2020 Vol. 37, No. 8

2020, 37(8): 1-5.

Abstract:

2020, 37(8): 1981-1988.

doi: 10.13801/j.cnki.fhclxb.20191129.002

Abstract:

The TiO2-g-C3N4 composites were prepared by a uniform precipitation method and the structure and morphology were characterized for g-C3N4 and TiO2-g-C3N4 composites by XRD and SEM. The photocatalytic activity of the as-prepared sample was evaluated by degradation of methyl orange under simulated sunlight. The composites with high catalytic performance were combined with the cement stone surface to obtain the photocatalytic cement stone. The results show that the TiO2-g-C3N4 composites prepared at 300℃ and 400℃ have strong heterojunctions, and N-doped TiO2 was produced at 500℃. The best photocatalytic activity of TiO2-g-C3N4 composites was obtained at 400℃, and the degradation rate reaches 91% under the simulated sunlight for 60 min. By fitting calculation, it is found that the photocatalytic rate of TiO2-g-C3N4 composites obtained at 400℃ is the fastest. The cement stone combined with the TiO2-g-C3N4 composites obtained at 400℃ still have good catalytic degradation performance, and the degradation rate can reach more than 90% under the simulated sunlight for 240 minutes. The TiO2-g-C3N4 composites can reduce the initial setting and final setting time of the cement stone at 400°C and improve its compressive strength.

The TiO2-g-C3N4 composites were prepared by a uniform precipitation method and the structure and morphology were characterized for g-C3N4 and TiO2-g-C3N4 composites by XRD and SEM. The photocatalytic activity of the as-prepared sample was evaluated by degradation of methyl orange under simulated sunlight. The composites with high catalytic performance were combined with the cement stone surface to obtain the photocatalytic cement stone. The results show that the TiO2-g-C3N4 composites prepared at 300℃ and 400℃ have strong heterojunctions, and N-doped TiO2 was produced at 500℃. The best photocatalytic activity of TiO2-g-C3N4 composites was obtained at 400℃, and the degradation rate reaches 91% under the simulated sunlight for 60 min. By fitting calculation, it is found that the photocatalytic rate of TiO2-g-C3N4 composites obtained at 400℃ is the fastest. The cement stone combined with the TiO2-g-C3N4 composites obtained at 400℃ still have good catalytic degradation performance, and the degradation rate can reach more than 90% under the simulated sunlight for 240 minutes. The TiO2-g-C3N4 composites can reduce the initial setting and final setting time of the cement stone at 400°C and improve its compressive strength.

2020, 37(8): 1989-1996.

doi: 10.13801/j.cnki.fhclxb.20191206.005

Abstract:

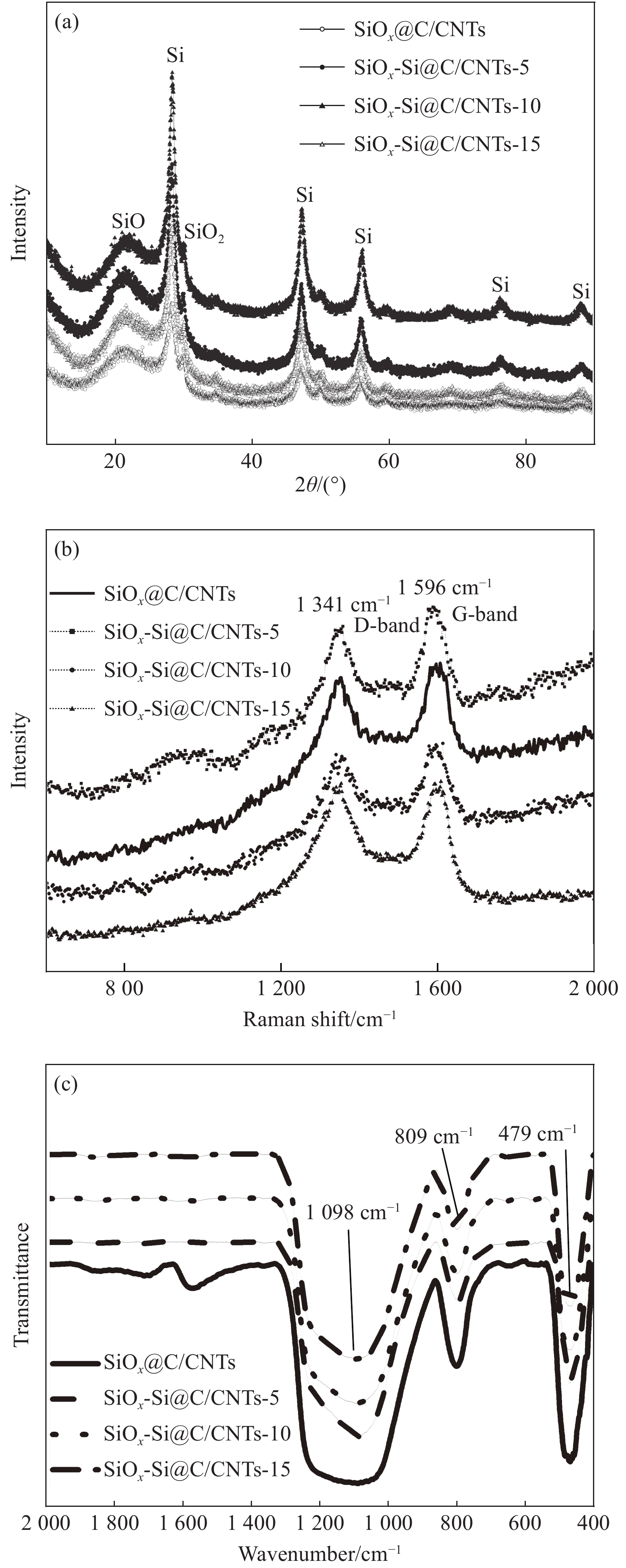

Based on the carbon coating and addition of conductive materials, a small amount of nano-Si was doped to further improve the first charge and discharge capacity and the first coulombic efficiency. The phase structure and micromorphology of the materials were analyzed by XRD, SEM, TEM, Raman and FTIR, and the electrochemical properties of the composites were analyzed by a constant current charge-discharge test. The results show that the composites with 10% nano-Si (SiOx-Si@C@carbon nanotubes(CNTs)-10) exhibit a first charge and discharge capacity of 1 348.1 mA•h/g and 1 874.4 mA•h/g, respectively, with the first coulombic efficiency of 71.9%. After 100 cycles, the reversible capacity of the composite is 1 116.2 mA•h/g, with the capacity retention rate of 82.8%. The discharge capacity is much higher than that of the material without nano-Si doping at different current densities. The SiOx-Si@C@CNTs composites show high first coulombic efficiency, good cycle performance and rate performance.

Based on the carbon coating and addition of conductive materials, a small amount of nano-Si was doped to further improve the first charge and discharge capacity and the first coulombic efficiency. The phase structure and micromorphology of the materials were analyzed by XRD, SEM, TEM, Raman and FTIR, and the electrochemical properties of the composites were analyzed by a constant current charge-discharge test. The results show that the composites with 10% nano-Si (SiOx-Si@C@carbon nanotubes(CNTs)-10) exhibit a first charge and discharge capacity of 1 348.1 mA•h/g and 1 874.4 mA•h/g, respectively, with the first coulombic efficiency of 71.9%. After 100 cycles, the reversible capacity of the composite is 1 116.2 mA•h/g, with the capacity retention rate of 82.8%. The discharge capacity is much higher than that of the material without nano-Si doping at different current densities. The SiOx-Si@C@CNTs composites show high first coulombic efficiency, good cycle performance and rate performance.

2020, 37(8): 1997-2004.

doi: 10.13801/j.cnki.fhclxb.20191129.001

Abstract:

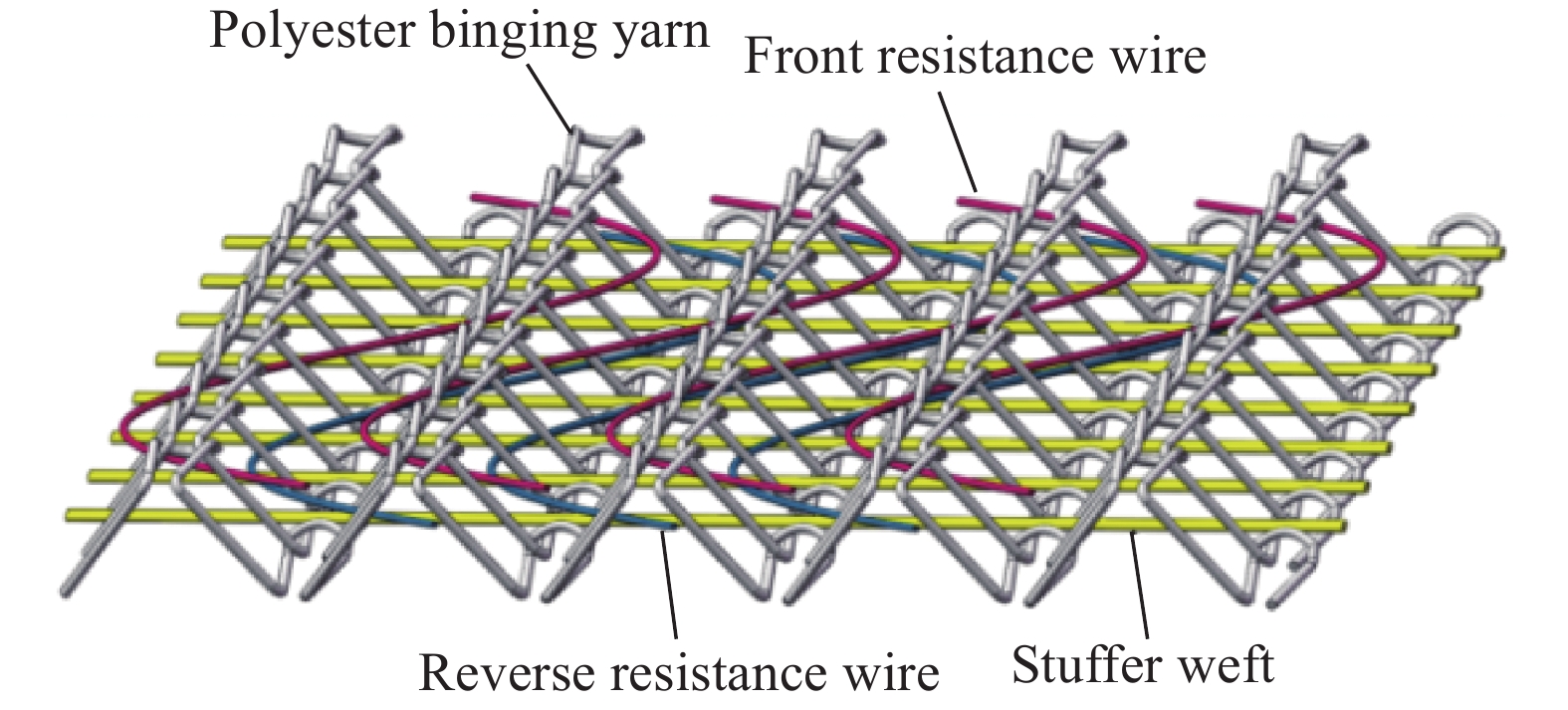

In order to develop a kind of electrically heated composites which can be used for anti-icing/de-icing protection of aircraft, three kinds of weft knitted biaxial fabric/epoxy resin composites were designed and prepared, and the effects of density of the resistance wire arrangement on the electrothermal properties and interlaminar shear properties of the composite were studied. The upper and lower layers of the electrically heated composite are glass fiber/epoxy resin prepreg, and the intermediate layer is electrically heated weft woven biaxial fabric, which is lined with warp yarn, binding yarn and weft yarn respectively using copper-nickel alloy wire, polyester fiber and glass fiber. Infrared temperature tester and material universal testing machine were used for the performance testing. The results show that: after applying voltage for 6 s, the surface temperature of the composite increases rapidly, and reaches the maximum equilibrium temperature around 60 s. The maximum equilibrium temperature of the composite surface is in direct proportion to the applied voltage; When the applied voltage is unchanged, the lower the density of the wire, the higher the maximum equilibrium temperature of the composite surface.The lower the arrangement density of the resistance wire, the greater the interlaminar shear strength of the composites. The density of the resistance wires is low, and the interlaminar shear strength of the composite is higher. The weft woven biaxial fabric/epoxy resin electrically heated composites has the characteristics of light weight, high strength, high heating rate, good formability and so on, which is suitable for anti-icing/de-icing of multiple parts of aircraft.

In order to develop a kind of electrically heated composites which can be used for anti-icing/de-icing protection of aircraft, three kinds of weft knitted biaxial fabric/epoxy resin composites were designed and prepared, and the effects of density of the resistance wire arrangement on the electrothermal properties and interlaminar shear properties of the composite were studied. The upper and lower layers of the electrically heated composite are glass fiber/epoxy resin prepreg, and the intermediate layer is electrically heated weft woven biaxial fabric, which is lined with warp yarn, binding yarn and weft yarn respectively using copper-nickel alloy wire, polyester fiber and glass fiber. Infrared temperature tester and material universal testing machine were used for the performance testing. The results show that: after applying voltage for 6 s, the surface temperature of the composite increases rapidly, and reaches the maximum equilibrium temperature around 60 s. The maximum equilibrium temperature of the composite surface is in direct proportion to the applied voltage; When the applied voltage is unchanged, the lower the density of the wire, the higher the maximum equilibrium temperature of the composite surface.The lower the arrangement density of the resistance wire, the greater the interlaminar shear strength of the composites. The density of the resistance wires is low, and the interlaminar shear strength of the composite is higher. The weft woven biaxial fabric/epoxy resin electrically heated composites has the characteristics of light weight, high strength, high heating rate, good formability and so on, which is suitable for anti-icing/de-icing of multiple parts of aircraft.

2020, 37(8): 2005-2014.

doi: 10.13801/j.cnki.fhclxb.20191207.001

Abstract:

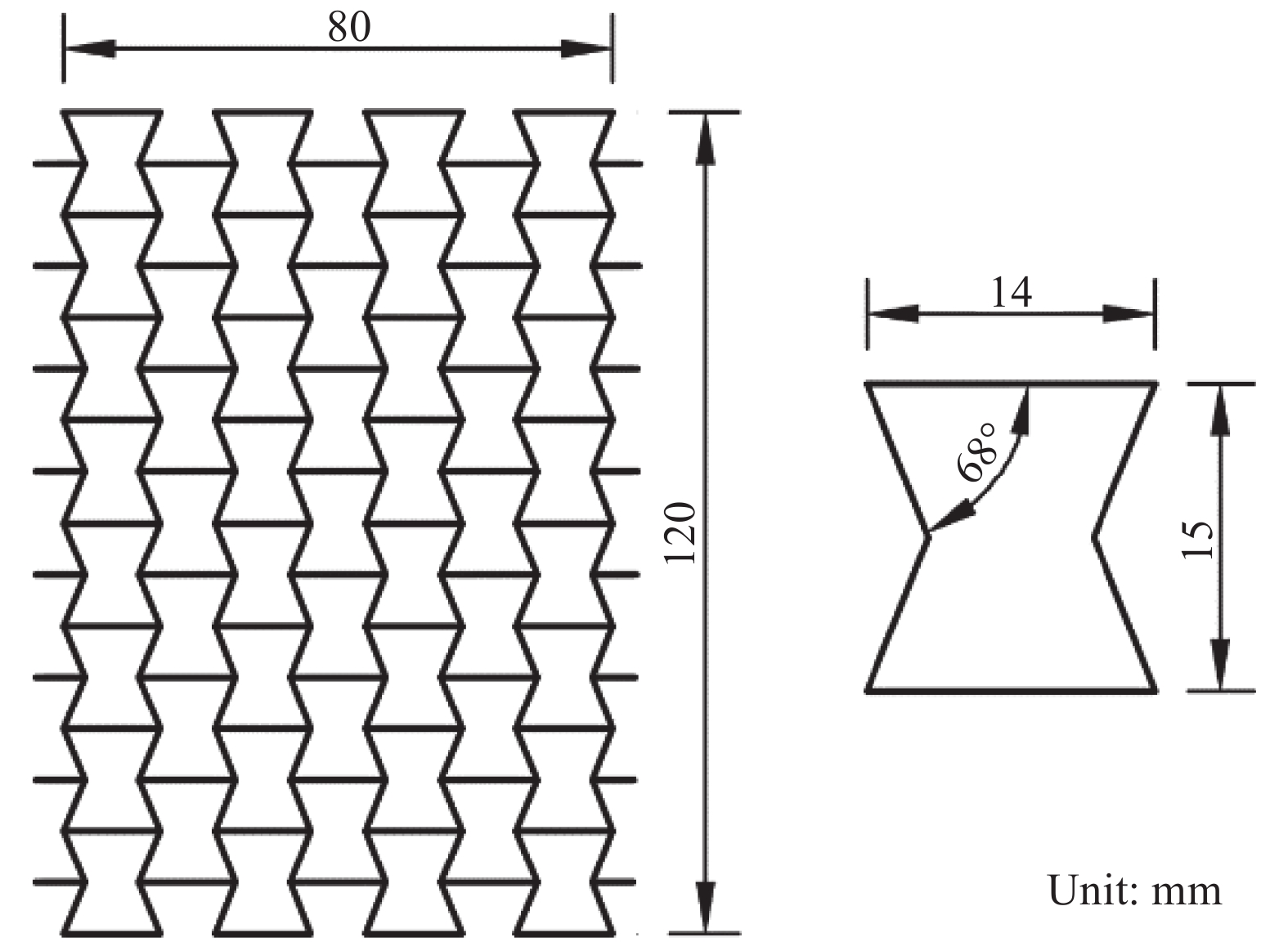

New composite sandwich structures filled with foam concrete were proposed to improve the failure mode subjected to compression and enhance the energy absorption capacity. The composite structures were made by filling foam concrete of different densities (409 kg/m3, 575 kg/m3, 848 kg/m3, 1 014 kg/m3) into negative Poisson's ratio aluminum structures. The failure modes and energy absorption capacities of the specimens subjected to quasi-static compression were compared among the empty auxetic structures, the auxetic structures filled with foam concrete as well as the standalone foam concrete control specimens. Based on the load-displacement relationship and failure mode, the findings can be reached: With foam concrete of relatively low density filled, the Poisson’s ratio of the auxetic composite structures is limited to a small value, leading to auxetic deformation of the cells and progressive compression mode of the whole structures. With foam concrete of relatively high density filled, the structures exhibit X-type shear failure, in which the cell walls around plastic hinges and shear bands fracture. The energy absorption increases, and the densification strain of the composite structures decreases, with increasing density of the foam concrete. However, with filler density greater than a certain value, the enhancement of energy absorption of the composite structures becomes less remarkable, and the specific energy absorption decreases, with increasing density of the filled foam concrete.

New composite sandwich structures filled with foam concrete were proposed to improve the failure mode subjected to compression and enhance the energy absorption capacity. The composite structures were made by filling foam concrete of different densities (409 kg/m3, 575 kg/m3, 848 kg/m3, 1 014 kg/m3) into negative Poisson's ratio aluminum structures. The failure modes and energy absorption capacities of the specimens subjected to quasi-static compression were compared among the empty auxetic structures, the auxetic structures filled with foam concrete as well as the standalone foam concrete control specimens. Based on the load-displacement relationship and failure mode, the findings can be reached: With foam concrete of relatively low density filled, the Poisson’s ratio of the auxetic composite structures is limited to a small value, leading to auxetic deformation of the cells and progressive compression mode of the whole structures. With foam concrete of relatively high density filled, the structures exhibit X-type shear failure, in which the cell walls around plastic hinges and shear bands fracture. The energy absorption increases, and the densification strain of the composite structures decreases, with increasing density of the foam concrete. However, with filler density greater than a certain value, the enhancement of energy absorption of the composite structures becomes less remarkable, and the specific energy absorption decreases, with increasing density of the filled foam concrete.

2020, 37(8): 2015-2028.

doi: 10.13801/j.cnki.fhclxb.20200212.005

Abstract:

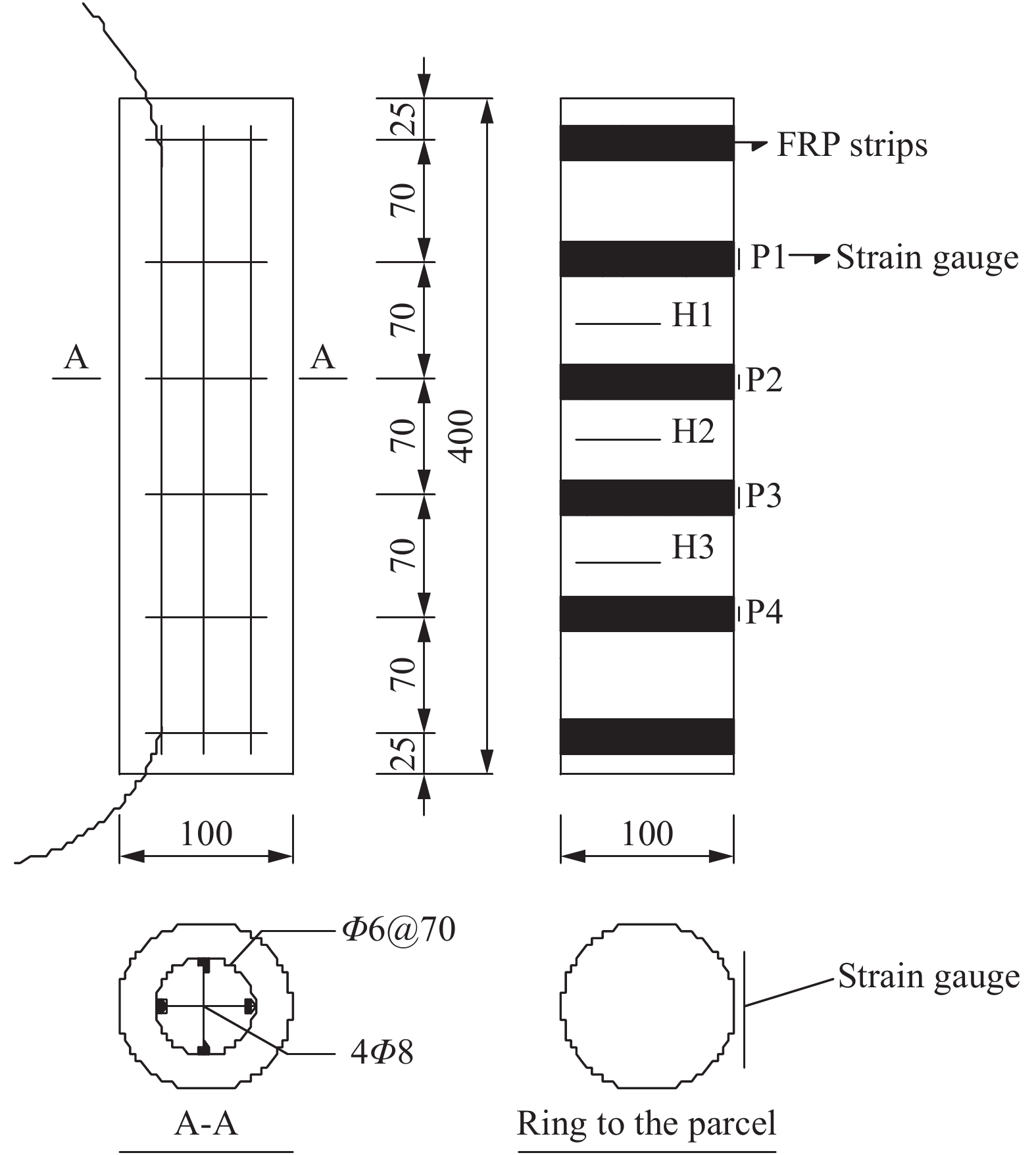

Through the test of corroded reinforced concrete columns which were strengthened with carbon fiber reinforced polymer (CFRP) composite strips and glass fiber reinforced polymer (GFRP) composite strips in the erosion environment, the influences of erosion environment on the concrete strength, the ultimate load and the axial load-displacement relationship curve of corroded and FRP strengthened concrete columns were analyzed. The result shows that the strength of the concrete is greatly affected by the freeze-thaw environment and is less affected by the dry and wet environment. The axial ultimate load of FRP reinforced damaged columns is related to the number of freeze-thaw cycles, the corrosion rate of steel bars and the type of FRP composite. With the increase of freeze-thaw cycles from 0 to 25, 50 and 75, the axial ultimate loads of corroded reinforced concrete columns strengthened with GFRP composite and CFRP composite strips are decreased by 10.97%, 13.37%, 16.04% and 5.95%, 4.66%, 4.33% respectively. The load-axial displacement curve of the FRP composite reinforced corrosion column reflects the stiffness and the energy consumption of the column, and both of which are affected by the type of erosion environment, the number of times of the erosion environment, the corrosion rate of steel bars and the type of FRP composite. Through the experimental research, the damage coefficient of concrete strength and the regression equation of the strength of corroded bar in the erosion environment were theoretically analyzed. A method for calculating the axial compression capacity of corroded reinforced concrete columns strengthened with FRP composite strips under erosion environment was presented.

Through the test of corroded reinforced concrete columns which were strengthened with carbon fiber reinforced polymer (CFRP) composite strips and glass fiber reinforced polymer (GFRP) composite strips in the erosion environment, the influences of erosion environment on the concrete strength, the ultimate load and the axial load-displacement relationship curve of corroded and FRP strengthened concrete columns were analyzed. The result shows that the strength of the concrete is greatly affected by the freeze-thaw environment and is less affected by the dry and wet environment. The axial ultimate load of FRP reinforced damaged columns is related to the number of freeze-thaw cycles, the corrosion rate of steel bars and the type of FRP composite. With the increase of freeze-thaw cycles from 0 to 25, 50 and 75, the axial ultimate loads of corroded reinforced concrete columns strengthened with GFRP composite and CFRP composite strips are decreased by 10.97%, 13.37%, 16.04% and 5.95%, 4.66%, 4.33% respectively. The load-axial displacement curve of the FRP composite reinforced corrosion column reflects the stiffness and the energy consumption of the column, and both of which are affected by the type of erosion environment, the number of times of the erosion environment, the corrosion rate of steel bars and the type of FRP composite. Through the experimental research, the damage coefficient of concrete strength and the regression equation of the strength of corroded bar in the erosion environment were theoretically analyzed. A method for calculating the axial compression capacity of corroded reinforced concrete columns strengthened with FRP composite strips under erosion environment was presented.

2020, 37(8): 2029-2035.

doi: 10.13801/j.cnki.fhclxb.20200103.001

Abstract:

Ethylenediamine modified attapulgite(EDA/ATP) adsorbent was synthesized by using clay-based adsorbent ATP as carrier. The EDA/ATP composite adsorbent was characterized by FTIR and TGA. The adsorbent was applied to the adsorption of Cr(VI) in aqueous. The effects of initial concentration of Cr(VI) solution, adsorption time, solution pH and the anion concentration Cl− and PO43− on the adsorption of Cr(VI) were studied. The FTIR and TGA results show that EDA has been successfully grafted onto the surface of ATP. The adsorption experimental results show that at 25℃ the maximum adsorption capacity of EDA/ATP composite for Cr(VI) is 153.78 mg·g−1, and the adsorption reaches equilibrium within 800~900 min. The adsorption experimental data conform to Freundlich adsorption isotherm model and the pseudo-second-order kinetics. The initial pH of solution is ranging from 2 to 10. With the increase of pH, the adsorption capacity first increases and then decreases. When the pH is 3, the adsorption capacity reaches the maximum adsorption amount. PO43− has greater effect on the adsorption than Cl−, and the maximum adsorption capacity decreases by 83 mg·g−1 when the concentration of PO43− is 20 mmol·L−1. The experimental results show that EDA/ATP composite can be used as a potential adsorbent for Cr(VI) in water treatment.

Ethylenediamine modified attapulgite(EDA/ATP) adsorbent was synthesized by using clay-based adsorbent ATP as carrier. The EDA/ATP composite adsorbent was characterized by FTIR and TGA. The adsorbent was applied to the adsorption of Cr(VI) in aqueous. The effects of initial concentration of Cr(VI) solution, adsorption time, solution pH and the anion concentration Cl− and PO43− on the adsorption of Cr(VI) were studied. The FTIR and TGA results show that EDA has been successfully grafted onto the surface of ATP. The adsorption experimental results show that at 25℃ the maximum adsorption capacity of EDA/ATP composite for Cr(VI) is 153.78 mg·g−1, and the adsorption reaches equilibrium within 800~900 min. The adsorption experimental data conform to Freundlich adsorption isotherm model and the pseudo-second-order kinetics. The initial pH of solution is ranging from 2 to 10. With the increase of pH, the adsorption capacity first increases and then decreases. When the pH is 3, the adsorption capacity reaches the maximum adsorption amount. PO43− has greater effect on the adsorption than Cl−, and the maximum adsorption capacity decreases by 83 mg·g−1 when the concentration of PO43− is 20 mmol·L−1. The experimental results show that EDA/ATP composite can be used as a potential adsorbent for Cr(VI) in water treatment.

2020, 37(8): 2036-2044.

doi: 10.13801/j.cnki.fhclxb.20191206.004

Abstract:

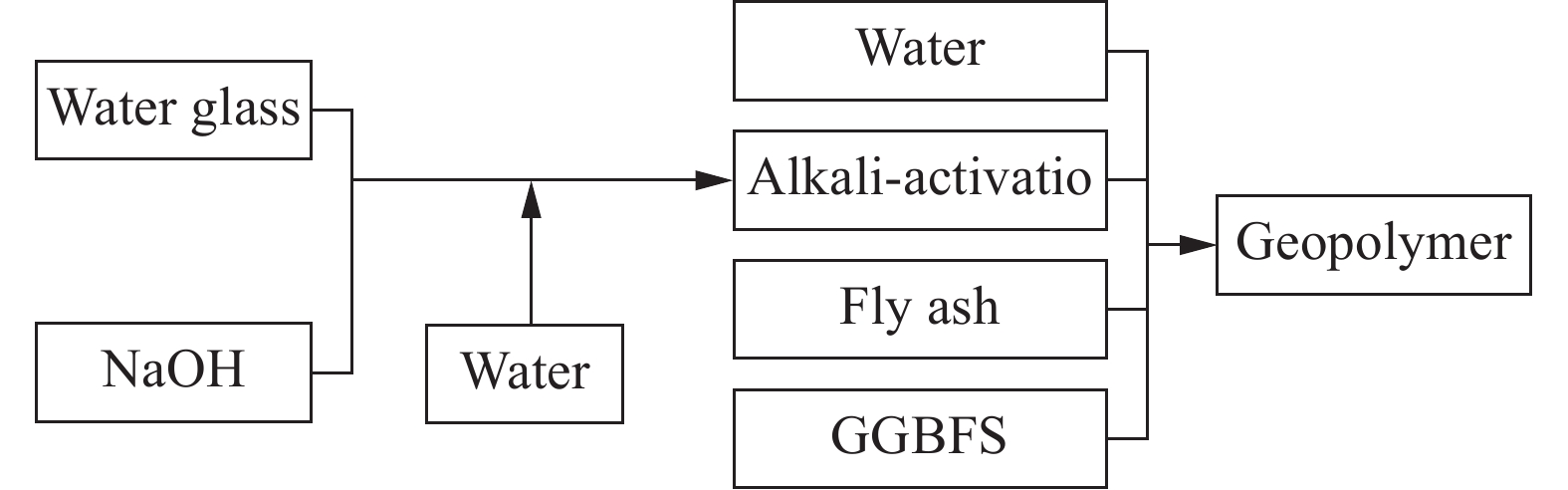

X-ray diffraction (XRD) and scanning electron microscopy (SEM) were used to observe the compound change law of geopolymer reaction and the hydration reaction of calcium silicate by adjusting the molar ratio of SiO2/Al2O3, CaO/Al2O3 and Na2O/Al2O3 in the geopolymer. Then the compound synergistic effect of geopolymer reaction and the hydration reaction of CaSiO3 was explored. Furthermore, the formation mechanism of early strength in geopolymer was revealed. The results show that the geopolymer reaction products contain a certain amount of quartz component. The physical properties and chemical properties of quartz are very stable and the quartz strength is high. The products of hydration reaction of CaSiO3 are mainly CaSiO3 hydrate whose internal structure is loose. With the mole ratios of SiO2/Al2O3 and CaO/Al2O3 increasing, the degree of geopolymer reaction increases first and then decreases, and the degree of hydration reaction of CaSiO3 increases first and then stabilizes and is greater than the degree of geological polymer reaction. When the SiO2/Al2O3 molar ratio is 3.8 and the CaO/Al2O3 molar ratio is 2.750, the compound synergistic effect of geopolymer reaction and hydration reaction of CaSiO3 is the best. At this time, the proportion of quartz in geopolymer is about 66wt%, the proportion of CaSiO3 hydrate in geopolymer is about 24wt% and the mechanical properties are good.

X-ray diffraction (XRD) and scanning electron microscopy (SEM) were used to observe the compound change law of geopolymer reaction and the hydration reaction of calcium silicate by adjusting the molar ratio of SiO2/Al2O3, CaO/Al2O3 and Na2O/Al2O3 in the geopolymer. Then the compound synergistic effect of geopolymer reaction and the hydration reaction of CaSiO3 was explored. Furthermore, the formation mechanism of early strength in geopolymer was revealed. The results show that the geopolymer reaction products contain a certain amount of quartz component. The physical properties and chemical properties of quartz are very stable and the quartz strength is high. The products of hydration reaction of CaSiO3 are mainly CaSiO3 hydrate whose internal structure is loose. With the mole ratios of SiO2/Al2O3 and CaO/Al2O3 increasing, the degree of geopolymer reaction increases first and then decreases, and the degree of hydration reaction of CaSiO3 increases first and then stabilizes and is greater than the degree of geological polymer reaction. When the SiO2/Al2O3 molar ratio is 3.8 and the CaO/Al2O3 molar ratio is 2.750, the compound synergistic effect of geopolymer reaction and hydration reaction of CaSiO3 is the best. At this time, the proportion of quartz in geopolymer is about 66wt%, the proportion of CaSiO3 hydrate in geopolymer is about 24wt% and the mechanical properties are good.

2020, 37(8): 2045-2054.

doi: 10.13801/j.cnki.fhclxb.20200103.002

Abstract:

Based on the core-shell structure design, flexible, stretchable, highly sensitive and stable polydimethylsiloxane silicone rubber@multiwalled carbon nanotubes/polydimethylsiloxane silicone rubber (PDMS@MWCNTs/PDMS) piezoresistive strain sensing fibers were fabricated via the simple and low-cost dip coating-curing method. The chemical structure, thermal stability and microstructures of silane coupling agent modified multiwalled carbon nanotubes (MWCNTs-KH570) were characterized by FTIR, XRD, TG and TEM. The effects of core-shell structure and MWCNTs-KH570 mass fraction on the electrical conductivity, the sensing properties and mechanical properties of the PDMS@MWCNTs/PDMS composite fibers, as well as the mechanics were investigated detailedly. The results show that KH570 is successfully grafted onto the surface of hydroxylation MWCNTs(MWCNTs—OH), leading to the good dispersibility and interface interaction in the shell layer PDMS matrix; The design of core-shell structure enables the PDMS@MWCNTs/PDMS composite fibers to have high electrical conductivity and sensing properties at the low filling; With increasing the MWCNTs-KH570 mass fraction, the PDMS@MWCNTs/PDMS composite fibers exhibit elevated electrical conductivity and sensing performances, and show superior repeatability and working stability in human joint motion monitoring.

Based on the core-shell structure design, flexible, stretchable, highly sensitive and stable polydimethylsiloxane silicone rubber@multiwalled carbon nanotubes/polydimethylsiloxane silicone rubber (PDMS@MWCNTs/PDMS) piezoresistive strain sensing fibers were fabricated via the simple and low-cost dip coating-curing method. The chemical structure, thermal stability and microstructures of silane coupling agent modified multiwalled carbon nanotubes (MWCNTs-KH570) were characterized by FTIR, XRD, TG and TEM. The effects of core-shell structure and MWCNTs-KH570 mass fraction on the electrical conductivity, the sensing properties and mechanical properties of the PDMS@MWCNTs/PDMS composite fibers, as well as the mechanics were investigated detailedly. The results show that KH570 is successfully grafted onto the surface of hydroxylation MWCNTs(MWCNTs—OH), leading to the good dispersibility and interface interaction in the shell layer PDMS matrix; The design of core-shell structure enables the PDMS@MWCNTs/PDMS composite fibers to have high electrical conductivity and sensing properties at the low filling; With increasing the MWCNTs-KH570 mass fraction, the PDMS@MWCNTs/PDMS composite fibers exhibit elevated electrical conductivity and sensing performances, and show superior repeatability and working stability in human joint motion monitoring.

2020, 37(8): 2055-2064.

doi: 10.13801/j.cnki.fhclxb.20191230.002

Abstract:

Wood-plastic composite (WPC) is a new kind of environment-friendly composite reinforced by wood fiber. In order to analyze the deformation behavior of WPC under the non-constant load and carry out effective design of long-term deformation of the structure, the creep/recovery deformation of WPC was analyzed. The superposition principle method was used to compare and analyze the overall prediction effect of the existing creep calculation model on WPC creep/recovery. The results show that none of the existing models can predict the creep recovery behavior well. The viscoelastic model based on fractional calculus was used to predict the creep/recovery behavior, and a modified fractional viscoelastic model with two-parameter method was proposed. The results show that the model can accurately reflect the static viscoelastic behavior of WPC. Based on the experimental data, the creep/recovery model parameters of different WPC materials were given.

Wood-plastic composite (WPC) is a new kind of environment-friendly composite reinforced by wood fiber. In order to analyze the deformation behavior of WPC under the non-constant load and carry out effective design of long-term deformation of the structure, the creep/recovery deformation of WPC was analyzed. The superposition principle method was used to compare and analyze the overall prediction effect of the existing creep calculation model on WPC creep/recovery. The results show that none of the existing models can predict the creep recovery behavior well. The viscoelastic model based on fractional calculus was used to predict the creep/recovery behavior, and a modified fractional viscoelastic model with two-parameter method was proposed. The results show that the model can accurately reflect the static viscoelastic behavior of WPC. Based on the experimental data, the creep/recovery model parameters of different WPC materials were given.

2020, 37(8): 2065-2075.

doi: 10.13801/j.cnki.fhclxb.20191030.004

Abstract:

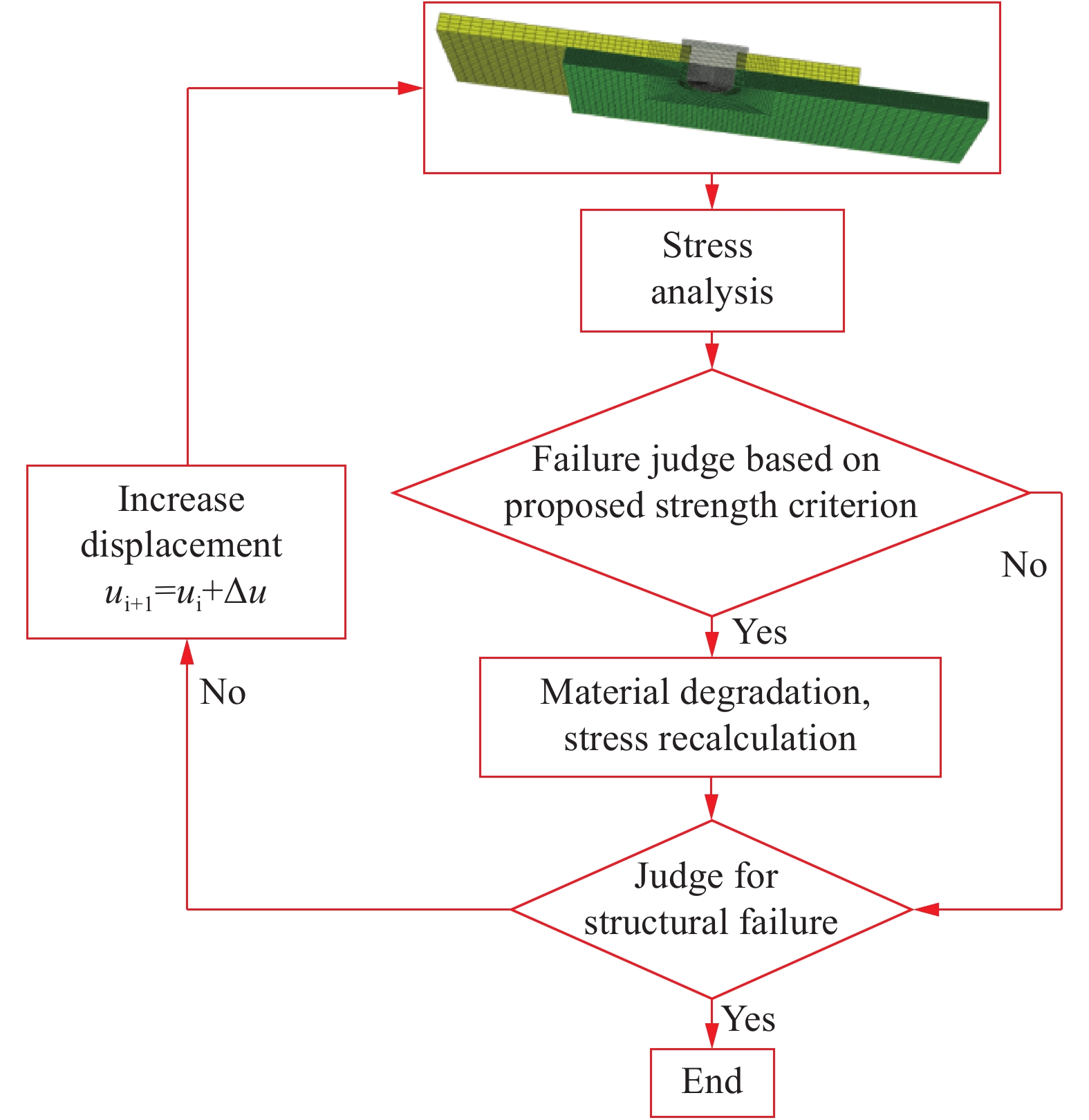

A continuum damage mechanics model for composites, considering the intralaminar (fibre and matrix failure) and interlaminar failure, was proposed to predict the progressive damage behavior of bolted joints. Based on Tsai-Wu strength criterion, a new failure-judgement formula was developed to distinguish the intralaminar and interlaminar failure. An exponent material degradation model was introduced to simulate the damage evolution of the composite. A continuum damage mechanics model was established to analyze the effect of 0° ply ratio and bolt diameter on the bearing characteristic of the composite bolted joints. The predicted results exhibit good agreement with the experimental results. These results show that high 0° ply ratio induces the shear-out failure of the composite bolted joints, decreasing the structural bearing capability. Increasing the bolt diameter can restrain the damage of the composite laminate and improve the bearing strength of the composite bolted joints.

A continuum damage mechanics model for composites, considering the intralaminar (fibre and matrix failure) and interlaminar failure, was proposed to predict the progressive damage behavior of bolted joints. Based on Tsai-Wu strength criterion, a new failure-judgement formula was developed to distinguish the intralaminar and interlaminar failure. An exponent material degradation model was introduced to simulate the damage evolution of the composite. A continuum damage mechanics model was established to analyze the effect of 0° ply ratio and bolt diameter on the bearing characteristic of the composite bolted joints. The predicted results exhibit good agreement with the experimental results. These results show that high 0° ply ratio induces the shear-out failure of the composite bolted joints, decreasing the structural bearing capability. Increasing the bolt diameter can restrain the damage of the composite laminate and improve the bearing strength of the composite bolted joints.

2020, 37(8): 1785-1795.

doi: 10.13801/j.cnki.fhclxb.20200507.001

Abstract:

With the rapid development of thermoplastic composites, traditional sizing agents are no longer able to meet the requirements as its incompatibility with thermoplastic matrices and low heat resistance. In light of this, it is fairly significant to master the technologies of sizing agents suitable for high performance thermoplastic composites. Brief introductions including chief purposes of sizing treatment, strengthening mechanisms at the interfaces between reinforcements and matrices, distinguishing features as well as main requirements of carbon fiber sizing agents for thermoplastic composites were presented in this paper. Researches of novel carbon fiber sizing agents consisting of polyamide, polyurethane, polyaryl ether, polyimide and other constituents for various thermoplastic matrices were reviewed in the order of service temperature. Both modification routes of diverse sizing agents for high performance thermoplastic composites and commercial applications provided by carbon fiber manufacturers were presented with their relative merits and existing drawbacks. Furthermore, their corresponding mechanisms and development status were also clarified. Finally, the future trends of sizing agents for thermoplastic composites were forecasted with relevant suggestions provided subsequently in view of different sizing agents to overcome current problems.

With the rapid development of thermoplastic composites, traditional sizing agents are no longer able to meet the requirements as its incompatibility with thermoplastic matrices and low heat resistance. In light of this, it is fairly significant to master the technologies of sizing agents suitable for high performance thermoplastic composites. Brief introductions including chief purposes of sizing treatment, strengthening mechanisms at the interfaces between reinforcements and matrices, distinguishing features as well as main requirements of carbon fiber sizing agents for thermoplastic composites were presented in this paper. Researches of novel carbon fiber sizing agents consisting of polyamide, polyurethane, polyaryl ether, polyimide and other constituents for various thermoplastic matrices were reviewed in the order of service temperature. Both modification routes of diverse sizing agents for high performance thermoplastic composites and commercial applications provided by carbon fiber manufacturers were presented with their relative merits and existing drawbacks. Furthermore, their corresponding mechanisms and development status were also clarified. Finally, the future trends of sizing agents for thermoplastic composites were forecasted with relevant suggestions provided subsequently in view of different sizing agents to overcome current problems.

2020, 37(8): 1796-1804.

doi: 10.13801/j.cnki.fhclxb.20200324.001

Abstract:

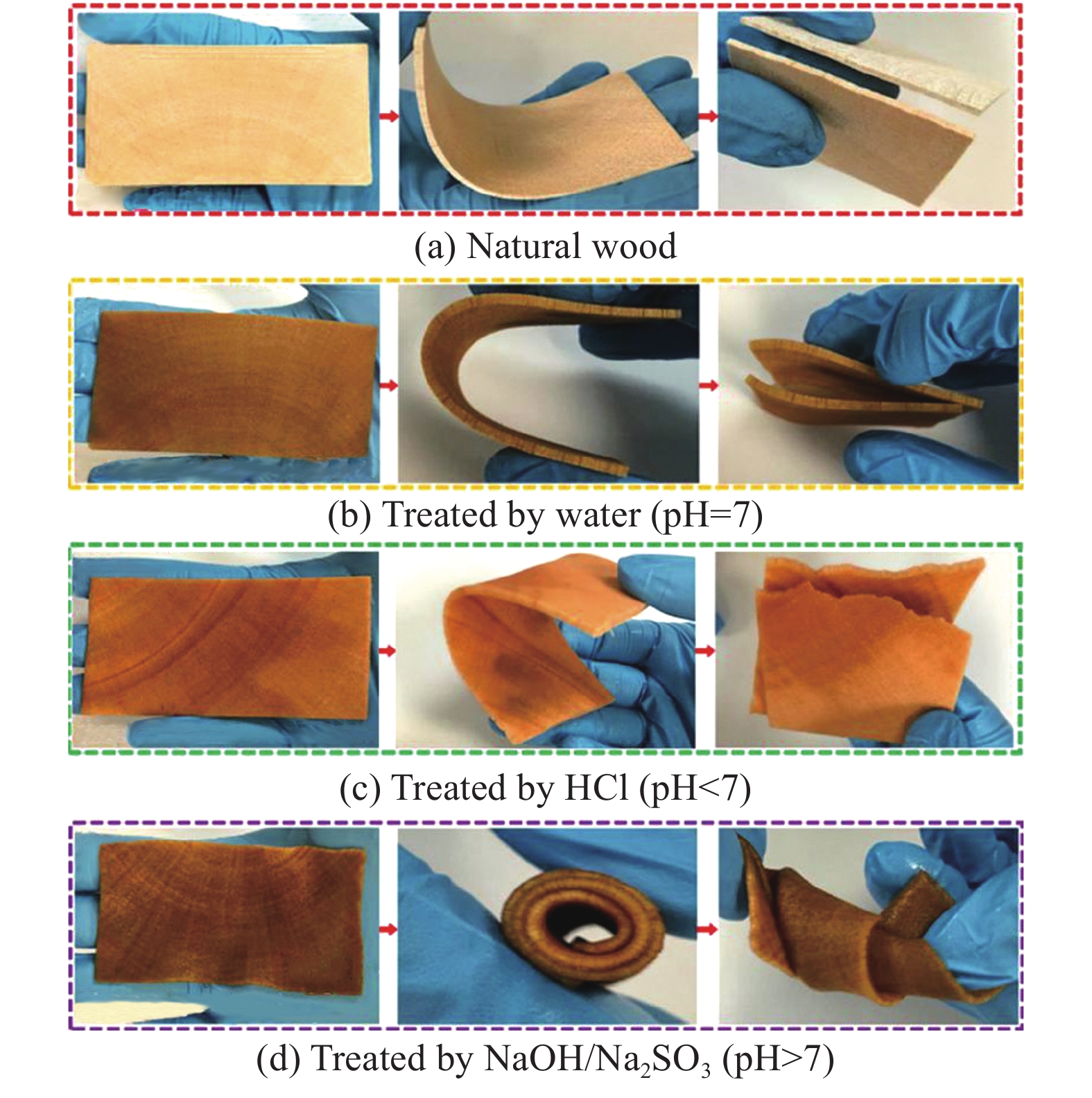

Wood is both ecological friendly and renewable, and is an ecological material consistent with sustainable development. By selectively removing hemicellulose and lignin, wood can be prepared into three-dimensional structural wood with high porosity, which can fully take advantage of its high porosity, orderly arrangement of fibers, large specific surface area and good bio-compatibility, outstanding anisotropy of the wood itself. It has potential development value in the fields of flexible electronic equipment, pollution control, smart windows, biomedicine, lithium batteries and building materials. This paper summarized the formation mechanism and preparation methods of functional high porosity three-dimensional structural materials represented by flexible wood, wood sponge, transparent wood, wood hydrogel, carbonized wood and densified wood. The existing problems are pointed out and the future research and development direction are discussed, hoping to provide new ideas for the research and development of new wood-based functional materials.

Wood is both ecological friendly and renewable, and is an ecological material consistent with sustainable development. By selectively removing hemicellulose and lignin, wood can be prepared into three-dimensional structural wood with high porosity, which can fully take advantage of its high porosity, orderly arrangement of fibers, large specific surface area and good bio-compatibility, outstanding anisotropy of the wood itself. It has potential development value in the fields of flexible electronic equipment, pollution control, smart windows, biomedicine, lithium batteries and building materials. This paper summarized the formation mechanism and preparation methods of functional high porosity three-dimensional structural materials represented by flexible wood, wood sponge, transparent wood, wood hydrogel, carbonized wood and densified wood. The existing problems are pointed out and the future research and development direction are discussed, hoping to provide new ideas for the research and development of new wood-based functional materials.

2020, 37(8): 1805-1822.

doi: 10.13801/j.cnki.fhclxb.20200512.002

Abstract:

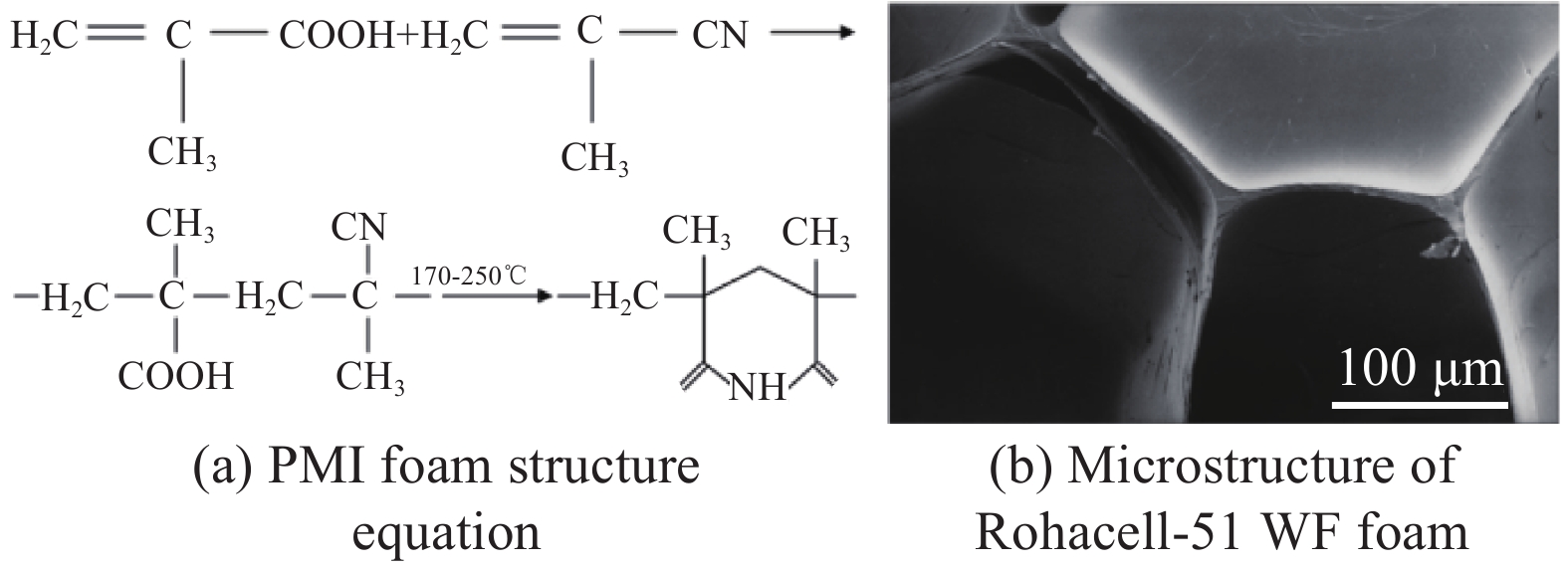

Polymethylimide (PMI) foam core sandwich has unique performance advantages, which leads to a wide application in aerospace structures. In order to promote the stabilization, serialization and high performance for PMI foam core sandwich, the present research situation and development trend of PMI foam core sandwich design and manufacturing technology for lifecycle were systematically reviewed. Firstly, the performance and application situation of PMI foam and its core sandwich were summarized, and the market demand of PMI foam core sandwich was analyzed. Then, the key technologies situations of PMI foam core sandwich lifecycle were curtly described, including the research of PMI foam, structure design and analysis, structure curing and forming, repair and maintenance, etc. Finally, the development trend of PMI foam core sandwich was prospected, so that to provide reference for further research.

Polymethylimide (PMI) foam core sandwich has unique performance advantages, which leads to a wide application in aerospace structures. In order to promote the stabilization, serialization and high performance for PMI foam core sandwich, the present research situation and development trend of PMI foam core sandwich design and manufacturing technology for lifecycle were systematically reviewed. Firstly, the performance and application situation of PMI foam and its core sandwich were summarized, and the market demand of PMI foam core sandwich was analyzed. Then, the key technologies situations of PMI foam core sandwich lifecycle were curtly described, including the research of PMI foam, structure design and analysis, structure curing and forming, repair and maintenance, etc. Finally, the development trend of PMI foam core sandwich was prospected, so that to provide reference for further research.

2020, 37(8): 1823-1831.

doi: 10.13801/j.cnki.fhclxb.20191206.006

Abstract:

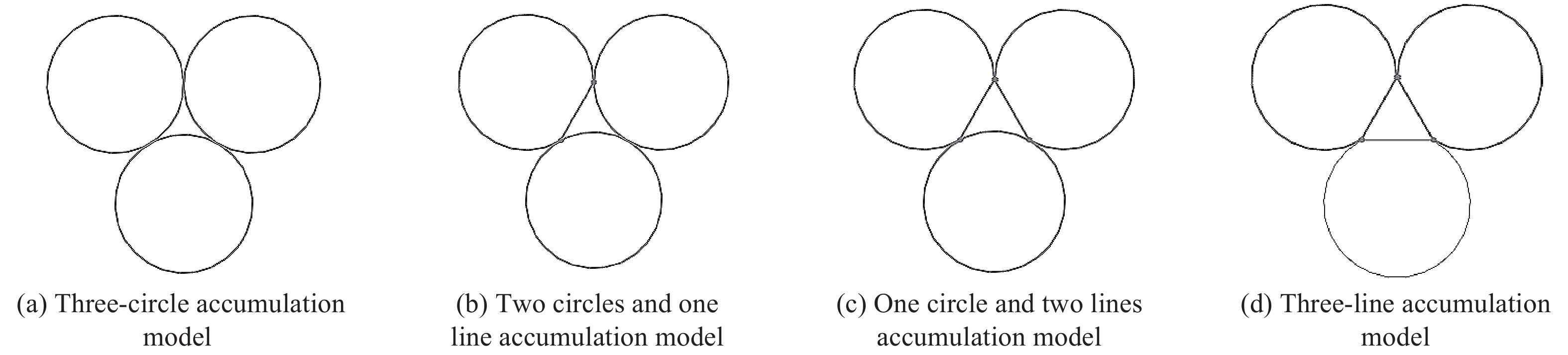

In order to further study the influence factors of compressive strength and flexural strength of steel-polypropylene fiber reinforced artificial granite (steel polypropylene fiber/artificial granite) composite, the void ratio of aggregate accumulation was studied by drainage method. The aggregate gradation and experimental index q were determined, and the compressive strength and flexural strength of a large number of specimens were tested. The influences of the mass fraction of each component and the void ratio of aggregate on the compressive strength and flexural strength of the steel polypropylene fiber/artificial granite composite were analyzed. The experimental results show that steel fibers and polypropylene fibers can significantly increase the flexural strength of steel polypropylene fiber/artificial granite composite. With the increase of the content of steel-polypropylene fibers, the compressive strength and flexural strength of the steel polypropylene fiber/artificial granite composite specimens increase gradually. When the mass ratio of steel fibers to polypropylene fibers is 30∶1 and the content of steel-polypropylene fiber is 1.7wt%, the compressive strength of the steel polypropylene fiber/artificial granite composite specimens increases gradually. The flexural strength of the steel polypropylene fiber/artificial granite specimens reaches the maximum when the steel-polypropylene fiber content is 1.9wt%. The closer the mass fraction of binder to the void ratio of the aggregate, the greater the compressive strength and flexural strength of the steel polypropylene fiber/artificial granite composite are. When the aggregate is 80wt% and the binder is 11wt%, the compressive strength and flexural strength of the steel polypropylene fiber/artificial granite specimen reach the maximum at the same time.

In order to further study the influence factors of compressive strength and flexural strength of steel-polypropylene fiber reinforced artificial granite (steel polypropylene fiber/artificial granite) composite, the void ratio of aggregate accumulation was studied by drainage method. The aggregate gradation and experimental index q were determined, and the compressive strength and flexural strength of a large number of specimens were tested. The influences of the mass fraction of each component and the void ratio of aggregate on the compressive strength and flexural strength of the steel polypropylene fiber/artificial granite composite were analyzed. The experimental results show that steel fibers and polypropylene fibers can significantly increase the flexural strength of steel polypropylene fiber/artificial granite composite. With the increase of the content of steel-polypropylene fibers, the compressive strength and flexural strength of the steel polypropylene fiber/artificial granite composite specimens increase gradually. When the mass ratio of steel fibers to polypropylene fibers is 30∶1 and the content of steel-polypropylene fiber is 1.7wt%, the compressive strength of the steel polypropylene fiber/artificial granite composite specimens increases gradually. The flexural strength of the steel polypropylene fiber/artificial granite specimens reaches the maximum when the steel-polypropylene fiber content is 1.9wt%. The closer the mass fraction of binder to the void ratio of the aggregate, the greater the compressive strength and flexural strength of the steel polypropylene fiber/artificial granite composite are. When the aggregate is 80wt% and the binder is 11wt%, the compressive strength and flexural strength of the steel polypropylene fiber/artificial granite specimen reach the maximum at the same time.

2020, 37(8): 1850-1860.

doi: 10.13801/j.cnki.fhclxb.20191206.002

Abstract:

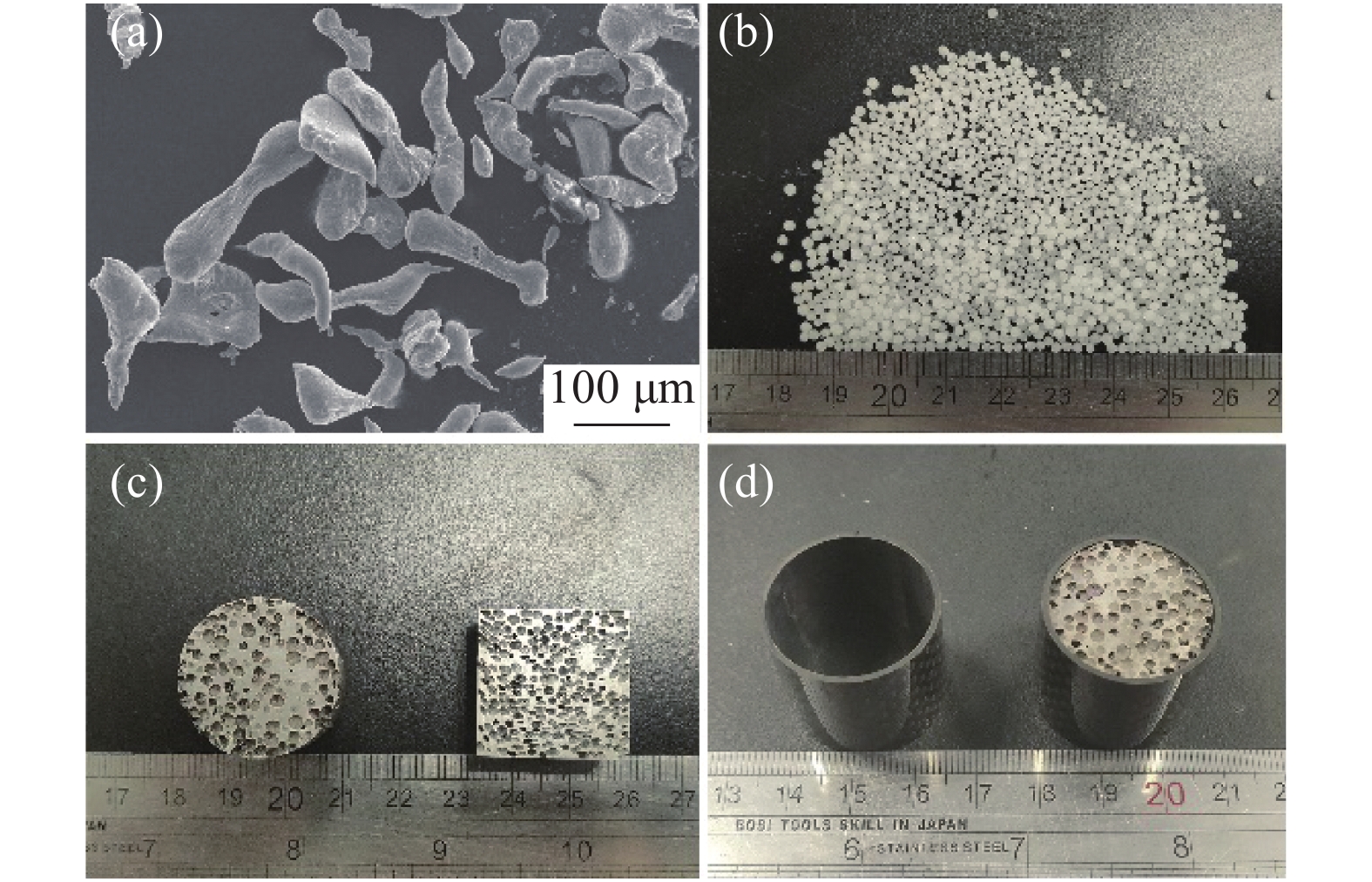

The Al foams made by space-holder method were physically inserted into carbon fiber reinforced plastic (CFRP) composite thin-wall tubes to obtain the composite structure of Al foam-filled CFRP composite thin-wall tubes. Quasi-static compression tests of CFRP composite tubes, Al foams and Al foam-filled CFRP composite thin-wall tubes were carried out to study their compression properties. Meanwhile, digital image correlation (DIC) was applied to analyze their deformation modes. Furthermore, the compressive properties, energy absorption properties and failure modes of Al foam-filled CFRP composite thin-wall tubes at different temperatures (25-150℃) were studied. The results show that Al foams as fillers change the compression deformation behavior of CFRP composite thin-walled tubes from the scattering flowering failure of a single CFRP composite tube to the fiber layer fracture failure of a foam-filled tube. Comparing to CFRP composite thin-walled tubes, the stress fluctuations of Al foam-filled CFRP composite thin-wall tubes decrease obviously. With environmental temperature increasing, both the compressive properties and energy absorption properties of CFRP composite thin-walled tubes, Al foams and Al foam-filled CFRP composite thin-wall tubes decrease. But the interaction between Al foams and CFRP composite thin-walled tubes is enhanced, the enhancement effect of Al foams on CFRP composite thin-walled tubes is more obvious at high temperature.

The Al foams made by space-holder method were physically inserted into carbon fiber reinforced plastic (CFRP) composite thin-wall tubes to obtain the composite structure of Al foam-filled CFRP composite thin-wall tubes. Quasi-static compression tests of CFRP composite tubes, Al foams and Al foam-filled CFRP composite thin-wall tubes were carried out to study their compression properties. Meanwhile, digital image correlation (DIC) was applied to analyze their deformation modes. Furthermore, the compressive properties, energy absorption properties and failure modes of Al foam-filled CFRP composite thin-wall tubes at different temperatures (25-150℃) were studied. The results show that Al foams as fillers change the compression deformation behavior of CFRP composite thin-walled tubes from the scattering flowering failure of a single CFRP composite tube to the fiber layer fracture failure of a foam-filled tube. Comparing to CFRP composite thin-walled tubes, the stress fluctuations of Al foam-filled CFRP composite thin-wall tubes decrease obviously. With environmental temperature increasing, both the compressive properties and energy absorption properties of CFRP composite thin-walled tubes, Al foams and Al foam-filled CFRP composite thin-wall tubes decrease. But the interaction between Al foams and CFRP composite thin-walled tubes is enhanced, the enhancement effect of Al foams on CFRP composite thin-walled tubes is more obvious at high temperature.

2020, 37(8): 1861-1867.

doi: 10.13801/j.cnki.fhclxb.20191118.001

Abstract:

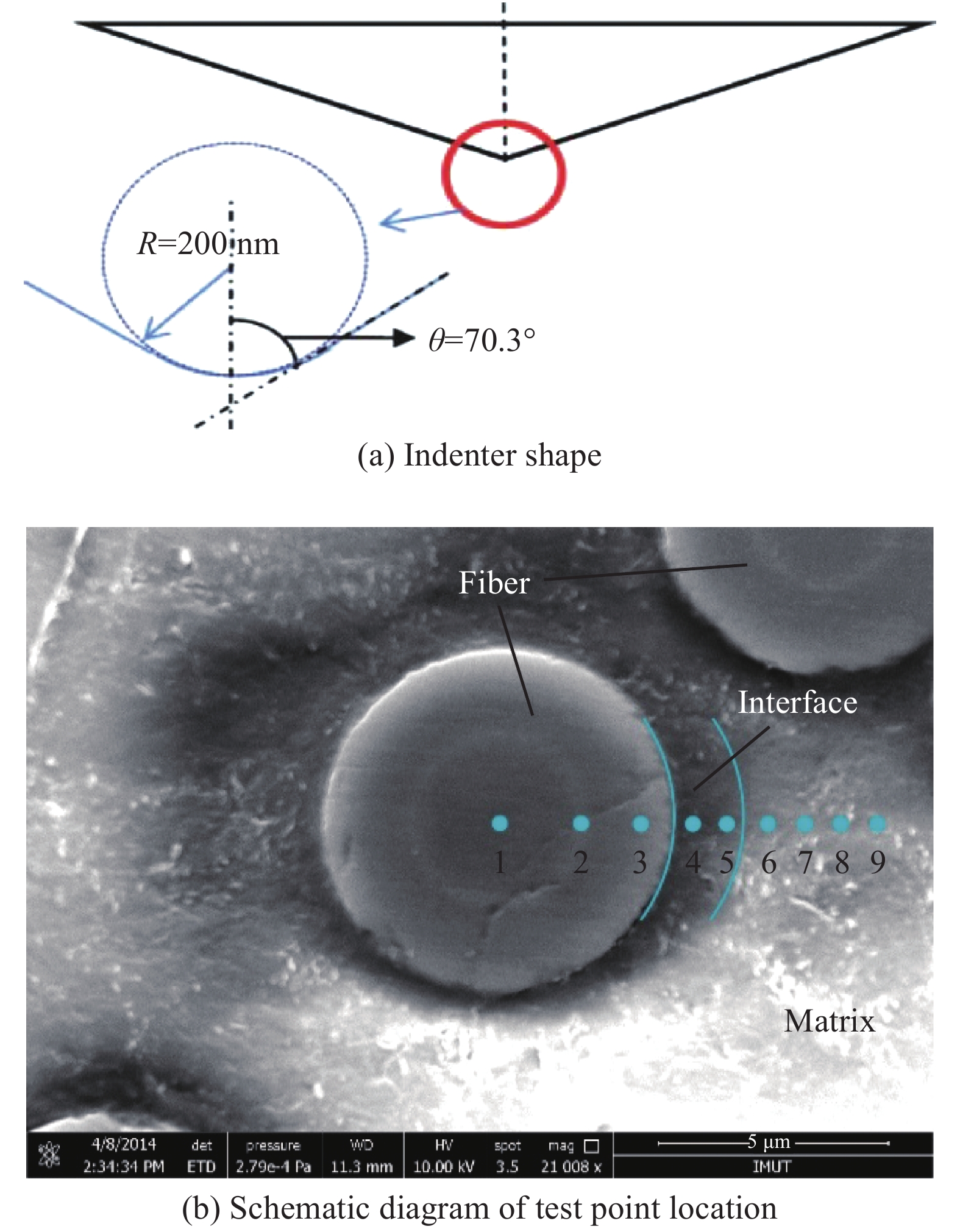

Carbon fiber reinforced resin composites are widely used in various fields because of their excellent performance. Since the resin matrix has viscoelastic properties, the composite material synthesized by resin also exhibits viscoelastic behavior. Creep is the most typical type of phenomenon in the viscoelastic deformation, so it is of great significance to study the microcreep properties for carbon fiber reinforced resin composites. Under different peak loads, the microcreep behavior of the resin matrix, interface and fiber for carbon fiber reinforced resin composites were analyzed by nanoindentation technique at room temperature. At the same creep time, the results show that the creep displacements of the fibers which are about 1/3 and 1/2 of the matrix under 2 mN and 10 mN. And the values of interfacial creep displacements are between the fiber and the matrix. The creep rate of steady state creep stage is less than 0.1%. The creep stress indexes of the matrix, interface and fiber are 3.6, 2.9 and 2.1. The first and second complex modulus and the viscosity of the dashpot and creep complicement for the matrix, interface and fiber were obtained using the Kelvin-Voigt model at different peak loads.

Carbon fiber reinforced resin composites are widely used in various fields because of their excellent performance. Since the resin matrix has viscoelastic properties, the composite material synthesized by resin also exhibits viscoelastic behavior. Creep is the most typical type of phenomenon in the viscoelastic deformation, so it is of great significance to study the microcreep properties for carbon fiber reinforced resin composites. Under different peak loads, the microcreep behavior of the resin matrix, interface and fiber for carbon fiber reinforced resin composites were analyzed by nanoindentation technique at room temperature. At the same creep time, the results show that the creep displacements of the fibers which are about 1/3 and 1/2 of the matrix under 2 mN and 10 mN. And the values of interfacial creep displacements are between the fiber and the matrix. The creep rate of steady state creep stage is less than 0.1%. The creep stress indexes of the matrix, interface and fiber are 3.6, 2.9 and 2.1. The first and second complex modulus and the viscosity of the dashpot and creep complicement for the matrix, interface and fiber were obtained using the Kelvin-Voigt model at different peak loads.

2020, 37(8): 1868-1874.

doi: 10.13801/j.cnki.fhclxb.20191125.001

Abstract:

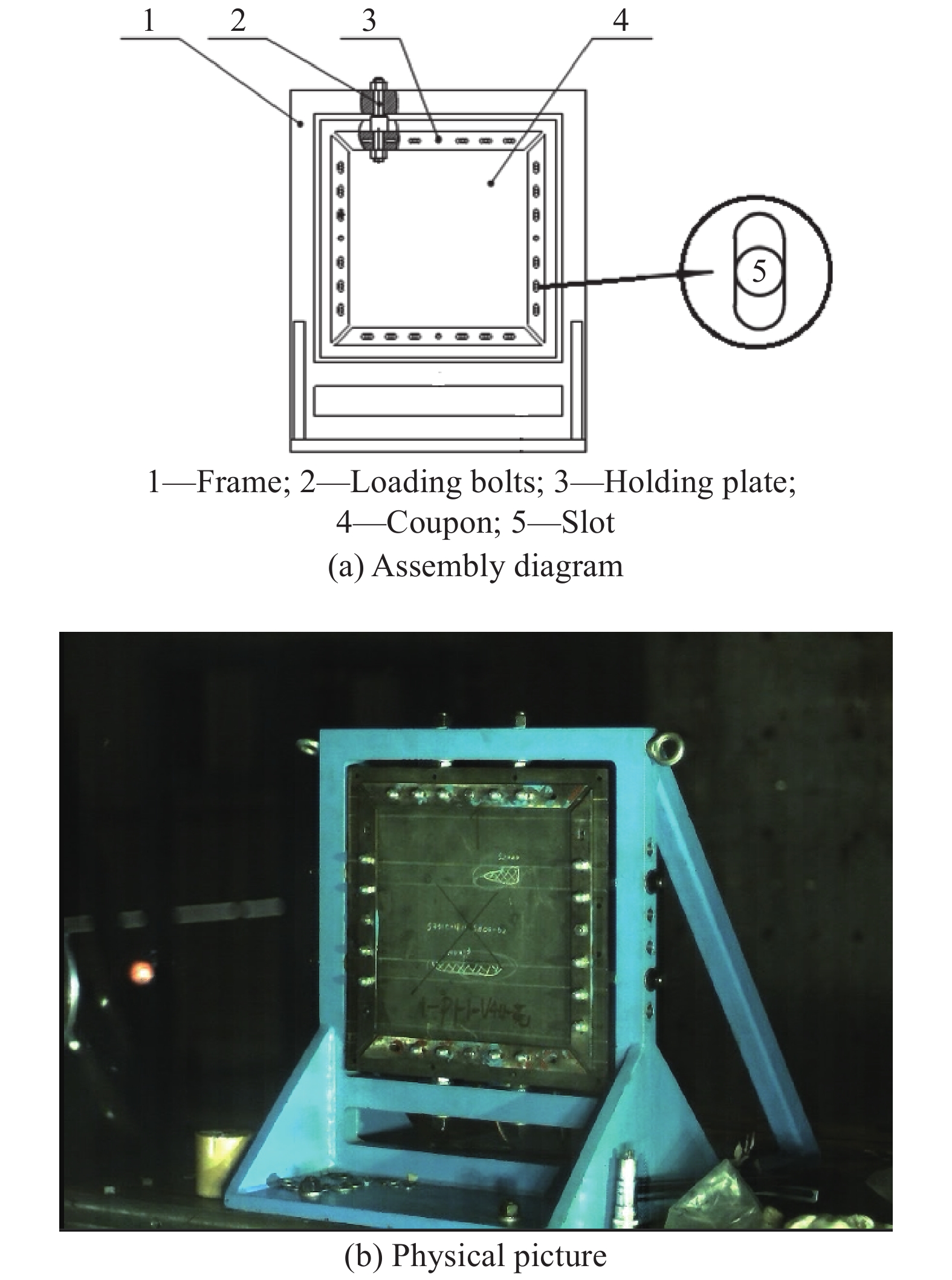

Taking the effect of the in-plane preloading into consideration, the impact behavior of composite panels was studied. A kind of in-plane loading device was designed to apply tension, compression and shear loads. The high-speed impact test method of preloaded composite structures was proposed with the gas gun and the in-plane loading device. Then high-speed impact tests for X850/IM+ and M21C/IMA composite panels were conducted. The test results show that the in-plane preload has a significant influence on the impact response. Compared with the non-preloaded impact process, the in-plane pre-tension raises the structural bending stiffness and the residual speed, resulting in a decrease of the penetration velocity and delamination area, while the effect of the in-plane pre-compression is opposite.

Taking the effect of the in-plane preloading into consideration, the impact behavior of composite panels was studied. A kind of in-plane loading device was designed to apply tension, compression and shear loads. The high-speed impact test method of preloaded composite structures was proposed with the gas gun and the in-plane loading device. Then high-speed impact tests for X850/IM+ and M21C/IMA composite panels were conducted. The test results show that the in-plane preload has a significant influence on the impact response. Compared with the non-preloaded impact process, the in-plane pre-tension raises the structural bending stiffness and the residual speed, resulting in a decrease of the penetration velocity and delamination area, while the effect of the in-plane pre-compression is opposite.

2020, 37(8): 1921-1931.

doi: 10.13801/j.cnki.fhclxb.20191031.003

Abstract:

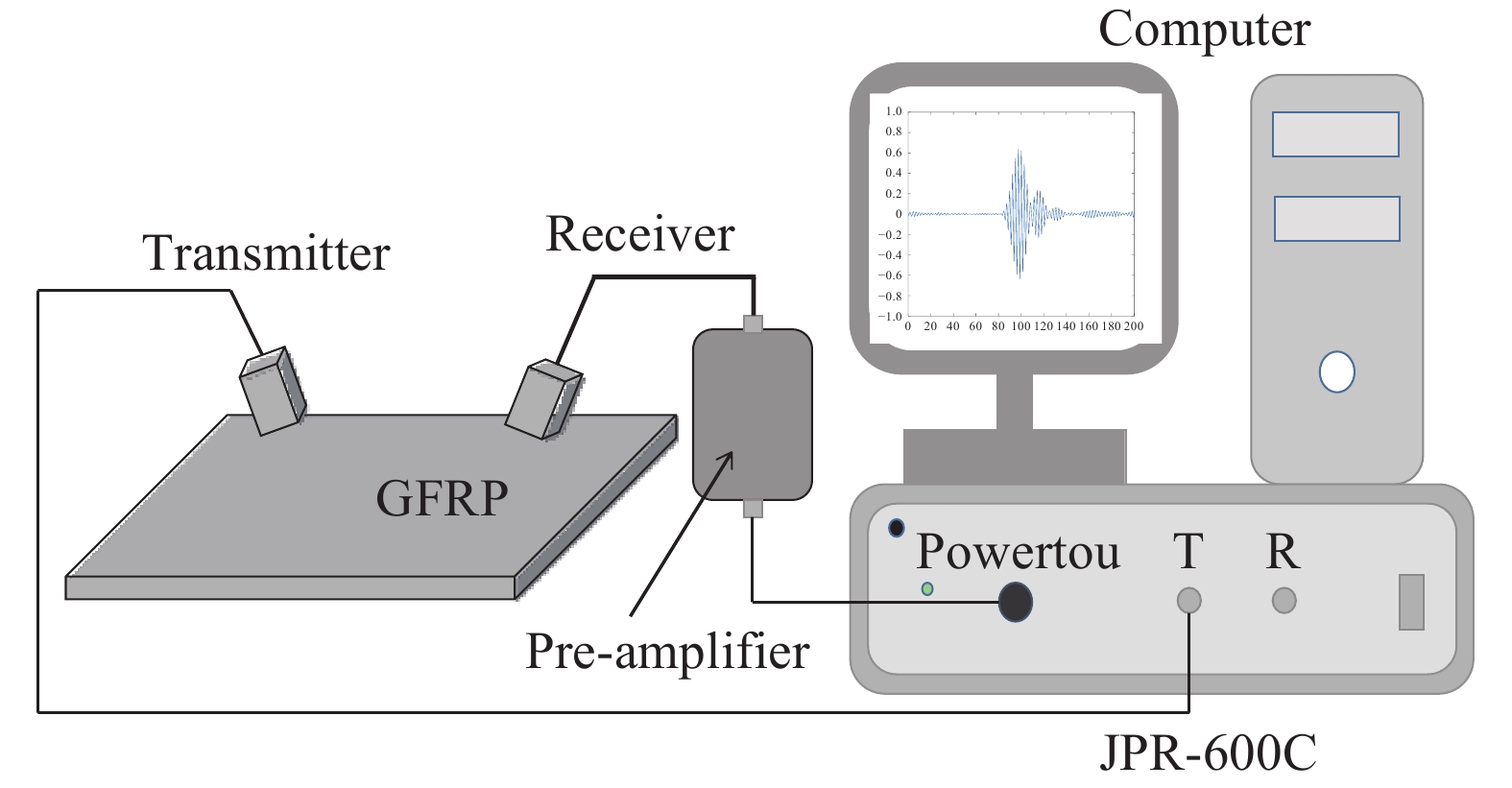

Aiming at the problem that the influence of environmental noise and insensitive damage factor make damage identification difficult and imaging error large for composite plate, a damage factor based on empirical mode decomposition(EMD) and correlation coefficient was proposed. The air-couple probe was used to obtain Lamb wave signal before and after the damage, and a group of intrinsic mode function (IMF) components of signal was obtained by EMD. According to the correlation coefficient, the IMF component which has the greatest correlation with the signal was obtained, and the relative change of its energy value was defined as the damage factor. The validity of the proposed algorithm was assessed by identifying damage and scaning imaging at composite plate. The results show that after EMD, the IMF component with the greatest correlation with the original signal is most sensitive to damage, and can be used as a damage factor to identify damage. Combining this damage factor with probability imaging algorithm for the air-coupled Lamb wave scanning can not only effectively image the defect in composite plate, but also has good noise resistance in simulated strong noise environment.

Aiming at the problem that the influence of environmental noise and insensitive damage factor make damage identification difficult and imaging error large for composite plate, a damage factor based on empirical mode decomposition(EMD) and correlation coefficient was proposed. The air-couple probe was used to obtain Lamb wave signal before and after the damage, and a group of intrinsic mode function (IMF) components of signal was obtained by EMD. According to the correlation coefficient, the IMF component which has the greatest correlation with the signal was obtained, and the relative change of its energy value was defined as the damage factor. The validity of the proposed algorithm was assessed by identifying damage and scaning imaging at composite plate. The results show that after EMD, the IMF component with the greatest correlation with the original signal is most sensitive to damage, and can be used as a damage factor to identify damage. Combining this damage factor with probability imaging algorithm for the air-coupled Lamb wave scanning can not only effectively image the defect in composite plate, but also has good noise resistance in simulated strong noise environment.

2020, 37(8): 1832-1840.

doi: 10.13801/j.cnki.fhclxb.20191206.003

Abstract:

SiO2 or TiO2 nanoparticles/fluorinated polyacrylate polymer (PFHI) composite coatings with thickness of 1 μm were prepared by incorporating nanoparticles into PFHI solution followed by dip-coating and thermal curing. The effects of the amount of SiO2 or TiO2 nanoparticles on the surface properties and corrosion resistance of the composite coatings were investigated. The corrosion electrochemical property of the SiO2 or TiO2/PFHI composite coatings in 3.5wt% NaCl solution was investigated by Tafel curves and electrochemical impedance spectroscopy (EIS). XPS, attenuated total reflection Fourier transform infrared (ATR-FTIR), TG-DTA, SEM, optical contact angle (OCA) were used to characterize the composite coatings. The results show that the addition of SiO2 or TiO2 nanoparticles could greatly improve the corrosion resistance of the PFHI coatings. The SiO2/PFHI composite coating with SiO2 to PFHI of 0.3 in mass ratio exhibits the best electrochemical corrosion resistance performance and the penetration resistance Rct is increased by two order of magnitude compared with the neat PFHI coating. The SiO2 or TiO2 nanoparticles combine with the PFHI tightly and increase the coating surface roughness to form the compact composite coatings, improving the hydrophobicity and compactness and the corrosion resistance of SiO2 or TiO2/PFHI composite coatings.

SiO2 or TiO2 nanoparticles/fluorinated polyacrylate polymer (PFHI) composite coatings with thickness of 1 μm were prepared by incorporating nanoparticles into PFHI solution followed by dip-coating and thermal curing. The effects of the amount of SiO2 or TiO2 nanoparticles on the surface properties and corrosion resistance of the composite coatings were investigated. The corrosion electrochemical property of the SiO2 or TiO2/PFHI composite coatings in 3.5wt% NaCl solution was investigated by Tafel curves and electrochemical impedance spectroscopy (EIS). XPS, attenuated total reflection Fourier transform infrared (ATR-FTIR), TG-DTA, SEM, optical contact angle (OCA) were used to characterize the composite coatings. The results show that the addition of SiO2 or TiO2 nanoparticles could greatly improve the corrosion resistance of the PFHI coatings. The SiO2/PFHI composite coating with SiO2 to PFHI of 0.3 in mass ratio exhibits the best electrochemical corrosion resistance performance and the penetration resistance Rct is increased by two order of magnitude compared with the neat PFHI coating. The SiO2 or TiO2 nanoparticles combine with the PFHI tightly and increase the coating surface roughness to form the compact composite coatings, improving the hydrophobicity and compactness and the corrosion resistance of SiO2 or TiO2/PFHI composite coatings.

2020, 37(8): 1841-1849.

doi: 10.13801/j.cnki.fhclxb.20200214.001

Abstract:

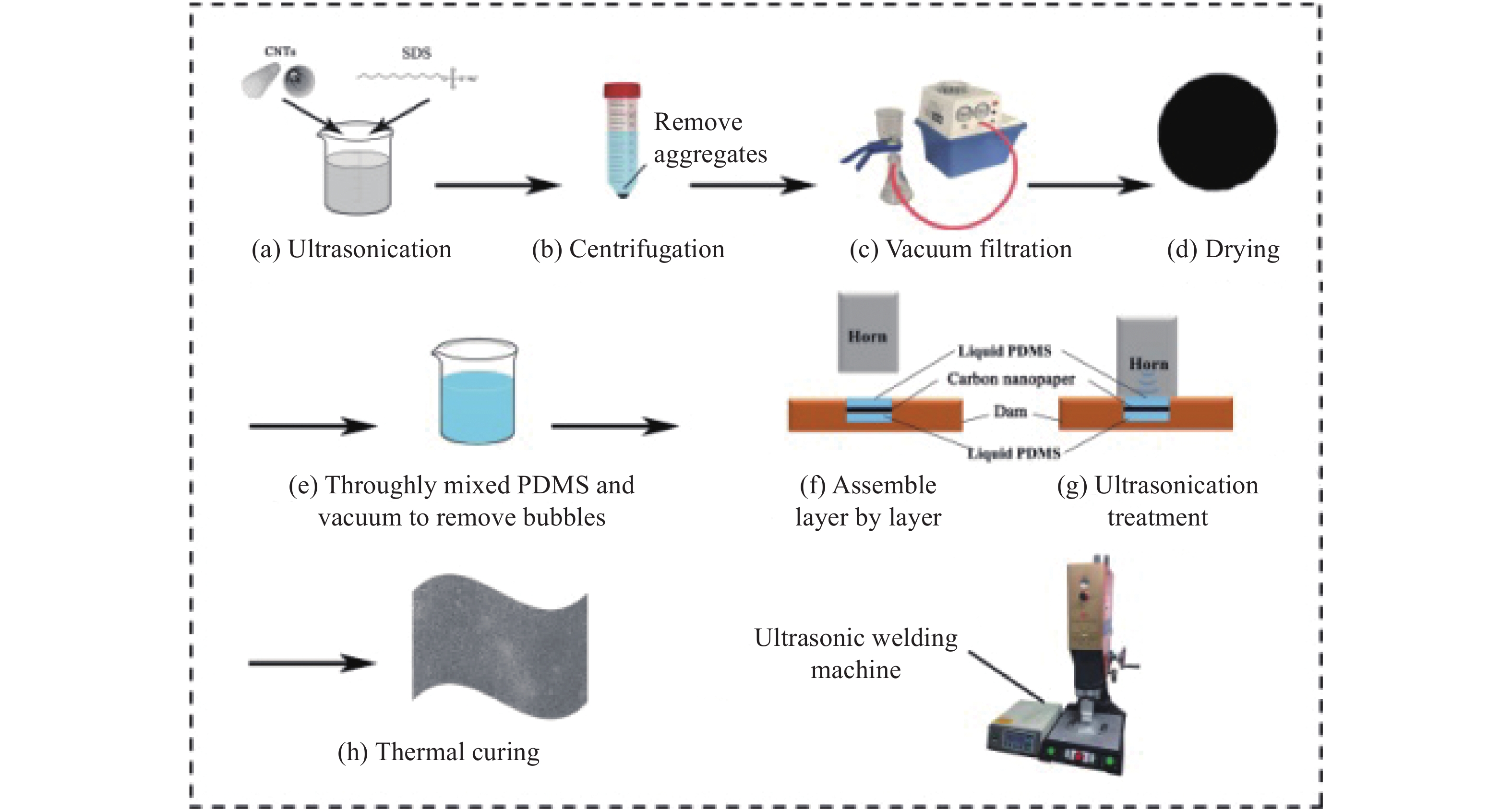

An ultrasonic-assisted forced infiltration method using plastic welding equipment was proposed to realize the efficient preparation of polymer-based thermal conductive composites. The carbon nanopapers (CNPs) consisted by pure carbon nanotubes (CNTs) were prepared using the method of vacuum filtration. The CNPs were placed into uncured polydimethylsiloxane (PDMS) viscous resin. The plastic welding equipment with high frequency and high power ultrasonic source was applied for the ultrasonic treatment, and the liquid PDMS would gradually infiltrated into CNPs depending on the energy transfer effect of ultrasonic wave. The CNPs/PDMS composites with high flexibility and excellent thermal conductivity could be obtained after CNPs/PDMS being cured at 100℃ for 30 min. The experimental results show that under the same amplitude condition, the thermal conductivity of CNPs/PDMS composites would increase first and then decrease with the increase of ultrasonic duration. The thermal conductivity reaches the peak value of 5.781 W/(m·K) when the ultrasonic duration is 1.9 s. The applicability of ultrasonic-assisted forced infiltration method for the preparation of flexible thermal conductive composites is verified in this research work.

An ultrasonic-assisted forced infiltration method using plastic welding equipment was proposed to realize the efficient preparation of polymer-based thermal conductive composites. The carbon nanopapers (CNPs) consisted by pure carbon nanotubes (CNTs) were prepared using the method of vacuum filtration. The CNPs were placed into uncured polydimethylsiloxane (PDMS) viscous resin. The plastic welding equipment with high frequency and high power ultrasonic source was applied for the ultrasonic treatment, and the liquid PDMS would gradually infiltrated into CNPs depending on the energy transfer effect of ultrasonic wave. The CNPs/PDMS composites with high flexibility and excellent thermal conductivity could be obtained after CNPs/PDMS being cured at 100℃ for 30 min. The experimental results show that under the same amplitude condition, the thermal conductivity of CNPs/PDMS composites would increase first and then decrease with the increase of ultrasonic duration. The thermal conductivity reaches the peak value of 5.781 W/(m·K) when the ultrasonic duration is 1.9 s. The applicability of ultrasonic-assisted forced infiltration method for the preparation of flexible thermal conductive composites is verified in this research work.

2020, 37(8): 1875-1883.

doi: 10.13801/j.cnki.fhclxb.20191226.001

Abstract:

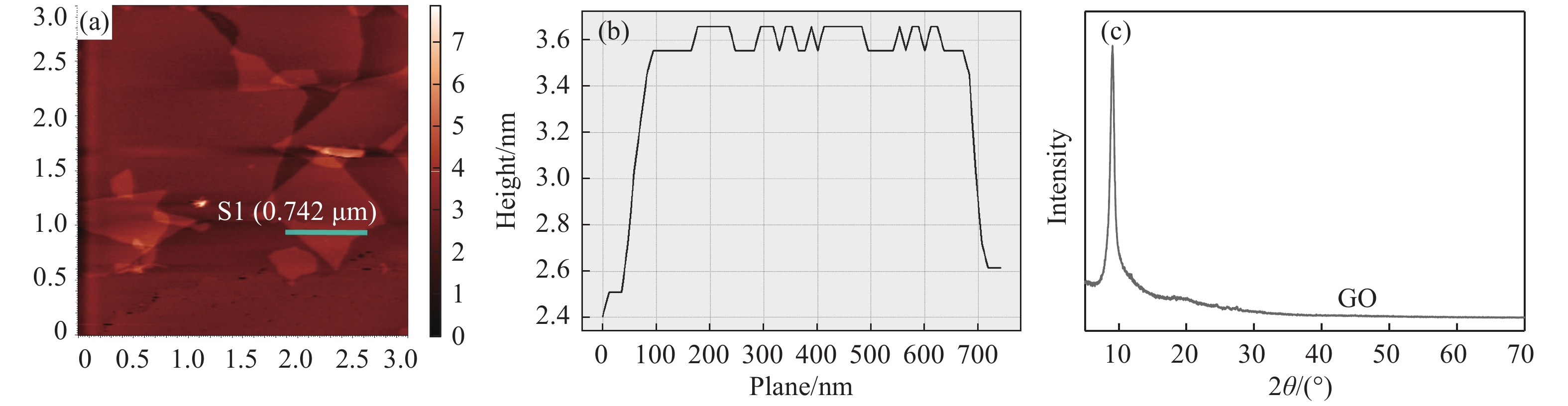

Based on cellulose nanofiber (CNF) and graphene oxide (GO) co-stabilized Pickering emulsion with dichloroethane solution of poly (methyl methacrylate) (PMMA) as the oil phase, the cellulose nanofiber-reduced graphene oxide/poly (methyl methacrylate) (CNF-rGO/PMMA) electromagnetic interference (EMI) shielding composites were subsequently prepared by filtration, reduction and hot-pressing method. The mass fraction of GO in the EMI shielding composites was adjusted by the polymer concentration in the oil phase and the volume ratio of water to oil phase. The effects of GO reduction method, the mass fraction of GO and hot-pressing process on the morphology, structure and property of the obtained CNF-rGO/PMMA EMI shielding composite were studied. The reduction of hydrazine hydrate can transfer GO to rGO more effectively. The hot-pressing process facilitated CNF-rGO sheets surrounding PMMA micro-particles to closely be compacted with PMMA and meanwhile to form a 3D network structure of CNF-rGO sheets which endowed an excellent electrical conductivity of the obtained CNF-rGO/PMMA EMI shielding composites. The CNF-rGO/PMMA EMI shielding composites have good EMI shielding effectiveness and stability in the range of 8.2-12.4 GHz with over 20 dB of EMI shielding effectiveness and possess application in civil EMI material.

Based on cellulose nanofiber (CNF) and graphene oxide (GO) co-stabilized Pickering emulsion with dichloroethane solution of poly (methyl methacrylate) (PMMA) as the oil phase, the cellulose nanofiber-reduced graphene oxide/poly (methyl methacrylate) (CNF-rGO/PMMA) electromagnetic interference (EMI) shielding composites were subsequently prepared by filtration, reduction and hot-pressing method. The mass fraction of GO in the EMI shielding composites was adjusted by the polymer concentration in the oil phase and the volume ratio of water to oil phase. The effects of GO reduction method, the mass fraction of GO and hot-pressing process on the morphology, structure and property of the obtained CNF-rGO/PMMA EMI shielding composite were studied. The reduction of hydrazine hydrate can transfer GO to rGO more effectively. The hot-pressing process facilitated CNF-rGO sheets surrounding PMMA micro-particles to closely be compacted with PMMA and meanwhile to form a 3D network structure of CNF-rGO sheets which endowed an excellent electrical conductivity of the obtained CNF-rGO/PMMA EMI shielding composites. The CNF-rGO/PMMA EMI shielding composites have good EMI shielding effectiveness and stability in the range of 8.2-12.4 GHz with over 20 dB of EMI shielding effectiveness and possess application in civil EMI material.

2020, 37(8): 1884-1893.

doi: 10.13801/j.cnki.fhclxb.20191014.001

Abstract:

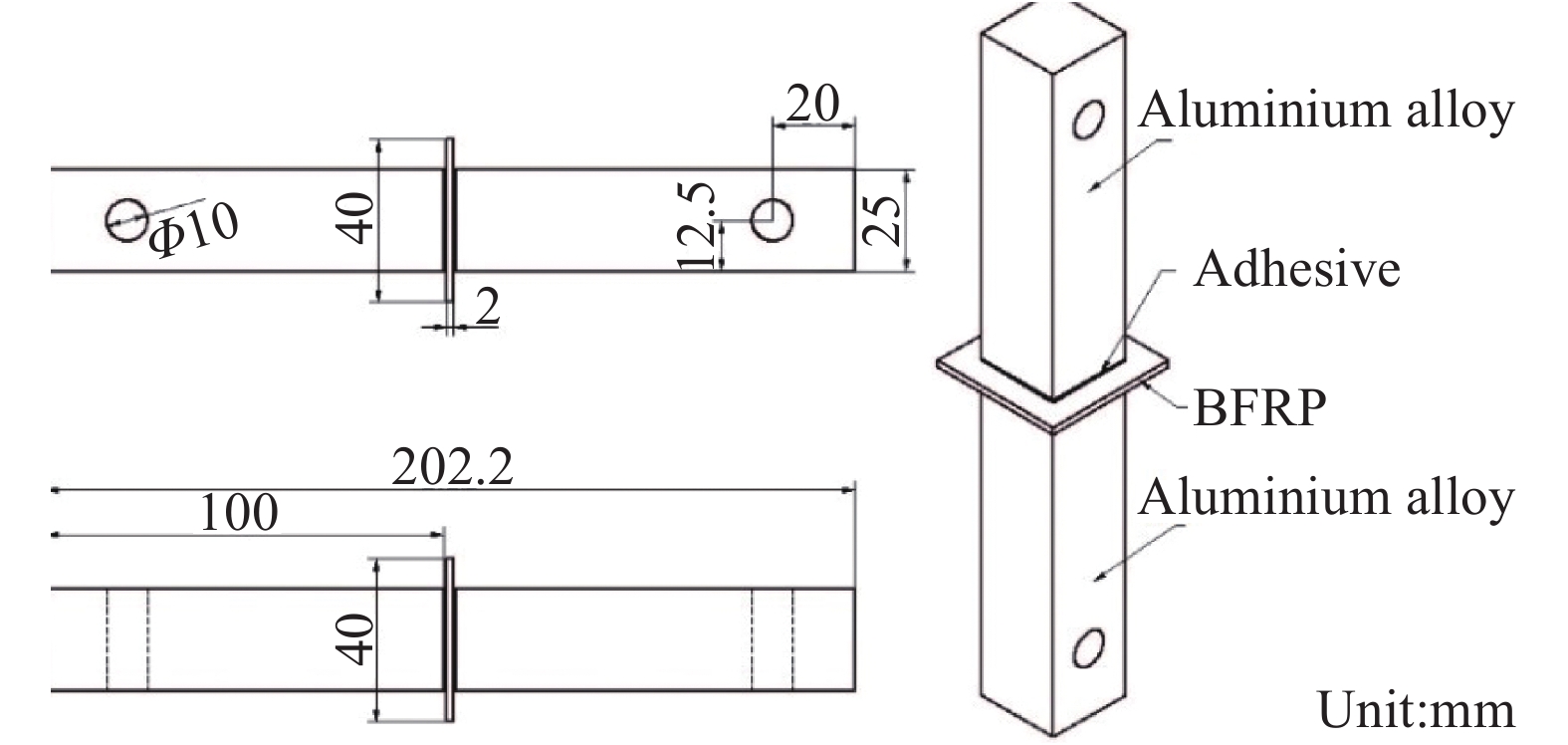

In order to provide reference and guidance for the application of aluminum alloy-basalt fiber reinforced polymer (BFRP) composite bonding structure in automobile industry, the aluminum alloy-BFRP bonding joints were manufactured. Considering the temperature range in the service of automobiles, the low-temperature aging environment of −10℃ and −40℃ was selected to accelerate the aging of joints for 0, 10, 20 and 30 days. The quasi-static tensile test and shear test were carried out on the bond joints after aging, and the quasi-static failure strength of aluminum alloy-BFRP composite bonding joints with different aging time was obtained. DSC and FTIR were combined to analyze the influence of low temperature aging on the chemical properties of adhesive joints, and the failure section of adhesive joints was analyzed by macroscopic analysis and SEM. The results show that the chemical properties of aluminum alloy-BFRP composite bonding joints are not significantly affected by the low-temperature aging, and the functional groups and glass conversion temperature (Tg) of BFRP composite do not change significantly in the low-temperature aging environment. The failure strength and failure mode of the joints are mainly affected by the thermal stress of adhesive and bonding substrate. As for tensile joints, with the increase of low-temperature aging time, the mechanical properties between BFRP composite fiber and resin matrix decrease, the proportion of fiber tearing in the failure section of aluminum alloy-BFRP composite joint decreases gradually, and the failure strength of tensile joints decreases gradually. After aging, the shear joint is still a cohesive failure, and the low-temperature aging of BFRP composite has little effect on the mechanical properties of aluminum alloy-BFRP composite joint. The decrease of failure strength of shear joint is mainly caused by the thermal stress which is the result of the inconsistency of thermal expansion coefficient between adhesive and bonding substrate. The second stress criterion formula was used to fit the variation rules of tensile stress and shear stress with aging time. On the basis of this failure criterion, according to the response surface principle, the three-dimensional surface of failure criterion with aging time was established to provide reference for the engineering application of bonding technology in body structure.

In order to provide reference and guidance for the application of aluminum alloy-basalt fiber reinforced polymer (BFRP) composite bonding structure in automobile industry, the aluminum alloy-BFRP bonding joints were manufactured. Considering the temperature range in the service of automobiles, the low-temperature aging environment of −10℃ and −40℃ was selected to accelerate the aging of joints for 0, 10, 20 and 30 days. The quasi-static tensile test and shear test were carried out on the bond joints after aging, and the quasi-static failure strength of aluminum alloy-BFRP composite bonding joints with different aging time was obtained. DSC and FTIR were combined to analyze the influence of low temperature aging on the chemical properties of adhesive joints, and the failure section of adhesive joints was analyzed by macroscopic analysis and SEM. The results show that the chemical properties of aluminum alloy-BFRP composite bonding joints are not significantly affected by the low-temperature aging, and the functional groups and glass conversion temperature (Tg) of BFRP composite do not change significantly in the low-temperature aging environment. The failure strength and failure mode of the joints are mainly affected by the thermal stress of adhesive and bonding substrate. As for tensile joints, with the increase of low-temperature aging time, the mechanical properties between BFRP composite fiber and resin matrix decrease, the proportion of fiber tearing in the failure section of aluminum alloy-BFRP composite joint decreases gradually, and the failure strength of tensile joints decreases gradually. After aging, the shear joint is still a cohesive failure, and the low-temperature aging of BFRP composite has little effect on the mechanical properties of aluminum alloy-BFRP composite joint. The decrease of failure strength of shear joint is mainly caused by the thermal stress which is the result of the inconsistency of thermal expansion coefficient between adhesive and bonding substrate. The second stress criterion formula was used to fit the variation rules of tensile stress and shear stress with aging time. On the basis of this failure criterion, according to the response surface principle, the three-dimensional surface of failure criterion with aging time was established to provide reference for the engineering application of bonding technology in body structure.

2020, 37(8): 1894-1903.

doi: 10.13801/j.cnki.fhclxb.20191206.001

Abstract:

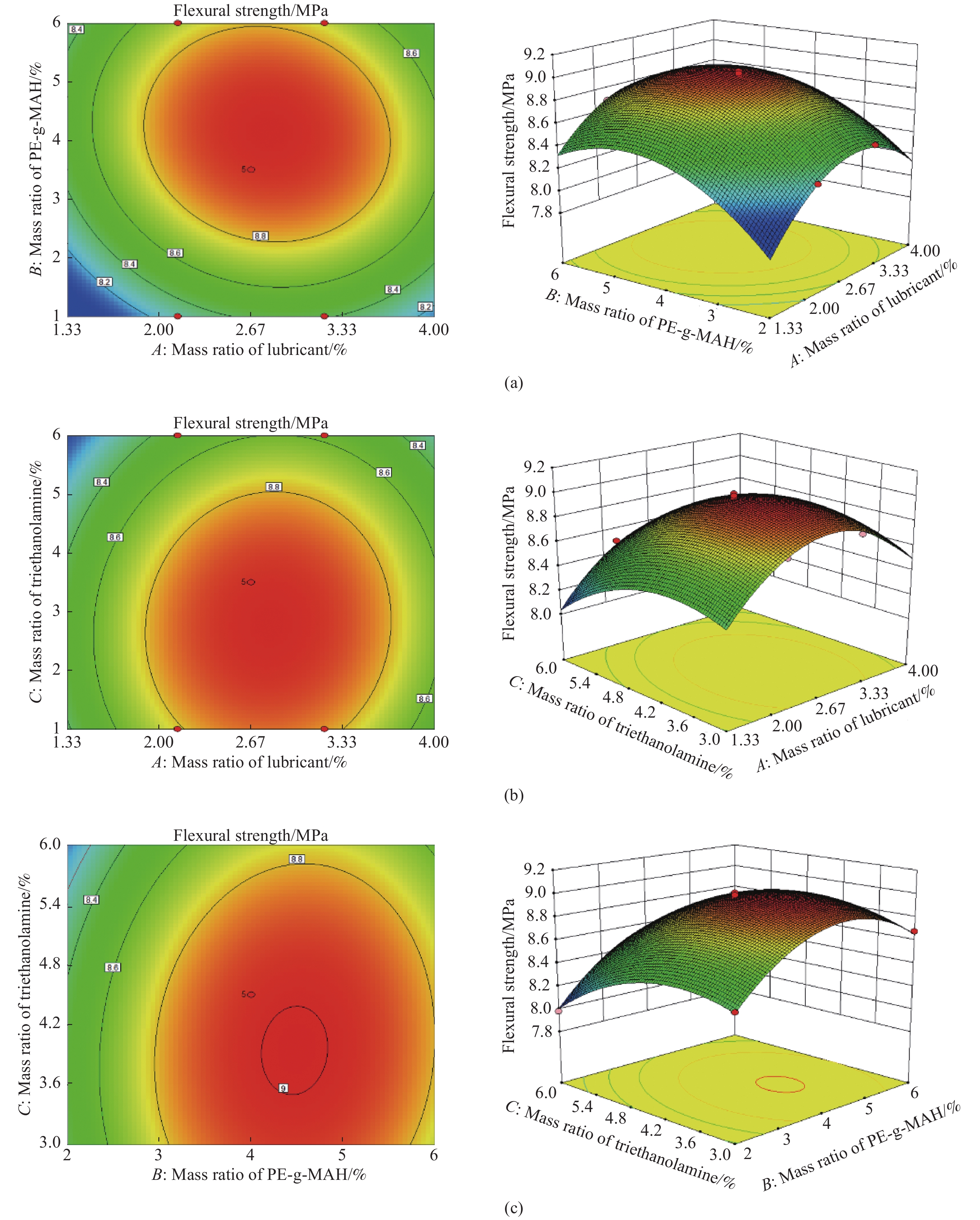

In order to realize the resource utilization of bloom algae and penicillin residue and further improve the mechanical properties of algae powder-penicillin residue/low density polyethylene (LDPE) composites, the mixture of penicillin residue with algae powder from Chao Lake and LDPE were used as the raw materials. The experimental scheme was designed by the response surface method, and the effects of the addition of polyethylene wax (PE-wax) and white oil, maleic anhydride grafted polyethylene (PE-g-MAH) and triethanolamine on the mechanical properties of the algae powder-penicillin residue/LDPE composites were studied. When the mass ratios of mixture of penicillin residue with algae powder and LDPE are 15.00% and 85.00%, the results of variance analysis of response surface regression equation show that the interaction between PE-g-MAH and triethanolamine is significant, but the interaction between lubricant and PE-g-MAH, lubricant and triethanolamine is not significant. The optimum process parameters predicted by the response surface regression model are as follows: when the mass ratios of lubricant, PE-g-MAH and triethanolamine are 3.08%, 4.33% and 4.23%, the tensile strength, flexural strength and flexural modulus of the algae powder-penicillin residue/LDPE composites are 12.30 MPa, 9.03 MPa and 220.00 MPa, respectively, which are increased by 10.81%, 29.74% and 34.97%, compared with the algae powder-penicillin residue/LDPE composites without additives.

In order to realize the resource utilization of bloom algae and penicillin residue and further improve the mechanical properties of algae powder-penicillin residue/low density polyethylene (LDPE) composites, the mixture of penicillin residue with algae powder from Chao Lake and LDPE were used as the raw materials. The experimental scheme was designed by the response surface method, and the effects of the addition of polyethylene wax (PE-wax) and white oil, maleic anhydride grafted polyethylene (PE-g-MAH) and triethanolamine on the mechanical properties of the algae powder-penicillin residue/LDPE composites were studied. When the mass ratios of mixture of penicillin residue with algae powder and LDPE are 15.00% and 85.00%, the results of variance analysis of response surface regression equation show that the interaction between PE-g-MAH and triethanolamine is significant, but the interaction between lubricant and PE-g-MAH, lubricant and triethanolamine is not significant. The optimum process parameters predicted by the response surface regression model are as follows: when the mass ratios of lubricant, PE-g-MAH and triethanolamine are 3.08%, 4.33% and 4.23%, the tensile strength, flexural strength and flexural modulus of the algae powder-penicillin residue/LDPE composites are 12.30 MPa, 9.03 MPa and 220.00 MPa, respectively, which are increased by 10.81%, 29.74% and 34.97%, compared with the algae powder-penicillin residue/LDPE composites without additives.

2020, 37(8): 1904-1910.

doi: 10.13801/j.cnki.fhclxb.20191113.006

Abstract:

The interlaminar fracture toughness of carbon fiber reinforced epoxy resin (CF/EP) composites was studied. The type II interlaminar fracture toughness (GIIC) was studied by adding four kinds of inorganic nano-particles and three kinds of thermoplastic particles into the interlaminar of CF/EP composites . One kind of inorganic nano-particle and one kind of thermoplastic particles with good operability and tougheness effect were selected to study the synergistic toughening property. The results show that the GIIC of CF/EP composites is improved with appropriate inorganic nano-particle, which is mainly due to the micro-structure formation between layers and fracture energy absorbed effectively. The comprehensive properties of nano sheet boehmite (AlOOH) are the best. When the content of AlOOH nano particles is 1wt%, the GIIC of CF/EP composites reaches 931 J/m2, which increases by 29.3%. Among the thermoplastic particles, the modified poly (aryl ether ketone) (PAEK) has the best comprehensive properties. Adding 10 wt%PAEK in the layers, the GIIC of the CF/EP composite can be increased by 32%. This is due to the diffusion of thermoplastic particles between layers along with the flow of EP matrix, forming a unique interlaminar continuous structure, which increases the resistance of crack propagation and effectively improves GIIC of the CF/EP composites. The GIIC of the CF/EP composites toughened by both 10wt%PAEK and 1wt%AlOOH reaches 1 368 J/m2, compared with the non-toughened CF/EP composites , which is increased by 90%. The toughening effect is greater than the sum of adding PAEK and AlOOH. This shows that the addition of both PAEK and AlOOH into the interlayer of CF/EP composites has a synergistic toughening effect.

The interlaminar fracture toughness of carbon fiber reinforced epoxy resin (CF/EP) composites was studied. The type II interlaminar fracture toughness (GIIC) was studied by adding four kinds of inorganic nano-particles and three kinds of thermoplastic particles into the interlaminar of CF/EP composites . One kind of inorganic nano-particle and one kind of thermoplastic particles with good operability and tougheness effect were selected to study the synergistic toughening property. The results show that the GIIC of CF/EP composites is improved with appropriate inorganic nano-particle, which is mainly due to the micro-structure formation between layers and fracture energy absorbed effectively. The comprehensive properties of nano sheet boehmite (AlOOH) are the best. When the content of AlOOH nano particles is 1wt%, the GIIC of CF/EP composites reaches 931 J/m2, which increases by 29.3%. Among the thermoplastic particles, the modified poly (aryl ether ketone) (PAEK) has the best comprehensive properties. Adding 10 wt%PAEK in the layers, the GIIC of the CF/EP composite can be increased by 32%. This is due to the diffusion of thermoplastic particles between layers along with the flow of EP matrix, forming a unique interlaminar continuous structure, which increases the resistance of crack propagation and effectively improves GIIC of the CF/EP composites. The GIIC of the CF/EP composites toughened by both 10wt%PAEK and 1wt%AlOOH reaches 1 368 J/m2, compared with the non-toughened CF/EP composites , which is increased by 90%. The toughening effect is greater than the sum of adding PAEK and AlOOH. This shows that the addition of both PAEK and AlOOH into the interlayer of CF/EP composites has a synergistic toughening effect.

2020, 37(8): 1911-1920.

doi: 10.13801/j.cnki.fhclxb.20191118.002

Abstract:

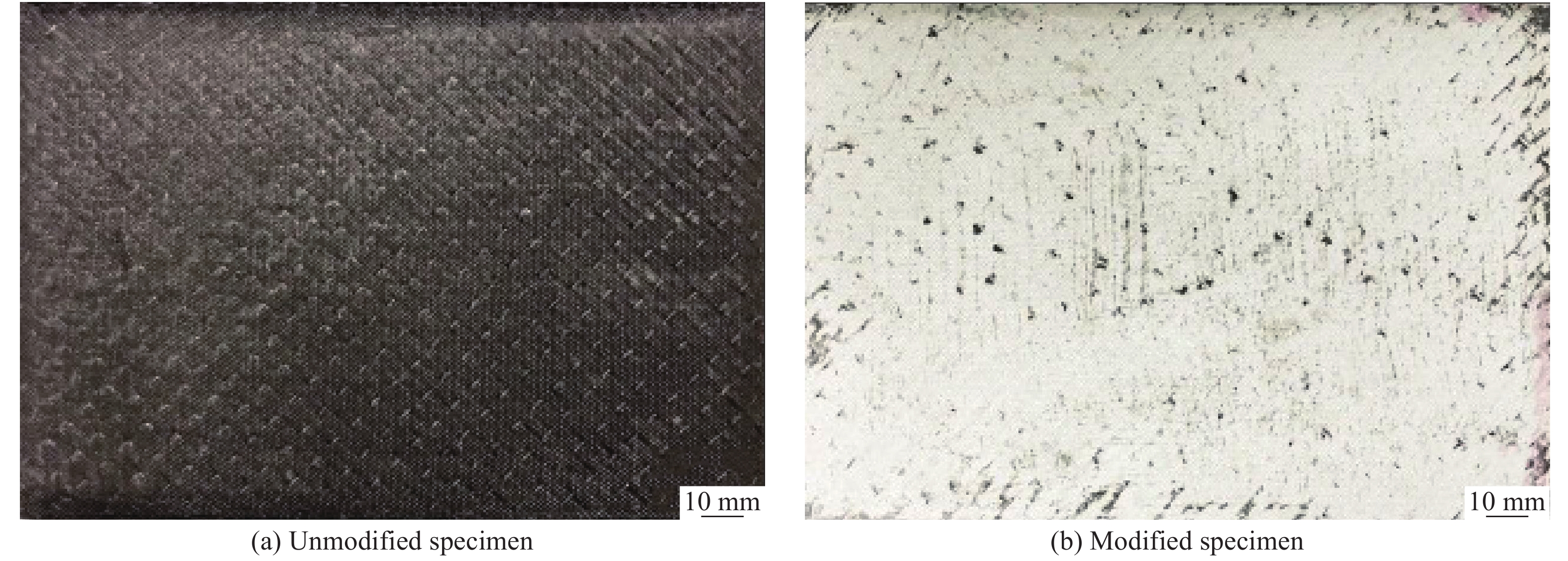

Aiming at the shortcoming of carbon fiber reinforced polymer (CFRP) composite with high-resistance resin matrix producing large amount of joule heat damage caused by lightning under the action of lightning current, this paper explored to solve this problem by improving the conductivity of matrix. In order to modify CFRP composite matrix, a conductive filler based on Ag powder was added into the epoxy resin matrix paste and the conductivity of the modified CFRP composite laminate increases 217.30 times in thickness direction. The single D component of lightning current with different peak values was used to conduct lightning damage test on the modified and unmodified CFRP composite laminates. The ultrasonic C-scan image of the damaged area, the residual temperature field of the specimen and simulated pyrolysis damage were compared to analyze the protection mechanism. The results show that the electrical conductivity of CFRP composite laminates is improved by Ag-powder-matrix modification, and the modification effect is the best in thickness direction. Under the condition of peak current of 20 kA, 40 kA and 60 kA, the damage areas of modified CFRP composite laminates decrease by 87.28%, 77.82% and 88.59%, respectively, and the maximum damage depths increase by 147.06%, 130.65% and 119.72%, respectively. Taking the damage volume as the final index, the Ag-powder-matrix modification can effectively reduce the lightning damage of CFRP composite, and the protection mechanism is to reduce pyrolysis and explosion impact by reducing the area of high temperature and the temperature rise range under the action of lightning current.

Aiming at the shortcoming of carbon fiber reinforced polymer (CFRP) composite with high-resistance resin matrix producing large amount of joule heat damage caused by lightning under the action of lightning current, this paper explored to solve this problem by improving the conductivity of matrix. In order to modify CFRP composite matrix, a conductive filler based on Ag powder was added into the epoxy resin matrix paste and the conductivity of the modified CFRP composite laminate increases 217.30 times in thickness direction. The single D component of lightning current with different peak values was used to conduct lightning damage test on the modified and unmodified CFRP composite laminates. The ultrasonic C-scan image of the damaged area, the residual temperature field of the specimen and simulated pyrolysis damage were compared to analyze the protection mechanism. The results show that the electrical conductivity of CFRP composite laminates is improved by Ag-powder-matrix modification, and the modification effect is the best in thickness direction. Under the condition of peak current of 20 kA, 40 kA and 60 kA, the damage areas of modified CFRP composite laminates decrease by 87.28%, 77.82% and 88.59%, respectively, and the maximum damage depths increase by 147.06%, 130.65% and 119.72%, respectively. Taking the damage volume as the final index, the Ag-powder-matrix modification can effectively reduce the lightning damage of CFRP composite, and the protection mechanism is to reduce pyrolysis and explosion impact by reducing the area of high temperature and the temperature rise range under the action of lightning current.

2020, 37(8): 1932-1943.

doi: 10.13801/j.cnki.fhclxb.20191022.001

Abstract:

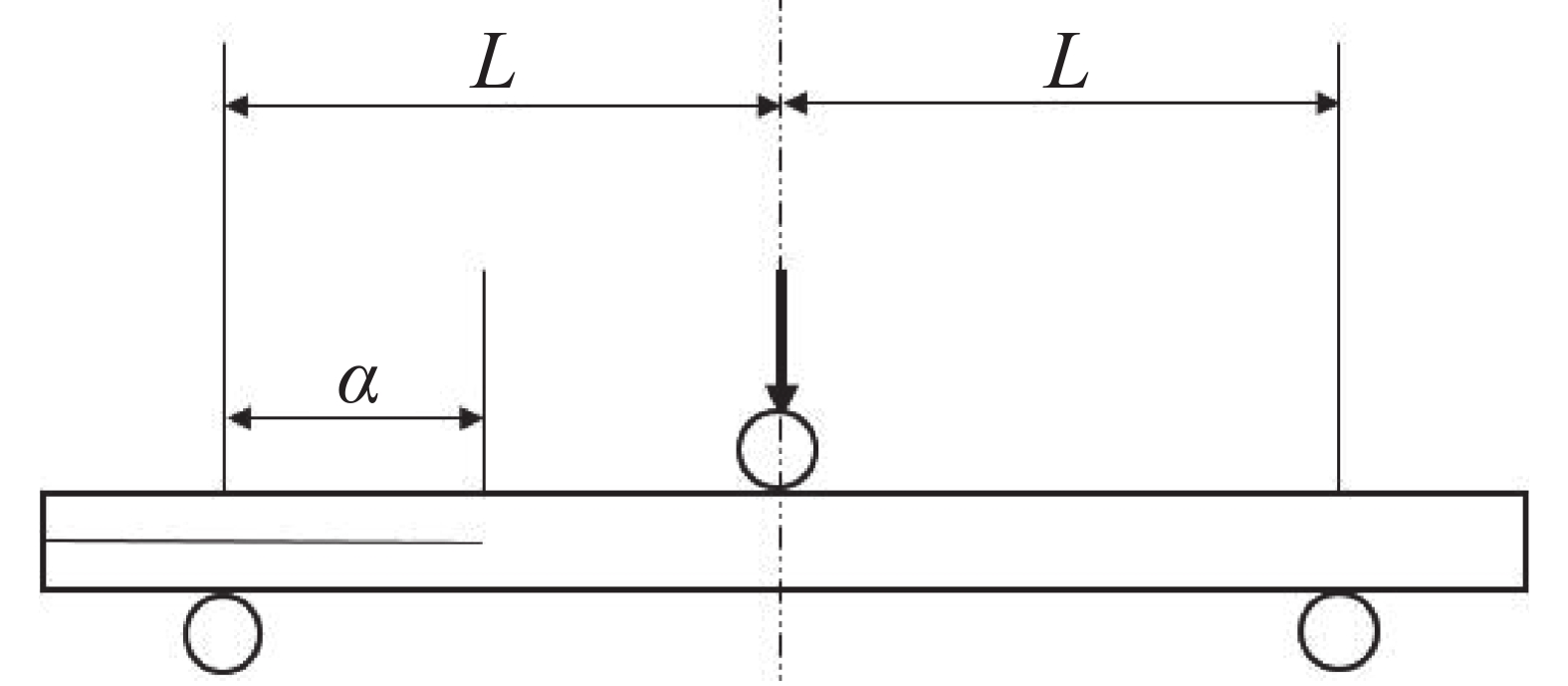

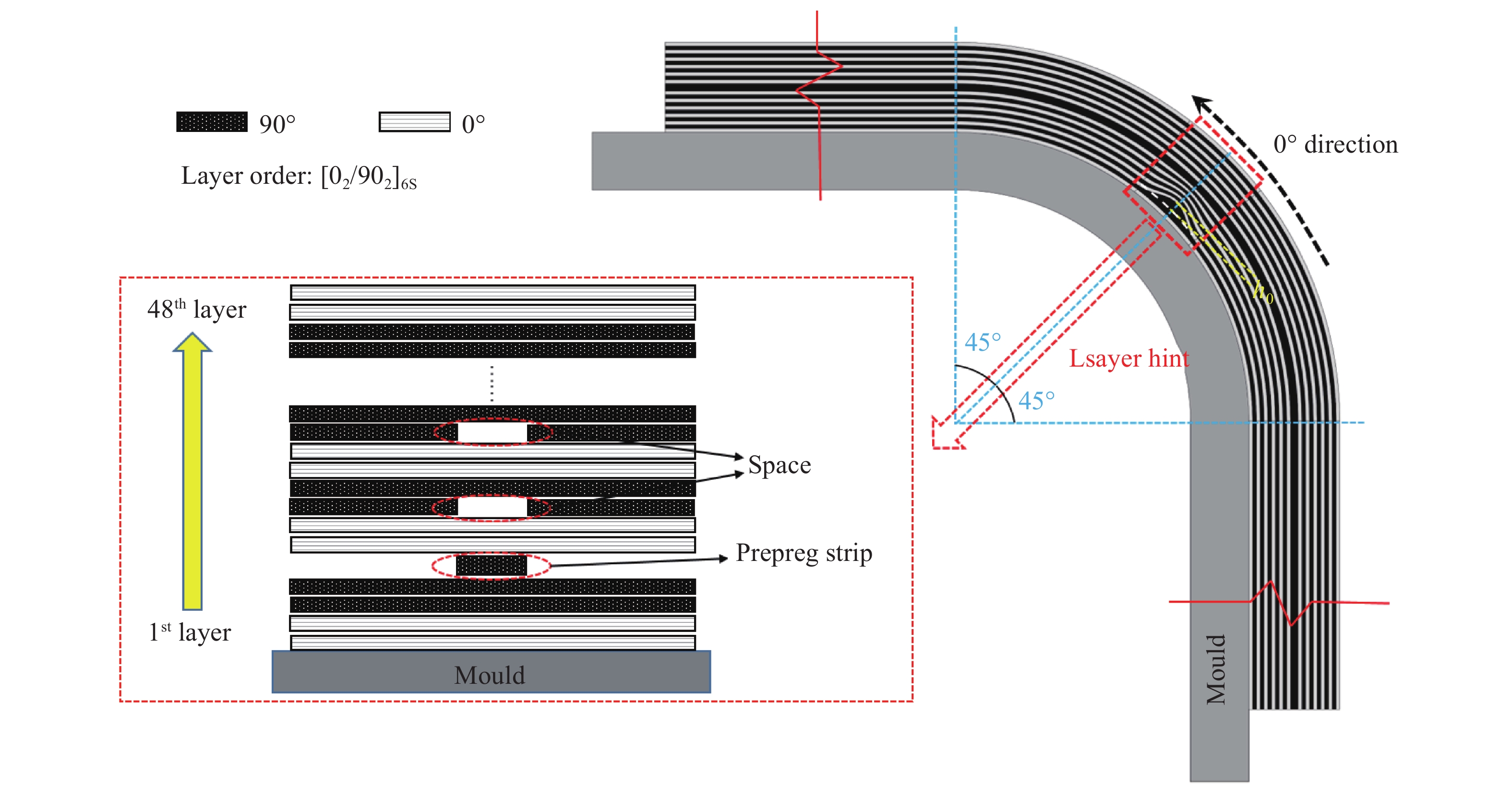

The mechanical responses and failure evolution process of L-shaped composite laminates with effect of wrinkle defects were investigated using experimental and numerical methods. In experimental study, L-shaped laminates containing different magnitudes of wrinkle defects were prepared with the aid of ‘transverse-strip’ method. The loading capability and damage propagation of L-shaped samples containing wrinkle defects were investigated within bending test and compared with ones of the intact samples. In numerical study, a progressive damage failure model was created based on 3D Hashin failure criterion. Afterwards, the numerical model was applied to predict the evaluation of stresses distribution and failure mode during failure process. The mechanism of wrinkle impact on the failure behavior of L-shaped laminates was explored further. Test result shows that wrinkle defects significantly reduce the loading capacity of L-shaped laminates and the spatial extension characteristic of delamination damage evolution is changed from the layer-by-layer extension to the aggregation extension of wrinkle area. The numerical predictions consist with the experimental observations. It is revealed that concentrations of transverse stress and out-of-plane stress at wrinkle area are the dominant factors response for the premature failure. In addition, the stress concentrations in wrinkle area destroy the tendency of layer-by-layer damage, leading to the wrinkled samples to exhibit agglomerated extended failure characteristics. The above-mentioned researches can provide a strategy to assess the structural integrity of L-shaped laminates containing wrinkle defects and determine their design of damage tolerance.

The mechanical responses and failure evolution process of L-shaped composite laminates with effect of wrinkle defects were investigated using experimental and numerical methods. In experimental study, L-shaped laminates containing different magnitudes of wrinkle defects were prepared with the aid of ‘transverse-strip’ method. The loading capability and damage propagation of L-shaped samples containing wrinkle defects were investigated within bending test and compared with ones of the intact samples. In numerical study, a progressive damage failure model was created based on 3D Hashin failure criterion. Afterwards, the numerical model was applied to predict the evaluation of stresses distribution and failure mode during failure process. The mechanism of wrinkle impact on the failure behavior of L-shaped laminates was explored further. Test result shows that wrinkle defects significantly reduce the loading capacity of L-shaped laminates and the spatial extension characteristic of delamination damage evolution is changed from the layer-by-layer extension to the aggregation extension of wrinkle area. The numerical predictions consist with the experimental observations. It is revealed that concentrations of transverse stress and out-of-plane stress at wrinkle area are the dominant factors response for the premature failure. In addition, the stress concentrations in wrinkle area destroy the tendency of layer-by-layer damage, leading to the wrinkled samples to exhibit agglomerated extended failure characteristics. The above-mentioned researches can provide a strategy to assess the structural integrity of L-shaped laminates containing wrinkle defects and determine their design of damage tolerance.

2020, 37(8): 1944-1950.

doi: 10.13801/j.cnki.fhclxb.20190618.001

Abstract:

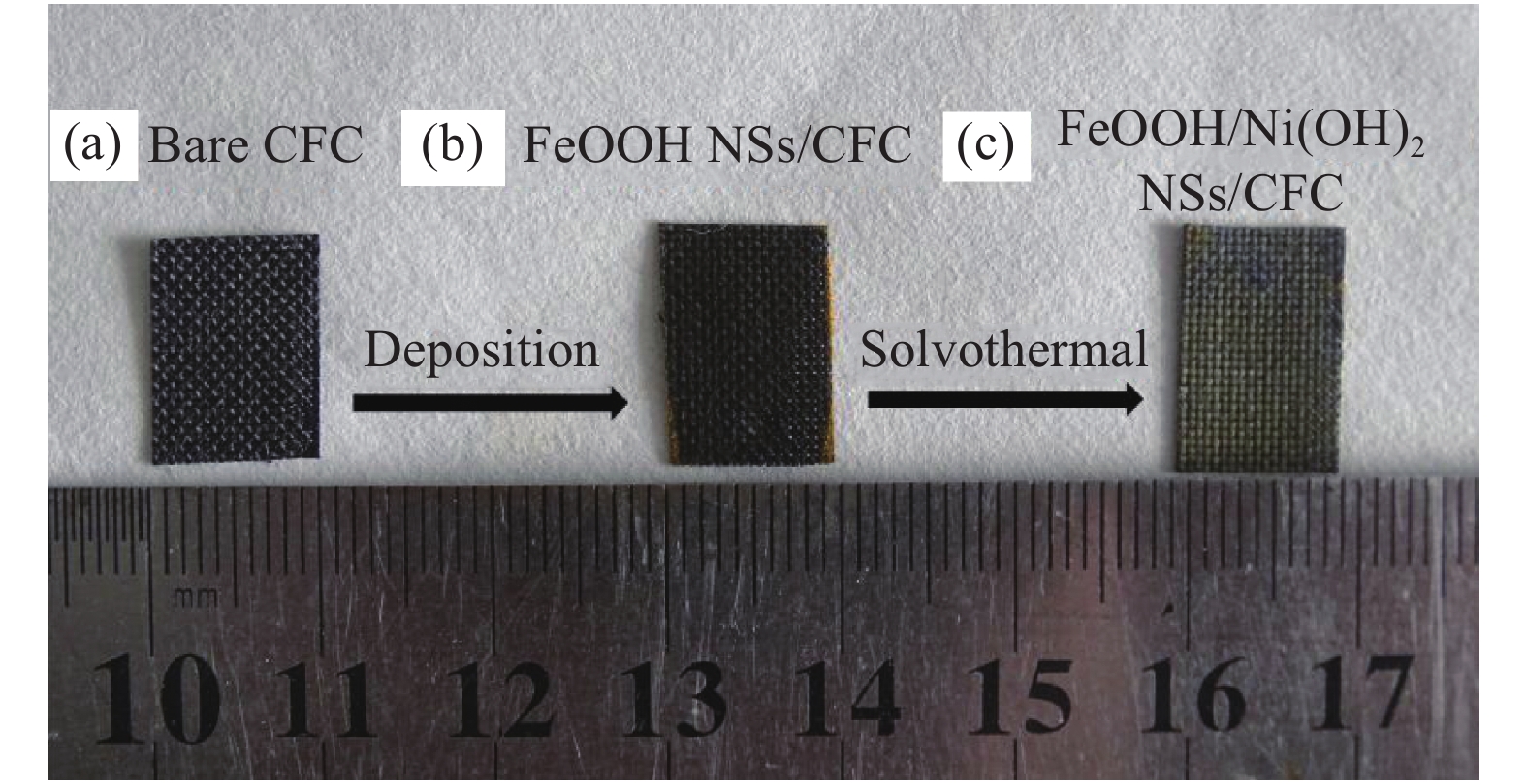

FeOOH-Ni(OH)2 composites were successfully prepared on carbon fiber cloth (CFC) by electrochemical deposition and hydrothermal method. The electrocatalytic oxygen evolution activity of the FeOOH-Ni(OH)2 composite is significantly improved compared with FeOOH and Ni(OH)2. The FeOOH-Ni(OH)2 electrodes require an overpotential as low as 270 mV and the tafel slope to deliver 10 mA·cm−2 for oxygen evolution reaction (OER) in 1 mol/L KOH. The electrochemical impedance spectroscopy further reveals the favorable kinetic during electrolysis. Moreover, The FeOOH-Ni(OH)2 composite has excellent stability in the alkaline medium, and its overpotential remains stable during the 24 h test at high current density(50 mA·cm−2). The strong electron interaction and synergistic reaction between FeOOH and Ni(OH)2 are enhanced effectively. The conductivity promotes the charge transfer, and the core-shell structure effectively enhances the electrocatalytic activity area, and further enhances its oxygen evolution properties.

FeOOH-Ni(OH)2 composites were successfully prepared on carbon fiber cloth (CFC) by electrochemical deposition and hydrothermal method. The electrocatalytic oxygen evolution activity of the FeOOH-Ni(OH)2 composite is significantly improved compared with FeOOH and Ni(OH)2. The FeOOH-Ni(OH)2 electrodes require an overpotential as low as 270 mV and the tafel slope to deliver 10 mA·cm−2 for oxygen evolution reaction (OER) in 1 mol/L KOH. The electrochemical impedance spectroscopy further reveals the favorable kinetic during electrolysis. Moreover, The FeOOH-Ni(OH)2 composite has excellent stability in the alkaline medium, and its overpotential remains stable during the 24 h test at high current density(50 mA·cm−2). The strong electron interaction and synergistic reaction between FeOOH and Ni(OH)2 are enhanced effectively. The conductivity promotes the charge transfer, and the core-shell structure effectively enhances the electrocatalytic activity area, and further enhances its oxygen evolution properties.

2020, 37(8): 1951-1959.

doi: 10.13801/j.cnki.fhclxb.20191230.001

Abstract:

In order to prepare graphite/Cu composites with excellent thermodynamic properties, the natural graphite flakes were highly oriented on the surface of copper foil by tape casting method. The high-oriented graphite flake/Cu composites with layered structure were prepared by vacuum hot-pressing method. The phases and morphology of graphite flake/Cu composites were characterized by XRD and SEM. The results show that the solvent used for casting is fully volatilized after heat-treated process. The aligned graphite flakes between two copper foil layers overlap each other and partially melted copper penetrates other copper layers across the pores of the graphite layer. This structure allows the graphite/Cu composite to achieve excellent thermophysical properties. As the volume fraction of graphite is 20vol% to 70vol%, the thermal conductivity of the graphite flake/Cu composite increases from 402 W/(m·K) to 743 W/(m·K) in high thermal conductivity plane, while the bending strength is 126~48 MPa.The heat transfer mechanism of graphite flake/Cu composites is discussed deeply and a thermal conductivity prediction model has been established.

In order to prepare graphite/Cu composites with excellent thermodynamic properties, the natural graphite flakes were highly oriented on the surface of copper foil by tape casting method. The high-oriented graphite flake/Cu composites with layered structure were prepared by vacuum hot-pressing method. The phases and morphology of graphite flake/Cu composites were characterized by XRD and SEM. The results show that the solvent used for casting is fully volatilized after heat-treated process. The aligned graphite flakes between two copper foil layers overlap each other and partially melted copper penetrates other copper layers across the pores of the graphite layer. This structure allows the graphite/Cu composite to achieve excellent thermophysical properties. As the volume fraction of graphite is 20vol% to 70vol%, the thermal conductivity of the graphite flake/Cu composite increases from 402 W/(m·K) to 743 W/(m·K) in high thermal conductivity plane, while the bending strength is 126~48 MPa.The heat transfer mechanism of graphite flake/Cu composites is discussed deeply and a thermal conductivity prediction model has been established.

2020, 37(8): 1969-1980.

doi: 10.13801/j.cnki.fhclxb.20191216.001

Abstract: