2023 Vol. 40, No. 1

2023, 40(1): 1-12.

doi: 10.13801/j.cnki.fhclxb.20220512.005

Abstract:

With the wide application of electronic equipment in military, communication, medical, transportation and other fields, the problems of electromagnetic interference and electromagnetic radiation are increasing. Wave absorbing materials can convert the electromagnetic wave energy into heat or other forms energy, which is a direct and effective means of electromagnetic pollution prevention and control. Therefore, researchers at home and abroad have invested a lot of research on the development and application of high-performance wave absorbing materials. Based on the current research status at home and abroad, the paper briefly summarizes the absorption theory and the classification of wave absorbing material. In addition, the paper focusses on the enhancement of electromagnetic adsorption performance from the structural design of materials. Finally, this paper prospects the development trend of wave absorption materials from the direction of compatibility, composite, intelligence and eco-friendly. The paper aims to provide research ideas and theoretical basis for the development of new and high-performance wave absorbing materials.

With the wide application of electronic equipment in military, communication, medical, transportation and other fields, the problems of electromagnetic interference and electromagnetic radiation are increasing. Wave absorbing materials can convert the electromagnetic wave energy into heat or other forms energy, which is a direct and effective means of electromagnetic pollution prevention and control. Therefore, researchers at home and abroad have invested a lot of research on the development and application of high-performance wave absorbing materials. Based on the current research status at home and abroad, the paper briefly summarizes the absorption theory and the classification of wave absorbing material. In addition, the paper focusses on the enhancement of electromagnetic adsorption performance from the structural design of materials. Finally, this paper prospects the development trend of wave absorption materials from the direction of compatibility, composite, intelligence and eco-friendly. The paper aims to provide research ideas and theoretical basis for the development of new and high-performance wave absorbing materials.

2023, 40(1): 13-37.

doi: 10.13801/j.cnki.fhclxb.20220419.008

Abstract:

For the excellent physical, chemical and mechanical properties of fiber reinforced composites, they are widely used in high-tech fields such as aerospace, automobiles, and new energy. Compared with traditional drilling and milling tools, less defects are generated when machining holes of fiber reinforced composites by abrasive tools, such as delamination, burrs, tearing and thermal damage after processing, especially, fiber reinforced ceramic matrix composites with higher hardness could be stably processed when using abrasive tools. In this paper, hole making mechanism of grinding fiber reinforced composites is reviewed, including chip formation, grinding axial force, grinding temperature, and so on. And then, the research status of hole making defects and their evaluation methods are discussed. Subsequently, hole-making quality and its influencing factors are analyzed. Besides, the abrasive tools for grinding fiber reinforced composite holes and their wear mechanisms are summarized. Finally, the development trends of grinding holes for fiber reinforced composites are concluded and forecasted.

For the excellent physical, chemical and mechanical properties of fiber reinforced composites, they are widely used in high-tech fields such as aerospace, automobiles, and new energy. Compared with traditional drilling and milling tools, less defects are generated when machining holes of fiber reinforced composites by abrasive tools, such as delamination, burrs, tearing and thermal damage after processing, especially, fiber reinforced ceramic matrix composites with higher hardness could be stably processed when using abrasive tools. In this paper, hole making mechanism of grinding fiber reinforced composites is reviewed, including chip formation, grinding axial force, grinding temperature, and so on. And then, the research status of hole making defects and their evaluation methods are discussed. Subsequently, hole-making quality and its influencing factors are analyzed. Besides, the abrasive tools for grinding fiber reinforced composite holes and their wear mechanisms are summarized. Finally, the development trends of grinding holes for fiber reinforced composites are concluded and forecasted.

2023, 40(1): 38-50.

doi: 10.13801/j.cnki.fhclxb.20220512.004

Abstract:

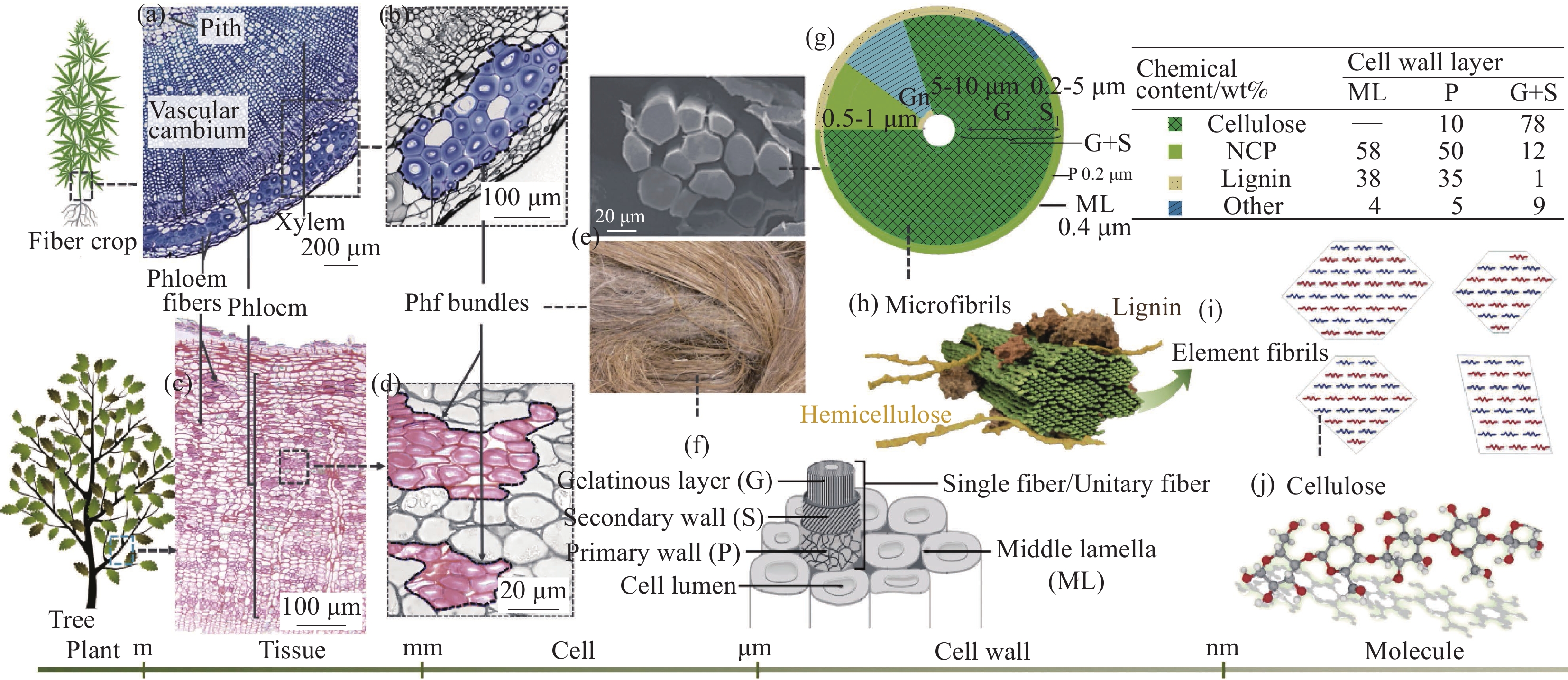

Phloem fiber (or Bast fiber), a kind of non-woody plant fiber, is widely used to reinforce composites due to its good mechanical properties and eco-friendliness. In the cell wall of phloem fiber, abundant cellulose microfibrils with the helical structure are embedded in an amorphous matrix composed of hemicellulose, pectin, and lignin. The variation of the cellulose microfibril angle forms a highly ordered hierarchical structure of the cell wall. The assembly structure and compositions at different scales are of great significance for mechanisms and principles of the excellent mechanical performance of phloem fiber. This work summarized the structural characteristics of phloem fibers represented by hemp and flax at the tissue level, cell wall level, ultrastructural level, and molecular level. The emphasis was focused on the underlying interactions at different levels which generated the special mechanical behavior of the phloem fibers during the axial stretching process. Finally, the existing problems were pointed out, and the development trends of future research were prospected. The extracted concepts may provide new ideas for improving the utilization of phloem fiber and serve as inspiration for biomimetic applications.

Phloem fiber (or Bast fiber), a kind of non-woody plant fiber, is widely used to reinforce composites due to its good mechanical properties and eco-friendliness. In the cell wall of phloem fiber, abundant cellulose microfibrils with the helical structure are embedded in an amorphous matrix composed of hemicellulose, pectin, and lignin. The variation of the cellulose microfibril angle forms a highly ordered hierarchical structure of the cell wall. The assembly structure and compositions at different scales are of great significance for mechanisms and principles of the excellent mechanical performance of phloem fiber. This work summarized the structural characteristics of phloem fibers represented by hemp and flax at the tissue level, cell wall level, ultrastructural level, and molecular level. The emphasis was focused on the underlying interactions at different levels which generated the special mechanical behavior of the phloem fibers during the axial stretching process. Finally, the existing problems were pointed out, and the development trends of future research were prospected. The extracted concepts may provide new ideas for improving the utilization of phloem fiber and serve as inspiration for biomimetic applications.

2023, 40(1): 51-61.

doi: 10.13801/j.cnki.fhclxb.20220412.001

Abstract:

Since the discovery of antibiotics, they have been widely used in the prevention and treatment of bacterial infections because they can hinder the growth of bacteria. However, the abuse of antibiotics in animal husbandry and agriculture leads to antibiotic pollution, which greatly threatens the safety of water sources, increases bacterial drug resistance, and brings great harm to the environment and human health. For these reasons, the detection of antibiotics has attracted extensive attention in recent years. Based on the electrochemical activity of most antibiotics, nano-modified-electrode can improve the sensitivity of electrochemical sensor by enhancing the electrochemical oxidation or reduction reaction of antibiotics in electrolyte. Various electrochemical sensors for the detection of antibiotics are described in detail in this paper, as well as their properties. Finally, the challenges and development prospects of nanomaterial electrochemical sensors in antibiotic detection are discussed.

Since the discovery of antibiotics, they have been widely used in the prevention and treatment of bacterial infections because they can hinder the growth of bacteria. However, the abuse of antibiotics in animal husbandry and agriculture leads to antibiotic pollution, which greatly threatens the safety of water sources, increases bacterial drug resistance, and brings great harm to the environment and human health. For these reasons, the detection of antibiotics has attracted extensive attention in recent years. Based on the electrochemical activity of most antibiotics, nano-modified-electrode can improve the sensitivity of electrochemical sensor by enhancing the electrochemical oxidation or reduction reaction of antibiotics in electrolyte. Various electrochemical sensors for the detection of antibiotics are described in detail in this paper, as well as their properties. Finally, the challenges and development prospects of nanomaterial electrochemical sensors in antibiotic detection are discussed.

2023, 40(1): 62-71.

doi: 10.13801/j.cnki.fhclxb.20220415.002

Abstract:

Thermosetting polyimide resin matrix composites have been widely used in aerospace industry, but the heat resistance of traditional organic polyimide matrix resins is gradually insufficient to satisfy the design and application requirement of the aircrafts, with the development of aerospace technology. Therefore, novel organic/inorganic hybrid polyimides resistant to higher temperature have become the focus of research. In this paper, the recent progress of organic/inorganic hybrid polyimide matrix resins was summarized. The synthetic pathway, structure design, performance control, curing process and degradation behavior of polyhedral oligomeric silsesquioxane-containing polyimide, carborane-containing polyimide and siloxane-containing polyimide were reviewed, providing a detailed description of the characteristics and thermo-resistant mechanism of the organic/inorganic hybrid polyimide resins. The challenges and opportunities for the future development of organic/inorganic hybrid polyimide resins were also discussed and analyzed.

Thermosetting polyimide resin matrix composites have been widely used in aerospace industry, but the heat resistance of traditional organic polyimide matrix resins is gradually insufficient to satisfy the design and application requirement of the aircrafts, with the development of aerospace technology. Therefore, novel organic/inorganic hybrid polyimides resistant to higher temperature have become the focus of research. In this paper, the recent progress of organic/inorganic hybrid polyimide matrix resins was summarized. The synthetic pathway, structure design, performance control, curing process and degradation behavior of polyhedral oligomeric silsesquioxane-containing polyimide, carborane-containing polyimide and siloxane-containing polyimide were reviewed, providing a detailed description of the characteristics and thermo-resistant mechanism of the organic/inorganic hybrid polyimide resins. The challenges and opportunities for the future development of organic/inorganic hybrid polyimide resins were also discussed and analyzed.

2023, 40(1): 72-82.

doi: 10.13801/j.cnki.fhclxb.20220112.002

Abstract:

The mode I double cantilever beam (DCB) test was commonly applied to investigate the material resistance to crack propagation in unidirectional composites, aiming at obtaining the interlaminar fracture toughness in mode I, which was an important input parameter for the study of delamination propagation and failure mechanism of composite materials. The DCB test must be suspended frequently for the multiple measurements of the crack length, which will not only have a potential effect on the propagation of crack and even lead to the measurement error, but also can be a time and effort consuming process. Digital image correlation (DIC) technology applied to crack propagation length measurement has the advantages of real-time tracking and precise positioning, effectively improving the measurement efficiency of the mode I fracture toughness, but it still has limitation when applied to discontinuous deformation behavior, and it is susceptible to interference from image noise, resulting in measurement error. This paper developed a real-time crack length detection method based on DIC and obtained the discontinuous deformation displacement field of the specimen through an image matching algorithm, and then proposed an identification method based on the degree of dispersion of the global lateral displacement, which realized the crack tip real-time capture. Then, compared with the traditional measurement method in the DCB test, the measurement error of the crack length does not exceed 2.76% on average, which verifies the accuracy and efficiency of the method, meanwhile, overcomes the measurement interference caused by roughness of the side surface, the poor speckle quality and the fiber bridging of the poly p-phenylene-2,6-benzoxazole (PBO)/epoxy composites. Finally, the effective initial value and steady-state propagation value of the mode I interlaminar fracture toughness.

The mode I double cantilever beam (DCB) test was commonly applied to investigate the material resistance to crack propagation in unidirectional composites, aiming at obtaining the interlaminar fracture toughness in mode I, which was an important input parameter for the study of delamination propagation and failure mechanism of composite materials. The DCB test must be suspended frequently for the multiple measurements of the crack length, which will not only have a potential effect on the propagation of crack and even lead to the measurement error, but also can be a time and effort consuming process. Digital image correlation (DIC) technology applied to crack propagation length measurement has the advantages of real-time tracking and precise positioning, effectively improving the measurement efficiency of the mode I fracture toughness, but it still has limitation when applied to discontinuous deformation behavior, and it is susceptible to interference from image noise, resulting in measurement error. This paper developed a real-time crack length detection method based on DIC and obtained the discontinuous deformation displacement field of the specimen through an image matching algorithm, and then proposed an identification method based on the degree of dispersion of the global lateral displacement, which realized the crack tip real-time capture. Then, compared with the traditional measurement method in the DCB test, the measurement error of the crack length does not exceed 2.76% on average, which verifies the accuracy and efficiency of the method, meanwhile, overcomes the measurement interference caused by roughness of the side surface, the poor speckle quality and the fiber bridging of the poly p-phenylene-2,6-benzoxazole (PBO)/epoxy composites. Finally, the effective initial value and steady-state propagation value of the mode I interlaminar fracture toughness.

2023, 40(1): 83-95.

doi: 10.13801/j.cnki.fhclxb.20211223.001

Abstract:

To meet the extreme thermal protection requirement of new-generation spacecrafts, nanoporous resin composites (IPC-90) with medium-density, high strength and excellent ablation/insulation properties had been prepared via a sol-gel polymerization using phenolic resin as nanoporous matrix and needled fiber fabric as the reinforcement. The effects of fiber type, namely quartz fiber (QF/IPC-90) and carbon fiber (CF/IPC-90) on the microstructure, mechanical properties, static thermal insulation, and ablation properties of the composites were systematically studied. The as-prepared IPC-90 with medium density of ~0.95 g/cm3 has excellent mechanical properties with tensile strength >120 MPa and bending strength >90 MPa. Due to the introduction of nanopore resin matrix and lightweight fiber felt, the resultant IPC-90 has relatively low room-temperature thermal conductivities (0.089 W/(m∙K) for QF/IPC-90 and 0.120 W/(m∙K) for CF/IPC-90), as well as low effective thermal conductivities at 1000℃. Furthermore, the possible ablation mechanisms under different temperatures were analyzed. It is found that both QF/IPC-90 and CF/IPC-90 have low linear ablation rates under the oxygen-propane ablation test below 2000℃, which are mainly caused by resin matrix pyrolysis and shrinkage. However, under the oxy-acetylene ablation test above 2000℃, the ablation of CF/IPC-90 is dominated by ultrahigh temperature carbonation-sublimation, while the severe ablation of CF/IPC-90 is caused by the melting of quartz fiber. Under the oxy-acetylene ablation of 4.2 MW/m2, the linear ablation rates of CF/IPC-90 and QF/IPC-90 are 0.073 mm/s and 0.186 mm/s, respectively, being similar to the conventional high-density phenolic composites.

To meet the extreme thermal protection requirement of new-generation spacecrafts, nanoporous resin composites (IPC-90) with medium-density, high strength and excellent ablation/insulation properties had been prepared via a sol-gel polymerization using phenolic resin as nanoporous matrix and needled fiber fabric as the reinforcement. The effects of fiber type, namely quartz fiber (QF/IPC-90) and carbon fiber (CF/IPC-90) on the microstructure, mechanical properties, static thermal insulation, and ablation properties of the composites were systematically studied. The as-prepared IPC-90 with medium density of ~0.95 g/cm3 has excellent mechanical properties with tensile strength >120 MPa and bending strength >90 MPa. Due to the introduction of nanopore resin matrix and lightweight fiber felt, the resultant IPC-90 has relatively low room-temperature thermal conductivities (0.089 W/(m∙K) for QF/IPC-90 and 0.120 W/(m∙K) for CF/IPC-90), as well as low effective thermal conductivities at 1000℃. Furthermore, the possible ablation mechanisms under different temperatures were analyzed. It is found that both QF/IPC-90 and CF/IPC-90 have low linear ablation rates under the oxygen-propane ablation test below 2000℃, which are mainly caused by resin matrix pyrolysis and shrinkage. However, under the oxy-acetylene ablation test above 2000℃, the ablation of CF/IPC-90 is dominated by ultrahigh temperature carbonation-sublimation, while the severe ablation of CF/IPC-90 is caused by the melting of quartz fiber. Under the oxy-acetylene ablation of 4.2 MW/m2, the linear ablation rates of CF/IPC-90 and QF/IPC-90 are 0.073 mm/s and 0.186 mm/s, respectively, being similar to the conventional high-density phenolic composites.

2023, 40(1): 96-108.

doi: 10.13801/j.cnki.fhclxb.20220225.002

Abstract:

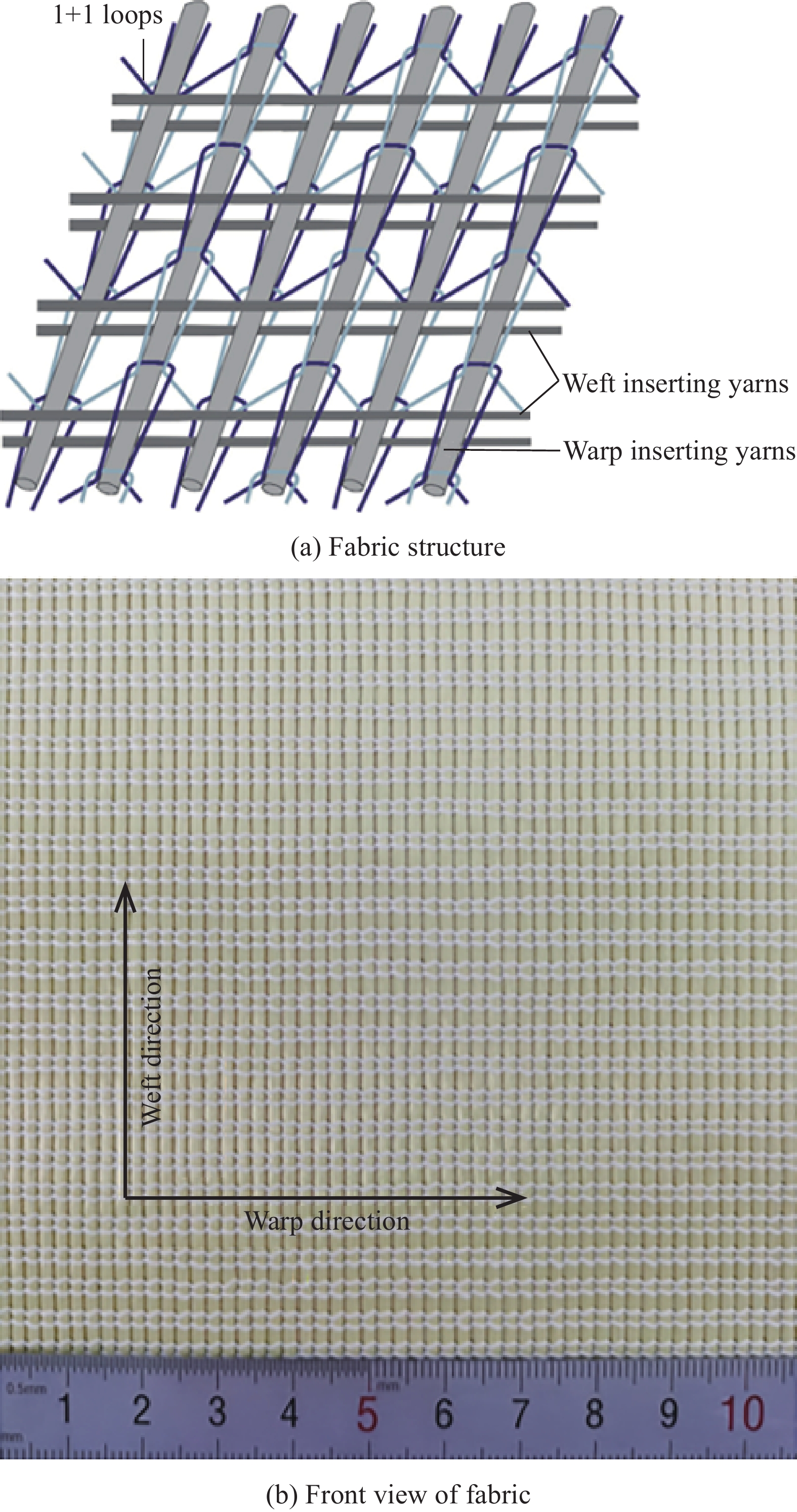

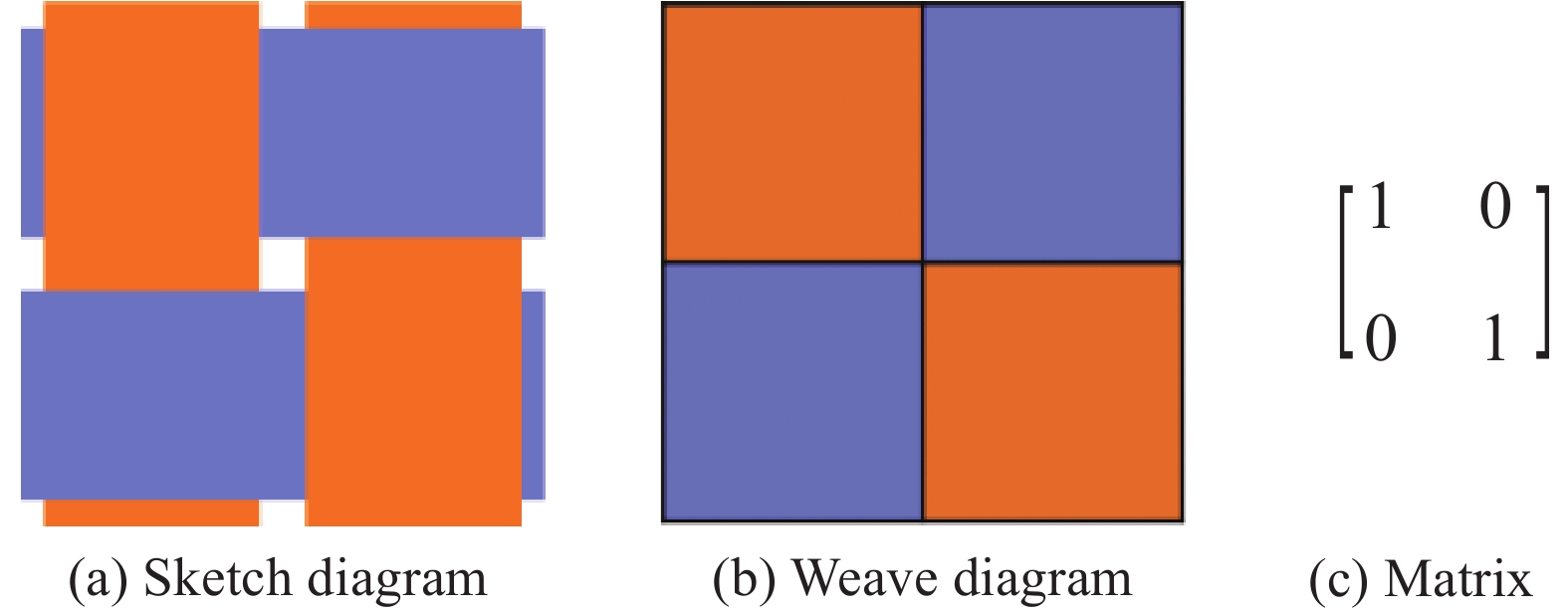

Several multilayered biaxial weft knitted (MBWK) fabric reinforced composites with different shear angles were prepared by changing the orientation of preform inserting yarns. The thermo-oxidative aging test was designed based on Arrhenius model and Ozawa method. The thermal and physical properties of the samples before and after aging were characterized by mechanical properties, DSC, FTIR and DMA tests. The experimental results show that: With the change of yarns’ shearing angle, the composite mechanical properties retention rate after thermo-oxidative aging is also significantly different, because the post curing will occur for the vinyl ester resin in the thermo-oxidative aging environment. Therefore, the bending modulus of the composite materials in the aging process presents downward trend after increased first, and the tensile properties are affected by the reinforcement structure. The degradation of adhesion strength at fiber/matrix interface makes the tensile modulus decrease continuously during the aging process. With the aging time prolongation, the curing degree of resin increases gradually, and the glass transition temperature Tg increases gradually. The peak value of energy storage modulus increases at the initial stage of aging due to molecular chain crosslinking, while decreasing of the peak value is caused by molecular chain fracture at the later stage of aging.

Several multilayered biaxial weft knitted (MBWK) fabric reinforced composites with different shear angles were prepared by changing the orientation of preform inserting yarns. The thermo-oxidative aging test was designed based on Arrhenius model and Ozawa method. The thermal and physical properties of the samples before and after aging were characterized by mechanical properties, DSC, FTIR and DMA tests. The experimental results show that: With the change of yarns’ shearing angle, the composite mechanical properties retention rate after thermo-oxidative aging is also significantly different, because the post curing will occur for the vinyl ester resin in the thermo-oxidative aging environment. Therefore, the bending modulus of the composite materials in the aging process presents downward trend after increased first, and the tensile properties are affected by the reinforcement structure. The degradation of adhesion strength at fiber/matrix interface makes the tensile modulus decrease continuously during the aging process. With the aging time prolongation, the curing degree of resin increases gradually, and the glass transition temperature Tg increases gradually. The peak value of energy storage modulus increases at the initial stage of aging due to molecular chain crosslinking, while decreasing of the peak value is caused by molecular chain fracture at the later stage of aging.

2023, 40(1): 109-118.

doi: 10.13801/j.cnki.fhclxb.20220223.001

Abstract:

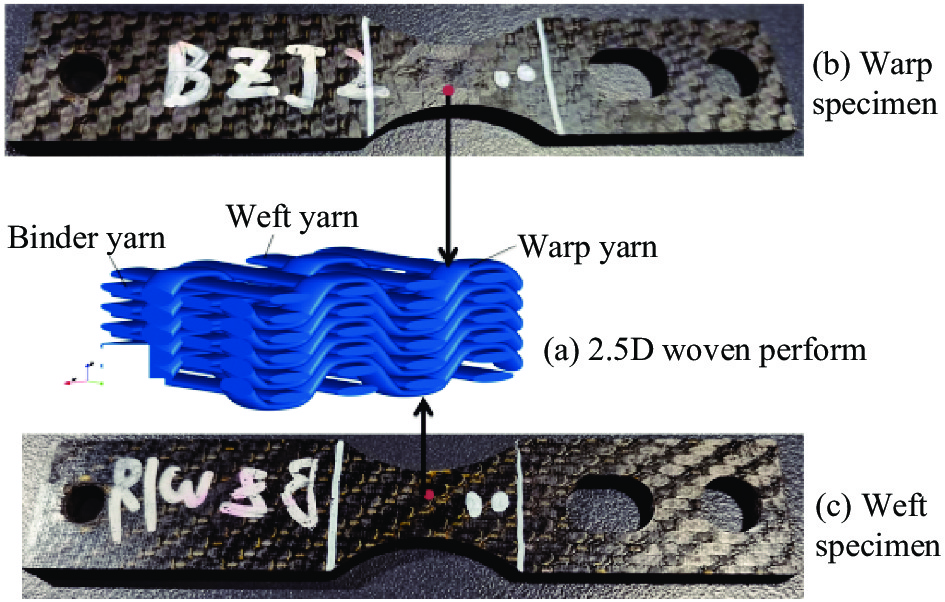

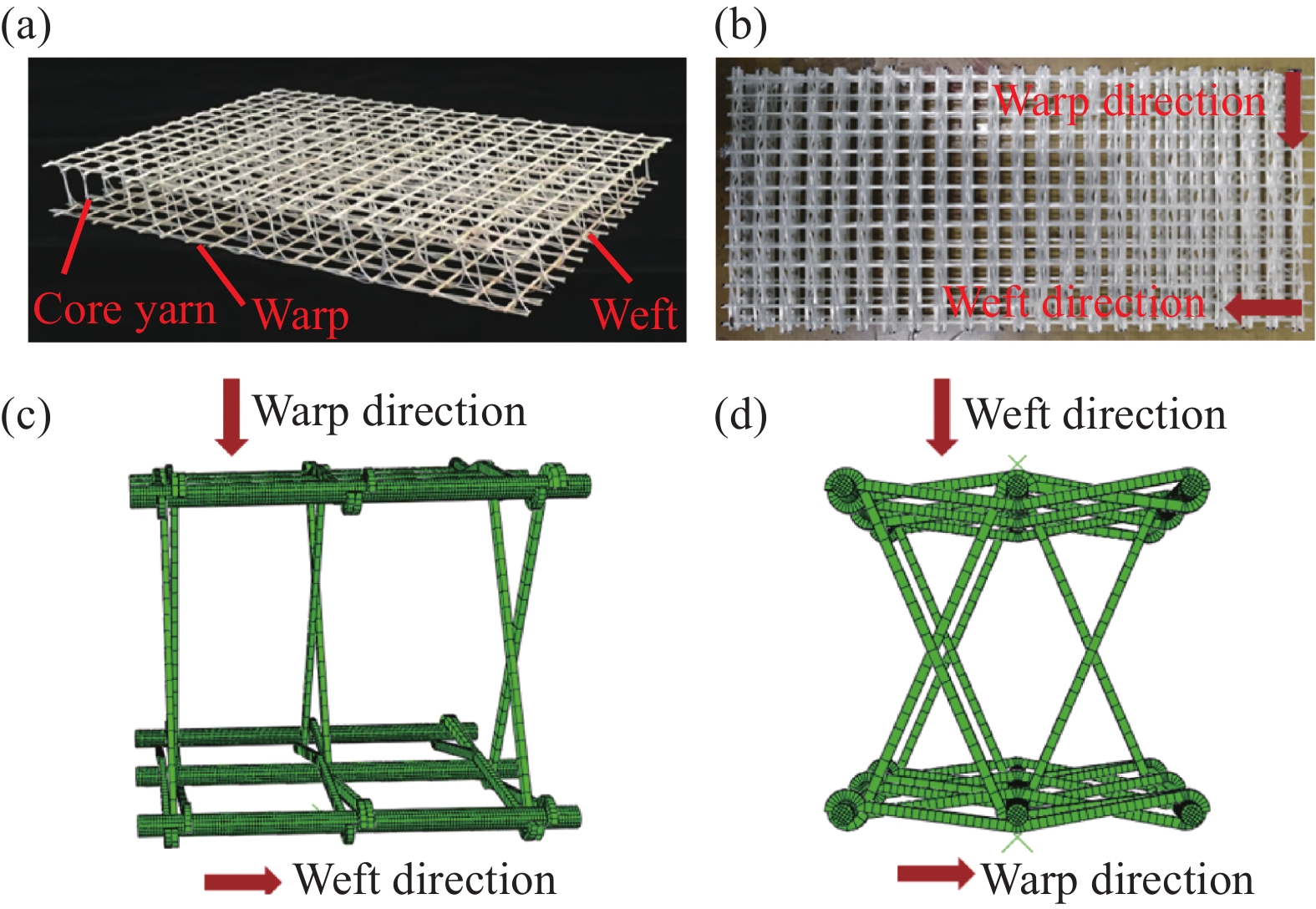

2.5D woven composites are resistant to delamination and impact, which have great application prospects in aeroengine structures. The first-order bending vibration fatigue tests under different stress levels were carried out for the specimens made of 2.5D woven carbon fiber reinforced bismaleimide resin matrix composites in the warp direction and weft direction, respectively. The experimental results show that the vibration fatigue performance of the warp specimens is better than that of the weft specimens. With the increase of stress levels, the lives of the specimens are shortened obviously, and the decline percentage of natural frequency increase, and the damage degree and damage propagation speed within specimens also increase. In the process of vibration fatigue test, the main failure mode of 2.5D woven composites was the loss of structural integrity caused by the debonding of the yarns and the matrixes, which leaded to the continuous decrease of the stiffness of the specimens. 3D CT reconstruction images of the internal damage of the specimens show that the damages spread throughout in the working section of the specimens. The higher the stress levels are, the greater the internal damage ranges and the higher the damage degrees are. And the internal damage state of the warp specimens is more serious than that of the weft specimens. The mathematical model of stress-life (S-N) curve of vibration fatigue of 2.5D woven composites is obtained by data fitting for vibration fatigue results under different nominal stress levels by using the log-log-linear life model, which can be used to predict the life of 2.5D woven composites.

2.5D woven composites are resistant to delamination and impact, which have great application prospects in aeroengine structures. The first-order bending vibration fatigue tests under different stress levels were carried out for the specimens made of 2.5D woven carbon fiber reinforced bismaleimide resin matrix composites in the warp direction and weft direction, respectively. The experimental results show that the vibration fatigue performance of the warp specimens is better than that of the weft specimens. With the increase of stress levels, the lives of the specimens are shortened obviously, and the decline percentage of natural frequency increase, and the damage degree and damage propagation speed within specimens also increase. In the process of vibration fatigue test, the main failure mode of 2.5D woven composites was the loss of structural integrity caused by the debonding of the yarns and the matrixes, which leaded to the continuous decrease of the stiffness of the specimens. 3D CT reconstruction images of the internal damage of the specimens show that the damages spread throughout in the working section of the specimens. The higher the stress levels are, the greater the internal damage ranges and the higher the damage degrees are. And the internal damage state of the warp specimens is more serious than that of the weft specimens. The mathematical model of stress-life (S-N) curve of vibration fatigue of 2.5D woven composites is obtained by data fitting for vibration fatigue results under different nominal stress levels by using the log-log-linear life model, which can be used to predict the life of 2.5D woven composites.

2023, 40(1): 119-130.

doi: 10.13801/j.cnki.fhclxb.20220221.001

Abstract:

Ultra-high molecular weight polyethylene (UHMWPE) fiber reinforced thermoplastic resin matrix composites for ballistic application were selected as the research object. Composite laminates with unidirectional orthogonal structure were prepared by hot pressing process. Based on the self-designed tensile test device, the in-plane tensile tests of UHMWPE fiber reinforced thermoplastic resin matrix composite on macro and quasi meso scales were carried out to investigate its in-plane tensile mechanical properties and failure modes. The results show that the in-plane tensile mechanical properties of UHMWPE composites for ballistic application on quasi meso scale are their intrinsic properties. With the increase of off-axis angle, the tensile fracture strength decreases exponentially. This is attributed to the failure mode changing from the tensile fracture failure of fiber to the interfacial failure between the fiber and resin matrix. Furthermore, the tensile failure strength of UHMWPE fiber reinforced thermoplastic resin matrix composites on the macro scale is 50.52% lower than that on the quasi-meso scale, because the in-plane tensile mechanical response on the macro scale is the coupling result of in-plane tensile deformation and interlayer delamination failure, that is, the lamination effect of laminates.

Ultra-high molecular weight polyethylene (UHMWPE) fiber reinforced thermoplastic resin matrix composites for ballistic application were selected as the research object. Composite laminates with unidirectional orthogonal structure were prepared by hot pressing process. Based on the self-designed tensile test device, the in-plane tensile tests of UHMWPE fiber reinforced thermoplastic resin matrix composite on macro and quasi meso scales were carried out to investigate its in-plane tensile mechanical properties and failure modes. The results show that the in-plane tensile mechanical properties of UHMWPE composites for ballistic application on quasi meso scale are their intrinsic properties. With the increase of off-axis angle, the tensile fracture strength decreases exponentially. This is attributed to the failure mode changing from the tensile fracture failure of fiber to the interfacial failure between the fiber and resin matrix. Furthermore, the tensile failure strength of UHMWPE fiber reinforced thermoplastic resin matrix composites on the macro scale is 50.52% lower than that on the quasi-meso scale, because the in-plane tensile mechanical response on the macro scale is the coupling result of in-plane tensile deformation and interlayer delamination failure, that is, the lamination effect of laminates.

2023, 40(1): 131-140.

doi: 10.13801/j.cnki.fhclxb.20220124.001

Abstract:

A series of polyimide materials were successfully prepared by embedding o-carborane cage structure into polyimide main chains. First, the diamine monomer (DNCB) containing o-carborane unit was designed and synthesized, and then copolymerized with 4,4'-diaminodiphenyl ether (ODA) and 3,3',4,4'-benzophenone tetracarboxylic anhydride (BTDA) to synthesize the polyamic acid (PAA) precursor solution. PAA films were prepared by solution casting method, and then polyimide films containing different contents of carborane unit were obtained after high-temperature thermal imidization. Thermogravimetric analysis (TGA) shows that the addition of DNCB significantly improves the thermal stability and thermal oxidation stability of polyimide materials. When the molar content of DNCB in all diamines reaches 40%, the temperature corresponding to 5wt% mass loss (T5%) increases by nearly 13℃, T10% increases by nearly 43℃ and the mass residual rate was as high as 82.6wt%. Under the air atmosphere, T5% increases by nearly 36℃, T10% increases by nearly 64℃, and the mass residual rate reaches as high as 83.1wt%. This is due to the oxidation of carborane cage and the formation of multi-layer passivation protective layer on the surface of the film, which prevents the degradation of internal polymer materials in contact with oxygen.

A series of polyimide materials were successfully prepared by embedding o-carborane cage structure into polyimide main chains. First, the diamine monomer (DNCB) containing o-carborane unit was designed and synthesized, and then copolymerized with 4,4'-diaminodiphenyl ether (ODA) and 3,3',4,4'-benzophenone tetracarboxylic anhydride (BTDA) to synthesize the polyamic acid (PAA) precursor solution. PAA films were prepared by solution casting method, and then polyimide films containing different contents of carborane unit were obtained after high-temperature thermal imidization. Thermogravimetric analysis (TGA) shows that the addition of DNCB significantly improves the thermal stability and thermal oxidation stability of polyimide materials. When the molar content of DNCB in all diamines reaches 40%, the temperature corresponding to 5wt% mass loss (T5%) increases by nearly 13℃, T10% increases by nearly 43℃ and the mass residual rate was as high as 82.6wt%. Under the air atmosphere, T5% increases by nearly 36℃, T10% increases by nearly 64℃, and the mass residual rate reaches as high as 83.1wt%. This is due to the oxidation of carborane cage and the formation of multi-layer passivation protective layer on the surface of the film, which prevents the degradation of internal polymer materials in contact with oxygen.

2023, 40(1): 141-150.

doi: 10.13801/j.cnki.fhclxb.20220315.001

Abstract:

Carbon fiber reinforced polymer (CFRP) drive shaft is widely used in lightweight fields such as automobile, aerospace, ship and cooling tower fan because of its excellent performance, but it is prone to burr, delamination and other defects in the drilling process. In order to reveal the formation mechanism of defects in CFRP pipe surface drilling, double point angle drills and candle stick drills were selected to drill CFRP pipe surface. Using the method of drilling blind holes and through holes by some steps, the force of the damaged part was analyzed to study the causes of hole entry tear, hole exit burr and delamination. According to the experimental results, it is found that the hole entry tear of the double point angle drill is large. The tear damage is located at the lowest point of the contact between the drill bit and the pipe surface, and it is mainly the fibers that are horizontally wound around the CFRP pipe. The reason is that the horizontally wound fibers have the largest buckling deformation and are more sensitive to the cutting force. The chisel edge of double point angle drill and candle stick drill had no effect on the final delamination of the hole, and the cutting action of the main cutting edge determined the hole final exit delamination. For using the same drill, the axial force is not the only factor affecting the delamination factor, and the cutting heat should also be considered. Compared with the double point angle drill, the candle stick drill can effectively cut the fiber due to the sharp outer corner edge, making smaller hole exit delamination.

Carbon fiber reinforced polymer (CFRP) drive shaft is widely used in lightweight fields such as automobile, aerospace, ship and cooling tower fan because of its excellent performance, but it is prone to burr, delamination and other defects in the drilling process. In order to reveal the formation mechanism of defects in CFRP pipe surface drilling, double point angle drills and candle stick drills were selected to drill CFRP pipe surface. Using the method of drilling blind holes and through holes by some steps, the force of the damaged part was analyzed to study the causes of hole entry tear, hole exit burr and delamination. According to the experimental results, it is found that the hole entry tear of the double point angle drill is large. The tear damage is located at the lowest point of the contact between the drill bit and the pipe surface, and it is mainly the fibers that are horizontally wound around the CFRP pipe. The reason is that the horizontally wound fibers have the largest buckling deformation and are more sensitive to the cutting force. The chisel edge of double point angle drill and candle stick drill had no effect on the final delamination of the hole, and the cutting action of the main cutting edge determined the hole final exit delamination. For using the same drill, the axial force is not the only factor affecting the delamination factor, and the cutting heat should also be considered. Compared with the double point angle drill, the candle stick drill can effectively cut the fiber due to the sharp outer corner edge, making smaller hole exit delamination.

2023, 40(1): 151-159.

doi: 10.13801/j.cnki.fhclxb.20220225.001

Abstract:

Thermal stress, DSC, FTIR, element analysis (EA), XRD, mechanical properties and density were used to analyze the thermal reaction characteristics of large tow polyacrylonitrile (PAN) precursors (48K) in combination with small tow PAN precursors (24K). The large tow carbon fibers were prepared by 50 min continuous pre-oxidation method, in which the evolution of structure and properties were studied. The results show that the thermal stress of large tow PAN precursors is 1.13-1.43 times of small tow PAN precursors, and the starting temperature is lower. The difference of thermal stress reaches maximum at 250℃ and the corresponding density of large tow fibers is 1.316 g/cm3. The crystal regions of PAN precursors transform into amorphous regions rapidly at the initial stage of reaction, and the grain size of the crystal regions increases first and then decreases. The monofilament tensile strength and modulus of large tow carbon fibers prepared by 50 min continuous pre-oxidation are 4240 MPa and 244 GPa, respectively, which are at the same level as those commercial foreign large tow carbon fibers.

Thermal stress, DSC, FTIR, element analysis (EA), XRD, mechanical properties and density were used to analyze the thermal reaction characteristics of large tow polyacrylonitrile (PAN) precursors (48K) in combination with small tow PAN precursors (24K). The large tow carbon fibers were prepared by 50 min continuous pre-oxidation method, in which the evolution of structure and properties were studied. The results show that the thermal stress of large tow PAN precursors is 1.13-1.43 times of small tow PAN precursors, and the starting temperature is lower. The difference of thermal stress reaches maximum at 250℃ and the corresponding density of large tow fibers is 1.316 g/cm3. The crystal regions of PAN precursors transform into amorphous regions rapidly at the initial stage of reaction, and the grain size of the crystal regions increases first and then decreases. The monofilament tensile strength and modulus of large tow carbon fibers prepared by 50 min continuous pre-oxidation are 4240 MPa and 244 GPa, respectively, which are at the same level as those commercial foreign large tow carbon fibers.

2023, 40(1): 160-170.

doi: 10.13801/j.cnki.fhclxb.20211215.002

Abstract:

The high density integration of components in electronic and electrical equipment makes the problem of heat dissipation increasingly prominent, and the demand for thermal conductive materials is increasing. In this paper, polyethylene terephthalate (PET) and hexagonal boron nitride (h-BN) were used as the matrix and thermally conductive filler, respectively, a series of h-BN/PET composites were prepared by melt blending method. The effect of the h-BN content and the crystallinity of the PET matrix on the thermal conductivity of the composites were investigated, and the thermal conduction mechanism of the composites was analyzed. The temperature dependence of the thermal conductivity and heat dissipation effect of the composites were explored from the perspective of material application. The results show that both the crystallinity of the PET matrix and the content of h-BN both contribute to the final thermal conductivity of the composites, and the thermal conductivity of the composites increases with the increase of the crystallinity and h-BN content. h-BN plays a role of heterogeneous nucleation, significantly accelerates the crystallization rate of PET and improves the crystallinity of PET. In compression molding, h-BN is driven by shear stress to oriented in the direction of flow in the PET matrix, resulting in the composite material showing obvious anisotropic characteristics. The orderly arrangement of h-BN in the in-plane direction provides more channels for phonons transmission. When the filling amount of h-BN reaches to 50wt%, the in-plane and through-plane thermal conductivity of the composites reach the maximum values of 3.00 W·(m·K)−1 and 2.19 W·(m·K)−1, respectively. h-BN/PET composites have good heat dissipation effect. The higher the h-BN content, the faster the cooling rate. The rule of temperature drop conforms to the exponential function during the heat dissipation process.

The high density integration of components in electronic and electrical equipment makes the problem of heat dissipation increasingly prominent, and the demand for thermal conductive materials is increasing. In this paper, polyethylene terephthalate (PET) and hexagonal boron nitride (h-BN) were used as the matrix and thermally conductive filler, respectively, a series of h-BN/PET composites were prepared by melt blending method. The effect of the h-BN content and the crystallinity of the PET matrix on the thermal conductivity of the composites were investigated, and the thermal conduction mechanism of the composites was analyzed. The temperature dependence of the thermal conductivity and heat dissipation effect of the composites were explored from the perspective of material application. The results show that both the crystallinity of the PET matrix and the content of h-BN both contribute to the final thermal conductivity of the composites, and the thermal conductivity of the composites increases with the increase of the crystallinity and h-BN content. h-BN plays a role of heterogeneous nucleation, significantly accelerates the crystallization rate of PET and improves the crystallinity of PET. In compression molding, h-BN is driven by shear stress to oriented in the direction of flow in the PET matrix, resulting in the composite material showing obvious anisotropic characteristics. The orderly arrangement of h-BN in the in-plane direction provides more channels for phonons transmission. When the filling amount of h-BN reaches to 50wt%, the in-plane and through-plane thermal conductivity of the composites reach the maximum values of 3.00 W·(m·K)−1 and 2.19 W·(m·K)−1, respectively. h-BN/PET composites have good heat dissipation effect. The higher the h-BN content, the faster the cooling rate. The rule of temperature drop conforms to the exponential function during the heat dissipation process.

2023, 40(1): 171-179.

doi: 10.13801/j.cnki.fhclxb.20220126.003

Abstract:

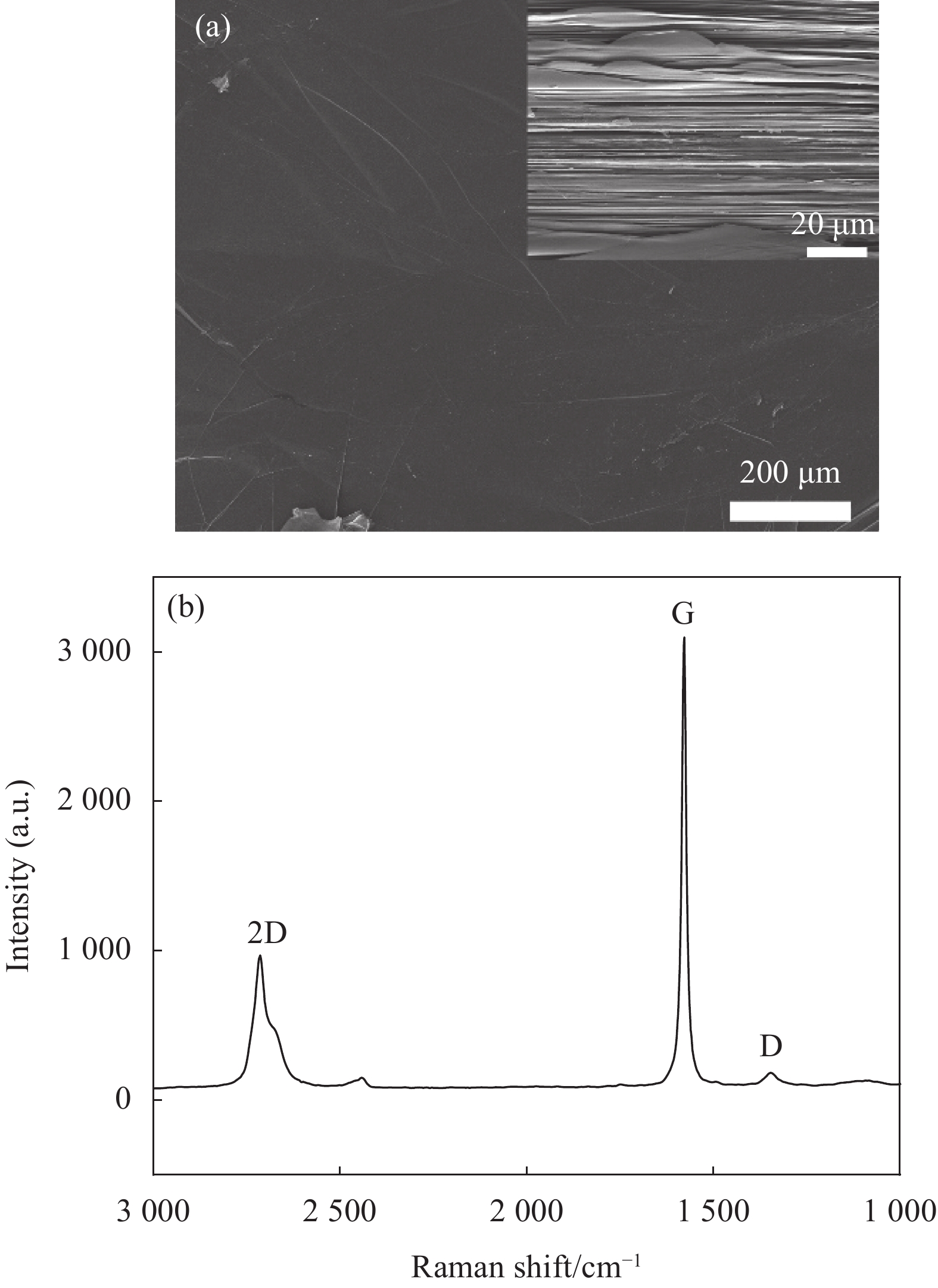

Silicon-carbon anode is an important issue for the development of lithium-ion battery materials. Aiming at the problems of uneven combination and poor interfacial contact of silicon-carbon anode prepared by traditional ball milling, this paper proposes a new strategy to synthesize Si-Fe-Fe3O4-C composite by ball milling in supercritical carbon dioxide (scCO2) fluid medium. It is found that during the process of ball milling mixture of nano-silicon and mesophase carbon microspheres (MCMB) in the scCO2 medium, CO2 and Fe reacts firstly to form a uniformly dispersed Si-FeCO3-C precursor, and then in situ high temperature decomposition of FeCO3 solid phase results in final Si-Fe-Fe3O4-C product. Under the infiltration of scCO2 fluid, MCMB microspheres exfoliate into graphite flakes, and achieve ideal combination with nano-silicon and Fe-Fe3O4. The introduction of Fe-Fe3O4 in the composite has significantly improved the lithium storage capacity, cycle stability and rate performance of silicon-carbon anode, the synthesized Si-Fe-Fe3O4-C composite material maintains a reversible capacity of 1065 mA·h·g−1 after 100 cycles at 0.2 A·g−1. The method shows the merits of facile operation procedure, easy industrial production and potential commercial application basing on the supercritical fluid permeability and strong diffusion ability.

Silicon-carbon anode is an important issue for the development of lithium-ion battery materials. Aiming at the problems of uneven combination and poor interfacial contact of silicon-carbon anode prepared by traditional ball milling, this paper proposes a new strategy to synthesize Si-Fe-Fe3O4-C composite by ball milling in supercritical carbon dioxide (scCO2) fluid medium. It is found that during the process of ball milling mixture of nano-silicon and mesophase carbon microspheres (MCMB) in the scCO2 medium, CO2 and Fe reacts firstly to form a uniformly dispersed Si-FeCO3-C precursor, and then in situ high temperature decomposition of FeCO3 solid phase results in final Si-Fe-Fe3O4-C product. Under the infiltration of scCO2 fluid, MCMB microspheres exfoliate into graphite flakes, and achieve ideal combination with nano-silicon and Fe-Fe3O4. The introduction of Fe-Fe3O4 in the composite has significantly improved the lithium storage capacity, cycle stability and rate performance of silicon-carbon anode, the synthesized Si-Fe-Fe3O4-C composite material maintains a reversible capacity of 1065 mA·h·g−1 after 100 cycles at 0.2 A·g−1. The method shows the merits of facile operation procedure, easy industrial production and potential commercial application basing on the supercritical fluid permeability and strong diffusion ability.

2023, 40(1): 180-191.

doi: 10.13801/j.cnki.fhclxb.20220117.004

Abstract:

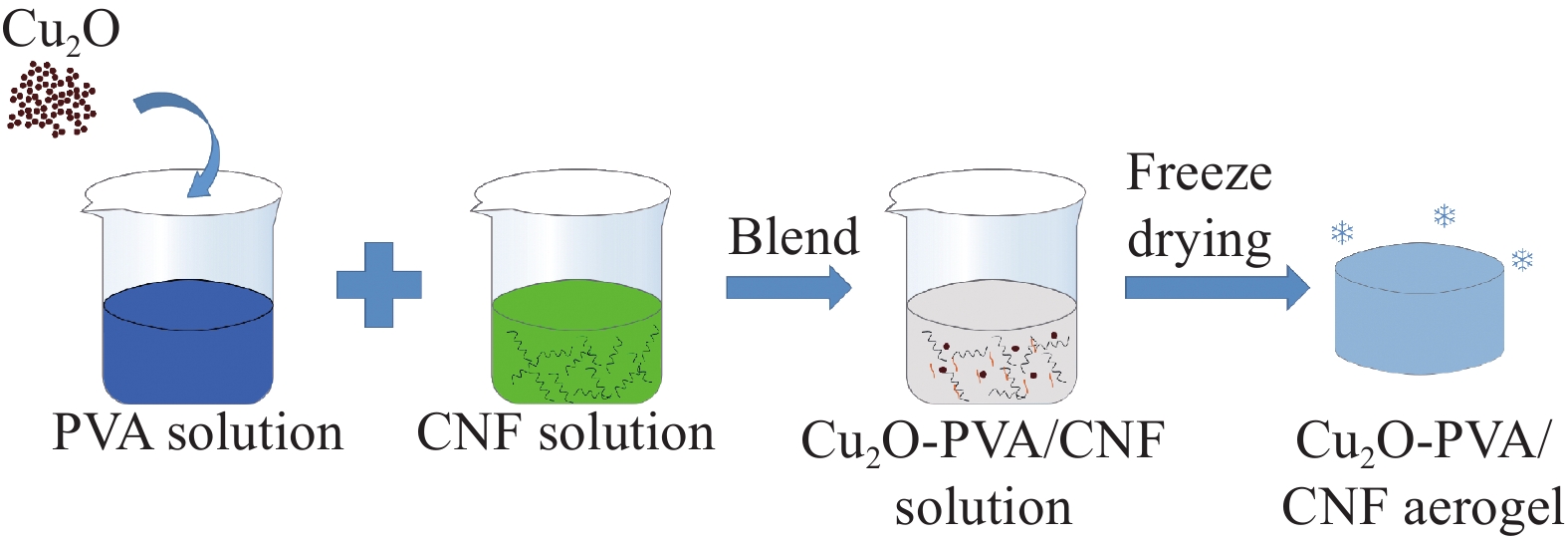

In order to improve the photocatalytic performance of cuprous oxide (Cu2O), Cu2O particles and polyvinyl alcohol (PVA) were added to nanocellulose (CNF) at the same time, and a functionalized cellulose-based aerogel (Cu2O-PVA/CNF) with three-dimensional (3D) porous structure and abundant active sites were successfully prepared by the exsitu method. The aerogel samples were characterized by scanning electron microscope, Fourier transform infrared spectroscopy, X-ray diffractometer, automatic specific surface area, and compression test. Taking the degradation of methylene blue (MB) as a model pollutant, the photocatalytic performance of 6wt%Cu2O-PVA/CNF composite catalyst was evaluated, the effects of different initial concentrations, catalyst dosages and solution pH conditions on the photodegradation of MB were investigated. The results show that the use of the three-dimensional porous cellulose aerogel improves the adsorption capacity of MB and prolongs the absorption of visible light. In particular, Cu2O doped in the cellulose matrix excites electron-holes under light, which increases the active sites, thereby improving the catalytic ability. The photodegradation rate of 6wt%Cu2O-PVA/CNF composite catalyst to MB reaches 95.6%, which is much higher than 79.6% of pure Cu2O. The photodegradation process of Cu2O-PVA/CNF composite catalyst follows the apparent quasi-first order dynamics model. In addition, compared with pure CNF aerogel, the addition of PVA increases its compressive strength by 4.4 times. The catalyst is reused after 5 photocatalytic cycles, and the visible light catalytic degradation rate of MB can still reach 71.06%. The Cu2O-PVA/CNF composite material is beneficial to the treatment of dye wastewater by solar radiation.

In order to improve the photocatalytic performance of cuprous oxide (Cu2O), Cu2O particles and polyvinyl alcohol (PVA) were added to nanocellulose (CNF) at the same time, and a functionalized cellulose-based aerogel (Cu2O-PVA/CNF) with three-dimensional (3D) porous structure and abundant active sites were successfully prepared by the exsitu method. The aerogel samples were characterized by scanning electron microscope, Fourier transform infrared spectroscopy, X-ray diffractometer, automatic specific surface area, and compression test. Taking the degradation of methylene blue (MB) as a model pollutant, the photocatalytic performance of 6wt%Cu2O-PVA/CNF composite catalyst was evaluated, the effects of different initial concentrations, catalyst dosages and solution pH conditions on the photodegradation of MB were investigated. The results show that the use of the three-dimensional porous cellulose aerogel improves the adsorption capacity of MB and prolongs the absorption of visible light. In particular, Cu2O doped in the cellulose matrix excites electron-holes under light, which increases the active sites, thereby improving the catalytic ability. The photodegradation rate of 6wt%Cu2O-PVA/CNF composite catalyst to MB reaches 95.6%, which is much higher than 79.6% of pure Cu2O. The photodegradation process of Cu2O-PVA/CNF composite catalyst follows the apparent quasi-first order dynamics model. In addition, compared with pure CNF aerogel, the addition of PVA increases its compressive strength by 4.4 times. The catalyst is reused after 5 photocatalytic cycles, and the visible light catalytic degradation rate of MB can still reach 71.06%. The Cu2O-PVA/CNF composite material is beneficial to the treatment of dye wastewater by solar radiation.

2023, 40(1): 192-200.

doi: 10.13801/j.cnki.fhclxb.20220214.003

Abstract:

Hard@soft composite carbon can improve the potassium storage performance synergistically by combining the advantage of hard carbon and soft carbon. But the potassium storage mechanism of different composite structure is lack. Here, rhodanine and F127 were used as the precursor of hard carbon, and the volatile matter of coal tar pitch was used as the precursor of soft carbon. Hard carbon, soft/hard hybrid carbon and soft carbon shell@hard carbon core composite were fabricated using co-carbonization and chemical vapor deposition. When used as the anode materials of potassium-ion battery, soft carbon shell@hard carbon core composite possesses high reversible capacity (365 mA·h·g−1 at 0.05 A·g−1), high cyclic stability (80% after 100 cycles), and excellent rate performance (177 mA·h·g−1 at 1 A·g−1). It can be ascribed to the abundance of active sites of hard carbon and the coating of soft carbon on the defect sites at the surface of hard carbon. Moreover, the soft carbon can improve the conductivity of the composite, which can enhance the rate performance of composite anode and release the voltage hysteresis. Benefiting from the synergistic potassium storage, soft carbon shell@hard carbon core composite anode shows much better performance than hard carbon anode.

Hard@soft composite carbon can improve the potassium storage performance synergistically by combining the advantage of hard carbon and soft carbon. But the potassium storage mechanism of different composite structure is lack. Here, rhodanine and F127 were used as the precursor of hard carbon, and the volatile matter of coal tar pitch was used as the precursor of soft carbon. Hard carbon, soft/hard hybrid carbon and soft carbon shell@hard carbon core composite were fabricated using co-carbonization and chemical vapor deposition. When used as the anode materials of potassium-ion battery, soft carbon shell@hard carbon core composite possesses high reversible capacity (365 mA·h·g−1 at 0.05 A·g−1), high cyclic stability (80% after 100 cycles), and excellent rate performance (177 mA·h·g−1 at 1 A·g−1). It can be ascribed to the abundance of active sites of hard carbon and the coating of soft carbon on the defect sites at the surface of hard carbon. Moreover, the soft carbon can improve the conductivity of the composite, which can enhance the rate performance of composite anode and release the voltage hysteresis. Benefiting from the synergistic potassium storage, soft carbon shell@hard carbon core composite anode shows much better performance than hard carbon anode.

2023, 40(1): 201-211.

doi: 10.13801/j.cnki.fhclxb.20220216.001

Abstract:

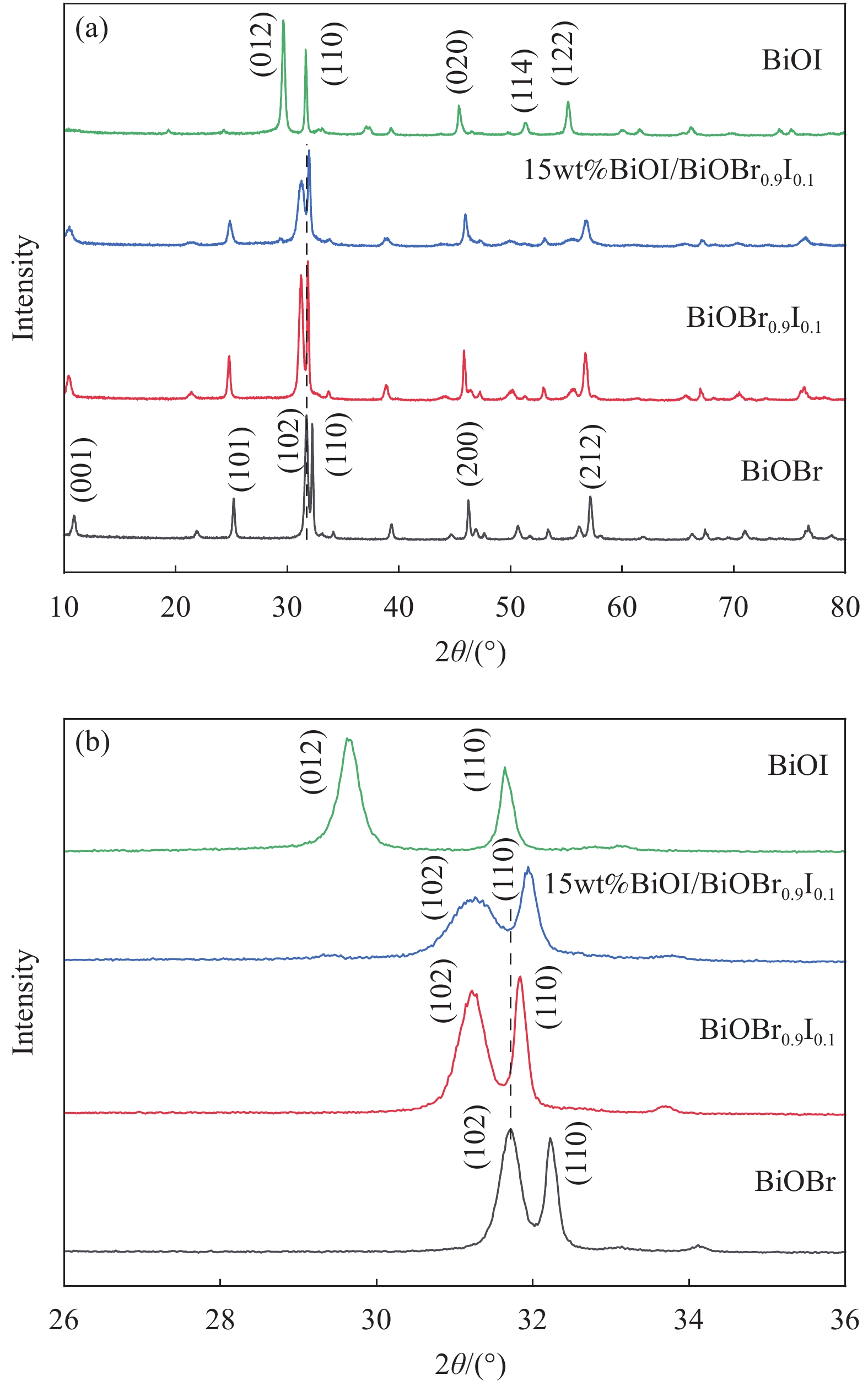

The pollution of pesticides seriously threatens the ecological environment and drinking water safety. A novel and efficient photocatalyst of BiOI/BiOBr0.9I0.1 was prepared through solvothermal method. The physicochemical properties, such as structure, morphology and optical properties, were characterized by detections of XRD, SEM, XPS, UV-vis DRS, PL, EIS, etc. The BiOI/BiOBr0.9I0.1 synthesized has a cluster-like accumulation structure, which facilitates the increase of active sites. The combination of solid solution and heterojunction broadens the photoresponse range of BiOBr, effectively prevents the recombination of photogenerated electron-hole pairs inside BiOI/BiOBr0.9I0.1 and improves the redox ability of photogenerated carriers. The results of photocatalytic experiments show that 15wt%BiOI/BiOBr0.9I0.1 reaches the best photocatalytic performance for 2,4-dichlorophenoxyacetic acid (2,4-D) under visible light, and the degradation efficiency of 2,4-D can reach 95% within 120 min. Furthermore, the degradation rate still reaches 80.9% after four cycles of experiments. According to the results of capture experiments and electron spin-resonance (ESR) tests, it can be confirmed that •O2− and h+ are the main active species. The BiOBr0.9I0.1 synthesized can effectively modulate the energy band structure of BiOBr. The heterojunction composed of BiOBr0.9I0.1 and BiOI is consistent with the characteristics of Z-scheme heterojunction, and the synergistic effect between the two strategies of constructing heterojunction and solid solution can be produced in enhancing the photocatalytic activity of BiOBr.

The pollution of pesticides seriously threatens the ecological environment and drinking water safety. A novel and efficient photocatalyst of BiOI/BiOBr0.9I0.1 was prepared through solvothermal method. The physicochemical properties, such as structure, morphology and optical properties, were characterized by detections of XRD, SEM, XPS, UV-vis DRS, PL, EIS, etc. The BiOI/BiOBr0.9I0.1 synthesized has a cluster-like accumulation structure, which facilitates the increase of active sites. The combination of solid solution and heterojunction broadens the photoresponse range of BiOBr, effectively prevents the recombination of photogenerated electron-hole pairs inside BiOI/BiOBr0.9I0.1 and improves the redox ability of photogenerated carriers. The results of photocatalytic experiments show that 15wt%BiOI/BiOBr0.9I0.1 reaches the best photocatalytic performance for 2,4-dichlorophenoxyacetic acid (2,4-D) under visible light, and the degradation efficiency of 2,4-D can reach 95% within 120 min. Furthermore, the degradation rate still reaches 80.9% after four cycles of experiments. According to the results of capture experiments and electron spin-resonance (ESR) tests, it can be confirmed that •O2− and h+ are the main active species. The BiOBr0.9I0.1 synthesized can effectively modulate the energy band structure of BiOBr. The heterojunction composed of BiOBr0.9I0.1 and BiOI is consistent with the characteristics of Z-scheme heterojunction, and the synergistic effect between the two strategies of constructing heterojunction and solid solution can be produced in enhancing the photocatalytic activity of BiOBr.

2023, 40(1): 212-218.

doi: 10.13801/j.cnki.fhclxb.20220225.004

Abstract:

With the aggravation of environmental pollution, the development and application of recycled polyester fibers based on bottle chip is of great significance. In this paper, recycled polyester hollow fibers and skin core type heat-bonded fibers were used as raw materials to prepare sound absorbing materials with multi-scale micropores by hot air consolidation. The structure and properties of polyester hollow fibers were characterized. Standing wave tube method was used to study the relationship between linear density and sound absorbing effect of hollow fibers, and a "multistage" sound absorbing theory was proposed. The results show that the hollow fibers with the linear density of 10 D has the largest hollowness, the best toughness and the best sound absorption effect. The sound absorption coefficient and noise reduction coefficient increase linearly with the increase of thickness. When the thickness is 2 cm, the noise reduction coefficient (NRC) is greater than 0.5, which is expected to become an ideal sound absorption material.

With the aggravation of environmental pollution, the development and application of recycled polyester fibers based on bottle chip is of great significance. In this paper, recycled polyester hollow fibers and skin core type heat-bonded fibers were used as raw materials to prepare sound absorbing materials with multi-scale micropores by hot air consolidation. The structure and properties of polyester hollow fibers were characterized. Standing wave tube method was used to study the relationship between linear density and sound absorbing effect of hollow fibers, and a "multistage" sound absorbing theory was proposed. The results show that the hollow fibers with the linear density of 10 D has the largest hollowness, the best toughness and the best sound absorption effect. The sound absorption coefficient and noise reduction coefficient increase linearly with the increase of thickness. When the thickness is 2 cm, the noise reduction coefficient (NRC) is greater than 0.5, which is expected to become an ideal sound absorption material.

2023, 40(1): 219-231.

doi: 10.13801/j.cnki.fhclxb.20220117.001

Abstract:

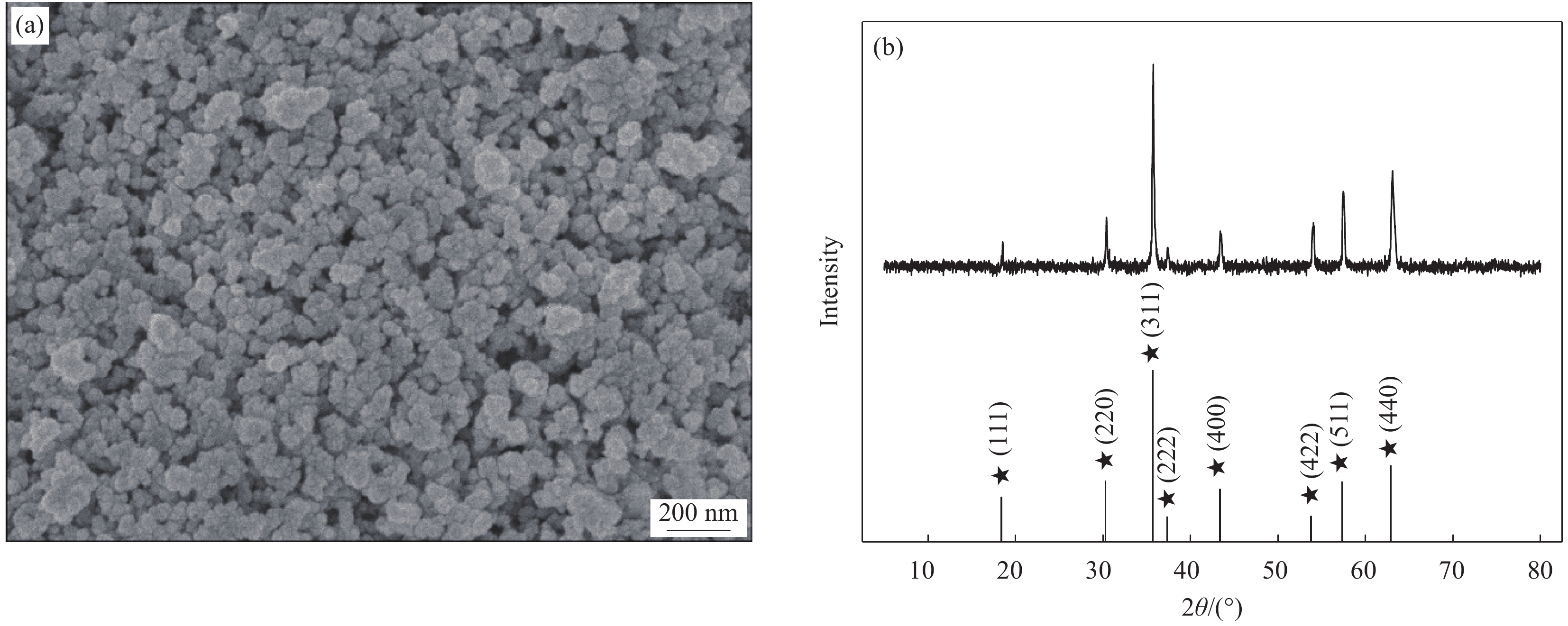

In order to solve the problem that Fe3O4 nanoparticles were easy to be corroded and agglomerated, it was decided to functionalize it. Magnetic nano-Fe3O4 particles were prepared under ultrasonic irradiation, then 2-diaminobenzenesulfonic acid (SP) and m-phenylenediamine (mPD) monomers were selected as introduction agents to prepare metal matrix composites Fe3O4-mPD/SP(95∶5), which were rich in amino, sulfonic acid and imine active functional groups, and nanocomposites were characterized by FTIR, TEM, XRD and other methods. The characterized results show that the magnetic nanocomposites prepared by ultrasonic strengthening method have the characteristics of good stability, high reaction activity, small particle size and larger specific surface area. The adsorption properties of Pb(II) by Fe3O4-mPD/SP were investigated which showed that the molar percentage of SP and mPD, reaction temperature, sorts of competitive cations and the pH value of solution all had effect on the adsorption of Pb(II). The adsorption isotherm conforms to the Freundlich model, and the adsorption of Pb(II) is a spontaneous process, Gibbs free energy ∆G0<0. It is found that the adsorption behavior of Pb(II) on nanocomposites can be well described by quasi secondary dynamics equation, kinetic constant k2=3.61×10−3 g·mg−1·min−1, equilibrium adsorption capacity qe=63.297 mg·g−1. It is speculated that the adsorption mechanism of this adsorbent includes ion exchange, complex adsorption and electrostatic adsorption.

In order to solve the problem that Fe3O4 nanoparticles were easy to be corroded and agglomerated, it was decided to functionalize it. Magnetic nano-Fe3O4 particles were prepared under ultrasonic irradiation, then 2-diaminobenzenesulfonic acid (SP) and m-phenylenediamine (mPD) monomers were selected as introduction agents to prepare metal matrix composites Fe3O4-mPD/SP(95∶5), which were rich in amino, sulfonic acid and imine active functional groups, and nanocomposites were characterized by FTIR, TEM, XRD and other methods. The characterized results show that the magnetic nanocomposites prepared by ultrasonic strengthening method have the characteristics of good stability, high reaction activity, small particle size and larger specific surface area. The adsorption properties of Pb(II) by Fe3O4-mPD/SP were investigated which showed that the molar percentage of SP and mPD, reaction temperature, sorts of competitive cations and the pH value of solution all had effect on the adsorption of Pb(II). The adsorption isotherm conforms to the Freundlich model, and the adsorption of Pb(II) is a spontaneous process, Gibbs free energy ∆G0<0. It is found that the adsorption behavior of Pb(II) on nanocomposites can be well described by quasi secondary dynamics equation, kinetic constant k2=3.61×10−3 g·mg−1·min−1, equilibrium adsorption capacity qe=63.297 mg·g−1. It is speculated that the adsorption mechanism of this adsorbent includes ion exchange, complex adsorption and electrostatic adsorption.

2023, 40(1): 232-243.

doi: 10.13801/j.cnki.fhclxb.20220120.007

Abstract:

A multiwalled carbon nanotubes (MWCNT)/natural rubber (NR) composite was prepared by two-roll method to achieve effective monitoring for the working performance of isolation bearings. The resistance-strain response behaviors of MWCNT/NR composites under constant strain and interval loading were studied. The results show that the stability, repeatability, monotonicity, symmetry and ‘shoulder peak’ effect of the resistance-strain response are depended on the constant strain loading. The variation amplitude of resistance tends to be stable with the increase of interval time, and the change of the amplitude can effectively be predicted via the theoretical model established. The piezoresistance behaviors for MWCNT/NR composite under different delamination forms show distinct characteristic, and the response mechanism is explained by Digimat and Workbench. A mathematical model that can completely characterize and predict the dynamic resistance-strain response was established and verified based on viscoelasticity of NR and conductivity network of MWCNT. The analytical results obtained by mathematical model are in good agreement with the experimental results, which lay a theoretical foundation for the industrial application of MWCNT/NR composites.

A multiwalled carbon nanotubes (MWCNT)/natural rubber (NR) composite was prepared by two-roll method to achieve effective monitoring for the working performance of isolation bearings. The resistance-strain response behaviors of MWCNT/NR composites under constant strain and interval loading were studied. The results show that the stability, repeatability, monotonicity, symmetry and ‘shoulder peak’ effect of the resistance-strain response are depended on the constant strain loading. The variation amplitude of resistance tends to be stable with the increase of interval time, and the change of the amplitude can effectively be predicted via the theoretical model established. The piezoresistance behaviors for MWCNT/NR composite under different delamination forms show distinct characteristic, and the response mechanism is explained by Digimat and Workbench. A mathematical model that can completely characterize and predict the dynamic resistance-strain response was established and verified based on viscoelasticity of NR and conductivity network of MWCNT. The analytical results obtained by mathematical model are in good agreement with the experimental results, which lay a theoretical foundation for the industrial application of MWCNT/NR composites.

2023, 40(1): 244-254.

doi: 10.13801/j.cnki.fhclxb.20220120.005

Abstract:

To cope with the increasing frequency of oil spills and to achieve the purification of oily waters, FeNi2O4−doped vinyl methacrylate-diethylenebenzene copolymer porous materials were fabricated via a high-internal-phase Pickering emulsion templating method. The material structure was characterised using FTIR, SEM, TGA, VSM, contact angle measurement, static mercury piezometry and universal testing machine. The results show that the material possesses a three-dimensional porous structure with pore sizes mainly distributed at 3 μm and 6-14 μm, and the large pore size can be modified. The material demonstrates good thermal stability with an initial thermal decomposition temperature of up to 300℃. The introduction of FeNi2O4 nanoparticles not only enhances the emulsion stability but also imparts magnetic responsiveness to the material. The materials exhibit good hydrophobicity and lipophilicity, with water contact angle of 151°, rolling angle of 5° and oil contact angle of 0°, fast oil absorption rate, good reusability and excellent oil-water adsorption selectivity. Its saturation adsorption multiplicity for a variety of oils and organic solvents reaches 40.80-93.08 g·g−1, and the oil retention rate are all above 90%. The pore structure regulation of the material was investigated and it was found that changing the internal comparison of the emulsion could regulate the macropore distribution, porosity, density, specific surface area, oil adsorption multiplicity and mechanical property of the material. In summary, superhydrophobic FeNi2O4/vinyl methacrylate-diethylenebenzene copolymer porous materials can efficiently separate oil from water, which is of practical significance for the treatment and purification of the aqueous environment.

To cope with the increasing frequency of oil spills and to achieve the purification of oily waters, FeNi2O4−doped vinyl methacrylate-diethylenebenzene copolymer porous materials were fabricated via a high-internal-phase Pickering emulsion templating method. The material structure was characterised using FTIR, SEM, TGA, VSM, contact angle measurement, static mercury piezometry and universal testing machine. The results show that the material possesses a three-dimensional porous structure with pore sizes mainly distributed at 3 μm and 6-14 μm, and the large pore size can be modified. The material demonstrates good thermal stability with an initial thermal decomposition temperature of up to 300℃. The introduction of FeNi2O4 nanoparticles not only enhances the emulsion stability but also imparts magnetic responsiveness to the material. The materials exhibit good hydrophobicity and lipophilicity, with water contact angle of 151°, rolling angle of 5° and oil contact angle of 0°, fast oil absorption rate, good reusability and excellent oil-water adsorption selectivity. Its saturation adsorption multiplicity for a variety of oils and organic solvents reaches 40.80-93.08 g·g−1, and the oil retention rate are all above 90%. The pore structure regulation of the material was investigated and it was found that changing the internal comparison of the emulsion could regulate the macropore distribution, porosity, density, specific surface area, oil adsorption multiplicity and mechanical property of the material. In summary, superhydrophobic FeNi2O4/vinyl methacrylate-diethylenebenzene copolymer porous materials can efficiently separate oil from water, which is of practical significance for the treatment and purification of the aqueous environment.

2023, 40(1): 255-269.

doi: 10.13801/j.cnki.fhclxb.20220101.001

Abstract:

The powdered LaFeO3 material had shortcomings such as easy agglomeration and difficult separation, so it was limited in large-scale applications. The deposition of powdered catalysts in polystyrene resin (PS) made up for the above shortcomings of powdered materials. Therefore, in this study, the self-assembled LaFeO3 gel was deposited on the PS through ultrasound-assisted sol-gel and hydrothermal methods. The dispersion and distribution of LaFeO3 on PS broadens the forbidden band width of LaFeO3, improves its redox ability, solves the problem of agglomeration, and consequently improves its photo-Fenton catalytic activity. The LaFeO3/PS composite prepared under the following experimental conditions shows the highest photocatalytic activity: La∶Fe∶Citric acid(CA) molar ratio=1∶1∶2, ultrasonic time 40 min, hydrothermal temperature 90℃, hydrothermal time 18 h, LaFeO3 initiator/polystyrene mass ratio=32∶1. The removal rate of tetracycline hydrochloride (TC) is up to 96.51%(rate of degradation k=0.0160 min−1) under visible light irradiation in the Fenton process catalyzed by LaFeO3/PS. Free radical capture experiments show that •O2− is the main active species. According to the capture experiment, the degradation mechanism of TC was proposed. Through LC/MS analysis, the degradation path of TC was obtained. The photo-Fenton process catalyzed by LaFeO3/PS is a promising technology for the degradation of organic pollutants due to the high stability of the catalyst and the efficient use of solar energy.

The powdered LaFeO3 material had shortcomings such as easy agglomeration and difficult separation, so it was limited in large-scale applications. The deposition of powdered catalysts in polystyrene resin (PS) made up for the above shortcomings of powdered materials. Therefore, in this study, the self-assembled LaFeO3 gel was deposited on the PS through ultrasound-assisted sol-gel and hydrothermal methods. The dispersion and distribution of LaFeO3 on PS broadens the forbidden band width of LaFeO3, improves its redox ability, solves the problem of agglomeration, and consequently improves its photo-Fenton catalytic activity. The LaFeO3/PS composite prepared under the following experimental conditions shows the highest photocatalytic activity: La∶Fe∶Citric acid(CA) molar ratio=1∶1∶2, ultrasonic time 40 min, hydrothermal temperature 90℃, hydrothermal time 18 h, LaFeO3 initiator/polystyrene mass ratio=32∶1. The removal rate of tetracycline hydrochloride (TC) is up to 96.51%(rate of degradation k=0.0160 min−1) under visible light irradiation in the Fenton process catalyzed by LaFeO3/PS. Free radical capture experiments show that •O2− is the main active species. According to the capture experiment, the degradation mechanism of TC was proposed. Through LC/MS analysis, the degradation path of TC was obtained. The photo-Fenton process catalyzed by LaFeO3/PS is a promising technology for the degradation of organic pollutants due to the high stability of the catalyst and the efficient use of solar energy.

2023, 40(1): 270-279.

doi: 10.13801/j.cnki.fhclxb.20220110.002

Abstract:

Based on the large number of reactive hydroxyl of green and low cost of tannin, its hold the similar mechanism as phenol and resorcinol reacted with formaldehyde. On the basis of carbon cryogels from traditional phenolic resin (phenol-urea-formaldehyde), a new type of carbon cryogels for efficient CO2 capture were successfully prepared by tannin modification. The surface chemistry and pore structure of carbon aerogel were characterized by scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR) and nitrogen adsorption and desorption analysis. The adsorption capacity, selectivity and adsorption heat of carbon cryogel were studied by carbon dioxide adsorption and desorption analysis. The results show that the new and efficient phenolic carbon cryogel can be prepared by using green and renewable biomass raw material tannin to partially replace the traditional phenol or resorcinol, which can not only significantly reduce the product cost, but also significantly improve the carbon dioxide adsorption performance. When the addition amount of tannin (15 g) is 50wt% of that of phenol, the sample has the maximum specific surface area (1376.31 m2·g−1) and micropore volume (0.55 cm3·g−1), which is a potential gas adsorption material. The corresponding CO2 adsorption capacity is as high as 5.36 mmol·g−1, and the selective adsorption and adsorption heat are 16.84 and 34.49 kJ·mol−1, respectively. The properties of phenolic carbon aerogels are significantly better than those of unmodified phenolic carbon aerogels, and also better than most of the traditional carbon aerogels. This is mainly attributed to its high specific surface area, micropore volume, suitable pore size distribution and good 3D network structure.

Based on the large number of reactive hydroxyl of green and low cost of tannin, its hold the similar mechanism as phenol and resorcinol reacted with formaldehyde. On the basis of carbon cryogels from traditional phenolic resin (phenol-urea-formaldehyde), a new type of carbon cryogels for efficient CO2 capture were successfully prepared by tannin modification. The surface chemistry and pore structure of carbon aerogel were characterized by scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR) and nitrogen adsorption and desorption analysis. The adsorption capacity, selectivity and adsorption heat of carbon cryogel were studied by carbon dioxide adsorption and desorption analysis. The results show that the new and efficient phenolic carbon cryogel can be prepared by using green and renewable biomass raw material tannin to partially replace the traditional phenol or resorcinol, which can not only significantly reduce the product cost, but also significantly improve the carbon dioxide adsorption performance. When the addition amount of tannin (15 g) is 50wt% of that of phenol, the sample has the maximum specific surface area (1376.31 m2·g−1) and micropore volume (0.55 cm3·g−1), which is a potential gas adsorption material. The corresponding CO2 adsorption capacity is as high as 5.36 mmol·g−1, and the selective adsorption and adsorption heat are 16.84 and 34.49 kJ·mol−1, respectively. The properties of phenolic carbon aerogels are significantly better than those of unmodified phenolic carbon aerogels, and also better than most of the traditional carbon aerogels. This is mainly attributed to its high specific surface area, micropore volume, suitable pore size distribution and good 3D network structure.

2023, 40(1): 280-289.

doi: 10.13801/j.cnki.fhclxb.20220112.001

Abstract:

Cu-Al2O3 composite has excellent conductivity and mechanical properties, and it widely used in the field of wear-resistant materials. In order to further improve the arc erosion resistance of composite under the condition of electro-friction, CNTs/Cu-Al2O3 composites with different contents of carbon nanotubes (CNTs) were prepared by internal oxidation combining with powder metallurgy. The distribution of reinforcing phase and the interface between CNTs and matrix in CNTs/Cu-Al2O3 composites were observed. The conductivity and mechanical properties of Cu-Al2O3 composites effected by CNTs were studied. The arc erosion resistance mechanism of CNTs/Cu-Al2O3 composites was mainly explored. The results show that in-situ nano-Al2O3 particles pin dislocation, CNTs are dispersed in the copper matrix due to the regulation of CNTs distribution by Al2O3 particles. Compared with Cu-Al2O3 composites, the arc duration and energy of CNTs/Cu-Al2O3 composites are obviously reduced and fluctuate more stable. In the process of arc erosion, CNTs in the molten pool will float to the surface to disperse the arc and reduce the concentrated erosion area. Nano-Al2O3 particles can stabilize the molten pool, reduce the splash of molten droplets and the mass loss of CNTs/Cu-Al2O3 composites. Among them, CNTs/Cu-3.5Al2O3 composites with 1.2vol%CNTs has the lowest and most stable arc duration and energy. This research result provides a favorable theoretical basis for the research of ablation resistant materials.

Cu-Al2O3 composite has excellent conductivity and mechanical properties, and it widely used in the field of wear-resistant materials. In order to further improve the arc erosion resistance of composite under the condition of electro-friction, CNTs/Cu-Al2O3 composites with different contents of carbon nanotubes (CNTs) were prepared by internal oxidation combining with powder metallurgy. The distribution of reinforcing phase and the interface between CNTs and matrix in CNTs/Cu-Al2O3 composites were observed. The conductivity and mechanical properties of Cu-Al2O3 composites effected by CNTs were studied. The arc erosion resistance mechanism of CNTs/Cu-Al2O3 composites was mainly explored. The results show that in-situ nano-Al2O3 particles pin dislocation, CNTs are dispersed in the copper matrix due to the regulation of CNTs distribution by Al2O3 particles. Compared with Cu-Al2O3 composites, the arc duration and energy of CNTs/Cu-Al2O3 composites are obviously reduced and fluctuate more stable. In the process of arc erosion, CNTs in the molten pool will float to the surface to disperse the arc and reduce the concentrated erosion area. Nano-Al2O3 particles can stabilize the molten pool, reduce the splash of molten droplets and the mass loss of CNTs/Cu-Al2O3 composites. Among them, CNTs/Cu-3.5Al2O3 composites with 1.2vol%CNTs has the lowest and most stable arc duration and energy. This research result provides a favorable theoretical basis for the research of ablation resistant materials.

2023, 40(1): 290-299.

doi: 10.13801/j.cnki.fhclxb.20220124.003

Abstract:

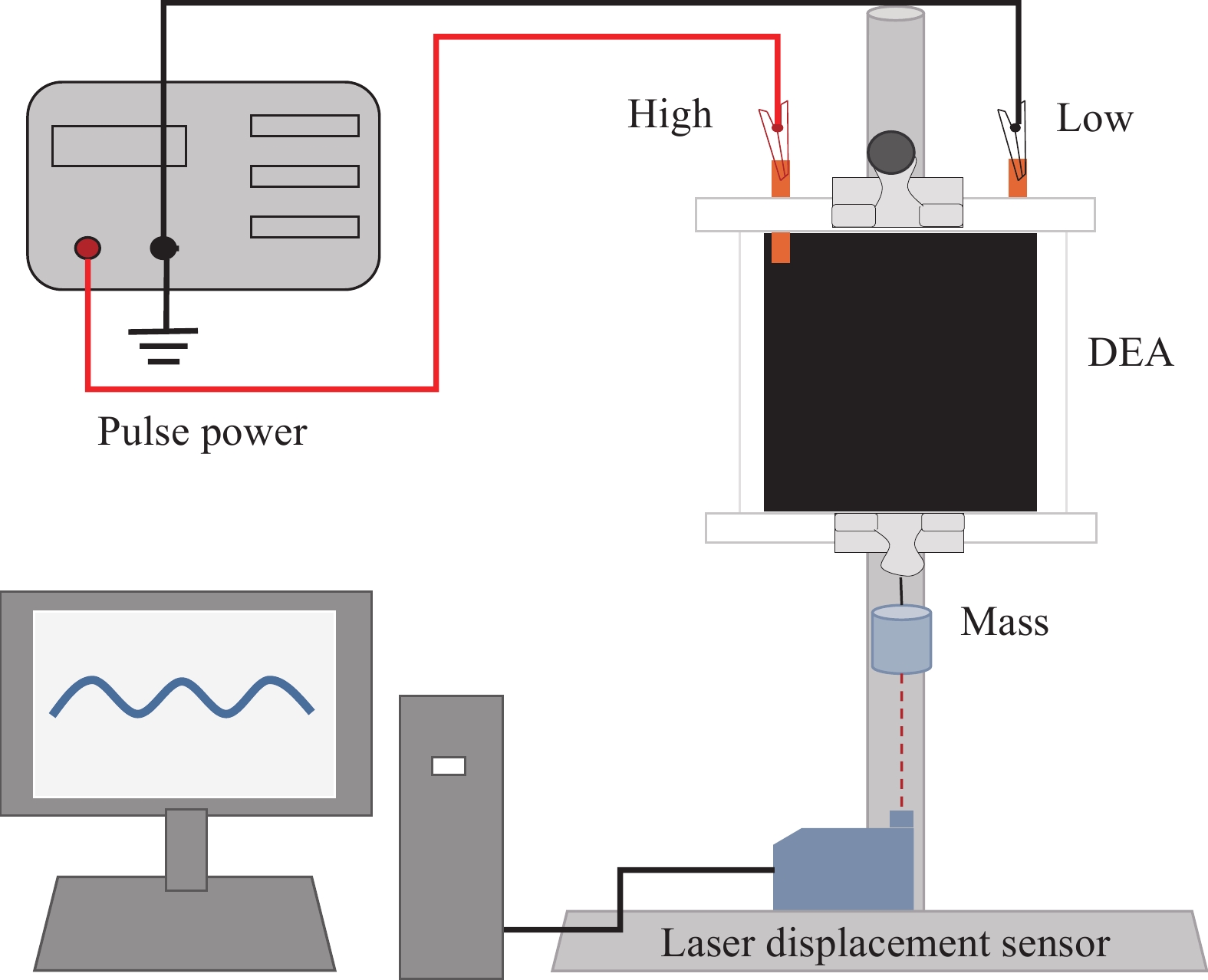

Flexible electrode of dielectric elastomer actuator (DEA) plays important roles in generating electric fields and constraining dielectric matrix deformation. By using one-dimensional multi-wall carbon nanotubes (MWCNT) and zero-dimensional conductive carbon black (CB) as co-conductive fillers, a series of polydimethyl siloxane (PDMS) composite electrode films (MWCNT-CB/PDMS) were designed with varying size, mechanical and electrical properties. The electrode films were adhered to the lateral surfaces of a polyvinyl chloride gel matrix film and imported into a pulsed high-voltage signal to obtain novel dielectric polymer actuators with various electromechanical behaviors. Tests of electromechanical properties reveal that, the increase of electrode coverage is beneficial to DEA’s strain, the increase of electrode thickness hampers its strain, while the strain exhibits an initial increase following decrease trend with increasing MWCNT loading. Orthogonal experiments show that, the MWCNT loading has a significant effect on the displacement output, while the electrode coverage and thickness present high-level significances to the displacement output. Under the optimal condition, the displacement output of DEA is 1.71 mm at maximum.

Flexible electrode of dielectric elastomer actuator (DEA) plays important roles in generating electric fields and constraining dielectric matrix deformation. By using one-dimensional multi-wall carbon nanotubes (MWCNT) and zero-dimensional conductive carbon black (CB) as co-conductive fillers, a series of polydimethyl siloxane (PDMS) composite electrode films (MWCNT-CB/PDMS) were designed with varying size, mechanical and electrical properties. The electrode films were adhered to the lateral surfaces of a polyvinyl chloride gel matrix film and imported into a pulsed high-voltage signal to obtain novel dielectric polymer actuators with various electromechanical behaviors. Tests of electromechanical properties reveal that, the increase of electrode coverage is beneficial to DEA’s strain, the increase of electrode thickness hampers its strain, while the strain exhibits an initial increase following decrease trend with increasing MWCNT loading. Orthogonal experiments show that, the MWCNT loading has a significant effect on the displacement output, while the electrode coverage and thickness present high-level significances to the displacement output. Under the optimal condition, the displacement output of DEA is 1.71 mm at maximum.

2023, 40(1): 300-309.

doi: 10.13801/j.cnki.fhclxb.20220222.002

Abstract:

The massive accumulation of industrial solid waste semi-coke ash (SCA) will cause damage to local ecological environment. To promote the large-scale consumption of industrial solid waste semi-coke ash and fabricate low-cost shape-stable phase change composites (SSPCCs), semi-coke ash was innovatively proposed as a skeleton material to fabricate the SSPCCs. To evaluate the feasibility of the semi-coke ash as the skeleton material of the SSPCCs, eight NaNO3/semi-coke ash SSPCC samples with different mass ratio of the semi-coke ash to NaNO3 were fabricated. The key performance of the NaNO3/semi-coke ash SSPCCs were investigated by the differential scanning calorimetry, laser flash analysis, scanning electron microscopy, constant speed pressurization method and X-ray diffraction. Results show that the sample NaNO3/SCA-50 without visual leakage and deformation holds the optimal mass ratio 5:5 of the semi-coke ash to NaNO3 with the thermal energy storage capacity of 338.24 J/g ranging from 100 to 380℃ and the mechanical strength of 96.98 MPa. After 4027 heating/cooling cycles, the sample NaNO3/SCA-50 keeps good thermal stability and chemical compatibility, which indicates that the semi-coke ash is feasible for the SSPCCs fabrication, and provides a new way for recycling the resource of the solid waste semi-coke ash.

The massive accumulation of industrial solid waste semi-coke ash (SCA) will cause damage to local ecological environment. To promote the large-scale consumption of industrial solid waste semi-coke ash and fabricate low-cost shape-stable phase change composites (SSPCCs), semi-coke ash was innovatively proposed as a skeleton material to fabricate the SSPCCs. To evaluate the feasibility of the semi-coke ash as the skeleton material of the SSPCCs, eight NaNO3/semi-coke ash SSPCC samples with different mass ratio of the semi-coke ash to NaNO3 were fabricated. The key performance of the NaNO3/semi-coke ash SSPCCs were investigated by the differential scanning calorimetry, laser flash analysis, scanning electron microscopy, constant speed pressurization method and X-ray diffraction. Results show that the sample NaNO3/SCA-50 without visual leakage and deformation holds the optimal mass ratio 5:5 of the semi-coke ash to NaNO3 with the thermal energy storage capacity of 338.24 J/g ranging from 100 to 380℃ and the mechanical strength of 96.98 MPa. After 4027 heating/cooling cycles, the sample NaNO3/SCA-50 keeps good thermal stability and chemical compatibility, which indicates that the semi-coke ash is feasible for the SSPCCs fabrication, and provides a new way for recycling the resource of the solid waste semi-coke ash.

2023, 40(1): 310-322.

doi: 10.13801/j.cnki.fhclxb.20220223.002

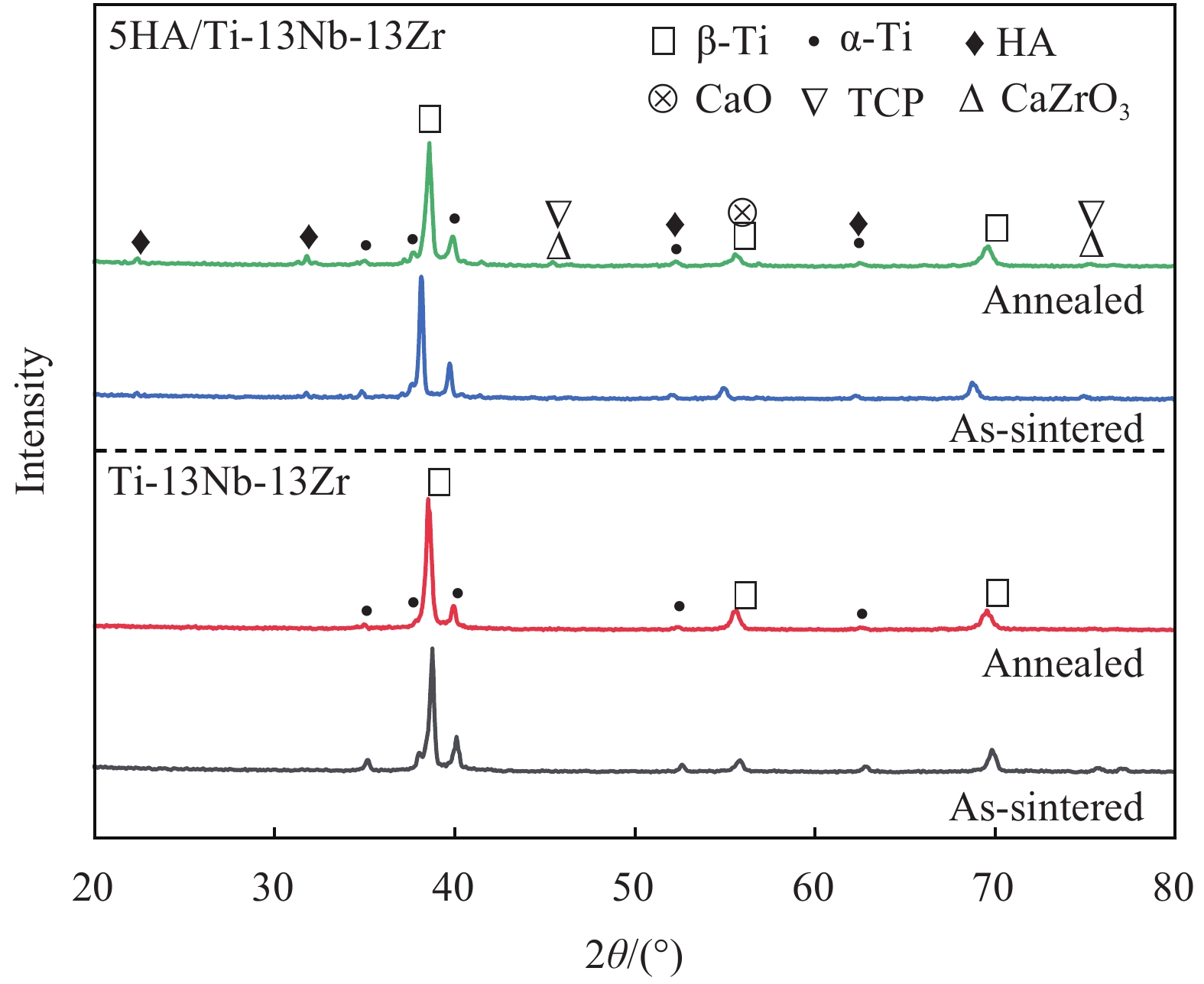

Abstract: