Influence of ratio of hole area for mesh plate layer on through-thickness permeability based on a new designed test bench

-

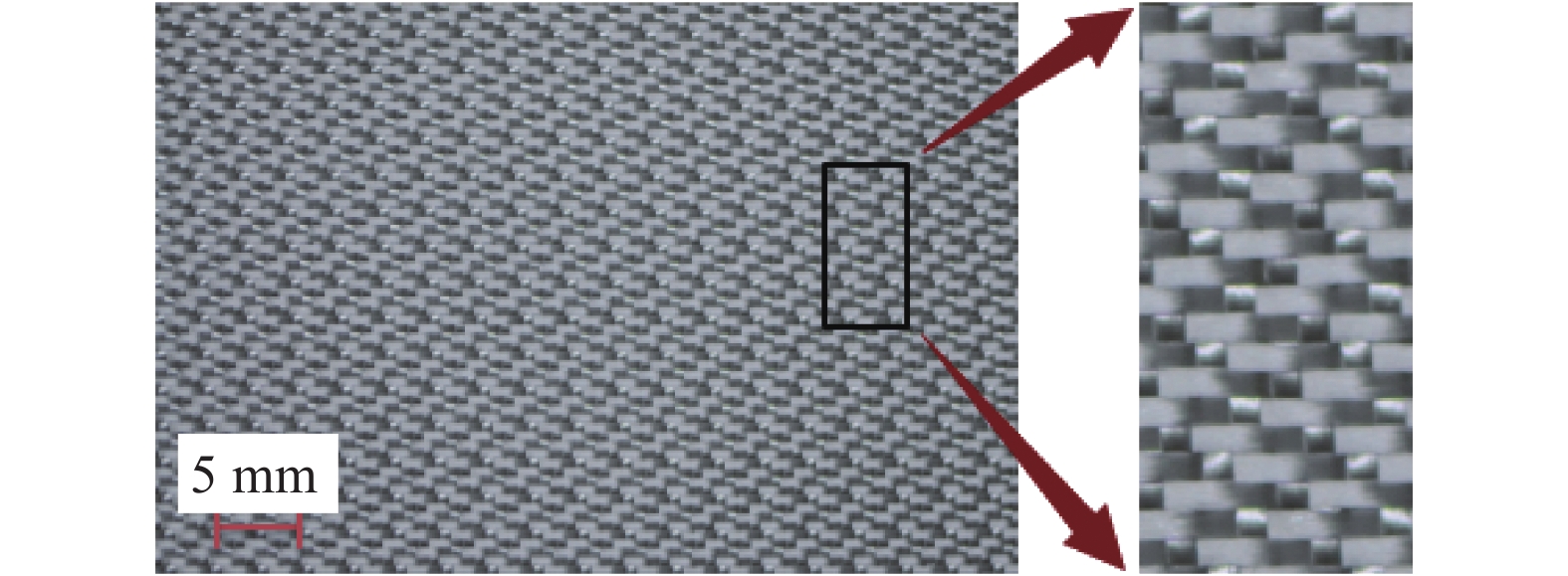

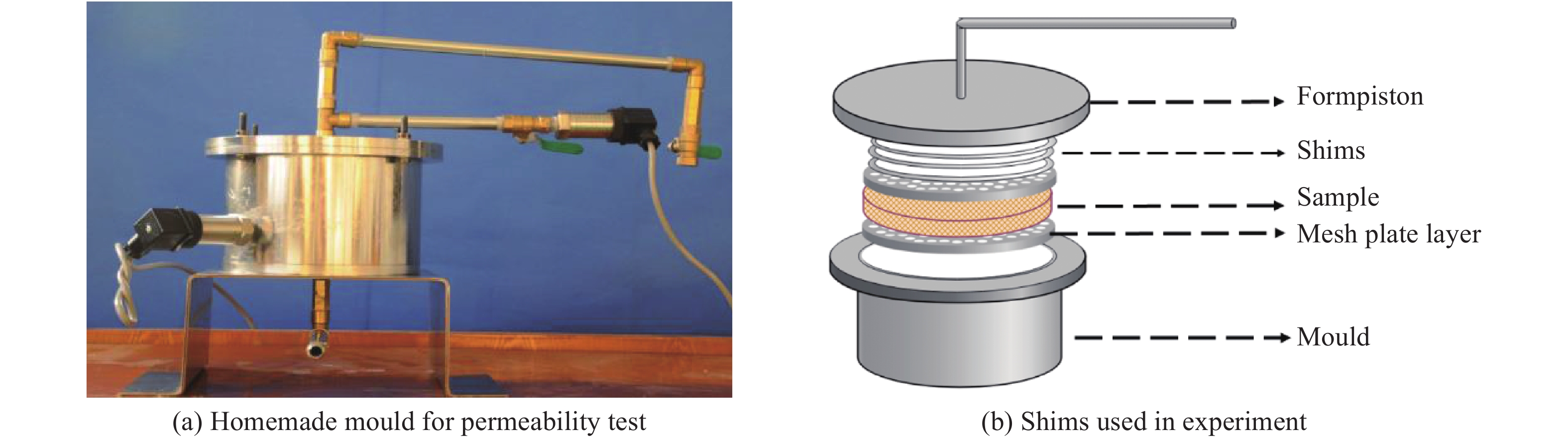

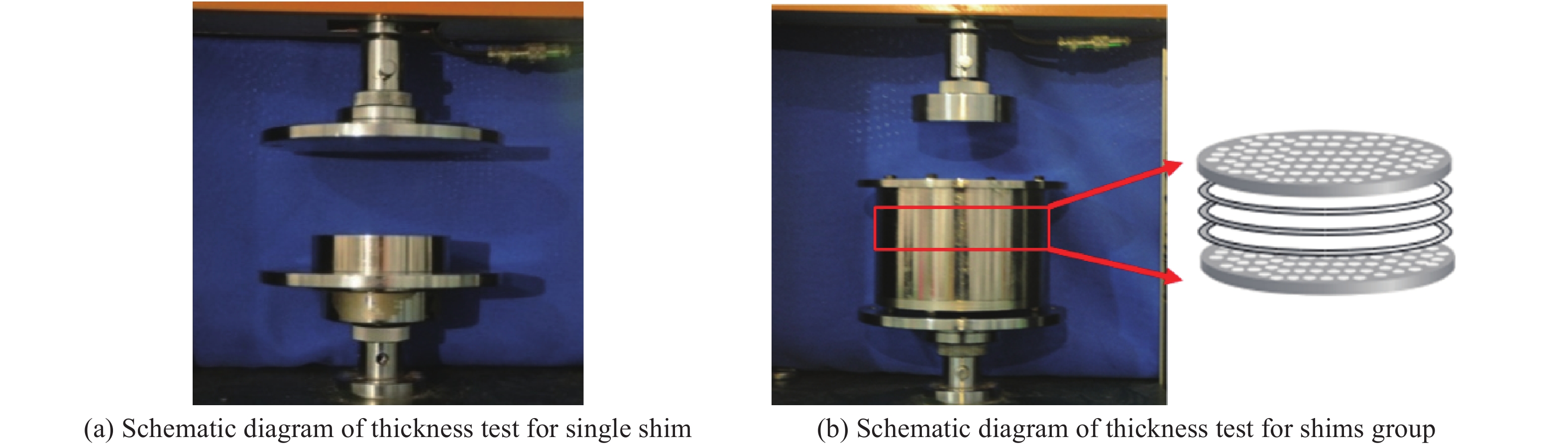

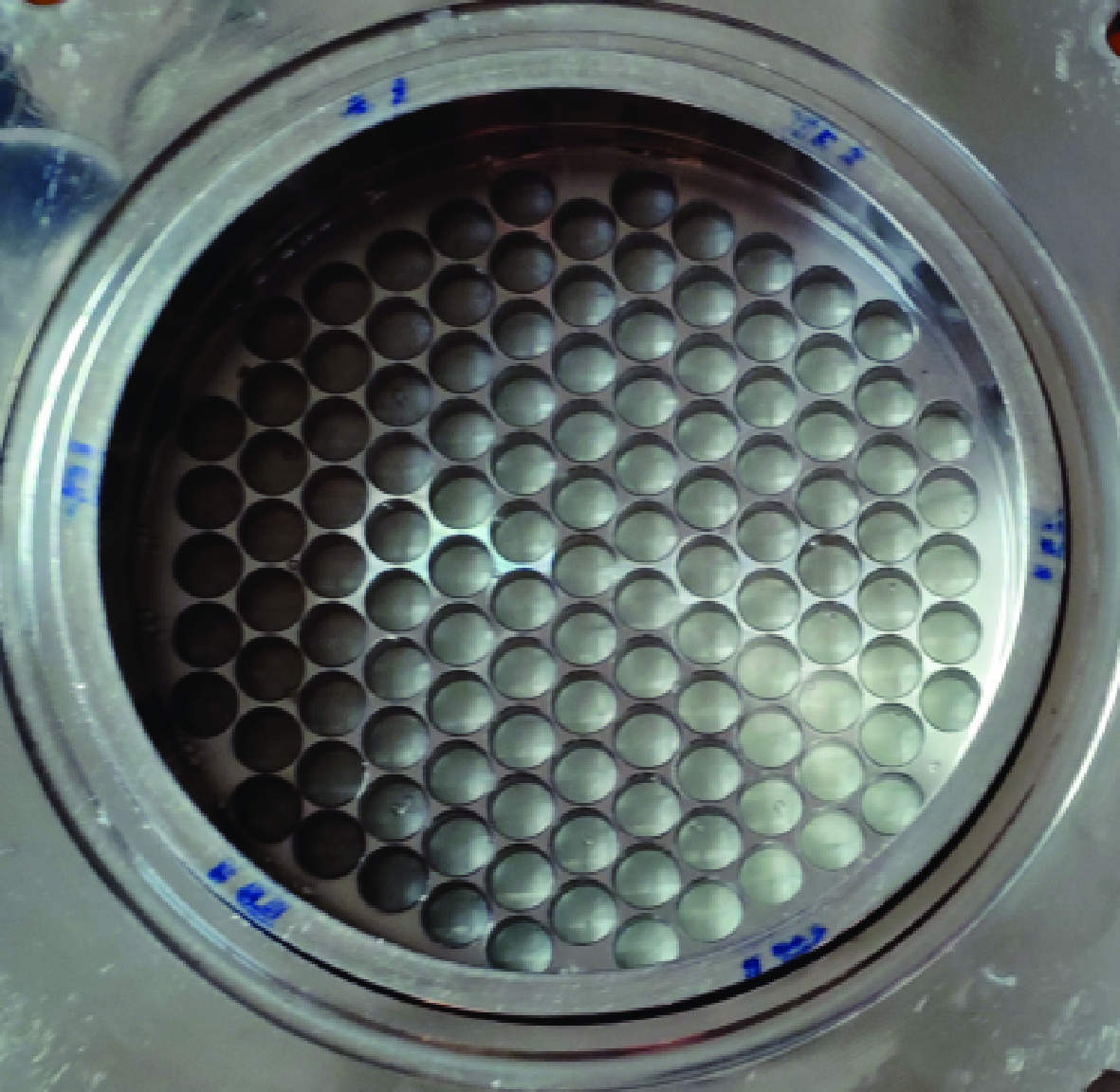

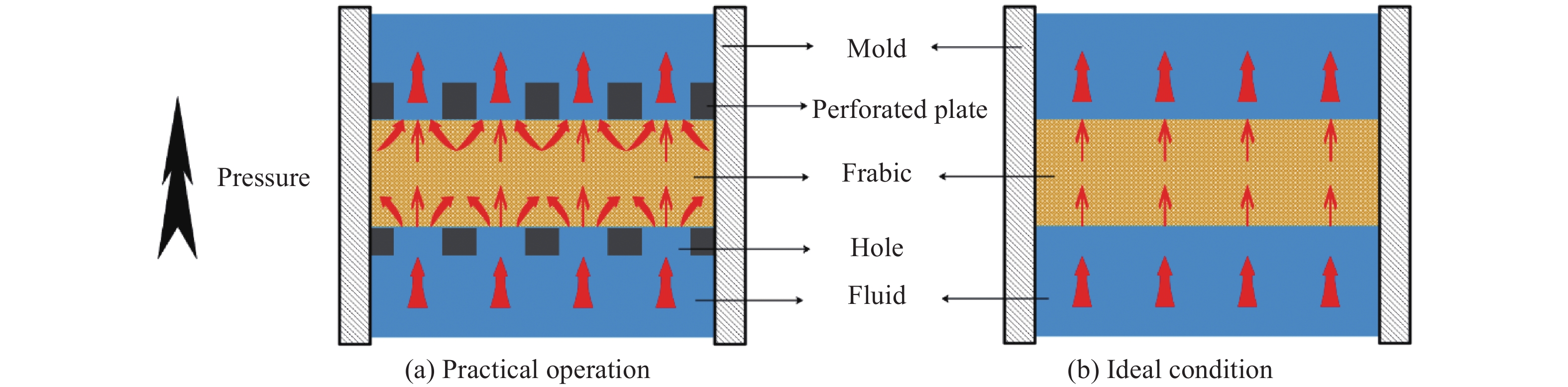

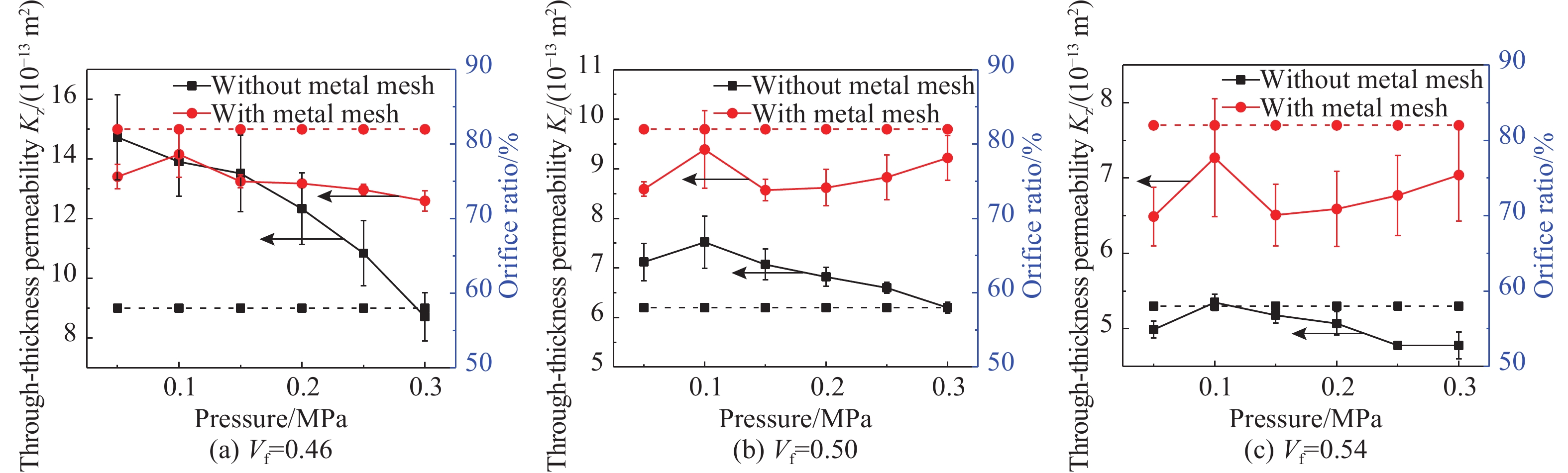

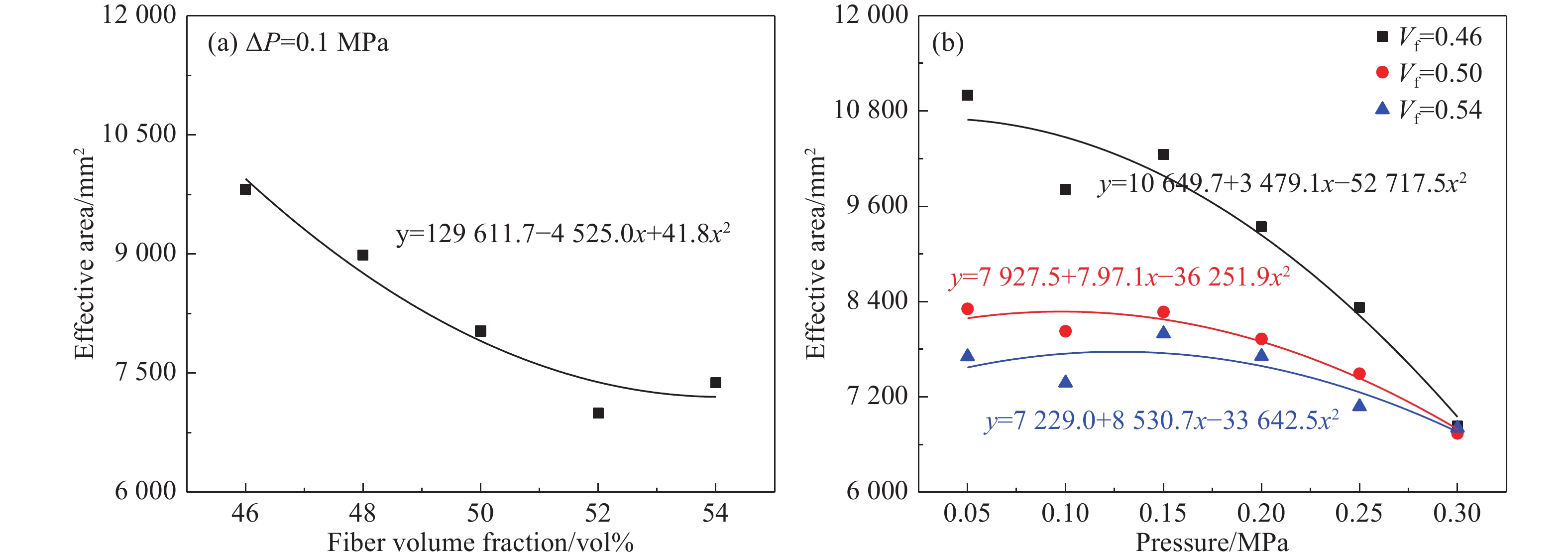

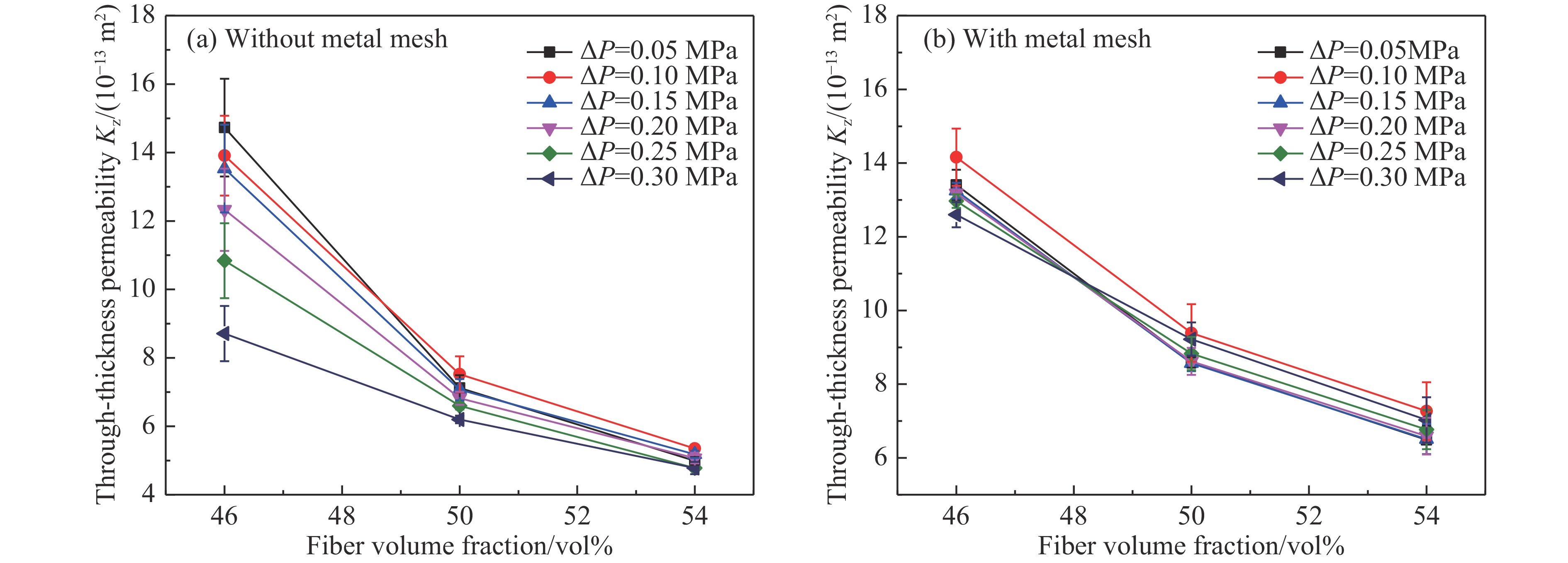

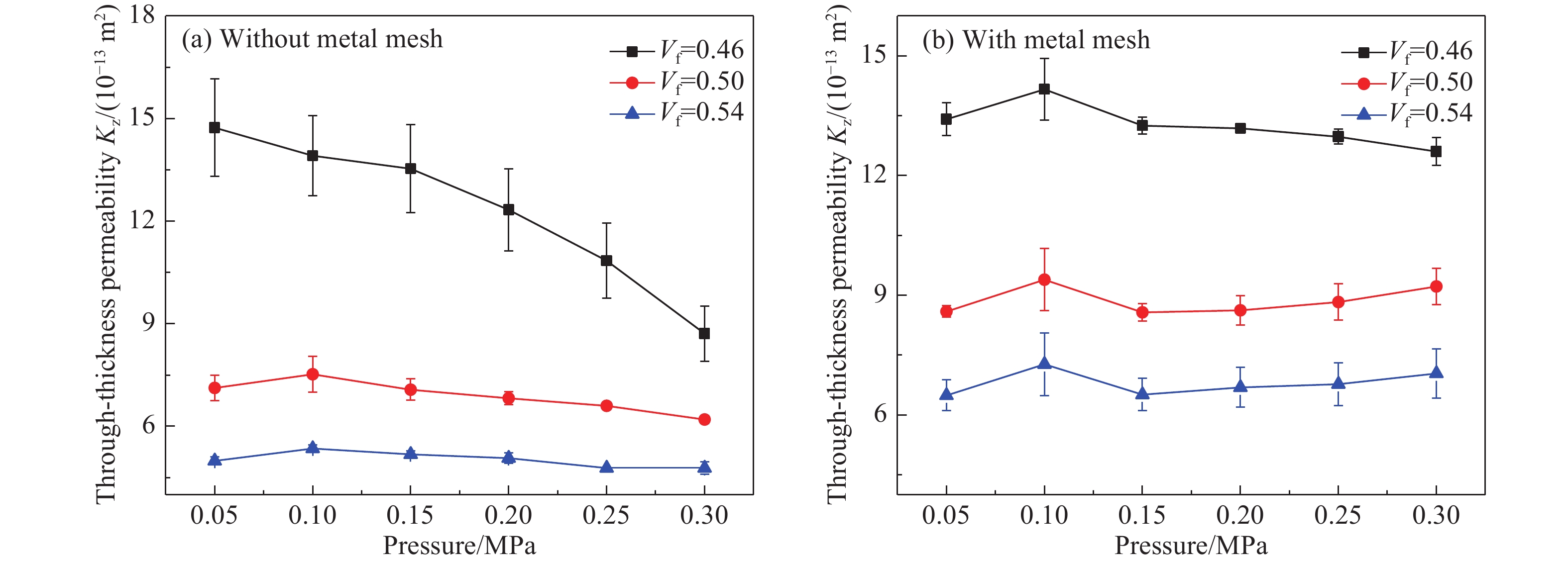

摘要: 纤维预成型体厚度方向渗透率的准确表征是液体模塑成型工艺制备大厚度复合材料计算机优化的关键。网孔板层是布置在试样上下表面、用于控制纤维厚度并防止纤维变形的刚性构件,其开孔率是纤维厚度方向渗透率Kz测量中的重要表征参数。本文首先通过实验对用于控制纤维预成型体厚度的垫圈进行校正;然后在排除纤维体积分数误差的前提下,通过金属网增大网孔板层的开孔率,测量缎纹织物SW220C-100b在不同压力和纤维体积分数下的Kz,提出有效计算面积的概念并得到其变化规律;最后,基于测试结果,研究注射压力和纤维体积分数对Kz的影响。结果表明:有效计算面积随着注射压力和纤维体积分数的增加而减小;纤维体积分数的增大会减小织物的Kz值,网孔板层开孔率的增大会减小注射压力对Kz的影响。Abstract: The accurate characterization of the through-thickness permeability of fiber preforms is the key to the computer optimization of the preparation of composites with large thickness by liquid composite molding. Mesh plate layer is an rigid component for the control of fiber thickness and the prevention of fiber’s deformation, which is placed on the upper and lower surface of the sample. The ratio of hole area for mesh plate layer is an important characteristic parameter in the measurement of through-thickness permeability Kz of fiber. Firstly, the shims used to control the thickness of fiber preforms were calibrated through experiments. On the premise of eliminating the error of fiber volume fraction, the ratio of hole area for mesh plate layer is increased through the metal mesh, the Kz of satin fabric SW220C-100b under different pressures and fiber volume fractions were measured, the concept of effective calculated area was proposed and the change rule of effective calculated area was obtained. Finally, based on the test results, the effects of injection pressure and fiber volume fraction on Kz were studied. The results show that the effective calculated area decreases with the increase of injection pressure and fiber volume fraction. The increase of fiber volume fraction will lead to the decrease of the Kz for fabric. The effect of injection pressure on Kz will be reduced by increasing the ratio of hole area for the mesh plate.

-

近年来,室内环境甲醛污染问题普遍。常用于净化室内空气中甲醛的方法有植物净化法[1]、物理化学吸附法[2]、低温等离子体法[3]、光催化法[4]和催化氧化法[5]。其中催化氧化法因去除甲醛效率高、处理量大、不存在吸附饱和、没有二次污染而被公认为是最理想的甲醛治理方法之一[6]。锰氧化物(MnOx) 具有结构多变、含有丰富变价电对,氧和电子的传递速率快的特性,在催化氧化甲醛方面活性较高而受到广泛关注[7-8 ],然而,在室温环境下,锰氧化物针对低浓度(如1.22 mg/m3左右)甲醛深度净化达到室内空气质量要求仍然是个难题。

凹凸棒石(坡缕石,Palygorskite)是一种层链状结构的镁铝硅酸盐矿物,由于其特殊的棒晶堆叠和孔道结构使该矿物具有优异的吸附性能和载体性能[9-10]。凹凸棒石作为一种功能材料被广泛用于水体富营养化、土壤重金属污染、空气污染等环境问题的治理[11-18],近些年,凹凸棒石被作为催化剂载体应用于催化降解甲醛气体。Liu等[19]用凹凸棒石负载铜锰氧化物用于高浓度甲醛(1227 mg/m3)的催化氧化,在207℃时能实现90%的CO2生成率,表现出优异的催化活性。Wang等[20]用蒙脱石、硅藻土、凹凸棒石等不同的矿物载体负载锰氧化物,评价其对低浓度甲醛(1.22 mg/m3)的催化氧化性能,结果发现凹凸棒石负载锰氧化物效果最佳,在气体空速150000 h−1的条件下1500 min内对甲醛的去除率保持在100%,同时提出将锰氧化物负载于高比表面积、高孔隙的载体是一种提高锰基催化剂活性的有效方法。但前人研究的载体凹凸棒石均为高品位、纯度高的样品,缺乏对低品位凹凸棒石黏土矿物的研究。

我国凹凸棒石资源储量丰富,苏皖地区、甘肃河西走廊一带、四川和贵州都有凹凸棒石的矿床分布[9],不同地区凹凸棒石黏土品位差异较大,存在大量低品位凹凸棒石黏土矿产,典型代表有甘肃临泽地区,该地区凹凸棒石黏土资源丰富,但是通常含有伊利石、伊蒙混层矿物、蒙脱石、石英、长石、方解石、白云石、磷灰石和纳米铁氧化物等杂质矿物,品位较低,常用的提纯工艺只能去除部分石英和碳酸盐类矿物,无法实现凹凸棒石黏土的富集[21-25],此外,该地区的大部分凹凸棒石黏土矿因铁含量高呈现红色,实际应用时常需进行脱色处理,开发与利用的难度加大[26]。

本文以预富集处理的临泽红色低品位凹凸棒石黏土(PPCI)悬浮液为原料,通过原位KMnO4和(NH4)2C2O4的氧化还原反应制备出MnOx/PPCI复合材料,采用XRD、拉曼光谱、SEM和TEM表征催化剂的组成及结构特征,用电化学测试、XPS研究催化剂的表面性质,并通过动态实验和静态实验研究催化剂对空气中甲醛的催化降解效能。以期提高低品位矿产资源的利用效率,同时开发出高效的室内甲醛净化催化剂。

1. 实验材料与方法

1.1 原材料

所使用的红色低品位凹凸棒石黏土(凹凸棒石含量约为40wt%)取自甘肃省临泽县正北山古城矿区,化学成分为(wt%):SiO2 44.47、Al2O3 11.26、CaO 10.23、Fe2O3 6.20、MgO 4.68、K2O 3.64、SO3 1.38、SrO 1.35、P2O5 0.86、其他2.08、烧失量13.85。原矿用醋酸-醋酸钠弱酸溶液(pH=4.6)浸泡过夜去除白云石、方解石等碳酸盐矿物,经静水沉降分离进一步去除石英等非黏土矿物组分,离心回收黏土组分,洗涤、干燥保存备用[9,27],记为PPCI。纯化后凹凸棒石黏土样品化学成分为(wt%):SiO2 48.89、Al2O3 15.52、Fe2O3 10.08、K2O 4.87、P2O5 2.88、MgO 2.88、CaO 2.61、其他2.12、烧失量10.15。

将3.00 g PPCI与不同质量的KMnO4(0.55 g、1.18 g、1.64 g、2.57 g、2.87 g、4.44 g、4.85 g)混合后加入装有100 mL去离子水的烧杯中磁力搅拌12 h,而后按KMnO4与(NH4)2C2O4质量比为1∶0.4的比例加入(NH4)2C2O4,将烧杯置于水浴锅中90℃反应10 h,冷却后离心、去离子水洗涤3次,固体在105℃烘箱中干燥24 h[28],然后研磨过0.22~0.38 mm筛备用。将样品酸溶后用火焰原子吸收法测定样品的实际锰负载量(wt%),分别为6.2、11.6、15.7、23.0、26.7、33.6、35.6,记为x δ-MnO2/PPCI,其中x表示Mn的实际负载量(表1)。

表 1 MnOx/预富集处理的临泽红色低品位凹凸棒石黏土(PPCI)的命名Table 1. Naming of MnOx/purifing palygorskite clay rich iron (PPCI) Sample Mn/wt% KMnO4/g PPCI/g 6.2 δ-MnO2/PPCI 6.2 0.55 3 11.6 δ-MnO2/PPCI 11.6 1.18 3 15.7 δ-MnO2/PPCI 15.7 1.64 3 23.0 δ-MnO2/PPCI 23.0 2.57 3 26.7 δ-MnO2/PPCI 26.7 2.87 3 33.6 δ-MnO2/PPCI 33.6 4.44 3 35.6 δ-MnO2/PPCI 35.6 4.85 3 1.2 材料的表征

使用日本岛津X射线荧光光谱分析仪(XRF-1800)进行物质的化学元素分析,测试前将样品置于马弗炉中860℃高温煅烧2 h,计算烧失量。使用丹东浩圆2700型X射线衍射仪(XRD,Dandong Haoyuan-DX-2007,China)分析固体样品的物相组成,Cu靶,扫描范围2θ=5°~70o,扫描速度5°/min。使用拉曼光谱分析仪(Lab RAM HR,France)在532 nm,2.5%的低激光条件下测定锰氧化物官能团的振动。使用高分辨透射电子显微镜(TEM,JEOL-2010) 和扫描电子显微镜(SEM,SU-8020)观测矿物形貌特征、催化剂组分界面关系和微观结构特征。用N2吸附脱附分析仪(Novawin3000e)测定催化剂的比表面积。使用X射线光电子能谱(Escalab250 Xi)测定催化剂中元素的价态。使用原位漫反射红外傅里叶变换光谱仪(Bruker,VERTEX70)检测甲醛与催化剂反应过程中催化剂表面官能团的变化情况,所有样品在反应前用N2吹扫20 min以去除表面吸附杂质,室温高纯空气为载气,甲醛浓度为167.5 mg/m3,每10 min记录一次XRD图谱。使用电化学工作站(CHI-660E)对PPCI、δ-MnO2和33.6 δ-MnO2/PPCI的电化学性能进行测试,将10 mg粉末状样品与2 mL的5wt%Nafion膜溶液超声混合后涂敷在1.2 cm×1.5 cm的亲水碳片上,80℃烘干后作为工作电极,用饱和甘汞电极和铂电极分别作为参比电极和辅助电极,在1 mol/L的KOH中完成测试。

1.3 催化降解甲醛实验

动态实验在固定床固相催化反应器上完成,0.1 g催化剂置于石英棉支撑的石英管(内径6 mm)中部,在4.5℃用100 mL/min的N2吹扫多聚甲醛得到甲醛气体,再用900 mL/min的合成空气使反应器进气甲醛浓度保持在1.22 mg/m3左右,反应体系的体积空速(Space velocity,GHSV)为150000 h−1。过程中用甲醛分析仪(Interscan 4160-2,USA)在线即时测定反应器进出口甲醛浓度。静态实验在密闭玻璃器皿中完成,通过水浴循环系统控制反应器的温度保持在25℃,先用100 mL/min的高纯空气吹扫清除舱体中残留气体,然后向舱内注入甲醛溶液,待其挥发至浓度稳定后,把0.1 g催化剂均匀分散在反应器底部,使其与气体甲醛充分接触,过程中使用在线气体分析仪(LB-MD4X,China)实时监测反应舱中甲醛浓度。甲醛去除率根据公式η=(C0−Ct)/C0×100%计算得到,其中C0和Ct分别表示甲醛的进口浓度和t时刻的出口浓度。

2. 结果与讨论

2.1 MnOx/PPCI复合催化剂的物相

系列MnOx/PPCI样品的XRD图谱如图1(a)所示,在2θ=20.9o、26.6o、42.6o、45.5o和50.1o处出现石英的衍射特征峰,在2θ=8.4o、13.7o、19.8°、27.9o和34.4o处出现凹凸棒石特征衍射峰。在2θ=8.4o附近出现多个微弱的衍射峰,归为伊利石、伊蒙混层矿物和蒙脱石等黏土矿物[22, 27]。XRD图谱中几乎观察不到锰氧化物的衍射峰,这与锰氧化物在凹凸棒石等矿物表面高度分散、结晶度很低有关[29-30]。

用拉曼光谱分析仪进一步鉴定PPCI负载锰氧化物物相。图1(b)显示在约507~497 cm−1、569~564 cm−1和665~634 cm−1处,δ-MnO2和所有负载型催化剂都观察到3个主要的拉曼带。这些条带与八面体MnO6的拉伸模式有关,其中507~497 cm−1处的条带对应八面体MnO6基团中Mn-O-Mn的弯曲振动[28],569~564 cm−1对应八面体MnO6层片基面上Mn—O的拉伸振动,665~634 cm−1对应MnO6基团上Mn—O的对称拉伸振动[31-32]。拉曼光谱的结果证实,PPCI负载锰氧化物物相为δ-MnO2。

2.2 MnOx/PPCI复合催化剂的微观形貌

图2(a)和图2(b)分别是PPCI的SEM和TEM图像。可以看出短棒状凹凸棒石与层片状伊蒙矿物杂乱堆积,这与XRD结果相吻合,样品中棒晶直径约为40~60 nm。图2(c)~2(e)是纯相δ-MnO2的SEM图像。SEM下的物相呈现无定形颗粒聚集体,样品在TEM图像下呈现松散的衣状结构,在高分辨TEM下观察到0. 227 nm的晶格条纹间距,对应δ-MnO2的(111)晶面。图2(f)是33.6 δ-MnO2/PPCI样品的TEM图像。对比图2(f)与图2(a),可以看出制备的复合材料棒晶直径明显增大,同时EDS能谱图2(j)~2(o)显示的元素Mg、Al、Si、O、Fe和Mn在33.6 δ-MnO2/PPCI表面的分布情况,表明δ-MnO2均匀包覆在凹凸棒石棒晶等矿物表面,且矿物中含有少量的Fe元素,在催化氧化甲醛过程中可能与Mn构成协同作用,使催化向有利的方向进行[33-35]。一般来说,高比表面积的催化剂可以提供更多的表面活性位点[36],用N2吸附脱附分析仪测定了催化剂的比表面积(表2),33.6 δ-MnO2/PPCI (73.2 m2/g)>PPCI (64.3 m2/g)>δ-MnO2 (41.4 m2/g),与低品位凹凸棒石原矿和δ-MnO2相比,负载型催化剂的比表面积有所提高,这可能与锰氧化物的在低品位凹凸棒石黏土矿物表面高度分散有关。

表 2 MnO2/PPCI复合材料的比表面积Table 2. Specific surface area of MnO2/PPCISample Surface area/(m2·g−1) PPCI 64.3 δ-MnO2 41.4 6.2 δ-MnO2/PPCI 46.6 11.6 δ-MnO2/PPCI 52.7 15.7 δ-MnO2/PPCI 55.4 23.0 δ-MnO2/PPCI 58.2 26.7 δ-MnO2/PPCI 67.8 33.6 δ-MnO2/PPCI 73.2 35.6 δ-MnO2/PPCI 59.8 2.3 MnOx/PPCI复合催化剂的表面化学性质

用XPS测试了催化剂表面元素Mn、O的化学状态,如图3所示。图3(b)中Mn2p3/2轨道位于641.1 eV、642.2 eV和643.1 eV分别对应Mn2+、Mn3+和Mn4+物种[37]。根据上述物种分峰面积,33.6 δ-MnO2/PPCI样品中Mn3+和Mn4+的总量占比0.92,略大于δ-MnO2样品(0.88),表明矿物载体的引入有利于更多Mn3+/Mn4+活性电对的暴露[5]。Mn3+和Mn4+在甲醛催化降解过程中均有重要的作用,Mn4+具有更强的氧化还原能力,Mn3+存在表明MnOx中有更多氧空位缺陷,更容易活化氧气,产生表面活性氧(4Mn4++O2−→4Mn4++2e−/Ov+0.5O2→2Mn4++2Mn3++Ov+0.5O2 ),其中Ov代表氧空位[28]。

根据Mn3S轨道上2个峰之间的结合能差ΔE3s,用经验公式计算Mn的平均氧化态(AOS),AOS=8.956–1.126ΔE3s[38],如图3(c)所示,33.6 δ-MnO2/PPCI (3.94)中Mn的AOS高于δ-MnO2(3.48),与Mn2p3/2的结果吻合。图3(d)中,O1s的3个拟合峰530.0 eV、531.4~531.5 eV、532.4~532.5 eV分别对应晶格氧物种(Olatt),吸附氧物种(Oads)和表面羟基物种(OOH)。可看出,纯相δ-MnO2中晶格氧和吸附氧是样品表面主要的氧物种,表面羟基物种仅占14%,而在33.6 δ-MnO2/PPCI样品中,表面羟基物种占比36%,远高于纯相δ-MnO2,这与低品位凹凸棒石表面的羟基基团有关,另外Si—O键的羟基化也会使OOH数量增多[30]。表面羟基在反应过程中既可以通过氢键作用,增强甲醛的吸附,又可以充当反应中心,将甲酸盐进一步氧化为H2O和CO2[39]。

催化剂的电子密度和电子转移过程在催化氧化反应中起着重要的作用,具有较高电子转移率的催化剂能够加速O2在其表面的解离过程[40],为此,对材料进行了电化学研究。如图4(a)所示,33.6 δ-MnO2/PPCI样品显示的循环伏安(CV)回路的积分面积比PPCI和δ-MnO2更大,说明33.6 δ-MnO2/PPCI具有更高的阳极电流,结果表明凹凸棒石负载锰氧化物形成的杂化纳米结构有助于提高材料的电化学活性。Wang等[20]曾研究不含铁的凹凸棒石负载δ-MnO2复合催化剂的电化学性能,在与本文类似条件下,CV曲线在0.6 V处的阳极电流为0.015 mA,显著低于本研究的0.022 mA,这可能与载体中存在的Fe元素会与Mn形成协同效应,从而增强催化剂电化学性能有关。通过Tafel曲线分析材料的电子转移性能,一般来说,较高的负电位使得氧化还原反应过程中的电子交换和转移变得容易,从图4(b)可以看出材料的负电位高低顺序依次为33.6 δ-MnO2/PPCI>δ-MnO2>PPCI,这与CV曲线结果一致。结合XPS、SEM和TEM的结果,可以看出δ-MnO2均匀地包覆在PPCI棒晶表面,使更多活性表面(如Mn4+/Mn3+氧化还原电对)得以暴露,从而增强了氧化还原过程的电荷运输。

2.4 MnOx/PPCI复合催化剂的甲醛去除实验结果

图5(a)为PPCI、δ-MnO2和x δ-MnO2/PPCI在环境温度(25℃)下对甲醛的动态去除效果。从实验结果来看,低品位凹凸棒石对甲醛有一定的去除效果,180 min内对甲醛的去除量为0.3 mg/g。δ-MnO2对甲醛有一定的催化氧化效果,在720 min时去除率为87%。x δ-MnO2/PPCI样品随着Mn负载量的增加,对甲醛的去除效率随之提高,当Mn负载量为33.6wt%时达到顶峰,720 min时去除率保持在99%,这与以高品位凹凸棒石(安徽官山,凹凸棒石含量>95%)为载体的催化剂对甲醛的去除效果(100%,720 min)相比,差异不大。负载量继续提高,去除效率反而下降,这是由于过量的δ-MnO2无法在低品位凹凸棒石上均匀分散,并在其表面出现堆叠和团聚的现象,从而导致催化剂比表面积和活性位点减少[39]。延长最优样品33.6 δ-MnO2/PPCI的反应时间至40 h,如图5(b)所示,反应8 h后甲醛去除率开始缓慢下降,在40 h时去除率为89.3%,说明样品的长时间运行稳定性良好。在静态实验中,如图5所示,δ-MnO2与Mn负载量为15.7wt%和33.6wt%的催化剂效能无明显差异。在33.6 δ-MnO2/PPCI去除甲醛过程中检测CO2的产生情况,图5(d)显示60 min后CO2浓度升至142.0 mg/m3,CO2选择性为65.8%。CO2选择性低于甲醛去除率原因是由于生成甲酸盐、碳酸盐等矿化中间产物。为进一步理解甲醛的降解动力学,用一级动力学模型和二级动力学模型来拟合甲醛去除过程中时间和浓度的关系。动力学拟合的一级和二级方程如下:

![]() 图 5 催化剂去除甲醛的动态效能 (a)、33.6 δ-MnO2/PPCI长时间动态稳定性测试 (b)、静态效能 (c) 和33.6 δ-MnO2/PPCI 静态去除甲醛过程中CO2浓度变化 (d)Figure 5. Dynamic performance (a), long-term stability of 33.6 δ-MnO2/PPCI under dynamic test (b), static performance (c) and change of the CO2 concertration during formaldehyde removal by 33.6 δ-MnO2/PPCI under static test (d)C—Concentration

图 5 催化剂去除甲醛的动态效能 (a)、33.6 δ-MnO2/PPCI长时间动态稳定性测试 (b)、静态效能 (c) 和33.6 δ-MnO2/PPCI 静态去除甲醛过程中CO2浓度变化 (d)Figure 5. Dynamic performance (a), long-term stability of 33.6 δ-MnO2/PPCI under dynamic test (b), static performance (c) and change of the CO2 concertration during formaldehyde removal by 33.6 δ-MnO2/PPCI under static test (d)C—ConcentrationlnCtC0=−k1t (1) 1Ct−1C0=k2t (2) 式中:t表示反应的时间(min);C0表示甲醛的初始浓度(mg·m−3);Ct表示t时刻甲醛的出口浓度(mg·m−3);k1(min−1)和k2(mg−1·m3·min−1)是由一级和二级动力学方程导出的速率参数。

动力学拟合的结果如图6所示,表3总结了试验样品的速率常数k和相关系数R2。可以看出,甲醛的反应动力学更符合二级动力学模型,催化剂的速率常数大小顺序为33.6 δ-MnO2/PPCI>δ-MnO2>15.7 δ-MnO2/PPCI>PPCI,进一步证明低品位凹凸棒石矿物负载δ-MnO2可以有效提高对甲醛的去除效率。

表 3 一级动力学和二级动力学模型的拟合数据Table 3. Fitting data of the first-order and second-order kinetic modelsOrder Parameter PPCI δ-MnO2 15.7 δ-MnO2/PPCI 33.6 δ-MnO2/PPCI First k1 −0.0012 −0.039 −0.038 −0.041 R2 0.7744 0.8031 0.8453 0.8108 Second k2 1.45×10−4 2.18×10−3 1.59×10−3 1.86×10−3 R2 0.8800 0.9891 0.9946 0.9872 Notes: k1—Reaction rate constants of first-kinetic model; k2—Reaction rate constants of second-kinetic model; R2—Correlation. 2.5 MnOx/PPCI复合催化剂的去除甲醛机制

为了进一步了解甲醛气体在催化剂表面的吸附行为和反应过程中产生的中间物种,将样品PPCI、δ-MnO2和 33.6 δ-MnO2/PPCI 在4000~1 000 cm−1范围内通入甲醛进行原位DRIFTS测试。PPCI样品的光谱图如图7(a)所示。可以观察到随着时间的推移,甲酸盐(HCOO−)的非对称振动吸收峰vas(COO)(1638 cm−1)、亚甲基二氧(Dioxymethylene, DOM)中v(CO) (1200、1134 cm−1)和碳酸盐(1289 cm−1)的峰有微弱的增强,说明甲醛在PPCI表面有微弱的矿化作用。同时发现PPCI表面出现羟基(3646、3556、3446 cm−1)和吸附水(1700 cm−1)的负振动峰,并随着反应时间增加而增强。这说明,PPCI在矿化甲醛的过程中会消耗表面羟基物种,而表面吸附水可以与表面活性氧作用生成羟基物种,补偿反应中消耗的羟基[20, 28]。δ-MnO2样品的光谱图如图7(b)所示,样品表面的甲酸盐物种(2832、1574、1346 cm−1)、亚甲基二氧(1207 cm−1)和碳酸盐物种(1387 cm−1)对应的峰强度随时间增强。图7(c)显示的是33.6 δ-MnO2/PPCI表面物种的变化情况,1386、1207和1140 cm−1处的峰归属于亚甲基二氧,2973、2831、1575和1346 cm−1处的峰归属于甲酸盐,1469和1677 cm−1处的峰归属于碳酸盐[28, 41-43]。在1700 cm−1处也观测到了33.6 δ-MnO2/PPCI复合催化剂消耗表面水分子负振动峰,结合凹凸棒石表面吸附水在矿化甲醛中被消耗的情况,推测复合催化剂反应过程中消耗的羟基(如Mn—OH),可通过表面吸附水与表面活性氧补偿再生[28]。此外,随着反应的进行,催化剂表面的中间产物(如甲酸盐等)的峰逐渐增强,表明甲醛分子不断被转化为中间产物,并最终氧化为CO2和水。通常甲酸盐被视为主要的甲醛转化中间物种,对1575 cm−1附近HCOO−的光谱峰进行积分后,计算出甲酸盐物种随反应时间累积分解速率(图7(d)),可以看出33.6 δ-MnO2/PPCI上甲酸盐的累积分解速率大于δ-MnO2, 说明甲醛在33.6 δ-MnO2/PPCI样品中转化速率更高,生成和脱附的甲酸盐物种更快。

根据原位DRIFTS的结果,可以推断甲醛在δ-MnO2/PPCI表面的降解机制。如图8所示,首先,气相中的游离氧分子可以被催化剂表面的氧空位捕获,然后被解离活化为Oads,与此同时,催化剂表面的Mn3+被Oads氧化为Mn4+[44]。甲醛通过氢键被表面羟基吸附到催化剂表面,凹凸棒石等黏土矿物富含的羟基物种可加快甲醛在复合催化剂的吸附过程。被吸附的甲醛首先被氧化为HCOOH中间体(DOM),DOM极不稳定,易被分解为H+和HCOO−,而后被表面活性氧和羟基近一步被分解为CO2和H2O[20, 45]。同时,Mn4+被产生的中间物种还原为Mn3+。在此过程中,消耗的表面活性氧物种通过Mn3+和Mn4+之间的氧化还原循环过程不断补充,消耗的表面羟基也可以通过消耗凹凸棒石表面水分子补偿再生。

3. 结 论

(1) 低品位凹凸棒石载锰复合材料具有较高的比表面积(73.2 m2/g),可以促进甲醛在催化剂表面的吸附。催化剂表面均匀分布的锰氧化物、Mn3+/Mn4+电对和丰富的羟基物种对甲醛的分解都有积极的影响。复合催化剂33.6 δ-MnO2/预富集处理的临泽红色低品位凹凸棒石黏土(PPCI)具有优异的氧化降解甲醛性能,甲醛浓度为1.22 mg/m3,反应空速150000 h−1,在720 min内对甲醛去除率保持在99%以上;静态实验中降解初始浓度为146 mg/m3的甲醛气体,60 min后CO2选择性为65.8%。

(2) δ-MnO2/PPCI降解甲醛反应遵循二级动力学。根据In situ-DRFIS的结果推断δ-MnO2/PPCI对甲醛的降解过程为:甲醛分子被催化剂表面的羟基吸附,与表面活性氧反应生成中间体亚甲基二氧(DOM)、甲酸盐和碳酸盐,甲酸盐进一步分解为H2O和CO2。

(3) 证实PPCI负载锰氧化物降解室内甲醛效能优于纯相δ-MnO2,为临泽地区PPCI资源的开发应用提供了新思路。

-

表 1 增强材料和流体相关参数

Table 1 Relevent parameters of reinforcements and liquid

Type Name Areal density/

(g·m−2)Volume density/

(kg·m−3)SF SW220C-100b 220 2 550 Silicone oil PMX-200 − 960 表 2 17层缎纹织物厚度方向渗透率Kz测试实验分组

Table 2 Experimental groups of through-thickness permeability Kz testing for SF with 17 layers

Fiber volume

fraction/vol%Pressure/MPa With metal mesh 46 0.05 0.1 0.15 0.2 0.25 0.3 48 − 0.1 − − − − 50 0.05 0.1 0.15 0.2 0.25 0.3 52 − 0.1 − − − − 54 0.05 0.1 0.15 0.2 0.25 0.3 Without metal mesh 46 0.05 0.1 0.15 0.2 0.25 0.3 48 − 0.1 − − − − 50 0.05 0.1 0.15 0.2 0.25 0.3 52 − 0.1 − − − − 54 0.05 0.1 0.15 0.2 0.25 0.3 表 3 试验机测试垫圈厚度

Table 3 Thickness values of shims tested in testing machine

Sequence numbers A B C D E F G Thickness/mm 2.944 4.933 1.865 0.181 0.183 0.181 0.187 Sequence numbers H I J K L M N Thickness/mm 0.231 0.181 0.186 4.918 0.233 27.944 9.986 表 4 垫圈组名义厚度和实验机所测厚度

Table 4 Nominal thickness and thickness measured by experimental machine of shims group

Nominal thickness/mm Selected shims Actual thickness/mm Error value/mm Percentage error/% 21.7008 BCKN 21.803 0.1022 0.47 14.3570 ABDEFGHIJKL 14.559 0.2020 1.40 10.7750 EGJLN 10.793 0.0180 0.17 8.2971 ABGL 8.283 −0.0141 −0.17 6.7821 CK 6.710 −0.0721 −1.06 5.8739 DEFHIK 5.955 0.0811 1.38 4.5070 ADEFGHIJL 4.634 0.1720 3.82 3.6698 ADEFI 3.624 −0.0458 1.25 2.8759 CDFHJL 2.877 0.0011 0.04 1.0988 DEFGIJ 1.132 0.0332 3.02 -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):12-12. DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):12-12(in Chinese).

[2] DING A, LI S, WANG J, et al. A new path-dependent constitutive model predicting cure-induced distortions in composite structures[J]. Composites Part A: Applied Science and Manufacturing,2017,95:183-196. DOI: 10.1016/j.compositesa.2016.11.032

[3] DING A, LI S, WANG J, et al. A new analytical solution for spring-in of curved composite parts[J]. Composites Science and Technology,2017,142:30-40. DOI: 10.1016/j.compscitech.2017.01.024

[4] ERMANNI P, FRATTA C D, TROCHU F. Molding: Liquid composite molding (LCM)[M]//NICOLAIS L. Wiley Encyclopedia of Composites. John Wiley & Sons, Inc., 2011.

[5] 邢丽英, 蒋诗才, 周正刚. 先进树脂基复合材料制造技术进展[J]. 复合材料学报, 2013, 30(2):1-9. XING Liying, JIANG Shicai, ZHOU Zhenggang. Progress of manufacturing technology development of advanced polymer matrix composites[J]. Acta Materiae Compositae Sinica,2013,30(2):1-9(in Chinese).

[6] 张默. 真空辅助树脂成型实时监测技术研究[D]. 上海: 东华大学, 2011. ZHANG Mo. Study on real-time monitoring of vacuum-assisted resin transfer mplding[D]. Shanghai: Donghua University, 2011(in Chinese).

[7] 朱锡, 黄若波, 石勇, 等. 安静型夹芯复合材料舵设计及其力学性能分析[J]. 海军工程大学学报, 2007, 19(4):90-93,110. DOI: 10.3969/j.issn.1009-3486.2007.04.022 ZHU Xi, HUANG Ruobo, SHI Yong, et al. Design and mechanical analysis of quiet type of sandwich composite rudder[J]. Journal of Naval University of Engineering,2007,19(4):90-93,110(in Chinese). DOI: 10.3969/j.issn.1009-3486.2007.04.022

[8] 张盛, 祖磊, 王继辉, 等. VIMP工艺中纤维增强体Z向渗透性分析[J]. 玻璃钢/复合材料, 2014(s1):160-164. ZHANG Sheng, ZU Lei, WANG Jihui, et al. Analysis of the Z direction permeability of the fiber reinforcement in VIMP[J]. Fiber Reinforced Plastics/Composites,2014(s1):160-164(in Chinese).

[9] 张璇, 白国娟, 王星星, 等. 三维织物厚度方向渗透率研究[J]. 中国胶粘剂, 2017, 26(5):26-29. ZHANG Xuan, BAI Guojuan, WANG Xingxing, et al. Study on the thickness-permeability of three-dimensional fabric[J]. China Adhesives,2017,26(5):26-29(in Chinese).

[10] 耿奕, 蒋金华, 陈南梁. 经编四轴向玻璃纤维织物的渗透行为和渗透率[J]. 纺织学报, 2017, 38(10):49-56. GENG Yi, JIANG Jinhua, CHEN Nanliang. Permeation behavior and permeability of warp-knitted quadri-axial glass fiber fabric[J]. Journal of Textile Research,2017,38(10):49-56(in Chinese).

[11] 蒋金华, 汪泽幸, 陈南梁. LCM中织物结构对3D渗透性的影响[J]. 玻璃钢/复合材料, 2012(5):9-18. DOI: 10.3969/j.issn.1003-0999.2012.05.002 JIANG Jinhua, WANG Zexing, CHEN Nanliang. Effects of fabric structure on 3D permeability in LCM[J]. Fiber Reinforced Plastics/Composites,2012(5):9-18(in Chinese). DOI: 10.3969/j.issn.1003-0999.2012.05.002

[12] 张娜, 赵子为, 刘春太, 等. 风力发电机叶片用玻璃纤维织物的渗透率[J]. 复合材料学报, 2013, 30(4):245-249. ZHANG Na, ZHAO Ziwei, LIU Chuntai, et al. Permeability of glass fabric for wind turbineblades[J]. Acta Materiae Compositae Sinica,2013,30(4):245-249(in Chinese).

[13] 董梦瑶, 鲁智力, 吕广超, 等. 喷涂碳纳米纤维对玻纤预制体渗透率的影响[J]. 玻璃钢/复合材料, 2016(11):100-106. DOI: 10.3969/j.issn.1003-0999.2016.11.018 DONG Mengyao, LU Zhili, LV Guangchao, et al. Effects of the glass fiber preforms' permeability for spraying carbon nanofiber[J]. Fiber Reinforced Plastics/Composites,2016(11):100-106(in Chinese). DOI: 10.3969/j.issn.1003-0999.2016.11.018

[14] 刘刚, 张朋, 李伟东, 等. 结构化增韧层增韧RTM复合材料预成型体的渗透特性[J]. 复合材料学报, 2014, 31(1):73-80. DOI: 10.3969/j.issn.1000-3851.2014.01.010 LIU Gang, ZHANG Peng, LI Weidong, et al. Infiltration characteristics of the preform of structured toughening layer toughening RTM composite[J]. Acta Materiae Compositae Sinica,2014,31(1):73-80(in Chinese). DOI: 10.3969/j.issn.1000-3851.2014.01.010

[15] WANG C, BAI G, WANG Y. et al. Permeability tests of fiber fabrics in the vacuum assisted resin transfer molding process[J]. Applied Composite Materials,2015,22(4):363-375. DOI: 10.1007/s10443-014-9412-5

[16] OUAGNE P, OUAHBI T, PARK C H, et al. Continuous measurement of fiber reinforcement permeability in the thickness direction: Experimental technique and validation[J]. Composites Part B: Engineering,2013,45(1):609-618. DOI: 10.1016/j.compositesb.2012.06.007

[17] KLUNKER F, DANZI M, ERMANNI P. Fiber deformation as a result of fluid injection: modeling and validation in the case of saturated permeability measurements in through thickness direction[J]. Journal of Composite Materials,2015,49(9):1091-1105. DOI: 10.1177/0021998314530766

[18] 王燕辉, 吴晓青. 单胞法预测玻璃纤维平纹织物的渗透率[J]. 纤维复合材料, 2014(3):14-16. WANG Yanhui, WU Xiaoqing. Prediction permeability of glass fiber plain fabric by unit cell method[J]. Fiber Composites,2014(3):14-16(in Chinese).

[19] ANTONUCCI V, ESPOSITO M, RICCIARDI M R, et al. Permeability characterization of stitched carbon fiber preforms by fiber optic sensors[J]. Express Polymer Letters,2011,5(12):1075-1084. DOI: 10.3144/expresspolymlett.2011.105

[20] XIAO X, LONG A, ZENG X. Through-thickness permeability modelling of woven fabric under out-of-plane deformation[J]. Journal of Materials Science,2014,49(21):7563-7574. DOI: 10.1007/s10853-014-8465-z

[21] 阳小林, 晏石林, 杨云飞. 玻璃纤维平面织物法向渗透率实验研究[C]//第十五届全国复合材料学术会议. 哈尔滨: 中国力学学会, 2008: 1092-1096. YANG Xiaolin, YAN Shilin, YANG Yunfei. Experimental study on normal permeability of glass fiber plane fabric[C]//The 15th National Academic Conference on Composite Materials. Harbin: Chinese Society of Theoretical and Applied Mechanics, 2008: 1092-1096 (in Chinese).

[22] 简抗抗, 张佐光, 顾轶卓, 等. 不同纤维堆积状态下饱和渗透率实验研究[J]. 复合材料学报, 2006, 23(1):1-11. DOI: 10.3321/j.issn:1000-3851.2006.01.001 JIAN Kangkang, ZHANG Zuoguang, GU Yizhuo, et al. Experimental research of saturated permeability with different fiber stacking states[J]. Acta Materiae Compositae Sinica,2006,23(1):1-11(in Chinese). DOI: 10.3321/j.issn:1000-3851.2006.01.001

[23] 李香林, 王继辉, 倪爱清, 等. 液体模塑成型工艺用纤维织物厚度方向饱和渗透率的预测模型[J]. 复合材料学报, 2019, 36(6):1428-1437. LI Xianglin, WANG Jihui, NI Aiqing, et al. Prediction model of through-thickness saturated permeability of fabric for liquid composite molding[J]. Acta Materiae Compositae Sinica,2019,36(6):1428-1437(in Chinese).

-

期刊类型引用(0)

其他类型引用(1)

-

下载:

下载: