Effect of thermoplastic polyurethane elastomer on the properties of polybutylene terephthalate matrix flame retardant composites

-

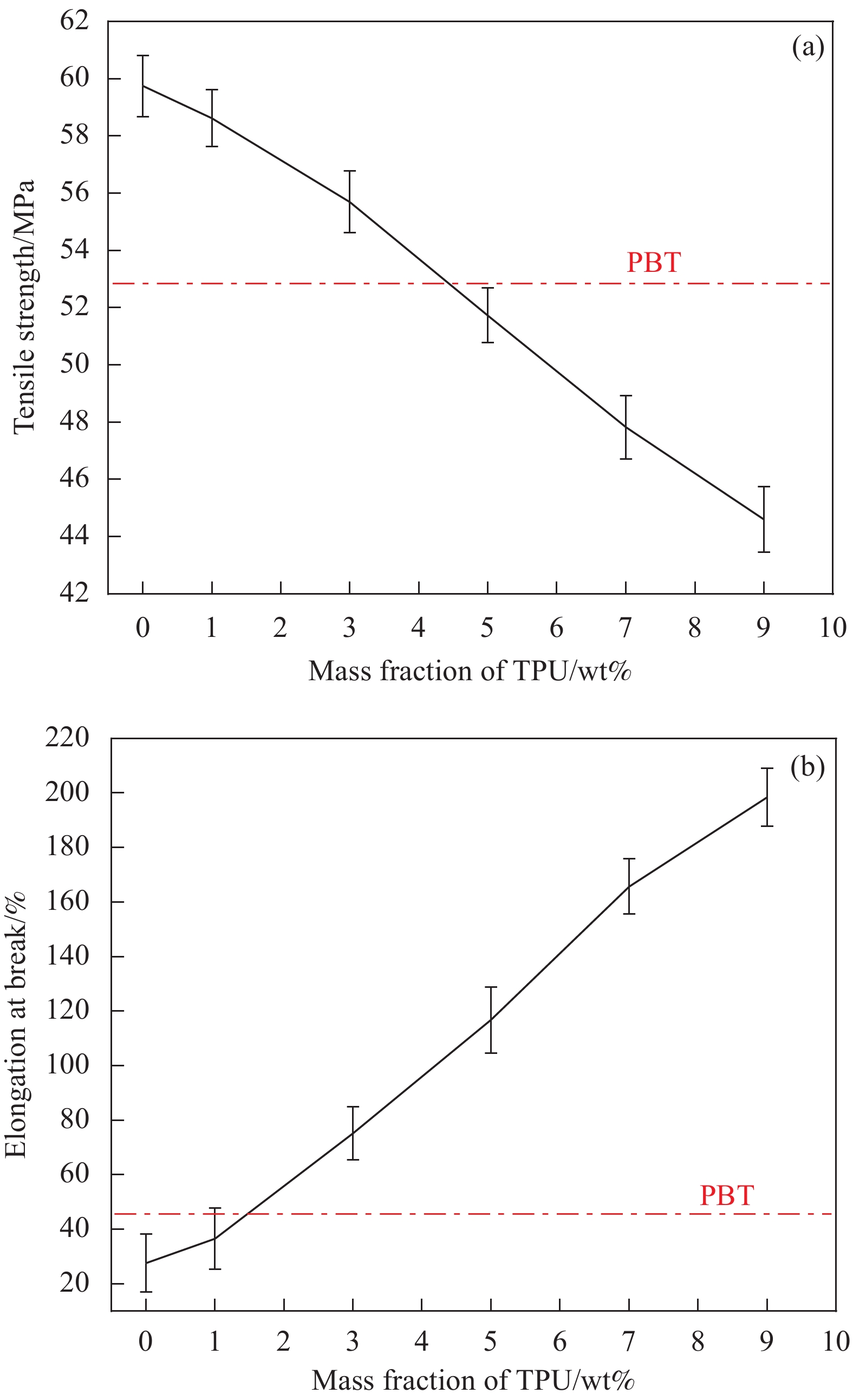

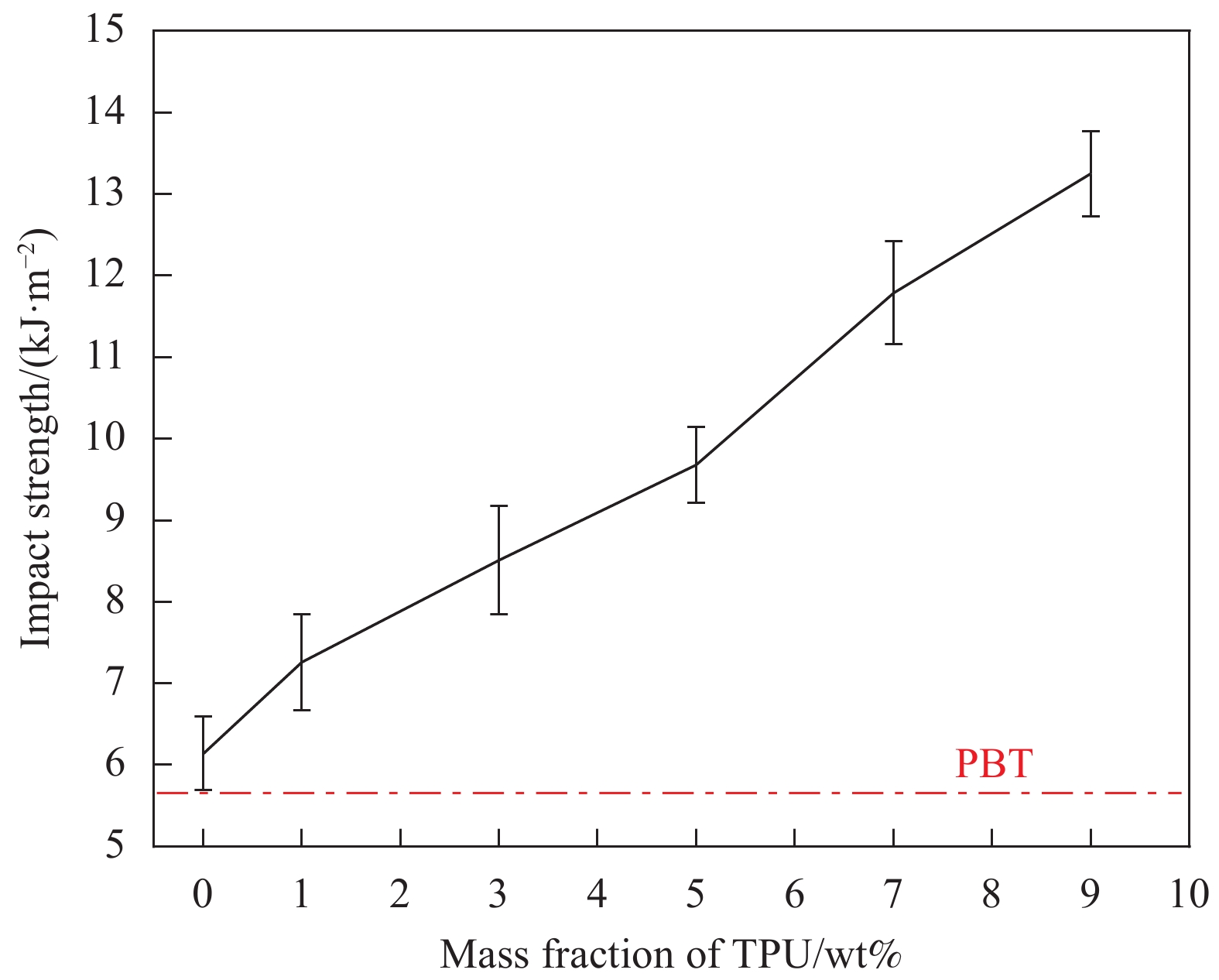

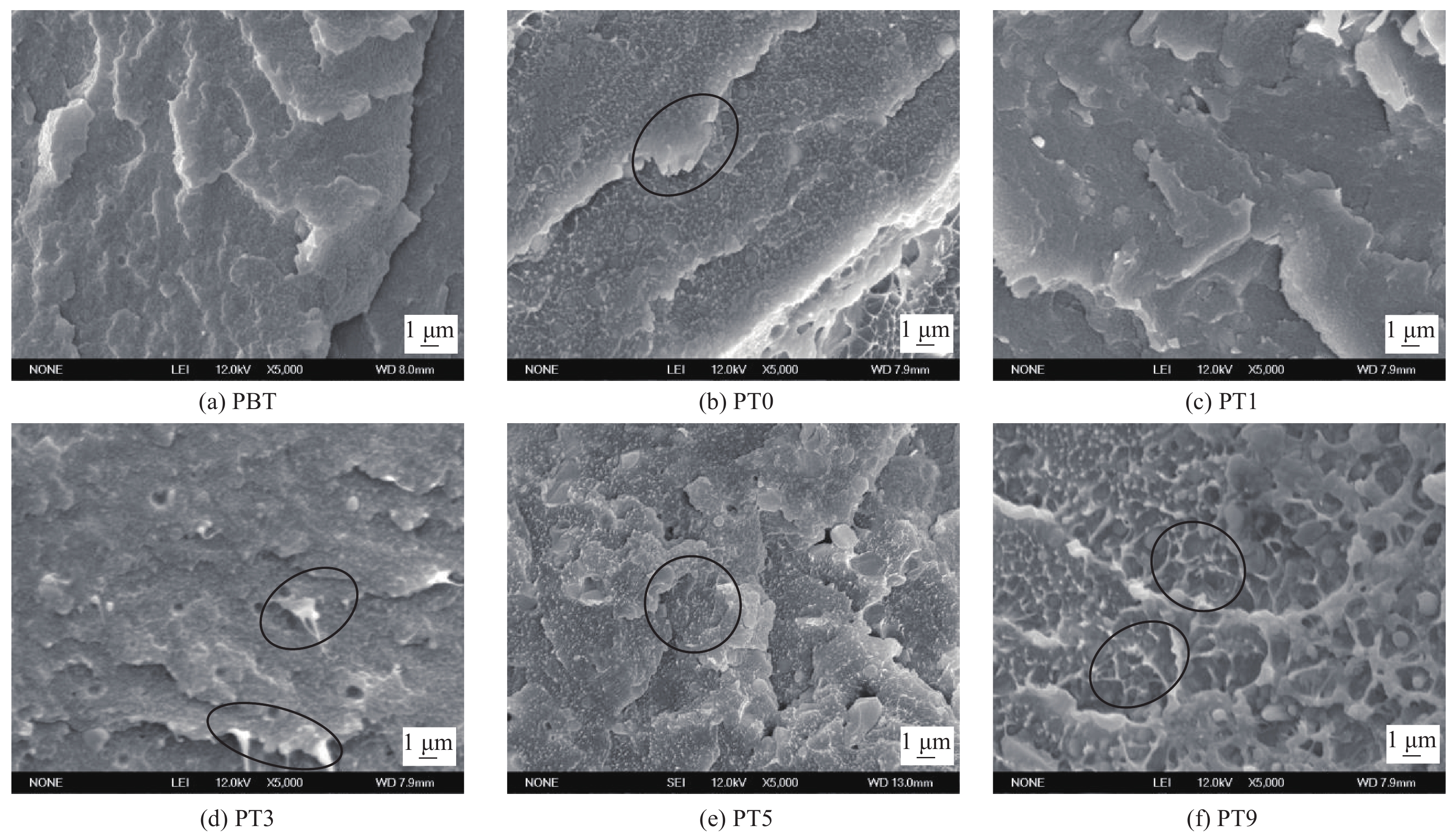

摘要: 以溴化聚苯乙烯(BPS)为阻燃剂,Sb2O3纳米颗粒(nano-Sb2O3)为协效阻燃剂,聚对苯二甲酸丁二醇酯(PBT)为基体,热塑性聚氨酯弹性体(TPU)为增韧组分,采用球磨分散和熔融共混的方法制备出TPU/nano-Sb2O3-BPS-PBT阻燃复合材料。通过DSC、拉伸、冲击和极限氧指数(LOI)等性能测试,研究了TPU质量分数对TPU/nano-Sb2O3-BPS-PBT阻燃复合材料力学性能与阻燃性能的影响。研究结果表明:TPU的加入可改善TPU/nano-Sb2O3-BPS-PBT阻燃复合材料的韧性;随着TPU质量分数的增加,TPU/nano-Sb2O3-BPS-PBT阻燃复合材料的缺口冲击强度上升,当TPU质量分数为9wt%时,其冲击强度相比于纯PBT提高了137%,断裂伸长率相比于纯PBT提高了340%,但该复合材料的拉伸强度有所下降。当TPU质量分数为3wt%时,该复合材料的拉伸强度大于纯PBT,冲击强度相比于纯PBT提高了52%,同时达到了难燃等级。此时,TPU/nano-Sb2O3-BPS-PBT阻燃复合材料表现出优异的综合性能。

-

关键词:

- 聚对苯二甲酸丁二醇酯 /

- Sb2O3 /

- 热塑性聚氨酯弹性体 /

- 复合材料 /

- 增韧

Abstract: Using brominated polystyrene (BPS) as flame retardant, Sb2O3 nanoparticles (nano-Sb2O3) as synergistic flame retardant, polybutylene terephthalate (PBT) as matrix and thermoplastic polyurethane elasticity (TPU) as a toughening component, TPU/nano-Sb2O3-BPS-PBT flame retardant composites were obtained by ball milling dispersion and melt-mixing methods. The mechanical and flame retardant properties of the TPU/nano-Sb2O3-BPS-PBT composites were studied by DSC, tensile, impact and limiting oxygen index (LOI) test. The results show that the TPU can enhance the toughness of the TPU/nano-Sb2O3-BPS-PBT flame retardant composites. With increasing of the mass fraction of TPU, the notched impact strength of the TPU/nano-Sb2O3-BPS-PBT flame retardant composites increases. Furthermore, when the mass fraction of TPU is 9wt%, its impact strength increases by 137% and the elongation at break increases by 340% compared with those of pure PBT, but its tensile strength decreases. The tensile strength of the composites is greater than that of pure PBT when the mass fraction of TPU is 3wt%, which its impact strength is 52% higher than that of the pure PBT. The TPU/nano-Sb2O3-BPS-PBT flame retardant composites reach flame-resistant grade and the composites show superior comprehensive performance.-

Keywords:

- polybutylene terephthalate /

- Sb2O3 /

- thermoplastic polyurethane elastomer /

- composites /

- toughening

-

-

表 1 热塑性聚氨酯弹性体(TPU)/Sb2O3纳米颗粒(nano-Sb2O3)-溴化聚苯乙烯(BPS)-聚对苯二甲酸丁二醇酯(PBT)阻燃复合材料各组分的质量分数

Table 1 Mass fraction of each component of thermoplastic polyurethane elasticity (TPU)/Sb2O3 nanoparticles (nano-Sb2O3)-brominated polystyrene (BPS)-polybutylene terephthalate (PBT) flame retardant composites

wt% Sample Abbr. Nano-Sb2O3 BPS TPU PBT PBT PBT 0 0 0 100 nano-Sb2O3-BPS-PBT PT0 5 10 0 85 1%TPU/nano-Sb2O3-BPS-PBT PT1 5 10 1 84 3%nano-Sb2O3-BPS-PBT PT3 5 10 3 82 5%nano-Sb2O3-BPS-PBT PT5 5 10 5 80 7%nano-Sb2O3-BPS-PBT PT7 5 10 7 78 9%nano-Sb2O3-BPS-PBT PT9 5 10 9 76 表 2 TPU/nano-Sb2O3-BPS-PBT阻燃复合材料的结晶参数

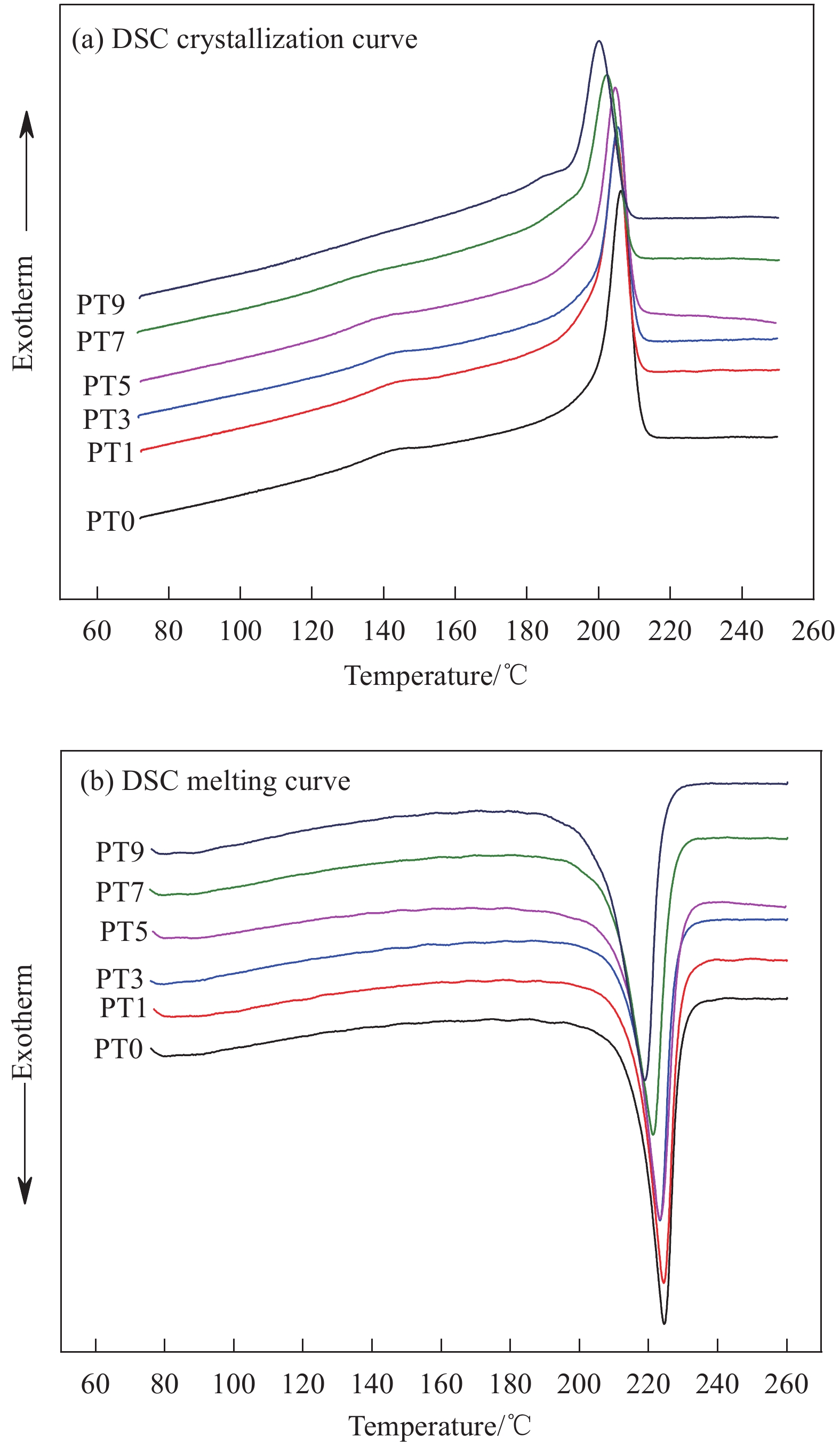

Table 2 Crystallization parameters of TPU/nano-Sb2O3-BPS-PBT flame retardant composites

Sample Tm/℃ ΔHm/(J·g−1) Tc/℃ ΔT/℃ Xc/% PT0 224.46 47.45 206.22 18.24 32.61 PT1 224.07 45.80 205.97 18.10 31.48 PT3 222.49 42.04 204.59 17.90 28.89 PT5 221.87 39.19 203.36 18.51 26.93 PT7 221.05 38.05 202.25 18.80 26.15 PT9 218.84 35.14 200.13 18.71 24.15 Notes: Tm—Melting temperature; Tc—Crystallization temperature; ΔHm—Melting enthalpy; Xc—Crystallinity. 表 3 PBT及TPU/nano-Sb2O3-BPS-PBT阻燃复合材料极限氧指数(LOI)值和UL94等级

Table 3 Limit oxygen index (LOI) value and UL94 rating of PBT and TPU/nano-Sb2O3-BPS-PBT flame retardant composites

PBT PT0 PT1 PT3 PT5 PT7 PT9 LOI/% 21.0 28.2 27.3 26.5 26.0 25.8 25.2 UL94 HB V-0 V-0 V-0 V-0 V-0 V-0 -

[1] 徐宁, 刘琪, 吕通建, 等. 阻燃增强PBT的增韧改性研究[J]. 工程塑料应用, 2015, 41(12):11-14. DOI: 10.3969/j.issn.1001-3539.2015.12.003 XU N, LIU Q, LV T J, et al. Toughening modification study of flame-retarding and reinforced PBT materials[J]. Engineering Plastics Application,2015,41(12):11-14(in Chinese). DOI: 10.3969/j.issn.1001-3539.2015.12.003

[2] HUANG J T, LIU H Y, LU X, et al. Thermal and mechanical properties of TPU/PBT reinforced by carbon fiber[C]// PROCEEDINGS OF PPS-31: The 31st International Conference of the Polymer Processing Society Conference Papers. AIP Publishing LLC, 2016, 1713(1): 120003.

[3] WANG R Y, CHEN X D, XU Q J. Progress of research on modification in polybutylene terephthalate[J]. Advanced Materials Research,2014,860-863:855-861.

[4] 陆波, 徐晓强, 亢萍, 等. 超韧PBT/PC共混物的研制[J]. 工程塑料应用, 2006(5):9-11. LU B, XU X Q, KANG P, et al. Study on supertoughness of PBT/PC blends[J]. Engineering Plastics Application,2006(5):9-11(in Chinese).

[5] WANG B L, WU D, ZHU L, et al. High-density polyethylene-based ternary blends toughened by PA6/PBT core-shell particles[J]. Polymer-Plastics Technology and Engineering,2017,56(17):1908-1915. DOI: 10.1080/03602559.2017.1295314

[6] DENG S Q, LIU Q, BAO X, et al. Toughening and compatibilization of acrylonitrile-butadiene-styrene/poly (ethylene terephthalate) blends using an oxazolinefunctionalized impact modifier[J]. Polymer-Plastics Technology and Engineering,2015,54(11):1184-1192. DOI: 10.1080/03602559.2014.1003225

[7] 陆蕾蕾, 沈澄英, 宋功品, 等. PC/PBT合金材料的制备与改性[J]. 安徽化工, 2016, 42(2):38-39, 41. DOI: 10.3969/j.issn.1008-553X.2016.02.011 LU L L, SHEN C Y, SONG G P, et al. Preparation and modification of PC/PBT alloy material[J]. Anhui Chemical Industry,2016,42(2):38-39, 41(in Chinese). DOI: 10.3969/j.issn.1008-553X.2016.02.011

[8] 莫文杰, 龚德君, 陈锐, 等. PC增韧PBT的性能和结构研究[J]. 广州化工, 2019, 47(9):58-60. DOI: 10.3969/j.issn.1001-9677.2019.09.025 MO W J, GONG D J, CHEN R, et al. Study on property and structure of PBT toughened with PC[J]. Guangzhou Chemical Industry,2019,47(9):58-60(in Chinese). DOI: 10.3969/j.issn.1001-9677.2019.09.025

[9] 蔡蕾, 綦春雨, 谭志勇, 等. LDPE加入对POE增韧PBT的影响[J]. 塑料工业, 2019, 47(5):49-52, 57. DOI: 10.3969/j.issn.1005-5770.2019.05.010 CAI L, QI C Y, TAN Z Y, et al. Effect of the introduction of LDPE into POE on the toughening PBT[J]. China Plastics Industry,2019,47(5):49-52, 57(in Chinese). DOI: 10.3969/j.issn.1005-5770.2019.05.010

[10] XU J L, YANG W L, NIU L, et al. Study on the surface modification of Sb2O3 nanoparticles by using mechanochemical method[J]. Inorganic and Nano-Metal Chemistry,2017,47(5):697-702. DOI: 10.1080/15533174.2016.1212224

[11] HUANG J T, LU X, ZHANG G Z, et al. Study on the rheological, thermal and mechanical properties of thermoplastic polyurethane/poly (butylene terephthalate) blends[J]. Polymer Testing,2014,36:69-74. DOI: 10.1016/j.polymertesting.2014.03.006

[12] ATA C T, KARIM S N, POUYA F K, et al. A study of the effect of TPU and clay nanoparticles on the mechanical behavior of PBT-based nanocomposites[J]. Mechanics of Advanced Composite Structures,2017,4(3):179-186.

[13] 刘伯元. 双螺杆反应挤出热塑性聚氨酯弹性体的研究[J]. 塑料技术, 2003, 38(5):25-29. LIU B Y. Study on the twin screw reactive extrusion of thermoplastic polyurethane elastomer[J]. Plastic Technology,2003,38(5):25-29(in Chinese).

[14] CHEN X L, MA C Y, JIAO C M. Enhancement of flameretardant performance of thermoplastic polyurethane with the incorporation of aluminum hypophosphite and iron-graphene[J]. Polymer Degradation and Stability,2016,129:275-285. DOI: 10.1016/j.polymdegradstab.2016.04.017

[15] NIU L, XU J L, KANG C H, et al. Influence of nano-Sb2O3 particles on mechanical properties of PBT flame retardant composites[J]. Ferroelectrics,2019,546(1):148-157. DOI: 10.1080/00150193.2019.1592467

[16] 徐建林, 张亮, 周生刚, 等. 表面活性剂对球磨法制备纳米Sb2O3粉末的影响[J]. 稀有金属材料与工程, 2014, 43(12):3003-3007. XU J L, ZHANG L, ZHOU S G, et al. Effect of surfactant on preparation of nano Sb2O3powder by ball milling[J]. Rare Metal Materials and Engineering,2014,43(12):3003-3007(in Chinese).

[17] 徐建林, 赵金强, 牛磊, 等. 纳米Sb2O3增强聚丙烯基复合材料力学性能[J]. 复合材料学报, 2018, 35(9):2465-2472. XU J L, ZHAO J Q, NIU L, et al. Mechanical properties of polypropylene matrix composites strengthened by nano Sb2O3[J]. Acta Materiae Compositae Sinica,2018,35(9):2465-2472(in Chinese).

[18] 李东红, 白静静, 李振中. 软段对热塑性聚氨酯弹性体结构及性能的影响[J]. 山西化工, 2014, 34(1):10-12. DOI: 10.3969/j.issn.1004-7050.2014.01.003 LI D H, BAI J J, LI Z Z. Effect of soft segment on structure-property of TPU[J]. Shanxi Chemical Industry,2014,34(1):10-12(in Chinese). DOI: 10.3969/j.issn.1004-7050.2014.01.003

[19] NIU L, XU J L, YANG W L, et al. Study on the synergetic fire-retardant effect of nano-Sb2O3 in PBT matrix[J]. Materials,2018,11(7):1060. DOI: 10.3390/ma11071060

[20] 肖文强, 夏元梦, 严磊, 等. PBT/TPU/氧化石墨烯三元共混物的制备及性能[J]. 弹性体, 2018, 28(3):1-6. DOI: 10.3969/j.issn.1005-3174.2018.03.001 XIAO W Q, XIA Y M, YAN L, et al. Preparation and properties of PBT/TPU/graphene oxide ternary blend[J]. Elastomer,2018,28(3):1-6(in Chinese). DOI: 10.3969/j.issn.1005-3174.2018.03.001

[21] HAO Y P, YANG H L, ZHANG H L, et al. Miscibility, crystallization behaviors and toughening mechanism of poly (butylene terephthalate)/thermoplastic polyurethane blends[J]. Fibers and Polymers,2018,19(1):1-10. DOI: 10.1007/s12221-018-7305-6

[22] NIU L, XU J L, YANG W L, et al. Crystallization, flame retardancy and mechanical properties of poly (butylene terephthalate)/brominated epoxy/nano-Sb2O3composites dispersed by high energy ball milling[J]. Journal of Macromolecular Science,2018,57(8):572-584. DOI: 10.1080/00222348.2018.1493173

-

期刊类型引用(2)

1. 李滋阳,王思佳,邓文举. 陶瓷颗粒增强金属基复合材料研究进展. 轻工科技. 2021(04): 41-44 .  百度学术

百度学术

2. 陈亚楠,金云学,牛牧野,陈洪美,杜文栋. Ni_3Al(Cr)合金室温干滑动摩擦磨损性能研究. 江苏科技大学学报(自然科学版). 2019(05): 18-26 .  百度学术

百度学术

其他类型引用(4)

-

下载:

下载: