Design of Hybridized Network Structure and Photoelectric Thermal Conversion Performance of polyethylene glycol-based Phase Change Composites

-

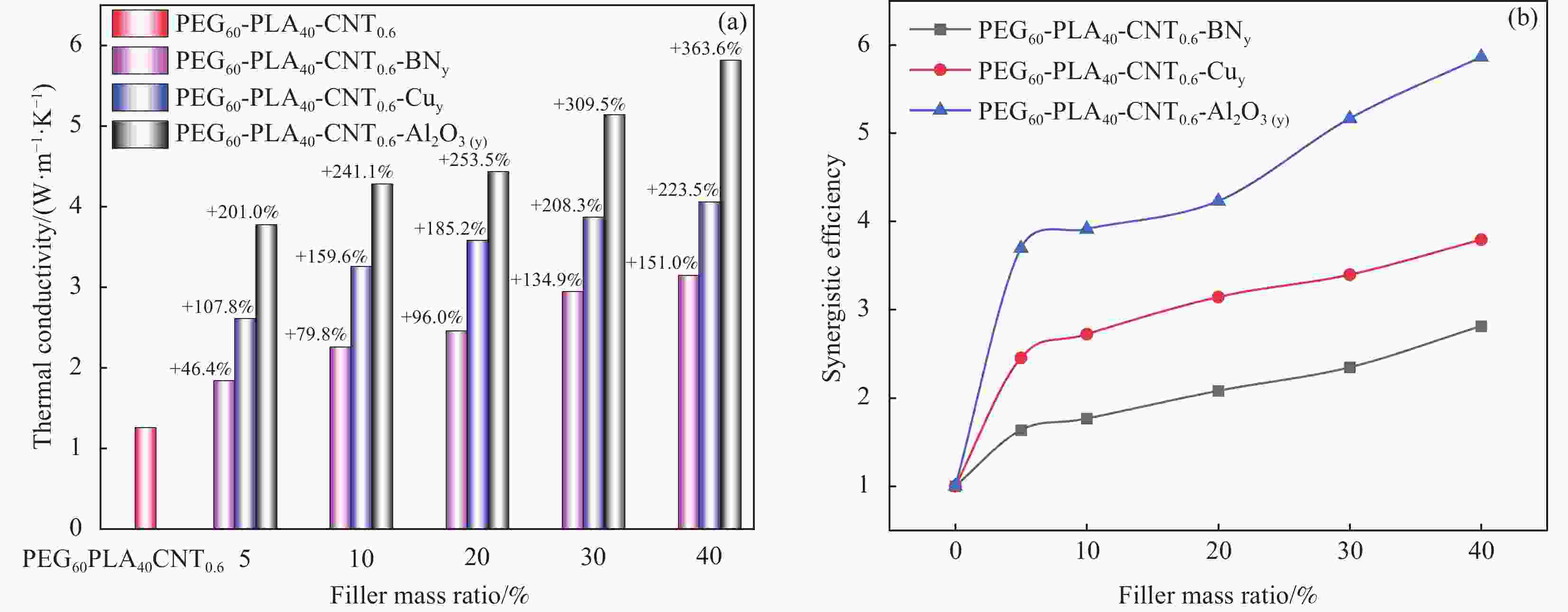

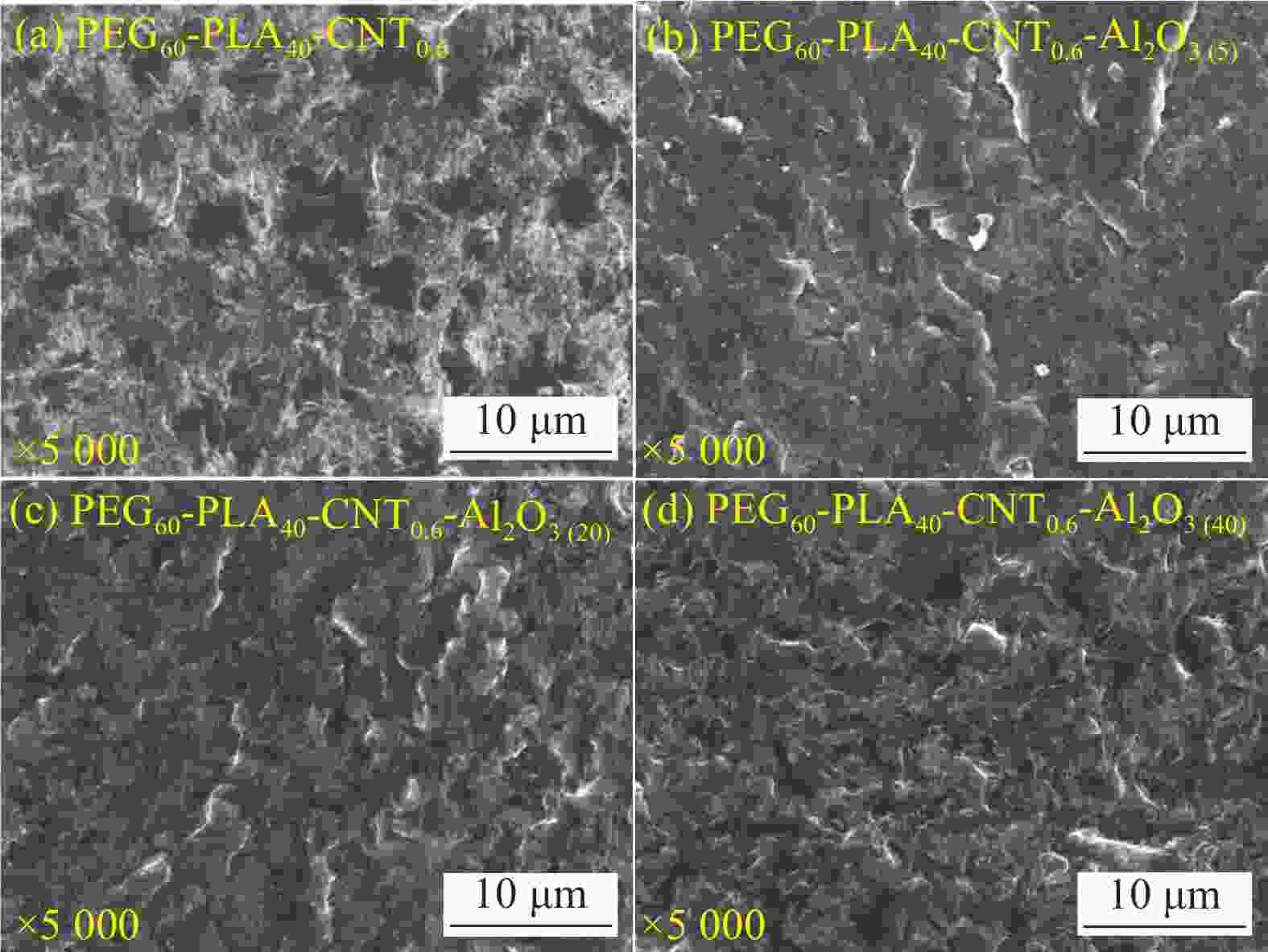

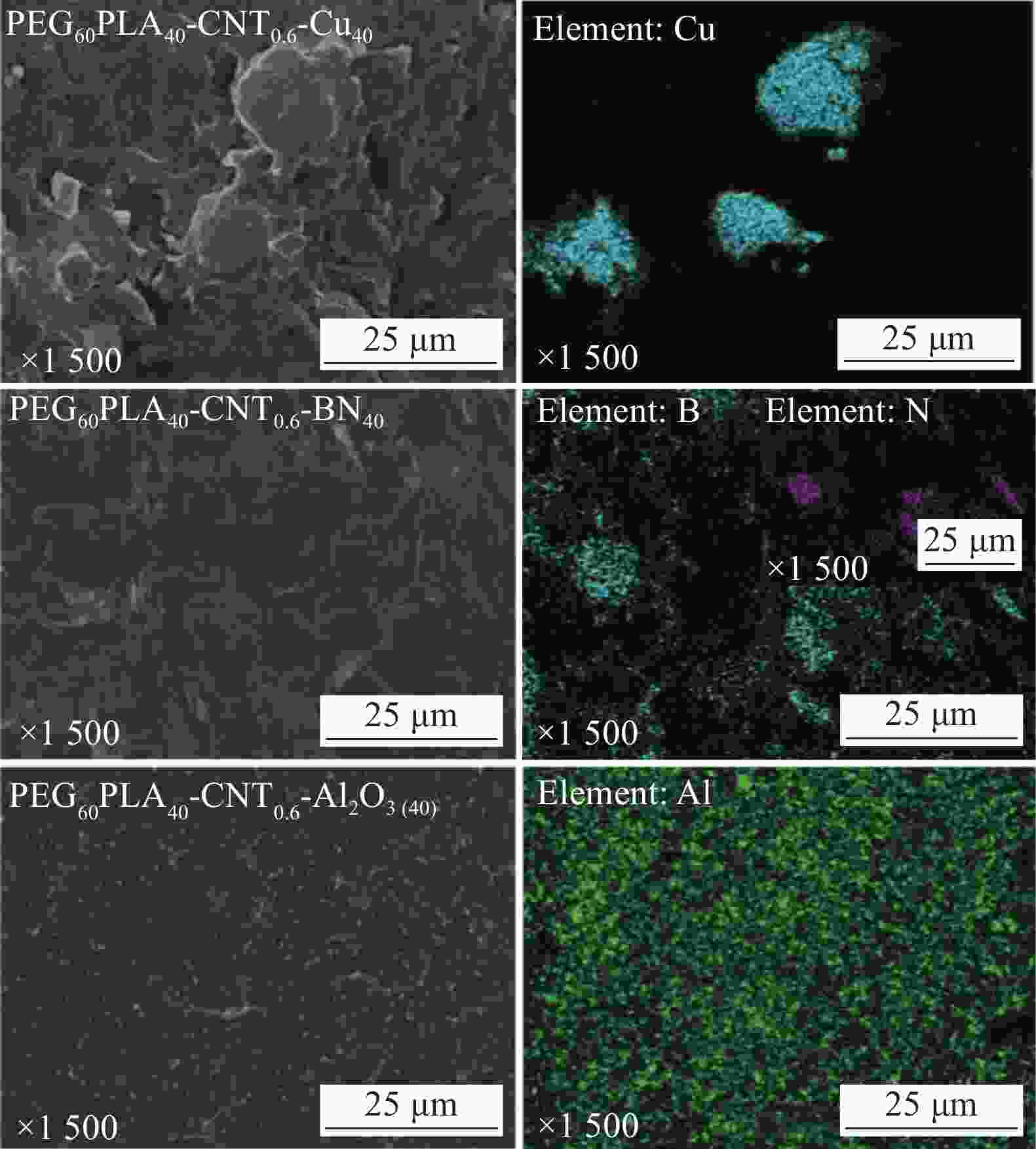

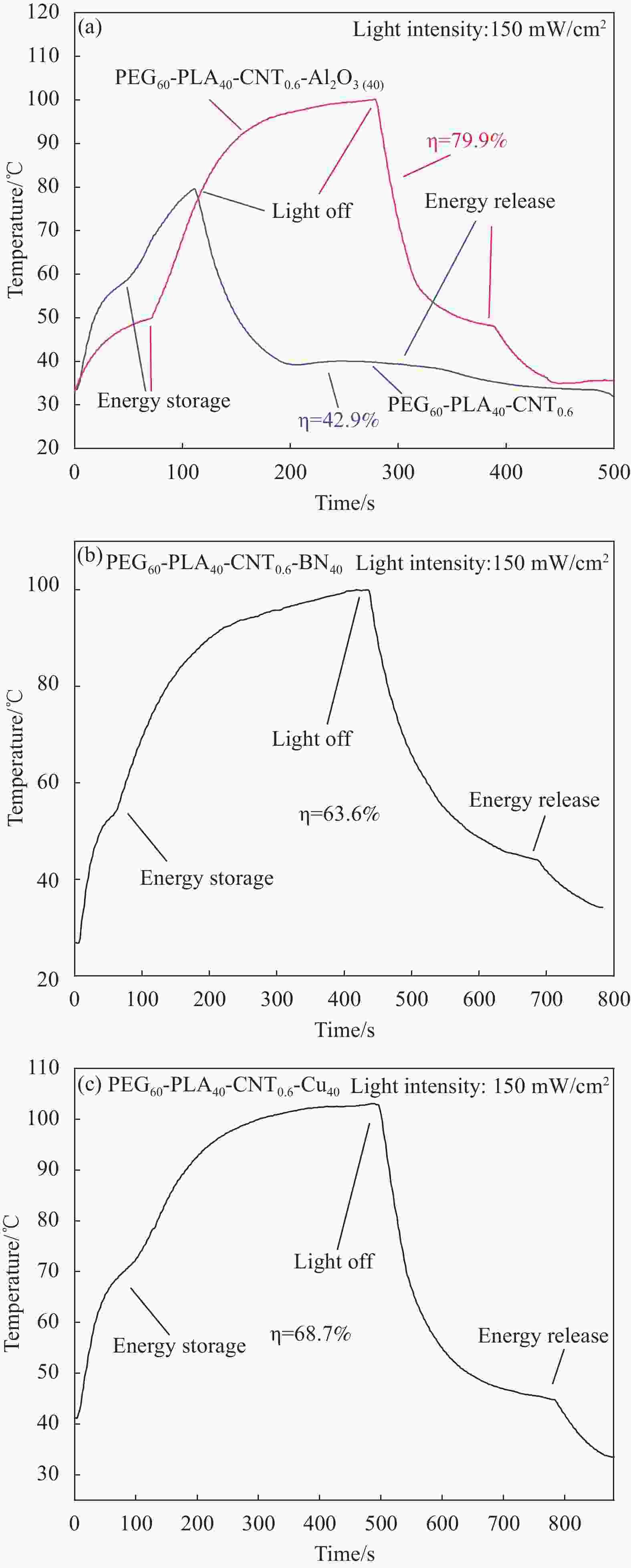

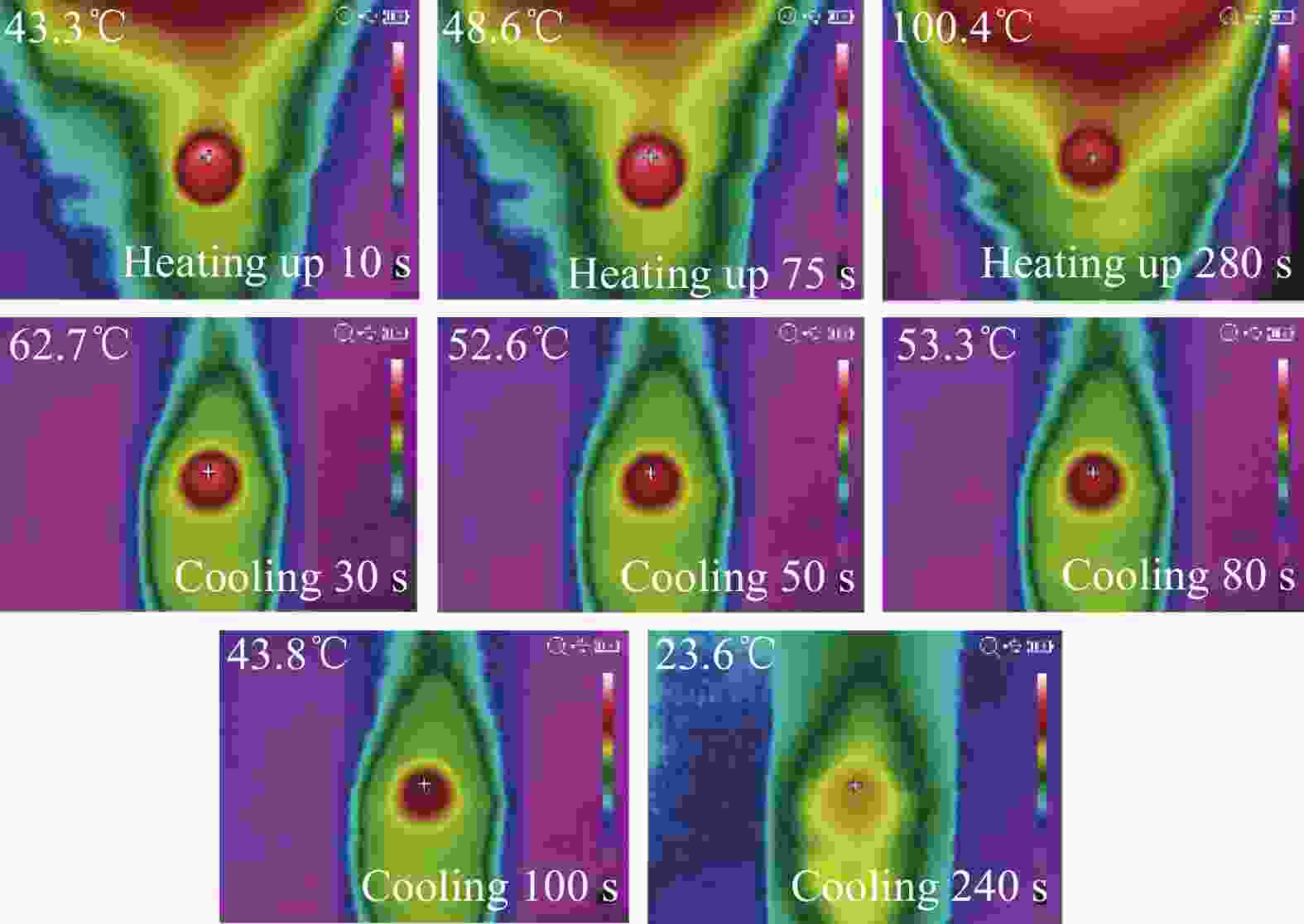

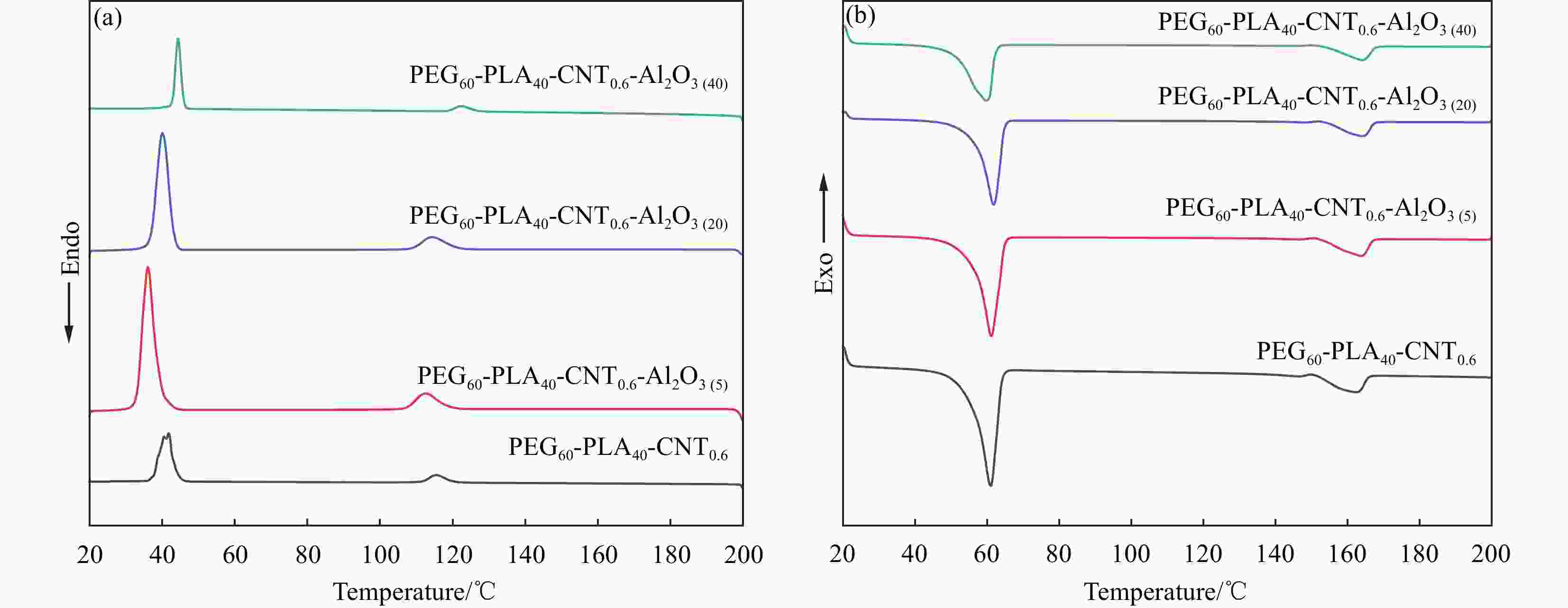

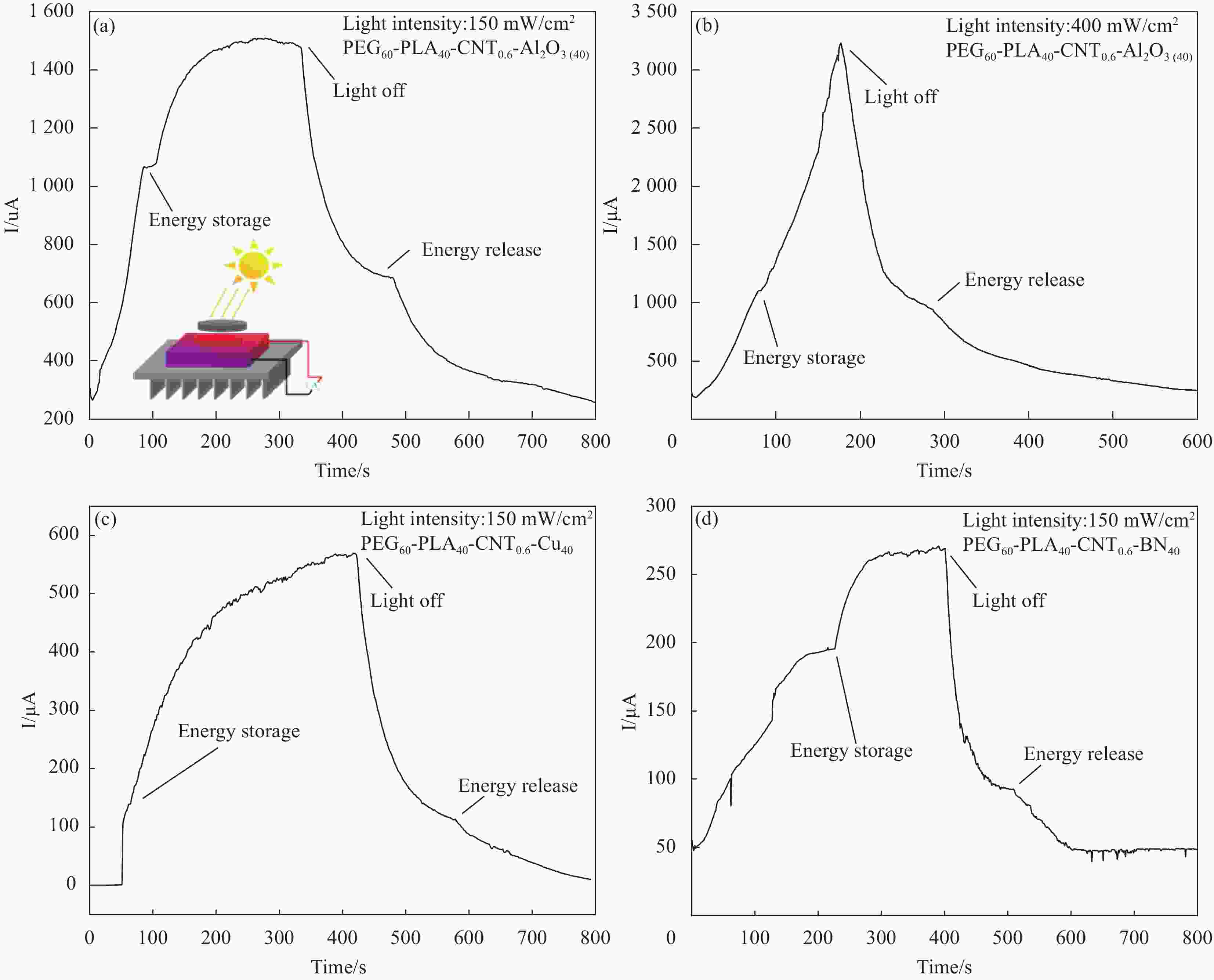

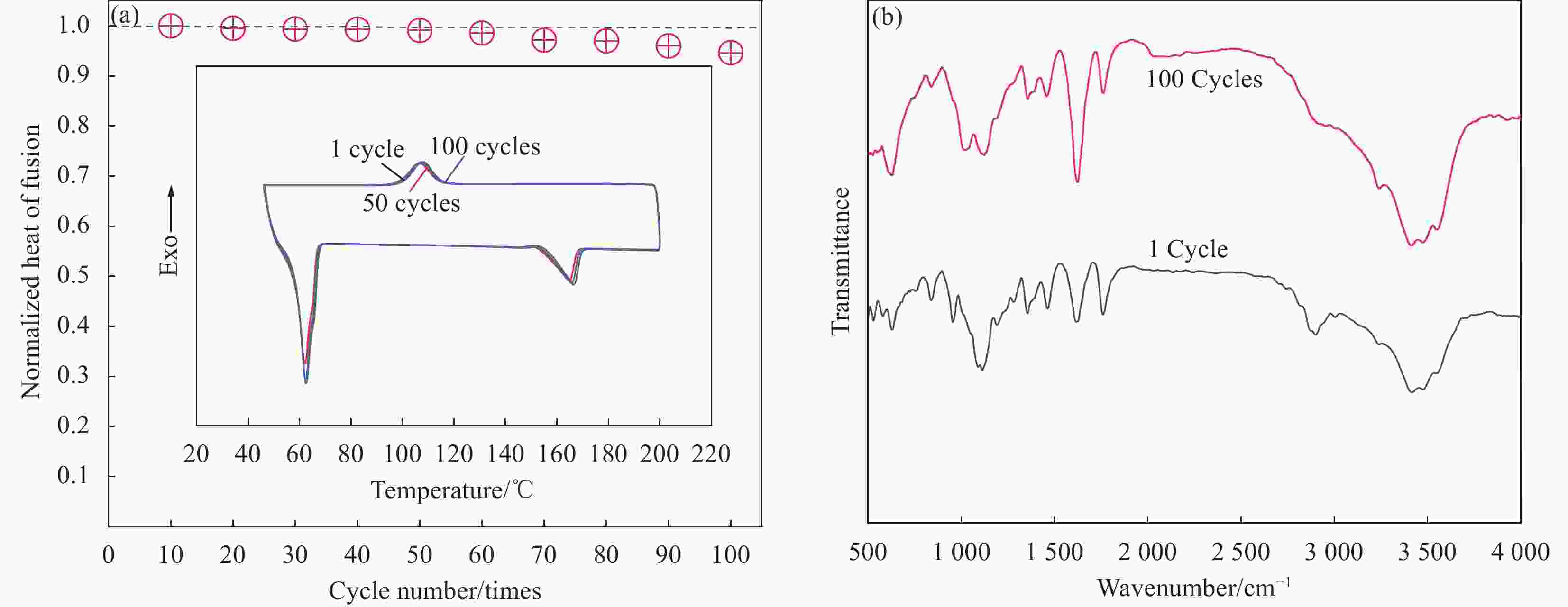

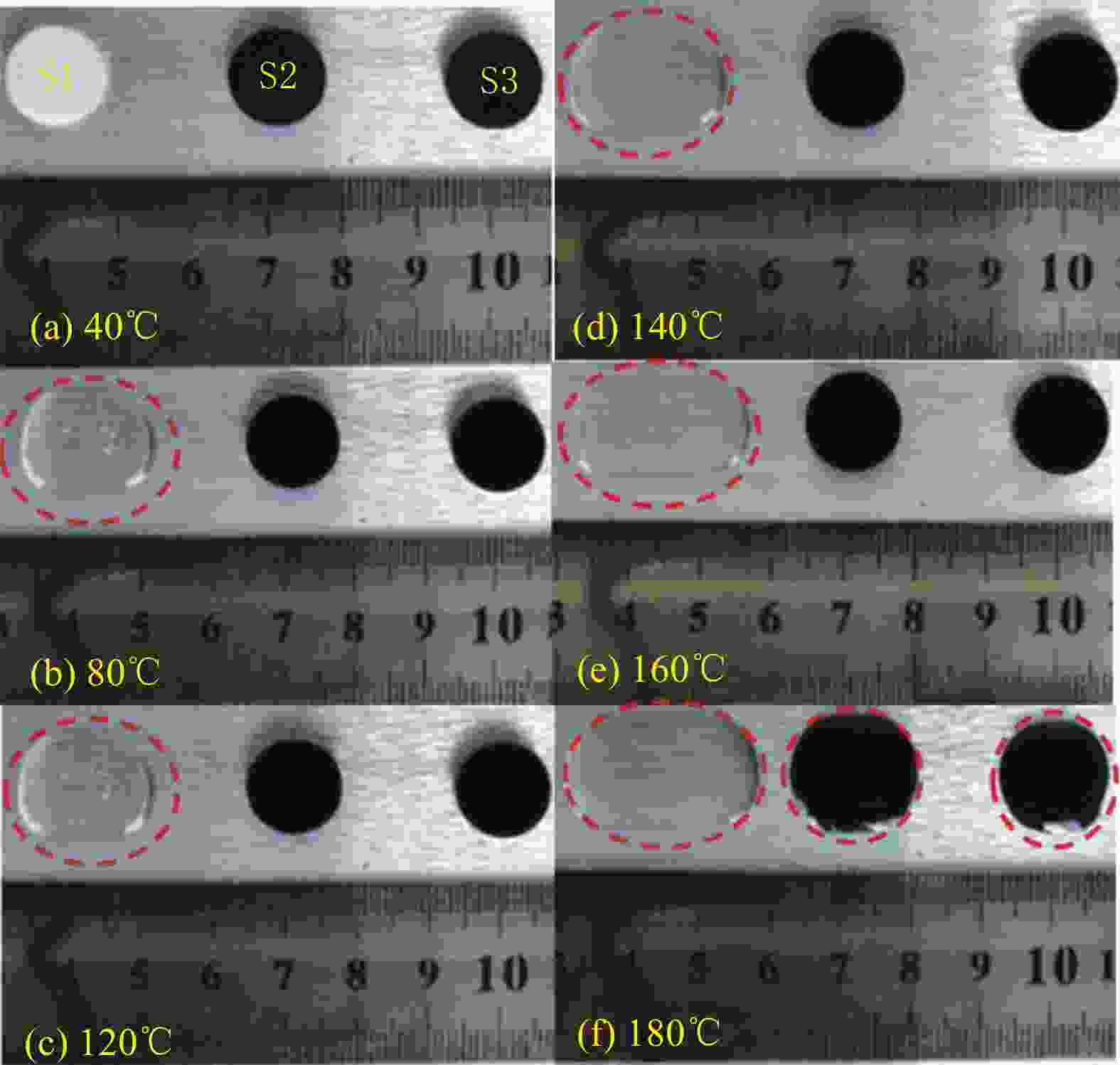

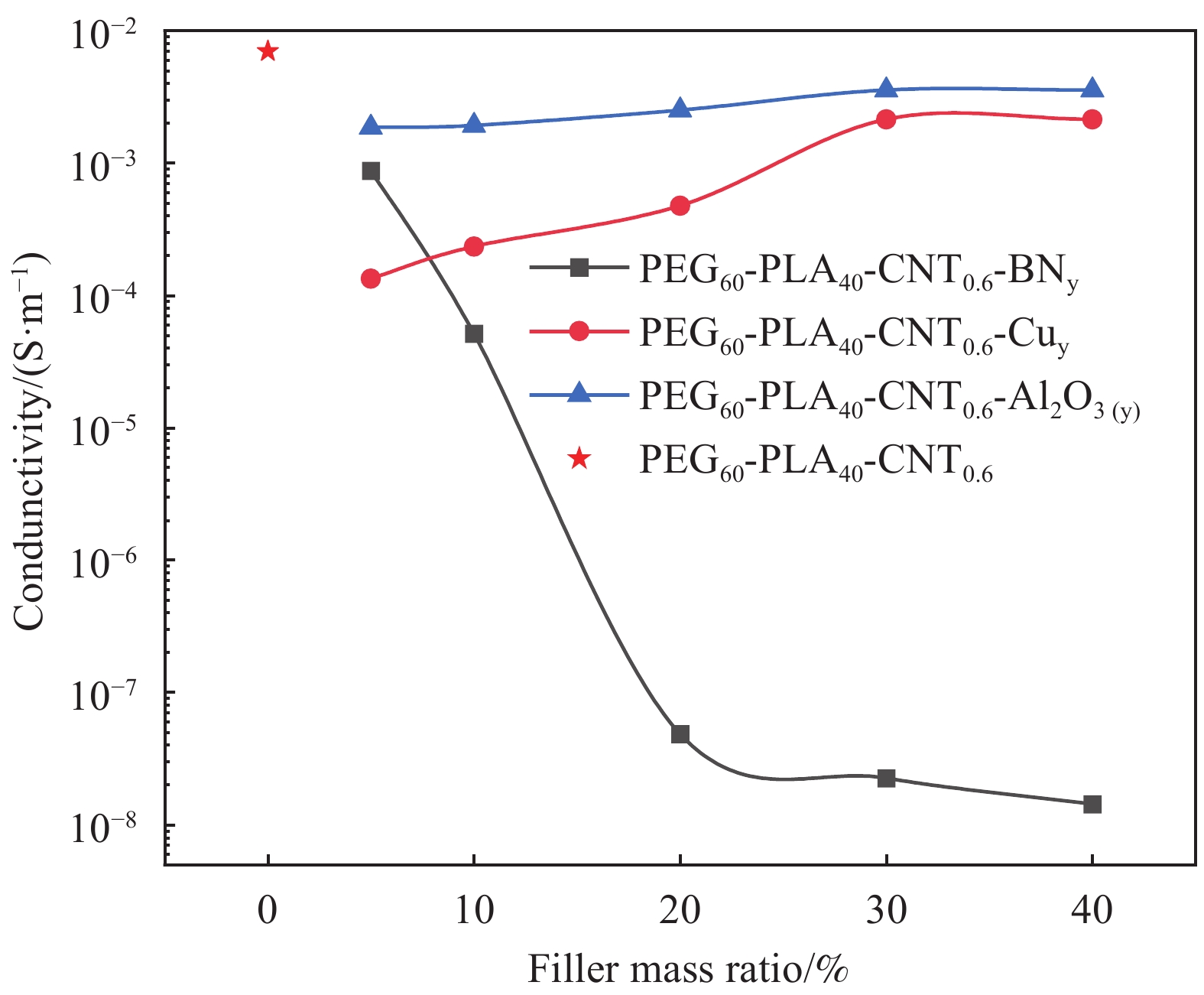

摘要: 为了探究不同结构的纳米粒子对聚乙二醇(PEG)基相变复合材料形状稳定性及光电转换效率的影响,本文将碳纳米管(CNTs)分别与氮化硼(BN)、三氧化二铝(Al2O3)以及铜粉(Cu)通过物理杂化的方式制备了PEG/PLA/CNT/X(y)相变储能复合材料。通过导电数据分析发现,Al2O3和Cu纳米填料的加入对PEG/PLA/CNT/X(y)复合材料的导电性能影响较小,使复合材料仍然具有较高的导电性能;而BN的引入使复合材料的导电性能急剧下降,当BN的质量含量比达到40%时,PEG60-PLA40-CNT0.6-BN40复合材料的电导率仅为8.71×10-7 S/m,呈现出明显的绝缘性。通过SEM和EDS能谱发现, Al2O3纳米粒子在复合材料内部均匀分布,当Al2O3质量含量比为40%时,PEG60-PLA40-CNT0.6-Al2O3(40)复合材料热导率和增强因子($ \varPhi $)值分别高达5.81 W/m·K和363.6%;相较于PEG60-PLA40复合材料,PEG60-PLA40-CNT0.6-Al2O3(40) 复合材料在160oC时仍具有较高的形状稳定性,没有出现PEG的泄露和塌陷现象。相比于其他纳米粒子,Al2O3的引入能够显著提高PEG60-PLA40-CNT0.6-Al2O3(40) 复合材料的光热转换效率($ \eta $),$ \eta $值从42.9%提升至72.9%。而且复合材料对光的响应灵敏度更高,响应速度更快,电流变化曲线更加平滑,具有优异的光电转换性能。$ $Abstract: PEG60PLA40CNT0.6X(y) phase-change energy storage composites were prepared in this paper by physically hybridizing carbon nanotubes (CNTs) with boron nitride (BN), aluminum trioxide (Al2O3), and copper powder (Cu), respectively, to investigate the effects of nanoparticles with different structures on the shape stability and photovoltaic conversion efficiency of polyethylene glycol (PEG) based phase-change composites. The incorporation of Al2O3 and Cu nanofillers has a minor effect on the electrical conductivity of the PEG/PLA/CNT/X(y) composites; however, the introduction of BN drastically reduces the electrical conductivity of the composites. When the mass ratio of BN reaches 40%, the electrical conductivity of the PEG60-PLA40-CNT0.6-BN40 composites is only 8.71×10-7 S/m, indicating obvious insulating properties. The spherical Al2O3 nanoparticles were found to be uniformly distributed inside the composites by SEM and EDS energy spectroscopy, and the thermal conductivity and enhancement factor ($ \varPhi $) values of PEG60-PLA40-CNT0.6-Al2O3(40) composites were as high as 5.81 W/m·K and 363.6%, respectively. Compared to the PEG60-PLA40 composites, the addition of Al2O3 improves the photothermal conversion efficiency ($ \eta $), photosensitive response rate, and current stability of PEG60-PLA40-CNT0.6-Al2O3(40) composites, raising the value from 42.9% to 72.9%.

-

表 1 PEG/PLA/CNTs/X(y)复合材料质量配比表

Table 1. the mass ration of PEG/PLA/CNTs/X(y) composites

Sample PLA/% CNTs/% PEG/% y/% PEG60-PLA40-CNT0.6 40 0.6 60 - PEG60-PLA40-CNT0.6-X (5) 40 0.6 60 5 PEG60-PLA40-CNT0.6-X(10) 40 0.6 60 10 PEG60-PLA40-CNT0.6-X (20) 40 0.6 60 20 PEG60-PLA40-CNT0.6-X (30) 40 0.6 60 30 PEG60-PLA40-CNT0.6-X (40) 40 0.6 60 40 Notes:“X”represents the thermally conductive particles, “y”represents the mass ratio of thermally conductive particles in PEG60-PLA40 composites. 表 2 复合材料中PEG相的DSC参数

Table 2. DSC parameters of PEG phase in composites

Samples T0

/℃Tp

/℃ΔHm

/(J·g-1)PEG60-PLA40-CNT0.6 43.4 41.9 100.5 PEG60-PLA40-CNT0.6-Al2O3(5) 39.6 36.6 95.6 PEG60-PLA40-CNT0.6-Al2O3(20) 43.4 40.6 88.9 PEG60-PLA40-CNT0.6-Al2O3(40) 46.0 44.7 85.2 Notes:T0 represents the onset crystalline temperature,Tp represents the peak crystalline temperature,ΔHm represents the PEG melting enthalpy. 表 3 复合材料中PLA相的DSC参数

Table 3. DSC parameters of PLA phase in composites

Samples T0

/℃Tp

/℃ΔHm

/(J·g-1)PEG60-PLA40-CNT0.6 120.2 115.5 16.4 PEG60-PLA40-CNT0.6-Al2O3(5) 119.3 112.7 17.1 PEG60-PLA40-CNT0.6-Al2O3(20) 121.5 114.4 16.4 PEG60-PLA40-CNT0.6-Al2O3(40) 127.1 122.5 16.7 Notes:T0 represents the onset crystalline temperature,Tp represents the peak crystalline temperature,ΔHm represents the PEG melting enthalpy. -

[1] JI R, WEI S, XIA Y, et al. Enhanced thermal performance of form-stable composite phase-change materials supported by novel porous carbon spheres for thermal energy storage[J]. Journal of Energy Storage, 2020, 27(C): 101134.1-101134.10. [2] 王绪彬, 张昌海, 张天栋, 等. 三维多孔氮化铝/环氧树脂复合材料的导热与电性能[J]. 复合材料学报, 2023, 40(6): 1-9 (in Chinese).WANG X B, ZHANG C H, ZHANG T D, et al. Thermal conductivity and electrical properties of three-dimensional porous aluminum nitride/epoxy composites[J]. Acta Materiae Compositae Sinica, 2023, 40(6): 3341-3349 (in Chinese). [3] JIANG Y, WANG Z, SHANG M, et al. Heat collection and supply of interconnected netlike graphene/polyethyleneglycol composites for thermoelectric devices[J]. Nanoscale, 2015, 7(25): 10950-3. doi: 10.1039/C5NR02051D [4] SONG N, HOU X, CHEN L, et al. A green plastic constructed from cellulose and functionalized graphene with high thermal conductivity[J]. ACS Applied Materials & Interfaces, 2017, 9: 17914. [5] SONG N, JIAO D, CUI S, et al. Highly anisotropic thermal conductivity of layer-by-layer assembled nanofibrillated cellulose/graphene nanosheets hybrid films for thermal management[J]. ACS Applied Materials & Interfaces, 2017, 9: 2924. [6] CUI S, JIANG F, SONG N, et al. Flexible films for smart thermal management: influence of structure construction of a two-dimensional graphene network on active heat dissipation response behavior[J]. ACS Applied Materials & Interfaces, 2019, 11(33): 30352-30359. [7] MADHULATHA G, MOHAN J, SATEESH P. Optimization of tube arrangement and phase change material for enhanced performance of solar air heater- A numerical analysis[J]. Journal of Energy Storage, 2021, 41(41): 102876.1-102876.10. [8] ALI H. Applications of combined/hybrid use of heat pipe and phase change materials in energy storage and cooling systems: A recent review[J]. Journal of Energy Storage, 2019, 26(C): 100986.1-100986.15. [9] VELMURUGAN K, KARTHIKEYAN V, KUMATASAMY S, et al. Thermal mapping of photovoltaic module cooling via radiation-based phase change material matrix: A case study of a large-scale solar farm in Thailand[J]. Journal of Energy Storage, 2022, 55(PD): 651-668. [10] FENG D, NAN J, FENG Y, et al. Numerical investigation on improving the heat storage and transfer performance of ceramic /D-mannitol composite phase change materials by bionic graded pores and nanoparticle additives[J]. International Journal of Heat and Mass Transfer, 2021, 179(179): 121748-121758. [11] LI G, ZHANG X, WANG J, et al. From anisotropic graphene aerogels to electron- and photo-driven phase change composites[J]. Journal of Material Chemistry A, 2016, 4(43): 17042-9. doi: 10.1039/C6TA07587H [12] ZENG X, SUN J, YAO Y, et al. A Combination of boron nitride nanotubes and cellulose nanofibers for the preparation of a nanocomposite with high thermal conductivity[J]. ACS Nano, 2017, 11: 5167. doi: 10.1021/acsnano.7b02359 [13] XIN G, SUN H, HU T, et al. Large-area freestanding graphene paper for superior thermal management[J]. Advanced Materials 2014, 26: 4521. [14] HAN Y, YANG Y, MALLICK T, et al. Nanoparticles to enhance melting performance of phase change materials for thermal energy storage[J]. Nanomaterials, 2022, 12(11): 1864. doi: 10.3390/nano12111864 [15] JIA X, LI Q, AO C, et al. High thermal conductive shape-stabilized phase change materials of polyethylene glycol/boron nitride@chitosan composites for thermal energy storage[J]. Composites, Part A. Applied science and manufacturing, 2020, 129(C): 105710 . [16] WANG Z, ZHANG H, DOU B, et al. Effect of copper metal foam proportion on heat transfer enhancement in the melting process of phase change materials[J]. Applied thermal engineering: Design, processes, equipment, economics, 2022, 201(PB): 117778-1-117778-14. [17] 赵中国, 薛嵘, 王筹萱, 等. 石墨烯-碳纳米管/聚乳酸/聚乙二醇相变储能复合材料的制备与温敏响应行为[J]. 复合材料学报, 2023: 1-10(in Chinese).ZHAO Z, XUE R, WANG C, et al. Preparation and temperature sensitive response behavior of graphene carbon nanotubes/polylactic acid/polyethylene glycol phase change energy storage composite materials[J]. Journal of Composite Materials, 2023: 1-10(in Chinese). [18] 申思扬, 赵中国, 苏巨桥, 等. 导电复合相变储能材料的制备及温敏响应性能[J]. 高分子材料科学与工程, 2023, 39(01): 151-159 (in Chinese).SHEN S, ZHAO Z, SU J, et al. Preparation and temperature sensitive response performance of conductive composite phase change energy storage materials[J]. Polymer Material Science and Engineering, 2023, 39(01): 151-159 (in Chinese). [19] ZHAN Y, ZHENG X, NAN B, et al. Flexible MXene/aramid nanofiber nanocomposite film with high thermal conductivity and flame retardancy[J]. European Polymer Journal, 2023, 186: 111847. doi: 10.1016/j.eurpolymj.2023.111847 [20] ZHAO Z, XUE R, MI D, et al. Regulating the temperature-sensing behavior of poly(lactic acid) by incorporating multiwalled carbon nanotubes and graphene nanoplatelets[J]. Polymer Composites, 2023, 44(10): 6379-6392. doi: 10.1002/pc.27565 [21] FENG C, WEI F, SUN K, et al. Emerging flexible thermally conductive films: mechanism, fabrication, application[J]. Nano-Micro Letters, 2022, 14(08): 1-34. [22] DING D, HUANG R, WANG X, et al. Thermally conductive silicone rubber composites with vertically oriented carbon fibers: A new perspective on the heat conduction mechanism[J]. Chemical Engineering Journal, 2022, 441: 136104. doi: 10.1016/j.cej.2022.136104 [23] YU J, SUNDQVIST B, Tonpheng B, et al. Thermal conductivity of highly crystallized polyethylene[J]. Polymer, 55(1): 195-200. [24] ZHANG W, ZHANG Z, YANG J, et al. Largely enhanced thermal conductivity of poly (vinylidene fluoride)/carbon nanotube composites achieved by adding graphene oxide[J]. Carbon, 2015, 90: 242-254. doi: 10.1016/j.carbon.2015.04.040 [25] YANG J, TANG L, BAO R, et al. Hybrid network structure of boron nitride and graphene oxide in shape-stabilized composite phase change materials with enhanced thermal conductivity and light-to-electric energy conversion capability[J]. Solar Energy Materials and Solar Cells, 2018, 174: 56-64. doi: 10.1016/j.solmat.2017.08.025 -

下载:

下载: