Mechanical properties and failure prediction of three-dimensional orthogonal fiber reinforced nanoporous resin composites

-

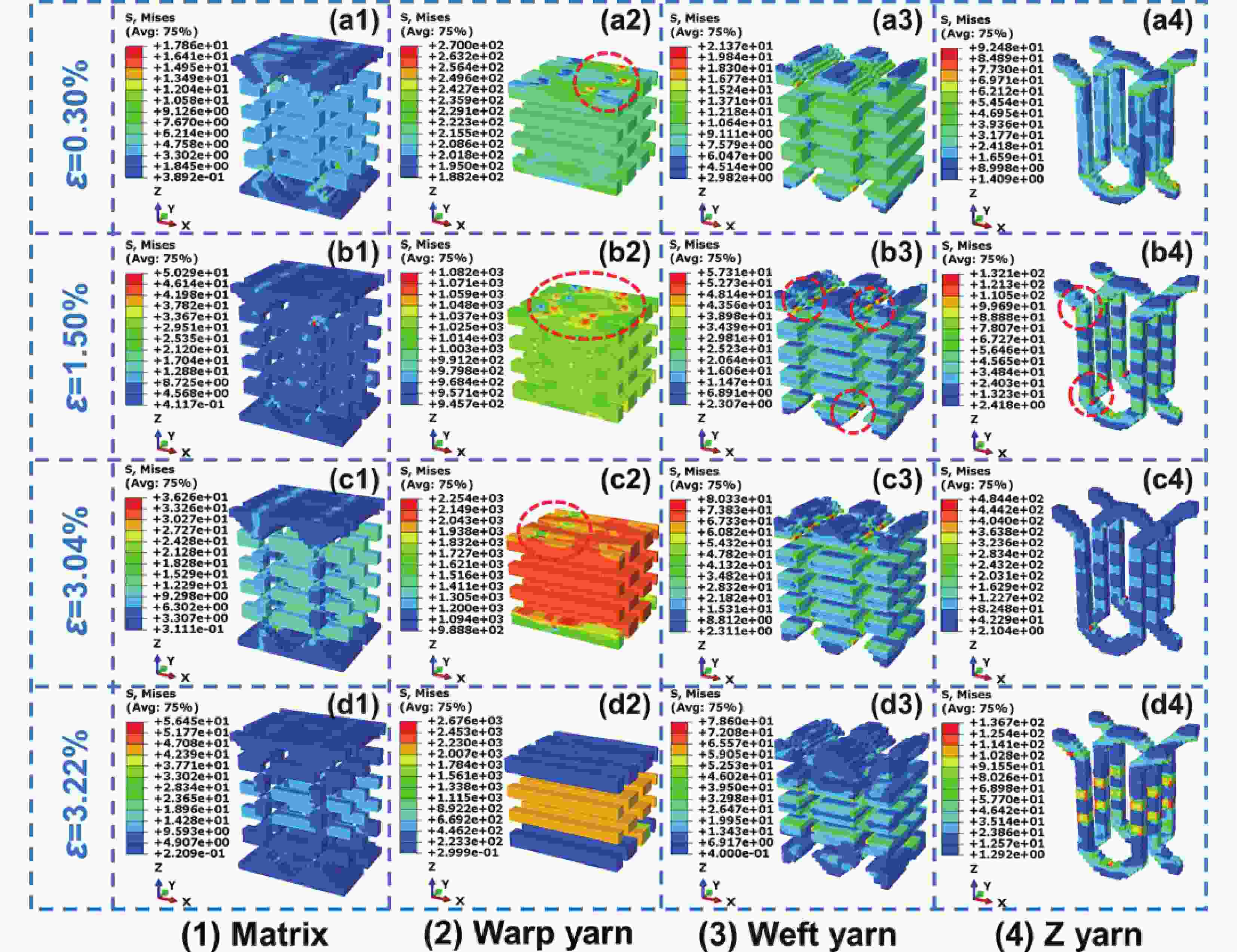

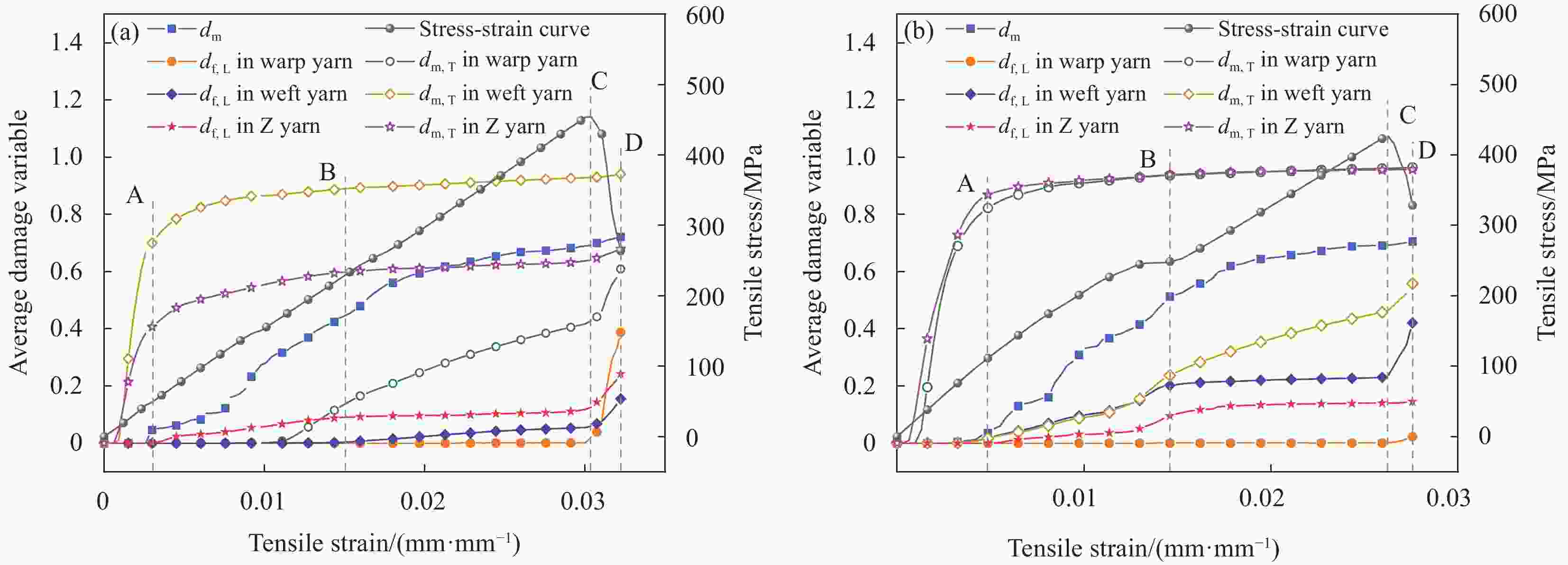

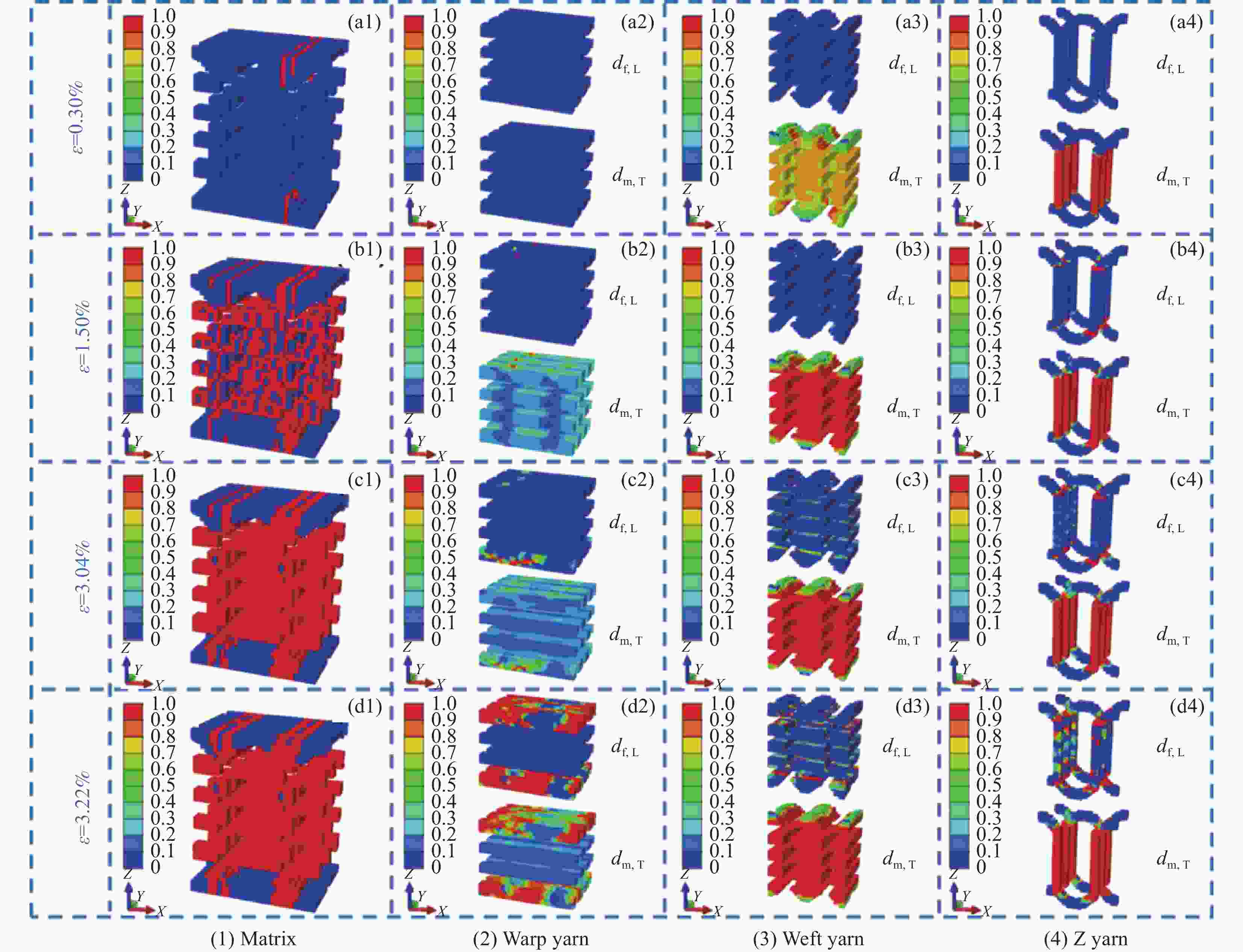

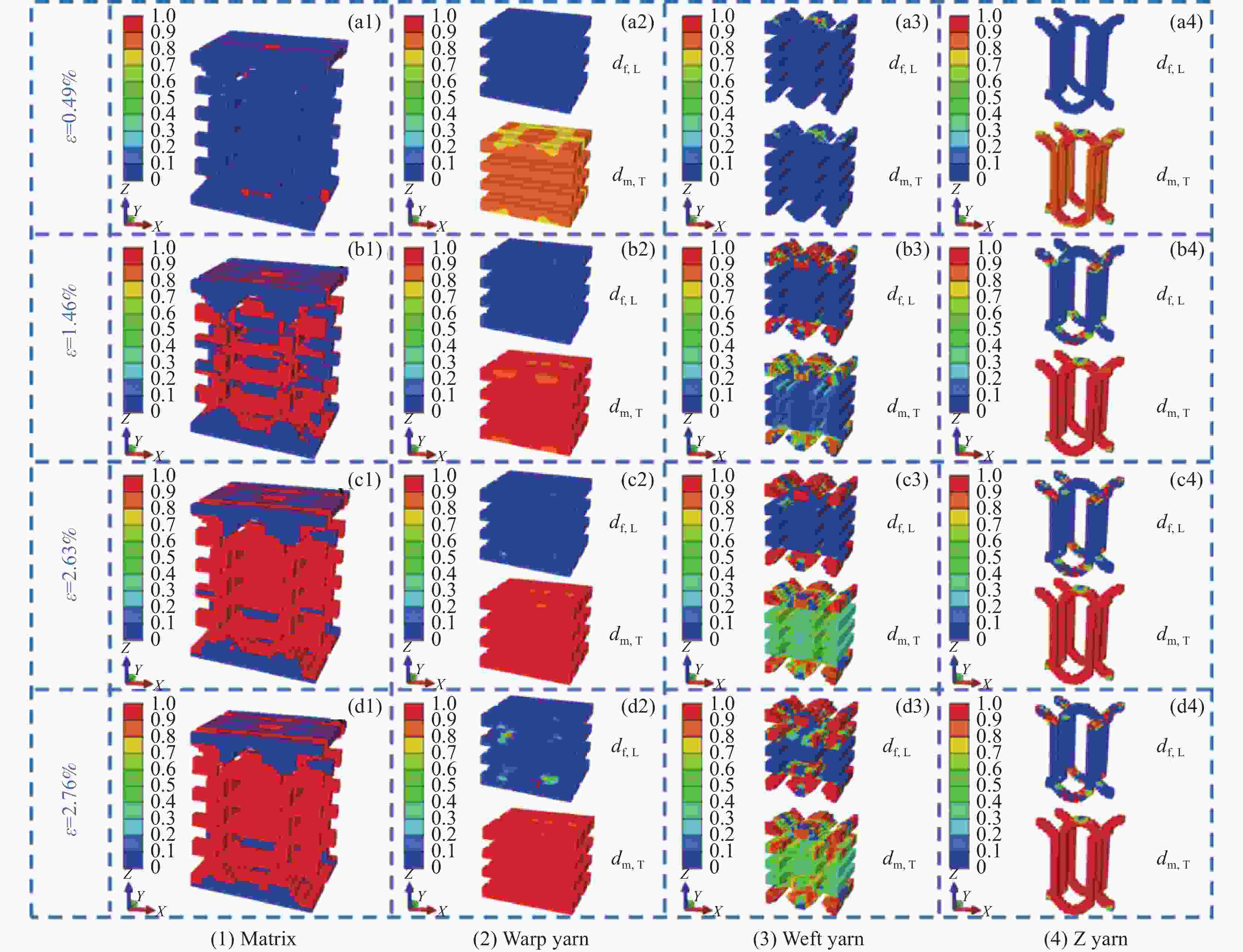

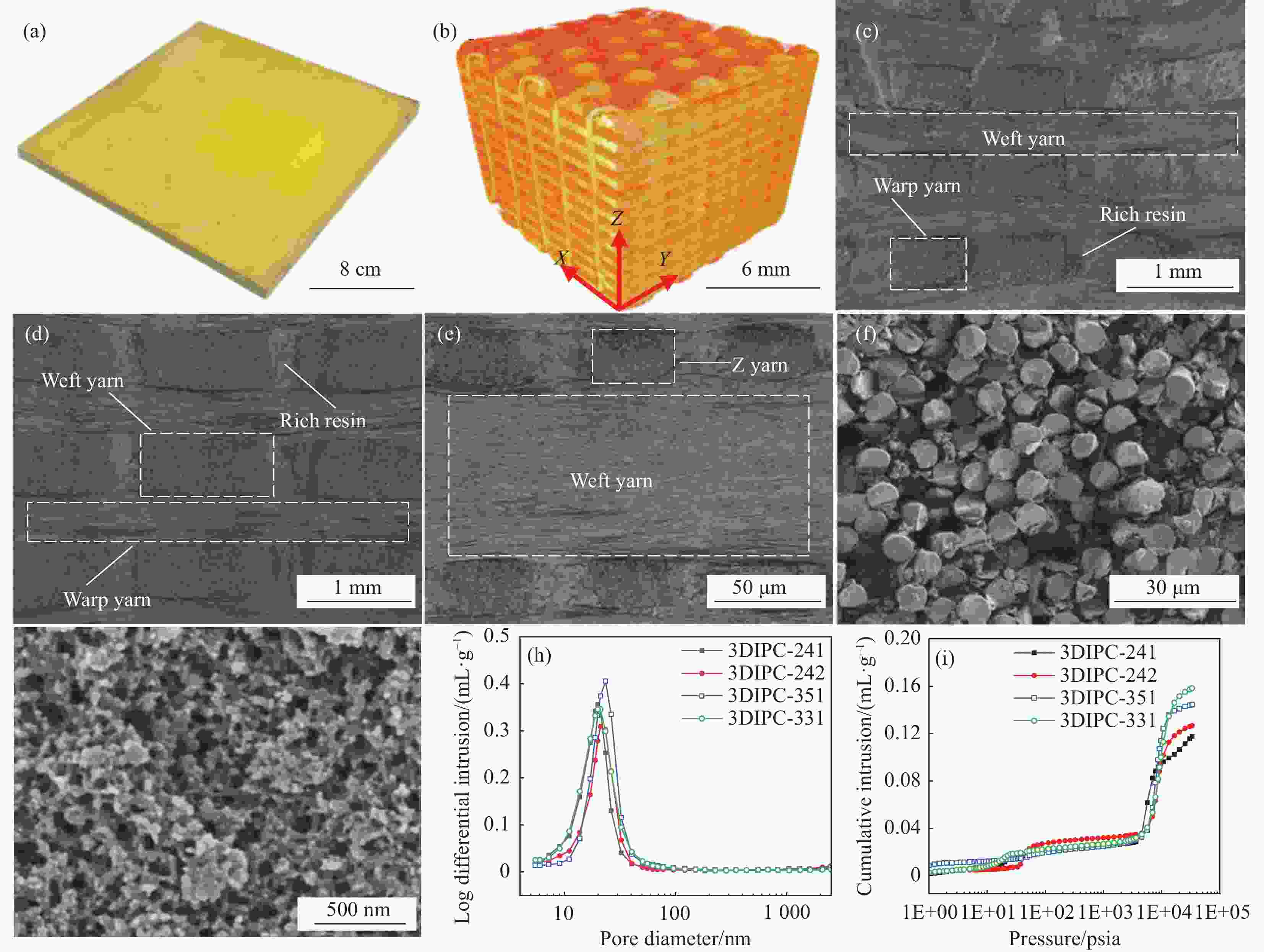

摘要: 针对飞行器的极端防隔热承载需求,以正交三向石英纤维预制体为增强体、高强度纳米孔酚醛树脂为基体,制备出正交三向纤维增强纳米孔树脂基复合材料(3DIPC)。所制备的3DIPC具有中等密度(~1.46 g·cm−3)、较低的室温热导率(<0.30 W·(m·K)−1)和线烧蚀率(~0.15 mm·s−1)以及优异的力学性能(拉伸强度 >400 MPa,压缩强度 >390 MPa,弯曲强度 >300 MPa,层间剪切强度 >30 MPa)。通过调整不同方向纱线的细度,系统地研究了纤维预制体细观结构改变对3DIPC力学性能的影响。结果表明,增大Z纱的细度可以提高3DIPC的压缩模量和层间剪切强度,但会导致其拉伸性能与压缩强度的降低;增大经纱的细度可以提高材料经向的拉伸与弯曲性能,但纬向的拉伸与弯曲性能呈降低趋势。最后,基于3DIPC的实际形貌建立了包含表面与内部结构的细观有限元模型,并结合复合材料的渐进损伤模型,采用ABAQUS有限元软件模拟了3DIPC的拉伸失效行为。结果表明,3DIPC的损伤始于纱线中的基体处,并随应变的增加扩展至纯基体与纤维。3DIPC的经纬向拉伸失效分别是由经向和纬向纤维断裂主导的,且表面Z纱和表面纬纱的纤维断裂是造成3DIPC在纬向拉伸前期损伤的主要原因。Abstract: To meet the extreme thermal protection and load-bearing requirement of aerospace vehicle, three-dimensional orthogonal fiber reinforced nanoporous resin composites (3DIPC) have been prepared using three-dimensional quartz fiber preform as reinforcement and high-strength nanoporous phenolic resin as matrix. The as-prepared 3DIPC exhibit a mid-density of ~1.46 g·cm−3, low room-temperature thermal conductivity (<0.30 W·(m·K)−1), low linear ablation rate (~0.15 mm·s−1) and excellent mechanical properties with tensile strength >400 MPa, compressive strength >390 MPa, bending strength >300 MPa and interlaminar shear strength >30 MPa. By adjusting the yarn fineness in different directions, the effects of meso-structure variations in fiber preforms on the mechanical properties of 3DIPC were systematically studied. The results show increasing the fineness of the Z yarn can enhance the compressive modulus and interlaminar shear strength of composite materials, but it leads to a deterioration of tensile properties and compressive strength. Increasing the fineness of the warp yarn can improve the tensile and bending properties in the warp direction, but the tensile and flexural properties in the weft direction will be reduced. Finally, a mesoscale finite element model incorporating both surface and internal structures was established based on the actual morphology of 3DIPC. Combining with the progressive damage model of the composite material, the tensile failure behavior of the 3DIPC was simulated using the finite element software ABAQUS. The results show that the damage in 3DIPC initiates at the matrix of yarns and propagates to pure matrix and the fibers of yarns as the strain increases. The failure of 3DIPC under tensile loading in the warp and weft direction is dominated by the fracture of fibers of warp and weft yarns, respectively. Furthermore, the fracture of fibers of surface-Z yarns and surface-weft yarns is the primary cause of early-stage damage in 3DIPC under tensile loading in the weft direction.

-

图 1 (a) 正交三向纤维增强纳米孔酚醛树脂基复合材料(3DIPC)的实物图;(b) 3DIPC-241的Micro-CT三维微观结构图;3DIPC-241沿经向(c)、纬向(d)和厚度方向截面(e)的SEM图像;(f) 纱线截面SEM图像;(g) 树脂基体SEM图像;3DIPC的孔径分布图(h)和压汞曲线(i)

Figure 1. (a) Physical illustration of three-dimensional orthogonal fiber reinforced nanoporous phenolic resin composite (3DIPC); (b) 3 D microstructure of 3DIPC-241 from micro-CT scanning; SEM images of the section along the warp direction (c), weft direction (d) and thickness direction (e); (f) SEM image of the section of yarn; (g) SEM image of resin matrix; Pore-size distribution (h) and mercury injection curve (i) of 3DIPC

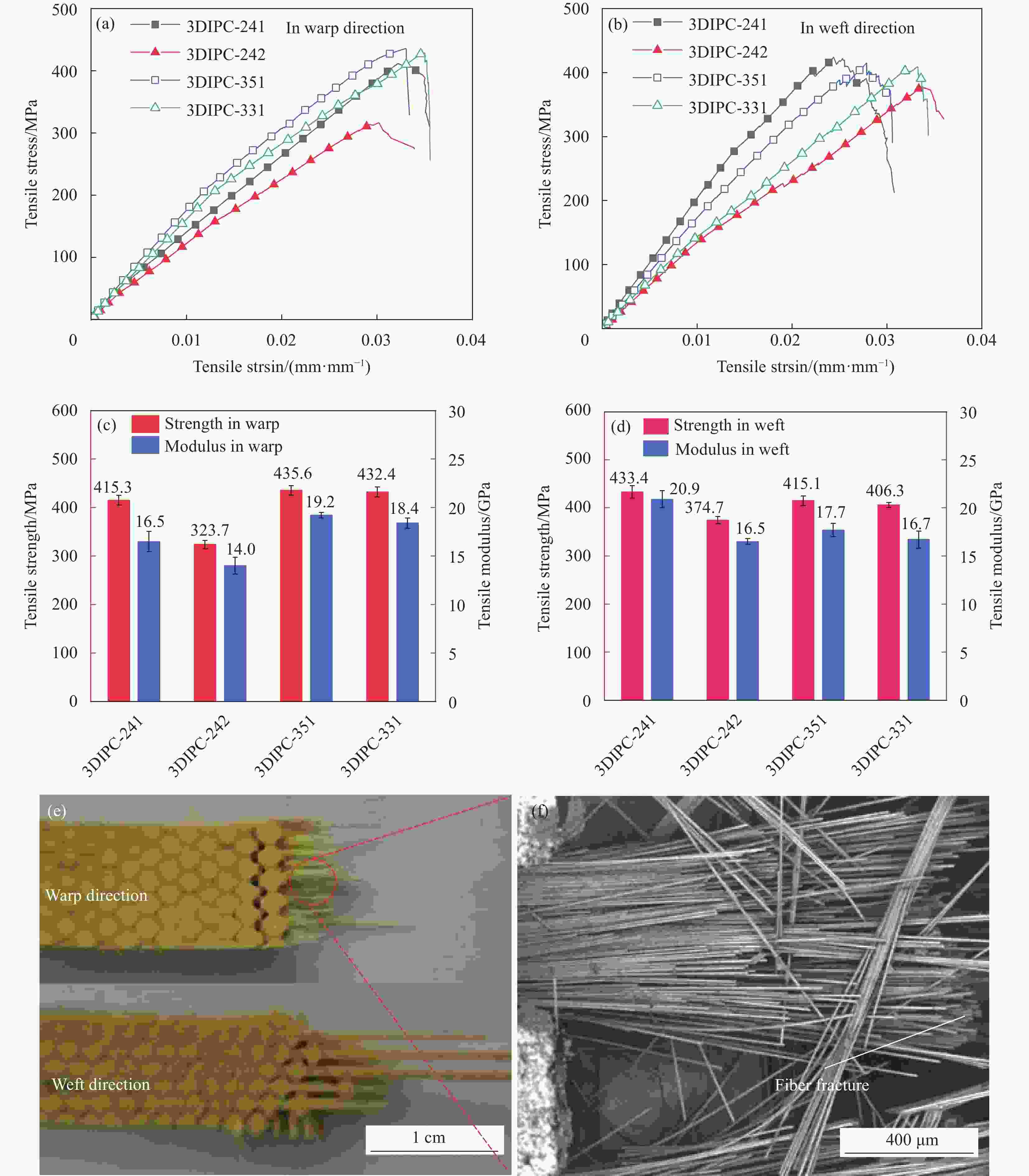

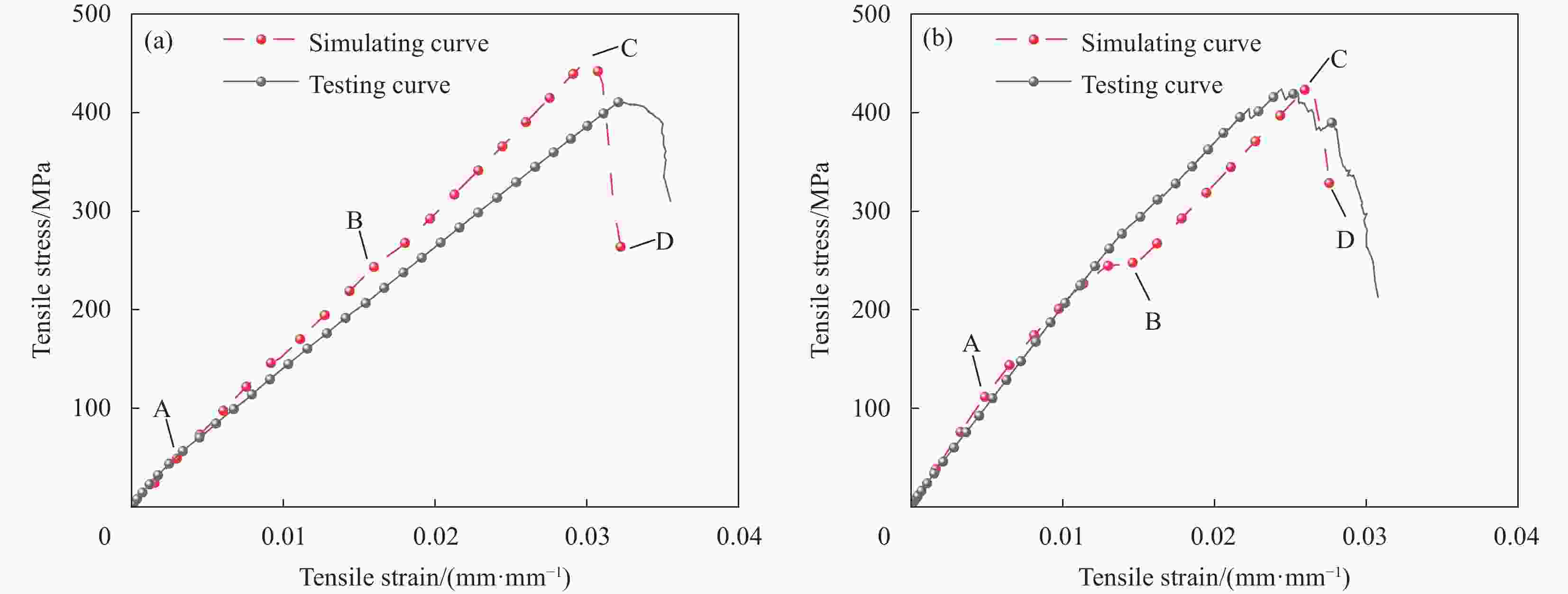

图 2 3DIPC经向(a)和纬向(b)拉伸应力-应变曲线;3DIPC经向(c)和纬向(d)拉伸性能;3DIPC-241拉伸断裂形貌(e)和经向断口处的SEM图像(f)

Figure 2. Tensile stress-strain curves of 3DIPC in the warp (a) and weft (b) directions; Tensile properties of 3DIPC in the warp (c) and weft (d) directions; Fracture morphology (e) and its corresponding SEM image (f) of 3DIPC-241 under tensile loading in the warp direction

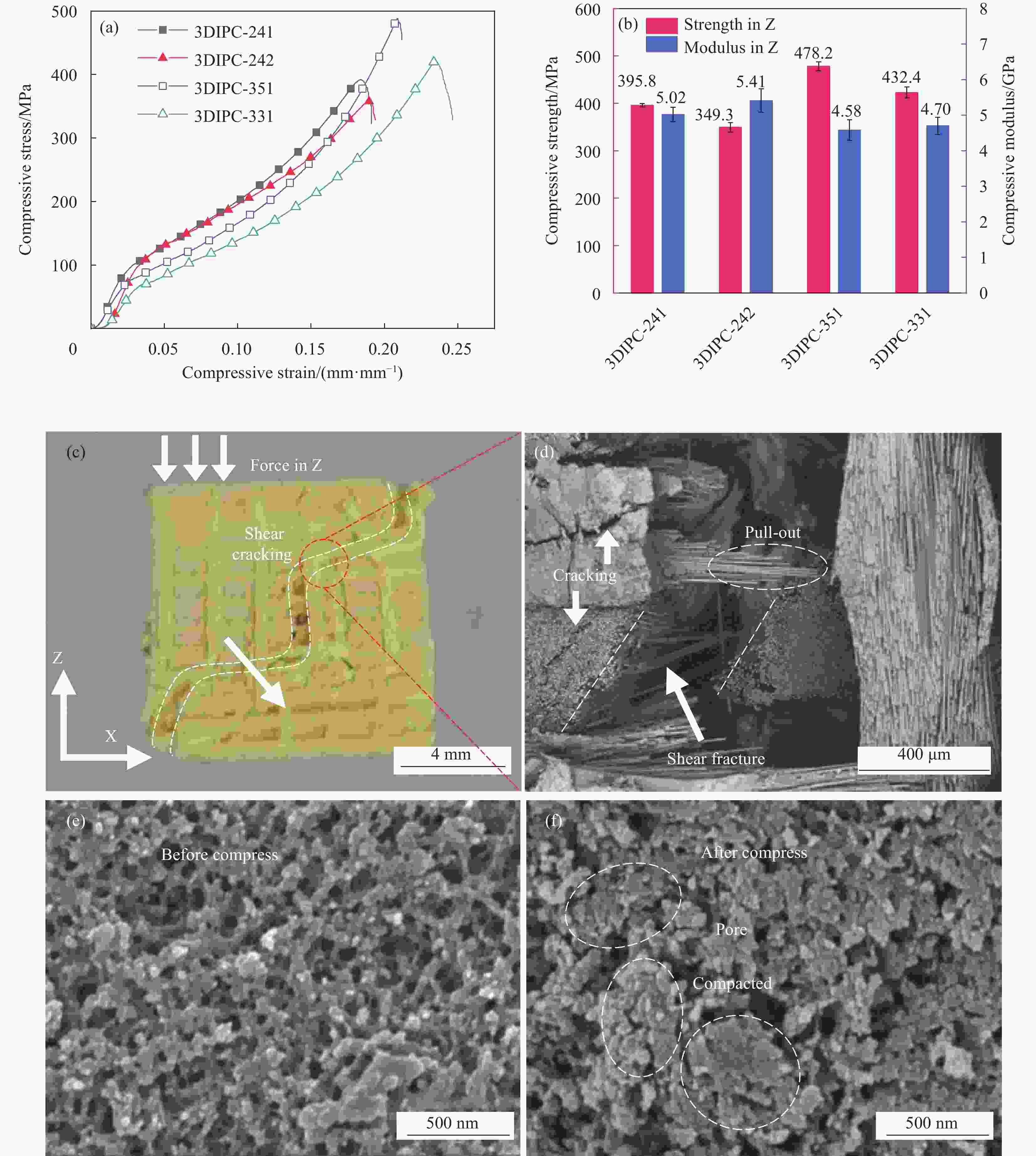

图 3 (a) 3DIPC厚度方向压缩的应力-应变曲线;(b) 3DIPC的压缩性能;3DIPC-241的压缩破坏形貌(c)和剪切开裂处的SEM图像(d);3DIPC-241中树脂基体压缩前(e)和压缩后(f)的高倍率SEM图像

Figure 3. (a) Compressive stress-strain curves of 3DIPC in the thickness direction; (b) Compressive properties of 3DIPC; The compressive failure morphology (c) and SEM image of the shear cracking in 3DIPC-241 (d); High magnification SEM images of the resin matrix in 3DIPC-241 before (e) and after (f) compression

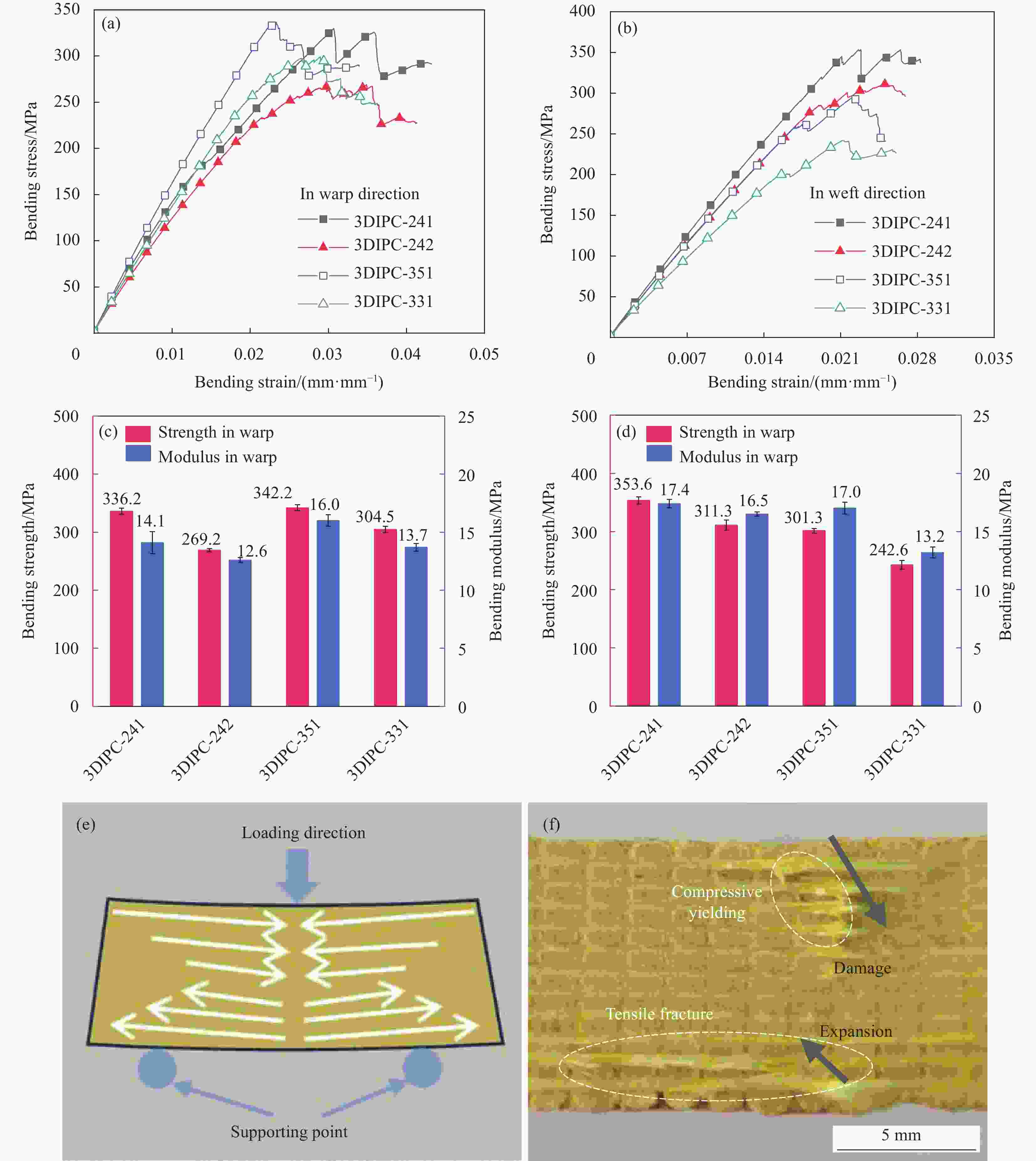

图 4 3DIPC经向(a)和纬向(b)弯曲应力-应变曲线;3DIPC经向(c)和纬向(d)的弯曲性能;(e) 3DIPC弯曲过程受力示意图;(f) 3DIPC-241弯曲破坏形貌

Figure 4. Bending stress-strain curves of 3DIPC in the warp (a) and weft (b) directions; Bending properties of 3DIPC in the warp (c) and weft (d) directions; (e) Force diagram for the bending process of 3DIPC; (f) Bending failure morphology of 3DIPC-241

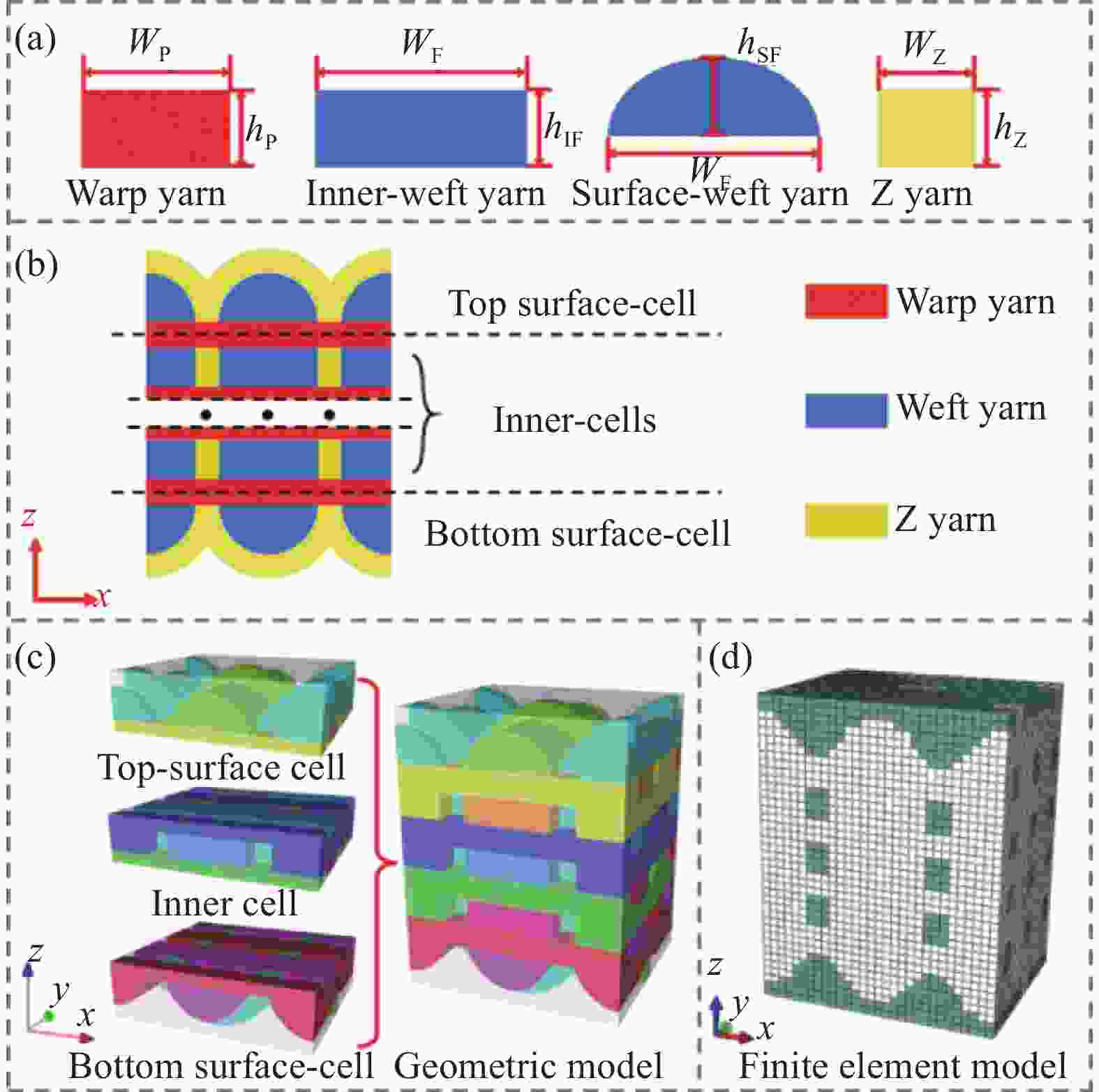

图 6 (a) 3DIPC纱线等效截面;(b) 3DIPC细观结构示意图;(c) 模型几何结构示意图;(d) 3DIPC基于体素网格的有限元模型

Figure 6. (a) Equivalent cross-section size of yarn of 3DIPC; (b) Schematic diagram of the mecro-scale structure of 3DIPC; (c) Schematic diagram of the geometric structure of model; (d) Finite element model based on voxel mesh of 3DIPC

图 10 3DIPC-241经向(a)和纬向(b)拉伸过程平均损伤变量演变

Figure 10. Evolution of average damage variable of 3DIPC-241 under tensile loading in warp (a) and weft (b) direction

$ {d}_{\mathrm{m}} $,$ {d}_{\mathrm{f},\mathrm{L}} $ and $ {d}_{\mathrm{m},\mathrm{T}} $ represent pure matrix damage, fiber damage in yarn and matrix damage in yarn, respectively

表 1 正交三向石英纤维预制体的织造参数

Table 1. Weaving parameters of three-dimensional orthogonal quartz fiber preforms

Fiber preform Warp density/

(yarns·cm−1)Fineness of warp yarn/tex Weft density/

(yarns·cm−1)Fineness of weft yarn/tex Fineness of z yarn/tex Fiber content/vol% Fiber content in different directions/vol% Warp Weft Z 241 10 195*2 6 195*4 195*1 50.3 19.50 25.53 5.32 242 10 195*2 6.1 195*4 195*2 50.4 16.88 22.66 10.81 351 9 195*3 5 195*5 195*1 50.0 22.79 23.21 3.99 331 9 195*3 7 195*3 195*1 50.0 23.93 20.48 5.58 表 2 正交三向纤维增强纳米孔酚醛树脂基复合材料(3DIPC)的基础物理性能

Table 2. Basic physical properties of three-dimensional orthogonal fiber reinforced nanoporous phenolic resin composites (3DIPC)

Sample Bulk density/

(g·cm−3)Thermal conductivity/

(W·(m·K)−1)Linear ablation rate/

(mm·s−1)Porosity/

%Most

probable

pore/nm3DIPC-241 1.46 0.240 0.147 20.7 20.0 3DIPC-242 1.47 0.289 0.150 20.0 21.1 3DIPC-351 1.47 0.245 0.155 21.1 23.4 3DIPC-331 1.46 0.243 0.150 21.0 21.1 表 3 3DIPC的层间剪切性能

Table 3. The interlaminar shear properties of 3DIPC

Sample Warp direction Weft direction Strength/MPa Strength/MPa 3DIPC-241 37.7±0.70 37.4±0.81 3DIPC-242 38.4±0.28 43.2±1.14 3DIPC-351 29.9±0.78 32.8±1.33 3DIPC-331 30.6±0.63 34.5±0.48 表 4 纱线等效横截面尺寸

Table 4. Equivalent cross-section size of yarn

Width of warp yarn WP/mm Height of warp yarn hP/mm Width of warp yarn WF/mm Height of inner-weft yarn hIF/mm Height of surface-weft yarn hSF/mm Width of warp yarn WZ/mm Width of warp yarn hZ/mm 0.7 0.37 1.3 0.48 0.61 0.3 0.37 表 5 纳米孔树脂基体和石英纤维的力学性能

Table 5. Mechanical properties of nanoporous resin matrix and quartz fiber

Material Young’s modulus $ {E} $/MPa Poisson's ratio $ \mu $ Shear modulus $ {G} $/MPa Tensile strength $ {{X}}_{\text{t}} $/MPa Compressive strength $ {{X}}_{\text{c}} $/MPa Shear strength $ {{X}}_{\text{s}} $/MPa Nanoporous resin matrix 1055 0.3 397 10.3 31.9 8.4 Quartz fiber 78000 0.22 31967 6000 1700 740 表 6 纱线的力学性能

Table 6. Mechanical properties of yarn

$ {{E}}_{\text{11}} $/MPa $ {{E}}_{\text{22}} $/MPa $ {{E}}_{\text{33}} $/MPa $ {{G}}_{\text{12}} $/MPa $ {{G}}_{\text{13}} $/MPa $ {{G}}_{\text{23}} $/MPa $ {\mu }_{\text{12}} $ $ {\mu }_{\text{13}} $ 54916.5 6040.4 6040.4 2283.1 2283.1 2283.1 0.253 0.253 $ {{\mu }}_{\text{23}} $ $ {{F}}_{\text{1t}} $/MPa $ {{F}}_{\text{1c}} $/MPa $ {{F}}_{\text{2t}} $/MPa $ {{F}}_{\text{2c}} $/MPa $ {{F}}_{\text{ls}} $/MPa $ {{F}}_{\text{ts}} $/MPa 0.322 4224.4 1196.9 6.90 35.90 16.95 16.95 Notes: $ {{E}}_{\text{11}} $, $ {{E}}_{\text{22}} $, $ {{E}}_{\text{33}} $-Elastic modulus in directions 1, 2 and 3; $ {{G}}_{\text{12}} $, $ {{G}}_{\text{13}} $, $ {{G}}_{\text{23}} $-Shear modulus in directions 12, 13 and 23; $ {\mu }_{\text{12}} $, $ {\mu}_{\text{13}} $ and $ {\mu}_{\text{2}\text{3}} $-Poisson’s ratio in directions 12, 13 and 23; $ {{F}}_{\text{1 t}} $ and $ {{F}}_{\text{1 c}} $-Tensile and compressive strength in direction 1; $ {{F}}_{\text{2 t}} $ and $ {\text{F}}_{\text{2 c}} $-Tensile and compressive strength in direction 2; $ {{F}}_{\text{ls}} $ and $ {{F}}_{\text{ts}} $-Shear strength in direction 12 and 23. 表 7 纱线的断裂能参数

Table 7. Fracture energy parameters of yarn

$ {{G}}_{\text{t}}^{\text{f}} $/(J·mm−2) $ {{G}}_{\text{c}}^{\text{f}} $/(J·mm−2) $ {{G}}_{\text{t}}^{\text{m}} $/(J·mm−2) $ {{G}}_{\text{c}}^{\text{m}} $/(J·mm−2) 80 80 1 1 Notes: $ {{G}}_{\text{t}}^{\text{f}} $, $ {{G}}_{\text{c}}^{\text{f}} $-Fracture energy of fiber in tensile and compression; $ {{G}}_{\text{t}}^{\text{m}} $,$ {{G}}_{\text{c}}^{\text{m}} $-Fracture energy of matrix in tensile and compression 表 8 3DIPC-241试验与模拟力学性能对比

Table 8. Comparison of mechanical properties between 3DIPC-241 experimental and simulated results

Tensile modulus/GPa Tensile strength/MPa Elongation at break/% Warp direction Weft direction Warp direction Weft direction Warp direction Weft direction Testing 16.5 20.9 415.3 433.4 3.40 3.08 Simulating 16.9 23.2 454.2 426.7 3.22 2.76 Error/% 2.42 11.0 9.37 −1.55 −5.29 −10.4 -

[1] 杜晨慧. 高超声速飞行器综合热管理及关键技术研究进展[J]. 装备环境工程, 2023, 20(1): 43-51.DU Chenhui. Research progress on integrated thermal management and key technology of hypersonic vehicles[J]. Equipment Environmental Engineering, 2023, 20(1): 43-51(in Chinese). [2] 蒋凌澜, 陈阳. 树脂基复合材料在航天飞行器气动热防护上的应用研究[J]. 玻璃钢/复合材料, 2014, (7): 78-84.JIANG Linglan, CHEN Yang. The application research of resin-based composites for aero-dynamic thermal protection system[J]. Fiber Reinforced Plastics/Composites, 2014, (7): 78-84(in Chinese). [3] 欧俊, 黄民忠, 黄瑶, 等. 基于DLP技术打印制备聚合物转化陶瓷基复合材料的研究[J]. 陶瓷学报, 2023, 44(1): 154-162.OU Jun, HUANG Minzhong, HUANG Yao, et al. Digital light processing-based fabrication of polymer-derived ceramic matrix composites[J]. Journal of Ceramics, 2023, 44(1): 154-162(in Chinese). [4] ELLERBY D, VENKATAPATHY E, GAGE P, et al. Heatshield for extreme entry environment technology (HEEET) thermal protection system (TPS)[C]//Materials Science & Technology Conference and Exhibition. Portland, 2019: 1359-1366. [5] Saleh M N, Soutis C. Recent advancements in mechanical characterisation of 3D woven composites[J]. Mechanics of Advanced Materials and Modern Processes, 2017, 3(1): 1-17. doi: 10.1186/s40759-016-0016-7 [6] 李涛涛. 碳/芳纶混杂正交三向复合材料拉伸疲劳性能实验研究[D]. 天津工业大学, 2016.LI Taotao. Experimental study on the tensile fatigue performance of carbon/aramid hybrid orthotropic three-way composites[D]. Tianjin University of Technology, 2016(in Chinese). [7] Fan W, Yuan L, D'Souza N, et al. Enhanced mechanical and radar absorbing properties of carbon/glass fiber hybrid composites with unique 3D orthogonal structure[J]. Polymer Testing, 2018, 69: 71-79. doi: 10.1016/j.polymertesting.2018.05.007 [8] Yang X, Sun Y, Li D, et al. Evaluation of multi-directional compression behaviors and failure of three-dimensional orthogonal woven composites via liquid nitrogen temperature[J]. Composites Communications, 2023: 101626. [9] 邓奇林, 杨敏, 姚彧敏, 等. 三向正交预制体织造参数对C/C复合材料性能的影响[J]. 材料工程, 2022, 50(5): 139-146.DENG Qilin, YANG Min, YAO Yumin, et al. Effect of three-directional orthogonal preform weaving parameters on properties of C/C composites[J]. Journal of Materials Engineering, 2022, 50(5): 139-146(in Chinese). [10] 钱逸星, 杨振宇, 卢子兴. 纺织复合材料力学性能数值模拟方法研究进展[J]. 航空制造技术, 2022, 65(16): 135-151.QIAN Yixing, YANG Zhenyu, LU Zixing. Research progress on numerical simulation of mechanical properties of textile composites[J]. Aeronautical Manufacturing Technology, 2022, 65(16): 135-151(in Chinese). [11] ZHENG T, GUO L, Benedictus R, et al. Micromechanics-based multiscale progressive failure simulation of 3D woven composites under compressive loading with minimal material parameters[J]. Composites Science and Technology, 2022, 219: 109227. doi: 10.1016/j.compscitech.2021.109227 [12] YANG X, AI J, ZHU H, et al. Multi-directional compression behaviors and failure mechanisms of 3D orthogonal woven composites: Parametric modeling and strength prediction[J]. Materials & Design, 2022, 222: 111108. [13] JIA X, XIA Z, GU B. Micro/meso-scale damage analysis of three-dimensional orthogonal woven composites based on sub-repeating unit cells[J]. The Journal of Strain Analysis for Engineering Design, 2012, 47(5): 313-328. doi: 10.1177/0309324712444671 [14] 国防科学技术工业委员会. 烧蚀材料烧蚀试验方法: GJB 323A-96[S]. 1996.The Commission of Science, Technology and Industry for National Defense of the PRC. Test methods for ablation for ablators: GJB 323A-96[S]. 1996 (in Chinese). [15] 中国国家标准化管理委员会. 纤维增强塑料拉伸性能试验方法: GB/T 1447-2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastic composites-Determination of tensile Properties: GB/T 1447-2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [16] 中国国家标准化管理委员会. 纤维增强塑料压缩性能试验方法: GB/T 1448-2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastic composites-Determination of compressive properties: GB/T 1448-2005[S]. Beijing: Standards Press of China, 2005 (in Chinese). [17] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449-2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastic composites-Determination of flexural properties: GB/T 1449-2005[S]. Beijing: Standards Press of China, 2005 (in Chinese). [18] 中国国家标准化管理委员会. 纤维增强塑料层间剪切强度试验方法: GB/T 1450.1-2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastic composites-Determination of interlaminar shear strength: GB/T 1450.1-2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [19] NIU Z, LI G, MA X, et al. Synergetic effect of O-POSS and T-POSS to enhance ablative resistant of phenolic-based silica fiber composites via strong interphase strength and ceramic formation[J]. Composites Part A:Applied Science and Manufacturing, 2022, 155: 106855. doi: 10.1016/j.compositesa.2022.106855 [20] LI L, LI Y, HUAN D, et al. Z-pin effect on interlaminar mechanical and ablation performance of quartz-phenolic composites[J]. Polymer Composites, 2022, 43(5): 3228-3241. doi: 10.1002/pc.26613 [21] 李云宽, 丁仁兴, 于淼. 模压石英/酚醛复合材料的力学和热物理性能[J]. 宇航材料工艺, 2013, 43(4): 49-51.LI Yunkuan, DING Renxing, YU Miao. Thermal and mechanical properties of moulded quartz phenolic composites[J]. Aerospace Materials & Technology, 2022, 43(4): 49-51(in Chinese). [22] 杨广超, 张鹏飞, 张凌峰, 等. ZrC和ZrB2对Csf/SiC-BN-(ZrC, ZrB2)复合材料组织及力学性能的影响[J]. 陶瓷学报, 2022, 43(04): 684-691.YANG Guangchao, ZHANG Pengfei, ZHANG Lingfeng, et al. Effects of ZrC and ZrB2 on microstructure and mechanical properties of Csf/SiC-BN-(ZrC, ZrB2) composites[J]. Journal of Ceramics, 2022, 43(04): 684-691(in Chinese). [23] CHENG H, FAN Z, HONG C, et al. Lightweight multiscale hybrid carbon-quartz fiber fabric reinforced phenolic-silica aerogel nanocomposite for high temperature thermal protection[J]. Composites Part A:Applied Science and Manufacturing, 2021, 143: 106313. doi: 10.1016/j.compositesa.2021.106313 [24] 钱震, 张鸿宇, 张琪凯, 等. 高强度—中密度纳米孔树脂基防隔热复合材料的制备与性能[J]. 复合材料学报, 2023, 40(1): 83-95. doi: 10.13801/j.cnki.fhclxb.20211223.001QIAN Zhen, ZHANG Hongyu, ZHANG Qikai, et al. Preparation and properties of high strength-medium density nanoporous resin-based ablation/insulation integrated composites[J]. Acta Materiae Compositae Sinica, 2023, 40(1): 83-95(in Chinese). doi: 10.13801/j.cnki.fhclxb.20211223.001 [25] 张倩倩. z向纱对三维正交复合材料细观结构和力学性能的影响[D]. 天津工业大学, 2013.ZHANG Qianqian. Effect of z-yarn on mesoscopic structure and mechanical properties of three-dimensional orthogonal composites[D]. Tianjin University of Technology, 2013(in Chinese). [26] GUO J, WEN W, ZHANG H, et al. Investigation of mechanical properties for 2.5D woven composites with different weft-layer-numbers by a triple-cell model system[J]. Journal of Industrial Textiles, 2020: 152808372095804. [27] LIN H, BROWN L P, LONG A C. Modelling and simulating textile structures using TexGen[J]. Advanced materials research, 2011, 331: 44-47. doi: 10.4028/www.scientific.net/AMR.331.44 [28] XIA Z, ZHOU C, YONG Q, et al. On selection of repeated unit cell model and application of unified periodic boundary conditions in micro-mechanical analysis of composites[J]. International journal of solids and structures, 2006, 43(2): 266-278. doi: 10.1016/j.ijsolstr.2005.03.055 [29] YU S, ZHANG D, QIAN K. Numerical analysis of macro-scale mechanical behaviors of 3D orthogonal woven composites using a voxel-based finite element model[J]. Applied Composite Materials, 2019, 26: 65-83. doi: 10.1007/s10443-018-9707-z [30] Chamis C C. Simplified composite micromechanics equations for hygral, thermal and mechanical properties[C]//Ann. Conf. of the Society of the Plastics Industry (SPI) Reinforced Plastics/Composites Inst. 1983. [31] 黄争鸣. 桥联理论研究的最新进展[J]. 应用数学和力学, 2015, 36(6): 563-581. doi: 10.3879/j.issn.1000-0887.2015.06.001HUANG Zhengming. Latest advancements of the bridging model theory[J]. Applied Mathematics and Mechanics, 2015, 36(6): 563-581(in Chinese). doi: 10.3879/j.issn.1000-0887.2015.06.001 [32] HASHIN Z. Fatigue failure criteria for unidirectional fiber composites[J]. Journal of applied mechanics, 1980, 47(4): 329-334. [33] SHI D, LIU C, CHENG Z, et al. On the tensile behaviors of 2D twill woven SiO2f/SiO2 composites at ambient and elevated temperatures: Mesoscale analysis and in situ experimental investigation[J]. Ceramics International, 2021, 47(9): 12680-12694. doi: 10.1016/j.ceramint.2021.01.128 [34] 张超, 许希武, 毛春见. 三维编织复合材料渐进损伤模拟及强度预测[J]. 复合材料学报, 2011, 28(2): 222-230. doi: 10.13801/j.cnki.fhclxb.2011.02.016ZHANG Chao, XU Xiwu, MAO Chunjian. Progressive damage simulation and strength prediction of 3D braided composites[J]. Acta Materiae Compositae Sinica, 2011, 28(2): 222-230(in Chinese). doi: 10.13801/j.cnki.fhclxb.2011.02.016 -

点击查看大图

点击查看大图

计量

- 文章访问数: 199

- HTML全文浏览量: 147

- 被引次数: 0

下载:

下载: