Preparation and performance of smart high strength and high ductile concrete

-

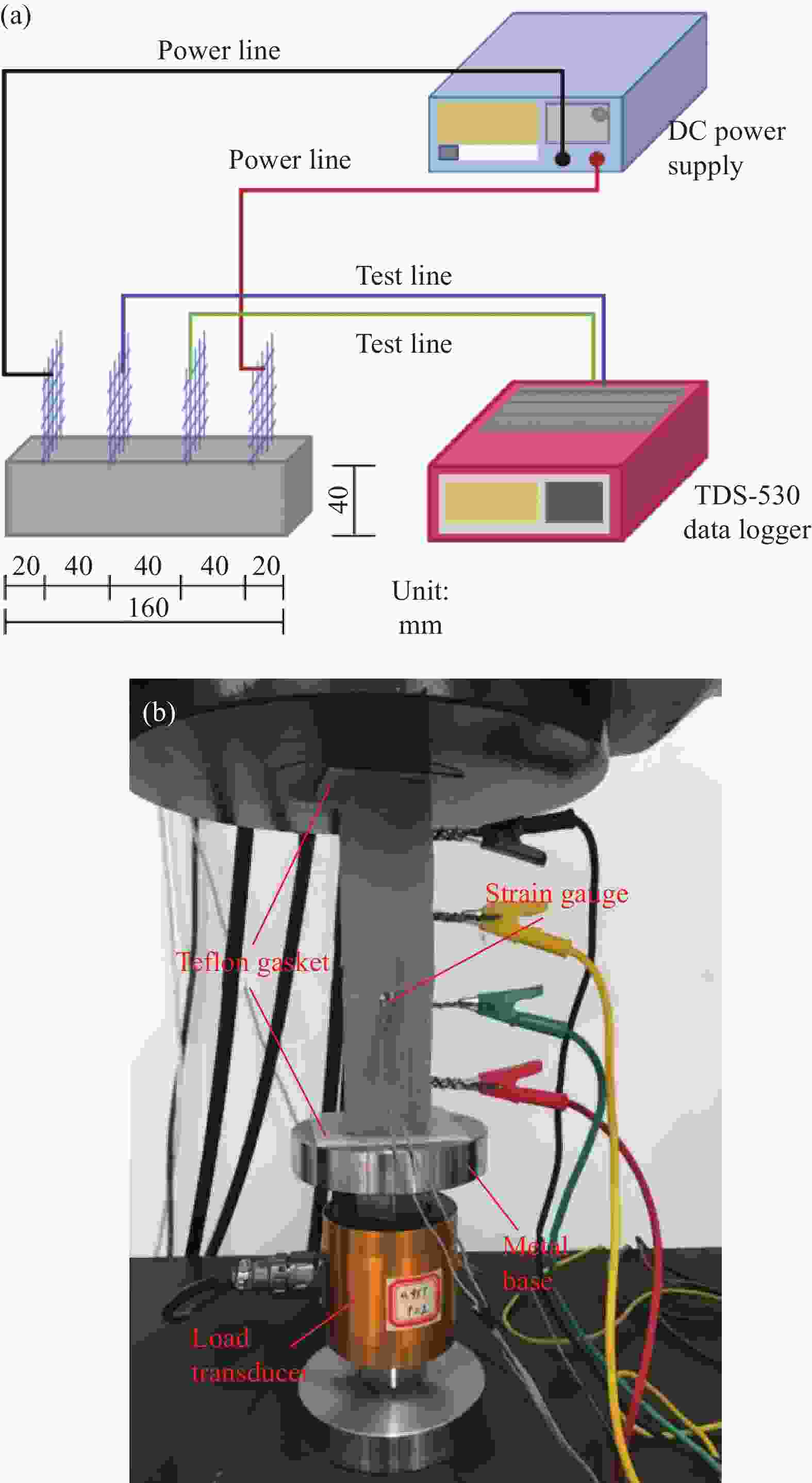

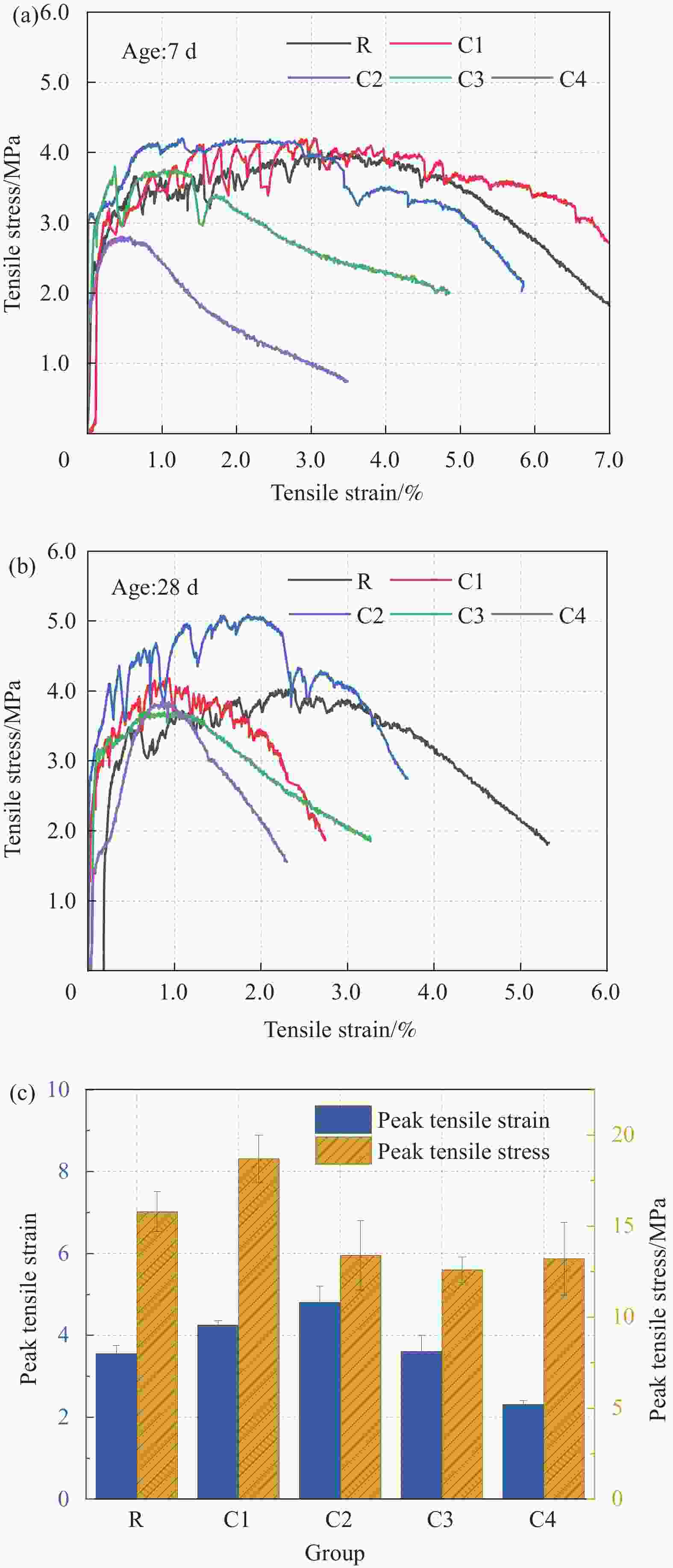

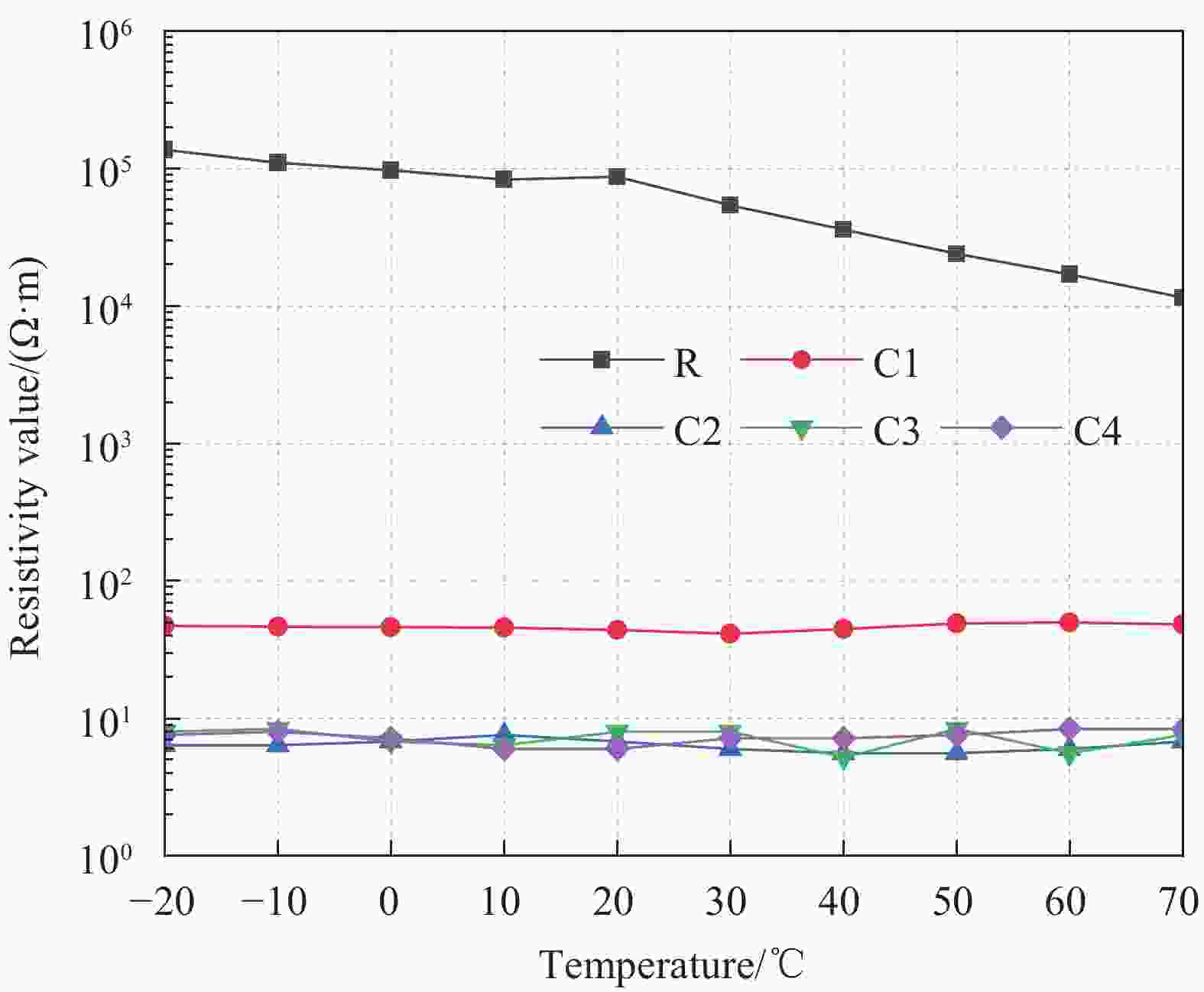

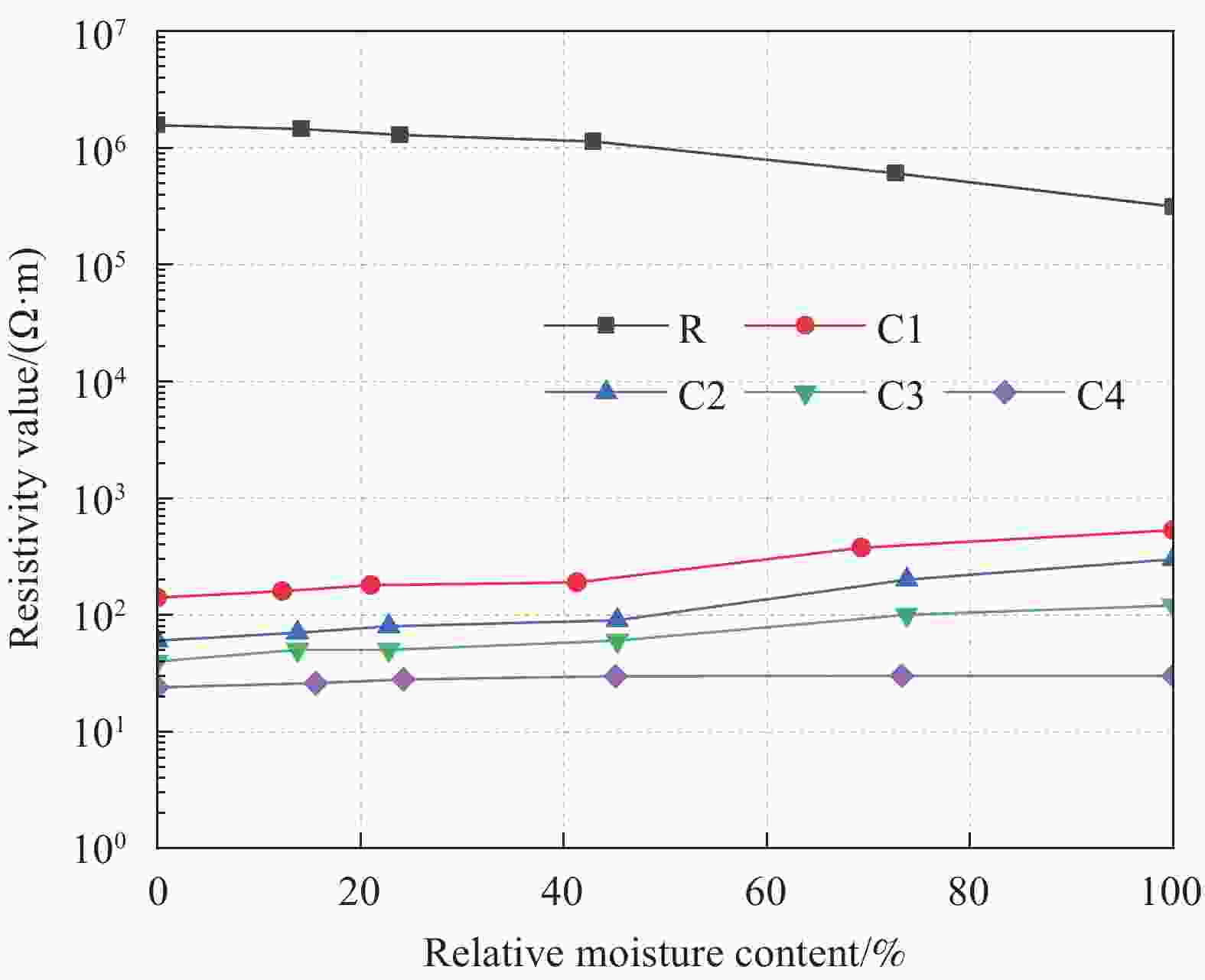

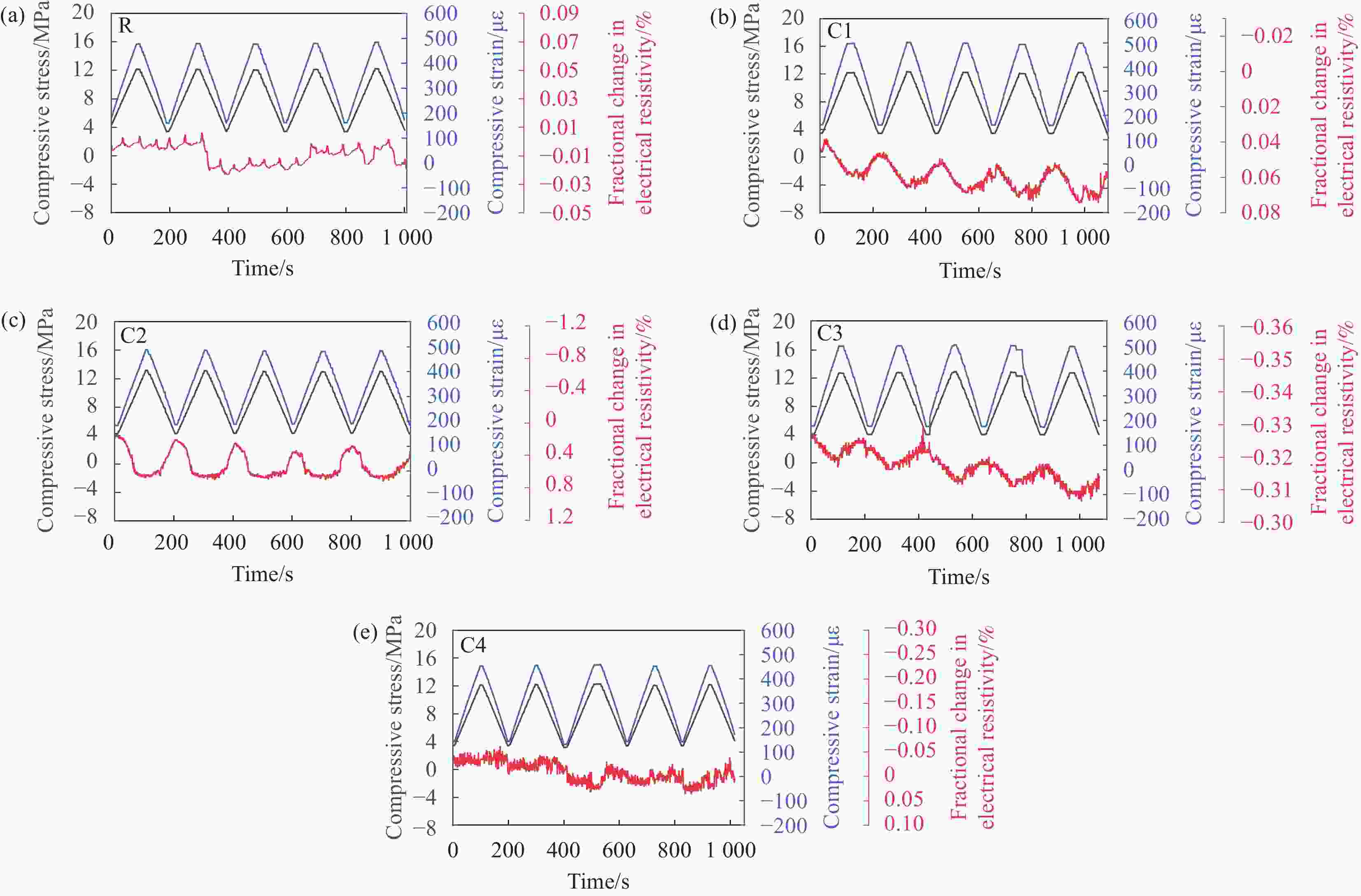

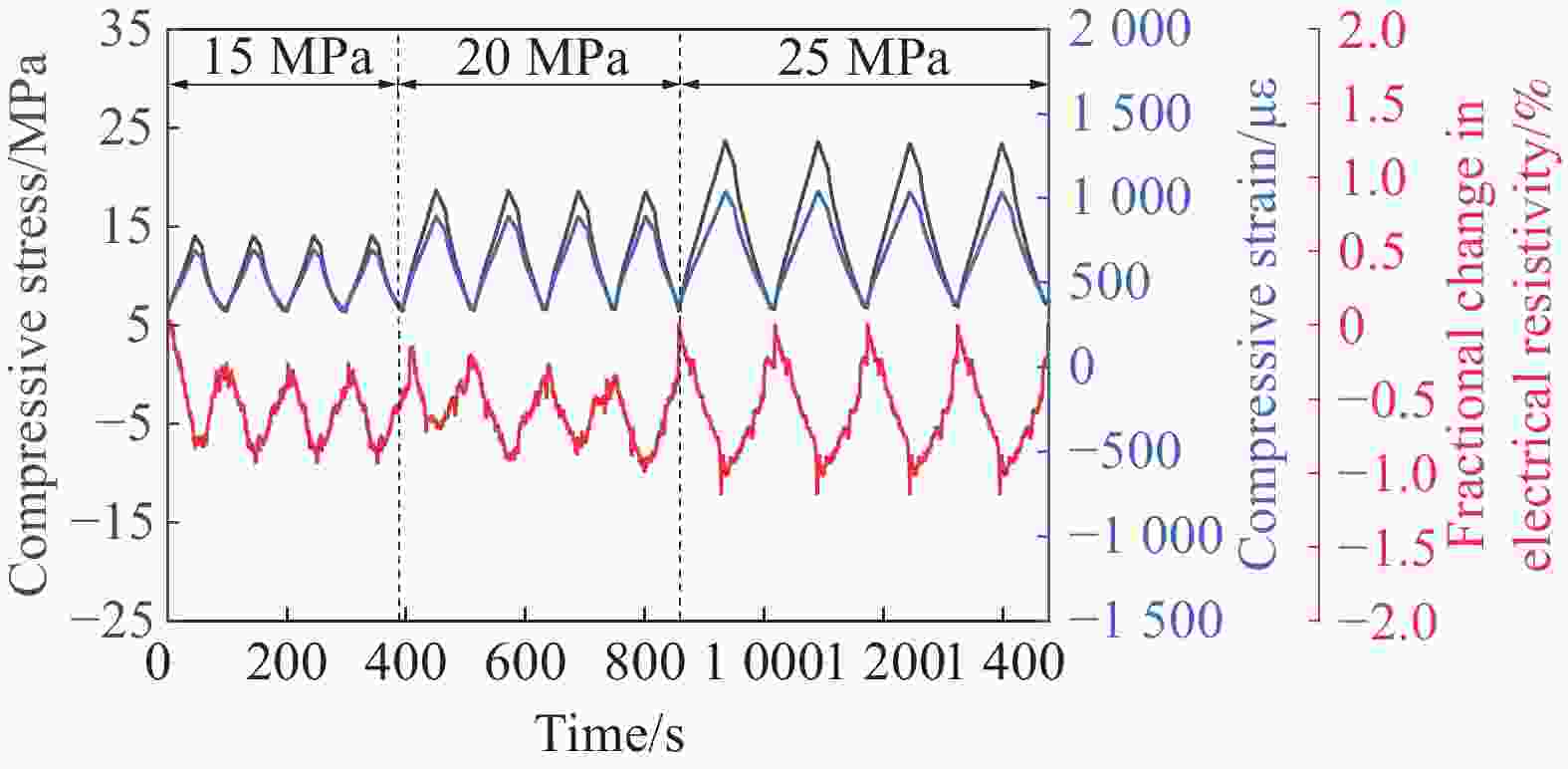

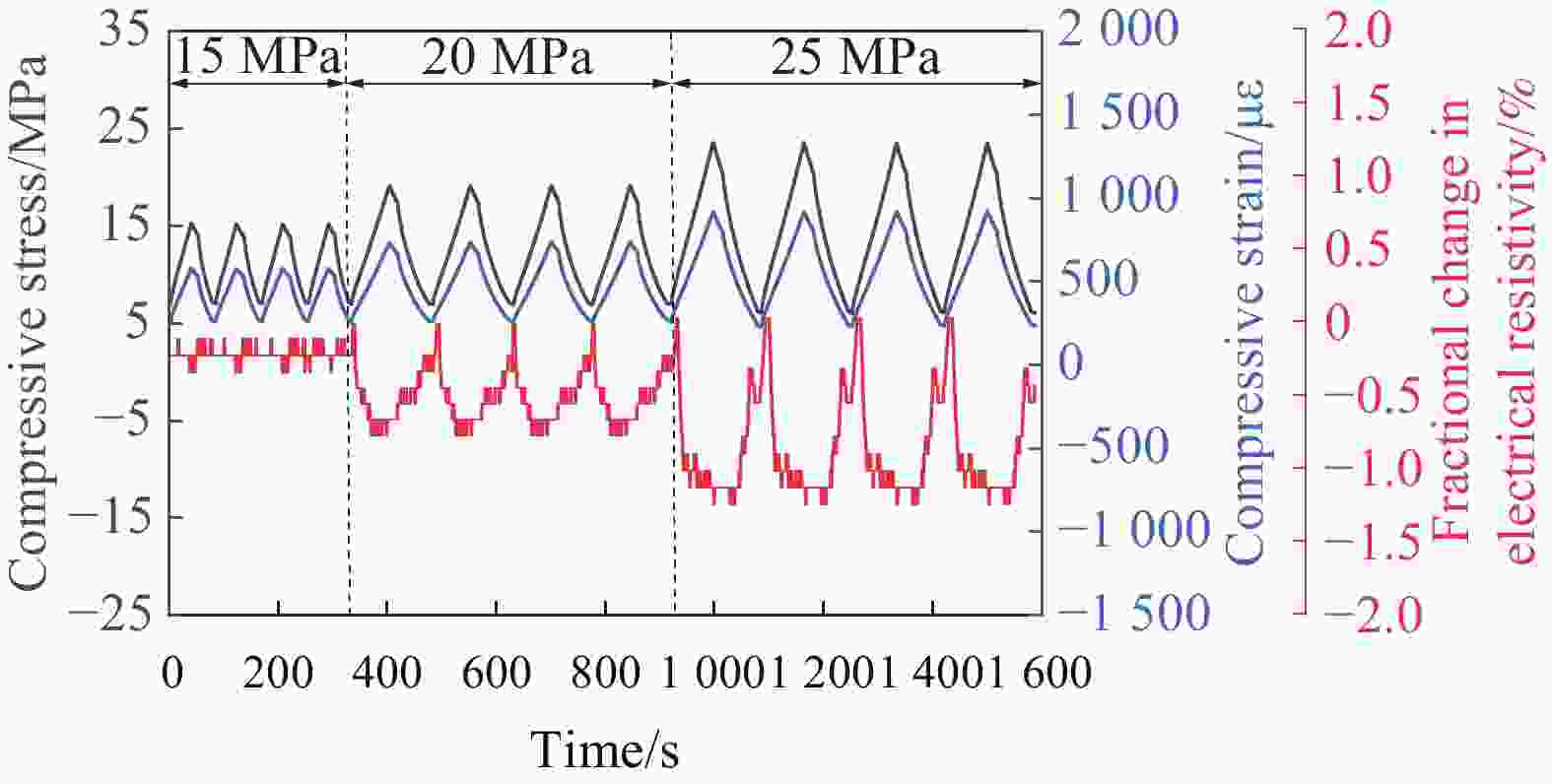

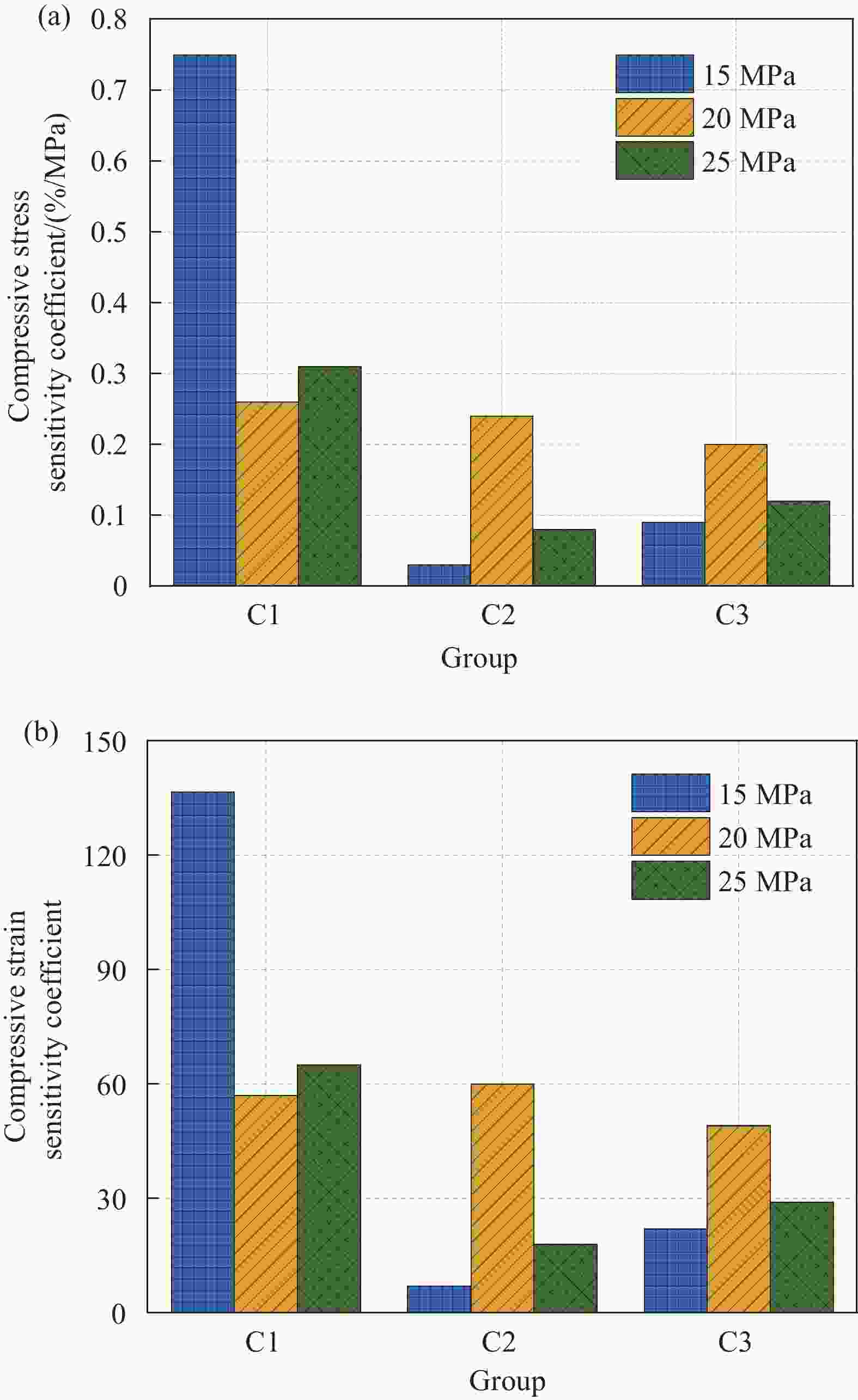

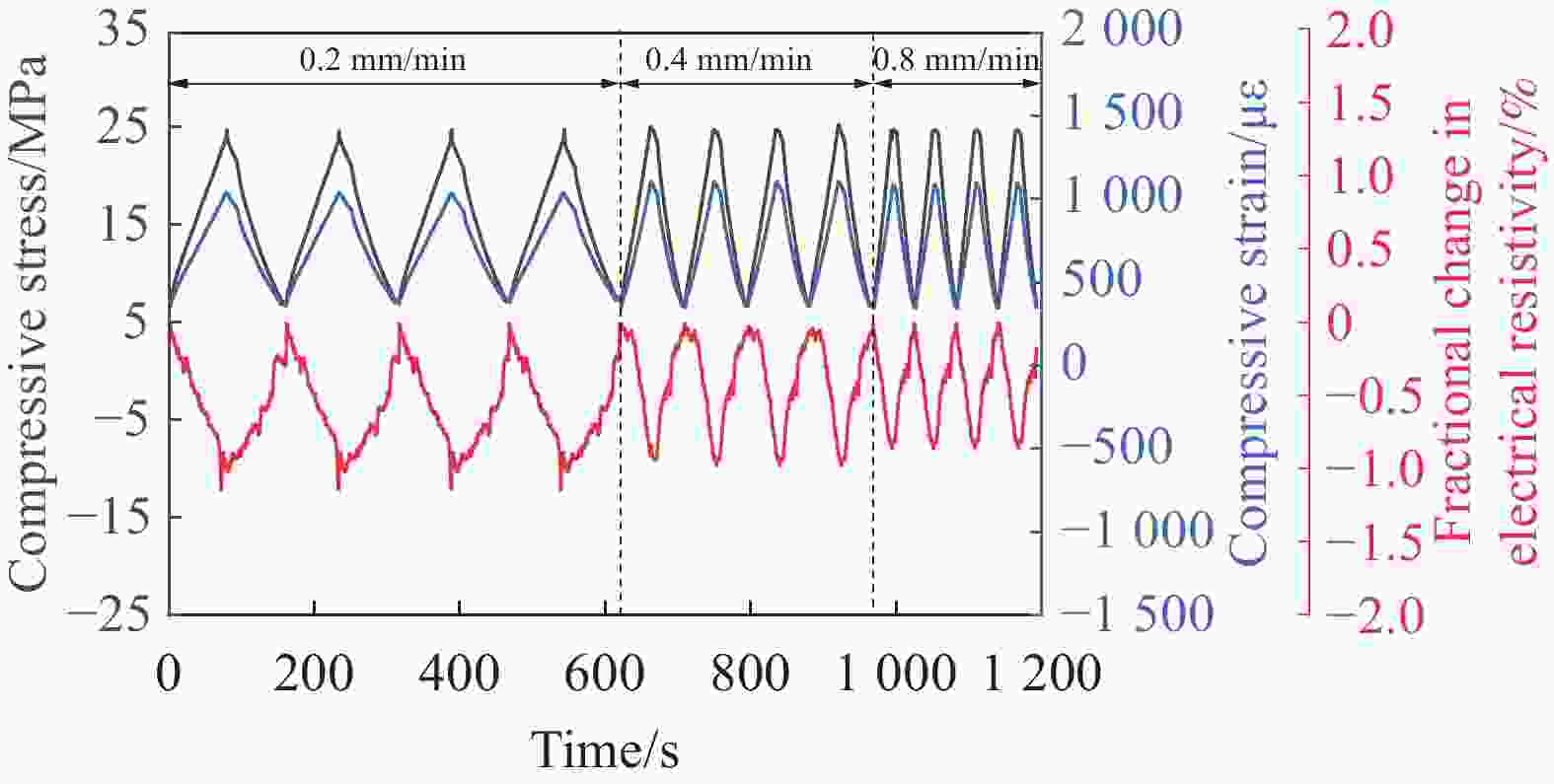

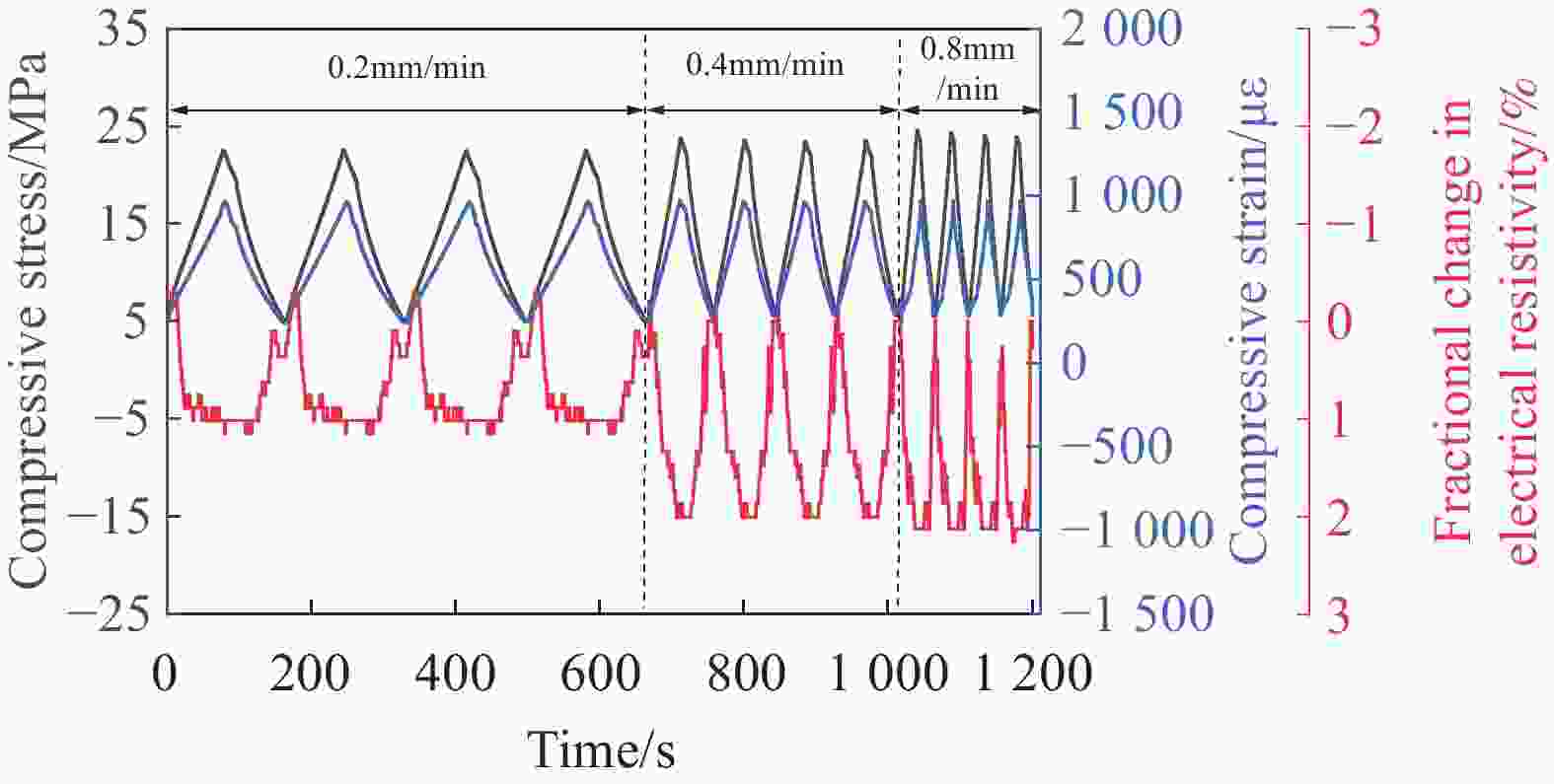

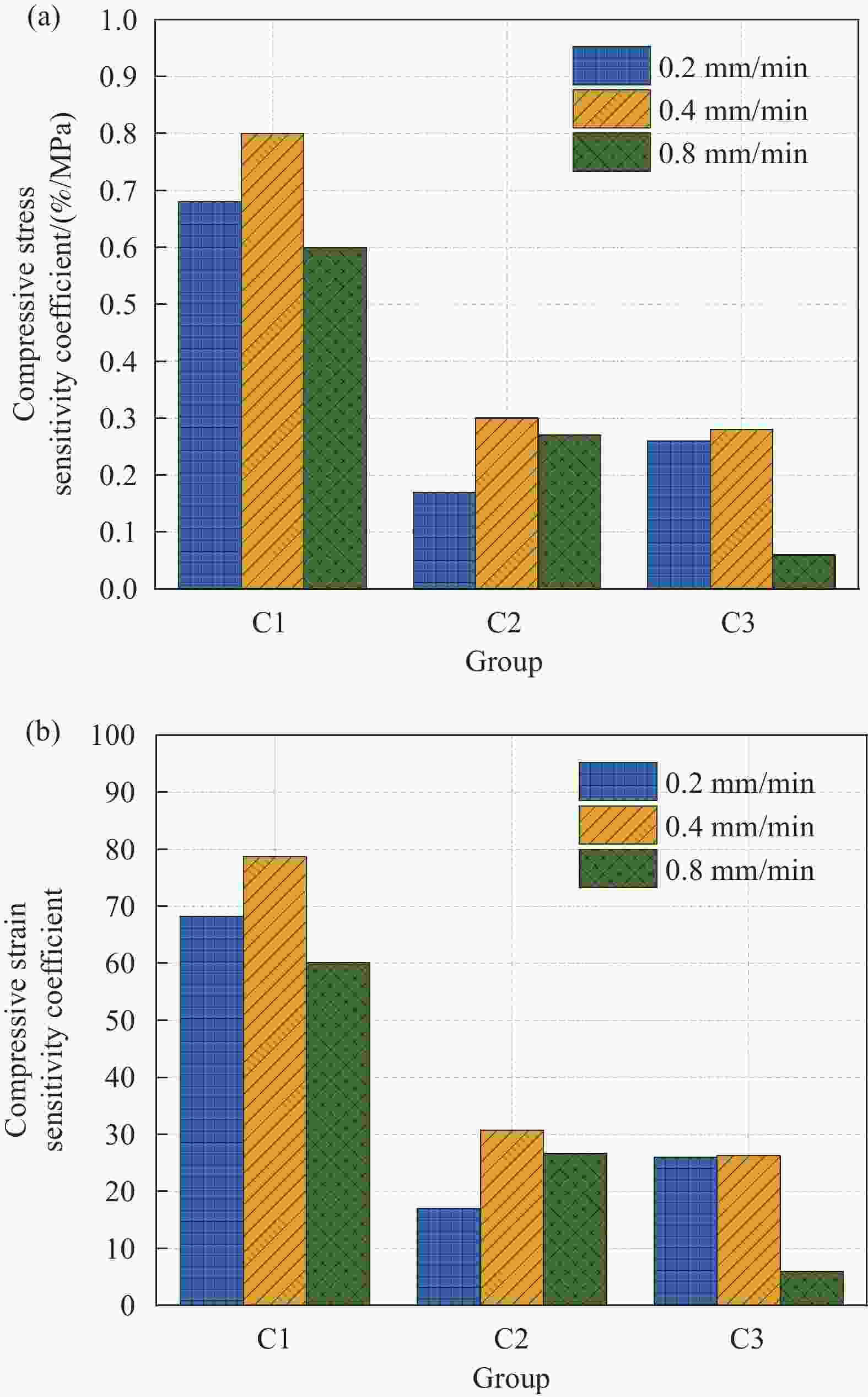

摘要: 研究通过混杂碳纤维(Carbon Fiber,CF)和聚乙烯纤维(Polyethylene Fiber,PE)制备出高强高韧性混凝土(High strength and high ductility concrete,HSHDC),并对其力学性能及机敏性特性进行了分析。研究表明0.25vol%CF掺量HSHDC的抗压强度较对照组提升7%、抗折强度增加13%、拉伸应变提高15.2%。HSHDC的电阻率值随CF掺量增加而显著降低,1.0vol%CF掺量HSHDC的电阻率值下降至10 Ω·m,较对照组降低三个数量级。在不同温度与相对含水率下,掺有CF的HSHDC电阻率表现出较好的稳定性,循环荷载作用下0.25vol%CF掺量HSHDC电阻率变化率与应力之间表现出良好的对应关系,压应力和压应变灵敏系数分别达到0.75%/MPa和136.5。0.25vol%CF掺量的HSHDC在加载幅度为15 MPa时的最大电阻率变化率为9.2%,加载速度为0.4 mm/min时峰值电阻率变化率达到7.9%。Abstract: In this study, high strength and high ductility concrete (HSHDC) was developed by mixing carbon fiber (CF) and polyethylene fiber (PE). The mechanical properties and agility of HSHDC were analyzed. The results show that the compressive strength, flexural strength and tensile strain of HSHDC with 0.25vol% CF content were 7% higher than those of control group. The resistivity of HSHDC decreases significantly with the increase of CF content, and the resistivity of HSHDC with 1.0vol%CF content was as low as 10 Ω·m, which was three orders of magnitude lower than that of the control group. With different temperature and relatively humidity conditions, the resistivity of HSHDC mixed with CF showed good stability. Under cyclic loading, the resistivity change rate of HSHDC with 0.25vol%CF content showed a good correspondence with the stress, and the compressive stress and compressive strain sensitivity coefficients reached 0.75%/MPa and 136.5, respectively. For HSHDC with 0.25vol%CF content, the maximum resistivity change rate was 9.2% when the loading amplitude was 15MPa, and the peak resistivity change rate was 7.87% when the loading speed was 0.4 mm/min.

-

表 1 PⅡ 52.5水泥的基本性能

Table 1. PⅡ 52.5 Basic properties of cement

Firing

loss/%Sulfur

trioxide/%Chloride

Ion/%Specific surface

area/(m2·kg−1)Initial setting

time/minFinal setting

time/minCompressive

Strength/MPaFlexural

Strength/MPa3 d 28 d 3 d 28 d 2.73 2.18 0.031 344 128 175 6.5 34.7 9.1 59.1 表 2 纤维的基本性能

Table 2. Basic properties of fibers

Fiber

typeDensity/

(g·cm−3)Length/

mmFiber

diameter/μmTensile

strength/MPaTensile modulus

of elasticity/GPaResistivity/

(Ω·cm)PE 0.97 12 24 3000 116 103-105 CF 1.75 12 7 3530 228 1.0-1.6 Notes: PE—Polyethylene fiber; CF—Carbon fiber. 表 3 高强高韧性混凝土(HSHDC)配合比设计及其流动性

Table 3. Mix ratio design and fluidity of high strength and high ductility concrete (HSHDC)

Group Cement/g Fly ash/g Silica fume/g Sand/g Water reducing

Agent/gWater/g PE/vol% CF/vol% Fluidity/mm R 700 500 200 400 6.0 364 2.00 0 181 C1 700 500 200 400 6.0 364 1.75 0.25 173 C2 700 500 200 400 6.0 364 1.50 0.50 169 C3 700 500 200 400 6.0 364 1.25 0.75 168 C4 700 500 200 400 6.0 364 1.00 1.00 165 -

[1] Ranade R, Li V. Composites properties of high-strength, high-ductility concrete[J]. ACI Materials Journal, 2013, (110): 413-422. [2] Yu K, Zhu W, Yao D. Micro-structural and mechanical properties of ultra-high performance engineered cementitious composites (UHP-ECC) incorporation of recycled fine powder (RFP)[J]. Cement and Concrete Research, 2019, 124(10): 105813. [3] Zhou Y, Xi B, Yu K, et al. Mechanical properties of hybrid ultra-high performance engineered cementitious composites incorporating steel and polyethylene fibers[J]. Mater, 2018, 11(8): 1448. doi: 10.3390/ma11081448 [4] Konsta-Gdoutos S M, Aza A C. Self sensing carbon nanotube (CNT) and nanofiber (CNF) cementitious composites for real time damage assessment in smart structures[J]. Cement and Concrete Composites, 2014, 53: 162-169. doi: 10.1016/j.cemconcomp.2014.07.003 [5] Chung L D D. Cement-matrix composites for smart structures[J]. Smart Materials and Structures, 2000, 9(4): 389-401. doi: 10.1088/0964-1726/9/4/302 [6] Kim G, Yang B, Ryu G, et al. The electrically conductive carbon nanotube (CNT)/cement composites for accelerated curing and thermal cracking reduction[J]. Composite Structures, 2016, 158: 20-29. doi: 10.1016/j.compstruct.2016.09.014 [7] Gomis J, Galao O, Gomis V, et al. Self-heating and deicing conductive cement. Experimental study and modeling[J]. Construction and Building Materials, 2015, 75: 442-449. doi: 10.1016/j.conbuildmat.2014.11.042 [8] Han B G, Ou J P. Embedded piezoresistive cement-based stress/strain sensor[J]. Sensors and Actuators A:Physical, 2007, 138(2): 294-298. doi: 10.1016/j.sna.2007.05.011 [9] Wang S, Chung D. Self-sensing of flexural strain and damage in carbon fiber polymer-matrix composite by electrical resistance measurement[J]. Carbon, 2006, 44(13): 2739-2751. doi: 10.1016/j.carbon.2006.03.034 [10] Ding Y, Han Z, Zhang Y, et al. Concrete with triphasic conductive materials for self-monitoring of cracking development subjected to flexure[J]. Composite Structures, 2016, 138: 184-191. doi: 10.1016/j.compstruct.2015.11.051 [11] Lin C, Chung D. Graphite nanoplatelet pastes vs. carbon black pastes as thermal interface materials[J]. Carbon, 2008, 47(1): 295-305. [12] Dong S F, Han B G, Ou J P, et al. Electrically conductive behaviors and mechanisms of short-cut super-fine stainless wire reinforced reactive powder concrete[J]. Cement & Concrete Composites, 2016: 48-65. [13] Chen P-W, Chung D D L. Carbon fiber reinforced concrete for smart structures capable of non-destructive flaw detection[J]. Smart Materials & Structures, 2(1): 22-30. [14] Shi Z Q, Chung D D L. Carbon fiber-reinforced concrete for traffic monitoring and weighing in motion[J]. Cement & Concrete Research, 1999, 29(3): 435-439. [15] Li H, Xiao H, Ou J. Effect of compressive strain on electrical resistivity of carbon black-filled cement-based composites[J]. Cement and Concrete Composites, 2006, 28(9): 824-828. doi: 10.1016/j.cemconcomp.2006.05.004 [16] MONTEIRO A O, CACHIM P B, COSTA P M F J. Self-sensing piezoresistive cement composite loaded with carbon black particles[J]. Cement and Concrete Composites, 2017, 81: 59-65. doi: 10.1016/j.cemconcomp.2017.04.009 [17] 刘金涛, 黄存旺, 杨杨, 等. 三维石墨烯-碳纳米管/水泥净浆的压敏性能[J]. 复合材料学报, 2022, 39(1): 313-321.LIU Jintao, HUANG Cunwang, YANG Yang, et al. Piezoresistivity of three dimensional graphene-carbon nanotubes/cement paste[J]. Acta Mater. Compositae Sin, 2022, 39(1): 313-321(in Chinese). [18] Demirciliolu E, Teomete E, Schlangen E, et al. Temperature and moisture effects on electrical resistance and strain sensitivity of smart concrete[J]. Construction and Building Materials, 2019, 224: 420-427. doi: 10.1016/j.conbuildmat.2019.07.091 [19] 赵娇. 碳纤维智能混凝土的电—热—力效应研究[D]. 南京理工大学, 2008.Zhao J. Study on electrothermal force effect of carbon fiber smart concrete [D]. Nanjing University of Science and Technology, 2008. [20] 袁娇, 刘小艳, 陈玉泉, 等. 碳纳米管水泥基复合材料温敏及湿敏性能研究[J]. 混凝土与水泥制品, 2020, (4): 5-8.Yuan J, Liu X Y, Chen Y Q, et al. Study on temperature and humidity sensitive of carbon/ nanotube cement composites[J]. China Concrete and Cement Products, 2020, (4): 5-8. [21] Han B G, Zhang L Y, Ou J P. Influence of water content on conductivity and piezoresistivity of cement-based material with both carbon fiber and carbon black[J]. Journal of Wuhan University of Technology Materials Science Edition, 2010, 25: 147-151. doi: 10.1007/s11595-010-1147-z [22] Li H, Xiao H G, Ou J P. Electrical property of cement-based composites filled with carbon black under long-term wet and loading condition[J]. Composites Science and Technology, 2008, 68(9): 2114-2119. doi: 10.1016/j.compscitech.2008.03.007 [23] 曹明莉, 许玲, 张聪. 高延性纤维增强水泥基复合材料的微观力学设计、性能及发展趋势[J]. 硅酸盐学报, 2015, 43(05): 632-642.Cao Mingli, Xu Ling, Zhang Cong. Review on Micromechanical Design, Performance and Development Tendency of Engineered Cementitious Composite. JOURNAL OF THE CHINESE CERAMIC SOCIETY. 2015, 43(05): 632-642. [24] C Li Victor. 高延性纤维增强水泥基复合材料的研究进展及应用[J]. 硅酸盐学报, 2007, 35(4): 531-535.LI Victor C. PROGRESS AND APPLICATION OF ENGINEERED CEMENTITIOUS COMPOSITES. JOURNAL OF THE CHINESE CERAMIC SOCIETY. 2007, 35(4): 531-535. [25] 王秀峰, 王永兰, 金志浩. 碳纤维增强水泥复合材料的机敏性[J]. 硅酸盐学报. 1998, 26(3): 253-257.Wang X F, Wng Y L, Jin Z H, The agility of carbon fiber reinforced cement composites[J]. Journal of Ceramics. 1998, 26 (3): 253-257. [26] 全国水泥标准化技术委员会(SAC/TC 184). 水泥胶砂强度检验方法(ISO法). GB/T 17671-2021.National Technical Committee for Cement Standardization (SAC/TC 184). Cement mortar strength test method (ISO method). GB/T 17671-2021. [27] 水泥胶砂流动度测定方法[S]. GB/T 2419-2005.Determination of fluidity of cement mortar [S]. GB/T 2419-2005. [28] SHEIBANY F, GHAEMIAN M. Effects of environmental action on thermal stress analysis of Karaj concrete arch dam[J]. Journal of Engineering Mechanics, 2006, 132(5): 532-544. doi: 10.1061/(ASCE)0733-9399(2006)132:5(532) [29] Zhang Y, Pan J, SUN X, et al. Simulation of thermal stress and control measures for rock-filled concrete dam in high-altitude and cold regions[J]. Engineering Structures, 2021, 230(1): 111721.1-111721.10. [30] Teomete E. The effect of temperature and moisture on electrical resistance, strain sensitivity and crack sensitivity of steel fiber reinforced smart cement composite[J]. Smart Materials and Structures, 2016, 25(7): 075024. doi: 10.1088/0964-1726/25/7/075024 [31] Forde M C, Mccarter J, Whittington H W. The conduction of electricity through concrete[J]. Magazine of Concrete Research, 1981, 33(114): 48-60. doi: 10.1680/macr.1981.33.114.48 [32] Chen B, Liu J Y, Wu K. Electrical responses of carbon fiber reinforced cementitious composites to monotonic and cyclic loading[J]. Cement and Concrete Research, 2005, 35(11): 2183-2191. doi: 10.1016/j.cemconres.2005.02.004 [33] Qing L Z, Fen S D, Yang Y W, et al. Multifunctionalities of Nanocarbon Materials Filled Cement-Based Composites[J]. Materials Science Forum, 2014, 809-810(809-810): 144-154. [34] 孙明清. 碳纤维混凝土与素混凝土的力电机敏性及其应用. 武汉理工大学博士学位论文. 2001.Sun M Q. Electrodynamic agility of carbon fiber concrete and plain concrete and its application. Wuhan University of Technology doctoral dissertation. 2001. [35] 毛起炤, 杨元霞, 李卓球, 等. 碳纤维增强水泥压敏性影响因素的研究[J]. 硅酸盐学报. 1997, 25(6): 110-113. 118.Mao Q Z, Yang Y X, Li Z Q, et al. Study on influencing factors of pressure sensitivity of carbon fiber reinforced cement[J]. Journal of Ceramics. 1997, 25(6): 110-113. 118. [36] H. A. Toutanji, T. EI-Korchi. R. N. Katz. Strength and reliability of carbon-fiber reinforced cement. ACI Mater. 1992 89(3): 269-274. [37] H. Sakia, K. Takahashi, Y. Mitsui, etc. Flexural behavior of carbon fiber reinforced cement composite. ACI SP-142. in: Fiber Reinforced Concrete. J. I. Daneel. S. P. Shah(Eds). ACI. Detroit. MI. 1994: 121-140. [38] Yu X, Kwon E. A carbon nanotube cement composite with piezoresistive properties[J]. Smart Materials and Structures, 2009, 18(5): 1-5. -

点击查看大图

点击查看大图

计量

- 文章访问数: 41

- HTML全文浏览量: 22

- 被引次数: 0

下载:

下载: