Micro-thermocompression molded light weight, high-strength, low thermal conductivity silicon carbide/graphite composites

-

摘要: 轻质隔热材料已在飞行器动力装置热防护系统中获得广泛应用,但现有的工艺技术难以实现高承载、轻质、隔热等多个技术目标的协同。基于微热压增材制造成形技术原理快速制备了一种轻质、高强度、低导热碳化硅/石墨复合材料。研究了不同成形密度下复合材料的抗压强度和导热系数变化规律,通过改变材料配方组成(包括热固性酚醛树脂粉末、高纯硅粉和可膨胀石墨质量分数)实现了复合材料的抗压强度和导热系数正反向调节,揭示了其内在机制。研究发现当酚醛树脂粉末、高纯硅粉、可膨胀石墨质量分数分别为30wt%、30wt%、2wt%时,所制备的碳化硅/石墨隔热复合材料兼具低密度(<1.2 g/cm3)、高抗压(>15 MPa)和低导热(<1 W/(m·K))性能,该复合材料在航空航天具有良好的应用前景。

-

关键词:

- 碳化硅/石墨隔热材料 /

- 微热压增材制造 /

- 导热系数 /

- 抗压强度 /

- 调控

Abstract: Light weight thermal insulation materials have been widely used in the thermal protection system of aircraft power plant, but the existing technology is difficult to achieve the synergy of many technical goals such as high load, light weight and thermal insulation. In this paper, a kind of lightweight, high strength and low thermal conductivity silicon carbide/graphite composite was rapidly prepared based on the principle of micro-hot pressing additive manufacturing and forming technology. The variation law of compressive strength and thermal conductivity of composite materials under different forming densities was studied. By changing the material formula composition (including thermosetting phenolic resin powder, high purity silicon powder and expandable graphite, etc.), the compressive strength and thermal conductivity of composite materials were adjusted forward and backward, and its internal mechanism was revealed. This research finds that when the mass fraction of phenolic resin powder, high purity silicon powder and expandable graphite is 30wt%, 30wt% and 2wt%, respectively, the silicon carbide/graphite thermal insulation composite has the properties of low density (<1.2 g/cm3), high compressive strength (>15 MPa) and low thermal conductivity (< 1 W/(m·K)), which has a good application prospect in aerospace. -

1. 柔性压力传感器简介

传感器可以通过将物理、化学和生物等信号的变化转换为电信号。柔性压力传感器能够将触觉信息转换成电信号,同时还具有柔性好、重量轻、灵敏度高、易于集成等特点,因其在健康监测、人工智能、人机交互、机器人等领域的良好应用而备受关注。

通常,柔性压力传感器根据传感机制分为四类:压阻[1-5]、电容[6-9]、压电[10-13]和摩擦电[14-16]。图1是四种柔性压力传感器的传感机制示意图。

压阻式压力传感器原理是当外部压力施加在传感器的敏感部件上时,传感材料的结构会发生变形,同时导电材料与电极之间的接触面积或通路会随着压力的变化而改变,从而影响传感器的电导率和电阻值,导致电阻发生变化[17]。这种变化可以通过测量电阻值来间接地反映压力的大小。

电容式压力传感器利用外部施加的压力刺激来改变传感器内部的电容。当压力施加在传感器表面时,传感器可动的敏感结构变形导致与可变介电常数或固定结构间隙间距发生变化,间距变化改变结构电容间隙的电容值[18],然后通过传感器电容值的变化来反映压力的大小。

压电式压力传感器利用外部施加的压力刺激来改变传感器内部的压电材料上下的极化电压。当压电压力传感器在外力作用下发生变形时,敏感层材料中的正电荷和负电荷会分离,在材料的两个相对表面上,正电荷和负电荷会以相反的方向重新排列,此时内部会形成电位差[19],通过传感器电位差的变化来反映压力的大小。

摩擦电式压力传感器的工作原理是当外部压力施加在传感器表面时,传感器内的摩擦电材料会发生形变或变形。这种形变导致材料内部的电荷分布发生改变,通过两个电极层之间摩擦引起的电荷转移,在两个电极层上产生正负电荷从而形成电位差[20],在材料的电极之间产生电压信号,其机制与压电式相似,不同的是摩擦压力传感器能够进行自供电,并对动态压力做出响应。

其中柔性压阻式传感器因其结构简单、成本低、信号采集方法便捷,成为最常用的压力传感器之一。然而,现有的柔性压阻式压力传感器在广泛的压力范围内常表现出灵敏度低、线性度差的问题,限制了其实际应用效果。为满足复杂应用需求,急需在关键性能上取得突破,包括提高灵敏度、扩大线性范围、降低检测限度和增强耐久性。对此,研究人员通过新型复合材料和创新微结构设计,大幅提升了传感器的整体性能,使其在多种应用场景下能够更加精准和可靠地检测压力变化。

针对现有的柔性压阻式压力传感器在灵敏度和线性度方面的不足,本综述的意义在于探讨和总结柔性压阻式压力传感器在宽压力范围内的线性度提升策略。本文综述了通过分层多孔结构、分层微结构及材料协同作用等方法提升传感器的线性度及传感范围最新研究进展,强调了优化传感器的结构设计和材料选择的重要性。这些旨在为柔性压阻式压力传感器的进一步发展提供系统的理论基础,推动该领域在实际应用中的广泛应用和技术进步。同时也为未来的研究方向指明了道路,包括多功能化、智能制造技术的应用以及生物兼容性材料的开发等。

2. 柔性压阻式压力传感器材料选择

柔性压阻式压力传感器通常由衬底材料、传感活性材料和电极材料构成。衬底材料提供机械支撑和柔性,确保传感器能够适应不规则表面;导电活性材料则是核心部分,通过其压阻效应感知压力变化;电极材料负责信号传导,确保与传感活性材料的良好接触和稳定的信号传输。这些组成部分协同工作,实现了传感器的出色压力感知能力和优异的柔性。

2.1 衬底材料

柔性衬底为压阻传感器提供了较大的可拉伸范围。常用的衬底材料包括高分子聚合物,例如聚二甲基硅氧烷(PDMS)[22-24],聚酰亚胺(PI)[25],聚氨酯(PU)[26],热塑性聚氨酯(TPU)[27],聚对苯二甲酸(PET)[28],聚偏氟乙烯(PVDF)和聚氯乙烯(PVC)等。除了高分子聚合物作为衬底材料,纸张;纺织品也是常用的柔性衬底材料。正是因为这些柔性衬底材料的使用才赋予了传感器良好的拉伸性和灵活性。

其中PDMS具有弹性模量低,弹性高,成型性好,透明,热稳定性好和耐腐蚀等优点,因此是制造柔性传感器最广泛使用的基底。Ge等人[29]通过快速热退火过程在石墨烯弹性体夹层结构上制造了厚的纳米皱纹,制造了一种基于热退火石墨烯-PDMS夹层结构的皱纹压阻传感器, 柔性衬底PDMS上构建了独特的皱纹结构,赋予了传感器良好的拉伸性,同时在拉伸应变下具有较高的灵敏度。Chen[30]等人通过简单的溶液混合和模板过程有效地构建了由 CNT/PDMS 敏感膜和叉指电极的两级微金字塔阵列组成的柔性压阻传感器,实现了快速响应/恢复时间(75/50 ms)和 15,000 次加载-卸载循环的长耐久性,同时还能够应用于高性能传感器监测人体生理信号和运动信号。He等人[31]通过制备了基于分级微孔PU@CNT薄膜的透气、灵敏、可长期穿戴的压阻传感器。多孔的PU@CNT薄膜表现出优异的空气和水蒸气渗透性,还具有高稳定性(>

8000 次循环)。相比PDMS,TPU具有更高的韧性和更强的抗机械损伤能力,使其在外力冲击和长期使用中更耐用。值得注意的是,TPU在经历超过

1000 次拉伸循环后,仍能保持材料特性,展现出在高频使用环境下的卓越稳定性和耐久性。因此,TPU逐渐成为柔性压力传感器领域广受关注的热门衬底材料。2.2 导电活性材料

压阻材料的选择在柔性压阻压力传感器的开发中起着至关重要的作用。由于聚合物基底材料通常具有良好的绝缘性能,必须选择合适的导电活性材料进行复合,以确保传感器整体具备有效的导电性。

根据化学性质的不同,导电活性材料可分为三大类。第一类是金属基导电材料。为了实现柔性和优化其导电性能,通常需要将金属转化为颗粒、纳米线或薄膜等形态。通过调整加工工艺,可以控制金属颗粒的尺寸、形态和长径比等参数,从而精确调节其导电特性。金属材料因其优异的导电性而在较低浓度下即可形成渗流网络[32],这使得传感器具有高灵敏度和低检测限。然而,由于金属材料的高生产成本以及其长期使用中可能出现的氧化问题,必须根据具体应用场景谨慎选择。

第二类导电材料为碳基材料,包括碳黑(CB)[33-35]、碳纳米管(CNT)[36-38]、石墨烯[39]等。这些材料以其成本效益、良好的化学稳定性和优异的导电性能著称,因此成为广泛研究的对象。碳基材料的延展性使其能够通过喷涂或印刷方式应用于柔性衬底,或者与衬底材料直接结合形成压阻传感元件。碳基材料的使用有助于实现传感器的稳定性和耐用性,同时保持较高的灵敏度。然而,需要注意的是,某些碳基材料可能在基底中发生聚集,因此适当的分散工艺对于提升传感器性能至关重要。

第三类导电材料是导电高分子材料,如聚乙烯二氧噻吩(PEDOT)[40]、聚苯胺、聚吡咯(PPy)[41]等。其导电机制主要依赖于离子和电子的输运,从而降低材料的电阻。当这些高分子材料与基底材料结合时,能够提供优良的延展性、柔韧性以及生物相容性,从而制备出具备优异导电性和抗拉强度的传感器。然而,与金属或碳基材料相比,这类材料的化学稳定性相对较差,这在某些实际应用中可能成为限制因素。

2.3 电极材料

电极材料是构成柔性压力传感器不可缺少的一部分,电极的作用是将导电活性层产生的电信号传输到信号接收器,在压力传感器受到压力产生形变的过程中,电极应该保持良好的导电性和稳定性。常见的电极材料有金属纳米颗粒、碳纳米材料、离子水凝胶[42]和导电聚合物等,而为了使电极保持柔性,通常将这些电极材料通过沉积或喷涂等手段附着在柔性基底上。也有通过构造微结构电极来改善传感器的性能,如图2所示,Hou等人[43]通过磁控溅射技术在具有三维微金字塔阵列结构的PDMS薄膜上沉积铜来构成上下电极,这种微结构电极与无微结构电极相比,显著的提升了传感器的灵敏度。

3. 提升线性传感范围的方法

传感器的线性度是指其输出信号(如电阻变化)与输入信号(如压力)之间的关系呈线性的程度。然而,由于材料的非线性压缩特性、导电网络在高压力下的饱和效应,往往产生容易产生非线性响应,非线性响应是指传感器输出信号与施加压力之间不呈线性关系的情况。高压或低压范围内,传感器可能会出现灵敏度下降、信号饱和或响应滞后等现象,从而导致非线性响应的产生,或在长期使用或高压环境下,材料可能出现疲劳或永久变形,传感层内的导电网络被破坏,导致传感器的性能下降,这些都有可能引起压力传感器的非线性响应。而在宽压力范围内保持良好的线性响应是提升线性传感范围不可缺少的。线性响应指的是传感器电阻变化与施加的压力成正比的关系。柔性压阻式压力传感器的响应线性需要内部具有稳定良好的导电网络保持高导电性,同时采用的基底材料需要具有良好的弹性,在响应压力反馈时,保证材料的压阻效应能够稳定自发的进行,通过设计合理的传感器结构有效的应力传递和分布是确保线性响应的关键。良好的结构设计可以确保在受到压力时各部分均匀变形,避免产生过大的非线性突变。而传统的柔性压阻式压力传感器在较高压力下往往会出现灵敏度下降和线性度偏离的问题,而提升灵敏度和扩大检测范围[44]时往往会牺牲线性响应。这限制了传感器在实际应用中的有效工作范围,尤其是在需要高精度压力测量的场景中。关于柔性压阻式传感器线性度方面的问题一直是研究的热门,图3展示了正常触摸、物体操作和人体循环所产生的典型压力主要分布在低压区(<10 kPa)和中压区(10 kPa -100 kPa)这些压力的检测对于包括可穿戴医疗健康系统和人机交互在内的广泛应用具有重要意义[45]。所以在柔性压力传感器实际应用时,当传感器的线性范围小于10 kPa时,可以认为这个线性传感范围较窄;而当传感器的线性范围大于100 kPa时,能够满足绝大部分的应用场景,可以认为超过0-100 kPa的线性范围即为宽线性范围,一般当R>0.98时可以认为该传感器的线性度优秀。同时将有效提高线性传感范围的方法总结如下。

3.1 分层多孔结构

分层多孔结构通过在传感器内部形成多个不同尺寸和形状的孔隙层,能够在压力作用下实现应力的分层传递和分布。这种设计使得每一层的孔隙都可以有效缓解压力集中现象,从而避免了在高压下出现应力集中和灵敏度下降的问题。通过均匀分布的应力传递,传感器在整个压力范围内都能够维持线性响应,即输出信号与施加的压力呈线性关系。同时分层多孔结构不仅提升了传感器的线性度,还在一定程度上提高了其灵敏度。这是因为多层结构可以更好地适应不同压力范围的变化,使得传感器在整个压力范围内都能保持高灵敏度。此外,由于各层孔隙能够分别响应不同的压力区间,整体结构的灵敏度和线性度得到了综合提升。

Zhu等人[46]通过模仿人类皮肤中细胞的分布模式,提出了一种具有梯度多孔结构的皮肤启发柔性压力传感器,如图4(a)所示,利用有限元分析(FEA)对不同多孔结构的应力分布进行了详细的模拟,最终确定了最佳的孔隙大小和分布方式,同时在实际制造中,使用碳黑(CB)/聚二甲基硅氧烷(PDMS)复合材料,通过3D打印技术生成梯度多孔结构,这种结构能够有效地分配和传递压力,从而在低压、中压和高压范围内保持均匀的压力分布,使得传感器在0-500 kPa的压力范围内保持稳定的线性输出,在0-500 kPa的超宽线性范围内表现出良好的灵敏度(

0.0048 kPa−1)。如图4(b)所示,Bang等人[47]通过3D打印技术设计了一种具有反晶格结构((RLS)的多层次多孔的PDMS海绵,将作为传感材料的多壁碳纳米管(MWCNTs)简单地涂覆海绵表面,然后用铜箔、胶带和PET薄膜分别作为电极、粘合层和保护层包装MWCNT涂层海绵制成传感器,根据建模分析可知,在RLS均匀变形的情况下,压缩率随着压力增加而增加,并且每个晶格结构在80 kPa下开始与上方和下方结构接触,压力增加了接触晶格之间的MWCNT的纳米接触,由于晶格结构之间的接触面积不断增加,占主导地位的传感机制也开始转变自发地随着压力的增加。这种规律的多层次多孔结构的海绵具有优异的压缩性,以及传感器内部的优势传感机制的自发稳定转变,使得有较高的线性度(决定系数R2=0.998)和在0.03-

1630 kPa测压范围内达到了1.26 kPa-1的灵敏度。3.2 分层微结构

分层微结构通过控制接触面积的逐步增加来提升传感器的线性度。不同层次的结构在不同压力下依次起作用,这样在压力逐步增加时,接触面积不会突然大幅度变化,而是平滑增加。这种接触面积的控制使得电阻变化趋于线性,从而提升传感器的线性度。这种设计方法不仅提升了传感器在低压下的灵敏度,还扩展了其在高压下的线性响应范围,是柔性压力传感器领域中的重要技术进展。

Shi等人[48]提出了一种由微结构复合材料层组成的多层柔性压力传感器,如图5(a)所示,该多层结构由氧化铟锡(ITO)-聚对苯二甲酸乙二醇酯(PET)电极夹在中间,多层复合层的点对点半球微结构构成,这种两层半球微结构以点对点的方式固定在接触上,并由超软弹性体框架封装。由于这种独特的半球点对点设计,使得制作的柔性压力传感器能够承载更大的压力,同时提供了更多的形变空间,在较强的压力下,相对接触电阻变化仍然会较大,因此,该传感器在0-583 kPa范围内的压力感知灵敏度为7.66 kPa−1,线性相关系数R2为0.99。

![]() 图 5 增加线性传感范围的分层微结构:(a) 多层复合层的点对点半球微结构的压力传感器的制作过程及性能论证[48];(b) 分层褶皱状微结构的石墨烯基气凝胶的制作过程及性能论证[49];(c) 具有分层结构的柔性压阻式压力传感器的制作过程和性能表征[50]Figure 5. Hierarchical porous structure for increasing linear sensing range (a) Fabrication process and performance demonstration of point-to-point hemispherical micro-structure pressure sensor with multilayer composite layer[48]; (b) Fabrication process and performance demonstration of graphene-based aerogel with layered pleated microstructures[49]; (c) Fabrication process and performance characterization of flexible piezoresistive pressure sensor with layered structure[50]

图 5 增加线性传感范围的分层微结构:(a) 多层复合层的点对点半球微结构的压力传感器的制作过程及性能论证[48];(b) 分层褶皱状微结构的石墨烯基气凝胶的制作过程及性能论证[49];(c) 具有分层结构的柔性压阻式压力传感器的制作过程和性能表征[50]Figure 5. Hierarchical porous structure for increasing linear sensing range (a) Fabrication process and performance demonstration of point-to-point hemispherical micro-structure pressure sensor with multilayer composite layer[48]; (b) Fabrication process and performance demonstration of graphene-based aerogel with layered pleated microstructures[49]; (c) Fabrication process and performance characterization of flexible piezoresistive pressure sensor with layered structure[50]图5(b)所示,Li等人[49]使用了甲基纤维素(MC)作为增强剂,通过与氧化石墨烯(GO)混合,然后经过定向冷冻和冻干,最终通过蒸汽辅助的热处理后,制备出一种定向和多层状皱褶的石墨烯气凝胶(MC/GA)的压阻传感器。通过有限元分析(FEA)表明,皱褶的层状结构有助于减小压力集中,从而提高了气凝胶的压缩性能,因此MC/GA具有很好的线性范围(0-17 kPa, R2 > 0.997),以及高达9.38 kPa−1的灵敏度。

Shi等人[50]通过将莲叶表面的微米和纳米级层次结构复制到PDMS基底上,并在其表面喷涂石墨烯墨水以形成导电层,如图5(c)所示,同时利用有限元分析模拟传感器在不同压力下的接触面积变化,分层微结构能快速稳定地增大与载荷的接触面积,证明了层级结构在提升灵敏度和扩展线性范围中的关键作用。这种多尺度分层仿生微结构设计能够在较低压力下能够集中应力,迅速增加接触面积,从而提高灵敏度;在较高压力下,则能够均匀分布压力,减缓接触面积的增加,保持线性响应,使传感器在0到25 kPa的压力范围内保持良好的线性响应,并且灵敏度达到了1.2 kPa−1。

3.3 协同效果

在柔性压力传感器的制备过程中,材料的选择和结构设计至关重要,而协同作用是提升传感器线性度和灵敏度的重要因素。协同作用指的是不同材料或结构在组合使用时,所展现出的性能优于单一材料或简单组合的性能。而协同作用对提升线性度的影响主要体现以下几方面。

(1)材料组合的协同作用在柔性压力传感器中,采用不同材料的复合可以产生预期之外的电学和力学特性。例如,将导电材料(如碳纳米管、导电聚合物、碳黑等)与柔性基底(如PDMS、TPU等)结合,能形成复杂的导电网络。材料的不同力学特性(例如韧性和刚性)能够在传感器受力时,相互作用,优化导电性能。

(2)微观结构之间的协同作用在材料设计中至关重要,通过不同微观结构的结合来达到一种协同作用,使其具有多种微观结构的优点,从而实现对传感器的线性度显著影响。例如,表面微结构着重于提升一定压力范围的灵敏度,而多孔结构则提供了更多形变空间,有助于均匀分布所承载的压力。施加压力过程中会导致多孔材料内部发生形变并增加与电极之间的导电通路,扩展载流子的移动路径,提高电导率。而通过调整表面微结构的图案和多孔结构的排列,能够优化复合微观结构,减少因材料畸变或位移引起的非线性误差,实现更均匀的应力分布,还使其在不同压力范围下仍保持较高的灵敏度,进而扩展了整体的线性范围。

(3)外部因素的刺激与协同增强通过引入外部刺激(如电场、磁场等)能够进一步提升传感器的性能。例如,施加外部电场可以诱导一些聚合物中载流子的定向移动,从而加强传感器的灵敏度。在一些复合材料中,磁场的施加能够增强材料的压缩模量,进一步改善传感器在高压下的线性响应。这些外部刺激与材料本身的性质结合,导致了协同作用的产生,从而显著提升传感器的整体性能。

这些协同效果不仅解决了传统传感器在高灵敏度与宽线性范围之间的矛盾,也为高性能传感器设计提供了新思路。

Chen等人[51]通过调节一种非线性协同作用,开发了既具有高灵敏度又具备宽线性范围的柔性压力传感器。如图6(a),传感层采用一种三维多孔结构的金字塔形碳泡沫,这种结构结合了锥形微结构和微观孔隙的优点,具备高的压阻性非线性,有助于提高传感器的灵敏度。同时使用了一种弹性体间隔物(刚度调节器),该组件用于调节传感层上的负载分布,其非线性弹性特性有助于扩展压力传感范围。最后通过理论模型分析,确定了传感层和调节器参数的最佳匹配范围,实现了感应层与调节器在整个压力范围内的协调工作,从而确保了传感器的线性响应。因为这种非线性协同效果,该传感器表现出前所未有优秀性能,在0至1.4 MPa的超高压力范围内实现了24.6 kPa−1的灵敏度,线性度系数R2达到了0.999,表现出极高的线性度。

![]() 图 6 提升线性度的协同作用:(a) 由双面锥体泡沫碳和刚度调节器构成的传感器的设计布局及性能展示[51];(b) p-CNT/CB/CIP/有机硅复合材料的制备原理和传感机制示意图[52];(c) LIG复合材料的制造原理图及性能展示[53]Figure 6. Synergy for increased linearity (a) Design layout and performance display of a sensor composed of a double-sided pyramidal carbon foam and stiffness regulator[51]; (b) Schematic diagram of preparation principle and sensing mechanism of p-CNT/CB/CIP/ silicone composites[52]; (c) Manufacturing schematic diagram and performance display of LIG composite materials[53]

图 6 提升线性度的协同作用:(a) 由双面锥体泡沫碳和刚度调节器构成的传感器的设计布局及性能展示[51];(b) p-CNT/CB/CIP/有机硅复合材料的制备原理和传感机制示意图[52];(c) LIG复合材料的制造原理图及性能展示[53]Figure 6. Synergy for increased linearity (a) Design layout and performance display of a sensor composed of a double-sided pyramidal carbon foam and stiffness regulator[51]; (b) Schematic diagram of preparation principle and sensing mechanism of p-CNT/CB/CIP/ silicone composites[52]; (c) Manufacturing schematic diagram and performance display of LIG composite materials[53]Huang等人[52]将碳酰铁粉(CIP)、CNT、CB和与硅胶复合材料经过混合、固化,并通过糖粒作为牺牲模板形成多孔结构,同时在传感器的制造过程中,采用了外加磁场来调整传感器的力学性能,提高了传感器在高压下的压缩模量,基于此制作了多孔结构压力传感器。因为多孔结构赋予了该传感器在低压水平下较低的压缩模量,从而提高了传感器的低压检测灵敏度和线性度;而在高压水平下,外加的磁场通过磁流变效应显著增强了材料的压缩模量,从而提高了传感器在高压下的线性响应范围。通过多孔结构的设计与外加磁场的协同效果,如图6(b)所示,使得传感器在80 Pa到220 kPa的压力检测范围内,表现出优异的线性响应(线性系数R= 0.999)比大多数线性响应的压力传感器更广。

还有Chen等人[53]设计了一种互锁波状阵列的双层激光诱导石墨烯(LIG)多孔复合材料压力传感器,如图6(c)所示。通过设计波形互锁阵列微结构,实现了不同层间的应力分布均匀化,由于石墨烯泡沫内部三维多孔结构和层间互锁波状阵列微结构的协同作用,使多尺度结构允许通过增加(减少)互锁波状阵列层间和内部石墨烯泡沫内部之间的接触面积来检测压力刺激,因此组装的双层LIG复合材料具有多种可变导电路径和易变形特性,从而扩大了传感器的线性工作范围,在0-100 kPa的宽压力范围内保持了良好的线性度(R2= 0.995)和高的压力分辨率。

协同作用在提高柔性压力传感器线性度的过程中发挥了不可或缺的作用。通过优化材料组合、微观结构相互协同、以及外部因素的引入等,能够实现更高的灵敏度和更广的线性传感范围。未来的研究应继续探索不同材料及结构的协同效应,以推动柔性压力传感技术的进一步发展。

为了更好了解这些研究不同方法对线性度的提升,表1对这些传感器的性能进行了总结归纳。尽管上述三种方法尽管从不同的角度出发,但在提升柔性压阻式压力传感器线性度方面的表现出了一些共同特点:

表 1 对不同方法提升线性度的性能总结Table 1. Performance summary of different methods to improve linearityMaterial Methods Sensitivity /kPa−1 Linear region /kPa linearity(R²) Ref. PDMSa/Au/CNTb/Paper Synergistic effect 2.06 2–150 kPa 0.99 [43] CBc/PDMS hierarchical porous structure 0.0048 0-500 kPa >0.98 [46] PDMS/MWCNTd sponge hierarchical porous structure 1.26 0.03- 1630 0.998 [47] ITOe/PETf/PDMS/Ecoflex hierarchical micro-structure 7.66 0-583 0.99 [48] MCg/GAh hierarchical micro-structure 9.38 0-17 >0.997 [49] PDMS/Graphene hierarchical micro-structure 1.2 0-25 >0.99 [50] Gold/Carbon foam/Ecoflex Synergistic effect 24.6 0- 1400 >0.99 [51] CB/CNT/CIPi/Silicone Synergistic effect 0.136 0.08-220 0.999 [52] PI/Graphene/PDMS Synergistic effect 0.045 0-100 0.995 [53] Carbon nanofibers /PDMS hierarchical porous structure 4.7 0.03- 1000 0.998 [67] PDMS/CNT Synergistic effect 40.12 0- 1000 >0.99 [69] Notes: a: Polydimethylsiloxane b: Carbon Nanotubes c: Carbon Black d: Multi-Walled Carbon Nanotube e: Indium Tin Oxide f: Polyethylene Terephthalate g: Methylcellulose h: Graphene-based Aerogel i: carbonyl iron powder (1)为了实现柔性压力传感器的宽线性传感范围,传感器的结构必须能够承受较大的压力,并在压力作用下产生均匀的形变,以确保压力均匀分布在传感器结构中。例如,分层微结构和分层多孔结构的应用可以使传感器在高压条件下保持结构完整性,避免损坏。

(2)通过调控导电材料的涂层厚度、隔层密度和各向异性,能够精准控制传感器的初始接触面积和压力响应行为,从而在不同压力条件下实现线性度的优化。

(3)传感器内部的导电机制应能随着压力的增加自发地进行稳定转变。在不同的压力范围内,传感器的导电机制各有主导:在较小的压力范围内,接触电阻主要由传感层与电极层之间的接触决定;而在较大的压力范围内,框架电阻的变化则起主导作用。而具有宽线性范围的柔性压阻传感器通常依赖多种导电机制的协同作用,调控这些机制是实现宽线性范围的关键。

(4)许多研究都借助有限元分析(FEA)来模拟传感器在不同压力下的形变行为。这种分析方法能够帮助研究者在设计阶段优化结构、材料选择以及相关参数调节,从而在实验前就对传感器的线性度进行有效预测。

通过对表1性能总结,我们发现采用分层多孔结构的压力传感器相比于分层微结构的传感器普遍具有更宽的线性传感范围。这是因为多孔结构能更有效地承载较大压力,随着压力增大,多孔层逐渐闭合,形成新的导电路径。这说明分层多孔结构在提升线性范围方面更具优势,但对灵敏度的贡献较少。相对而言,分层微结构能够均匀传递和分布压力,在拓宽线性范围的同时,更加注重提升传感器的灵敏度。这主要是因为随着压力增大,表面微结构的设计提供了更多接触面积,从而显著减少传感层与电极之间的接触电阻,导致相对电阻、电流变化增大。

协同作用能够兼具不同方法的优点,例如,多种微结构设计相结合,达到协同作用的效果,从而例如克服单一微结构的缺点。未来传感器发展会以协同作用为主要研究方向,重点不仅限于不同材料之间的协同作用、还包括微结构之间及外部刺激的协同作用等。如何调控好协同作用,是达到宽线性传感范围的关键,通过这些因素的综合调控,能够实现对传感器性能的全面提升。

4. 柔性压阻式压力传感器的应用

柔性压阻式压力传感器因其独特的柔韧性和优异的压力检测能力,近年来在多个应用领域中引起了广泛关注。这类传感器可以紧密贴合在曲面或不规则表面上,能够感知从微小振动到较大压力范围内的应力变化,因此在健康监测[54-56],运动检测[57-59]、电子皮肤[60-62]、机器人技术等中展现出巨大的应用潜力。

4.1 健康监测

健康监测是柔性压阻式压力传感器的一个重要应用领域,尤其是在日常健康管理和远程医疗中。柔性传感器能够检测微小的生理变化,如呼吸频率[63]、血压[64]和脉搏[65]等生理信号。这些传感器可以贴附在皮肤表面或嵌入到贴片中,以非侵入性的方式,长时间连续监测患者的健康状态,为医生提供及时、准确的诊断数据。

例如,柔性压阻式传感器可以用于监测呼吸模式。通过将传感器贴在胸部或腹部,传感器能够捕捉到呼吸运动带来的压力变化,从而实现对呼吸频率和深度的实时监测。如图7(a)所示,Li等人[49]将制作的MC/GA的压阻传感器放在鼻下,通过传感器探测到空气流动中的小扰动,成功的监测到了志愿者的呼吸频率。这种应用对慢性呼吸系统疾病患者具有重要意义,能够帮助医生评估病情发展,并为远程诊断和治疗提供数据支持。

Chen[53]等人将设计LIG多孔复合材料的柔性压力传感器粘附在乳胶手套上制造智能手套来监测脉搏,图7(b)显示了脉冲信号再现性极佳,心率约为72次每分钟被推断为与典型心跳一致。还有Chen[66]等人制作了一种指间型结构的柔性压阻式压力传感,该传感器具有高灵敏度和良好的线性传感范围,如图7(c)所示,将压力传感器安装在志愿者的食指上,可以检测到正常情况下(58次/ min−1)和运动后(102次/ min−1)指尖发出的细微脉搏信号。由于这些传感器具有高灵敏度和宽线性范围,它们可以精确地检测到身体各部位微小的压力变化,提供可靠的身体信息,以评估自身的健康状况。

4.2 运动检测

随着人们锻炼意识的增强,柔性压阻式压力传感器凭借着能够实时检测人体运动信号,如步态、姿势和运动强度等信息,在运动检测领域大放异彩。基于这些传感器的运动监测设备可以在宽广的压力范围内保持高灵敏度,精准捕捉到微小的体态变化。此外通过集成这些传感器,用户可以实时了解自己的运动状态,能够帮助用户调整运动姿势,预防运动损伤,同时提供高精度的运动数据,为运动员的训练提供科学依据。

Xu等人[67]报道了一种分层原位填充多孔压阻传感器,分层几何结构显著增加了接触面积,将应力分布到多层晶格和内部多孔结构上,从而实现了高灵敏度和线性度。将压力传感器固定在鞋底上,能够检测不同的运动状态,根据图8(a)中信号的清晰度、频率和强度,可以区分出步行、快走、跑步和跳跃等不同的运动。还有Yu等人[68]设计了一种基于分形电极(GFPSFE)的石墨烯泡沫压力传感器,分形电极的采用显著的提高了灵敏度和宽线性范围,如图8(b)所示,传感器能够准确检测手指的不同程度的弯曲动作。

此外,柔性压阻式传感器还可以集成在鞋垫中,用于步态分析和疲劳监测。在一些高强度运动或长期站立的场景中,这种传感器能够实时反馈足底压力分布,帮助用户调整姿势或休息,防止疲劳累积和运动损伤。例如,肖瑶[57]设计了一种PVC/CB 薄膜的微格栅结构柔性压力传感器,然后制备一种由24个微格栅结构 PVC/CB 柔性传感单元构成的阵列式压力鞋垫,以显示足底压力分布。图8(c)显示了高弓足分布、扁平足分布和正常足的压力分布以及正常步态下足底的压力分布。

这些关于运动检测方面的应用都无不展示了柔性压阻式压力传感器蓬勃的发展潜力。

4.3 电子皮肤

电子皮肤是机器人技术中柔性压阻式压力传感器的另一重要应用领域。电子皮肤旨在为机器人提供类似人类皮肤的触觉感知能力,使其能够感知外界的压力和振动等环境变化,从而实现更为精细的操作和交互。通过在机器人表面集成柔性压阻式压力传感器,可以使机器人感知触碰的力度,甚至分辨不同的物体材质,这对于人机协作、精密抓取和医疗辅助等应用至关重要。

例如Wang等[69]设计并制造了梯度孔/金字塔混合结构(GPPHS)导电复合薄膜,该薄膜具有高灵敏和宽线性传感范围,基于此柔性压力传感器开发了手势识别智能手套、假手触觉传感系统,如图9(a)所示展示了对球形和立方体物体进行不同的感知,以及多点触摸的传感能力。此外,Lu等人[70]报道了一种受蜘蛛腿和卷云须启发的用于可拉伸和可编织电子产品的仿生裂纹弹簧纤维传感器(CSFS),将CSFS集成到织物中,基于所设计的柔性传感器开发了一种人机界面系统,能够实现对机械手臂的精准控制,如图9(b)所示,实现对机器人手的准确实时手势控制,值得注意的是,当用户做出拳头姿势时,机器人手可以轻松抓取网球,这表明该系统在更复杂场景中的应用潜力巨大,例如在高风险情况下用间接智能操作代替人为干预。

4.4 人机交互

柔性压阻式压力传感器还可以应用于人机交互界面,如触控屏幕和按键输入设备中,感应用户施加的不同压力,从而实现更丰富的交互功能。在人机交互中,柔性压力传感器能够提供精确的触觉反馈,实现人与智能设备的无缝互动。例如,在智能座椅中,传感器可以检测用户的坐姿和体重分布,从而调整座椅的支撑力,提供个性化的舒适体验。

Chen等人[30]设计出了一种两级微金字塔阵列结构的柔性压阻传感器,独特的微结构设计使传感器具有较宽的传感范围及良好的灵敏度。如图10(a)所示,他们将所制作的导电薄膜层印刷在数字间电极上,构建了游戏控制键盘的压力传感阵列,其中四个传感单元分别控制键盘的上、下、左、右。传感阵列将压力信号通过单片机转换成方向信号传输给计算机,从而控制贪吃蛇游戏中蛇的运动方向。

另外如图10(b)所示,Chen等人[51]将所设计的宽线性范围的柔性压力传感器制作成4×4的传感器阵列,从而实现按键输入以及“轻”压和“硬”压识别。基于传感阵列和微控制器组成的双加密锁系统,通过结合传统密码输入和用户按键压力,实现了更高水平的安全性和用户友好性。

还有Zhu等人[71]将基于复合材料和数字间电极的柔性压阻式压力传感器与其他的软件和硬件相结合,开发了一种压力检测系统。该系统实现了将传感器的压阻响应换为数字信号,并通过STM32控制器传输到OLED终端显示器。如图10(c)所示,能够实时显示手指对传感器所施加压力的大小。

这些都体现了柔性压阻式传感器在人机交互应用上的潜力,同时通过将传感器与先进的软、硬件进行集成,有望进一步推动柔性电子技术的发展。

5. 总结与展望

提升柔性压阻式压力传感器的线性度是当前探索的重要方向之一,直接关系到其在实际应用中的性能和可靠性。通过分层多孔结构设计、分层微结构和多种协同作用的设计以及导电材料优化,研究者在提升传感器线性传感范围方面已取得显著进展。然而,未来仍需继续探索创新方法,特别是在复杂压力检测场景中保持良好线性度的解决方案。综上所述,总结了近年来提升柔性压阻式压力传感器线性传感范围的几种关键方法,并探讨了这些方法的共性,同时还归纳了这类传感器在健康监测、运动检测和电子皮肤方面的应用。在此为未来柔性压力传感器的发展提供了重要的理论和技术支持,预计将在实际应用中进一步推动该领域的发展。

(1)多功能传感器的开发:现代应用对传感器提出了多功能化的需求,即传感器不仅要能够感知压力,还要具备温度、湿度等多种感知功能。通过集成不同的传感功能模块,可以开发出具有更广泛应用前景的柔性传感器。通过在传感器材料中加入温度敏感材料或湿度敏感材料,可以开发出同时具备压力、温度和湿度感知能力的多功能传感器,从而满足智能穿戴设备对多参数监测的需求。

(2)智能制造技术的应用:随着工业4.0的发展,智能制造技术在传感器制造中的应用将更加广泛。人工智能和机器学习技术的引入可以优化传感器的设计流程,提升制造过程的精度和效率。同时,基于数据驱动的优化算法可以用于调整传感器的结构参数,进一步提高其线性度和灵敏度。通过机器学习算法,可以基于大量实验数据对传感器结构和材料选择进行优化,从而开发出更高性能的柔性压阻式传感器。

(3)提高传感器的稳定性和寿命:增强传感器的稳定性和使用寿命是未来发展的重点。未来的传感器设计需要考虑环境适应性,通过材料改性和结构优化,降低温度、湿度和噪声等环境因素对传感器性能的影响,提高其长期稳定性。同时未来柔性压力传感器应有良好的抗疲劳性能,针对柔性压力传感器在反复弯曲和负载卸载压力过程中可能出现的疲劳问题,研发具有更高疲劳强度的材料,以延长传感器的使用寿命。

(4)降低制造成本:降低制造成本是推动柔性压力传感器广泛应用的关键因素。随着市场对传感器需求的不断增长,如何在保持高性能的同时减少生产费用,这是一个关键的挑战,目前可以采用低成本且性能优异的替代材料,同时开发新型导电聚合物或复合材料,这些材料不仅成本较低,还能满足传感器对柔性和导电性的要求。

(5)生物兼容性和可降解材料的使用:随着柔性传感器在生物医学领域的应用越来越广泛,对传感器的生物兼容性和可降解性提出了更高的要求。研发具有生物相容性和可降解特性的材料,可以使传感器在医疗植入设备、可穿戴健康监测等领域的应用更加安全和广泛。

相信随着纳米材料和先进制造工艺的发展,柔性压阻式压力传感器在多功能化、微型化、降低环境污染及低成本的大规模制造方面也将迎来新的机遇。

-

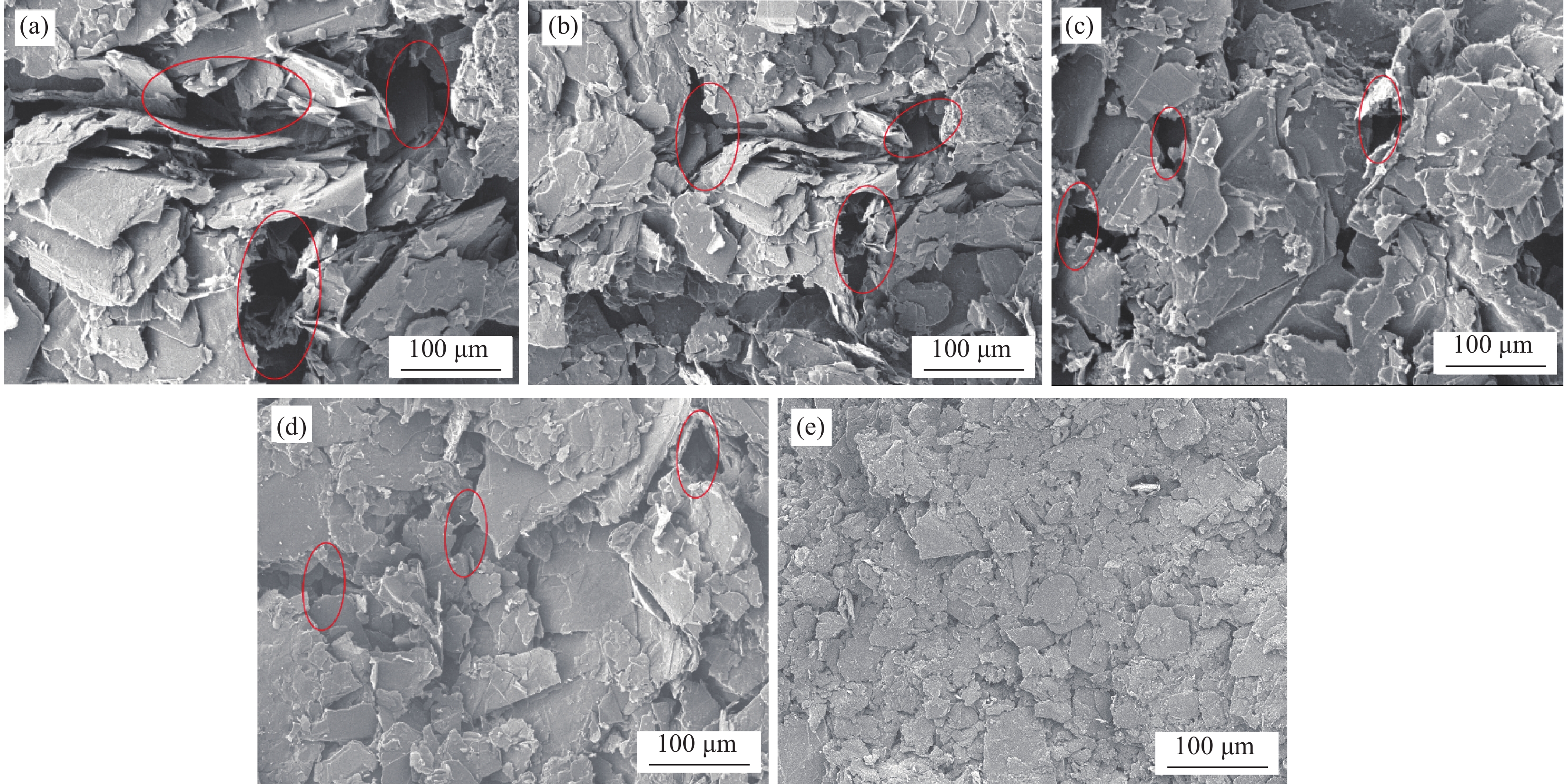

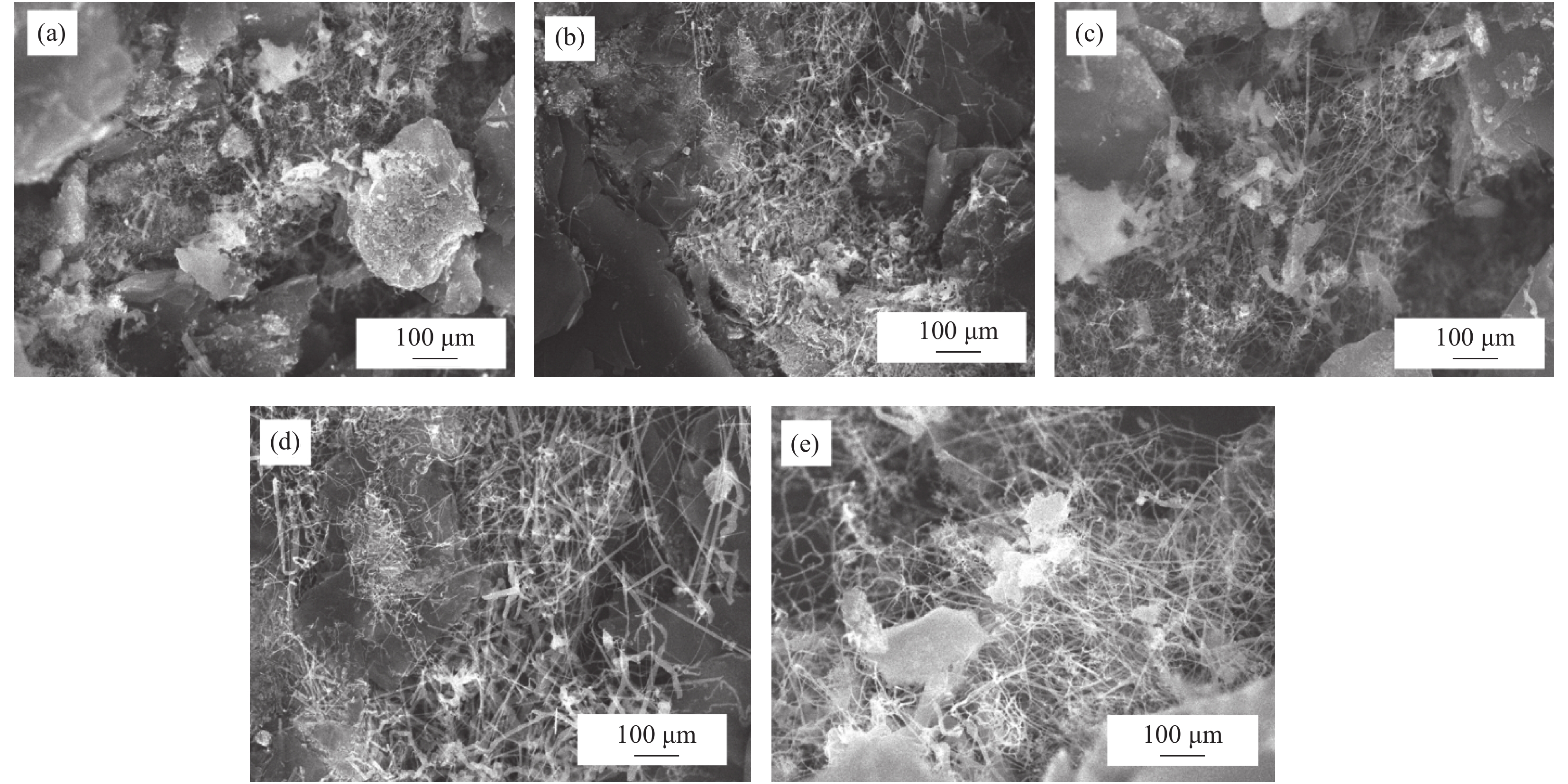

图 14 不同可膨胀石墨含量制备的可膨胀石墨-硅粉-酚醛树脂/石墨件内部微形貌图:(a) 0wt%;(b) 0.5wt%;(c) 1.0wt%;(d) 1.5wt%;(e) 2.0wt%

Figure 14. Internal micro morphology of expandable graphite-silica fume-phenolic resin/graphite prepared with different expandable graphite contents: (a) 0wt%; (b) 0.5wt%; (c) 1.0wt%; (d) 1.5wt%; (e) 2.0wt%

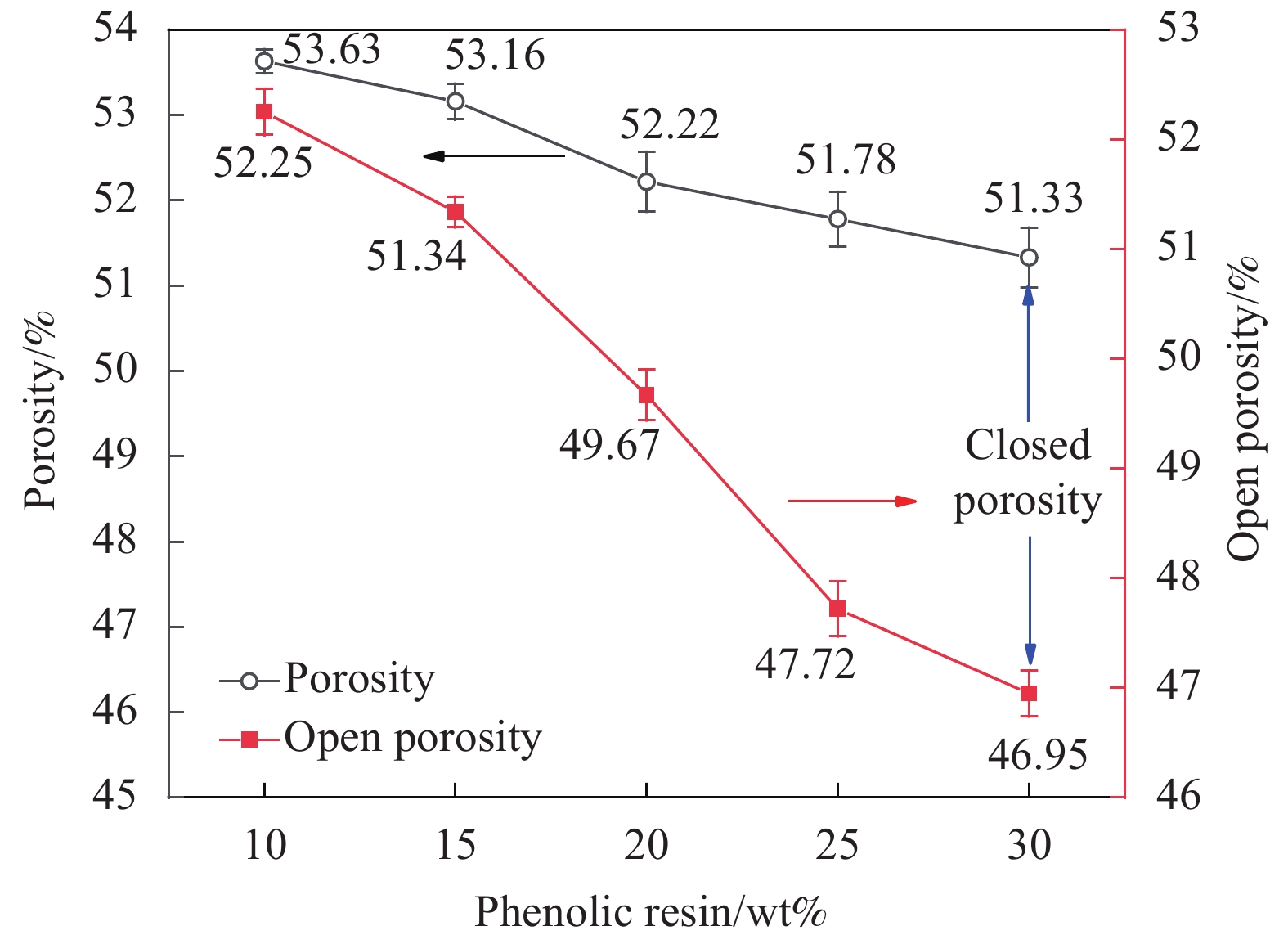

表 1 不同热固性酚醛树脂和天然鳞片石墨粉末的质量分数制备的酚醛树脂/石墨件

Table 1 Phenolic resin/graphite parts prepared by different mass fractions of thermosetting phenolic resin and natural flake graphite powder

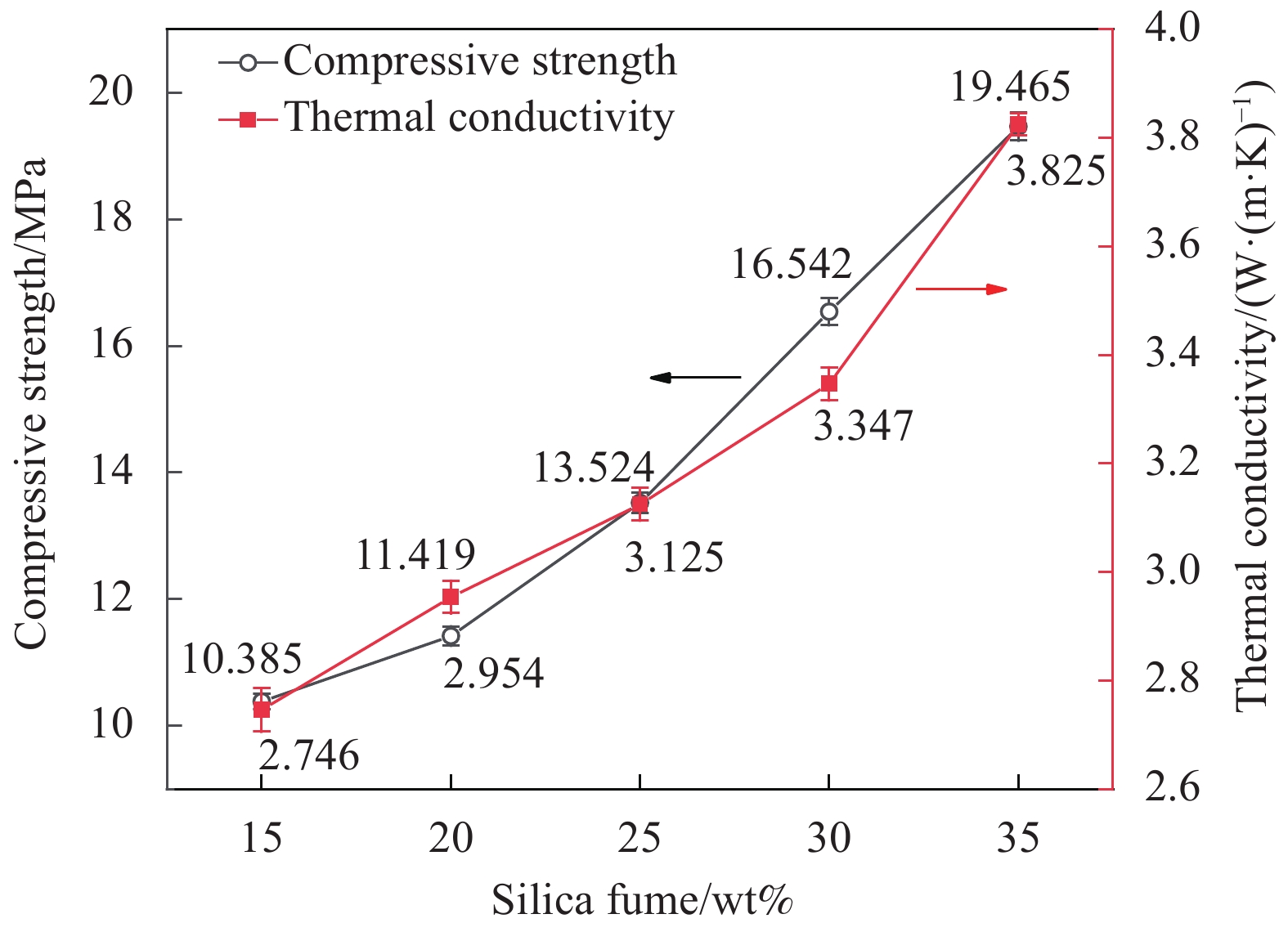

Materials Mass fraction/wt% Graphite 90 85 80 75 70 Phenolic resin 10 15 20 25 30 表 2 不同天然鳞片石墨粉末与高纯硅粉的质量分数制备的硅粉-酚醛树脂/石墨件

Table 2 Silicon powder-phenolic resin/graphite parts prepared by different mass fractions of natural flake graphite powder and high-purity silicon powder

Materials Mass fraction/wt% Graphite 55 50 45 40 35 Phenolic resin 30 30 30 30 30 Si 15 20 25 30 35 表 3 不同可膨胀石墨粉末的质量分数制备的可膨胀石墨-硅粉-酚醛树脂/石墨件

Table 3 Expandable graphite-silica fume-phenolic resin/graphite parts prepared with different mass fractions of expandable graphite powder

Materials Mass fraction/wt% Graphite 39.75 39.5 39.25 39.00 39.75 Phenolic resin 30 30 30 30 30 Si 30 30 30 30 30 Expandable graphite 0.25 0.50 0.75 1.00 1.25 表 4 与各种轻质隔热材料综合性能对比

Table 4 Comprehensive performance comparison with various lightweight thermal insulation materials

Material composition Forming methods Density/

(g·cm−3)Thermal conductivity/

(W·(m·K)−1)Compressive

strength/MPaRef. Expandable graphite, alumina fiber, aluminium silicate Press forming — 0.10 0.74 [25] Hollow balls, Al2O3-SiO2 Gel-casting 1.09 0.13 15.0 [26] Carbon fiber,

graphite fiberHigh temperature

graphitization treatment0.16 0.14 2.0 [27] Graphite felt core,

graphite paper, carbon fiberChemical vapor deposition 0.31 0.40 — [28] Graphite, phenolic resin, silicon, expandable graphite Micro-thermal press additive manufacturing 1.00 0.85 18.37 This work -

[1] 李庆彬, 潘志华. 轻质隔热材料的研究现状及其发展趋势[J]. 硅酸盐通报, 2011, 30(5):1089-1093. LI Qingbin, PAN Zhihua. Research status of lightweight thermal insulation materials and its development trend[J]. Silicate Bulletin,2011,30(5):1089-1093(in Chinese).

[2] LI X X, YAN L W, ZHANG Y B, et al. Lightweight porous silica ceramics with ultra-low thermal conductivity and enhanced compressive strength [J]. Ceramics International, 2022, 48(7):9788-9796.

[3] 王雪琴, 俞建勇, 丁彬. 纳米纤维隔热材料在航空航天领域的应用进展[J]. 纺织导报, 2018(S1):68-72. WANG Xueqin, YU Jianyong, DING Bin. Advances in the application of nanofiber insulation materials in aerospace field[J]. Textile Herald,2018(S1):68-72(in Chinese).

[4] 任海涛, 贾韬, 刘家臣, 等. 具有三维网络结构的莫来石纤维多孔隔热材料的制备及性能研究[J]. 航空科学技术, 2018, 29(4):73-78. REN Haitao, JIA Tao, LIU Jiachen, et al. Preparation and performance study of mullite fiber porous thermal insulation materials with three-dimensional network structure[J]. Aviation Science and Technology,2018,29(4):73-78(in Chinese).

[5] 郭俊. 新型低密度C/C隔热材料的制备研究[D]. 长沙: 中南大学, 2009. GUO Jun. Preparation of new low density C/C insulation materials[D]. Changsha: Central South University, 2009(in Chinese).

[6] YANG X G, SUN Y T, SHI D Q, et al. Experimental investigation on mechanical properties of a fiber-reinforced silica aerogel composite[J]. Materials Science and Engineering: A,2011,528(13-14):4830-4836.

[7] 刘丹丹. 石墨的应用及其发展前景[J]. 黑龙江冶金, 2016, 36(1):56-57. LIU Dandan. Application of graphite and its development prospect[J]. Heilongjiang Metallurgy,2016,36(1):56-57(in Chinese).

[8] 李晓娜, 夏鹏, 朱清. 全球石墨资源开发现状及我国石墨行业发展建议[J]. 现代矿业, 2021, 37(2): 5-9. LI Xiaona, XIA Peng, ZHU Qing. Development status of global graphite resources and development suggestions of China's graphite industry [J]. Modern Mining, 2021, 37 (2): 5-9(in Chinese).

[9] 吴海华. 李腾飞. 肖林楠. 等. 鳞片石墨粉末选择性激光烧结成型工艺研究[J]. 激光与光电子学展, 2016, 53(10):101409. DOI: 10.3788/LOP53.101409 WU Haihua, LI Tengfei, XIAO Linnan, et al. Study on selective laser sintering and forming process of flake graphite powder[J]. Laser and Optoelectronics Show,2016,53(10):101409(in Chinese). DOI: 10.3788/LOP53.101409

[10] 吴海华, 孙瑜, 陈奎, 等. 选择性激光烧结与凝胶注模成型制备高强度低导热系数石墨/陶瓷复合材料[J]. 激光与光电子学进展, 2019, 56(9):182-187. WU Haihua, SUN Yu, CHEN Kui, et al. Preparation of high-strength low thermal conductivity graphite/ceramic composites by selective laser sintering and gel injection molding[J]. Advances in Laser and Optoelectronics,2019,56(9):182-187(in Chinese).

[11] CHEN S W. Fabrication of PEM fuel cell bipolar plate by indirect selective laser sintering[J]. Strength of Materials,2006,20(10):1356-1362.

[12] 邵珠花. 高参数浸渍剂研制及浸渍工艺的研究[D]. 贵阳: 贵州大学, 2019. SHAO Zhuhua. Preparation of high parameter impregnant and Study on its impregnation process [D]. Guiyang: Guizhou University, 2019(in Chinese).

[13] 刘占军, 郭全贵, 史景利, 等. 高导热炭/陶复合材料的制备及其性能研究[J]. 材料工程, 2007(S1):1-7. LIU Zhanjun, GUO Quangui, SHI Jingli, et al. Preparation and properties of high thermal conductivity carbon/ceramic composites[J]. Materials Engineering,2007(S1):1-7(in Chinese).

[14] GUO N N, LEU M C. Effect of different graphite materials on the electrical conductivity and flexural strength of bipolar plates fabricated using selective laser sintering[J]. International Journal of Hydrogen Energy,2012,37(4):3558-3566. DOI: 10.1016/j.ijhydene.2011.11.058

[15] 韩永军, 李青彬. 燕青芝, 等. 反应烧结制备碳化硅增强石墨复合材料及其性能[J]. 新型炭材料, 2015, 30(1):92-96. HAN Yongjun, LI Qingbin, YAN Qingzhi, et al. Properties of silicon carbide-reinforced graphite composites prepared by a reactive sintering method[J]. New Carbon Materials,2015,30(1):92-96(in Chinese).

[16] 中国国家标准化管理委员会. 炭素材料显气孔率的测定方法: GB/T 24529—2009 [S]. 北京: 中国标准出版社, 2009. Standardization Administration of the People’s Republic of China. Determination method of apparent porosity of carbon materials: GB/T 24529—2009 [S]. Beijing: China Standards Press, 2009(in Chinese).

[17] 中华人民共和国国家质量监督检验检疫总局、中国国家标准化管理委员会. 不透性石墨材料试验方法 第3部分: 抗压强度: GB/T 13465.3—2014 [S]. 北京: 中国标准出版社, 2014. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People’s Republic of China. Test methods for impermeable graphite materials Part 3: Compressive strength: GB/T 13465.3—2014 [S]. Beijing: China Standards Press, 2009(in Chinese).

[18] 韩永军. 高强石墨基复合材料的低成本制备与性能研究[D]. 北京: 北京科技大学, 2015. HAN Yongjun. Low cost preparation and properties of high strength graphite matrix composites [D]. Beijing: Beijing University of Science and Technology, 2015(in Chinese).

[19] 刘瑞平, 汪长安. 造孔剂添加量对凝胶注模成型工艺制备8YSZ多孔陶瓷性能的影响[J]. 稀有金属材料与工程, 2013, 42(S1):422-425. LIU Ruiping, WANG Changan. Effect of pore forming additives on the properties of 8YSZ porous ceramics prepared by gel casting process[J]. Rare Metal Materials and Engineering,2013,42(S1):422-425(in Chinese).

[20] RICE R W. Comparison of stress concentration versus minimum solid area based mechanical property-porosity relations[J]. Journal of Materials Science,1993,28(8):2187-2190. DOI: 10.1007/BF00367582

[21] 李翠伟, 邓娜娜, 武令豪, 等. 泡沫注凝法制备孔结构可调的氧化锆多孔陶瓷[J]. 硅酸学报, 2019, 47(9):1214-1221. LI Cuiwei, DENG Nana, WU Linghao, et al. Zirconia porous ceramics with adjustable pore structure prepared by foam injection method,[J]. Silica Journal,2019,47(9):1214-1221(in Chinese).

[22] 邓先功, 韦婷婷, 冉松林, 等. 发泡–注凝成型法制备自结合莫来石多孔陶瓷[J]. 硅酸盐学报, 2017, 45(12):1803-1809. DENG Xiangong, WEI Tingting, RAN Songlin, et al. Preparation of self bonded mullite porous ceramics by foam injection molding[J]. Acta Silicate Sinica,2017,45(12):1803-1809(in Chinese).

[23] GONG L L, WANG Y H, CHENG X D, et al. Thermal conductivity of highly porous mullite materials[J]. International Journal of Heat and Mass Transfer,2013,67:253-259.

[24] 龚伦伦. 基于发泡和固化法的硅酸盐无机外墙保温材料制备与性能研究[D]. 合肥: 中国科学技术大学, 2014. GONG lunlun. Preparation and properties of silicate inorganic exterior insulation materials based on foaming and curing method [D]. Hefei: University of Science and Technology of China, 2014(in Chinese).

[25] 方凯. 氧化铝纤维基可膨胀隔热材料的制备与性能研究[D]. 北京: 中国建筑材料科学研究总院, 2016. FANG Kai. Preparation and properties of alumina fiber based expandable thermal insulation materials [D]. Beijing: China Academy of Building Materials Science, 2016(in Chinese).

[26] 黄春舒. 多孔轻质莫来石陶瓷制备及性能的研究[D]. 天津: 天津大学, 2012. HUANG Chunshu. Preparation and properties of porous lightweight mullite ceramics [D]. Tianjin: Tianjin University, 2012(in Chinese).

[27] FRIEDRICH Wegner, 钱承顺, 王元化. 用炭纤维和石墨纤维制造的高温隔热材料[J]. 炭素技术, 1983(3):11-13. FRIEDRICH Wegner, QIAN Chengshun, WANG Yuanhua. High temperature insulation materials made of carbon fiber and graphite fiber[J]. Carbon Technology,1983(3):11-13(in Chinese).

[28] YANG W, CHEN Z F, YU S J, et al. Preparation and characterization of new-type high-temperature vacuum insulation composites with graphite felt core material[J]. Materials & Design,2016,99:369-377.

-

下载:

下载: