Numerical simulation and theoretical analysis of flexural strengthening of RC beams with high-strength steel strand mesh/ECC

-

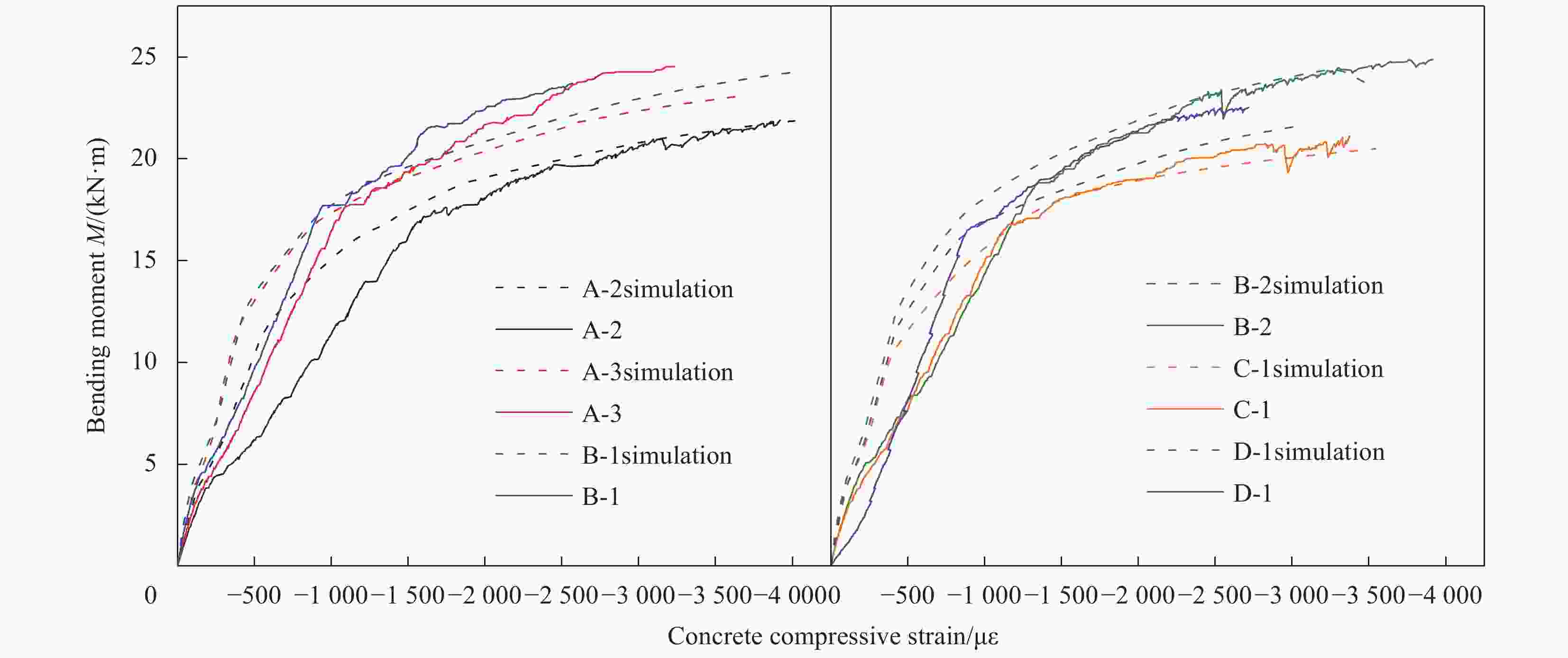

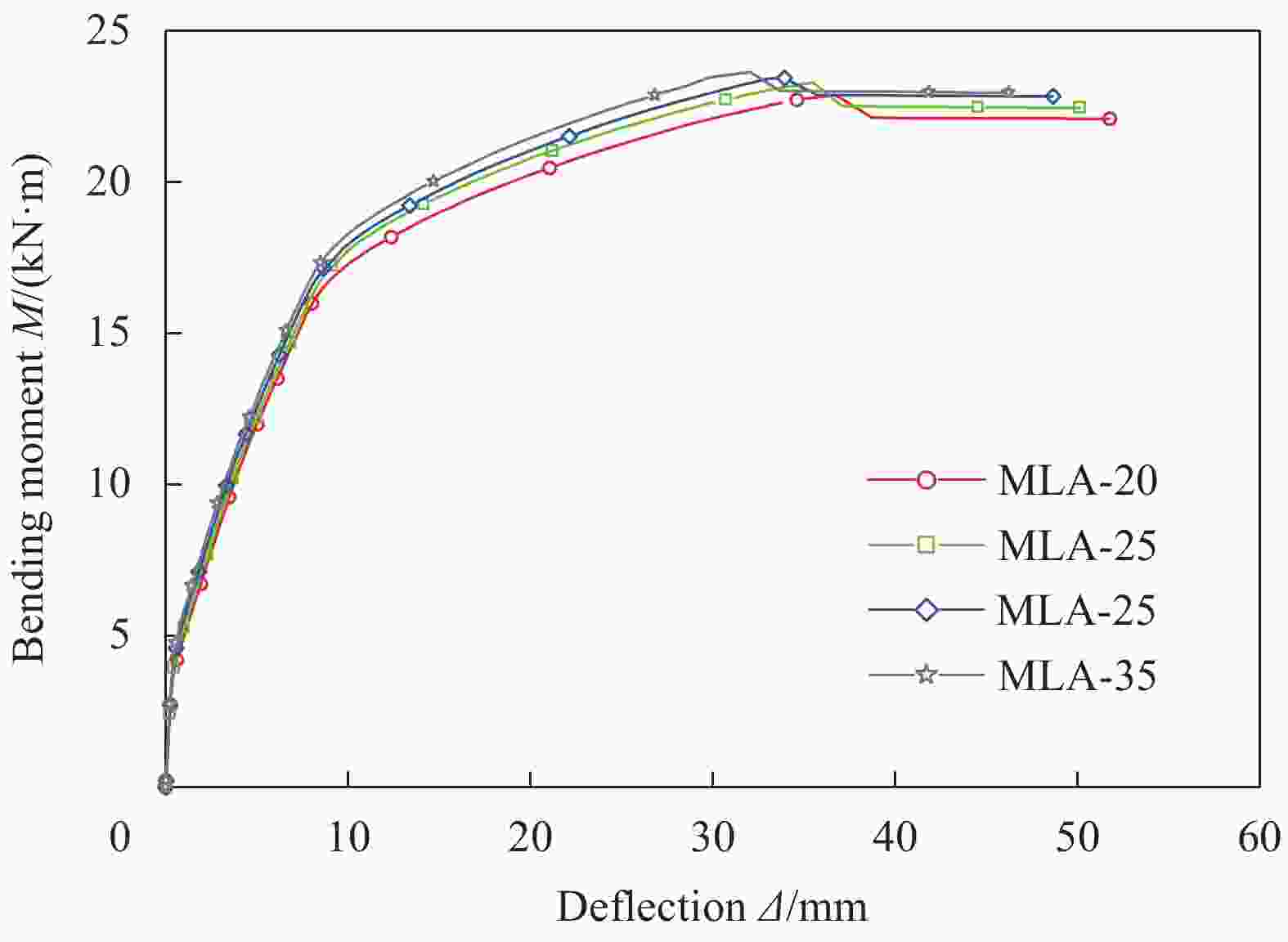

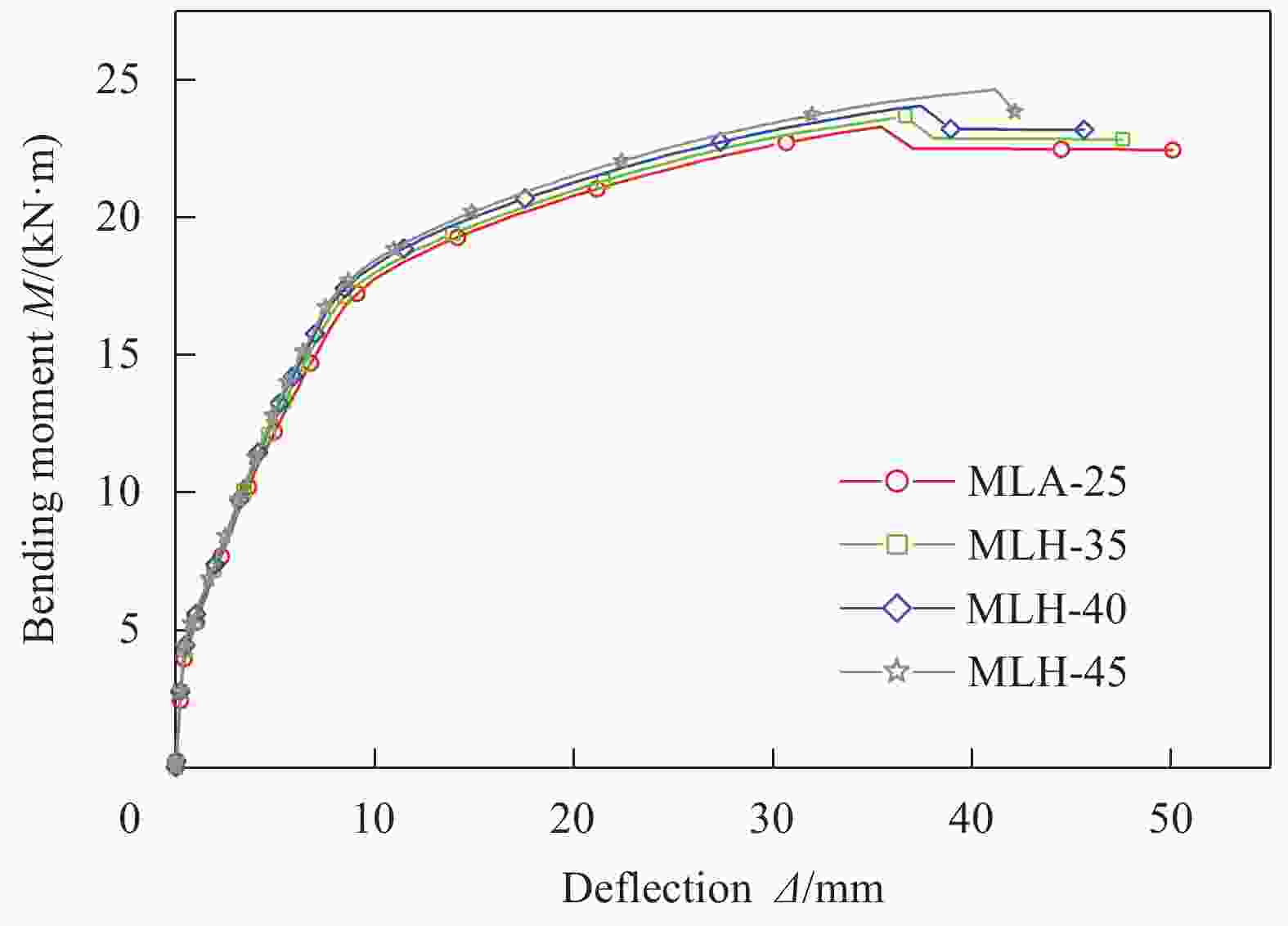

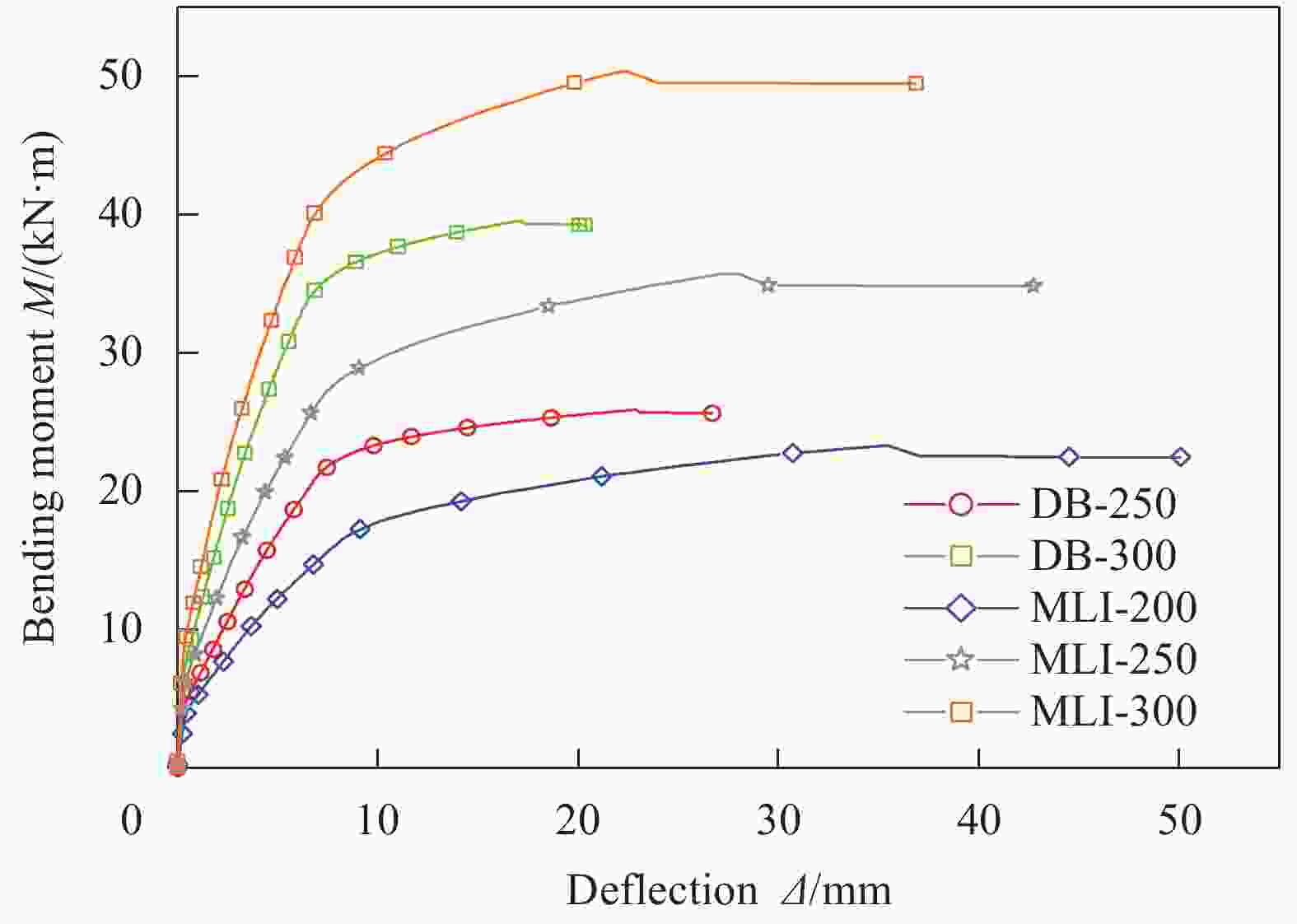

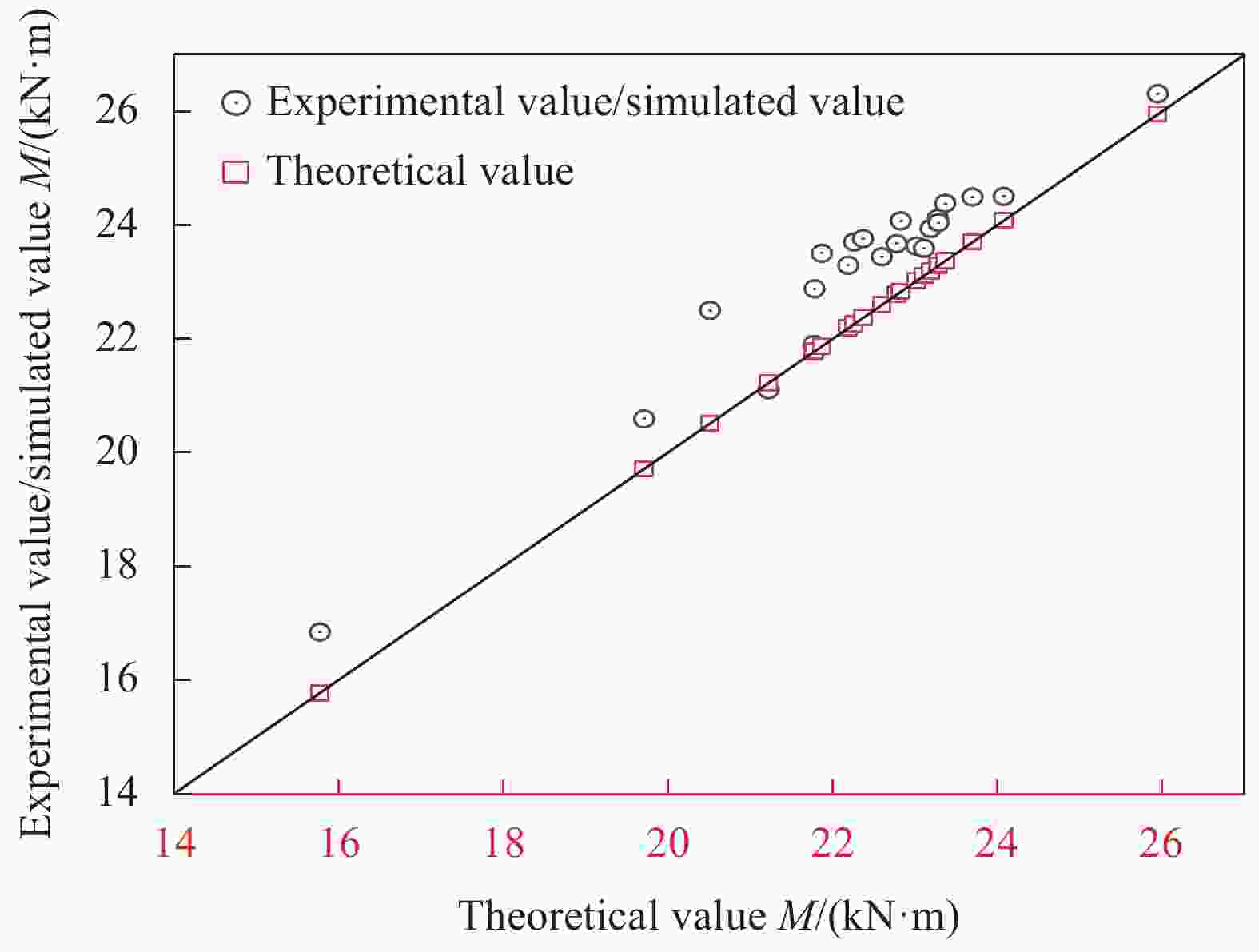

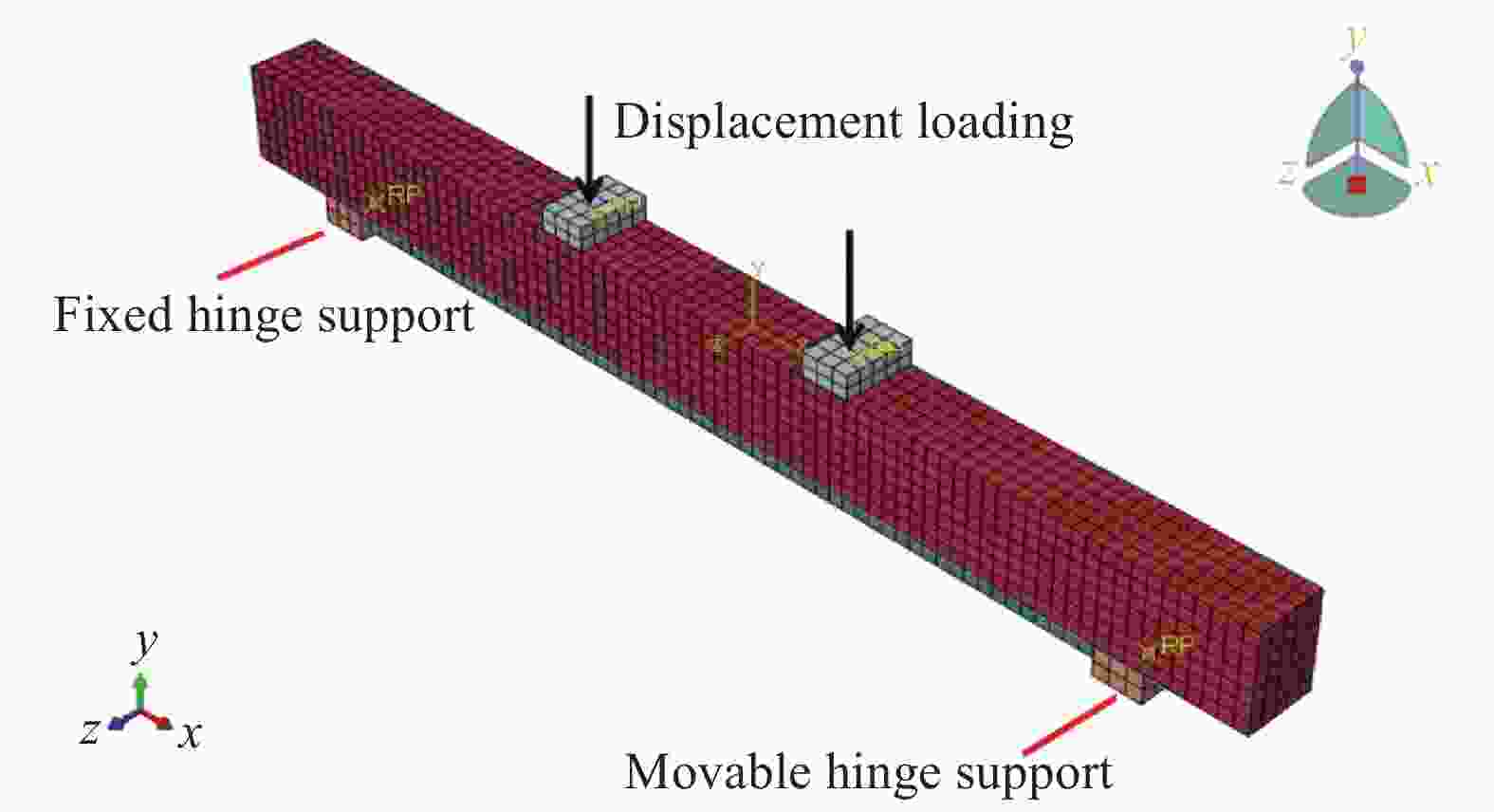

摘要: 采用有限元模拟与试验相结合的方法,研究了加固层材料用量、加固材料材性、RC梁特征参数等因素对高强钢绞线网/ECC (Engineered cementitious composites)抗弯加固RC (Reinforced concrete)梁受弯性能的影响规律。首先,建立了高强钢绞线网/ECC加固既有无损RC梁有限元分析模型,并与试验结果比较,验证了其准确性和有效性,并采用该模型对关键参数对加固梁受弯性能的影响规律进行系统性分析。结果表明:该加固方法可显著提升RC梁的受弯承载力、刚度、延性,提升幅度分别7.81%~61.84%,6.35%~40.90%,5.92%~50.16%;随着纵向钢绞线配筋率、加固层厚度和开裂应力的增大,承载力的提升幅度增大,而RC梁纵筋配筋率和截面高度增大会降低承载力的提升幅度;加固层厚度与纵向钢绞线配筋率的增大会增加刚度的提升幅度,而RC梁纵筋配筋率、混凝土强度和截面高度的增大会降低对刚度的提升幅度;延性的提升幅度随着混凝土强度的增大而增加。在此基础上结合相关力学理论,提出抗弯加固界限钢绞线用量计算公式及高强钢绞线网/ECC加固RC梁正截面承载力简化计算公式,与试验及数值模拟结果吻合良好。Abstract: Using a combination of finite element simulation and experimentation, the impact of reinforcement layer material quantity, properties of reinforcement materials, and characteristic parameters of RC (Reinforced Concrete) beams on the flexural performance of RC beams strengthened with high-strength steel wire mesh/ECC (Engineered Cementitious Composites) was investigated. Firstly, the finite element (FE) analysis model of existing nondestructive RC beams strengthened with high-strength steel wire mesh/ECC was established, and its effectiveness and accuracy were verified by comparing with the experimental results. The validated FE model was adopted to analyze the influencing factors of flexural performance of strengthened beams systematically. The results indicate that the strengthening method can significantly enhance the flexural bearing capacity, stiffness, and ductility of RC beams, with improvement ranges of 7.81% to 61.84%, 6.35% to 40.90%, and 5.92% to 50.16% respectively. With the increase of longitudinal steel strand reinforcement ratio, thickness and cracking stress of ECC, the promotion range of bearing capacity increases, while the increase of longitudinal steel reinforcement ratio and section height of RC beams decrease the increment of bearing capacity. The increase of the thickness of ECC and the reinforcement ratio of longitudinal steel strand increase the promotion range of stiffness, but the promotion range decreases with the increment of longitudinal reinforcement ratio, concrete strength and section height of RC beams. The increment of ductility only increases with the increase of concrete strength. On this basis, combined with relevant mechanical theories, the calculation formula for the limit amount of steel strands for flexural strengthening and simplified calculation formulas for the normal-section bearing capacity of RC beams reinforced by high-strength steel wire strand mesh-reinforced ECC are proposed, calculation results are in good agreement with experimental and numerical simulation results.

-

图 16 加固RC梁截面应变和应力分布

Figure 16. Distribution of cross-section strain and stress of strengthened RC beams

h—Height of the reinforced beam section; hsw—Distance from the steel strand to the top of the compression zone; h0—Effective height of the concrete section;h1—Thickness of the reinforcement layer; εc—Concrete compressive strain; εcu—Ultimate compressive strain value of concrete under non-uniform compression; xn—Height of the compression zone; εsw—Tensile strain in the steel strand; εsw,y—The strain corresponding to the nominal yield stress of the steel strand; εy—Ultimate tensile strain of the reinforcement; εe—Tensile strain of the reinforcement layer; Ts—Tensile force provided by the reinforcement; Tsw—Tensile force provided by the steel strand; TE—Tensile force provided by the reinforcement layer; Cc—Compressive force provided by the concrete

表 1 试件设计

Table 1. Design of test specimens

Test specimen d/mm ρ/%(n) ECC formula[26] A-2 3.0 0.580 (5) Formula 1 A-3 3.0 0.812 (7) Formula 1 B-1 3.0 0.580 (5) Formula 2 B-2 3.0 0.580 (5) Formula 3 C-1 4.5 0.515 (2) Formula 1 D-1 3.6 0.686 (4) Formula 1 Notes: d—Diameter of steel strand; n—Number of longitudinal steel strands; ρ—Longitudinal steel strand reinforcement ratio. 表 2 ECC力学性能指标

Table 2. Mechanical properties of ECC

ECC

formula[26]fe/MPa Ee/GPa σkm/MPa εkm/% σtu/MPa εe,u/% 1 37.3 14.1 1.37 0.025 2.18 1.88 2 46.5 14.6 1.91 0.035 2.81 0.75 3 36.6 14.3 1.86 0.032 2.30 2.47 Notes: fe—Compressive strength of ECC; Ee—Elastic modulus of ECC; σkm—Cracking stress of ECC;εkm—Cracking strain of ECC; σtu—Ultimate tensile strength of ECC; εe,u—Ultimate tensile strain of ECC. 表 3 高强钢绞线拉伸试验数据

Table 3. High-strength steel strand tensile test data

d/mm A/mm2 Erw/GPa σswu /MPa εu/% 3.0 4.35 139 1919.02 2.96 3.6 6.43 109 1521.21 3.47 4.5 9.65 130 1706.46 3.37 Notes: A—Cross-sectional area of the steel strand; Erw—Elastic modulus of steel strand;σswu—Ultimate tensile strength of the steel strand ; εu—Ultimate tensile strain of the steel strand 表 4 加固RC梁试件参数设计以及有限元计算结果

Table 4. Parameter design of strengthened RC beam specimens and finite element calculation results

Specimen

Numberρs/% ρrw/% σkm/MPa σtu/MPa FM Mcr/(kN·m) Ms,y/(kN·m) Mu/(kN·m) Be Bc μ△ DB-0 0.936 — — — — 2.73 13.14 15.62 — — 3.21 DB-14 1.283 — — — — 2.77 17.87 20.07 — — 2.23 DB-16 1.686 — — — — 2.81 22.09 23.94 — — 1.56 DB-18 2.148 — — — — 2.86 25.89 27.21 — — 1.15 DB-35 0.936 — — — — 2.84 13.35 15.99 — — 3.33 DB-40 0.936 — — — — 2.97 13.64 16.28 — — 3.42 DB-45 0.936 — — — — 3.07 14.22 16.75 — — 3.59 DB-250 0.936 — — — — 3.97 21.89 25.89 — — 2.97 DB-300 0.936 — — — — 5.61 34.72 39.54 — — 2.52 MLA-20 0.936 0.58 1.5 2.5 CP 3.72 16.32 22.88 1.22 1.17 4.39 MLA-25 0.936 0.58 1.5 2.5 CP 3.86 16.72 23.29 1.28 1.18 4.19 MLA-30 0.936 0.58 1.5 2.5 CP 4.05 17.15 23.44 1.35 1.19 3.91 MLA-35 0.936 0.58 1.5 2.5 CP 4.29 17.34 23.63 1.41 1.2 3.63 MLB-0 0.936 0 1.5 2.5 CP 3.77 15.54 16.84 1.27 1.12 4.82 MLB-3 0.936 0.348 1.5 2.5 CP 3.82 16.17 20.56 1.27 1.15 4.38 MLB-7 0.936 0.812 1.5 2.5 CE 3.99 17.29 24.36 1.28 1.22 3.74 MLB-9 0.936 1.044 1.5 2.5 CE 4.1 17.7 25.28 1.29 1.25 3.4 MLE-1.5 0.936 0.58 1.5 4.5 CP 3.86 16.78 23.59 1.29 1.18 3.97 MLE-2.0 0.936 0.58 2 4.5 CP 4.06 17.18 23.94 1.29 1.2 3.91 MLE-2.5 0.936 0.58 2.5 4.5 CP 4.24 17.56 24.12 1.29 1.21 3.88 MLE-3.0 0.936 0.58 3 4.5 CP 4.42 17.95 24.38 1.29 1.22 3.87 MLF-2.5 0.936 0.58 2.5 2.5 CP 4.24 17.24 23.76 1.29 1.2 4.22 MLF-3.5 0.936 0.58 2.5 3.5 CP 4.24 17.39 24.07 1.29 1.2 4.07 MLF-5.5 0.936 0.58 2.5 5.5 CP 4.24 17.67 24.49 1.29 1.21 3.77 MLG-14 1.283 0.58 1.5 2.5 CP 4 20.31 25.37 1.21 1.13 2.87 MLG-16 1.686 0.58 1.5 2.5 CP 4.12 24.46 28.44 1.17 1.09 1.95 MLG-18 2.148 0.58 1.5 2.5 CE 4.27 28.31 31.49 1.15 1.06 1.42 MLH-35 1.283 0.58 1.5 2.5 CE 3.99 17.03 23.67 1.23 1.15 4.37 MLH-40 1.686 0.58 1.5 2.5 CP 4.13 17.26 24.04 1.2 1.12 4.52 MLH-45 2.148 0.58 1.5 2.5 CP 4.24 17.38 24.41 1.17 1.1 4.65 MLI-250 0.936 0.58 1.5 2.5 R 5.67 27.25 35.71 1.15 1.17 3.86 MLI-300 0.936 0.58 1.5 2.5 CP 7.8 40.08 50.36 1.1 1.13 3.27 Notes: Specimen number (DB—Non-reinforced; ML—simulated RC beam, A-I—The group number;The number after the “-” indicates the value of the varying parameter in that group); ρs—RC beam longitudinal reinforcement ratio; ρrw—Longitudinal steel strand reinforcement ratio in the reinforcement layer; FM—Failure mode; CP—Due to concrete crushing to reach ultimate bearing capacity and concrete crushing occurs after the steel strand reaches nominal yield stress; CE—Due to concrete crushing to reach ultimate bearing capacity and concrete crushing occurs before the steel strand reaches nominal yield stress; R—Due to steel strand breaking to reach ultimate bearing capacity and steel strand breaking occurs before concrete crushing; Mcr—Cracking moment;Ms,y—Yield moment of reinforcement;Mu—Failure load; Be—Stiffness ratio in the elastic stage;Bc—Stiffness ratio during the cracked working stage. 表 5 高强钢绞线界限用量

Table 5. Limit dosage of high strength steel strand

Specimen

NumberSectional area

of the steel

strand /mm2Relative values of stress and strain

during concrete crushingσs/fy εs/εy σsw/fsw,y εsw/εsw,y MLB-0 0 — — — — MLB-1 4.35 (1) 1 11.98 Tensile rupture Tensile rupture MLB-2 6.70 (2) 1 10.53 1.16 2.05 MLB-3 13.05 (3) 1 9.98 1.14 1.77 MLB-4 17.40 (4) 1 9.46 1.13 1.42 MLB-5 21.75 (5) 1 9.04 1.09 1.33 MLB-6 26.10 (6) 1 8.65 1.04 1.14 MLB-7 30.45 (7) 1 7.23 0.99 0.99 MLB-8 34.80 (8) 1 6.32 0.98 0.95 MLB-9 39.15 (9) 1 3.99 0.96 0.87 -

[1] 卢长福, 曹忠民. 高强钢绞线网-渗透性聚合物砂浆加固技术研究综述[J]. 江西科技, 2009, 27(26): 932-936.LU Zhangfu, CAO Zhongmin. Review of Research on Strengthening Technique with Strength Steel Wire Mesh and Polymer Mortar[J]. Jiangxi Science, 2009, 27(26): 932-936(in Chinese). [2] LI V C. High performance fiber reinforced cementitious composites as durable material for concrete structure repair international[J]. International Journal for Restoration, 2004, 10(2): 163-180. [3] LI V C. Tailoring ECC for special attributes: a review[J]. International Journal of Concrete Structures and Materials, 2012, 6(3): 135-144. doi: 10.1007/s40069-012-0018-8 [4] ZHENG Y Z, WANG W W, BRIGHAM J C. Flexural behavior of reinforced concrete beams strengthened with a composite reinforcement layer: BFRP grid and ECC[J]. Construction and Building Materials, 2016, 115: 424-437. doi: 10.1016/j.conbuildmat.2016.04.038 [5] WU C, LI V C. CFRP-ECC hybrid for strengthening of the concrete structures[J]. Composite Structures, 2017, 178: 372-382. doi: 10.1016/j.compstruct.2017.07.034 [6] 郑宇宙, 王文炜, 戴建国, 等. FRP-UHTCC复合层抗剪增强钢筋混凝土梁受力性能试验研究[J]. 建筑结构学报, 2019, 40(8): 118-126.ZHENG Yuzhou, WANG Wenwei, DAI Jianguo, et al. Experimental study on mechanical performance of reinforced concrete beams shear strengthened with FRP UHTCC composite[J]. Journal of Building Structures, 2019, 40(8): 118-126(in Chinese). [7] 邓朗妮, 杨洲, 钟锰军, 等. FRP网格-ECC复合材料加固钢筋混凝土梁挠度[J]. 复合材料学报, 2023, 40(9): 4584-4596.DENG Langni, YANG Zhou, ZHONG Mengjun, et al. Deflection of reinforced concrete beams strengthened with FRP grid-engineered cementitious composite matrix composite[J]. Acta Materiae Compositae Sinica, 2023, 40(9): 4584-4596(in Chinese). [8] 朱忠锋, 王文炜. FRP编织网/ECC复合加固钢筋混凝土圆柱力学性能的试验研究[J]. 东南大学学报(自然科学版), 2016, 46(5): 1082-1087. doi: 10.3969/j.issn.1001-0505.2016.05.031ZHU Zhongfeng, WANG Wenwei. Experimental study on mechanical behaviour of circular reinforced concrete columns strengthened with FRP textile and ECC[J]. JOURNAL OF SOUTHEAST UNIVERSITY (Natural Science Edition), 2016, 46(5): 1082-1087(in Chinese). doi: 10.3969/j.issn.1001-0505.2016.05.031 [9] 郑宇宙, 王文炜. 复材网格-UHTCC复合增强钢筋混凝土梁抗弯性能试验研究[J]. 土木工程学报, 2017, 50(6): 23-32.ZHENG Yuzhou, WANG Wenwei. Experimental research on flexural behavior of RC beams strengthened with FRP grid-UHTCC composite[J]. CHINA CIVIL ENGINEERING JOURNAL, 2017, 50(6): 23-32(in Chinese). [10] 王冲. PVA-ECC钢丝网混凝土梁复合抗弯增强试验研究[D]. 南京: 东南大学, 2019.WANG Chong. Experimental study on the flexural behavior of concrete beams strengthened with PVA-ECC and steel wire meshes[D]. Nanjing: Southeast University, 2019. (in Chinese). [11] YANG X, GAO W Y, DAI J G, et al. Flexural strengthening of RC beams with CFRP grid-reinforced ECC matrix[J]. Composite Structures, 2018, 189: 9-26. doi: 10.1016/j.compstruct.2018.01.048 [12] 朱忠锋, 王文炜, 郑宇宙, 等. 基于非接触式观测技术的FRP/ECC复合材料反复受拉本构关系模型[J]. 土木工程学报, 2019, 52(10): 36-45+55.ZHU Zhongfeng, WANG Wenwei, ZHENG Yuzhou, et al. The constitutive model of FRP/ECC composite materials under uniaxial cyclic tensile loading based on the digital image correlation technique[J]. CHINA CIVIL ENGINEERING JOURNAL, 2019, 52(10): 36-45+55(in Chinese). [13] HOU W, LI Z Q, GAO W Y, et al. Flexural behavior of RC beams strengthened with BFRP bars-reinforced ECC matrix[J]. Composite Structures, 2020, 241: 112092. doi: 10.1016/j.compstruct.2020.112092 [14] 朱忠锋, 王文炜. 玄武岩格栅增强ECC复合材料反复荷载作用下本构关系模型[J]. 南京工业大学学报(自然科学版), 2017, 39(5): 44-50+62.ZHU Zhongfeng, WANG Wenwei. Constitutive model of basalt fiber reinforced polymer grid reinforced engineered cement composite under cyclic loading[J]. JOURNAL OF NANJING TECH UNIVERSITY (Natural Science Edition), 2017, 39(5): 44-50+62(in Chinese). [15] 齐宝欣, 李宜人. PVA-ECC-钢筋复合梁抗冲击的影响因素及破坏特性研究[J]. 沈阳建筑大学学报(自然科学版), 2022, 38(2): 236-244.QI Baoxin, LI Yiren. Influence Factors and Failure Characteristics of Impact Resistance of PVA-ECC-Reinforced Composite Beams[J]. Journal of Shenyang Jianzhu University (Natural Science), 2022, 38(2): 236-244(in Chinese). [16] ZHU J T, ZHANG K, WANG X L, et al. Bond-slip performance between high-strength steel wire rope meshes and engineered cementitious composites[J]. Journal of Materials in Civil Engineering, 2022, 34(5): 04022048. doi: 10.1061/(ASCE)MT.1943-5533.0004184 [17] LI K, WEI Y X, LI Y P, et al. Flexural behavior of reinforced concrete beams strengthened with high-strength stainless steel wire rope meshes reinforced ECC.[J]. Construction and Building Materials, 2023, 362: 129627. doi: 10.1016/j.conbuildmat.2022.129627 [18] LI K, LIU W K, ZHANG K, et al. Bond behavior of stainless steel wire ropes embedded in engineered cementitious composites[J]. Construction and Building Materials, 2021, 281: 122622. doi: 10.1016/j.conbuildmat.2021.122622 [19] WANG X L, YANG G H, QIAN W W, et al. Tensile behavior of high-strength stainless steel wire rope (HSSSWR)-reinforced ECC[J]. International Journal of Concrete Structures and Materials, 2021, 15(1): 43. doi: 10.1186/s40069-021-00480-x [20] 李可, 赵佳丽, 李志强, 等. 高强钢绞线网增强ECC抗弯加固无损RC梁试验[J]. 复合材料学报, 2022, 39(7): 3428-3440.LI Ke, ZHAO Jiali, LI Zhiqiang, et al. Experiment on non-damaged RC beams strengthened by high-strength steel wire strand meshes reinforced ECC in bending[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3428-3440(in Chinese). [21] 李可, 王宇, 李志强, 等. 高强钢绞线网增强ECC加固无损RC梁受弯承载力研究[J]. 建筑结构学报, 2022, 43(12): 82-90.LI Ke, WANG Yu, LI Zhiqiang, et al. Research on flexural bearing capacity of non-damaged RC beams strengthened by high-strength steel wire strand mesh-reinforced ECC[J]. Journal of Building Structures, 2022, 43(12): 82-90(in Chinese). [22] YUAN F, CHEN M C, PAN J L. Flexural strengthening of reinforced concrete beams with high-strength steel wire and engineered cementitious composites[J]. Construction and Building Materials, 2020, 254: 119284. doi: 10.1016/j.conbuildmat.2020.119284 [23] 中华人民共和国住房和城乡建设部. (GB50010-2010)混凝土结构设计规范(2015年版)[S]. 北京: 中国建筑工业出版社, 2016.Ministry of housing and urban rural development of the People’s Republic of China. (GB50010-2010) Code for design of concrete structures (2015) [S]. Beijing: China Building Industry Press, 2016 (in Chinese). [24] 钱文文. 高强不锈钢绞线网增强ECC拉伸和弯曲性能试验及理论研究[D]. 郑州: 郑州大学, 2018.QIAN Wenwen. Experimental and Theoretical Research on Tensile and Flexural Properties of High Strength Stainless Steel Strand Mesh Reinforced ECC[D]. Zhengzhou: Zhengzhou University, 2018. (in Chinese). [25] 刘伟康. ECC受压和受拉性能及本构模型研究[D]. 郑州大学, 2018.LIU Weikang. Study on the compression and tensile properties and the constitutive model of ECC [D]. Zheng zhou University, 2018. (in Chinese). [26] 李志强. 高强钢绞线网/ECC加固无损伤RC梁受弯性能研究[D]. 郑州: 郑州大学, 2021.LI Zhiqiang. Study on The Bending Performance of Non-damaged RC Beams Strengthened by High-strength Steel Wire Mesh Reinforced ECC[D]. Zhengzhou: Zhengzhou University, 2021. (in Chinese). [27] LIU X, JIANG Z J, YUAN Y, et al. Numerical investigation of the mechanical behavior of deformed segmental tunnel linings, strengthened by epoxy-bonded filament wound profiles[J]. Tunnelling and Underground Space Technology, 2018, 78: 231-244. doi: 10.1016/j.tust.2018.04.033 -

点击查看大图

点击查看大图

计量

- 文章访问数: 51

- HTML全文浏览量: 41

- 被引次数: 0

下载:

下载: