Effect of matrix modification on the properties of continuous glass fiber reinforced nylon composites

-

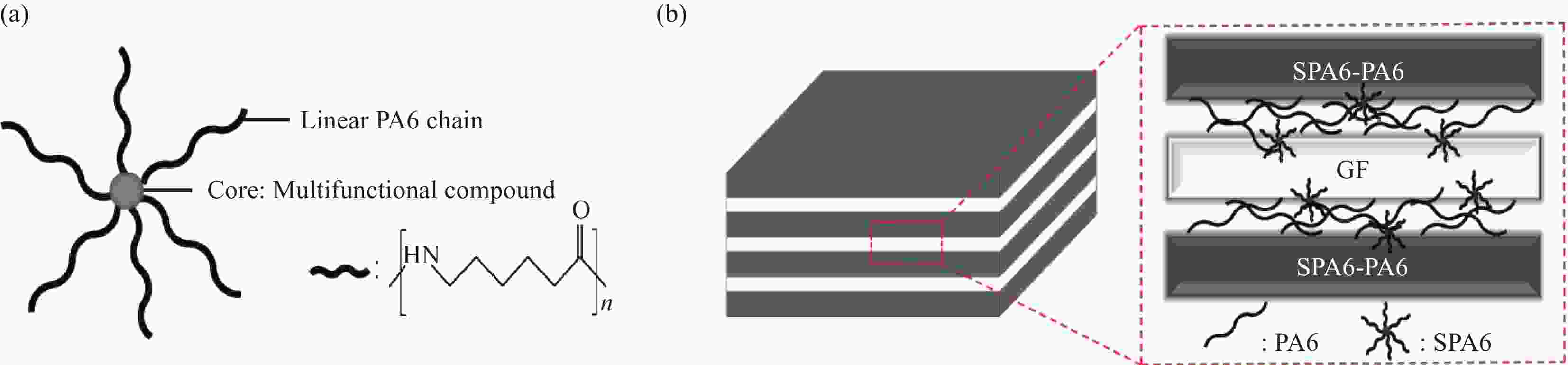

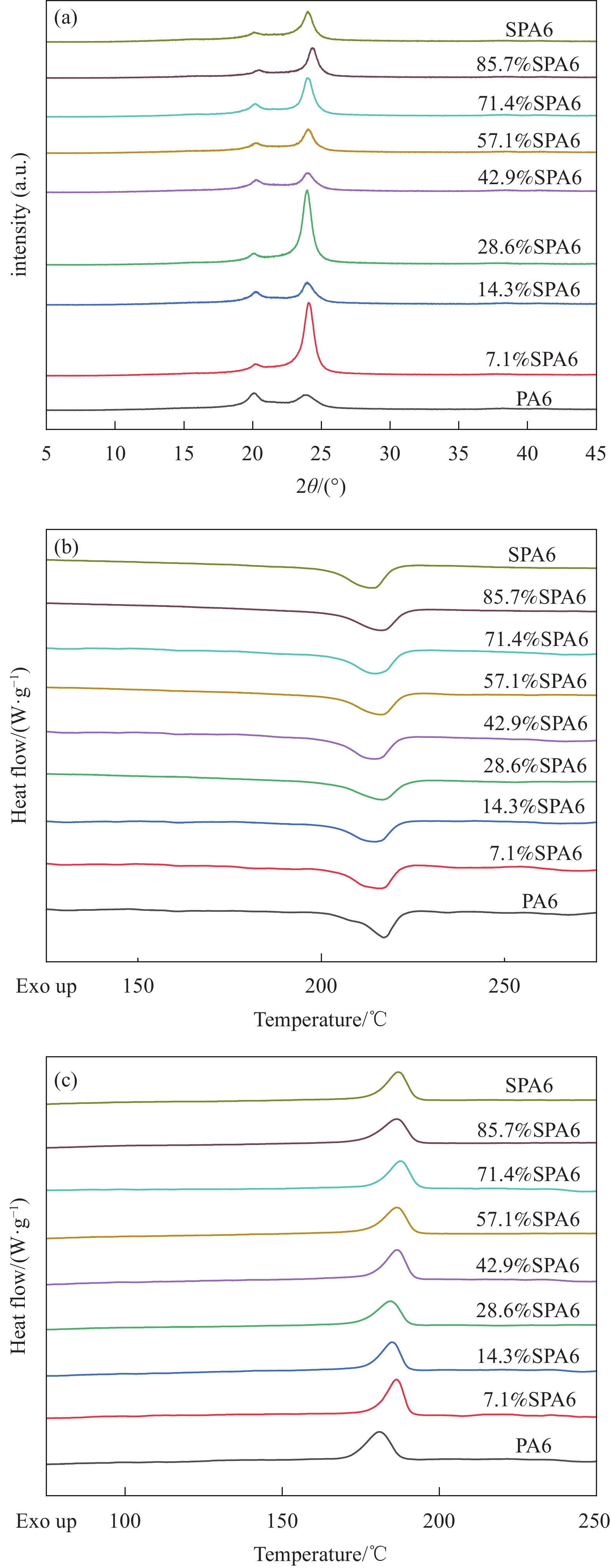

摘要: 提升连续玻璃纤维(cGF)增强尼龙6复合材料(cGF/PA6)力学性能的重要途径之一是改善玻纤与尼龙之间的界面结合。本研究将星形支化聚酰胺6(SPA6)应用于cGF/PA6复合材料体系,采用熔融挤出结合热压成型法制备了不同含量SPA6的连续玻璃纤维增强尼龙复合材料(cGF/PA6-SPA6)。通过接触角实验测得SPA6与cGF 具有更相近的极性。DSC检测结果表明PA6与SPA6共混后基体熔融温度相差不大、结晶温度和结晶度有所提高。三点弯曲法测得PA6-SPA6基体的弯曲强度相对于PA6和 SPA6有所降低,但cGF/5wt.%SPA6和cGF/10wt.%SPA6复合材料的弯曲强度相对于cGF/PA6分别提高了4.9%和6.4%。短梁剪切试验测得cGF/5wt.%SPA6和cGF/10wt.%SPA6复合材料的层间剪切强度相对于cGF/PA6分别提高了16.7%和15.6%。悬臂梁摆锤冲击实验测得cGF/PA6和cGF/SPA6复合材料的冲击强度分别是PA6和 SPA6的12倍和26.3倍。结合冲击断口形貌观察,可以推断在cGF/PA6复合材料中加入5wt.%或10wt.%的SPA6可以提高复合材料的弯曲和剪切强度,而对其冲击强度影响不大,且成本较低,具有一定的应用价值。Abstract: One of the important ways to improve the mechanical properties of continuous glass fiber (cGF) reinforced nylon 6 composites (cGF/PA6) is to improve the interface interactions between glass fiber and nylon 6. In this study, star-branched polyamide 6 (SPA6) was applied to cGF/PA6 composite system, and continuous glass fiber reinforced nylon composites with different contents of SPA6 (cGF/PA6-SPA6) were prepared by melt extrusion combined with hot pressing. The characterization of Contact Angle indicates that the polarity between SPA6 and cGF is more similar. DSC results show that there is not much difference in the melting temperature among PA6, SPA6 and PA6-SPA6 composite matrix, and both the crystallization temperature and crystallinity of PA6-SPA6 are increased. The flexural strength of PA6-SPA6 matrix is lower than that of PA6 and SPA6 measured by three-point flexural tests. However, compared with cGF/70wt.%PA6, the flexural strength of cGF/5wt.%SPA6 and cGF/10wt.%SPA6 composites increased by 4.9% and 6.4%, respectively, and the shearing strength of cGF/5wt.%SPA6 and cGF/10wt.%SPA6 composites increased by 16.7% and 15.6%, respectively. The impact strength of cGF/PA6 and cGF/SPA6 composites is 12 times and 26.3 times that of PA6 and SPA6, respectively. Combined with the observation of impact fracture morphology, it can be inferred that adding 5wt.% or 10wt.% SPA6 to cGF/PA6 composites can improve the flexural and shearing strength of the composites, while having little influence on the impact strength, and considering its cost-effectiveness, it proves to be of practical value for applications.

-

Key words:

- Nylon 6 /

- Star-branched nylon 6 /

- Nylon composites /

- Continuous glass fiber /

- Mechanical property

-

图 2 弯曲强度:(a) cGF/PA6-SPA6复合材料;(c) PA6-SPA6基体;层间剪切强度:(b) cGF/PA6-SPA6复合材料;(d) PA6-SPA6基体;(e) cGF/PA6、cGF/5wt.%SPA6复合材料载荷位移曲线

Figure 2. Flexural strength: (a) cGF/PA6-SPA6 composites; (c) PA6-SPA6 matrices; Interlamellar shearing strength: (b) cGF/PA6-SPA6 composites; (d) PA6-SPA6 matrices; (e) Load displacement curves of cGF/PA6 and cGF/5wt.%SPA6 composites

图 6 PA基复合材料宏观断口形貌:(a) cGF/PA6;(b) cGF/SPA6;PA基复合材料冲击断口形貌SEM图:(c) cGF/PA6;(d) cGF/SPA6;(e) cGF/50wt.%SPA6;(f) cGF/60wt.%SPA6

Figure 6. Macroscopic fracture morphology of PA composites: (a) cGF/PA6; (b) cGF/SPA6; SEM image of impact fracture morphology of PA composites: (c) cGF/PA6; (d) cGF/SPA6; (e) cGF/50wt.%SPA6; (f) cGF/60wt.%SPA6

Probe liquid $ {\gamma }_{\mathrm{L}\mathrm{V}} $/(mN·m−1) $ {\gamma }_{\mathrm{L}\mathrm{V}}^{\mathrm{d}} $/(mN·m−1) $ {\gamma }_{\mathrm{L}\mathrm{V}}^{\mathrm{p}} $/(mN·m−1) Water 72.8 21.8 51 Ethylene glycol 48.3 29.3 19 Notes:$ {\gamma }_{\mathrm{L}\mathrm{V}} $,$ {\gamma }_{\mathrm{L}\mathrm{V}}^{\mathrm{d}} $,$ {\gamma }_{\mathrm{L}\mathrm{V}}^{\mathrm{p}} $ are the surface tension, dispersion component, and polarity component of the tested liquid. 表 2 玻璃纤维(GF)、尼龙6(PA6)及星形支化聚酰胺6(SPA6)固体表面能色散分量、极性分量及总表面能

Table 2. Surface energy dispersion component, polarity component and total surface energy of Glass fiber (GF), Nylon 6 (PA6) and Star branched polyamide 6 (SPA6) solids

GF PA6 SPA6 $ {\gamma }_{\mathrm{S}\mathrm{V}}^{\mathrm{d}} $/(mN·m−1) 0.03 1.74 0.85 $ {\gamma }_{\mathrm{S}\mathrm{V}}^{\mathrm{p}} $/(mN·m−1) 90.82 35.05 39.56 $ {\gamma }_{SV} $/(mN·m−1) 90.85 36.79 40.41 表 3 PA6-SPA6试样名称和组成

Table 3. Name and composition of PA6-SPA6 samples

Sample name Sample composition/wt.% SPA6 PA6 7.1%SPA6 5 65 14.3%SPA6 10 60 28.6%SPA6 20 50 42.9%SPA6 30 40 57.1%SPA6 40 30 71.4%SPA6 50 20 85.7%SPA6 60 10 表 4 PA6-SPA6基体XRD参数

Table 4. XRD parameters of PA6-SPA6 matrix

Sample name α1(2θ)/(º) α2(2θ)/(º) Crystallinity/% PA6 20.10 23.88 27.8 7.1%SPA6 20.14 24.04 48.2 14.3%SPA6 20.26 24.00 32 28.6%SPA6 20.20 23.92 47.9 42.9%SPA6 20.21 24.04 30.1 57.1%SPA6 20.32 24.08 31.6 71.4%SPA6 20.12 23.92 37.8 85.7%SPA6 20.46 24.40 36.9 SPA6 20.12 24.00 32.8 Notes:α1 is the diffraction peak of PA6 (200) and (002) crystal planes, α2 is the diffraction peak of PA6 (202) crystal plane. 表 5 DSC二次升温曲线所测PA6-SPA6基体热性能

Table 5. Thermal properties of PA6-SPA6 matrix from DSC second heating curve

Sample Tm/℃ Tc/℃ ∆Hm/(J·g−1) Crystallinity /% PA6 217.56 180.14 52.31 27.5 7.1%SPA6 216.4 185.52 65.17 34.3 14.3%SPA6 215.06 184.06 55.61 29.3 28.6%SPA6 217.17 183.72 53.97 28.4 42.9%SPA6 215.04 185.69 60.37 31.8 57.1%SPA6 217.2 185.67 59.73 31.4 71.4%SPA6 215.08 186.75 68.9 36.3 85.7%SPA6 217.19 185.68 60.25 31.7 SPA6 215.85 187.17 70.74 37.2 Notes:Tm, Tc, and ∆Hm are the melting temperature, crystallization temperature, and fusion enthalpy of each sample. -

[1] ZHENG J, SIEGEL R W, TONEY C G. Polymer crystalline structure and morphology changes in nylon-6/ZnO nanocomposites[J]. Journal of Polymer Science Part B Polymer Physics, 2003, 41(10): 1033-1050. doi: 10.1002/polb.10452 [2] STEFAN N, STEFAN E, CHRISTIAN B, et al. Polymerization of ε-Caprolactam by Latent Precatalysts Based on Protected N-Heterocyclic Carbenes[J]. ACS Macro Letters, 2013, 2(7): 609-612. doi: 10.1021/mz400199y [3] ZHANG C, TJIU W W, LIU T, et al. Dramatically Enhanced Mechanical Performance of Nylon-6 Magnetic Composites with Nanostructured Hybrid One-Dimensional Carbon Nanotube Two-Dimensional Clay Nanoplatelet Heterostructures[J]. Journal of Physical Chemistry B, 2011, 115(13): 3392-3399. doi: 10.1021/jp112284k [4] TUNA B, BENKREIRA H. Reactive Extrusion of Polyamide 6 Using a Novel Chain Extender[J]. Polymer Engineering & Science, 2019, 59(s2): E25-E31. [5] WANG Y, HOU D-F, KE K, et al. Chemical-resistant polyamide 6/polyketone composites with gradient encapsulation structure: An insight into the formation mechanism[J]. Polymer, 2021, 212(1): 123173. [6] ZHANG T, KANG H-J. Enhancement of the Processability and Properties of Nylon 6 by Blending with Polyketone[J]. Polymers, 2021, 13(19): 3403-3418. doi: 10.3390/polym13193403 [7] TUNA B, BENKREIRA H. Chain extension of recycled PA6[J]. Polymer Engineering & Science, 2017, 58(7): 1037-1042. [8] PRASHANTH S, SUBBAYA KM, NITHIN K et al. Fiber Reinforced Composites-A Review[J]. Journal of Material Science & Engineering, 2017, 06(03): 1000341. [9] DRYZEK E, WRóBEL M, JUSZYŃSKA-GAŁĄZKA E. Free-Volume and Tensile Properties of Glass Fibre Reinforced Polyamide 6 Composites[J]. Acta Physica Polonica A, 2017, 132(5): 1501-1505. doi: 10.12693/APhysPolA.132.1501 [10] LI X, WANG X, YANG L, et al. Synergistic effect of polyfunctional silane coupling agent and styrene acrylonitrile copolymer on the water-resistant and mechanical performances of glass fiber-reinforced polyamide 6[J]. Polymers for Advanced Technologies, 2019, 30(8): 1951-1958. doi: 10.1002/pat.4627 [11] YáñEZ-MACíAS R, RIVERA-SALINAS J E, SOLíS-ROSALES S, et al. Mechanical behavior of glass fiber-reinforced Nylon-6 syntactic foams and its Young's modulus numerical study[J]. Journal of Applied Polymer Science, 2021, 138(27): 50648. doi: 10.1002/app.50648 [12] CHEN K, JIA M, SUN H, et al. Thermoplastic Reaction Injection Pultrusion for Continuous Glass Fiber-Reinforced Polyamide-6 Composites[J]. Materials, 2019, 12(3): 463. doi: 10.3390/ma12030463 [13] CAMINERO M A, CHACóN J M, GARCíA-MORENO I, et al. Interlaminar bonding performance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling[J]. Polymer Testing, 2018, 68: 415-423. doi: 10.1016/j.polymertesting.2018.04.038 [14] LUKE S S, SOARES D, MARSHALL J V, et al. Effect of fiber content and fiber orientation on mechanical behavior of fused filament fabricated continuous-glass-fiber-reinforced nylon[J]. Rapid Prototyping Journal, 2021, 27(7): 1346-1354. doi: 10.1108/RPJ-01-2021-0003 [15] WANG C, ZHANG Y, YI Y, et al. Thermal, morphological and mechanical properties of glass fiber reinforced star-branched polyamide 6[J]. Polymer Composites, 2022, 43(3): 1617-1625. doi: 10.1002/pc.26482 [16] NúñEZ CARRERO K C, HERRERO M, ASENSIO M, et al. Star-Branched Polyamides as the Matrix in Thermoplastic Composites[J]. Polymers, 2022, 14(5): 942. doi: 10.3390/polym14050942 [17] REN J M, MCKENZIE T G, FU Q, et al. Star Polymers[J]. Chemical Reviews, 2016, 116(12): 6743-6836. doi: 10.1021/acs.chemrev.6b00008 [18] WAN J, LI C, FAN H, et al. Elucidating isothermal crystallization behaviors of nylon-11s. Influence of star-chain branching[J]. Thermochimica Acta, 2012, 544: 99-104. doi: 10.1016/j.tca.2012.06.023 [19] MARTINO L, BASILISSI L, FARINA H, et al. Bio-based polyamide 11: Synthesis, rheology and solid-state properties of star structures[J]. European Polymer Journal, 2014, 59: 69-77. doi: 10.1016/j.eurpolymj.2014.07.012 [20] STEEMAN P, NIJENHUIS A. The effect of random branching on the balance between flow and mechanical properties of polyamide-6[J]. Polymer, 2010, 51(12): 2700-2707. doi: 10.1016/j.polymer.2010.04.017 [21] FU P, WANG M, LIU M, et al. Preparation and characterization of star-shaped nylon 6 with high flowability[J]. Journal of Polymer Research, 2010, 18(4): 651-657. [22] SCHAEFGEN J R, FLORY P J. Synthesis of Multichain Polymers and Investigation of their Viscosities1[J]. Journal of the American Chemical Society, 1948, 70(8): 2709-2718. doi: 10.1021/ja01188a026 [23] ZHU N, GONG H, HAN W, et al. Synthesis and characterization of star-branched polyamide 6 via anionic ring-opening polymerization with N, N′, N″-trimesoyltricaprolactam as a multifunctional activator[J]. Chinese Chemical Letters, 2015, 26(11): 1389-1392. doi: 10.1016/j.cclet.2015.06.005 [24] WANG C, HU F, YANG K, et al. Synthesis and properties of star-branched nylon 6 with hexafunctional cyclotriphosphazene core[J]. RSC Advances, 2015, 5(107): 88382-88391. doi: 10.1039/C5RA15598C [25] American Society for Testing and Material. Standard test method for flexural properties of polymer matrix composite material: ASTM D7264-07[S]. Pennsylvania, United States: ASTM International, 2007 . [26] American Society for Testing and Materials. Standard test method for short-beam strength of polymer matrix composite materials and their laminates: ASTM D2344—16[S]. West Conshohocken, United States: American Society for Testing and Materials International, 2016. [27] American Society for Testing and Materials. Standard test methods for determining the lzod pendulum impact resistance of plastics: ASTM D256—10[S]. West Conshohocken, United States: American Society for Testing and Materials International, 2018. [28] 中国国家标准化管理委员会. 热塑性塑料熔体质量流动速率和熔体体积流动速率的测定: GB/T 3682—2000[S]. 北京: 中国标准出版社, 2000Standardization Administration of China. Determination of the melt mass-flow rate (MFR) and the melt volume-flow rate (MVR) of thermoplastics: GB/T 3682—2000[S]. Beijing: Standards Press of China, 2000(in Chinese). [29] 中国国家标准化管理委员会. 纤维级聚己内酰胺(PA6)切片试验方法: GB/T 38138—2019[S]. 北京: 中国标准出版社, 2019.Standardization Administration of China. Test methods of fiber grade polycaprolactam (PA6) chip: GB/T 38138—2019[S]. Beijing: Standards Press of China, 2019(in Chinese). [30] CANTIN S, BOUTEAU M, BENHABIB F, et al. Surface free energy evaluation of well-ordered Langmuir–Blodgett surfaces[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2006, 276(1-3): 107-115. [31] YOUNG T. Thomas young-an essay on the cohesion of fluids pdf.[J]. Philosophical Transactions of the Royal Society of London, 1805, 95: 65-87. doi: 10.1098/rstl.1805.0005 [32] ZISMAN W A. Relation of the Equilibrium Contact Angle to Liquid and Solid Constitution[J]. advances in chemistry, 1964, 43(1): 1-51 [33] 杨浩邈, 黄鹏, 吴鹏, et al. 玻璃纤维表面能及其与不同树脂体系的润湿特性[J]. 机械工程材料, 2014, 38(10): 50-53.YANG Haomiao, HUANG Peng, WU Peng, et al. Surface energy of glass fiber and its wetting properties with different resin systems[J]. Materials For Machanical Engineering, 2014, 38(10): 50-53(in Chinese). [34] 张永, 周华龙, 王丰, et al. 尼龙66与尼龙6及其共混物的熔融与结晶行为[J]. 工程塑料应用, 2015, 43(6): 86-89. doi: 10.3969/j.issn.1001-3539.2015.06.020ZHANG Yong, ZHOU Hualong, WANG Feng, et al. Melting and crystallization behavior of nylon 66 and nylon 6 and their blends[J]. Engineering Plastics Application, 2015, 43(6): 86-89(in Chinese). doi: 10.3969/j.issn.1001-3539.2015.06.020 [35] 李向阳, 张鸿宇, 王晨, et al. 成核剂对尼龙6结晶与性能的影响[J]. 塑料, 2020, 49(6): 13-15.Li Xiangyang, ZHANG Hongyu, WANGChen, et al. Effect of nucleating agent on crystallization and properties of nylon 6[J]. Plastics, 2020, 49(6): 13-15(in Chinese). [36] XIE W, JIANG N, GAN Z. Effects of Multi-Arm Structure on Crystallization and Biodegradation of Star-Shaped Poly(ε-caprolactone)[J]. Macromolecular Bioscience, 2008, 8(8): 775-784. doi: 10.1002/mabi.200800011 -

下载:

下载: