Study on structure and performance control of carbon fiber reinforced poly(ether ketone ketone) molding composites

-

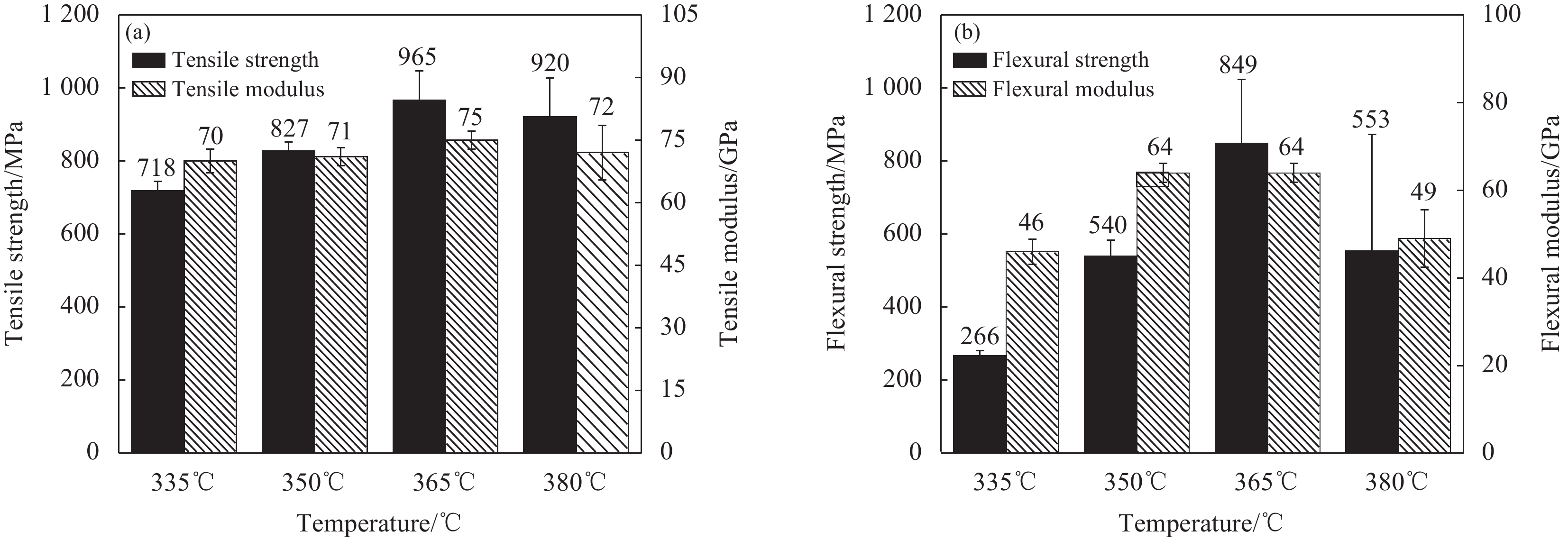

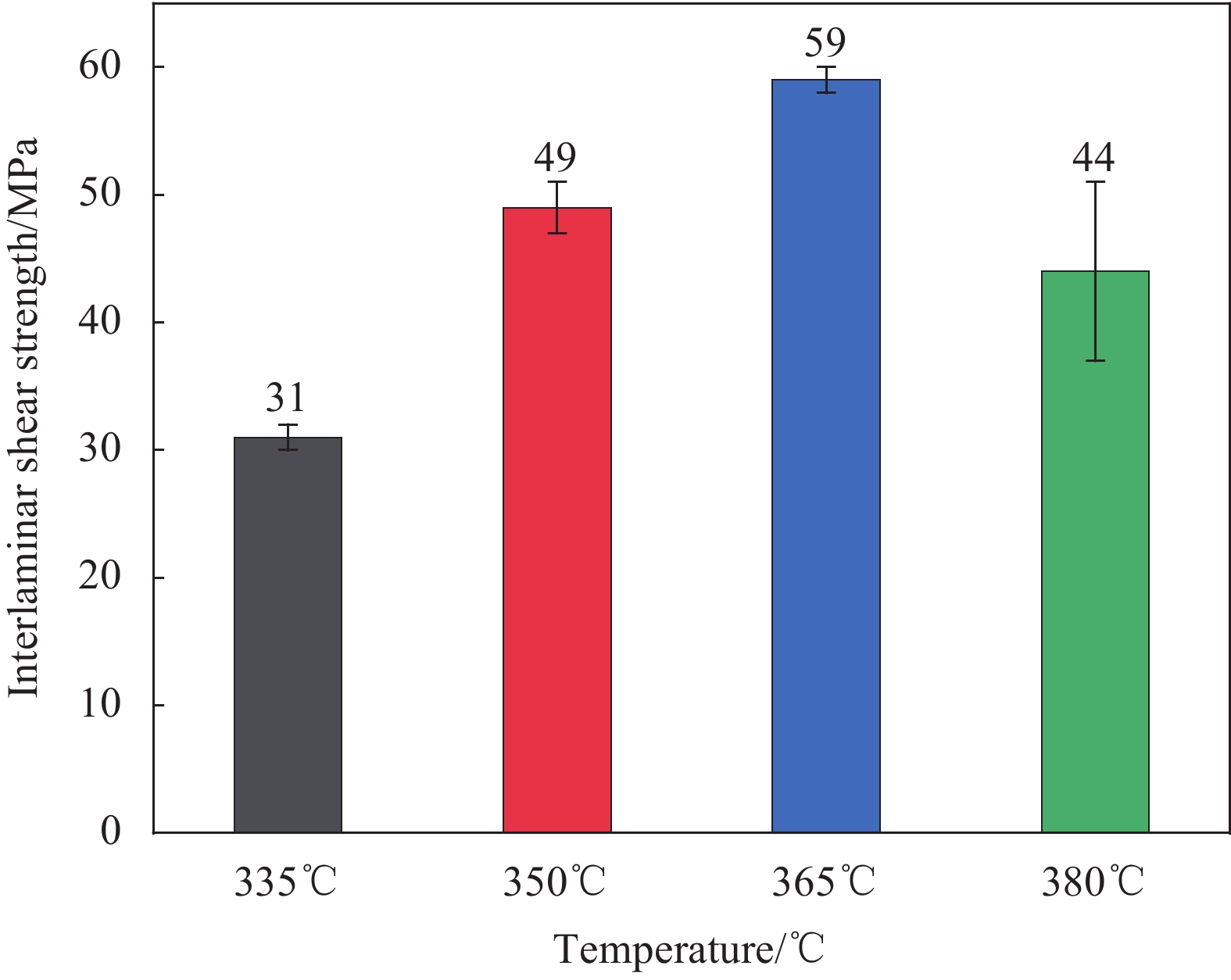

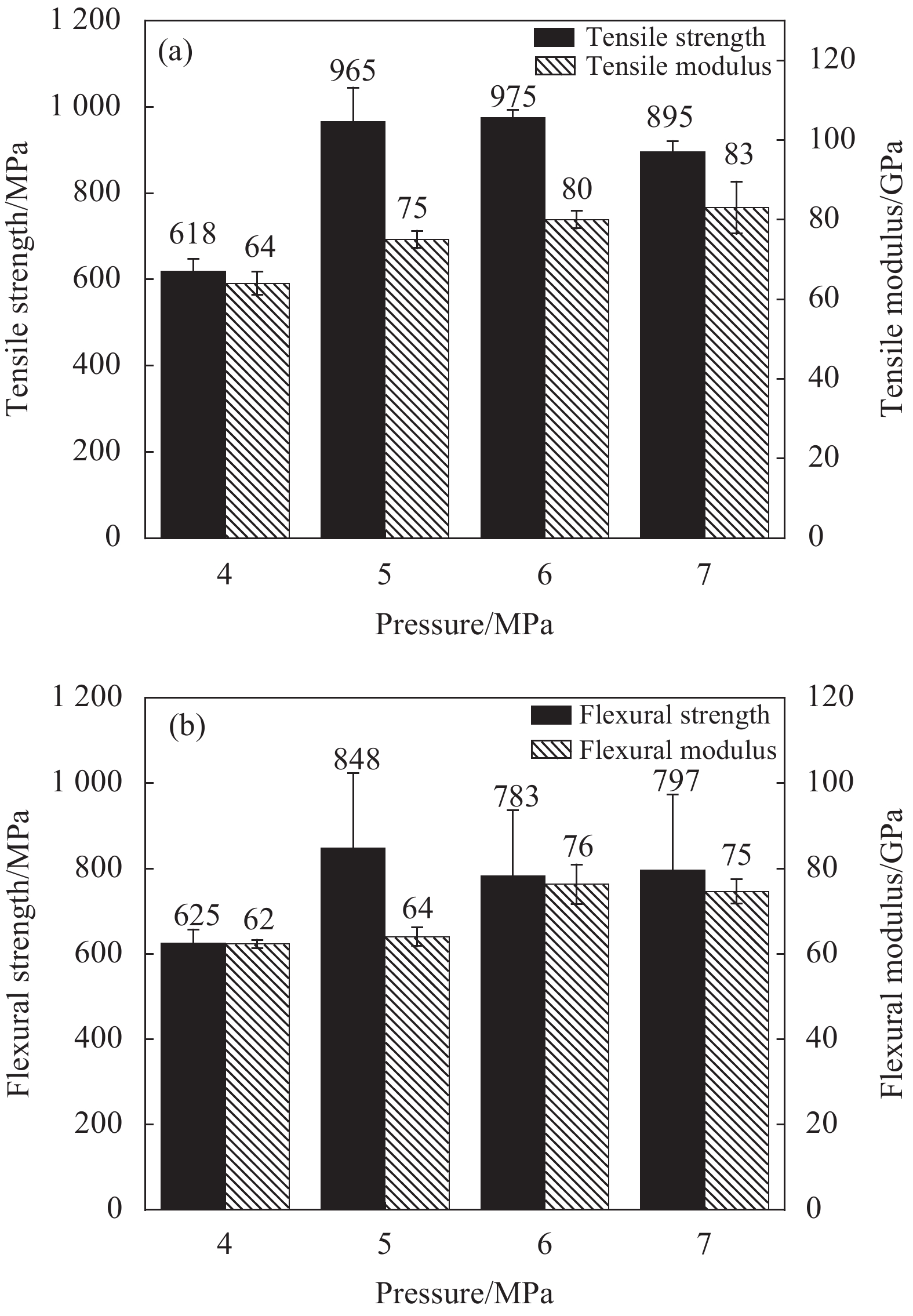

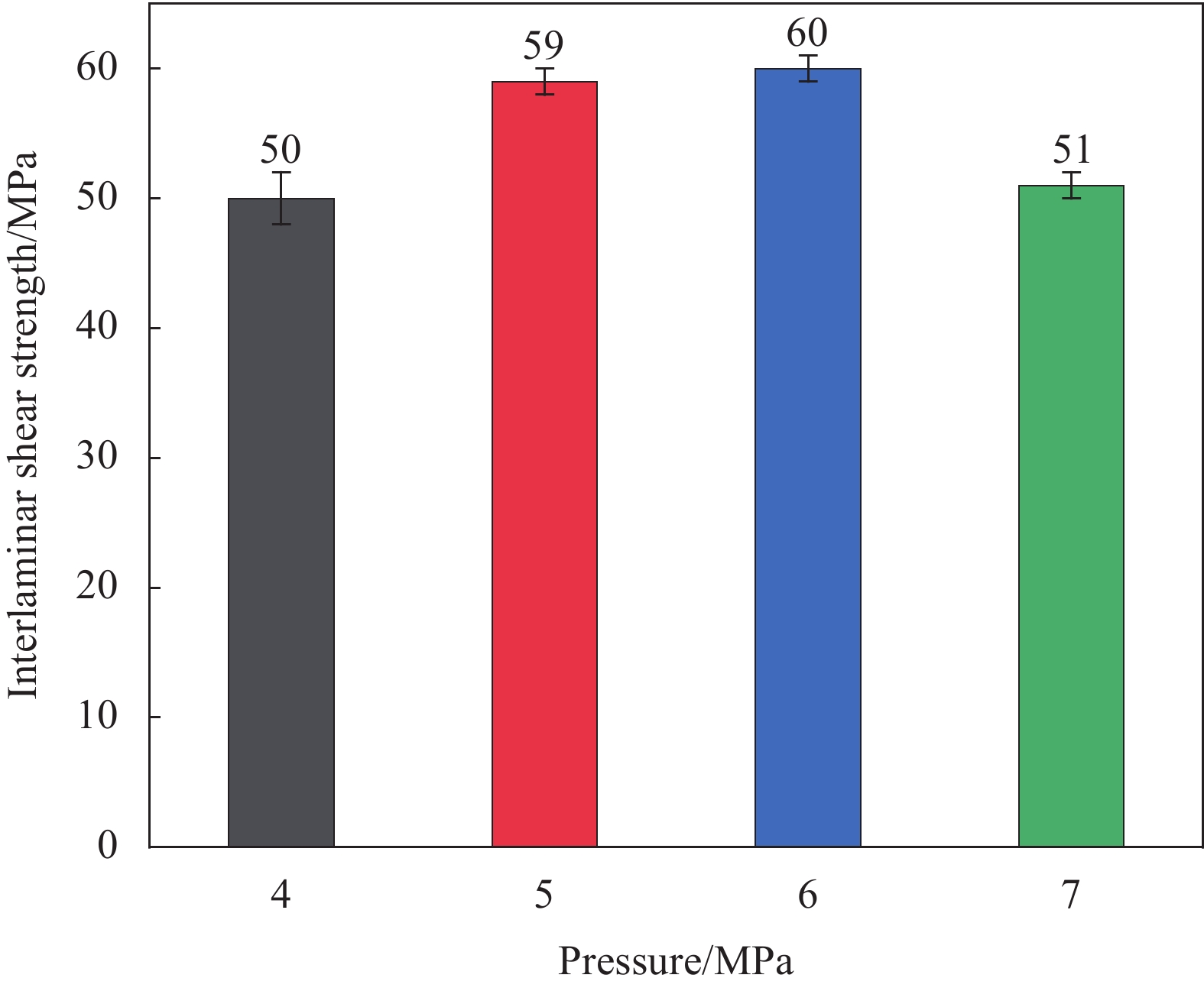

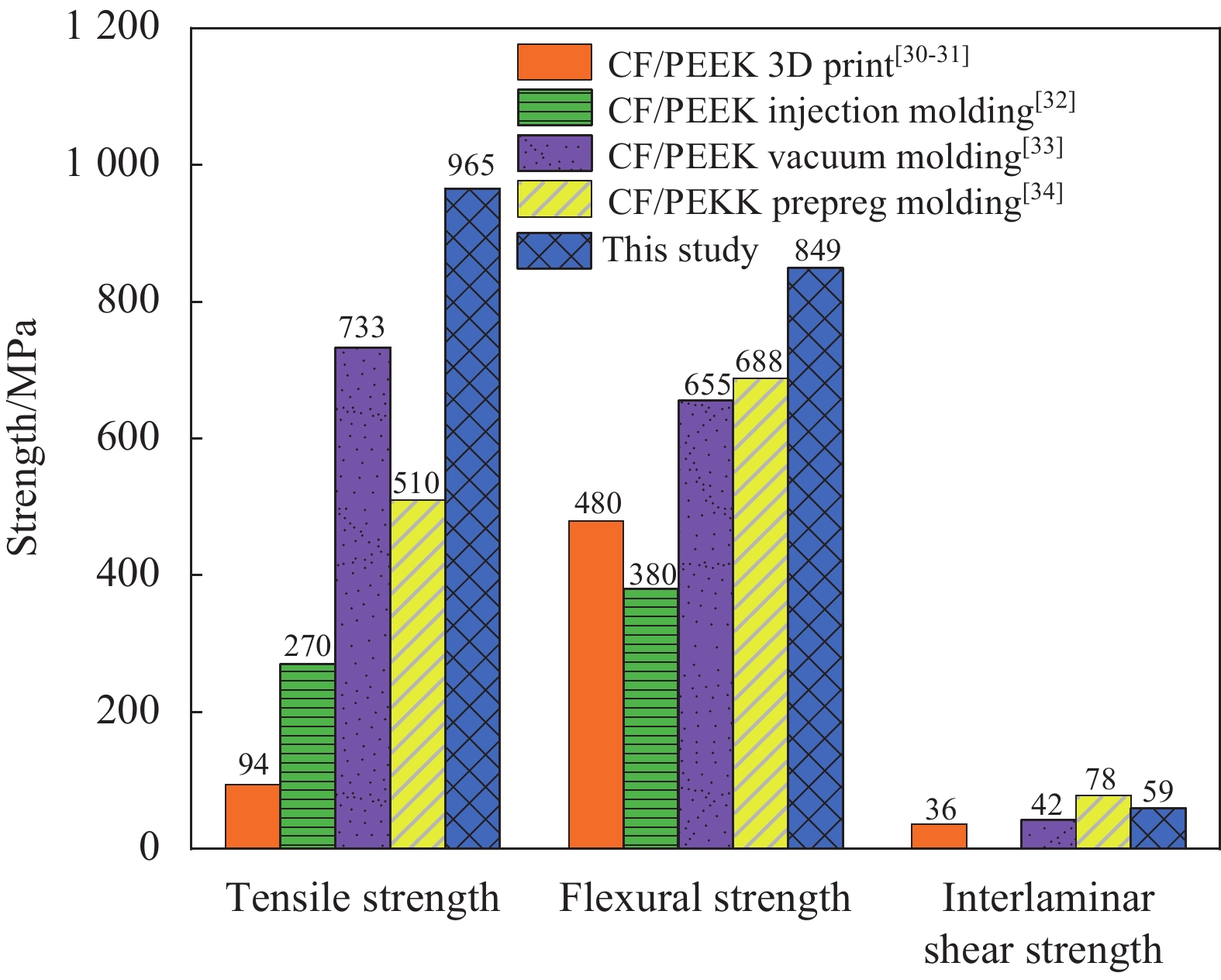

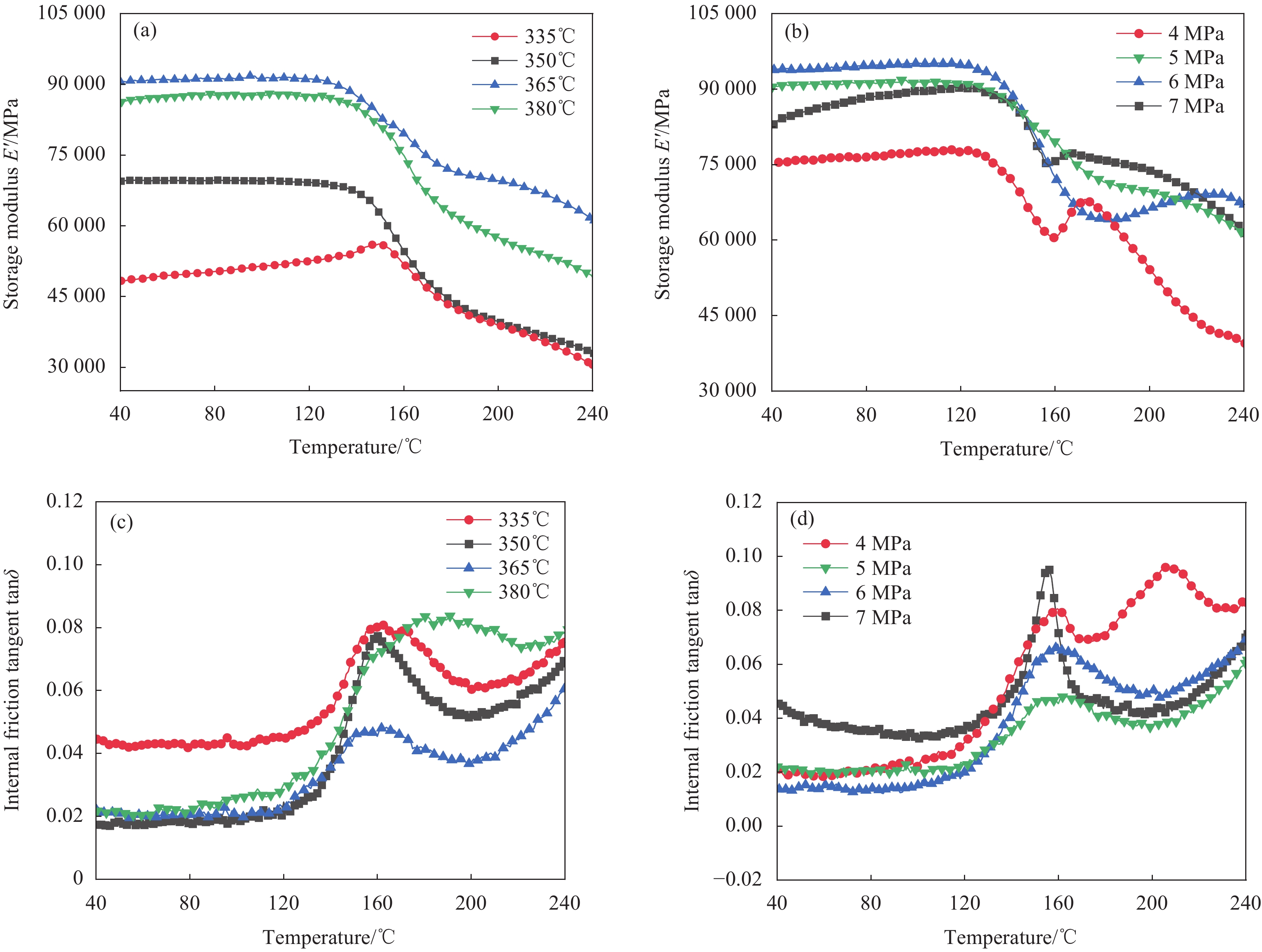

摘要: 为探究模压工艺参数对碳纤维增强聚醚酮酮复合材料(CF/PEKK)结构与性能的影响规律,采用真空模压工艺制备CF/PEKK复合材料层压板,系统讨论了模压温度和压力对树脂与纤维的界面结构、PEKK凝聚态结构及复合材料力学性能的影响,通过扫描电镜分析了复合材料的微观结构,讨论了复合材料的失效形式,采用X射线衍射观察了复合材料中PEKK的晶体结构,使用动态热机械分析研究了复合材料界面阻尼与模压成型工艺的关系。研究结果表明,在365℃的模压温度和5.0~6.0 MPa模压压力下,CF/PEKK复合材料的综合力学性能最优,其中拉伸强度达到965 MPa,弯曲强度849 MPa,层间剪切强度59 MPa,复合材料的断裂失效形式以树脂开裂与层间Z形断裂为主。

-

关键词:

- 碳纤维/聚醚酮酮复合材料 /

- 模压工艺 /

- 凝聚态结构 /

- 力学性能 /

- 失效形式

Abstract: In order to explore the effect of molding parameters on the structure and properties of carbon fiber reinforced poly(ether ketone ketone) composites (CF/PEKK), CF/PEKK composite laminates were prepared by vacuum molding in this paper. The effects of molding temperature and pressure on the interface structure between resin and fiber, the condensed structure of PEKK and the mechanical properties of the composites were discussed systematically. The microstructure and the failure modes of the composites was analyzed by scanning electron microscope. The crystal structure of PEKK in the composites was observed by X-ray diffraction. The relationship between interfacial damping and molding process of the composites was studied by dynamic mechanical analysis. The results show that under the molding temperature of 365℃ and molding pressure of 5.0-6.0 MPa, the comprehensive mechanical properties of CF/PEKK composites are the best, in which the tensile strength is 965 MPa, the bending strength is 849 MPa, and the inter-laminar shear strength is 59 MPa. The fracture failure modes of the composites are mainly zigzag cracking and resin breakage.-

Keywords:

- CF/PEKK composites /

- molding process /

- condensed structure /

- mechanical properties /

- failure modes

-

交通建设电气化是一种绿色、环保的发展理念,对能源结构及经济转型有着重要的推动作用[1–3]。环氧树脂具有优异的绝缘性、高强度及化学稳定性,可在交通电气化建设中广泛应用于电缆接头与终端[4-5]、变压器[6-7]、路面材料[8-9]及防护涂层[10-11]等方面。然而传统环氧树脂在固化交联后难以回收、有效降解和再生利用,造成了严重的资源浪费和环境污染[12-14],因此,研究与开发可回收环氧树脂是十分必要的。

构建共价自适应网络为回收环氧树脂提供了技术方案[15-19]。共价自适应网络内具有大量可逆动态共价键,在外界条件刺激下能够激发共价自适应网络内部的键交换反应,致使网络发生重组[20-24]。

孙文杰等[25]通过异氰酸酯和仲胺构筑受阻脲键,键入到环氧链段中,制备出了具有修复能力的氢化环氧树脂,力学性能修复率达到70%以上;Memon等[26]以生物基香兰素和石油基对羟基苯甲醛为原料合成了两种含动态亚胺键的固化剂,固化的环氧树脂具有可再加工和可降解性,回收后的环氧树脂力学性能损失较小;Tian等[27]以生物基甘油三酯为环氧单体、香兰素衍生亚胺化合物为固化剂合成了可回收的生物基环氧树脂,拉伸强度恢复率达到85%以上。然而,目前学者们研究的可回收环氧树脂机械强度普遍较差[28-29],且对于其回收前后电气性能的研究较少[25, 30-32]。

本文采用了光敏油基树脂和环氧树脂的光-热双固化方法,通过酯交换原理,在无催化剂的高温高压环境下实现了双固化环氧树脂的高性能回收,研究了双固化环氧树脂的回收过程,分析了回收树脂颗粒粒径及热压压强对回收树脂力学性能和电气性能的影响。

1. 实验材料及方法

1.1 原材料

双酚A型环氧树脂(DGEBA):工业纯,南京强山新材料有限公司;甲基六氢苯酐(MHHPA)、2-乙基-4-甲基咪唑(EMI-2,4):工业纯,上海麦克林生化科技有限公司;环氧大豆油丙烯酸酯(AESO):工业纯,山东国化化学有限公司;二缩三丙二醇二丙烯酸酯(TPGDA)、三羟甲基丙烷三丙烯酸酯(TMPTA)、环氧丙烯酸酯(EA):分析纯,山东嘉颖化工科技有限公司;光引发剂819 (BAPO):分析纯,上海光易化工有限公司。

1.2 实验过程

环氧树脂:将DGEBA、MHHPA和EMI-2,4分别按质量分数为53.5wt%、46.0wt%和0.5wt%在温度60℃下搅拌而成。

光敏油基树脂:将AESO、TPGDA、TMPTA、EA和BAPO分别按质量分数为37.5wt%、32.5wt%、25.0wt%、5.0wt%和1.0wt%在避光条件下搅拌可得。

双固化环氧树脂:在避光条件下,按照环氧树脂含量50wt%、光敏油基树脂含量50wt%的比例称取原料,使用真空搅拌脱泡机(TMV-700TT,思迈达智能设备有限公司)对原料进行充分搅拌,基于互穿聚合物原理,使用光固化三维打印机(LD-002H,创想三维公司)对光敏树脂组分进行光固化;待三维打印结束后,将打印好的样品进行脱模处理,使用异丙醇清洗后,将样品放入真空干燥箱(上海一恒,DZF-6030A),采用阶梯固化的方式对环氧树脂组分进行热固化,在140℃、150℃和160℃按顺序分别加热1 h后,再在150℃和140℃按顺序分别加热1 h。

回收树脂:使用BJ-150粉碎机(拜杰)对样品进行预处理,得到粒径较大的颗粒,随后使用XL-30C超微粉碎机(杭州旭众)对样品进行二次处理。使用282 μm和125 μm孔径的筛网,分别将粉碎后的回收颗粒分类为大粒径(L)和小粒径(S)。回收树脂是在220℃下以5 MPa、10 MPa和15 MPa的热压压强下热处理3 h制得。实验过程示意图如图1所示。

1.3 测试与表征

采用瑞士Leica DMI8显微镜观测了回收树脂颗粒形貌,使用SEM (Apreo 2C,赛默飞公司)观测了回收树脂的断面形貌;采用美国Perkin Elmer公司PE Spectrum 400型傅里叶变换红外光谱仪进行测试,KBr压片,室温,在400~

4000 cm−1范围内进行数据采集,扫描次数为32次;采用微机控制电子万能试验机(菱悦精密仪器,503B)分别按照GB/T 9341—2008[33]和GB/T 1040.2—2006[34]对试样进行弯曲强度和拉伸强度测试;使用德国Novocontrol公司Concept 80宽频介电谱仪对双固化环氧树脂的介电性能进行测试,试样尺寸为20 mm×20 mm×1 mm,测试频率范围为10−1~106 Hz,测试前需将试样在60℃的真空环境下干燥24 h,以排除试样吸收的水分对介电性能的影响;按照GB/T 1408.1—2016[35]对试样进行工频交流击穿试验,采用100 kV的试验变压器,选用球-球电极在矿物油中进行工频交流击穿试验,以防止试验发生沿面闪络,重复测试15次,采用威布尔分布进行分析。2. 结果与讨论

L粒径颗粒与S粒径颗粒的微观、宏观形貌及粒径分布如图2所示。比较L粒径和S粒径的微观形貌可得,粒径越小,颗粒越不均匀,形状越不规则。对两种粒径大小的回收颗粒进行了粒径分析,由粒径分布可知,S回收颗粒的粒径均小于350 μm,约65%的S颗粒粒径在90~210 μm之间;L回收颗粒的粒径小于840 μm,大约有80%的颗粒处于200~500 μm之间,可以得出,L回收颗粒的粒径相比于S回收颗粒分布范围更加集中。

回收机制如图3所示,本质为酯键的动态交换反应,该反应涉及交联网络中的羟基和酯键。在高压下,粉末颗粒间的间隙逐渐缩小,高温使双固化环氧树脂内部的酯键、羟基呈现活跃态,高分子链段热运动加剧,此时,羟基会对与其相近的酯键上羰基进行亲核攻击,旧酯键中醚键断裂、羟基脱氢与羰基碳形成新的醚键,最终形成新的羟基和酯键[36-38]。三维交联网络中酯键不断断裂-重组,使接触界面的分子链相互“焊接”,形成了界面愈合的现象,体现出双固化环氧树脂可回收、再加工的“塑性”性能。

探究了热压压强为15 MPa时L粒径和S粒径树脂颗粒不同愈合阶段的界面微观形貌,如图4所示,初始态的S树脂颗粒间无明显接触且独立分布,随着温度、热压压强施加,颗粒发生形变,使颗粒表面相互接触,这是由于颗粒间提供了动态交换位点,引起了网络重组,从而引发树脂颗粒间的界面愈合。在中间态时,颗粒间还存在着未愈合的界面,可观察到较多的空隙及缺陷,在最后阶段,颗粒间的空隙逐渐消失,界面键合较完整,界面的愈合程度逐渐升高。L树脂颗粒从初始态到最后阶段颗粒间的空隙逐渐减少,但仍存在明显的树脂颗粒界面缺陷。

为探究双固化环氧树脂的固化过程,使用傅里叶变换红外光谱仪对试样进行测试,图5(a)为双固化环氧树脂不同固化阶段的傅里叶变换红外光谱。观察发现,经过光固化后,双固化环氧树脂在

1635 cm−1处的C=C特征吸收峰和1407 cm−1处的乙烯基(—C—H)伸缩振动吸收峰消失,而位于912 cm−1处的环氧基(C—O—C)特征吸收峰依旧存在;在经过热固化后,双固化环氧树脂的C—O—C特征吸收峰消失,说明了双固化环氧树脂中光敏树脂的C=C仅参与了光固化反应,环氧树脂的C—O—C仅参与了热固化反应,光、热固化反应独立且充分发生。探究了双固化环氧树脂回收前后交联网络结构变化,以S粒径树脂颗粒在15 MPa热压压强下回收为例,图5(b)为其回收前后的傅里叶变换红外光谱,观察发现,

1733 cm−1处为酯键中羰基的伸缩振动吸收峰,羟基的伸缩振动吸收峰在3450 cm−1处,回收前后特征峰值基本一致,表明经过热压之后双固化环氧树脂的交联网络化学结构没有发生明显变化。树脂固化未完全会促进树脂颗粒的界面愈合,为排除这种影响,测试了双固化环氧树脂的热流随温度变化曲线,如图5(c)所示。观察发现,双固化环氧树脂在50~300℃温度下没有放热峰出现,表明双固化环氧树脂已经完全固化。

图6为两种回收树脂颗粒在不同热压压强下的弯曲强度和拉伸强度。由图可知,双固化环氧树脂的弯曲强度为85 MPa,拉伸强度为51 MPa,其拉伸强度在上述文献[16-19, 22-24, 28-29]的比较中具有较强的优越性,相应数值比较如表1所示,一定程度上说明了双固化环氧树脂的力学性能良好。

表 1 不同文献中的拉伸强度比较Table 1. Comparison of the tensile strength among the different literatureRecyclable polymer Catalyst Tensile strength/

MPaRef. EP Yes 12.0 [16] 60 Yes 10.3 [17] EC-30 Yes 9.9 [18] 2.5%Zn-PAM/ER Yes 28.0 [19] M-4 Yes 7.0 [22] HBE-1/SA No 47.0 [23] P-VDNET No 41.0 [24] Dual dynamic vitrimer Yes 1.6 [28] EPTMP/APDS Yes 2.0 [29] 15 MPa-S particle No 51.0 This article Notes:EP—Epoxy polymer; 60—60wt% monoepoxide content in prepolymer; EC-30—30wt% esilica-cross-linked composites; 2.5%Zn-PAM/ER—2.5wt%Zn(OAc)2 content in poly(acrylonitrile-co-zinc methacrylate) epoxy polymer; M-4—4mol% catalyst-loading polymer; HBE-1/SA—Polymer cured by hyperbranched epoxy and succinic anhydride; P-VDNET—Schiff base cross-linked networks; EPTMP/APDS—Epoxy polymer cured by 4-aminophenyl disulfide. 随着热压压强的逐渐增加,回收树脂的弯曲强度和拉伸强度逐渐增大,L树脂颗粒在15 MPa的热压压强下回收的弯曲强度和拉伸强度相比于5 MPa时分别提升了73.2%和76.7%,S树脂颗粒在15 MPa的热压压强下回收的弯曲强度和拉伸强度相比于5 MPa时分别提升了21.8%和76.7%,S树脂颗粒回收后的力学性能要远大于L树脂颗粒回收后的力学性能,在15 MPa的热压压强下,S树脂颗粒相比于L树脂颗粒的弯曲强度要高63.7%,拉伸强度要高68.2%;相比于回收前,在15 MPa的热压压强下S树脂颗粒在弯曲强度上恢复了92.0%,在拉伸强度上恢复了93.7%。

图7为S和L粒径回收树脂颗粒在相应热压压强下回收后的断面形貌。由图可知,S粒径回收树脂颗粒在5 MPa的热压压强下断面形貌有较强的颗粒感,随着热压压强的升高,断面形貌的颗粒感下降,且逐渐变得较均匀,宏观上样品由不透明的米黄色变为了接近透明的棕红色,如图7(a)~7(c)所示;L粒径回收颗粒在15 MPa下断面形貌仍然有明显的缺陷,样品在宏观上呈现出不均匀的形态,如图7(d)所示。

图8为双固化环氧树脂回收前后的介电常数随频率变化曲线,由图可知,双固化环氧树脂的介电常数较小,约为5.2;无论是L粒径还是S粒径回收树脂相比于回收前介电常数均降低,这是由于回收树脂相比于回收前其基体内部可能存在孔隙,使空气得以进入基体,导致回收树脂介电常数下降。

在工频下,L粒径回收树脂在5 MPa时介电常数约为3.9,相比于回收前(约5.2)下降了约25.0%,在15 MPa时介电常数(约4.5)下降了约13.5%,S粒径回收树脂在5 MPa时的介电常数要高于L粒径回收树脂,约为4.7,相比于回收前下降了约9.6%,在15 MPa时介电常数(约5.1)与回收前基本相当;随着热压压强的提升,回收树脂的介电常数会逐渐升高,原因是内部的孔隙在热压作用下逐渐被消除,在工频下,L粒径回收树脂当热压压强从5 MPa提升至15 MPa时其介电常数提升了15.4%,S粒径回收树脂提升了8.5%。

图9为回收树脂介电损耗随频率变化曲线,由图可得,双固化环氧树脂的介电损耗较小,约为0.01;由图9(a)可知,低频下L粒径回收树脂的介电损耗极高,在热压压强为5 MPa时回收树脂介电损耗高于0.4,原因是基体内部存在大量的缺陷。随着热压压强的升高,低频下介电损耗大幅度降低,在15 MPa下介电损耗为0.075,相比于5 MPa时降低了近81.7%,但仍然处于较高的水平;在中频和高频段回收树脂的介电损耗与回收前的介电损耗差距随着频率升高而减小,但仍然高于回收前的介电损耗。

由图9(b)可知,S粒径回收树脂的介电损耗基本在0.03以内,远低于L粒径回收树脂,低频下5 MPa时S粒径回收树脂的介电损耗约为0.03,在15 MPa时介电损耗降低至0.015,降幅约50%,仅比回收前高0.005;在中频和高频下基本与回收前的介电损耗相差不大。与近几年可回收树脂的相关研究报道[25, 30-32]进行对比后可得,本文所报道的可回收环氧树脂介电损耗最低,一定程度上说明了该树脂的介电性能良好,见表2。

图10为双固化环氧树脂回收前后的击穿强度,由图可知,回收前双固化环氧树脂的击穿强度较好,约为30.57 kV·mm−1,随着热压压强的升高,L粒径回收树脂击穿强度的尺寸参数和形状参数略有提升,说明L粒径回收树脂的击穿强度和其数值的稳定性均有小幅度提高,但远低于回收前树脂的击穿强度,这是由于内部孔隙的绝缘强度远低于树脂,放电优先从孔隙处发生,对树脂的击穿强度影响较大,在热压压强为15 MPa时L粒径回收树脂的击穿强度为22.29 kV·mm−1,相比于回收前树脂的击穿强度恢复率达到72.9%;S粒径回收树脂击穿强度的尺寸参数和形状参数均有大幅度提升,也说明了S粒径回收树脂的击穿强度和其数值的稳定性均有大幅度提升,在15 MPa时S粒径回收树脂的击穿强度虽然在稳定性上与回收前有着不小的差距,但是尺寸参数(30.08 kV·mm−1)接近于回收前的树脂,恢复率达到98.4%。

表 2 不同文献中介电损耗比较Table 2. Comparison of the dielectric loss among the different literatureRecyclable polymer Dielectric loss

before recyclingDielectric loss

after recyclingRef. HEP-2-2 0.047 - [25] UV-E-S 0.125 0.9 [30] PDMS-3 0.05 0.055 [31] C6 0.02 - [32] 15 MPa-S particle 0.01 0.015 This article Notes: HEP-2-2—Molar ratio of hydrogenated bisphenol A epoxy and amine is 2∶2; UV-E-S—Photo/thermal dual cured resin with disulfide bond; PDMS-3—Silicone with dynamic hindered urea bonds; C6—Six carbons between cross-link junctions. 3. 结 论

(1)双固化环氧树脂的光、热固化反应独立且充分;经过热压之后双固化环氧树脂的交联网络化学结构没有发生明显变化;双固化环氧树脂已经完全固化,不会影响愈合过程;

(2)较高的压力有利于缩小颗粒间距离,较小的树脂颗粒具有更大的比表面积,有利于颗粒间界面充分接触,两者协同增强了树脂颗粒界面愈合,进而增强其回收性能;

(3)回收前双固化环氧树脂的力学性能良好;当热压压强为15 MPa时小粒径(S)树脂颗粒力学性能恢复效果较优,在弯曲强度上恢复了92.0%,在拉伸强度上恢复了93.7%;

(4)回收前双固化环氧树脂的介电性能良好;当热压压强为15 MPa时S树脂颗粒介电性能较优,工频下介电常数约为5.1,介电损耗约为0.015,与回收前相差不大;

(5)回收前双固化环氧树脂的击穿强度良好;当热压压强为15 MPa时S树脂颗粒击穿强度恢复效果较优,恢复率达到98.4%。

-

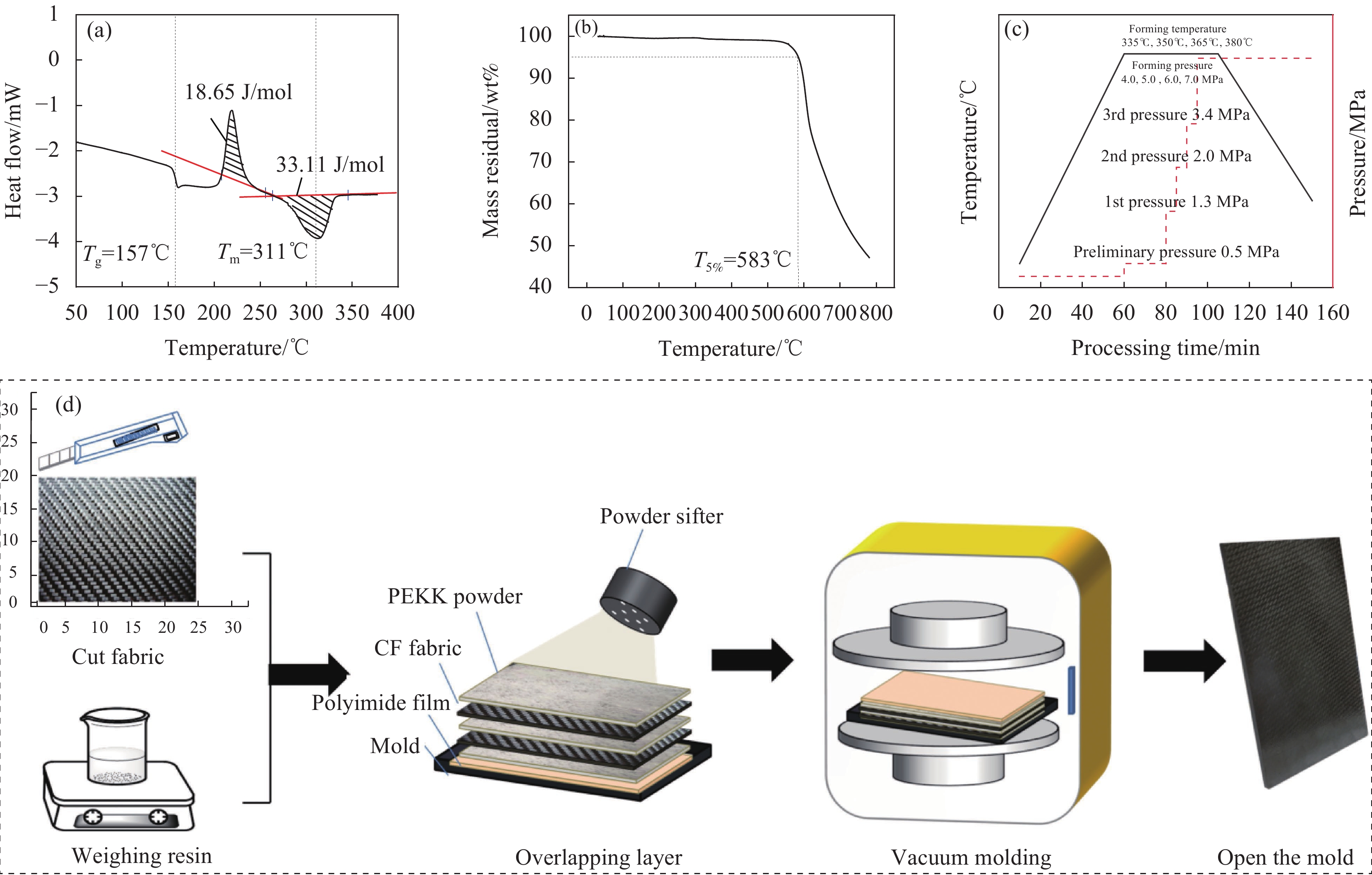

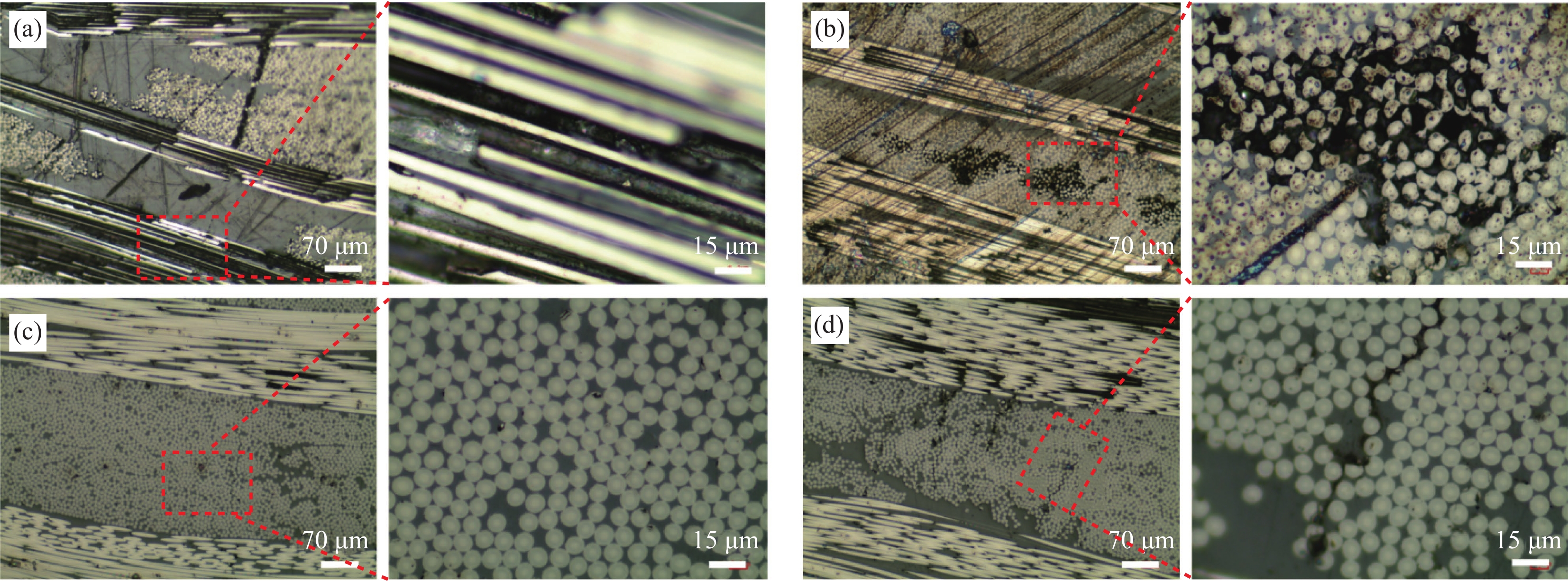

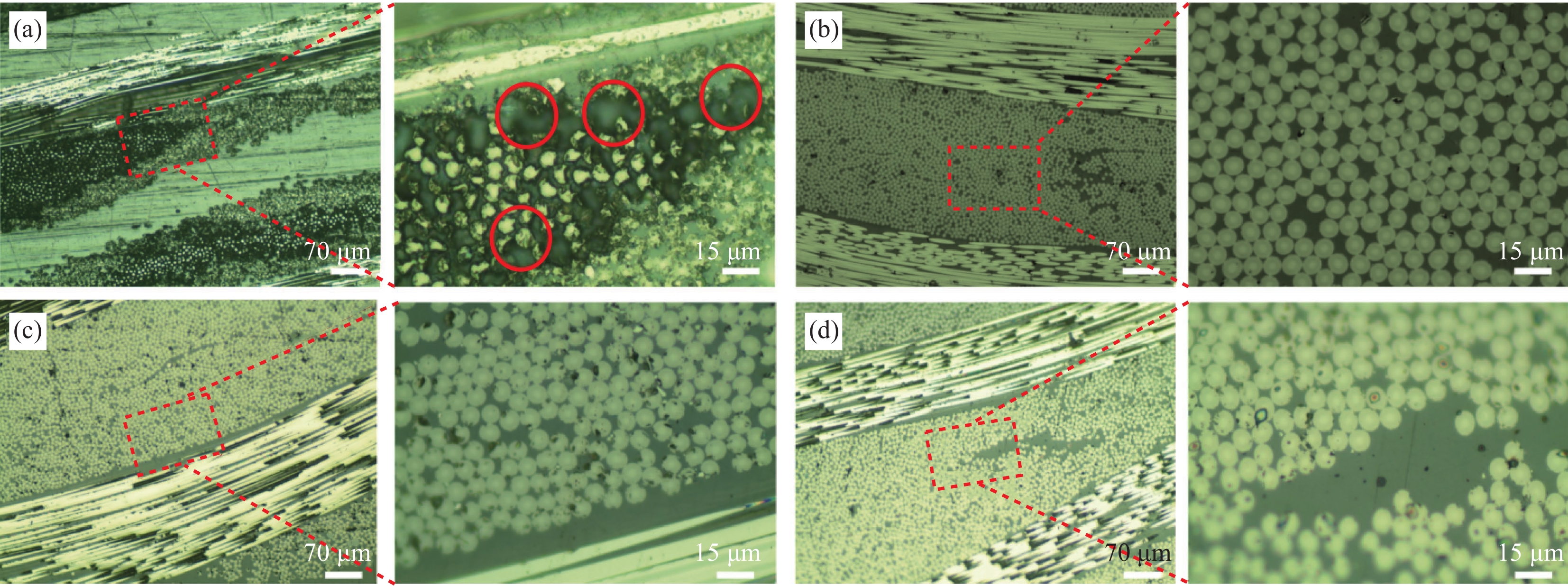

图 1 聚醚酮酮(PEKK)树脂粉末的热力学性能:(a) DSC曲线;(b) TGA曲线;碳纤维(CF)/PEKK复合材料模压工艺流程 (c) 和CF/PEKK复合材料层压板制备过程 (d)

Figure 1. Thermal properties of poly(ether ketone ketone) (PEKK) resin powder: (a) DSC curve; (b) TGA curve; Molding process of carbon fiber (CF)/PEKK composites (c) and preparation process of CF/PEKK composite laminates (d)

Tg—Glass transition temperature; Tm—Melting temperature; T5%—Decomposition temperature

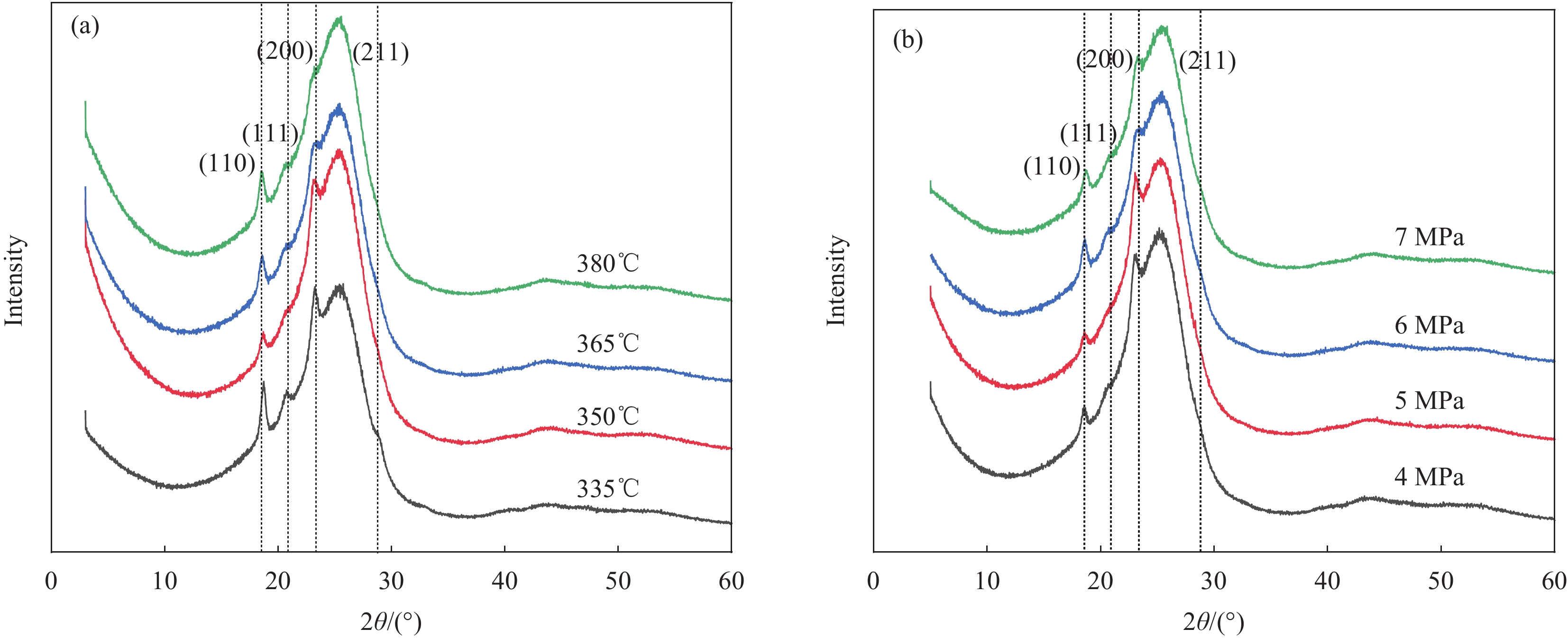

表 1 不同模压工艺参数对CF/PEKK复合材料结晶性影响

Table 1 Effect of different molding parameters on the crystallinity of CF/PEKK composites

335℃ 350℃ 365℃ 380℃ 4.0 MPa 5.0 MPa 6.0 MPa 7.0 MPa XS(110)/nm 16.9 18.7 23.2 22.3 22.6 23.2 20.4 19.4 XC/% 8.97 8.32 11.14 10.89 8.69 11.14 11.61 10.90 Notes: XS(110)—Grain size of PEKK (110) crystal plane; XC—XRD crystallinity of PEKK. -

[1] 杨洋, 见雪珍, 袁协尧, 等. 先进热塑性复合材料在大型客机结构零件领域的应用及其制造技术[J]. 玻璃钢, 2017, 4(194):3-17. YANG Yang, JIAN Xuezhen, YUAN Xieyao, et al. Application and manufacturing technology of advanced thermoplastic composites in structural parts of large passenger aircraft[J]. Fiber Reinforced Plastics,2017,4(194):3-17(in Chinese).

[2] 谌广昌, 姚佳楠, 张金栋, 等. 高性能热塑性复合材料在直升机结构上的应用与展望[J]. 航空材料学报, 2019, 39(5):24-33. CHEN Guangchang, YAO Jianan, ZHANG Jindong, et al. Application and prospect of high performance thermoplastic composites in helicopter structure[J]. Journal of Aeronautical Materials,2019,39(5):24-33(in Chinese).

[3] DAS T K, GHOSH P, DAS N C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: A review[J]. Advanced Composites and Hybrid Materials,2019,2(2):214-233. DOI: 10.1007/s42114-018-0072-z

[4] 邢丽英, 冯志海, 包建文, 等. 碳纤维及树脂基复合材料产业发展面临的机遇与挑战[J]. 复合材料学报, 2020, 37(11):2700-2706. XING Liying, FENG Zhihai, BAO Jianwen, et al. Opportunities and challenges for the development of carbon fiber and resin matrix composites industry[J]. Acta Materiae Compositae Sinica,2020,37(11):2700-2706(in Chinese).

[5] Teijin Carbon. A350XWB-World’s first aircraft using CFRTP for primary structure parts, delivered to JAL in Tokyo[EB/OL]. (2019-06-20)[2021-08-01]..

[6] MATHIJSEN D. Leading the way in thermoplastic composites[J]. Reinforced Plastics,2016,60(6):405-407. DOI: 10.1016/j.repl.2015.08.067

[7] 邓德鹏, 康敬欣, 刘勇. 特种工程塑料聚醚酮酮的性能[J]. 工程塑料应用, 2016, 44(9):83-86. DENG Depeng, KANG Jingxin, LIU Yong. Properties of special engineering plastics polyether ketone[J]. Application of Engineering Plastics,2016,44(9):83-86(in Chinese).

[8] 饶先花, 曹民, 代惊奇, 等. 国内外特种工程塑料聚芳醚酮的生产、应用及发展前景[J]. 塑料工业, 2012, 40(9):18-22. RAO Xianhua, CAO Min, DAI Jingqi, et al. Production, application and development prospect of special engineering plastics poly(aryl ether ketone)[J]. Plastics Industry,2012,40(9):18-22(in Chinese).

[9] 肇研, 刘寒松. 连续纤维增强高性能热塑性树脂基复合材料的制备与应用[J]. 材料工程, 2020, 48(8):49-61. ZHAO Yan, LIU Hansong. Preparation and application of continuous fiber reinforced high performance thermoplastic resin matrix composites[J]. Materials Engineering,2020,48(8):49-61(in Chinese).

[10] 张佳新, 梅启林. CF/PPS编织复合材料的制备及力学性能研究[J]. 复合材料科学与工程, 2020(1):76-81. ZHANG Jiaxin, MEI Qilin. Preparation and mechanical properties of CF/PPS braided composites[J]. Composite Science and Engineering,2020(1):76-81(in Chinese).

[11] 宋清华, 肖军, 文立伟, 等. 模压工艺对玻璃纤维增强聚丙烯复合材料层合板力学性能的影响[J]. 复合材料学报, 2016, 33(12):2740-2748. SONG Qinghua, XIAO Jun, WEN Liwei, et al. Effect of molding process on mechanical properties of glass fiber reinforced polypropylene composite laminates[J]. Acta Materiae Compositae Sinica,2016,33(12):2740-2748(in Chinese).

[12] 敖玉辉, 石飞, 尚垒, 等. 碳纤维增强聚醚醚酮复合材料的制备与性能[J]. 高分子材料科学与工程, 2014, 30(6):161-164. AO Yuhui, SHI Fei, SHANG Lei, et al. Preparation and properties of carbon fiber reinforced PEEK composites[J]. Polymer Materials Science and Engineering,2014,30(6):161-164(in Chinese).

[13] 刘亚男, 刘晨晓, 朱明浩, 等. 模压CF/PEKK与自动铺丝CF/PEEK热塑性复合材料对比研究[J]. 航空制造技术, 2021, 4(11):50-57. LIU Ya'nan, LIU Chenxiao, ZHU Minghao, et al. Comparative study on molded CF/PEKK and automatic wire laying CF/PEEK thermoplastic composites[J]. Air Manufacturing Technology,2021,4(11):50-57(in Chinese).

[14] DAI G, ZHAN L, GUAN C, et al. Optimization of molding process parameters for CF/PEEK composites based on Taguchi method[J]. Composites and Advanced Materials, 2021, 30(14): 713-715.

[15] 王洋, 熊平, 周利庄, 等. 模压工艺对聚酰亚胺树脂力学性能的影响[J]. 塑料科技, 2018, 46(7):73-75. WANG Yang, XIONG Ping, ZHOU Lizhuang, et al. Effect of molding process on mechanical properties of polyimide resin[J]. Plastics Science and Technology,2018,46(7):73-75(in Chinese).

[16] CHEN J, WANG K, DONG A, et al. A comprehensive study on controlling the porosity of CCF300/PEEK composites by optimizing the impregnation parameters[J]. Polymer Composites,2018,39(10):3765-3779. DOI: 10.1002/pc.24407

[17] 张照. 碳纤维织物增强聚醚醚酮基(CFF/PEEK)航空复合材料的制备及其界面改性[D]. 上海: 东华大学, 2017. ZHANG Zhao. Preparation and interface modification of carbon fiber fabric reinforced polyetheretherketone (CFF/PEEK) aviation composites[D]. Shanghai: Donghua University, 2017(in Chinese).

[18] 中华人民共和国国家质量监督检验检疫总局. 纤维增强塑料拉伸性能试验方法: GB/T 1447—2005[S]. 北京: 中国标准出版社, 2005. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Test method for tensile properties of fiber reinforced plastics: GB/T 1447—2005[S]. Beijing: China Standards Press, 2005(in Chinese).

[19] 中华人民共和国国家质量监督检验检疫总局. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Test method for flexural properties of fiber reinforced plastics: GB/T 1449—2005[S]. Beijing: China Standards Press, 2005(in Chinese).

[20] 中华人民共和国国家质量监督检验检疫总局. 聚合物基复合材料短梁剪切强度试验方法: GB/T 30969—2014[S]. 北京: 中国标准出版社, 2014. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Test method for shear strength of short beams of polymer matrix composites: GB/T 30969—2014[S]. Beijing: China Standards Press, 2014(in Chinese).

[21] CHEN J, WANG K, ZHAO Y. Enhanced interfacial interactions of carbon fiber reinforced PEEK composites by regulating PEI and graphene oxide complex sizing at the interface[J]. Composites Science and Technology,2018,154:175-186. DOI: 10.1016/j.compscitech.2017.11.005

[22] HASSAN E A M, YANG L, ELAGIB T H H, et al. Synergistic effect of hydrogen bonding and π-π stacking in interface of CF/PEEK composites[J]. Composites Part B: Engineering,2019,171:70-77. DOI: 10.1016/j.compositesb.2019.04.015

[23] 许并社. 材料科学概论[M]. 北京: 北京工业大学出版社, 2002. XU Bingshe. Introduction to materials science[M]. Beijing: Beijing University of Technology Press, 2002(in Chinese).

[24] CHOUPIN T, FAYOLLE B, REGNIER G, et al. Isothermal crystallization kinetic modeling of poly(etherketoneketone) (PEKK) copolymer[J]. Polymer,2017,111:73-82. DOI: 10.1016/j.polymer.2017.01.033

[25] 王维, 吴选征, 漆宗能. 聚醚醚酮/碳纤维复合材料的界面结构以及结晶形态的研究[J]. 高分子学报, 1989(5): 544-551. WANG Wei, WU Xuanzheng, QI Zongneng. Study on interfacial structure and crystalline morphology of PEEK/CF composites[J]. Acta Polymer Sinica, 1989(5): 544-551(in Chinese).

[26] 席代坤. 聚醚醚酮及聚醚醚酮/碳富勒烯复合体系在高压下结晶行为的研究[D]. 成都: 西南交通大学, 2012. XI Daikun. Study on crystallization behavior of PEEK and PEEK/c-fullerene composites under high pressure[D]. Chengdu: Southwest Jiaotong University, 2012(in Chinese).

[27] ALI R, IANNACE S, NICOLAIS L. Effects of processing conditions on the impregnation of glass fibre mat in extrusion/calendering and film stacking operations[J]. Composites Science & Technology,2003,63(15):2217-2222.

[28] 李洪峰, 曲春艳, 王德志, 等. 短切玻纤增强PEKK与BDM/DABPA共混体系固化反应动力学及断裂韧性[J]. 材料导报, 2018, 32(6):971-976. DOI: 10.11896/j.issn.1005-023X.2018.06.022 LI Hongfeng, QU Chunyan, WANG Dezhi, et al. Curing reaction kinetics and fracture toughness of chopped glass fiber reinforced PEKK and BDM/DABPA blends[J]. Mater-ials Guide,2018,32(6):971-976(in Chinese). DOI: 10.11896/j.issn.1005-023X.2018.06.022

[29] REN F, YU Y, YANG J, et al. A mathematical model for continuous fiber reinforced thermoplastic composite in melt impregnation[J]. Applied Composite Materials, 2016, 24(3): 1-16.

[30] WANG P, ZOU B, DING S, et al. Effects of FDM-3D printing parameters on mechanical properties and microstructure of CF/PEEK and GF/PEEK[J]. Chinese Journal of Aeronautics, 2021, 34(9): 236-246.

[31] LUO M A, TIAN X A, SHANG J A, et al. Impregnation and interlayer bonding behaviours of 3D-printed continuous carbon-fiber-reinforced poly-ether-ether-ketone composites[J]. Composites Part A: Applied Science and Manufacturing,2019,121:130-138. DOI: 10.1016/j.compositesa.2019.03.020

[32] VICTREX. Victrex peek 150CA30[EB/OL]. (2021-08-27)[2021-08-01].Website: www.victrex.com/zh-Hans/datasheets.

[33] 冯明祥. CF/PEEK复合材料制备及SPEEK改性CF研究[D]. 哈尔滨: 哈尔滨工业大学, 2018. FENG Mingxiang. Preparation of CF/PEEK composites and study on SPEEK modified CF[D]. Harbin: Harbin Institute of Technology, 2018(in Chinese).

[34] 王杰. 连续碳纤维增强聚醚酮酮板材的研究[D]. 淄博: 山东理工大学, 2019. WANG Jie. Study on continuous carbon fiber reinforced polyether ketone sheet[D]. Zibo: Shandong University of Technology, 2019(in Chinese).

[35] ALEXANDRE M A, DANTRAS E, LACABANNE C, et al. Effect of PEKK oligomers sizing on the dynamic mechanical behavior of poly(ether ketone ketone)/carbon fiber composites[J]. Journal of Applied Polymer Science,2019,137(24):48818.

-

期刊类型引用(9)

1. 戎乐,黄盛,杨晗,姜卓群,周莉,王占学. CMC S弯喷管材料-结构多尺度优化设计研究. 推进技术. 2024(09): 199-209 .  百度学术

百度学术

2. 方光武,贾蕴发,高希光,宋迎东. 陶瓷基复合材料疲劳损伤模拟与界面优化设计. 现代技术陶瓷. 2022(01): 48-56 .  百度学术

百度学术

3. 李西敏,杨韬,彭必友,陈刚,韩锐,王倩. 二氧化钛陶瓷浆料的制备及其直写成型3D打印. 复合材料学报. 2022(07): 3510-3517 .  本站查看

本站查看

4. 杨绘峰,高存法. 功能梯度界面相对周期分布纤维增强复合材料反平面剪切的影响. 固体力学学报. 2021(01): 53-62 .  百度学术

百度学术

5. 王章文,张军,方国东,孟松鹤. 界面层对纤维增韧陶瓷基复合材料力学性能影响的研究进展. 装备环境工程. 2020(01): 77-89 .  百度学术

百度学术

6. 林聪,贾德君,李范春,薛涛华. 缝线对缝合增强三明治结构(陶瓷-气凝胶-陶瓷)热防护结构静力特性的影响. 复合材料学报. 2020(02): 432-441 .  本站查看

本站查看

7. 周金秋,王振军,杨思远,蔡长春,余欢,徐志锋. 连续石墨纤维增强铝基复合材料准静态拉伸损伤演化与断裂力学行为. 复合材料学报. 2020(04): 907-918 .  本站查看

本站查看

8. 任嘉成,方光武,钟毅,高希光,宋迎东. 多层界面相对陶瓷基复合材料横向开裂的影响模拟. 机械强度. 2020(05): 1207-1213 .  百度学术

百度学术

9. 张立峰,王盛,乔伟林,李战,甄婷婷,王映. 单向陶瓷基复合材料横向弯曲试验研究. 机械设计. 2019(11): 80-83 .  百度学术

百度学术

其他类型引用(8)

-

下载:

下载: