Preparation of calcite/biochar composite by co-pyrolysis and its adsorption properties and mechanism for Pb(II)

-

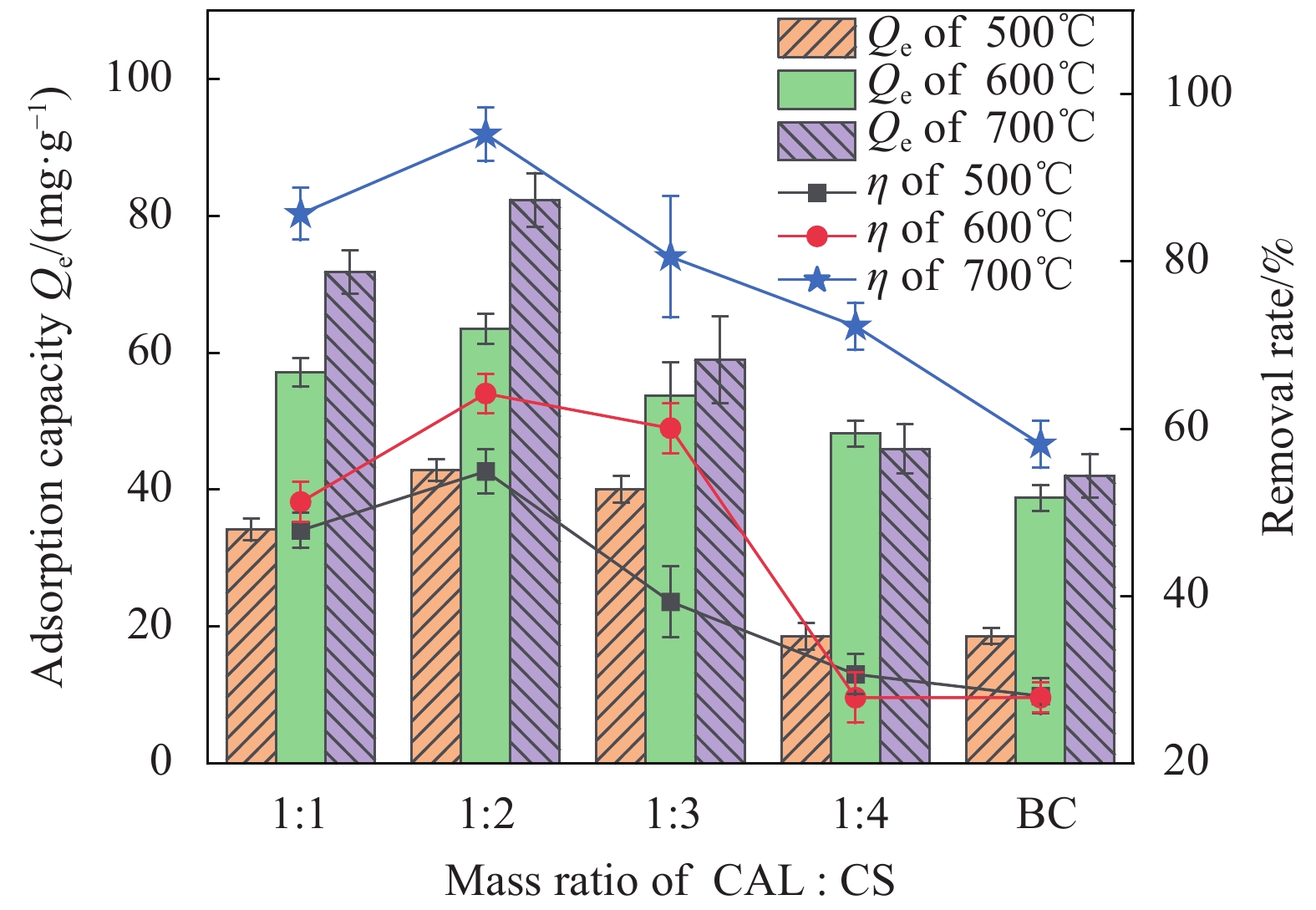

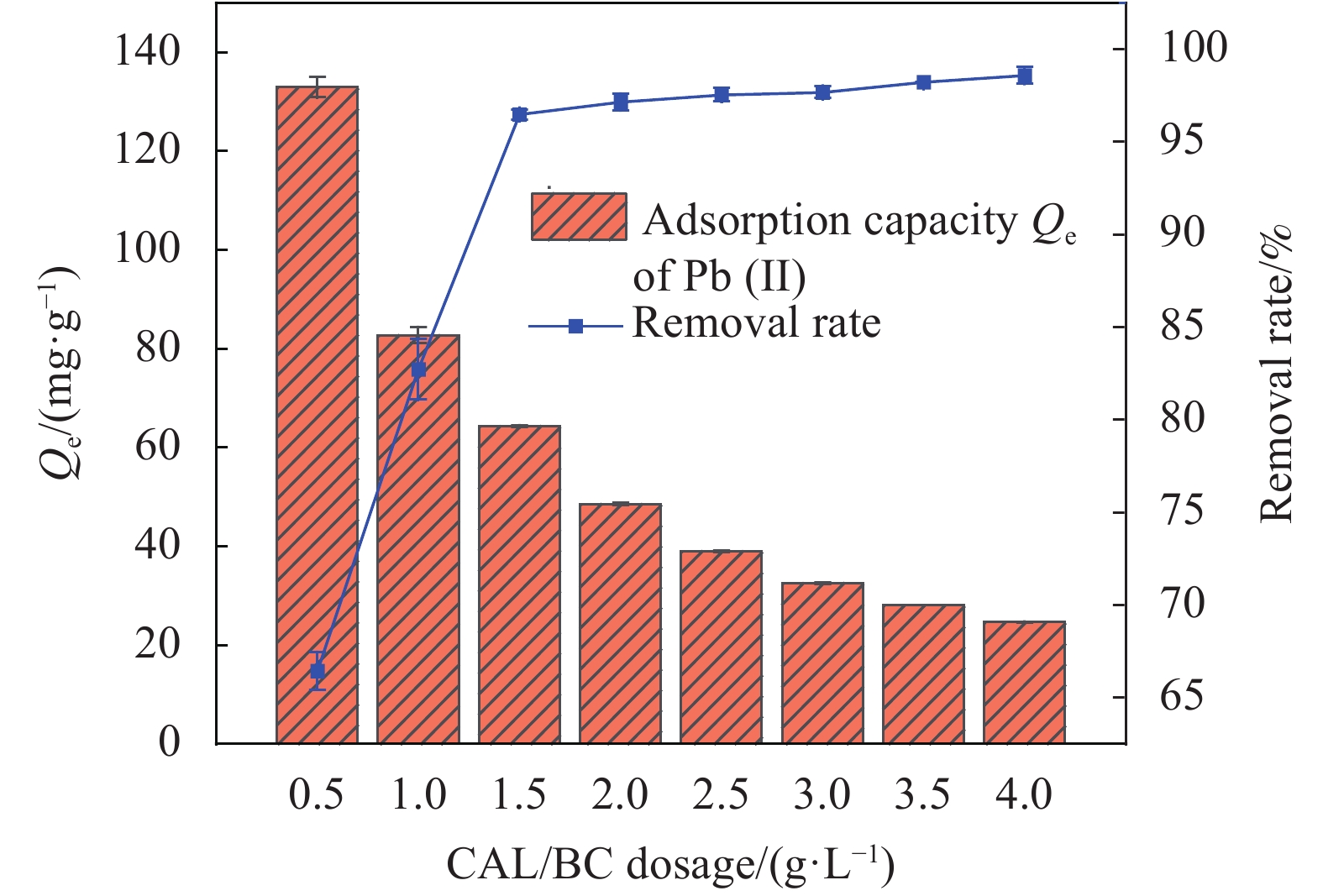

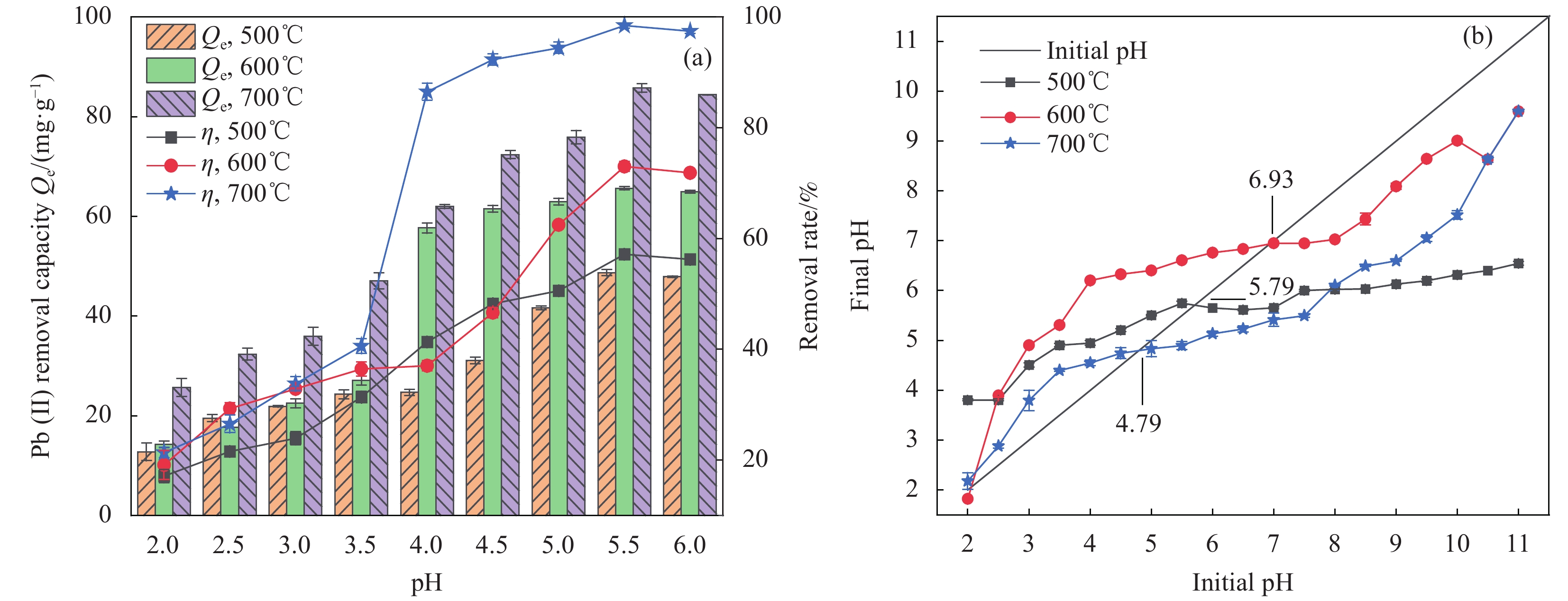

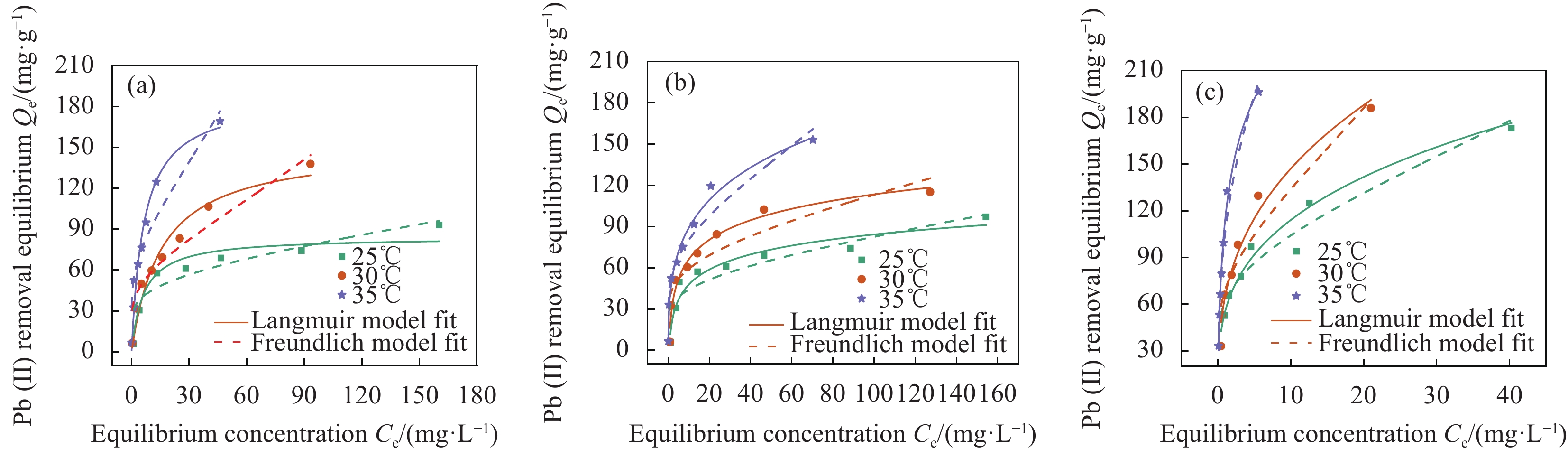

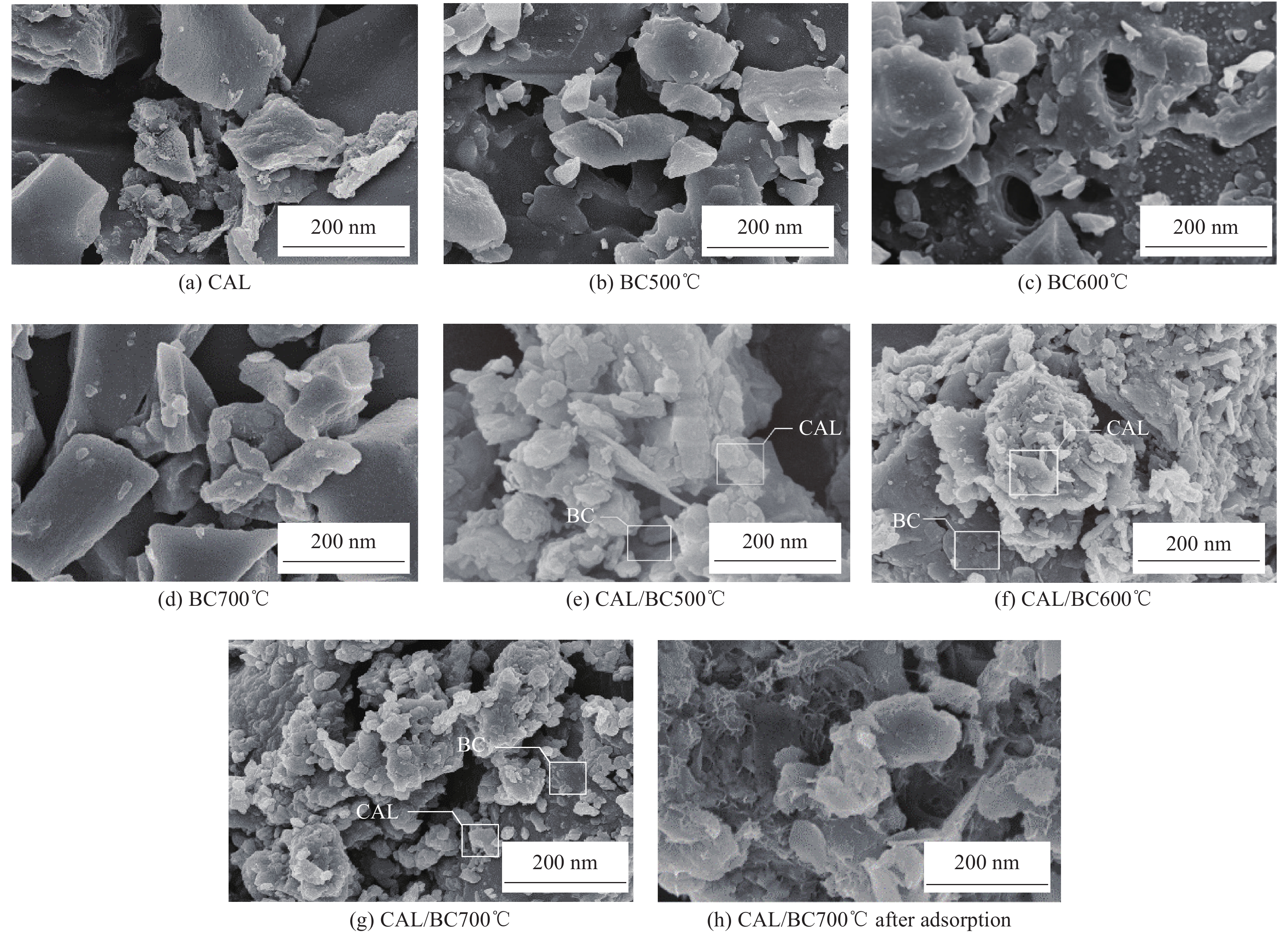

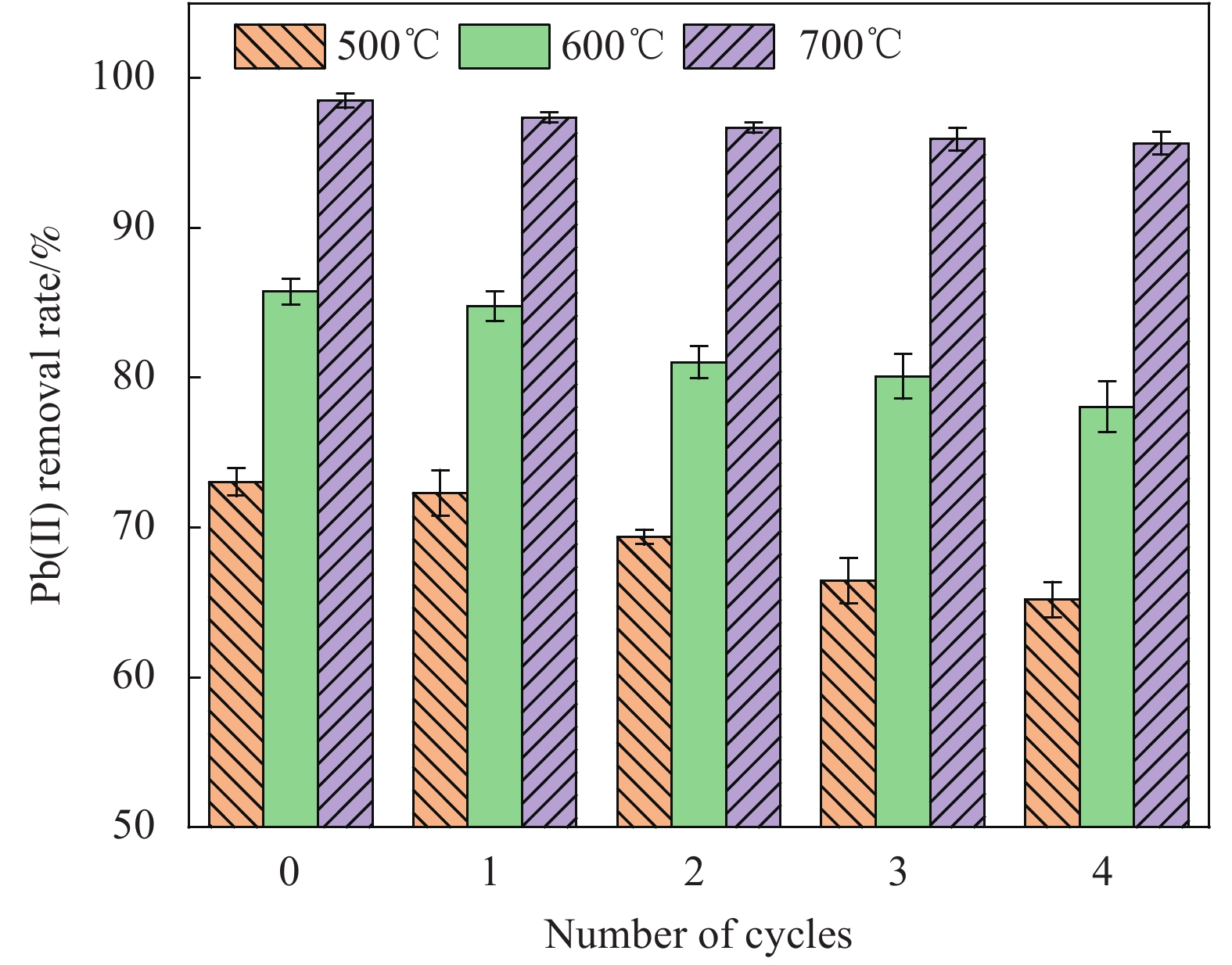

摘要: 为了制备一种高效吸附含Pb(II)废水的生物炭材料,以椰壳(CS)和方解石(CAL)为原料,采用共热解法分别在500℃、600℃、700℃制备了方解石/生物炭(CAL/BC)复合材料。通过SEM、ICP-MS、BET、XRD、FTIR等方法对CAL/BC复合材料的表面微观形态和结构进行了表征。结果发现,三种热解温度条件下,CAL均能够与CS紧密结合,而且CAL/BC具有较大的比表面积,表面含有丰富的官能团。批量吸附实验结果表明,CAL和CS质量比为1∶2,pH值为5.5,吸附剂添加量为1.5 g·L−1,此时CAL/BC复合材料对Pb(II)的吸附量分别为95.24 mg·g−1(500℃)、99.01 mg·g−1(600℃)、185.19 mg·g−1(700℃),可见热解温度为700℃时,吸附效果最佳。吸附过程符合二级动力学模型和Langmuir等温线模型。CAL/BC复合材料吸附Pb(II)的主要机制是沉淀、离子交换、阳离子-π作用、孔隙填充和静电引力。此外,CAL/BC复合材料在4次吸附-解吸循环后仍能保持较高的Pb(II)去除率。因此,共热解法制备的CAL/BC复合材料在处理废水中的Pb(II)方面具有广阔的应用前景。Abstract: In order to obtain a biochar material which adsorbs PB (II) in wastewater efficiently, calcite/biochar (CAL/BC) composite was prepared by co-pyrolysis at 500℃, 600℃ and 700℃, using coconut shell (CS) and calcite (CAL) as raw materials. The surface morphology and structure of CAL/BC composites were characterized by SEM, ICP-MS, BET, XRD and FTIR. The results show that CAL and CS combine tightly under the three pyrolysis tempera-tures, and CAL/BC has a large specific surface area and a large number of functional groups. The maximum adsorption capacities of PB (II) on CAL/BC composite (CAL∶ CS=1∶ 2, mass ratio) prepared at 500℃, 600℃, and 700℃ are 95.24 mg·g−1, 99.01 mg·g−1, and 185.19 mg·g−1. The optimum adsorption condition is pH=5.5 and the amount of adsorbent is 1.5 g·L−1. The adsorption process conforms to the second-order kinetic model and Langmuir isotherm model. The mechanisms of adsorption of Pb(II) on CAL/BC composites are precipitation, ion exchange, cation-π action, pore filling and electrostatic gravitation. In addition, the removal rate of Pb(II) by CAL/BC composite remains high level after 4 adsorption-desorption cycles. Therefore, the CAL/BC composite prepared by co-pyrolysis has a excellent application prospect in the treatment of Pb(II) in wastewater.

-

Keywords:

- calcite /

- coconut shell /

- biochar /

- composites /

- Pb(II) /

- adsorption

-

细菌、病毒等病原微生物给人类健康带来严重危害,使用抗菌材料已成为一种迫切的需求和选择。光催化作为新兴的绿色环保技术备受关注,为杀菌消毒提供了一种新的解决方法。光催化材料在光照激发下产生的电子(e−)和空穴(h+)会直接攻击微生物细胞,使其细胞膜、细胞壁和细胞内物质受到破坏而失去活性;光生h+和e−会与H2O和溶解氧等反应产生·OH、·O2−和H2O2等活性氧(ROS),这些活性氧作用于细菌而起到抗菌作用。

WO3是一种经典的N型光催化剂,化学性质稳定、无毒,对可见光有较好的吸收,带隙 Eg在2.5~3.0 eV [1]。但是较窄的带隙使得载流子的复合速率较快,导致光催化效率不高。引入金属纳米颗粒可以提高电荷分离效率、降低还原反应的超电势,从而提高光催化效率。当前报道了引入Zn、Cu[2]和Ag[3]等金属纳米粒子后,由于SPR效应,可见光吸收范围扩大,光催化性能显著提升。例如,Zhu等[4]采用水热法合成尺寸均匀的WO3纳米板,负载Ag后,催化剂的吸光范围被拓宽。此外,Ag0可以作为电子捕获中心,改善光催化中的电荷分离过程,实验发现Ag/WO3在2 h内能够灭杀99.9%的E. coli和枯草芽孢杆菌(B. subtilis)。Arshad等[5]采用沉淀法将Zn负载到WO3上,该催化剂也表现出对E. coli优异的灭菌性能。Sanaz Mohammadi[6]通过共沉淀法制备了Zn-WO3、Cu-WO3、Zn和Cu共掺杂WO3,发现Zn和Cu共掺杂WO3在可见光下对E. coli的抗菌效果最佳。

尽管贵金属纳米粒子在可见光区的SPR效应非常显著,可以增强半导体材料的可见光催化性能,但是其价格昂贵,难以满足实际需求。近年来,半金属Bi因成本低、具有SPR效应被作为一种应用于光催化剂表面改性的替代品。Bi0修饰的半导体材料被陆续报道,如Bi/Bi2O3[7]、Bi/BiOI[8]、Bi/Bi3O4Cl[9]和Bi/Bi2WO6等[10]。迄今,Bi0修饰WO3的抗菌材料尚未见公开报道。此外,Bi的引入方式包括硼氢化钠(NaBH4)还原、紫外还原、溶剂热有机物辅助还原等方法。其中,紫外还原法可在室温下进行,以光生电子作为还原剂,避免额外投加化学还原剂。因此,本文以WO3为基底,Bi(NO3)3·5H2O为铋源,通过紫外还原法在WO3表面沉积非金属Bi0,制备了具有可见光响应的Bi/WO3复合材料。以E. coli和S. aureus为研究对象,考察了所制备复合材料的光催化抗菌性能,并对反应机制进行了探究。

1. 实验材料及方法

1.1 原材料

Na2WO4·2H2O (阿拉丁试剂(上海)有限公司),NaOH(西陇科学股份有限公司),C6H8O7 (天津博迪化工股份有限公司),Bi(NO3)3·5H2O (成都市科龙化工试剂厂),E. coli (ATCC 8099)来自广东环凯微生物有限公司、S. aureus (ATCC 25923)来自青岛海博生物技术有限公司,蛋白胨、牛肉膏和NaCl均来自杭州微生物试剂有限公司,所有样品均为分析纯,未经过进一步纯化使用。

1.2 Bi/WO3制备

根据文献[11]水热法合成WO3,之后利用紫外还原法制备Bi/WO3,将1 mmol WO3和0.2 mmol Bi(NO3)3·5H2O加入到50 mL的甲醇溶液中,将混合溶液转移到50 mL厌氧瓶中加上盖子,通N2除氧,外加紫外光照射120 min后用甲醇和蒸馏水各洗涤3次,在真空干燥箱中以60℃烘干,通过调整0.2、0.4、0.6和0.8 mmol的Bi(NO3)3·5H2O得到不同比例复合材料,将得到Bi/WO3材料分别标记为0.2 mmol Bi/WO3、0.4 mmol Bi/WO3、0.6 mmol Bi/WO3和0.8 mmol Bi/WO3。

1.3 材料表征

采用Regaku D/Max-2500型X射线衍射仪(XRD)分析制备催化剂的晶相;利用VANTAGE ESI型X射线光电子能谱(XPS)分析确定化学组成;利用光电子能谱仪(AXIS SUPRA,Kratos, UK)分析催化剂的紫外-可见漫反射光谱(UV-Vis DRS),通过ESR光谱学(Bruker EPR ELEXSYS 500)检测·O2−和·OH。

1.4 光电化学测试

利用CHI660E电化学工作站(上海辰华)在三电极体系中测试光电化学性能。以氙灯(XQ-500,λ≥420 nm)作为光源,所有的样品粉末均通过刮刀法以导电电极作为基底制成薄膜电极。将制备完成的Bi/WO3电极置于0.1 M Na2SO4和Na2SO3混合溶液中,作为工作电极,分别以Pt和Ag/AgCl电极为对电极和参比电极,在明暗交替下,得到时间-电流曲线(i-t)。在莫特-肖基特(M-S plots)和交流阻抗(EIS)测试中,以0.5 mol/L Na2SO4为电解质溶液,采用上述相同电极体系。

1.5 细菌培养

取E. coli干粉加入到复苏液中,用无菌滴管吸取适量混合溶液加入到灭过菌的液体培养基中,在恒温培养箱中以37℃培养24 h。振荡均匀后取5 mL进行离心分离。弃上层清液后用0.9wt%生理盐水进行洗涤后稀释离心的细菌,调整细菌浓度至2.8×107~3.2×107 CFU/mL,S. aureus也采用上述操作步骤。

1.6 抗菌实验

利用CEL-HXF-300型氙灯(λ ≥ 420 nm,100 mW/cm2)进行光催化实验,反应溶液距离光源13 cm,催化剂浓度为1 g/L。先进行30 min暗反应确保吸附-解吸平衡,开灯后间隔30 min取样,取1 mL菌液到无菌离心管中,用生理盐水进行梯度稀释,稀释到104的菌液滴加到固体琼脂平板上进行平板涂布。37℃孵育24 h后采用平板计数法计算活细胞数,对所有样品进行3次平行试验。

2. 结果与讨论

2.1 Bi/WO3的微观结构

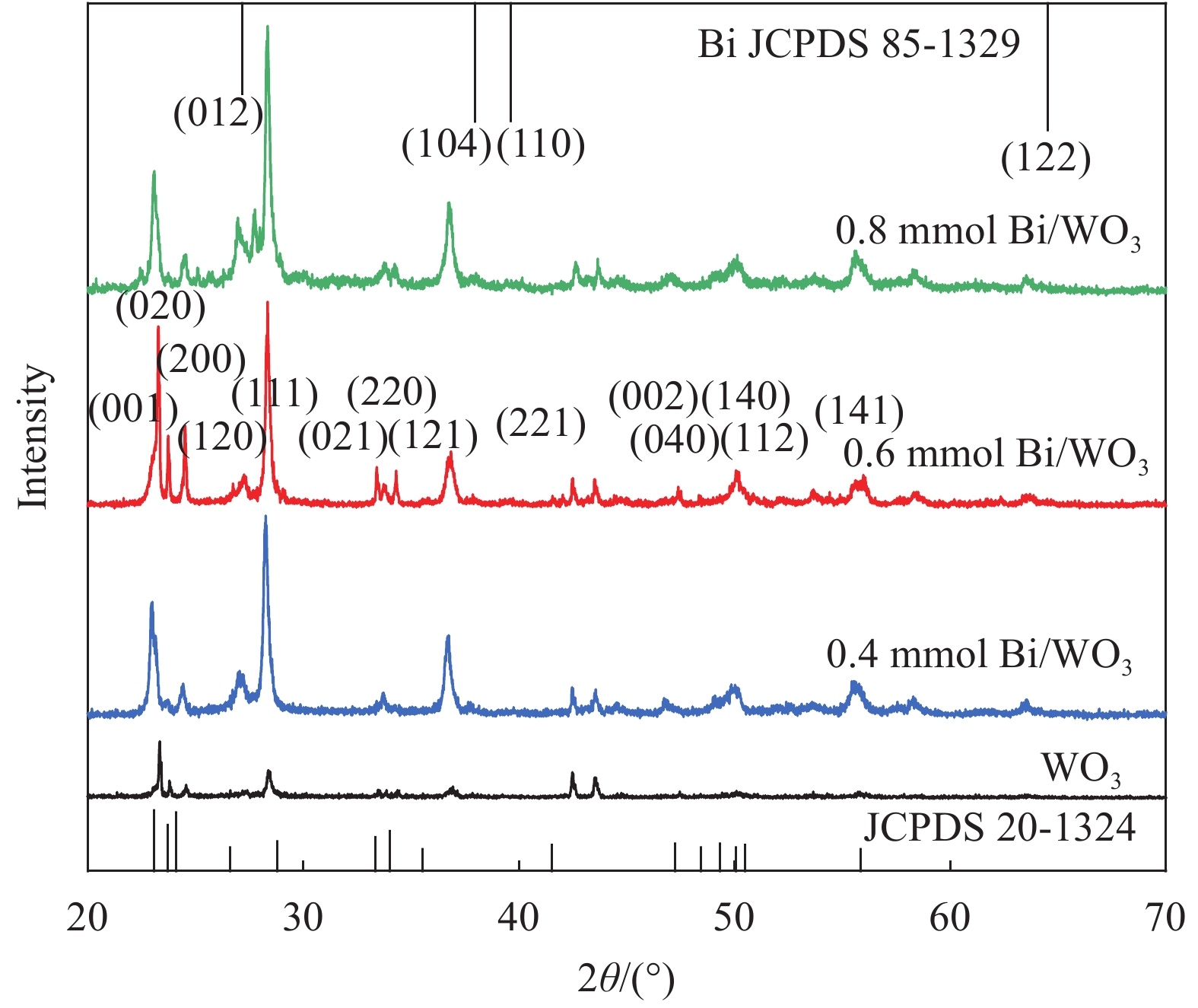

图1为WO3和不同比例Bi/WO3的XRD图谱。可知,在2θ=23.1°、23.7°、24.1°、26.6°、28.8°、33.3°、34.0°、35.5°、41.5°、47.2°、48.4°、50.1°、50.5°和55.8°中出现的(001)、(020)、(200)、(120)、(111)、(021)、(220)、(121)、(221)、(002)、(040)、(140)、(112)和(141)晶面,其衍射峰与WO3的标准卡片JCPDS 75-2187[12]相匹配,Bi/WO3系列的XRD图谱中增加了Bi的特征峰,在2θ=27.2°和64.5°处出现(012)和(122)晶面,对应标准卡片JCPDS 85-1329[13],证明了Bi单质的存在,说明紫外还原法得到的Bi/WO3中含有Bi0,随着Bi(NO3)3·5H2O用量的增多,Bi0的相对强度也逐渐提高。

2.2 Bi/WO3的化学组成

为了分析Bi/WO3的化学成分和元素价态,对0.6 mmol Bi/WO3进行了XPS表征,结果如图2所示。W、Bi、C和O元素的峰清晰可见,表明了0.6 mmol Bi/WO3光催化剂的表面元素组成,其中W与O的原子比例约为1∶3,与WO3的化学计量基本一致。此外,W4f图谱(内插图)中35.8 eV和37.9 eV的峰分别为W4f7/2和W4f5/2[11],对应WO3的W6+。针对Bi4f (内插图),Bi3+与催化剂制备过程中加入的Bi(NO3)3·5H2O价态一致,说明在紫外还原后Bi3+仍然占主导。除了两个特征的主峰外还发现了157.6 eV和165.1 eV处的小峰[14],对应于单质Bi。通过对拟合之后的峰面积对比发现Bi0只占5.1%,说明紫外还原Bi单质的能力有限,Bi0只占较少的量。

2.3 Bi/WO3的光学性能

通过测定WO3和0.6 mmol Bi/WO3的UV-Vis DRS谱对样品的光学性能进行了分析。如图3所示,WO3具有可见光吸收,波长从400 nm开始,复合Bi0以后,可见光吸收进一步增强。经过Kubelka-Munk变换后得到WO3的Eg为2.52 eV,而经过还原后负载Bi的0.6 mmol Bi/WO3带隙变小。

2.4 Bi/WO3的光电化学性能

通过刮刀法将光催化剂负载到FTO上,测试光催化剂材料的i-t曲线(图4(a))和EIS图谱(图4(b))。由图4(a)可知,负载Bi0后的WO3光电流均显著提升,且以0.6 mmol Bi/WO3为最佳样。此外,如图4(b)所示,0.6 mmol Bi/WO3的阻抗环半径明显低于WO3和其余比例,意味着电子传输阻力大大减小,表明Bi0的引入有利于电子的转移。综上,0.6 mmol Bi/WO3比WO3在可见光照射的条件下有更优异的光电响应和电子传送速率,这些都有利于促进光催化反应。

2.5 Bi/WO3的光催化剂抗菌性

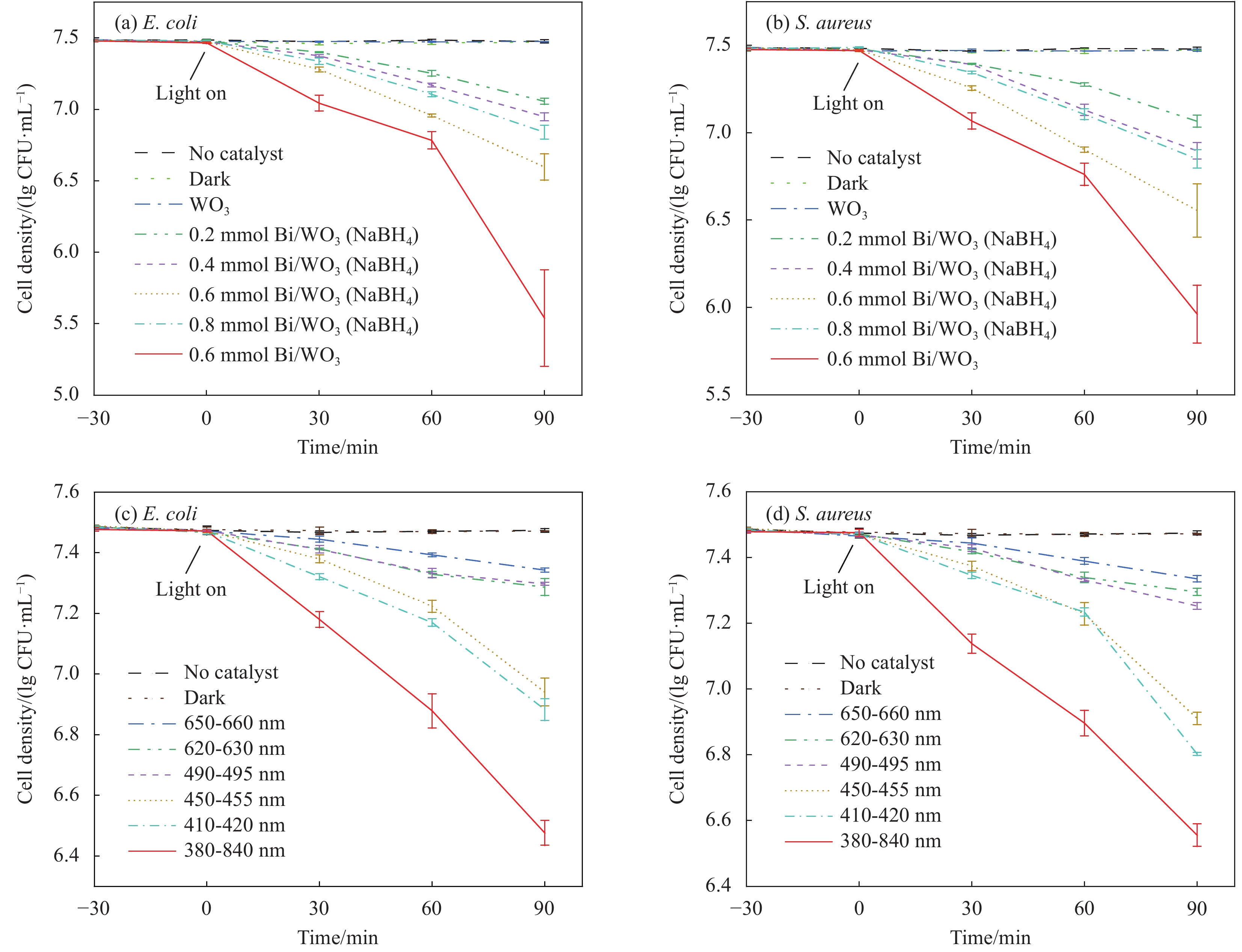

Bi/WO3对E. coli和S. aureus的抗菌结果如图5(a)和图5(b)所示,对照组中细菌存活率没有变化,排除黑暗和自然生长干扰。可见光照射下,WO3和经过紫外还原处理的WO3(UV)均对E. coli和S. aureus表现出较差的抗菌效果,说明紫外还原产生的氧空位对灭菌过程影响微弱。但经过Bi0修饰后的Bi/WO3系列光催化剂具有显著增强的抗菌效果,其中以0.6 mmol Bi/WO3最佳。

由图5(c)~5(d)可以看出:可见光照射90 min后,0.6 mmol Bi/WO3能够使E. coli和S. aureus显著减少,而纯WO3对细菌几乎无作用。BET测试发现WO3的比表面积(16.1 m2/g)比0.6 mmol Bi/WO3 (9.3 m2/g)小,说明性能提升并非由比表面积增大所致。此外,以NaBH4还原法制备Bi/WO3,实验结果如图6(a)和图6(b)所示。可以看出:Bi/WO3(NaBH4)对E. coli和S. aureus也具有抗菌效果,但是相比较紫外还原法制备的0.6 mmol Bi/WO3,其抗菌效果较弱。

以优化的0.6 mmol Bi/WO3为光催化剂,以100 W LED灯为光源,进一步考察了其在不同波长光照射下的抗菌效果,实验结果如图6(c)和图6(d)所示。实验发现0.6 mmol Bi/WO3在380~840 nm的白光下效果最佳,在650~660 nm的长波下也具有一定抗菌效果,说明0.6 mmol Bi/WO3具有宽光谱抗菌效应。

2.6 Bi/WO3对抗菌性能的影响

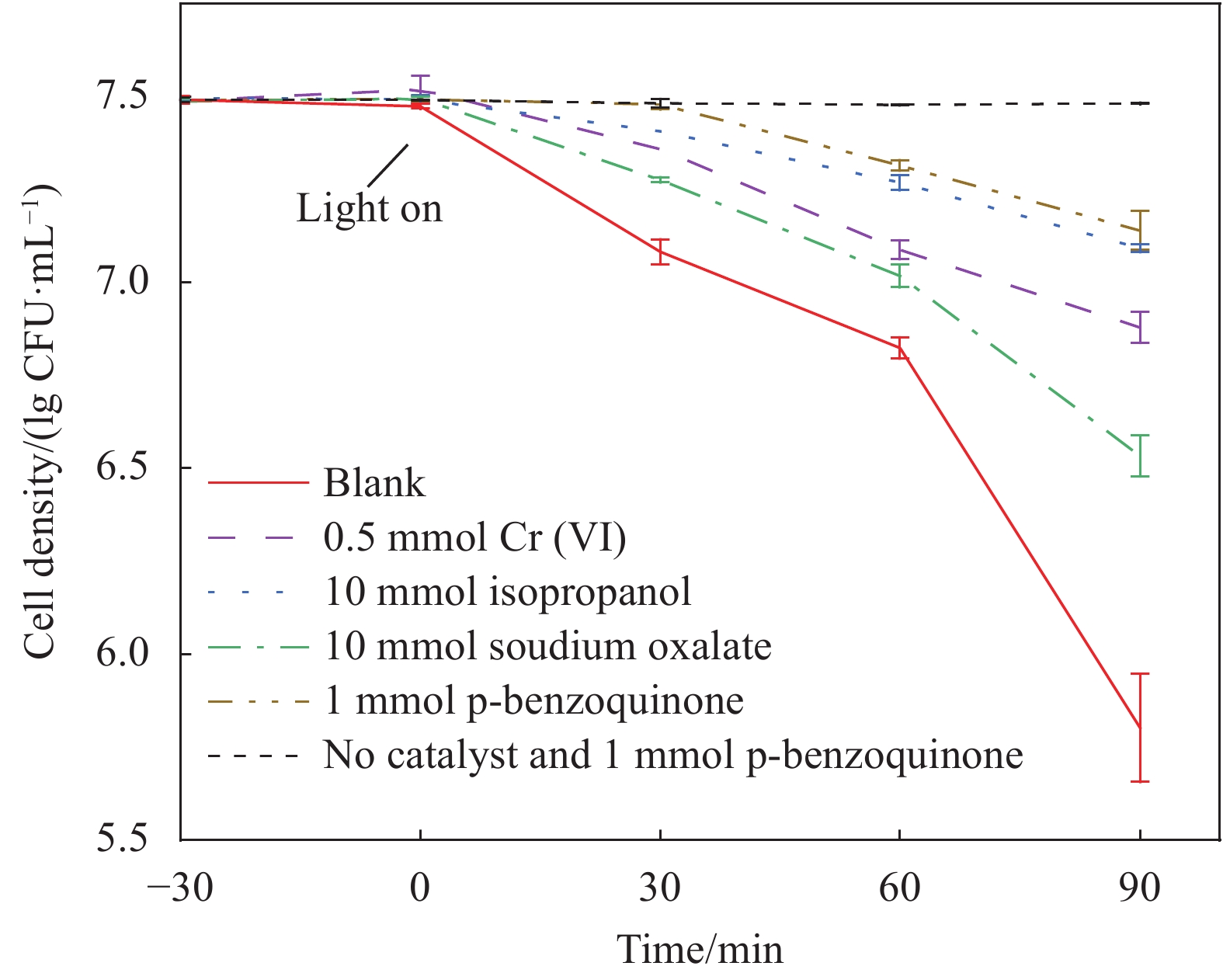

在可见光照射下,光催化剂被激发产生h+和e−;同时h+、e−与O2、H2O结合生成O2·−和·OH,这些活性物种会与细菌发生氧化/还原反应并最终杀灭细菌。通过加入捕获剂探究0.6 mmol Bi/WO3抗菌过程中的主要活性物种。加入10 mmol/L异丙醇(Isopropanol)、1 mmol/L对苯醌(p-benzoquinone)、0.5 mmol/L Cr(Ⅵ)和10 mmol/L草酸钠(Soudium oxlate)[15]分别捕获O2·−、·OH、e−和h+,图7为不同捕获剂添加对0.6 mmol Bi/WO3对E. coli的性能影响。可以看出,加入对苯醌后,E. coli密度变化最小。这可能是由于对苯醌捕获O2·−,导致对细菌的作用的O2·−数量减少,抗菌效果因此减弱,故推测O2·−在本体系中起主要作用。此外,发现添加其余捕获剂后的抗菌效果不如p-benzoquinone和Isopropanol的变化明显,说明O2·−和·OH可能在抗菌过程中起主要作用。

2.7 Bi/WO3的结构特性

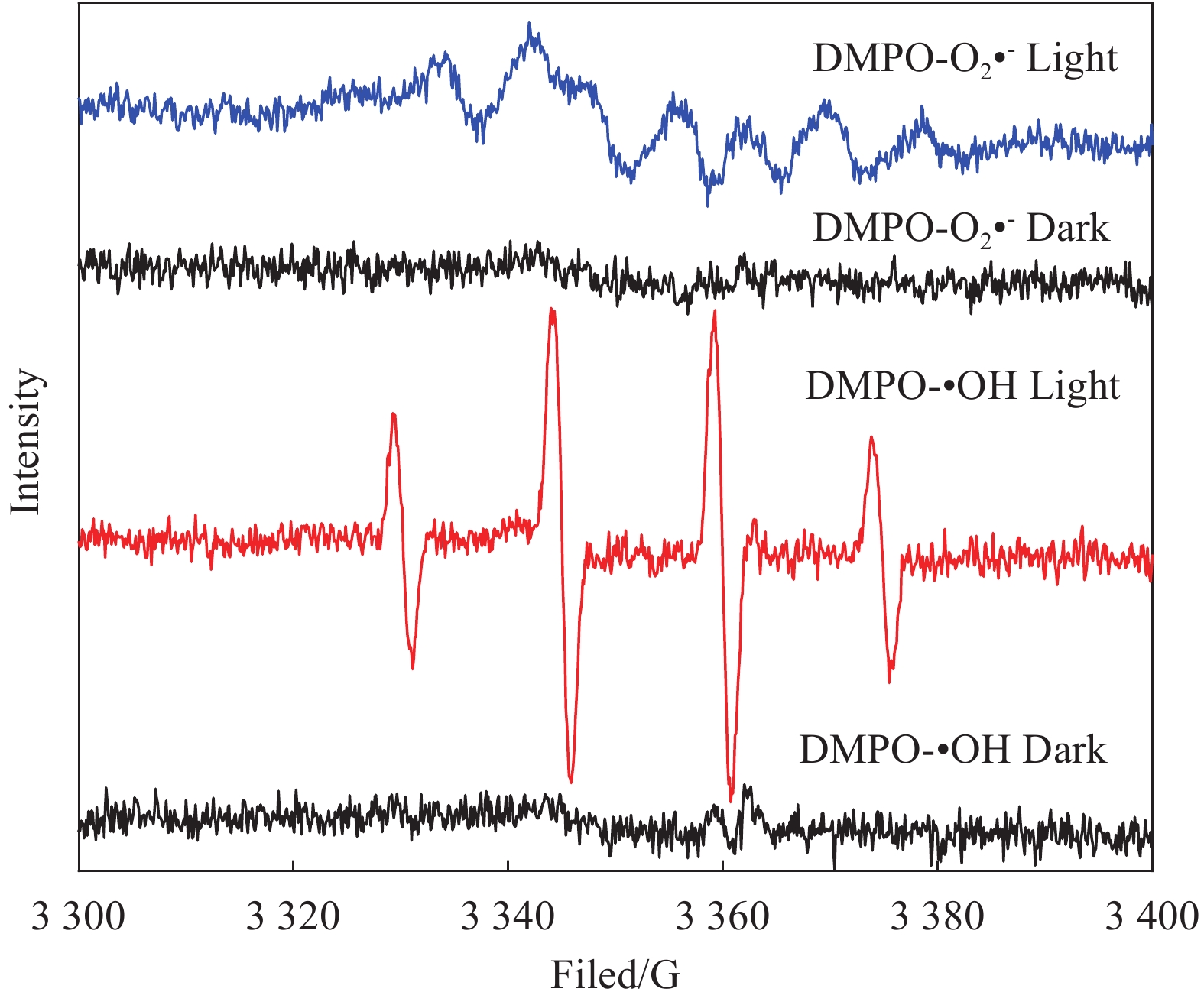

通过ESR测试光催化过程中产生的活性物种[16],分别测定0.6 mmol Bi/WO3在黑暗和光照条件下产生的活性自由基,结果如图8所示。在黑暗条件下几乎不产生O2·−和·OH,可见光下会产生明显的O2·−和·OH峰,进一步地验证淬灭剂实验的结果。

2.8 Bi/WO3光催化抗菌机制

在WO3表面引入Bi0后,提升了可见光吸收,促进了电荷分离,抗菌性能显著提升,为探究抗菌机制,需弄清体系中催化剂的导带(CB)、价带(VB)位置。进一步测试了WO3的M-S plots,如图9(a)所示,推测WO3的平带电势为+0.8 V vs. NHE。由于WO3是典型的N型半导体,其光催化剂的CB相比平带电势负0.1 V左右,故换算后得出WO3的CB为+0.7 V vs. NHE。结合禁带宽度(2.52 eV),推测VB的位置在+3.22 V vs. NHE,氧化能力足够强,能氧化水生成·OH,但纯WO3的CB较正,无法活化氧气生成O2·− (−0.13 V vs. NHE)[17],故虽有可见光吸收,但光催化活性较低。引入Bi0后,由于半金属Bi (−0.17 eV)的SPR效应,Bi吸收可见光后产生的电子可以传递给O2生成O2·−。此外,电子可以从Bi迁移到WO3的CB上,促进电荷分离,反应机制图如图9(b)所示。

3. 结 论

通过紫外还原法在WO3表面沉积具有表面等离子体(SPR)效应的半金属Bi0,制备了具有可见光响应的Bi/WO3复合光催化材料。由于Bi0的SPR效应,复合后可见光吸收增强,光生电荷有效分离,电子转移阻力降低,针对E. coli和S. aureus,在可见光照射下能高效灭菌。优选得到0.6 mmol Bi/WO3能够在120 min灭杀99%以上的细菌,机制研究推测导致灭活的主要活性物种是·OH和·O2−。本研究为开发新型、非贵金属可见光催化抗菌材料提高了可行的借鉴,进一步可拓展基底为高比表面积、高可见光响应的其他类型催化剂,如MOF、COF等。

-

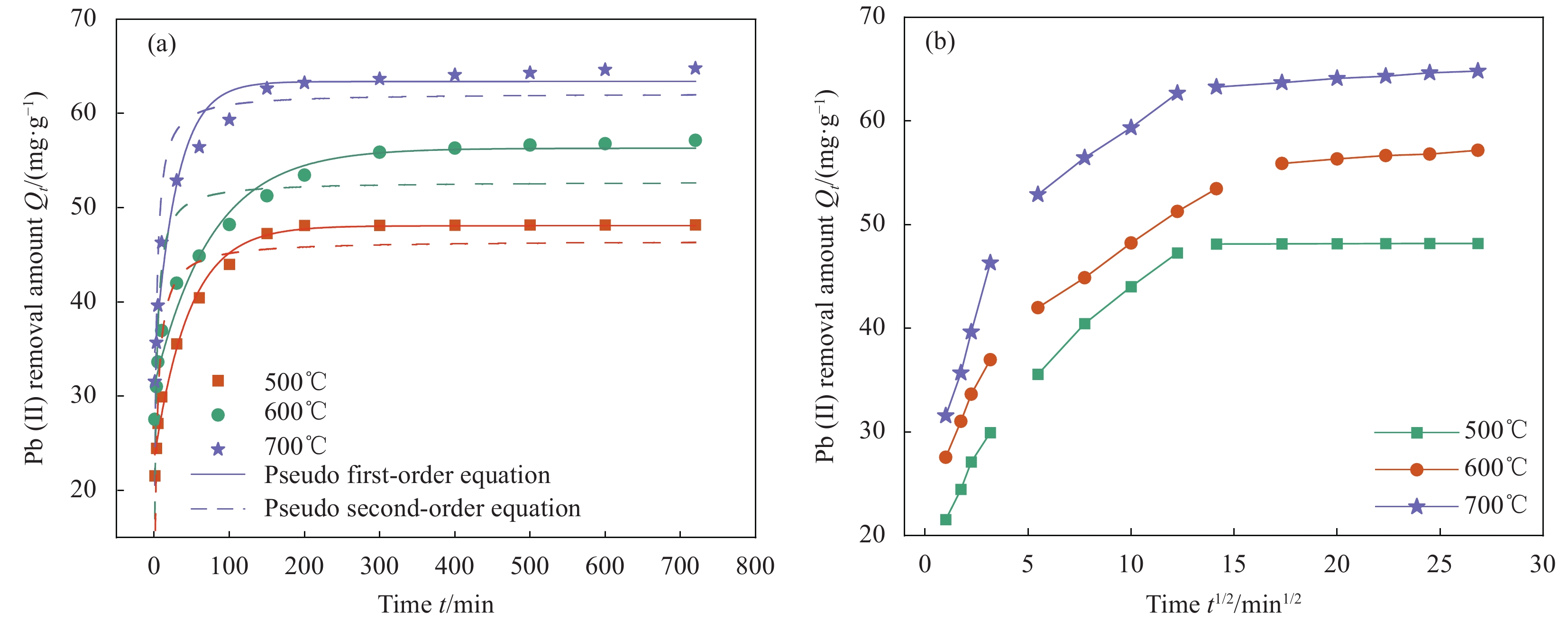

图 4 吸附时间对不同温度条件下制备的CAL/BC复合材料对Pb(II)吸附量的影响的准一级和准二级动力学模型拟合 (a) 和颗粒内扩散模型 (b)

Figure 4. Effect of adsorption time on Pb(II) adsorption capacity by CAL/BC composite prepared at different temperatures and fits of pseudo first-order and pseudo second-order kinetic models (a), intra-particle diffusion model (b)

表 1 不同温度下制备的CAL/BC复合材料吸附Pb(II)的动力学参数

Table 1 Kinetic parameters of Pb(II) adsorption by the CAL/BC composite prepared at different temperatures

Temprature/℃ Qe,exp/(mg·g−1) Pseudo-first-order Pseudo-second-order k1/min−1 Qe,calu/(mg·g−1) R2 k2/(g·mg−1·min−1) Qe,calu/(mg·g−1) R2 500 48.1844 3.1670 23.7362 0.9847 0.0035 48.7805 0.9998 600 57.1612 3.1963 24.4419 0.9752 0.0017 57.8035 0.9986 700 64.8022 3.0806 21.7715 0.9151 0.0029 64.9351 0.9999 Note: Qe,exp—Equilibrium sorption capacity obtained from experiment; k1—First-order apparent sorption rate constant; Qe,calu—Equilibrium sorption capacity calculated by pseudo-first order kinetics or pseudo-second order kinetics; k2—Second-order apparent sorption rate constant; R2—Correlation coefficient. 表 2 不同温度下制备的CAL/BC复合材料吸附Pb(II)的颗粒内扩散参数

Table 2 Intra-particle diffusion parameters of Pb(II) adsorption by the CAL/BC composite prepared at different temperatures

Temprature/

℃Film diffusion Intra-particle diffusion Equilibrium stage Kp1/

(mg·g−1·min−0.5)C1/

(mg·g−1)R2 Kp2/

(mg·g−1·min−0.5)C2/

(mg·g−1)R2 Kp3/

(mg·g−1·min−0.5)C3/

(mg·g−1)R2 500 3.9312 17.7720 0.9894 1.7142 26.6200 0.9910 0.0043 48.0720 0.9938 600 4.3769 23.3990 0.9932 1.3454 34.6150 0.9987 0.1284 53.7210 0.9845 700 6.8956 24.2800 0.9960 1.4274 45.1810 0.9987 0.1239 61.5500 0.9912 Note:Kp1, Kp2, Kp3—Rate constants at different stages of internal diffusion; C1, C2, C3—Intercept of corresponding concentration. 表 3 不同温度下制备的CAL/BC复合材料吸附Pb(II)的Langmuir和Freundlich吸附等温线参数

Table 3 Langmuir and Freundlich adsorption isotherm parameters of Pb(II) adsorption by the CAL/BC composite prepared at different temperatures

Adsorption temprature/℃ Temprature/℃ Langmuir Freundlich Qmax/(mg·g−1) KL/(L·mg−1) R2 1/n KF/(mg·g−1) R2 25 500 95.24 0.0798 0.9831 0.4455 2.7511 0.7557 600 99.01 0.0728 0.9742 0.4512 2.6437 0.7659 700 185.19 0.2935 0.9903 0.3461 219.7260 0.9717 30 500 151.52 0.0746 0.9718 0.5204 6.7442 0.9408 600 123.46 0.1070 0.9913 0.2761 67.4520 0.9672 700 204.08 0.4153 0.9925 0.4022 328.3842 0.9372 35 500 185.19 0.1949 0.9811 0.4841 70.2934 0.9691 600 158.73 0.2079 0.9816 0.3882 82.7148 0.9548 700 222.22 1.3235 0.9941 0.4343 1 150.8854 0.9763 Note: Qmax—Maximum sorption capacity; KL—Adsorptive constant of Langmuir model; 1/n—Empirical parameter varied with the degree of heterogeneity of adsorbing sites; KF—Adsorptive constant of Freundlich model. 表 4 复合前后材料元素含量及BET比表面积

Table 4 Element mass and BET specific surface area of materials before and after composite

Material Element mass fraction/wt% SBET/(m2·g−1) C O Ca Mg BC500℃ 67.44 0 0.26 0.15 5.69 BC600℃ 77.45 0 0.10 0.06 103.39 BC700℃ 85.48 3.81 0.10 0.04 347.43 CAL 4.54 47.80 22.00 14.58 9.30 CAL/BC500℃ 15.81 16.59 18.09 13.82 50.86 CAL/BC600℃ 21.12 14.89 17.66 10.43 93.20 CAL/BC700℃ 0 15.07 18.03 10.65 285.89 Note: SBET—BET surface area. -

[1] BOGUSZ A, OLESZCZUK P, DOBROWOLSKI R. Application of laboratory prepared and commercially available biochars to adsorption of cadmium, copper and zinc ions from water[J]. Bioresource Technology,2015,196:540-549. DOI: 10.1016/j.biortech.2015.08.006

[2] LU X W, NING X A, LEE P H, et al. Transformation of hazardous lead into lead ferrite ceramics: Crystal structures and their role in lead leaching[J]. Journal of Hazardous Materials,2017,336(15):139-145.

[3] CUONG D V, LIU N L, NGUYEN V A, et al. Meso/micropore-controlled hierarchical porous carbon derived from activated biochar as a high-performance adsorbent for copper removal[J]. Science of the Total Environment,2019,692:844-853. DOI: 10.1016/j.scitotenv.2019.07.125

[4] GUPTA V K, AGARWAL S, SALEH T A. Synthesis and characterization of alumina-coated carbon nanotubes and their application for lead removal[J]. Journal of Hazardous Materials,2011,185(1):17-23. DOI: 10.1016/j.jhazmat.2010.08.053

[5] BAI J, CHAO Y Q, CHEN Y M, et al. The effect of interaction between Bacillus subtilis DBM and soil minerals on Cu(II) and Pb(II) adsorption.[J]. Journal of Environmental Sciences (China),2019,78:328-337. DOI: 10.1016/j.jes.2018.11.012

[6] RWIZA M J, OH S, KIM K, et al. Comparative sorption isotherms and removal studies for Pb(II) by physical and thermochemical modification of low-cost agro-wastes from Tanzania[J]. Chemosphere,2018,195:135-145. DOI: 10.1016/j.chemosphere.2017.12.043

[7] AWUAL M R, ISLAM A, HASAN M M, et al. Introducing an alternate conjugated material for enhanced lead(II) capturing from wastewater[J]. Journal of Cleaner Production,2019,224:920-929. DOI: 10.1016/j.jclepro.2019.03.241

[8] BOUABIDI Z B, EL-NAAS M H, CORTES D, et al. Steel-Making dust as a potential adsorbent for the removal of lead (II) from an aqueous solution[J]. Chemical Engineering Journal,2018,334:837-844. DOI: 10.1016/j.cej.2017.10.073

[9] KAZEMI M, JAHANSHAHI M, PEYRAVI M. Hexavalent chromium removal by multilayer membrane assisted by photocatalytic couple nanoparticle from both permeate and retentate[J]. Journal of Hazardous Materials,2018,344:12-22. DOI: 10.1016/j.jhazmat.2017.09.059

[10] ROQUE F, DIAZ K, ANCCO M, et al. Biodepuration of domestic sewage, textile effluents and acid mine drainage using starch-based xerogel from recycled potato peels[J]. Water Science and Technology,2018,77(5):1250-1261. DOI: 10.2166/wst.2018.008

[11] SONG M, WEI Y X, CAI S P, et al. Study on adsorption properties and mechanism of Pb2+ with different carbon based adsorbents[J]. Science of The Total Environment,2018,618:1416-1422. DOI: 10.1016/j.scitotenv.2017.09.268

[12] HU B W, GUO X J, ZHENG C, et al. Plasma-enhanced amidoxime/magnetic graphene oxide for efficient enrichment of U(VI) investigated by EXAFS and modeling techniques[J]. Chemical Engineering Journal,2019,357:66-74. DOI: 10.1016/j.cej.2018.09.140

[13] QIU M Q, WANG M, ZHAO Q Z, et al. XANES and EXAFS investigation of uranium incorporation on nZVI in the presence of phosphate[J]. Chemosphere,2018,201:764-771. DOI: 10.1016/j.chemosphere.2018.03.057

[14] GAO L Y, DENG J H, HUANG G F, et al. Relative distribution of Cd2+ adsorption mechanisms on biochars derived from rice straw and sewage sludge[J]. Bioresource Technology,2019,272:114-122. DOI: 10.1016/j.biortech.2018.09.138

[15] JIANG Y H, LI A Y, DENG H, et al. Characteristics of nitrogen and phosphorus adsorption by Mg-loaded biochar from different feedstocks[J]. Bioresource Technology,2019,276:183-189. DOI: 10.1016/j.biortech.2018.12.079

[16] WANG J L, WANG S Z. Preparation, modification and environmental application of biochar: A review[J]. Journal of Cleaner Production,2019,227:1002-1022. DOI: 10.1016/j.jclepro.2019.04.282

[17] ABDELHAFEZ A A, LI J H. Removal of Pb(II) from aqueous solution by using biochars derived from sugar cane bagasse and orange peel[J]. Journal of the Taiwan Institute of Chemical Engineers,2016,61:367-375. DOI: 10.1016/j.jtice.2016.01.005

[18] WANG H Y, GAO B, WANG S S, et al. Removal of Pb(II), Cu(II), and Cd(II) from aqueous solutions by biochar derived from KMnO4 treated hickory wood[J]. Bioresource Technology,2015,197:356-362. DOI: 10.1016/j.biortech.2015.08.132

[19] ZHANG J J, SHAO J G, JIN Q Z, et al. Effect of deashing on activation process and lead adsorption capacities of sludge-based biochar[J]. Science of the Total Environment,2020,716:137016. DOI: 10.1016/j.scitotenv.2020.137016

[20] 卢琨, 侯媛媛. 海南省椰子产业分析与发展路径研究[J]. 广东农业科学, 2020, 47(6):145-151. LU K, HOU Y Y. Analysis and development path of coconut industry in Hainan province[J]. Guangdong Agricultural Sciences,2020,47(6):145-151(in Chinese).

[21] ADENIYI A G, ONIFADE D V, IGHALO J O, et al. A review of coir fiber reinforced polymer composites[J]. Composites Part B: Engineering,2019,176:107305. DOI: 10.1016/j.compositesb.2019.107305

[22] PRAJAPATI A K, MONDAL M K. Comprehensive kinetic and mass transfer modeling for methylene blue dye adsorption onto CuO nanoparticles loaded on nanoporous activated carbon prepared from waste coconut shell[J]. Chemosphere,2020,307:112949.

[23] UMAR I A, ABDULRAHEEM G, BALA S, et al. Kinetics, equilibrium and thermodynamics studies of C. I. Reactive Blue 19 dye adsorption on coconut shell based activated carbon[J]. International Biodeterioration & Biodegradation,2015,102:265-273.

[24] ZHAO X Y, ZENG X L, QIN Y, et al. An experimental and theoretical study of the adsorption removal of toluene and chlorobenzene on coconut shell derived carbon[J]. Chemosphere,2018,206:285-292. DOI: 10.1016/j.chemosphere.2018.04.126

[25] DASSHARMA D, SAMANTA S, KUMAR S D N, et al. A mechanistic insight into enrofloxacin sorptive affinity of chemically activated carbon engineered from green coconut shell[J]. Journal of Environmental Chemical Engineering,2020,8(5):104140. DOI: 10.1016/j.jece.2020.104140

[26] JANG H M, KAN E. Engineered biochar from agricultural waste for removal of tetracycline in water[J]. Bioresource Technology,2019,284:437-447. DOI: 10.1016/j.biortech.2019.03.131

[27] LYU H H, TANG J C, HUANG Y, et al. Removal of hexavalent chromium from aqueous solutions by a novel biochar supported nanoscale iron sulfide composite[J]. Chemical Engineering Journal,2017,322:516-524. DOI: 10.1016/j.cej.2017.04.058

[28] MA H, LI J B, LIU W W, et al. Novel synthesis of a versatile magnetic adsorbent derived from corncob for dye removal[J]. Bioresource Technology,2015,190:13-20. DOI: 10.1016/j.biortech.2015.04.048

[29] LI X P, WANG C B, ZHANG J G, et al. Preparation and application of magnetic biochar in water treatment: A critical review[J]. Science of The Total Environment,2020,711:134847. DOI: 10.1016/j.scitotenv.2019.134847

[30] ZHU R H, ZHU R L, GE F, et al. Effect of heating temperature on the sequestration of Cr3+ cations on montmorillonite[J]. Applied Clay Science,2016,121-122:111-118. DOI: 10.1016/j.clay.2015.11.027

[31] YAO Y, GAO B, FANG J, et al. Characterization and environmental applications of clay-biochar composites[J]. Chemical Engineering Journal,2014,242:136-143. DOI: 10.1016/j.cej.2013.12.062

[32] HEBERLING F, TRAINOR T P, LÜTZENKIRCHEN J, et al. Structure and reactivity of the calcite-water interface[J]. Journal of Colloid and Interface Science,2011,354(2):843-857. DOI: 10.1016/j.jcis.2010.10.047

[33] SDIRI A., HIGASHI T, JAMOUSSI F, et al. Effects of impurities on the removal of heavy metals by natural limestones in aqueous systems[J]. Journal of Environmental Management,2012,93(1):245-253. DOI: 10.1016/j.jenvman.2011.08.002

[34] MERRIKHPOUR H, JALALI M. Waste calcite sludge as an adsorbent for the removal of cadmium, copper, lead, and zinc from aqueous solutions[J]. Clean Technologies and Environmental Policy,2012,14(5):845-855. DOI: 10.1007/s10098-012-0450-0

[35] SADJADI S, AKBARI M, LÉGER B, et al. Eggplant-derived biochar-halloysite nanocomposite as supports of pd nanoparticles for the catalytic hydrogenation of nitroarenes in the presence of cyclodextrin[J]. ACS Sustainable Chemistry & Engineering,2019,7:6720-6731.

[36] KIM S A, KAMALA-KANNAN S, LEE K, et al. Removal of Pb(II) from aqueous solution by a zeolite-nanoscale zerovalent iron composite[J]. Chemical Engineering Journal,2013,217:54-60. DOI: 10.1016/j.cej.2012.11.097

[37] ZHAO Y L, ZHANG R Y, LIU H B, et al. Green preparation of magnetic biochar for the effective accumulation of Pb(II): Performance and mechanism[J]. Chemical Engineering Journal,2019,375:122011. DOI: 10.1016/j.cej.2019.122011

[38] ZHOU X H, ZHOU J J, LIU Y C, et al. Preparation of iminodiacetic acid-modified magnetic biochar by carbonization, magnetization and functional modification for Cd(II) removal in water[J]. Fuel,2018,233:469-479. DOI: 10.1016/j.fuel.2018.06.075

[39] BUDIMIROVIĆ D, VELIČKOVIĆ Z S, DJOKIĆ V R, et al. Efficient As(V) removal by α-FeOOH and α-FeOOH/α-MnO2 embedded PEG-6-arm functionalized multiwall carbon nanotubes[J]. Chemical Engineering Research and Design,2017,119:75-86. DOI: 10.1016/j.cherd.2017.01.010

[40] ZAHEER Z, BAWAZIR W A, AL-BUKHARI S M, et al. Adsorption, equilibrium isotherm, and thermodynamic studies to the removal of acid orange 7[J]. Materials Chemistry and Physics,2019,232:109-120. DOI: 10.1016/j.matchemphys.2019.04.064

[41] 陈泽文, 周子晗, 吴美仪, 等. 埃洛石纳米管/聚间苯二胺复合材料去除Cr(Ⅵ)的性能[J]. 复合材料学报, 2020, 37(3):493-503. CHEN Z W, ZHOU Z H, WU M Y, et al. Adsorption properties of halloysite nanotubes/poly (m-phenylenediamine) composites for Cr(Ⅵ)[J]. Acta Materiae Compositae Sinica,2020,37(3):493-503(in Chinese).

[42] ZHENG L C, YANG Y B, MENG P P, et al. Absorption of cadmium (II) via sulfur-chelating based cellulose: Characterization, isotherm models and their error analysis[J]. Carbohydrate Polymers,2019,209:38-50. DOI: 10.1016/j.carbpol.2019.01.012

[43] SONG Z G, LIAN F, YU Z H, et al. Synthesis and characterization of a novel MnOx-loaded biochar and its adsorption properties for Cu2+ in aqueous solution[J]. Chemical Engineering Journal,2014,242(242):36-42.

[44] CAO Y Y, SHEN G H, ZHANG Y, et al. Impacts of carbonization temperature on the Pb(II) adsorption by wheat straw-derived biochar and related mechanism[J]. Science of the Total Environment,2019,692:479-489. DOI: 10.1016/j.scitotenv.2019.07.102

[45] FAN Y H, WANG H, DENG L Y, et al. Enhanced adsorption of Pb(II) by nitrogen and phosphorus Co-doped biochar derived from Camellia oleifera shells[J]. Environmental Research,2020,191:110030. DOI: 10.1016/j.envres.2020.110030

[46] 贾陆营, 连勇, 张津, 等. 羟基硅酸镁粉体表面改性及作为润滑油添加剂的摩擦学性能研究[J]. 表面技术, 2020, 49(4):213-221. JIA L Y, LIAN Y, ZHANG J, et al. Surface modification and tribological properties of magnesium silicate hydroxide powder as lubricant additive[J]. Surface Technology,2020,49(4):213-221(in Chinese).

[47] LIU J, YANG X Y, LIU H H, et al. Modification of calcium-rich biochar by loading Si/Mn binary oxide after NaOH activation and its adsorption mechanisms for removal of Cu(II) from aqueous solution[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2020,601:124960. DOI: 10.1016/j.colsurfa.2020.124960

[48] XU X B, HU X, DING Z H, et al. Waste-art-paper biochar as an effective sorbent for recovery of aqueous Pb(II) into value-added PbO nanoparticles[J]. Chemical Engineering Journal,2017,308:863-871. DOI: 10.1016/j.cej.2016.09.122

[49] CAI D Q, WANG L H, ZHANG G L, et al. Controlling pesticide loss by natural porous micro/nano composites: Straw ash-based biochar and biosilica[J]. ACS Applied Materials & Interfaces,2013,5(18):9212-9216.

[50] 张晓涛, 王喜明. 木质纤维素/纳米蒙脱土复合材料对废水中Cu(II)的吸附及解吸[J]. 复合材料学报, 2015, 32(2):385-394. ZHANG X T, WANG X M. Adsorption and desorption of Cu(II) in wastewater by lignocellulose/nano-montmorillonite composites[J]. Acta Materiae Compositae Sinica,2015,32(2):385-394(in Chinese).

[51] WU X P, GAO P, ZHANG X L, et al. Synthesis of clay/carbon adsorbent through hydrothermal carbonization of cellulose on palygorskite[J]. Applied Clay Science,2014,95:60-66. DOI: 10.1016/j.clay.2014.03.010

[52] YAMADA S. Cation–π interactions in organic crystals[J]. Coordination Chemistry Reviews,2020,415:213301. DOI: 10.1016/j.ccr.2020.213301

[53] MAZIARZ P, MATUSIK J, RADZISZEWSKA A. Halloysite-zero-valent iron nanocomposites for removal of Pb(II)/Cd(II) and As(V)/Cr(VI): Competitive effects, regeneration possibilities and mechanisms[J]. Journal of Environmental Chemical Engineering,2019,7(6):103507. DOI: 10.1016/j.jece.2019.103507

-

期刊类型引用(4)

1. 高生旺,赵星鹏,陆迦勒,崔娟,王国英,张青. Ag-BiOBr/WO_3复合材料的制备及强化磺胺异噁唑去除性能. 复合材料学报. 2023(03): 1455-1467 .  本站查看

本站查看

2. 李茂,楼婷飞,李奇. 中空碳球负载TiO_2纳米颗粒用于增强光催化抗菌性能. 无机化学学报. 2023(08): 1489-1500 .  百度学术

百度学术

3. 王雪颖,张鹤凡,曹德路,许春兰,卢昶雨,闫巧芝,郝新丽. 铋基复合氧化物光催化剂的制备改性及其在环保领域的应用. 应用化工. 2023(09): 2643-2646 .  百度学术

百度学术

4. 杨纯,李玥,陈国峰,周贵寅,刘四化. 纳米介孔TiO_2光催化剂对染料污水的去除研究. 化工新型材料. 2021(08): 210-214 .  百度学术

百度学术

其他类型引用(0)

-

下载:

下载: