2023 Vol. 40, No. 2

2023, 40(2): 637-648.

doi: 10.13801/j.cnki.fhclxb.20220621.001

Abstract:

Waste plastics have been accumulated in rivers, lakes and seas. The micro/nano plastics generated by aging and decomposition pollute the water quality seriously and threaten the ecological environment and the safety of drinking water for residents. Traditional treatment methods including physical flocculation and biodegradation, still have problems such as long treatment period and low adsorption efficiency. Natural biomass contains large numbers of active hydroxyl and carboxyl groups. Physical treatment or chemical modification of biomass can be conducted to improve the pore structure and increase the specific surface area, and can be used as a green material for adsorbing micro/nano plastics. This work starts with the conventional treatment methods and the basic characteristics of micro/nano plastics, and briefly summarizes the potential effects and harm of different types of micro/nano plastics on plants, animals and human beings. Then research status of biomass materials (biochar, cellulose, chitin, etc.) in the field of the adsorption of micro/nano plastics is systematically introduced and the adsorption behavior, law and action mechanism of biomass materials on micro/nano plastics are analyzed and summarized. Finally, the future development prospects of the adsorption of micro/nano plastics by biomass materials are prospected.

Waste plastics have been accumulated in rivers, lakes and seas. The micro/nano plastics generated by aging and decomposition pollute the water quality seriously and threaten the ecological environment and the safety of drinking water for residents. Traditional treatment methods including physical flocculation and biodegradation, still have problems such as long treatment period and low adsorption efficiency. Natural biomass contains large numbers of active hydroxyl and carboxyl groups. Physical treatment or chemical modification of biomass can be conducted to improve the pore structure and increase the specific surface area, and can be used as a green material for adsorbing micro/nano plastics. This work starts with the conventional treatment methods and the basic characteristics of micro/nano plastics, and briefly summarizes the potential effects and harm of different types of micro/nano plastics on plants, animals and human beings. Then research status of biomass materials (biochar, cellulose, chitin, etc.) in the field of the adsorption of micro/nano plastics is systematically introduced and the adsorption behavior, law and action mechanism of biomass materials on micro/nano plastics are analyzed and summarized. Finally, the future development prospects of the adsorption of micro/nano plastics by biomass materials are prospected.

2023, 40(2): 649-664.

doi: 10.13801/j.cnki.fhclxb.20220505.001

Abstract:

In recent years, with the aggravation of energy crisis, thermoelectric materials which can directly convert heat energy to electric energy have attracted much attention. Among many types of thermoelectric materials, organic-inorganic hybrid nanocomposites have unique advantages. Compared with inorganic materials, organic materials have the advantages of low cost, light weight, good mechanical flexibility and low thermal conductivity. Once different types of addictions are introduced to form nanocomposites, additional phonon-interface scattering can further reduce the thermal conductivity. Moreover, carrier filtering effect induced by band mismatch between organic and inorganic materials enhances Seebeck coefficient. Therefore, abundance works have proved that organic-inorganic hybrid nanocomposites have the potential to obtain promoted thermoelectric figure of merit (ZT), and have bright application prospects in micro-thermoelectric refrigeration devices, flexible wearable power generation devices, temperature sensors and other fields. This paper focuses on the thermoelectric properties of poly(3, 4-ethylenedioxythiophene)∶poly(styrene sulfonate) (PEDOT∶PSS) thermoelectric materials and its nanocomposites. The physical methods and chemical reagent modification methods to improve the thermoelectric properties of PEDOT∶PSS are reviewed. The research progress of the thermoelectric properties of PEDOT∶PSS based nanocomposites with different types of inorganic fillers is further discussed. The inherent mechanisms of the improvement of thermoelectric properties of PEDOT∶PSS based nanocomposites are also revealed in detail.

In recent years, with the aggravation of energy crisis, thermoelectric materials which can directly convert heat energy to electric energy have attracted much attention. Among many types of thermoelectric materials, organic-inorganic hybrid nanocomposites have unique advantages. Compared with inorganic materials, organic materials have the advantages of low cost, light weight, good mechanical flexibility and low thermal conductivity. Once different types of addictions are introduced to form nanocomposites, additional phonon-interface scattering can further reduce the thermal conductivity. Moreover, carrier filtering effect induced by band mismatch between organic and inorganic materials enhances Seebeck coefficient. Therefore, abundance works have proved that organic-inorganic hybrid nanocomposites have the potential to obtain promoted thermoelectric figure of merit (ZT), and have bright application prospects in micro-thermoelectric refrigeration devices, flexible wearable power generation devices, temperature sensors and other fields. This paper focuses on the thermoelectric properties of poly(3, 4-ethylenedioxythiophene)∶poly(styrene sulfonate) (PEDOT∶PSS) thermoelectric materials and its nanocomposites. The physical methods and chemical reagent modification methods to improve the thermoelectric properties of PEDOT∶PSS are reviewed. The research progress of the thermoelectric properties of PEDOT∶PSS based nanocomposites with different types of inorganic fillers is further discussed. The inherent mechanisms of the improvement of thermoelectric properties of PEDOT∶PSS based nanocomposites are also revealed in detail.

2023, 40(2): 665-677.

doi: 10.13801/j.cnki.fhclxb.20220527.002

Abstract:

With low dimensionality, flexibility, shape-adaptable, and high integration with textiles, fiber batteries can meet the energy supply needs of circuit elements of flexible electronics. In recent years, research on fiber batteries has not only focused on active materials composited in electrodes, but exploring multi-functional, scalable, and highly integrated systems of fiber batteries. In addition, certain breakthroughs have been made in the large-scale production of fiber-based batteries, including battery assembly, integration, and continuous production. Based on this, this paper discusses the recent research results of fiber batteries in terms of fiber substrate materials and preparation processes, and it also review the latest breakthroughs in the industrial production of fiber batteries. Finally, this paper summarize the problems in the development of fiber batteries and analyze the key difficulties that need to be overcome in the future.

With low dimensionality, flexibility, shape-adaptable, and high integration with textiles, fiber batteries can meet the energy supply needs of circuit elements of flexible electronics. In recent years, research on fiber batteries has not only focused on active materials composited in electrodes, but exploring multi-functional, scalable, and highly integrated systems of fiber batteries. In addition, certain breakthroughs have been made in the large-scale production of fiber-based batteries, including battery assembly, integration, and continuous production. Based on this, this paper discusses the recent research results of fiber batteries in terms of fiber substrate materials and preparation processes, and it also review the latest breakthroughs in the industrial production of fiber batteries. Finally, this paper summarize the problems in the development of fiber batteries and analyze the key difficulties that need to be overcome in the future.

2023, 40(2): 678-687.

doi: 10.13801/j.cnki.fhclxb.20220412.002

Abstract:

In recent years, the demand for energy storage equipment gradually increases, and supercapacitors are favored by researchers because of their excellent performances. Two dimensional transition MXenes are two-dimensional sheet materials similar to graphene, which have unique structure and rich functional groups. Ti3C2TX MXenes have the advantages of good conductivity, high specific area and high specific capacitance, and can be widely used as excellent electrode materials for supercapacitors. However, Ti3C2TX materials have the problems of easy oxidation and self-stacking, and needs to be modified and optimized as electrode materials. This paper mainly introduces the preparation methods of Ti3C2TX materials, such as HF etching, fluoride etching, alkali etching and electrochemical etching, as well as the research methods of performance modification of Ti3C2TX in the application process of supercapacitors, including the construction of Ti3C2TX porous structure, surface modification and preparation of Ti3C2TX composite electrode. The future progress trend of Ti3C2TX supercapacitors is also prospected.

In recent years, the demand for energy storage equipment gradually increases, and supercapacitors are favored by researchers because of their excellent performances. Two dimensional transition MXenes are two-dimensional sheet materials similar to graphene, which have unique structure and rich functional groups. Ti3C2TX MXenes have the advantages of good conductivity, high specific area and high specific capacitance, and can be widely used as excellent electrode materials for supercapacitors. However, Ti3C2TX materials have the problems of easy oxidation and self-stacking, and needs to be modified and optimized as electrode materials. This paper mainly introduces the preparation methods of Ti3C2TX materials, such as HF etching, fluoride etching, alkali etching and electrochemical etching, as well as the research methods of performance modification of Ti3C2TX in the application process of supercapacitors, including the construction of Ti3C2TX porous structure, surface modification and preparation of Ti3C2TX composite electrode. The future progress trend of Ti3C2TX supercapacitors is also prospected.

2023, 40(2): 688-709.

doi: 10.13801/j.cnki.fhclxb.20220511.002

Abstract:

Flexible electronics have excellent flexibility, enabling seamless integration with clothing, and have great potential in various practical wearable applications. One-dimensional fibrous electronic devices have become a research hotspot in the field of smart wearables due to their excellent flexibility, weavability and comfort. First, the research progress of one-dimensional stretchable electrodes for fiber-like flexible electronic devices is reviewed, and then introduced the high-performance one-dimensional fibrous flexible electronics representative during the preparation of conductive material, manufacturing technology, as well as the further application of the one-dimensional flexible fiber become various main preparation methods for all kinds of electronic devices. Finally, we think critically about the opportunities and challenges of one-dimensional wikis smart wearable electronics.

Flexible electronics have excellent flexibility, enabling seamless integration with clothing, and have great potential in various practical wearable applications. One-dimensional fibrous electronic devices have become a research hotspot in the field of smart wearables due to their excellent flexibility, weavability and comfort. First, the research progress of one-dimensional stretchable electrodes for fiber-like flexible electronic devices is reviewed, and then introduced the high-performance one-dimensional fibrous flexible electronics representative during the preparation of conductive material, manufacturing technology, as well as the further application of the one-dimensional flexible fiber become various main preparation methods for all kinds of electronic devices. Finally, we think critically about the opportunities and challenges of one-dimensional wikis smart wearable electronics.

2023, 40(2): 710-725.

doi: 10.13801/j.cnki.fhclxb.20220512.006

Abstract:

The marine engineering equipment manufacturing industry in China is in the critical stage of survival and development. The anti-corrosion coating is one of the most effective ways to reduce the corrosion rate of the substrate and improve its service life. Conductive polymers (CPs) coatings have been widely used in the field of metal corrosion protection due to its advantages of environmental protection, simple preparation and unique conductive and anticorrosive mechanism. This work summarizes the anticorrosion mechanism of CPs coatings, introduces the current situation of preparing conductive polymer coating by two methods of chemical oxidation and electrochemical synthesis, and focuses on the improvement effect of doping modification, copolymerization modification and layered design of CPs coatings on the corrosion resistance of the coating. Finally, the possible research hotspots and development trends of CPs coatings in the field of corrosion protection are proposed.

The marine engineering equipment manufacturing industry in China is in the critical stage of survival and development. The anti-corrosion coating is one of the most effective ways to reduce the corrosion rate of the substrate and improve its service life. Conductive polymers (CPs) coatings have been widely used in the field of metal corrosion protection due to its advantages of environmental protection, simple preparation and unique conductive and anticorrosive mechanism. This work summarizes the anticorrosion mechanism of CPs coatings, introduces the current situation of preparing conductive polymer coating by two methods of chemical oxidation and electrochemical synthesis, and focuses on the improvement effect of doping modification, copolymerization modification and layered design of CPs coatings on the corrosion resistance of the coating. Finally, the possible research hotspots and development trends of CPs coatings in the field of corrosion protection are proposed.

2023, 40(2): 726-740.

doi: 10.13801/j.cnki.fhclxb.20220923.002

Abstract:

Perovskite tandem solar cells have developed rapidly and become one of the hotspots in the field of solar photovoltaic research. With the optimization of the structure and preparation process, the power conversion efficiency (PCE) of tandem device has been improved greatly. The perovskite/silicon tandem solar cell has been greatly improved and the efficiency has reached 31.3% for monolithic tandems. We sorts out the development of the tandem solar cell with wide bandgap perovskite as the top sub-cell and crystalline silicon cells and other novel medium-narrow bandgap cells (perovskite cells, organic cells, copper indium gallium selenide (CIGS) cells) as the bottom sub-cells in recent years and systematically summarized the key point and challenge in materials, structures, and optoelectronic properties of top cell, intermediate interconnection layers and bottom cells in this review with the hope that provide some ideas for further improving the PCE of tandem cells. The optical and electrical optimization requirements for low-cost and high-efficiency tandem solar cells in the future are also highlighted.

Perovskite tandem solar cells have developed rapidly and become one of the hotspots in the field of solar photovoltaic research. With the optimization of the structure and preparation process, the power conversion efficiency (PCE) of tandem device has been improved greatly. The perovskite/silicon tandem solar cell has been greatly improved and the efficiency has reached 31.3% for monolithic tandems. We sorts out the development of the tandem solar cell with wide bandgap perovskite as the top sub-cell and crystalline silicon cells and other novel medium-narrow bandgap cells (perovskite cells, organic cells, copper indium gallium selenide (CIGS) cells) as the bottom sub-cells in recent years and systematically summarized the key point and challenge in materials, structures, and optoelectronic properties of top cell, intermediate interconnection layers and bottom cells in this review with the hope that provide some ideas for further improving the PCE of tandem cells. The optical and electrical optimization requirements for low-cost and high-efficiency tandem solar cells in the future are also highlighted.

2023, 40(2): 741-752.

doi: 10.13801/j.cnki.fhclxb.20220321.004

Abstract:

Bismaleimide (BMI) resin has been widely used in aerospace, electronics and other industrial fields because of its excellent properties. In order to meet the needs of structural components for high-speed aircraft, the additional phenolic modifier is introduced to improve the thermo-mechanical properties of BMI resin. The propargyl etherified novolac (PN) and allyl etherified phenolic (AN) as an addition modifier were synthesized by Williamson etherification. The PN and AN were used to modify N, N'-(4, 4'-diphenylmethylane) bismaleimide (BDM)/2, 2'-diallyl bisphenol A (DABPA) resin system (BD) in melting mixing to obtain the ternary blended resins of BDPN and BDAN. The processability and cure reactions of the BDPN and BDAN were studied. The thermal property and mechanical property of the cured BD, BDPN and BDAN were further investigated. The results show that the ternary blended resins exhibit good solubility and meltability, and have an above 50℃ of process window. There is only a single exothermal peak in DSC curves of BDPN and BDAN. The peak temperatures of BDPN and BDAN are lower than that of BD. The Fourier transform infrared (FTIR) was used to monitor the curing reactions of BD, BDPN and BDAN resins. The reactions of Ene, Diels-Alder, Claisen rearrangement and addition of alkyne and maleimido group were detected during curing. The cured PN resin has good thermo-oxidative stability. The residual yield at 800℃ (Yr800℃) of cured BD in air increases from 3.7% to 23.1% after the BD resin was modified with PN resin. The temperature of 5wt% mass loss (Td5) of the cured BDPN in air is higher than 400℃. The limited oxygen index (LOI) of the cured BD, BDPN and BDAN resins are 30.2%, 32.5% and 31.0%, respectively. The cured resins are nonflammable. The impact strength and flexural modulus of the cured BD resin increase with addition of PN and AN resins. The impact strength and flexural modulus of the cured AN modified BD resin increase by 19% and 30% respec-tively. However, the flexural strength of the BDPN and BDAN resins decrease since the crosslinked density of the cured modified resins decline. The water absorption in boiling water of the cured BDPN and BDAN resins are lower than that of the cured BD resin, and decrease by 8.6% and 14% after 40 h. The flexural strength, flexural modulus and interlaminar shear strength (ILSS) of the T300 carbon fiber cloth (T300CF) reinforced BDAN composite (T300CF/BDAN) at room temperature are higher than that of the T300CF reinforced BD composite. The flexural strength of the T300CF/BDPN at 200℃ retains a 98.6% retention, reaches to 575 MPa. The propargyl etherified novolac can used to improve the heat properties of bismaleimide which is a new approach for modification of bismaleimides, and promising to be utilized in preparation of the structural components of composite with heat-resistance at 200℃.

Bismaleimide (BMI) resin has been widely used in aerospace, electronics and other industrial fields because of its excellent properties. In order to meet the needs of structural components for high-speed aircraft, the additional phenolic modifier is introduced to improve the thermo-mechanical properties of BMI resin. The propargyl etherified novolac (PN) and allyl etherified phenolic (AN) as an addition modifier were synthesized by Williamson etherification. The PN and AN were used to modify N, N'-(4, 4'-diphenylmethylane) bismaleimide (BDM)/2, 2'-diallyl bisphenol A (DABPA) resin system (BD) in melting mixing to obtain the ternary blended resins of BDPN and BDAN. The processability and cure reactions of the BDPN and BDAN were studied. The thermal property and mechanical property of the cured BD, BDPN and BDAN were further investigated. The results show that the ternary blended resins exhibit good solubility and meltability, and have an above 50℃ of process window. There is only a single exothermal peak in DSC curves of BDPN and BDAN. The peak temperatures of BDPN and BDAN are lower than that of BD. The Fourier transform infrared (FTIR) was used to monitor the curing reactions of BD, BDPN and BDAN resins. The reactions of Ene, Diels-Alder, Claisen rearrangement and addition of alkyne and maleimido group were detected during curing. The cured PN resin has good thermo-oxidative stability. The residual yield at 800℃ (Yr800℃) of cured BD in air increases from 3.7% to 23.1% after the BD resin was modified with PN resin. The temperature of 5wt% mass loss (Td5) of the cured BDPN in air is higher than 400℃. The limited oxygen index (LOI) of the cured BD, BDPN and BDAN resins are 30.2%, 32.5% and 31.0%, respectively. The cured resins are nonflammable. The impact strength and flexural modulus of the cured BD resin increase with addition of PN and AN resins. The impact strength and flexural modulus of the cured AN modified BD resin increase by 19% and 30% respec-tively. However, the flexural strength of the BDPN and BDAN resins decrease since the crosslinked density of the cured modified resins decline. The water absorption in boiling water of the cured BDPN and BDAN resins are lower than that of the cured BD resin, and decrease by 8.6% and 14% after 40 h. The flexural strength, flexural modulus and interlaminar shear strength (ILSS) of the T300 carbon fiber cloth (T300CF) reinforced BDAN composite (T300CF/BDAN) at room temperature are higher than that of the T300CF reinforced BD composite. The flexural strength of the T300CF/BDPN at 200℃ retains a 98.6% retention, reaches to 575 MPa. The propargyl etherified novolac can used to improve the heat properties of bismaleimide which is a new approach for modification of bismaleimides, and promising to be utilized in preparation of the structural components of composite with heat-resistance at 200℃.

2023, 40(2): 753-760.

doi: 10.13801/j.cnki.fhclxb.20220412.003

Abstract:

Carbon nanotube (CNT)/epoxy resin can be widely used to bond advanced structural parts in the aerospace field due to its excellent mechanical and bonding properties. However, how to effectively reduce the agglomeration of carbon nanotubes and ensure low cost and environmental protection of the preparation process is the key to the practical application of the nano-binder. Therefore, this paper proposes a protein dispersed carbon nanotube reinforced epoxy resin adhesive and investigates its bonding performance. The results show that the soy protein isolate (SPI) after a certain acid or alkali denaturation treatment can effectively reduce the agglomeration of carbon nanotubes and significantly improve the bonding performance of epoxy resin. When the CNT loading is 0.1wt%, the bonding property of acid and alkali treated SPI-CNT/epoxy is increased by 26.6% and 26.7%. While the CNT loading increases to 0.3wt%, the bonding property enhancement of the two treated methods comes to 10.2% and 18.3%, the alkali method is 79% higher than the acid one.

Carbon nanotube (CNT)/epoxy resin can be widely used to bond advanced structural parts in the aerospace field due to its excellent mechanical and bonding properties. However, how to effectively reduce the agglomeration of carbon nanotubes and ensure low cost and environmental protection of the preparation process is the key to the practical application of the nano-binder. Therefore, this paper proposes a protein dispersed carbon nanotube reinforced epoxy resin adhesive and investigates its bonding performance. The results show that the soy protein isolate (SPI) after a certain acid or alkali denaturation treatment can effectively reduce the agglomeration of carbon nanotubes and significantly improve the bonding performance of epoxy resin. When the CNT loading is 0.1wt%, the bonding property of acid and alkali treated SPI-CNT/epoxy is increased by 26.6% and 26.7%. While the CNT loading increases to 0.3wt%, the bonding property enhancement of the two treated methods comes to 10.2% and 18.3%, the alkali method is 79% higher than the acid one.

2023, 40(2): 761-770.

doi: 10.13801/j.cnki.fhclxb.20220330.001

Abstract:

Low-velocity impact is a common damage mode for polymer matrix composites during transportation and service, often results in structural damage, performance degradation, and loss of load-bearing capacity, which affects the use of the composites. To address the problem of poor delamination resistance of 2D fiber-reinforced polymer matrix composites under impact loading, binary and ternary Nylon 6 (PA6)-based composites were prepared by melt extrusion combined with hot pressing, and the pendulum impact performance and drop hammer low-velocity impact response of continuous glass fiber (GF), glass beads (GB) and both co-reinforced PA6-based composites were comparatively investigated. The results show that: (1) GF and GB can significantly improve the impact resistance of PA6, and the enhancement effect of GF is significantly higher than that of GB; (2) Impact strength of GB-reinforced PA6-based composites (GB/PA6) showed a trend of increasing and then decreasing with increasing GB incorporation, with the maximum impact strength at 25wt% incorporation; the energy dissipation mechanism of 25wt%GB/PA6 under impact loading was found to be a new mechanism of slip energy dissipation of GB in PA6 matrix, in addition to interfacial debonding and pinning effects; (3) The fibers in GF and GB co-reinforced PA6 composites (GB-GF/PA6) play a major reinforcing role, and both pendulum impact tests and drop impact tests demonstrate a synergistic reinforcing effect; (4) The synergistic reinforcing effect of GF and GB co-reinforcement is due to the increased resistance to type II crack expansion of the co-reinforced composites under impact loading, resulting in the reinforcement of the composite against delamination. Thus, demonstrating that the introduction of an appropriate amount of spherical GB into the matrix is an economical and effective way to improve the resistance of 2D fiber-reinforced polymer matrix composites to low-velocity impact.

Low-velocity impact is a common damage mode for polymer matrix composites during transportation and service, often results in structural damage, performance degradation, and loss of load-bearing capacity, which affects the use of the composites. To address the problem of poor delamination resistance of 2D fiber-reinforced polymer matrix composites under impact loading, binary and ternary Nylon 6 (PA6)-based composites were prepared by melt extrusion combined with hot pressing, and the pendulum impact performance and drop hammer low-velocity impact response of continuous glass fiber (GF), glass beads (GB) and both co-reinforced PA6-based composites were comparatively investigated. The results show that: (1) GF and GB can significantly improve the impact resistance of PA6, and the enhancement effect of GF is significantly higher than that of GB; (2) Impact strength of GB-reinforced PA6-based composites (GB/PA6) showed a trend of increasing and then decreasing with increasing GB incorporation, with the maximum impact strength at 25wt% incorporation; the energy dissipation mechanism of 25wt%GB/PA6 under impact loading was found to be a new mechanism of slip energy dissipation of GB in PA6 matrix, in addition to interfacial debonding and pinning effects; (3) The fibers in GF and GB co-reinforced PA6 composites (GB-GF/PA6) play a major reinforcing role, and both pendulum impact tests and drop impact tests demonstrate a synergistic reinforcing effect; (4) The synergistic reinforcing effect of GF and GB co-reinforcement is due to the increased resistance to type II crack expansion of the co-reinforced composites under impact loading, resulting in the reinforcement of the composite against delamination. Thus, demonstrating that the introduction of an appropriate amount of spherical GB into the matrix is an economical and effective way to improve the resistance of 2D fiber-reinforced polymer matrix composites to low-velocity impact.

2023, 40(2): 771-781.

doi: 10.13801/j.cnki.fhclxb.20220305.001

Abstract:

Delamination between face sheets and core is one of the most common damage mode of carbon-fiber sandwich panels under impact loading, which seriously affects structural safety. Firstly, short-Kevlar-fibers were used for toughening the interface of carbon-fiber/aluminum-honeycomb sandwich panel. Secondly, low velocity impact and compression after impact tests were conducted for plain and toughened specimens. The residual compression strength, energy absorption and failure mode were compared. Finally, the strains of plain and toughened specimens during compression after impact test were obtained by digital image correlation (DIC). The results show that short-Kevlar-fiber toughening is capable to effectively increase the impact damage resistance of carbon-fiber/aluminum-honeycomb sandwich panel, and the damage threshold load of toughened specimens is signifi-cantly higher than that of plain specimens. Compared with the plain specimens, the residual compression strength values after impact of toughened specimens are increased by 2.68%, 9.24%, 4.65% and 11.13%, respectively, under four different impact energies. Meanwhile the energy absorption values of toughened specimens are increased by 69.09%, 52.88%, 55.03% and 101.70%, respectively. Furthermore, DIC observations were used to investigate the toughening effects of short-Kevlar-fibers and the strengthening mechanism.

Delamination between face sheets and core is one of the most common damage mode of carbon-fiber sandwich panels under impact loading, which seriously affects structural safety. Firstly, short-Kevlar-fibers were used for toughening the interface of carbon-fiber/aluminum-honeycomb sandwich panel. Secondly, low velocity impact and compression after impact tests were conducted for plain and toughened specimens. The residual compression strength, energy absorption and failure mode were compared. Finally, the strains of plain and toughened specimens during compression after impact test were obtained by digital image correlation (DIC). The results show that short-Kevlar-fiber toughening is capable to effectively increase the impact damage resistance of carbon-fiber/aluminum-honeycomb sandwich panel, and the damage threshold load of toughened specimens is signifi-cantly higher than that of plain specimens. Compared with the plain specimens, the residual compression strength values after impact of toughened specimens are increased by 2.68%, 9.24%, 4.65% and 11.13%, respectively, under four different impact energies. Meanwhile the energy absorption values of toughened specimens are increased by 69.09%, 52.88%, 55.03% and 101.70%, respectively. Furthermore, DIC observations were used to investigate the toughening effects of short-Kevlar-fibers and the strengthening mechanism.

2023, 40(2): 782-793.

doi: 10.13801/j.cnki.fhclxb.20220323.001

Abstract:

The numerical simulation of the vacuum assisted resin infusion (VARI) process of perforated sandwich composite was verified experimentally, and process optimization was presented thereafter. Firstly, the permeabilities of the fabric and holes of perforated core were obtained experimentally and numerically, respectively. Then, 3D simulation was carried out for the infusion process of the perforated sandwich composite structure and verified by real-scale infusion experiments. Finally, based on the simulation, the process was optimized by investigating the effects of injection position and type on the filling time and product porosity, and later a methodology was proposed to predict the filling time needed. The results show that the numerical simulation is in good agreement with the experiment. The flow patterns during the filling and the porosities of the perforated sandwich structures are in good match with experimental results. The filling time prediction method can be used for practical production instruction. The selection of proper parameters, such as injection position and type, can minimize molding time and product porosity.

The numerical simulation of the vacuum assisted resin infusion (VARI) process of perforated sandwich composite was verified experimentally, and process optimization was presented thereafter. Firstly, the permeabilities of the fabric and holes of perforated core were obtained experimentally and numerically, respectively. Then, 3D simulation was carried out for the infusion process of the perforated sandwich composite structure and verified by real-scale infusion experiments. Finally, based on the simulation, the process was optimized by investigating the effects of injection position and type on the filling time and product porosity, and later a methodology was proposed to predict the filling time needed. The results show that the numerical simulation is in good agreement with the experiment. The flow patterns during the filling and the porosities of the perforated sandwich structures are in good match with experimental results. The filling time prediction method can be used for practical production instruction. The selection of proper parameters, such as injection position and type, can minimize molding time and product porosity.

2023, 40(2): 794-803.

doi: 10.13801/j.cnki.fhclxb.20220325.002

Abstract:

Civilian aircraft interior wall panel materials are mainly fibre/resin composites, which have a certain fire hazard, so the study of their thermal stability and combustion characteristics is of great significance for aircraft fire protection. A thermogravimetric analyzer was used to study the influence of different heating rates on the pyrolysis of two typical aircraft siding materials: Carbon fiber/epoxy resin and glass fiber/epoxy resin, and the apparent activation energy and pre-digital factor of the decomposition stage were obtained using the Kissinger method. The cone calorimeter was used to study the combustion characteristics of two prepregs in different fire environments, and four evaluation indicators of fire growth index (\begin{document}$ {\delta _{{\rm{FGI}}}} $\end{document} ![]()

![]()

\begin{document}$ {\delta _{{\rm{FPI}}}} $\end{document} ![]()

![]()

\begin{document}$ {\delta _{{\rm{THRI}}}} $\end{document} ![]()

![]()

\begin{document}$ {\delta _{{\rm{TSPI}}}} $\end{document} ![]()

![]()

\begin{document}$ {\delta _{{\rm{FGI}}}} $\end{document} ![]()

![]()

\begin{document}$ {\delta _{{\rm{THRI}}}} $\end{document} ![]()

![]()

\begin{document}$ {\delta _{{\rm{TSPI}}}} $\end{document} ![]()

![]()

\begin{document}$ {\delta _{{\rm{FPI}}}} $\end{document} ![]()

![]()

Civilian aircraft interior wall panel materials are mainly fibre/resin composites, which have a certain fire hazard, so the study of their thermal stability and combustion characteristics is of great significance for aircraft fire protection. A thermogravimetric analyzer was used to study the influence of different heating rates on the pyrolysis of two typical aircraft siding materials: Carbon fiber/epoxy resin and glass fiber/epoxy resin, and the apparent activation energy and pre-digital factor of the decomposition stage were obtained using the Kissinger method. The cone calorimeter was used to study the combustion characteristics of two prepregs in different fire environments, and four evaluation indicators of fire growth index (

2023, 40(2): 804-813.

doi: 10.13801/j.cnki.fhclxb.20220424.004

Abstract:

The warp and fill fiber strands interlacing in two mutually orthogonal directions to one another results in the fiber curvature, namely the waviness, which is the inherent characteristic of plain woven fabric composite. First, a mathematical description was developed to accurately represent the 3D architecture morphology of the unit cell for plain woven fabric composite. Next, an analytical multi-parameter model of plain woven fabric composite was established based on the classical lamination theory and iso-stress assumption. Meanwhile, the bending-extension coupling effect due to asymmetry along the thickness-direction as well as the architecture morphology of the unit cell was embedded in this model. The validation of several typical cases shows that the predicted effective elastic properties of plain woven fabric composite agree well with the numerical values of the finite element model, the results of the analytical model and the experimental data cited in the related literatures. Also, the predictions of the analytical multi-parameter model, especially the Z-direction ones, are more approaching to the experimental data than counterparts of other analytical models aforementioned. Furthermore, the influence of the structural parameters such as the waviness ratio of the fiber strand containing both the undulation direction and the cross section, the thickness of the preform consisting of the warp and fill fiber strands, the length of the curved section of the fiber strand and the spacing between the adjacent fiber strands on the elastic properties of plain woven fabric composite is elaborated. The present approach of the analytical multi-parameter model provides a reference for evaluating the mechanical properties of textile composite.

The warp and fill fiber strands interlacing in two mutually orthogonal directions to one another results in the fiber curvature, namely the waviness, which is the inherent characteristic of plain woven fabric composite. First, a mathematical description was developed to accurately represent the 3D architecture morphology of the unit cell for plain woven fabric composite. Next, an analytical multi-parameter model of plain woven fabric composite was established based on the classical lamination theory and iso-stress assumption. Meanwhile, the bending-extension coupling effect due to asymmetry along the thickness-direction as well as the architecture morphology of the unit cell was embedded in this model. The validation of several typical cases shows that the predicted effective elastic properties of plain woven fabric composite agree well with the numerical values of the finite element model, the results of the analytical model and the experimental data cited in the related literatures. Also, the predictions of the analytical multi-parameter model, especially the Z-direction ones, are more approaching to the experimental data than counterparts of other analytical models aforementioned. Furthermore, the influence of the structural parameters such as the waviness ratio of the fiber strand containing both the undulation direction and the cross section, the thickness of the preform consisting of the warp and fill fiber strands, the length of the curved section of the fiber strand and the spacing between the adjacent fiber strands on the elastic properties of plain woven fabric composite is elaborated. The present approach of the analytical multi-parameter model provides a reference for evaluating the mechanical properties of textile composite.

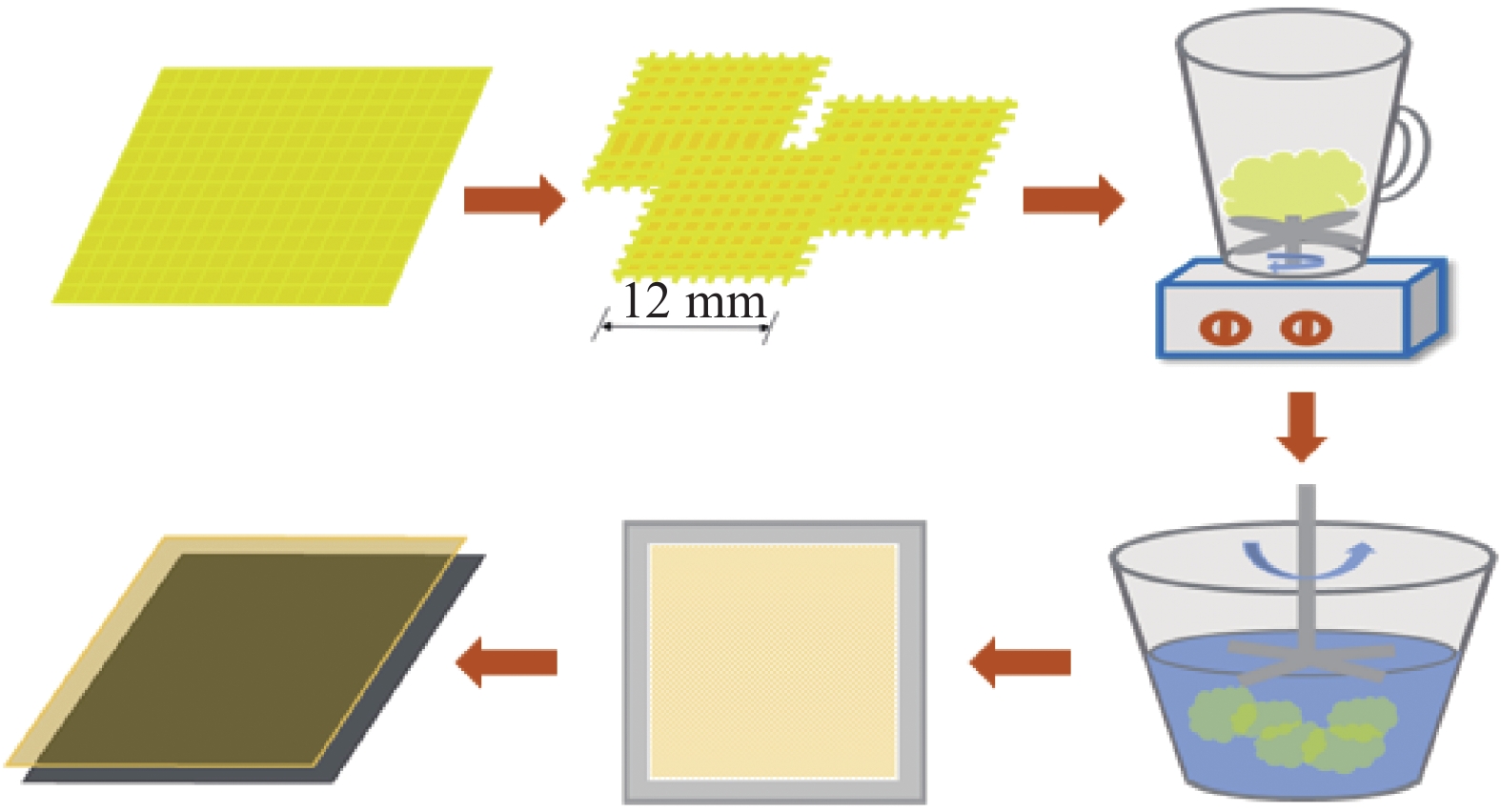

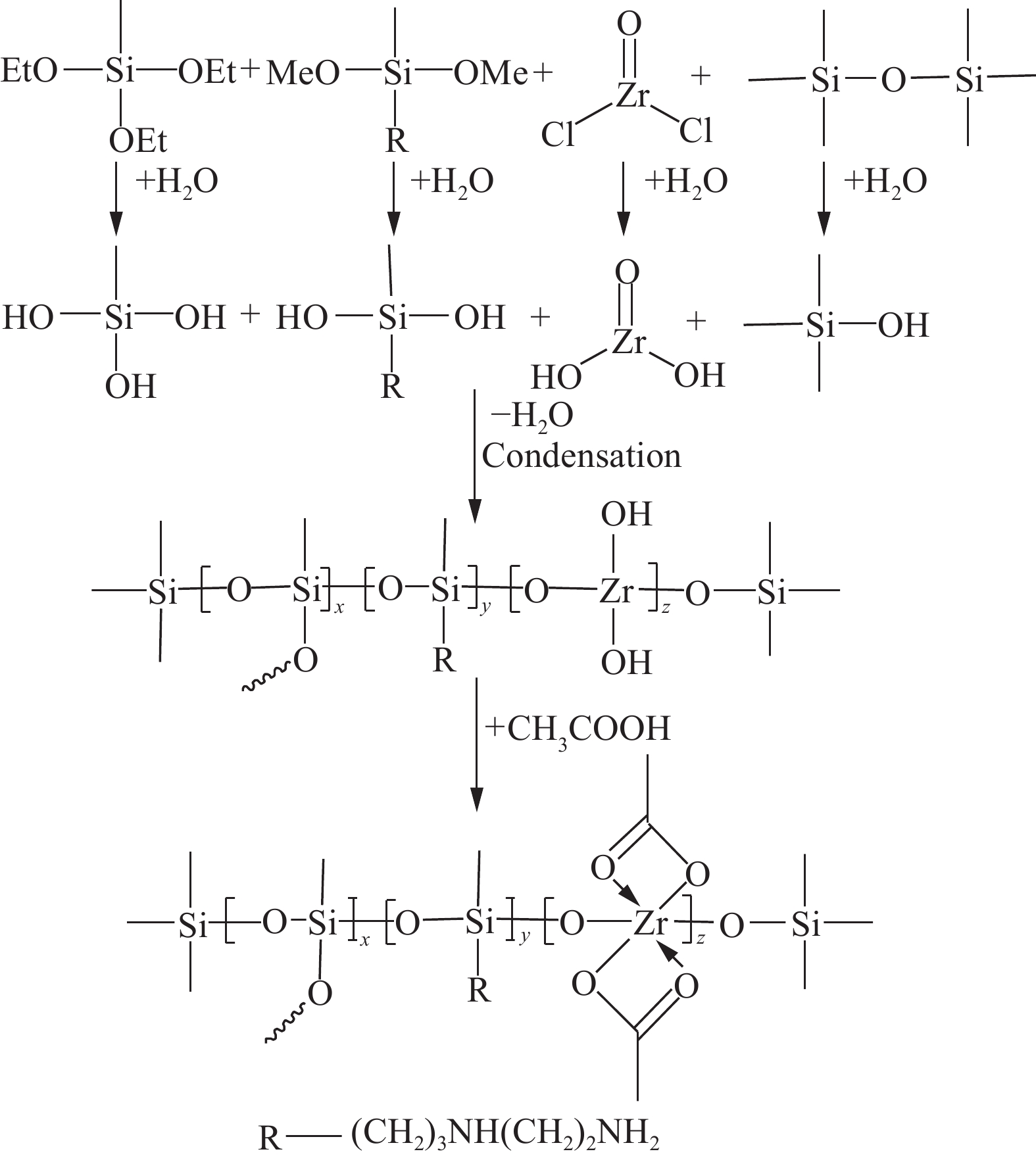

Water-soluble zirconium hybrid silicone resin sizing for improvement heat resistance of basalt fibre

2023, 40(2): 814-824.

doi: 10.13801/j.cnki.fhclxb.20220426.001

Abstract:

The working temperature of the existing high-temperature basalt fibre filter bag is 280℃, they are difficult to work for a long time when the temperature is above 300℃. In order to improve the heat resistance of basalt fibres, in this paper, a kind of water-soluble zirconium hybrid silicone resin sizing agent was synthesized and used for basalt fibre surface modification. Microstructure and properties of zirconium hybrid silicone resin and modified fibers were characterized by FTIR, TG-DSC, SEM, AFM, DCA and tensile test. The results show the decompose temperature of zirconium hybrid silicone resin is 323-360℃. The surfaces of the sized fibres are coated by dense and uniform silicone resin films. These films increase the surface roughness and surface areas of the fibre surfaces, improve the surface energies, change the surface morphologies, repair the surface micro defects. Themechanical tests show that after heat treatment of 2 h at 300℃, the breaking force of optimum sample is 376.0 N, and the breaking elongation is 2.647%, which are better than the related performance of uncoated fibre (287.8 N, 1.932%). Therefore, the zirconium hybrid silicone sizing agent could significantly improve the heat resistance of basalt fibre.

The working temperature of the existing high-temperature basalt fibre filter bag is 280℃, they are difficult to work for a long time when the temperature is above 300℃. In order to improve the heat resistance of basalt fibres, in this paper, a kind of water-soluble zirconium hybrid silicone resin sizing agent was synthesized and used for basalt fibre surface modification. Microstructure and properties of zirconium hybrid silicone resin and modified fibers were characterized by FTIR, TG-DSC, SEM, AFM, DCA and tensile test. The results show the decompose temperature of zirconium hybrid silicone resin is 323-360℃. The surfaces of the sized fibres are coated by dense and uniform silicone resin films. These films increase the surface roughness and surface areas of the fibre surfaces, improve the surface energies, change the surface morphologies, repair the surface micro defects. Themechanical tests show that after heat treatment of 2 h at 300℃, the breaking force of optimum sample is 376.0 N, and the breaking elongation is 2.647%, which are better than the related performance of uncoated fibre (287.8 N, 1.932%). Therefore, the zirconium hybrid silicone sizing agent could significantly improve the heat resistance of basalt fibre.

2023, 40(2): 825-835.

doi: 10.13801/j.cnki.fhclxb.20220321.003

Abstract:

Fabrication of the polymer-based composites with excellent high temperature resistance and thermal conductivity is very important for the packaging protection, efficient heat dissipation and processing of electronic components. In this work, high temperature resistant and thermally conductive hexagonal boron nitride (BN)/semi-aromatic polyamide 12T (PA12T) composites with uniform dispersion and orientation filler structure were prepared by mixed solvent dispersion (MSD) method, and the microstructure, thermal conductivity, high-temperature resistance, dielectric and mechanical properties of the composites were systematically characterized. The results show that the BN powder and PA12T powder can be suspended uniformly in the mixed solvent. Next, combining the vacuum-assisted self-assembly technique and vacuum hot compression method, the composites with uniformly dispersed and oriented BN structure are fabricated successfully. When the content of BN is 40wt% in BN/PA12T composite, the in-plane thermal conductivity of the composite prepared by the MSD method is 2.73 W/(m·K), which is 1.72 times that of the composite (1.59 W/(m·K)) prepared by the mechanical mixing (MM) method. Furthermore, the composite prepared by the MSD method also possesses excellent mechanical properties, low dielectric permittivity of 3.6 and dielectric loss of 0.016, outstanding high-temperature resistance with the initial decomposition temperature of 446℃ and Vicat softening temperature of more than 250℃. Therefore, the BN/PA12T composite prepared by the MSD method will have a wide range of applications in the fields of electronic packaging and thermal management.

Fabrication of the polymer-based composites with excellent high temperature resistance and thermal conductivity is very important for the packaging protection, efficient heat dissipation and processing of electronic components. In this work, high temperature resistant and thermally conductive hexagonal boron nitride (BN)/semi-aromatic polyamide 12T (PA12T) composites with uniform dispersion and orientation filler structure were prepared by mixed solvent dispersion (MSD) method, and the microstructure, thermal conductivity, high-temperature resistance, dielectric and mechanical properties of the composites were systematically characterized. The results show that the BN powder and PA12T powder can be suspended uniformly in the mixed solvent. Next, combining the vacuum-assisted self-assembly technique and vacuum hot compression method, the composites with uniformly dispersed and oriented BN structure are fabricated successfully. When the content of BN is 40wt% in BN/PA12T composite, the in-plane thermal conductivity of the composite prepared by the MSD method is 2.73 W/(m·K), which is 1.72 times that of the composite (1.59 W/(m·K)) prepared by the mechanical mixing (MM) method. Furthermore, the composite prepared by the MSD method also possesses excellent mechanical properties, low dielectric permittivity of 3.6 and dielectric loss of 0.016, outstanding high-temperature resistance with the initial decomposition temperature of 446℃ and Vicat softening temperature of more than 250℃. Therefore, the BN/PA12T composite prepared by the MSD method will have a wide range of applications in the fields of electronic packaging and thermal management.

2023, 40(2): 836-843.

doi: 10.13801/j.cnki.fhclxb.20220419.005

Abstract:

Metal nanoparticles show great application on prospect in catalysis, bacteriostasis, water pollution treatment and biomedicine, because of their unique physical and chemical properties. Metal nanoparticles tend to agglomerate in the processes of preparation and use. Therefore, improving the stability of nanoparticles is of great significance to improve their application performance. In this study, porous polyacrylonitrile nanofibers (PPAN NFs) were prepared by electrostatic spinning using polyacrylonitrile (PAN) as substrate and polyvinylpyrrolidone (PVP) as the pore-making agent. On this basis, Ag-PPAN NFs and Cu-PPAN NFs were prepared by in-situ loading of silver and copper nanoparticles on the surface of PPAN NFs by impregnation deposition. The morphologies and structures of the prepared nanofibers were characterized by FESEM, EDS and XRD, and the antibacterial properties of Ag-PPAN NFs and Cu-PPAN NFs against E. coli, S. aureus and C. albicans were studied by bacteriostatic zone method and FESEM observation. The results show that PPAN NFs provide a rich mesoporous structure for loading of Ag NPs and Cu NPs and inhibited the aggregation of nanoparticles. The prepared Ag-PPAN NFs and Cu-PPAN NFs show good antibacterial activities against E. coli, S. aureus and C. albicans, and which could be used as a new kind of antibacterial fiber material.

Metal nanoparticles show great application on prospect in catalysis, bacteriostasis, water pollution treatment and biomedicine, because of their unique physical and chemical properties. Metal nanoparticles tend to agglomerate in the processes of preparation and use. Therefore, improving the stability of nanoparticles is of great significance to improve their application performance. In this study, porous polyacrylonitrile nanofibers (PPAN NFs) were prepared by electrostatic spinning using polyacrylonitrile (PAN) as substrate and polyvinylpyrrolidone (PVP) as the pore-making agent. On this basis, Ag-PPAN NFs and Cu-PPAN NFs were prepared by in-situ loading of silver and copper nanoparticles on the surface of PPAN NFs by impregnation deposition. The morphologies and structures of the prepared nanofibers were characterized by FESEM, EDS and XRD, and the antibacterial properties of Ag-PPAN NFs and Cu-PPAN NFs against E. coli, S. aureus and C. albicans were studied by bacteriostatic zone method and FESEM observation. The results show that PPAN NFs provide a rich mesoporous structure for loading of Ag NPs and Cu NPs and inhibited the aggregation of nanoparticles. The prepared Ag-PPAN NFs and Cu-PPAN NFs show good antibacterial activities against E. coli, S. aureus and C. albicans, and which could be used as a new kind of antibacterial fiber material.

2023, 40(2): 844-851.

doi: 10.13801/j.cnki.fhclxb.20220228.002

Abstract:

Carbon-based materials, as non-noble catalysts, have attracted extensive attention in the field of cathode catalysts for fuel cells due to their high conductivity, long-term stability, low-cost and environmental friendliness. Especially, the oxygen reduction reaction (ORR) activity of carbon materials can be significantly improved after co-doping with transition metal and heteroatoms. In this work, transition metal (Co, Fe, Ni, Mn) and phosphorus (P) co-doped porous carbon (TM-P-C) was prepared via self-assembly method combined with a carbonization process, in which polyether (F127) was introduced as soft template, phenol and formaldehyde as carbon precursor, tetraphenylphosphine bromide as phosphorus source, and nitrate as transition metal source. The electrocatalytic activity of TM-P-C for ORR in alkaline electrolyte was studied by using the rotating ring-disk electrode (RRDE) technique. The results reveal that TM-P-C exhibits high electrocatalytic performance for ORR in 0.1 mol/L KOH, and the activity follows P-Co-C>P-Ni-C>P-Fe-C>P-Mn-C. Moreover, the ORR performance of P-Co-C is compared to that of commercial 20wt%Pt/C catalyst. The diffusion limiting current density of P-Co-C reaches that of 20wt%Pt/C and a negative shift of about 66 mV exists in the half-wave potential of P-Co-C as compared to 20wt%Pt/C, indicating the four-electron pathway during the ORR. The enhancement in the activity for ORR is mainly attributed to the synergistic effect of P and transition metal doping in carbon of TM-P-C. Moreover, TM-P-C shows excellent long-term stability and methanol toxicity resistance, superior to that of commercial 20wt%Pt/C.

Carbon-based materials, as non-noble catalysts, have attracted extensive attention in the field of cathode catalysts for fuel cells due to their high conductivity, long-term stability, low-cost and environmental friendliness. Especially, the oxygen reduction reaction (ORR) activity of carbon materials can be significantly improved after co-doping with transition metal and heteroatoms. In this work, transition metal (Co, Fe, Ni, Mn) and phosphorus (P) co-doped porous carbon (TM-P-C) was prepared via self-assembly method combined with a carbonization process, in which polyether (F127) was introduced as soft template, phenol and formaldehyde as carbon precursor, tetraphenylphosphine bromide as phosphorus source, and nitrate as transition metal source. The electrocatalytic activity of TM-P-C for ORR in alkaline electrolyte was studied by using the rotating ring-disk electrode (RRDE) technique. The results reveal that TM-P-C exhibits high electrocatalytic performance for ORR in 0.1 mol/L KOH, and the activity follows P-Co-C>P-Ni-C>P-Fe-C>P-Mn-C. Moreover, the ORR performance of P-Co-C is compared to that of commercial 20wt%Pt/C catalyst. The diffusion limiting current density of P-Co-C reaches that of 20wt%Pt/C and a negative shift of about 66 mV exists in the half-wave potential of P-Co-C as compared to 20wt%Pt/C, indicating the four-electron pathway during the ORR. The enhancement in the activity for ORR is mainly attributed to the synergistic effect of P and transition metal doping in carbon of TM-P-C. Moreover, TM-P-C shows excellent long-term stability and methanol toxicity resistance, superior to that of commercial 20wt%Pt/C.

2023, 40(2): 852-859.

doi: 10.13801/j.cnki.fhclxb.20220303.002

Abstract:

In order to improve the molding fluidity of fumed silica (FS)/cast polyurethane (PU) system, in the process of preparing prepolymer, the fumed silica (FS) was modified by 2, 4-toluene diisocyanate (TDI) to obtain TDI modified silica (NCO@FS), and TDI modified silica/reinforced pouring polyurethane (NCO@FS/PU) elastomer composite material was prepared by in-situ polymerization. NCO@FS and FS were characterized by fourier transform infrared spectroscopy (FTIR), X-ray photoelectron spectroscopy (XPS) and contact angle testing. The results show that the active hydroxyl groups on the surface of FS react with the —NCO groups of TDI to form urethane groups aminoester group (—NHCOO), which improves the interfacial compatibility and interfacial bonding between silica and casting polyurethane. When the mass fraction of NCO@FS in the composite material is 1.5wt%, the tensile and tearing strengths of the NCO@FS/PU composite material are 57 MPa and 110.5 kN/m, respectively, which are 31.6% and 23.6% higher than that of pure casting PU. The glass transition temperature dropped from 3.4°C to –11.2°C, and the loss factor tanδ dropped from 0.59 to 0.46. TDI modified fumed silica is suitable for preparing silica-reinforced cast polyurethane composites.

In order to improve the molding fluidity of fumed silica (FS)/cast polyurethane (PU) system, in the process of preparing prepolymer, the fumed silica (FS) was modified by 2, 4-toluene diisocyanate (TDI) to obtain TDI modified silica (NCO@FS), and TDI modified silica/reinforced pouring polyurethane (NCO@FS/PU) elastomer composite material was prepared by in-situ polymerization. NCO@FS and FS were characterized by fourier transform infrared spectroscopy (FTIR), X-ray photoelectron spectroscopy (XPS) and contact angle testing. The results show that the active hydroxyl groups on the surface of FS react with the —NCO groups of TDI to form urethane groups aminoester group (—NHCOO), which improves the interfacial compatibility and interfacial bonding between silica and casting polyurethane. When the mass fraction of NCO@FS in the composite material is 1.5wt%, the tensile and tearing strengths of the NCO@FS/PU composite material are 57 MPa and 110.5 kN/m, respectively, which are 31.6% and 23.6% higher than that of pure casting PU. The glass transition temperature dropped from 3.4°C to –11.2°C, and the loss factor tanδ dropped from 0.59 to 0.46. TDI modified fumed silica is suitable for preparing silica-reinforced cast polyurethane composites.

2023, 40(2): 860-871.

doi: 10.13801/j.cnki.fhclxb.20220307.002

Abstract:

Thermoelectric conversion technology can convert a large amount of waste heat energy into electric energy for reuse. It is a green energy conversion technology, which can effectively improve energy utilization, and alleviate the energy crisis and environmental pollution caused by the over-exploitation and utilization of coal, oil and other major fossil energy. Therefore, it has been widely concerned by researchers and has become a research hotspot recently. Base on this, one of the more excellent electronic conductive polymers, poly(3, 4-ethylenedioxythiophene) (PEDOT), was used as the research subject, and multiwall carbon nanotubes (MWCNT)/PEDOT composites were synthesized by chemical in situ oxidation synthesis method. X-ray diffraction, raman spectroscopy, transmission electron microscope and positron annihilation lifetime spectroscopy were used to study the microstructure of the composites, the results of which indicate that when the MWCNT content is higher than 24.9wt%, the MWCNTs of MWCNT/PEDOT composites aggregate seriously and are badly dispersed. Thermal and electrical measurements of MWCNT/PEDOT composites show that their electrical conductivity increases sustainably with the MWCNT content increasing. For the pure PEDOT sample, the electrical conductivity is only 7.5 S·m−1, and the electrical conductivity of MWCNT/PEDOT sample is up to 566.59 S·m−1 at MWCNT content of 30.1wt%, the increase is nearly 76 times. Meanwhile, the power factor of the composites increases rapidly from 14.5×10−4 to 814.3×10−4 μW·(m·K2)−1 with the increase of 56, which is mainly due to the high conductivity of MWCNT and the π-π interaction between PEDOT molecular chain and MWCNT. With the increase of MWCNT content, the decrease of the first lifetime τ1 of positron annihilation in materials of PAL test confirms that the interface between MWCNT and PEDOT became smaller and the interfacial interaction between the MWCNT and PEDOT was weakened. As a result, the thermal conductivity of the composite exhibits a bit increase with the addition of MWCNT, but it was far lower than the increase of power factor. Eventually, the thermoelectric figure of merit (ZT, an index or measure of the thermoelectric properties of a thermoelectric material) value of the MWCNT/PEDOT composites increases from 0.015×10−4 to 0.45×10−4, that's a nearly 30-fold increase. In summary, the doped MWCNT of higher conductivity can greatly enhance the thermoelectric properties of electronic conductive polymers of PEDOT.

Thermoelectric conversion technology can convert a large amount of waste heat energy into electric energy for reuse. It is a green energy conversion technology, which can effectively improve energy utilization, and alleviate the energy crisis and environmental pollution caused by the over-exploitation and utilization of coal, oil and other major fossil energy. Therefore, it has been widely concerned by researchers and has become a research hotspot recently. Base on this, one of the more excellent electronic conductive polymers, poly(3, 4-ethylenedioxythiophene) (PEDOT), was used as the research subject, and multiwall carbon nanotubes (MWCNT)/PEDOT composites were synthesized by chemical in situ oxidation synthesis method. X-ray diffraction, raman spectroscopy, transmission electron microscope and positron annihilation lifetime spectroscopy were used to study the microstructure of the composites, the results of which indicate that when the MWCNT content is higher than 24.9wt%, the MWCNTs of MWCNT/PEDOT composites aggregate seriously and are badly dispersed. Thermal and electrical measurements of MWCNT/PEDOT composites show that their electrical conductivity increases sustainably with the MWCNT content increasing. For the pure PEDOT sample, the electrical conductivity is only 7.5 S·m−1, and the electrical conductivity of MWCNT/PEDOT sample is up to 566.59 S·m−1 at MWCNT content of 30.1wt%, the increase is nearly 76 times. Meanwhile, the power factor of the composites increases rapidly from 14.5×10−4 to 814.3×10−4 μW·(m·K2)−1 with the increase of 56, which is mainly due to the high conductivity of MWCNT and the π-π interaction between PEDOT molecular chain and MWCNT. With the increase of MWCNT content, the decrease of the first lifetime τ1 of positron annihilation in materials of PAL test confirms that the interface between MWCNT and PEDOT became smaller and the interfacial interaction between the MWCNT and PEDOT was weakened. As a result, the thermal conductivity of the composite exhibits a bit increase with the addition of MWCNT, but it was far lower than the increase of power factor. Eventually, the thermoelectric figure of merit (ZT, an index or measure of the thermoelectric properties of a thermoelectric material) value of the MWCNT/PEDOT composites increases from 0.015×10−4 to 0.45×10−4, that's a nearly 30-fold increase. In summary, the doped MWCNT of higher conductivity can greatly enhance the thermoelectric properties of electronic conductive polymers of PEDOT.

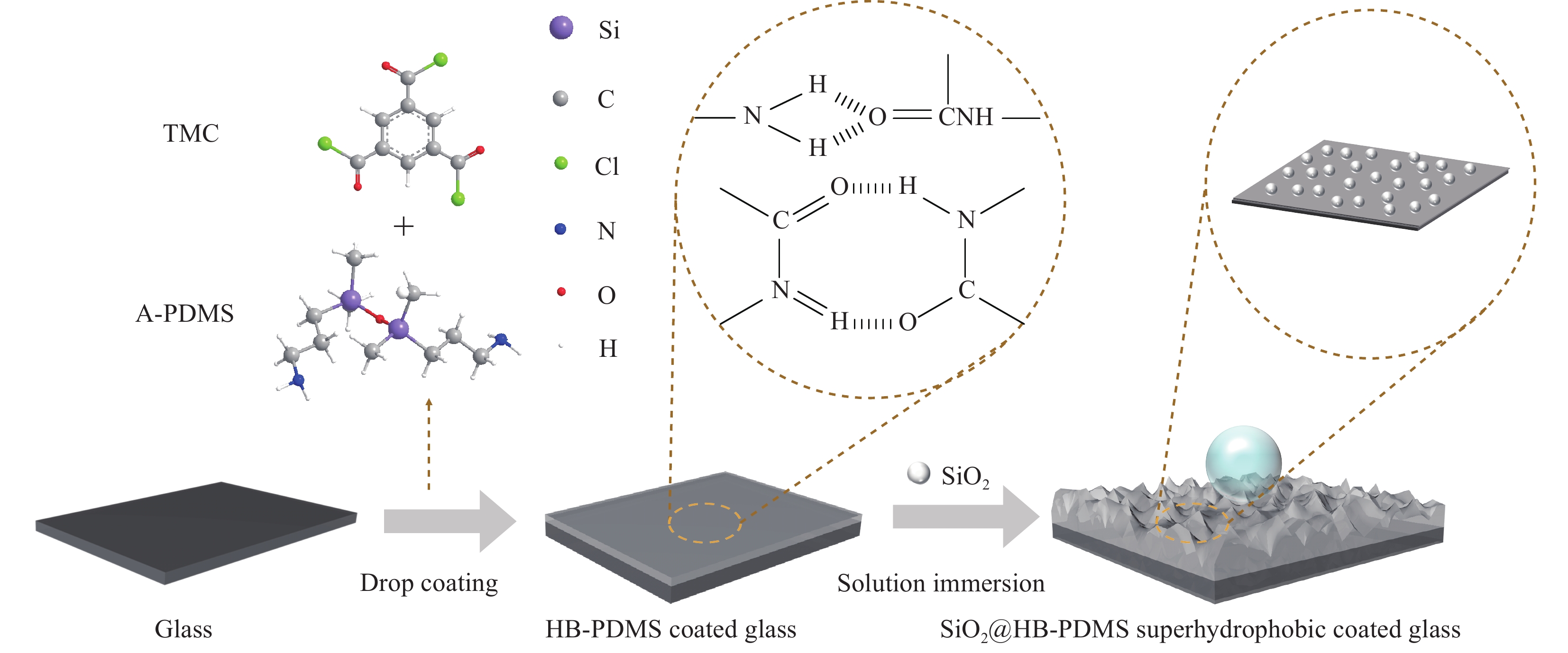

2023, 40(2): 872-883.

doi: 10.13801/j.cnki.fhclxb.20220331.002

Abstract:

In practical application, affected by chemical corrosion, scratch and wear and other external environment, superhydrophobic coating is easy to aging, cracking and even falling off, resulting in coating failure. Therefore, to solve this problem, a self-healing superhydrophobic surface with weather resistance was designed: Hyperbranched polydimethylsiloxane (PDMS) was used as a flexible substrate and low surface energy material, and nano-silica was introduced to construct the surface rough structure to prepare the superhydrophobic coating. When SiO2 particle size is 50 nm and solid content is 30wt%, the superhydrophobic coating with contact angle of 154.87° is obtained. The coating shows good mechanical stability after 5 times of tape peeling test. After 10 temperature difference cycling tests and 24 h UV irradiation, the surface contact angle is still greater than 150°, indicating that the coating has good weather resistance. The scratches can be partially healed by heat treatment at 80℃ for 2 h, indicating that the coating has certain self-healing function. At the same time, Tafel and Nyquist test results indicates that superhydrophobic treatment can significantly improve the corrosion resistance of the substrate, and the coating has obvious self-cleaning effect as well. In conclusion, the nano-SiO2@hyperbranched PDMS composite superhydrophobic coating prepared in this work has self-healing function, which provides a new research strategy for the development of self-healing superhydrophobic coating.

In practical application, affected by chemical corrosion, scratch and wear and other external environment, superhydrophobic coating is easy to aging, cracking and even falling off, resulting in coating failure. Therefore, to solve this problem, a self-healing superhydrophobic surface with weather resistance was designed: Hyperbranched polydimethylsiloxane (PDMS) was used as a flexible substrate and low surface energy material, and nano-silica was introduced to construct the surface rough structure to prepare the superhydrophobic coating. When SiO2 particle size is 50 nm and solid content is 30wt%, the superhydrophobic coating with contact angle of 154.87° is obtained. The coating shows good mechanical stability after 5 times of tape peeling test. After 10 temperature difference cycling tests and 24 h UV irradiation, the surface contact angle is still greater than 150°, indicating that the coating has good weather resistance. The scratches can be partially healed by heat treatment at 80℃ for 2 h, indicating that the coating has certain self-healing function. At the same time, Tafel and Nyquist test results indicates that superhydrophobic treatment can significantly improve the corrosion resistance of the substrate, and the coating has obvious self-cleaning effect as well. In conclusion, the nano-SiO2@hyperbranched PDMS composite superhydrophobic coating prepared in this work has self-healing function, which provides a new research strategy for the development of self-healing superhydrophobic coating.

2023, 40(2): 884-892.

doi: 10.13801/j.cnki.fhclxb.20220402.001

Abstract:

Nano FeS has excellent adsorption performance for Cr(VI) because of large specific surface area and strong reducibility, but it is unstable and prone to agglomeration. In order to overcome these disadvantages, the biomimetic FeS composites (bioFeS) were prepared by co-precipitation-roasting method using rape pollen as a biological template. The surface morphology and structure of bioFeS composites were characterized by SEM, XRD and XPS. The effects of adsorbent dosage, reaction time, reaction temperature, initial Cr(VI) concentration and pH on adsorption capacity of Cr(VI) on bioFeS composites were studied to investigate the reaction mechanism using Cr(VI) as the target pollutant. The results show that rape pollen biotemplate successfully disperse FeS with a large specific surface area. The adsorption capacity of Cr(VI) on bioFeS composites can reach 88.95 mg·g−1 at a reaction time of 120 min, pH of 1, adsorbent dosing of 0.2 g·L−1 and a reaction temperature of 25℃. The adsorption process conforms to quasi-secondary kinetics and the Langmuir isothermal adsorption model. The coexisting ions NO3− and SO42− will inhibit the adsorption capacity of Cr(VI). Combining with adsorption kinetics, thermodynamics and XPS surface element analysis, the mechanism of chromium removal by bioFeS composites mainly involves adsorption and chemical reduction. The method of removal of Cr(VI) in wastewater by bioFeS composites has a promising application.

Nano FeS has excellent adsorption performance for Cr(VI) because of large specific surface area and strong reducibility, but it is unstable and prone to agglomeration. In order to overcome these disadvantages, the biomimetic FeS composites (bioFeS) were prepared by co-precipitation-roasting method using rape pollen as a biological template. The surface morphology and structure of bioFeS composites were characterized by SEM, XRD and XPS. The effects of adsorbent dosage, reaction time, reaction temperature, initial Cr(VI) concentration and pH on adsorption capacity of Cr(VI) on bioFeS composites were studied to investigate the reaction mechanism using Cr(VI) as the target pollutant. The results show that rape pollen biotemplate successfully disperse FeS with a large specific surface area. The adsorption capacity of Cr(VI) on bioFeS composites can reach 88.95 mg·g−1 at a reaction time of 120 min, pH of 1, adsorbent dosing of 0.2 g·L−1 and a reaction temperature of 25℃. The adsorption process conforms to quasi-secondary kinetics and the Langmuir isothermal adsorption model. The coexisting ions NO3− and SO42− will inhibit the adsorption capacity of Cr(VI). Combining with adsorption kinetics, thermodynamics and XPS surface element analysis, the mechanism of chromium removal by bioFeS composites mainly involves adsorption and chemical reduction. The method of removal of Cr(VI) in wastewater by bioFeS composites has a promising application.

2023, 40(2): 893-903.

doi: 10.13801/j.cnki.fhclxb.20220314.002

Abstract:

The preparation of bifunctional catalysts with high stability and high activity for hydrogen production from water is one of the important step in the large-scale commercial application of hydrogen energy. Herein, the flake amorphous phytic acid-nickel iron bimetallic composite (NiFe-PA) has been prepared on foamed nickel (NF) by two-step room temperature impregnation using phytic acid (PA), ferric chloride hexahydrate (FeCl3·6H2O) and nickel chloride hexahydrate (NiCl2·6H2O) as the starting materials. The electrocatalytic performance of NiFe-PA modified NF electrode (NiFe-PA/NF) for water electrolysis in alkaline condition (1.0 mol/L KOH) was investigated by linear sweep voltammetry (LSV). The results show that NiFe-PA/NF, as a bifunctional catalyst, has excellent oxygen and hydrogen evolution properties due to the synergistic effect between Ni and Fe. The overpotentials are only 220 mV at 50 mA·cm−2 for oxygen evolution reaction (OER) and 135 mV at 10 mA·cm−2 hydrogen evolution reaction (HER). The NiFe-PA/NFs were then assembled into a two-electrode system for overall water splitting, and the cell voltage required to reach the current density of 10 mA·cm−2 was only 1.61 V, which is lower than the precious metal catalyst system of RuO2/NF||Pt-C/NF (1.64 V). It can also satisfy the hydrogen production driven by solar panels (2 V) under solar illumination conditions. Furthermore, owing to the high stability and corrosion resistance of the PA-metal complex, the catalytic stability of NiFe-PA/NF can be maintained at least for 175 h and 75 h, respectively, for the OER and HER at 100 mA·cm−2, indicating the high catalytic stability of NiFe-PA/NF at high current densities.

The preparation of bifunctional catalysts with high stability and high activity for hydrogen production from water is one of the important step in the large-scale commercial application of hydrogen energy. Herein, the flake amorphous phytic acid-nickel iron bimetallic composite (NiFe-PA) has been prepared on foamed nickel (NF) by two-step room temperature impregnation using phytic acid (PA), ferric chloride hexahydrate (FeCl3·6H2O) and nickel chloride hexahydrate (NiCl2·6H2O) as the starting materials. The electrocatalytic performance of NiFe-PA modified NF electrode (NiFe-PA/NF) for water electrolysis in alkaline condition (1.0 mol/L KOH) was investigated by linear sweep voltammetry (LSV). The results show that NiFe-PA/NF, as a bifunctional catalyst, has excellent oxygen and hydrogen evolution properties due to the synergistic effect between Ni and Fe. The overpotentials are only 220 mV at 50 mA·cm−2 for oxygen evolution reaction (OER) and 135 mV at 10 mA·cm−2 hydrogen evolution reaction (HER). The NiFe-PA/NFs were then assembled into a two-electrode system for overall water splitting, and the cell voltage required to reach the current density of 10 mA·cm−2 was only 1.61 V, which is lower than the precious metal catalyst system of RuO2/NF||Pt-C/NF (1.64 V). It can also satisfy the hydrogen production driven by solar panels (2 V) under solar illumination conditions. Furthermore, owing to the high stability and corrosion resistance of the PA-metal complex, the catalytic stability of NiFe-PA/NF can be maintained at least for 175 h and 75 h, respectively, for the OER and HER at 100 mA·cm−2, indicating the high catalytic stability of NiFe-PA/NF at high current densities.

2023, 40(2): 904-910.

doi: 10.13801/j.cnki.fhclxb.20220325.001

Abstract:

As a promising environmental remediation technology, the development of efficient and stable photocatalysts with visible light response is one of the important studies in photocatalysis technology. In this work, g-C3N4/porous organic polymers (POPs) composite photocatalysts were prepared via atmospheric solvothermal method. Different ratios of g-C3N4 were in-situ loaded on conjugated porous organic polymers TAPB-DMTP POP synthesized with 1, 3, 5-tris(4-aminophenyl) benzene (TAPB) and 2, 5-dimethoxybenzene-1, 4-diformaldehyde (DMTP) as monomers. The chemical structure and optical properties of g-C3N4/POPs materials were characterized by XRD, FTIR, BET, TGA, UV-Vis DRS, current-time (i-t) and EIS methods. Cr(VI) was selected as the model pollutant, the photocatalytic reduction activities of g-C3N4/POPs photocatalysts with different g-C3N4 loading ratios were explored under visible light conditions, and the effects of pH value, catalyst dosage and substrate concentration were further investigated. The results shows that g-C3N4/POP-2 exhibits the best photocatalytic reduction performance at pH=2 with the reduction efficiency of 99.1% after 30 min of visible illumination. The reduction efficiency of Cr(VI) is significantly improved over g-C3N4/POP-2 compared with pure g-C3N4 and TAPB-DMTP POP, and the fitted first-order kinetics rate are 22.0 times and 2.2 times that of g-C3N4 and TAPB-DMTP POP, respectively. This composite also exhibits excellent photocatalytic stability as the Cr(VI) reduction rate reaches more than 90% after five cycles.

As a promising environmental remediation technology, the development of efficient and stable photocatalysts with visible light response is one of the important studies in photocatalysis technology. In this work, g-C3N4/porous organic polymers (POPs) composite photocatalysts were prepared via atmospheric solvothermal method. Different ratios of g-C3N4 were in-situ loaded on conjugated porous organic polymers TAPB-DMTP POP synthesized with 1, 3, 5-tris(4-aminophenyl) benzene (TAPB) and 2, 5-dimethoxybenzene-1, 4-diformaldehyde (DMTP) as monomers. The chemical structure and optical properties of g-C3N4/POPs materials were characterized by XRD, FTIR, BET, TGA, UV-Vis DRS, current-time (i-t) and EIS methods. Cr(VI) was selected as the model pollutant, the photocatalytic reduction activities of g-C3N4/POPs photocatalysts with different g-C3N4 loading ratios were explored under visible light conditions, and the effects of pH value, catalyst dosage and substrate concentration were further investigated. The results shows that g-C3N4/POP-2 exhibits the best photocatalytic reduction performance at pH=2 with the reduction efficiency of 99.1% after 30 min of visible illumination. The reduction efficiency of Cr(VI) is significantly improved over g-C3N4/POP-2 compared with pure g-C3N4 and TAPB-DMTP POP, and the fitted first-order kinetics rate are 22.0 times and 2.2 times that of g-C3N4 and TAPB-DMTP POP, respectively. This composite also exhibits excellent photocatalytic stability as the Cr(VI) reduction rate reaches more than 90% after five cycles.

2023, 40(2): 911-928.

doi: 10.13801/j.cnki.fhclxb.20220415.004

Abstract:

Multi-material composite is an effective method to prepare light-weight, broadband and strong absorbing materials. In this paper, polylactic acid (PLA) was used as the matrix material, and FeSiAl, MoS2 and graphene (GN) were used as fillers. FeSiAl-MoS2-GN/PLA composites, which were used for fused deposition modeling (FDM), prepared by the two-step process of ball milling and melt extrusion. The phase structure, microscopic morphology and electromagnetic properties of composites were characterized by XRD, Raman spectroscopy, SEM and vector network analyzer, respectively. And the effect of graphene content on the electromagnetic wave absorbing properties of composites was also investigated. The research shows that graphene, FeSiAl and MoS2 are randomly dispersed in the PLA matrix and form a complex conductive network; Multi-material composites build rich dielectric/magnetic heterointerfaces, which are beneficial to promote interface polarization; The higher the graphene content, the stronger the electromagnetic wave absorbing properties of composites; When the graphene content is 5wt%, the minimum reflection loss is −27.90 dB at a thickness of 1.7 mm, and the effective absorption bandwidth is 4.96 GHz (12.64-17.60 GHz) at a thickness of 1.9 mm. Its excellent absorbing properties are attributed to the perfect impedance matching and the synergy between dielectric and magnetic losses.

Multi-material composite is an effective method to prepare light-weight, broadband and strong absorbing materials. In this paper, polylactic acid (PLA) was used as the matrix material, and FeSiAl, MoS2 and graphene (GN) were used as fillers. FeSiAl-MoS2-GN/PLA composites, which were used for fused deposition modeling (FDM), prepared by the two-step process of ball milling and melt extrusion. The phase structure, microscopic morphology and electromagnetic properties of composites were characterized by XRD, Raman spectroscopy, SEM and vector network analyzer, respectively. And the effect of graphene content on the electromagnetic wave absorbing properties of composites was also investigated. The research shows that graphene, FeSiAl and MoS2 are randomly dispersed in the PLA matrix and form a complex conductive network; Multi-material composites build rich dielectric/magnetic heterointerfaces, which are beneficial to promote interface polarization; The higher the graphene content, the stronger the electromagnetic wave absorbing properties of composites; When the graphene content is 5wt%, the minimum reflection loss is −27.90 dB at a thickness of 1.7 mm, and the effective absorption bandwidth is 4.96 GHz (12.64-17.60 GHz) at a thickness of 1.9 mm. Its excellent absorbing properties are attributed to the perfect impedance matching and the synergy between dielectric and magnetic losses.

2023, 40(2): 929-939.

doi: 10.13801/j.cnki.fhclxb.20220414.001

Abstract:

Waterborne polyurethane (PU) is a kind of environment-friendly coating material, widely used in leather, textile, construction coating and other fields. As a coating for leather and textile, the water vapor permeability (WVP) of polyurethane determines the wearing comfort of clothing. However, the water vapor permeability of conventional waterborne polyurethane is poor and needs to be modified to obtain coatings with excellent WVP. CaCl2 and Heptafluorodecyl trimethoxysilane (FAS-17) were used to modify diatomite to prepare hydrophobic diatomite base materials. The effects of modification conditions on the structure and properties of diatomite were investigated. The modified diatomite with excellent performance was combined with PU emulsion and the WVP of composite film was studied. The results indicate that the diatomite modified with 30wt%CaCl2 and 0.8wt%FAS-17 present the best comprehensive performance with increased specific surface area and pore structure. The moisture-regulating performance is improved and further enhanced by surface hydrophobic modification of FAS-17. After modified diatomite FAS-17-CaCl2-D with best performance is combined with PU, the WVP of FAS-17-CaCl2-D/PU composite film increase first then decrease with the increasing of FAS-17-CaCl2-D dosage, and the hydrophobicity is improved. The composite PU film with 1% of FAS-17-CaCl2-D shows the largest WVP, which increased by 16.3% compared with pure PU film. The SEM-EDS reveal that the the surface and cross section of FAS-17-CaCl2-D/PU composite film appear the characteristic elements of FAS-17-CaCl2-D such as Si, Ca and F. The pores appeared at the interface between PU and FAS-17-CaCl2-D provided channels for the transfer of water vapor, resulting in improved WVP. The WVP enhanced PU in this work are expected to be applied in textile and leather coatings to improve the thermal comfort.

Waterborne polyurethane (PU) is a kind of environment-friendly coating material, widely used in leather, textile, construction coating and other fields. As a coating for leather and textile, the water vapor permeability (WVP) of polyurethane determines the wearing comfort of clothing. However, the water vapor permeability of conventional waterborne polyurethane is poor and needs to be modified to obtain coatings with excellent WVP. CaCl2 and Heptafluorodecyl trimethoxysilane (FAS-17) were used to modify diatomite to prepare hydrophobic diatomite base materials. The effects of modification conditions on the structure and properties of diatomite were investigated. The modified diatomite with excellent performance was combined with PU emulsion and the WVP of composite film was studied. The results indicate that the diatomite modified with 30wt%CaCl2 and 0.8wt%FAS-17 present the best comprehensive performance with increased specific surface area and pore structure. The moisture-regulating performance is improved and further enhanced by surface hydrophobic modification of FAS-17. After modified diatomite FAS-17-CaCl2-D with best performance is combined with PU, the WVP of FAS-17-CaCl2-D/PU composite film increase first then decrease with the increasing of FAS-17-CaCl2-D dosage, and the hydrophobicity is improved. The composite PU film with 1% of FAS-17-CaCl2-D shows the largest WVP, which increased by 16.3% compared with pure PU film. The SEM-EDS reveal that the the surface and cross section of FAS-17-CaCl2-D/PU composite film appear the characteristic elements of FAS-17-CaCl2-D such as Si, Ca and F. The pores appeared at the interface between PU and FAS-17-CaCl2-D provided channels for the transfer of water vapor, resulting in improved WVP. The WVP enhanced PU in this work are expected to be applied in textile and leather coatings to improve the thermal comfort.

2023, 40(2): 940-949.

doi: 10.13801/j.cnki.fhclxb.20220325.003

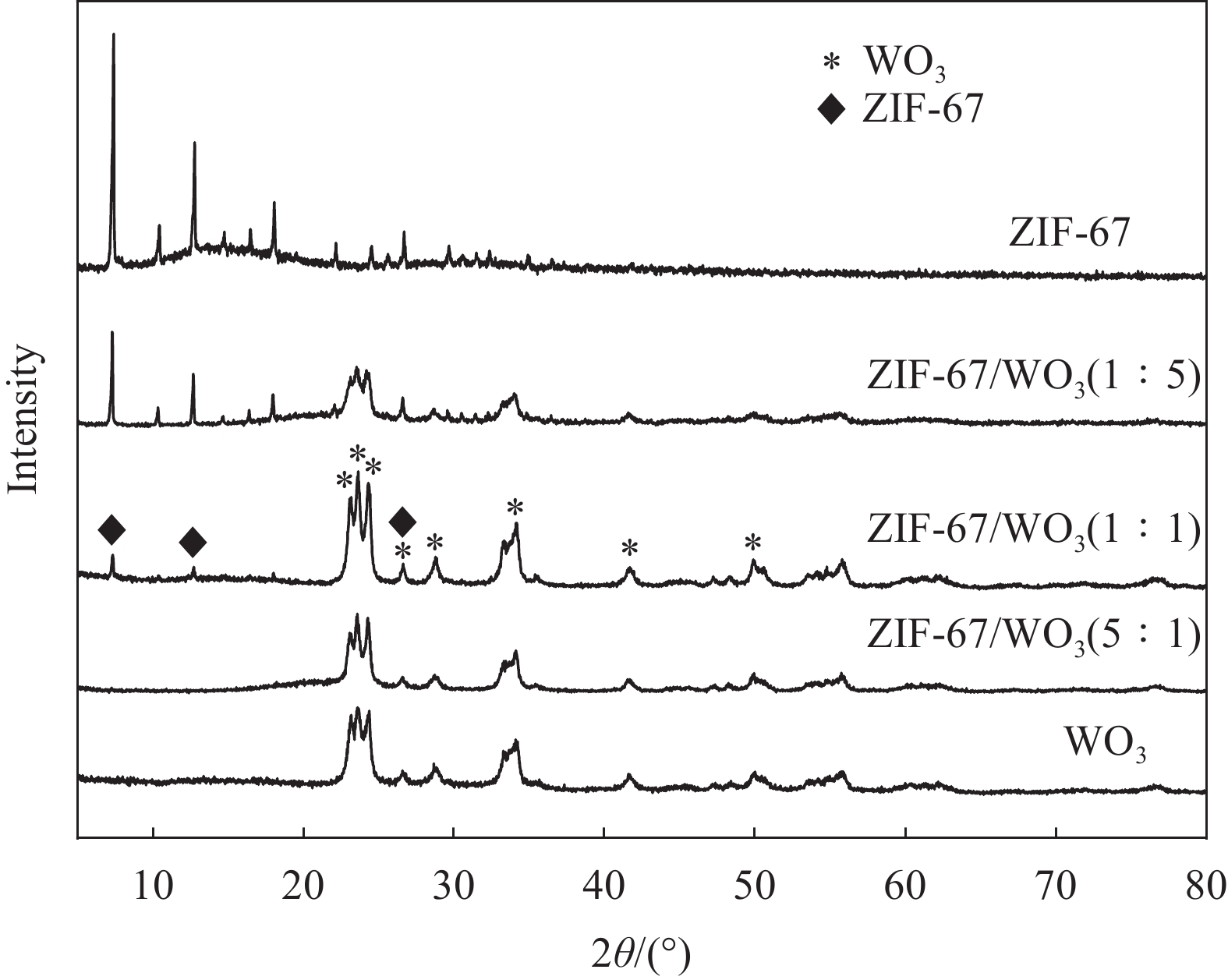

Abstract: