Degradation mechanism of tensile properties and life prediction of hybrid carbon/basalt fiber reinforced polymer bars in seawater sea-sand concrete

-

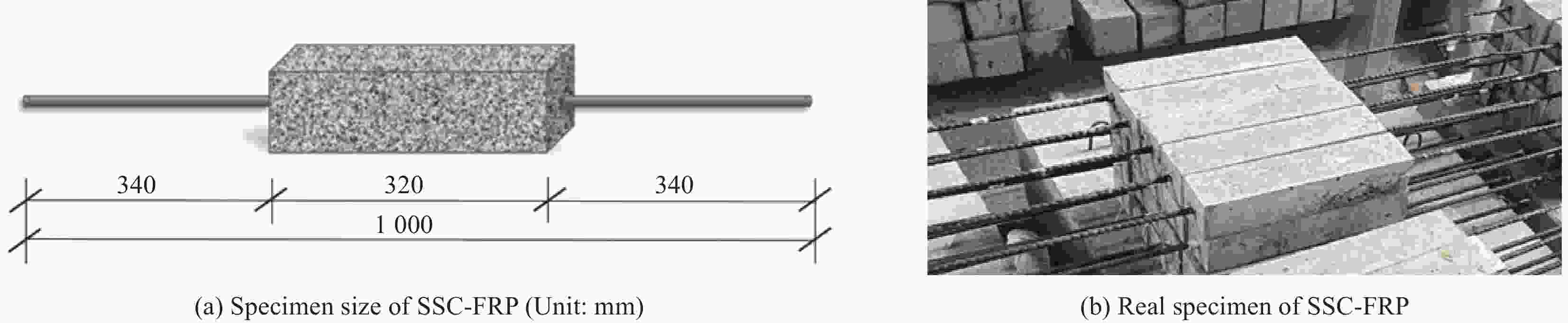

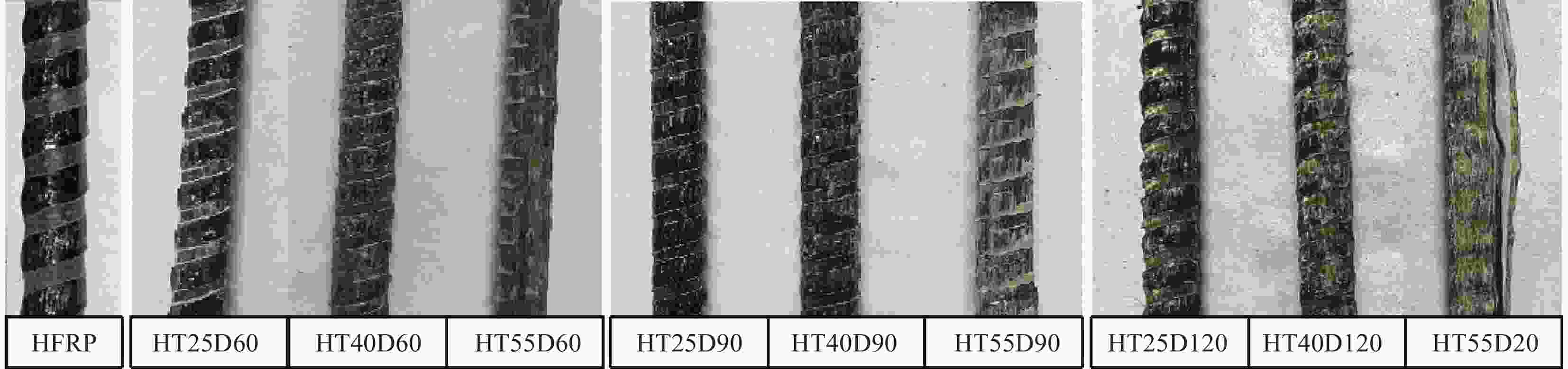

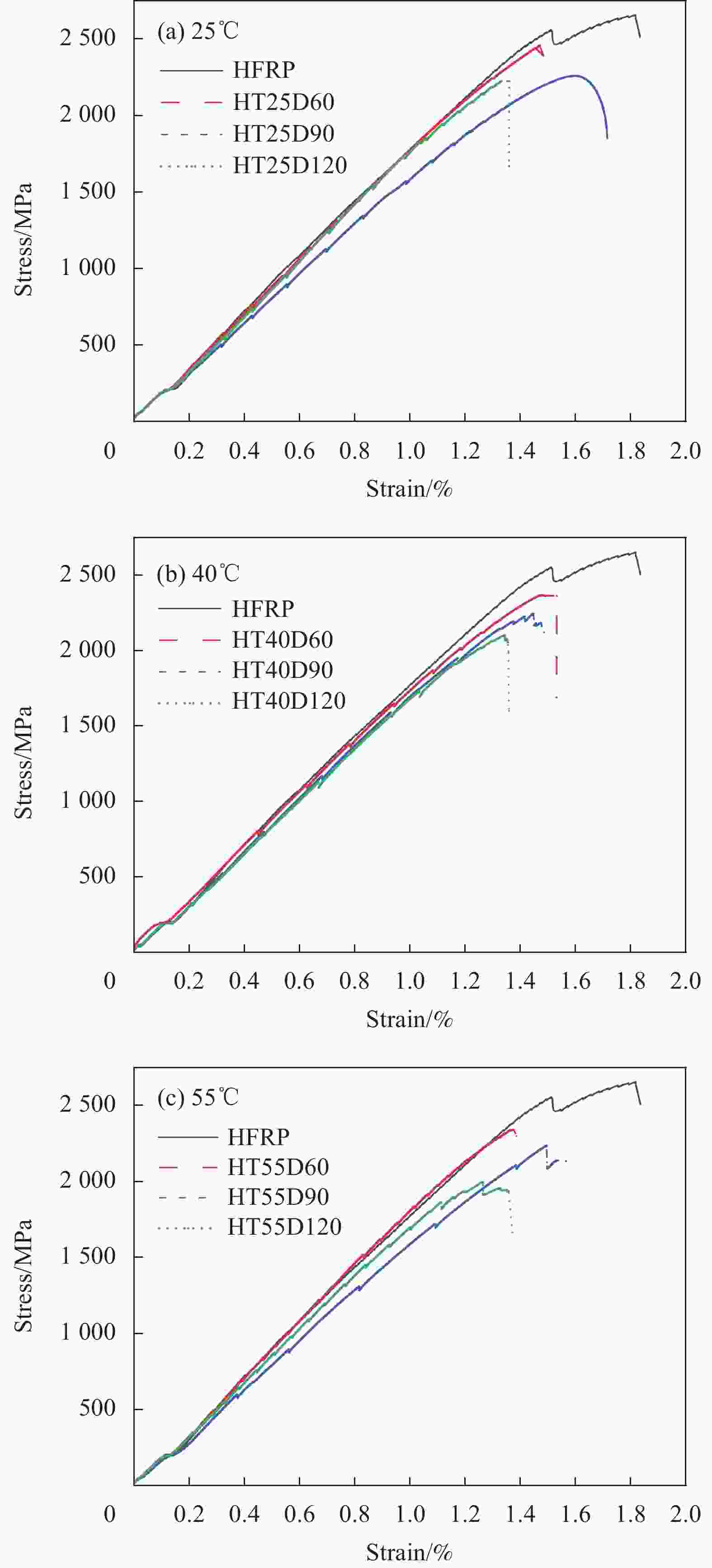

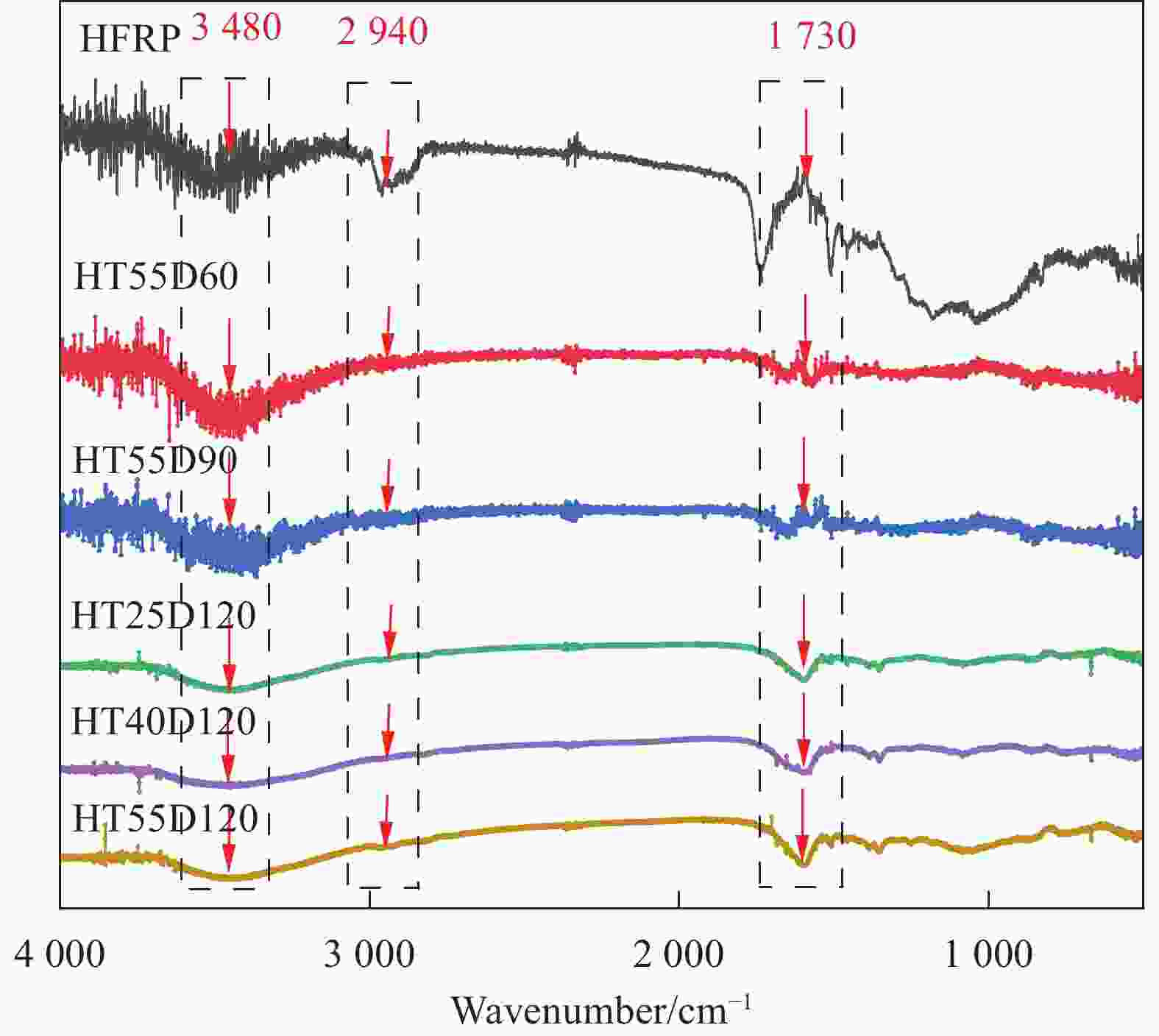

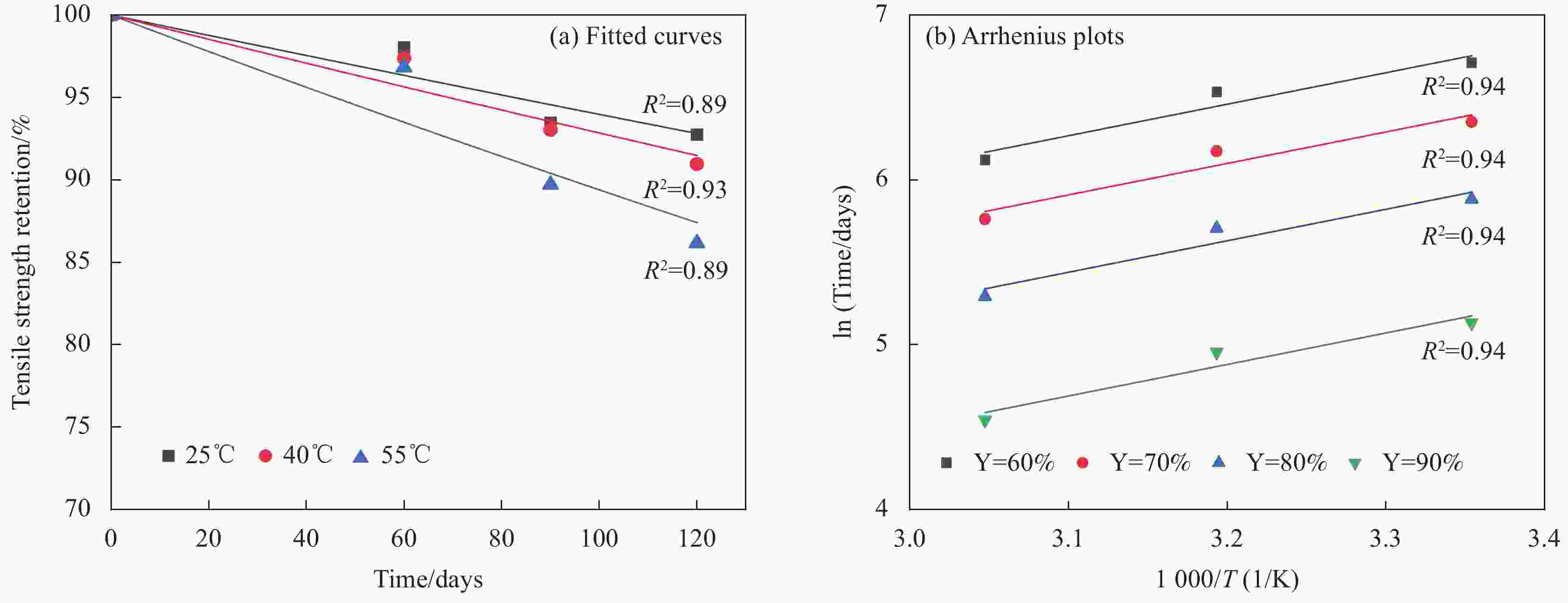

摘要: 为了研究海水浸泡下海水海砂混凝土(Seawater sea-sand concrete,SSC)中以环氧树脂为基体的混杂碳-玄武岩纤维复材筋(CF-BF/Epoxy)拉伸性能退化规律,在不同温度(25、40和55℃)下对SSC中的CF-BF/Epoxy进行海水浸泡,周期为60、90和120天,通过拉伸试验对CF-BF/Epoxy在SSC中的拉伸性能进行了研究,并利用SEM和FTIR对其微观结构的变化进行了分析。结果显示,环境温度对CF-BF/Epoxy的拉伸性能有明显影响,在55℃下浸泡120d后,抗拉强度下降了13.84%,弹性模量在3%范围内轻微波动,CF-BF/Epoxy出现伪延性;玄武岩纤维和碳纤维混杂延缓了SSC中OH−进一步向CF-BF/Epoxy内部侵蚀,而外层玄武岩纤维区域的树脂水解和树脂-纤维界面退化是CF-BF/Epoxy拉伸性能退化的主要原因。最后基于Arrhenius方程预测,嵌入SSC中的CF-BF/Epoxy的抗拉强度保持率将在584~803天内降至70%。

-

关键词:

- 混杂碳-玄武岩纤维复材筋 /

- 海水海砂混凝土 /

- 抗拉强度 /

- 退化机理 /

- 寿命预测

Abstract: To investigate the degradation pattern of tensile properties of epoxy resin-based hybrid carbon-basalt fiber reinforcing bars (CF-BF/Epoxy) in seawater sea-sand concrete (SSC) under seawater immersion, the CF-BF/Epoxy in SSC were soaked in seawater at different temperatures (25°C, 40°C, and 55°C) for durations of 60, 90 and 120 days. The tensile performance of the CF-BF/Epoxy in SSC was examined through tensile tests, and the changes in their microstructure were analyzed by SEM and FTIR. The results indicate that ambient temperature significantly affects the tensile properties of CF-BF/Epoxy. After 120 days of immersion at 55°C, the tensile strength decreases by 13.84%, the elastic modulus experiences a slight fluctuation within a 3% range, and pseudo-ductility is observed in the CF-BF/Epoxy. Additionally, blending of basalt fibers and carbon fibers delay the further intrusion of OH- from SSC into CF-BF/Epoxy, while the hydrolysis of the resin in the outer basalt fiber region and the degradation of the resin-fiber interface are identified as the primary causes of the decline in the tensile properties of CF-BF/Epoxy. Lastly, based on the Arrhenius equation, it is predicted that the tensile strength retention rate of CF-BF/Epoxy embedded in SSC will drop to 70% between 584 and 803 days.-

Key words:

- CF-BF/Epoxy /

- Seawater Sea-sand Concrete /

- tensile strength /

- degradation mechanism /

- life prediction

-

表 1 海水海砂混凝土配合比

Table 1. Mixing ratio of seawater sea sand concrete

Raw materials Cement Artificial seawater Coarse aggregate Sea-sand Water reducer Mass/(kg·m−3) 370 185 1113 682 0.111 Note:Water reducer agent in kg. 表 2 人工海水的化学成分

Table 2. Chemical composition of artificial seawater

Composition NaCl MgCl2 Na2SO4 CaCl2 KCl NaHCO3 Concentration/(g·L−1) 24.53 5.20 4.09 1.16 0.695 0.201 表 3 嵌入SSC中CF-BF/Epoxy的加速老化试验

Table 3. Accelerated aging test of CF-BF/Epoxy embedded in SSC

Types of FRP bars Test environment Exposure temperature/℃ Exposure period/days Number of interlaminar

shear specimensCF-BF/Epoxy Artificial seawater immersion 25 60,90,120 5 40 60,90,120 5 55 60,90,120 5 表 4 CF-BF/Epoxy拉伸性能测试结果

Table 4. Test results of tensile properties of CF-BF/Epoxy

Specimen of FRP bars Tensile strength Elastic modulus Ultimate strain/% Average /MPa Retention /% CV/% Average /GPa Retention /% CV/% Average Retention /% HFRP 2437.41 100 1.2 146.87 100 3.3 1.66 100 HT25 D60 2390.00 98.05 1.3 144.84 98.62 1.6 1.65 99.40 HT25 D90 2278.19 93.47 3.6 144.76 98.56 3.4 1.57 94.81 HT25 D120 2260.69 92.75 4.4 143.18 97.49 1.6 1.58 95.12 HT40 D60 2373.33 97.37 4.7 142.49 97.02 3.2 1.67 99.34 HT40 D90 2267.46 93.03 6.6 143.22 97.51 2.0 1.58 95.37 HT40 D120 2217.14 90.96 5.1 142.52 97.04 2.2 1.56 93.72 HT55 D60 2360.00 96.82 1.5 143.60 97.78 2.3 1.64 99.00 HT55 D90 2186.67 89.71 4.2 145.03 98.75 3.9 1.51 90.83 HT55 D120 2100.00 86.16 1.7 145.13 98.82 1.0 1.45 87.17 Note: HFRP denotes unaged CF-BF/Epoxy specimens; HTxDy denotes CF-BF/Epoxy specimens immersed at x°C for y days. 表 5 CF-BF/Epoxy在SSC中寿命预测的时移因子(FTS)参数

Table 5. FTS parameters for life prediction of CF-BF/Epoxy wrapped by SSC

Types of FRP bars Solution temperature/℃ FTS Qingdao(12.3℃) Fuzhou(20.1℃) Haikou(23.8℃) CF-BF/Epoxy 25 1.33 1.11 1.03 40 1.81 1.51 1.39 55 2.39 2.00 1.84 表 6 不同文献中FRP筋拉伸试验结果和寿命预测结果

Table 6. Tensile test results and life prediction of FRP bars in different literatures

References Parameters of

FRP barExposure condition Tensile test results Life prediction Duration/

DaysTensile strength retention/% Tensile strength retention/% Service-life/years Location This study 8 mm CF-BF/Epoxy SSC(pH=13.3) 120(25℃) 92.75 70 2.6 Qingdao(12.3℃) 90(40℃) 93.03 70 1.8 Fuzhou(20.1℃) 90(55℃) 89.71 70 1.6 Haikou(23.8℃) Yi[15] 8 mmBFRP SMSSC(pH=12.5) 180(25℃) 86.88 70 5.1 Qingdao(12.3℃) 90(40℃) 75.42 70 2.4 Fuzhou(20.1℃) 90(55℃) 60.81 70 1.7 Haikou(23.8℃) Wang[16] 6 mmBFRP Simulated SSC pore

solutions(pH=13.4)63(32℃) 92.7 70 20.4 Hall's Harbor Quay (7.6℃) 63(40℃) 81.7 63(55℃) 26 70 14.6 Waterloo Creek Bridge(9.9℃) Natural environments - 91.6 5 Hall's Harbor Quay (7.6℃) 86.4 6 Waterloo Creek Bridge(9.9℃) Mufti[37] GFRP(E-glass in a vinylester matrix) Natural environments - No significant degradation 5~8 Halls Harbor Wharf Joffre Bridge Chatham Bridge Growchild Trail Bridge Waterloo Greek Bridge -

[1] XIAO J, NANNI C Q A, ZHANG K. Use of sea-sand and seawater in concrete construction: current status and future opportunities[J]. Construct Build Mater 2017, 155: 1101–11. [2] WANG Z, ZHAO X L, XIAN G, et al. Long-term durability of basalt- and glass-fibre reinforced polymer (BFRP/GFRP) bars in seawater and sea sand concrete environment[J]. Construction and Building Materials, 2017, 139: 467-89. doi: 10.1016/j.conbuildmat.2017.02.038 [3] TURCO V, SECONDIN S, MORBIN A, et al. Flexural and shear strengthening of un-reinforced masonry with FRP bars[J]. Composites Science and Technology, 2006, 66(2): 289-96. doi: 10.1016/j.compscitech.2005.04.042 [4] SHI J W, CAO W H, CHEN L, et al. Durability of wet lay-up BFRP single-lap joints subjected to freeze–thaw cycling[J]. Construction and Building Materials, 2020, 238: 117664. doi: 10.1016/j.conbuildmat.2019.117664 [5] 高婧, 范凌云. CFRP筋与海水海砂混凝土粘结性能试验与机制分析[J]. 复合材料学报, 2022, 39(03): 1194-204. doi: 10.13801/j.cnki.fhclxb.20210512.001GAO Jing, FAN Lingyun. Experiment on bond performance between CFRP bar and seawater sea sand concrete and its working mechanism[J]. Acta Materiae Compositae Sinica, 2022, 39(03): 1194-204(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210512.001 [6] SWOLFS Y, GORBATIKH L, VERPOEST I. Fibre hybridisation in polymer composites: A review[J]. Composites Part A:Applied Science and Manufacturing, 2014, 67: 181-200. doi: 10.1016/j.compositesa.2014.08.027 [7] SWOLFS Y, VERPOEST I, GORBATIKH L. Maximising the hybrid effect in unidirectional hybrid composites[J]. Materials & Design, 2016, 93: 39-45. [8] JALALVAND M, CZéL G, WISNOM M R. Parametric study of failure mechanisms and optimal configurations of pseudo-ductile thin-ply UD hybrid composites[J]. Composites Part A:Applied Science and Manufacturing, 2015, 74: 123-31. doi: 10.1016/j.compositesa.2015.04.001 [9] CZéL G, JALALVAND M, WISNOM M R, et al. Design and characterisation of high performance, pseudo-ductile all-carbon/epoxy unidirectional hybrid composites[J]. Composites Part B:Engineering, 2017, 111: 348-56. doi: 10.1016/j.compositesb.2016.11.049 [10] 曹升虎, 吴智深, 马凯, 等. 混杂碳纤维/玄武岩纤维塑料筋的张拉力学性能[J]. 玻璃钢/复合材料, 2014, 245(08): 83-87.CAO Shenghu, WU Zhishen, MA Kai, et al. Tensile Properties of hybrid carbon fiber/basalt fiber plastic reinforcement[J]. Glass fiber Reinforced plastic/Composite Materials, 2014, 245(08): 83-87(in Chinese). [11] PROTCHENKO K, ZAYOUD F, URBANSKI M, et al. Tensile and Shear Testing of Basalt Fiber Reinforced Polymer (BFRP) and Hybrid Basalt/Carbon Fiber Reinforced Polymer (HFRP) Bars[J]. Materials (Basel), 2020, 13(24): 5839. doi: 10.3390/ma13245839 [12] GUO F, AL-SAADI S, SINGH RAMAN R K, et al. Durability of fiber reinforced polymer (FRP) in simulated seawater sea sand concrete (SWSSC) environment[J]. Corrosion Science, 2018, 141: 1-13. doi: 10.1016/j.corsci.2018.06.022 [13] 郝志豪, 戴建国, 王召, 等. GFRP筋的拉伸性能劣化对其与海水海砂混凝土粘结性能的影响[J]. 复合材料学报, 2023, 41: 1-11. doi: 10.13801/j.cnki.fhclxb.20230523.001HAO Zhihao, DAI Jianguo, WANG Zhao, et al. Effect of tensile performance degradation of GFRP bars on their bond performance with seawater sea-sand concrete[J]. Acta Materiae Compositae Sinica, 2023, 41: 1-11(in Chinese). doi: 10.13801/j.cnki.fhclxb.20230523.001 [14] LU C, NI M, CHU T, et al. Comparative Investigation on Tensile Performance of FRP Bars after Exposure to Water, Seawater, and Alkaline Solutions[J]. Journal of Materials in Civil Engineering, 2020, 32(7): 04020170. doi: 10.1061/(ASCE)MT.1943-5533.0003243 [15] YI Y, ZHU D, RAHMAN M Z, et al. Tensile properties deterioration of BFRP bars in simulated pore solution and real seawater sea sand concrete environment with varying alkalinities[J]. Composites Part B:Engineering, 2022, 243: 110115. doi: 10.1016/j.compositesb.2022.110115 [16] 王自柯. FRP筋在模拟海水—海砂混凝土孔溶液浸泡下的耐久性研究 [D]. 哈尔滨: 哈尔滨工业大学, 2018.WANG Zike. Study on the durability performances of fiber reinforced polymer (FRP) bars exposed to simulated seawater and sea sand concerte pore solution [D]. Harbin: Harbin Institute of Technology, 2018 (in Chinese). [17] 周平, 白艳博, 李承高, 等. 模拟海水-海砂混凝土环境下连续玻璃纤维增强聚丙烯复合材料杆层间剪切性能的演化[J]. 复合材料学报, 2024, 41(1): 313-322. doi: 10.13801/j.cnki.fhclxb.20230516.003ZHOU Ping, BAI Yanbo, LI Chenggao, et al. Interlaminar shear behavior of glass-fibre reinforced polypropylene rod under seawater and sea sand concrete simulation environment[J]. Acta Materiae Compositae Sinica, 2024, 41(1): 313-322(in Chinese). doi: 10.13801/j.cnki.fhclxb.20230516.003 [18] PAN Y, YAN D. Study on the durability of GFRP bars and carbon/glass hybrid fiber reinforced polymer (HFRP) bars aged in alkaline solution[J]. Composite Structures, 2021, 261. [19] WANG X, WU G, WU Z, et al. Evaluation of prestressed basalt fiber and hybrid fiber reinforced polymer tendons under marine environment[J]. Materials & Design, 2014, 64: 721-8. [20] 耿健智, 朱德举, 郭帅成, 等. 基于不同地域海砂的海水海砂混凝土力学性能试验研究[J]. 材料导报, 2022, 36(03): 152-9. doi: 10.11896/cldb.21010189GENG Jianzhi, ZHU Deju, GUO Shuaicheng, et al. Experimental Study on Mechanical Properties of Seawater Sea-sand Concrete with Sea-sands from Different Regions[J]. Materials Reports B, 2022, 36(03): 152-9(in Chinese). doi: 10.11896/cldb.21010189 [21] ASTM. Standard practice for the preparation of substitute ocean water: ASTM D1141–98(2013)[S]. West Conshohocken, PA, 2013. [22] ACI. Guide for the design and construction of structural concrete reinforced with fiber-reinforced polymer (FRP) bars: ACI 440.1R-15[S]. American Concrete Institute, 2015. [23] HARRIS H G, SOMBOONSONG W. New Ductile Hybrid FRP Reinforcing Bar for Concrete Structures[J]. Journal of Composites for Construction, 1988, 2(1): 28-37. [24] GAO D, ZHANG Y, WEN F, et al. Design method and experiment verification for hybrid fiber reinforced polymer bars with both tensile ductility and different strength grades[J]. Journal of Building Engineering, 2022, 46: 103723. doi: 10.1016/j.jobe.2021.103723 [25] SERBESCU A, GUADAGNINI M, PILAKOUTAS K. Mechanical Characterization of Basalt FRP Rebars and Long-Term Strength Predictive Model[J]. Journal of Composites for Construction, 2015, 19(2): 04014037. doi: 10.1061/(ASCE)CC.1943-5614.0000497 [26] ROBERT M, BENMOKRANE B. Combined effects of saline solution and moist concrete on long-term durability of GFRP reinforcing bars[J]. Construction and Building Materials, 2013, 38: 274-84. doi: 10.1016/j.conbuildmat.2012.08.021 [27] KIM H-Y, PARK Y-H, YOU Y-J, et al. Short-term durability test for GFRP rods under various environmental conditions[J]. Composite Structures, 2008, 83(1): 37-47. doi: 10.1016/j.compstruct.2007.03.005 [28] KAMAL A S M, BOULFIZA M. Durability of GFRP Rebars in Simulated Concrete Solutions under Accelerated Aging Conditions[J]. Journal of Composites for Construction, 2011, 15(4): 473-81. doi: 10.1061/(ASCE)CC.1943-5614.0000168 [29] YVETTE N, MARéCHAL Y, MERMILLIOD N. Epoxy−Amine Reticulates Observed by Infrared Spectrometry. I: Hydration Process and Interaction Configurations of Embedded H2O Molecules[J]. The Journal of Physical Chemistry B, 1999, 103(24): 4979-4985. doi: 10.1021/jp984809y [30] WIMONLAK N, KOENIG J L. Interfacial behavior of epoxy/E-glass fiber composites under wet-dry cycles by fourier transform infrared microspectroscopy[J]. Polymer composites, 1999, 20(1): 38-47. doi: 10.1002/pc.10333 [31] YANG Y, XIAN G, LI H, et al. Thermal aging of an anhydride-cured epoxy resin[J]. Polymer Degradation and Stability, 2015, 118: 111-9. doi: 10.1016/j.polymdegradstab.2015.04.017 [32] GEORGE S. Infrared and Raman characteristic group frequencies: tables and charts[J]. John Wiley & Sons, 2004. [33] DAVALOS J F, CHEN Y, RAY I. Long-term durability prediction models for GFRP bars in concrete environment[J]. Journal of Composite Materials, 2011, 46(16): 1899-914. [34] CHEN Y, DAVALOS J F, RAY I. Durability prediction for GFRP reinforcing bars using short-term data of accelerated aging tests[J]. Journal of composites for construction, 2006, 10(4): 279-286. doi: 10.1061/(ASCE)1090-0268(2006)10:4(279) [35] ROBERT M, COUSIN P, BENMOKRANE B. Durability of GFRP reinforcing bars embedded in moist concrete[J]. Journal of Composites for Construction, 2009, 13(2): 66-73. doi: 10.1061/(ASCE)1090-0268(2009)13:2(66) [36] WU G, DONG Z-Q, WANG X, et al. Prediction of Long-Term Performance and Durability of BFRP Bars under the Combined Effect of Sustained Load and Corrosive Solutions[J]. Journal of Composites for Construction, 2015, 19(3): 04014058. doi: 10.1061/(ASCE)CC.1943-5614.0000517 [37] MUFTI A, BANTHIA N, BENMOKRANE B, et al. Durability of GFRP Composite Rods[J]. Concrete International, 2007, 29(02): 37-42. -

下载:

下载: