Study on the evolution of pore structure of manufactured aggregate concrete under sulfate freeze-thaw based on nuclear magnetic resonance technology

-

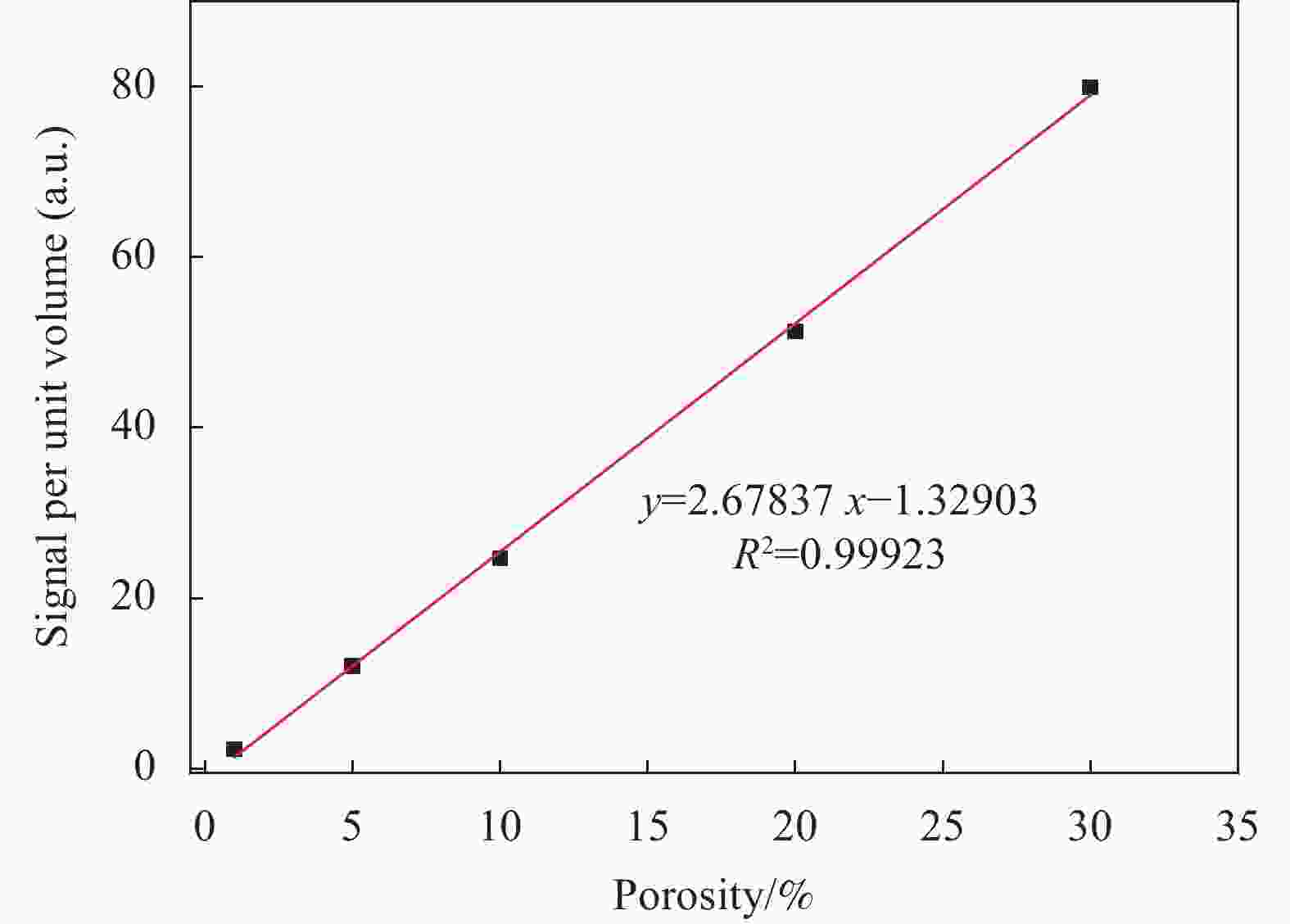

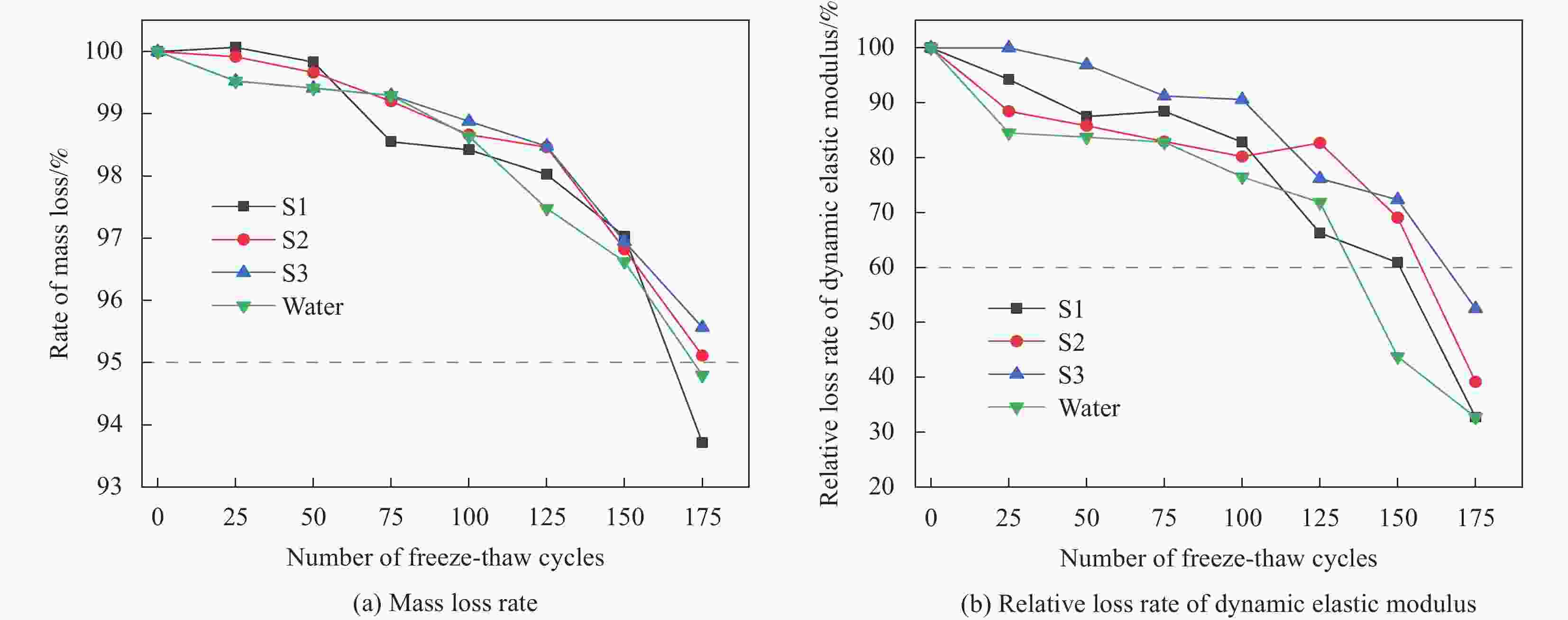

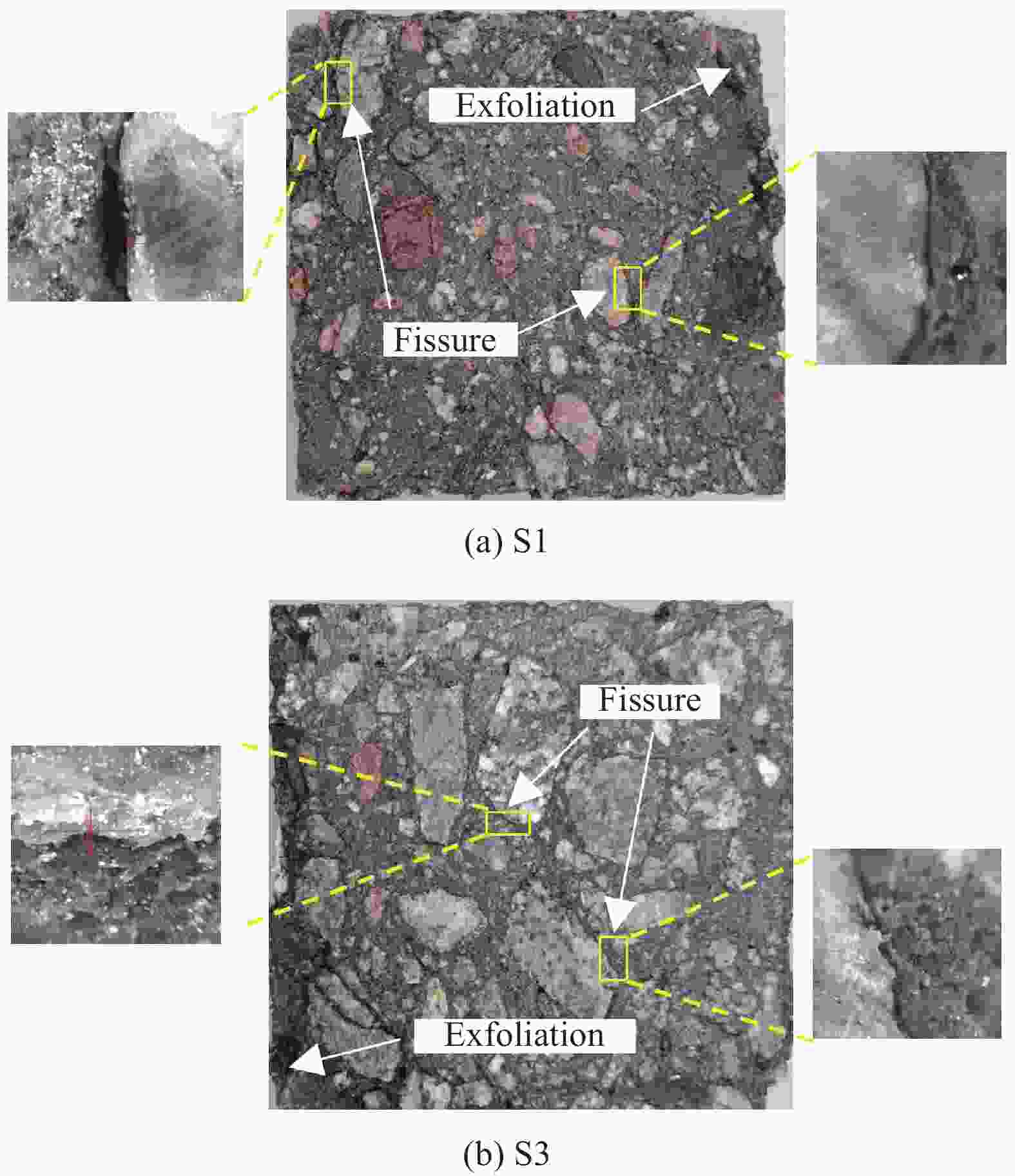

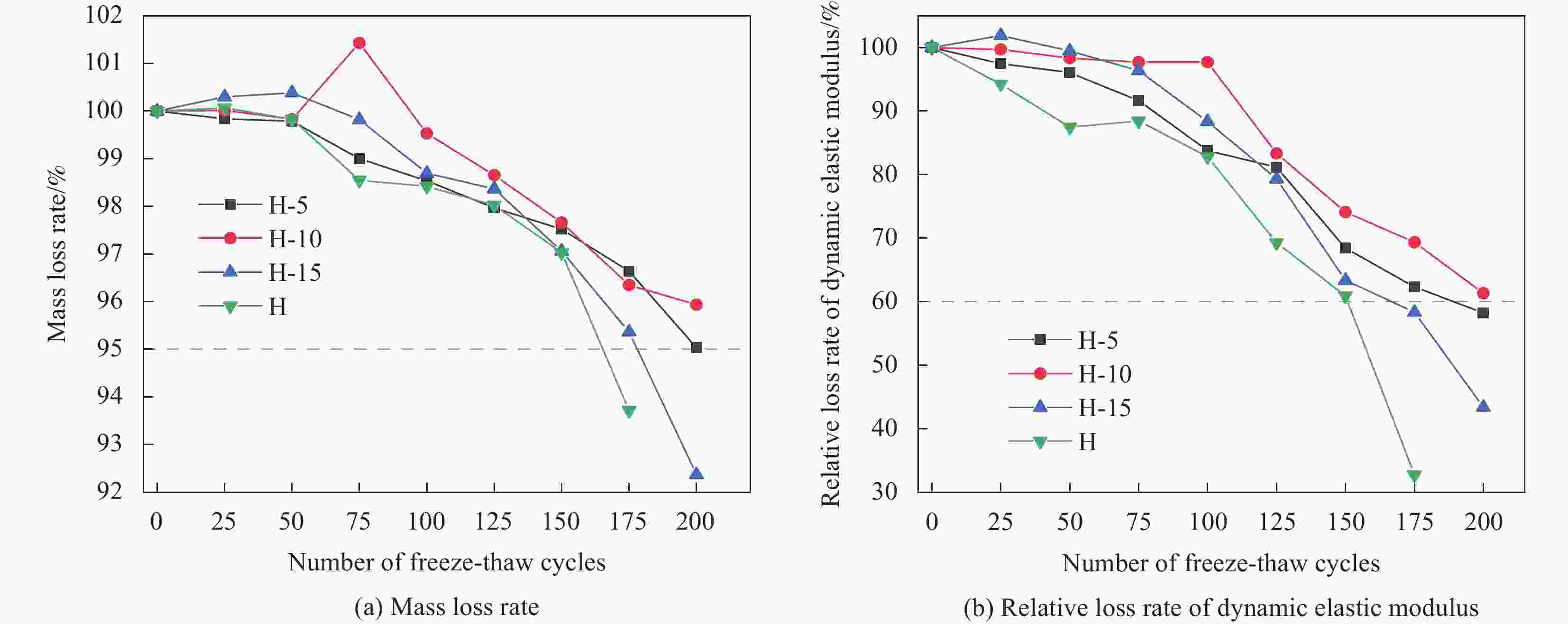

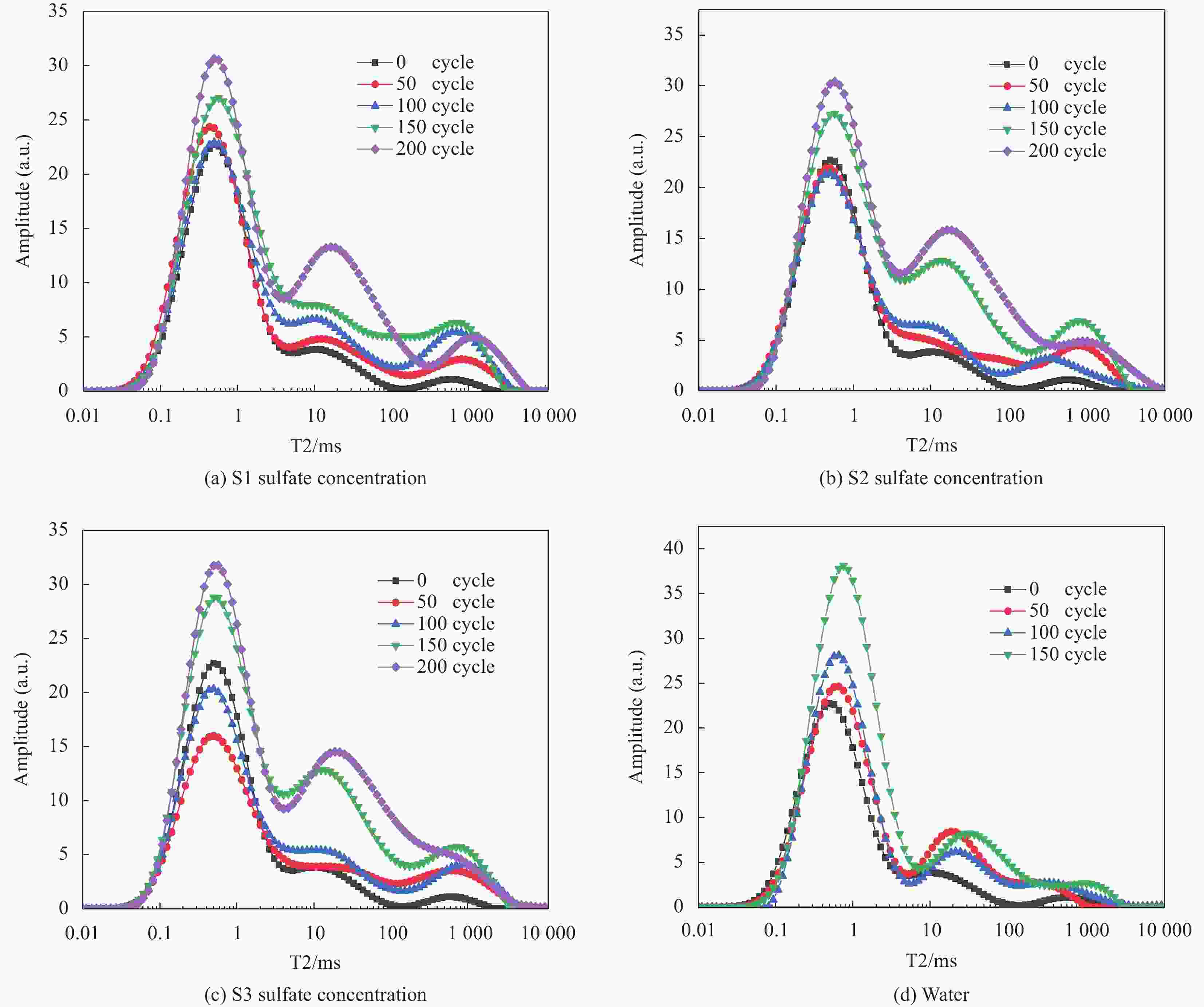

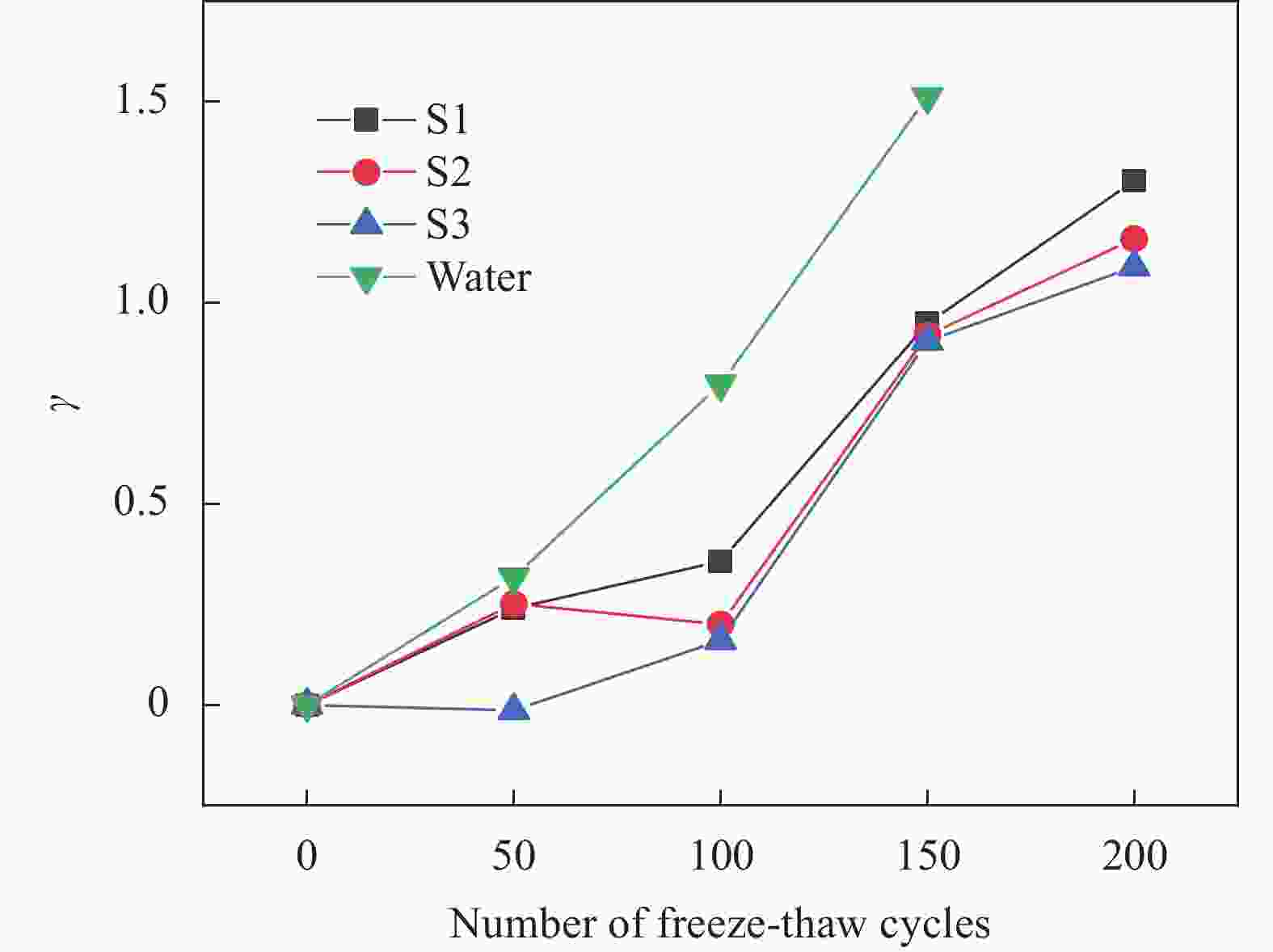

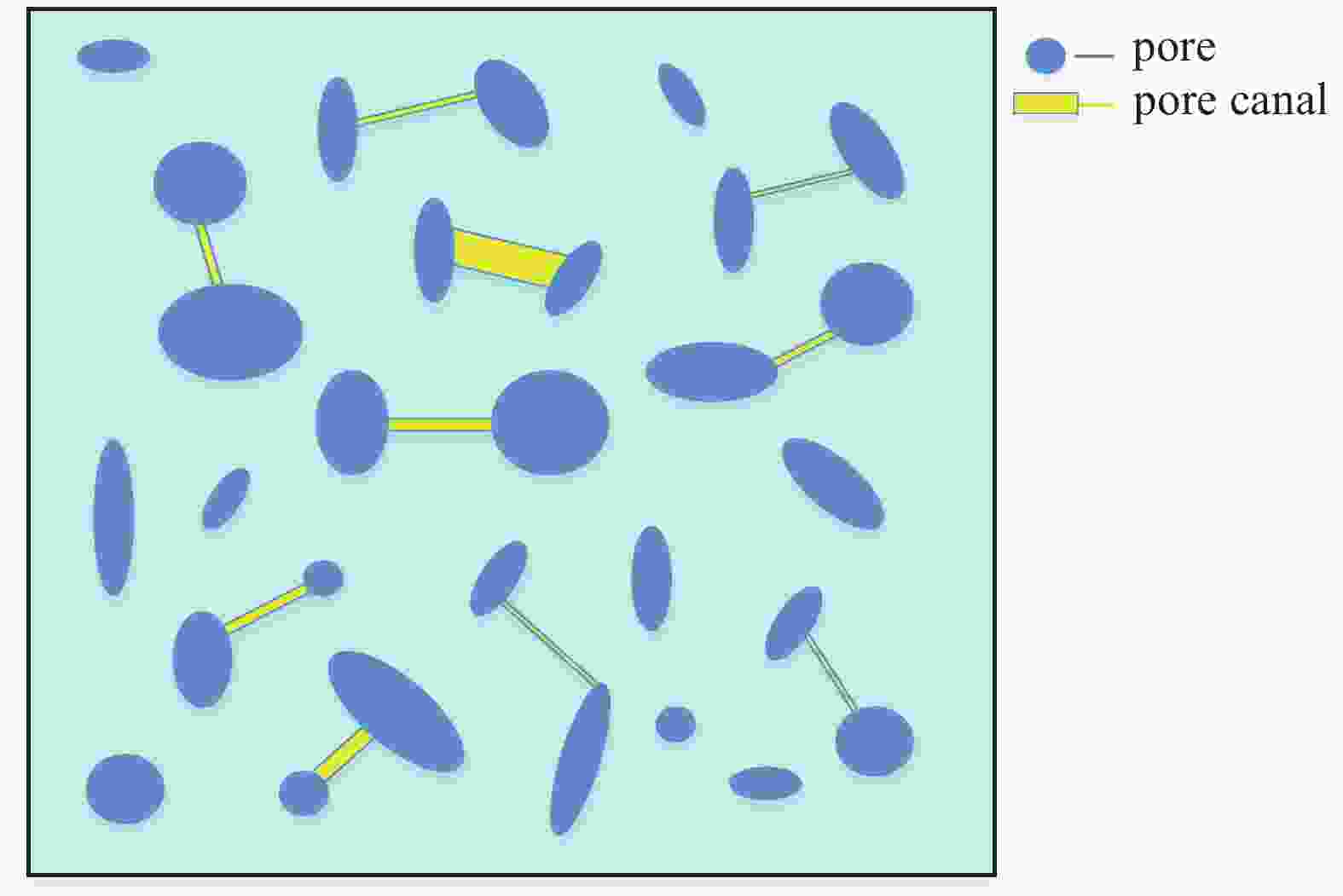

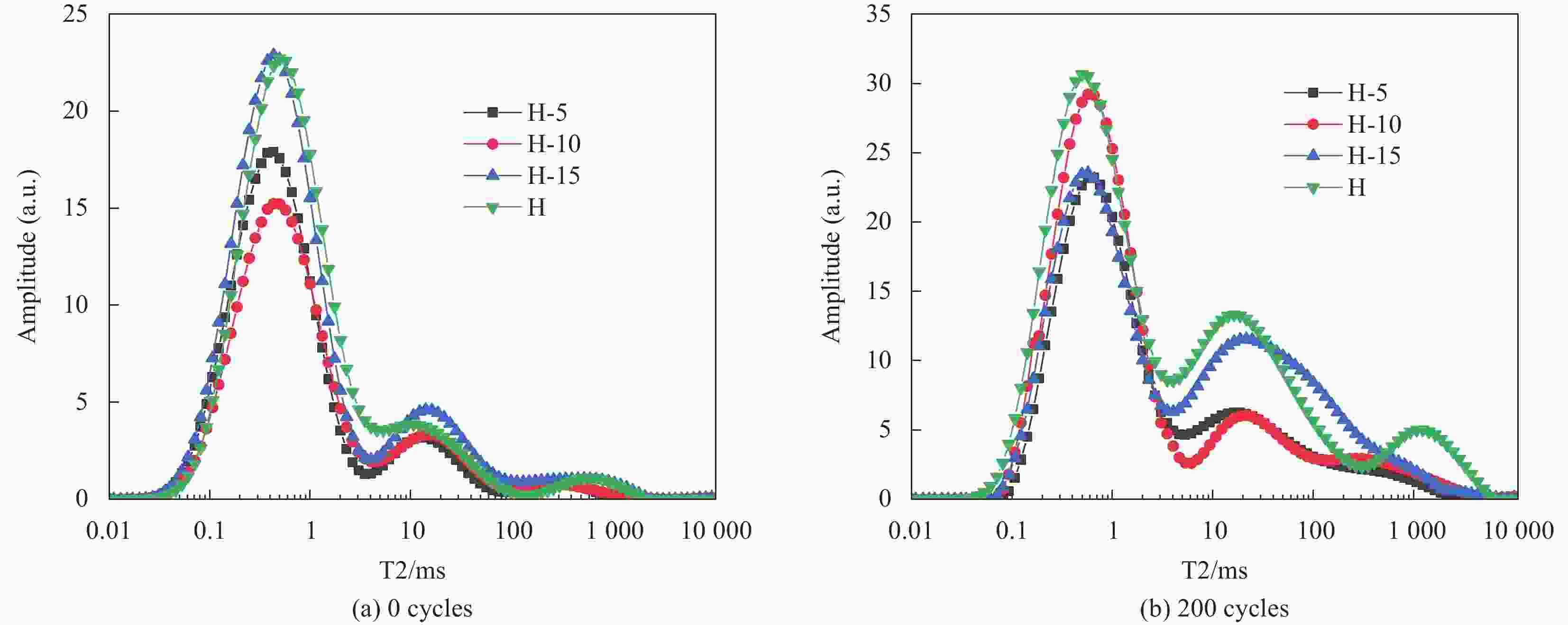

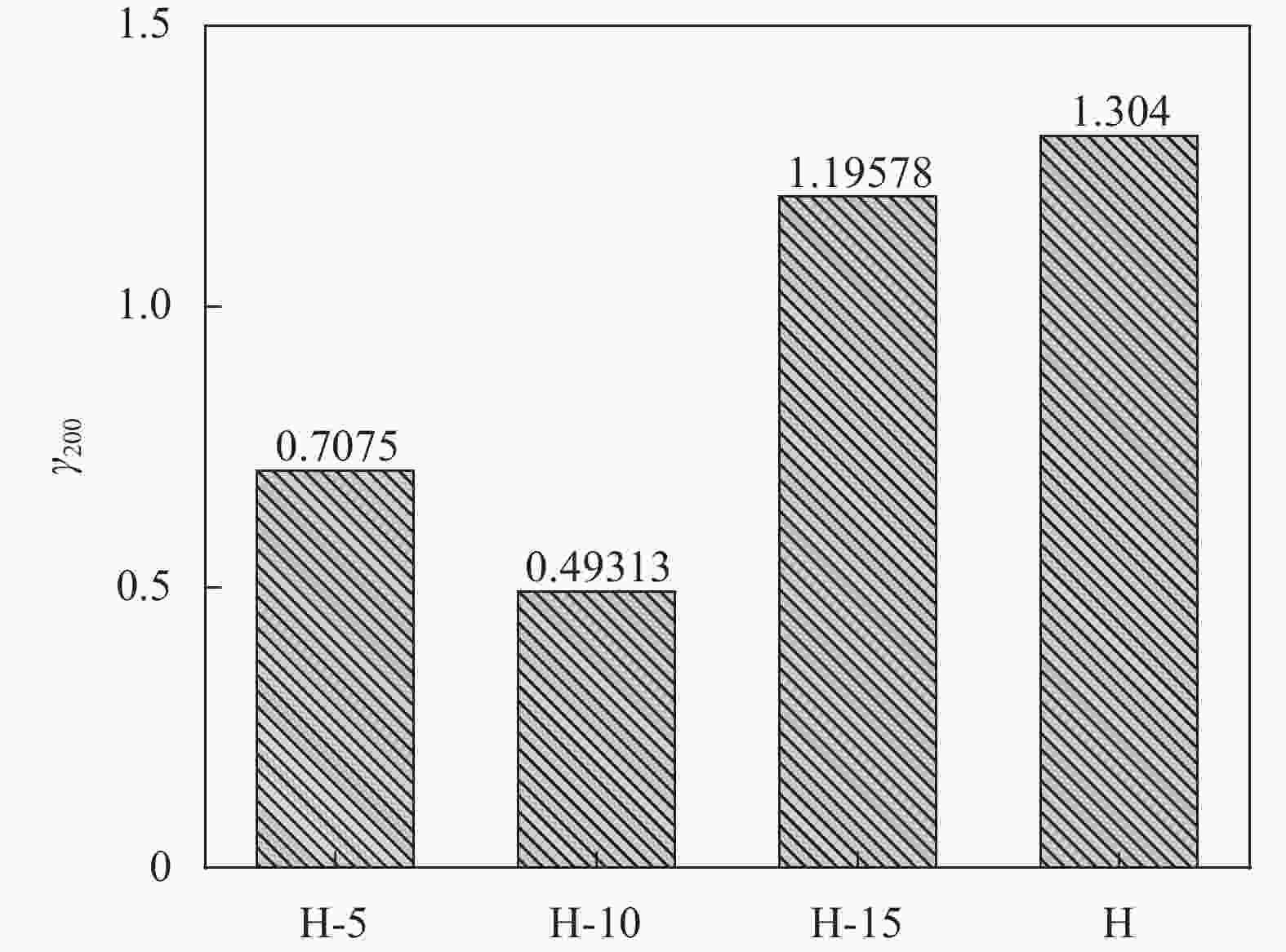

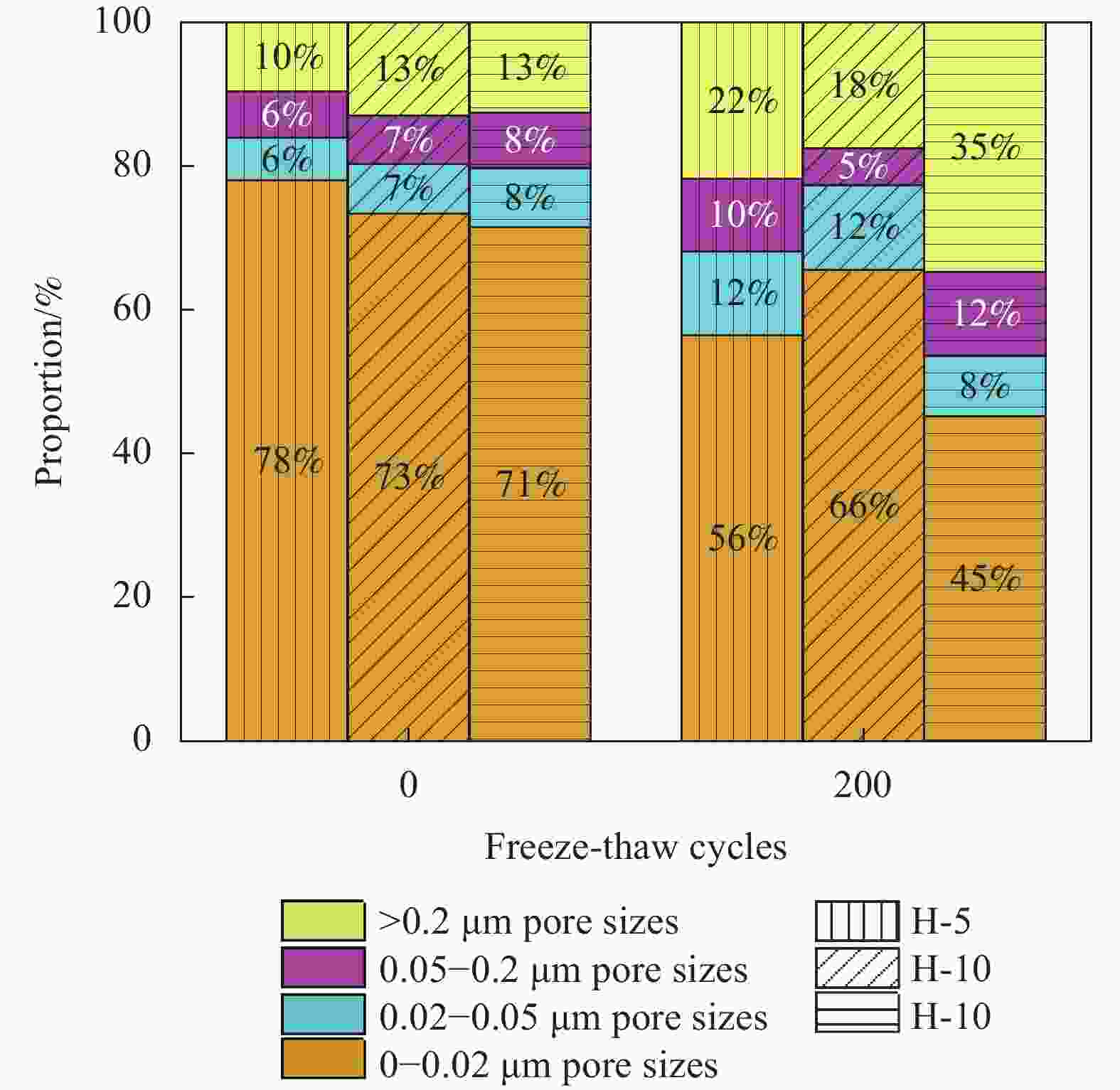

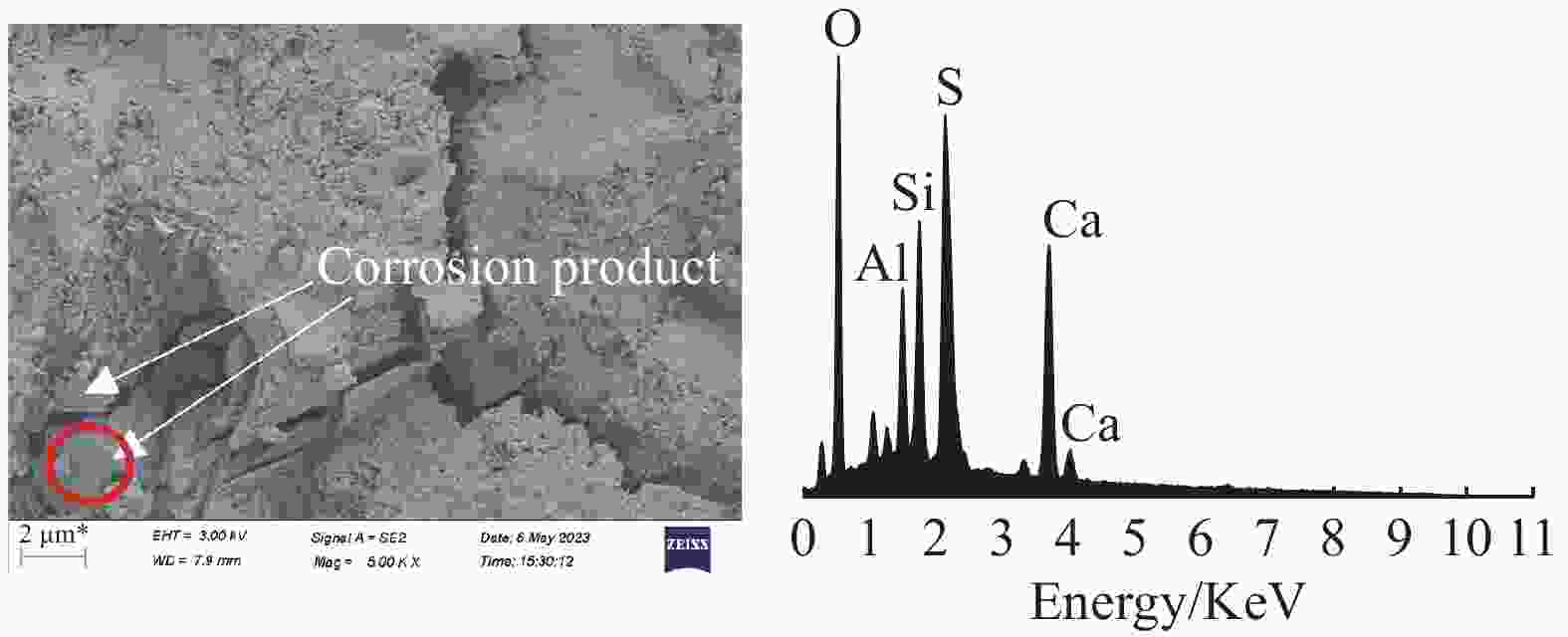

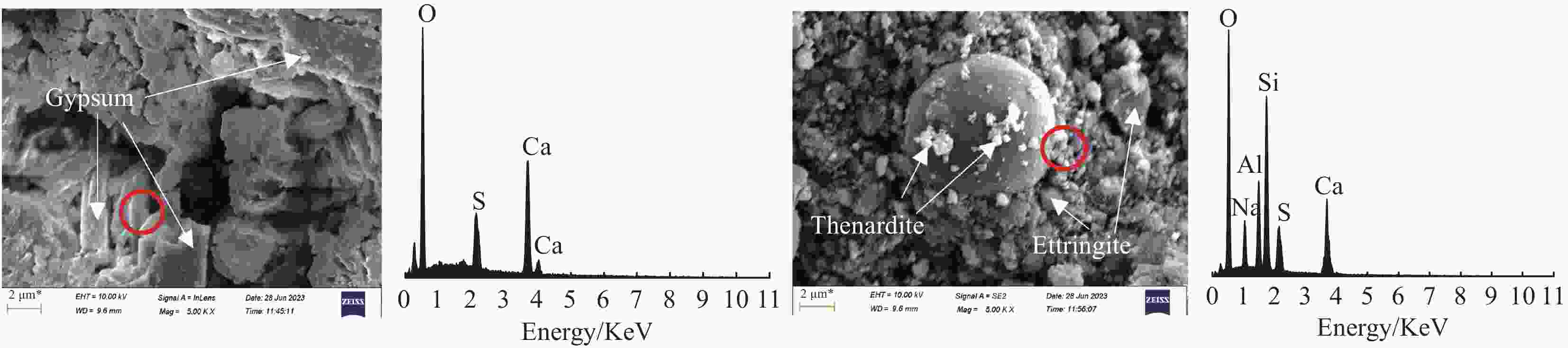

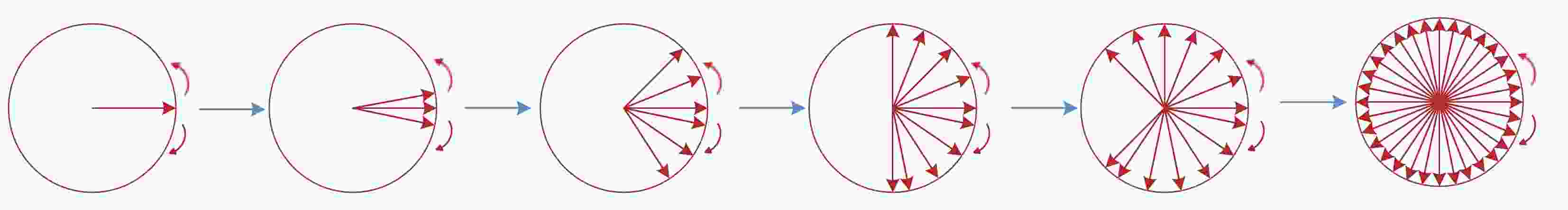

摘要: 我国西北地区昼夜温差大且存在大量盐渍土环境,因此西北地区的大量建筑无法避免的受到硫酸盐与冻融的耦合作用,使结构内部产生大量孔隙并最终导致其损伤失效。本文采用核磁共振(Nuclear Magnetic Resonance,NMR)对硫酸盐与冻融耦合作用下机制骨料混凝土的孔径分布和孔隙率等孔结构参数进行分析,并探究了硫酸盐浓度、冻融循环次数以及石粉掺量对机制骨料混凝土孔结构的影响规律。结果表明:硫酸盐降低了机制骨料混凝土的冻融劣化速率,随着硫酸盐浓度的增加降低效果更显著;机制骨料混凝土的孔隙率随冻融循环次数增加而增大;机制骨料混凝土孔隙率随着石粉掺量的增多呈现先减小后增大,当石粉掺量控制在10%左右时具有最佳的孔结构;硫酸盐冻融的耦合作用下的化学侵蚀产物除了钙矾石和石膏外还存在无水芒硝,但是低温抑制了硫酸盐的化学侵蚀使得物理侵蚀占据主导作用。Abstract: There is a large temperature difference between day and night in the northwest region of China and there is a large amount of saline soil environment. Therefore, a large number of buildings in the northwest region are inevitably subjected to the coupling effect of sulfate and freeze-thaw, resulting in a large number of pores inside the structure and ultimately leading to its damage and failure. Nuclear Magnetic Resonance (NMR) was used to analyze the pore size distribution, porosity and other pore structure parameters of manufactured aggregate concrete under the coupling effect of sulfate and freeze-thaw, and the influences of sulfate concentration, freeze-thaw cycles and stone powder content on the pore structure of manufactured aggregate concrete were explored. The results show that sulfate reduces the freeze-thaw deterioration rate of the mechanism aggregate concrete, and the deterioration effect is more significant with the increase of sulfate concentration. The porosity of machine-made aggregate concrete increases with the increase of freeze-thaw cycles. The porosity of mechanism aggregate concrete decreases first and then increases with the increase of stone powder content. It has the best pore structure when the content of stone powder is controlled at about 10%. In addition to ettringite and gypsum, there is also anhydrous mirabilite in the chemical erosion products under the coupling effect of sulfate freeze-thaw, but the low temperature inhibits the chemical erosion of sulfate and makes physical erosion dominant.

-

表 1 机制骨料混凝土配合比(kg/m3)

Table 1. Mix proportion of manufactured aggregate concrete (kg/m3)

Numbering Fly ash Cement Water Powder content Manufactured sand Manufactured gravel Water reducing admixture H 100 320 160 0 765 1015 6 H-5 100 320 160 38 727 1015 6 H-10 100 320 160 77 689 1015 6 H-15 100 320 160 115 651 1015 6 Notes:H is the benchmark group of granite mechanism aggregate concrete ; h-5, H-10 and H-15 are mechanism aggregate concrete with 5%, 10% and 15% mass fraction of stone powder, respectively. 表 2 机制骨料混凝土反演曲线峰面积

Table 2. Peak area of inversion curve of manufactured aggregate concrete

Type of solution 0 cycle 50 cycle 100 cycle 150 cycle 200 cycle S1 452.314 561.025 614.135 881.399 1042.084 S2 452.314 566.348 543.383 868.502 976.961 S3 452.314 456.477 525.213 861.833 945.207 Water 452.314 598.368 813.333 1136.531 - -

[1] TEODURU G. Aggregate - the decisive element in the frost resistance of concrete[C]. Concrete Durability. Katherine and bryant mather international conference, hold at Atlanta, Georfia, USA, 27 APRIL-MAY 1987. [2] TORQUATO S, HASLACH HW. Random Heterogeneous Materials: Microstructure and Macroscopic Properties[J]. Applied Mechanics Reviews, 2002, 55(4): B62-B63. doi: 10.1115/1.1483342 [3] KAI L, GARBOCZI E J, LIU X Y. A quantitative characterization of spatial arrangement of air voids in mortars via X-ray CT and numerical calculations[J]. Construction and Building Materials, 2022, 360: 129550. doi: 10.1016/j.conbuildmat.2022.129550 [4] KOCAB D, KUCHARCZYKOVA B, DANEK P, et al. Destructive and non-destructive assessment of the frost resistance of concrete with different aggregate[J]. IOP Conference Series:Materials Science and Engineering, 2018, 379(1): 012022. [5] KRAUSS P, PARET T. Review of Properties of Concrete, 5th Ed. , by A. M. Neville[J]. Journal of Performance of Constructed Facilities, 2014, 28(3): 630-630. [6] MARIA L N, Ofelia C, Ioan A, et al. Freeze-Thaw Effect on Road Concrete Containing Blast Furnace Slag: NMR Relaxometry Investigations[J]. Materials, 2021, 14(12): 3288. doi: 10.3390/ma14123288 [7] ALIGIZAKI K K. Pore Structure of Cement-Based Materials[M]. Taylor and Francis; CRC Press: 2014-04-21. [8] A. M. Neville. Properties of Concrete[M], Vol. 4, Longman London, 1995. [9] VERBECK, G. J. Hardened Concrete—Pore Structure[S]. ASTM: West Conshohocken, PA, USA, 1955; pp. 136-142. [10] NEVILLE, A. M. Properties of Concrete[M]. Bucharest Technical Publishing House: Bucharest, Romania, 1979. [11] 方小婉, 娄宗科, 高亚磊等. 硫酸盐侵蚀下混凝土抗冻耐久性研究进展[J]. 混凝土, 2019, (12): 6-10+17.FANG Xiaowan, LOU Zongke, GAO Yalei et al. Research progress on frost resistance durability of concrete under sulfate attack[J]. Concrete, 2019, (12): 6-10+17(in Chinese). [12] 苑立冬. 硫酸盐侵蚀与冻融循环共同作用下混凝土耐久性试验研究[D]. 西安建筑科技大学, 2013.WAN Lidong. Experimental Study on the Durability of Concrete under the Combined Action of Sulfate Erosion and Freeze-thaw Cycle. Xi 'an University of Architecture and Technology, 2013. (in Chinese) [13] 余红发. 盐湖地区高性能混凝土的耐久性、机理与使用寿命预测方法[D]. 东南大学, 2007.YU Hongfa. Study on High Performance Concrete in Salt Lake: Durability, Mechanism and Service Life Prediction [D]. Southeast University, 2007. (in Chinese) [14] 王萧萧, 申向东, 王海龙等. 盐蚀-冻融循环作用下天然浮石混凝土的抗冻性[J]. 硅酸盐学报, 2014, 42(11): 1414-1421. doi: 10.7521/j.issn.0454-5648.2014.11.11WANG Xiaoxiao, SHEN Xiangdong, WANG Hailong et al. Frost-Resistance of Natural Pumice Concrete due to Salt Corrosion and Freeze-Thaw Circulation[J]. Journal of the Chinese Ceramics, 2014, 42(11): 1414-1421(in Chinese). doi: 10.7521/j.issn.0454-5648.2014.11.11 [15] 王怀才, 杨建波, 余圣爱等. 冻融盐蚀作用对混凝土耐久性影响研究进展[J]. 青海交通科技, 2019, (03): 118-121. doi: 10.3969/j.issn.1672-6189.2019.03.026WANG Huacai, YANG Jianbo, YU Shengai et al. Research progress on effect of concrete durability in freezing-thawing and salt[J]. Qinghai Transportation Science and Technology, 2019, (03): 118-121(in Chinese). doi: 10.3969/j.issn.1672-6189.2019.03.026 [16] 孙丛涛, 牛荻涛. 混凝土抗盐冻性能试验研究[J]. 硅酸盐通报, 2010, 29(04): 762-767. doi: 10.16552/j.cnki.issn1001-1625.2010.04.041SUN Congtao, NIU Ditao. Experimental Study on Frost-salt Resistance of Concrete[J]. Bulletin of Silicate, 2010, 29(04): 762-767(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2010.04.041 [17] 巴恒静, 李中华, 关辉. 混凝土抗盐冻性能影响因素的研究[J]. 混凝土, 2008, (11): 1-3. doi: 10.3969/j.issn.1002-3550.2008.11.001BA Hengjing, LI Zhonghua, GUAN Hui. Influencing factors of the deicer-salt resistance of the concrete[J]. Concrete, 2008, (11): 1-3(in Chinese). doi: 10.3969/j.issn.1002-3550.2008.11.001 [18] 曹芙波, 黄旭彤, 杨晓刚, 等. 基于复合盐浓度再生混凝土抗冻性能试验研究[J/OL]. 长江科学院院报: 1-9[2023-12-14CAO Fubo, HUANG Xutong, YANG Xiaogang, et al. Frost Resistance of Recycled Aggregate Concrete Based on Multi-Salt Concentrations [J/OL]. Yangtze river proceedings of the national academy of sciences: 1-9 [2023-12-14]. (in Chinese) [19] GUO L, CHUNHUA F, YAJUN L, et al. Effect of Hydrophobic Treatments on Improving the Salt Frost Resistance of Concrete[J]. Materials (Basel, Switzerland), 2020, 13(23): 5361. doi: 10.3390/ma13235361 [20] SARAVANAN S, JAGADEESH P. Strength and durability studies on concrete made with manufactured sand[J]. ARPN Journal of Engineering and Applied Sciences, 2018, 13(16): 4572-4580. [21] Li Y, ZHANG G, YANG J, et al. Investigation of Pore Structure of Lightweight Ultra-High-Performance Concrete under Curing Regimes[J]. ACI Materials Journal, 2022, 119(6): 133-148. [22] ZHANG S, ZHENG S, WANG E, et al. Grey model study on strength and pore structure of self-compacting concrete with different aggregates based on NMR[J]. Journal of Building Engineering, 2023, 64(6355): 105560. [23] Li Y, MA H, WEN L, et al. Influence of pore size distribution on concrete cracking with different AEA content and curing age using acoustic emission and low-field NMR[J]. Journal of Building Engineering, 2022, 58: 105059. doi: 10.1016/j.jobe.2022.105059 [24] MARIA L N, OFELIA C, IOAN A, et al. Freeze-Thaw Effect on Road Concrete Containing Blast Furnace Slag: NMR Relaxometry Investigations[J]. Materials, 2021, 14(12): 3288. doi: 10.3390/ma14123288 [25] 李展, 倪振强, 刘万荣. 养护条件对机制砂混凝土性能影响的研究现状与解决方案[J]. 价值工程, 2023, 42(12): 20-22. doi: 10.3969/j.issn.1006-4311.2023.12.006LI Zhan, NI Zhenqiang, LIU Wanrong. Research Status and Solutions on the Effect of Maintenance Conditions on the Performance of Machine-made Sand Concrete[J]. Value Engineering, 2023, 42(12): 20-22(in Chinese). doi: 10.3969/j.issn.1006-4311.2023.12.006 [26] 于本田, 刘通, 王焕, 等. 机制砂中片状颗粒对水泥胶砂性能的影响[J]. 材料导报, 2021, 35(14): 14058-14064.YU Bentian, LIU Tong, WANG Huan, et al. Properties of Cement Mortar with Flake Particle in Manufactured Sand[J]. Materials Review, 2019, 35(14): 14058-14064. (in Chinese) [27] 王振, 李化建, 黄法礼, 等. 石灰岩机制砂混凝土抗冻性能研究[J]. 建筑材料学报, 2023, 26(05): 516-523+537. doi: 10.3969/j.issn.1007-9629.2023.05.009WANG Zhen, LI Huajian, HUANG Fali, et al. Frost Resistance of Limestone Manufactured Sand Concrete[J]. Journal of Building Materials, 2023, 26(05): 516-523+537(in Chinese). doi: 10.3969/j.issn.1007-9629.2023.05.009 [28] 葛成龙, 周海龙, 陈岩, 等. 不同MB值机制砂混凝土的性能和微观孔隙结构[J]. 硅酸盐通报, 2023, 42(3): 888-897. doi: 10.3969/j.issn.1001-1625.2023.3.gsytb202303014GE Chenglong, ZHOU Hailong, CHEN Yan, et al. Properties and Micro-Pore Structure of Manufactured Sand Concrete with Different MB Values[J]. Journal of silicate bulletin, 2023, 42(3): 888-897(in Chinese). doi: 10.3969/j.issn.1001-1625.2023.3.gsytb202303014 [29] LI S, TANG D, PAN Z, et al. Characterization of the stress sensitivity of pores for different rank coals by nuclear magnetic resonance[J]. Fuel, 2013, 111: 745-754. [30] 中国国家标准化管理委员会. 建设用砂: GB/T 14684—2011[S]. 北京: 中国标准出版社, 2011.Standardization Administration of the People’s Republic of China. Sand for construction: GB/T 14684—2011[S]. Beijing: China Standards Press, 2011(in Chinese). [31] 中国国家标准化管理委员会. 普通混凝土长期性能和耐久性能试验方法标准: GB/T 50082—2009[S]. 北京: 中国标准出版社, 2010.Standardization Administration of the People’s Republic of China. Standard for test methods of long-term performance and durability of ordinary concrete : GB/T 50082—2009[S]. Beijing: China Standards Press, 2010(in Chinese). [32] 杨 耀. 基于核磁共振技术的混凝土干湿—冻融循环破坏研究[D]. 哈尔滨工业大学, 2019.YANG Yao. Research on destruction of concrete under condition of wetting-drying and freezing-thawing cycles based on nuclear magnetic resonance technology [D]. Harbin industrial university, 2019. (in Chinese) [33] 薛慧君. 风蚀区冻融盐蚀环境下风积沙混凝土耐久性损伤劣化机理研究[D]. 内蒙古农业大学, 2018.XUE Huijun. Research on Durability Damage and Deterioration Mechanism of Aeolian Sand Concrete in Freeze-thaw and Salt Corrosion Environment of Wind Erosion Area [D]. Inner Mongolia Agricultural University, 2018. (in Chinese) [34] 薛慧君, 申向东, 邹春霞, 等. 基于NMR的风积沙混凝土冻融孔隙演变研究[J]. 建筑材料学报, 2019, 22(02): 199-205. doi: 10.3969/j.issn.1007-9629.2019.02.006XUE Huijun, SHEN Xiangdong, ZOU Chunxia, et al. Freeze-Thaw Pore Evolution of Aeolian Sand Concrete Based on Nuclear Magnetic Resonance[J]. Journal of Building Materials, 2019, 22(02): 199-205(in Chinese). doi: 10.3969/j.issn.1007-9629.2019.02.006 [35] CHEN J H, LI Y L, ZHOU H et al. Nuclear Magnetic Reson ance Study on Concrete Pore Structure Evolution Under Different Curing Environments[J]. JOM, 2022, 74(5): 1819-1827. doi: 10.1007/s11837-022-05221-3 [36] SHEN W G, LIU Y, WANG Z W, et al. Influence of manufactured sand’s characteristics on its concrete performance[J]. Construction and Building Materials, 2018, 172: 574-583. doi: 10.1016/j.conbuildmat.2018.03.139 [37] ZHAO S B, DING X X, ZHAO M S, et al. Experimental study on tensile strength development of concrete with manufactured sand[J]. Construction and Building Materials, 2017, 138: 247-253. doi: 10.1016/j.conbuildmat.2017.01.093 [38] LI B X, WANG J L, ZHOU M K. Effect of limestone fines content in manufactured sand on durability of low- and high-strength concretes[J]. Construction and Building Materials, 2009, 23(8): 2846-2850. doi: 10.1016/j.conbuildmat.2009.02.033 [39] ZHOU M K, WANG J L, ZHU L D, et al. Effects of Manufactured-sand on Dry Shrinkage and Creep of High-strength Concrete[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2008, 23(2): 249-253. doi: 10.1007/s11595-006-2249-5 [40] WANG J L, YANG Z F, LIU Y H. Effects of the lithologic character of manufactured sand on properties of concrete[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2014, 29(6): 1213-1218. doi: 10.1007/s11595-014-1070-9 [41] 王稷良, 周明凯, 贺图升, 等. 石粉对机制砂混凝土抗渗透性和抗冻融性能的影响(英文)[J]. 硅酸盐学报, 2008, (04): 482-486. doi: 10.3321/j.issn:0454-5648.2008.04.010WANG Jiliang, ZHOU Mingkai, HE Tusheng, et al. Effect of stone dust on resistance to chloride ion permeation and resistance to freezing of manufactured sand concrete[J]. Chinese Journal of Ceramics, 2008, (04): 482-486(in Chinese). doi: 10.3321/j.issn:0454-5648.2008.04.010 [42] 王稷良. 机制砂特性对混凝土性能的影响及机理研究[D]. 武汉理工大学, 2008.WANG Jiliang. Research of Effects and Mechanism of Manufactured Sand Characteristics on Portland Cement Concrete [D]. Wuhan University of Technology, 2008. (in Chinese) [43] 王雨利, 王稷良, 周明凯, 等. 机制砂及石粉含量对混凝土抗冻性能的影响[J]. 建筑材料学报, 2008, 11(06): 726-731. doi: 10.3969/j.issn.1007-9629.2008.06.019WANG Yuli, WANG Jiliang, ZHOU Mingkai, et al. Effects of Manufactured Fine Aggregate and Aggregate Micro Fines on Frost-Resistant Performance of Concrete[J]. Journal of Building Materials, 2008, 11(06): 726-731(in Chinese). doi: 10.3969/j.issn.1007-9629.2008.06.019 [44] 吴明威, 付兆岗, 李铁翔, 等. 机制砂中石粉含量对混凝土性能影响的试验研究[J]. 铁道建筑技术, 2000, (04): 46-49+0. doi: 10.3969/j.issn.1009-4539.2000.04.020WU Mingwei, FU Zhaogang, LI Tiexiang, et al. Experimental study on the effect of stone powder content in mechanical sand on the performance of concrete[J]. Railway Construction Technology, 2000, (04): 46-49+0(in Chinese). doi: 10.3969/j.issn.1009-4539.2000.04.020 [45] 金海军, 于继寿, 李立辉, 等. 在硫酸盐环境下冻融-干湿循环对混凝土的影响[J]. 混凝土, 2012, (272): 46-50.JIN Haijun, YU Jishou, LI Lihui, et al. Study on sulphate environment under freeze-thaw and dry-wet cycling of concrete[J]. Concrete, 2012, (272): 46-50(in Chinese). [46] 姜磊, 牛荻涛. 硫酸盐与冻融复合作用下混凝土劣化规律[J]. 中南大学学报(自然科学版), 2016, 47(09): 3208-3216.JIANG Lei, NIU Ditao. Damage degradation law of concrete in sulfate solution and freeze-thaw environment[J]. Journal of Central South University (Natural Science Edition), 2016, 47(09): 3208-3216(in Chinese). [47] THAULOW N, SAHU S. Mechanism of concrete deterioration due to salt crystallization[J]. Materials Characterization, 2004, 53(2): 123-127. [48] HAYNES H H, ROBERT O, MICHAEL N, et al. Salt Weathering Distress on Concrete Exposed to Sodium Sulfate Environment[J]. ACI Materials Journal, 2008, 105(1): 35-43. [49] RODRIGUEZ-NAVARRO C, DOEHNE E, SEBASTIAN E. How does sodium sulfate crystallize? Implications for the decay and testing of building materials[J]. Cement and Concrete Research, 2000, 30(10): 1527-1534. doi: 10.1016/S0008-8846(00)00381-1 [50] FU H, WANG X, ZHANG L, et al. Investigation of the factors that control the development of pore structure in lacustrine shale: A case study of block X in the Ordos Basin, China[J]. Journal of Natural Gas Science and Engineering, 2015, 26(C): 1422-1432. [51] QIN L, CHENG Z, LIU S M, et al. Changes in the petrophysical properties of coal subjected to liquid nitrogen freeze-thaw – A nuclear magnetic resonance investigation[J]. Fuel, 2017, 194: 102-114. doi: 10.1016/j.fuel.2017.01.005 [52] 王立久, 袁大伟. 关于混凝土冻害机理的思考[J]. 低温建筑技术, 2007, (05): 1-3. doi: 10.3969/j.issn.1001-6864.2007.05.001WANG Lijiu, YUAN Dawei. THE RESEARCH OF MECHANISM OF FREEZE-THAW DAMAGE IN CONCRETE[J]. Low Temperature Building Technology, 2007, (05): 1-3(in Chinese). doi: 10.3969/j.issn.1001-6864.2007.05.001 [53] ÇELIK T, MARAR K. Effects of crushed stone dust on some properties of concrete[J]. Cement and Concrete Research, 1996, 26(7): 1121-1130. doi: 10.1016/0008-8846(96)00078-6 [54] UCHIKAW H, HANEHARA S, HIRAO H. Influence of microstructure on the physical properties of concrete prepared by substituting mineral powder for part of fine aggregate[J]. Cement and Concrete Research, 1996, 26(1): 101-111. doi: 10.1016/0008-8846(95)00193-X [55] COLLEPARDI M. A state-of-the-art review on delayed ettringite attack on concrete[J]. Cement and Concrete Composites, 2003, 25(4-5): 401-407. doi: 10.1016/S0958-9465(02)00080-X [56] RAJASEKARAN G. Sulphate attack and ettringite formation in the lime and cement stabilized marine clays[J]. Ocean Engineering, 2005, 32(8-9): 1133-1159. doi: 10.1016/j.oceaneng.2004.08.012 [57] XIAO J, DENG D H, LIU Z Q, et al. On the ettringite form of sulfate attack: Part 1the formation mechanism of secondary ettringite in concrete due to sulfate attack[J]. Journal of Wuhan University of Technology-materials science edition, 2006, 21(Z1): 5863. [58] A. LEEMANN, R. LOSER. Analysis of concrete in a vertical ventilation shaft exposed tosulfate-containing groundwater for 45 years[J]. Cement and Concrete Composites, 2011, 33: 74-83. [59] 姜磊. 硫酸盐侵蚀环境下混凝土劣化规律研究[D]. 西安建筑科技大学, 2014.JIANG Lei. Study on Deterioration of Concrete under Sulfate Attack [D]. Xi 'an University of Architecture and Technology, 2014. (in Chinese) [60] ZHANG Y Q, Yu H F, Sun W, et al. Frost resistance of concrete under action of magnesium sulfate attack[J]. Journal of Building Materials, 2011, 14(5): 698-702. [61] SANTHANAM M. Studies on Sulfate Attack: Mechanisms, Test Method, and Modeling [D]. West Lafayette: Purdue University, 2001. [62] 金祖权. 西部地区严酷环境下混凝土的耐久性与寿命预测[D]. 东南大学, 2006.JIN Zuquan. Durability and service life prediction of concrete exposedto harsh environment in West of China [D]. Southeast University, 2006. (in Chinese) [63] 李星星, 王思敬, 肖锐铧, 等. 硫酸钠溶液在降温结晶过程中的盐胀与冻胀[J]. 岩土工程学报, 2016, 38(11): 2069-2077. doi: 10.11779/CJGE201611017LI Xingxing, WANG Sijing, XIAO Ruihua, et al. Saline expansion and frost heave of sodium sulfate solution during cooling crystallization process[J]. Chinese Journal of Geotechnical Engineering, 2016, 38(11): 2069-2077(in Chinese). doi: 10.11779/CJGE201611017 [64] 齐 晓, 肖前慧, 邱继生, 等. 冻融循环与硫酸盐侵蚀共同作用下再生混凝土的微观结构研究[J]. 硅酸盐通报, 2023, 42(4): 1194-1204. doi: 10.3969/j.issn.1001-1625.2023.4.gsytb202304007QI Xiao, XIAO Qianhui, QIU Jisheng, et al. Microstructure of Recycled Aggregate Concrete under Combined Action of Freeze-Thaw Cycles and Sulfate Attack[J]. Silicate bulletin, 2023, 42(4): 1194-1204(in Chinese). doi: 10.3969/j.issn.1001-1625.2023.4.gsytb202304007 [65] 高润东. 复杂环境下混凝土硫酸盐侵蚀微—宏观劣化规律研究[D]. 清华大学, 2010.GAO Rundong. Micro-Macro Degradation Regularity of Sulfate Attack on Concrete under Complex Environments [D]. Tsinghua University, 2010. (in Chinese) -

点击查看大图

点击查看大图

计量

- 文章访问数: 116

- HTML全文浏览量: 69

- 被引次数: 0

下载:

下载: