Resistance welding technology of carbon fiber/polyphenylene sulfide thermoplastic composites

-

摘要: 本文针对航空器结构用碳纤维/聚苯硫醚(CF/PPS)复合材料为研究对象,开展电阻焊接工艺研究;利用CF/PPS复合材料混编织物作为电阻元件,成功制备了CF/PPS复合材料层板电阻焊接接头;重点利用Taguchi方法和方差分析获取CF/PPS复合材料层板电阻焊接最佳工艺参数(电流为12 A,压力为1.5 MPa,时间为30 min)及各参数对焊接接头剪切强度的贡献(电流为83.37%,压力为9.55%,时间为6.02%)。最佳焊接工艺参数焊接的接头单搭接剪切强度约为17.88 MPa;同时,对最佳参数焊接试样(H-LSS)和较低剪切强度试样(L-LSS)的焊接接头截面和剪切失效断口形貌进行了观察和分析。结果表明:H-LSS试样的焊缝区域树脂填充和浸润良好,且主要剪切失效形式为层间剪切失效,即为纤维与树脂基体脱黏及CF/PPS织物复合材料断裂混合失效;L-LSS试样的焊缝区域树脂填充和浸润较差,存在较多空隙,且剪切失效形式为焊缝界面脱黏失效。Abstract: The resistance welding technology of carbon fiber/polyphenylene sulfide (CF/PPS) composites for aircraft structure was studied. The resistance welding of CF/PPS composite laminates were successfully fabricated by using CF/PPS composite blended fabrics as resistance elements. Taguchi method and variance analysis were used to obtain the optimum parameters (current is 12 A, pressure is 1.5 MPa, time is 30 min) of resistance welding of CF/PPS composite laminates. The contribution of each welding parameters to the shear strength of welded were obtained (current is 83.37%, pressure is 9.55%, time is 6.02%). The single lap shear strength of welded was about 17.88 MPa with the optimum welding parameters. Meanwhile, the cross-section and shear failure fracture morphology of welded joints were observed and analyzed with the welding specimens with optimum parameters(H-LSS) and the lower shear strength specimen(L-LSS). The results show that the weld area of H-LSS sample is well filled and infiltrated, and the main failure mode is interlaminar shear failure, which involves damage to the adherends, the heating element or both of them. The welded area of L-LSS specimen has poor resin filling and wetting, and there are more voids, and the shear failure mode is interfacial shear failure and occurs at the interface between the weld and adherends.

-

纤维增强树脂复合材料拥有高强、轻质、耐腐蚀、抗疲劳、吸波隐身等优异性能,在航空航天、军工、汽车、化工及电子等先进工业领域得到广泛应用[1-4]。按树脂基体性质可以将纤维增强树脂复合材料分为两大类,即热固性树脂基复合材料和热塑性树脂基复合材料;相较而言,热塑性树脂基复合材料具有:(1)韧性好,疲劳强度高,冲击损伤容限高;(2)预浸料和热塑性树脂存储没有期限要求;(3)热成型工艺性好,成型周期短,生产效率高;(4)边角料或废料可再熔融成型或回收利用,环境友好[5]。因此,热塑性树脂基复合材料随着工业技术发展越来越受到青睐。以聚醚醚酮(PEEK)、聚醚酮酮(PEKK)、聚苯硫醚(PPS)和聚醚酰亚胺(PEI)等为代表的高性能热塑性树脂基复合材料的出现,为航空航天结构材料选材提供了富有竞争性的解决方案,且随着产品线的延伸和技术成熟度的不断提高,高性能热塑性树脂基复合材料在航空航天结构材料体系中的地位越来越重要,并逐渐打破以环氧树脂及双马来酰亚胺树脂等为代表的传统热固性树脂基复合材料的垄断地位。

航空航天结构大而复杂,在制造和装配时需要通过连接技术将不同的部件连接在一起来实现,因此需要可靠、自动化和经济的连接技术。机械连接是目前航空结构的主要连接方法,具有制造工艺简单、厚度方向起到增强作用和便于拆装等优点;但也引入许多问题,特别是钻孔存在应力集中、孔边分层、纤维损伤、重量增加和热膨胀系数不匹配等问题[6-7]。胶接连接使连接应力集中最小化,具有优越的抗疲劳性能,但胶接需要严格的表面处理,对污染和环境非常敏感(如粉尘、水分和加工油污等),胶粘剂有存储寿命、胶接工艺复杂和周期长等问题[8]。热塑性树脂基复合材料具有可焊性,其焊接工艺已被认为是热塑性树脂基复合材料连接的有效替代技术,利用热塑性树脂基复合材料焊接可以在很大程度上消除这些问题。最具潜力的焊接方法主要有超声波焊接[9]、感应焊[10]、电阻焊[11]和激光焊[12]等。

热塑性树脂基复合材料焊接在国外已经有较长的研究历程,且相应成果已经成功应用于民用客机及战斗机结构中[2],而国内热塑性树脂基复合材料的制造及相应技术尚处于起步阶段[13]。因此,本文针对航空结构用碳纤维/聚苯硫醚(CF/PPS)热塑性复合材料,采用CF/PPS复合材料混编织物电阻元件对其织物层压板进行电阻焊接;电流、压力和加热时间是电阻焊接的重要工艺参数,采用正交实验、Taguchi方法和方差分析(ANOVA)研究分析CF/PPS热塑性复合材料电阻焊接最佳工艺参数和其对接头强度的影响,同时对其焊接接头单搭接剪切强度和断口进行测试分析,获取其失效机制。该方法也是热塑性树脂基复合材料焊接技术的有益探索。

1. 实验材料及方法

1.1 原材料

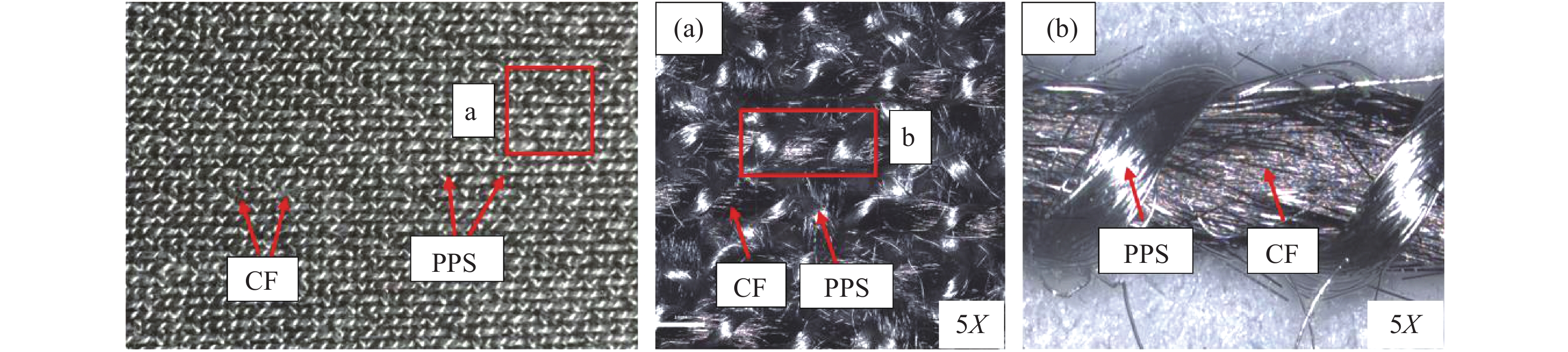

碳纤维/聚苯硫醚(CF/PPS)复合材料层压板是利用加拿大Barrday公司提供的AS4 3K 5HS CF织物/PPS树脂预浸料在XLB-660.660.3型平板硫化机上热压成型;热压工艺为:温度为320℃±10℃,保温时间为30 min,压力为2 MPa,冷却速率为5℃/min,压制过程排气两次;试板铺层结构为[0]8,试板厚度为2 mm,CF体积分数约为54vol%。AS4 3K 5HS CF/PPS复合材料混编织物的混编方式如图1所示,PPS树脂薄膜由日本东丽公司提供,PPS树脂膜厚度为50 μm。

1.2 电阻焊接装置

采用中国民航大学自主研制的复合材料焊接设备(CAUC-CW100),如图2所示,该设备能进行多种形式电载荷施加(直流、交流和脉冲电流),采用伺服电子压力缸进行多段恒位移或压力压装控制,数据采集器可进行焊接件的焊接接头温度、压力和位移变化的信息实时采集等功能。

电阻焊接:利用CF电热特性,在试样的焊接表面放置CF混编织物,并在焊接件上下焊接表面放置PPS树脂薄膜,CF在电热作用时产生焦耳热,熔融被焊接的焊接表面及PPS树脂薄膜,并在压力作用下形成焊接接头。在焊缝中间布置K型伯劳焊点热电偶,对焊缝温度检测,焊接示意图及尺寸如图3所示。

1.3 Taguchi方法和实验设计

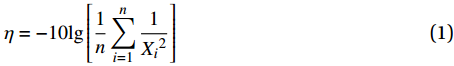

Taguchi方法是以正交表为基础来获取可得到CF/PPS复合材料层板焊接质量的优化工艺方案,与传统正交实验相比,该方法利用信噪比(S/N)来衡量指标的波动[14-16]。本研究质量特性为CF/PPS复合材料层板电阻焊接单搭接的剪切强度,3个关键焊接工艺参数即电流、压力和焊接时间作为因素,基于相同比例给出水平变化,如表1所示;因此优化目标即是获得最大的信噪比。CF/PPS复合材料层板电阻焊接剪切强度属于越大越优的质量指标,其信噪比公式为[11]

表 1 因素和水平Table 1. Factors and levelsParameters Levels 1 2 3 4 Factor A(Current/A) 8 10 12 14 Factor B(Pressure/MPa) 0.5 1.0 1.5 2.0 Factor C(Time/min) 10 20 30 40 η=−10lg[1nn∑i=11Xi2] (1) 式中:η是CF/PPS复合材料层板电阻焊接质量特性,即信噪比(dB);Xi是第i个CF/PPS复合材料层板电阻焊接试样剪切强度(MPa);n是每组试验中的重复数(本研究n=6)。

设计L16实验,得到各次CF/PPS复合材料层板电阻焊接实验的焊接剪切强度,然后利用式(1)计算出各次实验的信噪比,结果如表2所示。

表 2 CF/PPS复合材料层板的正交实验参数及结果Table 2. Input parameters of orthogonal arrays and performance characteristics of CF/PPS composite laminatesExpt.run Factor Performance Current

A/APressure

B/MPaTime

C/minLSS/MPa η 1 8 0.5 10 3.68 11.32 2 8 1.0 20 5.34 14.55 3 8 1.5 30 6.86 16.73 4 8 2.0 40 5.37 14.60 5 10 0.5 20 9.02 19.10 6 10 1.0 10 8.65 18.74 7 10 1.5 40 12.46 21.91 8 10 2.0 30 10.34 20.29 9 12 0.5 30 13.05 22.31 10 12 1.0 40 16.78 24.50 11 12 1.5 10 14.28 23.09 12 12 2.0 20 12.15 21.69 13 14 0.5 40 7.49 17.49 14 14 1.0 30 9.65 19.69 15 14 1.5 20 9.84 19.86 16 14 2.0 10 7.51 17.51 Average η 18.96 Notes: LSS—Lap shear strength; η—Signal to noise ratio. 同时,采用方差分析(ANOVA)来获取CF/PPS热塑性复合材料层板电阻焊接各个工艺参数对其剪切强度影响的贡献度。

1.4 焊接接头力学性能测试

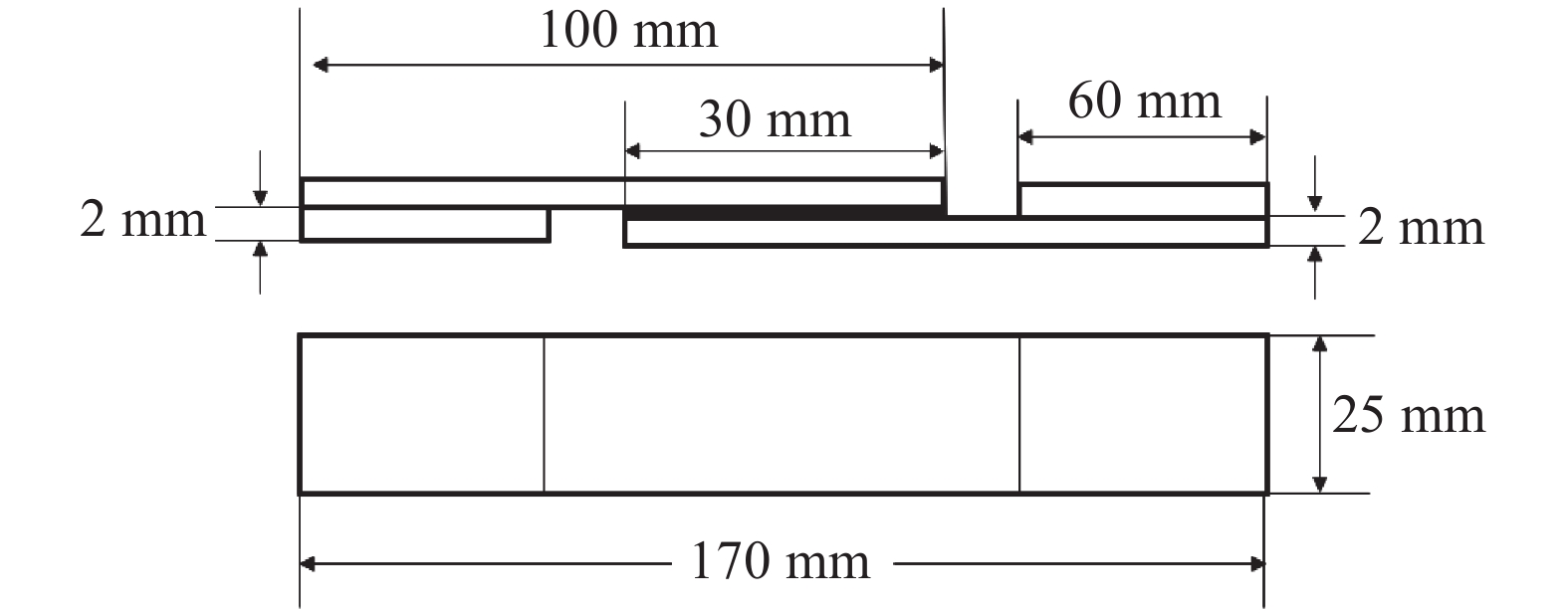

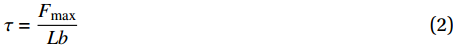

参考ASTM D1002—10标准[17],采用Instron5982电子万能材料试验机对CF/PPS复合材料层板焊接的单搭接剪切强度(LSS)进行测试,试验件尺寸如图4所示。

剪切强度τ(MPa)

计算如下: τ=Fmax (2) 式中:L为搭接长度(mm);b为搭接宽度(mm);Fmax为最大拉伸力(N)。

1.5 剪切断口分析

采用激光共聚焦显微镜(OLYMPUS 4100)和SEM(Quanta FEG250)对Taguchi方法优化最佳焊接参数的焊接试样(记为H-LSS)和本实验方案中较低剪切强度试样(记为L-LSS)的截面形貌和剪切测试断口形貌进行观察,分析焊缝结构、铺展形态及其失效形式和机制。

2. 结果与讨论

2.1 CF/PPS复合材料的焊接

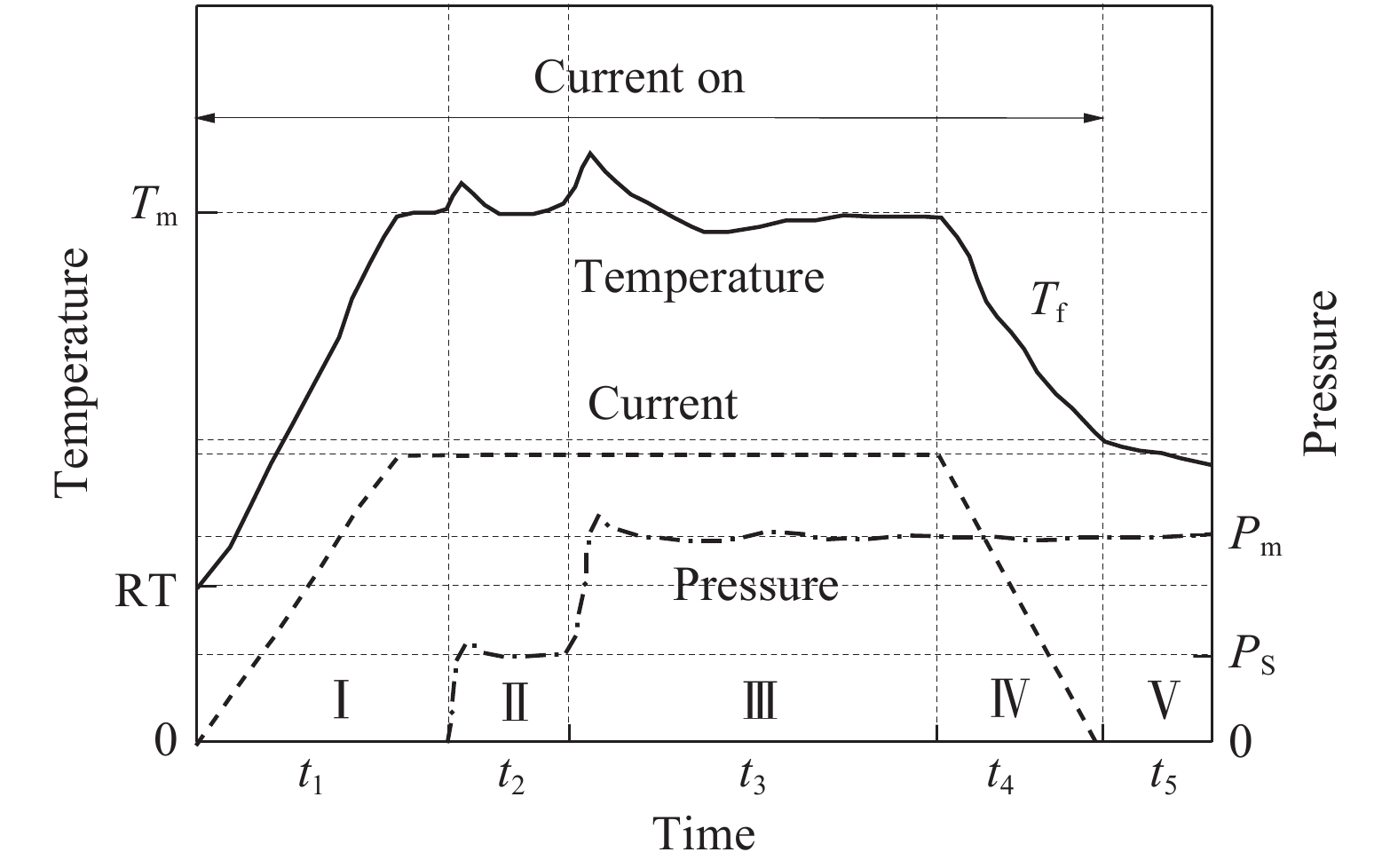

图5为CF/PPS复合材料电阻焊接控制过程。可知,CF/PPS复合材料电阻焊接控制过程主要为五个阶段。第Ⅰ阶段:通电,以一定速率增加电流强度,CF/PPS复合材料混编织物电热作用产生的焦耳热也随之增加,PPS膜及焊接件表面受热软化变形,达到PPS树脂热熔温度(Tm);第Ⅱ阶段:初始压紧(预压力Ps),释放焊接件焊接界面与CF/PPS复合材料混编织物间的间隙,保证受热均匀;第Ⅲ阶段:增加焊接压力(达到额定压力Pm),保持恒温恒压,焊接件的焊接界面及PPS膜热熔,在压力作用下热塑性树脂流动,分子链热运动和扩散缠结;第Ⅳ阶段:调节电流以一定冷却速率(Tf,本实验Tf≈5℃/min)冷却,固化;第Ⅴ阶段:采用压缩空气冷却,焊接接头热收缩,完成焊接。在第Ⅱ和第Ⅲ阶段施加压力时会出现温度小幅度迅速升高后降低,这是由于施加压力使焊缝紧密,焦耳热集聚增加,随后在热传导和热扩散作用下又缓慢减小,同时压力也增大,这是由于高温使焊接接头自由体积膨胀。依据表2焊接参数完成试样焊接,如图6所示,CF/PPS复合材料层板焊接接头无明显变形。

![]() 图 5 CF/PPS复合材料电阻焊接控制过程Figure 5. Resistance welding control process of CF/PPS composites (Tm—PPS hot melt temperature; Ps—Pre-pressure during welding; Pm—Rated pressure during welding; Tf—Cooling rate; RT—Room temperature; t1—Temperature rise time of resistance welding; t2—Pre-pressure time; t 3—Constant temperature and pressure time; t4—Cooling time at Tf rate; t5—Natural cooling time)

图 5 CF/PPS复合材料电阻焊接控制过程Figure 5. Resistance welding control process of CF/PPS composites (Tm—PPS hot melt temperature; Ps—Pre-pressure during welding; Pm—Rated pressure during welding; Tf—Cooling rate; RT—Room temperature; t1—Temperature rise time of resistance welding; t2—Pre-pressure time; t 3—Constant temperature and pressure time; t4—Cooling time at Tf rate; t5—Natural cooling time)2.2 CF/PPS复合材料的工艺参数优化与性能预测

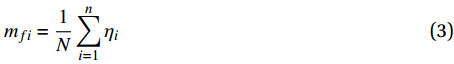

预测CF/PPS复合材料层板电阻焊接工艺参数最优组合需要计算各个因素的信噪比均值,计算如下:

{m_{fi}} = \frac{1}{N}\sum\limits_{i = 1}^n {{\eta _i}} (3) 式中:f是因素;i是水平;N是实验次数;η是信噪比。

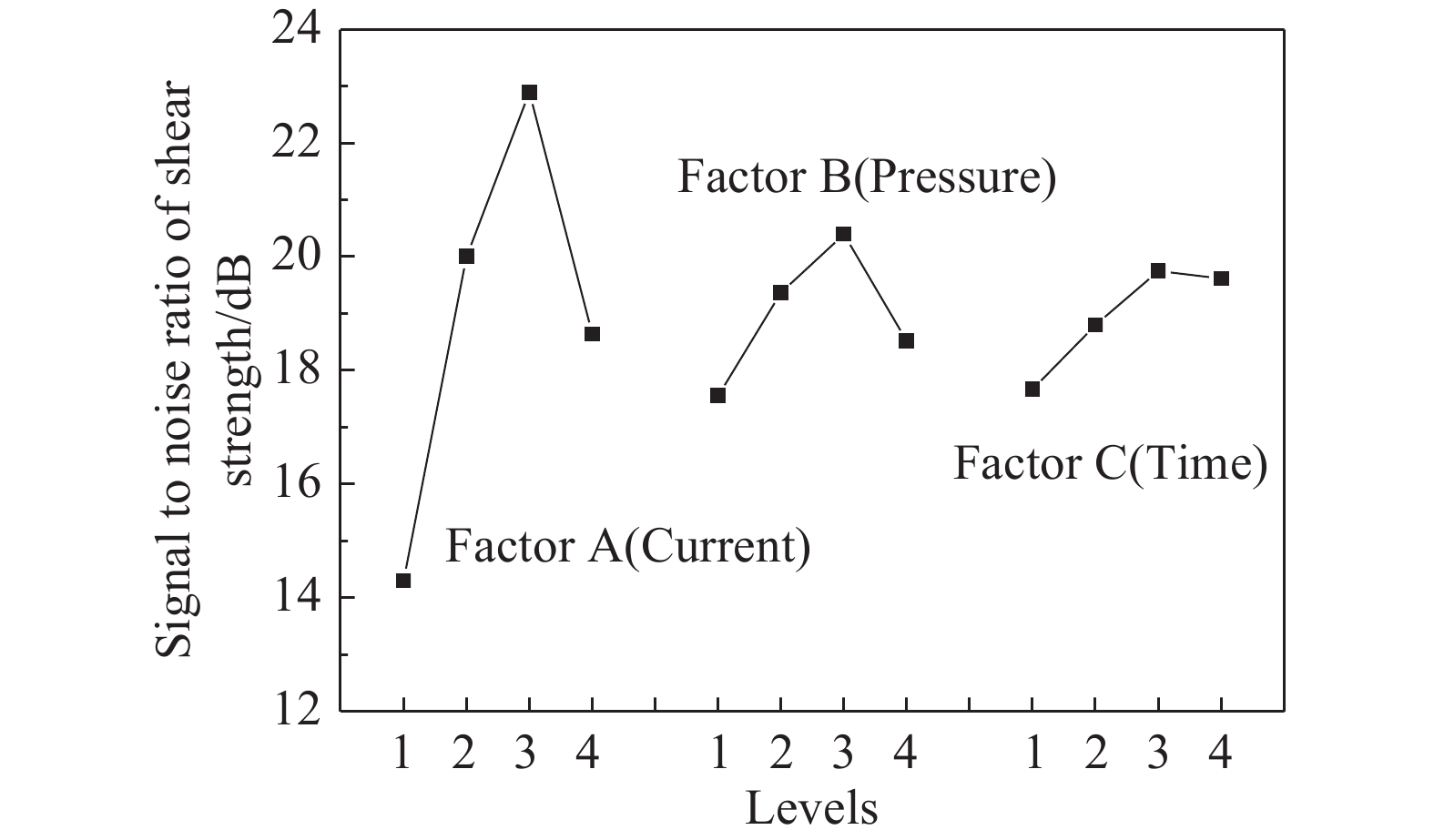

利用式(3)计算得到各因素的信噪比,比较得到该因素下的最大值是该因素的主效应,所有因素都取主效应即是预测的最优组合。CF/PPS复合材料电阻焊接工艺参数主效应图如图7所示。

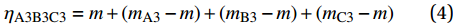

可以看出,随着焊接电流、压力和焊接时间的增加,CF/PPS复合材料层板电阻焊接单搭接剪切强度均呈先增大后减小的变化趋势,获得最优焊接参数水平为A3、B3、C3 (即电流为12 A,压力为1.5 MPa,时间为30 min),其信噪比为[11]

{\eta _{\rm A3B3C3}} = m + ({m_{\rm A3}} - m) + ({m_{\rm B3}} - m) + ({m_{\rm C3}} - m) (4) 式中:ηA3B3C3为优化因素水平的预测信噪比;m为总体信噪比均值;mA3、mB3、mC3分别为因素的主效应。

由式(1)、式(3)、式(4)可得,预测最优因素水平焊接参数的CF/PPS复合材料层板电阻焊接单搭接剪切强度为18.07 MPa,同时用实验对预测结果进行验证,采用预测最优化焊接参数焊接CF/PPS复合材料单搭接试样,并测试了其剪切强度,如表3所示,可以看出,CF/PPS复合材料单搭接试样剪切强度均值为17.88 MPa,Taguchi方法预测剪切强度和实验测试剪切强度非常接近,表明Taguchi方法可有效应用到热塑性树脂基复合材料焊接工艺参数优化中。

表 3 CF/PPS复合材料Taguchi方法预测最优因子水平、焊接接头剪切强度和实验验证结果Table 3. Taguchi method for predicting optimal factor level, weld joint shear strength and experimental verification results of CF/PPS compositesFactor A Factor B Factor C Optimal parameter 12 1.5 30 Taguchi method predicted optimum shear strength/MPa 18.07 Verification experiment results shear strength/MPa 17.88 为了更准确地研究各焊接工艺参数对CF/PPS热塑性复合材料层压板焊接接头质量影响的大小,对表2中信噪比(S/N)进行方差分析,如表4所示。可以看出,各参数方差均值和贡献分数表明焊接电流强度为CF/PPS热塑性复合材料焊接剪切强度的最主要影响因素,其贡献值为83.37%,压力其次,贡献值为9.55%,时间贡献值为6.02%。同时所有参数均具有90%以上的置信度。

表 4 CF/PPS复合材料层压板焊接接头信噪比方差分析Table 4. Analysis of variance of signal-to-noise ratio of CF/PPS composite laminate welded jointsANOVA-Signal-to-noise ratio values Process parameters Level mean value SS df Variance F Sig. P Level 1 Level 2 Level 3 Level 4 Factor A(Current) 14.30 20.01 22.90 18.64 153.704 3 51.235 156.957 0 83.37 Factor B(Pressure) 17.56 19.37 20.40 18.52 17.600 3 5.867 17.972 0.02 9.55 Factor C(Time) 17.67 18.80 19.75 19.62 11.107 3 3.702 11.343 0.05 6.02 Errors – – – – 1.959 6 0.326 – – 1.06 Total – – – – 184.370 15 – – – 100.00 Notes: SS—Sum of squares of mean deviation; df—Degrees of freedom; F—F statistics; Sig.—Significance; P—Probability. 2.3 CF/PPS复合材料电阻焊接剪切断口的微观形貌

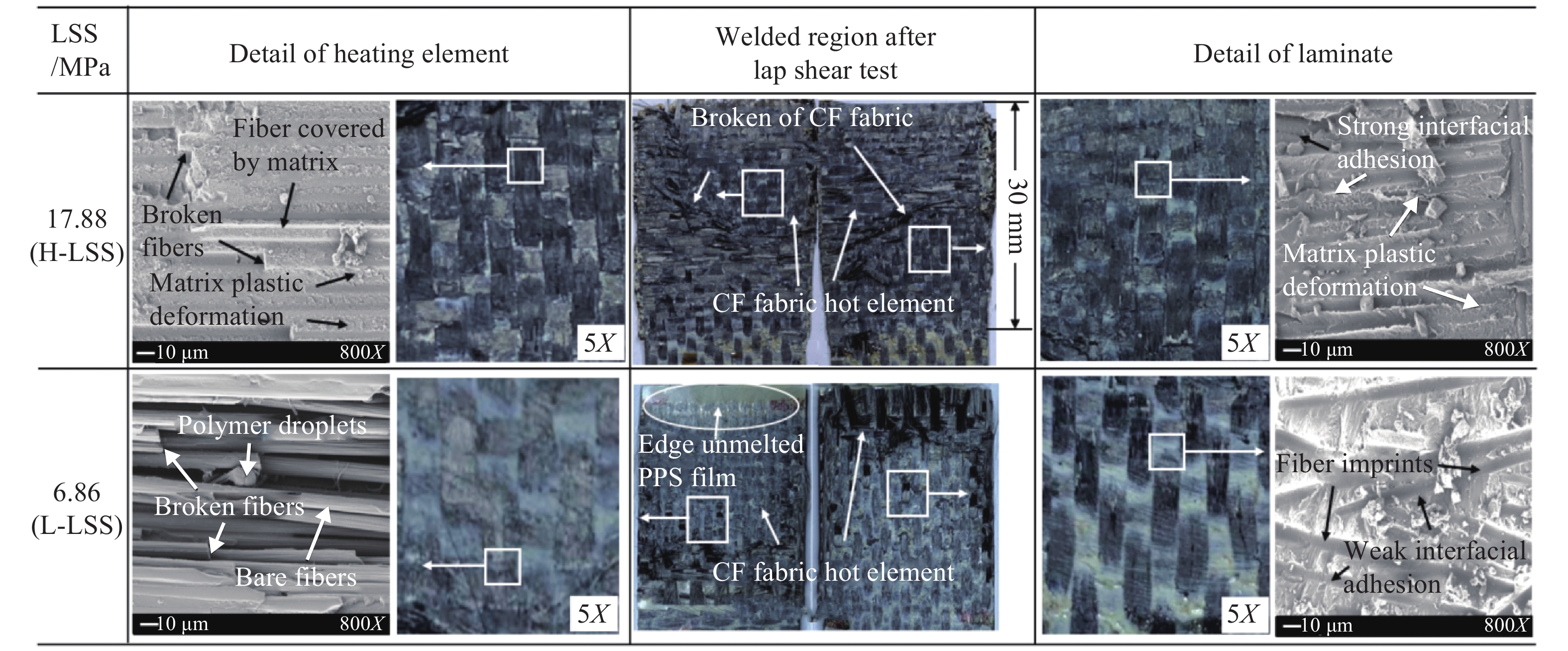

图8和图9为H-LSS和L-LSS两类试样的截面形貌和剪切断口形貌。

从图8可以看出,最佳焊接工艺参数焊接的H-LSS试样焊接接头中CF/PPS复合材料混编织物、PPS膜及接层板紧密结合,焊缝中无空隙及脱黏区域等缺陷,CF/PPS复合材料混编织物很好地植入到焊接层板结合界面,且PPS膜和层板PPS基体很好地融合、扩渗及结合。而L-LSS试样的焊缝中存在空隙,CF/PPS复合材料混编织物中CF和PPS树脂的浸润较差,有大量裸纤维存在,表明其焊缝结合较差。

由图9 可以看出,植入的CF/PPS复合材料混编织物断裂,焊接层板的焊接界面也有纤维拔出和断裂,表明焊接接头在剪切力作用时,CF/PPS复合材料混编织物起到了焊缝增强相作用,且与焊接层板很好地结合,是典型复合材料层板层间失效断裂破坏模式,即焊接层板和CF/PPS复合材料混编织物都受损失效。H-LSS试样中植入的CF/PPS复合材料混编织物的纤维断裂平齐,纤维上黏附大量树脂,与之对应黏结的层板表面树脂基体在纤维拔出后出现明显破碎和塑性变形,证明CF/PPS复合材料混编织物、PPS膜及层板焊接界面间树脂与纤维充分浸润、扩渗链接和结合,保证了力的有效传递。而 L-LSS试样在剪切力作用下焊接接头失效形式为CF/PPS复合材料混编织物与焊接层板界面脱黏失效,即CF/PPS复合材料混编织物和被焊接层板的焊接界面胶层脱黏。这是由于在该工艺参数下树脂和纤维的浸润差,焊缝区域边缘处有部分PPS膜未完全熔化,焊缝区域存在大量空隙和裸纤维(如图8 中L-LSS试样),在剪切力作用下诱发裂纹产生,导致接头性能较低;由图9 也可看出,L-LSS试样中CF/PPS复合材料混编织物的纤维与树脂的浸润和包裹较差,拔出纤维上树脂附着很少且不均匀,与之黏接的层板树脂基体上有明显纤维压痕,在剪切力作用下,CF/PPS复合材料混编织物中的纤维拔出,而层板树脂无明显形变,表明其结合强度较弱,剪切强度低。

由上述实验结果及分析可知,CF/PPS复合材料层板电阻焊接工艺参数(电流、压力和时间)的变化直接影响着焊接接头的性能。随着电流强度的增加,焊接接头剪切强度呈先增大后减小的趋势,这是由于在较低电流时,CF混编织物电阻元件电热作用产生的焦耳热不足以充分软化和熔化PPS树脂,使焊缝处树脂扩渗和黏接不够充分,导致焊接接头剪切强度低;在较大电流时,CF电阻元件产生足够的焦耳热,使被焊接件的焊接界面充分均匀受热,PPS树脂充分受热软化、流动、扩渗和熔融胶接,使焊接接头剪切强度增大。但电流强度过大,产生热量过大,会使PPS树脂产生分子链断裂、热降解和烧蚀变性等不良影响[7],使焊接接头性能下降。CF/PPS复合材料层板电阻焊接需要一定的压力,由于熔融态PPS黏度较大,且流动困难,其流动是若干分子链段运动推动另一部分分子链段再运动并形成整个大分子重心移动[18],因此焊接压力是热塑性树脂基复合材料焊接的重要因素之一,压力过低时,不足以使受热软化和熔融的树脂充分流动与纤维浸润,无法排除焊缝中的气体,会增加焊缝中空隙等缺陷[19-20];而压力过高,会使焊缝软化和热熔树脂挤压排出,使焊缝的树脂含量过低,从而影响焊缝的有效黏接,因此,焊接压力过高或过低都会导致其剪切强度减小。焊接时间为电流流经CF混编织物电阻元件产生热量持续的过程,保证焊接接头所需热量,其对焊接接头性能的影响与焊接压力类似,焊接时间短,会引起树脂流动、扩渗和浸润不充分;焊接时间过长会导致焊接件的焊接界面树脂热解和烧蚀,同时引起焊接接头整体软化及纤维排布变形,使剪切强度减小。

3. 结 论

对航空结构用碳纤维/聚苯硫醚(CF/PPS)热塑性复合材料层压板,通过植入CF/PPS复合材料混编织物电阻元件进行电阻焊接技术研究。

(1)采用植入CF/PPS复合材料混编织物电阻元件对CF/PPS复合材料层板进行电阻焊接,工艺简单,设备成本低,焊接接头无异质材料引入,无明显应力集中。

(2) Taguchi方法可用于CF/PPS复合材料电阻焊接工艺参数设计和优化分析中,优化预测得到最佳焊接工艺参数为:电流为12 A,压力为1.5 MPa,时间为30 min,剪切强度为18.07 MPa;采用该参数验证CF/PPS复合材料层板焊接剪切强度为17.88 MPa,与其预测结果相近。方差分析得到CF/PPS复合材料层压板电阻焊接工艺参数电流贡献率最高,为83.37%,其次是压力,为9.55%,时间贡献率为6.02%。

(3) CF/PPS复合材料层压板电阻焊接接头横截面和剪切断口观察分析表明,最佳参数焊接试样(H-LSS)焊接接头界面结合良好,CF/PPS复合材料混编织物很好融合进焊缝,主要剪切失效形式为层间失效。较低剪切强度试样(L-LSS)焊接接头失效形式主要为界面脱黏失效。

(4)电阻焊接技术可以推广于商业和工业任何类型热塑性树脂基复合材料的连接。

-

图 5 CF/PPS复合材料电阻焊接控制过程

Figure 5. Resistance welding control process of CF/PPS composites (Tm—PPS hot melt temperature; Ps—Pre-pressure during welding; Pm—Rated pressure during welding; Tf—Cooling rate; RT—Room temperature; t1—Temperature rise time of resistance welding; t2—Pre-pressure time; t 3—Constant temperature and pressure time; t4—Cooling time at Tf rate; t5—Natural cooling time)

表 1 因素和水平

Table 1 Factors and levels

Parameters Levels 1 2 3 4 Factor A(Current/A) 8 10 12 14 Factor B(Pressure/MPa) 0.5 1.0 1.5 2.0 Factor C(Time/min) 10 20 30 40 表 2 CF/PPS复合材料层板的正交实验参数及结果

Table 2 Input parameters of orthogonal arrays and performance characteristics of CF/PPS composite laminates

Expt.run Factor Performance Current

A/APressure

B/MPaTime

C/minLSS/MPa η 1 8 0.5 10 3.68 11.32 2 8 1.0 20 5.34 14.55 3 8 1.5 30 6.86 16.73 4 8 2.0 40 5.37 14.60 5 10 0.5 20 9.02 19.10 6 10 1.0 10 8.65 18.74 7 10 1.5 40 12.46 21.91 8 10 2.0 30 10.34 20.29 9 12 0.5 30 13.05 22.31 10 12 1.0 40 16.78 24.50 11 12 1.5 10 14.28 23.09 12 12 2.0 20 12.15 21.69 13 14 0.5 40 7.49 17.49 14 14 1.0 30 9.65 19.69 15 14 1.5 20 9.84 19.86 16 14 2.0 10 7.51 17.51 Average η 18.96 Notes: LSS—Lap shear strength; η—Signal to noise ratio. 表 3 CF/PPS复合材料Taguchi方法预测最优因子水平、焊接接头剪切强度和实验验证结果

Table 3 Taguchi method for predicting optimal factor level, weld joint shear strength and experimental verification results of CF/PPS composites

Factor A Factor B Factor C Optimal parameter 12 1.5 30 Taguchi method predicted optimum shear strength/MPa 18.07 Verification experiment results shear strength/MPa 17.88 表 4 CF/PPS复合材料层压板焊接接头信噪比方差分析

Table 4 Analysis of variance of signal-to-noise ratio of CF/PPS composite laminate welded joints

ANOVA-Signal-to-noise ratio values Process parameters Level mean value SS df Variance F Sig. P Level 1 Level 2 Level 3 Level 4 Factor A(Current) 14.30 20.01 22.90 18.64 153.704 3 51.235 156.957 0 83.37 Factor B(Pressure) 17.56 19.37 20.40 18.52 17.600 3 5.867 17.972 0.02 9.55 Factor C(Time) 17.67 18.80 19.75 19.62 11.107 3 3.702 11.343 0.05 6.02 Errors – – – – 1.959 6 0.326 – – 1.06 Total – – – – 184.370 15 – – – 100.00 Notes: SS—Sum of squares of mean deviation; df—Degrees of freedom; F—F statistics; Sig.—Significance; P—Probability. -

[1] 杨洋, 见雪珍, 袁协尧, 等. 先进热塑性复合材料在大型客机结构零件领域的应用及其制造技术[J]. 玻璃钢, 2017(4):1-15. YANG Y, JIAN X Z, YUAN X R, et al. Application of advanced thermoplastic composite materials in the field of large passenger aircraft structural parts and its manufacturing technology[J]. Fiber Reinforced Plastics,2017(4):1-15(in Chinese).

[2] 郭云竹. 热塑性复合材料研究及其在航空领域中的应用[J]. 纤维复合材料, 2016, 33(3):20-23. DOI: 10.3969/j.issn.1003-6423.2016.03.005 GUO Y Z. Research on thermoplastic composites and its application in the field of aviation[J]. Fiber Composites,2016,33(3):20-23(in Chinese). DOI: 10.3969/j.issn.1003-6423.2016.03.005

[3] 初明越, 阳玉球, 赵德方, 等. 接头尺寸对玻璃纤维/热塑性树脂复合材料机械连接性能的影响[J]. 复合材料学报, 2019, 36(6):1353-1363. CHU M Y, YANG Y Q, ZHAO D F, et al. Effect of joint dimension on the mechanically fastened joint properties of glass fiber/thermoplastic resin composites[J]. Acta Materiae Compositae Sinica,2019,36(6):1353-1363(in Chinese).

[4] 张衡, 严飙, 龚友坤, 等. 碳纤维机织物增强热塑性树脂复合材料热冲压叠层模型[J]. 复合材料学报, 2017, 34(12):2741-2746. ZHANG H, YAN B, GONG Y K, et al. A lamination model for thermostamping of carbon woven fabric reinforced thermoplastic resin composites[J]. Acta Materiae Compositae Sinica,2017,34(12):2741-2746(in Chinese).

[5] 秦明. 热塑性聚芳醚酮类树脂基复合材料的制备及连接技术研究[D]. 杭州: 浙江大学, 2004. QIN M. Study on poly aryl ether ketone matrix thermoplastic composites: Processing and fusion bonding technologies[D]. Hangzhou: Zheng Jiang University, 2004(in Chinese).

[6] SHI H, VILLEGAS I F, BERSEE H E N. Strength and failure modes in resistance welded thermoplastic composite joints: Effect of fibre-matrix adhesion and fibre orientation[J]. Composites Part A: Applied Science and Manufacturing,2013,55:1-10. DOI: 10.1016/j.compositesa.2013.08.008

[7] KOUTRAS N, VILLEGAS I F, BENEDICTUS R. Influence of temperature on the strength of resistance welded glass fibre reinforced PPS joints[J]. Composites Part A: Applied Science and Manufacturing,2018,105:57-67. DOI: 10.1016/j.compositesa.2017.11.003

[8] SHI H, VILLEGAS I F, OCTEAU M, et al. Continuous resistance welding of thermoplastic composites: Modelling of heat generation and heat transfer[J]. Composites Part A: Applied Science and Manufacturing,2015,70:16-26. DOI: 10.1016/j.compositesa.2014.12.007

[9] PALARDY G, SHI H, LEVY A, et al. A study on amplitude transmission in ultrasonic welding of thermoplastic composites[J]. Composites Part A: Applied Science and Manufacturing,2018,113:339-349. DOI: 10.1016/j.compositesa.2018.07.033

[10] AHMED T J, STAVROV D, BERSEE H E N, et al. Induction welding of thermoplastic composites: An overview[J]. Composites Part A: Applied Science and Manufacturing,2006,37(10):1638-1651. DOI: 10.1016/j.compositesa.2005.10.009

[11] PANNEERSELVAM K, ARAVINDAN S, NOORUL H A. Study on resistance welding of glass fiber reinforced thermoplastic composites[J]. Materials & Design,2012,41:453-459.

[12] BRODHUN J, BLASS D, DILGER K. Laser transmission welding of thermoplastic fasteners: Influence of temperature distribution in a scanning based process[J]. Procedia CIRP,2018,74:533-537. DOI: 10.1016/j.procir.2018.08.123

[13] 李明. 热塑性树脂基复合材料在民机上的应用研究[J]. 科技视界, 2016(26):9-10. DOI: 10.3969/j.issn.2095-2457.2016.26.007 LI M. Application of thermoplastic resin matrix composites in civil aircraft[J]. Science & Technology Vision,2016(26):9-10(in Chinese). DOI: 10.3969/j.issn.2095-2457.2016.26.007

[14] 刘海印, 周平金, 许若芬. 简述运用田口试验设计方法改善PCB板自动焊接工艺[J]. 科技视界, 2018(16):62-63. LIU H Y, ZHOU P J, XU R F. Brief introduction of improving automatic welding process of PCB board by Taguchi test design method[J]. Science & Technology Vision,2018(16):62-63(in Chinese).

[15] 谢英, 姬国华, 刘萌萌, 等. Taguchi正交实验技术在微孔注塑中的应用[J]. 橡塑技术与装备, 2009, 35(7):7-10. DOI: 10.3969/J.ISSN.1009-797X.2009.07.002 XIE Y, JI G H, LIU M M, et al. Application of Taguchi orthogonal experimental technology in the microporous injection molding[J]. China Rubber/Plastics Technology & Equipment,2009,35(7):7-10(in Chinese). DOI: 10.3969/J.ISSN.1009-797X.2009.07.002

[16] 张启明, 姜银松, 胡静, 等. 基于田口方法铝合金电子束焊接工艺参数优化[J]. 压力容器, 2018, 35(3):14-18. DOI: 10.3969/j.issn.1001-4837.2018.03.003 ZHANG Q M, JIANG Y S, HU J, et al. Optimization of aluminum alloy electron beam welding parameters based on Taguchi method[J]. Pressure Vessel Technology,2018,35(3):14-18(in Chinese). DOI: 10.3969/j.issn.1001-4837.2018.03.003

[17] ASTM International. Standard test method for apparent shear strength of single-lap-joint adhesively bonded metal specimens by tension loading: ASTM D1002—10[S]. West Conshohocken: ASTM International, 2010.

[18] BARBOSA L C M, SOUZA S D B, BOTELHO E C, et al. Fractographic evaluation of welded joints of PPS/glass fiber thermoplastic composites[J]. Engineering Failure Analysis,2019,102:60-68. DOI: 10.1016/j.engfailanal.2019.04.032

[19] ARIAS M,ZIEGMANN G. The impulse resistance welding: a new technique for joining Advanced thermoplastic composite parts[C]//Proceeding of the 41st International Sampe Symposium. United States: [s. n.], 1996: 1361-1371.

[20] ACHERJEE B, KUAR A, MITRA S, et al. Experimental investigation on laser transmission welding of PMMA to ABS via response surface modeling[J]. Optics & Laser Technology,2012,44(5):1372-1383.

-

期刊类型引用(8)

1. 王涣翔,赵刚,徐剑. 硅烷偶联剂改性金属加热元件提高碳纤维/聚苯硫醚热塑性复合材料电阻焊接强度. 复合材料科学与工程. 2024(05): 76-84+91 .  百度学术

百度学术

2. 姚鑫,霍红宇,安学锋,张宝艳. 碳纤维加热元件的制备及其对热塑性复合材料电阻焊接接头性能的影响. 复合材料学报. 2024(06): 2900-2908 .  本站查看

本站查看

3. 叶璐,张代军,李军,栗付平,陈祥宝. 碳纤维增强聚芳醚酮热塑性复合材料电阻焊接工艺研究. 复合材料科学与工程. 2024(08): 45-52 .  百度学术

百度学术

4. 熊需海,焦梦媛,田琳,李桂洋,王道晟. 先进聚合物基复合材料电阻植入焊技术研究进展. 材料工程. 2023(07): 1-11 .  百度学术

百度学术

5. 肇研,孙铭辰,张思益,王凯. 连续碳纤维增强高性能热塑性复合材料的研究进展. 复合材料学报. 2022(09): 4274-4285 .  本站查看

本站查看

6. 路鹏程,李志歆,王志平,邱运朋. CF/PPS复合材料层板电阻焊接研究. 塑料工业. 2021(01): 60-64+88 .  百度学术

百度学术

7. 王家锋,苏佳煜,朱姝,周剑锋,杨丽丽. 基于导热板的碳纤维增强聚醚醚酮复合材料感应焊接温度调控. 复合材料学报. 2021(08): 2625-2634 .  本站查看

本站查看

8. 杨爽,王静,杨帅,李金虹,刘金. 电阻焊接技术在复合材料领域应用进展. 冶金与材料. 2021(05): 127-128 .  百度学术

百度学术

其他类型引用(7)

-

下载:

下载: