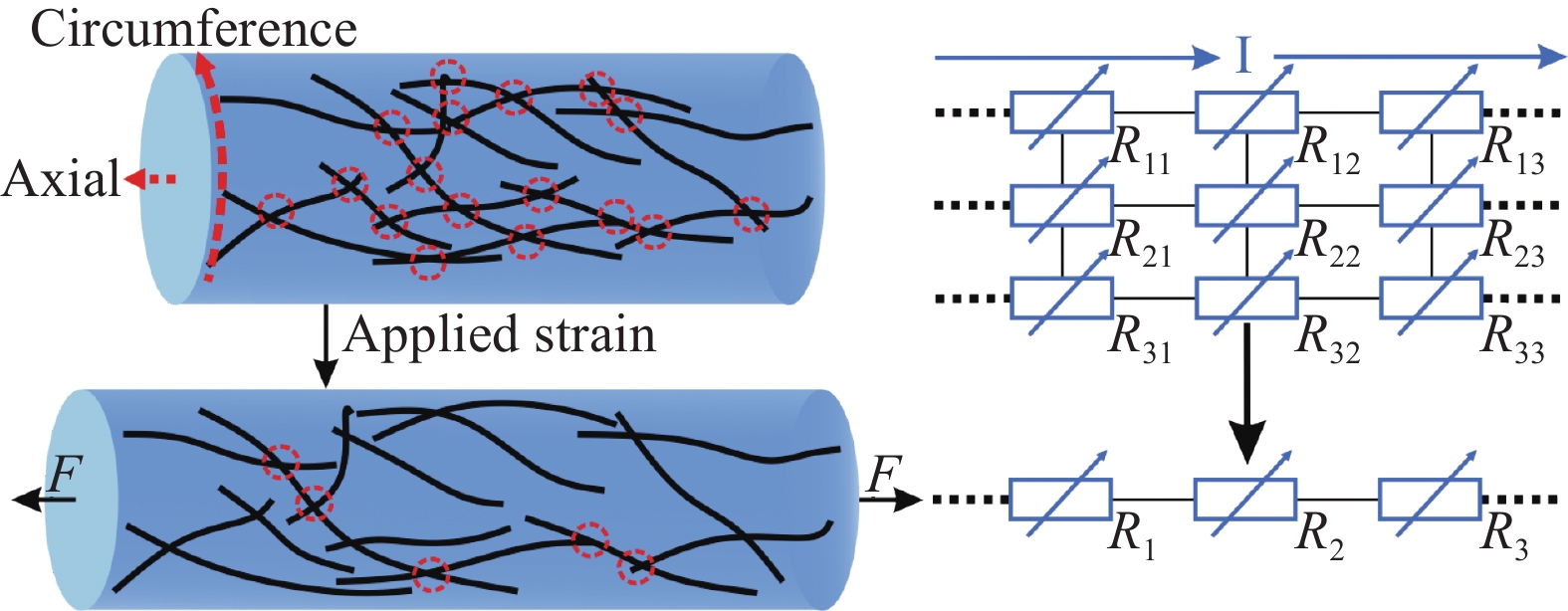

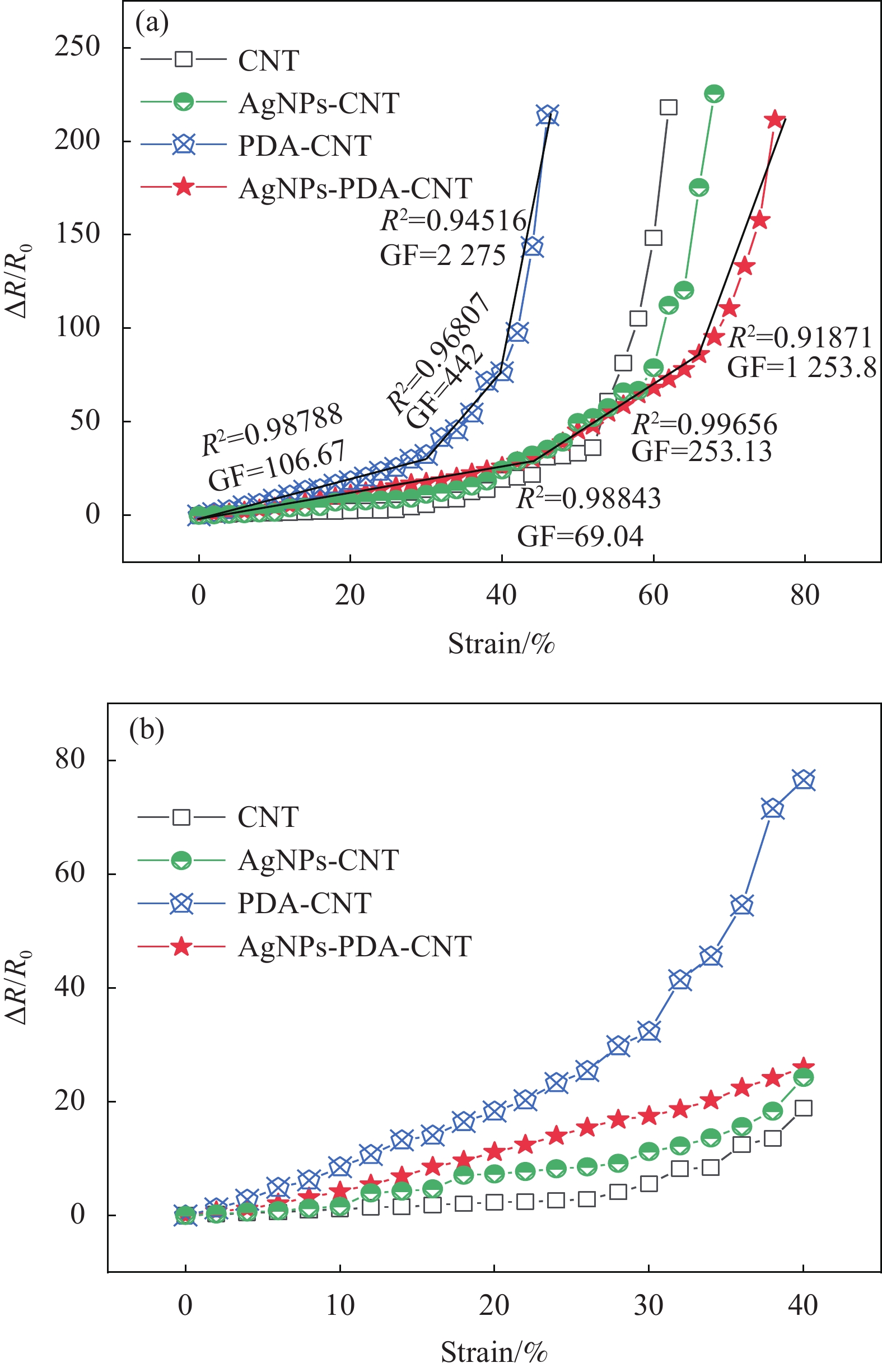

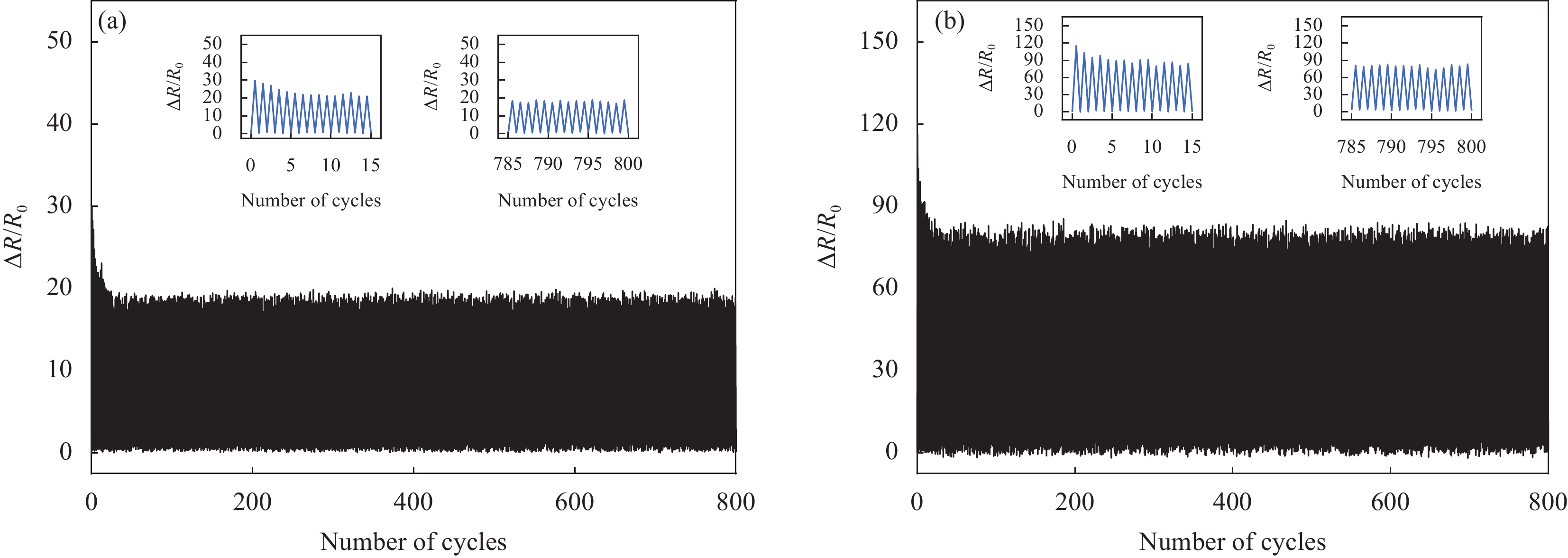

摘要: 着眼医疗保健、软机器人和人机交互等领域柔性应变传感器需兼备高灵敏和宽工作应变范围,本文设计基于纳米银颗粒-聚多巴胺-碳纳米管(AgNPs-PDA-CNT)的敏感材料体系,制备一种层层包覆型三明治结构柔性应变传感器。材料表征和特性测试结果表明:借助PDA黏附性和还原性,AgNPs均匀分散且固定在PDA-CNT表面。独特制备工艺使AgNPs-PDA-CNT导电材料紧密结合硅橡胶毛细管内壁和聚二甲基硅氧烷(PDMS),AgNPs-PDA-CNT渗入PDMS且浓度呈梯度分布。传感器具有高灵敏系数(GF)和宽工作应变范围(0%~44%时GF为69.04,44%~66%时GF为253.13,66%~76%时GF为1253.8)、快速响应(75 ms)和恢复(90 ms)、良好稳定性和重复性。将传感器应用于人体运动精确监测、软体手指本体感知与软抓手抓取行为监测,取得良好应用效果。Abstract: Since flexible strain sensors require high sensitivity and a wide strain range in healthcare, soft robotics and human-computer interaction, this work designed a flexible strain sensor based on silver nanoparticles-polydopamine-carbon nanotubes (AgNPs-PDA-CNT) sensitive material system, and prepared a layer coated sandwich structure flexible strain sensor. The results of material characterization and property test showed that AgNPs were uniformly dispersed and fixed on the surface of PDA-CNT by virtue of PDA adhesion and reducibility. The AgNPs-PDA-CNT conductive material is closely bonded to the inner wall of silicone rubber capillary tube and polydimethylsiloxane (PDMS). AgNPs-PDA-CNT penetrates into PDMS and the concentration is in gradient distribution. The sensor has high sensitivity coefficient (GF) and wide strain range (69.04 when 0%-44%, 253.13 when 44%-66%, 1253.8 when 66%-76%), fast response (75 ms) and recovery (90 ms), good stability and repeatability. The sensor is applied to human motion monitoring, soft finger ontology sensing and soft grasping behavior monitoring, and good application results are achieved.

-

Keywords:

- strain sensor /

- carbon nanotubes /

- polydopamine /

- silver nanoparticles /

- polydimethylsiloxane /

- flexible

-

作为影响混凝土结构耐久性的常见因素之一,碱-硅酸反应(ASR)是骨料中某些矿物与混凝土孔隙溶液中碱羟基(K+、Na+、OH–)之间的化学反应[1]。在碱性溶液中,亚稳硅与碱反应形成的有害凝胶,具有亲水性和可膨胀性。当内部的膨胀应力达到一定程度时,混凝土便形成裂缝,从而很大程度上降低了构件的力学性能与使用寿命[2]。碱活性骨料在世界各地广泛分布且曾被大量使用,已有多处桥梁、大坝、建筑物结构遭受ASR破坏[3]。在使用碱活性骨料的混凝土结构中,一定环境条件下,骨料的活性水平越高,混凝土的膨胀破坏程度往往越大[4]。

近年来,由于环保层面的严格管控等,混凝土骨料出现资源供应不足的趋势[5-7]。同时由于经济和时效性等因素,在一些缺乏优质砂石骨料的特殊地区,无法避免使用有潜在碱活性的骨料浇筑混凝土结构。因此,探索抑制ASR的有效方法具有重要研究价值与意义。已有研究表明,粉煤灰和其他辅助胶凝材料(SCMs)可以影响混凝土内部离子的流动,降低内部的碱性和相对湿度,从而抑制ASR的发生[8-9]。例如,Tapas等[10]研究表明,利用25wt%粉煤灰改性的混凝土具有良好的抗ASR反应性能。Abbas等[11]发现掺入10wt%和40wt%的甘蔗渣灰(SBA)时,砂浆棒膨胀率分别降低了20%和40%。高鹏等[12]研究表明,复掺废旧轮胎橡胶粉(WRP)和硅灰(SF)可以有效抑制ASR。上述外掺方法对ASR有一定的抑制效果,然而有研究表明内掺SCMs会导致结构的早期强度低、抗开裂能力差等缺陷[13-14]。

近年来,微生物诱导碳酸钙沉淀(MICP)技术受到了越来越多的关注,其在防腐与控制、地基改良、自修复生物建筑材料及再生骨料强化等方面有着广泛的研究[15-22]。Liu等[23]探讨了MICP处理生物砖表面对其综合性能的影响,发现经MICP多次处理的生物砖抗侵蚀性能大幅度提升,且抗弯强度有小幅增长。花素珍等[24]利用再生骨料固载混菌对混凝土进行自修复处理,表明矿化后再生骨料吸水率和压碎指标分别降低了27%和20%,混凝土裂缝修复率达到60%以上,且抗压强度提高了12.9%。Wang等[25]利用MICP处理再生骨料以改善其界面过渡区,发现再生骨料因MICP生成的CaCO3附着促使其质量增加了12%,吸水率降低了33%。

综上所述,目前关于MICP对建筑材料在抗渗透性能、骨料界面增强及混凝土裂缝修复等方面的影响,已经开展了大量研究[26-28]。对于碱活性骨料而言,MICP可能会在活性骨料及由其制成的混凝土或砂浆表面形成CaCO3层,有可能会阻止碱性离子和水的入侵,从而贡献于ASR的抑制,这值得深入的探索。然而目前关于利用MICP抑制ASR的研究鲜有报道。

因此,本文利用MICP分别对潜在活性骨料(锦屏砂岩)及由其制成的砂浆棒进行表面矿化处理,以确定MICP不同的处理方式及次数对抑制ASR的影响规律。为进一步探讨MICP的作用机制,利用SEM、EDS及XRD等手段对不同处理次数的试件在碱激发后开展了微观分析。上述研究旨在为碱活性骨料在实际工程中的资源化利用,缓解混凝土砂石资源的紧张趋势提供一定的理论依据。

1. 试验材料及方法

1.1 原材料的制备

本文采用细胞外形呈杆状的巴氏芽孢杆菌(Sporosarcina pasteurii DSM 33)开展微生物矿化作用。菌种购于中国普通微生物菌种保藏管理中心,以冻干粉状态保存于真空干燥的安瓿瓶内。液体培养基由20 g/L的酵母提取液、15 g/L的NH4Cl、0.1 mmol/L的NiCl2、10 mol/L的NaOH溶液和蒸馏水组成;配制后的培养基溶液pH值为9.25左右,为巴氏芽孢杆菌适宜的生长环境[29]。处理砂浆棒时胶结液的组成为1 mol/L的尿素(提供CO3 2−)和1 mol/L的醋酸钙溶液(提供Ca2+);处理活性骨料时,为达到更好的沉积效果,分别采用2 mol/L。细菌培养完成后采用电导率法[30]测得脲酶活性介于20~25 U/mL。利用分光光度计测定细菌溶液在600 nm波长处光密度(OD600)值为4.0,换算相应细胞浓度为5.68×108 cells/mL。

选取主要由微晶石英组成、根据砂浆棒快速法所得28 天膨胀率为0.28%的锦屏砂岩作为研究对象。砂浆棒制作时骨料的粒度分布见表1,水泥采用P·O 42.5级普通硅酸盐水泥。试件的具体配合比见表2。

表 1 骨料粒度级配表Table 1. Grain size distribution of aggregates usedSize/mm 2.5-5 1.25-2.5 0.63-1.25 0.315-0.63 0.16-0.315 Mass/wt% 10 25 25 25 15 表 2 试件砂浆配合比Table 2. Design of mortar proportion for specimenCement/g Water/g Aggregate/g

(Before MICP)Size/(mm3) Purpose 450 225 1350 40×40×160 Measuring mechanical properties 400 188 900 25.4×25.4×285 Measuring expansion rate Notes: The total CaCO3 deposition on the aggregate surface increased by approximately 1.9% per two treatments;MICP—Microbial induced calcium carbonate precipitation. 1.2 MICP处理方法

对于处理砂浆棒表面的试件,本文利用原状活性骨料分别制作表2所示砂浆棒试件,其处理方式如图1(a)中的(1)所示。首先将标准养护1天的试件表面残余水分擦拭干净,然后在试件的6个表面均匀喷淋细菌溶液,静置15 min后将试件置入胶结溶液中24 h,以使其充分发生反应,以上步骤定义为一次处理。关于直接对活性骨料处理的方式(图1(a)中的(3)),将MICP溶液(体积比为1∶1的细菌及胶结溶液的混合液)完全浸没骨料24 h定义为一次处理;为了在骨料表面形成均匀覆盖的CaCO3层,每次处理后,将骨料从容器中取出,随机重新混合并再次装入容器中开展下一次处理。参考相关研究对MICP生成CaCO3含量的设置[31-32],并综合考虑其对处理效果的影响,本文设置如表3所示的处理次数。

表 3 试件参数Table 3. Details of specimensNo. Number of processes MICP processing objects Processing time point Curing method Content of analysis Control 0 — — 80℃ in 1 mol/L

NaOH solutionMechanical properties,

expansion rate,

microanalysisB1 1 Mortar bars made from original

reactive aggregatesAfter pouring B2 2 B3 3 A2 2 Reactive aggregates Before pouring A4 4 A6 6 Notes: Control is the untreated standard group; B represents the MICP treatment of mortar bar surface; A represents the treatment of aggregate surface, and the number of processes represents the treatment times. 处理完成后,为去除砂浆/骨料表面残留的溶液及未充分粘结的CaCO3沉淀,参照Zhang等[33]处理方法,用流水充分冲洗试样表面。

1.3 CaCO3含量测定

如图1(b)所示,为评估MICP处理砂浆棒时在其表面生成CaCO3的效率,将MICP处理前及处理完成后的试件先后置于干燥环境中,测量恒定质量,CaCO3沉积量可由下式求得:

S=S1−S0S0×100% (1) 式中:S为砂浆棒的CaCO3沉积量占比(%);S0为试件初始质量(g);S1为试件处理后质量(g)。

为评价MICP处理骨料时表面CaCO3的沉积量,将处理后的骨料随机取出约10 g,取样3次,在80℃的烘箱中烘干至恒重。同时,由表4可知,锦屏砂岩骨料主要由SiO2和Al2O3组成,与稀盐酸不反应或反应较慢。此外,根据前期验证试验,发现在短时间内将未处理骨料浸泡于稀盐酸溶液中不会明显改变骨料质量。因此,用1 mol/L的稀盐酸溶解表面的CaCO3涂层[34-35],并干燥24 h至恒重。最后由下式得到骨料表面CaCO3沉积量:

M=M1−M0M0×100% (2) 式中:M为骨料的CaCO3沉积量占比(%);M1为MICP处理后的骨料质量(g);M0为酸洗去除CaCO3涂层后的骨料质量(g)。

表 4 锦屏砂岩的化学成分(wt%)Table 4. Chemical composition of Jinping sandstone (wt%)Materials SiO2 Al2O3 CaO Fe2O3 K2O Na2O Others Jinping sandstone 63.62 16.55 7.93 4.41 2.81 2.49 2.19 1.4 力学性能及膨胀率测定

参照规范GB/T 17671—2021《水泥胶砂强度检验方法(ISO法)》[36],依据试验配比(表2)制备尺寸为40 mm×40 mm×160 mm的标准三联胶砂试件,用于测定力学性能。参照规范DL/T 5151—2014《水工混凝土砂石骨料试验规程》[37],制备尺寸为25.4 mm×25.4 mm×285 mm的砂浆棒试件,放置于碱骨料养护箱中,注入由NaOH (分析纯)配制的1 mol/L碱激发溶液,并控制溶液温度为80℃。分别于第3、7、14及28天利用比长仪测量试样长度,根据式(3)计算膨胀率。每次进行3组平行试验,结果取平均值。

εt=Lt−L0L0−2Δ×100% (3) 式中:εt为砂浆棒试件第t天的膨胀率(%);Lt为砂浆棒试件第t天的长度(mm);L0为砂浆棒试件的基准长度(mm);Δ为膨胀测头的长度(mm)。

1.5 微观试验

采用BRUKER生产D8 ADVANCE型X射线衍射仪(XRD)分析碱激发28天后骨料表面的物相组成,在20°~70° (2θ)范围内以5°/min的速度对样品进行扫描。同时,采用日立产S-3400N型扫描电镜(SEM-EDS),为保证电镜成像清晰且结果准确,试验选用表面平整的骨料,将其烘干后喷金处理。通过对碱活性骨料显微观察以分析其在MICP处理后的形貌变化。采用EDS测试产物的元素组成,分析MICP抑制ASR的规律和机制。

2. MICP抑制ASR的结果分析

2.1 MICP处理砂浆棒抑制ASR的试验结果分析

2.1.1 MICP处理次数对砂浆棒表面CaCO3沉积量的影响

表5和图2分别展示了经MICP多次处理后砂浆棒表面的CaCO3含量及其表观形貌。由图2可知,与未处理试件Control组相比,经MICP处理后,可以在试件表面清晰地观察到白色CaCO3涂层,且涂层材料随着处理次数的增多变得更加致密;当处理3次时,试件表面几乎已被CaCO3 沉淀层完全覆盖。由此得出,浸泡法处理砂浆棒试件的CaCO3含量应该与处理次数密切相关。由表5可见,每次MICP处理将平均生成含量约为砂浆棒质量2.4%的CaCO3沉积。

表 5 CaCO3在砂浆棒表面的质量比Table 5. Mass ratio of CaCO3 on the surface of mortar barNo. Processing times S0/g S1/g S2/g S/% B1 1 601.86 617.45 15.59 2.59 B2 2 603.52 632.67 29.15 4.83 B3 3 601.31 644.84 43.53 7.24 Notes: S0—Initial mass of specimen; S1—Mass of specimen after treatment; S2—Calculated content of CaCO3; S—Percentage of CaCO3 deposits in mortar bars. The data in the table are the average values obtained from three parallel specimens. 2.1.2 MICP处理砂浆棒对试件膨胀率及力学性能的影响

处理砂浆棒后碱激发时间与膨胀率之间的关系如图3(a)所示。由图可知,在碱激发前3天中,不同组别的膨胀率均略有增加且相差不大,这可能是由于锦屏砂岩属于慢活性骨料[38-39],膨胀率在前3天受碱激发影响较小,此时的膨胀作用主要由高温养护引起。然而,随着碱激发时间的增加,砂浆棒膨胀率逐渐变大。28天时,Control组膨胀率约为0.28%,而MICP处理3次的B3试件膨胀率仅为0.182%。与Control组相比,B1、B2、B3的膨胀率分别降低了约3.2%、27.9%和35.0%。

试件的力学性能也出现了上述类似的变化趋势。如图3(b)和图3(c)所示,在碱激发28天后,Control组的力学性能为最低,其抗压和抗折强度为22.5 MPa 和5.4 MPa,相比之下,经MICP处理的B1、B2和B3组抗压强度分别提升了约1.8%、11.1%和13.8%,抗折强度分别增加了约1.9%、13.0%和13.0%。

上述结果表明,MICP浸泡处理砂浆棒可以有效抑制ASR,且处理次数越多,抑制效果愈发明显。原因推测如下,经MICP处理的试件表面所附着的致密CaCO3层减少了外界碱性离子及水溶液的侵入,抑制了内部ASR凝胶的生成,从而减少了内部的膨胀损伤。但是,由于砂浆棒表面处理无法阻碍砂浆内部碱性溶液与活性骨料间的反应,且试件表面的CaCO3层随时间的推移可能会有一定程度的脱落,对于性能的提升可能存在一定的限度。因而,在后述章节中将探讨MICP直接处理活性骨料表面对抑制ASR程度的影响。

2.2 MICP处理骨料抑制ASR的试验结果分析

2.2.1 MICP处理次数对骨料表面CaCO3沉积量的影响

不同处理次数下骨料表面CaCO3沉积状况如表6和图4所示,随着新鲜MICP混合液的加入,骨料颗粒表面出现清晰可见的白色CaCO3涂层。随处理次数的增多,骨料表面的CaCO3沉积覆盖范围逐渐扩大,且厚度逐渐增加。从表6可以看出,CaCO3的含量与处理次数成正比,浸泡法每次处理形成的平均CaCO3含量约为骨料质量的0.96%。

表 6 骨料表面CaCO3质量占比Table 6. Mass proportion of CaCO3 on the aggregate surfaceNo. Processing times M0/g M1/g M2/g M/% A2 2 9.89 10.08 0.19 1.94 A4 4 9.70 10.06 0.36 3.80 A6 6 9.58 10.13 0.55 5.74 Notes: M0—Mass of aggregate after acid washing; M1—Mass of aggregate after MICP treatment; M2—Calculated content of CaCO3; M—Percentage of CaCO3 deposited in the aggregate. The data in the table are the average values obtained from three parallel samples. 2.2.2 MICP处理骨料对试件膨胀率及力学性能的影响

图5(a)给出了各组试件膨胀率与碱激发时间的关系。由图可知各组变化趋势及相互之间的差异趋势与处理砂浆棒工况类似。碱激发前3天内,膨胀率增长较慢且不同处理次数组别之间差距较小,原因同样考虑为该时间段高温比ASR引起的膨胀更显著所致。随碱激发时间的推移,膨胀率增长速率明显加快,各组之间差异愈加明显。28天时,A2、A4和A6较Control组膨胀率分别下降了约13.9%、43.6%和59.6%。

图5(b)和图5(c)展示了力学性能与碱激发天数之间的关系。由图可知,相较Control组,MICP的处理促使抗压与抗折强度有明显的提升,且提升幅度与处理次数成正相关。28天时,A6组别抗压及抗折强度可达28.2 MPa及6.7 MPa,相比Control组分别提升了约25.3%和24.1%。与本试验相比,Abbas等[11]研究表明含有40wt%甘蔗渣灰的砂浆试件,使ASR膨胀率降低了40%,但抗压强度同样降低了44.7%;此外,刘刚[40]的研究表明,掺入 30wt%Al2O3的混凝土试件,使ASR膨胀率降低了16.8%,而抗压强度却降低了37.3%。然而,本文的MICP处理方式在更好抑制膨胀率的同时,可以有效提升力学性能。

由上述试验结果可知,MICP处理骨料与砂浆棒两种方式均表现出对ASR的抑制作用,但随处理次数的增多,两种方式的抑制效果不尽相同,具体的数据对比及机制分析将在后续章节中详细探讨。

2.3 MICP处理方式对ASR抑制效果的影响

分别通过对潜在活性骨料表面处理(A处理)及砂浆棒表面处理(B处理)探讨了MICP对ASR的抑制效果。图6为CaCO3含量对相对膨胀率及抗压强度增长率的影响。由图6(a)可知,两种处理方式均可以有效抑制ASR,且CaCO3的沉积量越多,抑制效果越好。为进一步探讨膨胀率及力学性能随CaCO3含量变化的规律,图6(b)展示了数据的拟合关系。由图可知,砂浆的相对膨胀率与 CaCO3含量呈高度负相关,A与B处理方式下相对膨胀率的拟合公式分别为式(4)与式(5)。

Exp.(A)=0.40+14.9424.90+(CaC.(A))3,R2=0.97 (4) Exp.(B)=0.65+20.6058.86+(CaC.(B))3,R2=0.93 (5) 式中:Exp.(A/B)表示A(B)处理方式下试件的相对膨胀率(处理组与对照组膨胀率之比);CaC.(A/B)表示A(B)处理方式下CaCO3的沉积量占比;R2表示决定系数。

力学性能,如抗压强度增长率与CaCO3含量呈高度正相关,A处理与B处理方式下,抗压强度增长率拟合关系分别为式(6)和式(7):

Com.(A)=0.25−4.9219.68+(CaC.(A))3,R2=0.98 (6) Com.(B)=0.14−7.8055.74+(CaC.(B))3,R2=0.94 (7) 式中,Com.(A/B)表示A(B)处理方式下试件的抗压强度增长率。

如图6(b)所示,对比A与B两种方式处理效果可知,在同等CaCO3含量下,A处理方式的抗压强度增长率曲线始终位于B的上方,且相对膨胀率始终在B的下方。这表明,MICP直接处理骨料拥有更好的ASR抑制效果,相关机制探讨等将在第3章中展开。

3. 微观分析及机制探讨

为探讨MICP抑制ASR的机制,开展了微观结构及成分分析。以未处理(Control)和处理6次(A6)骨料表面的SEM结果为例,Control组骨料表面可以观察到不规则形状的凝胶产物,且部分产物已凝结成颗粒状,如图7所示。然而,经MICP处理6次后骨料表面表现出清晰的凝固和较小不规则形状的晶体簇。

通过EDS进一步表征了骨料表面的化学成分,如表7中分析结果所示,推测EDS光谱的Si、Na和O元素主要来自于ASR凝胶[41-43]。同时,与文献[12, 44]研究结果类似,可以发现未处理骨料表面物质XRD图谱中没有明显的衍射峰。这是由于碱-硅酸凝胶为非晶态物质,没有明确的晶面[45]。然而,经MICP处理的骨料表面,其Ca元素占比明显增加,且存在C和O元素,表征了骨料表面存在CaCO3晶体。进一步从处理骨料表面的XRD图谱(图8(b))可以证实表面的CaCO3晶体以方解石和球霰石的形式存在[46]。

表 7 碱激发28天时骨料表面EDS元素的原子比例Table 7. Atomic proportion of EDS elements on aggregate surface at 28 days of alkali activationNo. K/at% C/at% O/at% Na/at% Al/at% Si/at% Au/at% Ca/at% Control 1.52 — 44.34 9.35 3.24 34.49 3.03 4.03 A2 — 10.74 37.01 5.79 1.91 27.21 0.71 15.63 A4 — 13.54 42.93 3.04 0.97 18.24 1.99 19.29 A6 — 18.70 44.46 1.04 0.63 10.48 1.17 23.52 值得注意的是,随着处理次数的增多(表7 EDS结果),Si和Na元素原子比例分别从34.49at%和9.35at%减少至10.48at%和1.04at%,Ca元素原子比例从4.03at%增加至23.52at%。这表明经MICP处理形成的CaCO3层对ASR凝胶的形成产生了显著的抑制作用。另外,关于本文中两种MICP处理方式之间抑制效果的区别,推测机制为:与经MICP处理后的骨料相比,直接对砂浆棒表面处理时无法阻碍内部微孔溶液中碱性离子和水与骨料中活性SiO2之间发生反应,致使MICP处理砂浆棒的ASR抑制效果相较直接处理骨料不够显著,如图9所示。

4. 结 论

本文探讨了微生物诱导碳酸钙沉淀(MICP)在不同处理方式及处理次数下抑制活性骨料碱-硅酸反应(ASR)的规律与机制,主要结论如下:

(1) 碱激发的试验结果表明,与MICP处理方式无关,MICP处理的次数越多,对ASR抑制的效果越好。直接处理活性骨料时,随处理次数从2次增加至6次,28天抗压、抗折强度分别提升了约16.5%和15.5%,膨胀率降低了约53.1%;

(2) 与MICP处理砂浆棒表面的方式相比,MICP直接处理骨料表面的抑制效果更优。当砂浆棒表面处理3次时(CaCO3沉积量占比为7.24%),28天抗压、抗折强度相比对照组分别提升了约13.8%、13.0%,膨胀率降低了35%。当活性骨料处理6次时(CaCO3沉积量占比为5.74%),抗压、抗折强度相比对照组分别提升了约25.3%、24.1%,膨胀率下降了59.6%;

(3) 经SEM、EDS及XRD分析可知,与对照组相比,对骨料进行MICP处理后其表面生成的CaCO3晶体(方解石和球霰石)明显增多,导致ASR凝胶数量显著减少。直接对骨料进行处理时,其表面覆盖的CaCO3紧密连接,可以有效阻断孔隙中已有及外部侵入的碱性离子和水分与活性SiO2之间的反应,与处理砂浆棒时仅能阻隔外部离子相比,有更优的ASR抑制效果。

-

图 6 各导电材料对传感器的应变与相对电阻的全程(a) 和40%应变内 (b) 变化关系比较

Figure 6. Comparison of strain and relative resistance of conductive material to sensor in the whole process (a) and within 40% strain (b)

R0—Initial resistance; ΔR/R0—Amount of change in relative resistance due to strain; R2—Fit coefficient; GF—Sensitivity coefficient

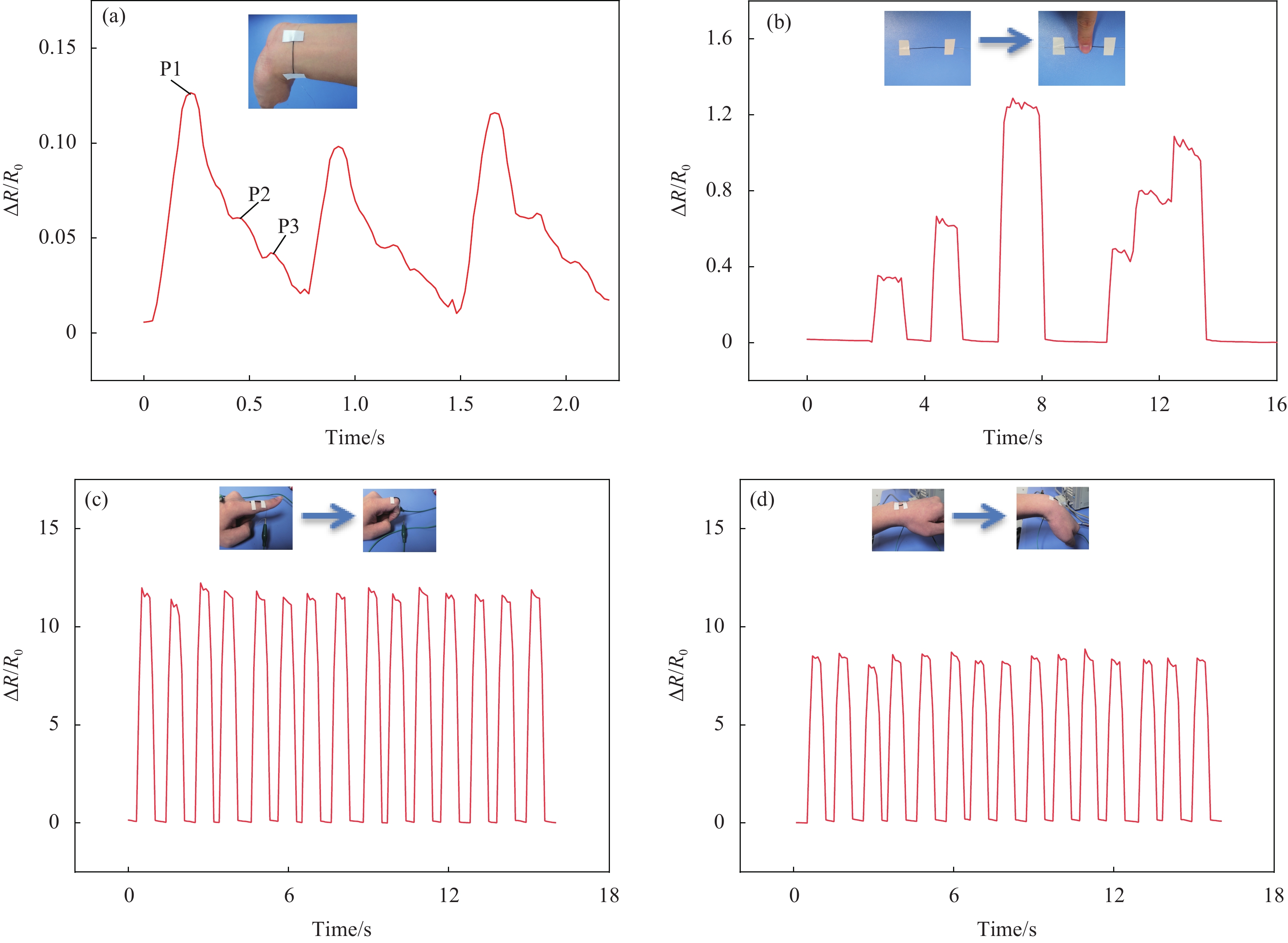

图 7 SR-(AgNPs-PDA-CNT)/PDMS-PDMS柔性应变传感器在持续大应变(a)、60%应变瞬态输入响应(b)、5次小应变(c)和大应变(d)下相对电阻随时间的变化

Figure 7. Relative resistance of SR-(AgNPs-PDA-CNT)/PDMS-PDMS flexible strain sensor changes with time under continuous large strain (a), 60% strain transient input response (b), 5 times small strain (c) and large strain (d)

图 9 SR-(AgNPs-PDA-CNT)/PDMS-PDMS柔性应变传感器的应用:脉搏 (a)、按压 (b)、手指弯曲 (c)、手腕弯曲 (d)、软体手指弯曲角度与相对电阻变化关系 (e) 和软抓手抓取行为感知 (f)

Figure 9. Application of SR-(AgNPs-PDA-CNT)/PDMS-PDMS flexible strain sensor: Pulse (a), compression (b), finger (c) bending, wrist bending (d), relationship between soft finger bending angle and relative resistance (e) and perception of soft grip grasping behavior (f)

P1—Dominant wave; P2—Tidal wave; P3—Dicrotic wave

-

[1] 张阳阳, 黄英, 刘月, 等. 基于多传感器信息融合的人类抓握特征学习及物体识别[J]. 机器人, 2020, 42(3):267-276. ZHANG Yangyang, HUANG Ying, LIU Yue, et al. Human grasp feature learning and object recognition based on multi-sensor information fusion[J]. Robot,2020,42(3):267-276(in Chinese).

[2] SONG Z Q, LI W Y, BAO Y, et al. Breathable and skin-mountable strain sensor with tunable stretchability, sensitivity, and linearity via surface strain delocalization for versatile skin activities’ recognition[J]. ACS Applied Materials & Interfaces,2018,10:42826-42836.

[3] 向东, 张学忠, 陈小雨, 等. 基于双向拉伸制备还原氧化石墨烯-碳纳米管复合薄膜的高性能柔性压阻传感器[J]. 复合材料学报, 2022, 39(3):1120-1130. XIANG Dong, ZHANG Xuezhong, CHEN Xiaoyu, et al. High performance flexible piezoresistive strain sensor based on biaxially stretched conductive polymer composite films with reduced graphene oxide-carbon nanotubes[J]. Acta Materiae Compositae Sinica,2022,39(3):1120-1130(in Chinese).

[4] 李瑞青, 李思明, 陈天骄, 等. 基于可膨胀微球/聚二甲基硅氧烷复合介电层的柔性电容式压力传感器[J]. 复合材料学报, 2021, 38(7):2152-2161. LI Ruiqing, LI Siming, CHEN Tianjiao, et al. Flexible capacitive pressure sensor based on expandable microsphere/ polydimethylsiloxane composite dielectric layer[J]. Acta Materiae Compositae Sinica,2021,38(7):2152-2161(in Chinese).

[5] CHEN Y, WANG L, WU Z F, et al. Super-hydrophobic, durable and cost-effective carbon black/rubber composites for high performance strain sensors[J]. Composites Part B: Engineering,2019,176:107358. DOI: 10.1016/j.compositesb.2019.107358

[6] GUO D J, PAN X D, XIE Y, et al. Effects of service condition on the performance of conductive polymer composites for flexible strain sensors[J]. Sensors and Actuators A: Physi-cal,2020,318(9):112494.

[7] 潘朝莹, 马建中, 张文博, 等. 柔性导电高分子复合材料在应变传感器中的应用[J]. 化学进展, 2020, 32(10):1592-1607. PAN Chaoying, MA Jianzhong, ZHANG Wenbo, et al. Flexible conductive polymer composites in strain sensors[J]. Progress in Chemistry,2020,32(10):1592-1607(in Chinese).

[8] SUN H L, DAI K, ZHAI W, et al. A highly sensitive and stretchable yarn strain sensor for human motion tracking utilizing a wrinkle-assisted crack structure[J]. ACS Applied Materials & Interfaces,2019,11(39):36052-36062.

[9] ZHU G J, REN P G, GUO H, et al. Highly sensitive and stretchable polyurethane fiber strain sensors with embedded silver nanowires[J]. ACS Applied Materials & Interfaces,2019,11(26):23649-23658.

[10] 张明艳, 杨振华, 吴子剑, 等. 新型三明治结构聚二甲基硅氧烷/聚偏氟乙烯-纳米Ag线/聚二甲基硅氧烷柔性应变传感器的制备与性能[J]. 复合材料学报, 2020, 37(5):1024-1032. ZHANG Mingyan, YANG Zhenhua, WU Zijian, et al. Preparation and properties of a novel sandwich structure polydimethylsiloxane/polyvinylidene fluoride-Ag nanowires/ polydimethylsiloxane flexible strain sensor[J]. Acta Mate-riae Compositae Sinica,2020,37(5):1024-1032(in Chinese).

[11] ZOU Q S, HE K, OU-YANG J, et al. Highly sensitive and durable sea-urchin-shaped silver nanoparticles strain sensors for human-activity monitoring[J]. ACS Applied Mate-rials& Interfaces,2021,13(12):14479-14488.

[12] WANG X, LI J F, SONG H N, et al. Highly stretchable and wearable strain sensor based on printable carbon nano-tube layers/polydimethylsiloxane composites with adjustable sensitivity[J]. ACS Applied Materials & Interfaces,2018,10(8):7371-7380.

[13] 张啸梅, 杨凯, 焦明立, 等. 纺织材料基可穿 戴柔性应力/应变传感器的发展及应用[J]. 上 海纺织科技, 2020, 48(8):17-21. ZHANG Xiaomei, YANG Kai, JIAO Mingli, et al. Development and application of fiber-based wearable flexible stress/strain sensors[J]. Shanghai Textile Science & Technology,2020,48(8):17-21(in Chinese).

[14] AMJADI M, KYUNG K, PARK I, et al. Stretchable, skin-mountable, and wearable strain sensors and their potential applications: A review[J]. Advanced Functional Materials,2016,26(11):1678-1698. DOI: 10.1002/adfm.201504755

[15] LEE H A, MA Y, ZHOU F, et al. Material-independent surface chemistry beyond polydopamine coating[J]. Accounts of Chemical Research,2019,52(3):704-713. DOI: 10.1021/acs.accounts.8b00583

[16] RYU J H, MESSERSMITH P B, LEE H. Polydopamine surface chemistry: A decade of discovery[J]. ACS Applied Materials& Interfaces,2018,10(9):7523-7540.

[17] CHOI G H, RHEE D K, PARK A R. Ag nanoparticle/polydopamine-coated inverse opals as highly efficient catalytic membranes[J]. ACS Applied Materials & Interfaces,2016,8(5):3250-3257.

[18] ZHANG Y Y, HUANG Y, LIU P, et al. Highly stretchable strain sensor with wide linear region via hydrogen bond-assisted dual-mod cooperative conductive network for gait detection[J]. Composites Science and Technology,2020,191:108070. DOI: 10.1016/j.compscitech.2020.108070

[19] QI P D, LI N, QU C B, et al. Understanding the cycling performance degradation mechanism of a graphene-based strain sensor and an effective corresponding improvement solution[J]. ACS Applied Materials & Interfaces,2020,12(20):23272-23283.

[20] WU X X, NIU F F, ZHONG A, et al. Highly sensitive strain sensors based on hollow packaged silver nanoparticle-decorated three-dimensional graphene foams for wearable electronics[J]. RSC Advances,2019,9:39958-39964. DOI: 10.1039/C9RA08118F

[21] ZHANG R, LI S Q, YING C, et al. Bioinspired design of flexible strain sensor with high performance based on gradient filler distributions[J]. Composites Science and Technology,2020,200(45):108319.

[22] ZHANG R, YING C, GAO H, et al. Highly flexible strain sensors based on polydimethylsiloxane/carbon nanotubes (CNTs) prepared by a swelling/permeating method and enhanced sensitivity by CNTs surface modification[J]. Composites Science and Technology,2019,171:218-225.

[23] BOLAND C S, KHAN U, BACKES C, et al. Sensitive, high-strain, high-rate bodily motion sensors based on graphene-rubber composites[J]. ACS Nano,2014,8(9):8819-8830. DOI: 10.1021/nn503454h

[24] 葛怡, 于晓灵, 张艳丹, 等. 全氟辛基季胺碘化物改性碳纳米管对天然橡胶胶乳性能的影响[J]. 复合材料学报, 2017, 34(12):2841-2845. GE Yi, YU Xiaoling, ZHANG Yandan, et al. Effect of trimethyl-1-propanaminium iodide modified carbon nano-tube on properties of natural rubber latex[J]. Acta Materiae Compositae Sinica,2017,34(12):2841-2845(in Chinese).

[25] PHAN H T, HAES A J. What does nanoparticle stability mean[J]. The Journal of Physical Chemistry,2019,123(27):16495-16507.

[26] PEI Z, LIU Y, ZHANG Q, et al. Highly sensitive, stretchable strain sensor based on Ag@COOH-functionalized CNTs for stroke and pronunciation recognition[J]. Advanced Electronic Materials,2019,5(7):1900227. DOI: 10.1002/aelm.201900227

[27] LI W J, LI Y, SHENG M, et al. Enhanced adhesion of carbon nanotubes by dopamine[J]. Langmuir,2019,35(13):4527-4533. DOI: 10.1021/acs.langmuir.9b00192

[28] 汤健, 闫涛, 潘志娟. 导电复合纤维基柔性应变传感器的研究进展[J]. 纺织学报, 2020, 42(5):168-177. TANG Jian, YAN Tao, PAN Zhijuan. Research progress of flexible strain sensors based on conductive composite fibers[J]. Journal of Textile Research,2020,42(5):168-177(in Chinese).

-

下载:

下载: