Fluorinated poly(aryl ether ketone) superhydrophobic coatings and their properties

-

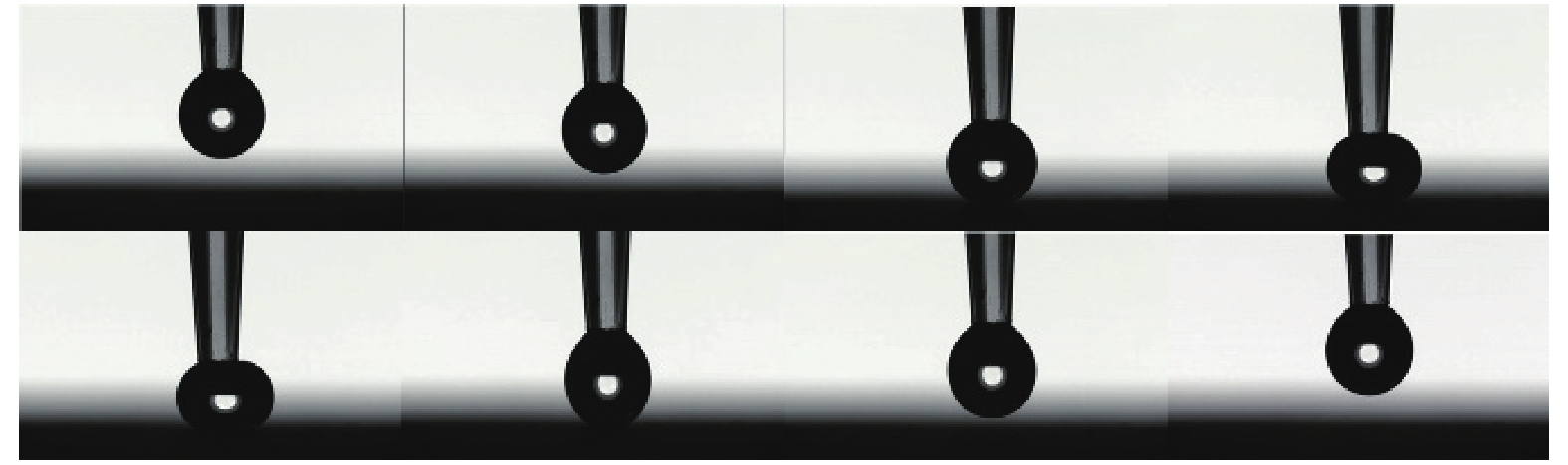

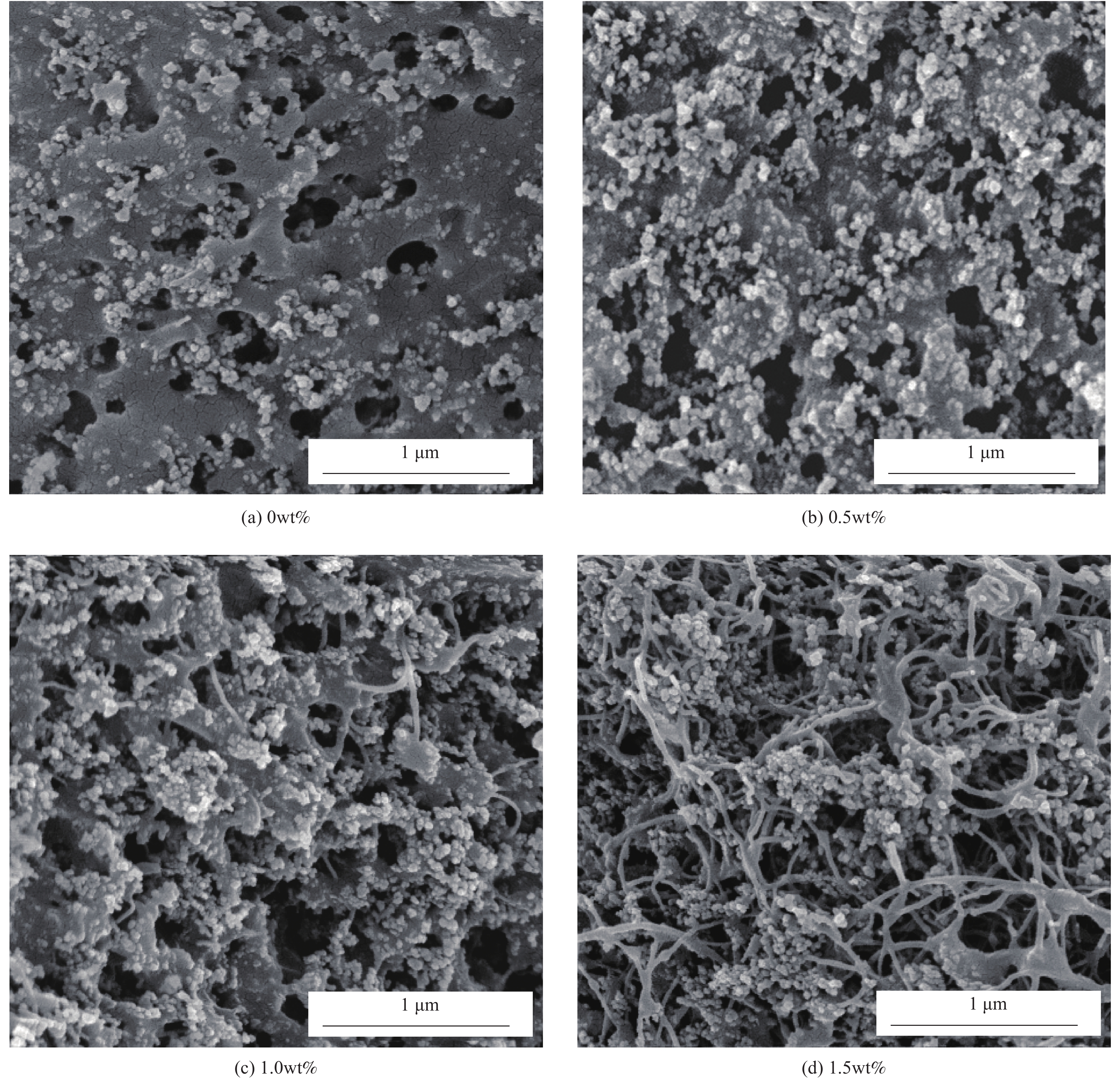

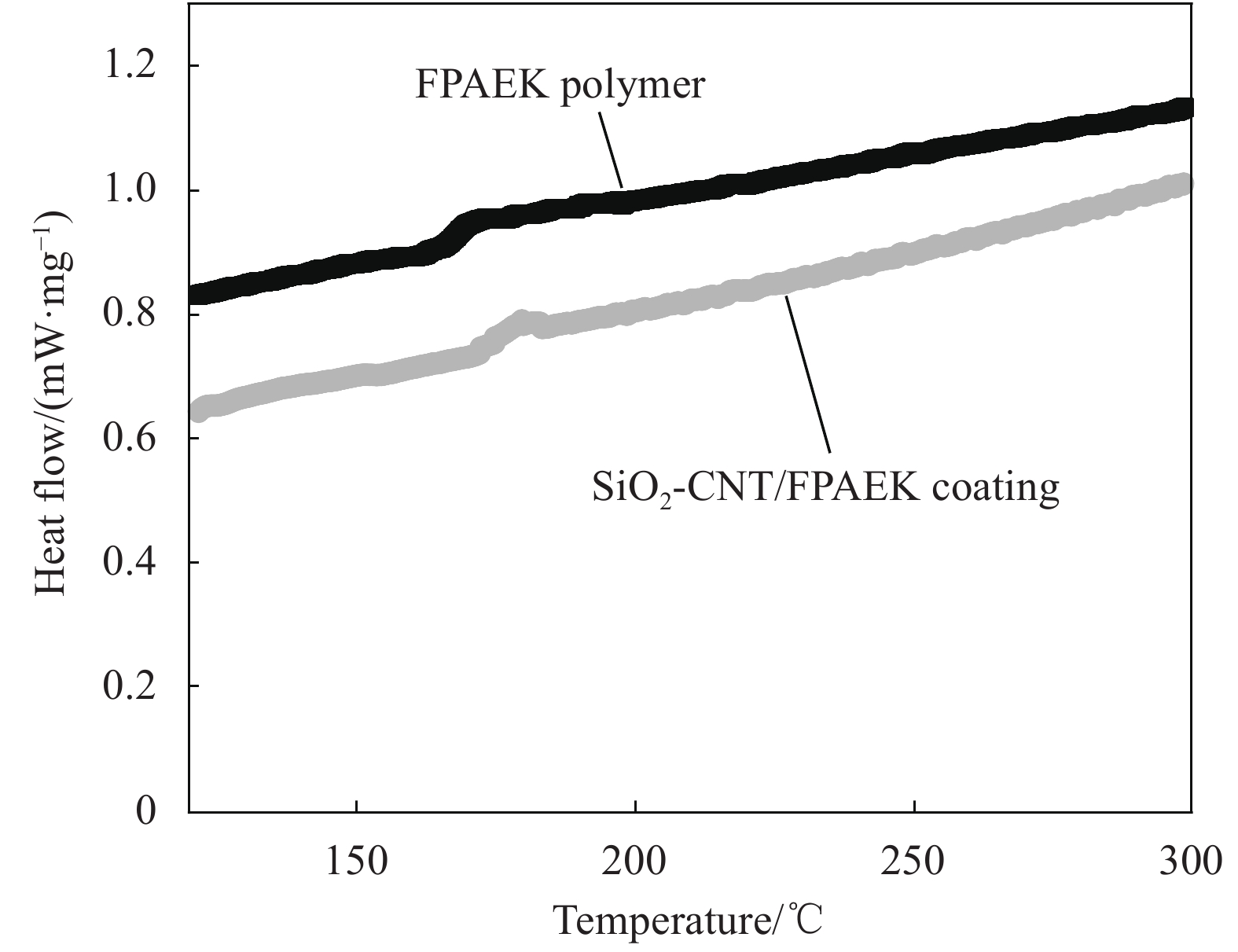

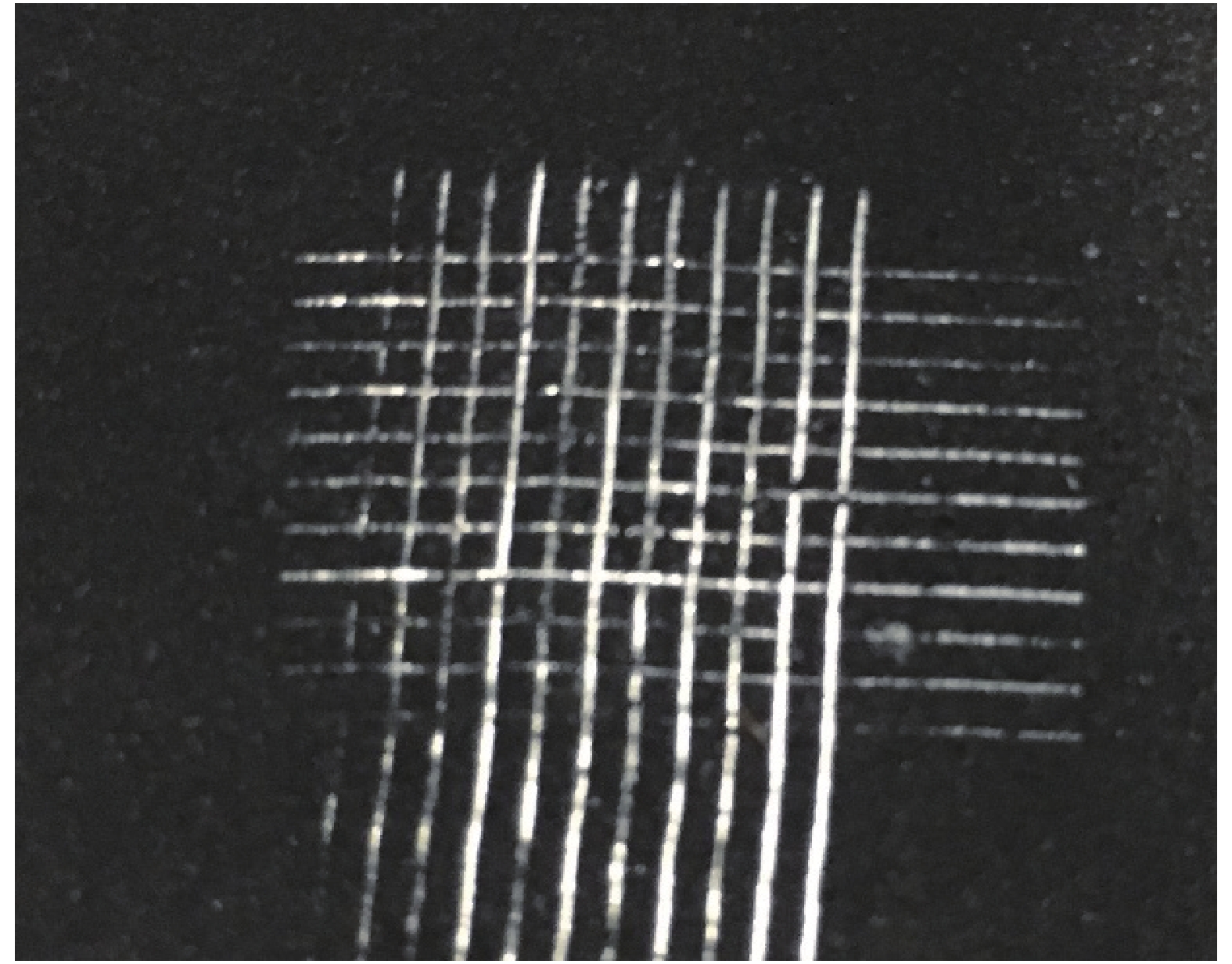

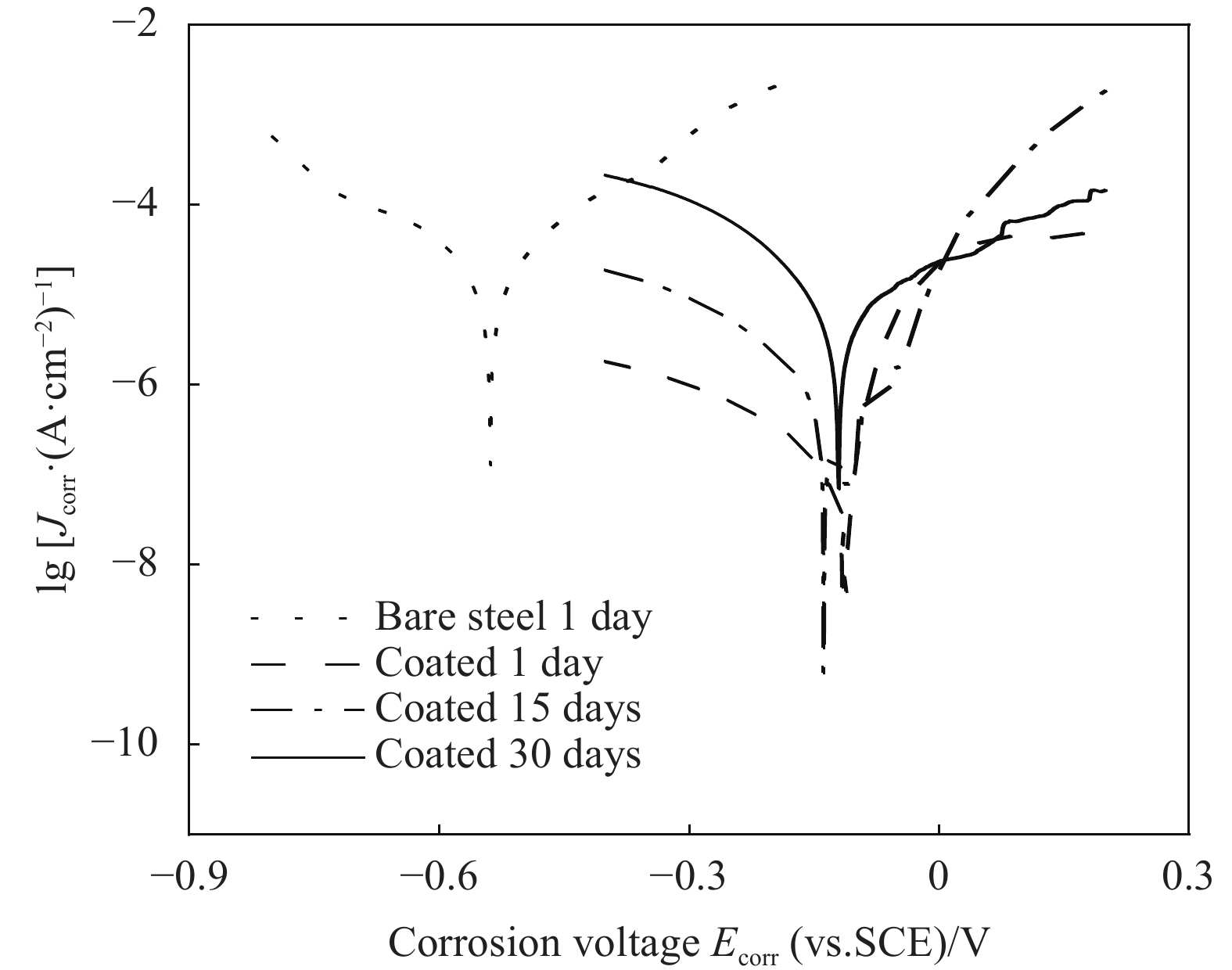

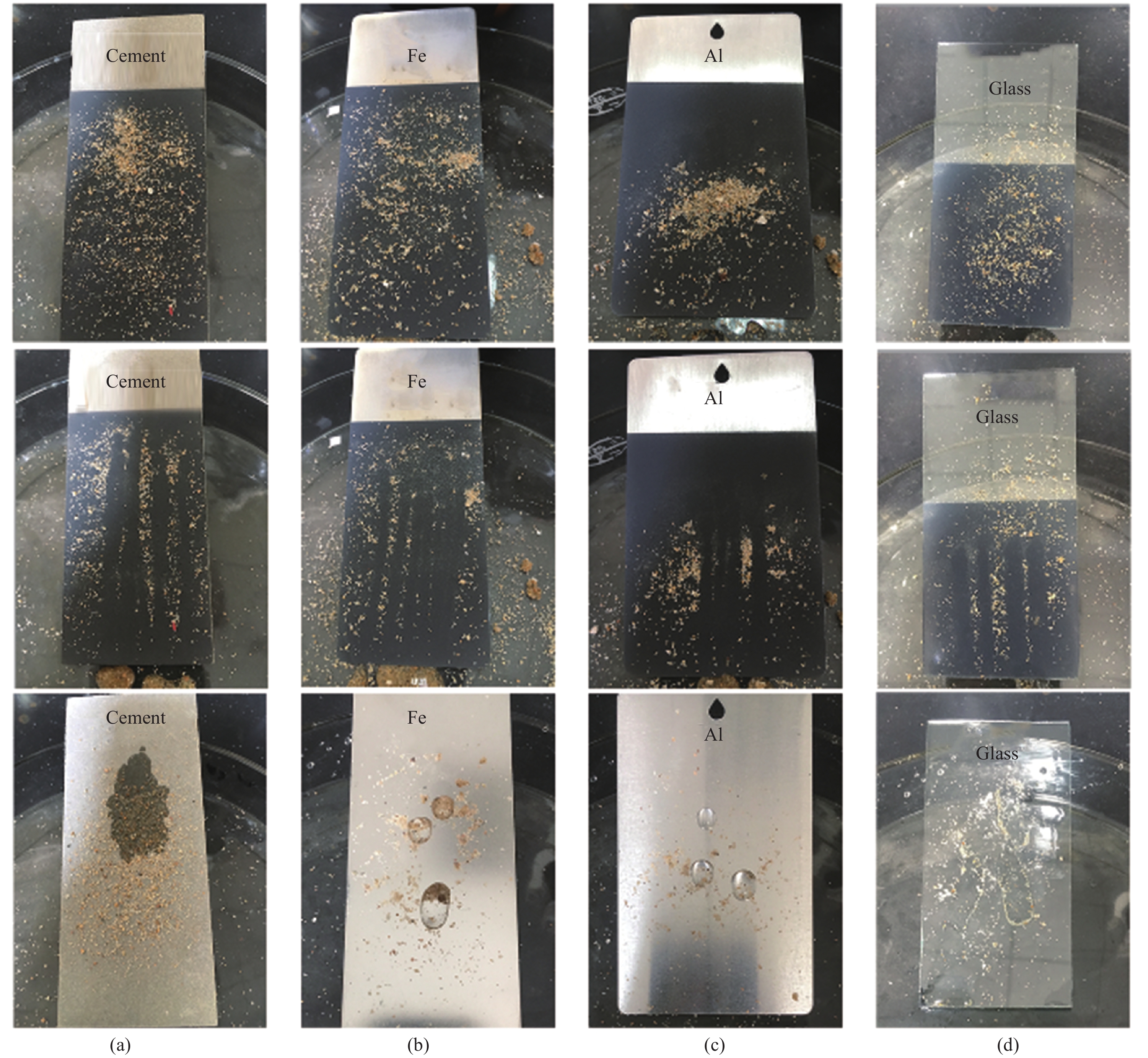

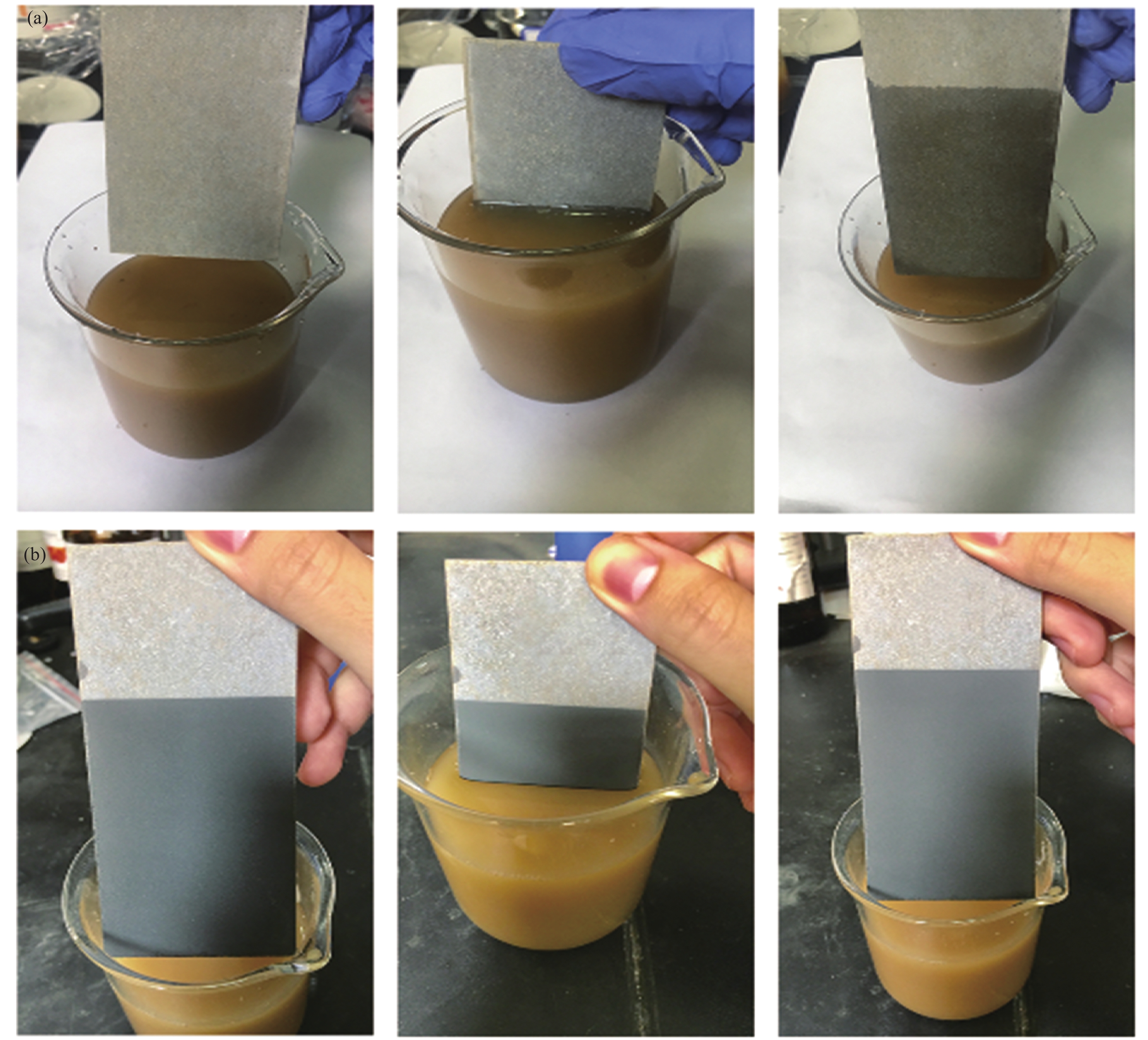

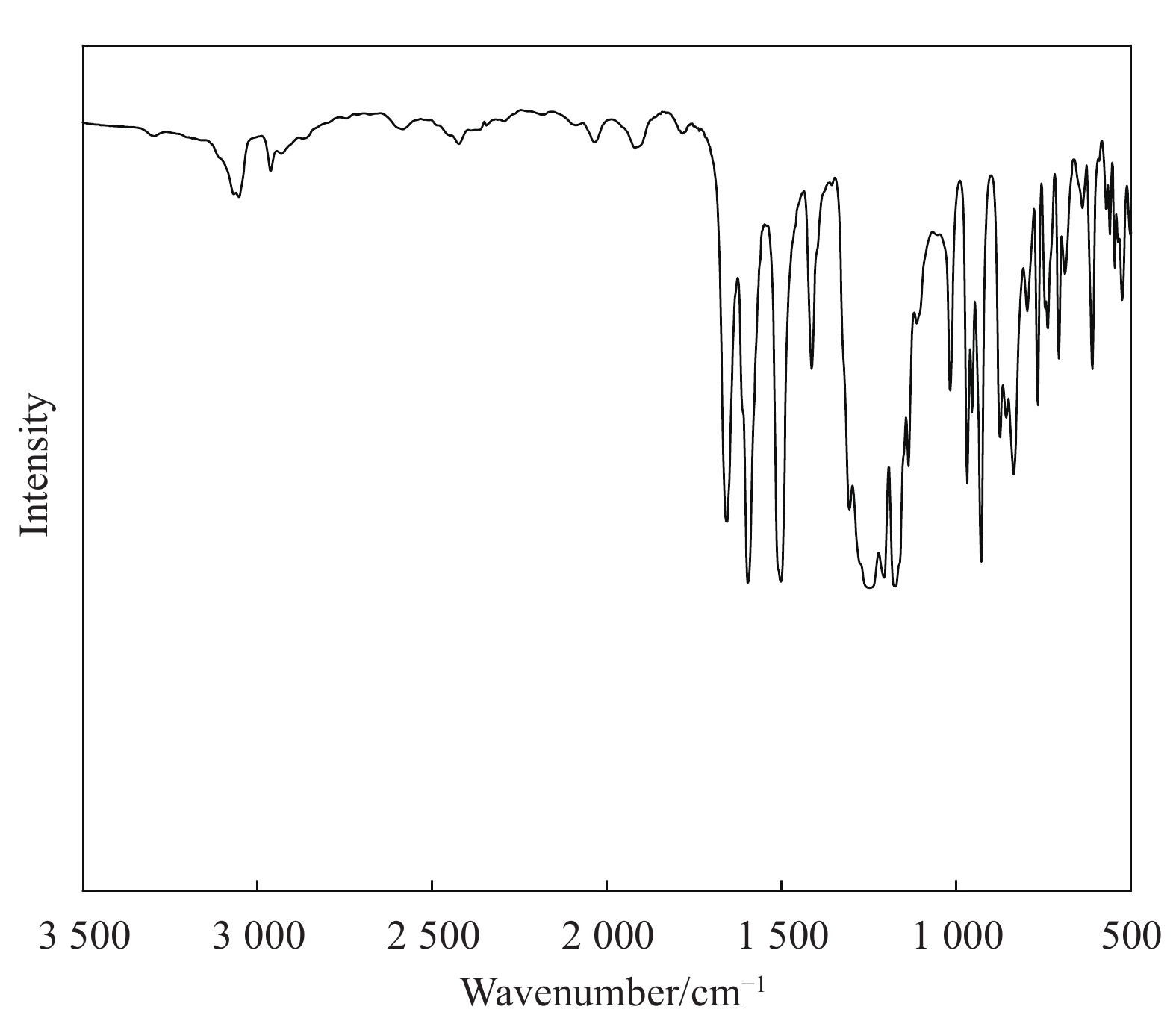

摘要: 使用由双酚AF和4,4-二氟二苯甲酮缩聚而得的含氟聚芳醚酮(FPAEK)为树脂基体,以疏水气相SiO2和碳纳米管(CNT)为无机掺杂纳米粒子,采用一步喷涂法在铝板表面制备了一种SiO2-CNT/FPAEK超疏水涂层。研究发现,当SiO2和CNT掺杂量都为1wt%时,所得涂层的超疏水性能最好,其水接触角WCA可达到167°,滚动角SA为3°。该涂层的玻璃转化温度和初始分解温度分别达到170℃和480℃,热稳定性优异。将该涂层分别在pH=1的HCl溶液、pH=13的NaOH溶液和质量分数为3.5wt%的NaCl溶液中浸泡13天,WCA都维持在150°以上,说明具有较好的化学稳定性。经过80个摩擦循环测试后,该涂层的WCA还维持在151°,说明具有较好的机械稳定性。电化学测试表明,该涂层可以将马口铁的腐蚀电压Ecorr从−0.538 V提高到−0.112 V,而腐蚀电流Jcorr从2.105×10−5 A下降到1.94×10−7 A,说明具有优异的防腐蚀性能。此外,将基底换成常见的铁板、水泥板、玻璃板和聚乙烯塑料板,同样获得了超疏水涂层。涂层表面的污染物可以被自由滚落的水珠轻易带走,表明涂层具有良好的自清洁性能。可见,所得SiO2-CNT/FPAEK超疏水涂层具有广阔的应用前景。Abstract: Superhydrophobic coatings were prepared by a facilespraying process from a fluorinated poly(aryl ether ketone) (FPAEK) solution containing hydrophobic fumed SiO2 and carbon nanotube (CNT) as inorganicdopants. The FPAEK was polymerized from 4,4′-(hexafluoroisopropylidene)diphenol and 4,4-difluorophenophenone. It has been found that when the doping amounts of SiO2 and CNT are both 1wt%, the water contact angle WCA of the SiO2-CNT/FPAEK coating is 167° and the sliding angle SA is 4°. The glass transition temperature and initial decomposition temperature of the SiO2-CNT/FPAEK coating are 170℃ and 480℃, respectively, demonstrating its excellent thermal stability. After immersing in pH=1 of HCl solution, pH=13 of NaOH solution, and 3.5wt% mass fraction of NaCl solution for 13 days, the SiO2-CNT/FPAEK coating maintains its WCA above 150°, demonstrating its excellent chemical stability. After 80 friction testing cycles, the SiO2-CNT/FPAEK coating maintains the WCA at 151°, demonstrating its good mechanical stability. In the electrochemical tests, the corrosion voltage Ecorr of the steel plate is increased from −0.538 V to −0.112 V and the corrosion current Jcorr is decreased from 2.105×10−5 A to 1.94×10−7 A after coating with the SiO2-CNT/FPAEK, demonstrating its good anti-corrosion property. Replacing the substrate with iron plate, cement plate, glass plate and polyethyleneplate, the superhydrophobic coatings are also obtained. The dust and other contaminants can be easily removed from the superhydrophobic coatings by the falling water droplets, demonstrating its good self-cleaning property. Therefore, the SiO2-CNT/FPAEK superhydrophobic coating has prospect applications.

-

Keywords:

- superhydrophobic coating /

- SiO2 /

- carbon nanotube /

- anti-corrosion /

- self-cleaning

-

-

表 1 喷涂和未喷涂SiO2-CNT/FPAEK的马口铁在3.5wt%的NaCl溶液中浸泡不同时间后的电化学参数

Table 1 Electrochemical parameters of the bare and the SiO2-CNT/FPAEK coated steels after immersing in 3.5wt% NaCl solution for different time

Simples Immersion time/day Ecorr(vs.SCE)/V Jcorr/(A·cm−2) Bare steel 1 −0.538 2.105×10−5 SiO2-CNT/FPAEK coated 1 −0.112 1.940×10−7 SiO2-CNT/FPAEK coated 15 −0.138 5.124×10−7 SiO2-CNT/FPAEK coated 30 −0.121 6.591×10−6 Notes: Ecorr—Corrosion voltage; Jcorr—Corrosion current. -

[1] DALAWAI S, ALY M A S, LATTHE S S, et al. Recent advances in durability of superhydrophobic self-cleaning technology: A critical review[J]. Pro-gress in Organic Coatings,2020,138:105381. DOI: 10.1016/j.porgcoat.2019.105381

[2] 王武, 来华, 成中军, 等. 液滴在超疏水形状记忆微阵列表面上定向/非定向滚动的可逆调控[J]. 高等学校化学学报, 2020, 41(11):2538-2544. WANG Wu, LAI Hua, CHENG Zhongjun, et al. Reversible regulation of droplet directional/anti-directional rolling onsuperhydrophobic shape memory microarray surface[J]. Chemical Journal of Chinese Universities,2020,41(11):2538-2544(in Chinese).

[3] 武壮壮, 马国佳, 崔向中, 等. 微纳结构超疏水表面的浸润性及防冰性能[J]. 复合材料学报, 2020, 37(11):2769-2775. WU Zhuangzhuang, MA Guojia, CUI Xiangzhong, et al. Wettability and anti-icing performance of micro-nano structure superhydrophobic surface[J]. Acta Materiae Compositae Sinica,2020,37(11):2769-2775(in Chinese).

[4] YUAN R X, LIU H, CHEN Y G, et al. Design ambient-curable superhydrophobic/electroactive coating toward durable pitting corrosion resistance[J]. Chemical Engineering Journal,2019,374:840-851. DOI: 10.1016/j.cej.2019.05.209

[5] ZHAO Z Q, WANG H Y, LIU Z J, et al. Durable fluorine-free superhydrophobic polyethersulfone (PES) composite coating with uniquely weathering stability, anti-corrosion and wear-resistance[J]. Progress in Organic Coatings,2019,127:16-26. DOI: 10.1016/j.porgcoat.2018.11.006

[6] ZHANG W B, ZHU Y Z, LIU X, et al. Salt-induced fabrication of superhydrophilic and under-water superoleophobic PAA-g-PVDF membranes for effective separation of oil-in-water emulsions[J]. Angewandte Chemie-International Edition,2014,53:856-860. DOI: 10.1002/anie.201308183

[7] CAO C Y, GE M Z, HUANG J Y, et al. Robust fluorine-free superhydrophobicPDMS-ormosil@fabrics for highly effective self-cleaning and efficient oil-water separation[J]. Journal of Materials Chemistry A,2016,4:12179. DOI: 10.1039/C6TA04420D

[8] BATHLOTT W, NEINHUIS C. Purity of the sacred lotus, or escapefrom contamination in biological surfaces[J]. Planta,1997,202(1):1-8. DOI: 10.1007/s004250050096

[9] 赵美蓉, 周惠言, 康文倩, 等. 超疏水表面制备方法的比较[J]. 复合材料学报, 2021, 38(2):361-379. ZHAO Meirong, ZHOU Huiyan, KAN Wenqian, et al. A comparison of methods for fabricating superhydrophobic surface[J]. Acta Materiae Compositae Sinica,2021,38(2):361-379(in Chinese).

[10] WANG D P, ZHAO A W, LI L, et al. Bioinspired ribbed hair arrays with robust superhydrophobicity fabricated by micro/nanosphere lithography and plasma etching[J]. RSC Advances,2015,5:96404-96411. DOI: 10.1039/C5RA18439H

[11] ZHANG A Y, LIAO R J, DIXON S C, et al. Transparent superhydrophobic PTFE films via one-step aerosol assisted chemical vapor deposition[J]. RSC Advances,2017,7:29275-29283. DOI: 10.1039/C7RA04116K

[12] TADANAGE K, MORINAGA J, MINAMI T, et al. Superhydrophobic-superhydrophilic micropatterning on flowerlike alumina coating film by the sol-gel method[J]. Chemistry of Materials,2000,2:590-592.

[13] KUMAR D, LI L, CHEN Z. Mechanically robust polyvinylidene fluoride (PVDF) based superhydrophobic coatings for self-cleaning applications[J]. Progress in Organic Coatings,2016,101:385-390. DOI: 10.1016/j.porgcoat.2016.09.003

[14] BEN W, LIANG W X, GUO Z G, et al. Biomimetic superlyophobic and superlyophilic materials applied for oil/water separation: A new strategy beyond nature[J]. Chemical Society Reviews,2015,44:336-361. DOI: 10.1039/C4CS00220B

[15] PAN Y L, LIU L M, ZHANG Z J, et al. Surfaces with controllable super-wettability and applications for smart oil-water separation[J]. Chemical Engineering Journal,2019,378:122178. DOI: 10.1016/j.cej.2019.122178

[16] WANG B F, ZHANG Y K, SONG J, et al. Investigation and prediction on regulation of hydrophobicity of polymethyl methacrylate (PMMA) surface by femtosecond laser irradiation[J]. Coatings, 2020, 10(4): 386.

[17] LIU C H, ZHANG L L, ZHANG X R, et al. Bioinspired free-standing one-dimensional photonic crystals with janus wettability for water quality monitoring[J]. ACS Applied Materials & Interfaces,2020,12(36):40979-40984.

[18] WANG X L, HU H Y, YE Q, et al. Superamphiphobic coatings with coralline-like structure enabled by one-step spray of polyurethane/carbon nanotube composites[J]. Journal of Materials Chemistry,2012,22:9624-9631. DOI: 10.1039/c2jm30744h

[19] YANG Z Q, WANG L D, SUN W, et al. Superhydrophobic epoxy coating modified by fluorographene used for anti-corrosion and self-cleaning[J]. Applied Surface Science,2017,401:146-155. DOI: 10.1016/j.apsusc.2017.01.009

[20] LI H, ZHAO Y H, YUAN X Y. Facile preparation of superhydrophobic coating by spraying a fluorinated acrylic random copolymer micelle solution[J]. Soft Matter,2013,9:1005-1009. DOI: 10.1039/C2SM26689J

[21] HONG T, JEONG S M, CHOI Y K, et al. Superhydrophobic, elastic, and conducting polyurethane-carbon nanotube-silane-aerogel composite microfiber[J]. Polymers,2020,12(8):1772.

[22] FIHRI A, BOVERO E, AL-SHAHRANI, et al. Recent progress in superhydrophobic coatings used for steel protection: A review[J]. Colloids and Surfaces A-Physicochemical and Engineering Aspects,2017,520:378-390.

[23] 梁晓蕾, 刘创华, 米欣, 等. SiO2或TiO2纳米粒子/含氟聚丙烯酸酯复合涂层的制备及其防腐蚀性能[J]. 复合材料学报, 2020, 37(8):1832-1840. LIANG Xiaolei, LIU Chuanghua, MI Xin, et al. Preparation and corrosion resistance of SiO2 or TiO2 nano particles/fluorinated polyacrylate polymer composite coatings[J]. Acta Materiae Compositae Sinica,2020,37(8):1832-1840(in Chinese).

[24] 曹京宜, 张海永, 杨文静, 等. KCC-1/PVDF超疏水与超滑表面的制备及其性能研究[J]. 表面技术, 2020, 49(6): 163-169. CAO Jingyi, ZHANG Haiyong, YANG Wenjing, et al. Preparation and properties of KCC-1/PVDF superhydrophobic and ultra-slip surfaces[J]. Surface Technology, 2020, 49(6): 163-169(in Chinese).

[25] WANG S L, YU X Q, ZHANG Y F. Large-scale fabrication of translucent, stretchable and durable superhydrophobic composite films[J]. Journal of Materials Chemistry A,2017,5:23489. DOI: 10.1039/C7TA08203G

[26] LI Y, CHEN S S, WU M C. All Spraying Processes for the fabrication of robust, self-healing, superhydrophobic coatings[J]. Advance Materials,2014,26:3344-3348. DOI: 10.1002/adma.201306136

-

下载:

下载: