Bayesian diagnosis and prognosis of delamination damage in the stiffened composite structure

-

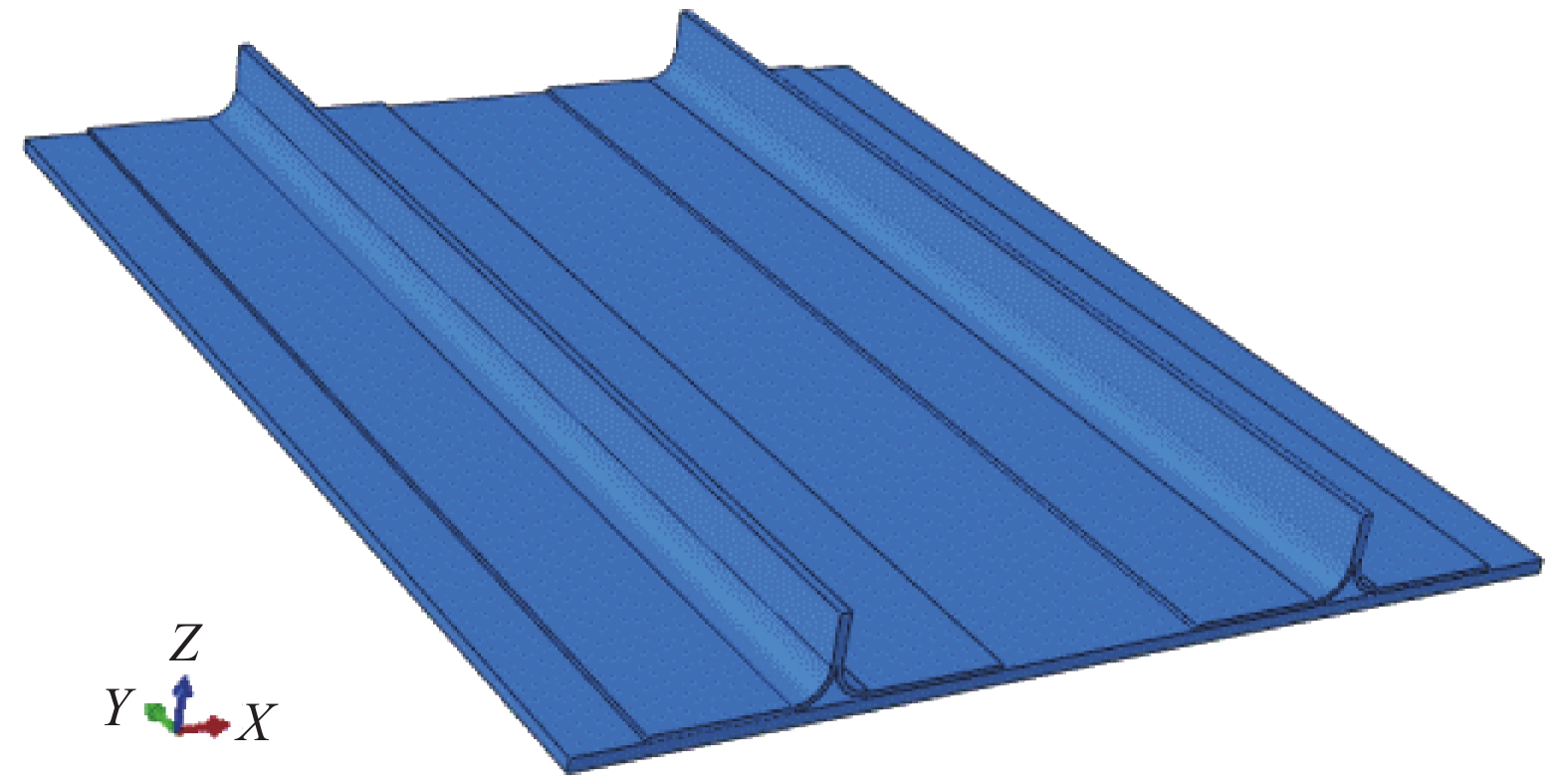

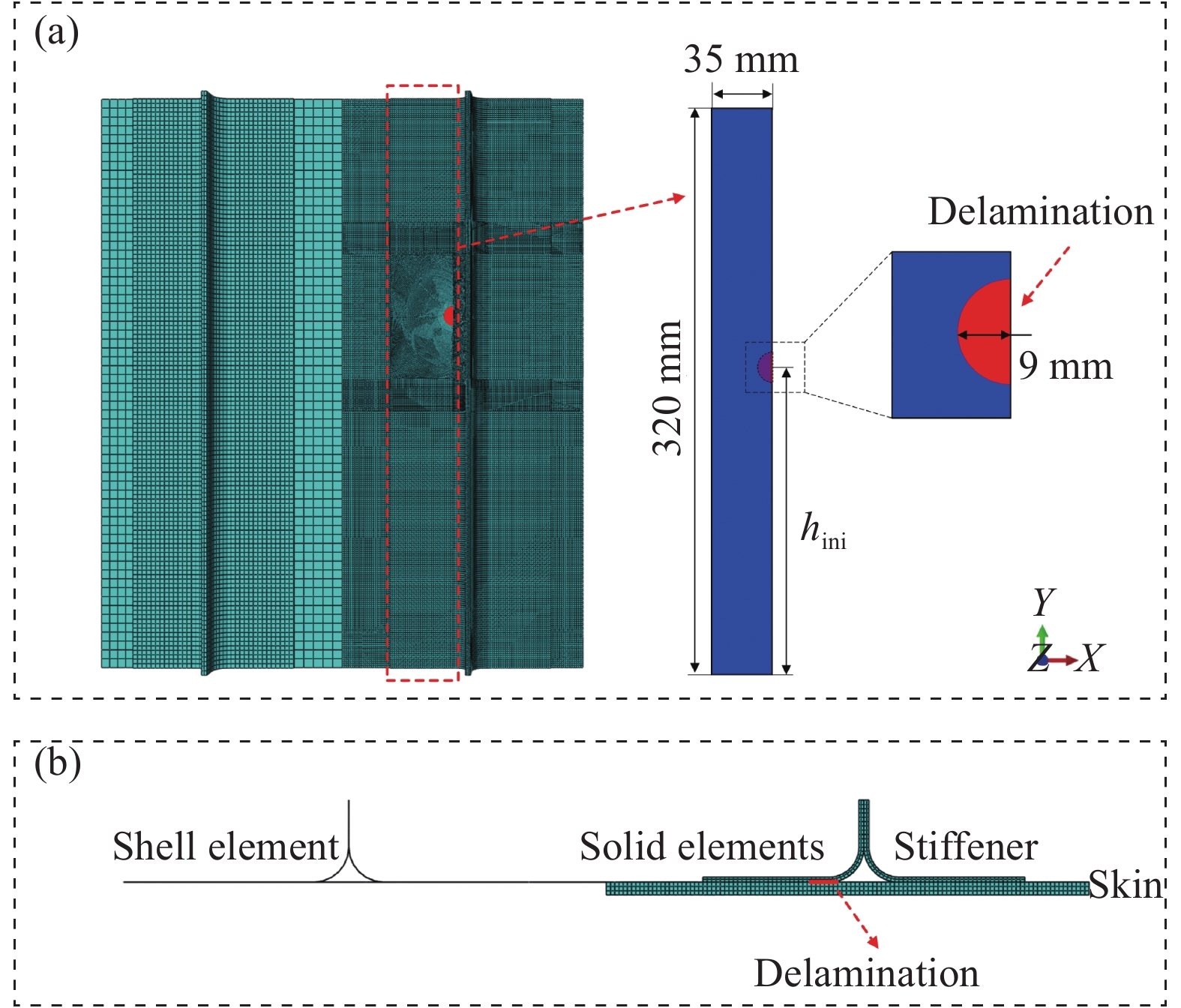

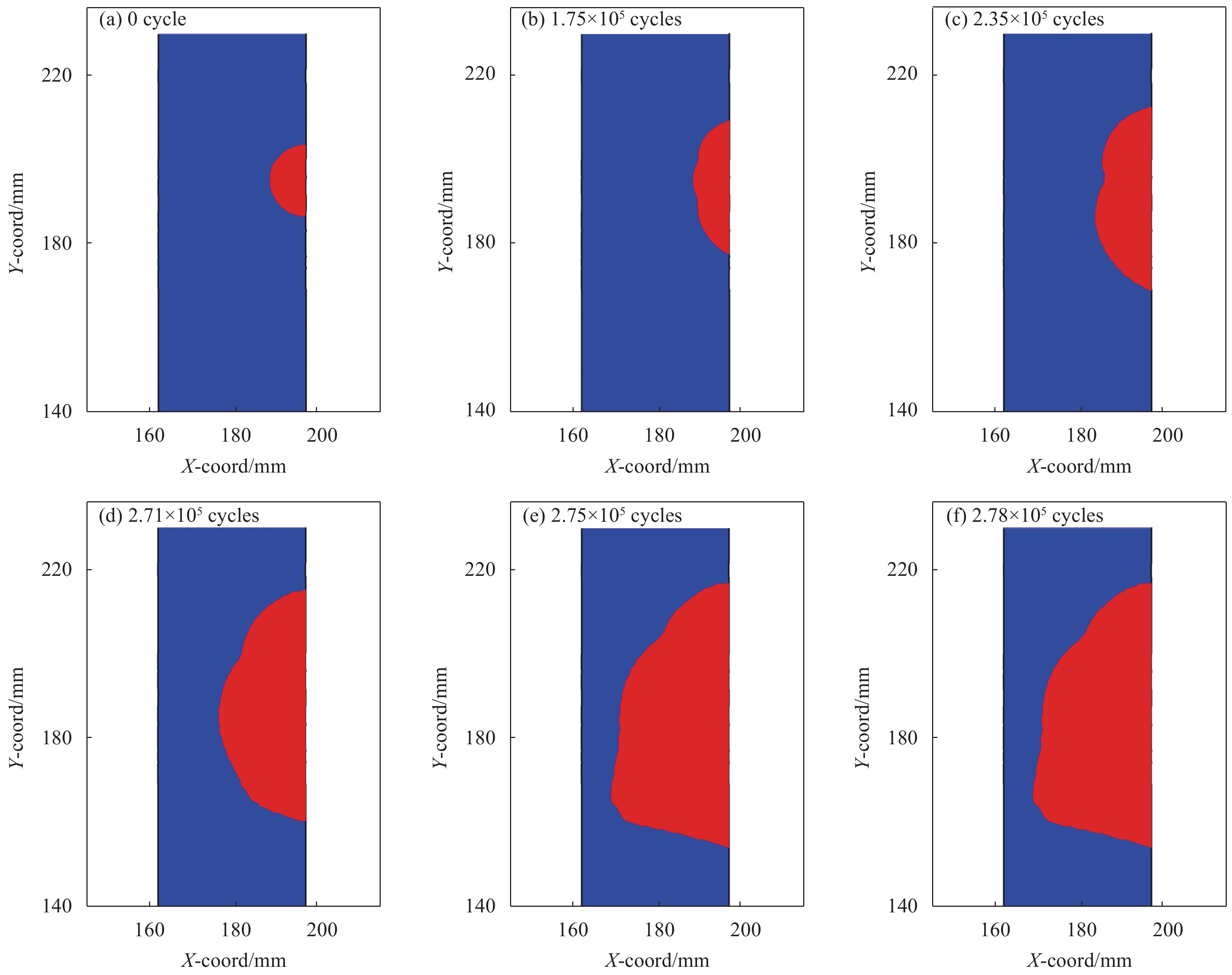

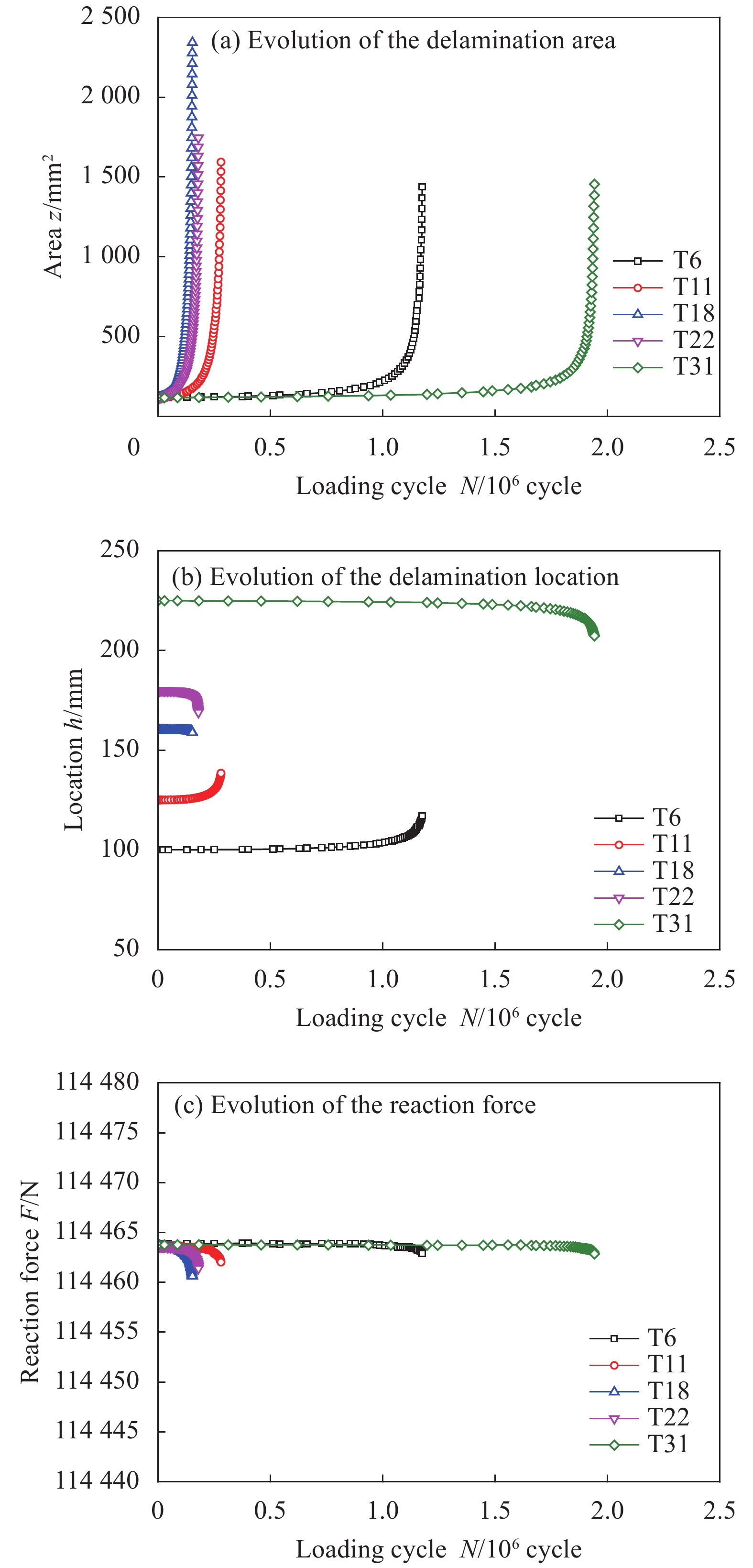

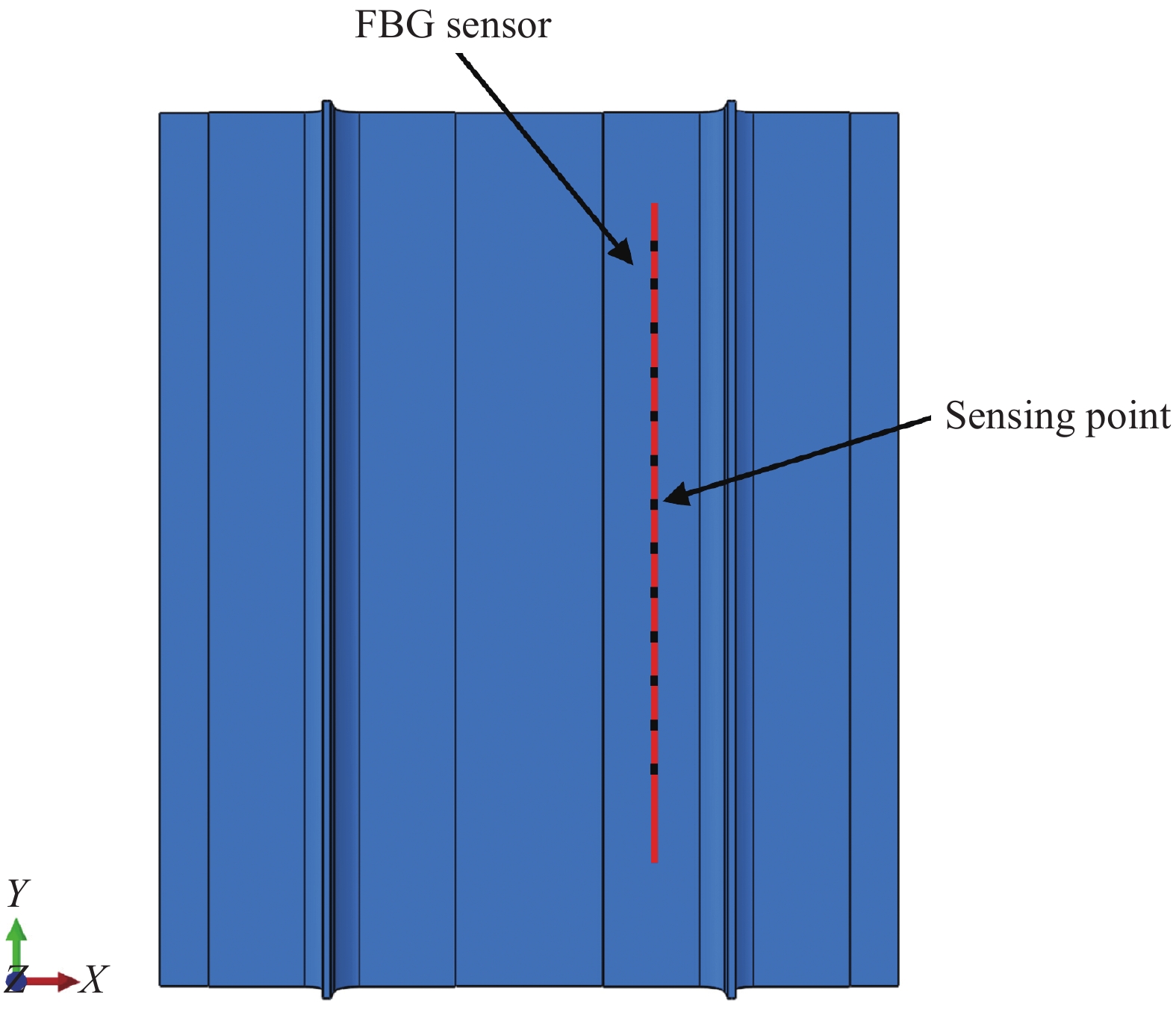

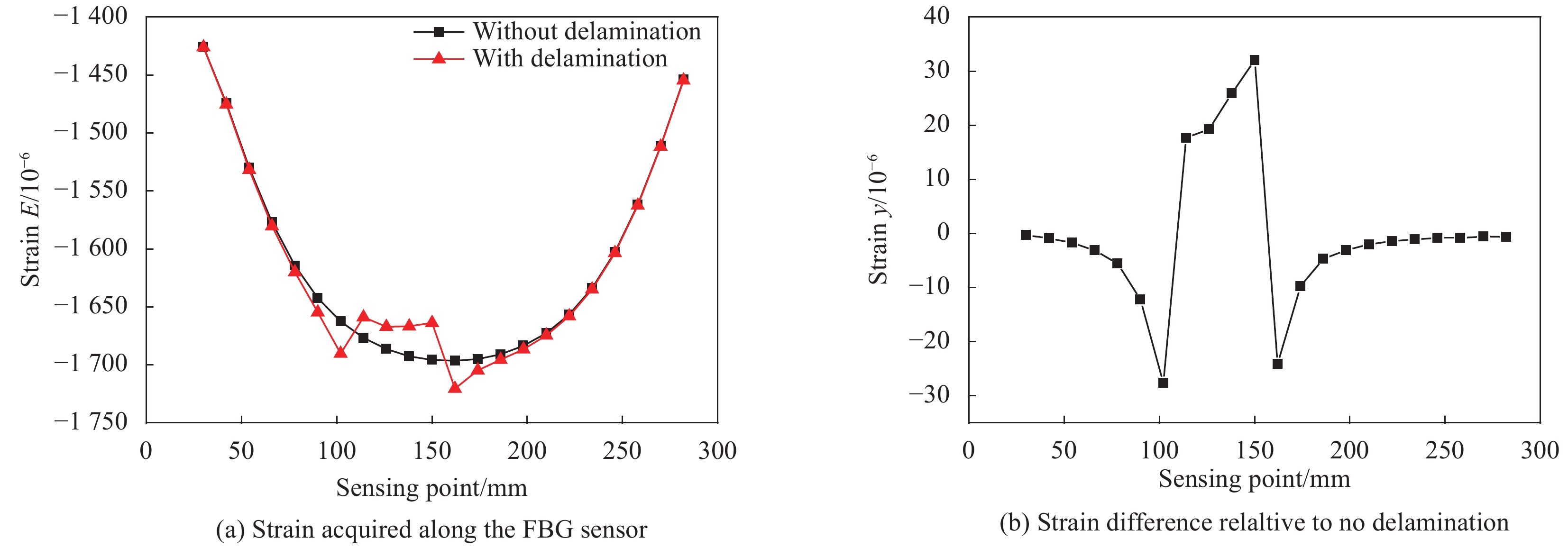

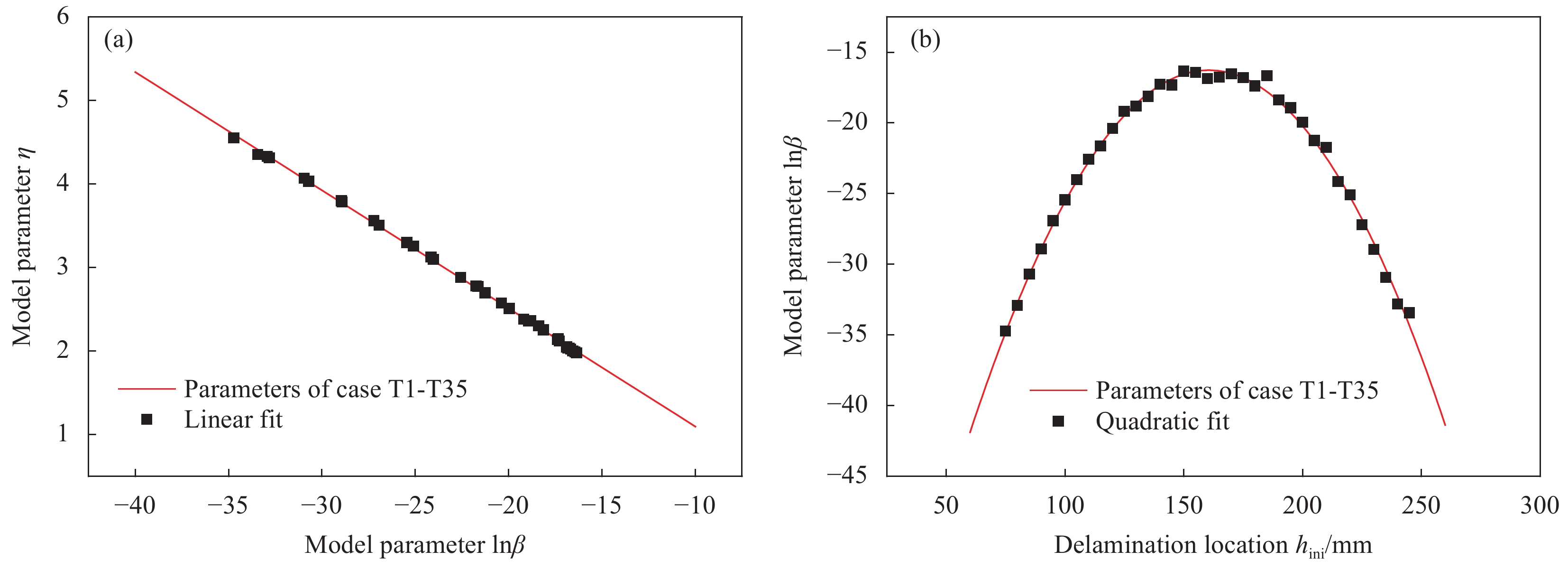

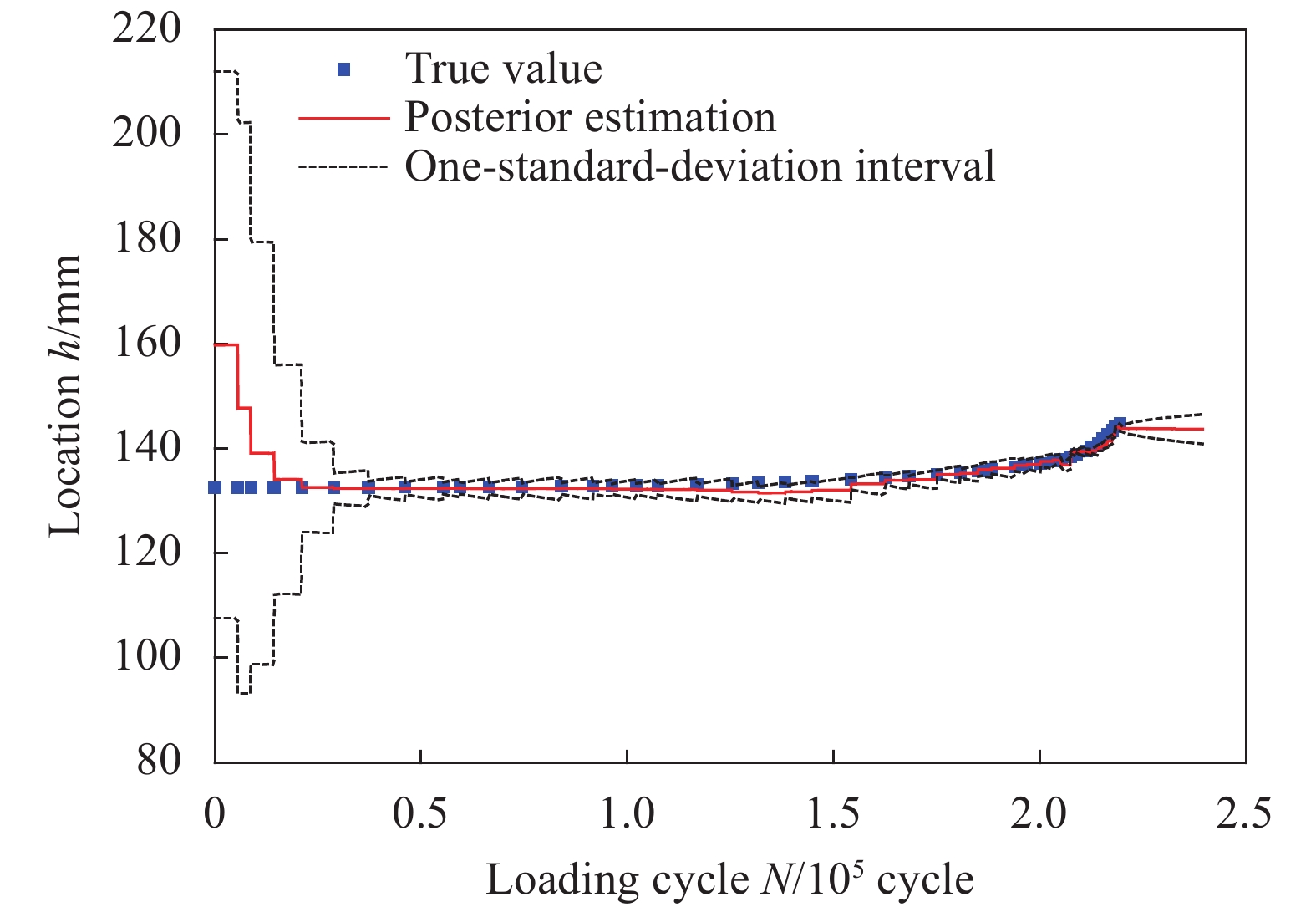

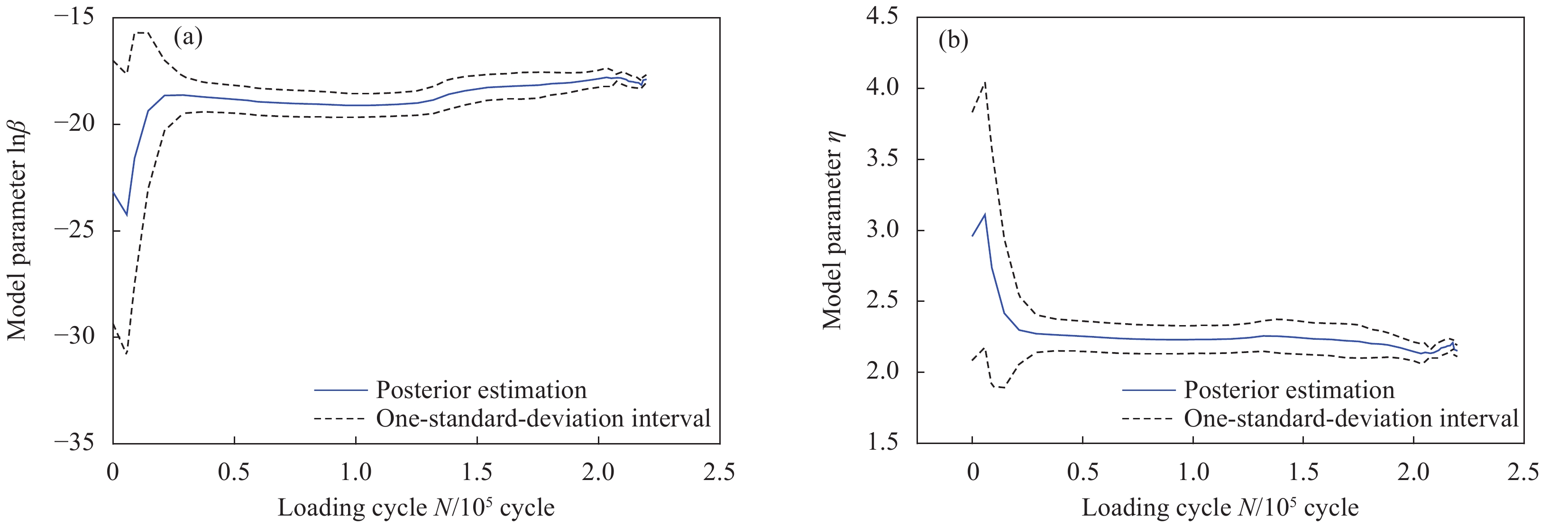

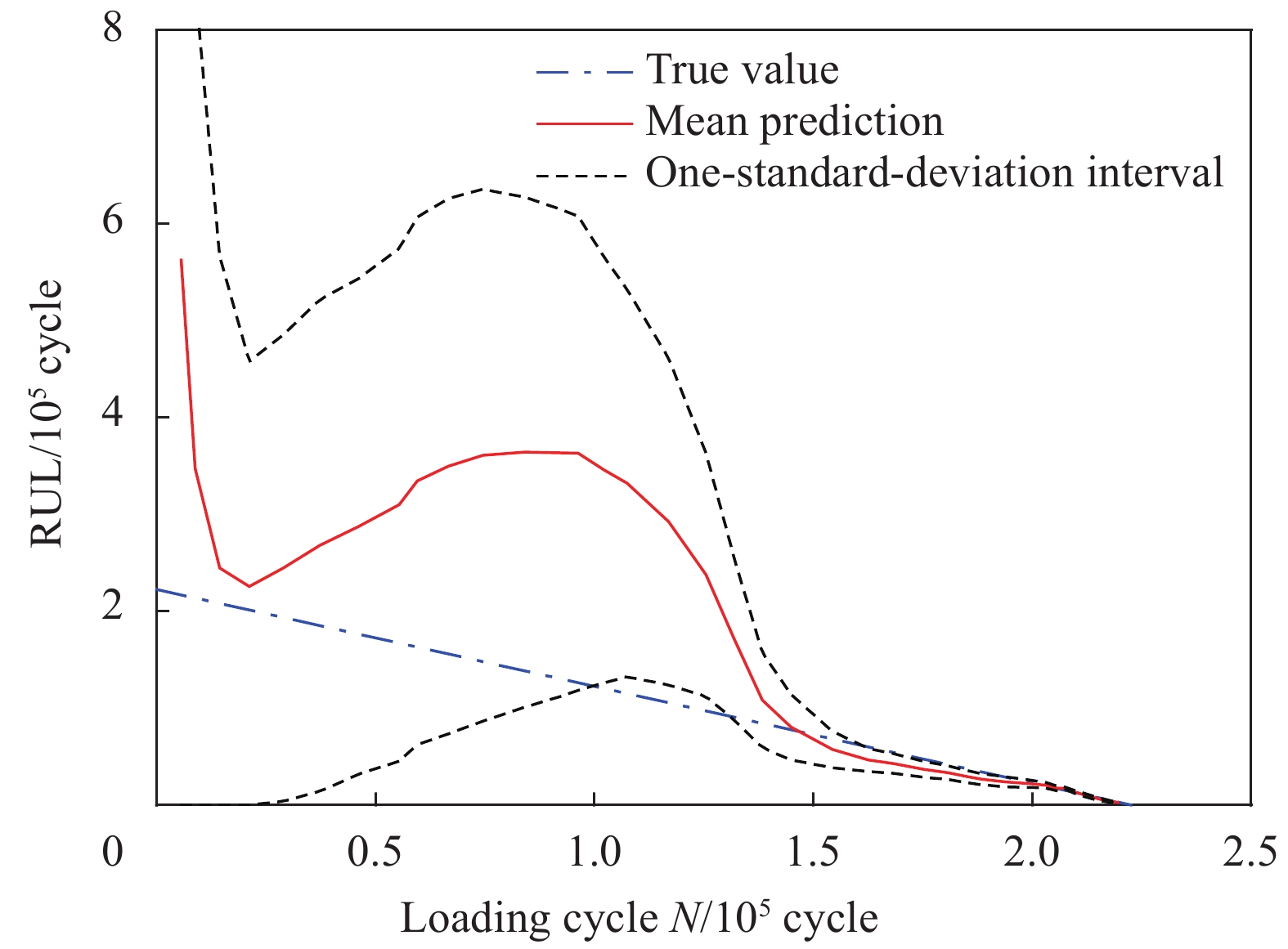

摘要: 针对复合材料结构疲劳损伤的在线监测和预测问题,提出了一种基于结构健康监测 (Structural health monitoring, SHM) 和贝叶斯理论的结构分层损伤诊断及结构剩余使用寿命预测方法。在贝叶斯概率理论框架下,采用指数模型描述复合材料结构疲劳分层损伤面积的先验演化规律,融合在线SHM数据对结构分层损伤状态,以及损伤面积演化模型的参数进行联合后验估计,即为损伤诊断结果。进一步通过后验估计得到的损伤状态和模型参数预测未来时刻结构分层损伤面积的演化,从而得到当前复合材料结构的剩余使用寿命预测结果。通过有限元仿真的加筋复合材料结构疲劳分层扩展对所提出的方法进行了验证。结果表明,方法可以在线准确地诊断结构分层损伤状态以及预测结构的剩余使用寿命。Abstract: Aiming at the on-line diagnosis and prognosis of composite structures, a method for structural delamination diagnosis and remaining useful life (RUL) prediction was proposed based on structural health monitoring (SHM) and the Bayesian theory. Within the Bayesian probabilistic framework, an exponential model was adopted to describe the prior progression of the fatigue delamination in the composite structure. Then, on-line SHM data were incorporated for diagnosing the delamination state, as well as parameters of the damage area progression model. The posterior estimations denoted the diagnosis result, based on which the progression of the delamination area in the future was predicted, giving the RUL of the current composite structure. The proposed method was validated on the simulated fatigue delamination growth in a stiffened composite structure through the finite element method. The result shows the accuracy of this method for on-line diagnosing the delamination damage, as well as predicting the RUL of the structure.

-

-

表 1 碳纤维增强环氧树脂基复合材料力学性能参数

Table 1 Mechanical properties of the carbon fiber reinforced epoxy resin matrix composites

Property Value E1/MPa 157486 E2/MPa 9946 v 0.24 G12/MPa 4950 G13/MPa 4950 G23/MPa 3208 Notes: E1 and E2 are Young’s moduli in 1 and 2 direction, respectively; v is Poisson’s ratio; G12, G13 and G23 are shear moduli in 1-2 plane, 1-3 plane and 2-3 plane, respectively. 表 2 仿真疲劳分层损伤扩展的虚拟裂纹闭合技术(VCCT)参数

Table 2 Virtual crack closure technique (VCCT) parameters for simulating fatigue delamination growth

Parameter Value GIC/(MPa·mm−1/2) 0.45 GIIC/(MPa·mm−1/2) 1.38 GIIIC/(MPa·mm−1/2) 1.38 C1 1×10−5 C2 1 C3 1×104 C4 5 Notes: GIC is the critical mode I energy release rate; GIIC is the critical mode II energy release rate; GIIIC is the critical mode III energy release rate; C1 and C2 are the material constants determining the onset of delamination growth; C3 and C4 are the material constants determining the fatigue delamination growth rate. -

[1] 邢丽英, 冯志海, 包建文, 等. 碳纤维及树脂基复合材料产业发展面临的机遇与挑战[J]. 复合材料学报, 2020, 37(11):2700-2706. XING Liying, FENG Zhihai, BAO Jianwen, et al. Facing opportunity and challenge of carbon fiber and polymer matrix composites industry development[J]. Acta Materiae Compositae Sinica,2020,37(11):2700-2706(in Chinese).

[2] 朱元林, 温卫东, 刘礼华, 等. 碳/碳复合材料疲劳损伤失效试验研究[J]. 复合材料学报, 2016, 33(2):386-393. ZHU Yuanlin, WEN Weidong, LIU Lihua, et al. Test research on fatigue damage failure of C/C composites[J]. Acta Materiae Compositae Sinica,2016,33(2):386-393(in Chinese).

[3] SENTHILKUMAR M, SREEKANTH T G, MANIKANTA R S. Nondestructive health monitoring techniques for composite materials: A review[J]. Polymers and Polymer Composites,2021,29(5):528-540.

[4] GÜEMES A, FERNANDEZ-LOPEZ A, POZO A R, et al. Structural health monitoring for advanced composite structures: A review[J]. Journal of Composites Science,2020,4(1):13. DOI: 10.3390/jcs4010013

[5] YUAN S F, LAI X S, ZHAO X, et al. Distributed structural health monitoring system based on smart wireless sensor and multi-agent technology[J]. Smart Materials and Structures, 2006, 15(1): 1-8.

[6] 袁慎芳. 结构健康监控[M]. 北京: 国防工业出版社, 2007. YUAN S F. Structural health monitoring and damage control[M]. Beijing: National Defense Industry Press, 2007 (in Chinese).

[7] 袁慎芳, 刘凌峰, 邱雷, 等. C/C热防护结构弹性波仿真分析方法及损伤影响[J]. 复合材料学报, 2019, 35(10):2448-2457. YUAN Shenfang, LIU lingfeng, QIU Lei, et al. Elastic wave simulation analysis method and damage effect on elastic waev in C/C thermal protection structures[J]. Acta Materiae Compositeae Sinica,2019,35(10):2448-2457(in Chinese).

[8] 鲍峤, 袁慎芳, 邱雷, 等. 基于阵列传感器的复合材料结构损伤MUSIC成像方法[J]. 复合材料学报, 2017, 34(2):456-462. BAO Qiao, YUAN Shenfang, QIU Lei, et al. A damage imaging method based on MUSIC algorithm of linear sensor array for composite structure[J]. Acta Materiae Compositeae Sinica,2017,34(2):456-462(in Chinese).

[9] LIU Y, MOHANTY S, CHATTOPADHYAY A. Condition based structural health monitoring and prognosis of composite structures under uniaxial and biaxial loading[J]. Journal of Nondestructive Evaluation,2010,29(3):181-188. DOI: 10.1007/s10921-010-0076-2

[10] ELEFTHEROGLOU N, LOUTAS T. Fatigue damage diagnostics and prognostics of composites utilizing structural health monitoring data and stochastic processes[J]. Structural Health Monitoring,2016,15(4):473-488. DOI: 10.1177/1475921716646579

[11] TODD M, GREGORY W, KEY C, et al. Composite laminate fatigue damage detection and prognosis using embedded fiber Bragg Gratings[C]//Smart Materials, Adaptive Structures and Intelligent Systems. American Society of Mechanical Engineers, 2018, 51951: V002T05A011.

[12] 陈健, 袁慎芳, 王卉, 等. 基于高斯权值-混合建议分布粒子滤波的疲劳裂纹扩展预测[J]. 航空学报, 2017, 38(11):168-176. CHEN Jian, YUAN Shenfang, WANG Hui, et al. Using Gaussian weighting-mixture proposal distribution particle filter for fatigue crack growth prediction[J]. Acta Aeronautica et Astronautica Sinica,2017,38(11):168-176(in Chinese).

[13] CHEN J, YUAN S F, JIN X. On-line prognosis of fatigue cracking via a regularized particle filter and guided wave monitoring[J]. Mechanical Systems and Signal Processing,2019,131:1-17. DOI: 10.1016/j.ymssp.2019.05.022

[14] CHIACHIO J, CHIACHIO M, SAXENA A, et al. An energy-based prognostics framework to predict fatigue damage evolution in composites[C]//Proceedings of the Annual Conference of the Prognostics and Health Management Society. 2013, 1: 363-371.

[15] ARULAMPALAM M S, MASKELL S, GORDON N, et al. A tutorial on particle filters for online nonlinear/non-Gaussian Bayesian tracking[J]. IEEE Transactions on Signal Processing,2002,50(2):174-188. DOI: 10.1109/78.978374

[16] CORBETTA M, SBARUFATTI C, GIGLIO M, et al. A Bayesian framework for fatigue life prediction of composite laminates under co-existing matrix cracks and delamination[J]. Composite Structures,2018,187:58-70. DOI: 10.1016/j.compstruct.2017.12.035

[17] DATTA S, NEERUKATTI R K, CHATTOPADHYAY A. Buckypaper embedded self-sensing composite for real-time fatigue damage diagnosis and prognosis[J]. Carbon,2018,139:353-360. DOI: 10.1016/j.carbon.2018.06.059

[18] BANERJEE P, PALANISAMY R P, HAQ M, et al. Data-driven prognosis of fatigue-induced delamination in composites using optical and acoustic NDE methods [C]//2019 IEEE International Conference on Prognostics and Health Management, 2019: 1-10.

[19] CRISTIANI D, SBARUFATTI C, GIGLIO M. Damage diagnosis and prognosis in a composite structure by surrogate modelling and particle filtering[C]//12th International Workshop on Structural Health Monitoring: Enabling Intelligent Life-Cycle Health Management for Industry Internet of Things (IIOT), IWSHM 2019. DEStech Publications Inc., 2019, 1: 1565-1572.

[20] DOUCET A, GODSILL S, ANDRIEU C. On sequential Monte Carlo sampling methods for Bayesian filtering[J]. Statistics and Computing,2000,10(3):197-208. DOI: 10.1023/A:1008935410038

[21] FENG X, GILCHRIST M D, KINLOCH A J, et al. Development of a method for predicting the fatigue life of CFRP components[J]. International Conference on Fatigue of Composites, 1997: 407-414.

[22] KRUEGER R, O'BRIEN T K. A shell/3D modeling technique for the analysis of delaminated composite laminates[J]. Composites Part A: Applied Science and Manufacturing,2001,32(1):25-44. DOI: 10.1016/S1359-835X(00)00133-0

-

期刊类型引用(2)

1. 柯俊,李志虎,秦玉林. 金属主簧-复合材料副簧复合刚度计算模型. 汽车实用技术. 2021(05): 39-43 .  百度学术

百度学术

2. 曾婷,王咏莉,尹忠旺,苏婷慧,师志峰,饶猛. 端面凸轮下压机构支承轴承冲击失效分析及优化(英文). 机床与液压. 2017(24): 37-42 .  百度学术

百度学术

其他类型引用(5)

-

下载:

下载: