Effect of nano-calcium carbonate modified by lactic acid oligomers on the properties of polylactic acid

-

摘要: 采用直接缩聚法制备了乳酸低聚物,用该物质对纳米碳酸钙(CaCO3)进行改性,得到改性纳米碳酸钙(g-CaCO3)。将g-CaCO3与聚乳酸(PLA)通过溶液共混制备了g-CaCO3/PLA复合材料。通过FTIR、吸油值等对g-CaCO3进行了表征,并采用SEM、DSC、万能试验机、流变测试仪、透湿仪、紫外-可见-近红外(UV-Vis-AIR)分光光度计研究了g-CaCO3对PLA结构和性能的影响。结果表明,乳酸低聚物的改性降低了CaCO3的吸油值,改善了CaCO3与PLA的界面相容性,促进了CaCO3在PLA基体中的分散;同时,g-CaCO3在PLA基体中起到成核剂的作用,改善了PLA材料的结晶能力;随着g-CaCO3添加量的增加,g-CaCO3/PLA复合材料的拉伸强度和断裂延伸率呈先上升后下降的趋势,当添加5wt%的g-CaCO3时,拉伸强度比5%CaCO3/PLA复合材料高50%,比纯PLA高20%,当添加量达到10wt%时,拉伸强度仍比纯PLA高出13%;加入g-CaCO3能够提高复合材料的储能模量和复数黏度;此外,g-CaCO3的加入,提高了PLA材料对紫外可见光和水蒸气的阻隔性能。Abstract: Lactic acid oligomer was prepared by direct condensation method and used as modifier of nano-calcium carbonate (CaCO3) to developed modified nano-calcium carbonate (g-CaCO3). g-CaCO3 was blended with polylactic acid (PLA) by solution blending to prepare g-CaCO3/PLA composites. The g-CaCO3 was characterized by FTIR and oil absorption value etc. SEM, DSC, universal testing machine, rheometer, water vapor transmission tester and UV-Vis-AIR spectrophotometer were used to study the g-CaCO3 on the structure and performances of the PLA. The results show that the modification of lactic acid oligomer reduces the absorption value of CaCO3, promotes compatibility between CaCO3 and PLA and improves the dispersion of CaCO3 in PLA matrix. At the same time, the g-CaCO3 acts as nucleating agent in PLA matrix, improving the crystallization ability of the PLA. The tensile strength and strain at break of the g-CaCO3/PLA composites first rise and then fall as the g-CaCO3 content increasing. When the g-CaCO3 content is 5wt%, the tensile strength is 50% higher than that of 5%CaCO3/PLA composite. When the addition amount of g-CaCO3 reaches 10wt%, the tensile strength is still 13% higher than that of pure PLA. The storage modulus and complex viscosity of the composites are improved by adding g-CaCO3. In addition, the addition of g-CaCO3 enhances the barrier property of PLA to ultraviolet visible light and water vapor.

-

Keywords:

- lactic acid oligomer /

- nano-calcium carbonate /

- modification /

- PLA /

- composite /

- mechanical property

-

近年来,大量石油基塑料的使用造成了严重的环境污染,这使开发可降解和生物来源的环保型塑料成为了研究热点。聚乳酸(PLA)是一种环保型高分子材料,具有良好的生物相容性和可降解性,被认为是具有广阔发展前景的绿色生物基塑料,可作为包装、纺织和汽车工业中石油基塑料的良好替代品[1-3]。但PLA在成本、力学性能及阻隔性能等方面存在的缺陷,限制了其更广泛的应用[4-5]。为了改善PLA的性能,降低材料成本,扩大其在生产和生活中的应用范围,对其进行改性具有一定的必要性。根据以往的研究经验,采用纳米填料对PLA进行填充改性是一种方便、高效率的改性方法[6]。

纳米碳酸钙(CaCO3)具有较好的稳定性和生物相容性,是世界上产量最高、成本最低的无机纳米粒子[7]。将它作为填料,能在改善PLA固有缺陷的同时,降低材料成本,还能保持材料的生物降解性能[8-9]。据报道,CaCO3已成为塑料、橡胶和涂料工业中重要的无机填料之一[10-11]。

然而,CaCO3表面的亲水特性,使其与PLA基体的相容性较差,极易在材料中发生团聚现象。而这种现象,会使复合材料产生界面缺陷,导致PLA的力学性能劣化。因此,改善界面相容性将是提高CaCO3/PLA复合材料力学性能的关键所在。常用的表面改性剂有脂肪酸、磷酸盐、硅烷偶联剂等,但这些改性剂存在的难生物降解问题和与PLA不相容的问题是改性CaCO3填充PLA改性效果的关键障碍[12]。

通过直接缩聚法制备乳酸低聚物,再将其接枝到CaCO3表面。采用溶液共混法制备g-CaCO3/PLA复合材料,评价了g-CaCO3的添加量对PLA复合材料结晶能力、力学、流变及阻隔性能的影响。为制备低成本、高性能且保持原有生物降解性能的PLA复合材料提供一条新途径。

1. 实验材料及方法

1.1 原材料

PLA,2003D,美国Natureworks公司;g-CaCO3,平均粒径50~100 nm,福建鸿丰纳米技术有限公司;L-乳酸和1,4-二氧六环,国药集团化学试剂有限公司;二氯甲烷,上海联宇化工有限公司。

1.2 乳酸低聚物的制备

取200 mL的L-乳酸加入到500 mL的三颈烧瓶中,调节反应真空度至0.09 MPa,油浴加热至100℃,在磁力搅拌下预脱水1 h。随后保持真空度不变,升温至135℃继续脱水2 h。最后,保持温度恒定在135℃,调节真空度至100 Pa,持续反应4 h后得到乳酸低聚物。

1.3 g-CaCO3的制备

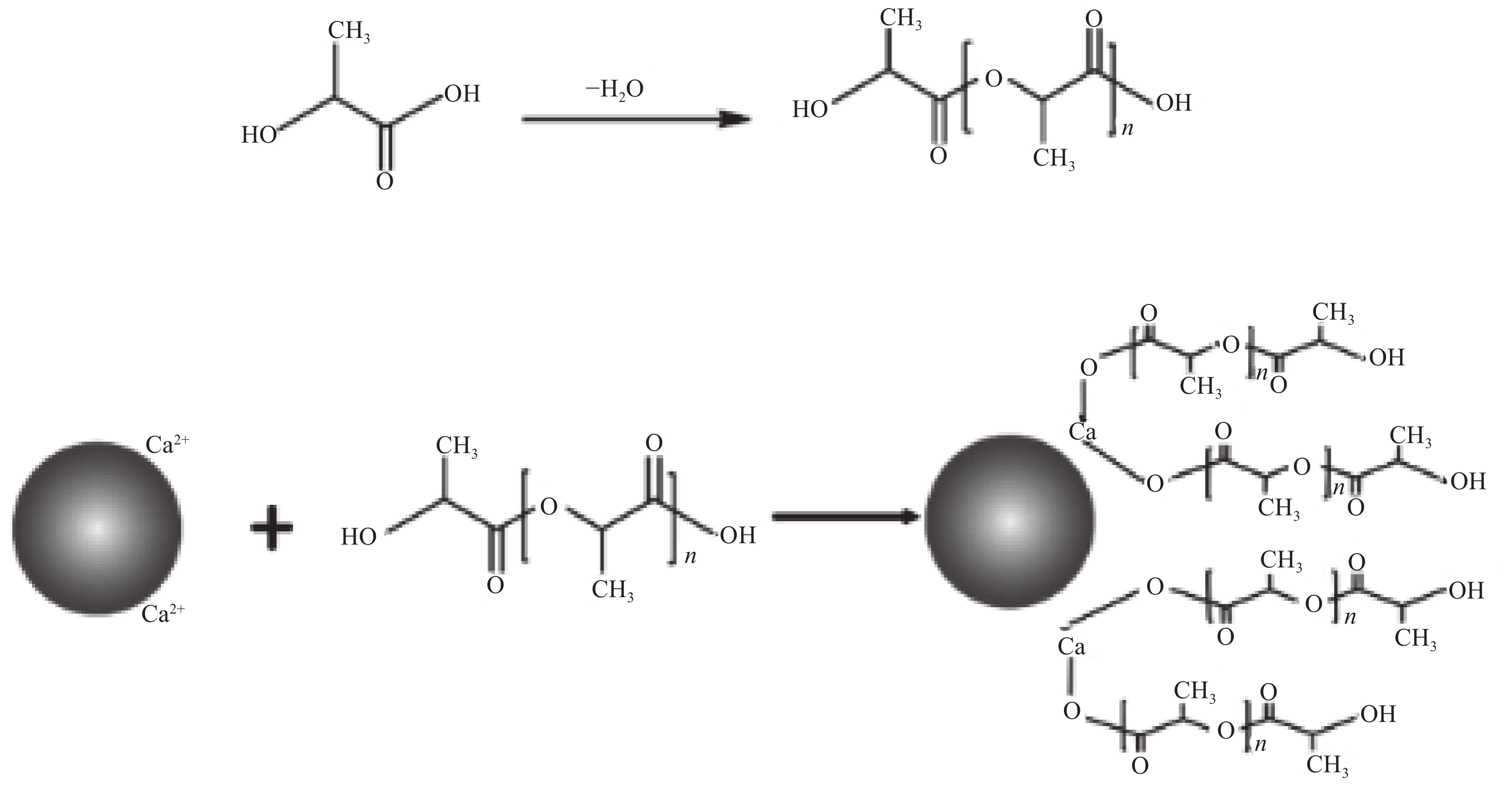

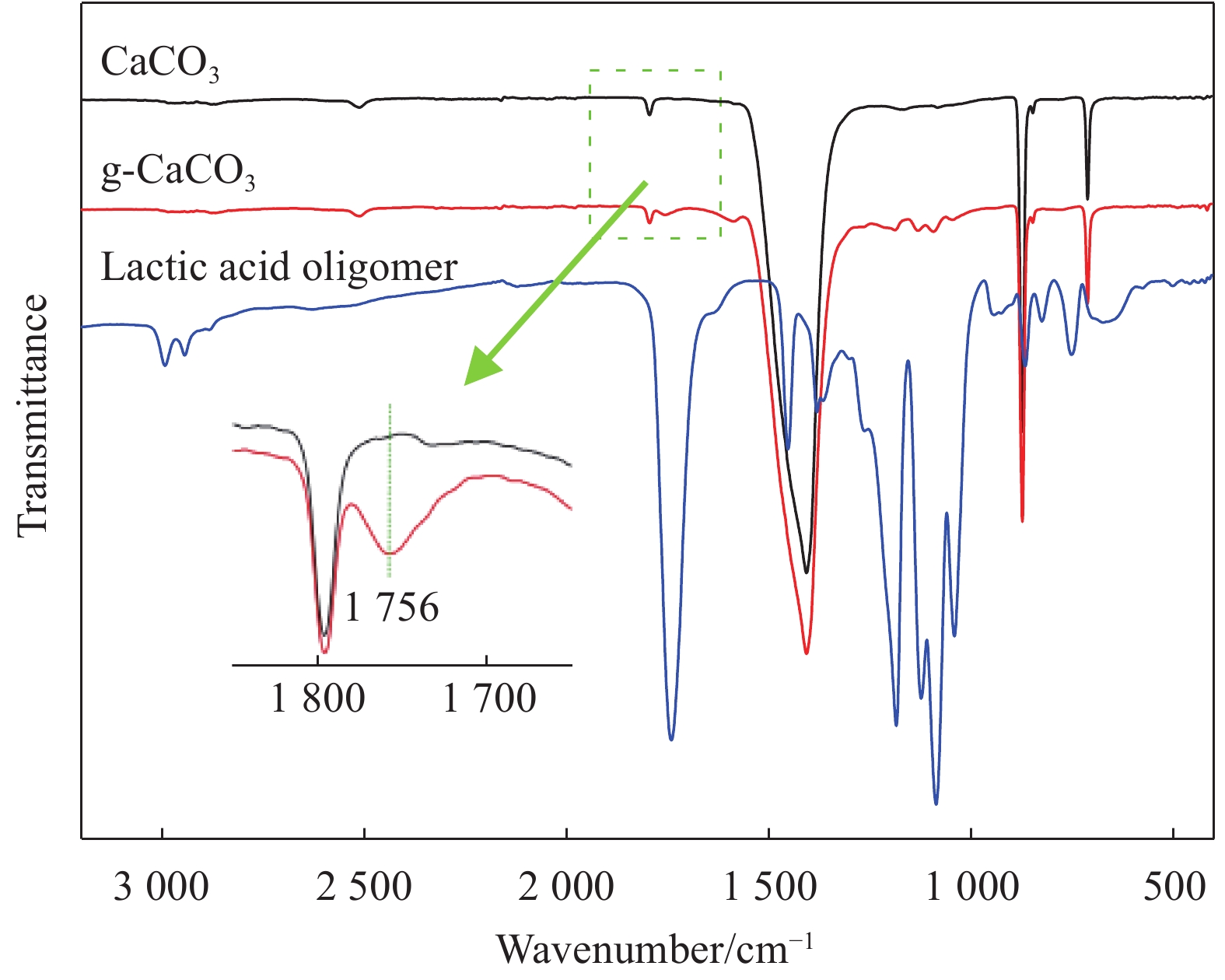

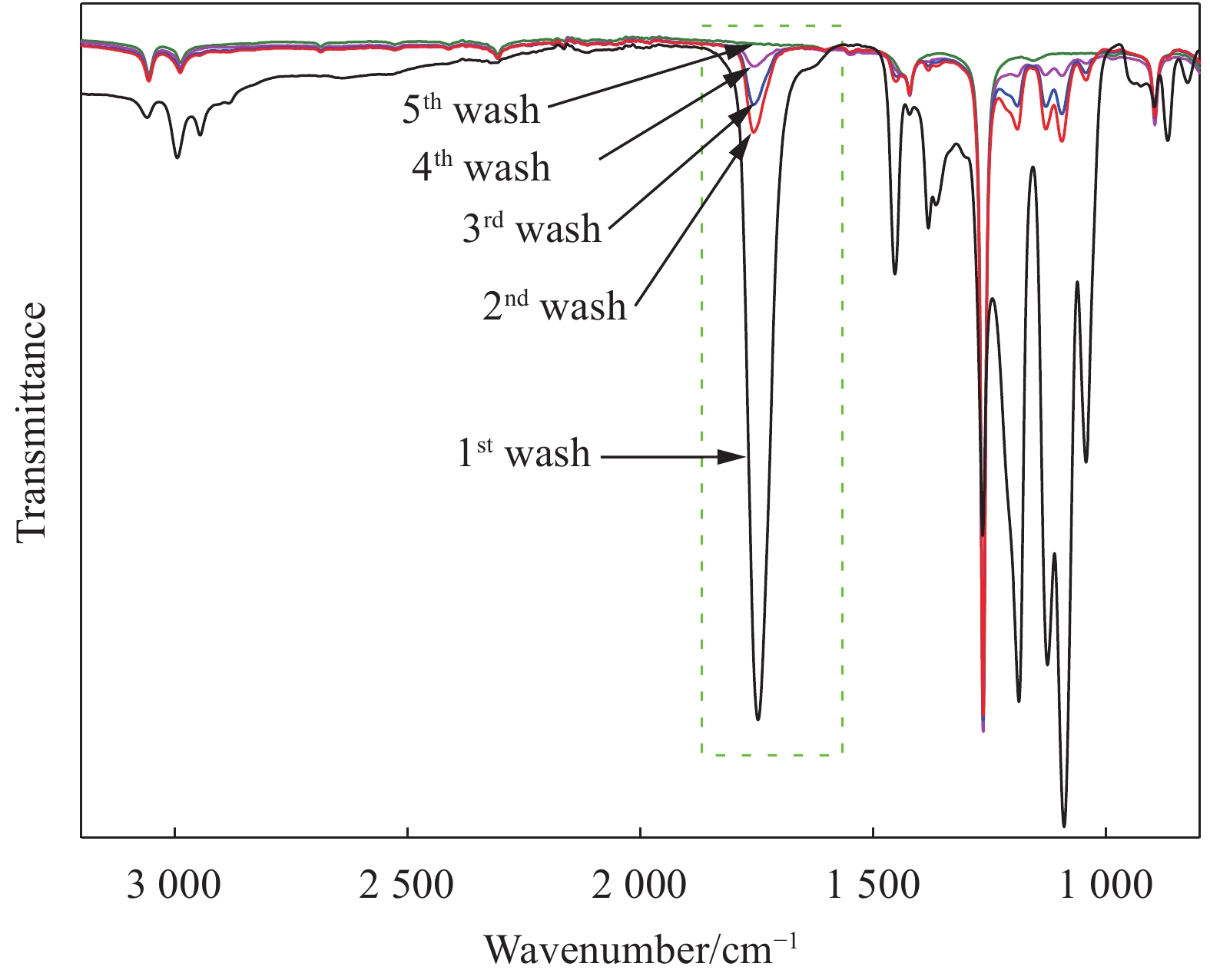

将8 g CaCO3分散到50 mL二氧六环溶液中,加入2 g乳酸低聚物,得到的分散液在室温下机械搅拌1 h,然后在80℃和0.09 MPa真空度的条件下保持20 min,除去溶剂。此后每升温10℃,保持3 min,直到140℃,反应20 min。反应结束后,用二氯甲烷反复洗涤反应产物,直至最后一次洗涤残液的红外曲线中羰基特征峰完全消失,表明完全去除了游离的乳酸低聚物,残液的红外曲线如图1所示。最后,产物在40℃条件下真空干燥4 h,制得g-CaCO3。制备原理如图2所示,乳酸低聚物分子中的羧基基团可与CaCO3表面的钙离子形成羧酸钙沉淀,从而附着在CaCO3表面,而另一端的烷基链与PLA完全相容,并且与PLA链发生缠结,从而可以使CaCO3更好的分散。

1.4 CaCO3/PLA及g-CaCO3/PLA复合材料的制备

将PLA颗粒在真空烘箱中于50℃干燥24 h后加入二氯甲烷溶液中,剧烈搅拌至溶解均匀。按表1中的配比称取CaCO3和g-CaCO3研磨后加入上述混合液中。将混合液机械搅拌和超声处理后浇铸成膜,蒸发去除溶剂,样品在60℃条件下真空干燥24 h。最后,在175℃和0.25M Pa的条件下将复合材料热压,时间5 min,淬火冷却后制得尺寸为75 mm×6 mm×0.3 mm的哑铃型CaCO3/PLA及g-CaCO3/PLA复合材料样条。

表 1 聚乳酸(PLA)基复合材料的组分Table 1. Component of polylactic acid (PLA) matrix compositesSample number Mass fraction/wt% PLA g-CaCO3 CaCO3 5% CaCO3/PLA 95 — 5 Pure PLA 100 0 — 2.5% g-CaCO3/PLA 97.5 2.5 — 5% g-CaCO3/PLA 95 5 — 10% g-CaCO3/PLA 90 10 — 20% g-CaCO3/PLA 80 20 — 30% g-CaCO3/PLA 70 30 — 1.5 测试与表征

采用PerkinElmer SpectrumⅡ型(珀金埃尔默仪器有限公司)傅里叶变换红外光谱仪采集红外光谱。扫描范围为4000~400 cm−1。

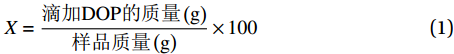

称取1.00 g CaCO3或g-CaCO3置于玻璃板上,滴加DOP(邻苯二甲酸二辛酯)的同时用调刀连续翻动研磨,粉末呈粘稠团状后停止滴加[13]。吸油值(g/100 g)以下式计算:

X=滴加DOP的质量(g)样品质量(g)×100 (1) 用S-4800型(日本日立公司)场发射扫描电子显微镜观察热压后PLA基复合材料的断面。断面经喷金后进行形貌观察。

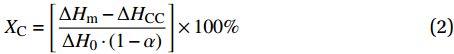

采用204 F1型(德国NETZSCH公司)差示扫描量热仪(DSC)研究PLA及g-CaCO3/PLA复合材料在N2环境中的结晶行为。所有样品从20℃升温至200℃保持2 min以消除热历史,再降至20℃保持2 min并再次升温至200℃。加热和冷却速率均为10℃/min,记录降温与二次升温过程曲线。样品的结晶度根据下式计算:

XC=[ΔHm−ΔHCCΔH0⋅(1−α)]×100% (2) 其中:ΔHm为熔融焓;ΔHCC为冷结晶焓;

ΔH0 为理想熔融焓值(93.0 J/g);α 为PLA复合材料中g-CaCO3的含量。根据拉伸强度测试标准GB/T 1040—2006[14],采用H5K-S型(英国亨斯菲尔德公司)万能电子试验机进行拉伸测试,加载速率为10 mm/min。

采用HAAKE-MARS 60型流变仪(美国Thermo)测试流变性能,测试温度175℃,平行板直径为25 mm,间隔1 mm,频率扫描在应变为1%的条件下进行,角频率范围为0.06~100 rad/s。

采用UV-3600型(日本岛津公司)紫外-可见-近红外分光光度计在250~800 nm的波长范围内对热压后片状样品的透光率进行评价。

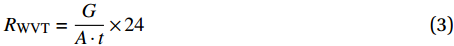

采用YG601H型电脑型织物透湿仪(宁波纺织仪器)研究薄膜的水蒸气阻隔性能。在38℃、相对湿度90%条件下测量。水蒸气透过率RWVT(g/m2/d)的计算方式如下:

RWVT=GA⋅t×24 (3) 其中:G为透湿杯的质量变化(g);A为测试面积(0.00283 m2);t为测试时间(h)。

2. 结果与讨论

2.1 g-CaCO3的改性效果评价

CaCO3、g-CaCO3和乳酸低聚物的FTIR图谱如图3所示。CaCO3在711、873和1406 cm−1处有三个特征峰,分别对应于C—O—C、CO32−和C—O[15]。改性后,在1765 cm−1处出现了新的吸收带,是CaCO3表面接枝的乳酸低聚物的羰基峰(C=O)[16]。结果表明,乳酸低聚物成功接枝在CaCO3的表面。

吸油值对CaCO3的质量和性能有直接的影响,吸油值越低,CaCO3表面的亲油性越好。如图4所示,g-CaCO3的吸油值为18.0 (g/100g),与未改性CaCO3相比,吸油值降低了45%,这是因为用乳酸低聚物对CaCO3进行改性后,降低了CaCO3的表面能,堆积密度降低,粒子间的间隙减小,从而粉体的吸油量也减小。通过对比改性前后CaCO3的吸油值,说明乳酸低聚物对CaCO3的改性是有效的。

图5中,将CaCO3和g-CaCO3分别分散在二氯甲烷中。由于CaCO3具有较高的表面能,外加自重,很快形成聚集并沉淀在底部,10 min后混合液的上层接近澄清。但g-CaCO3保持良好的分散和稳定性,证实g-CaCO3的确具有亲油性表面。

2.2 g-CaCO3/PLA复合材料的断面形貌

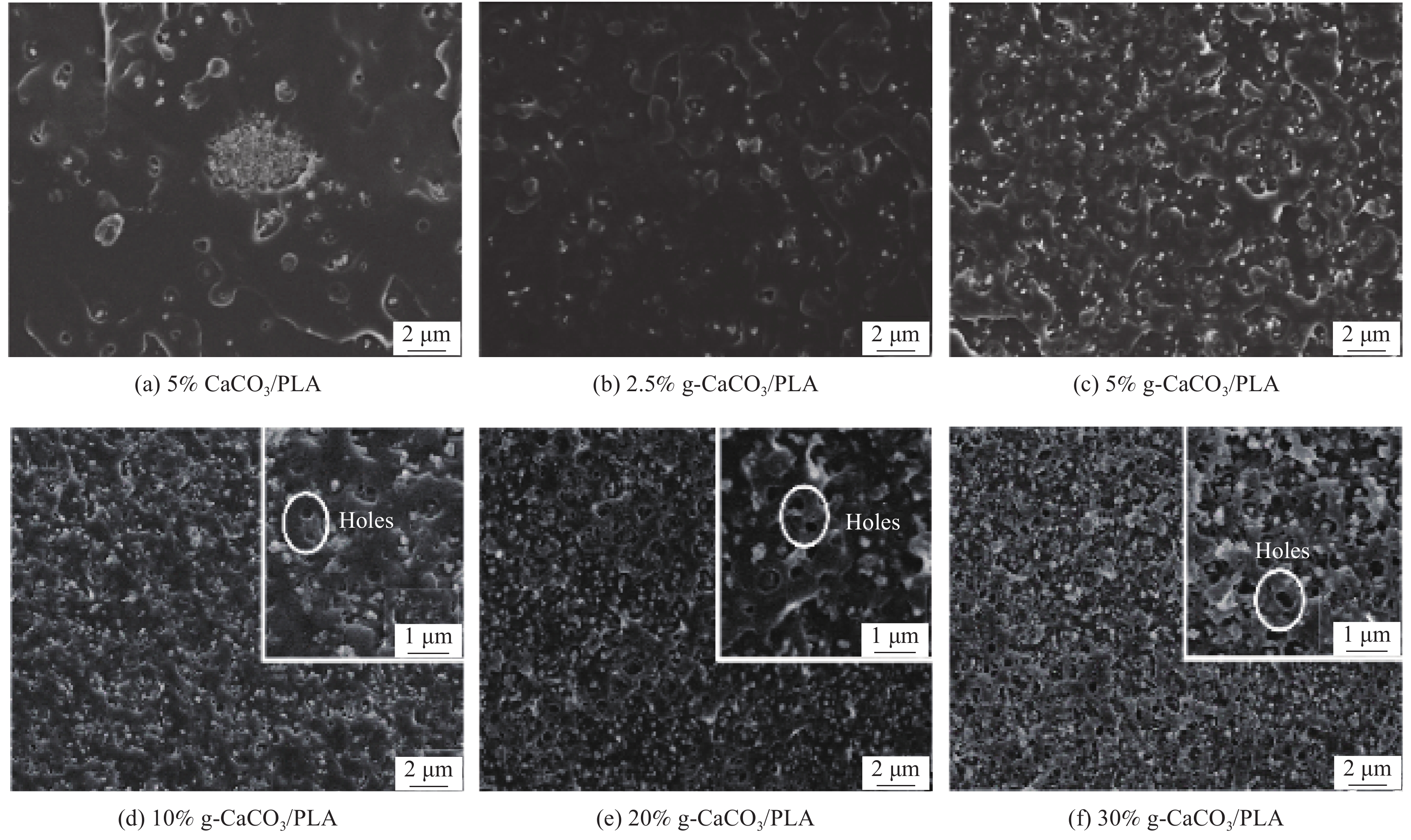

图6是CaCO3/PLA及g-CaCO3/PLA复合材料的SEM图像。所有材料的断面均表现出脆性断裂,观察到的白色颗粒是CaCO3。由图6(a)可见,CaCO3在PLA基体中分散性很差,呈现大尺寸聚集,严重的地破坏了复合材料的结构。由图6(b)~6(f)可知,g-CaCO3填充到PLA基体中分散的更均匀,团聚现象减弱,颗粒较小,说明乳酸低聚物改善了CaCO3与PLA之间的相容性,促进了CaCO3的分散。进一步增加g-CaCO3的添加量,复合材料断面变得粗糙,可观察到g-CaCO3在复合材料断裂时脱离基体留下的孔洞,这表明少量的g-CaCO3可以与PLA基体良好结合,超过一定限度后,g-CaCO3仍然会从PLA基体中脱离[17]。

2.3 g-CaCO3/PLA复合材料的结晶性能

图7为纯PLA及g-CaCO3/PLA复合材料DSC曲线。图7(a)所示的所有降温曲线中没有出现结晶峰,原因是PLA结晶速率较慢,添加g-CaCO3对PLA结晶性能的改善不够明显,所有样品在10℃/min或更高的冷却速率下都无法结晶[18-19]。通过分析图7(b)所示的二次升温曲线及对应的相关数据,发现g-CaCO3对PLA的玻璃化转变温度Tg无明显影响,冷结晶温度Tcc随g-CaCO3添加量的增加而逐渐降低,这是由于g-CaCO3起到成核剂的作用,改善了PLA的结晶能力,使其可以在较低的温度下结晶[20-22]。同时,由于g-CaCO3的加入,模糊的双熔融峰变得更容易辨别,并且随着g-CaCO3添加量的增加,处于较高温度的肩峰逐渐增强,进一步转化为主峰,这是由于PLA中较无序和亚稳的α′型晶体转变为更完善的α晶体[23]。此外,所有复合材料的Xc均高于纯PLA,且随g-CaCO3添加量的增加而增加,由于g-CaCO3在PLA基质中作为异相成核剂,可以有效促进晶核的形成,有助于提高PLA的结晶度和结晶速率,表2列出了所有的特征温度和结晶度。

表 2 纯PLA和g-CaCO3/PLA复合材料DSC二次升温曲线对应的数据Table 2. DSC data of pure PLA and g-CaCO3/PLA composites during the second heating scanSample number Tg/℃ Tcc/℃ Tm1/℃ Tm2/℃ ∆Hcc/(J·g-1) ∆Hm/(J·g-1) Xc/% Pure PLA 61.0 122.8 165.3 169.7 35.9 38.5 2.8 2.5% g-CaCO3/PLA 61.2 120.7 163.7 169.7 35.3 38.1 3.1 5% g-CaCO3/PLA 61.4 117.1 163.7 169.6 33.7 37.0 3.7 10% g-CaCO3/PLA 60.9 116.7 162.7 169.1 29.2 33.9 5.6 20% g-CaCO3/PLA 58.7 114.2 162.4 169.1 27.6 32.7 6.9 30% g-CaCO3/PLA 60.7 113.7 161.9 168.8 21.3 26.0 7.2 Notes:Tg is glass transition temperature; Tcc is cold crystallization temperature; Tm1 and Tm2 are the melting temperature; ΔHcc is the enthalpy of cold crystallization; ΔHm is the enthalpy of melting; Xc is the crystallization. 2.4 g-CaCO3/PLA复合材料的拉伸性能

图8为5% CaCO3/PLA、纯PLA和不同填料含量的g-CaCO3/PLA复合材料的拉伸性能。当填料含量为5wt%时,CaCO3导致PLA的拉伸强度和断裂延伸率降低,g-CaCO3/PLA复合材料的拉伸强度比CaCO3/PLA复合材料高50%。因此乳酸低聚物的改性有利于CaCO3在PLA中的分散,从而使得力学性能得到一定程度的提高[24]。

与纯PLA相比,随着g-CaCO3添加量的增加,g-CaCO3/PLA复合材料的拉伸强度和断裂延伸率呈先上升后下降的趋势。当添加量达到5wt%时,拉伸强度达到峰值,比纯PLA高20%。当添加10wt%的g-CaCO3时,拉伸强度仍比纯PLA高出13%。这是因为乳酸低聚物充当CaCO3与PLA间的桥梁,提高了界面相互作用。将g-CaCO3混入PLA基体中,当复合材料受外力作用时,应力可以从分子链传递到填料中,材料受力更加均匀。

2.5 g-CaCO3/PLA复合材料的流变性能

复合材料的熔融流变对填料与基体的特性和相互作用等方面表现出极强的敏感性。因此,研究复合材料的流变性能对于了解两相之间的相互作用以及复合材料的熔体加工性能具有重要意义。

从图9(a)可以看到纯PLA和所有复合材料的复数黏度(η*)在高频区均表现出“剪切变稀”行为,并且所有复合材料的黏度随着g-CaCO3添加量增加而逐渐增大。这是由于g-CaCO3和PLA较强的相互作用阻碍了聚合物的流动,从而获得更高的黏度[25]。

如图9(b)所示,纯PLA的储能模量(G′)高度遵循均聚物的终端行为[26],而复合材料的储能模量明显偏离这一行为。这些结果表明在g-CaCO3/PLA复合材料中形成了纳米网络,复合材料发生了从类液相到类固相的行为转变,象征着g-CaCO3的良好分散。

2.6 g-CaCO3/PLA复合材料的阻隔性能

纯PLA及g-CaCO3/PLA复合材料薄膜的光学性能如图10所示。从图10(a)可见,纯PLA呈透明色,由于碳酸钙本身为白色,且对光线有一定的阻隔作用,g-CaCO3添加量越大,PLA薄膜的透明度越低,最终变为白色。图10(b)为薄膜的透光率,PLA在整个波长范围内都是透明的,具有较弱的紫外光屏蔽能力。与纯PLA相比,所有g-CaCO3/PLA复合材料的透光率都比较低,这与视觉外观结果一致。因此,g-CaCO3的加入可提高PLA材料的紫外光阻隔性能,扩大PLA在避光药瓶和食品包装中的应用。

水蒸气透过薄膜时,首先接触并溶解到薄膜中,然后在膜的高分子链间扩散,最后从膜的另一侧解吸[27]。纯PLA及g-CaCO3/PLA复合材料薄膜的水蒸气透过率(RWVT)如图11所示。所有复合材料的RWVT均低于纯PLA。随着g-CaCO3添加量的增加,复合材料的RWVT明显降低,原因是g-CaCO3在PLA基体中具有较好的分散性,且表面与PLA基体完全相容,界面结构致密,延长了水蒸气透过薄膜材料的有效路径,导致水蒸气的扩散更加曲折[28];同时,g-CaCO3起成核剂的作用,提高了PLA复合材料的结晶度,增加了结晶区域的面积[29],使屏障效应更加有效。

3. 结 论

(1) 乳酸低聚物的改性降低了CaCO3的吸油值,促进了CaCO3在聚乳酸(PLA)基体中的分散。改性纳米碳酸钙(g-CaCO3)起成核剂的作用,提高PLA材料的结晶能力。

(2) g-CaCO3/PLA复合材料的拉伸强度和断裂延伸率随g-CaCO3添加量的增加先上升后下降,g-CaCO3的添加量为5wt%时,拉伸强度比5%CaCO3/PLA复合材料高50%,比纯PLA高20%。添加10wt%的g-CaCO3,拉伸强度仍比纯PLA高13%。

(3) g-CaCO3的加入能够提高复合材料的储能模量和复数黏度,改善了PLA材料对紫外可见光和水蒸气的阻隔性能,扩大了PLA材料在更多领域的应用。

-

表 1 聚乳酸(PLA)基复合材料的组分

Table 1 Component of polylactic acid (PLA) matrix composites

Sample number Mass fraction/wt% PLA g-CaCO3 CaCO3 5% CaCO3/PLA 95 — 5 Pure PLA 100 0 — 2.5% g-CaCO3/PLA 97.5 2.5 — 5% g-CaCO3/PLA 95 5 — 10% g-CaCO3/PLA 90 10 — 20% g-CaCO3/PLA 80 20 — 30% g-CaCO3/PLA 70 30 — 表 2 纯PLA和g-CaCO3/PLA复合材料DSC二次升温曲线对应的数据

Table 2 DSC data of pure PLA and g-CaCO3/PLA composites during the second heating scan

Sample number Tg/℃ Tcc/℃ Tm1/℃ Tm2/℃ ∆Hcc/(J·g-1) ∆Hm/(J·g-1) Xc/% Pure PLA 61.0 122.8 165.3 169.7 35.9 38.5 2.8 2.5% g-CaCO3/PLA 61.2 120.7 163.7 169.7 35.3 38.1 3.1 5% g-CaCO3/PLA 61.4 117.1 163.7 169.6 33.7 37.0 3.7 10% g-CaCO3/PLA 60.9 116.7 162.7 169.1 29.2 33.9 5.6 20% g-CaCO3/PLA 58.7 114.2 162.4 169.1 27.6 32.7 6.9 30% g-CaCO3/PLA 60.7 113.7 161.9 168.8 21.3 26.0 7.2 Notes:Tg is glass transition temperature; Tcc is cold crystallization temperature; Tm1 and Tm2 are the melting temperature; ΔHcc is the enthalpy of cold crystallization; ΔHm is the enthalpy of melting; Xc is the crystallization. -

[1] 洪浩群, 刘灏, 张海燕. 甘蔗渣的改性方法对甘蔗渣/聚乳酸复合材料结构与性能的影响[J]. 复合材料学报, 2018, 35(9):2369-2378. HONG Haoqun, LIU Hao, ZHANG Haiyan. Effect of modifying methods of bagasse on structure and properties of bagasse/polylactic acid composites[J]. Acta Materiae Compositae Sinica,2018,35(9):2369-2378(in Chinese).

[2] ZHANG Y, DENG B Y, LIU Q S. Rheology and crystallisation of PLA containing PLA-grafted gsilica[J]. Plastics, Rubber and Composites,2014,43(9):309-314. DOI: 10.1179/1743289814Y.0000000099

[3] 贾仕奎, 朱艳, 王忠, 陈立贵, 付蕾. POE-g-MA对纳米CaCO3/聚乳酸复合材料热及流变性能影响[J]. 复合材料学报, 2017, 34(2):256-262. JIA Shikui, ZHU Yan, WANG Zhong, et al. Influences of POE-g-MA on thermal and rheological properties of nano-CaCO3/PLA composites[J]. Acta Materiae Compositae Sinica,2017,34(2):256-262(in Chinese).

[4] MAHMOODI A, GHODRATI S, KHORASANI M. High-strength, low-permeable, and light-protective composite films based on a hybrid gpigment and biodegradable PLA for food packaging applications[J]. ACS Omega,2019,4(12):14947-14954. DOI: 10.1021/acsomega.9b01731

[5] CHOW W S, LEU Y Y, ISHAK Z A M. Mechanical, thermal and morphological properties of injection molded poly (lactic acid)/calcium carbonate composites[J]. Periodica Polytechnica, Mechanical Engineering,2016,60(1):15-20. DOI: 10.3311/PPme.8319

[6] BOUAKAZ B S, PILLIN I, HABI A, et al. Synergy between fillersin organomontmorillonite/graphene-PLA nanocomposites[J]. Applied Clay Science,2015,116:69-77.

[7] LIANG J Z, ZHOU L, TANG C Y, et al. Crystalline properties of poly (L-lactic acid) composites filled with nanometer calcium carbonate. Composites Part B: Engineering, 2013, 45: 1646-1650.

[8] 王红娟, 容腾, 容敏智, 等. CaCO3增强马来酸化蓖麻油树脂及其泡沫塑料[J]. 复合材料学报, 2014, 31(6):1383-1393. WANG Hongjuan, RONG Teng, RONG Zhimin, et al. CaCO3 reinforced maleated castor oil resin and its foam plastics[J]. Acta Materiae Compositae Sinica,2014,31(6):1383-1393(in Chinese).

[9] LIANG J Z, ZHOU L, TANG C Y, et al. Crystalline properties of poly (L-lactic acid) composites filled with gmeter calcium carbonate[J]. Composites Part B: Engineering,2013,45:1646-1650. DOI: 10.1016/j.compositesb.2012.09.086

[10] KIM D W, LEE J Y, LEE S M, et al. Surface modification of calcium carbonate gparticles by fluorosurfactant[J]. Colloids and Surfaces,2018,536:213-223. DOI: 10.1016/j.colsurfa.2017.05.002

[11] SHIMPI N, MALI A, HANSORA D P, et al. Synthesis and surface modification of calcium carbonate particles using ultrasound cavitation technique[J]. Gscience and Gengineering,2015,3(1):8-12.

[12] YAN S F, YIN J B, YANG Y, et al. Surface-grafted silica linked with L-lactic acid oligomer: A novel nanofiller to improve the performance of biodegradable poly(L-lactide)[J]. Polymer,2007,48:1688-1694. DOI: 10.1016/j.polymer.2007.01.037

[13] 常迎星, 王丹丹, 巩艳萍, 等. 纳米碳酸钙吸油值的研究[J]. 化学试剂, 2019, 41(6):577-580. CHANG Yingxing, WANG Dandan, GONG Yanping, et al. Oil absorption value of nano-calcium carbonate[J]. Huaxue Shiji,2019,41(6):577-580(in Chinese).

[14] 中国国家标准化管理委员会(标准制定单位). 塑料拉伸性能的测定: GB/T 1040—2006[S]. 北京: 中国标准出版社, 2006. Standardization Administration of the People’s Republic of China. Plastics: Determination of tensile properties: GB/T 1040—2006[S], Beijing: China Standards Press, 2006(in Chinese).

[15] SHIRSATH S R, BHANVASE B A, SONAWANE S H, et al. A novel approach for continuous synthesis of calcium carbonate using sequential operation of two sonochemical reactors[J]. Ultrasonics Sonochemistry,2017,35(Pt A):124-133.

[16] TVERDOKHLEBOV S I, BOLBASOV E N, SHESTERIKOV E V, et al. Modification of polylactic acid surface using RF plasma discharge with sputter deposition of a hydroxyapatite target for increased biocompatibility[J]. Applied Surface Science,2015,329:32-39. DOI: 10.1016/j.apsusc.2014.12.127

[17] 高成涛, 谢海波, 郭建兵, 等. 海藻酸盐协效碳酸钙对聚乳酸热性能及断面形貌的影响[J]. 塑料科技, 2019, 47(12):83-88. GAO Chengtao, XIE Haibo, GUO Jianbing, et al. Synergistic effect of alginate blended with calcium carbonate on thermal behavior and morphology of polylactic acid[J]. Plastics Science and Technology,2019,47(12):83-88(in Chinese).

[18] YOKOHARA T, YAMAGUCHI M. Structure and properties for biomass-based polyester blends of PLA and PBS[J]. European Polymer Journal,2008,44(3):677-685. DOI: 10.1016/j.eurpolymj.2008.01.008

[19] MAHDAVI M, YOUSEFZADE O, GARMABI H. A simple method for preparation of microcellular PLA/calcium carbonate gcomposite using super critical nitrogen as a blowing agent: Control of microstructure[J]. Advances in Polymer Technology,2018,37(8):3017-3026. DOI: 10.1002/adv.21972

[20] 袁彩霞, 罗卫华, 袁光明, 等. 增容纳米纤维素/聚乳酸复合材料的制备与性能[J]. 复合材料学报, 2016, 33(12):2718-2724. YUAN Caixia, LUO Weihua, YUAN Guangming, et al. Prepartion and properities of compatobilizad cellulose gcrystal/poly(lactic acid) composites[J]. Acta Materiae Compositae Sinica,2016,33(12):2718-2724(in Chinese).

[21] FRONE A N, PANAITESCU D M, CHIULAN I, et al. The effect of cellulose gfibers on the crystallinity and structure of poly (lactic acid) composites[J]. Journal of Materials Science,2016,51(21):9771-9791. DOI: 10.1007/s10853-016-0212-1

[22] JIANG L, ZHANG J W, WOLCOTT M P. Comparison of polylactide/g-sized calcium carbonate and polylactide/montmorillonite composites: Reinforcing effects and toughening mechanisms[J]. Polymer Testing,2007,48(26):7632-7644.

[23] ZHANG Y C, WU J, WANG B J, et al. Cellulose gfibril-reinforced biodegradable polymer composites obtained via a Pickering emulsion approach[J]. Cellulose,2017,24(8):3313-3322. DOI: 10.1007/s10570-017-1324-8

[24] LI X H, TJONG S C, MENG Y Z, et al. Fabrication and properties of poly (propylene carbonate)/calcium carbonate composites[J]. Journal of Polymer Science, Part B: Polymer Physics,2003,41(15):1806-1813. DOI: 10.1002/polb.10546

[25] DI Y W, IANNACE S, NICOLAIS L. Poly(lactic acid)/organoclay nanocomposites: Thermal, rheological properties and foam processing[J]. Journal of Polymer Science, Part B: Polymer Physics,2005,43(6):689-698.

[26] GONG G, WU J S, LIN Y, et al. Dynamic rheological behavior of isotactic polypropylene filled with nano-calcium carbonate modified by stearic acid coating[J]. Journal of Macromolecular Science, Part B: Physics,2009,48(2):329-343. DOI: 10.1080/00222340802679938

[27] 邰晶磊. 聚乳酸涂布—热压复合纸的制备及其水蒸汽渗透行为的研究[D]. 广州: 华南理工大学, 2014. TAI Jinglei. The preparation of polylactic acid coating-hot pressing composite paper and its water vapor permeability behavior research[D]. Guangzhou: South China University of Technology, 2014(in Chinese).

[28] 宋志勇, 李乃状, 张蕾, 等. 改性二氧化硅对SiO2/PLA复合膜性能的影响[J]. 包装工程, 2020, 41(15):142-148. SONG Zhiyong, LI Naizhuang, ZHANG Lei, et al. Effect of modified silica on properties of SiO2/PLA composite films[J]. Packaging Engineering,2020,41(15):142-148(in Chinese).

[29] KARKHANIS S S, STARK N M, SABO R C, et al. Water vapor and oxygen barrier properties of extrusion-blown poly (lactic acid)/cellulose crystals composite films[J]. Composites Part A: Applied Science and Manufacturing,2018,114:204-221. DOI: 10.1016/j.compositesa.2018.08.025

-

期刊类型引用(4)

1. 罗文倩,何丽秋,黎京鸿,王吉林,李世令,阳鹏,莫淑一,龙飞. 超声辅助法制备片状Ca-Mg复相碳酸盐及其对PBAT复合材料性能的影响. 复合材料学报. 2025(01): 323-335 .  本站查看

本站查看

2. 李玲,胡灿,张靖倩,郑和淇,曾广胜. 聚乳酸/癸二酸二苯基二酰肼的制备及其性能. 包装学报. 2023(01): 55-61 .  百度学术

百度学术

3. 南晶敏,画莉,万沛涵,欧梦,汪波,万茂生. 水性复合改性剂改性重质碳酸钙及其PP复合材料. 工程塑料应用. 2023(07): 135-140 .  百度学术

百度学术

4. 吴海华,胡正浪,李雨恬,钱鹏,刘力,周建新. 铁镍合金/聚乳酸复合材料的熔融沉积成形制备及其电磁吸收性能和力学性能. 复合材料学报. 2022(01): 158-168 .  本站查看

本站查看

其他类型引用(2)

-

下载:

下载: