Experimental and mechanism exploration of alkali-silica reaction inhibition by microbial mineralization

-

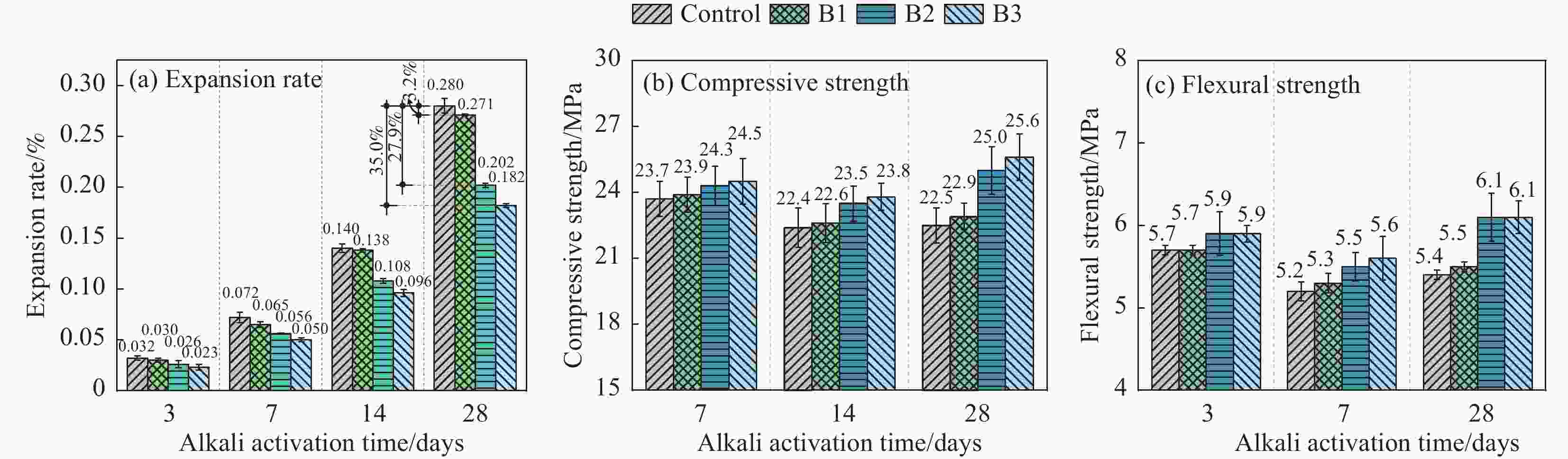

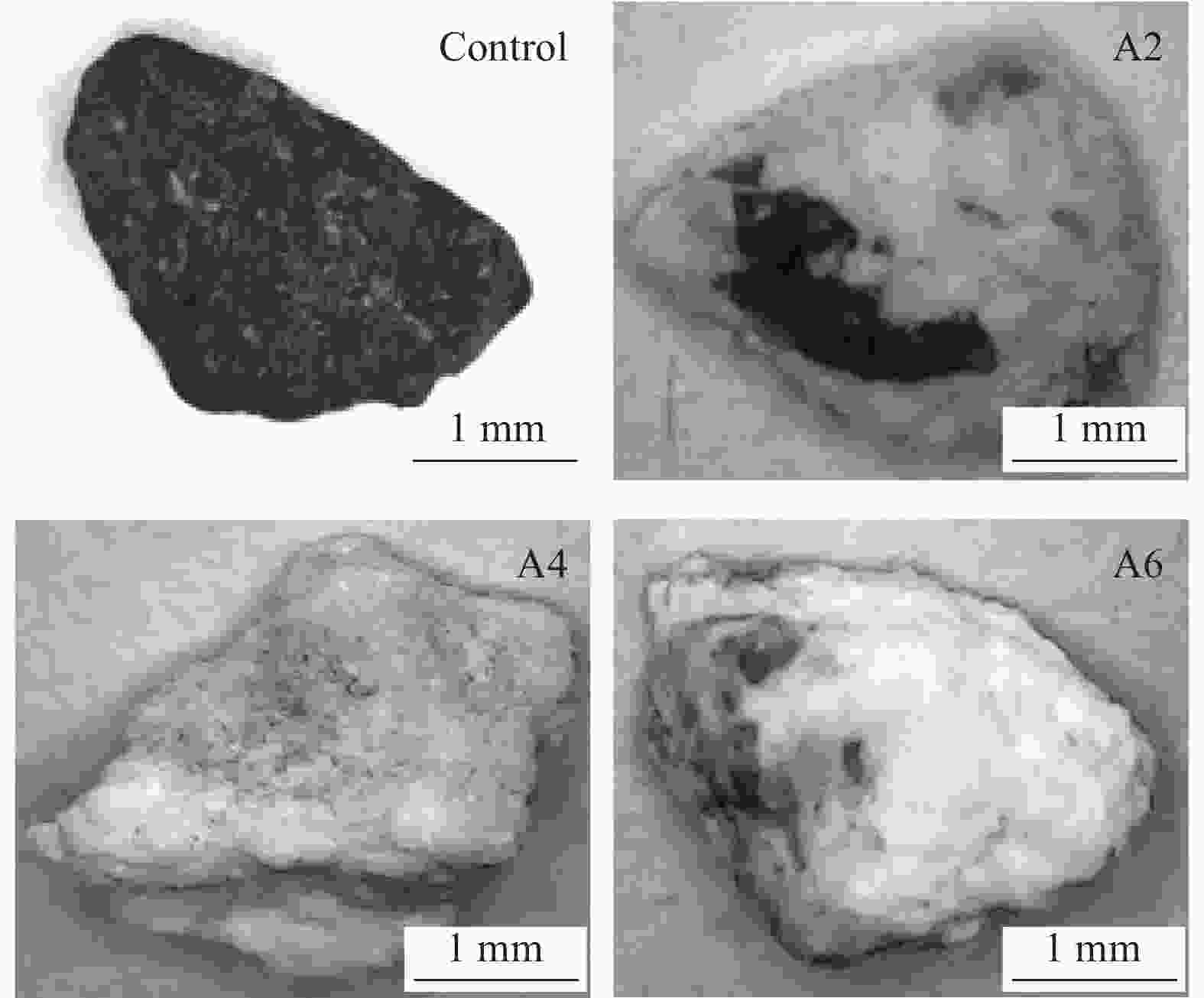

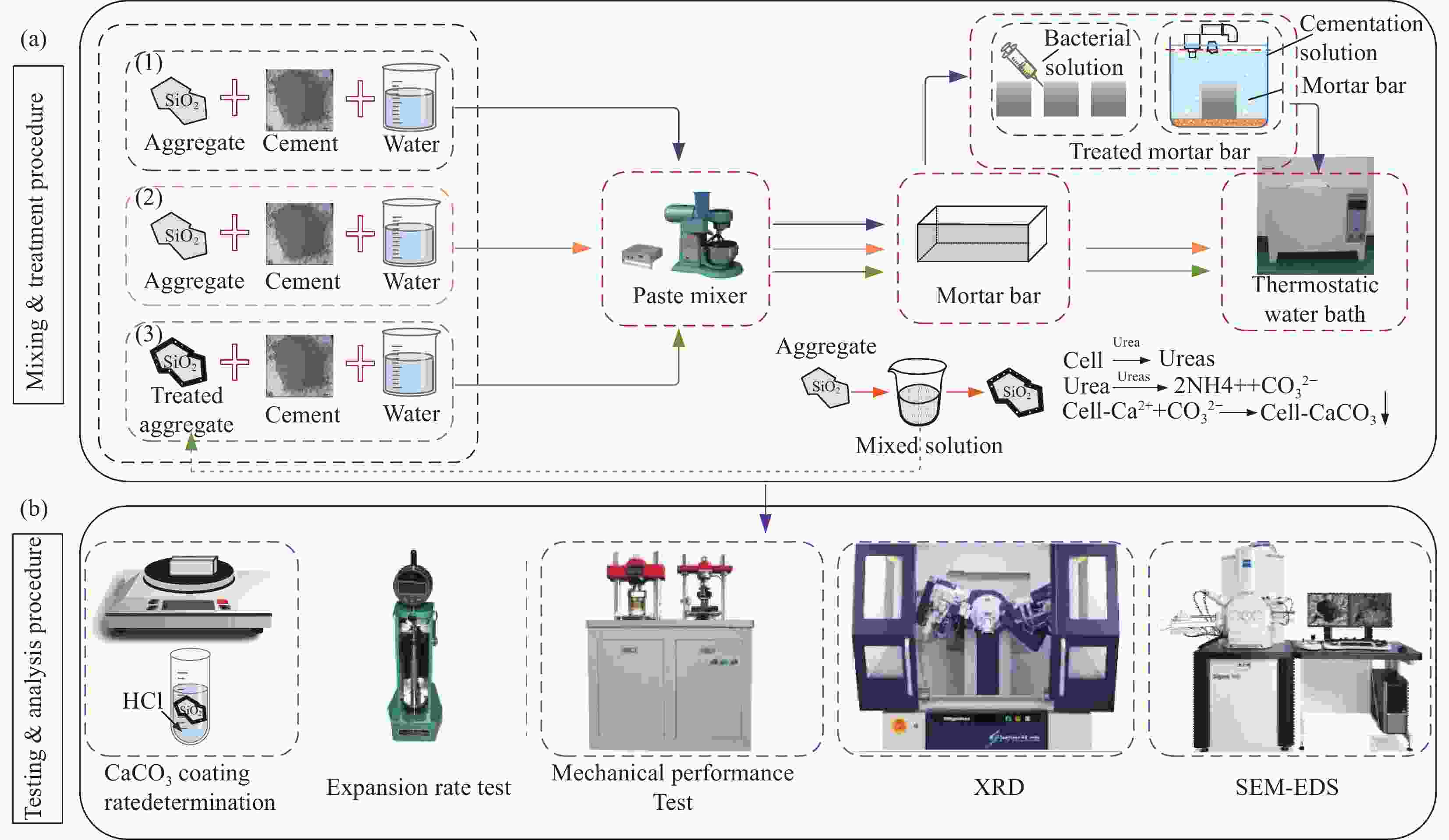

摘要: 碱-硅酸反应(ASR)是混凝土中碱性孔隙溶液和骨料中反应性非结晶SiO2之间的反应,会导致混凝土膨胀和开裂,及力学性能下降。本研究基于巴氏芽孢杆菌微生物诱导碳酸钙沉淀(MICP)技术,采用不同处理次数及方式(表面处理潜在活性骨料及其制成的砂浆棒),综合评价MICP对ASR的抑制规律与机制。结果表明,MICP处理可以在骨料及砂浆棒表面形成具有黏附作用的致密CaCO3层,从而阻止碱性离子和水的入侵,且抑制效果随处理次数的增多而变强;与对照组相比,处理砂浆棒时,力学性能最大提升了13.8%,膨胀率下降了35%;处理骨料时,由于表面CaCO3层可同时阻隔孔隙溶液中已有及外部入侵的碱性离子与水分,其力学性能提升了25.3%,膨胀率下降了59.6%,具有更好的抑制效果。微观结构和成分分析表明,经MICP处理后骨料表面Si和Na原子比例分别下降了69.6%和88.9%,表明ASR凝胶显著减少。Abstract: Alkali-silica reaction (ASR) is a reaction between alkaline pore solutions in concrete and reactive non-crystalline SiO2 in aggregates, which leads to expansion and cracking of the concrete, and degradation of mechanical properties. In this study, based on the microbial induced calcium carbonate precipitation (MICP) technique of Bacillus pasteurus, various treatment frequencies and methods, including surface treatments of potentially active aggregates and mortar bars made by them, to comprehensively evaluate the inhibition law and mechanism of MICP on ASR. The results showed that the MICP treatment could form a dense CaCO3 layer with adhesive effect on the surface of aggregates and mortar bars, thus preventing the intrusion of alkaline ions and water, and the inhibiting effect became stronger with the treatment numbers; Compared with the control group, the maximum increase in mechanical properties of 13.8%, and the decrease in expansion rate of 35% were observed when the mortar bars were treated; When treating the aggregate, the mechanical properties were improved by 25.3% and the expansion rate was reduced by 59.6% with a better inhibition effect, as the surface CaCO3 layer could simultaneously block the alkaline ions and water existing in the pore solution and invading from outside. Microstructural and compositional analyses showed that the proportion of Si and Na atoms on the aggregate surface decreased by 69.6% and 88.9%, respectively, after treatment, indicating a significant reduction in the ASR gel.

-

Key words:

- MICP /

- Alkali-silica Reaction /

- Jinping sandstone /

- Mechanical properties /

- Expansion rate

-

表 1 骨料粒度级配表

Table 1. Grain size distribution of aggregates used

Size/mm 2.5-5 1.25-2.5 0.63-1.25 0.315-0.63 0.16-0.315 Mass/wt% 10 25 25 25 15 表 2 试件砂浆配合比

Table 2. Design of mortar proportion for specimen

Cement/g Water/g Aggregate/g

(before MICP)Size/(mm×mm×mm) Purpose 450 225 1350 40×40×160 Measuring mechanical properties 400 188 900 25.4×25.4×285 Measuring expansion rate Notes: The total CaCO3 deposition on the aggregate surface increased by approximately 1.9% per two treatments;MICP−Microbial induced calcium carbonate precipitation. 表 3 试件参数表

Table 3. Details of specimens

No. Number of processes MICP processing objects Processing time point Curing method Content of analysis Control 0 - - 80℃ in 1 mol/L NaOH

solutionMechanical properties,

expansion rate,

microanalysisB1 1 Mortar bars made from original

reactive aggregatesAfter pouring B2 2 B3 3 A2 2 Reactive aggregates Before pouring A4 4 A6 6 Notes: Control is the untreated standard group, B represents the MICP treatment of mortar bar surface, A represents the treatment of aggregate surface, and the number of processes represents the treatment times. 表 4 锦屏砂岩的化学成分

Table 4. Chemical composition of Jinping sandstone

Materials SiO2/wt% Al2O3/wt% CaO/wt% Fe2O3/wt% K2O/wt% Na2O/wt% Others/wt% Jinping sandstone 63.62 16.55 7.93 4.41 2.81 2.49 2.19 表 5 CaCO3在砂浆棒表面的质量比例

Table 5. Mass ratio of CaCO3 on the surface of mortar bar

No. Processing times S0/g S1/g S2/g S/% B1 1 601.86 617.45 15.59 2.59 B2 2 603.52 632.67 29.15 4.83 B3 3 601.31 644.84 43.53 7.24 Notes: S0−Initial mass of specimen; S1−Mass of specimen after treatment; S2−Calculated content of CaCO3; S−Percentage of CaCO3 deposits in mortar bars; The data in the table are the average values obtained from three parallel specimens. 表 6 骨料表面CaCO3质量占比

Table 6. The mass proportion of CaCO3 on the aggregate surface

No. Processing times M0/g M1/g M2/g M/% A2 2 9.89 10.08 0.19 1.94 A4 4 9.70 10.06 0.36 3.80 A6 6 9.58 10.13 0.55 5.74 Notes: M0−Mass of aggregate after acid washing; M1−Mass of aggregate after MICP treatment; M2−Calculated content of CaCO3; M− Percentage of CaCO3 deposited in the aggregate; The data in the table are the average values obtained from three parallel samples. 表 7 碱激发28天时骨料表面EDS元素的原子比例

Table 7. 7 Atomic proportion of EDS elements on aggregate surface at 28 days of alkali activation

No. K/% C/% O/% Na/% Al/% Si/% Au/% Ca/% Control 1.52 - 44.34 9.35 3.24 34.49 3.03 4.03 A2 - 10.74 37.01 5.79 1.91 27.21 0.71 15.63 A4 - 13.54 42.93 3.04 0.97 18.24 1.99 19.29 A6 - 18.70 44.46 1.04 0.63 10.48 1.17 23.52 -

[1] AHMED H, ZAHEDI A, SANCHEZ L F M, et al. Condition assessment of ASR-affected reinforced concrete columns after nearly 20 years in service[J]. Construction and Building Materials, 2022, 347: 128570. doi: 10.1016/j.conbuildmat.2022.128570 [2] 刘玮, 张玉, 李珠等. 膨胀珍珠岩内养护混凝土抗压强度增长机制及数学模型的建立[J]. 复合材料学报, 2022, 39(11): 5423-5435. DOI: 10.13801/j. cnki.fhclxb. 20210930. 001.LIU Wei, ZHANG Yu, LI Zhu, et al. Growth mechanism of the compressive strength of expanded perlite internal curing concrete and establishment of mathematical model[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5423-5435. DOI: 10.13801/j. cnki.fhclxb. 20210930. 001. (in Chinese). [3] LU C, BU S, ZHENG Y, et al. Deterioration of concrete mechanical properties and fracture of steel bars caused by alkali-silica reaction: A review[C] Structures, 2022, 35: 893-902. [4] BARRETO Santos M, DE Brito J, SANTOS Silva A. A review on alkali-silica reaction evolution in recycled aggregate concrete[J]. Materials, 2020, 13(11): 2625. doi: 10.3390/ma13112625 [5] 李小伟, 曹旗. FRP配筋海水珊瑚骨料混凝土材料及构件力学性能研究进展[J]. 复合材料学报, 2022, 39(03): 926-941.LI Xiaowei, CAO Qi. Research progress on mechanical properties of FRP reinforced seawater coral aggregate concrete materials and structural components[J]. Acta Materiae Compositae Sinica, 2022, 39(03): 926-941(in Chinese). [6] 王兴国, 姜茂林, 陈旭等. 不同预浸骨料-PVA纤维对再生混凝土力学性能的影响[J]. 复合材料学报, 2022, 39(03): 1205-1214.WANG Xingguo, JIANG Maolin, CHEN Xu, et al. Effect of different pre-soaked aggregate-PVA fiber on the mechanical properties of recycled aggregate concrete[J]. Acta Materiae Compositae Sinica, 2022, 39(03): 1205-1214(in Chinese). [7] 鲍玖文, 李树国, 张鹏等. 再生粗骨料硅烷浸渍处理对混凝土介质传输性能的影响[J]. 复合材料学报, 2020, 37(10): 2602-2609.BAO Jiuwen, LI Shuguo, ZHANG Peng, et al. Effect of recycled coarse aggregate after strengthening by silane impregnation on mass transport of concrete[J]. Acta Materiae Compositae Sinica, 2020, 37(10): 2602-2609(in Chinese). [8] DE Souza D J, SANCHEZ L F M. Evaluating the efficiency of SCMs to avoid or mitigate ASR-induced expansion and deterioration through a multi-level assessment[J]. Cement and Concrete Research, 2023, 173: 107262. doi: 10.1016/j.cemconres.2023.107262 [9] FANIJO E O, KASSEM E, IBRAHIM A. ASR mitigation using binary and ternary blends with waste glass powder[J]. Construction and Building Materials, 2021, 280: 122425. doi: 10.1016/j.conbuildmat.2021.122425 [10] TAPAS M J, THOMAS P, VESSALAS K, et al. Comparative study of the efficacy of fly ash and reactive aggregate powders in mitigating alkali-silica reaction[J]. Journal of Building Engineering, 2023, 63: 105571. doi: 10.1016/j.jobe.2022.105571 [11] ABBAS S, SHARIF A, AHMED A, et al. Prospective of sugarcane bagasse ash for controlling the alkali-silica reaction in concrete incorporating reactive aggregates[J]. Structural Concrete, 2020, 21(2): 781-793. doi: 10.1002/suco.201900284 [12] 高鹏, 王永博, 薛刚等. 橡胶粉、硅灰及二元混合物对ASR的抑制作用[J/OL]. 建筑材料学报: 1-12[2023-09-28]. http://kns.cnki.net/kcms/detail/31.1764. TU.20220613.1835.034.html.GAO Peng, WANG Yongbo, XUE Gang, et al. Influence of Waste Rubber Powder, Silica Fume and Binary Blends with Them on Mitigating Alkali-Silica Reaction (ASR) [J/OL]. Journal of Building Materials: 1-12[2023-09-28]. http://kns.cnki.net/kcms/detail/31.1764. TU. 20220613. 1835. 034. html. (in Chinese). [13] 万聪聪, 姜天华. 高性能地聚物混凝土早期收缩特性[J/OL]. 复合材料学报: 1-16. [2023-09-28]. https://doi.org/10.13801/j.cnki.fhclxb.20230529.001.WAN Congcong, JIANG Tianhua. Early shrinkage characteristics of high performance geopolymer concrete[J/OL]. Acta Materiae Compositae Sinica: 1-16 [2023-09-28]. https: //doi. org/10. 13801/j. cnki. fhclxb. 20230529. 001. (in Chinese). [14] 胡明玉, 陈露璐, 郑江等. 粉煤灰和抛光渣抑制碱硅酸反应及其机理研究[J]. 建筑材料学报, 2020, 23(04): 739-747.HU Mingyu, CHEN Lulu, ZHENG Jiang, et al. Mechanism of Fly Ash and Ceramic Polishing Powder on Inhibition Alkali-Silica Reaction[J]. Journal of Building Materials, 2020, 23(04): 739-747(in Chinese). [15] KANWAL M, KHUSHNOOD R A, ADNAN F, et al. Assessment of the MICP potential and corrosion inhibition of steel bars by biofilm forming bacteria in corrosive environment[J]. Cement and Concrete Composites, 2023, 137: 104937. doi: 10.1016/j.cemconcomp.2023.104937 [16] QIAN C, WANG J, WANG R, et al. Corrosion protection of cement-based building materials by surface deposition of CaCO3 by Bacillus pasteurii[J]. Materials Science and Engineering:C, 2009, 29(4): 1273-1280. doi: 10.1016/j.msec.2008.10.025 [17] 程晓辉, 麻强, 杨钻等. 微生物灌浆加固液化砂土地基的动力反应研究[J]. 岩土工程学报, 2013, 35(08): 1486-1495.CHENG Xiaohui, MA Qiang, YANG Zuan, et al. Dynamic response of liquefiable sand foundation improved by bio-grouting[J]. Chinese Journal of Geotechnical Engineering, 2013, 35(08): 1486-1495(in Chinese). [18] ARPAJIRAKUL S, PUNGRASMI W. Efficiency of microbially-induced calcite precipitation in natural clays for ground improvement[J]. Construction and Building Materials, 2021, 282: 122722. doi: 10.1016/j.conbuildmat.2021.122722 [19] 刘士雨, 俞缙, 刘文强等. 基于MICP的珊瑚砂砂浆裂缝自修复新型细菌载体[J]. 建筑材料学报, 2021, 24(04): 687-693.LIU Shiyu, YU Jin, LIU Wenqiang, et al. New Bacterial Carrier for the Crack Self-healing in Coral Sand Mortar Based on MICP[J]. Journal of Building Materials, 2021, 24(04): 687-693(in Chinese). [20] 王剑云, 柯懿耘, 温建峰等. 微生物菌体对砂浆疏水性能的提升及机理分析[J]. 硅酸盐学报, 2023, 51(05): 1165-1173.WANG Jianyun, KE Yiyun, WEN Jianfeng, et al. Application of Microorganisms to Improve Hydrophobic Properties of Mortar and Its Mechanisms[J]. Journal of the Chinese Ceramic Society, 2023, 51(05): 1165-1173(in Chinese). [21] 朱亚光, 戎丹萍, 徐培蓁等. 供氧剂浓度和浸泡位置对MICP再生骨料性能的影响[J]. 材料导报, 2021, 35(04): 4074-4078+4087.ZHU Yaguang, RONG Danping, XU Peizhen, et al. Influence of Oxygen Supply Agent Concentration and Soaking Position on MICP Recycled Aggregate Properties[J]. Materials Reports, 2021, 35(04): 4074-4078+4087(in Chinese). [22] ZHANG R, WANG J. Effect of regulating urease activity on the properties of bio-CaCO3 precipitated on recycled aggregates[J]. Construction and Building Materials, 2023, 403: 133119. doi: 10.1016/j.conbuildmat.2023.133119 [23] LIU S, DU K, HUANG W, et al. Improvement of erosion-resistance of bio-bricks through fiber and multiple MICP treatments[J]. Construction and Building Materials, 2021, 271: 121573. doi: 10.1016/j.conbuildmat.2020.121573 [24] 花素珍, 张家广, 高沛, 等. 增强再生骨料固载混菌的混凝土裂缝自修复性能[J]. 复合材料学报, 2023, 41: 1-12.HUA Suzhen, ZHANG Jiaguang, GAO Pei, et al. Self-healing of concrete cracks by immobilizing non-axenic bacteria with enhanced recycled aggregates[J]. Acta Materiae Compositae Sinica, 2023, 41: 1-12(in Chinese). [25] WANG R, JIN P, DING Z, et al. Surface modification of recycled coarse aggregate based on Microbial Induced Carbonate Precipitation[J]. Journal of Cleaner Production, 2021, 328: 129537. doi: 10.1016/j.jclepro.2021.129537 [26] 张鹏, 郭得阳, 鲍玖文等. 基于微生物矿化作用的混凝土自愈合性能研究进展[J]. 硅酸盐学报, 2022, 50(02): 544-554.ZHANG Peng, GUO Deyang, BAO Jiuwen, et al. Self-Healing Performance of Concrete Based on Microbial Mineralization: A Review[J]. Journal of the Chinese Ceramic Society, 2022, 50(02): 544-554(in Chinese). [27] 徐培蓁, 陈发滨, 李泉荃等. 微生物矿化沉积对再生骨料界面过渡区的影响[J]. 材料导报, 2020, 34(06): 6095-6099.XU Peizhen, CHEN Fabin, LI Quanquan, et al. Effect of Microbial Mineralization Deposition on Interfacial Transition Zone of Recycled Aggregate[J]. Materials Reports, 2020, 34(06): 6095-6099(in Chinese). [28] 李锺奥, 陆春华, 成亮等. 扩散法用于微生物矿化修复混凝土竖向裂缝的试验研究[J]. 材料导报, 2023, 37(13): 125-130.LI Zhongao, LU Chunhua, CHENG Liang, et al. Experimental Study on Repairing Vertical Cracks of Concrete by Microbial Mineralization with Diffusion Method[J]. Materials Reports, 2023, 37(13): 125-130(in Chinese). [29] CHENG L, KOBAYASHI T, SHAHIN M A. Microbially induced calcite precipitation for production of “bio-bricks” treated at partial saturation condition[J]. Construction and Building Materials, 2020, 231: 117095. doi: 10.1016/j.conbuildmat.2019.117095 [30] YANG Y, CHU J, XIAO Y, et al. Seepage control in sand using bioslurry[J]. Construction and Building Materials, 2019, 212: 342-349. doi: 10.1016/j.conbuildmat.2019.03.313 [31] ZHAO Y, PENG L, FENG Z, et al. Optimization of microbial induced carbonate precipitation treatment process to improve recycled fine aggregate[J]. Cleaner Materials, 2021, 1: 100003. doi: 10.1016/j.clema.2021.100003 [32] LIU K, OUYANG J, SUN D, et al. Enhancement mechanism of different recycled fine aggregates by microbial induced carbonate precipitation[J]. Journal of Cleaner Production, 2022, 379: 134783. doi: 10.1016/j.jclepro.2022.134783 [33] ZHANG R, XIE D, WU K, et al. Optimization of sodium alginate aided bio-deposition treatment of recycled aggregates and its application in concrete[J]. Cement and Concrete Composites, 2023, 139: 105031. doi: 10.1016/j.cemconcomp.2023.105031 [34] LI Z, LIU H, WANG F, et al. Experimental study to improve the mechanical properties of graphite tailings sand through microbially induced calcium carbonate precipitation[J]. Construction and Building Materials, 2023, 409: 134165. doi: 10.1016/j.conbuildmat.2023.134165 [35] ZHANG J, SU P, LI L. Microbial induced carbonate precipitation modified steel slag: Mechanical improvement and erosion resistance to sulfate attack[J]. Journal of Cleaner Production, 2023, 405: 136982. doi: 10.1016/j.jclepro.2023.136982 [36] 国家标准化管理委员会(标准制定单位). 水泥砂浆强度试验方法(ISO法): GB/T 17671-2021[S]. 北京: 中国标准出版社, 2021.National Standardization Administration (standard setting unit). Test Method for the Strength of cement mortar (ISO method): GB/T 17671-2021[S]. Beijing: Standards Press of China, 2021. (in Chinese). [37] 中国电力企业联合会. DL/T 5151-2014, 水工混凝土砂石骨料试验规程[S]. 北京: 中国电力出版社, 2014.China Electricity Council. DL/T 5151-2014, Code for testing aggregates of hydraulic concrete[S]. Beijing: China Electric Power press, 2014. (in Chinese). [38] 杨黔, 蒋正武, 张兵兵等. 浅变质岩骨料碱活性特征及抑制措施[J]. 建筑材料学报, 2019, 22(06): 941-948.YANG Qian, JIANG Zhengwu, ZHANG Bingbing, et al. Alkali Activity and Inhibition of Low-Grade Metamorphic Rock Aggregates[J]. Journal of Building Materials, 2019, 22(06): 941-948(in Chinese). [39] 卢佳林, 邓敏, 莫立武. LiNO3抑制碱硅酸反应的效果及作用机理[J]. 混凝土, 2012, 9: 19-22, 29.LU Jialin, DENG Min, MO Liwu, Effects of lithium nitrate on mitigating ASR expansion and its mechanism[J]. Concrete, 2012, 9: 19-22, 29. (in Chinese). [40] 刘刚. 含铝物质对混凝土中碱-硅酸反应抑制作用的研究[D]. 河北联合大学, 2014.LIU Gang, Effect of the Substances Containing Aluminum on Suppressing Alkali-Silica Reaction in Concrete[D]. Hebei United University, 2014. (in Chinese). [41] HAY R, OSTERTAG C P. New insights into the role of fly ash in mitigating alkali-silica reaction (ASR) in concrete[J]. Cement and Concrete Research, 2021, 144: 106440. doi: 10.1016/j.cemconres.2021.106440 [42] KHAN M N N, SAHA A K, SARKER P K. Evaluation of the ASR of waste glass fine aggregate in alkali activated concrete by concrete prism tests[J]. Construction and Building Materials, 2021, 266: 121121. doi: 10.1016/j.conbuildmat.2020.121121 [43] LIAUDAT J, CAROL I, LÓPEZ C M, et al. ASR expansions at the level of a single glass-cement paste interface: experimental results and proposal of a reaction-expansion mechanism[J]. Construction and Building Materials, 2019, 218: 108-118. doi: 10.1016/j.conbuildmat.2019.05.106 [44] FANIJO E O, KOLAWOLE J T, ALMAKRAB A. Alkali-silica reaction (ASR) in concrete structures: Mechanisms, effects and evaluation test methods adopted in the United States[J]. Case Studies in Construction Materials, 2021, 15: e00563. doi: 10.1016/j.cscm.2021.e00563 [45] LEEMANN A, SHI Z, LINDGÅRD J. Characterization of amorphous and crystalline ASR products formed in concrete aggregates[J]. Cement and Concrete Research, 2020, 137: 106190. doi: 10.1016/j.cemconres.2020.106190 [46] YU X, CHU J, WU S, et al. Production of biocement using steel slag[J]. Construction and Building Materials, 2023, 383: 131365. doi: 10.1016/j.conbuildmat.2023.131365 -

点击查看大图

点击查看大图

计量

- 文章访问数: 90

- HTML全文浏览量: 57

- 被引次数: 0

下载:

下载: