Effect of Mg on microstructure and mechanical properties of in-situ TiB2/Al-4.5Cu composites

-

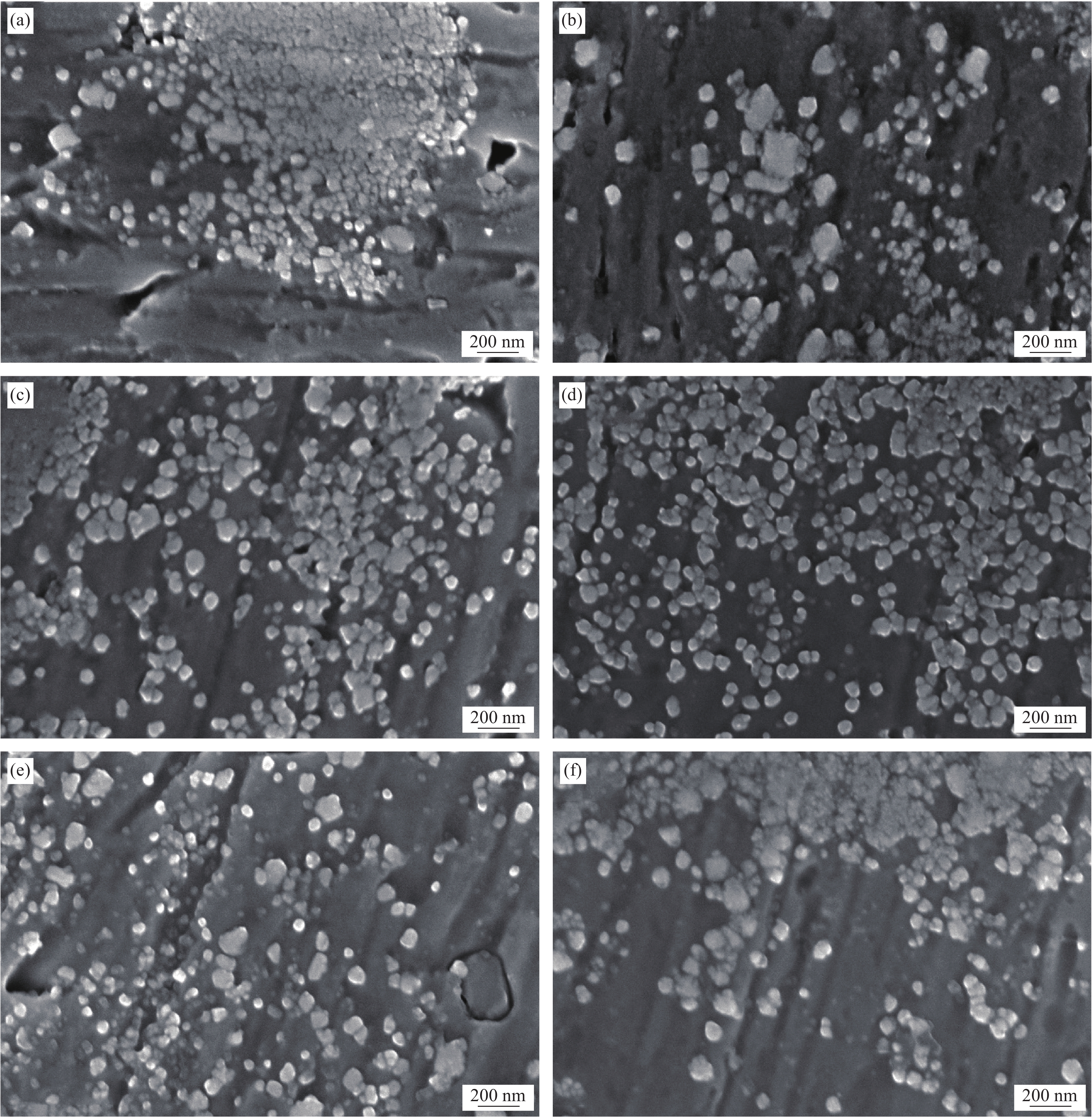

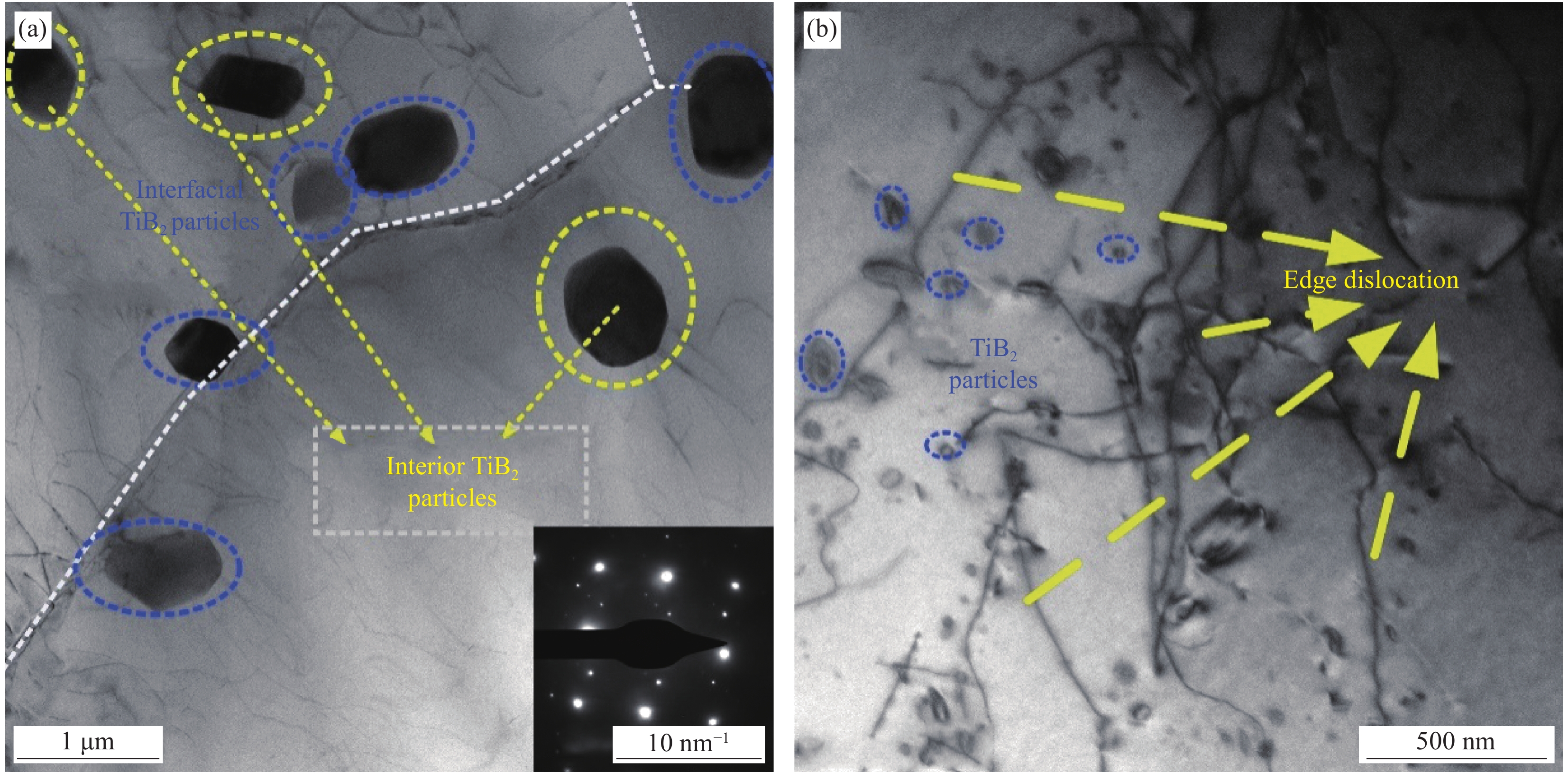

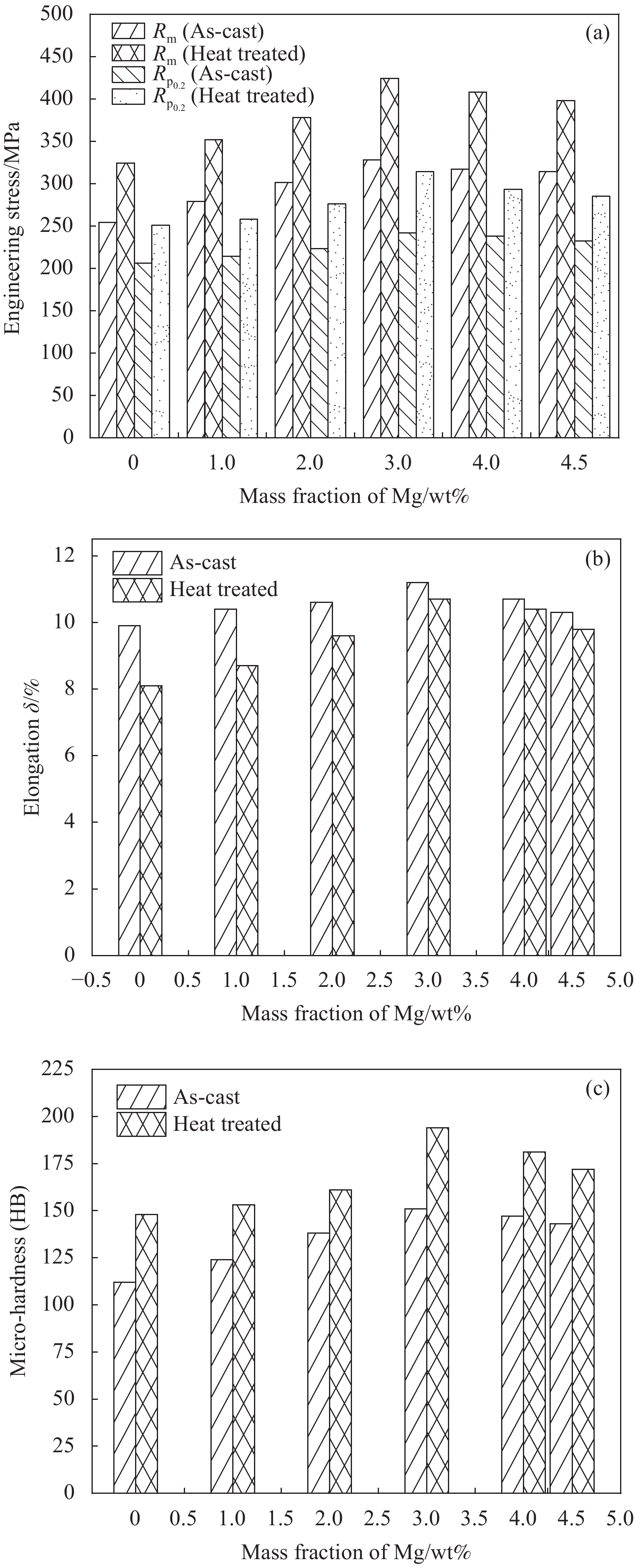

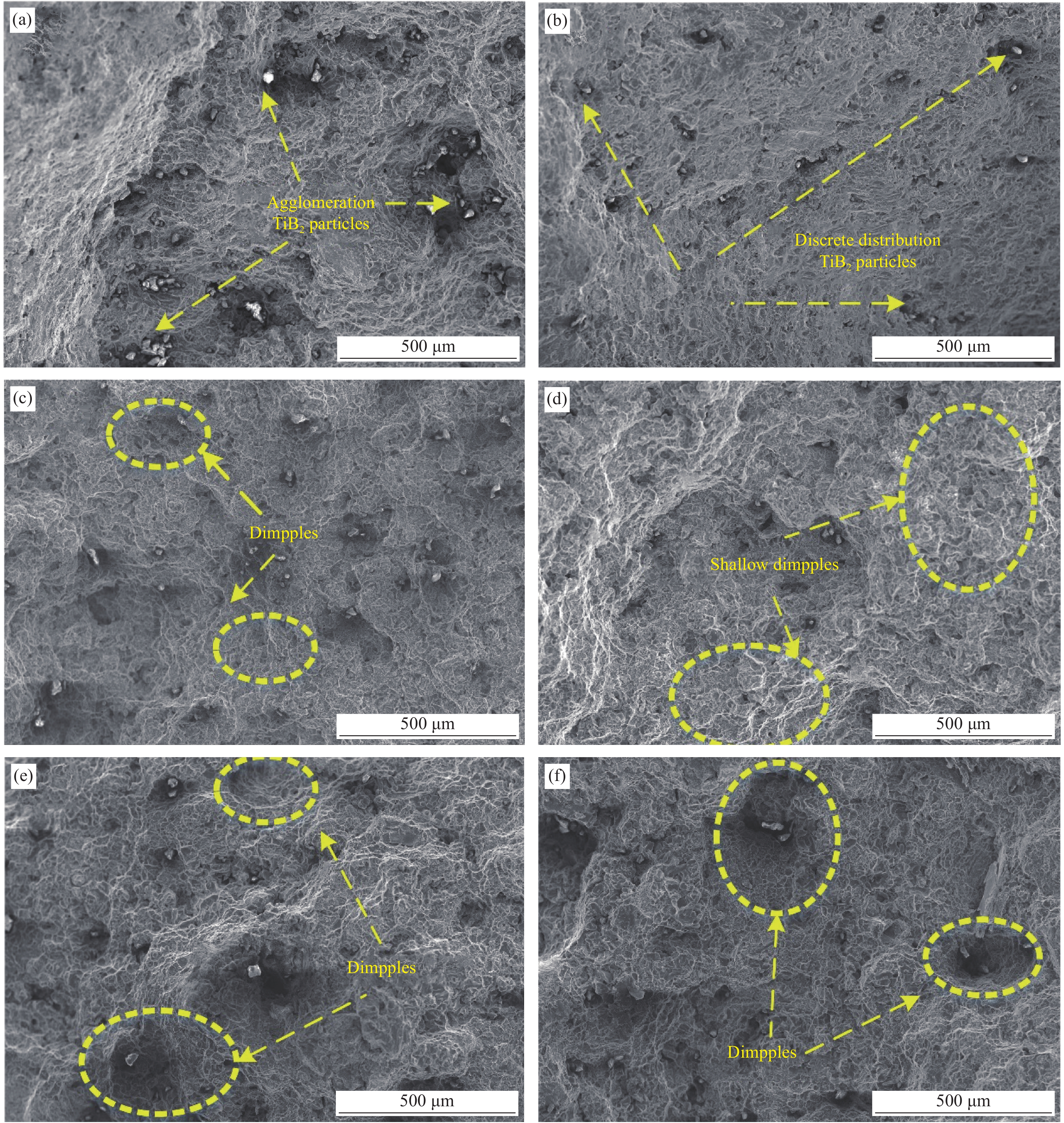

摘要: 采用Al-K2TiF6-KBF4混合盐原位自生反应法,制备了不同Mg质量分数的3wt% TiB2/Al-4.5Cu复合材料。采用SEM、TEM、HM硬度测试和室温拉伸等方法研究了Mg含量和多级热处理对3wt% TiB2/Al-4.5Cu复合材料微观组织和力学性能的影响。微观组织观察发现:Mg质量分数为3wt%时,经过多级热处理后,TiB2颗粒的团聚现象明显改善,反应生成的TiB2颗粒平均尺寸约为130 nm,基体内伴随有大量弥散分布的纳米级颗粒,且α-Al的晶粒尺寸也明显减小。力学测试结果表明:多级热处理后,3wt% TiB2/Al-4.5Cu复合材料的硬度和抗拉强度随Mg含量的增加而提高,但过量的Mg (≥4wt%)会造成TiB2颗粒细化效果下降。分析表明:Mg的加入能够降低TiB2/α-Al界面能,减少脆性相Al3Ti、Al2B的生成,并通过反应生成的MgAl2O4使界面结构变成TiB2/MgAl2O4/α-Al,从而有效抑制了TiB2的团聚,改善了TiB2颗粒与Al液界面的润湿性,提高了形核率,进一步细化了α-Al晶粒尺寸。

-

关键词:

- TiB2/Al-4.5Cu复合材料 /

- Mg /

- 微观组织 /

- 硬度 /

- 力学性能

Abstract: The 3wt% TiB2/Al-4.5Cu composites with different mass fraction of Mg were fabricated by Al-K2TiF6-KBF4 molten salt reaction method. The influences of Mg and multistage heat treatment on the microstructure and mechanical properties of the 3wt% TiB2/Al-4.5Cu composite were studied by means of SEM, TEM, HM hardness test and room temperature tensile test. The microstructure observation shows that the agglomeration of TiB2 particles is obviously improved after multistage heat treatment along with addition of Mg, In particular, with 3wt% Mg, the average size of TiB2 particles is about 130 nm, accompanied by a large number of dispersed nano particles, and the grain size of α-Al is also significantly reduced. The mechanical test results show that after multistage heat treatment, the hardness and tensile strength of the 3wt% TiB2/Al-4.5Cu composite are enhanced with the increase of Mg content. However, excess Mg content (mass fraction≥4wt%) will decrease the refinement effect of TiB2 particles. The analysis reveals that addition of Mg can reduce the interfacial energy of TiB2/α-Al and block the formation of brittle phase Al3Ti, Al2B. Meanwhile, the MgAl2O4 formed by reaction makes the interface become into the TiB2/MgAl2O4/α-Al, which could restrain the agglomeration of TiB2 particles and improve the wettability of the interface between TiB2 particles and Al liquid, increase the nucleation rate and refine the grain size.-

Keywords:

- TiB2/Al-4.5Cu composites /

- Mg /

- microstructure /

- hardness /

- mechanical properties

-

随着电子信息的发展,电子材料的集成度越来越高,电子设备运行过程中,输出功率只占一部分,其他功率通过元器件热能形式散发出来。如果热量无法得到有效散发,设备温度将不断提高,当超过极限温度元器件会发生损坏[1-2]。日益突出的散热问题推动了电子封装材料的发展,传统电子封装材料已经无法满足新时代电子元器件散热的需求,因此研究新型的电子封装材料是信息技术发展的当务之急[3-4]。

近年来,石墨膜/铝复合材料在热管理领域备受关注[5-7],是得益于石墨膜平面方向热导率超过

1200 W/(m·K)[8]。与铝基复合,能够弥补石墨膜自身易碎的缺点,同时也实现了石墨膜间的无胶复合。石墨膜/铝复合材料在面内方向展现出较高的热导率,是一种优异的电子封装材料。目前,石墨膜/铝复合材料研究主要在于材料的制备[9]和界面优化[10-12]等方面,其优势体现在面内方向导热能力较好。但由于石墨膜晶体的结构与石墨一致,呈现出高度的各向异性,在石墨膜厚度方向上的热导率仅为38 W/(m·K)[13-14],因此随着石墨膜体积分数的增加,石墨膜/铝复合材料纵向导热能力逐渐削弱。黄宇[6]使用真空热压法制备了石墨膜体积分数为17.4vol%~69.4vol%的石墨膜/铝层叠复合材料,复合材料面内热导率从356 W/(m·K)增加到902 W/(m·K),纵向热导率从63.3 W/(m·K)降低到7.2 W/(m·K)。Chang等[8]使用压力渗透法制备石墨膜/铝层叠复合材料,将石墨膜与铝箔叠放于模具烧结及铝基体浸渍。结果发现层叠复合材料由于合金中Si的存在没有界面反应物生成,面内热导率可高达743 W/(m·K),但纵向热导率最高仅为18 W/(m·K)。田聪[9]制备三明治结构的石墨膜/环氧树脂/铝导热基板,所制备的复合材料面内热导率在448.1~491.1 W/(m·K)之间,而纵向热导率为35.9 W/(m·K)。目前大部分石墨膜/铝复合材料的热导率在纵向和面内方向上存在数量级差异的问题,然而材料纵向导热能力对于新型电子封装材料至关重要[15],这限制了该系列复合材料在散热材料领域方面的应用。近期,复合材料增强相构型逐渐被相关学者所重视。通过合理的构型设计可以使高导热增强相成为复合材料中的导热通道,有利于减少热量在界面传导的损失,从而提升复合材料的热导率。如Lin等[16]使用糖模板法将氮化硼纳米片(BNNS)作为互连填料,随后通过注入聚二甲基硅氧烷(PDMS)并采用热压法制备复合材料。结果表明,相较于缺乏互连结构的复合材料,具有互连构型的复合材料在面内和面外导热系数分别提高了14倍和4倍。Yang 等[17]使用真空浸渗法将经过氧化石墨烯膜(GO)和石墨烯纳米片(GNP)组成的石墨烯气凝胶(HGA)引入聚乙二醇(PEG),在基体材料中形成连续的导热通道,当HGA质量分数仅为2.2wt%,复合材料热导率上升了361%。高导热增强相充当导热通道已经证明了其对研究电子封装领域材料热性能有提升作用。

金刚石具有很好的热性能,室温下热导率为700~

2200 W/(m·K)[18],可以作为石墨膜/铝复合材料高导热增强相。目前在石墨叠层增强金属基复合材料中,鲜有关于高导热增强相作为导热通道设计的研究报道。本文提出了一种在石墨膜/铝复合材料中引入金刚石作为导热通道的设计方法,金刚石嵌入铝基体的同时,作为桥梁连接上下石墨膜,已达到提高复合材料纵向热导率的目的。金刚石引入石墨膜/铝复合材料后,金刚石与铝基体的界面问题仍需考虑。有研究学者发现,金刚石通过表面镀覆Ti[19]、WC[20]或W[21–24]镀层后,可以提高金刚石与铝基体的界面结合,降低界面热阻。由于W镀层具有自身热导率最高178 W/(m·K)、且在铝中固溶度最小等优点[25] ,本文使用磁控溅射法对金刚石表面进行钨层镀覆以改善金刚石增强石墨膜/铝复合材料界面问题,随后采用快速热压烧结法(FHP)制备金刚石增强石墨膜/铝复合材料。通过改变芯层厚度改变金刚石体积分数(0vol%~30vol%)并揭示其对复合材料导热性能的影响规律。1. 实验部分

1.1 原材料

本文采用郑州黄河旋风有限公司生产的金刚石,平均粒径约为300 μm,密度为3.5 g/cm3;石墨膜源于苏州达昇电子材料有限公司,厚度约为70 μm,密度为1.7 g/cm3;Al-12Si粉体源于河北峰烨金属材料有限公司,平均粒径约为30 μm且纯度大于99.7%。采用物理气相沉积(PVD)技术在金刚石镀覆金属钨层,其XRD图谱如图1(c)所示。镀钨金刚石表面主要是WC、W2C与金刚石的衍射峰。镀钨金刚石SEM图像如图1(a)所示,金刚石颗粒的各个晶面都被完整地包裹,并且钨镀层呈现出平整致密的特征。图1(b)和图1(d)分别为金刚石(100)晶面与(111)晶面部分区域EDS分析,值得注意的是,与(111)晶面相比,镀钨金刚石的(100)晶面呈现出更加致密的特性。

![]() 图 1 (a) 镀钨金刚石颗粒的SEM图像;(b) 镀钨金刚石(100)晶面EDS分析;(c) 镀钨金刚石XRD图谱;(d) 镀钨金刚石(111)晶面EDS分析Figure 1. (a) SEM image of W-coated diamond particle; (b) EDS analysis of W-coated diamond particles on (100) facet; (c) XRD pattern of W-coated diamond particle; (d) EDS analysis of W-coated diamond particles on (111) facet

图 1 (a) 镀钨金刚石颗粒的SEM图像;(b) 镀钨金刚石(100)晶面EDS分析;(c) 镀钨金刚石XRD图谱;(d) 镀钨金刚石(111)晶面EDS分析Figure 1. (a) SEM image of W-coated diamond particle; (b) EDS analysis of W-coated diamond particles on (100) facet; (c) XRD pattern of W-coated diamond particle; (d) EDS analysis of W-coated diamond particles on (111) facet1.2 金刚石增强石墨膜/铝复合材料制备

使用快速热压烧结法(FHP)制备金刚石增强石墨膜/铝复合材料。为了研究金刚石表面对复合材料界面的影响,设置镀钨金刚石与未镀金刚石两组对照组。将不同体积分数(0vol%~30vol%)的金刚石颗粒与Al-12Si粉体均匀混合。随后将混合粉体放入底部带有石墨膜的模具中,并在混合粉体整体表面覆盖一层石墨膜,形成石墨膜-金刚石/铝夹芯-石墨膜三明治结构。将模具放入炉中,抽真空至10 Pa以内开始加热,以100℃/min升至400℃,之后以30℃/min升至540℃。加载压力维持在40 MPa,保温10 min后,随炉冷却至室温,最终得到金刚石增强石墨膜/铝复合材料。

1.3 表征方法

通过扫描电子显微镜(TESCAN Mira4)观察复合材料微观结构。使用阿基米德排水法测量样品密度。在室温条件下采用热分析设备(NETZSCH LFA467)测试了复合材料热扩散系数(α),为确保数据的准确性,使用3个闪射点测量样品,得到样品3个热扩散数值,通过下式计算热导率:

λ=αρCp (1) 其中:λ为热导率;Cp为比热容,通过理论计算得出;密度ρ采用阿基米德排水法测得,为了更方便直观地评估样品导热能力,采用红外热成像分析仪(FLIR SC300)输出样品在受热条件下表面温度的红外图像。

2. 结果与讨论

2.1 金刚石增强相构型设计

本文采用高导热金刚石作为石墨膜/铝复合材料的增强相,为了达到金刚石能够充当石墨膜/铝复合材料导热通道目的,金刚石需要穿透Al-12Si芯层并且不会将石墨膜刺穿,理想效果如图2所示。其中图2(a)为快速热压烧结示意图。图2(b)展示了理想复合材料结构。图2(c)为图2(b)放大图,即所有金刚石均都够贯穿Al-12Si芯层,芯层上下表面都可观察到金刚石的突起,并且突起的部分刺入了上下两层石墨膜。这种金刚石穿透Al-12Si层,刺入上下石墨膜中构建了石墨膜-金刚石-石墨膜的导热通道。换言之,金刚石在复合膜中起到了“顶梁柱”的作用。

2.2 复合材料微观形貌

如前所述,金刚石能否贯穿中间的铝层并刺入上下石墨膜中,是导热通道构建的关键。本文首先对未镀金刚石制备的金刚石增强石墨膜/铝复合材料进行观察,看金刚石是否能够穿透Al-12Si芯层并且一定程度刺入上下两层石墨膜。表征方法如下:将样品表面石墨膜沿边缘撕去,分别观察芯层上表面是否有金刚石突起及上下层石墨膜是否有金刚石刺入的痕迹。芯层表面和上下两层石墨膜宏观形貌分别为图3(a)与图3(c)所示。在图3(a)中,芯层表面框线区域内出现凸出的金刚石颗粒,这些金刚石颗粒突出Al-12Si芯层表面。采用SEM对芯层表面进行观察。图3(b)展示了复合材料芯层表面金刚石颗粒的放大区域,可清晰观察到金刚石突出Al-12Si芯层表面。图3(c)中虚线区域展示了金刚石颗粒在上下两层石墨膜各自留下对称压痕,表明金刚石在复合材料中发挥支撑作用。两种现象验证了金刚石成功穿透Al-12Si芯层并连接上下两层石墨膜。

![]() 图 3 (a) 金刚石穿透铝基宏观图(已去除上下表面石墨膜);(b) 金刚石颗粒的SEM图像;(c) 石墨膜上压痕宏观图;(d) 石墨膜上压痕的SEM图像Figure 3. (a) Macroscopic morphology of diamond penetration of aluminum base (with upper and lower surface graphite film removed); (b) SEM image of diamond particle; (c) Macroscopic morphology of graphite film indentations; (d) SEM image of indentation on graphite film

图 3 (a) 金刚石穿透铝基宏观图(已去除上下表面石墨膜);(b) 金刚石颗粒的SEM图像;(c) 石墨膜上压痕宏观图;(d) 石墨膜上压痕的SEM图像Figure 3. (a) Macroscopic morphology of diamond penetration of aluminum base (with upper and lower surface graphite film removed); (b) SEM image of diamond particle; (c) Macroscopic morphology of graphite film indentations; (d) SEM image of indentation on graphite film图3(d)展示了金刚石在石墨膜表面形成的个别压痕,说明当金刚石突出铝基层并接触到石墨膜后,会对石墨膜内部结构造成损伤。这种损伤可能会对石墨膜自身热导率出现影响。图4展示了石墨膜表面凹痕对其热导率的影响,可以看到表面凹痕小于20 μm对石墨膜本征热导率影响小于4%。因此,需要将金刚石的刺入深度控制在20 μm左右。本文通过石墨膜厚度(70 μm)、金刚石(300 μm)粒径叠加高度和控制复合材料中间Al-12Si芯层厚度计算,复合材料样品总厚度约为440 μm时,在保证可以实现金刚石穿透铝基连接上下两层石墨膜的构型设计前提下,能够有效维持石墨膜本身的高热导率特性。

图5(a)与图5(b)展示了本文制备的未镀金刚石增强石墨膜/铝复合材料横截面宏观特征及SEM形貌。可以观察到石墨膜与Al-12Si芯层没有明显孔洞或裂纹,说明石墨膜与Al-12Si芯层结合良好。图5(c)呈现了经过剪切处理后的复合材料断口的宏观特征,在剪切力作用下石墨膜与芯层仍保持良好的结合。金刚石颗粒所在断口区域的SEM图像如图5(d)所示。可以发现金刚石颗粒连接上下两层石墨膜在复合材料中充当“顶梁柱”作用,从另一角度验证了连通结构已经建立。同时金刚石颗粒与基体的结合情况是重要观察部位,图5(d)中实线所指的是金刚石的(111)晶面与铝基体间的孔隙,其来源可能是烧结过程中金刚石与铝基结合较差,这种较弱的界面结合会对复合材料的导热性能产生不利影响[26],也有可能是金刚石在剪切力作用下与铝基体分离。Che等[27]研究表明,相比(100)晶面,Al4C3更难在金刚石(111)晶面生成,因此金刚石(111)晶面与铝基的结合效果不佳。

研究表明,对金刚石进行表面镀钨处理可以有效改善与铝基体的界面结合[28]。采用SEM对剪切后镀钨金刚增强石墨膜/铝复合材料断口及撕开石墨膜后芯层表面进行观察。如图6(a)所示,镀钨金刚石与上下表面联通。从图6(b)可以观察到,撕开复合材料上层石墨膜后,镀钨金刚石在Al-12Si芯层中凸显出来。此外,根据图6(c)所示的EDS分析结果显示,在突出的镀钨金刚石表面上粘附有残留的石墨膜,这说明石墨膜与镀钨金刚石之间存在良好结合。图6(d)展示了镀钨金刚石增强石墨膜/铝复合材料断口形貌,可观察到嵌在铝基体中的镀钨金刚石与基体结合较紧密,没有出现孔洞,说明镀层的存在改善了金刚石与铝基体的润湿性。此外,复合材料经过剪切后金刚石顶部和底部连接石墨膜,表明复合材料内部已形成连通结构。通过EDS分析镀钨金刚石(111)晶面,从图6(f)中观察到铝基体残留在其表面,这说明引入钨镀层可以增强铝基体在金刚石表面的附着力,避免了金刚石与铝基体的选择性粘附[29]。与图5(c)未镀金刚石增强复合材料断口形貌相比,镀钨金刚石增强复合材料具有更高的内部界面强度,从而减少界面孔隙对复合材料的影响。

![]() 图 6 (a) 镀钨复合材料断口的SEM图像;(b) 撕开石墨膜后镀钨复合材料芯层表面的SEM图像;(c) 图6(b)的EDS分析;(d) 图6(a)中放大的镀钨金刚石颗粒SEM图像;(e) 图6(d)的EDS分析;(f) 镀钨金刚石(111) 晶面EDS分析Figure 6. (a) SEM image of W-coated composites fracture; (b) SEM image of the composite core surface after tearing the graphite film; (c) EDS analysis of Fig.6(b); (d) Enlarged SEM image of W-coated diamond particles in Fig.6(a); (e) EDS analysis of Fig.6(d); (f) EDS analysis of W-coated diamond (111) facet

图 6 (a) 镀钨复合材料断口的SEM图像;(b) 撕开石墨膜后镀钨复合材料芯层表面的SEM图像;(c) 图6(b)的EDS分析;(d) 图6(a)中放大的镀钨金刚石颗粒SEM图像;(e) 图6(d)的EDS分析;(f) 镀钨金刚石(111) 晶面EDS分析Figure 6. (a) SEM image of W-coated composites fracture; (b) SEM image of the composite core surface after tearing the graphite film; (c) EDS analysis of Fig.6(b); (d) Enlarged SEM image of W-coated diamond particles in Fig.6(a); (e) EDS analysis of Fig.6(d); (f) EDS analysis of W-coated diamond (111) facet2.3 金刚石体积分数对金刚石增强石墨/铝复合材料热性能影响

分别对未镀金刚石与镀钨金刚石增强石墨膜/铝复合材料进行面内方向和厚度方向上热导率测试,结果如图7(a)所示。当未镀金刚石体积分数为10vol%时,复合材料面内热导率可达到最高为614 W/(m·K)。随着金刚石体积分数超过10vol%,复合材料面内热导率逐渐降低。当未镀金刚石体积分数为30vol%时,复合材料面内热导率降低至498 W/(m·K)。这种低热导率可能是由复合材料内部的缺陷导致的[30],如孔隙、内应力、氧化等。根据前文中未镀金刚石增强复合材料断口微观结构特征分析,主要原因是复合材料内部存在界面孔隙。与此同时,如图7(b)所示,随着金刚石体积分数的增加,复合材料纵向热导率不断提升。当金刚石体积分数为30vol%时,复合材料纵向热导率达到最高值153 W/(m·K)。这是由于金刚石的引入为石墨膜/铝复合材料提供纵向导热通道,如图7(f)所示。复合材料纵向导热通道数量逐渐增多,金刚石“顶梁柱”的作用愈发凸显,从而使复合材料纵向导热能力效果不断提升。金属导热是以自由电子为主,金刚石的热传递是由声子主导。由此,金刚石与金属基材料构成复合材料是通过金刚石的声子与金属中的电子耦合完成的。相较于未镀金刚石增强复合材料,金刚石表面碳化物的构成可以有效地将电子与声子匹配,从而提高所在复合材料的导热性能。当镀钨金刚石体积分数为10vol%时,镀钨金刚石增强石墨膜/铝复合材料在面内方向上热导率达到658 W/(m·K),相较于未镀金刚石增强复合材料提高了7%。当镀钨金刚石体积分数为30vol%时,纵向热导率达到177 W/(m·K),相较于未镀金刚石增强复合材料提高了34%。该结果表明,高导热金刚石在引入镀层后,可以显著提升复合材料在面内方向和纵向上的热导率。为了更直接观察金刚石增强石墨膜/铝复合材料的导热性能,使用热成像设备对样品进行分析,如图7(c)所示。在相同金刚石体积分数与时间条件下,镀钨金刚石增强石墨膜/铝复合材料表面温度相较于未镀金刚石增强复合材料均提高了0.5℃。这说明在模拟应用中,镀钨金刚石增强复合材料具有更出色的导热性能。

![]() 图 7 镀钨金刚石增强石墨膜/铝复合材料热导率与未镀对比:(a) 面内方向;(b) 厚度方向;(c) 未镀金刚石所在复合材料热成像图;(d) 镀钨金刚石所在复合材料热成像图;(e) 石墨膜/铝复合材料模拟热流图;(f) 金刚石增强石墨膜/铝复合材料模拟热流图Figure 7. Comparison of thermal conductivity of W-coated diamond reinforced graphite film/aluminum composite with original: (a) In-plane direction; (b) Thickness direction; (c) Diamond in the composite material by infrared thermal imagery; (d) W-coated diamond in the composite by infrared thermal imagery; (e) Simulated heat flow diagram of graphite film/aluminum composite; (f) Diamond reinforced graphite film/aluminum composite simulation heat flow diagram

图 7 镀钨金刚石增强石墨膜/铝复合材料热导率与未镀对比:(a) 面内方向;(b) 厚度方向;(c) 未镀金刚石所在复合材料热成像图;(d) 镀钨金刚石所在复合材料热成像图;(e) 石墨膜/铝复合材料模拟热流图;(f) 金刚石增强石墨膜/铝复合材料模拟热流图Figure 7. Comparison of thermal conductivity of W-coated diamond reinforced graphite film/aluminum composite with original: (a) In-plane direction; (b) Thickness direction; (c) Diamond in the composite material by infrared thermal imagery; (d) W-coated diamond in the composite by infrared thermal imagery; (e) Simulated heat flow diagram of graphite film/aluminum composite; (f) Diamond reinforced graphite film/aluminum composite simulation heat flow diagram3. 结 论

本文采用快速热压烧结法成功制备了镀钨金刚石与未镀金刚石增强石墨膜/铝复合材料,探究了金刚石体积分数及其表面改性处理对复合材料导热性能的影响,主要结论如下:

(1)通过在石墨膜/铝复合材料引入高导热金刚石,成功在复合材料内部构建了纵向导热通道;

(2)随着金刚石体积分数(0vol%~30vol%)的增加,复合材料在面内方向上的热导率呈现出先上升后降低的趋势。当金刚石体积分数为10vol%时,复合材料在面内方向的热导率达到最高值为614 W/(m·K)。与此同时,复合材料纵向热导率持续增加。当金刚石体积分数为30vol%时,复合材料纵向热导率达到最高值为132 W/(m·K);

(3)金刚石表面包裹W镀层显著提高金刚石与铝基体的结合强度。当镀钨金刚石体积分数为10vol%时,镀钨金刚石增强石墨/铝复合材料相较于未镀金刚石增强复合材料在面内方向上的热导率提升了7%,达到658 W/(m·K)。同时,在纵向热传导方面也会有所增强,当镀钨金刚石体积分数达到30vol%,相较于未镀金刚石增强复合材料提升了34%,达到177 W/(m·K)。

-

图 2 3wt% TiB2/Al-4.5Cu复合材料多级热处理后TiB2颗粒的微观形貌: (a)不含Mg; (b) 1wt% Mg; (c) 2wt% Mg; (d) 3wt% Mg; (e) 4wt% Mg; (f) 4.5wt% Mg

Figure 2. Morphologies of TiB2 particles in multistage-heat treated 3wt% TiB2/Al-4.5Cu composites: (a) Without Mg; (b) 1wt% Mg; (c) 2wt% Mg; (d) 3wt% Mg; (e) 4wt% Mg; (f) 4.5wt% Mg

图 4 多级热处理前后3wt% TiB2/Al-4.5Cu复合材料力学性能随Mg质量分数的变化: (a)室温拉伸强度; (b)延伸率; (c)微观硬度(HB)

Figure 4. Mechanical properties of 3wt% TiB2/Al-4.5Cu composites varying with Mg mass fraction before and after multistage heat treatment: (a) Tensile strength; (b) Elongation; (c) Micro hardness (HB)

Rm—Tensile strength; Rp0.2—Proof strength

表 1 实验所用原料

Table 1 Raw materials of experiment

Raw material Al Mg Al-50Cu KBF4 K2TiF6 Na3AlF6 Purity/% >99.9 >99.9 >99.9 99.99 99.99 99.99 -

[1] 苏杰, 李亚智, 张代龙, 等. 原位自生TiB2颗粒增强2024-T4铝基复合材料断裂行为数值模拟[J]. 复合材料学报, 2018, 35(1):132-141. SU Jie, LI Yazhi, ZHANG Dailong, et al. Numerical simulation of fracture behavior of in-situ TiB2 particle reinforced 2024-T4 aluminum matrix composites[J]. Acta Materiae Compositae Sinica,2018,35(1):132-141(in Chinese).

[2] SUN J, WANG X Q, CHEN Y, et al. Effect of Cu element on morphology of TiB2 particles in TiB2/Al-Cu composites[J]. Transactions of Nonferrous Metals Society of China,2020,30(5):1148-1156. DOI: 10.1016/S1003-6326(20)65285-2

[3] LIU J, LIU Z W, DONG Z W, et al. On the preparation and mechanical properties of in situ small-sized TiB2/Al-4.5Cu composites via ultrasound assisted RD method[J]. Journal of Alloys and Compounds,2018,765:1008-1017. DOI: 10.1016/j.jallcom.2018.06.303

[4] MA Y, ADDAD A, JI G, et al. Atomic-scale investigation of the interface precipitation in a TiB2 nanoparticles reinforced Al-Zn-Mg-Cu matrix composite[J]. Acta Materialia,2020,185:287-299.

[5] 童攀, 林立, 王全兆, 等. 颗粒尺寸对B4C增强铝基中子吸收材料界面反应与力学性能的影响[J]. 复合材料学报, 2019, 36(4):927-937. TONG Pan, LIN Li, WANG Quanzhao, et al. Effects of particle size on interfacial reaction and mechanical properties of B4C reinforced aluminum matrix neutron absorber materials[J]. Acta Materiae Compositae Sinica,2019,36(4):927-937(in Chinese).

[6] VIVEKANANDA A S, BALASIVANANDHA P S, PASKARAMOORTHY R. Influence of process parameters of aluminothermic reduction process on grain refinement of in-situ Al/TiB2 composites[J]. Materials Today: Proceedings,2018,5(1):1071-1075. DOI: 10.1016/j.matpr.2017.11.184

[7] SUSWAGATA P, PRASANTA S, GOUTAM S. Tribological characteristics of stir-cast Al-TiB2 metal matrix composites in lubricated condition using taguchi based grey relation analysis[J]. Materials Today: Proceedings,2018,5(11):23629-23637. DOI: 10.1016/j.matpr.2018.10.152

[8] SURESH S, SHENBAG N, MOORTHI V. Aluminium-titanium diboride (Al-TiB2) metal matrix composites: Challenges and opportunities[J]. Procedia Engineering,2012,38:89-97. DOI: 10.1016/j.proeng.2012.06.013

[9] LIU K, NABAWY A M, CHEN X G. Influence of TiB2 nanoparticles on elevated-temperature properties of Al-Mn-Mg 3004 alloy[J]. Transactions of Nonferrous Metals Society of China,2017,27(4):771-778. DOI: 10.1016/S1003-6326(17)60088-8

[10] ZHAO Y, ZHENG Q L, LIU Z W. Ultrasound-induced distribution of nano-sized TiB2 particles within α-Al grains during solidification of Al-7Si alloy[J]. Materials Letters,2020,274:128030. DOI: 10.1016/j.matlet.2020.128030

[11] MENG J S, SHI X P, ZHANG S J, et al. Friction and wear properties of TiN-TiB2-Ni based composite coatings by argon arc cladding technology[J]. Surface and Coatings Technology,2019,374:437-447. DOI: 10.1016/j.surfcoat.2019.06.015

[12] AGRAWAL S, GHOSE A K, CHAKRABARTY I. Effect of rotary electromagnetic stirring during solidification of in-situ Al-TiB2 composites[J]. Materials & Design,2017,113:195-206.

[13] REN S B, HE X B, QU X H, et al. Effect of Mg and Si in the aluminum on the thermo-mechanical properties of pressureless infiltrated SiCP/Al composites[J]. Composites Science and Technology,2007,67(10):2103-2113. DOI: 10.1016/j.compscitech.2006.11.006

[14] 童慧, 胡正飞, 祁昌亚, 等. Ca含量对SiC/Al泡沫复合材料性能和结构的影响[J]. 复合材料学报, 2016, 33(11):2576-2583. TONG Hui, HU Zhengfei, QI Changya, et al. Effect of Ca content on property and structure of SiC/Al foam composites[J]. Acta Materiae Compositae Sinica,2016,33(11):2576-2583(in Chinese).

[15] XUE J, WANG J, HAN Y F, et al. Behavior of CeO2 additive in in-situ TiB2 particles reinforced 2014 Al alloy composite[J]. Transactions of Nonferrous Metals Society of China,2012,22(5):1012-1017. DOI: 10.1016/S1003-6326(11)61277-6

[16] 赵瑞锋, 刘忠侠, 杨明生, 等. Mg对原位合成TiB2/Al-7Si复合材料的微观组织及力学性能的影响[J]. 中国有色金属学报, 2009, 19(9):1548-1554. DOI: 10.3321/j.issn:1004-0609.2009.09.003 ZHAO Ruifeng, LIU Zhongxia, YANG Mingsheng, et al. Effect of Mg on microstructures and mechanical properties of in-situ TiB2/Al-7Si composite[J]. The Chinese Journal of Nonferrous Metals,2009,19(9):1548-1554(in Chinese). DOI: 10.3321/j.issn:1004-0609.2009.09.003

[17] PAI B C, RAMANI G, PILLAI R M, et al. Role of magnesium in cast aluminium alloy matrix composites[J]. Journal of Materials Science,1995,30(8):1903-1911. DOI: 10.1007/BF00353012

[18] SINGH S, PAL K. Influence of surface morphology and UFG on damping and mechanical properties of composite reinforced with spinel MgAl2O4-TiB2 core-shell microcomposites[J]. Materials Characterization,2017,123:244-255. DOI: 10.1016/j.matchar.2016.11.042

[19] RAJAN T P D, NARAYAN P K, PILLAI R M, et al. Solidification and casting/mould interfacial heat transfer characteristics of aluminum matrix composites[J]. Composites Science and Technology,2007,67(1):70-78. DOI: 10.1016/j.compscitech.2006.03.028

[20] CHOI S W, CHO H S, KUMAI S. Effect of the precipitation of secondary phases on the thermal diffusivity and thermal conductivity of Al-4.5Cu alloy[J]. Journal of Alloys and Compounds,2016,688:897-902. DOI: 10.1016/j.jallcom.2016.07.137

[21] WU L, ZHOU C, LI X F, et al. Microstructural evolution and mechanical properties of cast high-Li-content TiB2/Al-Li-Cu composite during heat treatment[J]. Journal of Alloys and Compounds,2018,739:270-279. DOI: 10.1016/j.jallcom.2017.12.126

[22] 张文龙, 陈嘉颐, 吴桢干, 等. (Al2O3)f/Al复合材料在强界面结合下的疲劳损伤模式[J]. 复合材料学报, 2003, 20(1):106-110. ZHANG Wenlong, CHEN Jiayi, WU Zhengan, et al. Fatigue damage mode of (Al2O3)f/Al composite[J]. Acta Materiae Compositae Sinica,2003,20(1):106-110(in Chinese).

[23] 中国国家标准化管理委员会. 金属材料拉伸试验第1部分: 室温试验方法: GB/T 228.1—2010[S]. 北京: 中国标准出版社, 2010. Standardization Administration of the People’s Republic of China. Metallic material-tensile testing Part 1: method of test at room temperature: GB/T 228.1—2010[S]. Beijing: China Standards Press, 2011(in Chinese).

[24] WANG M, WANG Y, LIU J, et al. Effects of Zn content on microstructures and mechanical properties of in-situ TiB2/Al-Zn-Mg-Cu composites subjected to hot extrusion[J]. Materials Science and Engineering A,2019,742:364-372. DOI: 10.1016/j.msea.2018.11.030

[25] ZHANG L L, ZHENG Q J, JIANG H X, et al. Interfacial energy between Al melt and TiB2 particles and efficiency of TiB2 particles to nucleate α-Al[J]. Scripta Materialia,2019,160:25-28. DOI: 10.1016/j.scriptamat.2018.09.042

[26] ZHAO B W, YANG Q, WU L, et al. Effects of nanosized particles on microstructure and mechanical properties of an aged in-situ TiB2/Al-Cu-Li composite[J]. Materials Science and Engineering A,2019,742:573-583. DOI: 10.1016/j.msea.2018.11.032

[27] DAVARI M, JABBAREH M A. Modeling the interfacial energy of embedded metallic nanoparticles[J]. Journal of Physics and Chemistry of Solids,2020,138:109261. DOI: 10.1016/j.jpcs.2019.109261

[28] 郭建, 沈宁福. SiC颗粒增强Al基复合材料中有害界面反应的控制[J]. 材料科学与工程, 2002, 20(4):605-608, 600. GUO Jian, SHEN Ningfu. Control of detrimental interface reaction in SiCP/Al composite materials[J]. Materials Science & Engineering,2002,20(4):605-608, 600(in Chinese).

[29] 邱丰, 佟昊天, 沈平, 等. 综述: SiC/Al界面反应与界面结构演变规律及机制[J]. 金属学报, 2019, 55(1):87-100. QIU Feng, TONG Haotian, SHEN Ping, et al. Overview: SiC/Al interface reaction and interface structure evolution mechanism[J]. Acta Metallurgica Sinica,2019,55(1):87-100(in Chinese).

[30] LIU R, YIN X M, FENG K X, et al. First-principles calculations on Mg/TiB2 interfaces[J]. Computational Materials Science,2018,149:373-378. DOI: 10.1016/j.commatsci.2018.03.045

-

期刊类型引用(3)

1. 李梦涵,魏娜,徐瑞琪,杨泽钰,崔洪芝. 三维碳纳米管/硅藻土基多孔陶瓷复合材料的制备及其光热水蒸发性能. 复合材料学报. 2023(08): 4577-4586 .  本站查看

本站查看

2. 吴玉萍,王乾廷,孙炜,周忠华,谢宗丽,宋铭雨. 含椭圆叶片状SiO_2/聚乙烯醇渗透汽化复合膜的制备与性能. 复合材料学报. 2022(06): 2783-2791 .  本站查看

本站查看

3. 赵士雄. 反渗透复合膜制备及其改性方法研究进展. 云南化工. 2022(06): 20-21+38 .  百度学术

百度学术

其他类型引用(1)

-

下载:

下载: