Connection technology and mechanical properties of sandwich structure with the core of elastic damping metal spiral wire mesh

-

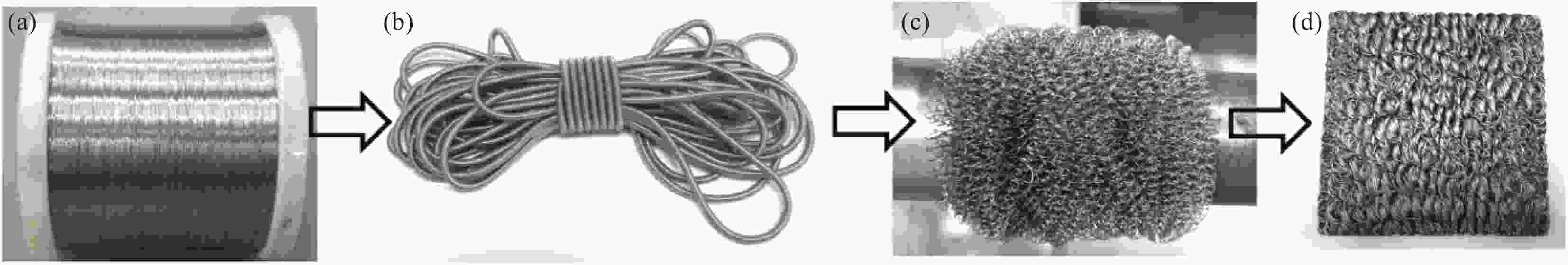

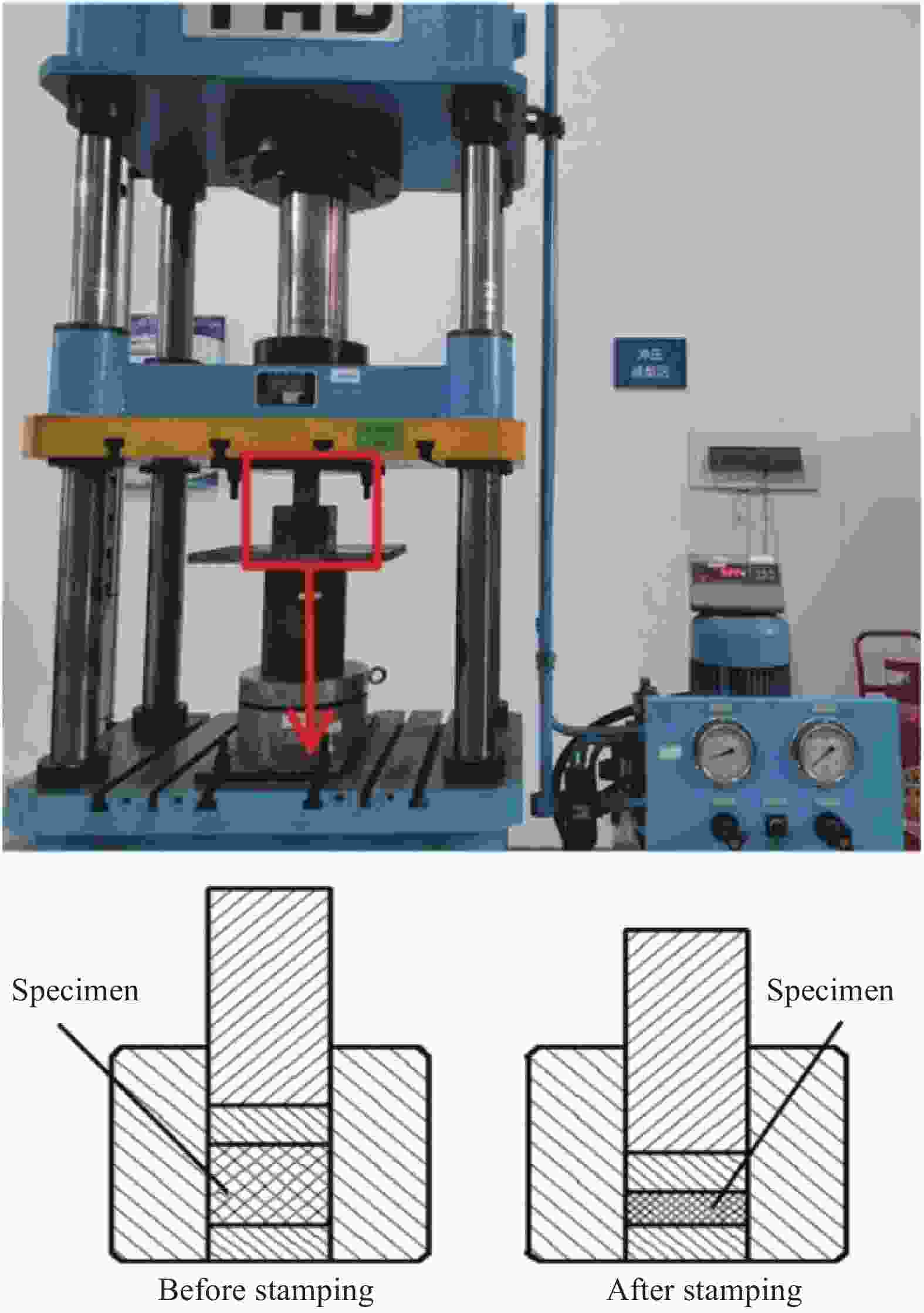

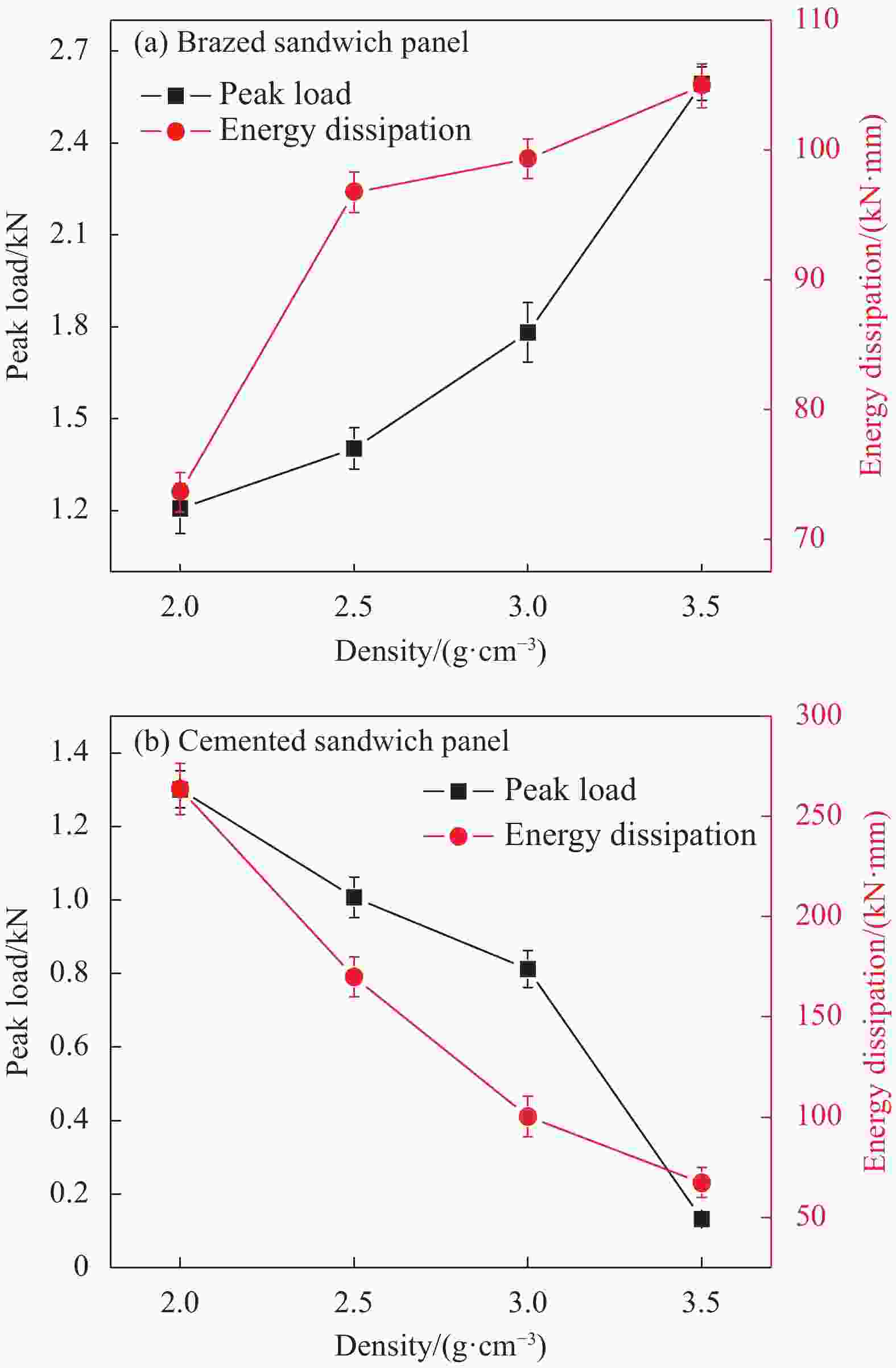

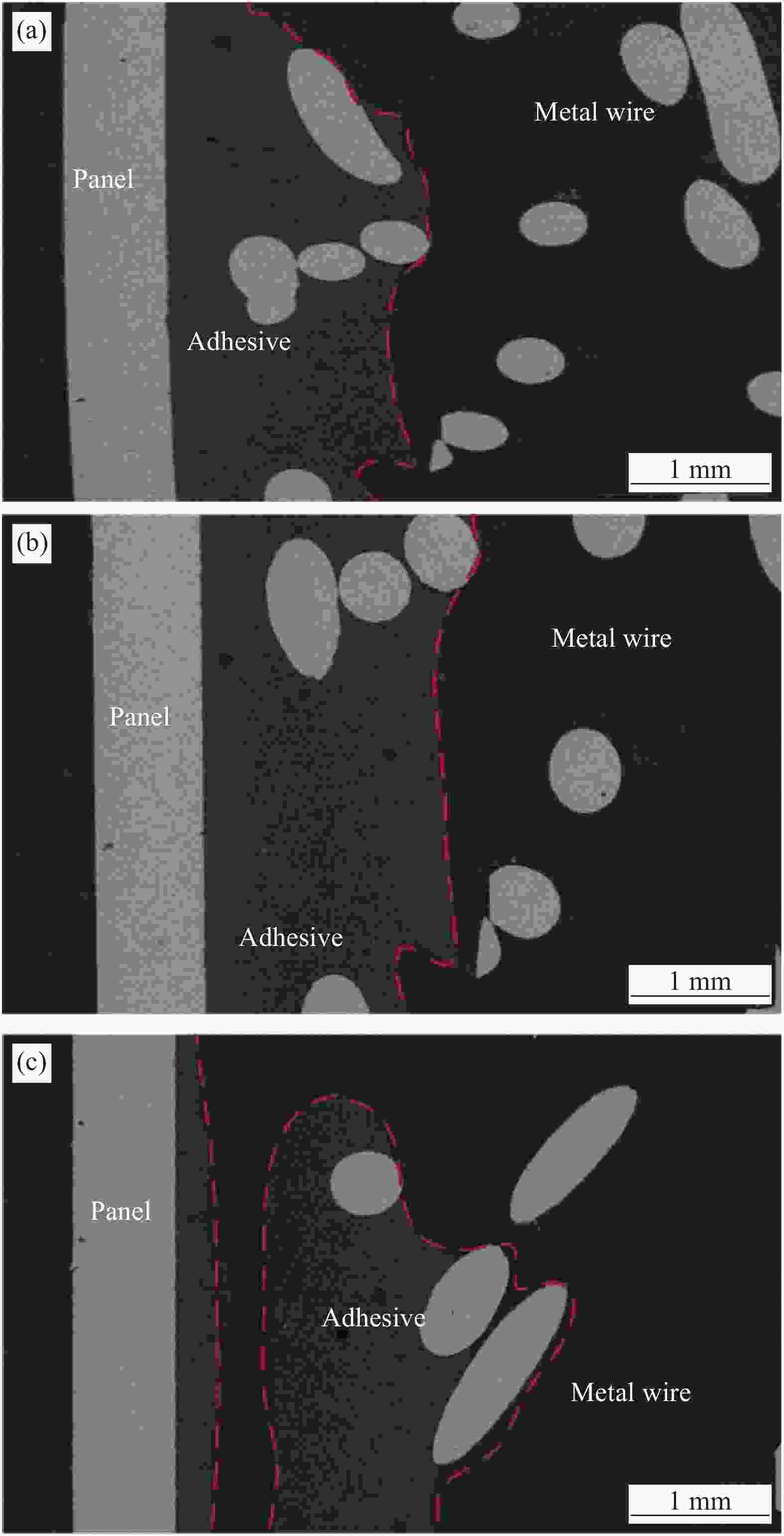

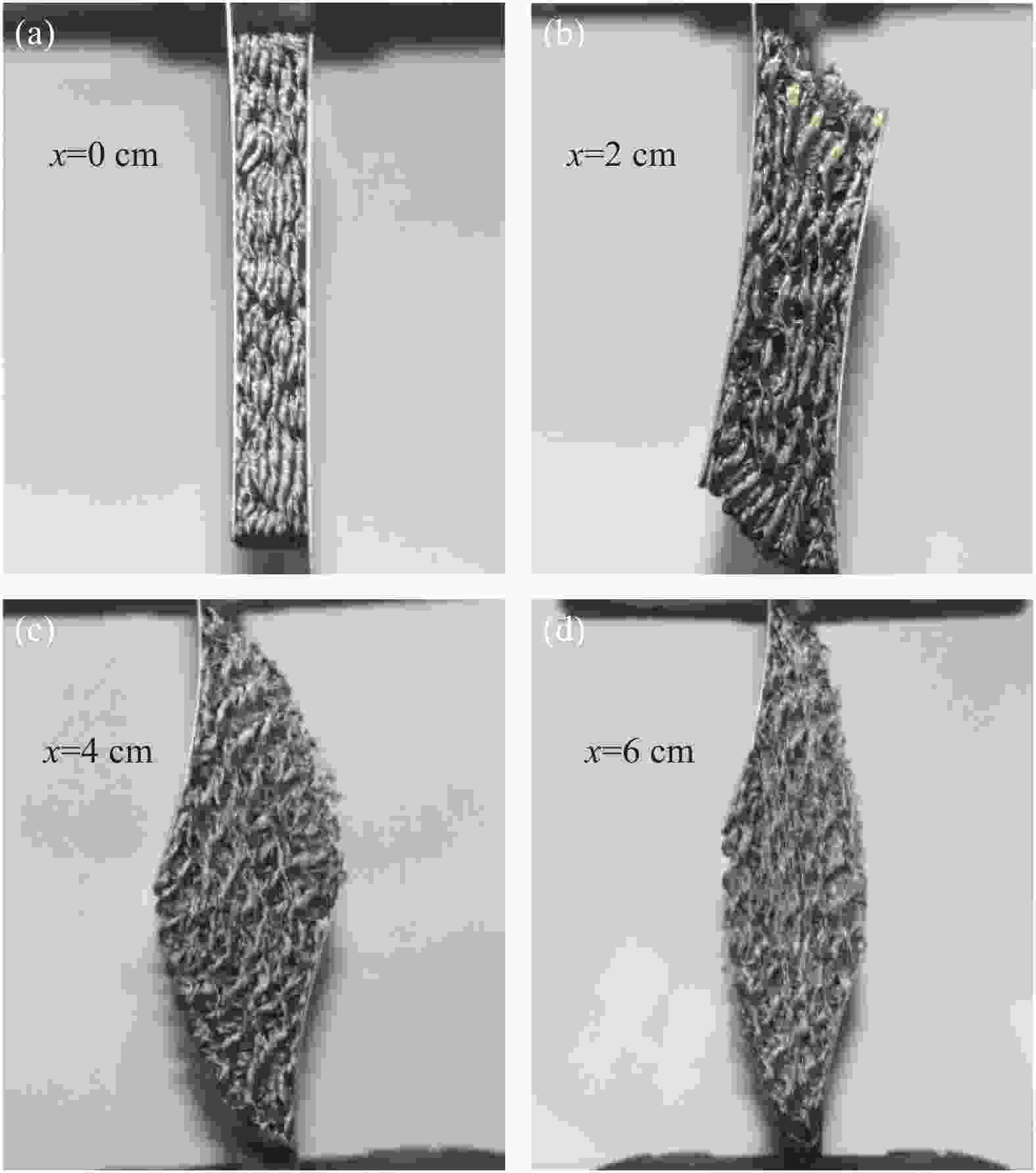

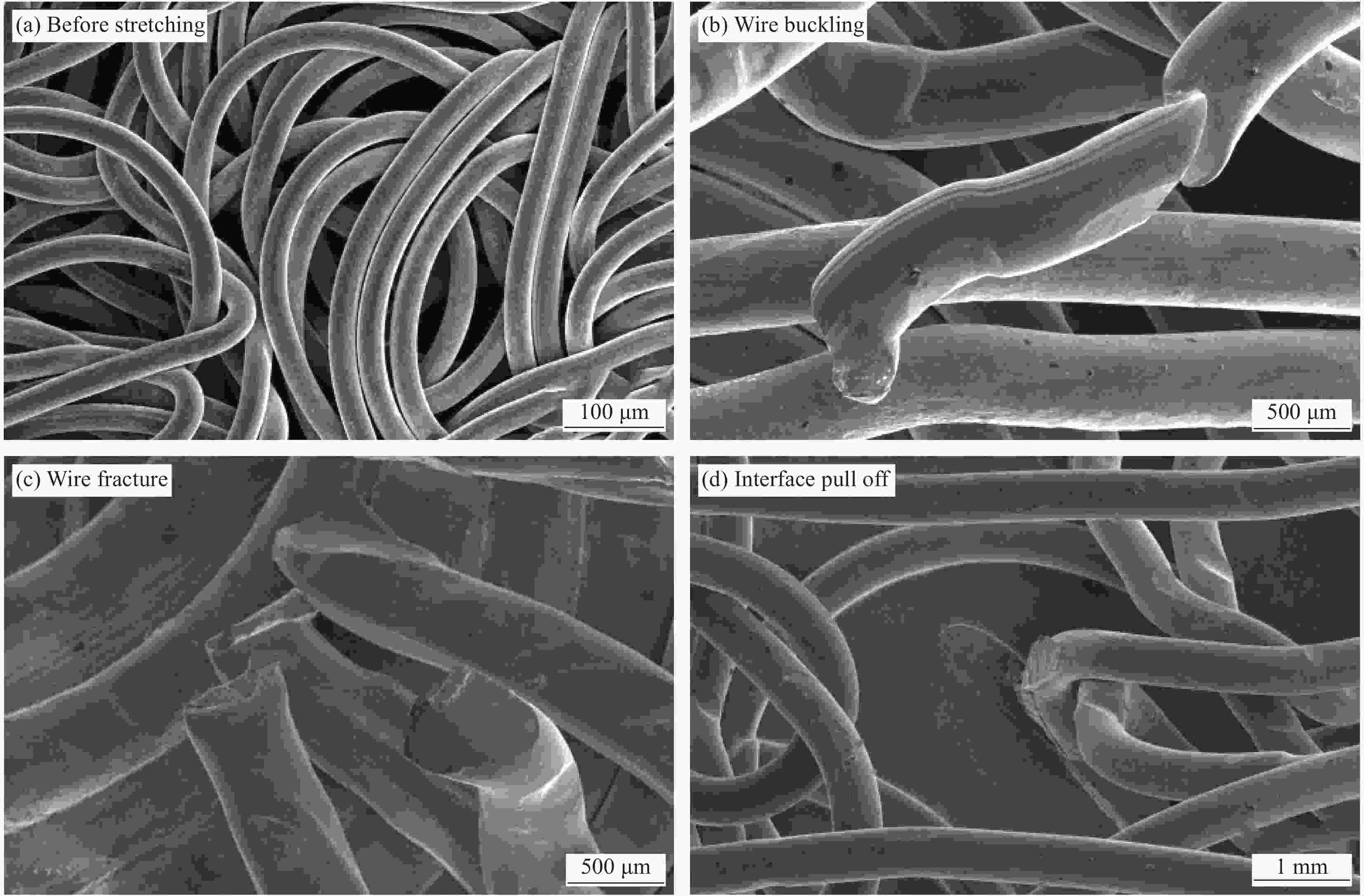

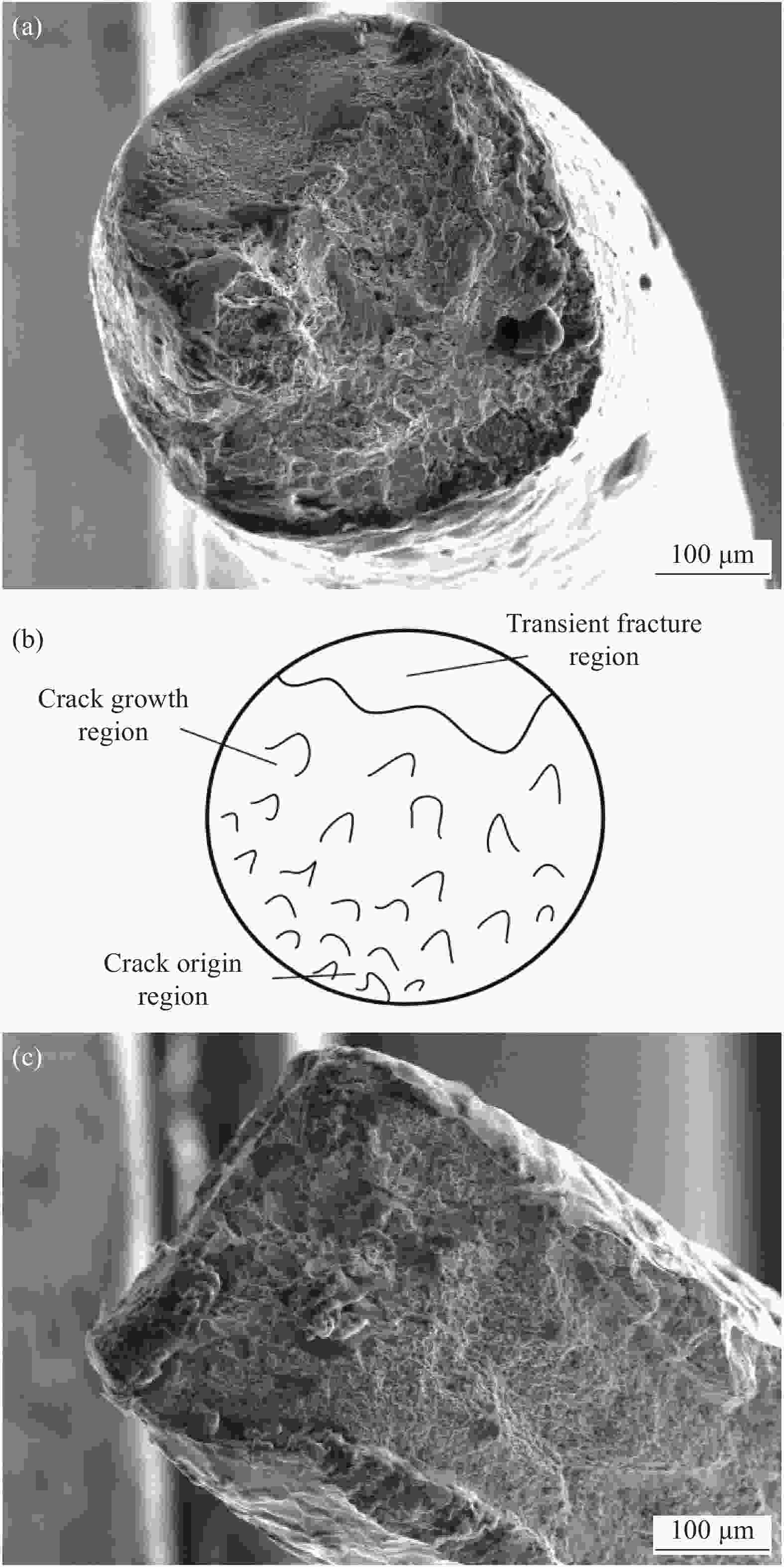

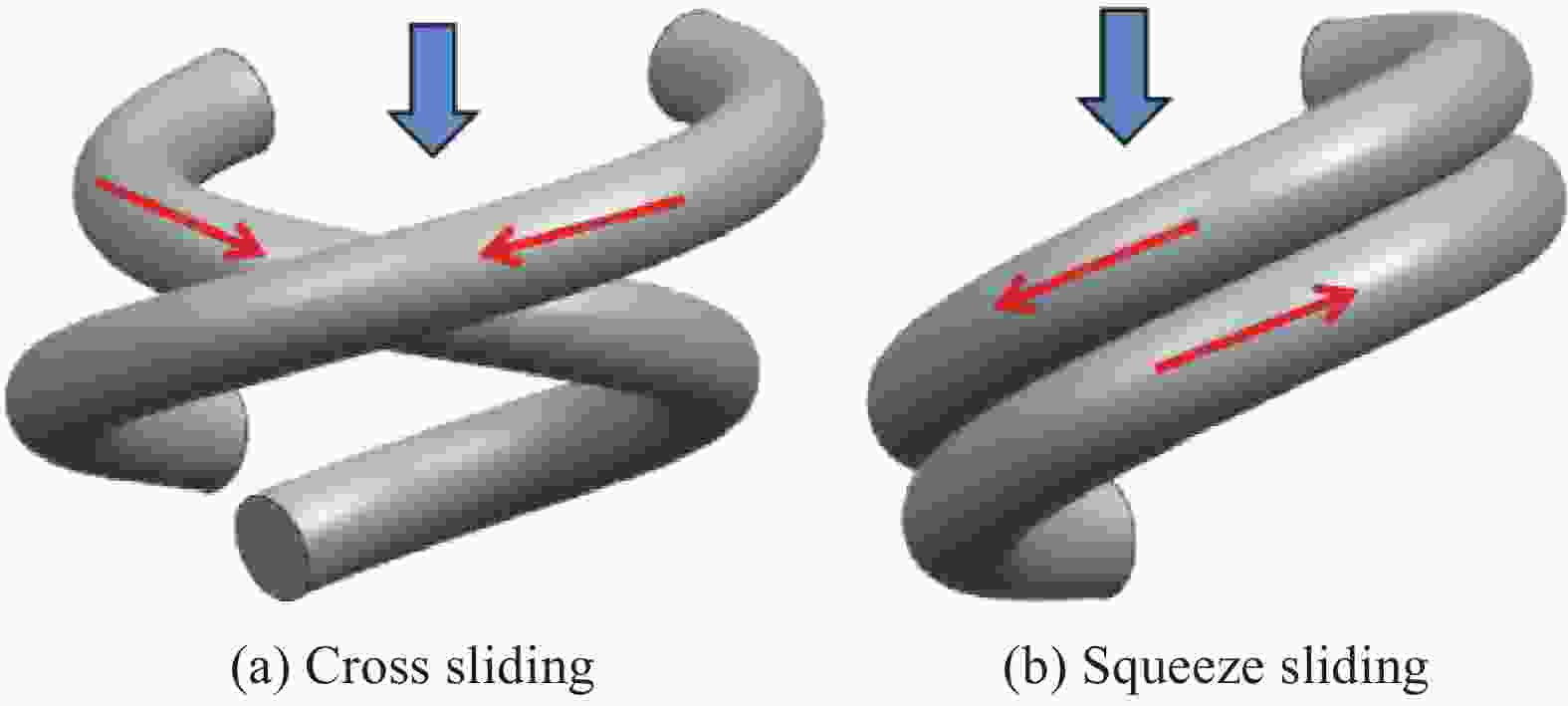

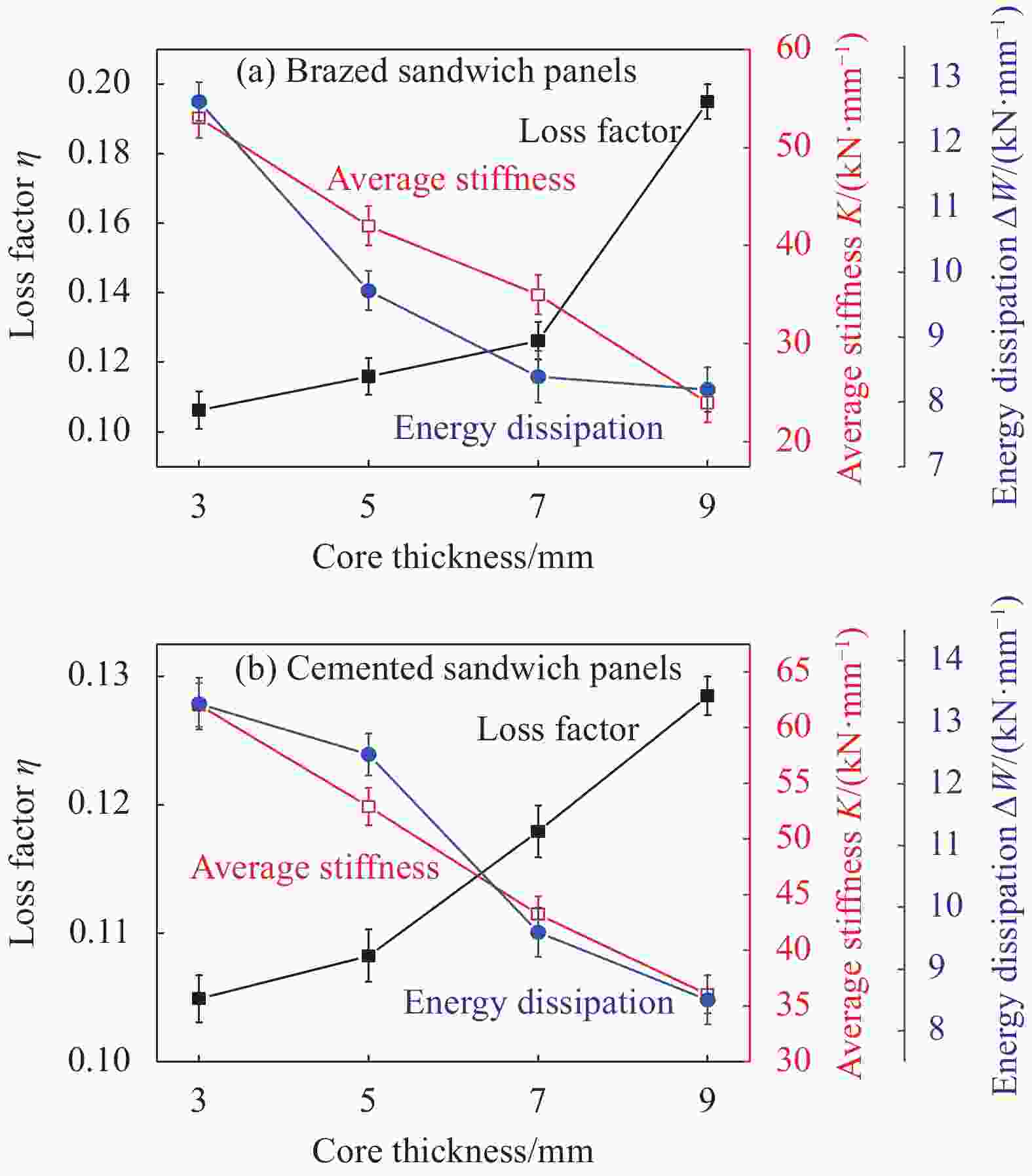

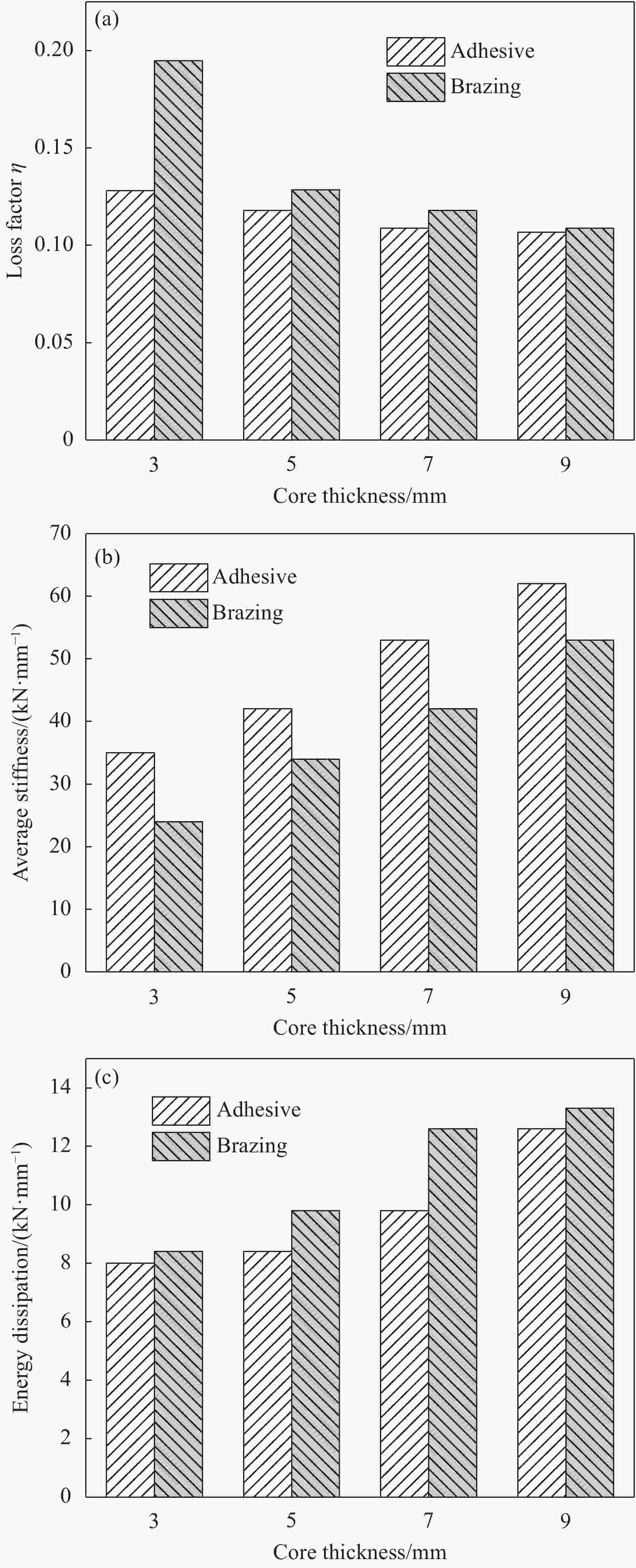

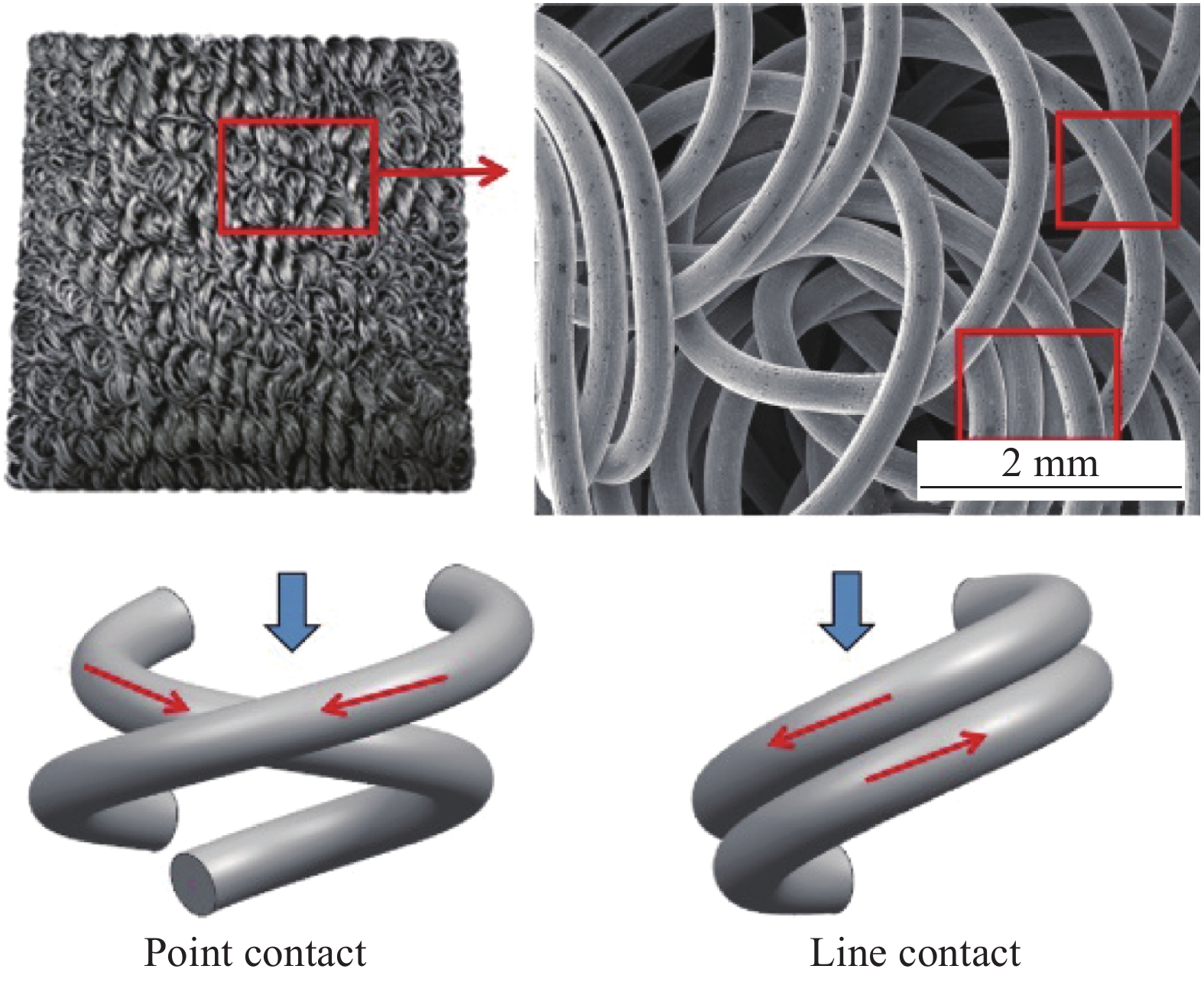

摘要: 针对弹性阻尼螺旋金属丝网夹芯结构界面连接性能不明确的问题,分别采用真空钎焊和胶结两种典型连接工艺,进行了面内压缩和拉伸剪切力学性能试验,结合SEM和EDS等材料微观表征方法,展开夹芯结构界面结合的物理机制和力学特性的研究。研究结果表明:钎焊连接界面相对胶结更均匀连续,钎料中Ni、Si元素与芯材、面板中的Fe、Cr元素扩散现象明显,形成良好的冶金结合。在压缩载荷作用下,钎焊夹芯板和胶结夹芯板的损耗因子最高分别达到了0.194和0.128,两种方式制备的夹芯板都具有较大的能量耗散能力。钎焊和胶结夹芯板的拉伸剪切载荷峰值分别达到了2 589 N和1 302 N,前者峰值载荷随芯材密度的增加而增加,而后者却与之相反;两种工艺在拉伸剪切过程中的失效破坏形式明显不同,胶结表现为面板与芯材的脱粘失效,钎焊主要发生芯材金属丝网的裂纹扩展和断裂失效,未发生面/芯分离。本研究对金属多孔夹芯结构的连接和力学性能分析具有一定的理论和应用指导意义。Abstract: Aiming at the problem of unclear interface connection performance of the sandwich structure with the core of elastic damping spiral wire mesh, two typical connection processes of vacuum brazing and cementing were adopted. The physical interface bonding mechanism and mechanical properties of the sandwich structure have been studied in-depth through compression and shear tests and microscopic characterizations such as SEM and EDS. The results show that the interface characteristics by brazing process are uniform and continuous rather than that by cementing process. The brazing interface of the sandwich panel has formed a good metallurgical bond, i.e., the Ni and Si elements in the brazing filler metal diffuse obviously with the Fe and Cr elements in the panel and core material. The highest loss factors of the brazed sandwich panel and the cemented sandwich panel under the static compression load can reach 0.194 and 0.128, respectively. This means that the sandwich panel with metal spiral mesh has a large energy dissipation capacity. The peak loads of tensile shear test for the brazed cemented sandwich panels are up to 2 589 N and 1 302 N, respectively. The peak load of the former increases with the increase of the core material density, while the latter is the opposite. The failure mode of the brazed sandwich panel in the tensile shear experiment is peeling of the panel and the core material, while the cemented sandwich panel mainly occurs crack propagation and fracture of core material. This research provides a theoretical and application guideline for the connection and mechanical performance analysis of porous metallic sandwich structures.

-

表 1 SUS304不锈钢原材料的性能参数

Table 1. Performance parameters of SUS304 material

Element Fe Ni C Si Mn S P Cr Content/wt% ≥71 8.01 ≤0.08 ≤1.00 ≤2.00 ≤0.03 ≤0.035 17.12 Property Young′s modulus/GPa Density/(g·cm−3) Tensile strength/MPa Yield strength/MPa Value 199 7.93 680 340 表 2 JL101金属胶的性能参数

Table 2. Performance parameters of JL101 metal glue

Colour Density/(g·cm−3) Compressive strength/MPa Tensile strength/MPa Cast iron 1.64 87.6 26.8 Shear strength/MPa Bending strength/MPa Hardness(Shore D) Working temperature/℃ 19.8 50 75 −60-300 表 3 BNi2钎料的化学成分

Table 3. Chemical composition of solder BNi2

Composition Ni Cr Si B Fe Co C P W Content/wt% ≥84 6-8 4-5 2.75-3.5 2.5-3.5 ≤0.1 ≤0.06 ≤0.02 ≤0.02 Property Solid phase line/℃ Liquidus line/℃ Value 970 1000 表 4 金属螺旋丝网复合夹芯板面内压缩试验参数

Table 4. In-plane compression test parameters of sandwich structure with the core of elastic damping metal spiral wire mesh

Name Length/mm Width/mm Density/(g·cm−3) Thickness/mm Connection C1-1 60 60 3.0 3 Brazing C1-2 60 60 3.0 5 Brazing C1-3 60 60 3.0 7 Brazing C1-4 60 60 3.0 9 Brazing C2-1 60 60 3.0 3 Adhesive C2-2 60 60 3.0 5 Adhesive C2-3 60 60 3.0 7 Adhesive C2-4 60 60 3.0 9 Adhesive 表 5 金属螺旋丝网复合夹芯板面内剪切拉伸试验参数

Table 5. In-plane shear tensile test parameters of sandwich structure with the core of elastic damping metal spiral wire mesh

Name Length/mm Width/mm Density/(g·cm−3) Thickness/mm Connection S1-1 140 60 2.0 5 Brazing S1-2 140 60 2.5 5 Brazing S1-3 140 60 3.0 5 Brazing S1-4 140 60 3.5 5 Brazing S2-1 140 60 2.0 5 Adhesive S2-2 140 60 2.5 5 Adhesive S2-3 140 60 3.0 5 Adhesive S2-4 140 60 3.5 5 Adhesive -

[1] 张大义, 夏颖, 张启成, 等. 金属橡胶力学性能研究进展与展望[J]. 航空动力学报, 2018, 33(6):1432-1445.ZHANG Dayi, XIA Ying, ZHANG Qicheng, et al. Research progress and prospects of the mechanical properties of metal rubber[J]. Journal of Aeronautical Dynamics,2018,33(6):1432-1445(in Chinese). [2] LU C Z, LI J, ZHOU B, et al. Experimental investigation of stiffness characteristics and damping properties of a metallic rubber material[J]. Mechanics of Composite Materials,2017,53(4):541-550. doi: 10.1007/s11029-017-9684-6 [3] 卢成壮, 李静媛, 周邦阳, 等. 金属丝特性对金属橡胶疲劳性能的影响[J]. 振动与冲击, 2018, 37(24):137-142.LU Chengzhuang, LI Jingyuan, ZHOU Bangyang, et al. The effect of metal wire properties on the fatigue properties of metal rubber[J]. Journal of Vibration and Shock,2018,37(24):137-142(in Chinese). [4] 黄凯, 白鸿柏, 路纯红, 等. 复杂构型金属橡胶毛坯铺设路径规划[J]. 航空动力学报, 2018, 33(7):1575-1583.HUANG Kai, BAI Hongbai, LU Chunhong, et al. Path planning for the laying of metal rubber blanks with complex configurations[J]. Journal of Aeronautics and Dynamics,2018,33(7):1575-1583(in Chinese). [5] ZHANG W, XUE X, BAI H. Mechanical and electrical properties of Cu-Steel bimetallic porous composite with a double-helix entangled structure[J]. Composite Structures,2021,255:112886. [6] WANG Y J, ZHANG Z J, XUE X M, et al. Experimental investigation on enhanced mechanical and damping performance of corrugated structure with metal rubber[J]. Thin-Walled Structures,2020,154:106816. doi: 10.1016/j.tws.2020.106816 [7] 王志华, 李世强, 李鑫, 等. 轻质多孔金属及其夹芯结构力学行为的研究进展[J]. 太原理工大学学报, 2017, 48(3):492-503.WANG Zhihua, LI Shiqiang, LI Xin, et al. Research progress on the mechanical behavior of lightweight porous metals and their sandwich structures[J]. Journal of Taiyuan University of Technology,2017,48(3):492-503(in Chinese). [8] XIN Y, YAN H, YANG S, et al. Experimental study on the indentation of epoxy resin-aluminum honeycomb composite sandwich panel[J]. Mechanics of Advanced Materials and Structures,2019,28(12):1-15. [9] KAVERMANN S W, BHATTACHARYYA D. Experimental investigation of the static behaviour of a corrugated plywood sandwich core[J]. Composite Structures,2019,207:836-844. doi: 10.1016/j.compstruct.2018.09.094 [10] KASIRAJAN S, ENTHIL KS, PANDIYARAJAN R. Experimental investigation of basalt/s-glass/epoxy/PVC H-130 hybrid sandwich composite[J]. Journal of the Chinese Institute of Engineers,2020,43(8):725-733. doi: 10.1080/02533839.2020.1771211 [11] LI H, HU Y, FU X, et al. Effect of adhesive quantity on failure behavior and mechanical properties of fiber metal laminates based on the aluminum-lithium alloy[J]. Composite Structures,2016,152:687-692. doi: 10.1016/j.compstruct.2016.05.098 [12] ZHANG P, CHENG Y, LIU J, et al. Experimental and numerical investigations on laser-welded corrugated-core sandwich panels subjected to air blast loading[J]. Marine Structures,2015,40:225-246. doi: 10.1016/j.marstruc.2014.11.007 [13] 张军, 程和法, 黄笑梅, 等. 钎焊方法制备泡沫铝/铝夹芯板的组织及性能[J]. 焊接学报, 2019, 40(8):144-149.ZHANG Jun, CHENG Hefa, HUANG Xiaomei, et al. Microstructure and properties of aluminum foam/aluminum sandwich panel prepared by brazing method[J]. Transactions of the China Welding Institution,2019,40(8):144-149(in Chinese). [14] HANGAI Y, NAKANO Y, KOYAMA S, et al. Fabrication of aluminum tubes filled with aluminum alloy foam by friction welding[J]. Materials,2015,8(10):7180-7190. doi: 10.3390/ma8105373 [15] LIN H, LUO H, HUANG W, et al. Diffusion bonding in fabrication of aluminum foam sandwich panels[J]. Journal of Materials Processing Technology,2016,230:35-41. doi: 10.1016/j.jmatprotec.2015.10.034 [16] 张军, 程和法, 秦晓雄, 等. 钎焊工艺制备泡沫铝/铝夹芯板及其力学行为研究[J]. 材料研究与应用, 2017, 11(3):167-171. doi: 10.3969/j.issn.1673-9981.2017.03.006ZHANG Jun, CHENG Hefa, QIN Xiaoxiong, et al. Preparation of foamed aluminum/aluminum sandwich panel by brazing process and its mechanical behavior[J]. Materials Research and Application,2017,11(3):167-171(in Chinese). doi: 10.3969/j.issn.1673-9981.2017.03.006 [17] 栾旭, 梁军, 王超, 等. 金属蜂窝夹芯板疲劳行为的试验研究[C]. 上海: China SAMPE' 2008国际学术研讨会, 2008.LUAN Xu, LIANG Jun, WANG Chao, et al. Experimental research on fatigue behavior of metal honeycomb sandwich panels[C]. Shanghai: China SAMPE' 2008 International Symposium, 2008(in Chinese). [18] 乔吉超, 奚正平, 汤慧萍, 等. 金属纤维多孔材料的压缩行为[J]. 稀有金属材料与工程, 2008, 37(12):2173-2176. doi: 10.3321/j.issn:1002-185X.2008.12.024QIAO Jichao, XI Zhengping, TANG Huiping, et al. Compression behavior of porous metal fiber materials[J]. Rare Metal Materials and Engineering,2008,37(12):2173-2176(in Chinese). doi: 10.3321/j.issn:1002-185X.2008.12.024 [19] 王宇, 胡正飞, 姚骋, 等. 液态扩散焊制备泡沫铝夹芯板及其疲劳行为[J]. 复合材料学报, 2018, 35(6):1652-1660.WANG Yu, HU Zhengfei, YAO Cheng, et al. Preparation and fatigue behavior of aluminum foam sandwich panel by liquid diffusion welding[J]. Journal of Composite Materials,2018,35(6):1652-1660(in Chinese). [20] ZHOU Y, XU Y, LIU H, et al. Debonding identification of Nomex honeycomb sandwich structures based on the increased vibration amplitude of debonded skin[J]. Composites Part B: Engineering,2020,200:108233. doi: 10.1016/j.compositesb.2020.108233 [21] MARKAKI A E, CLYNE T W. Mechanics of thin ultra-light stainless steel sandwich sheet material[J]. Acta Materialia,2003,51(5):1341-1350. [22] MARKAKI A E, CLYNE T W. Mechanics of thin ultra-light stainless steel sandwich sheet material[J]. Acta Materialia,2003,51(5):1351-1357. doi: 10.1016/S1359-6454(02)00529-3 [23] 白鸿柏. 金属橡胶材料及工程应用[M]. 北京: 科学出版社, 2014.BAI Hongbai. Metal rubber materials and engineering applications[M]. Beijing: Science Press, 2014. [24] MA Y, ZHANG Q, WANG Y, et al. Topology and mechanics of metal rubber via X-ray tomography[J]. Materials & Design,2019,181:108067. [25] REN Z, SHEN L, HUANG Z, et al. Study on multi-point random contact characteristics of metal rubber spiral mesh structure[J]. IEEE Access,2019,7:132694-132710. doi: 10.1109/ACCESS.2019.2935818 [26] HU J, DU Q, GAO J, et al. Compressive mechanical behavior of multiple wire metal rubber[J]. Materials & Design,2018,140:231-240. [27] MA Y, ZHANG Q, ZHANG D, et al. Size-dependent mechanical behavior and boundary layer effects in entangled metallic wire material systems[J]. Journal of Materials Science,2017,52(7):3741-3756. -

下载:

下载: