Multivariable optimization design method of composite stiffener based on critical stiffness

-

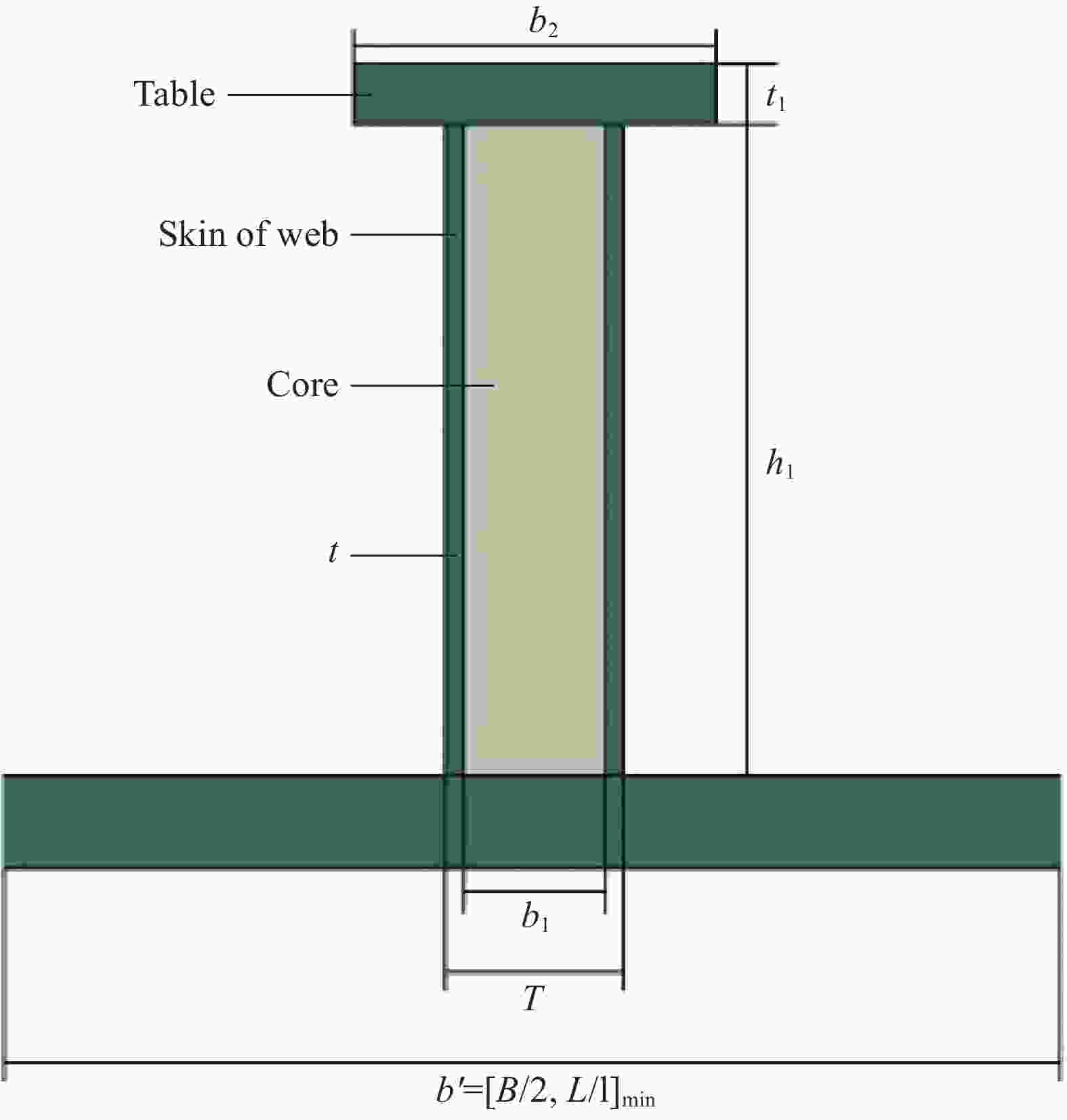

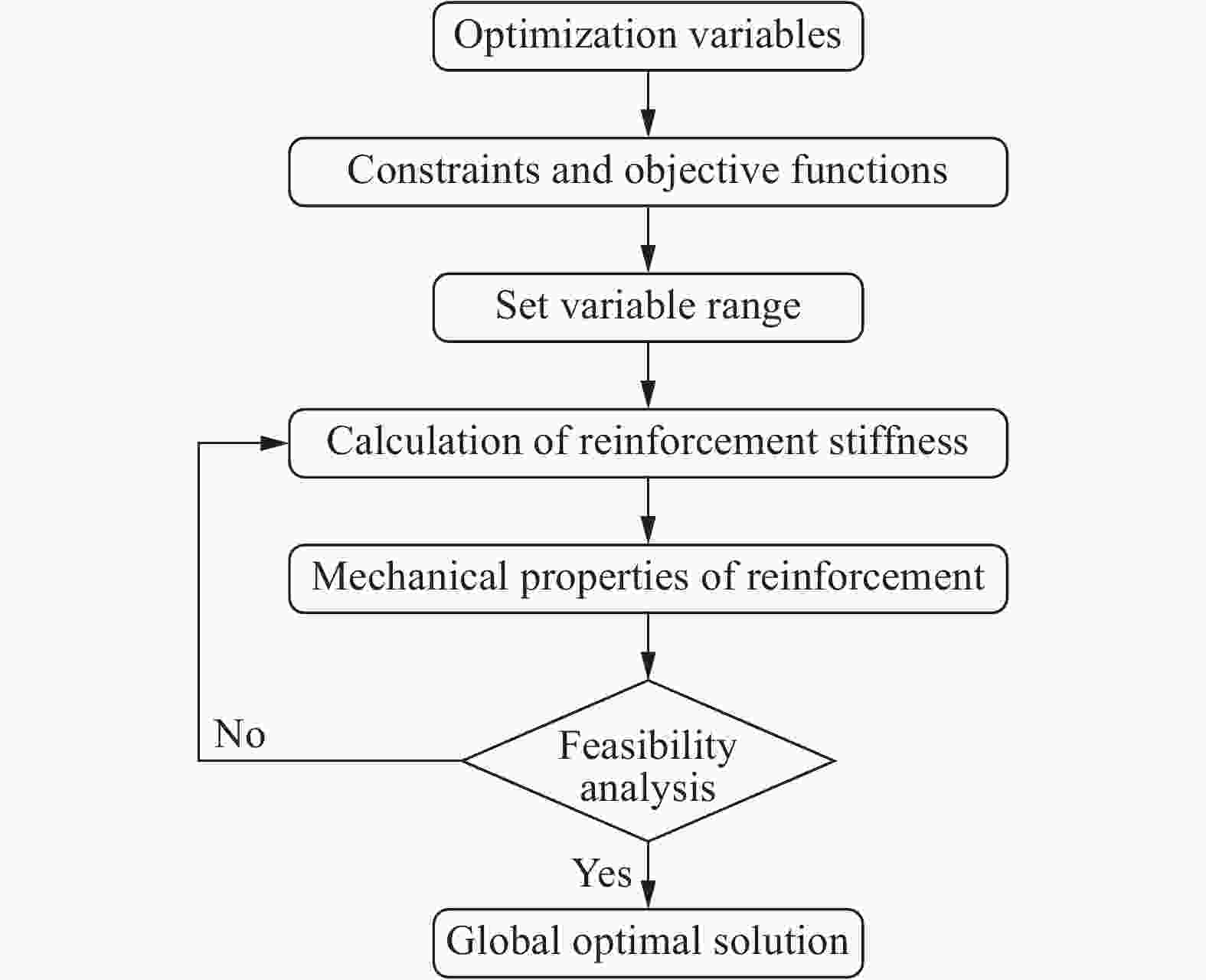

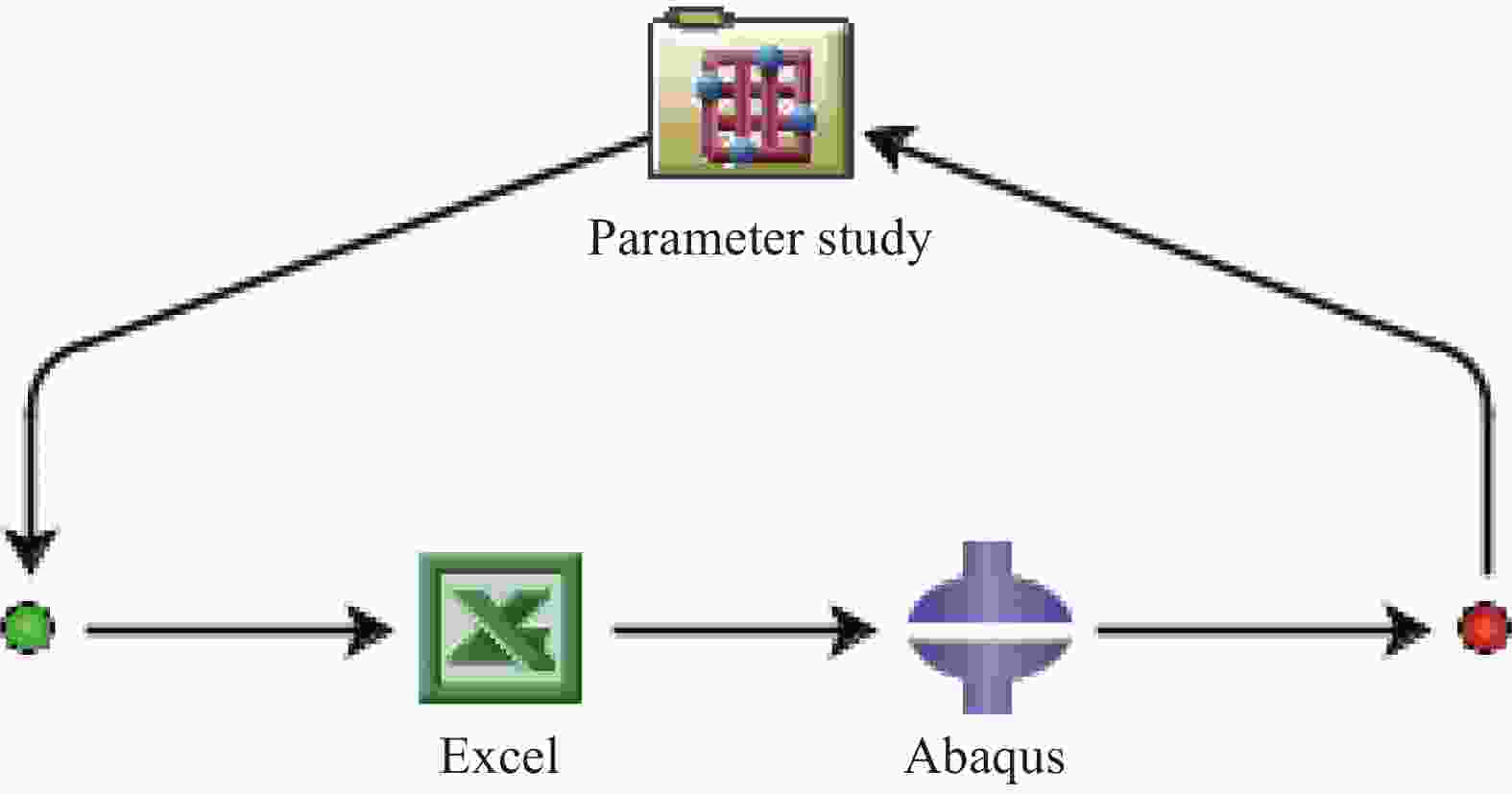

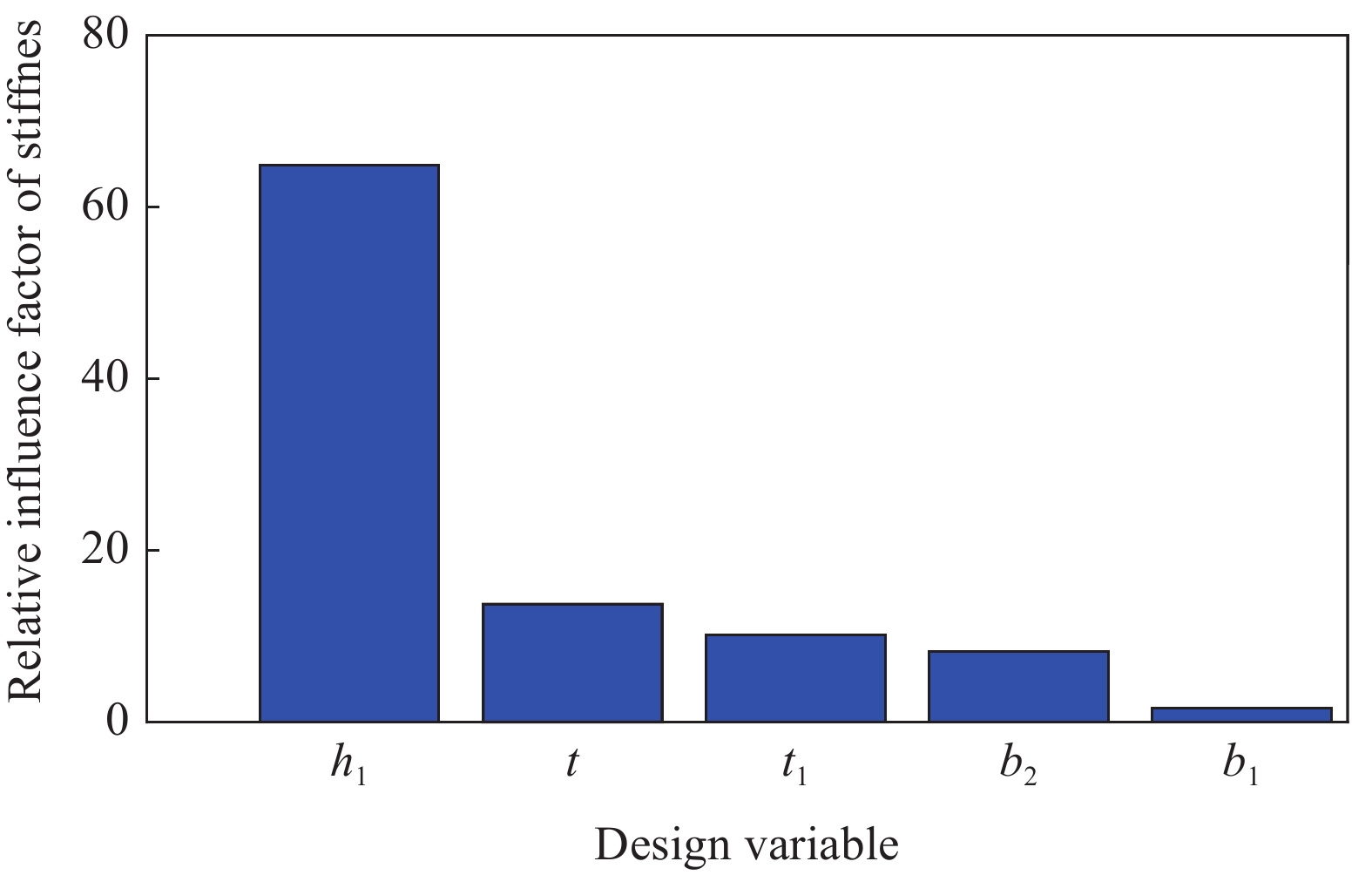

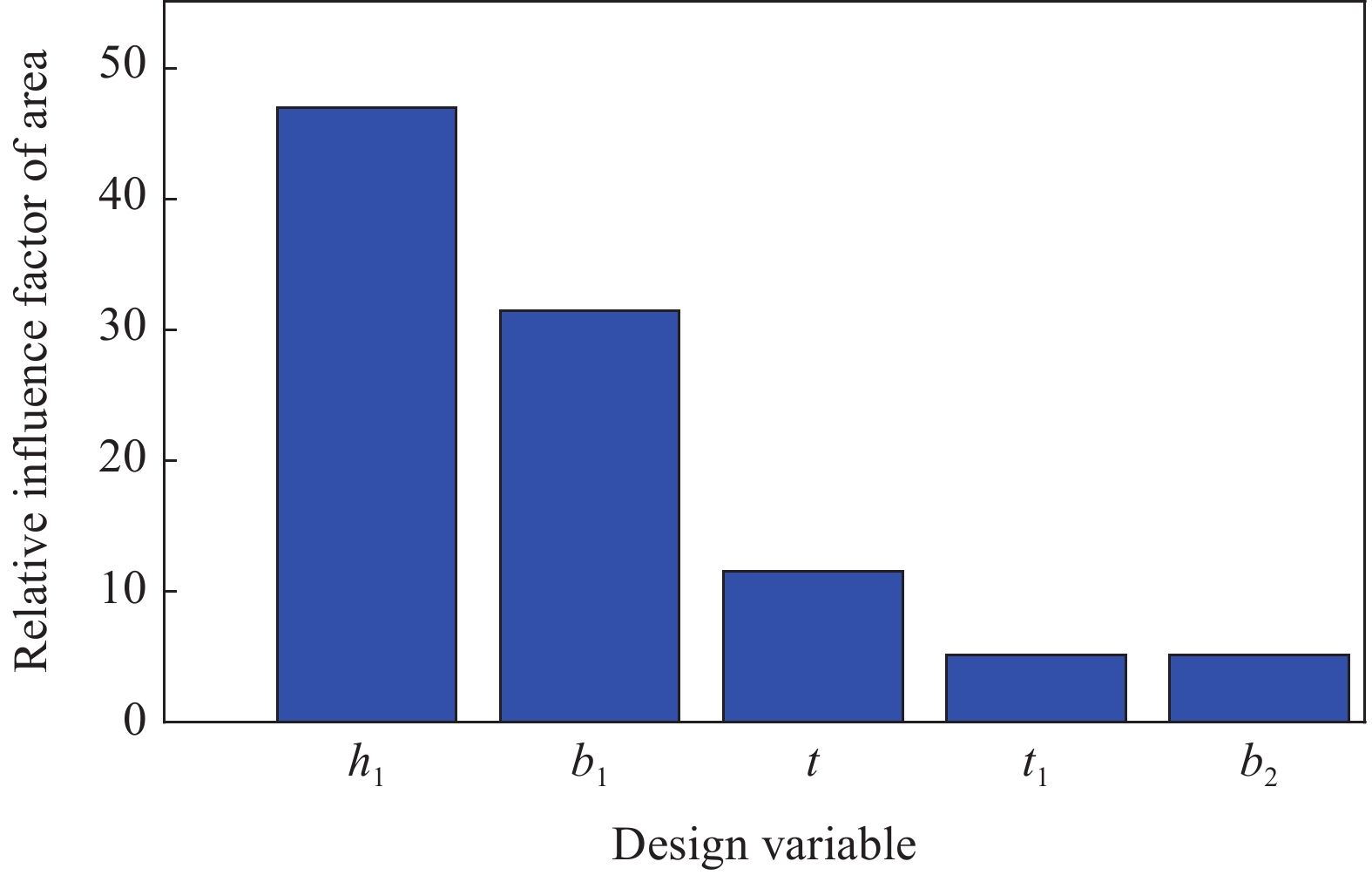

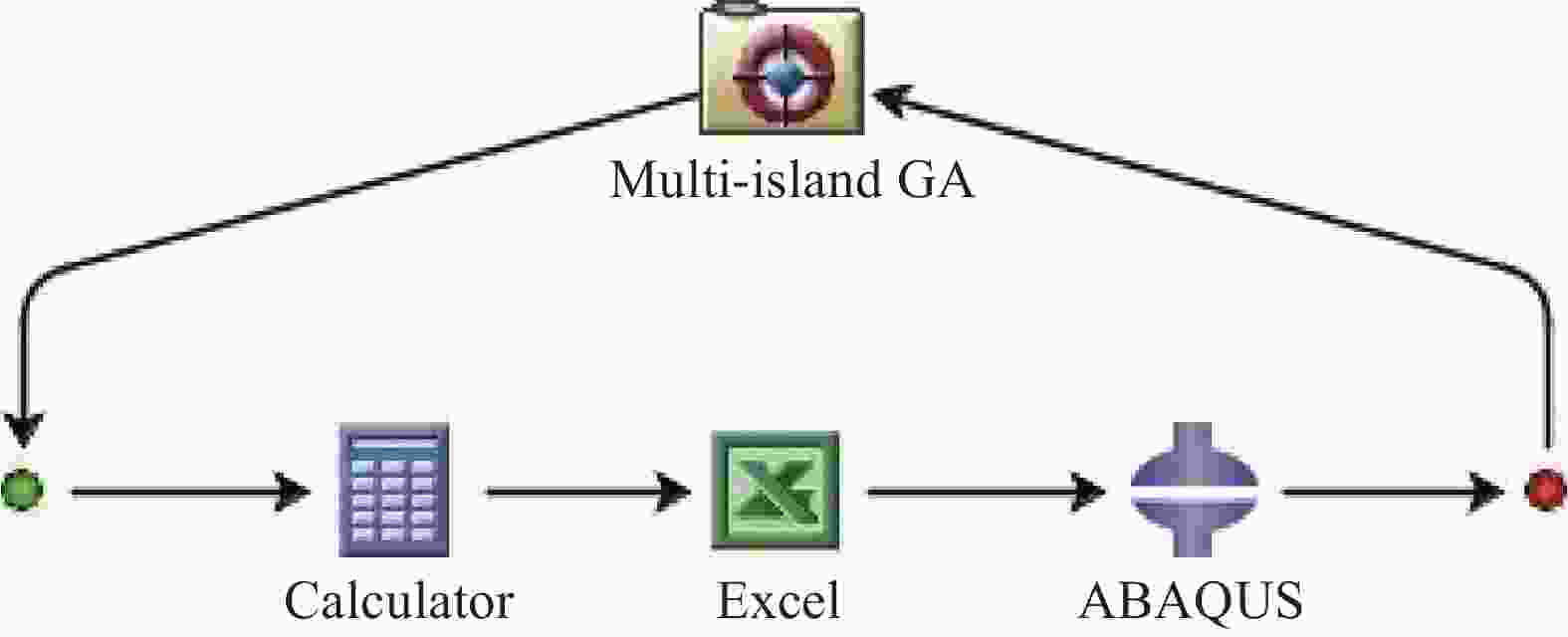

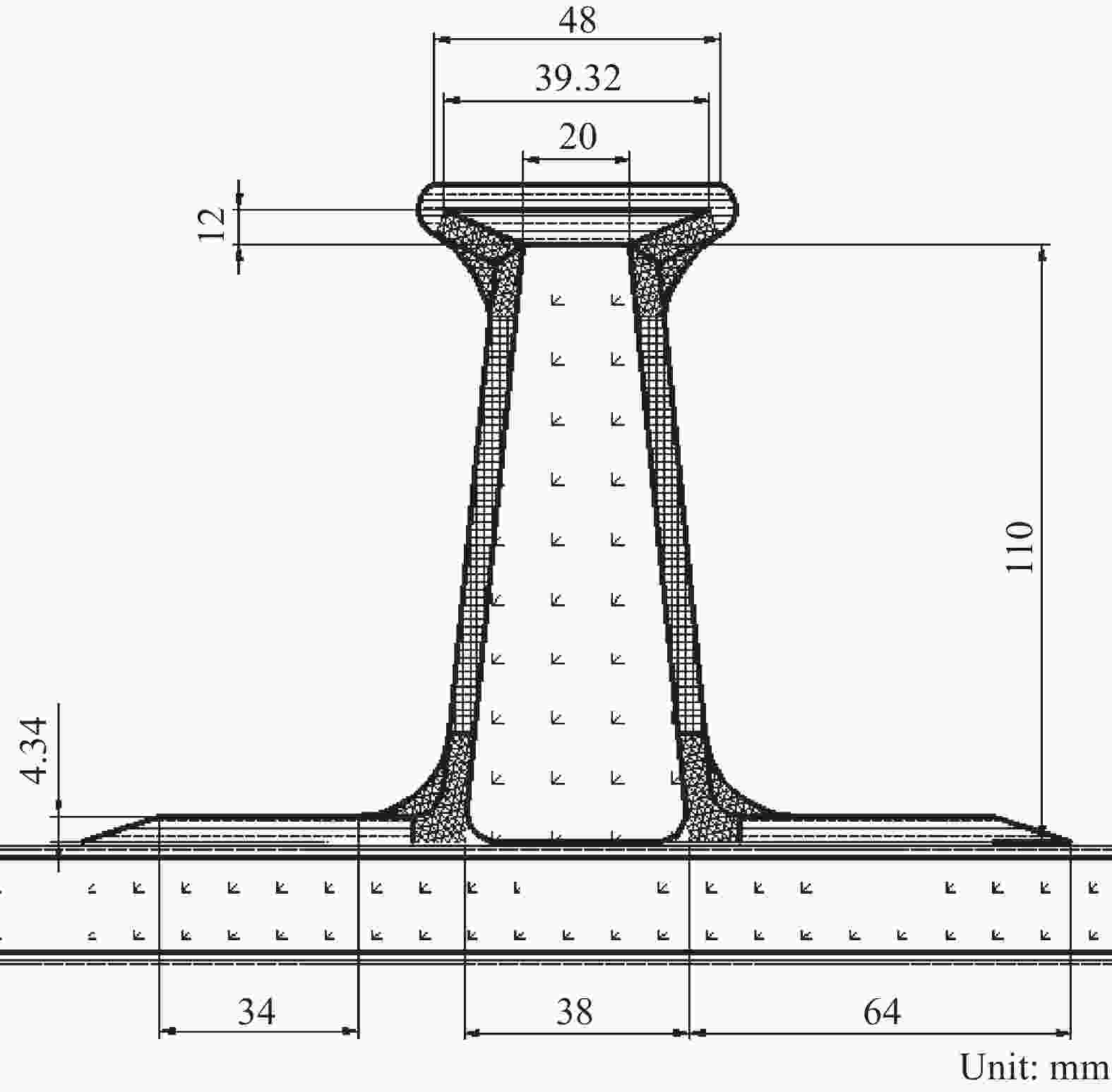

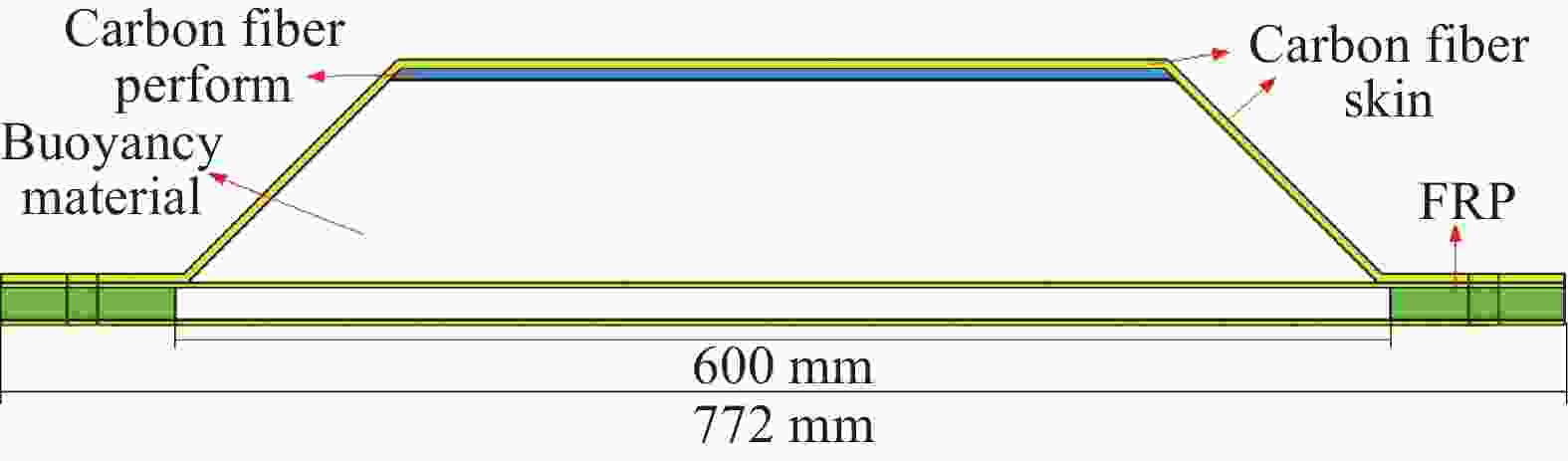

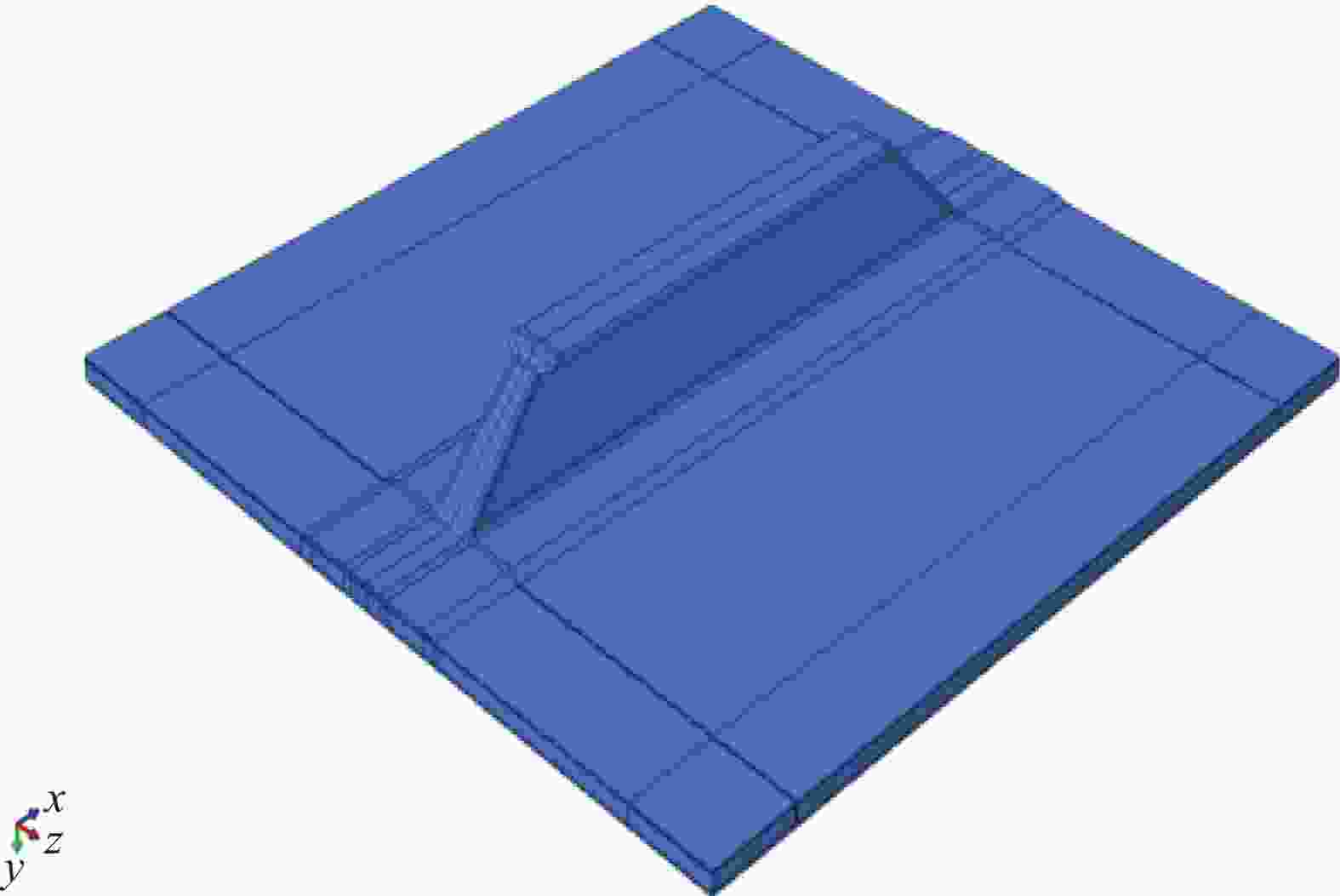

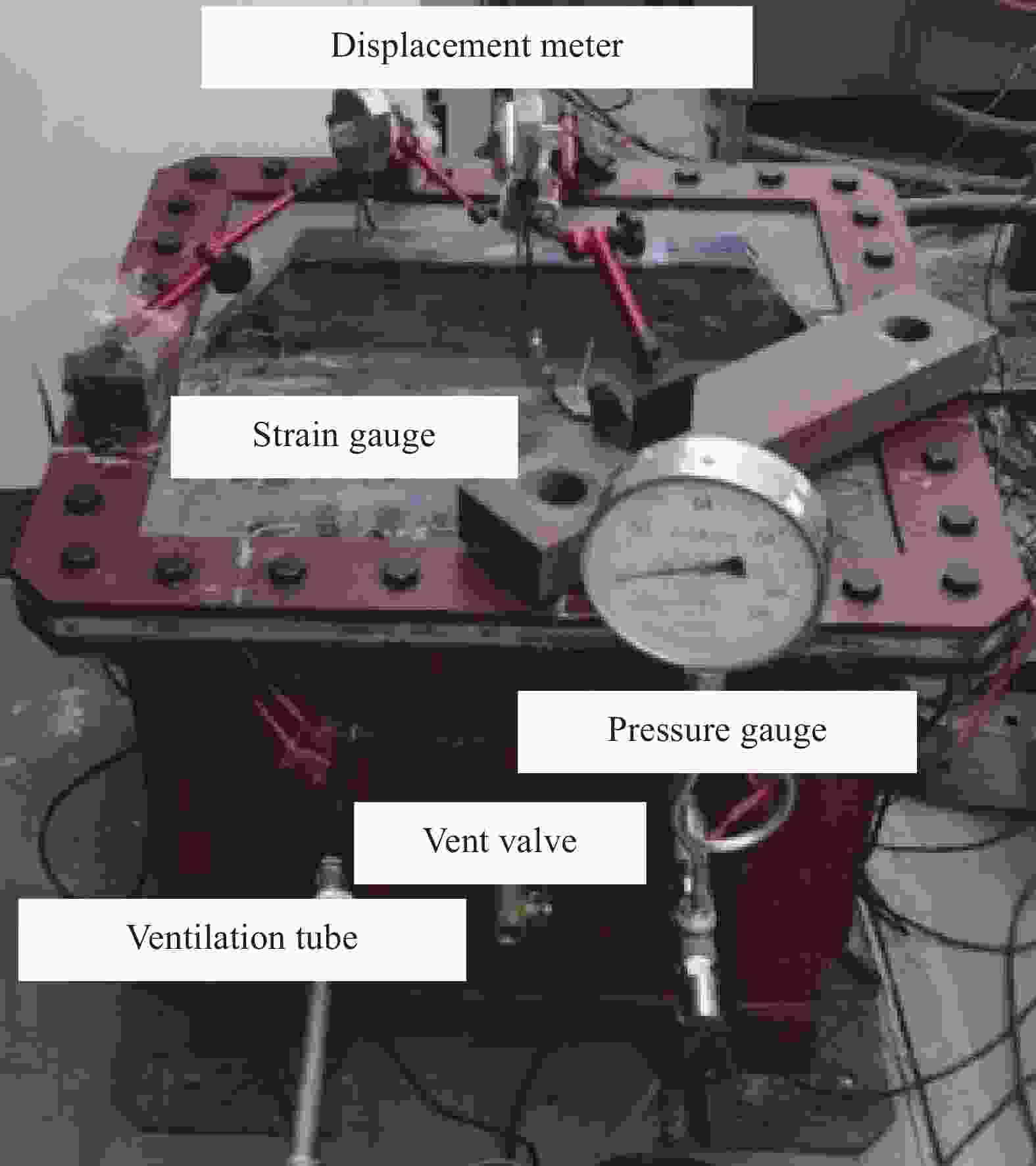

摘要: 以船舶结构优化设计为背景,针对目前结构安全余量过高导致加筋板板筋刚度过匹配现状,提出板筋刚度匹配临界刚度的概念,推导了板筋刚度比关系式。以T型复合材料筋材为对象,建立优化模型,基于Isight软件平台对设计变量进行灵敏度分析,简化设计变量。采用多岛遗传算法对筋材开展多变量优化设计,结合工程实际在筋材优化结果基础上确定设计方案,并开展复合材料加筋板力学性能试验研究,验证了多变量优化设计方法的可行性。研究表明:利用提出的加筋板板筋刚度比关系式,可以指导板筋刚度匹配设计;对T型复合材料筋材进行优化设计时,提升腹板高度对优化目标影响最明显;在等刚度约束前提下,提出的T型筋材优化设计方案能够较好地实现优化目标,同时保证了较优的经济性。Abstract: Based on the optimization design of ship structure, in view of the current situation that the structural safety margin is too high and the stiffener of stiffened plate is over matched, the concept of the critical stiffness of the stiffener matching was proposed, and the relationship between the stiffness ratio of plate and stiffener was derived. The optimization model of T-type composite stiffener was established. Based on Isight software platform, sensitivity analysis of design variables was carried out to simplify design variables. The Multi-Island genetic algorithm was used to carry out the multivariable optimization design of stiffener. Then, combined with the engineering practice, the design scheme was determined on the basis of the stiffener optimization results. The feasibility of the multivariable optimization design method was verified by the experimental study on the mechanical properties of composite stiffened plates. Research shows that the stiffness ratio formula of the stiffened plate can be used to guide the design of stiffener stiffness matching. In the optimization design of T-type composite reinforcement, the effect of web height on the optimization target is the most obvious. Under the condition of equal stiffness constraint, the optimal design scheme of T-type stiffener can achieve the optimization goal and ensure the better economy.

-

Key words:

- composites /

- stiffener /

- critical stiffness /

- multivariable /

- optimal design

-

表 1 材料性能参数

Table 1. Material performance parameters

Material Young's modulus/GPa Shear strength/MPa Compressive strength/MPa Tensile strength/MPa Density/

(g∙cm−3)Poisson's

ratioBuoyancy material 1.1 3 20 — 0.65 0.4 T700/350 58.7 47.2 424 797 1.46 0.045 表 2 碳纤维增强环氧树脂复合材料T型筋材优化结果

Table 2. Optimization results of carbon fiber reiforced epoxy T-type stiffener

Number of cycles b1 t t1 h1 M S Design feasibility 21 36.20 3.51 19.51 102.75 4633.38 5284.24 9 125 35.98 3.51 19.51 102.75 4612.59 5257.16 9 325 35.98 3.51 19.51 102.75 4612.48 5257.09 9 328 35.97 3.51 19.53 102.75 4612.33 5256.24 9 393 33.32 4.10 16.22 109.98 4612.75 5239.33 9 494 33.32 4.10 16.22 109.94 4611.48 5237.75 9 692 33.32 4.10 16.22 109.94 4611.00 5237.09 9 693 33.24 4.10 16.22 109.94 4603.67 5227.24 9 800 33.24 4.10 16.22 109.94 4603.64 5227.20 9 892 33.24 4.09 16.22 109.94 4602.55 5226.44 9 Notes: M—Mass of the stiffener; S—Cross sectional area. 表 3 碳纤维增强环氧树脂复合材料加筋板测点试验值与仿真值(载荷为100 kPa)

Table 3. Experimental values and simulation values of carbon fiber reinforced epoxy stiffened plate (Load is 100 kPa)

Measuring point Test value Simulation value Error/% Strain Ⅰ#/10−6 219.3 238.9 8.9 Strain Ⅱ#/10−6 535.6 579.8 8.3 Displacement 1#/mm 0.36 0.34 5.6 Displacement 2#/mm 0.23 0.22 5.7 -

[1] 高海昌, 梅志远, 杨国威, 等. 夹层结构主动温控变阻尼振动控制技术[J]. 复合材料学报, 2020, 37(4):816-823.GAO Haichang, MEI Zhiyuan, YANG Guowei, et al. Active temperature controlled variable damping technology for sandwich structure[J]. Acta Materiae Compositae Sinica,2020,37(4):816-823(in Chinese). [2] 杜春雷. 压缩载荷下基于刚度匹配性的复合材料加筋板破坏分析[D]. 大连: 大连理工大学, 2014.DU Chunlei. Failure analysis of intergral stiffened compo-site panel considering stiffness matching under uniaxial compression[D]. Dalian: Dalian University of Technology, 2014(in Chinese). [3] 韩国凯, 解维华, 孟松鹤, 等. 防隔热一体化复合材料整体性能优化设计方法[J]. 复合材料学报, 2019, 36(2):450-460.HAN Guokai, XIE Weihua, MENG Songhe, et al. Optimization design method of integrated thermal protection/iusulation composite material[J]. Acta Materiae Compositae Sinica,2019,36(2):450-460(in Chinese). [4] HAMZEHKOLAEI N S, MIRI M, RASHKI M. Reliability based design optimization of rotating FGM cylindrical shells with temperature-dependent probabilistic frequency constrains[J]. Aerospace Science and Technology,2017,68:223-239. doi: 10.1016/j.ast.2017.05.004 [5] 刘哲, 金达锋, 范志瑞. 基于密度分布曲线法的复合材料变刚度铺层优化[J]. 复合材料学报, 2015, 32(6):1737-1744.LIU Zhe, JIN Dafeng, FAN Zhirui. Ply optimization of variable stiffness for composite based on density distribution curve method[J]. Acta Materiae Compositae Sinica,2015,32(6):1737-1744(in Chinese). [6] OOTAO Y, TANIGAW A Y, ISHIMARU O. Optimization of material composition of functionally graded plate for thermal stress relaxation using a genetic algorithm[J]. Journal of Thermal Stresses,2000,23:257-271. doi: 10.1080/014957300280434 [7] LIEU Q X, LEE J. Modeling and optimization of functionally graded plates under thermomechanical load using isogeometric analysis and adaptive hybrid evolutionary firefly algorithm[J]. Composite Structures,2017,179:89-106. doi: 10.1016/j.compstruct.2017.07.016 [8] 邬沛, 李玉顺, 许达, 等. 基于遗传算法的钢-竹组合工字形梁截面优化设计[J]. 建筑结构学报, 2020, 41(1):149-154.WU Pei, LI Yushun, XU Da, et al. Multi-objective optimal section design of I-shaped section steel-bamboo compo-site beam using genetic algorithm[J]. Journal of Building Structures,2020,41(1):149-154(in Chinese). [9] DE MUNCK M, DE SUTTER S, VERBRUGGEN S, et al. Multi-objective weight and cost optimization of hybrid compo-site-concrete beams[J]. Composite Structures,2015,134:369-377. doi: 10.1016/j.compstruct.2015.08.089 [10] 杨丰福, 田海英, 颜昌翔, 等. Isight环境下基于视轴抖动误差的镜头结构优化[J]. 红外与激光工程, 2019, 48(1):0118005. doi: 10.3788/IRLA201948.0118005YANG Fengfu, TIAN Haiying, YAN Changxiang, et al. Optimization of the lens structure based on the line of sight jitter error in Isight environment[J]. Infrared and Laser Engineering,2019,48(1):0118005(in Chinese). doi: 10.3788/IRLA201948.0118005 [11] SENOUCI A B, AL-ANSARI M S. Cost optimization of composite beams using genetic algorithms[J]. Advances in Engineering Software,2009,40(11):1112-1118. doi: 10.1016/j.advengsoft.2009.06.001 [12] KIHM H, YANG H S. Design optimization of a 1-m lightweight mirror for a space telescope[J]. Optical Engineering,2013,52(9):091806. doi: 10.1117/1.OE.52.9.091806 [13] 金达锋, 刘哲, 范志瑞. 基于遗传算法的复合材料层合板削层结构铺层优化[J]. 复合材料学报, 2015, 32(1):236-242.JIN Dafeng, LIU Zhe, FAN Zhirui. Ply optimization of composite laminate with ply drop based on genetic algorithm[J]. Acta Materiae Compositae Sinica,2015,32(1):236-242(in Chinese). [14] CORREIA V M F, MADEIRA J F A, ARAÚJO A L, et al. Multiobjective optimization of ceramtic-metal functionally graded plates using a higher order model[J]. Composite Structures,2018,183:146-160. doi: 10.1016/j.compstruct.2017.02.013 [15] 赵群, 丁运亮, 金海波. 基于压弯刚度匹配论则的复合材料加筋板结构优化设计[J]. 南京航空航天大学学报, 2010, 42(3):357-362. doi: 10.3969/j.issn.1005-2615.2010.03.020ZHAO Qun, DING Yunliang, JIN Haibo. Structual optimization design of composite stiffened panels based on matching regulations of compression and bending stiffness[J]. Journal of Nanjing University of Aeronautics and Astronautics,2010,42(3):357-362(in Chinese). doi: 10.3969/j.issn.1005-2615.2010.03.020 [16] 赵群, 丁运亮, 金海波. 一种基于复合材料加筋板结构效率的稳定性优化方法[J]. 复合材料学报, 2010, 27(3):169-176.ZHAO Qun, DING Yunliang, JIN Haibo. Buckling optimization method based on structure efficiency of composite stiffened panels[J]. Acta Materiae Compositae Sinica,2010,27(3):169-176(in Chinese). [17] 肖志鹏, 钱文敏, 周磊. 考虑壁板刚度匹配的大型飞机复合材料机翼气动弹性优化设计[J]. 北京航空航天大学学报, 2018, 44(8):1629-1635.XIAO Zhipeng, QIAN Wenmin, ZHOU Lei. Aeronautics and optimization design of composite wing for large aircraft with panel stiffness matching[J]. Journal of Beijing University of Aeronautics,2018,44(8):1629-1635(in Chinese). [18] 吴梵, 朱锡, 梅志远. 船舶结构力学[M]. 北京: 国防工业出版社, 2010: 137.WU Fan, ZHU Xi, MEI Zhiyuan. Ship structural mechanics[M]. Beijng: National Defense Industry Press, 2010: 137(in Chinese). [19] 中国船级社. 纤维增强塑料船建造规范2016[S]. 北京: 人民交通出版社, 2016.China Classification Society. Code for construction of FRP ships 2016[S]. Beijing: China Communications Press, 2016(in Chinese). [20] 杨成, 陈建钧, 袁伟杰, 等. 复合材料光伏支架梁结构优化分析[J]. 太阳能学报, 2020, 41(3):306-310.YANG Cheng, CHEN Jianjun, YUAN Weijie, et al. Structual optimization of composite photovoltaic supporting beam[J]. Acta Energiae Solaris Sinica,2020,41(3):306-310(in Chinese). -

下载:

下载: