Quasi-static and dynamic shear properties of C/C composite pins

-

摘要: 根据复合材料销钉剪切试验的需要,设计剪切试验装置。利用电子万能试验机和落槌冲击试验系统完成C/C复合材料销钉在准静态和动态加载工况下的面内剪切力学性能试验,并通过SEM试验系统分析其剪切失效模式和失效机制。结果表明:C/C复合材料销钉抗剪切强度具有明显的应变率效应,随着加载速率的增加,其抗剪切强度显著提高;C/C复合材料在不同加载速率下失效模式不同,准静态加载工况下纤维与基体严重剥离,纤维束丧失整体承载能力,其破坏过程表现出“伪塑性”失效特征;动态加载工况下纤维与基体未发生明显剥离,纤维束整体承载,其破坏过程表现为“脆性”失效特征。C/C复合材料在不同加载速率下剪切失效模式的不同可归结为内部缺陷扩展的应变率效应。Abstract: A shear test machine was designed according to the needs of composite pins’ shear tests. An electric universal testing machine was used to test the quasi-static in-plane shear properties of C/C composites, and a drop weight impact testing machine was used to test the dynamic in-plane shear properties of C/C composites. Then the shear failure mode and shear failure mechanism of C/C composite pins were analyzed using the SEM test apparatus. The results show that the shear failure strength of C/C composite pins is sensitive to strain rate, and it increases remarkably with the increasing strain rate. The shear failure mode of C/C composites is sensitive to the strain rate. Under quasi-static loading, the fiber/matrix interface is seriously debonded and the C/C composites show “pseudo-plastic” failure characteristics, while under dynamic loading, almost all the fibers are surrounded by matrix and the composites show “brittle” failure characteristics. The difference of C/C composites’ shear failure modes under different loading rates is related to the strain rate sensitivity of the expansion of internal-cracks.

-

Keywords:

- C/C composites /

- shear /

- strain rate /

- failure mode /

- failure mechanism

-

C/C复合材料具有比强度高、比刚度高、高温下力学性能稳定等特点,已被广泛应用于航空航天领域。研究表明,C/C复合材料的使用温度可达到2600℃,且在特定使用温度范围内随着温度的升高,其强度不降反升,因此被当作高速飞行器热结构的理想材料,如航天飞机的鼻锥、热防护系统及火箭发动机的喷管、喉衬、燃烧室等[1-3]。国内外学者对C/C复合材料力学性能进行了大量研究工作,主要集中于研究材料在准静态下的拉伸、压缩、弯曲及剪切力学性能[4-8]。

飞行器结构长期服役于振动、噪声及冲击等动态环境下[9],且大量研究表明,复合材料具有应变率效应[10-18],因此关于C/C复合材料动态力学性能的研究显得尤为重要。目前,关于C/C复合材料动态力学性能的研究相对较少,且主要集中于动态压缩力学性能的研究。袁秦鲁等[16-17]采用分离式霍普金森压杆(SHPB)试验系统研究了C/C复合材料的动态压缩力学性能,研究表明,C/C复合材料的压缩强度和刚度随着应变率的增大而提高,并认为其破坏模式的不同可归结为基体及界面强度的应变率效应。Li等[18]研究了应变率对C/C复合材料纵向和横向压缩力学性能的影响规律,研究表明,C/C复合材料在纵向和横向上的压缩性能均具有明显应变率效应,随着应变率的增大,C/C复合材料的压缩强度和弹性模量均显著增大。由于复合材料制备工艺的限制,大型飞行器结构整体成型较为困难,一般采用先局部成型,后通过销钉、螺栓等机械连接方式组装成整体[19-22]。同时,受到高速飞行器苛刻服役环境的限制,适用于高温环境的C/C复合材料是理想的连接件材料,目前C/C复合材料螺栓已成功应用于航空航天部件的连接。郭飞等[23-24]采用可靠性分析方法研究了C/C复合材料销钉不同加载方向上的剪切力学性能,并提出基于损伤理论的剪切本构模型。王杰等[25]以C/C复合材料螺栓和圆柱销为对象,研究了沿不同纤维增强方向加工螺栓的准静态力学性能,研究表明,沿平行于碳布铺层方向加工的连接件抗剪强度较高。但对于高速飞行器主要受动态剪切载荷作用的复合材料连接件,关于动态剪切力学性能的研究却十分匮乏。

本文以C/C复合材料销钉为研究对象,通过自行设计的剪切试验装置完成准静态和多种加载速率下的动态剪切试验,研究加载速率对其剪切力学性能的影响规律。利用SEM观察C/C复合材料销钉的剪切失效断面,分析其在不同加载速率下的失效模式。最终将试验测得的载荷-位移数据与SEM断面扫描结果相结合,分析不同加载速率下C/C复合材料的剪切失效机制。

1. 试验材料及方法

1.1 原材料及装置

试件为四川骏瑞碳纤维材料有限公司生产的同一批次圆柱形针刺C/C复合材料销钉。该批次C/C复合材料的表观密度约为1.62 g/cm3,其铺层方式为:0°无纬布、胎网、90°无纬布、胎网循环铺层到一定厚度,再通过垂直于碳布方向进行针刺,以提高其层间性能。最后通过机械加工获得长为68 mm、直径为8.95 mm的C/C复合材料销钉,其轴线方向为0°无纬布内纤维方向。

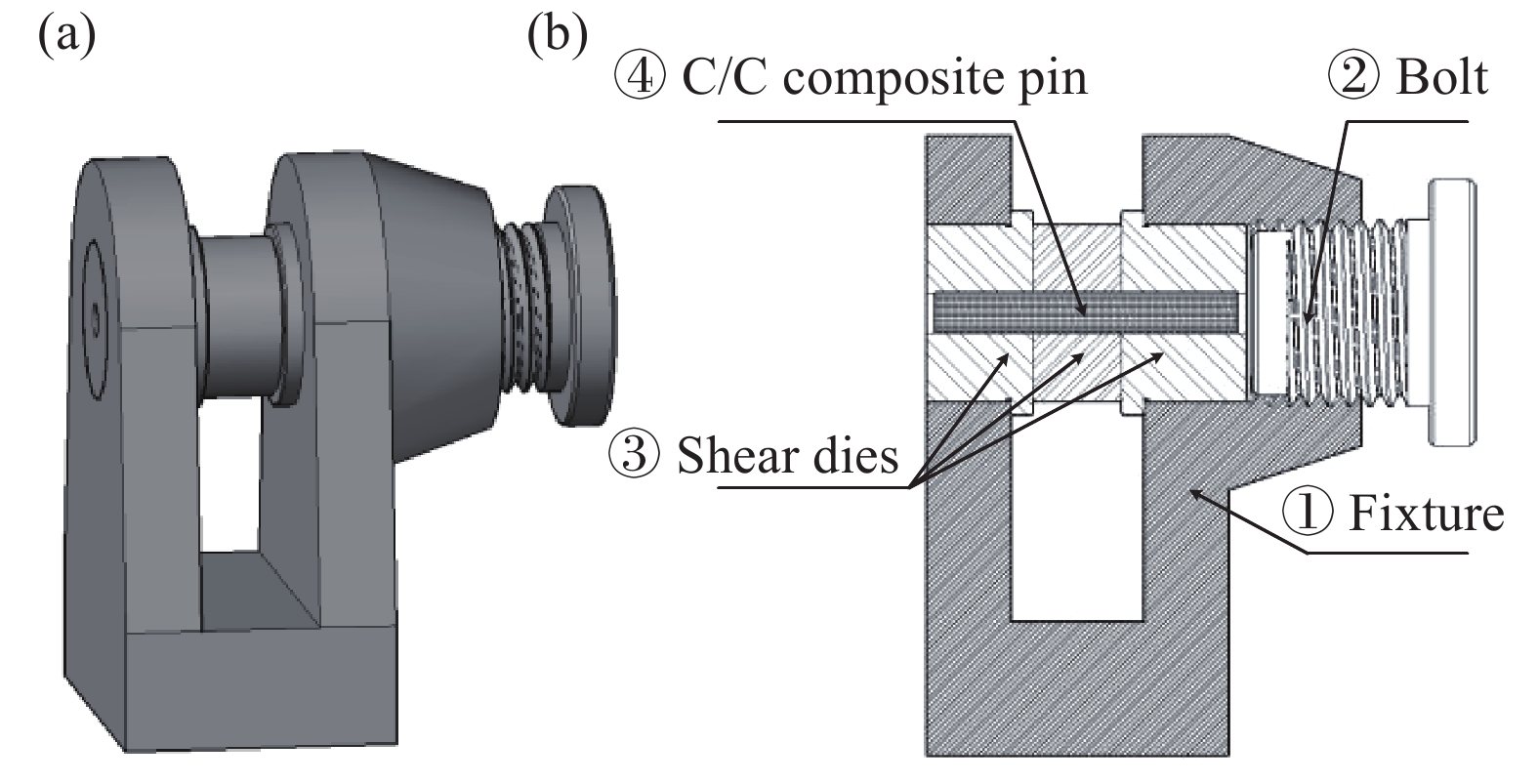

图1为根据ASTM B769—11[26]的技术要求及本试验需要设计的C/C复合材料销钉剪切测试装置(图1(a)为三维图,图1(b)为剖面图),由带内螺纹固定装置、带外螺纹预紧装置、3个剪切内环组成,其中C/C复合材料销钉贯穿于三个剪切内环中。为降低试验中内环之间摩擦力而引起的试验误差,内环间的接触面采用磨床加工,试验前将未放置试件的剪切试验装置在电子万能试验机上加载测得剪切内环之间最大摩擦力仅为12 N左右,在本次试验中可忽略其对试验结果的影响。进行剪切试验时,首先将C/C复合材料销钉贯穿放置于3个剪切内环中,然后拧紧预紧装置实现内环之间的完全贴合,最后通过对中部剪切内环施加竖向载荷以完成对C/C复合材料销钉剪切力学性能的测量。本团队之前已开展了C/C复合材料在不同方向上准静态剪切力学性能研究,研究表明,C/C复合材料的剪切性能在不同方向上具有一定的差异性[23],为排除剪切方向对研究结果的影响,本文仅开展不同加载速率下C/C复合材料面内剪切试验研究,该装置同样适用于研究其他方向上C/C复合材料剪切性能的应变率效应。

1.2 试验方法

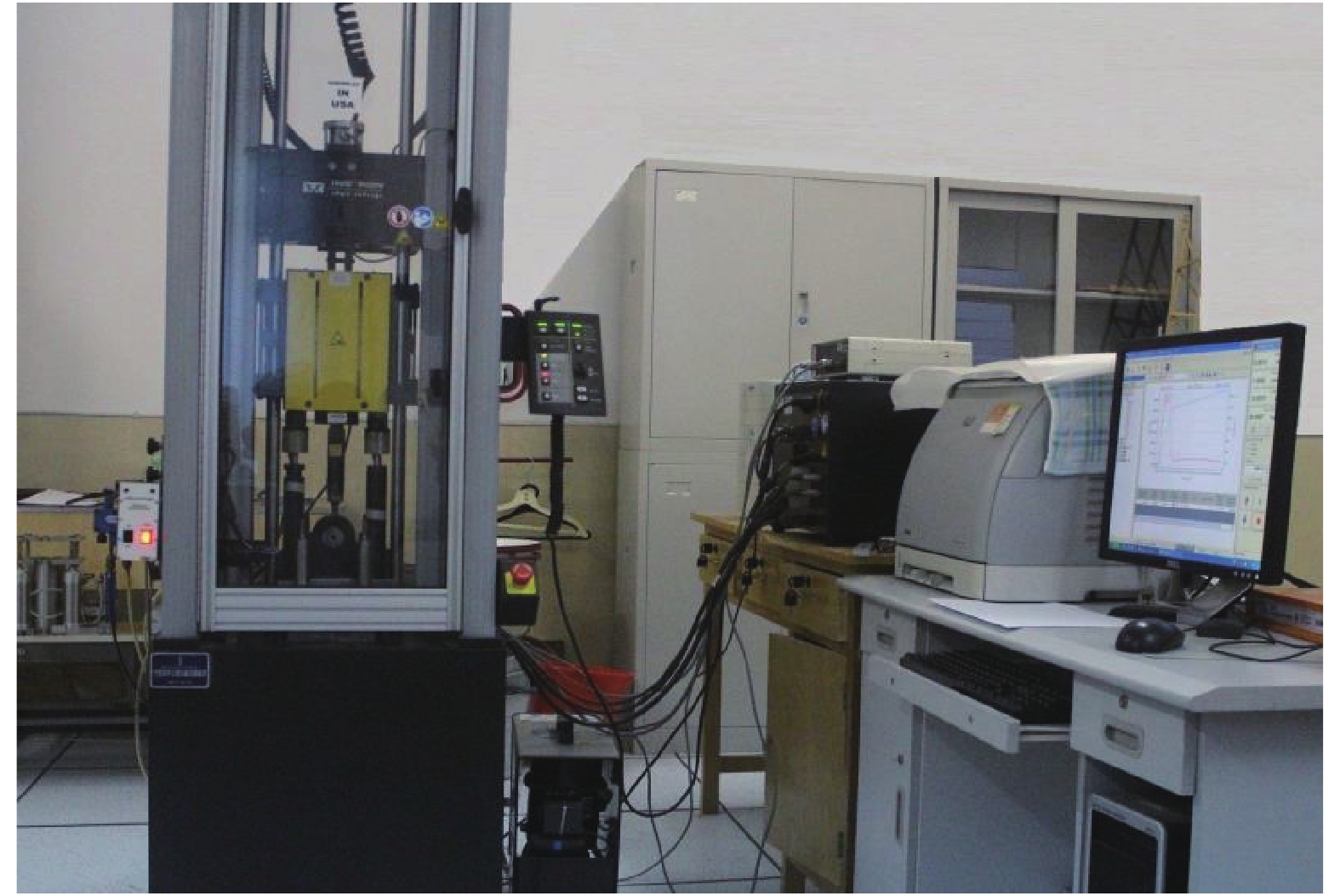

C/C复合材料销钉准静态压缩剪切试验在美国Instron公司生产的3367双立柱电子万能试验机上完成,加载速率为0.3 mm/min,共完成5次试验。销钉抗剪切强度为

τmax (1) 式中:

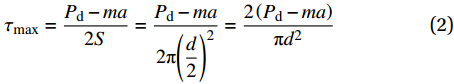

{P_{\rm{s}}} 为准静态加载极限载荷;S为销钉截面积;d为销钉剪切面平均直径,取5次测量的平均值。C/C复合材料销钉动态剪切试验在美国Instron公司生产的9250HV落槌冲击试验机上完成,试验系统如图2所示。分别完成了1 m/s、5 m/s和10 m/s加载速率下的销钉冲击剪切试验,每种加载工况各完成不少于5次试验。在整个冲击加载过程中,锤头的速率变化不大,可认为是匀速加载,但由于加载时间较短,在计算抗剪切强度时应考虑中部剪切内环加速度项的影响,C/C复合材料销钉冲击抗剪切强度为

{\tau _{\max }} = \frac{{{P_{\rm{d}}} - ma}}{{2S}} = \frac{{{P_{\rm{d}}} - ma}}{{2{\rm{{\text{π}} }}{{\left( {\dfrac{d}{2}} \right)}^2}}} = \frac{{2\left( {{P_{\rm{d}}} - ma} \right)}}{{{\rm{{\text{π}} }}{d^2}}} (2) 式中:

{P_{\rm{d}}} 为冲击加载极限载荷;m为中部内环质量,为0.179 kg;a为中部剪切内环加速度,可根据速度梯度求得。2. 结果与分析

2.1 C/C复合材料销钉的剪切破坏形貌

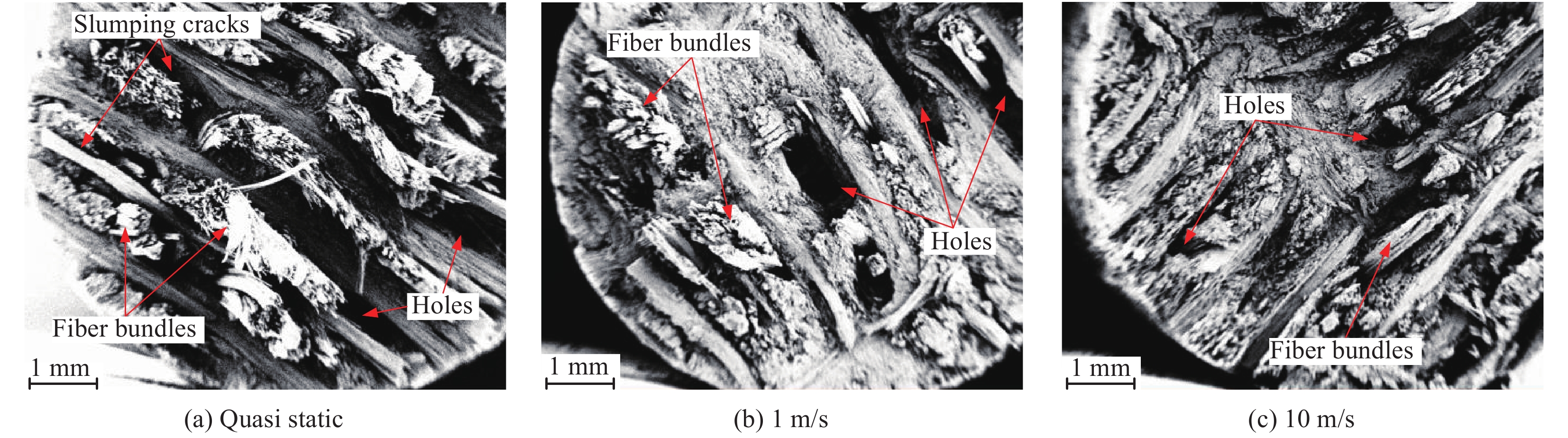

图3为C/C复合材料销钉在不同加载速率下的宏观剪切断面。从图3(a)可以看出,在准静态加载工况下,C/C复合材料销钉拔出纤维较多且较长,同时在断面上形成大量由于纤维束拔出而留下的孔洞;在相互垂直的纤维束之间有较多滑移裂缝,该裂缝是由于C/C复合材料销钉在剪切载荷作用下其轴向纤维束受到非轴向拉拔载荷作用而发生与非轴向纤维束相对滑动产生的;C/C复合材料在准静态下的失效模式以纤维束的拉拔破坏为主。从图3(b)可以看出,与准静态相比,在加载速率为1 m/s的工况下,C/C复合材料销钉剪切断面上拔出纤维束相对较少,虽有一定量的纤维拔出孔洞,但其数量明显少于准静态剪切断面上的孔洞。从图3(c)可以看出,在加载速率为10 m/s的工况下,C/C复合材料销钉的剪切断面相对较为平整,大量纤维束沿着剪切面被剪断,其剪切断面上纤维束拔出量及孔洞量明显少于准静态和加载速率为1 m/s工况下的剪切断面;C/C复合材料在高加载速率下的失效模式以沿剪切面的剪切破坏为主。

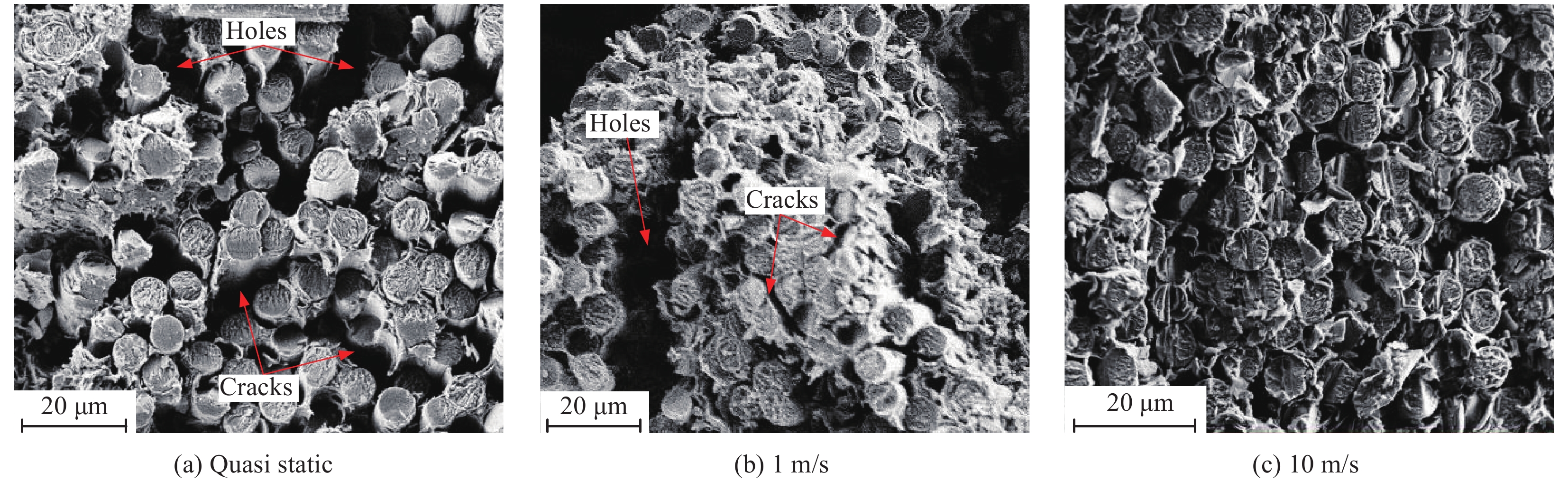

图4为C/C复合材料销钉在不同加载速率下剪切断面拔出纤维束的SEM图像。由图4(a)可见,在准静态加载速率下,纤维束溃散成大量的单丝纤维而丧失整体性,且断裂的单丝纤维长度参差不齐,从纤维束的局部放大图可以发现,拔出纤维表面较为光滑,几乎没有附着碳基体。从图4(b)可以看出,纤维束内存在大量由于纤维和基体分离而出现的裂纹,但相邻的几根纤维仍能通过基体黏结在一起,形成小的纤维束,相对于准静态下拔出的纤维束,其具有一定的整体性。从图4(c)可以看出,纤维与纤维之间通过基体黏接在一起,纤维束断裂面相对较为平整,纤维束内有少量裂纹,且仅限于局部位置,未发展成连通裂纹,从拔出纤维束的局部放大图也可以看出,碳基体紧紧包裹碳纤维,其纤维与基体结合较为紧密。

图5(a)~5(c)分别对应准静态、1 m/s和10 m/s加载速率下纤维束沿剪切面剪断的SEM图像。可以看出,随着加载速率的增大在剪切面上被剪断的纤维束表现出更好的整体性。当准静态加载时,纤维束的剪切断面内纤维与基体发生严重分离而出现大量的裂纹,在剪切载荷作用下大量纤维沿着剪切面被剪断,然而有少量纤维由于缺乏基体的约束被拔出从而在剪切面上形成孔洞。随着加载速率的提高,1 m/s加载工况下在纤维束剪切断面上仅有少量裂纹出现,同时也有少量纤维被拔出而形成孔洞;10 m/s加载工况下纤维束剪切断面较为平整,剪切面上几乎没有纤维与基体分离的裂纹和纤维拔出而形成的孔洞。

由于制备工艺的限制,C/C复合材料内部不可避免地存在大量微孔隙、微裂纹等缺陷。在准静态加载过程中,由于加载时间较长,其基体内部缺陷充分扩展,基体对纤维束的约束力降低,C/C复合材料销钉在面内剪切载荷作用下轴向纤维束在铺层面内发生沿剪切方向的偏移,轴向纤维束由受剪切应力为主变为受拉伸应力为主,最终其失效模式以纤维束的拉拔破坏为主;同时纤维束内基体对纤维的约束力也降低,纤维束溃散成较多单丝纤维而丧失整体承载能力,在载荷作用下单丝纤维分别在其薄弱截面发生破坏,因此纤维断裂长度参差不齐,且纤维表面较为光滑,即使在局部以剪切应力为主的纤维束剪切断面上由于缺乏基体的约束也有少量纤维被拔出。随着加载时间的缩短,在加载速率为1 m/s的工况下,基体内部缺陷虽有一定程度的扩展,并在纤维束内形成连通裂纹,但大量相邻的纤维仍能通过基体黏结成小的纤维束,使其具有一定的整体承载能力。当加载速率达到10 m/s时,由于加载时间非常短,基体内部缺陷未能充分扩展形成连通裂纹,基体对纤维束具有较强的约束力,C/C复合材料销钉在剪切载荷作用下轴向纤维束在铺层面内较难发生沿剪切方向的偏移,最终轴向纤维束和基体共同发生剪切破坏,其失效模式以沿着剪切面的剪切破坏为主;同时纤维束内基体对纤维的约束力也较强,纤维束表现出较好的整体承载能力,在载荷作用下纤维束整体承载,直至共同达到极限强度时发生破坏,在纤维束上形成较为平整的断裂面,且断裂后纤维与基体仍保持较为紧密的结合。C/C复合材料销钉在不同剪切加载速率下表现出不同失效模式可归因于其材料内部缺陷扩展的应变率效应。

2.2 C/C复合材料销钉的剪切力学性能

图6为C/C复合材料销钉在不同剪切加载速率下的典型剪切载荷-位移曲线。可知,在加载初期由于C/C复合材料销钉内部应力较小,未达到组分材料的强度极限,材料内部几乎没有发生损伤扩展现象,载荷-位移曲线表现出较好的线性特征,仅在加载速率为1 m/s的工况下其载荷-位移曲线有小幅振荡,主要是由于在冲击载荷作用下C/C复合材料销钉发生振动引起的,但振幅较小,可忽略其对试验结果的影响。随着加载的进行,材料内部缺陷开始扩展,部分组分材料开始达到极限强度而发生损伤,通过对剪切断面分析可知,损伤在材料内部的扩展与加载速率有关,最终在宏观层面上表现为载荷-位移曲线的差异性。

在准静态加载时,C/C复合材料的剪切破坏具有明显的“伪塑性”特征,即C/C复合材料销钉在达到极限抗剪切强度后没有立即失效,而是出现较长的“载荷平台区”,但组分材料碳纤维和碳基体均为脆性材料,宏观上表现出的“塑性”现象是由于材料内部复杂的细观结构导致的。当加载速率较慢时,随着加载的进行,碳基体内部缺陷得到充分扩展,基体承载能力急剧下降,因此材料在较小变形时即达到“塑性”阶段;随着加载的继续进行,基体对纤维束的约束力急剧下降,纤维束溃散成较多的单丝纤维,丧失基体约束的纤维在剪切载荷作用下更易发生偏转,在宏观层面表现为较大的剪切变形及较低的剪切刚度;同时由于C/C复合材料内部纤维排布的非均匀性及纤维强度的离散性,在载荷作用下部分纤维提前达到极限强度而发生破坏,应力在C/C复合材料内发生重分布,未达到极限强度的纤维继续承载,C/C复合材料销钉抗剪切承载力变化不大,而出现较长的“载荷平台区”。从SEM断面扫描分析可知,在加载速率为1 m/s的工况下,C/C复合材料的纤维束整体性较准静态略微加强,但仍有较多裂纹扩展及连通现象,因此其载荷-位移曲线表现出与准静态相似的“伪塑性”特征,但其抗剪切承载力有一定程度的提高,且“载荷平台区”缩短。当加载速率分别为5 m/s和10 m/s时,由于加载速率较快,C/C复合材料销钉内部缺陷未能充分扩展,纤维和基体紧密结合,材料表现出较好的整体性,由于基体限制了纤维的偏移,C/C复合材料销钉的剪切变形相较于准静态更小;同时由于材料整体承载,失效也几乎同时发生,因此C/C复合材料抗剪切承载力相较于准静态更大,在宏观的载荷-位移曲线上表现为C/C复合材料销钉达到极限承载力后的突然失效,其破坏过程近似于“脆性”失效。

图7为C/C复合材料销钉在不同加载速率下的抗剪切强度。可以看出,随着加载速率的增加,C/C复合材料销钉的平均抗剪切强度显著提高,同一加载速率下的抗剪切强度虽有一定离散性,但其偏差远小于加载速率对抗剪切强度的影响。准静态加载工况下,C/C复合材料销钉的平均抗剪切强度为40.23 MPa。在加载速率分别为1 m/s、5 m/s和10 m/s的工况下,C/C复合材料销钉的平均抗剪切强度分别为51.67 MPa、113.25 MPa和149.43 MPa,较准静态分别提高了28.4%、181.5%、271.5%。C/C复合材料销钉抗剪切强度的变化与材料在不同加载速率下的失效模式有关,准静态和低加载速率下C/C复合材料内部纤维与基体严重剥离,其整体性较差,表现出较低的抗剪切强度;高加载速率下C/C复合材料内部纤维与基体紧密结合,材料保持较好的整体性能,其抗剪切强度显著提高。

3. 结 论

(1) 低剪切加载速率下,C/C复合材料销钉断面上有较多且较长的拔出纤维束,其失效模式表现为纤维束的拉拔破坏为主;高剪切加载速率下,C/C复合材料销钉断面上有大量纤维束被剪断,其失效模式表现为沿剪切面的剪切破坏为主。

(2) C/C复合材料销钉在不同加载速率下其加载曲线具有一定的差异性,在低加载速率下,当C/C复合材料销钉达到极限抗剪切强度后仍具有较长的“载荷平台区”,表现为“伪塑性”失效特征;在高加载速率下,当C/C复合材料销钉达到极限抗剪切强度后立即破坏,表现为“脆性”失效特征。

(3) C/C复合材料销钉在不同剪切加载速率下表现出失效模式的差异性可归因于其材料内部缺陷扩展的应变率效应,低加载速率下缺陷扩展得较为充分,纤维与基体严重剥离,其整体性较差,表现出较低的抗剪切强度;而高加载速率下缺陷未能充分扩展,纤维与基体结合较为紧密,材料保持较好的整体性能,其抗剪切强度显著提高。

-

-

[1] HE Q C, LI H J, WANG C C, et al. Microstructure and ablation property of gradient ZrC-SiC modified C/C composites prepared by chemical liquid vapor deposition[J]. Ceramics International,2019,45(10):13283-13296. DOI: 10.1016/j.ceramint.2019.04.018

[2] 李贺军, 史小红, 沈庆凉, 等. 国内C/C复合材料研究进展[J]. 中国有色金属学报, 2019, 29(9):2142-2154. LI H J, SHI X H, SHEN Q L, et al. Research and development of C/C composites in China[J]. The Chinese Journal of Nonferrous Metals,2019,29(9):2142-2154(in Chinese).

[3] HE Q C, LI H J, YIN X M, et al. Microstructure, mechanical and anti-ablation properties of SiCnw/PyC core-shell networks reinforced C/C-ZrC-SiC composites fabricated by a multistep method of chemical liquid-vapor deposition[J]. Ceramics International,2019,45(16):20414-20426. DOI: 10.1016/j.ceramint.2019.07.018

[4] KOGO Y, KIKKAWA A, SAITO W, et al. Comparative study on tensile fracture behavior of monofilament and bundle C/C composites[J]. Composites Part A: Applied Science and Manufacturing,2006,37(12):2241-2247. DOI: 10.1016/j.compositesa.2005.12.015

[5] HATTA H, SUZUKI K, SHIGEI T, et al. Strength improvement by densification of C/C composites[J]. Carbon,2001,39(1):83-90. DOI: 10.1016/S0008-6223(00)00083-X

[6] ZHANG J, LUO R, XIANG Q, et al. Compressive fracture behavior of 3D needle-punched carbon/carbon composites[J]. Materials Science and Engineering A,2011,528(15):5002-5006. DOI: 10.1016/j.msea.2011.03.055

[7] LI D, YAO Q, JIANG N, et al. Bend properties and failure mechanism of a carbon/carbon composite with a 3D needle-punched preform at room and high temperatures[J]. New Carbon Materials,2016,31(4):437-444. DOI: 10.1016/S1872-5805(16)60023-9

[8] BRADLEY L R, BOWEN C R, MCENANEY B, et al. Shear properties of a carbon/carbon composite with non-woven felt and continuous fibre reinforcement layers[J]. Carbon,2007,45(11):2178-2187. DOI: 10.1016/j.carbon.2007.06.072

[9] 张伟, 庞宝君, 张泽华, 等. 航天器波纹防护屏高速撞击实验研究[J]. 宇航学报, 2000, 21(1):79-84. DOI: 10.3321/j.issn:1000-1328.2000.01.013 ZHANG W, PANG B J, ZHANG Z H, et al. High-velocity impact experimental investigation of spacecraft corrugated bumper shielding[J]. Journal of Astronautics,2000,21(1):79-84(in Chinese). DOI: 10.3321/j.issn:1000-1328.2000.01.013

[10] NARESH K, SHANKAR K, RAO B S, et al. Effect of high strain rate on glass/carbon/hybrid fiber reinforced epoxy laminated composites[J]. Composites Part B: Engineering,2016,100:125-135. DOI: 10.1016/j.compositesb.2016.06.007

[11] WANG M, ZHANG P W, FEI Q G. Transverse properties prediction of polymer composites at high strain rates based on unit cell model[J]. Journal of Aerospace Engineering,2017,31(2):04017102.

[12] 吴以婷, 葛东云, 李辰. 湿热环境下 Carbon/Epoxy 复合材料层合板动态压缩性能[J]. 复合材料学报, 2016, 33(2):259-264. WU Y T, GE D Y, LI C. Dynamic compressive properties of Carbon/Epoxy laminates under hygrothermal environment[J]. Acta Materiae Compositae Sinica,2016,33(2):259-264(in Chinese).

[13] GAO Y B, TANG T G, YI C H, et al. Study of static and dynamic behavior of TiB2-B4C composite[J]. Materials and Design,2016,92:814-822;. DOI: 10.1016/j.matdes.2015.12.123

[14] XIE W B, ZHANG W, KUANG N H, et al. Experimental investigation of normal and oblique impacts on CFRPs by high velocity steel sphere[J]. Composites Part B: Engineering,2016,99:483-493. DOI: 10.1016/j.compositesb.2016.06.020

[15] HUANG W, ZHANG W, CHEN T, et al. Dynamic response of circular composite laminates subjected to underwater impulsive loading[J]. Composites Part A: Applied Science and Manufacturing, 2018, 109: 63-74.

[16] YUAN Q L, LI Y L, LI H J, et al. Quasi-static and dynamic compressive fracture behavior of carbon/carbon composites[J]. Carbon,2008,46(4):699-703. DOI: 10.1016/j.carbon.2008.01.031

[17] 袁秦鲁, 李玉龙, 李贺军, 等. C/C复合材料压缩破坏的应变率效应研究[J]. 无机材料学报, 2007, 22(2):311-314. DOI: 10.3321/j.issn:1000-324X.2007.02.024 YUAN Q L, LI Y L, LI H J, et al. Strain rate sensitivity of C/C composites under compression[J]. Journal of Inorganic Materials,2007,22(2):311-314(in Chinese). DOI: 10.3321/j.issn:1000-324X.2007.02.024

[18] LI D S, DUAN H W, WANG W, et al. Strain rate and temperature effect on mechanical properties and failure of 3D needle-punched carbon/carbon composites under dynamic loading[J]. Composite Structures,2017,172:229-241. DOI: 10.1016/j.compstruct.2016.11.082

[19] LAN F T, LI K Z, LI H J, et al. Joining of carbon/carbon composites for nuclear applications[J]. Journal of Materials Science,2009,44(14):3747-3750. DOI: 10.1007/s10853-009-3501-0

[20] ZHOU Y D, FEI Q G, TAO J Y. Profile design of loaded pins in composite single lap joints: From circular to non-circular[J]. Results in Physics,2016,6:471-480. DOI: 10.1016/j.rinp.2016.07.010

[21] ZHOU Y D, FEI Q G. Evaluation of opening-hole shapes for rivet connection of a composite plate[J]. Proceedings of the Institution of Mechanical Engineers Part C: Journal of Mechanical Engineering Science,2017,231(20):3810-3817. DOI: 10.1177/0954406216652169

[22] ZHOU Y D, HANG X C, WU S Q, et al. Frequency-dependent random fatigue of panel-type structures made of ceramic matrix composites[J]. Acta Mechanica Solida Sinica,2017,30(2):165-173. DOI: 10.1016/j.camss.2017.03.010

[23] GUO F, FEI Q G, LI Y B, et al. Novel statistical analysis method for determining shear strength of C/C composite pin[J]. Ceramics International,2020,46(4):5262-5270. DOI: 10.1016/j.ceramint.2019.10.275

[24] 郭飞, 费庆国, 李彦斌, 等. 基于 Weibull 模型的 C/C 复合材料销钉剪切强度分布及本构关系[J]. 复合材料学报, 2019, 36(2):461-468. GUO F, FEI Q G, LI Y B, et al. Shear strength distribution and constitutive model of C/C composite pins based on Weibull model[J]. Acta Materiae Compositae Sinica,2019,36(2):461-468(in Chinese).

[25] 王杰, 李克智, 郭领军, 等. 炭布叠层穿刺C/C复合材料螺栓连接件微观组织和力学性能[J]. 固体火箭技术, 2012, 35(2):248-252. DOI: 10.3969/j.issn.1006-2793.2012.02.022 WANG J, LI K Z, GUO L J, et al. Microstructure and mechanical properties of C/C composite bolts[J]. Journal of Solid Rocket Technology,2012,35(2):248-252(in Chinese). DOI: 10.3969/j.issn.1006-2793.2012.02.022

[26] ASTM International. Standard test method for shear testing of aluminum alloys: ASTM B769—11[S]. West Conshohocken: ASTM International, 2016.

-

期刊类型引用(6)

1. 陶洋,李存静,逄增媛,张典堂. 展宽布/网胎针刺C/C复合材料制备及力学性能. 复合材料学报. 2024(04): 1934-1944 .  本站查看

本站查看

2. 钱奇伟,张昕,杨贞军,沈镇,校金友. 基于CT图像深度学习的三维编织C/C复合材料微观组分与缺陷智能识别. 复合材料学报. 2024(07): 3536-3543 .  本站查看

本站查看

3. 马宇,张大海,吴军,荆瑞,徐培飞,费庆国. 飞行器陶瓷基复合材料轻量化结构设计研究进展. 航空材料学报. 2024(04): 1-15 .  百度学术

百度学术

4. 陈波,刘晓倩,杨兴林,温卫东,翁晶萌,张俊苗. 碳/碳复合材料室温和700℃面内剪切疲劳试验. 航空发动机. 2023(04): 168-174 .  百度学术

百度学术

5. 马昕,刘海韬,孙逊. 连续纤维增强陶瓷基复合材料连接件的研究进展. 材料工程. 2023(08): 1-11 .  百度学术

百度学术

6. 陈波,刘晓倩,杨兴林,温卫东,翁晶萌,张俊苗. 碳/碳复合材料高温剪切疲劳试验研究. 涂层与防护. 2022(01): 43-49 .  百度学术

百度学术

其他类型引用(3)

-

下载:

下载: