Effects of temperature and strain rate on hardening behavior of carbon fiber reinforced polyether ether ketone composite under shear load

-

摘要: 碳纤维增强聚醚醚酮(CF/PEEK)是一种高性能热塑性复合材料,在航空航天领域有着广阔的应用前景。由于PEEK具有温度和应变率相关的非线性行为,导致CF/PEEK复合材料在基体主导的面内剪切方向也有类似的力学行为。本文在不同的温度和应变率下对CF/PEEK复合材料试件进行了剪切实验,将应力-应变曲线分为线性与非线性部分,发现温度和应变率对CF/PEEK复合材料的屈服应力有着较大的影响。随着温度从20℃升高到130℃屈服应力下降了66%左右,下降速度先快后慢,随着应变率从10−5 s−1提高到0.1 s−1屈服应力均匀增大了35%左右。将所得规律拟合背应力经验公式,修改了经典的热塑性复合材料本构模型的屈服函数。并编写VUMAT用户子程序对CF/PEEK复合材料剪切实验进行数值分析,与实验结果对比发现非线性阶段的剪切应力-应变关系及屈服点的剪切应力吻合良好,但是由于纤维和PEEK基体的浸润性较差,导致CF/PEEK复合材料内部存在孔隙缺陷,影响了CF/PEEK复合材料的初始剪切弹性行为,导致加载初始阶段存在偏差。Abstract: Carbon fiber reinforced polyether ether ketone (CF/PEEK) is a high-performance thermoplastic composite with broad application in aerospace. PEEK has a non-linear behavior related to temperature and strain rate, which makes CF/PEEK have similar mechanical behavior in plane shear direction. In this paper, shear experiments were carried out on CF/PEEK specimens at different temperatures and strain rates. The stress-strain curve was divided into linear and non-linear parts. It is found that temperature and strain rate have a greater influence on the yield stress of CF/PEEK. With the increase of temperature from 20℃ to 130℃, the yield stress decreases by about 66%, and the rate of decrease is fast and then slow. With the increase of strain rate from 10−5 s−1 to 0.1 s−1, the yield stress increases uniformly by about 35%. This phenomenon is fitted into an empirical formula of back stress, and the yield function of the classic elastoplastic constitutive model of thermoplastic composites is modified, which is applied in VUMAT to analysis the shear behavior of CF/PEEK. Compared with the experimental results, it is found that the yield point and the nonlinear stage are in good agreement. However, due to the poor infiltration of fibers and PEEK matrix, CF/PEEK composites have porosity defects inside, which affectes the initial elastic behavior of CF/PEEK composites and resultes in the deviation in the initial loading stage.

-

Keywords:

- CF/PEEK /

- non-linear behavior /

- strengthening behavior /

- temperature /

- strain rate

-

碳纤维增强聚醚醚酮(CF/PEEK)是一种高性能热塑性复合材料,与传统的碳纤维增强环氧树脂热固性复合材料相比,具有高温力学性能好、热稳定性好、抗冲击、易修复、易存储及成型效率高等特点。因此CF/PEEK复合材料在航空航天领域有着广泛的应用前景[1-4]。然而,区别于热固性树脂,PEEK是一种半结晶聚合物,在玻璃化转变温度(约143℃)以下时为玻璃态,在单轴加载下,表现出与温度和应变率相关的非线性强化行为:首先进入弹性变形阶段,然后随着变形区域变形增大,PEEK的结晶部分开始产生滑移达到屈服阶段,最后PEEK进入非线性变形阶段直至失效。但是由于PEEK的结晶度、应变率和温度等因素对结晶部分滑移、蠕变行为及损伤演化的影响,导致PEEK的屈服点上下波动。借鉴金属的相关研究,定义由于外界因素改变,导致PEEK屈服应力增大这种现象为材料的强化行为[5-8]。由于PEEK这种材料特性,导致CF/PEEK复合材料在基体主导的面内剪切方向上也存在类似的非线性强化行为,这给结构设计带来了新的挑战[9-11]。因此,有必要深入研究温度和应变率对CF/PEEK复合材料的非线性强化行为的影响。

关于应变率和温度对CF/PEEK复合材料弹性阶段材料行为的影响已有了相关研究。Touchard等[12]利用X射线、微应变计、激光散斑等观察手段,对不同铺层方式的CF/PEEK复合材料在不同温度下的剪切件进行观察,发现在低温时纵向弹性模量变化不大,在玻璃化转变温度时纵向弹性模量变化很快。温度与模量的关系用双曲拟合函数描述,并且高温引起材料流动加快,导致强度降低。Lagattu等[13]对PEEK树脂进行了室温下多应变率的拉伸试验,发现应变率与PEEK的纵向弹性模量呈线性关系,随着应变率增加PEEK中大分子取向流动加快,导致弹性模量略微增大。Vieille等[14]开展了120℃和室温下CF/聚苯硫醚(PPS)复合材料的拉伸、压缩和弯曲实验,试验结果表明温度对CF/PPS复合材料的拉伸和压缩弹性模量影响不大,温度升高导致拉伸模量降低了11%,压缩强度降低了25%,弯曲强度降低了31%。

应变率和温度对CF/PEEK复合材料非线性行为的影响规律也有了一定的研究基础。Barba等[15]研究了半结晶聚合物的强化行为,发现在玻璃态材料进入塑性变形时,半结晶聚合物存在滑移现象导致了强化效应,使材料屈服应力增大。Sun[16]建立了一个CF/PEEK复合材料的单参数流动法则,将塑性势函数视为与剪应力相关的单参数方程,近似描述了温度和应变率对CF/PEEK复合材料的非线性过程的影响,但未考虑PEEK的应变强化效应。Wang等[17]对热塑性复合材料进行了不同温度下的加卸载剪切试验,并通过修改Sun的单参数塑性势函数建立了损伤-塑性模型,但仍未考虑PEEK的强化行为,导致理论计算结果与实验结果存在偏差。

本文根据ASTM-D5379标准[18]对CF/PEEK复合材料标准件进行不同温度和应变率下的剪切实验,分别研究了应变率和温度对CF/PEEK强化行为的影响,将所得规律拟合成经验公式对Sun[16]的模型进行了修改,并通过VUMAT用户子程序实现CF/PEEK复合材料的数值分析。

1. 实验材料及方法

1.1 原材料

本文采用的材料为君华特塑公司提供的铺层为[0]16的碳纤维增强聚醚醚酮(CF/PEEK)复合材料。CF质量分数为66wt%,PEEK结晶度为35%,室温下力学性能见表1。根据ASTM-D5379标准[18],采用辽宁万临科技有限公司生产的WL2030BA水刀切割机将CF/PEEK板材切成剪切标准件。

表 1 碳纤维增强聚醚醚酮(CF/PEEK)复合材料力学性能Table 1. Properties of carbon fiber reinforced polyether ether ketone (CF/PEEK) compositeProperty Value Longitudinal modulus E1/GPa 130.00 Transverse moduli E2, E3/GPa 7.86 Transverse shear modulus G23/GPa 3.63 Axial shear moduli G12, G13/GPa 5.86 Poisson’s ratio in 23 direction ν23 0.51 Poisson’s ratios in 12 and 13 directions ν12, ν13 0.28 1.2 实验方法

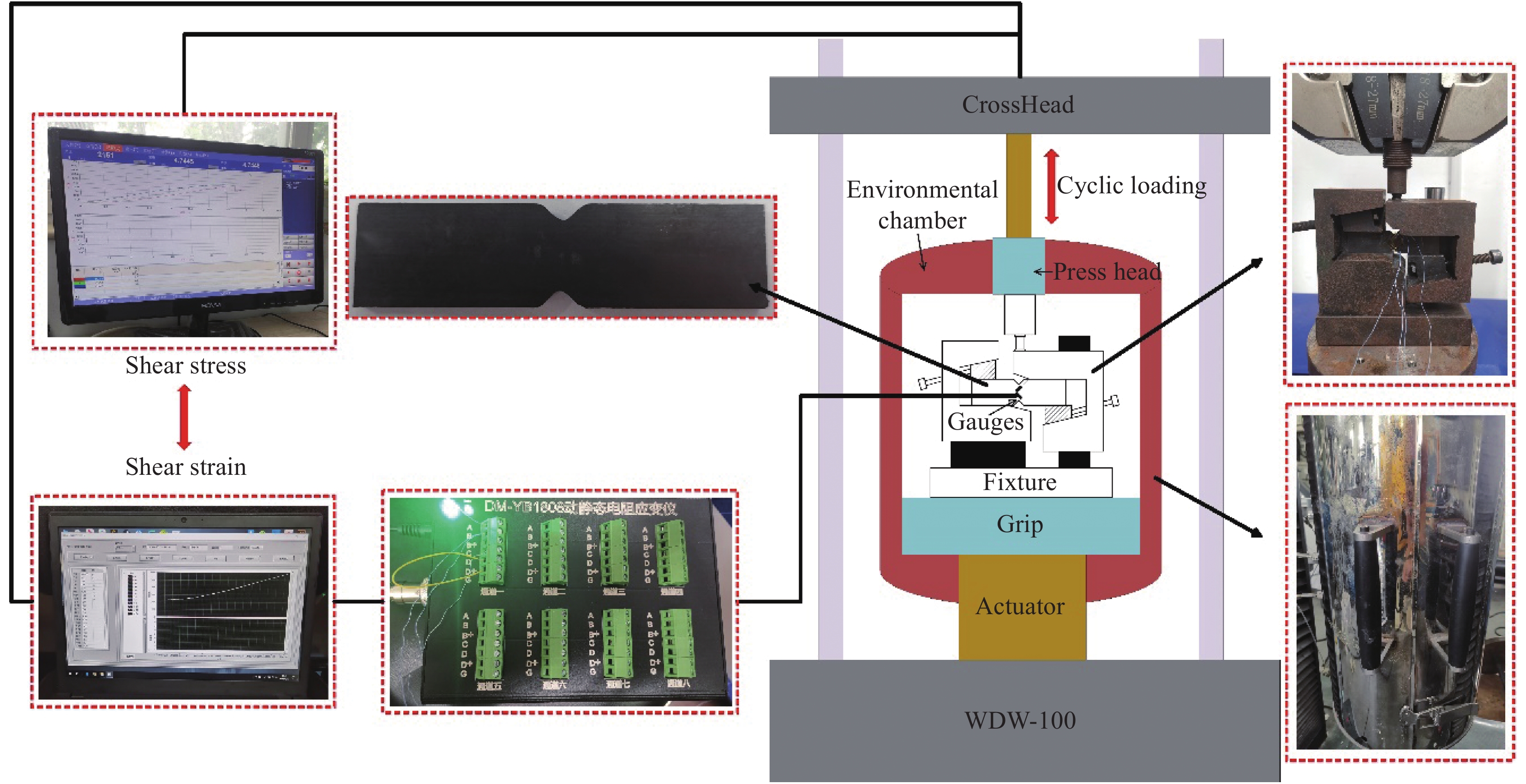

根据WEEKS等[19]的理论模型,可采用面内剪应力表示CF/PEEK复合材料平面应力状态下的屈服函数。因此,为了研究温度和应变率对CF/PEEK复合材料屈服和强化行为的影响,参考WEEKS等[19]的实验数据,取三组温度(20℃、80℃、130℃)和三组应变率(1.0×10−5 s−1、1.0×10−3 s−1、0.1 s−1)设计全因素剪切实验。如图1所示,将两个高温应变片分别安装在剪切标准件的±45°方向,并以半桥方式连接,其显示的数值为剪应变ε12=|ε+45°|+|ε−45°|。采用上海协强仪器制造有限公司生产的配有环境箱的CTM-8000万能试验机进行剪切加载实验,将采集所得剪应变实时反馈给试验机,控制加载速率使应变率恒定。曲线出现明显屈服现象后继续加载,直到载荷突然下降时,停止加载。假设在特定应变率和温度下,本文研究的CF/PEEK复合材料的初始屈服应力是确定的,定义为线性阶段和非线性阶段分界点的应力值,记为σs。用背应力σB表示材料强化的程度,即两种不同温度和应变率下屈服应力的差值。

2. 结果与讨论

2.1 温度对CF/PEEK复合材料强化行为的影响

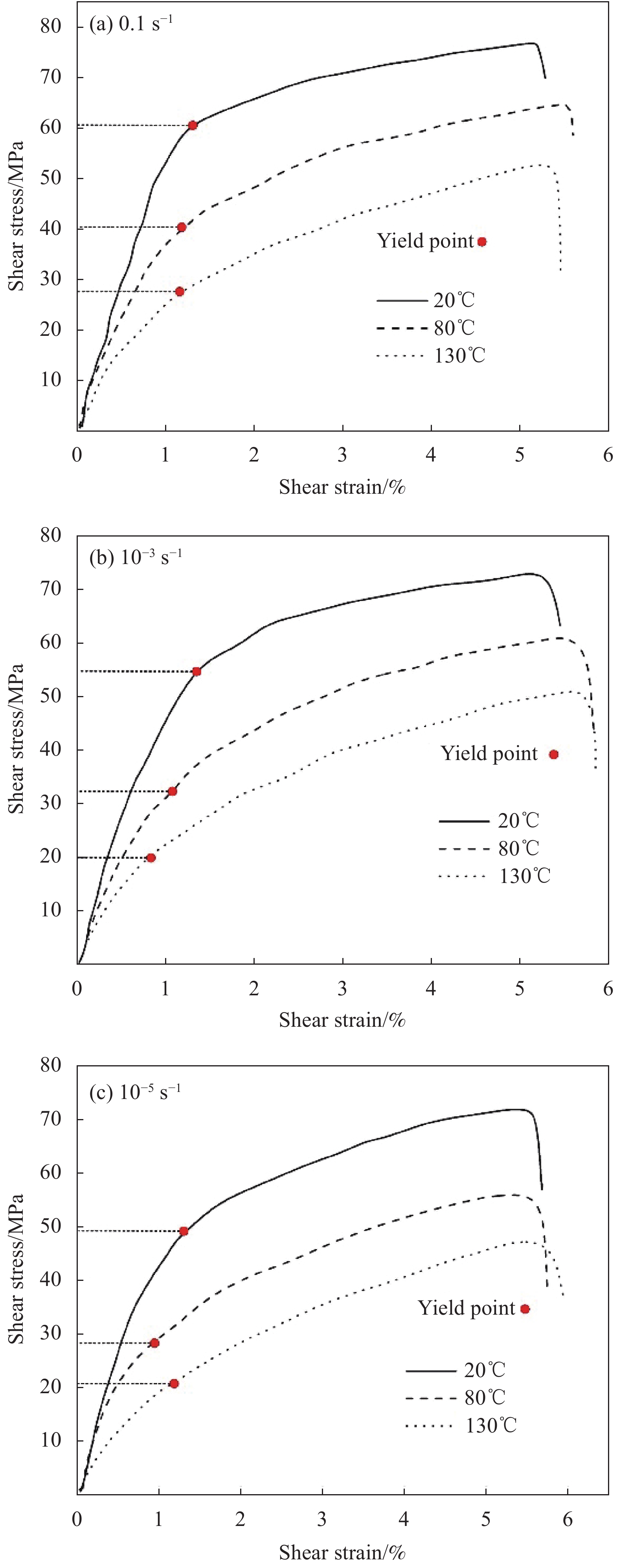

图2为CF/PEEK复合材料在不同应变率及温度下的应力-应变曲线。可见,CF/PEEK复合材料在面内剪切载荷下存在明显的非线性行为,可以近似表示为线弹性关系和指数非线性关系之和,与文献[19]结论符合。可以看到,温度和应变率共同影响了CF/PEEK复合材料线弹性部分的模量、指数非线性部分的相关系数。这两方面已经有了相关的研究[17-19]。

但是,WEEKS等[19]和WANG等[17]忽略了温度和应变率对CF/PEEK复合材料强化行为的影响,近似认为线弹性和非线性阶段的分界点是固定的。从实验结果来看,这显然是不合理的。由于CF和PEEK浸润性较差,CF/PEEK复合材料内部存在孔隙缺陷,导致初始剪切应力-应变曲线不完全是线性的[20]。定义剪切应力对应变的二阶导数下降值达到1.5时为材料线性和非线性的分界点,此时的应力即为屈服应力。从图2可以看到温度对CF/PEEK复合材料的强化行为有较大的影响,在20℃屈服应力大约在50~60 MPa,升温到80℃时屈服应力极具下降45%左右,当温度达到130℃(玻璃化转变温度附近)时屈服应力下降23%左右,随着温度的升高,屈服应力下降更缓慢。总体表现为,随着温度从20℃升高到130℃屈服应力下降了66%左右,下降速度先快后慢。

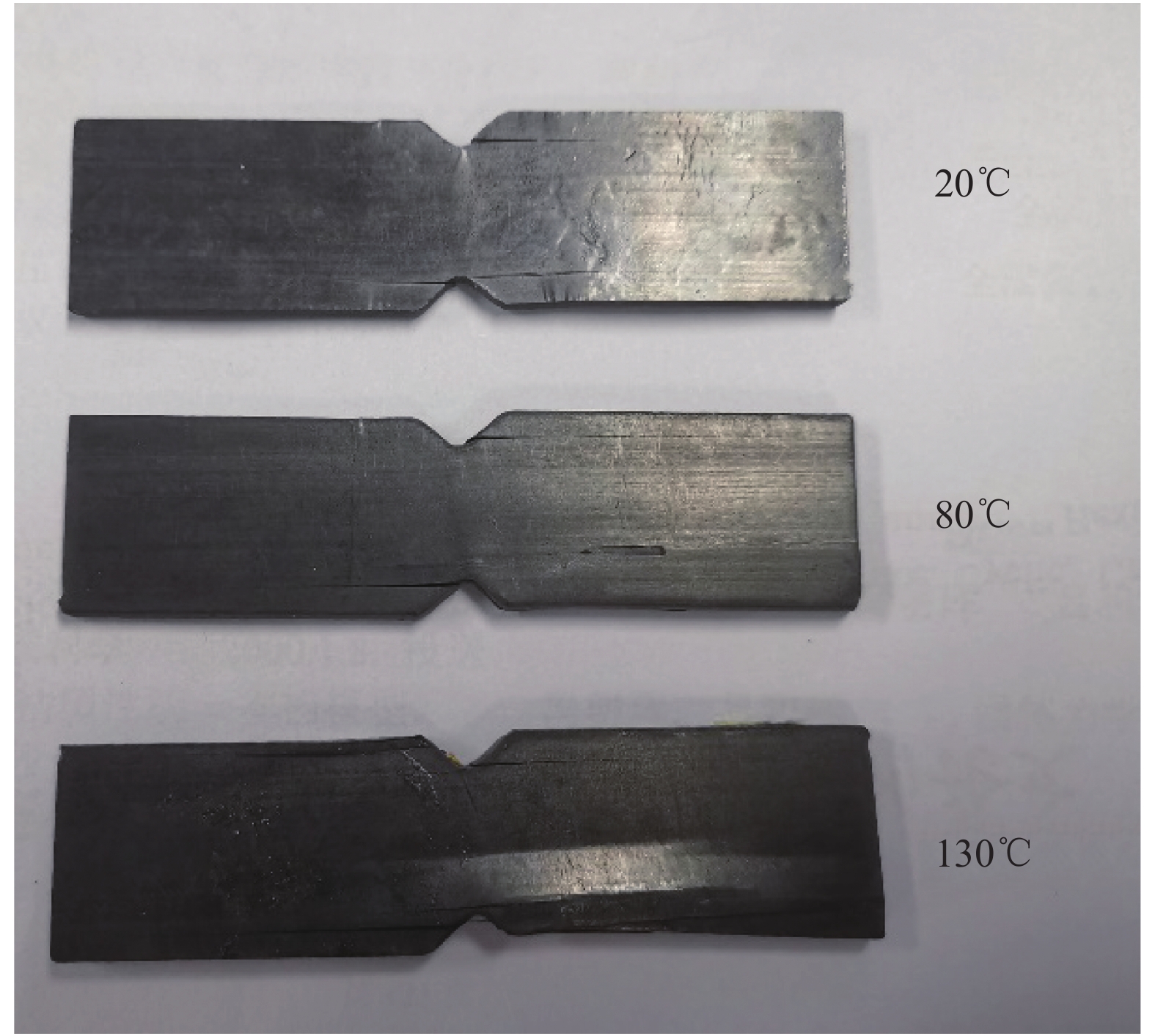

这是由于PEEK是一种半结晶聚合物,其结晶和非晶相随机分布,随着温度升高,PEEK树脂流动性增强,模量和变形抗力降低,玻璃化转变温度以上PEEK树脂表现为高弹态,熔化温度以上PEEK树脂表现为黏流态。PEEK树脂大分子间及PEEK树脂与CF间的摩擦力也随之降低,使变形更容易。另外,随着温度的升高,聚合物的能量也增加,当能量增加到足以克服晶格以某种方式移动所需的势能时,半晶体聚合物就处于活动状态。因此,聚合物的体积膨胀增大,半结晶聚合物中形成了自由空间,使CF/PEEK复合材料更容易塑性变形[21-24]。如图3所示,这两种特性使CF/PEEK复合材料在宏观上表现为随着温度升高,剪切区域越大,变形越容易,材料变得更“软”。

2.2 应变率对CF/PEEK复合材料强化行为的影响

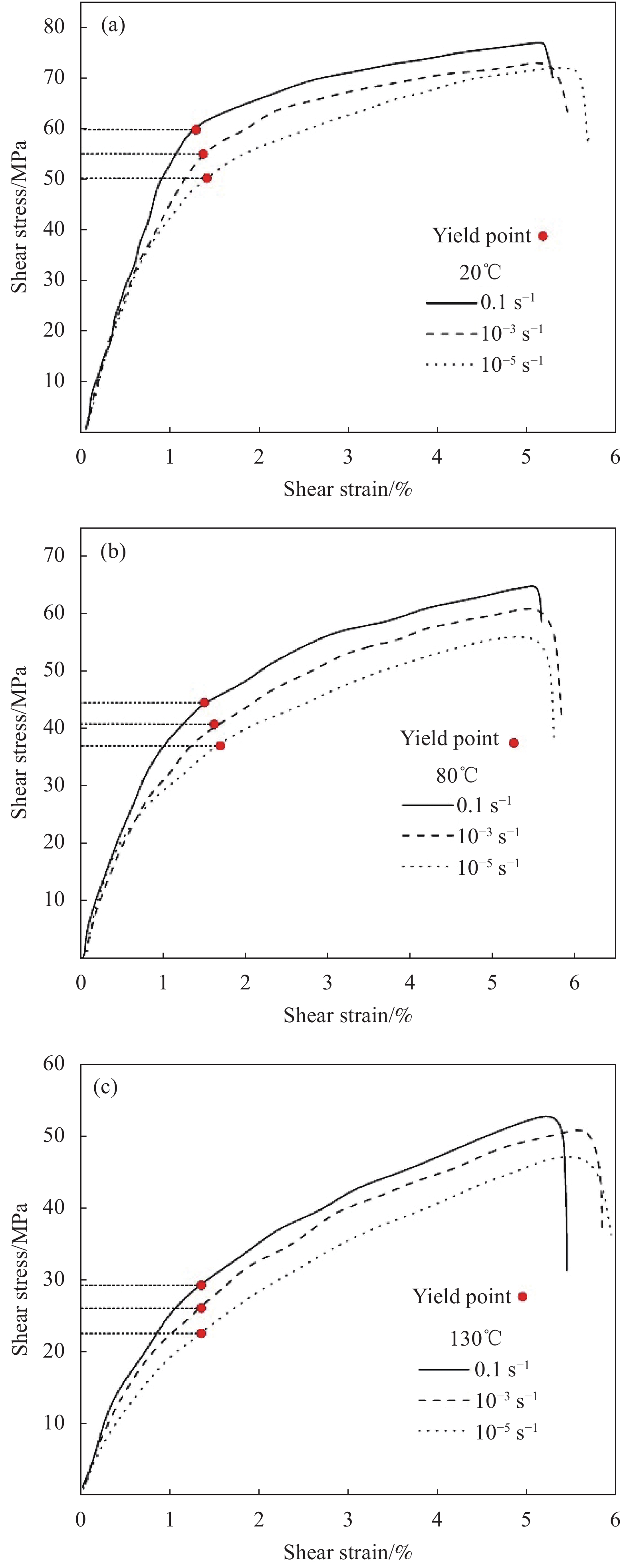

图4为CF/PEEK复合材料在不同应变率及温度下的应力-应变曲线。可以看出,CF/PEEK复合材料与很多塑性材料相似[21-23],有着较强的应变率效应。主要体现在随着应变率的升高,CF/PEEK复合材料的屈服应力提高。在20℃时,应变率从10−5 s−1提高到0.1 s−1,屈服应力均匀提高20%左右,在80℃时,应变率从10−5 s−1提高到0.1 s−1,屈服应力均匀提高35%左右,在130℃时,应变率从10−5 s−1提高到0.1 s−1,屈服应力均匀提高43%左右。总体表现为,随着应变率从10−5 s−1升高到0.1 s−1,屈服应力均匀提高了35%左右。

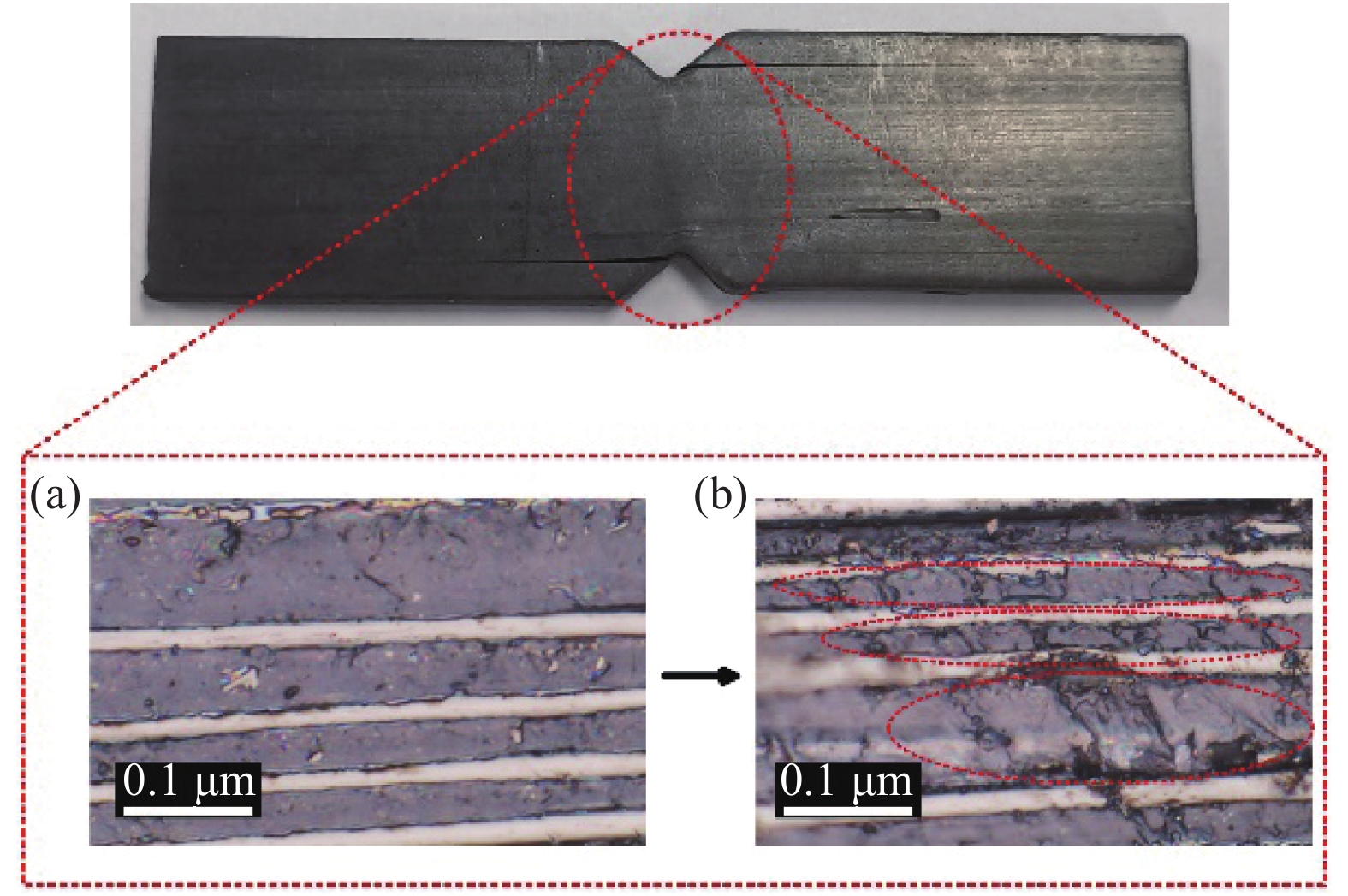

可见CF/PEEK复合材料的屈服强度与应变率正相关。这种现象主要是由于PEEK树脂由线性聚合物链组成,在高温下存在类似假塑性流体的特性,较大的应变率使分子链取向加速,树脂内部分子间及树脂与纤维间的摩擦力增大,加大了变形阻力。另外,PEEK树脂有着应变率相关的蠕变行为,其结晶部分在塑性变形后由于应力松弛会产生反向滑移蠕变,而由于CF/PEEK复合材料中的纤维限制了PEEK树脂晶界的移动,导致在较大的应变率下CF/PEEK复合材料中存在与变形方向相反的残余应力,使变形更加困难。CF/PEEK复合材料的这两种材料特性在宏观上表现为随着应变率的增大屈服强度的提高[24-26]。如图5所示,将剪切试件沿剪切平面用水刀切开,对比剪切试验前后,观察到了CF/PEEK复合材料试件中的滑移区域。

2.3 经验公式拟合与数值仿真

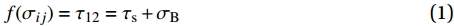

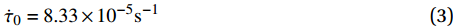

基于WEEKS等[19]针对CF/PEEK复合材料的非线性本构模型,修改屈服函数,引入背应力σB。将平面应力状态下,CF/PEEK的屈服函数表示为

f(σij)=τ12=τs+σB (1) 其中,τs是SUN的模型中的屈服应力。基于本文的实验结果,将背应力σB拟合为

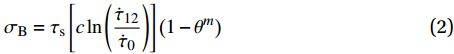

σB=τs[cln(˙τ12˙τ0)](1−θm) (2) 其中:c=0.082;m=0.891;

˙τ12 是应变率。˙τ0=8.33×10−5s−1 (3) θ=TTg−T (4) 其中:T是加载温度;Tg是PEEK的玻璃化转变温度,取Tg=143℃[27]。

从前文的分析可知,升高温度增加PEEK树脂内的能量克服晶格能,从而使屈服应力降低,而提高应变率只是增加了基体与纤维间的摩擦力和PEEK树脂结晶部分晶界的变形抗力,从而导致屈服应力提高。因此,温度直接影响了PEEK树脂的屈服行为,而应变率只是间接阻碍了PEEK的剪切变形过程。本文拟合的背应力公式很好地反映了这种力学行为的机制,从拟合后的表达式可以看出,应变率对背应力的影响是对数关系,而温度对背应力的影响是指数关系,即背应力受温度的影响更大。且在玻璃化转变温度以下时,温度对背应力的影响越来越大,应变率对背应力的影响近似为线性,这与理论分析和实验数据吻合较好。

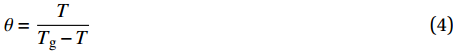

将修改后的屈服函数代入WEEKS等[19]的CF/PEEK复合材料的非线性本构模型中,并嵌入ABAQUS定义材料性能的用户子程序VUMAT中,通过数值手段分析CF/PEEK复合材料的在80℃、0.1 s−1和20℃、10−5 s−1下的面内剪切行为。不考虑夹具的变形,将夹具简化为对试件左侧上下面的约束条件,根据实验所得加载规律,对右侧上表面施加1.1 mm/s和1.1×10−4 mm/s的速度载荷,对剪切区域进行精细网格划分,共有12 080个C3D8R单元。CF/PEEK复合材料单向板力学性能见表1,ABAQUS定义材料性能用户子程序VUMAT的算法逻辑及剪切试件模型如图6所示。

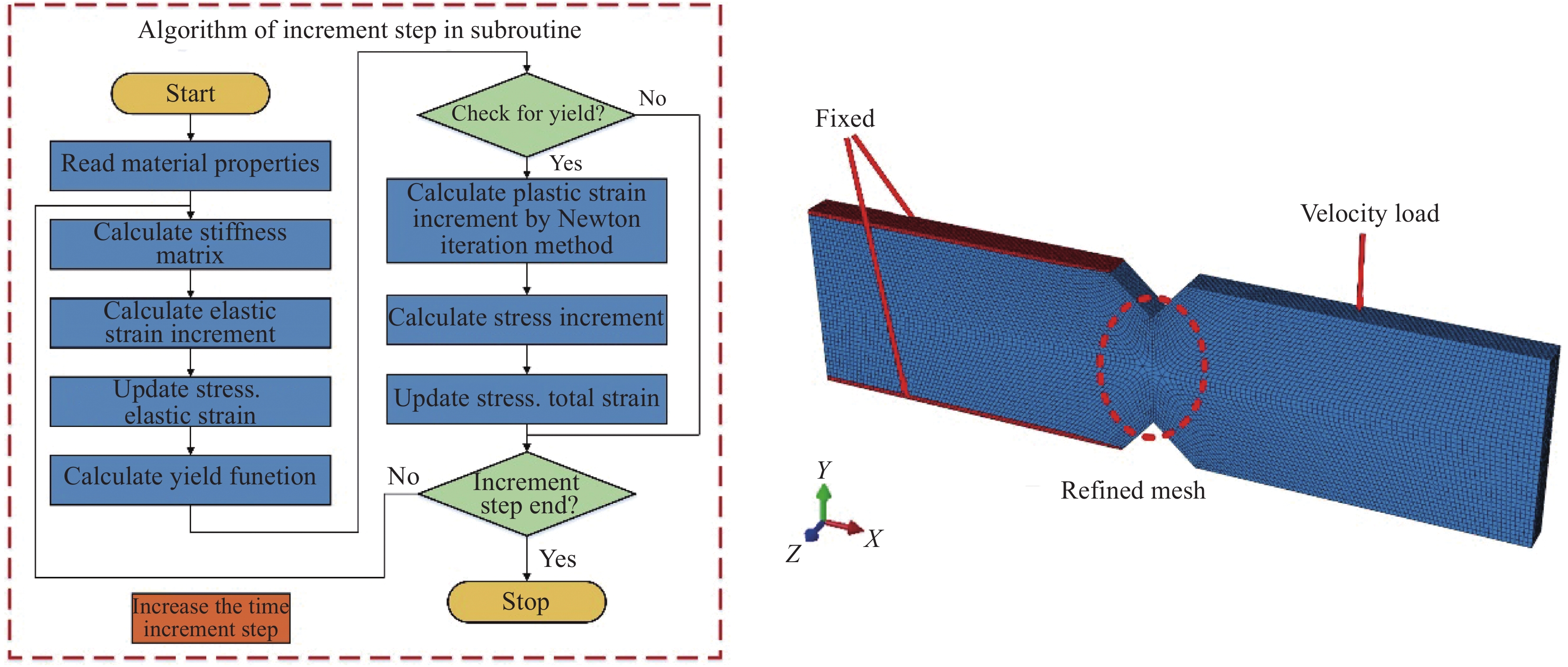

图7为 CF/PEEK复合材料剪切数值分析结果与实验结果对比。可知,数值仿真曲线真实地反映了应变率和温度对CF/PEEK复合材料强化行为的影响,并且在屈服后的非线性阶段与实验曲线偏差在10%~15%左右。但是在初始加载阶段仿真结果和实验偏差较大,实验曲线不是完全的线性增长,这是由于PEEK与CF没有完全浸润,导致CF/PEEK复合材料中存在孔隙缺陷,影响了CF/PEEK复合材料的初始弹性行为。因此,可以在本文建立的模型基础上引入孔隙演化模型,进一步更准确地描述CF/PEEK复合材料的非线性行为。

3. 结 论

(1) 温度和应变率对碳纤维增强聚醚醚酮(CF/PEEK)复合材料的屈服应力有着较大的影响。随着温度从20℃升高到130℃屈服应力下降了66%左右,下降速度先快后慢,随着应变率从10−5 s−1提高到0.1 s−1屈服应力均匀增大了35%左右。

(2) 提出了经验背应力公式来描述温度和应变率对CF/PEEK复合材料强化行为的影响,并修改了WEEKS等[19]关于CF/PEEK复合材料的本构模型描述CF/PEEK复合材料的非线性行为。数值模拟结果在非线性阶段的剪切应力-应变关系及屈服点的剪切应力与实验吻合良好,但是由于CF/PEEK复合材料内部的孔隙缺陷对材料线性行为的影响,导致在初始加载阶段与实验偏差较大。

-

表 1 碳纤维增强聚醚醚酮(CF/PEEK)复合材料力学性能

Table 1 Properties of carbon fiber reinforced polyether ether ketone (CF/PEEK) composite

Property Value Longitudinal modulus E1/GPa 130.00 Transverse moduli E2, E3/GPa 7.86 Transverse shear modulus G23/GPa 3.63 Axial shear moduli G12, G13/GPa 5.86 Poisson’s ratio in 23 direction ν23 0.51 Poisson’s ratios in 12 and 13 directions ν12, ν13 0.28 -

[1] SOURAV C, JÜRGEN P, BEATE K. Influence of different carbon nanotubes on the electrical and mechanical properties of melt mixed poly (ether sulfone)-multi walled carbon nanotube composites[J]. Composites Science and Technology, 2012, 72(15): 2820-2828.

[2] GENEVIEVE P, SHI H J, ARTHUR L. A study on amplitude transmission in ultrasonic welding of thermoplastic composites[J]. Composites Part A: Applied Science and Manufacturing, 2018, 113: 342-345.

[3] IRENE FERNANDEZ V, PABLO V R. On avoiding thermal degradation during welding of high-performance thermoplastic composites to thermoset composites[J]. Compo-sites Part A: Applied Science and Manufacturing, 2015, 77: 175-180.

[4] ZHANG Y B, SUN L Y. Effects of strain rate and high temperature environment on the mechanical performance of carbon fiber reinforced thermoplastic composites fabricated by hot press molding[J]. Composites Part A: Applied Science and Manufacturing,2020,134:105905.

[5] LI Jianjun, LU Wenjun, CHEN Shaohua, et al. Revealing extra strengthening and strain hardening in heterogeneous two-phase nanostructures[J]. International Journal of Plasticity,2020,126:26-28.

[6] GE Chao, YU Qingbo, QU Zhuojun. On dynamic response and fracture-induced initiation characteristics of aluminum particle filled PTFE reactive material using hat-shaped specimens[J]. Materials & Design,2020,188:107472.

[7] 杨王玥. 低碳钢多道次热变形中的应变强化相变与铁素体动态再结晶[J]. 金属学报, 2000(11):1192-1196. DOI: 10.3321/j.issn:0412-1961.2000.11.017 YANG Wangyue. Strain-enhanced phase transition and ferrite dynamic recrystallization in multi-step thermal deformation of low carbon steel[J]. Acta Metalica Sinica,2000(11):1192-1196(in Chinese). DOI: 10.3321/j.issn:0412-1961.2000.11.017

[8] JEONG H T. Strain hardening behavior and strengthening mechanism in Mg-rich Al-Mg binary alloys subjected to aging treatment[J]. Materials Science & Engineering A,2020,794:139862.

[9] TOSHIJI M, HIDETOSHI S. Strengthening Mg-Al-Zn alloy by repetitive oblique shear strain with caliber roll[J]. Scripta Materialia,2009,62(2):113-116.

[10] ESMAEELI E, MANNING E, BARROS J A. Strain hardening fibre reinforced cement composites for the flexural strengthening of masonry elements of ancient structures[J]. Construction and Building Materials,2013,38(C):1010-1021.

[11] 欧华杰, 陈港, 朱朋辉. 纳米纤维素-碳纳米管/热塑性聚氨酯复合薄膜的制备及应变响应性能[J]. 复合材料学报, 2020, 37(11):2735-2742. OU Huajie, CHEN Gang, ZHU Penghui. Preparation and strain sensitive performance of cellulose nanofibercarbon nanotubes/thermoplastic polyurethane composite films[J]. Acta Materiae Compositae Sinica,2020,37(11):2735-2742(in Chinese).

[12] TOUCHARD F, LAFARIE-FRENOT M C, GUÉDRA-DEGEORGES D. Mechanical behaviour characteristics of a thermoplastic composite used in structural components[J]. Composites Science and Technology,1996,56(7):785-791. DOI: 10.1016/0266-3538(96)00021-8

[13] LAGATTU F, LAFARIE-FRENOT M C. Variation of PEEK matrix crystallinity in APC-2 composite subjected to large shearing deformations[J]. Composites Science and Technology,2000,60(4):605-612. DOI: 10.1016/S0266-3538(99)00169-4

[14] VIEILLE B, AUCHER J, TALEB L. Influence of temperature on the behavior of carbon fiber fabrics reinforced PPS laminates[J]. Materials Science and Engineering: A,2009,517(1-2):51-60. DOI: 10.1016/j.msea.2009.03.038

[15] BARBA D, ARIAS A, GARCIA-GONZALEZ D. Temperature and strain rate dependences on hardening and softening behaviours in semi-crystalline polymers: Application to PEEK[J]. International Journal of Solids and Structures, 2020, 182-183: 206-210.

[16] SUN C T. A simple flow rule for characterizing nonlinear behavior of fiber composites[J]. Journal of Composite Materials, 1989, 23(10): 1009-1020.

[17] WANG Shiyu, ZHANG Jiazhen, FANG Guodong. Mathematical description of mechanical behavior of woven fabric reinforced PPS-based composites at high temperature[J]. Polymer Composites,2019,40(3):1097-1102. DOI: 10.1002/pc.24807

[18] ASTM. Stand test method for shear properties of compo-site materials by the V-notched beam method: ASTM D5379/D5379M-05[S]. West conshohocken: ASTM, 2012.

[19] WEEKS C A, SUN C T. Modeling non-linear rate-dependent behavior in fiber-reinforced composites[J]. Compo-sites Science and Technology,1998,58(3):603-611.

[20] HASSAN E, GE D, YANG L, et al. Highly boosting the interlaminar shear strength of CF/PEEK composites via introduction of PEKK onto activated CF[J]. Composites Part A: Applied Science and Manufacturing,2018,112:155-160. DOI: 10.1016/j.compositesa.2018.05.029

[21] YANG Zhengling. Strain rate dependent shear localization and deformation mechanisms in the CrMnFeCoNi high-entropy alloy with various microstructures[J]. Materials Science & Engineering A,2020,793:139854.

[22] CHEN W H, HE W, CHEN Z, et al. Extraordinary room temperature tensile ductility of laminated Ti/Al composite: Roles of anisotropy and strain rate sensitivity[J]. International Journal of Plasticity,2020,133:102806.

[23] PRAKASH G, SINGH N K , GUPTA N K. Deformation behaviours of Al2014-T6 at different strain rates and temperatures[J]. Structures,2020,26:193-203.

[24] MA C, TAI N H, WU S H, et al. Creep behavior of carbon-fiber-reinforced polyetheretherketone (PEEK) [±45] 4 s laminated composites (I)[J]. Composites Part B: Engineering,1997,28(4):407-417.

[25] ZOU Huiran, YIN Weilong, CAI Chaocan, et al. The out-of-plane compression behavior of cross-ply AS4/PEEK thermoplastic composite laminates at high strain rates[J]. Materials, 2018, 11(11): 2312.

[26] ABBASNEZHAD N, KHAVANDI A, FITOUSSI J. Influence of loading conditions on the overall mechanical behavior of polyether-ether-ketone (PEEK)[J]. International Journal of Fatigue, 2018, 109: 83-92.

[27] ALVAREDO Á, MARTÍN M, CASTELL P, et al. Non-isothermal crystallization behavior of PEEK/graphene nanoplatelets composites from melt and glass states[J]. Polymers,2019,11(1):124.

-

期刊类型引用(1)

1. 李新娅,王宁,卢佳浩,张鹏,夏兆鹏,侯耒. 基于改进Weibull模型的高强缝合锚钉缝线强度预测. 现代纺织技术. 2024(06): 52-60 .  百度学术

百度学术

其他类型引用(1)

-

下载:

下载: