Preparation and properties of wear-resistant superhydrophobic coatings based on SiO2/ aramid nanofibers "grape" structure

-

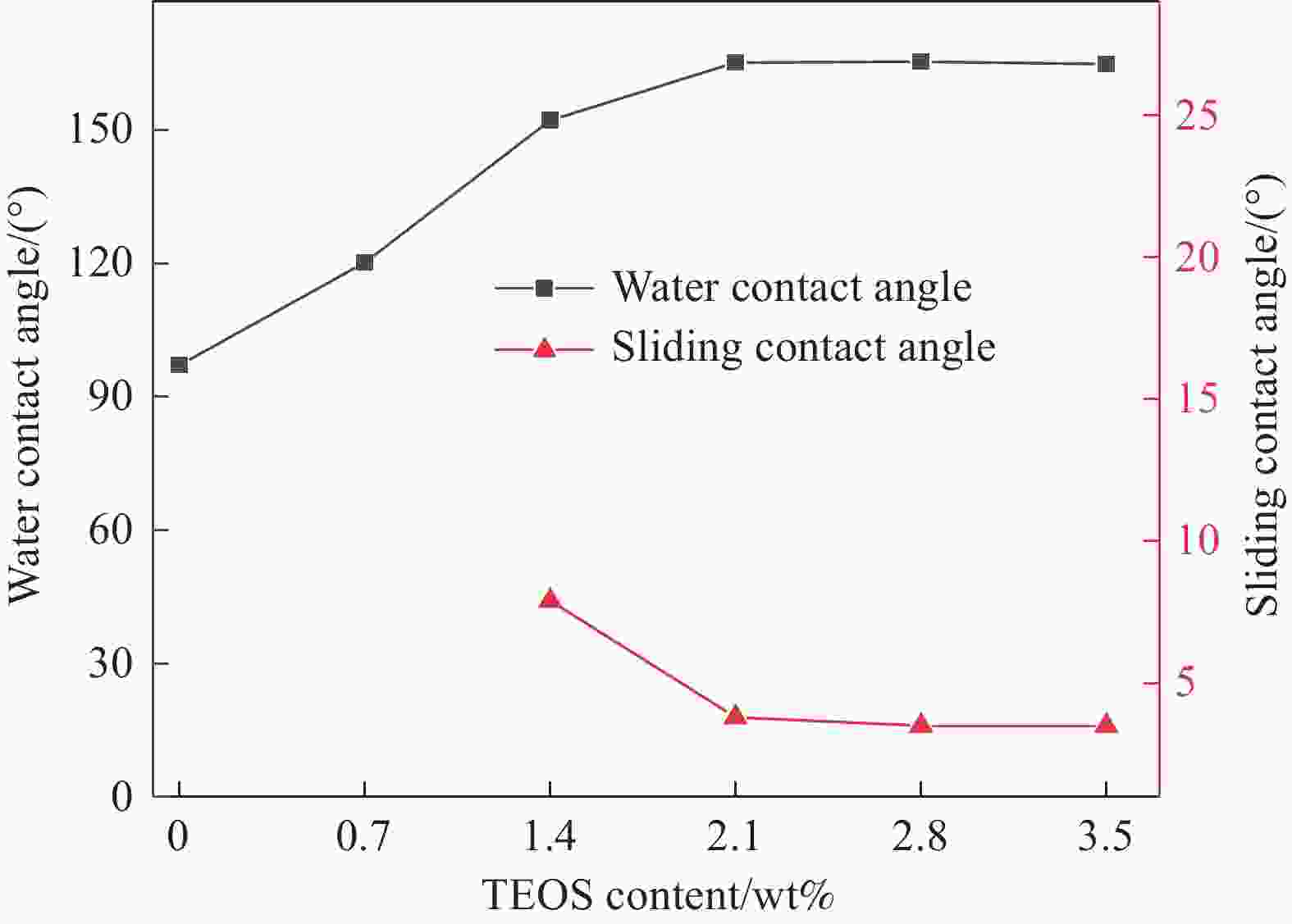

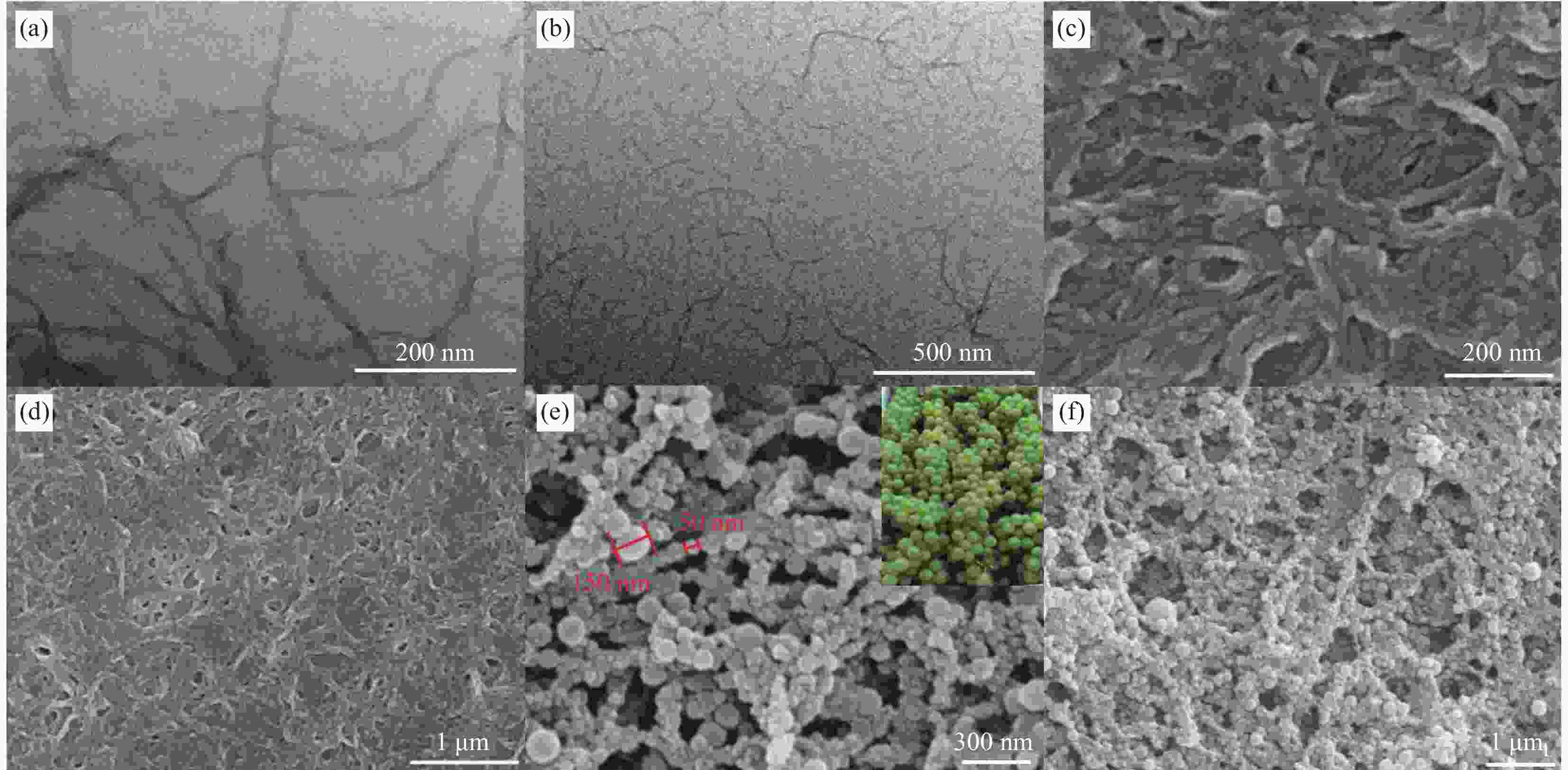

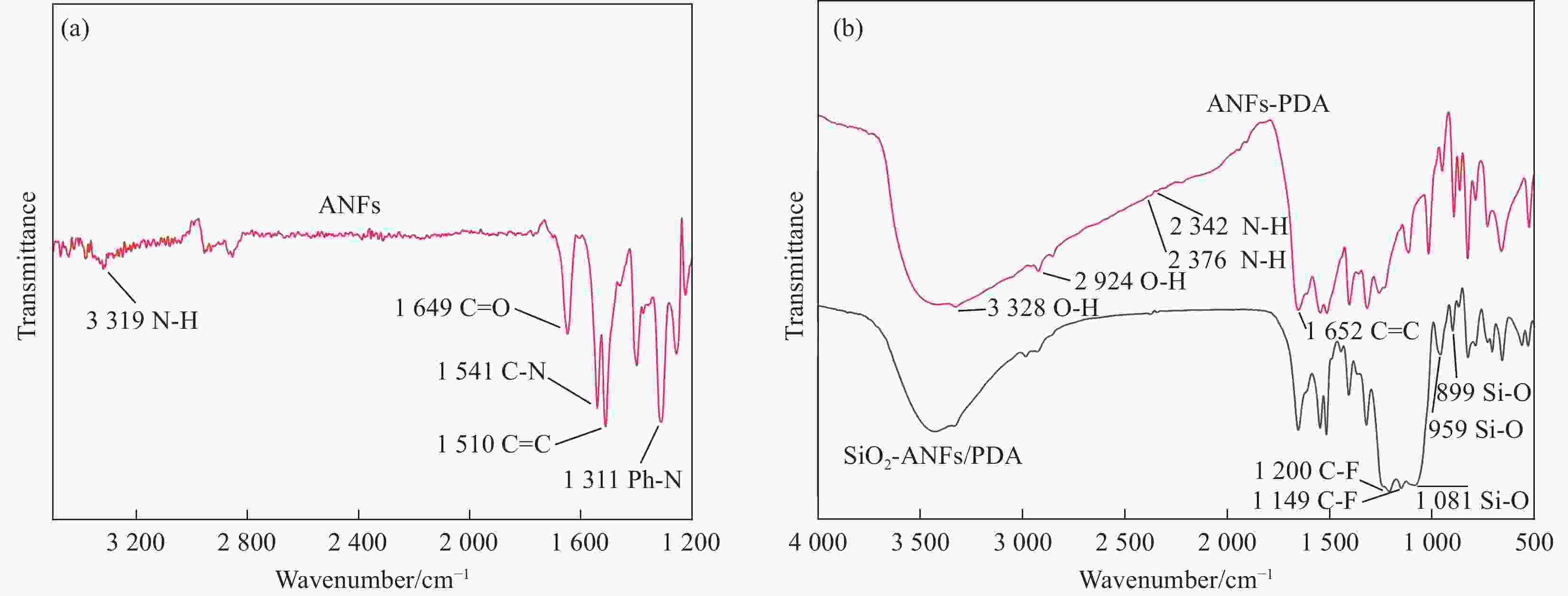

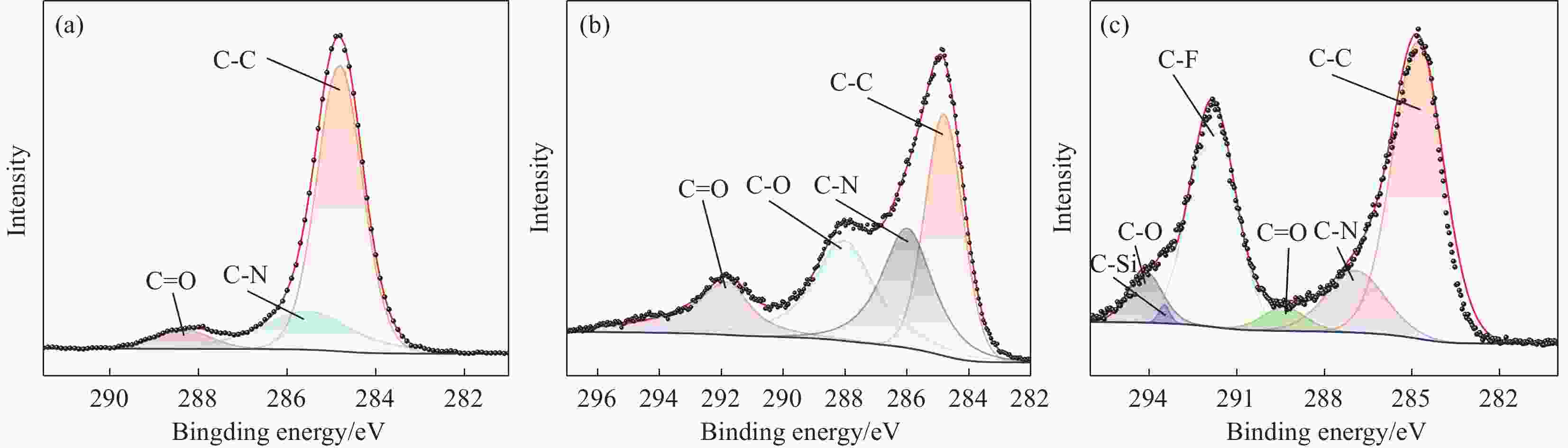

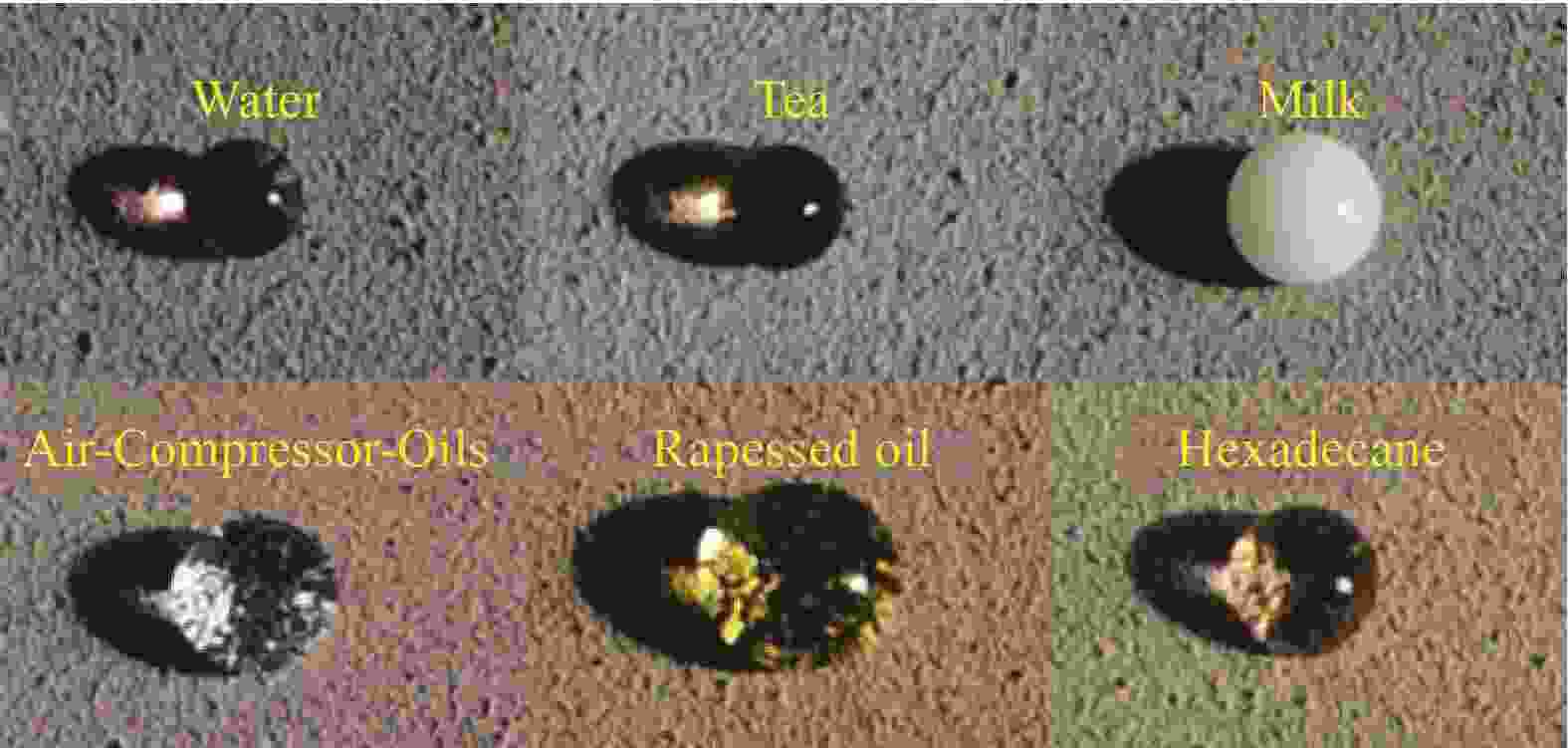

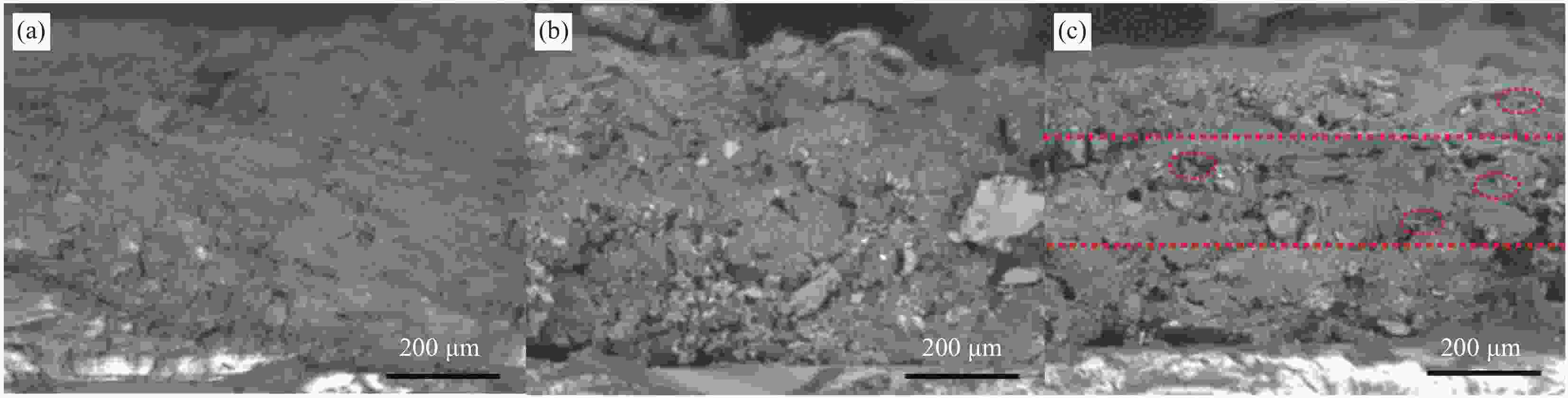

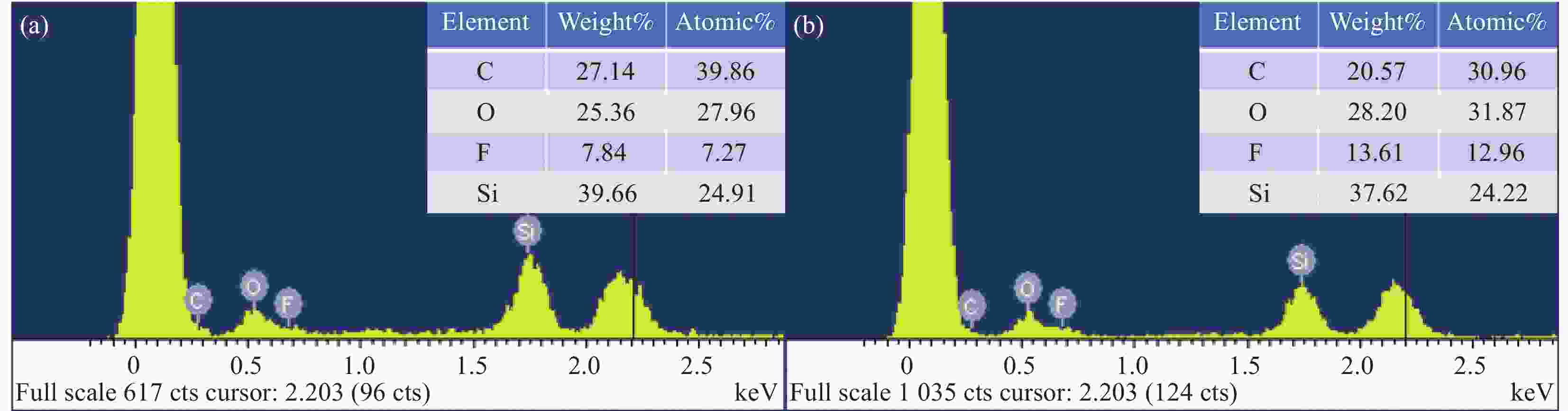

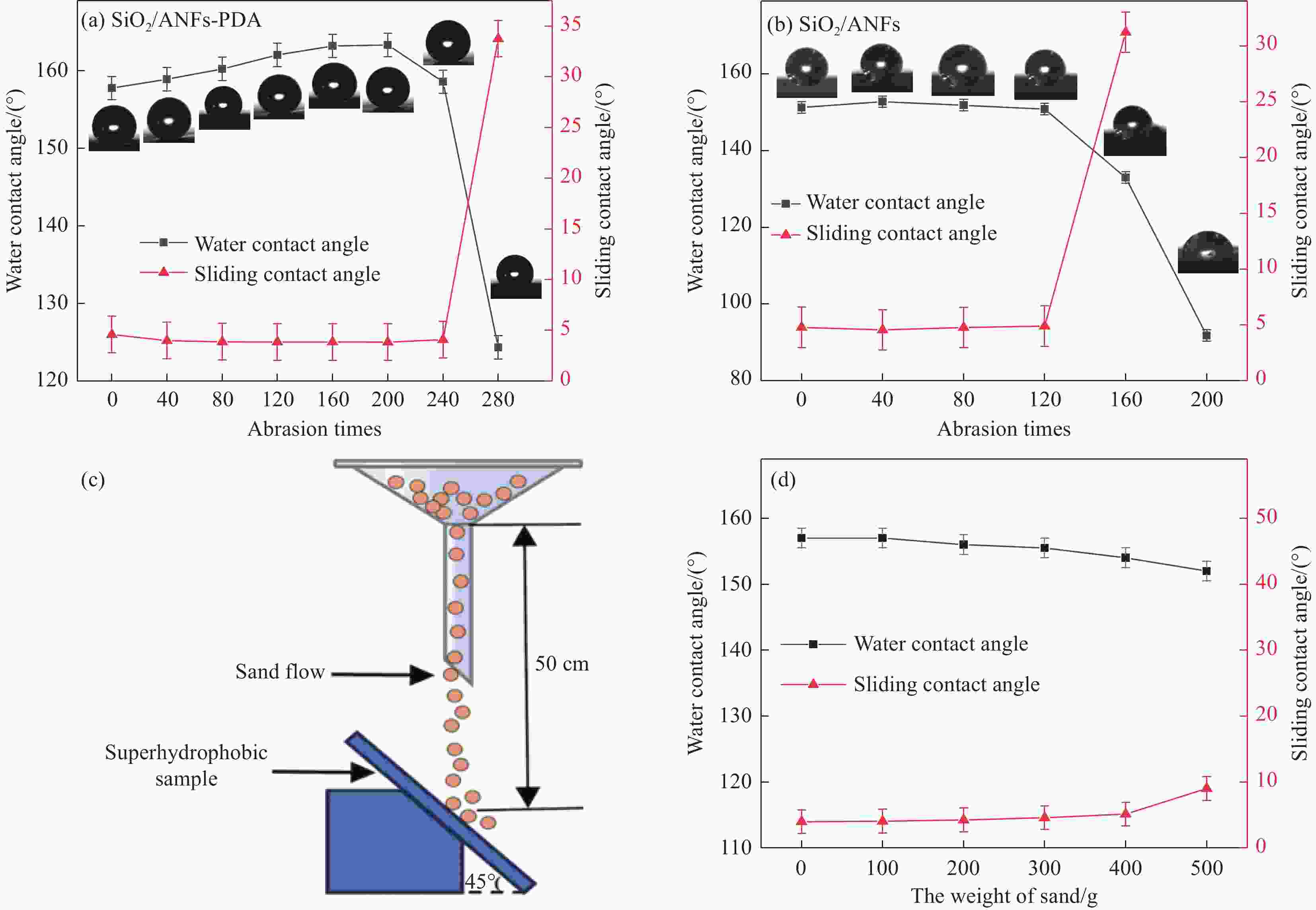

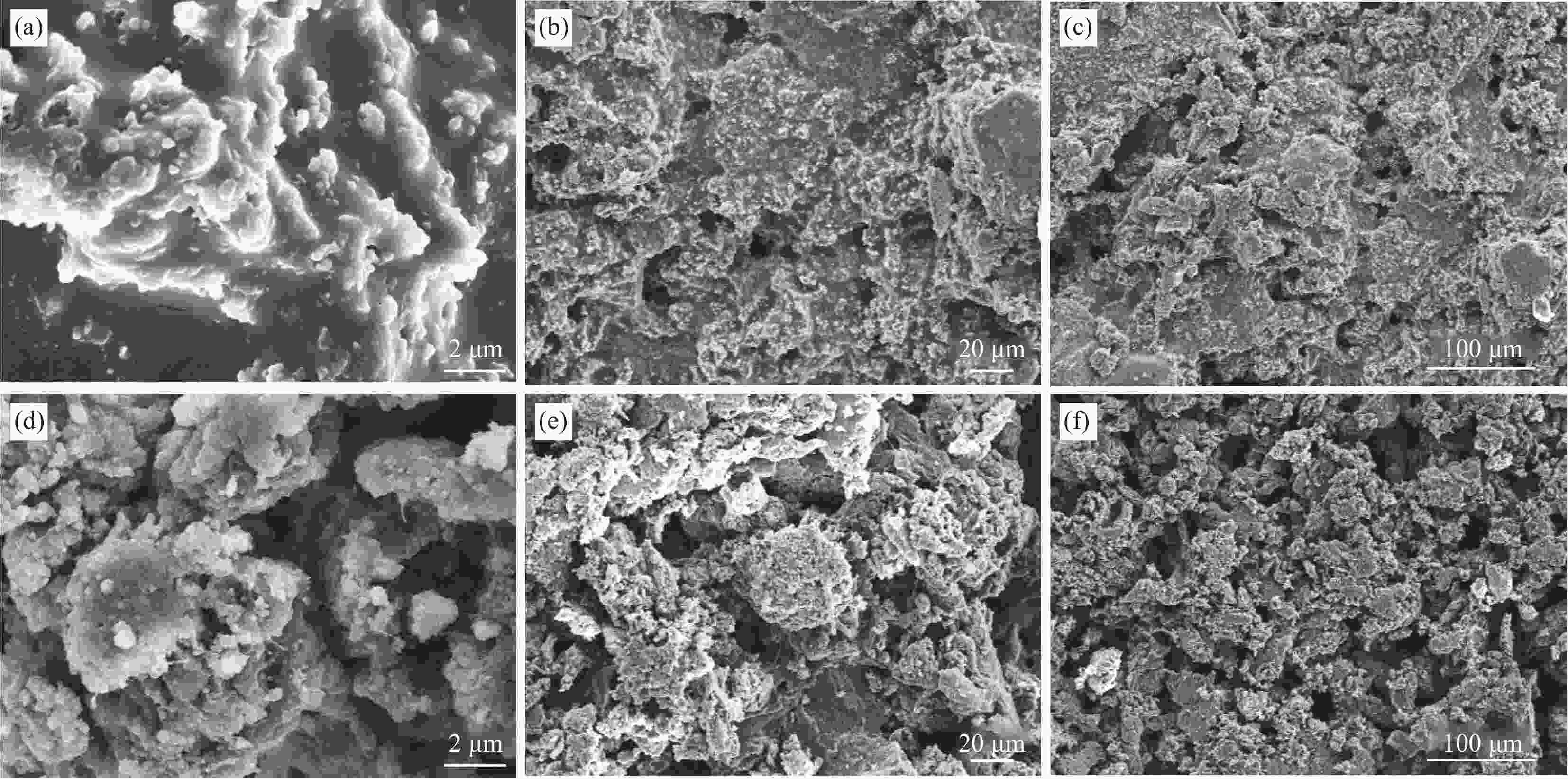

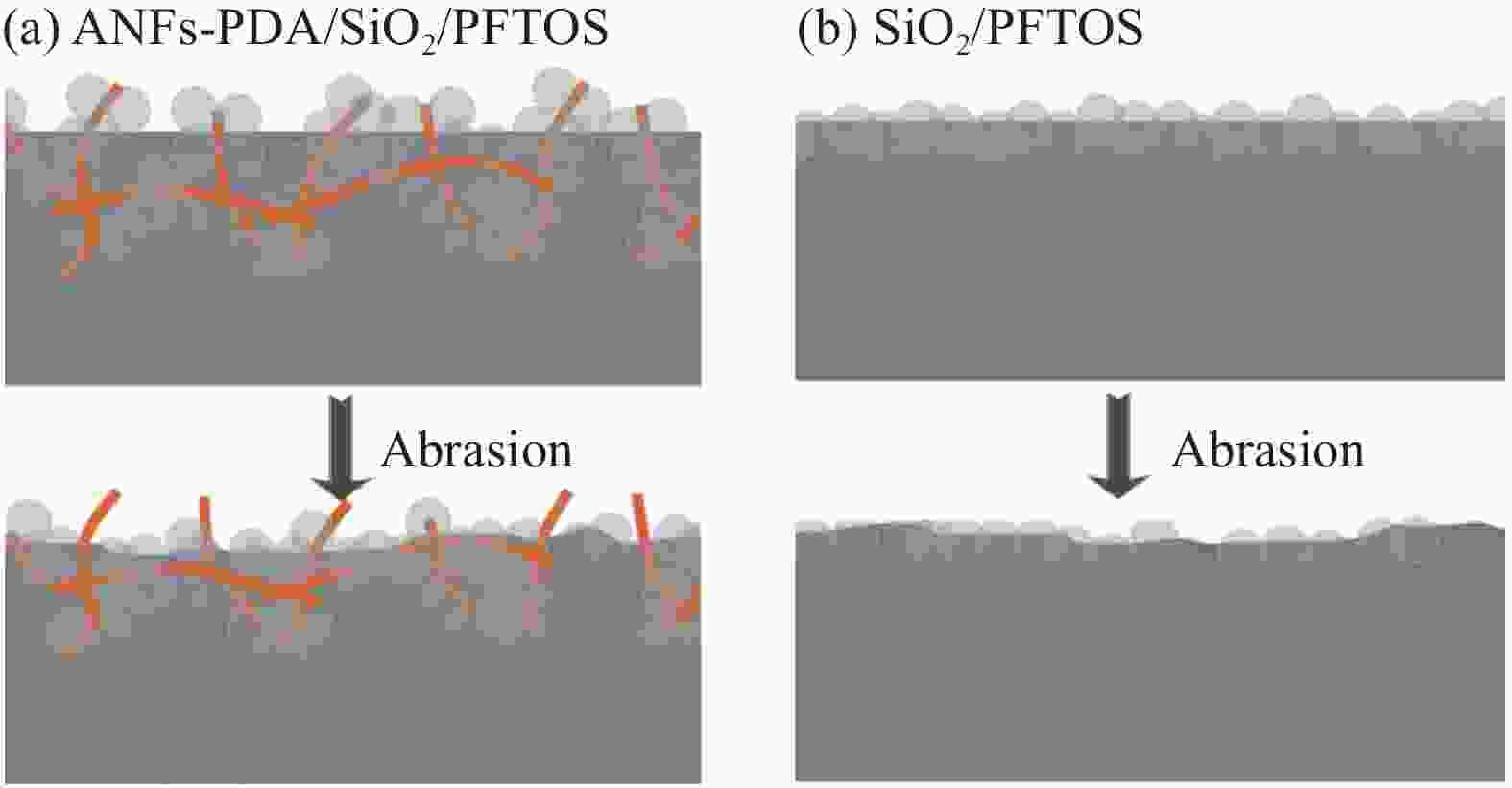

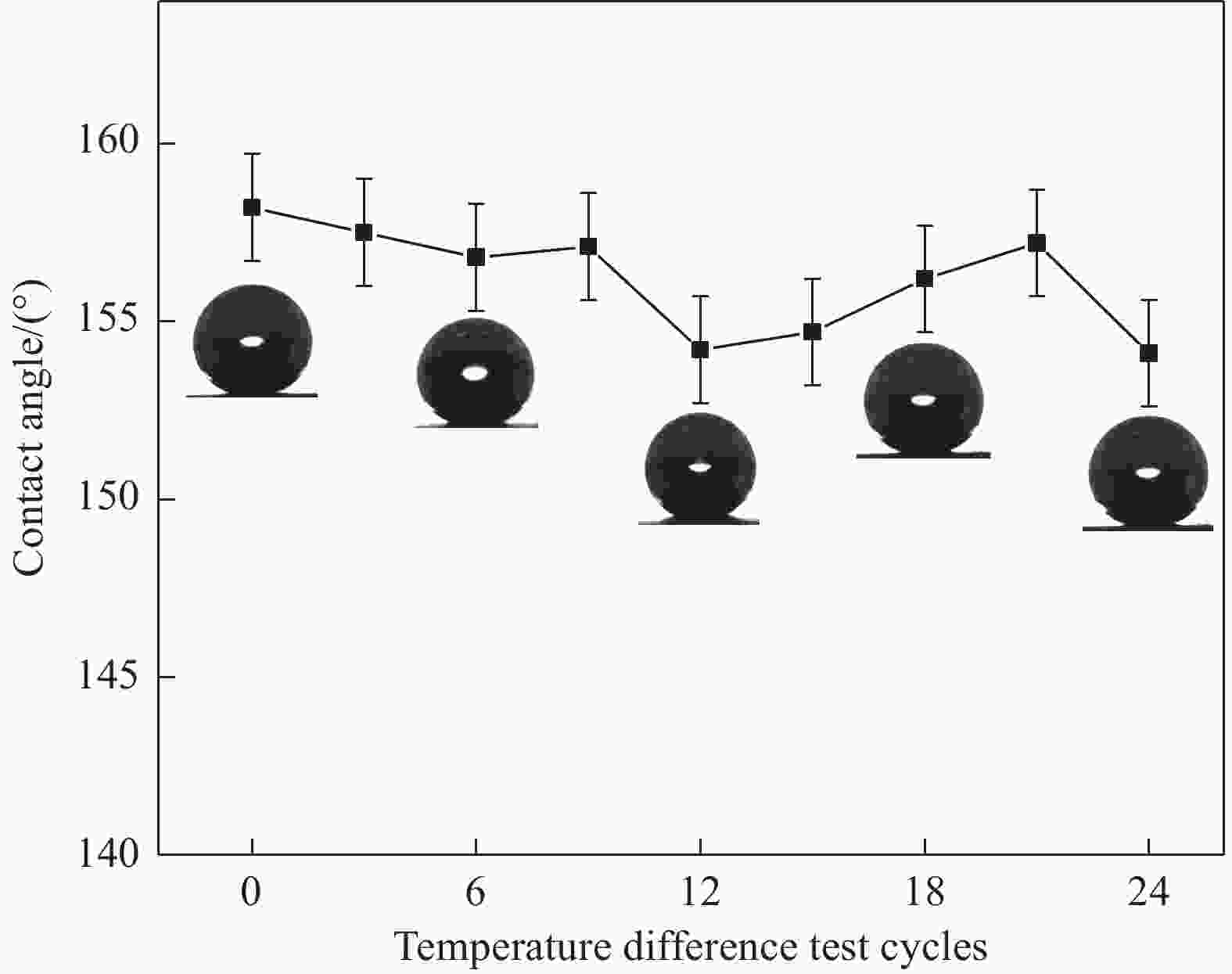

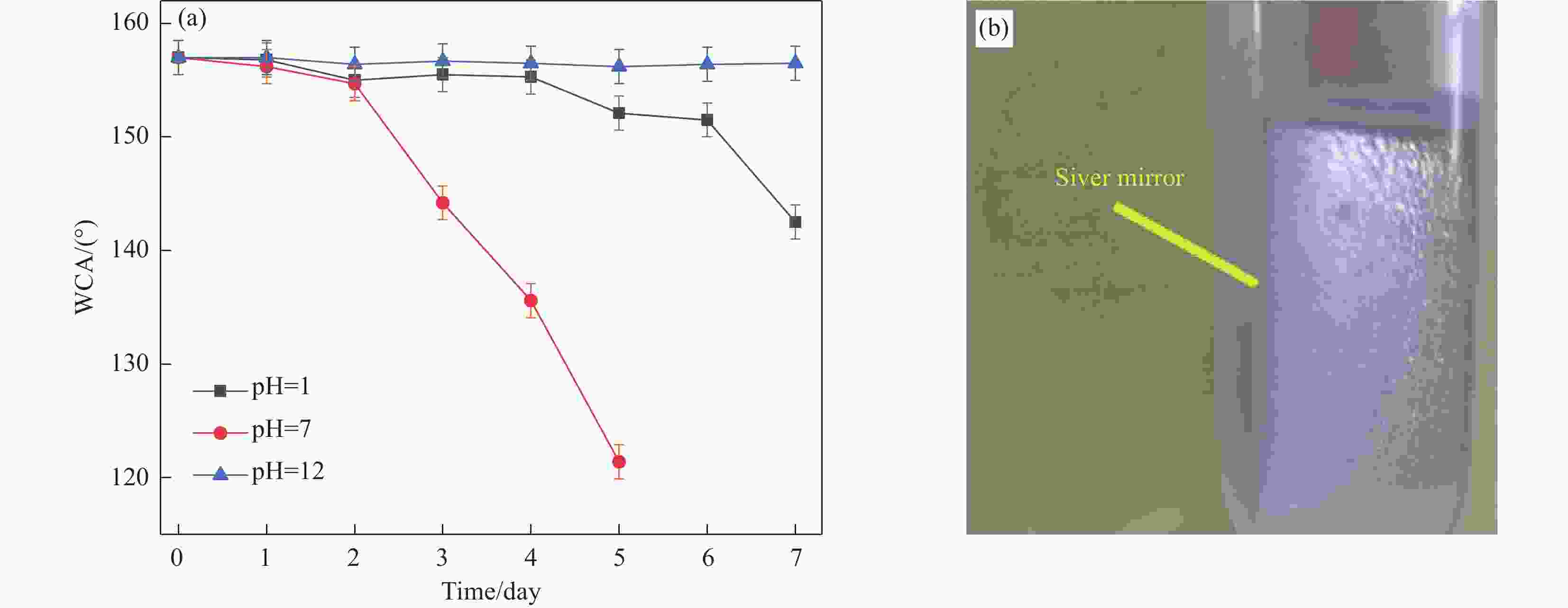

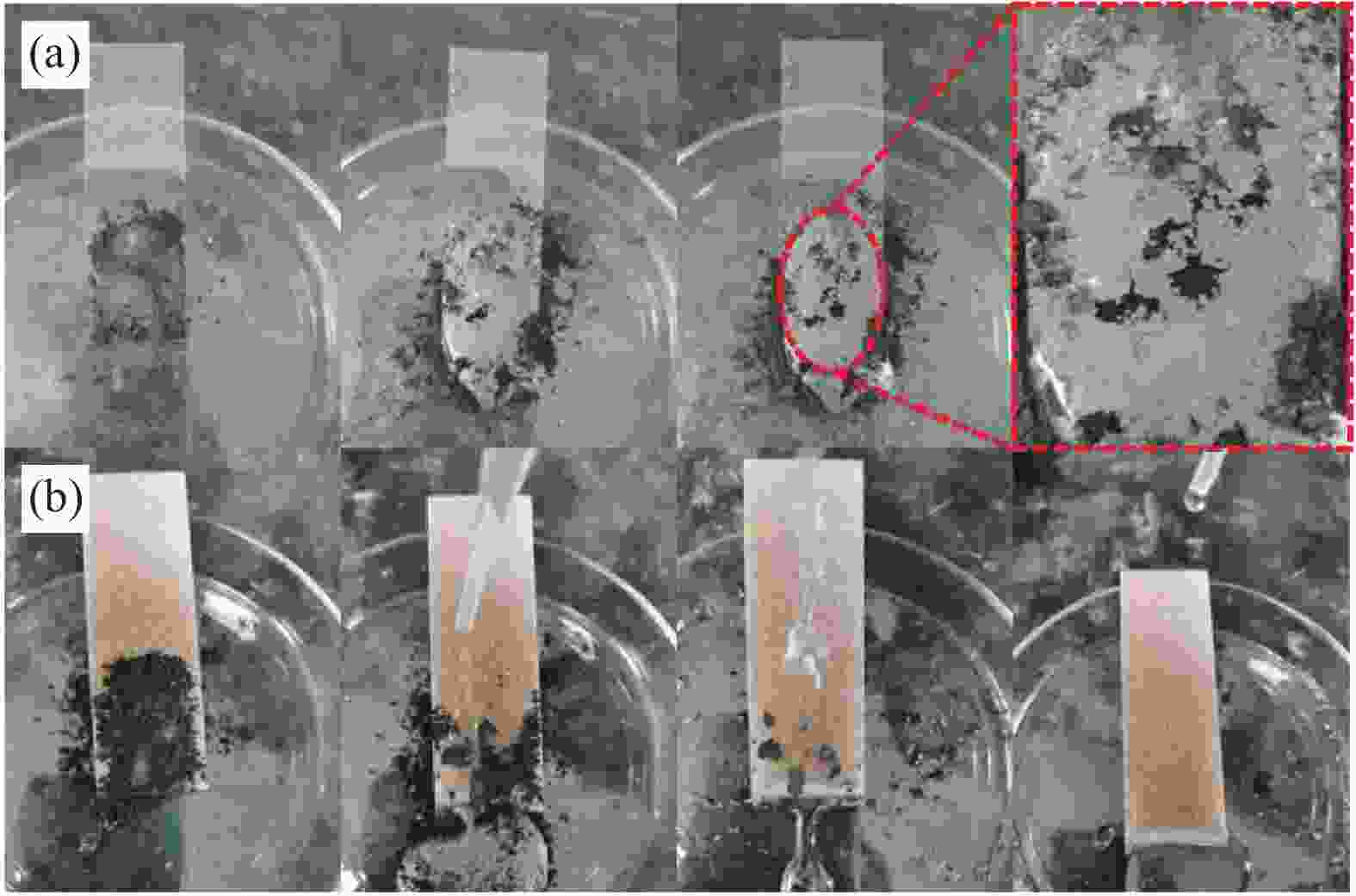

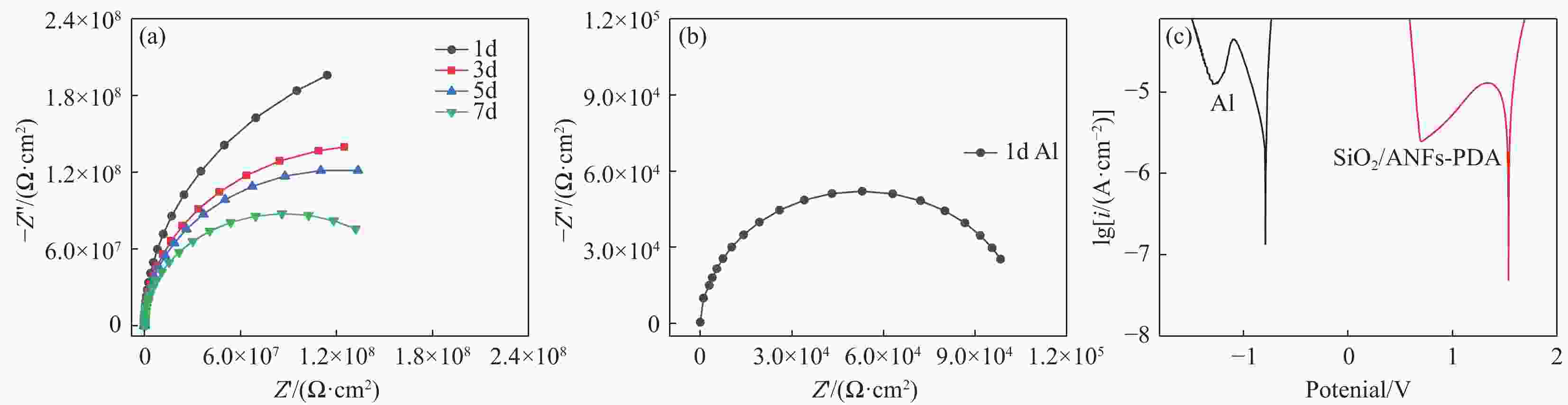

摘要: 超疏水材料由于其超高的防水性在工业防腐等领域展现出巨大的应用前景,然而在实际使用过程中,涂层表面的微纳结构和低表面能物质会被不断损耗从而影响超疏水性能。本文主要以聚多巴胺(PDA)包裹的芳纶纳米纤维(ANFs)作为一种微纳米构筑单元,在其上通过溶胶凝胶法原位生长纳米SiO2,并通过对其进行低表面能改性构建“葡萄”形超疏水结构,最后通过“粘接剂-超疏水粒子”喷涂得到超疏水涂层。当正硅酸乙酯(TEOS)添加量为2.1wt%时,超疏水涂层的接触角(WCA)为158°±1.5°。所制得的涂层具有良好的力学性能,在分别经过200 g砝码在25 μm砂纸下的240次磨损和400 g砂冲实验,仍能保持良好的超疏水性能。通过Nyquist测试表明样片阻抗弧明显变大、Tafel测试表明腐蚀电位正移,喷涂超疏水涂层后能够有效提升防腐性能。Abstract: Hydrophobic materials have shown great potential in industrial corrosion prevention due to their extremely high waterproofing properties. However, in practical applications, the micro-nano structure and low surface energy of the coating surface are continuously worn away, affecting the superhydrophobic performance. This study focuses on using polydopamine (PDA) coated aramid nanofibers (ANFs) as micro-building units to grow nano-SiO2 through sol-gel condensation and construct a "grape-like" superhydrophobic structure through low surface energy modification. Finally, a superhydrophobic coating is obtained by spray-coating with a "binder-superhydrophobic particles" mixture. When the ethyl orthosilicate (TEOS) addition is 2.1wt%, the contact angle of the superhydrophobic coating is 158°±1.5°, respectively. The resulting coating exhibits good mechanical properties and maintains its superhydrophobic performance even after undergoing 240 cycles of abrasion on 25 μm sandpaper with a 200 g weight and a sand erosion test with a 400 g load. Nyquist testing shows a significant increase in impedance arc, and Tafel testing indicates a positive shift in corrosion potential, demonstrating that the spray-coated superhydrophobic coating can effectively enhance corrosion resistance.

-

Key words:

- superhydrophobicity /

- aramid nanofibers /

- polydopamine /

- SiO2 /

- coating /

- mechanical properties

-

图 9 (a) SAP涂层在200 g砝码25 μm砂纸磨损下的WCA和SCA; (b) ASF涂层在200 g砝码25 μm砂纸磨损下的WCA和SCA; (c)落砂实验示意图;(d)SAP涂层随落砂磨损下的WCA和SCA

Figure 9. (a) SAP’s WCA and SCA of the coating under the wear of 200 g weight and 25 μm sandpaper; (b) ASP’s WCA and SCA of the coating under the wear of 200 g weight and 25 μm sandpaper; (c) Schematic diagram of sand impinging test; (d) SAP’s WCA and SCA of coating under sand impinging

表 1 底层不同预固化时间对涂层疏水性能的影响

Table 1. The effect of different hardening times of the first layer on the hydrophobic properties of coatings

Hardening time/min 20 22 24 26 28 30 WCA/(º) 144 147 158 158 × × SCA/(º) 27 18 5 5 × × Notes: When the pre-curing time is greater than 26 minutes, the mechanical performance of the coating is poor, and the testing data becomes meaningless. 表 2 涂层附着力测试

Table 2. Coating adhesion test

Adhesion tesr times 0 1 4 7 Sample

WCA 157° 157° 156° 153° -

[1] ZHANG L, ZHOU A G, SUN B R, et al. Functional and versatile superhydrophobic coatings via stoichiometric silanization[J]. Nature communications, 2021, 12(1): 982. doi: 10.1038/s41467-021-21219-y [2] JELIA P R, AGRAWAL A, SINGH R K, et al. Design of textured surfaces for super-hydrophobicity[J]. Sādhanā, 2017, 42: 1915-1927. [3] WANG Z, MA H, CHU B, et al. Super-hydrophobic modification of porous natural polymer “luffa sponge” for oil absorption[J]. Polymer, 2017, 126: 470-476. doi: 10.1016/j.polymer.2017.05.068 [4] ZHENG J, QU G, YANG B, et al. Facile pr-eparation of robust superhydrophobic ceramic surfaces with mechanical stability, durability, and self-cleaning function[J]. Applied Surf-ace Science, 2022, 576: 151875. doi: 10.1016/j.apsusc.2021.151875 [5] LATTHE S S, SUTAR R S, KODAG V S, et al. Self–cleaning superhydrophobic coatings: Potential industrial applications[J]. Progress in Organic Coatings, 2019, 128: 52-58. doi: 10.1016/j.porgcoat.2018.12.008 [6] ENGLAND M W, SATO T, URATA C, et al. Transparent gel composite films with multiple functionalities: Long-lasting anti-fogging, underwater superoleophobicity and anti-bacterial activity[J]. Journal of colloid and interface science, 2017, 505: 566-576. doi: 10.1016/j.jcis.2017.06.038 [7] GU W, SONG K, CHENG Z, et al. Water-Based Robust Transparent Superamphiphobic Coatings for Resistance to Condensation, Frosting, Icing, and Fouling[J]. Advanced Materials Interfaces, 2020, 7(10): 1902201. doi: 10.1002/admi.201902201 [8] ZENG D, LI Y, HUAN D, et al. Robust epoxy-modified superhydrophobic coating for aircraft anti-icing systems[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2021, 628: 127377. doi: 10.1016/j.colsurfa.2021.127377 [9] CHEN R, ZHANG Y, XIE Q, et al. Transparent polymer-ceramic hybrid antifouling coating with superior mechanical properties[J]. Advanced Functional Materials, 2021, 31(19): 2011145. doi: 10.1002/adfm.202011145 [10] HWANG G B, PATIR A, PAGE K, et al. Buoyancy increase and drag-reduction through a simple superhydrophobic coating[J]. Nanoscale, 2017, 9(22): 7588-7594. doi: 10.1039/C7NR00950J [11] WANG N, WANG Y, SHANG B, et al. Bioinspired one-step construction of hierarchical superhydrophobic surfaces for oil/water separation[J]. Journal of colloid and interface science, 2018, 531: 300-310. doi: 10.1016/j.jcis.2018.07.056 [12] WANG S, YU X, ZHANG Y. Large-scale fabrication of translucent, stretchable and durable superhydrophobic composite films[J]. Journal of Materials Chemistry A, 2017, 5(45): 23489-23496. doi: 10.1039/C7TA08203G [13] YE H, ZHU L, LI W, et al. Simple spray deposition of a water-based superhydrophobic coating with high stability for flexible applications[J]. Journal of Materials Chemistry A, 2017, 5(20): 9882-9890. doi: 10.1039/C7TA02118F [14] GU W, LI W, ZHANG Y, et al. Ultra-durable superhydrophobic cellular coatings[J]. Nature Communications, 2023, 14(1): 5953. doi: 10.1038/s41467-023-41675-y [15] LU Y, SATHASIVAM S, SONG J, et al. Robust self-cleaning surfaces that function when exposed to either air or oil[J]. Science, 2015, 347(6226): 1132-1135. doi: 10.1126/science.aaa0946 [16] CHEN F, WANG Y, TIAN Y, et al. Robust and durable liquid-repellent surfaces[J]. Chemical Society Reviews, 2022. [17] WANG P, LI C, ZHANG D. Recent advances in chemical durability and mechanical stability of superhydrophobic materials: Multi-strategy design and strengthening[J]. Journal of Materials Science & Technology, 2022, 129: 40-69. [18] ZHANG X, WANG H, LIU Z, et al. Fabrication of durable fluorine-free superhydrophobic polyethersulfone (PES) composite coating enhanced by assembled MMT-SiO2 nanoparticles[J]. Applied Surface Science, 2017, 396: 1580-1588. doi: 10.1016/j.apsusc.2016.11.217 [19] NINE M J, COLE M A, JOHNSON L, et al. Robust superhydrophobic graphene-based composite coatings with self-cleaning and corrosion barrier properties[J]. ACS applied materials & interfaces, 2015, 7(51): 28482-28493. [20] XIAO Z, WANG Q, YAO D, et al. Enhancing the robustness of superhydrophobic coatings via the addition of sulfide[J]. Langmuir, 2019, 35(20): 6650-6656. doi: 10.1021/acs.langmuir.9b00690 [21] ZHAO Y, LI X, SHEN J, et al. The potential of Kevlar aramid nanofiber composite membranes[J]. Journal of materials chemistry A, 2020, 8(16): 7548-7568. doi: 10.1039/D0TA01654C [22] 张美云, 罗晶晶, 杨斌, 等. 芳纶纳米纤维的制备及应用研究进展[J]. 材料导报, 2020, 34(5): 5158-5166. doi: 10.11896/cldb.18120041ZHANG MEIYUN, LUO JINGJING, YANG BIN, et al. Research progress of preparation and application of aramid nanofibers[J]. Materials Reports, 2020, 34(5): 5158-5166(in Chinese). doi: 10.11896/cldb.18120041 [23] Yang B, Wang L, Zhang M, et al. Fabrication, applications, and prospects of aramid nanofiber[J]. Advanced Functional Materials, 2020, 30(22): 2000186. doi: 10.1002/adfm.202000186 [24] LI Y, CAO Y. The molecular mechanisms underlying mussel adhesion[J]. Nanoscale Advances, 2019, 1(11): 4246-4257. doi: 10.1039/C9NA00582J [25] TRAN N T, FLANAGAN D P, ORLICKI J A, et al. Polydopamine and polydopamine–silane hybridsurface treatments in structural adhesive applications[J]. Langmuir, 2018, 34(4): 1274-1286. doi: 10.1021/acs.langmuir.7b03178 [26] ZHANG X, LIU Z, ZHANG X, et al. High-adhesive superhydrophobic litchi-like coatings fabricated by in-situ growth of nano-silica on polyethersulfone surface[J]. Chemical Engineering Journal, 2018, 343: 699-707. doi: 10.1016/j.cej.2018.03.012 [27] WANG N, WANG Y, SHANG B, et al. Bioinspired one-step construction of hierarchical superhydrophobic surfaces for oil/water separation[J]. Journal of colloid and interface science, 2018, 531: 300-310. doi: 10.1016/j.jcis.2018.07.056 [28] ZHANG T, DENG J, ZHANG L Z. A photothermal self-healing superhydrophobic coating with anti-frosting and anti-corrosion properties[J]. Progress in Organic Coatings, 2023, 180: 107569. doi: 10.1016/j.porgcoat.2023.107569 [29] WU B, LYU J, PENG C, et al. Inverse infuse-on processed hierarchical structure towards superhydrophobic coatings with ultrahigh mechanical robustness[J]. Chemical Engineeri-ng Journal, 2020, 387: 124066. doi: 10.1016/j.cej.2020.124066 [30] 中国国家标准化管理委员会(标准制定单位). 水泥胶砂强度检验方法(ISO法): GB/T 17671-2021[S]. 北京: 中国标准出版社, 2021.Standardization Administration of the People’s Republic of China. Test method of cement mortar strength(ISO method): GB/T 17671-2021[S]. Beijing: China Standards Press, 2005(in Chinese). [31] 中国国家标准化管理委员会(标准制定单位). 色漆和清漆的划格试验: GB/T 9286-1998[S]. 北京: 中国标准出版社, 1988.Standardization Administration of the People’s Republic of China. Paints and varnishes-cross cut test for films: GB/T 9286-1998[S]. Beijing: China Standards Press, 1988(in Chinese). [32] 朱航, 刘静, 雷西萍, 等. 十四酸改性SiO2/超支化PDMS自修复涂层的制备及其超疏水性能[J]. 复合材料学报, 2024, 41(1): 270-282.ZHU HANG, LIU JING, LEI XI PING, et al, Preparation of myristic acid modified SiO2/hyperbranched-PDMS self-healing coating and its superhydrophobic performance [J], Acta Materiae Composita Sinica, 2024, 41(1): 270-282. (in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 41

- HTML全文浏览量: 24

- 被引次数: 0

下载:

下载: