Experimental study on axial compression performance of T-section concrete filled steel and FRP tubular composite columns

-

摘要: 内置复材约束的T形截面钢管混凝土组合柱(T-section concrete filled steel and GFRP tubular composite column,T-SCFC)包括外部钢管、夹层混凝土、玻璃纤维增强树脂复合材料(Glass fiber reinforced polymer,GFRP)管和核心混凝土。对14根不同截面形式的约束混凝土短柱和3组内置不同复材管壁厚的T形截面钢管混凝土组合柱进行轴压试验,对比分析了方钢管混凝土短柱(Square concrete filled steel tube,CFST)、复材管约束混凝土短柱(Concrete filled GFRP tube,CFFT)、内置复材约束方钢管混凝土短柱(Steel-concrete-GFRP-concrete tube,SCFC)和T-SCFC柱在轴压荷载作用下的力学性能。建立与试件同尺寸的有限元模型,并开展数值参数分析,研究不同钢管壁厚和核心混凝土强度对T-SCFC柱轴心受压性能的影响。结果表明:内置约束复材管可以明显提高方钢管混凝土短柱的受压性能,显著延缓SCFC短柱在轴压荷载作用下的钢材屈服和鼓曲;T-SCFC柱在达到峰值荷载前,荷载-轴向位移曲线呈双线性增长,复材断裂后试件保持较高的残余承载力呈延性破坏,可以将复材断裂作为该类组合柱的失效点,增加复材管壁厚可以明显提高试件承载力;有限元模型计算结果与试验吻合较好;增加钢管壁厚可明显提高试件的承载力,提高试件核心混凝土强度仅对试件的等效屈服荷载有一定提高作用,对试件峰值承载力的影响较小。Abstract: The T-section concrete filled steel and glass fiber reinforced polymer (GFRP) tubular composite column (T-SCFC) is composed of external steel tube, sandwich concrete, GFRP tube and core concrete. Axial compression tests were carried out on 14 confined concrete short columns with different cross-section forms and three groups of concrete-filled steel tubular T-section columns with different wall thicknesses of GFRP tube. The mechanical properties of square concrete filled steel tube (CFST), concrete filled FRP tube (CFFT), steel-concrete-FRP-concrete (SCFC) short columns and T-SCFC columns under axial compression were compared and analyzed. The finite element model with the same size as the specimen was established, and the numerical parameter analysis was carried out to study the influence of steel tube wall thickness and core concrete strength on the axial compression performance of T-SCFC columns. The results show that the built-in GFRP tube can significantly improve the compression performance of concrete filled square steel tubular short columns, and significantly delay the steel yield and buckling of SCFC short columns under axial compression load. Before the peak load, the load-axial displacement curve of T-SCFC column increases bilinearly, and the residual bearing capacity of the specimen maintains high after fracture of the GFRP. The fracture of GFRP can be used as the failure point of the composite column. Increasing the wall thickness of GFRP tube can significantly improve the bearing capacity of the specimen. The calculation results of the finite element model are in good agreement with the test. Increasing the wall thickness of the steel tube can significantly improve the bearing capacity of the specimen. Improving the strength of the core concrete of the specimen only has a certain effect on the equivalent yield load of the specimen, and has little effect on the peak bearing capacity of the specimen.

-

在装配式钢结构住宅中,矩形钢管混凝土柱因截面规则、便于与梁进行焊接、截面受力合理、承载力高、构件截面积小等优点被广泛使用。与普通矩形钢管混凝土柱易凸出墙体[1]降低建筑功能相比,钢管混凝土异形柱可按工程使用需求进行截面设计,做到异形柱的肢厚与墙体厚度相同,使室内没有结构柱的阳角及梁边[2-3]。在轴向荷载作用下异形柱阴角处几乎没有约束作用且存在应力集中,钢管壁容易与混凝土分离,混凝土性能得不到充分发挥[4-5]。

玻璃纤维增强聚合物复合材料(Glass fiber reinforced polymer,GFRP)因轻质、高强、耐腐蚀等特点,近些年在土木工程领域得到较广泛的工程应用[6]。在混凝土柱外部布置GFRP,可对内部混凝土产生较好的约束作用,从而提高柱子的力学性能[7]。现有研究表明,在轴压荷载作用下GFRP管对核心混凝土具有较好的约束作用,可充分发挥GFRP和混凝土的力学性能[8]。

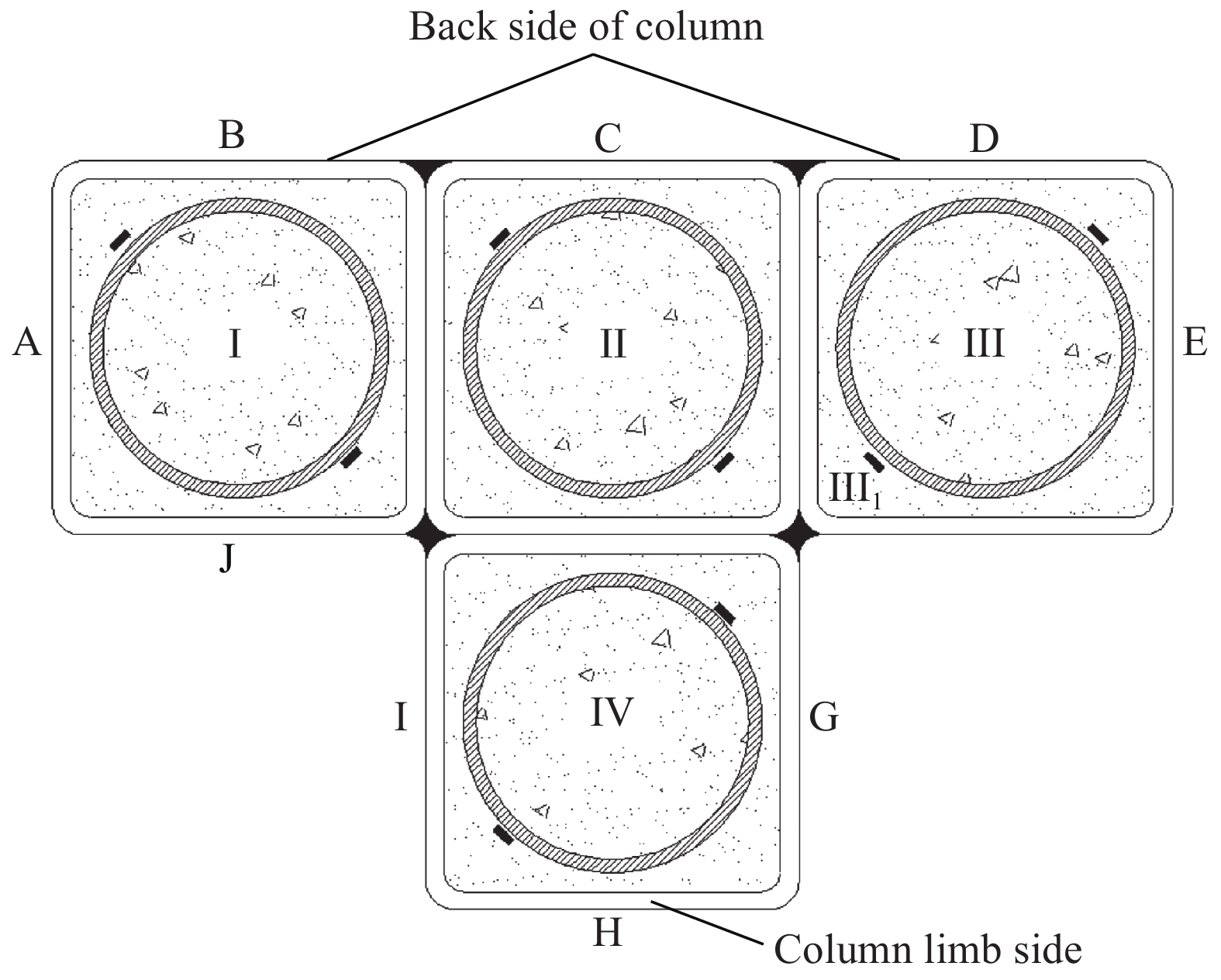

基于上述研究现状,本研究提出一种内置复材约束的方钢管混凝土异形截面组合柱,可获得灵活多变的截面形式(图1)。该组合柱外部为方钢管焊接成的异形截面,方钢管边长一般取为相邻墙厚,内部设置GFRP管,并在截面空腔内填充混凝土。在受到轴压荷载时,GFRP管可对内部混凝土形成有效约束,从而使异形柱获得更高的承载能力。

为研究该新型组合柱的受力性能,对方钢管混凝土短柱(Square concrete filled steel tube,CFST)、复材管约束混凝土短柱(Concrete filled GFRP tube,CFFT)、内置复材约束方钢管混凝土短柱(Steel-concrete-FRP-concrete,SCFC)和内置复材约束的T形截面钢管混凝土组合柱(T-SCFC)开展了轴压试验研究,对试件的破坏模式、荷载-位移关系、荷载-应变关系以及延性进行分析。采用ABAQUS-6.14建立试件同尺寸数值模型,分析钢管壁厚和核心混凝土强度对T-SCFC柱承载力的影响,为工程应用提供参考。

1. 试验概况

1.1 试件设计及制作

试验共设计20个试件(表1),包括1组CFST短柱,3组CFFT短柱,3组SCFC短柱和3组T-SCFC柱,每组试件各2个。内置GFRP缠绕管壁厚分别为1 mm、2 mm和3 mm,缠绕方向与轴向夹角为85°。核心混凝土强度等级为C40,外部方钢管对混凝土的约束作用较弱,夹层混凝土在试件内起填充作用。在试件加工过程中,夹层混凝土浇筑空间较小,振捣难度大,难以保证夹层混凝土的密实度,采用含有小粒径骨料的机制砂代替粗骨料,夹层混凝土强度较难达到与核心混凝土相同的强度等级,因此选用强度较低的C15来验证该类组合柱在轴压荷载作用下的力学性能。钢材均采用Q235B级钢,方钢管外径尺寸为100 mm×100 mm,方钢管之间通过倒角处的构造角焊缝连接,采用V形坡口焊缝,焊缝沿着试件纵向满焊,焊脚尺寸取5 mm。试件设计尺寸如图2所示,试件基本参数见表1。

表 1 不同截面形式混凝土组合柱试件基本参数Table 1. Basic parameters of concrete composite column specimens with different section formsSpecimen tf/mm ts/mm H/mm CFST-A/B — 4.5 300 CFFT-1-A/B 1 — 300 CFFT-2-A/B 2 — 300 CFFT-3-A/B 3 — 300 SCFC-1-A/B 1 4.5 300 SCFC-2-A/B 2 4.5 300 SCFC-3-A/B 3 4.5 300 T-SCFC-1-A/B 1 4.5 900 T-SCFC-2-A/B 2 4.5 900 T-SCFC-3-A/B 3 4.5 900 Notes: CFST—Square concrete filled steel tube; CFFT—Concrete filled GFRP tube; SCFC—Steel-concrete-FRP-concrete; T-SCFC—T-section concrete filled steel and GFRP tubular composite column; The naming formats of CFST, CFFT, SCFC and T-SCFC specimens are “CFST-y”, “CFFT-x-y”, “SCFC-x-y” and “T-SCFC-x-y”, x, y represent tube wall thickness and parallel specimen number, respectively; tf—Wall thickness of GFRP tube; ts—Wall thickness of steel tube; H-Height of specimen. 内置复材约束钢管混凝土组合柱由核心混凝土、GFRP缠绕管、夹层混凝土、钢管4部分组成。加工过程中,首先在GFRP管内浇筑核心混凝土,自然养护7天后,将试件底部打磨平整并在GFRP管表面粘贴应变片后放入钢管内并浇筑夹层混凝土,浇筑核心混凝土和夹层混凝土时各预留10个立方体试块,与试件在同等自然条件下养护28天。

1.2 材料力学性能测试

试件采用的钢管为Q235B级钢,根据《金属拉伸材性试验测试方法》GB/T 228—2010[9]测定钢材的弹性模量和屈服强度,如表2所示。

表 2 钢材力学性能Table 2. Mechanical properties of steelMaterial ft/MPa fy /MPa E/105MPa Q235B 381.56 313.22 2.02 Notes: ft—Tensile strength; fy—Yield strength; E—Elastic modulus. GFRP缠绕管采用机械缠绕工艺制作,以环氧树脂和玻璃纤维丝为基本材料,纤维缠绕方向与轴向夹角为85°,壁厚分别为1 mm、2 mm和3 mm。依据ASTM D2290—2012[10]和《纤维增强热固性塑料管轴向压缩性能试验方法》(GB/T5350—2005) [11]对复材管进行环向拉伸和轴向压缩性能测试,材料性能参数见表3。依据《混凝土物理力学性能试验方法标准》(GB/T 50081—2019)[12]测得核心和夹层混凝土的立方体抗压强度分别为38.87 MPa和14.33 MPa。

1.3 加载方案及测点布置

短柱轴压试验采用500 t压力试验机加载,T-SCFC轴压试验采用1000 t压力试验机加载。加载前使试件各方向的轴线均与加载端头的轴线对齐,采用预估峰值荷载的10%对试件进行预加载,并根据预加载时传感器数据判定试件是否对中。对试件施加轴向位移荷载,加载速率取2 mm/min。当试件承载力下降至峰值荷载的75%或施加的轴向位移达到试件高度的10%,试件变形过大,判定试件破坏。采用3个拉线位移计测量试件的纵向位移,加载装置如图3所示。

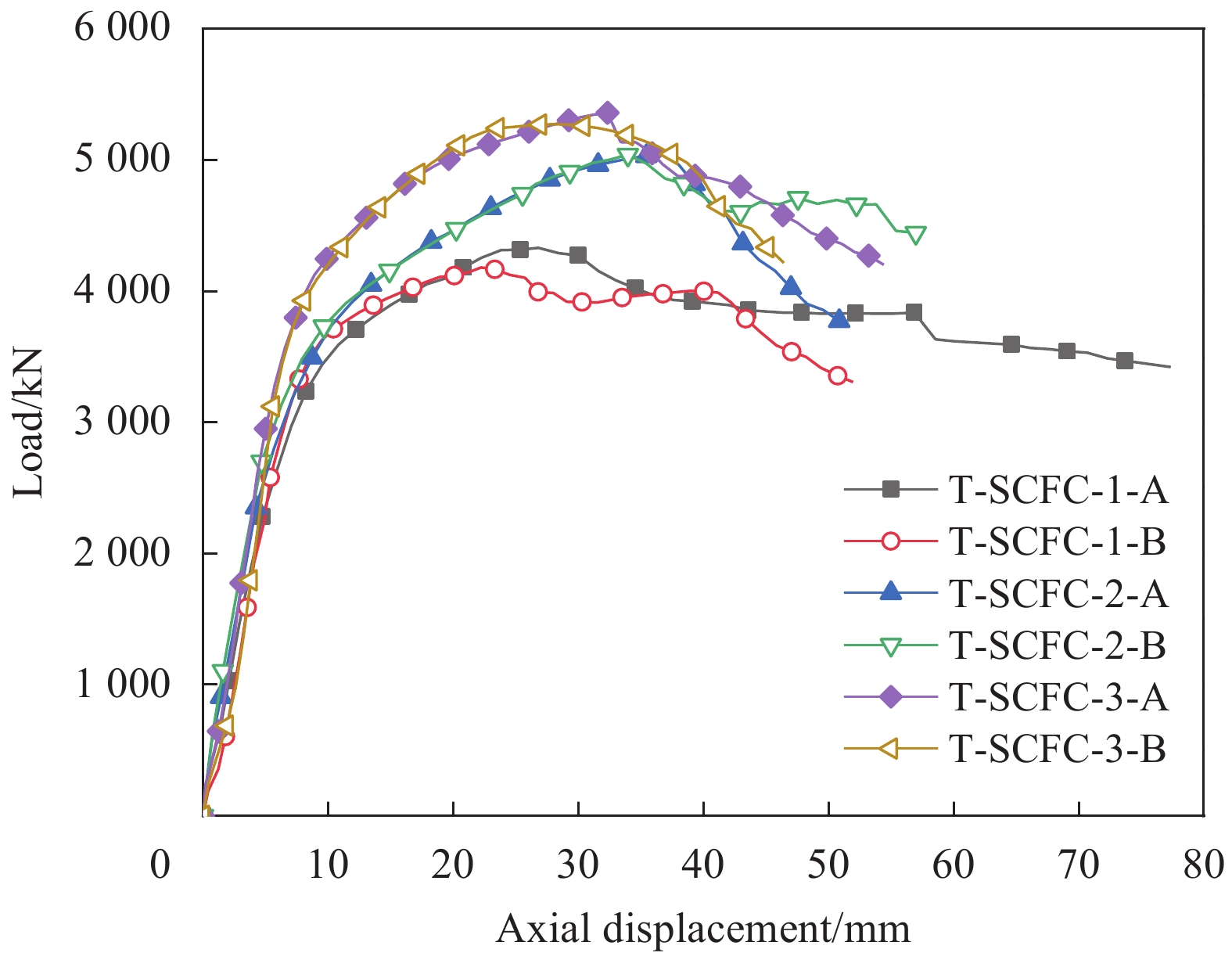

表 3 玻璃纤维增强树脂复合材料(GFRP)管力学性能Table 3. Mechanical properties of glass fiber reinforced polymer (GFRP) tubetf/mm Eh/GPa σh/MPa εh Ea/GPa σa/MPa 1 81.13 823.26 0.012 6.63 127.29 2 62.33 610.97 0.010 4.57 110.41 3 65.17 683.51 0.011 3.46 134.95 Notes: Eh—Hoop tensile modulus; σh—Hoop tensile strength; εh—Cyclic tensile ultimate strain; Ea—Axial compression modulus; σa—Axial compressive strength. 在短柱轴压试件中间截面设置纵、横向应变片,应变测点及编号如图4(a)、4(b)所示。其中,CFFT柱的应变测点布置和编号均与SCFC短柱复材管表面应变测点一致。

![]() 图 4 应变测点布置及编号Figure 4. Layout and number of strain measuring pointsT-SCFC-H/2 Sx (Sy) represents the transverse (longitudinal) strain of H/2 section steel tube of T-SCFC column, respectively; FRP tubes built in the T-SCFC were numbered with Roman numerals, taking the FRP tube I as an example, Ix(Iy) represents the transverse (longitudinal) strain of the H/2 section of the GFRP tube, and two transverse strain measuring points I1/2, I9/10 were added to the H/4 and 3H/4 sections of the GFRP tube, respectively.

图 4 应变测点布置及编号Figure 4. Layout and number of strain measuring pointsT-SCFC-H/2 Sx (Sy) represents the transverse (longitudinal) strain of H/2 section steel tube of T-SCFC column, respectively; FRP tubes built in the T-SCFC were numbered with Roman numerals, taking the FRP tube I as an example, Ix(Iy) represents the transverse (longitudinal) strain of the H/2 section of the GFRP tube, and two transverse strain measuring points I1/2, I9/10 were added to the H/4 and 3H/4 sections of the GFRP tube, respectively.2. 试验结果与讨论

2.1 不同截面形式混凝土组合柱试验现象及破坏模式

当纵向位移在0~3 mm 范围内,CFST短柱无明显试验现象。随着荷载的增加,试件表面不同高度处发生局部鼓曲。继续加载,鼓曲向相邻面发展,方钢管角部向外膨胀,试件鼓曲处趋近圆形截面发展,最终形成与高度方向存在一定夹角的斜向剪切滑移带,如图5所示。

在轴向荷载作用下,CFFT短柱首先在表面出现白色斑点并逐渐发展为白色条纹。继续加载,白色条纹继续扩展,变得密集,形成沿环向的贯穿裂纹并不停地发出噼啪声,伴随着较大的复材断裂声复材管发生断裂,构件呈脆性破坏。试件加载及破坏过程如图6所示。

SCFC短柱在轴压荷载作用下在距端部50 mm处出现鼓曲,试件发出逐渐密集的噼啪声,钢管鼓曲逐渐向试件相邻表面发展;伴随着较大的复材断裂声,试件承载力迅速下降,钢管鼓曲处变形快速发展;随后试件保持较高的承载力进入较稳定的受力状态;继续加载,钢管鼓曲处形成环形鼓曲,最终试件变形过大,停止加载,如图7所示。

与CFST短柱相比,SCFC短柱在发生相同的轴向位移时钢管鼓曲变形较小,试件表面鼓曲出现在同一截面高度,结合后续有限元计算结果可知,试件仅在GFRP发生断裂处产生较大的侧向膨胀,混凝土未发生较大的剪切变形。相比于CFFT短柱发生脆性破坏,SCFC短柱具有较好的延性和残余承载力。

6根T-SCFC柱在轴压荷载作用下发生两种不同的破坏模式。根据试件的破坏模式将其分为两组,第一组试件发生局部强度破坏,包括T-SCFC-1-A、T-SCFC-1-B和T-SCFC-2-B;第二组试件先发生局部强度破坏后整体弯曲,包括T-SCFC-2-A、T-SCFC-3-A和T-SCFC-3-B。分别以典型试件T-SCFC-1-A和T-SCFC-3-A为例,介绍T-SCFC柱在轴压荷载作用下的两种破坏过程。为便于对加载过程中对试验现象进行描述,将试件的各立面进行编号,如图8所示。

T-SCFC-1-A试件在加载初期表现出较好的弹性行为;试件屈服后开始发出细小的噼啪声,柱肢侧钢管上下端均出现局部鼓曲;随着轴向荷载增加试件发出较大的复材断裂声,试件随后保持较高的残余承载力进入相对稳定的承载阶段;继续加载,柱背侧(A、B、C面)上部钢管出现鼓曲并不断向柱中截面发展,形成褶皱形鼓曲,试件向柱背侧倾斜,当试件轴向位移达到77 mm时,试件D、E面相交的钢管角部炸开,试件破坏,如图9所示。

加载初期,T-SCFC-3-A试件无明显试验现象;达到试件等效屈服荷载后,试件发出纤维断裂的噼啪声,柱肢侧端部钢管出现鼓曲变形,柱背侧中部钢管屈曲,试件开始发生弯曲变形;继续加载,试件发出较大的复材纤维断裂声,承载力下降,柱背侧中部钢管出现鼓曲并很快形成褶皱,当承载力下降至峰值荷载的75%时,试验结束。试件破坏过程如图10所示。

对比在轴压荷载作用下发生两种不同破坏模式的T-SCFC柱,结合后面有限元计算结果推断,复材管端部对混凝土约束作用较弱,端部附近复材纤维易发生断裂,外部钢管受混凝土挤压均首先在试件端部发生局部鼓曲;对于复材管壁厚较小试件,试件端部主要由钢管为混凝土提供约束作用,最终试件发生局部强度破坏;对于复材管壁厚较大试件,发生局部破坏后试件中部产生一定的侧向水平位移,随后在附加弯矩作用下试件发生整体弯曲破坏。

2.2 不同截面形式混凝土组合柱荷载-轴向位移曲线

取拉线位移计的均值作为试件轴向位移,绘制14个短柱轴压试件的荷载-轴向位移曲线,如图11所示。CFST柱在加载前期表现为弹性变形;随着轴向位移增大,试件达到屈服荷载后钢管产生明显的侧向鼓曲变形,随后试件承载力很快达到峰值并表现出软化行为;继续加载,混凝土被压得密实,钢材进入强化阶段,试件承载力表现出一定的上升趋势,但试件变形较大。

具有3种不同复材管壁厚的CFFT短柱的荷载-轴向位移曲线均近似双线性增长[13]。由图11(b)可知,随着复材管壁厚的增加,试件的等效屈服荷载和峰值承载力均得到明显提高。其中,等效屈服荷载采用冯鹏等建议的方法[14]进行确定。CFFT柱在复材管断裂前达到峰值承载力,表现为脆性破坏。

SCFC短柱的荷载-轴向位移曲线在达到峰值荷载前表现为近似双线性的单调递增,在试件发出明显的复材断裂声后,试件承载力呈阶梯状下降,表现出较好的延性破坏特征。由图11(c)可知,随着内置复材管壁厚增加,SCFC短柱的峰值承载力明显提高。与CFST短柱相比,SCFC短柱承载力得到明显提高,具体见表4。

表 4 SCFC与CFST短柱轴压承载力对比Table 4. Comparison of axial compressive bearing capacity between SCFC and CFST short columnsSpecimen Ny/kN Nmax/kN ηy/% ηmax/% CFST-A/B 673.60 800.38 — — SCFC-1-A/B 806.00 978.24 19.6 22.20 SCFC-2-A/B 885.32 1097.08 31.4 37.07 SCFC-3-A/B 991.67 1298.56 47.2 62.20 Notes: Ny—Equivalent yield load; Nmax—Peak load; ηy—Increase ratio of equivalent yield load; ηmax—Increase ratio of peak load. 短柱轴压试验主要结果见表5。采用如下延性系数评价14个短柱轴压试件的变形能力[15]:

表 5 不同截面形式混凝土组合柱轴压试验主要结果Table 5. Main results of concrete composite columns with different section forms under axial compression loadSpecimen Nmax/kN Ny/kN Nmax/ Ny Nmax-a/kN Ny-a/kN μa η/% Failure mode CFST-A 803.02 688.53 1.17 800.38 673.60 2.93 — Softening CFST-B 797.73 658.66 1.21 CFFT-1-A 454.41 201.53 2.25 428.49 215.47 4.91 — Brittle failure CFFT-1-B 402.56 229.40 1.75 CFFT-2-A 620.42 315.04 1.97 606.75 325.32 3.30 41.60 CFFT-2-B 593.07 335.60 1.77 CFFT-3-A 827.34 432.45 1.91 835.77 414.89 4.11 95.05 CFFT-3-B 844.20 397.32 2.12 SCFC-1-A 1002.60 839.20 1.19 978.24 806.00 3.13 — Ductile failure SCFC-1-B 953.87 772.79 1.23 SCFC-2-A 1093.48 929.99 1.18 1097.08 885.32 4.78 12.15 SCFC-2-B 1100.69 840.65 1.31 SCFC-3-A 1309.79 1019.08 1.29 1298.56 991.67 3.31 32.74 SCFC-3-B 1287.33 964.26 1.34 Notes: Nmax-a—Mean value of peak load for specimens with same parameters; Ny-a—Mean value of equivalent yield load for specimens with same parameters; μa—Average ductility coefficient; η—Peak load increase ratio. μ=eu/ey (1) 其中:μ为延性系数;eu为峰值荷载对应的轴向位移;ey为等效屈服荷载对应的轴向位移。

与CFST短柱相比,SCFC短柱表现出明显的强化行为,达到峰值荷载前试件的延性获得提高。与内置复材壁厚2 mm的试件相比,内置复材壁厚为3 mm的SCFC短柱达到峰值荷载时的破坏更突然,试件延性降低。CFFT短柱荷载-位移曲线在达到峰值荷载前近似双线性增长,表现出一定的延性特征,但试件在复材断裂时发生脆性破坏。

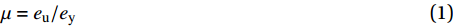

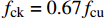

取拉线位移计均值为试件轴向位移,绘制3组内置不同复材管壁厚的T-SCFC柱荷载-轴向位移曲线,如图12所示。可知,在达到试件峰值荷载前6根T-SCFC柱的荷载-轴向位移曲线均近似双线性增长;峰值荷载点后,发生局部强度破坏的试件(T-SCFC-1-A/B、T-SCFC-2-B)具有较高的残余承载力,荷载-轴向位移曲线呈阶梯状下降,试件表现出较好的延性,最终破坏模式为钢管角部或焊缝被撕裂;对于先发生局部强度破坏后整体弯曲的试件(T-SCFC-2-A、T-SCFC-3-A/B)在峰值荷载点之后,试件在附加弯矩作用下发生弯曲变形,复材管对混凝土的约束作用未得到充分发挥,试件承载力近似线性下降。

根据T-SCFC柱的荷载位移曲线的特征,可将试件的加载过程分为:初始弹性阶段、屈服过渡阶段、强化阶段和延性破坏阶段。

(1)初始弹性阶段:加载初期,T-SCFC柱各组成部分均在弹性范围内发生变形,试件整体表现出良好的初始刚度,荷载-轴向位移曲线在出现拐点之前呈线性增长。

(2)屈服过渡阶段:随着荷载增大,试件内部混凝土开裂后发生膨胀,复材管开始为核心混凝土提供被动约束。钢管达到屈服应变,在试件端部产生局部鼓曲,试件刚度降低,荷载-轴向位移曲线表现为平滑的非线性曲线。

(3)强化阶段:屈服过渡阶段之后荷载-轴向位移曲线出现第二个近似线性的增长阶段,刚度低于初始弹性阶段,此时复材管和钢管共同为混凝土提供约束作用。强化阶段中后期,可以观察到钢管端部发生明显鼓曲并向相邻表面发展;伴随着较大的复材纤维断裂声,试件达到峰值承载力。

(4)延性破坏阶段:对于发生局部强度破坏的试件,复材管发生断裂后试件承载力快速下降至峰值承载力的90%左右,荷载-轴向位移曲线呈阶梯状下降;对于发生局部强度破坏后整体弯曲的试件,在达到峰值时复材管连续发出纤维断裂声,随后荷载-轴向位移曲线近似线性下降。

T-SCFC柱和SCFC短柱均在试件发出较大的复材断裂声后达到峰值承载力,随后呈延性破坏。以上分析表明,可以将复材断裂作为SCFC的承载力失效特征点。

为量化评价复材管壁厚对T-SCFC柱承载力的影响,采用内置复材壁厚1 mm试件的承载力对另两组试件进行归一化处理。发现内置复材壁厚2 mm和3 mm试件的峰值承载力分别比内置复材壁厚1 mm的T-SCFC柱提高18.48%和24.93%,等效屈服承载力分别提高3.96%和14.4%。T-SCFC柱轴压试验主要结果见表6。

表 6 T-SCFC柱轴压试验主要结果Table 6. Main results of T-SCFC columns under axial compression loadSpecimen NTmax/kN NTy/kN NTmax/ NTy NTmax-a/kN NTy-a/kN μT-a ηTmax/% ηTy/% T-SCFC-1-A 4330.79 3431.66 1.26 4255.69 3528.83 2.59 — — T-SCFC-1-B 4180.59 3626 1.15 T-SCFC-2-A 5044 3739 1.35 5042 3668.41 3.74 18.48 3.96 T-SCFC-2-B 5040 3597.82 1.40 T-SCFC-3-A 5360 4145.16 1.29 5316.50 4037.08 3.52 24.93 14.40 T-SCFC-3-B 5273 3929 1.34 Notes: NTmax—Peak load capacity of T-SCFC; NTy—Equivalent yield load of T-SCFC; NTmax-a—Mean value of peak load for specimens with same parameters; NTy-a—Mean value of equivalent yield load for specimens with same parameters; μT-a—Average ductility coefficient; ηTmax-Peak load increase ratio; ηTy—Increase ratio of equivalent yield load. 图13对比了3组内置不同复材管壁厚的4个SCFC短柱承载力的直接叠加和T-SCFC柱峰值承载力,可知4个同参数SCFC短柱承载力之和低于T-SCFC柱的峰值承载力,差值均小于15%。表明多个SCFC焊接形成T形截面组合柱后可以协同受力,使构件获得较高的承载能力。SCFC短柱与T-SCFC柱均在复材断裂时达到峰值承载力,二者均表现为强度破坏,并在破坏过程中保持较高的残余承载力和延性。

2.3 不同截面形式混凝土组合柱荷载-应变曲线

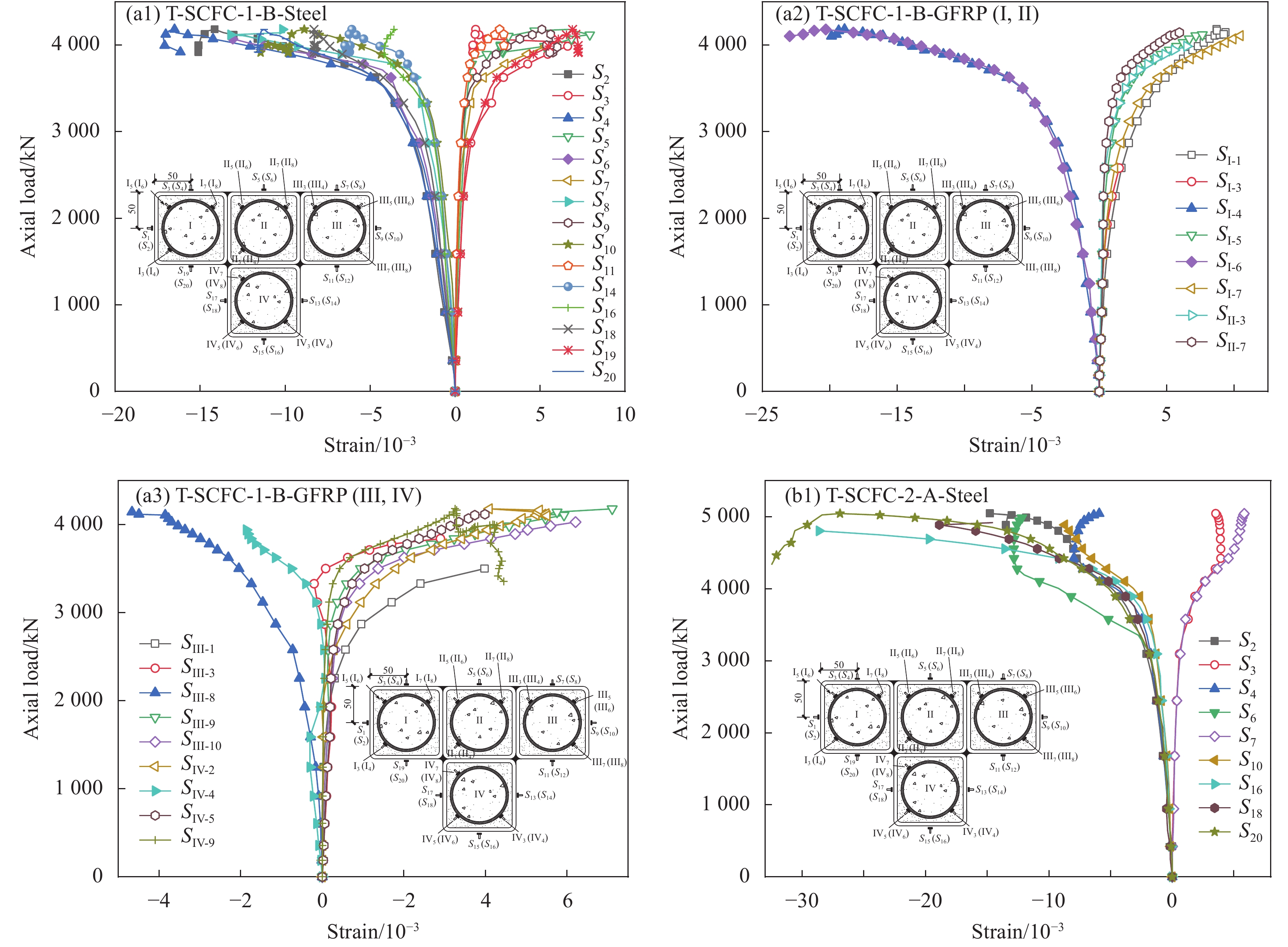

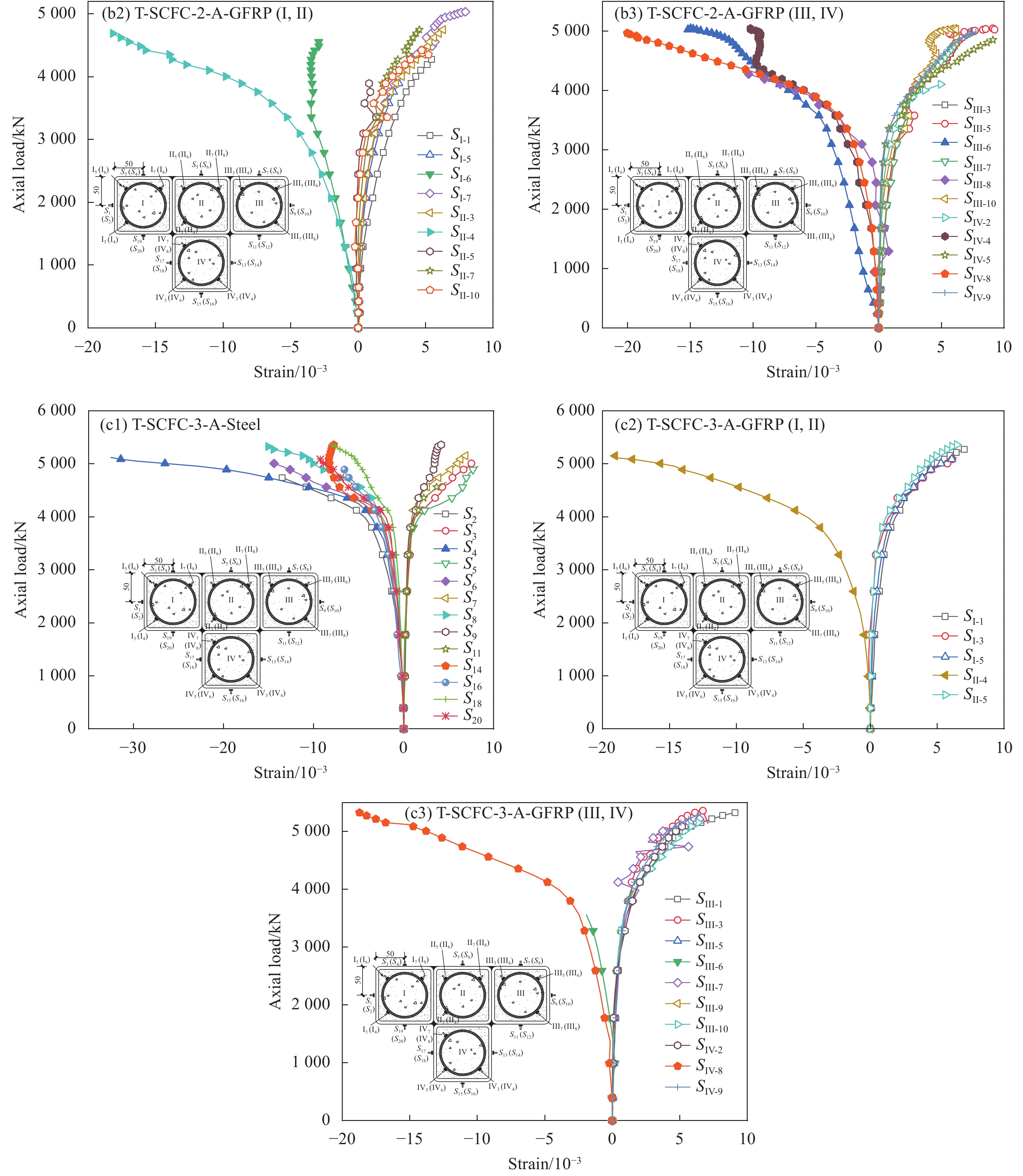

图14给出了短柱轴压试验典型试件柱中截面的荷载-应变曲线。其中,所有应变数据均采用DH3818静态应变系统进行采集,应变受拉为正,受压为负。

加载初期,CFST柱荷载-应变曲线呈线性增长,钢管纵向受压应变大于横向受拉应变。初始弹性阶段钢管主要发生纵向弹性变形,对混凝土基本没有约束作用。当钢管达到屈服应变后,试件刚度下降。接近峰值荷载时,钢管纵、横向应变快速增加,随后试件发生较大侧向变形并出现软化行为。

3组CFFT短柱的荷载-应变曲线均呈典型的双线性增长。加载初期,复材管纵向应变大于横向应变。达到试件等效屈服荷载后,混凝土开裂,复材管为其提供侧向约束,复材管环向受拉,横向应变快速增加,试件进入强化阶段。达到峰值承载力时,复材管的横向应变达到极限断裂应变,复材管发生断裂,试件丧失承载力。

3组SCFC短柱的荷载-应变曲线在达到峰值前均表现为明显的双线性增长。加载初期钢管与复材管应变曲线均呈线性增长,试件各组成部分处于变形协调状态。随着荷载增加,混凝土开裂,钢管达到屈服应变,曲线增长趋势变缓,复材管开始对核心混凝土发挥约束作用,荷载-应变曲线表现为非线性。继续加载,荷载-应变曲线再次近似线性增长,表现为明显的强化行为。此时钢材发生强化,发生横向鼓曲变形后的钢管趋近于圆形截面,对混凝土的约束效应提高。强化阶段后期,钢管与复材管共同为混凝土提供约束,横向应变均增长较快。

3组T-SCFC柱轴压试件各选取1个绘制荷载-应变曲线,如图15所示。加载初期荷载-应变曲线呈线性增长,试件各组成部分变形协调。

钢管平均应变达到1.5×10−3时,荷载增长趋势变缓,试件进入屈服过渡阶段,内置复材管壁厚1 mm、2 mm和3 mm的T-SCFC试件的承载力分别为2580 kN、2701 kN和3462 kN,表明增加复材管壁厚可以明显提高钢材屈服时T-SCFC柱的承载力;钢管屈服时,3种复材壁厚对应环向的应变分别为1.059×10−3、0.819×10−3和0.575×10−3,表明钢材屈服时复材管开始为核心混凝土提供被动约束,复材管的环向应变随着复材厚度的增大而减小,复材管的约束作用尚未完全发挥。荷载-轴向位移曲线呈非线性增长,试件进入屈服过渡阶段。

试件进入强化阶段后,钢材发生强化,钢管趋近于圆形截面,对混凝土的约束效果提高,此时钢管与复材管共同为混凝土提供约束作用,荷载-应变曲线以较低的增长速率再次呈线性增长。

强化阶段中后期,发生局部强度破坏的试件向柱背侧倾斜,柱背侧的钢管纵向应变(S4、S6、S8)增长较快,而柱肢侧钢管纵向应变(S12、S14、S16、S18)增长趋势变缓甚至出现减小的现象,与试件的破坏模式一致,表明试件在接近峰值荷载时出现一定的偏心受压。对于先发生局部强度破坏后整体弯曲的试件,受压侧的钢管应变迅速增大,弯曲时受拉侧的钢管应变出现负增长。

T-SCFC柱在复材管断裂前达到峰值承载力,柱中截面复材管应变远低于复材管环拉试验的极限断裂应变,且峰值点后试件保持较高的残余承载力,表明构件失效时复材管仅发生部分断裂,试件破坏过程中具有较好的延性。

3. T-SCFC数值分析

3.1 T-SCFC试件同尺寸数值模型创建

采用有限元软件ABAQUS 6.14建立T-SCFC试验构件同尺寸的数值模型。钢管采用二次减缩积分实体单元C3D20R,混凝土采用线性减缩积分实体单元C3D8R,GFRP管采用连续壳单元SC8R。混凝土、钢管和复材接触面的法向行为均设置为“硬接触”,切向行为设置为“库伦摩擦”,考虑到材料之间的粘结作用、模型的计算效率及收敛性问题[16],接触面以刚度较大的材料为主面。其中,钢管和混凝土接触面,以钢管为主面,混凝土为从面,摩擦系数取0.4[17];复材管和混凝土接触面,以混凝土为主面,复材管为从面,摩擦系数取0.3[18]。在试件承载力达到峰值前,试件焊缝未开裂,钢管之间未出现滑移,数值模型中采用“Tie”约束模拟钢管之间的相互作用。在试件加载端截面形心处设置面外参考点并与端部截面耦合,在参考点上施加轴向位移,并锁定其他各方向的自由度,试件另一端设为完全固定[19-20]。

轴压试件采用Q235B级无缝钢管制作,数值建模时根据现有研究[21]采用简化的理想弹塑性模型更合理。采用材性试验结果,将钢材屈服强度设为313.22 MPa。

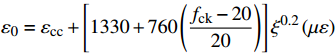

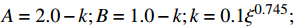

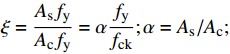

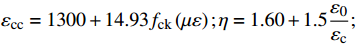

在轴压荷载作用下,混凝土受到GFRP管和钢管的约束作用,处于三向受压转态,选取混凝土塑性损伤模型(Concrete damaged plasticity,CDP)对其进行数值模拟。参考现有研究成果[22-23],CDP的模拟参数取值见表7。混凝土在受到被动约束时,混凝土的塑性有所增加,而塑性性能的增加与约束效应系数有关。本文采用韩林海等[24]提出的核心混凝土等效应力-应变关系模型。

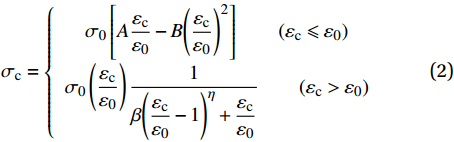

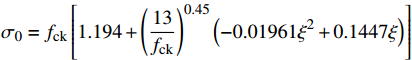

表 7 混凝土塑性损伤参数取值Table 7. Concrete damaged plasticity parameter valuesψ ε σb0/σb0σc0σc0 Kc μ 30 0.1 1.16 0.6667 0.0005 Notes: ψ—Dilatancy angle; ε—Flow potential eccentricity; σb0/σc0—Ratio of initial equibiaxial compressive yield stress to initial uniaxial compressive yield stress; Kc—Ratio of the second stress invariant on the tensile meridian; μ—Viscosity parameter. 混凝土的应力

σc -应变εc 关系如下:σc={σ0[Aεcε0−B(εcε0)2](εc⩽ (2) 式中:

{\sigma }_{0}={f}_{\rm{c}\rm{k}}\left[1.194+{\left(\frac{13}{{f}_{\rm{c}\rm{k}}}\right)}^{0.45}\left(-0.01961{\xi }^{2}+0.1447\xi \right)\right] {\varepsilon }_{0}={\varepsilon }_{{\rm{cc}}}+\left[1330+760\left(\frac{{f}_{\rm{c}\rm{k}}-20}{20}\right)\right]{\xi }^{0.2}\left(\mu \varepsilon \right) A=2.0-k;B=1.0-k;k=0.1{\xi }^{0.745} ; \xi =\frac{{A}_{\rm{s}}{f}_{\rm{y}}}{{A}_{\rm{c}}{f}_{\rm{y}}}=\alpha \frac{{f}_{\rm{y}}}{{f}_{\rm{c}\rm{k}}} ; \alpha ={A}_{\rm{s}}/{A}_{\rm{c}} ; {\varepsilon }_{\rm{c}\rm{c}}=1300+14.93{f}_{\rm{c}\rm{k}}\left(\mu \varepsilon \right);\eta =1.60+1.5\frac{{\varepsilon }_{0}}{{\varepsilon }_{{\rm{c}}}} ; \beta =\left\{\begin{array}{c}\dfrac{0.75}{1+\sqrt{\xi }}{f}_{\rm{c}\rm{k}}^{0.1}\qquad\left(\xi \leqslant 3.0\right)\\ \dfrac{0.75}{\left(1+\sqrt{\xi }\right){\left(\xi -2\right)}^{2}}{f}_{\rm{c}\rm{k}}^{0.1}\qquad\left(\xi > 3.0\right)\end{array}\right. 其中:

{f}_{{\rm{y}}} 为钢材屈服极限;{f}_{\rm{c}\rm{k}}=0.67{f}_{\rm{c}\rm{u}} ,{f}_{\rm{c}\rm{u}} 为混凝土立方试块抗压强度;{A}_{\rm{s}} 为钢管横截面面积;{A}_{\rm{c}} 为混凝土横截面面积;\xi 为约束效应系数。试件采用的GFRP管纤维缠绕角度与轴向呈85°,采用连续壳单元创建复合层,对部件施加局部柱坐标系,1方向为环向,2方向为轴向,3方向为纤维铺层方向,结合现有研究[25-26]、GFRP管分离圆盘试验结果和Hashin破坏准则[27]定义复材的失效点和材料属性。GFRP材料属性参数见表8。

表 8 GFRP管模型参数Table 8. Model parameters of GFRP tubeThickness/mm 1 2 3 E1/GPa 81.13 62.33 65.17 E2=E3/GPa 6.63 4.57 3.46 ν12=ν13 0.33 0.33 0.33 ν23 0.35 0.32 0.33 G12= G13/GPa 6.5 6.5 6.5 G23/GPa 2.24 1.54 1.17 采用六面体结构网格对钢管模型进行划分,尺寸为10 mm×10 mm。为增加计算过程中的收敛性,减少应力集中处单元出现自锁现象,对方钢管的棱边进行局部网格细化。核心混凝土和夹层混凝土均采用六面体扫掠划分,网格尺寸10 mm×10 mm。采用六面体中性轴算法网格对GFRP管模型进行划分,网格尺寸取5 mm×5 mm,扫掠路径取复材管纤维铺层方向,即GFRP管壁厚方向。装配完成后有限元模型如图16所示。

3.2 数值模型验证

将有限元模型计算得到的荷载-轴向位移曲线与试验曲线进行对比,如图17所示。

3组T-SCFC柱的数值模拟结果与试验值吻合较好。峰值荷载点后,有限元模拟的荷载-轴向位移曲线与试验结果呈相似的下降趋势,此时数值模型中GFRP管的环向应力在局部达到极限强度,表明采用连续壳单元并考虑Hashin损伤的GFRP管数值模型可以较好模拟该类组合柱中复材管的破坏。有限元计算结果与轴压试验的峰值承载力误差在5%以内,见表9。表明数值模型在预测试件峰值承载力方面具有较高的准确性。图18给出了T-SCFC柱数值模拟的破坏模式,可知有限元分析结果与试验现象也吻合较好。以上对比表明本文建立的数值模型在预测构件破坏方面具有较高的可行性。

表 9 T-SCFC数值模拟结果与试验对比Table 9. Comparison of numerical simulation and experimental results of T-SCFCSpecimen NTmax-a/kN NTmax-F/kN NTmax-a /NTmax-F T-SCFC-1-A/B 4255.69 4419.39 0.96 T-SCFC-2-A/B 5042.00 5002.74 1.01 T-SCFC-3-A/B 5316.50 5590.95 0.95 Note: NTmax-F—Peak load of numerical simulation. 3.3 T-SCFC数值模型参数分析

T-SCFC柱由核心混凝土、复材管、夹层混凝土和钢管组成,其轴向承载力主要由外部钢管和内置复材约束芯柱贡献。本节以上文中承载力和延性较高,且数值模拟以较为精确的内置复材壁厚2 mm 的T-SCFC柱数值模型为基础,开展相应的数值参数分析。研究钢管壁厚和核心混凝土强度对T-SCFC柱在轴压荷载作用下力学性能的影响规律,具体数值试件设计见表10。

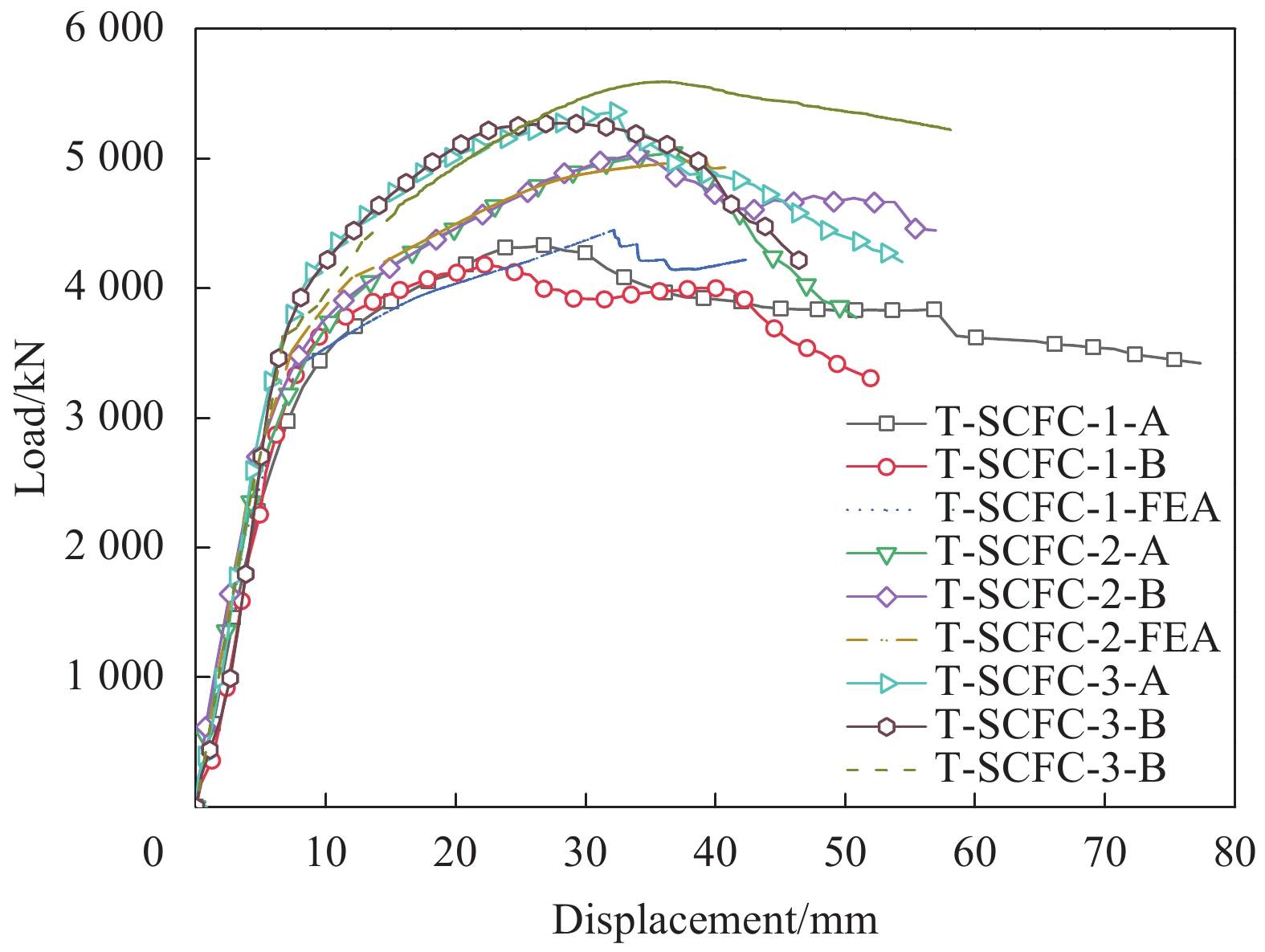

表 10 T-SCFC数值试件基本参数Table 10. Basic parameters of numerical specimens of T-SCFCNumerical specimen fcu/MPa ts/mm T-SCFC-40-2.5 40 2.5 T-SCFC-40-3.5 40 3.5 T-SCFC-40-4.5 40 4.5 T-SCFC-40-5.5 40 5.5 T-SCFC-30-4.5 30 4.5 T-SCFC-50-4.5 50 4.5 T-SCFC-60-4.5 60 4.5 Notes: The naming format of T-SCFC specimens is “T-SCFC-x-y”, x, y represent core concrete strength and wall thickness of steel tube respectively; fcu—Core concrete strength. 考虑不同钢管壁厚的试件数值分析得到的荷载-轴向位移曲线如图19所示,可知随着钢管壁厚的增加,T-SCFC柱在弹性变形阶段的刚度有一定提高,试件的等效屈服承载力和峰值承载力明显提高。为量化评价钢管壁厚对该类组合柱轴压承载力的影响,将钢管壁厚为2.5 mm试件的承载力与不同钢管壁厚试件进行对比,钢管壁厚3.5 mm、4.5 mm和5.5 mm的T-SCFC柱的等效屈服荷载分别提高21.8%、50.51%和66.83%,峰值承载力分别提高5.07%、20.95%和35.51%,见表11。

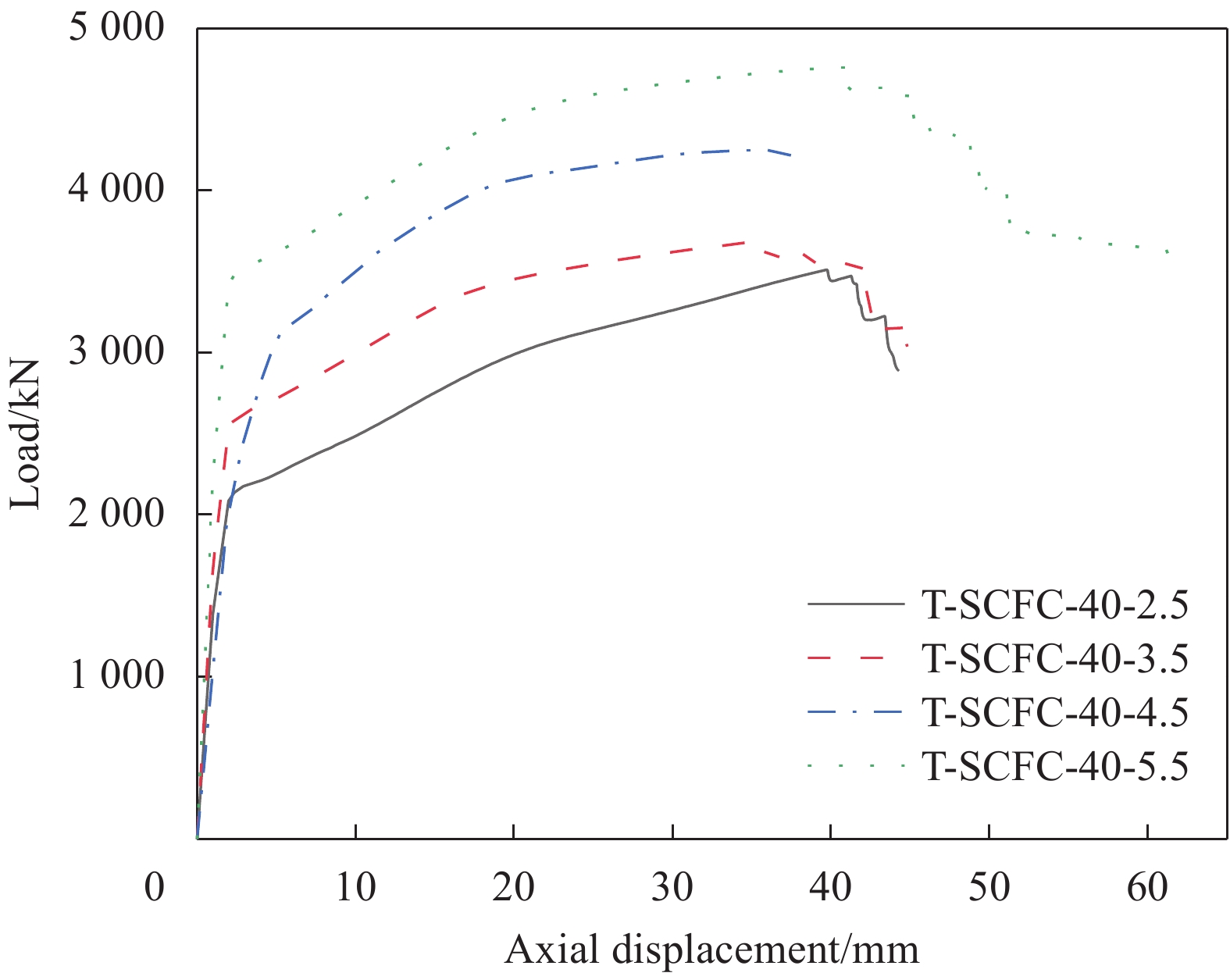

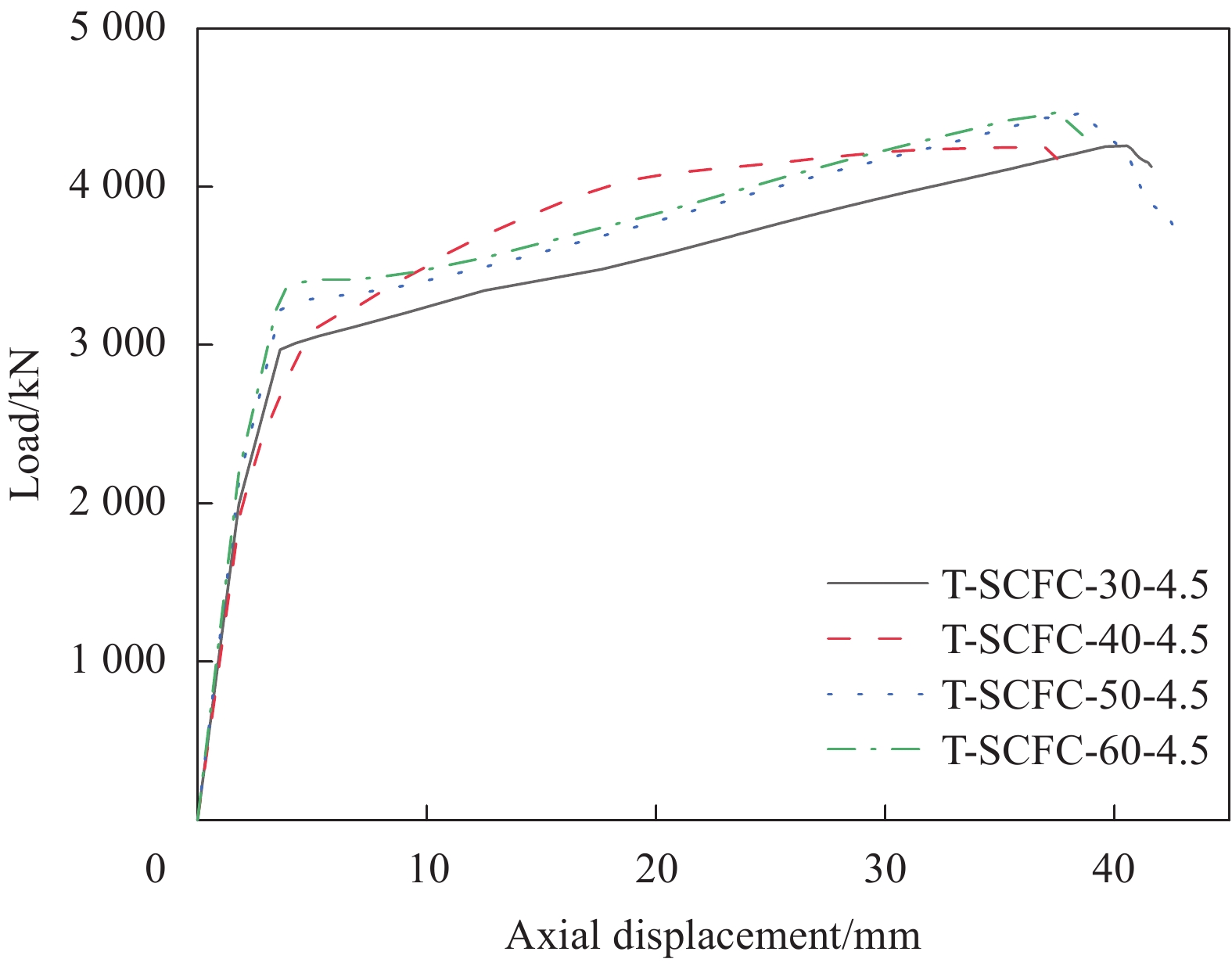

表 11 钢管壁厚对T-SCFC试件承载力的影响Table 11. Influence of wall thickness of steel tube on bearing capacity of T-SCFC specimensSpecimen Ny/kN Nmax/kN ηy/% ηmax/% T-SCFC-40-2.5 2085.40 3511.92 — — T-SCFC-40-3.5 2539.99 3689.89 21.80 5.07 T-SCFC-40-4.5 3138.71 4247.65 50.51 20.95 T-SCFC-40-5.5 3479.03 4759.08 66.83 35.51 考虑不同核心混凝土强度的试件有限元分析得到的荷载-轴向位移曲线如图20所示,可知提高核心混凝土强度对T-SCFC柱的等效屈服承载力有一定提高,但是对初始刚度和峰值承载力的影响不大。将核心混凝土强度为30 MPa试件的承载力与填充不同核心混凝土强度的数值计算结果对比,核心混凝土强度为40 MPa、50 MPa和60 MPa的T-SCFC柱的等效屈服荷载分别提高5.64%、8.4%和12.23%,见表12。

具有不同核心混凝土强度的T-SCFC柱在轴压荷载作用下具有相近的峰值承载力,当核心混凝土强度由30 MPa提高至50 MPa时,T-SCFC柱的峰值承载力提高4.33%,与文献[7]中SCFC短柱轴压试验结果一致,表明本文建立的有限元数值模型具有较高的准确性。试件承载力达到等效屈服荷载时混凝土开裂,核心混凝土被压碎发生膨胀并受到GFRP管和外部方钢管的侧向约束处于围压状态,使试件的峰值承载力得到提高。当复材管内环向应力达到极限强度发生脆性断裂时,混凝土受到的约束作用迅速衰减,试件承载力快速下降,在轴向荷载作用下混凝土挤压钢管壁,钢管快速鼓曲。以上分析表明,可以将GFRP管断裂作为T-SCFC柱的承载力失效点。强化阶段后期核心混凝土被压碎,不同核心混凝土强度对试件峰值承载力的影响较小。

表 12 核心混凝土强度对T-SCFC试件承载力的影响Table 12. Influence of core concrete strength on bearing capacity of T-SCFC specimensSpecimen Ny/kN Nmax/kN ηy/% ηmax/% T-SCFC-30-4.5 2971.21 4260.06 — — T-SCFC-40-4.5 3138.71 4247.84 5.64 −0.29 T-SCFC-50-4.5 3220.93 4444.46 8.40 4.33 T-SCFC-60-4.5 3334.59 4456.23 12.23 4.60 4. 结 论

(1) 方钢管混凝土短柱在达到屈服荷载后很快达到峰值,随后出现软化行为发生较大变形,复材约束混凝土短柱呈脆性破坏,内置约束复材管可以明显提高方钢管混凝土短柱的受压性能,可以明显延缓内置复材约束方钢管混凝土短柱在轴压荷载作用下的钢材屈服和鼓曲。

(2) 内置复材约束的T形截面钢管混凝土组合柱在达到峰值荷载前,荷载-轴向位移曲线呈双线性,在复材断裂后试件保持较高的残余承载力呈阶梯状下降,可以将复材管断裂作为试件的失效点,且随着复材管壁厚的增加试件承载力得到明显提高。

(3) 采用连续壳单元和Hashin破坏准则建立的复材缠绕管模型可以较好模拟玻璃纤维增强树脂复合材料(GFRP)管在轴压荷载作用下的受力和破坏过程,与试验结果吻合较好。

(4) 数值参数分析表明,增加钢管壁厚可以明显提高试件的等效屈服荷载和峰值承载力,而提高试件核心混凝土强度仅对试件的等效屈服荷载有一定提高作用,对试件峰值承载力的影响较小。

-

图 4 应变测点布置及编号

Figure 4. Layout and number of strain measuring points

T-SCFC-H/2 Sx (Sy) represents the transverse (longitudinal) strain of H/2 section steel tube of T-SCFC column, respectively; FRP tubes built in the T-SCFC were numbered with Roman numerals, taking the FRP tube I as an example, Ix(Iy) represents the transverse (longitudinal) strain of the H/2 section of the GFRP tube, and two transverse strain measuring points I1/2, I9/10 were added to the H/4 and 3H/4 sections of the GFRP tube, respectively.

表 1 不同截面形式混凝土组合柱试件基本参数

Table 1 Basic parameters of concrete composite column specimens with different section forms

Specimen tf/mm ts/mm H/mm CFST-A/B — 4.5 300 CFFT-1-A/B 1 — 300 CFFT-2-A/B 2 — 300 CFFT-3-A/B 3 — 300 SCFC-1-A/B 1 4.5 300 SCFC-2-A/B 2 4.5 300 SCFC-3-A/B 3 4.5 300 T-SCFC-1-A/B 1 4.5 900 T-SCFC-2-A/B 2 4.5 900 T-SCFC-3-A/B 3 4.5 900 Notes: CFST—Square concrete filled steel tube; CFFT—Concrete filled GFRP tube; SCFC—Steel-concrete-FRP-concrete; T-SCFC—T-section concrete filled steel and GFRP tubular composite column; The naming formats of CFST, CFFT, SCFC and T-SCFC specimens are “CFST-y”, “CFFT-x-y”, “SCFC-x-y” and “T-SCFC-x-y”, x, y represent tube wall thickness and parallel specimen number, respectively; tf—Wall thickness of GFRP tube; ts—Wall thickness of steel tube; H-Height of specimen. 表 2 钢材力学性能

Table 2 Mechanical properties of steel

Material ft/MPa fy /MPa E/105MPa Q235B 381.56 313.22 2.02 Notes: ft—Tensile strength; fy—Yield strength; E—Elastic modulus. 表 3 玻璃纤维增强树脂复合材料(GFRP)管力学性能

Table 3 Mechanical properties of glass fiber reinforced polymer (GFRP) tube

tf/mm Eh/GPa σh/MPa εh Ea/GPa σa/MPa 1 81.13 823.26 0.012 6.63 127.29 2 62.33 610.97 0.010 4.57 110.41 3 65.17 683.51 0.011 3.46 134.95 Notes: Eh—Hoop tensile modulus; σh—Hoop tensile strength; εh—Cyclic tensile ultimate strain; Ea—Axial compression modulus; σa—Axial compressive strength. 表 4 SCFC与CFST短柱轴压承载力对比

Table 4 Comparison of axial compressive bearing capacity between SCFC and CFST short columns

Specimen Ny/kN Nmax/kN \eta y/% \eta max/% CFST-A/B 673.60 800.38 — — SCFC-1-A/B 806.00 978.24 19.6 22.20 SCFC-2-A/B 885.32 1097.08 31.4 37.07 SCFC-3-A/B 991.67 1298.56 47.2 62.20 Notes: Ny—Equivalent yield load; Nmax—Peak load; \eta y—Increase ratio of equivalent yield load; \eta max—Increase ratio of peak load. 表 5 不同截面形式混凝土组合柱轴压试验主要结果

Table 5 Main results of concrete composite columns with different section forms under axial compression load

Specimen Nmax/kN Ny/kN Nmax/ Ny Nmax-a/kN Ny-a/kN μa \eta /% Failure mode CFST-A 803.02 688.53 1.17 800.38 673.60 2.93 — Softening CFST-B 797.73 658.66 1.21 CFFT-1-A 454.41 201.53 2.25 428.49 215.47 4.91 — Brittle failure CFFT-1-B 402.56 229.40 1.75 CFFT-2-A 620.42 315.04 1.97 606.75 325.32 3.30 41.60 CFFT-2-B 593.07 335.60 1.77 CFFT-3-A 827.34 432.45 1.91 835.77 414.89 4.11 95.05 CFFT-3-B 844.20 397.32 2.12 SCFC-1-A 1002.60 839.20 1.19 978.24 806.00 3.13 — Ductile failure SCFC-1-B 953.87 772.79 1.23 SCFC-2-A 1093.48 929.99 1.18 1097.08 885.32 4.78 12.15 SCFC-2-B 1100.69 840.65 1.31 SCFC-3-A 1309.79 1019.08 1.29 1298.56 991.67 3.31 32.74 SCFC-3-B 1287.33 964.26 1.34 Notes: Nmax-a—Mean value of peak load for specimens with same parameters; Ny-a—Mean value of equivalent yield load for specimens with same parameters; μa—Average ductility coefficient; \eta —Peak load increase ratio. 表 6 T-SCFC柱轴压试验主要结果

Table 6 Main results of T-SCFC columns under axial compression load

Specimen NTmax/kN NTy/kN NTmax/ NTy NTmax-a/kN NTy-a/kN μT-a ηTmax/% ηTy/% T-SCFC-1-A 4330.79 3431.66 1.26 4255.69 3528.83 2.59 — — T-SCFC-1-B 4180.59 3626 1.15 T-SCFC-2-A 5044 3739 1.35 5042 3668.41 3.74 18.48 3.96 T-SCFC-2-B 5040 3597.82 1.40 T-SCFC-3-A 5360 4145.16 1.29 5316.50 4037.08 3.52 24.93 14.40 T-SCFC-3-B 5273 3929 1.34 Notes: NTmax—Peak load capacity of T-SCFC; NTy—Equivalent yield load of T-SCFC; NTmax-a—Mean value of peak load for specimens with same parameters; NTy-a—Mean value of equivalent yield load for specimens with same parameters; μT-a—Average ductility coefficient; ηTmax-Peak load increase ratio; ηTy—Increase ratio of equivalent yield load. 表 7 混凝土塑性损伤参数取值

Table 7 Concrete damaged plasticity parameter values

\psi \varepsilon { { {\sigma _{{\rm{b0}}} } } \mathord{\left/{\vphantom { { {\sigma _{b0} } } { {\sigma _{c0} } } }} \right.} { {\sigma _{{\rm{c0}}} } } } {K_{\rm{c}}} \mu 30 0.1 1.16 0.6667 0.0005 Notes: \psi —Dilatancy angle; \varepsilon —Flow potential eccentricity; σb0/σc0—Ratio of initial equibiaxial compressive yield stress to initial uniaxial compressive yield stress; Kc—Ratio of the second stress invariant on the tensile meridian; μ—Viscosity parameter. 表 8 GFRP管模型参数

Table 8 Model parameters of GFRP tube

Thickness/mm 1 2 3 E1/GPa 81.13 62.33 65.17 E2=E3/GPa 6.63 4.57 3.46 ν12=ν13 0.33 0.33 0.33 ν23 0.35 0.32 0.33 G12= G13/GPa 6.5 6.5 6.5 G23/GPa 2.24 1.54 1.17 表 9 T-SCFC数值模拟结果与试验对比

Table 9 Comparison of numerical simulation and experimental results of T-SCFC

Specimen NTmax-a/kN NTmax-F/kN NTmax-a /NTmax-F T-SCFC-1-A/B 4255.69 4419.39 0.96 T-SCFC-2-A/B 5042.00 5002.74 1.01 T-SCFC-3-A/B 5316.50 5590.95 0.95 Note: NTmax-F—Peak load of numerical simulation. 表 10 T-SCFC数值试件基本参数

Table 10 Basic parameters of numerical specimens of T-SCFC

Numerical specimen fcu/MPa ts/mm T-SCFC-40-2.5 40 2.5 T-SCFC-40-3.5 40 3.5 T-SCFC-40-4.5 40 4.5 T-SCFC-40-5.5 40 5.5 T-SCFC-30-4.5 30 4.5 T-SCFC-50-4.5 50 4.5 T-SCFC-60-4.5 60 4.5 Notes: The naming format of T-SCFC specimens is “T-SCFC-x-y”, x, y represent core concrete strength and wall thickness of steel tube respectively; fcu—Core concrete strength. 表 11 钢管壁厚对T-SCFC试件承载力的影响

Table 11 Influence of wall thickness of steel tube on bearing capacity of T-SCFC specimens

Specimen Ny/kN Nmax/kN ηy/% ηmax/% T-SCFC-40-2.5 2085.40 3511.92 — — T-SCFC-40-3.5 2539.99 3689.89 21.80 5.07 T-SCFC-40-4.5 3138.71 4247.65 50.51 20.95 T-SCFC-40-5.5 3479.03 4759.08 66.83 35.51 表 12 核心混凝土强度对T-SCFC试件承载力的影响

Table 12 Influence of core concrete strength on bearing capacity of T-SCFC specimens

Specimen Ny/kN Nmax/kN ηy/% ηmax/% T-SCFC-30-4.5 2971.21 4260.06 — — T-SCFC-40-4.5 3138.71 4247.84 5.64 −0.29 T-SCFC-50-4.5 3220.93 4444.46 8.40 4.33 T-SCFC-60-4.5 3334.59 4456.23 12.23 4.60 -

[1] 郝际平, 孙晓岭, 薛强, 等. 绿色装配式钢结构建筑体系研究与应用[J]. 工程力学, 2017, 34(1):1-13. HAO Jiping, SUN Xiaoling, XUE Qiang, et al. Research and application of green prefabricated steel structure building system[J]. Engineering Mechanics,2017,34(1):1-13(in Chinese).

[2] 孙晓岭, 郝际平, 薛强, 等. 壁式钢管混凝土柱抗震性能试验研究[J]. 建筑结构学报, 2018, 39(6):92-101. SUN Xiaoling, HAO Jiping, XUE Qiang, et al. Experimental study on seismic performance of wall concrete filled steel tubular columns[J]. Journal of Building Structures,2018,39(6):92-101(in Chinese).

[3] 程杰, 齐玉军, 谢志锦. 玻璃纤维增强聚合物复合材料约束壁式钢管混凝土短柱轴压性能试验[J]. 复合材料学报, 2021, 38(6):1825-1837. CHENG Jie, QI Yujun, XIE Zhijin. Experiment on axial compression performance of glass fiber reinforced polymer-walled concrete-filled steel tube columns[J]. Acta Materiae Compositae Sinica,2021,38(6):1825-1837(in Chinese).

[4] XIONG Q, CHEN Z, ZHANG W, et al. Compressive behaviour and design of L-shaped columns fabricated using concrete-filled steel tubes[J]. Engineering Structures,2017,152:758-770.

[5] WANG F C, HAN L H. Analytical behavior of special-shaped CFST stub columns under axial compression[J]. Thin-Walled Structures,2018,129:404-417.

[6] 叶列平, 冯鹏. FRP在工程结构中的应用与发展[J]. 土木工程学报, 2006, 39(3):24-36. DOI: 10.3321/j.issn:1000-131X.2006.03.004 YE Lieping, FENG Peng. Applications and development of fiber-reinforced polymer in engineering structures[J]. China Civil Engineering Journal,2006,39(3):24-36(in Chinese). DOI: 10.3321/j.issn:1000-131X.2006.03.004

[7] 程实. 配置复材管内约束的方钢管混凝土柱轴压及抗震性能研究[D]. 北京: 清华大学, 2016. CHENG Shi. Research on axial compression and seismic performance of concrete filled square steel tubular columns with composite tube constraints [D]. Beijing: Tsinghua University, 2016 (in Chinese).

[8] 张冰, 魏威, 冯贵森, 等. 纤维缠绕角度对GFRP约束混凝土短柱轴压性能的影响[J]. 建筑结构学报, 2019, 40(S1):192-199. ZHANG Bing, WEI Wei, FENG Guisen, et al. Effect of fiber winding angle on axial compression performance of GFRP confined concrete short columns[J]. Journal of Building Structures,2019,40(S1):192-199(in Chinese).

[9] 国家市场监督管理总局. 金属材料拉伸试验第1部分: 室温试验方法: BG/T 228.1—2010[S]. 北京: 中国标准出版社, 2011. State Administration for Market Regulation. Tensile test of metal materials Part 1: Room temperature test method: BG/T 228.1—2010[S]. Beijing: China Standard Press, 2011 (in Chinese).

[10] ASTM. Standard test method for apparent hoop tensile strength of plastic or reinforced plastic pipe by split disk method: ASTM D 2290—2012[S]. US: American Society for Testing and Materials, 2012.

[11] 国家市场监督管理总局. 纤维增强热固性塑料管轴向压缩性能试验方法: GB/T 5350—2005[S]. 北京: 中国标准出版社, 2005. State Administration for Market Regulation. Test method for axial compression properties of fiber reinforced thermosetting plastic pipes: GB/T 5350—2005[S]. Beijing: China Standard Press, 2005 (in Chinese).

[12] 中华人民共和国住房和城乡建设部. 普通混凝土力学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国建筑工业出版社, 2019. Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test methods of mechanical properties of ordinary concrete: GB/T 50081—2019[S]. Beijing: China Construction Industry Press, 2019 (in Chinese).

[13] 郭莹, 许天祥, 刘界鹏. 圆CFRP-钢复合管约束高强混凝土短柱轴压试验研究[J]. 建筑结构学报, 2019, 40(5):124-131. GUO Ying, XU Tianxiang, LIU Jiepeng. Experimental study on axial compression of circular CFRP-steel composite tube confined high strength concrete short columns[J]. Journal of Architectural Structures,2019,40(5):124-131(in Chinese).

[14] 冯鹏, 强翰霖, 叶列平. 材料、构件、结构的“屈服点”定义与讨论[J]. 工程力学, 2017, 34(3):36-46. FENG Peng, QIANG Hanlin, YE Lieping. The definition and discussion of 'yield point' of materials, components and structures[J]. Engineering Mechanics,2017,34(3):36-46(in Chinese).

[15] WANG X X, QI Y J, SUN Y L, et al. Compressive behavior of composite concrete columns with encased FRP confined concrete cores[J]. Sensors,2019,19(8):1792.

[16] 高鹏, 赵元鸿, 洪丽, 等. 圆角半径对碳纤维增强聚合物复合材料布约束型钢混凝土矩形短柱轴压性能的影响[J]. 复合材料学报, 2020, 37(4):775-785. GAO Peng, ZHAO Yuanhong, HONG Li, et al. The effect of fillet radius on axial compression performance of carbon fiber reinforced polymer composite cloth confined steel reinforced concrete rectangular short columns[J]. Journal of Composite Materials,2020,37(4):775-785(in Chinese).

[17] SCHNEIDER S P. Axially loaded concrete-filled steel tubes[J]. Journal of Structural Engineering,1998,119(10):1125-1138.

[18] 张伟, 唐站站, 杨艳. 等. 复合受力模式下 CFRP-混凝土界面剥离分析方法[J]. 建筑结构学报. ZHANG Wei, TANG Zhanzhan, YANG Yan, et al. Analysis method of CFRP-concrete interface debonding under combined stress mode[J]. Journal of Architectural Structures. (in Chinese).

[19] GUADES E, ARAVINTHAN T, ISLAM M. Characterisation of the mechanical properties of pultruded fibre-reinforced polymer tube[J]. Materials & Design,2014,63:305-315.

[20] TENG J G, HU Y M. Behaviour of FRP-jacketed circular steel tubes and cylindrical shells under axial compression[J]. Construction & Building Materials,2007,21(4):827-838.

[21] 方小丹, 林斯嘉. 复式钢管高强混凝土柱轴压试验研究[J]. 建筑结构学报, 2014, 35(4):236-245. FANG Xiaodan, LIN Sijia. Experimental study on axial compression of composite high strength concrete filled steel tubular columns[J]. Journal of Building Structures,2014,35(4):236-245(in Chinese).

[22] 鲁国昌, 叶列平, 杨才千, 等. FRP管约束混凝土的轴压应力-应变关系研究[J]. 工程力学, 2006(9):98-103. DOI: 10.3969/j.issn.1000-4750.2006.09.017 LU Guochang, YE Lieping, YANG Caiqian, et al. Research on axial compression stress-strain relationship of FRP tube confined concrete[J]. Engineering Mechanics,2006(9):98-103(in Chinese). DOI: 10.3969/j.issn.1000-4750.2006.09.017

[23] LI B B, JIANG J F, XIONG H B, et al. Improved concrete plastic-damage model for FRP-confined concrete based on true tri-axial experiment[J]. Composite Structures,2021,269:114051.

[24] 韩林海, 陶忠. 方钢管混凝土轴压力学性能的理论分析与试验研究[J]. 土木工程学报, 2001(2):17-25. DOI: 10.3321/j.issn:1000-131X.2001.02.004 HAN Linhai, TAO Zhong. Theoretical analysis and experimental study on mechanical properties of concrete filled square steel tubular under axial compression[J]. Journal of Civil Engineering,2001(2):17-25(in Chinese). DOI: 10.3321/j.issn:1000-131X.2001.02.004

[25] GRAY P J, MCCARTHY C T. An analytical model for the prediction of through-thickness stiffness in tension-loaded composite bolted joints[J]. Composite Structures,2012,94(8):2450-2459. DOI: 10.1016/j.compstruct.2012.02.011

[26] EGAN B, MCCARTHY C T, MCCARTHY M A, et al. Stress analysis of single-bolt, single-lap, countersunk composite joints with variable bolt-hole clearance[J]. Composite Structures,2012,94(3):1038-1051. DOI: 10.1016/j.compstruct.2011.10.004

[27] 刘万雷, 常新龙, 张晓军, 等. 基于改进Hashin准则的复合材料低速冲击损伤研究[J]. 振动与冲击, 2016, 35(12):209-214. LIU Wanlei, CHANG Xinlong, ZHANG Xiaojun, et al. Research on low-speed impact damage of composites based on improved Hashin criterion[J]. Vibration and Impact,2016,35(12):209-214(in Chinese).

-

期刊类型引用(2)

1. 王晓东,徐永杰,董方栋,王昊,郑娜娜. 凯夫拉与陶瓷复合结构抗侵彻性能数值仿真. 兵工学报. 2022(09): 2360-2366 .  百度学术

百度学术

2. 黄浩杰,梁森,周越松. 陶瓷/UHMWPE异形复合材料靶板抗侵彻性能研究. 复合材料科学与工程. 2022(11): 49-53+62 .  百度学术

百度学术

其他类型引用(2)

-

下载:

下载: