Torsion properties of carbon fiber reinforced polymer composite-metal transmission shaft based on delamination damage analysis

-

摘要: 为提高油动四旋翼无人机载重能力,对碳纤维增强树脂复合材料(CFRP)-金属传动轴进行研究。CFRP-金属传动轴扭转强度影响因素为CFRP管制孔质量问题和传动过程中销钉对连接孔的挤压作用。研究导致CFRP管孔入出口分层损伤的力学行为,揭示了CFRP管制孔质量的影响机制并优化了制孔工艺。利用扭转试验对销接式CFRP-金属传动轴和附有内外衬套的混合式CFRP-金属传动轴进行对比分析。结果表明:在CFRP管内外附有铝合金衬套可有效减少制孔时的分层损伤,使孔入口质量提高了4.4%,孔出口质量高了8.3%,同时抑制销钉对连接孔的挤压作用。优化后的传动轴承受扭矩从499 N·m提高到952 N·m。Abstract: To improve the load capacity of the oil powered quadrotor unmanned aerial vehicle, carbon fiber reinforced polymer composite (CFRP)-metal transmission shafts are studied. The factors affecting the torsional strength of CFRP-metal transmission shafts are the quality of CFRP pipe holes and the extrusion effect of pins on connecting holes during transmission. By studing the mechanical behaviors causing delamination damage at the entrance and exit of CFRP tube, the influence mechanism of the quality of CFRP pipe holes was revealed and the hole making process was optimized. A comparative analysis between pin-connection CFRP-metal transmissions shafts and hybrid CFRP-metal transmission shafts with inner and outer bushing was carried out by torsion tests. The results show that the addition of the inside and outside aluminum alloy bushing of CFRP tubes can effectively reduce the delamination damage during drilling. The quality of the entrance and exit of holes can be increased by 4.4% and 8.3%, respectively. Meanwhile, the extrusion effect of the pins on the connecting holes is restrained. The torque values of the optimized transmission bearing is increased from 499 N·m to 952 N·m.

-

随着科学技术的发展,四旋翼无人机的强大功能已逐步显现出来,在军用和民用领域上均有大量的应用,引起了学术界的广泛关注[1-2]。重载油动四旋翼无人机的发动机是动力的来源,需通过传动系统将动力传输到支臂,并通过旋翼进行输出驱动。因此,传动系统是重载油动四旋翼无人机的重要结构系统。为提高重载油动四旋翼无人机的性能和竞争力,需对传动系统中各个零件进行轻量化设计。由于传统金属制作而成的传动轴存在质量重、比强度低等问题,因此需找到一种质量轻、比强度高的材料。

碳纤维增强树脂复合材料(CFRP)比强度高、比刚度大、材料性能可以设计、抗疲劳性能强、减振性能好,被广泛应用于航空、航天、汽车、造船及土建领域[3]。因此,本文采用由CFRP管与金属接头制作而成的CFRP-金属传动轴作为重载油动四旋翼无人机的传动轴,既能减轻重载油动四旋翼无人机的结构质量又能提高传动轴的力学性能。由于传动轴需传递高扭矩,因此CFRP管与金属构件连接方式首选机械连接,但采取机械连接应注意连接失效和制孔问题,在CFRP与金属连接中易发生局部的应力集中现象,连接的失效模式多,且难以预测强度。CFRP管制孔过程中易出现孔加工损伤、孔缺陷难预测等问题,会严重影响连接结构的力学性能[4]。

由于试验结果无法观察到CFRP中间某一层具体孔分层损伤情况,因此采用有限元与试验相结合的方法对加工损伤进行分析。针对复合材料切削的有限元仿真,国内外学者[5-6]主要关注二维切削仿真,但二维切削模型存在无法同时分析面内与面外(即层间)失效及刀具的螺旋角等对钻削加工影响的问题,三维切削仿真不仅能解决二维切削仿真存在的问题,且仿真结果更接近实际,现已逐渐成为CFRP钻削仿真建模所关注的重点。如Phadnis等 [7]建立了复合材料三维钻削有限元模型,用Cohesive单元模拟复合材料中的层间分层,分析了钻孔工艺参数对分层损伤的影响。齐振超[8]建立了三维钻削CFRP有限元模型,直观表现了分层产生过程和应力场分布规律。针对复合材料制孔试验研究,国内外学者[9-10]主要关注改变加工参数来提高制孔质量,目前在该方向上已取得一定研究成果,但在改进加工方式的方向上研究较少,因此可研究改进加工方法使孔质量大幅度提高。如王福吉等[11]在加工CFRP时用冷却工艺来提高加工质量。Capello[12]分析了在工件底面有支撑和无支撑时的分层机制差异,且试验结果表明,添加支撑可阻止碳纤维的弯曲,减少分层。

由于金属材料比CFRP具有更高挤压强度等优点,可综合两者优点在实际中应用。针对复合材料与金属构件连接,国内外学者[13-14]主要关注CFRP层合板与金属构件连接研究。目前对于CFRP管与金属构件连接研究相对较少,但在实际生活中的汽车、飞机等领域应用十分广泛,常使用CFRP管与金属连接件替换一些管类零件来提高设备各个方面性能,因此CFRP管与金属构件连接有着重要的研究意义。如Kim等[15]设计了一种由铝和CFRP组成的单件混合式传动轴,连接方式采用多齿钢环连接,提高了可靠性,降低了传动轴质量。石国成等[16]研究了CFRP轴管与金属轴头过盈连接装配及扭转过程中的接头应力、接触面应力的变化规律,并对金属轴头与CFRP管进行失效判断。

本文为提高CFRP-金属传动轴承受扭矩的能力,从改进制孔工艺方法和优化连接方法两方面着手。一方面,首先根据钻头钻削CFRP管的力学行为提出一种加工方式,其后利用有限元仿真和试验相结合的方法来验证该加工方式的可行性,并利用超景深显微镜观测孔入出口分层损伤,定量计算孔质量,得到最适合的加工参数。另一方面,分析销接式碳纤维-金属传动轴扭转失效的原因,提出附有内外衬套的混合式连接方法来提高传动轴的承受扭矩能力,并通过扭转试验验证了优化方法的有效性。

1. 碳纤维增强树脂复合材料(CFRP)管的加工损伤

1.1 CFRP钻削过程

钻削是加工CFRP中最常用的工序之一,在对CFRP钻削加工过程中,孔入出口极易产生分层及毛刺加工损伤。

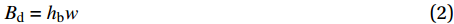

横刃开始接触CFRP到主切削刃全部进入CFRP中的切削过程,钻削力由零到达峰值。横刃对CFRP的挤压拉铰作用将孔入口处的碳纤维剪切和粉碎,引导主切削刃进行切削。随着麻花钻不断向下进给,存在主切削刃对CFRP表面产生周向力作用和由于螺旋槽几何形状的原因产生一个向上的剥离分力,导致CFRP最外几层铺层被掀起,碳纤维不能被切削刃切断而引起孔入口处产生分层及毛刺加工损伤,如图1(a)所示。

横刃开始作用于CFRP最外几层铺层到主切削刃部分从材料中钻出的过程,此时钻削轴向力最大。在CFRP钻孔过程中,随着切削的深入,未切削部分厚度减小,CFRP的剩余刚度也随之减小,此时当刀具接近孔出口时,碳纤维在CFRP剩余刚度不足以支撑其被切削的情况下,发生弯曲位移(如悬臂梁一端受力),进而产生裂纹,进一步发展成为分层现象,如图1(b)所示。

1.2 钻削CFRP时碳纤维的微观弯曲行为

CFRP在微观上是由碳纤维、树脂和界面组成的多相混合态,其切削加工中包含切削力作用下碳纤维的断裂、树脂/界面的开裂,然后演化至宏观切屑形成的过程[17]。在切削过程中被切削掉的主体是碳纤维,由于碳纤维与树脂、界面的强度和模量差距很大,导致在切削CFRP过程中树脂与界面极易开裂,进而形成加工损伤。为真实反映出碳纤维在钻削力作用下的变形,采用两参数弹性地基梁理论求出单碳纤维在切削力作用下的挠度。

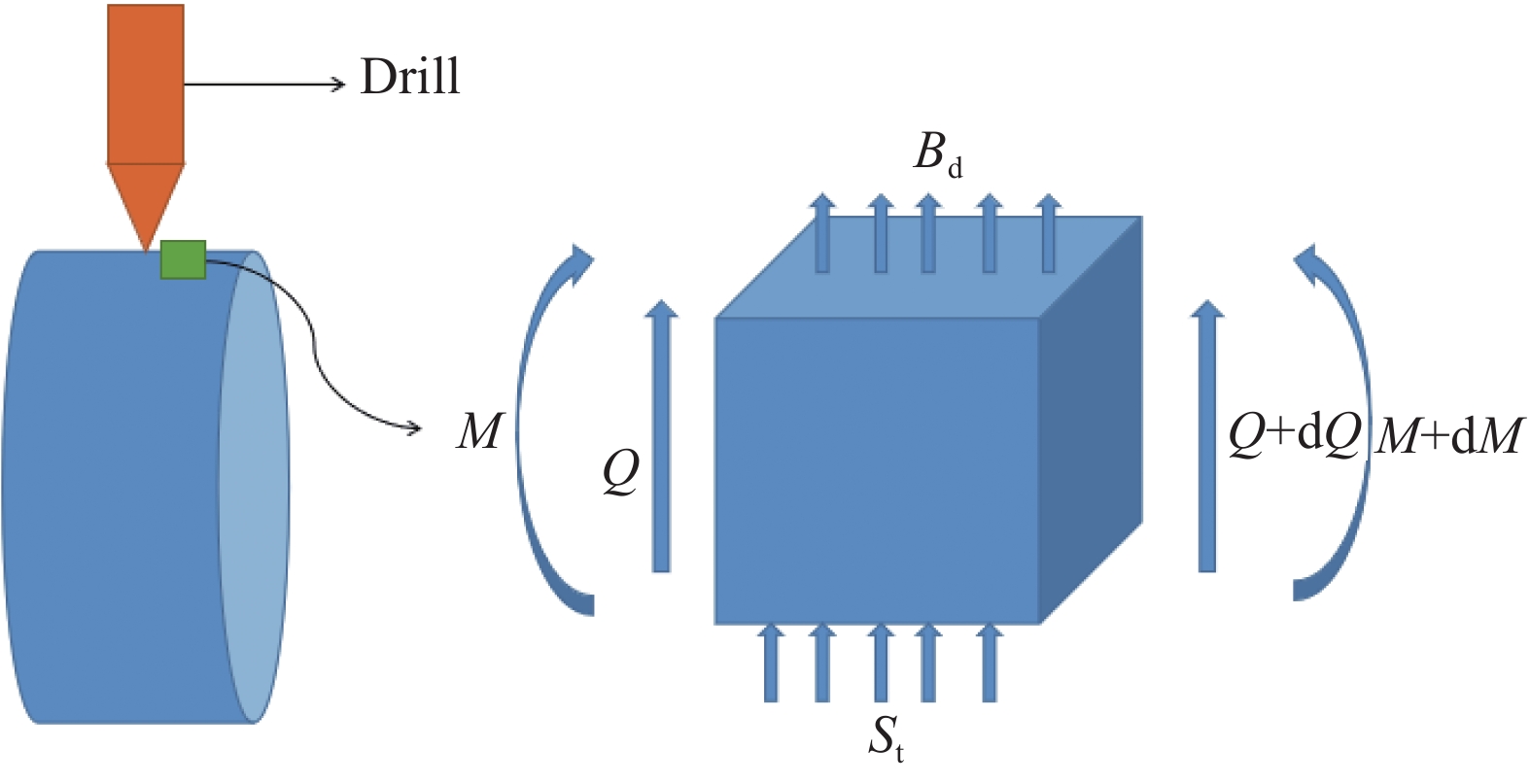

取长度为

dx 的微小单元体,在切削过程中的受力情况如图2所示。考虑到麻花钻在钻削CFRP过程中周围材料对碳纤维的约束作用,计算如下[18]:

St=hαw−hα1d2w(x)dx2 (1) 式中:

hα 为周围材料对碳纤维的法向支撑系数;hα1 为周围材料对碳纤维的切向支撑系数;w 为纤维挠度。界面对纤维的黏结作用为[17]

Bd=hbw (2) 式中,

hb 为叠合面的等效模量。最后,基于长度为

dx 的微小单元体的平衡方程,可得单碳纤维弹性地基梁的变形控制方程[17]为EfIfd4w(x)dx4−hα1d2w(x)dx2+(hα+hb)w(x)=0 (3) 式中:

Ef 为碳纤维弹性模量;If 为截面惯性矩。通过宏观上CFRP钻削过程分析可知,孔入出口分层、毛刺损伤主要由法向轴向力所致,且周围材料对纤维的切向约束主要作用于碳纤维层的层内,因此

hα1=0 ,得到单纤维弹性地基梁的变形控制方程[19]为EfIfd4w(x)dx4+(hα+hb)w(x)=0 (4) 1.3 钻削附有衬套CFRP管的力学行为

基于CFRP钻削过程分析,提出一种加工方式即在CFRP管内外附有衬套。在CFRP管附有外衬套,可抑制孔入口边缘最外几层铺层被掀起,使切削刃能够有效切削掉碳纤维,减少孔入口分层及毛刺损伤,如图3(a)所示。在CFRP管附有内衬套可增强孔出口边缘最外几层铺层的承载能力,使未切削层避免脱离基体,让切削刃能够有效切削掉碳纤维,减小孔出口分层及毛刺损伤,如图3(b)所示。

在CFRP管附有外衬套可对孔入口边缘最外几层碳纤维产生沿着法向向下的支撑力,使碳纤维在钻削轴向力作用下的弯曲量变小,降低发生树脂与界面开裂行为的可能。

由于周围材料对碳纤维法向向上的支撑作用对该过程纤维弯曲变形无影响,因此

hα=0 。得到附有外衬套的单碳纤维弹性地基梁的变形控制方程为EfIfd4w(x)dx4+(hβ+hb)w(x)=0 (5) 式中,

hβ 为外衬套对碳纤维法向支撑系数。CFRP管附有内衬套,可对孔出口边缘最外几层碳纤维提供沿着法向向上的支撑力。随着碳纤维支撑能力的增强,可削弱钻削轴向力对碳纤维的作用,降低发生树脂与界面开裂行为的可能。

得到附有内衬套的单碳纤维弹性地基梁的变形控制方程为

EfIfd4w(x)dx4+(hγ+hb)w(x)=0 (6) 式中,由于内衬套的泊松比、模量与CFRP不同,因此采用

hγ 来代表综合周围材料与内衬套的支撑系数。2. CFRP三维钻削仿真

2.1 三维Hashin失效准则

对CFRP管制孔过程中,连接孔的边缘部位经常出现分层和基体的断裂、挤裂等失效模式[20]。为使模拟结果更加准确、形象,本文采用三维Hashin失效准则。三维Hashin失效准则能够精准地区分纤维拉伸断裂、纤维压缩屈曲、基体在横向拉伸和剪切下的断裂、基体在横向压缩和剪切下的挤裂这几种主要失效模式[21]。

纤维方向上拉伸和压缩失效准则表达式分别为

(σ11XT)2+(τ12SL)2+(σ13S13)2⩾ {{\left(\frac{{{\sigma }_{11}}}{{{X}_{\text{C}}}}\right)}^{2}}\geqslant 1,\ \ \ \ \ \ \ \ \ \ \ \ \ \ {{\sigma }_{11}}<0 (7) 基体方向上拉伸剪切失效准则表达式为

\left( {\frac{{{\sigma _{22}} + {\sigma _{33}}}}{{{Y_{\rm{T}}}}}} \right) + \frac{{{\sigma _{23}}^2 - {\sigma _{22}}{\sigma _{33}}}}{{{S_{{{23}^2}}}}} + \frac{{{\sigma _{12}}^2}}{{{S_{12}}^2}} + \frac{{{\sigma _{13}}^2}}{{{S_{13}}^2}} \geqslant 1 (8) 基体方向上压缩剪切失效准则表达式为

\begin{split} &\left[{\left( {\dfrac{{{Y_{\rm{C}}}}}{{2{S_{23}}}}} \right)^2} - 1\right]\left( {\dfrac{{{\sigma _{22}} + {\sigma _{33}}}}{{{Y_{\rm{C}}}}}} \right) + \left( {\dfrac{{{\sigma _{22}} + {\sigma _{33}}}}{{2{S_{13}}}}} \right) + \\ & \dfrac{{{\sigma _{23}}^2 - {\sigma _{22}}{\sigma _{33}}}}{{{S_{23}}^2}} + {\left( {\dfrac{{{\sigma _{12}}}}{{{S_{12}}}}} \right)^2} + {\left( {\dfrac{{{\sigma _{13}}}}{{{S_{13}}}}} \right)^2} \geqslant 1\\ & \;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\left( {{\sigma _{22}} + {\sigma _{33}} < 0} \right) \end{split} (9) 式中:

{\sigma _{{{ij}}}} 为不同方向的应力分量,i 和j 取1、2、3,分别表示面内顺纤维方向、面内垂直于纤维方向及垂直于面内方向;{X_{\rm{T}}} 、{Y_{\rm{T}}} 分别为沿纤维和基体方向的拉伸许用应力;{X_{\rm{C}}} 和{Y_{\rm{C}}} 分别为沿纤维和基体方向的压缩许用应力;{S_{12}} 、{S_{13}} 、{S_{23}} 为不同方向的面内剪切强度。采用有限元方法模拟钻削CFRP过程,当钻头挤压和剪切的应力达到Hashin失效准则时,破坏单元所代表的材料会被切削掉。

2.2 仿真模型建立

本文利用ABAQUS有限元分析软件建立T700 CFRP管模型,TORAY公司所制的CFRP管外径为40 mm,内径为36 mm,共铺设16层,每层厚度为0.125 mm。了解到适当增加45°铺层比例有利于增加传动轴的扭转性能,0°铺层可增强传动轴承受适当的轴向力[22]。因此,铺层方向采用0°与45°交叉铺层,CFRP管所涉及的材料性能参数如表1所示。

表 1 T700 CFRP的材料参数Table 1. Parameters of T700 CFRPE1/MPa E2=E3/MPa ν12=ν13 ν23 G12=G13=G23/MPa XT/MPa XC/MPa YT/MPa YC/MPa S12=S13/MPa S23/MPa ρ/(kg·m−3) 115000 6430 0.34 0.28 6000 1500 700 30 100 60 30 1790 Notes: {E_i}—Tensile moduli in different directions; {G_{ij}}—Shear moduli in plane in directions of i and j;ν{}_{ij} —Poisson’s ratios in plane in directions of i and j; i, j—1, 2 or 3; ρ—Density. 利用UG建模软件建立一个直径为5 mm、顶角为130°的麻花钻。厦门金鹭特种合金有限公司生产的复合3D麻花钻整体材料属性是硬质合金,密度为14600 kg/m3,弹性模量为580 GPa,泊松比为0.22,钻头与工件之间的摩擦系数为0.20[23]。

2.3 边界条件和网格划分

将CFRP管完全固定,以确保CFRP管在钻削过程中不发生位移。为缩短运算时间和不考虑麻花钻变形前提下,将钻头设置为刚体,并赋予麻花钻头轴线向下的进给量和绕着轴线的转速。衬套与管壁之间一旦存在间隙,衬套可能会失去对管壁的支撑作用,导致抑制加工损伤效果减弱,因此衬套根据CFRP管内外径尺寸配做。在仿真中为便于计算将铝合金衬套的约束定义为固定约束,铝合金衬套看作是一个不会变形的刚体。由于网格单元类型的选择和网格划分质量关系到模型计算准确度,因此对CFRP管钻削部位和钻头的横刃、切削刃进行网格细化以减小计算误差。

CFRP管单元形状是六面体,利用扫略网格的划分方式,算法采用中性轴算法并进行最小化网格过渡。CFRP管钻削部位的网格大小划分为0.1 mm,其余部分网格大小划分为0.3 mm,单元类型为八节点线性六面体单元,减缩积分,沙漏控制(C3D8R)。钻头采用自由网格划分方式,钻头横刃、切削刃的网格大小划分为0.1 mm,其余部分网格大小划分为0.3 mm,单元类型为四节点线性四面体单元(C3D4)。CFRP钻削加工模型如图4所示。

2.4 CFRP分层评价方法

Davim等[24]基于数字图像分析技术的方法,提出了以“修正分层系数”为指标来评价CFRP制孔质量。对比不同主轴转速与进给速率对“分层系数”和“修正分层系数”的研究,发现修正分层系数更适合全面评价 CFRP 的制孔质量。

CFRP损伤区域示意图如图5所示。修正分层系数

{F_{{\rm{da}}}} 是在分层系数的基础上考虑了损伤面积的大小,因此能够更加准确全面地反映出制孔质量,计算如下:{F_{{\rm{da}}}} = \beta \frac{{{D_{\max }}}}{{{D_0}}} + {\beta _1}\frac{{{A_{\max }}}}{{{A_0}}} (10) 式中:

{A_{\max }} 为以{D_{\max }} 为直径的最大损伤区域面积;{A_0} 为以{D_0} 为直径的区域面积;\beta 和{\beta _1} 为相关比重系数,计算如下:{A_{\max }} = {\text{π}} \frac{{D_{\max }^2}}{4} (11) {A_0} = {\text{π}} \frac{{D_0^2}}{4} (12) {\beta _1} = \frac{{{A_{\rm{d}}}}}{{{A_{\max }} - {A_0}}} (13) {\beta _1} + \beta = 1 (14) {F_{{\rm{da}}}} = \beta {F_{\rm{d}}} + {\beta _1} F_{\rm{d}}^2 (15) 2.5 仿真结果与分析

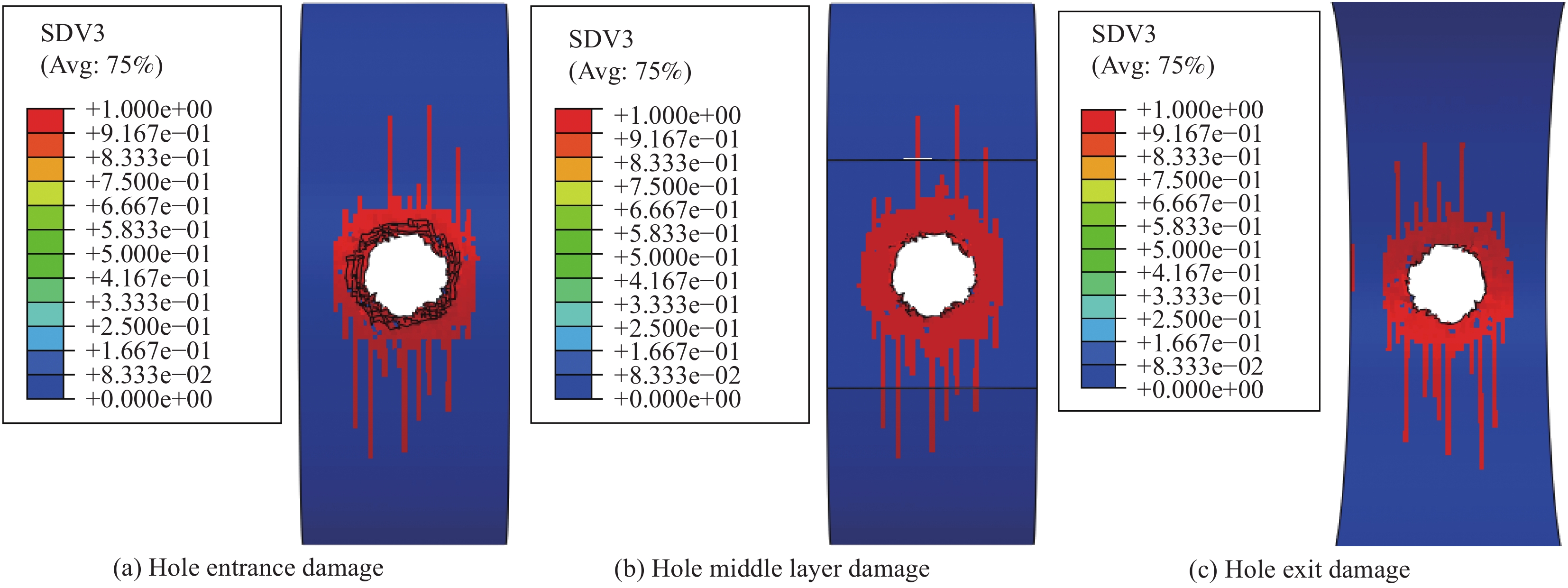

三维钻削仿真试验选取在加工参数(转速n=5000 r/min,进给速度f=40 mm/min)下对CFRP管进行钻削仿真试验。图6 和图7分别为CFRP管直接钻削及附有衬套的CFRP管分层损伤情况。可知,孔出入口形貌呈椭圆形,但损伤程度不一样,孔入口的长轴与短轴之比小于孔出口,即孔出口的分层损伤程度最为严重。由图6可知,孔入口最大损伤面积的直径为5.44 mm,修正分层因子为1.12,孔出口最大损伤面积的直径为5.65 mm,修正分层因子为1.18。由图7可知,孔入口最大损伤面积的直径为5.33 mm,修正分层因子为1.07,孔出口最大损伤面积的直径为5.36 mm,修正分层因子为1.08。以修正分层因子为评价标准,孔入口质量提高了4.4%,孔出口质量提高了8.3%。综上所述,在CFRP管内外附有铝合金衬套可使孔质量得到大幅度提高。

3. CFRP管制孔的工艺

3.1 制孔试验

制孔试验设备为BM850T立式加工中心,可用于加工板类、盘类件、壳体件、模具等精度高、工序多、形状复杂的零件。利用超景深显微镜VHX-900F对孔质量进行测量和观察。

为再次验证在CFRP管内外附有铝合金衬套可抑制加工损伤,采用两种加工方式进行制孔试验:(1)将CFRP管直接装夹在工作台上进行制孔,如图8(a)所示;(2)首先将根据CFRP管内外径尺寸配做的铝合金衬套附在CFRP管内外,然后将装配好的CFRP管装夹在工作台上进行制孔试验,如图8(b)所示。

在制孔过程中刀具与材料之间剧烈的摩擦会产生大量切削热,且制孔过程属于半封闭加工,CFRP散热能力较差,导致切削热不能及时排出,一旦切削热达到环氧树脂基体玻璃化转变温度时,CFRP力学性能会大幅度削弱。为避免切削热对制孔工艺研究的影响,在制孔过程中注入切削液并采用啄式钻孔。

为得到最适合加工参数和了解加工参数对孔质量的影响,钻削加工参数取值范围为:主轴转速n=1 000、2 000、3 000、4 000、5 000、6 000 r/min;进给速度f=40、60、80、100、120 mm/min。由于制孔数量较多,因此每20个孔更换一次刀具。

3.2 制孔试验结果与分析

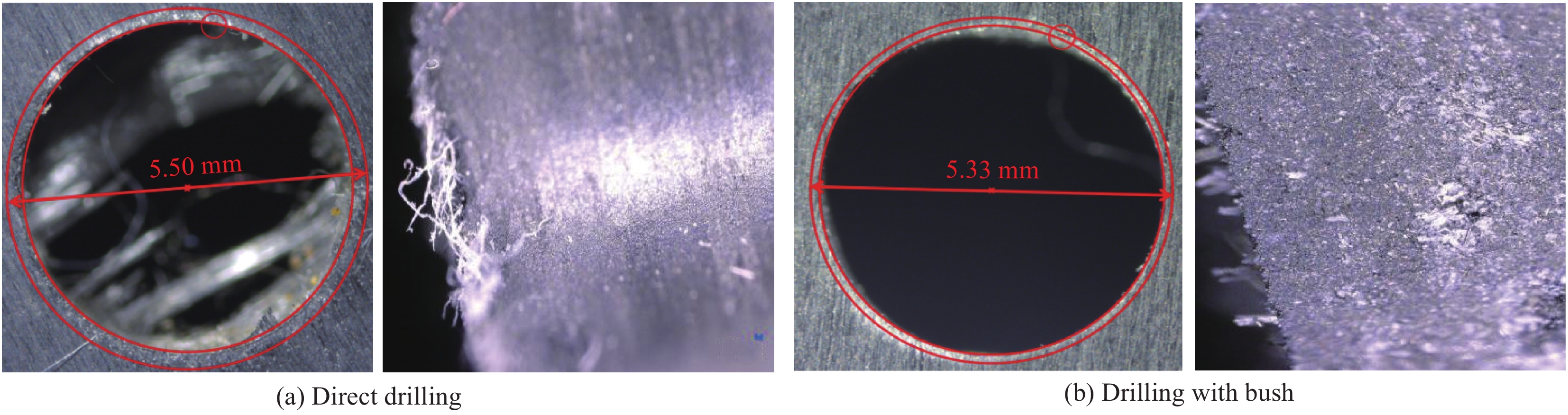

3.2.1 CFRP管孔的入口分层

超景深显微镜VHX-900F观测在加工参数(n=5 000 r/min,f=40 mm/min)下孔入口损伤形貌如图9所示。由图9(a)可知,在CFRP管直接装夹制孔方式下,孔入口最大损伤面积的直径为5.50 mm,修正分层因子为1.13,孔入口有少量毛刺,透过孔入口可看到孔出口有大量毛刺。由图9(b)可知,在CFRP管附有衬套制孔方式下,孔入口最大损伤面积的直径为5.33 mm,修正分层因子为1.08,孔入口无毛刺但有轻微啃边损伤,孔出口可见度较高且有少量毛刺。

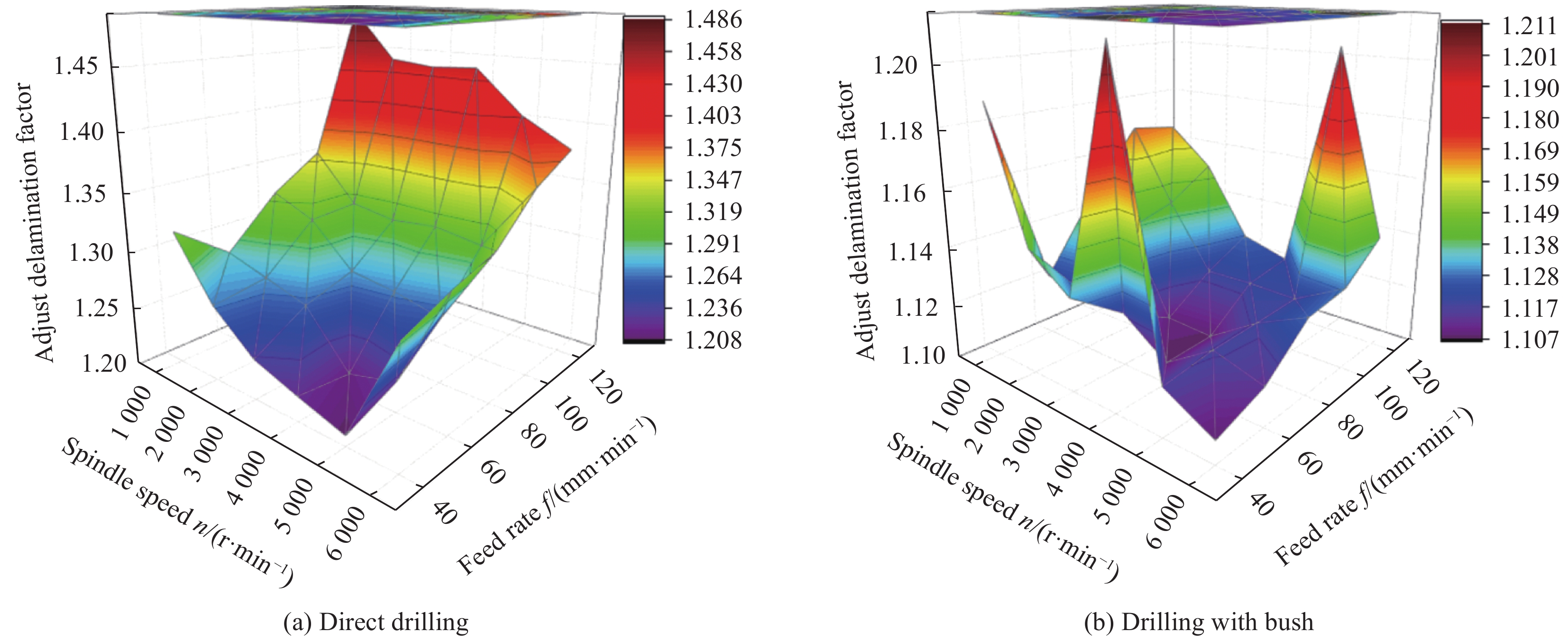

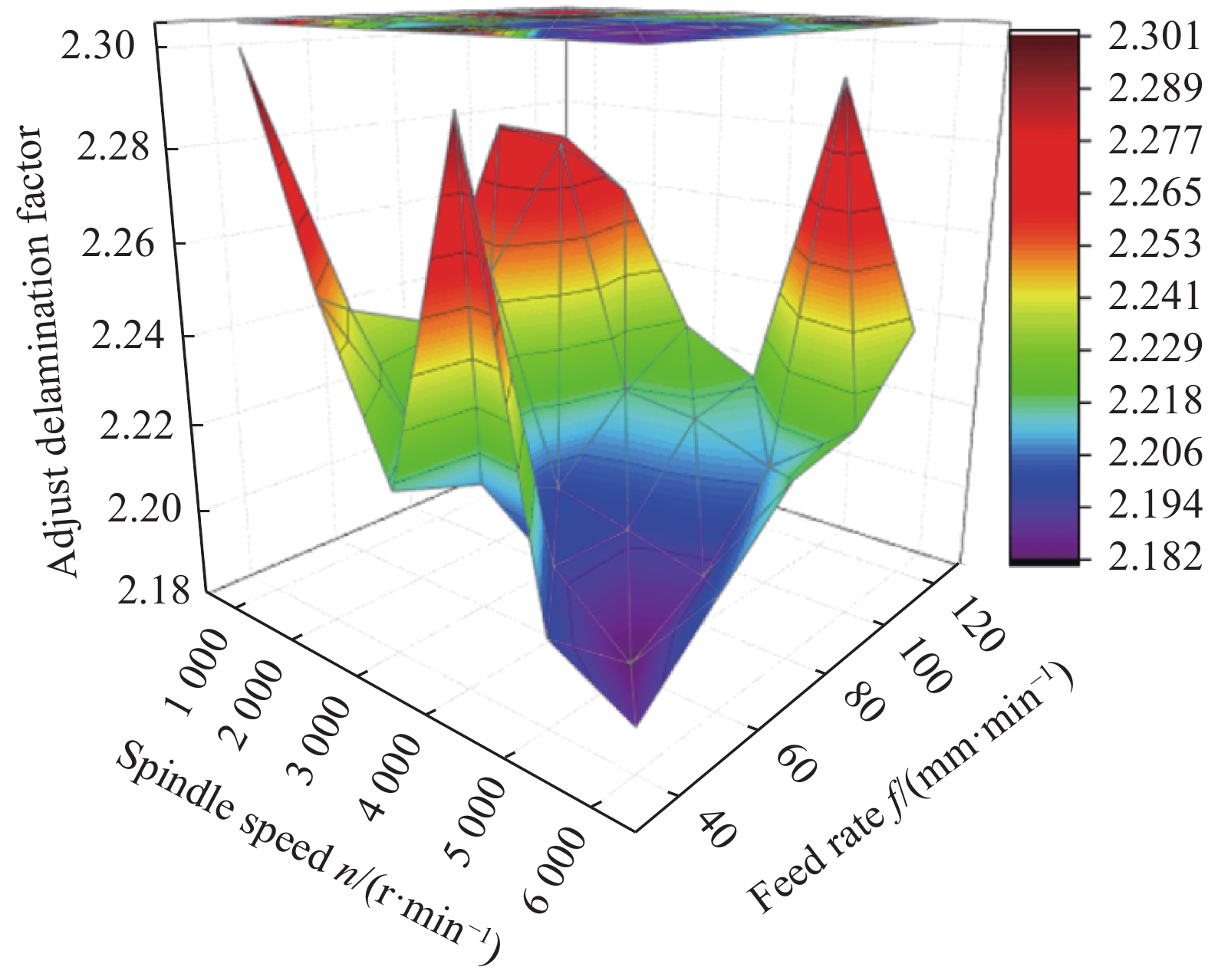

采用修正分层因子评价方法来定量计算两种加工方式在不同加工参数下孔入口质量,所需数据采用超景深显微镜测得。图10(a)为采用CFRP管直接装夹制孔方式在不同加工参数下孔入口损伤程度。图10(b)为采用CFRP管附有衬套制孔方式在不同加工参数下孔入口损伤程度。

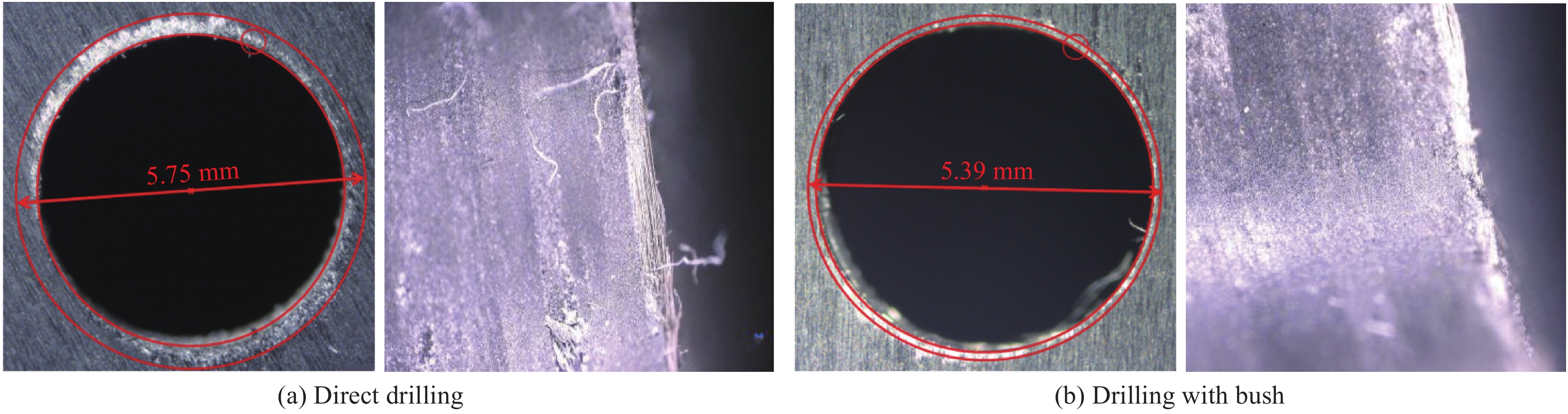

3.2.2 CFRP管孔的出口分层

超景深显微镜VHX-900F观测在加工参数(n=5 000 r/min、f=40 mm/min)下孔出口损伤形貌如图11所示。由图11(a)可知,在CFRP管直接装夹制孔方式下,孔出口最大损伤面积的直径为5.75 mm,修正分层因子为1.21。由图11(b)可知,在CFRP管附有衬套制孔方式下,孔出口最大损伤面积的直径为5.39 mm,修正分层因子为1.12。通过孔出口截面可以看出来直接钻削制孔比附有衬套钻削制孔的分层损伤情况严重。

采用修正分层因子评价方法来定量计算两种加工方式在不同加工参数下孔出口质量,所需数据使用超景深显微镜测得。图12(a)为采用CFRP管直接装夹制孔方式在不同加工参数下孔出口损伤程度。图12(b)为采用CFRP管附有衬套制孔方式在不同加工参数下孔出口损伤程度。

3.2.3 制孔试验结果与分析

采用修正分层因子评价方法计算出孔入口质量提高了4.4%,孔出口质量提高了8.3%,与仿真结果相符。但试验与仿真最大损伤面积直径不同,仿真模拟结果比试验结果小,二者之间的相对误差约为2.3%,相对误差的产生可能是由于钻削热、加工环境因素和材料本身所导致的,仿真模拟并未考虑到。综上所述,本文所建立的三维钻削仿真模型可准确模拟出在钻削CFRP过程中产生的分层损伤情况。

考虑到所制孔用于连接须同时注意孔入口和孔出口质量,提出一种在相同加工参数下孔出入口修正分层因子相加的方法来判断连接孔质量,结果如图13所示。可知,用于制孔最适合加工参数(n=5000 r/min,f=40 mm/min),CFRP连接孔总修正分层因子为2.20。

4. CFRP-金属传动轴扭转试验

4.1 试验方法及设备

采用扭转试验对销接式CFRP-金属传动轴和混合式CFRP-金属传动轴进行对比验证。扭转试验设备为微机控制扭转试验机,量程为1000 N·m。试验机具有扭转值、扭转角自动跟踪测量、加载速率指示及峰值保持等功能,可进行试验数据自动处理和显示。CFRP-金属传动轴进行扭转试验需将传动轴一端进行固定,对另一端增大扭矩。

4.2 销接式CFRP-金属传动轴扭转试验

4.2.1 销接式CFRP-金属传动轴试件

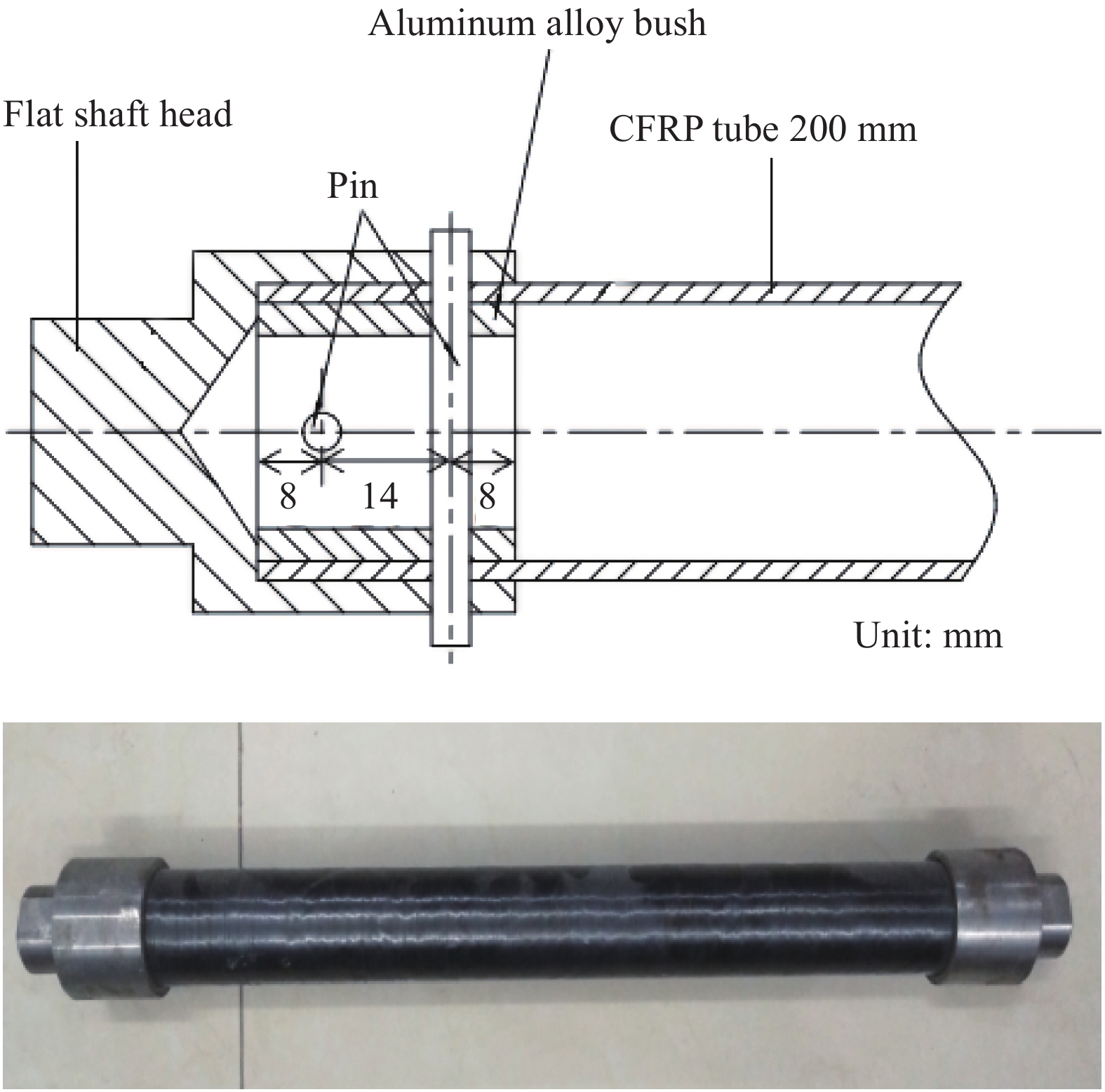

销接式CFRP-金属传动轴采用销钉将CFRP管两端内径与金属轴头连接,销钉和CFRP管上5 mm连接孔无间隙配合连接。连接孔位置采用十字交叉方式,端距为8 mm,孔中心距为14 mm。

销接式CFRP-金属传动轴采用多销钉双搭接连接形式,即用多个销钉将CFRP管与金属轴头进行连接,使作用在紧固件孔内壁的载荷相对均匀。

4.2.2 销接式CFRP-金属传动轴试验结果

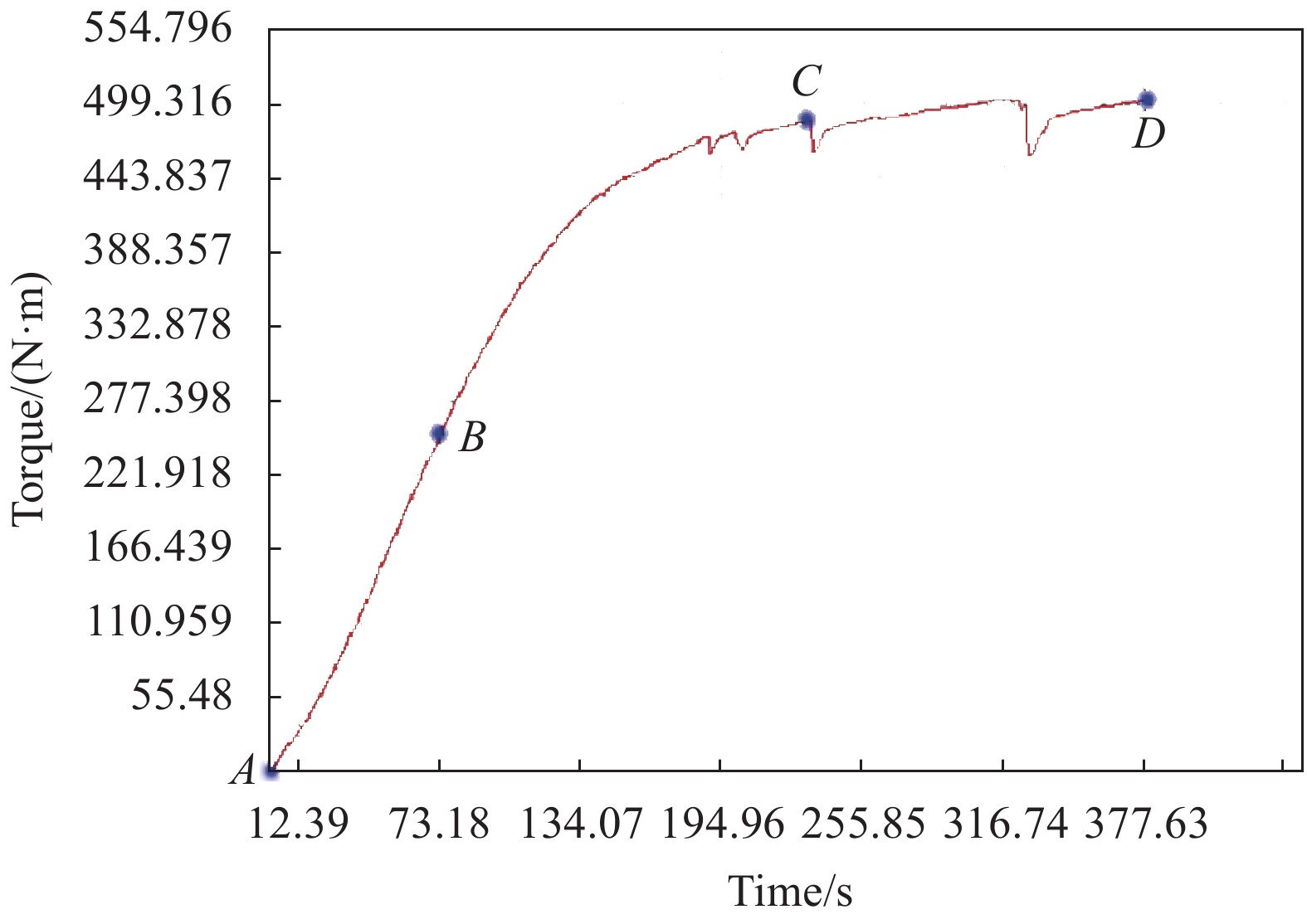

图14为销接式CFRP-金属传动轴扭矩-时间曲线。可知,在AB阶段时,曲线斜率不变,扭矩与时间成线性关系,此时通过CFRP管和金属轴头之间的摩擦力、销钉和连接孔之间的挤压力来传递扭转载荷。销接式CFRP-金属传动轴传动正常,未失效。在BC阶段时,曲线的斜率逐渐减小,扭矩与时间成非线性关系,此时连接孔出入口处分层损伤程度出现细微增长。销接式CFRP-金属传动轴传动正常,未失效。在CD阶段时,曲线的斜率几乎为0,说明销接式CFRP-金属传动轴已经完全失效,最大扭矩为499 N·m。曲线中出现跳动是由于CFRP管连接孔损伤积累所造成的。

4.2.3 销接式CFRP-金属传动轴试验分析

CFRP在工作时易发生表面开裂、纤维断裂、剪切破坏、脱层等局部失效形式。制孔已经使连接孔周围纤维不连续,结构的完整性遭到破坏,在传动过程中会不断加剧连接孔损伤,最后引发连接结构失效。

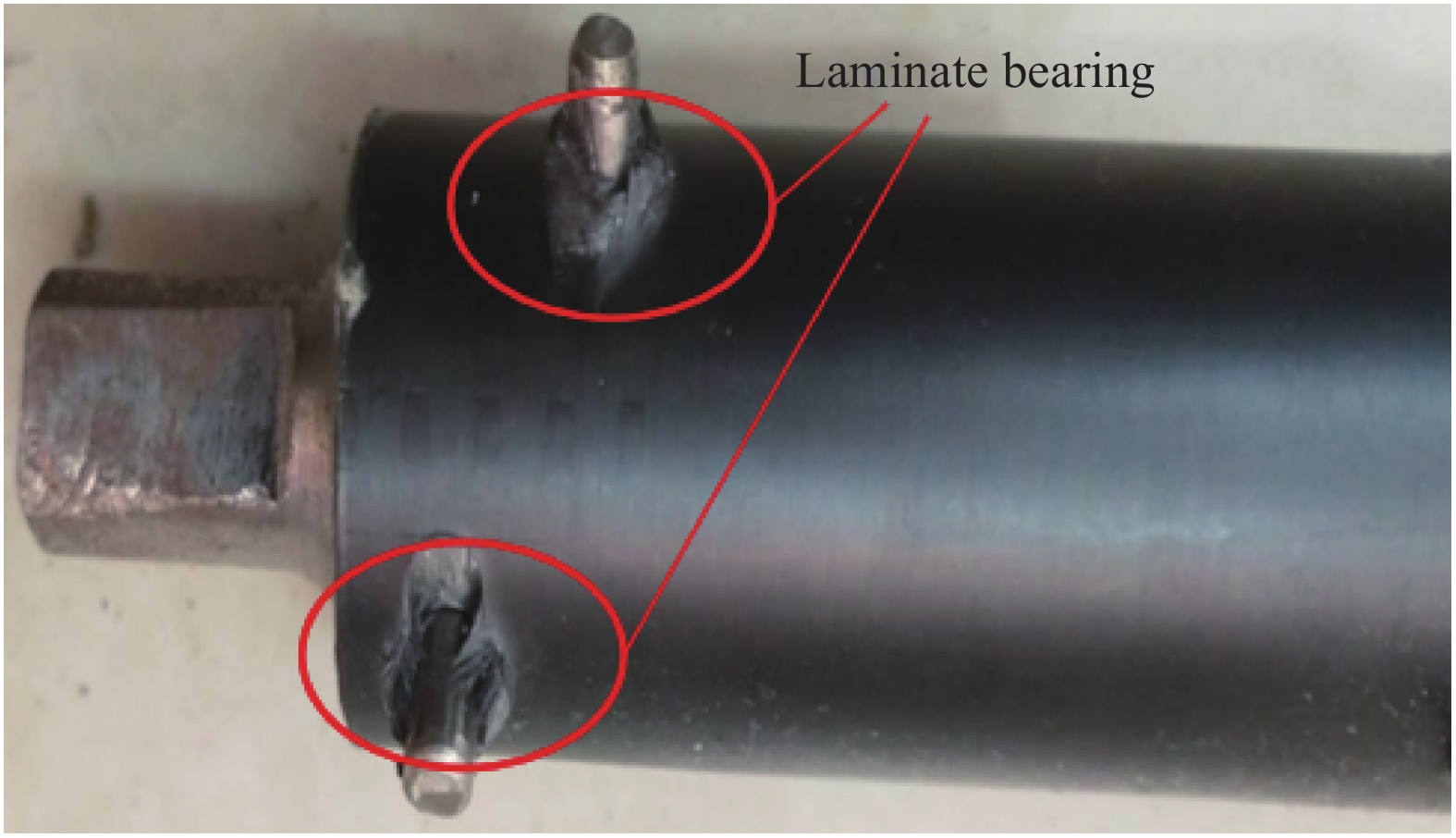

观察试件,发现失效部位发生在CFRP管连接孔处,破坏部位是由销钉对连接孔的挤压作用产生的挤压破坏和在传递扭矩过程中产生的纤维劈裂破坏所造成,销接式CFRP-金属传动轴扭转失效如图15所示。

4.3 混合式连接CFRP-金属传动轴扭转试验

基于销接式CFRP-金属传动轴试验分析结果,提出一种混合式CFRP-金属传动轴连接方法,在CFRP管内外无间隙添加7075-T651铝合金衬套,制孔后用销钉将CFRP管、铝合金衬套、金属轴头连接起来。该连接方式既能抑制纤维沿垂直于纤维层表面的翘起,又能增加与CFRP管的接触面积,分担一部分扭矩,减轻销钉对CFRP管连接孔的挤压作用。由于传动轴需装夹在微机控制扭转试验机,因此将混合式CFRP-金属传动轴外衬套替换成用45号钢做成金属轴头形式。为能够进一步提高传动轴承受扭矩能力,在金属轴头和CFRP管接触部位、销钉和连接孔处进行胶接,以降低连接孔边的应力集中现象,并承担小部分扭转力。混合式CFRP-金属传动轴如图16所示。

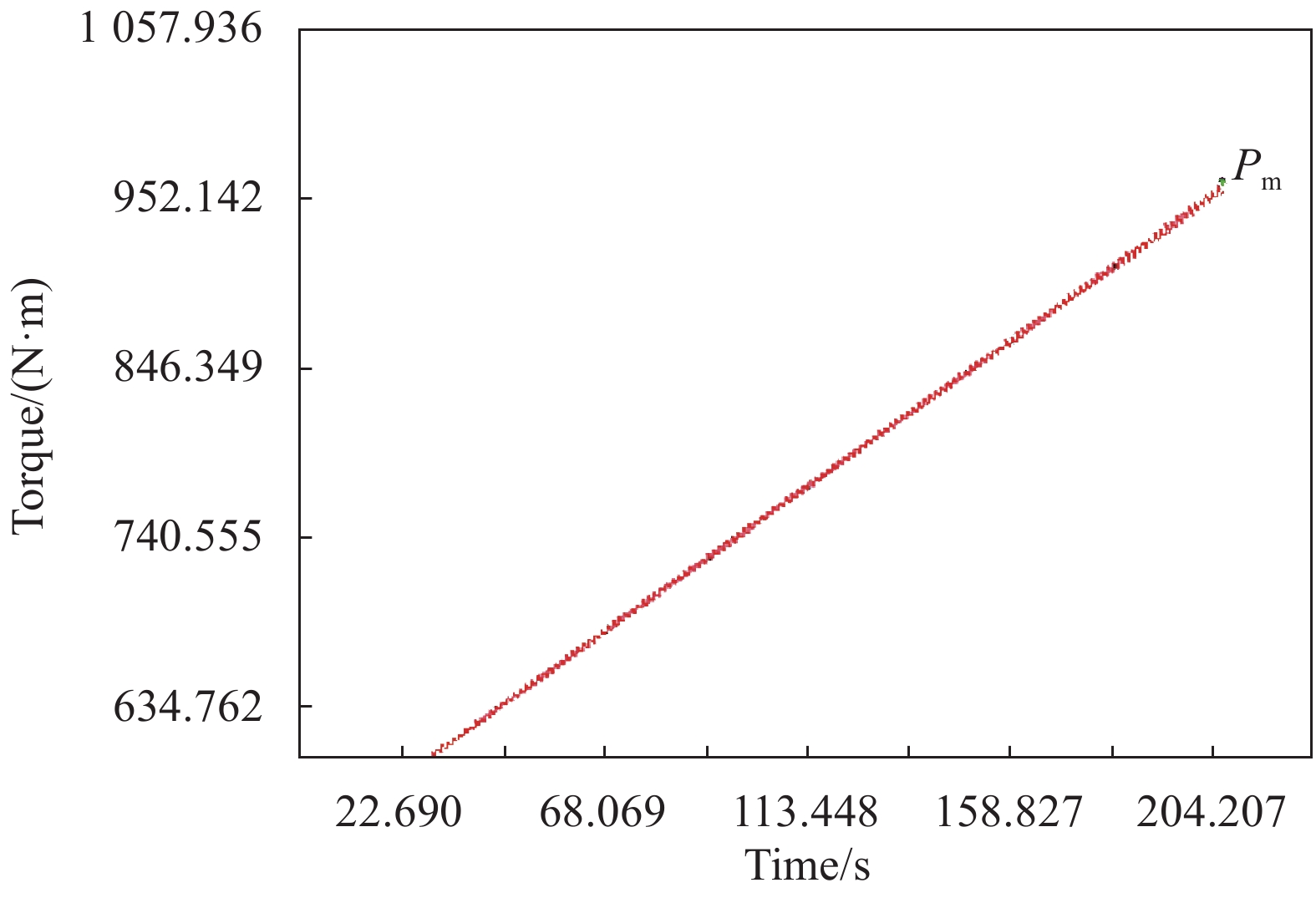

图17为混合式CFRP-金属传动轴扭矩-时间曲线。可知,混合式CFRP-金属传动轴的最大输出扭矩为952 N·m,输出扭矩已超出重载油动四旋翼无人机传动轴所需的800 N·m。

5. 结 论

(1)通过研究导致碳纤维增强树脂复合材料(CFRP)管孔入出口分层损伤的力学行为,提出一种在CFRP管内外添加铝合金衬套的方法,可抑制制孔过程中碳纤维弯曲进而减少孔分层损伤情况。

(2)采用三维Hashin失效准则的判定方法,对CFRP管有无附有铝合金衬套的加工方式进行对比验证,仿真结果显示,孔入口质量提高了4.4%,孔出口质量提高了8.3%。

(3)利用超景深显微镜观测不同加工方式、加工参数下CFRP管的孔入出口损伤形貌,利用定量计算方法判定孔质量,优化制孔工艺,最终得到制孔最优加工参数。

(4)基于扭转试验结果对比分析可知,混合式CFRP-金属传动轴的铝合金衬套可抑制销钉对连接孔的作用,并有效抑制分层损伤增加,CFRP-金属传动轴承受扭矩值从499 N·m提高到952 N·m。

(5)试验证明,在CFRP管内外附有铝合金衬套既能抑制制孔过程中孔出入口分层损伤,又能抑制由销钉对连接孔挤压作用造成的分层损伤加剧现象。

-

表 1 T700 CFRP的材料参数

Table 1 Parameters of T700 CFRP

E1/MPa E2=E3/MPa ν12=ν13 ν23 G12=G13=G23/MPa XT/MPa XC/MPa YT/MPa YC/MPa S12=S13/MPa S23/MPa ρ/(kg·m−3) 115000 6430 0.34 0.28 6000 1500 700 30 100 60 30 1790 Notes: {E_i}—Tensile moduli in different directions; {G_{ij}}—Shear moduli in plane in directions of i and j;ν{}_{ij} —Poisson’s ratios in plane in directions of i and j; i, j—1, 2 or 3; ρ—Density. -

[1] 宿敬亚, 樊鹏辉, 蔡开元. 四旋翼飞行器的非线性PID姿态控制[J]. 北京航空航天大学学报, 2011, 37(9):1054-1058. SU Jingya, FAN Penghui, CAI Kaiyuan. Nonlinear PID attitude control of four-rotor aircraft[J]. Journal of Beijing University of Aeronautics and Astronautics,2011,37(9):1054-1058(in Chinese).

[2] OMID M, SALEH M. Adaptive sliding mode control for finite-time stability of quad-rotor UAVs with parametric uncertainties[J]. ISA Transactions,2018,72:1-14.

[3] 陈燕, 葛恩德, 傅玉灿, 等. 碳纤维增强树脂基复合材料制孔技术研究现状与展望[J]. 复合材料学报, 2015, 32(2):301-316. CHEN Yan, GE Ende, FU Yucan, et al. Research status and prospect of carbon fiber reinforced resin matrix composite pore making technology[J]. Acta Materiae Compositae Sinica,2015,32(2):301-316(in Chinese).

[4] 郭东明. 高性能精密制造[J]. 中国机械工程, 2008, 29(7):757-765. DOI: 10.3321/j.issn:1004-132X.2008.07.001 GUO Dongming. High-performance precision manufacturing[J]. China Mechanical Engineering,2008,29(7):757-765(in Chinese). DOI: 10.3321/j.issn:1004-132X.2008.07.001

[5] ABENA A, SOO S L, ESSA K. A finite element simulation for orthogonal cutting of UD-CFRP incorporating a novel fibre-matrix interface model[J]. Procedia CIRP,2015,31:539-544.

[6] 殷俊伟, 贾振元, 王福吉, 等. 基于CFRP切削过程仿真的面下损伤形成分析[J]. 机械工程学报, 2016, 52(17):58-64. DOI: 10.3901/JME.2016.17.058 YIN Junwei, JIA Zhenyuan, WANG Fuji, et al. Analysis of surface damage formation based on CFRP cutting process simulation[J]. Journal of Mechanical Engineering,2016,52(17):58-64(in Chinese). DOI: 10.3901/JME.2016.17.058

[7] PHADNIS V A, MAKHDUM F, ROY A, et al. Drilling in carbon/epoxy composite: Experimental investigations and finite element implementation[J]. Composites Part A: Applied Science and Manufacturing,2013,47:41-51. DOI: 10.1016/j.compositesa.2012.11.020

[8] 齐振超. CFRP/金属叠层结构钻削力建模与分层控制方法研究[D]. 西安: 西北工业大学, 2015. QI Zhenchao. Drilling force modeling and delamination control for CFRP/metal laminated structures research on the method of preparation[D]. Xi’an: Northwest Polytechnical University, 2015(in Chinese).

[9] 章伟, 黄威武, 屈植华, 等. 碳纤维复合材料-钛合金叠层板钻孔工艺研究[J]. 硬质合金, 2017, 34(1):21-26. ZHANG Wei, HUANG Weiwu, QU Zhihua, et al. Research on drilling technology of carbon fiber composites-titanium alloy laminate[J]. Cemented Carbide,2017,34(1):21-26(in Chinese).

[10] RAHME P, LANDON Y, LACHAUD F, et al. Drilling of thick composite material with a small-diameter twist drill[J]. The International Journal of Advanced Manufacturing Technology,2015,76(9-12):1543-1553.

[11] 王福吉, 成德, 赵猛, 等. 冷却空气流向对CFRP制孔刀具磨损及孔质量的影响[J]. 复合材料学报, 2019, 36(2):410-417. WANG Fuji, CHENG De, ZHAO Meng, et al. Effect of cooling air flow on wear and hole quality of CFRP drilling tools[J]. Acta Materiae Compositae Sinica,2019,36(2):410-417(in Chinese).

[12] CAPELLO E. Workpiece damping and its effect on delamination damage in drilling thin composite laminates[J]. Journal of Materials Processing Technology,2004,148(2):186-195.

[13] 房子昂, 赵丽滨, 刘丰睿, 等. 碳纤维/树脂复合材料多钉连接钉载系数测试方法[J]. 复合材料学报, 2019, 36(12):2795-2804. FANG Ziang, ZHAO Libin, LIU Fengrui, et al. Test method for nailing load coefficient of carbon fiber/resin composite multi-nailing joint[J]. Acta Materiae Compositae Sinica,2019,36(12):2795-2804(in Chinese).

[14] 刘志明, 许昶. 碳纤维增强环氧树脂复合材料与铝板胶螺混合连接接头失效仿真[J]. 复合材料学报, 2019, 36(10):2308-2315. LIU Zhiming, XU Chang. Failure simulation of composite joint of carbon fiber reinforced epoxy resin composite and aluminum plate rubber screw[J]. Acta Materiae Compositae Sinica,2019,36(10):2308-2315(in Chinese).

[15] KIM H S, LEE D G. Optimal design of the press fit joint for a hybrid aluminum/composite drive shaft[J]. Composite Structures,2004,70(1):33-47.

[16] 石国成, 张锦光, 马祥禹, 等. 碳纤维轴管与金属轴头过盈连接研究[J]. 玻璃钢/复合材料, 2019(5):51-55. SHI Guocheng, ZHANG Jinguang, MA Xiangyu, et al. Study on interference connection between carbon fiber shaft tube and metal shaft head[J]. Glass Fiber Reinforced Plastics/Composites,2019(5):51-55(in Chinese).

[17] 宿友亮. 切削CFRP中材料的力学行为研究[D]. 大连: 大连理工大学, 2017. SU Youliang. Mechanical behavior of materials in cutting CFRP[D]. Dalian: Dalian University of Technology, 2017(in Chinese).

[18] QI Z C, ZHANG K F, LI Y, et al. Critical thrust force predicting modeling for delamination-free drilling of metal-FRP stacks[J]. Composite Structures,2014,107:604-609.

[19] 王福吉, 胡海波, 张博宇, 等. 复合材料成型分层缺陷在钻削横刃挤压阶段的扩展行为[J]. 机械工程学报, 2019, 55(11):197-204. DOI: 10.3901/JME.2019.11.197 WANG Fuji, HU Haibo, ZHANG Boyu, et al. Extended behavior of lamination defects in composite forming during drilling and transverse edge extrusion[J]. Journal of Mechanical Engineering,2019,55(11):197-204(in Chinese). DOI: 10.3901/JME.2019.11.197

[20] 张明辉, 周储伟, 鲁浩. 碳纤维复合材料单向板钻孔分层损伤的数值模拟[J]. 机械工程材料, 2019, 43(9):73-77. ZHANG Minghui, ZHOU Chuwei, LU Hao. Numerical simulation of delamination damage in borehole of carbon fiber composite plate[J]. Materials for Mechanical Engineering,2019,43(9):73-77(in Chinese).

[21] 孙少周, 周光明, 王新峰. 含分层复合材料层板的压缩性能[J]. 材料科学与工程学报, 2011, 29(4):601-604. SUN Shaozhou, ZHOU Guangming, WANG Xinfeng. Compressive properties of laminated composite laminates[J]. Journal of Materials Science and Engineering,2011,29(4):601-604(in Chinese).

[22] KHAN A A, BIMAL S, DEY K K, et al. Current conveyor based R- and C- multiplier circuits[J]. AEUE: International Journal of Electronics and Communications,2002,56(5):312-316.

[23] 李桂玉. 叠层复合材料钻削加工缺陷产生机理及工艺参数优化[D]. 济南: 山东大学, 2011. LI Guiyu. Mechanism of defect generation and optimization of process parameters in drilling of laminated composite materials[D]. Jinan: Shandong University, 2011(in Chinese).

[24] DAVIM J P, RUBIO J C, ABRAO A M. A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates[J]. Composites Science and Technology,2006,67(9):1939-1945.

-

期刊类型引用(7)

1. 尹文潇,章桥新,余金桂. CFRP弧面结构件钻削工艺参数对材料损伤的影响研究. 工具技术. 2024(09): 80-87 .  百度学术

百度学术

2. 聂慧阳,倪德,刘之扬,文湘隆,童诗坛,张锦光. 法兰轴管一体成型的全碳纤维复合材料传动轴制备与扭转试验. 工程塑料应用. 2024(12): 97-102 .  百度学术

百度学术

3. 邱新义,李鹏南,牛秋林,李树健,李常平,唐玲艳. CFRP管面钻削缺陷形成机制. 复合材料学报. 2023(01): 141-150 .  本站查看

本站查看

4. 陈根余,陶能如,李明全,王彪,肖铮铭. 碳纤维复合材料激光制孔技术研究进展. 复合材料学报. 2022(04): 1395-1410 .  本站查看

本站查看

5. 赵文辉,孙晓恒,张伟东,郑鹏,杨帆. 四旋翼飞行器齿轮箱-支臂组件动态特性分析. 兵工学报. 2022(05): 1175-1184 .  百度学术

百度学术

6. 李艳芬,袁涛. 金属材料损伤分析中的物理冶金分析技术研究. 冶金与材料. 2022(05): 66-68 .  百度学术

百度学术

7. 李树健,戴隆宇,邹适,李常平,李鹏南,邱新义. CFRP管钻孔加工中管径对钻削轴向力与损伤特性的影响. 航空制造技术. 2022(22): 36-43 .  百度学术

百度学术

其他类型引用(4)

-

下载:

下载: